Introduction: Navigating the Global Market for alternator life expectancy

In the dynamic landscape of global commerce, understanding the life expectancy of alternators is crucial for B2B buyers seeking reliable automotive solutions. Sourcing high-quality alternators that meet the demands of various applications can significantly impact operational efficiency and cost-effectiveness. This comprehensive guide delves into the essential aspects of alternator life expectancy, including the factors influencing lifespan, types of alternators available, and their specific applications across diverse industries.

International buyers from regions such as Africa, South America, the Middle East, and Europe—especially Germany and Vietnam—face unique challenges in sourcing these critical components. Fluctuating supply chains, varying quality standards, and differing regional demands necessitate a thorough understanding of the market. This guide provides actionable insights into supplier vetting processes, cost considerations, and maintenance practices that extend alternator life.

By empowering B2B buyers with knowledge about the intricacies of alternator longevity, this resource aims to facilitate informed purchasing decisions. Whether you are looking to enhance vehicle performance, improve reliability, or reduce downtime, understanding alternator life expectancy will equip you with the tools needed to navigate the global market effectively.

Table Of Contents

- Top 3 Alternator Life Expectancy Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator life expectancy

- Understanding alternator life expectancy Types and Variations

- Key Industrial Applications of alternator life expectancy

- 3 Common User Pain Points for ‘alternator life expectancy’ & Their Solutions

- Strategic Material Selection Guide for alternator life expectancy

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator life expectancy

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator life expectancy’

- Comprehensive Cost and Pricing Analysis for alternator life expectancy Sourcing

- Alternatives Analysis: Comparing alternator life expectancy With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator life expectancy

- Navigating Market Dynamics and Sourcing Trends in the alternator life expectancy Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator life expectancy

- Strategic Sourcing Conclusion and Outlook for alternator life expectancy

- Important Disclaimer & Terms of Use

Understanding alternator life expectancy Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternators | Average lifespan of 7-10 years or 80,000-150,000 miles. | Automotive repair shops, fleet services | Pros: Affordable, widely available. Cons: May require frequent replacements in harsh conditions. |

| Heavy-Duty Alternators | Designed for high-output applications, longer lifespan. | Trucks, construction equipment | Pros: Durable, withstands extreme conditions. Cons: Higher initial cost, heavier weight. |

| Performance Alternators | Enhanced output for high-performance vehicles, shorter lifespan. | Racing teams, aftermarket upgrades | Pros: Increased power output, improved performance. Cons: Higher wear and cost, less longevity. |

| Marine Alternators | Resistant to corrosion and moisture, specialized design. | Marine vessels, yachts | Pros: Built for harsh environments, reliable. Cons: More expensive, limited availability. |

| Renewable Energy Alternators | Tailored for solar and wind energy systems, variable output. | Renewable energy projects, off-grid systems | Pros: Efficient energy conversion, eco-friendly. Cons: Requires specialized knowledge for installation. |

What Are Standard Alternators and Where Are They Used?

Standard alternators are the most common type found in vehicles, typically lasting between 7 to 10 years or 80,000 to 150,000 miles. These alternators are suitable for general automotive applications, making them ideal for automotive repair shops and fleet services. When purchasing, B2B buyers should consider factors such as warranty options and the availability of compatible models for various vehicle types, as this can significantly affect operational costs.

How Do Heavy-Duty Alternators Differ?

Heavy-duty alternators are engineered for high-output applications, such as trucks and construction equipment, where durability is paramount. They often have a longer lifespan due to their robust construction, making them a preferred choice for industries that operate in demanding conditions. Buyers should evaluate the specific power requirements of their equipment and ensure compatibility, as the higher upfront costs can be offset by reduced replacement frequency.

What Makes Performance Alternators Unique?

Performance alternators are tailored for high-performance vehicles and racing applications, providing enhanced electrical output. While they are designed for power, they typically have a shorter lifespan due to increased wear from high demand. B2B buyers in the automotive aftermarket should assess the balance between performance needs and longevity, as these units can be more costly and may require more frequent replacements.

Why Choose Marine Alternators?

Marine alternators are specifically designed to resist corrosion and moisture, making them essential for marine vessels and yachts. Their specialized design ensures reliability in harsh marine environments, which is crucial for operators in the maritime industry. Buyers should consider the specific environmental challenges their vessels face and ensure they select alternators that meet marine standards, despite the higher costs associated with these units.

How Do Renewable Energy Alternators Function?

Renewable energy alternators are optimized for use in solar and wind energy systems, featuring variable output to meet fluctuating energy demands. They are ideal for renewable energy projects and off-grid systems. B2B buyers should focus on efficiency ratings and compatibility with existing energy systems, as these factors can directly impact energy generation effectiveness and overall project viability.

Key Industrial Applications of alternator life expectancy

| Industry/Sector | Specific Application of alternator life expectancy | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Quality control in alternator production | Ensures reliability and reduces warranty claims | Supplier certifications, production capacity, and material quality |

| Mining | Power generation for heavy machinery | Enhances operational uptime and efficiency | Durability in harsh environments, maintenance support, and parts availability |

| Agriculture | Power supply for irrigation systems | Maximizes crop yield through reliable operation | Energy efficiency, compatibility with existing systems, and service agreements |

| Renewable Energy | Backup power systems for solar/wind installations | Guarantees consistent energy supply during outages | Adaptability to various energy systems, lifespan, and environmental resistance |

| Transportation & Logistics | Fleet management and vehicle maintenance | Reduces downtime and maintenance costs | Cost-effectiveness, warranty terms, and compatibility with diverse vehicle types |

How Does Alternator Life Expectancy Impact Automotive Manufacturing?

In the automotive manufacturing sector, understanding alternator life expectancy is crucial for quality control. Manufacturers need to ensure that the alternators produced meet specific longevity standards to minimize warranty claims and enhance customer satisfaction. By sourcing high-quality components and implementing rigorous testing protocols, manufacturers can boost their reputation and market share, particularly in regions with demanding climates like Africa and the Middle East.

Why is Alternator Life Expectancy Important in Mining Operations?

In mining, heavy machinery relies heavily on alternators for power generation. The life expectancy of these components directly affects operational uptime and efficiency. For businesses in this sector, sourcing alternators that can withstand extreme conditions is vital. International buyers should prioritize suppliers that offer robust warranties and extensive service support, ensuring minimal downtime in remote locations.

How Does Alternator Life Expectancy Benefit Agricultural Applications?

In agriculture, alternators play a key role in powering irrigation systems. A reliable alternator ensures that these systems operate continuously, maximizing crop yield. Buyers in this sector must consider energy-efficient models that are compatible with existing irrigation setups. Additionally, sourcing from manufacturers that offer long-term maintenance support can significantly enhance operational reliability, especially in rural areas of South America and Africa.

What Role Does Alternator Life Expectancy Play in Renewable Energy Systems?

For renewable energy applications, such as solar and wind installations, alternators serve as backup power systems. Their life expectancy is critical in ensuring a consistent energy supply during outages. Businesses in this field should look for alternators that are adaptable to various energy systems and resilient to environmental factors. Sourcing from suppliers with proven track records can help mitigate risks associated with energy supply interruptions.

How Does Alternator Life Expectancy Affect Transportation and Logistics?

In transportation and logistics, the efficiency of fleet management is heavily influenced by the life expectancy of alternators. Reliable alternators reduce maintenance costs and vehicle downtime, leading to improved operational efficiency. For international buyers, it’s essential to consider cost-effective solutions that offer compatibility across diverse vehicle types. Additionally, favorable warranty terms can provide peace of mind for businesses looking to optimize their fleet operations.

3 Common User Pain Points for ‘alternator life expectancy’ & Their Solutions

Scenario 1: Understanding Variability in Alternator Lifespan

The Problem: B2B buyers in the automotive industry often face uncertainty regarding the life expectancy of alternators. Variability in the expected lifespan, which can range from 60,000 to over 200,000 miles depending on multiple factors, makes it challenging for fleet managers or automotive retailers to make informed decisions on inventory and maintenance schedules. This unpredictability can lead to increased downtime, customer dissatisfaction, and ultimately financial losses.

The Solution: To address this challenge, it’s essential for B2B buyers to implement a comprehensive monitoring and maintenance program. Start by establishing clear guidelines based on the specific operating conditions of your vehicles—considering factors such as driving habits, climate, and electrical loads. Regular inspections and testing of alternators using multimeters can help identify early signs of wear. Additionally, investing in high-quality alternators that are designed for longevity can mitigate the risks associated with unexpected failures. Collaborate with suppliers who offer detailed specifications and insights into their products’ expected lifespans based on real-world usage data. This proactive approach will enable better inventory management and reduce operational risks.

Scenario 2: Coping with Sudden Alternator Failures

The Problem: Sudden alternator failures can be a nightmare for businesses that rely on a fleet of vehicles. These failures often occur without warning, leaving drivers stranded and operations disrupted. For B2B buyers, this not only affects service delivery but also escalates repair costs and impacts customer trust. Understanding the signs of a failing alternator can be difficult, especially in regions where technical expertise is limited.

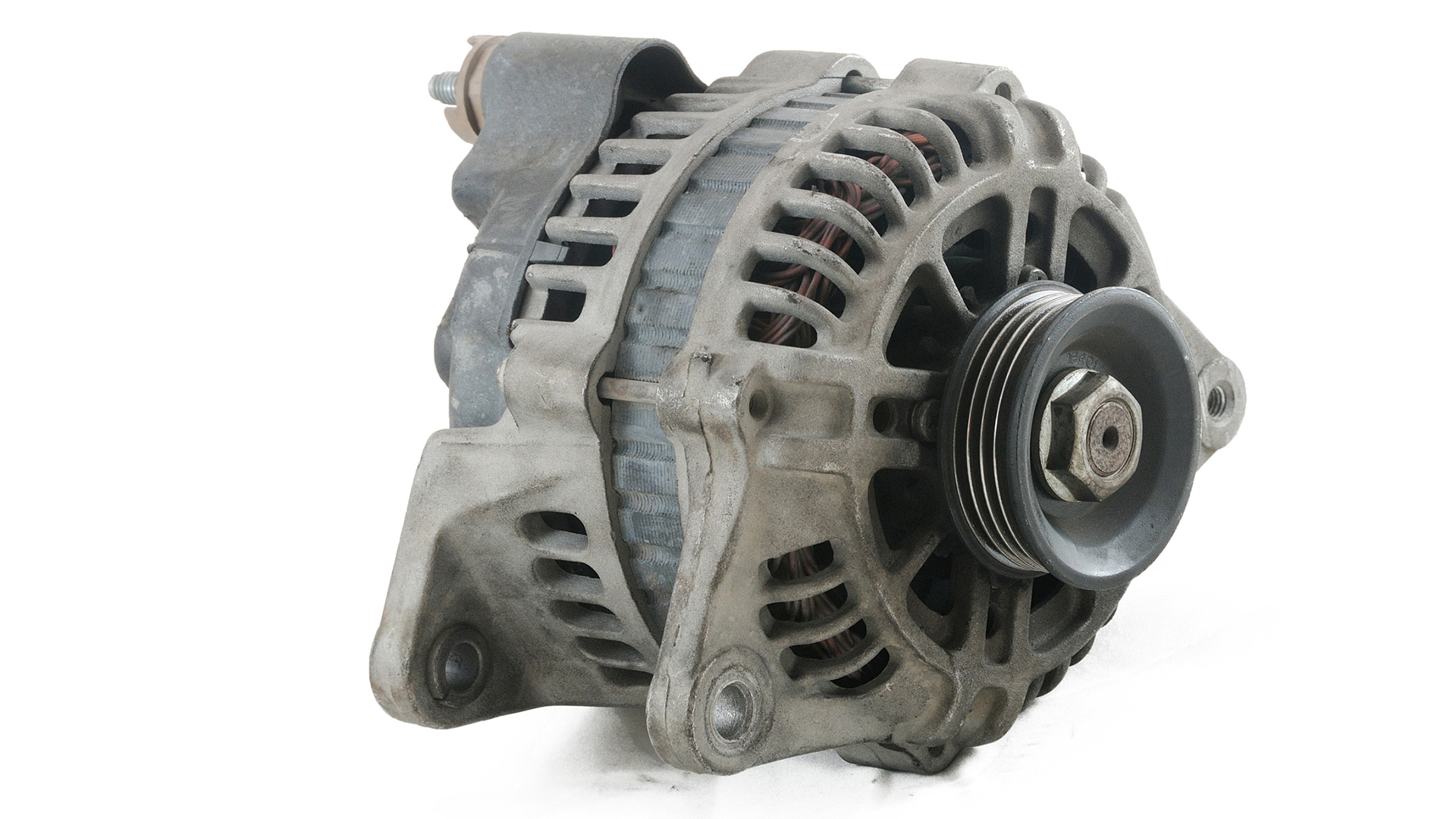

Illustrative image related to alternator life expectancy

The Solution: Implementing a robust preventative maintenance strategy can significantly reduce the likelihood of unexpected alternator failures. Train your fleet personnel to recognize early warning signs such as dimming lights, unusual noises, or dashboard warning lights. Establish a routine inspection schedule that includes testing the alternator’s output and checking for wear on belts and connections. Additionally, consider partnering with local automotive service providers for periodic training sessions, ensuring that your team is well-equipped to handle minor repairs and can quickly identify when to seek professional help. This dual approach of employee training and systematic inspections can help maintain vehicle reliability and minimize downtime.

Scenario 3: Managing Electrical Loads on Alternators

The Problem: As vehicles become increasingly equipped with advanced electronics, the demand on alternators grows. Many B2B buyers are unaware of how excessive electrical loads can significantly shorten alternator life expectancy. This oversight can lead to frequent replacements and increased maintenance costs, particularly in vehicles that are outfitted with aftermarket accessories or specialized equipment.

The Solution: To effectively manage electrical loads, start by conducting a thorough assessment of your vehicles’ power requirements. Document the specifications of all installed electronics and compare them against the alternator’s output capacity. If your vehicles regularly exceed the alternator’s capabilities, consider upgrading to a higher-capacity alternator that can handle the additional load. Additionally, educate your team on the importance of energy-efficient practices, such as turning off non-essential electronics when the engine is off. By aligning electrical demands with the alternator’s specifications, you can extend its lifespan and reduce the frequency of replacements, ultimately leading to cost savings and improved operational efficiency.

Illustrative image related to alternator life expectancy

Strategic Material Selection Guide for alternator life expectancy

What Materials are Commonly Used in Alternator Manufacturing?

When selecting materials for alternators, it is crucial to consider their properties and how they impact the longevity and performance of the component. Below, we analyze four materials commonly used in alternator construction: aluminum, copper, steel, and plastic.

How Does Aluminum Contribute to Alternator Life Expectancy?

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of around 150°C, making it suitable for automotive applications where heat dissipation is critical. Aluminum also offers good corrosion resistance, particularly when anodized.

Pros:

– Lightweight, reducing overall vehicle weight and improving fuel efficiency.

– Excellent thermal conductivity aids in heat dissipation.

– Corrosion-resistant, enhancing durability in various environments.

Cons:

– Lower tensile strength compared to steel, making it less suitable for high-stress applications.

– More expensive than some alternatives, which can impact overall production costs.

Impact on Application:

Aluminum is compatible with various media, including automotive fluids, and its lightweight nature can contribute to better vehicle performance. However, its lower strength may limit its use in high-stress components.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for aluminum grades. In regions with high humidity, such as parts of Africa and South America, ensuring proper anodization can enhance corrosion resistance.

What Role Does Copper Play in Alternator Efficiency?

Copper is primarily used for windings in alternators due to its excellent electrical conductivity, which is crucial for efficient power generation. It can handle high temperatures and has a melting point of approximately 1,085°C, making it suitable for high-performance applications.

Pros:

– Superior electrical conductivity ensures efficient power transfer.

– High-temperature tolerance prevents performance degradation.

– Ductile and malleable, allowing for intricate winding designs.

Cons:

– Higher cost compared to aluminum and other materials, which can increase the overall manufacturing expense.

– Prone to corrosion if not properly insulated, which can lead to electrical failures.

Impact on Application:

Copper windings can significantly enhance the alternator’s efficiency and lifespan, particularly in high-demand scenarios. However, buyers must consider insulation materials to prevent corrosion.

Illustrative image related to alternator life expectancy

Considerations for International Buyers:

Compliance with JIS and other international standards is essential, especially in regions with varying electrical requirements. Buyers in Europe may prefer copper due to its established reliability in high-performance applications.

How Does Steel Contribute to Alternator Durability?

Steel is often used in alternator frames and brackets due to its high tensile strength and durability. It can withstand high pressures and has a temperature rating of around 250°C, making it suitable for various automotive applications.

Pros:

– High strength and durability ensure long-lasting performance.

– Cost-effective compared to aluminum and copper for structural components.

– Good resistance to mechanical wear.

Cons:

– Heavier than aluminum, which can negatively impact vehicle weight and efficiency.

– Susceptible to corrosion if not properly coated or treated.

Impact on Application:

Steel’s strength makes it ideal for components that experience significant mechanical stress. However, its weight can be a disadvantage in applications where fuel efficiency is a priority.

Considerations for International Buyers:

Buyers should verify compliance with ASTM standards for steel grades. In regions with high humidity, such as the Middle East, protective coatings are essential to prevent corrosion.

What Benefits Does Plastic Offer in Alternator Design?

Plastic is increasingly being used for non-structural components in alternators, such as covers and insulators, due to its lightweight and insulating properties. It can withstand temperatures up to 120°C, depending on the type of plastic used.

Pros:

– Lightweight, contributing to overall vehicle weight reduction.

– Excellent electrical insulation properties prevent short circuits.

– Cost-effective and easy to mold into complex shapes.

Cons:

– Lower thermal and mechanical resistance compared to metals, limiting its use in high-stress areas.

– May degrade over time under UV exposure or extreme temperatures.

Impact on Application:

Plastic can enhance the design flexibility of alternators, allowing for innovative solutions. However, its limitations in high-stress applications must be considered.

Considerations for International Buyers:

Buyers should ensure that plastics meet relevant international standards, particularly in regions with high UV exposure, such as Africa and South America.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for alternator life expectancy | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and components | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Copper | Windings | Superior electrical conductivity | Higher cost and corrosion risk | High |

| Steel | Frames and brackets | High strength and durability | Heavier and corrosion-prone | Low |

| Plastic | Non-structural components | Lightweight and insulating | Lower thermal resistance | Low |

This strategic material selection guide aims to provide B2B buyers with actionable insights to enhance the life expectancy of alternators, ensuring optimal performance and reliability in diverse operating conditions.

Illustrative image related to alternator life expectancy

In-depth Look: Manufacturing Processes and Quality Assurance for alternator life expectancy

What Are the Main Stages in the Manufacturing Process of Alternators?

The manufacturing of alternators involves several critical stages, each designed to ensure durability and efficiency, which directly impacts life expectancy. Understanding these stages can help B2B buyers evaluate potential suppliers and their manufacturing capabilities.

1. Material Preparation

The first step in alternator manufacturing is the careful selection and preparation of raw materials. High-quality metals such as aluminum and copper are typically used for the housing and internal components due to their excellent electrical conductivity and resistance to corrosion. The materials undergo rigorous testing for purity and strength to ensure they can withstand operational stresses.

Additionally, insulation materials are selected based on their thermal and electrical properties, ensuring that they can handle the heat generated during operation. The preparation phase may also involve cutting materials into required dimensions, which is essential for achieving precise fits in later assembly stages.

2. Forming

Once materials are prepared, the next phase is forming. This stage includes several techniques such as casting, forging, and machining. For instance, the alternator housing is often die-cast from aluminum, which allows for complex shapes and lightweight structures.

Illustrative image related to alternator life expectancy

Machining processes are then used to create precise grooves and slots for components like the rotor and stator. Each part is manufactured to exact specifications, as tolerances are critical in ensuring the alternator operates efficiently and reliably.

3. Assembly

The assembly phase combines the various components into a complete alternator. This stage involves the installation of the rotor, stator, diodes, and bearings, followed by securing the housing. Automation plays a significant role in this process, with robotic systems often employed for precision and speed.

Quality control measures are integrated during assembly, such as torque checks on fasteners and alignment tests of rotating components, which are vital for preventing premature wear and failure.

4. Finishing

The final stage in the manufacturing process is finishing, which may include surface treatments like anodizing or painting to enhance corrosion resistance and aesthetic appeal. Additionally, components may undergo a cleaning process to remove any machining residues or contaminants that could affect performance.

Finishing also includes the installation of electrical connectors and seals, ensuring that the alternator is ready for installation in vehicles or other applications.

How Is Quality Assurance Implemented in Alternator Manufacturing?

Quality assurance (QA) is paramount in the production of alternators, particularly because they are critical components in automotive and industrial applications. A robust QA system ensures that every alternator meets international standards and customer expectations.

What International Standards Are Relevant for Alternator Quality?

For global B2B buyers, adherence to international quality standards is essential. ISO 9001 is one of the most recognized quality management standards, outlining requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer consistently provides products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking for compliance with European safety standards or API standards for automotive components are crucial. These certifications assure buyers that the alternators have undergone rigorous testing and meet high-quality benchmarks.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control in alternator manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage checks raw materials for defects or inconsistencies before production begins. Materials that do not meet specifications are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, random inspections are conducted to verify that components are being produced according to specifications. This may include dimensional checks and functional tests of sub-assemblies.

-

Final Quality Control (FQC): Before shipping, finished alternators undergo comprehensive testing. This includes electrical performance tests, load testing, and visual inspections for any cosmetic defects.

What Common Testing Methods Are Used to Ensure Alternator Quality?

Testing methods are critical for validating the quality and performance of alternators. Common methods include:

-

Electrical Testing: This assesses the alternator’s output voltage and current under various load conditions, ensuring it meets the required specifications.

-

Thermal Testing: Alternators are subjected to high-temperature environments to evaluate their performance and durability under extreme conditions.

-

Vibration Testing: This simulates the operational environment of the alternator to identify potential failures due to vibration or mechanical stress.

-

Endurance Testing: Alternators are run for extended periods to assess their long-term reliability and performance degradation over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure product reliability. Here are several strategies:

-

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insights into the supplier’s QA processes and adherence to international standards.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certificates.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s capabilities and adherence to quality standards.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing alternators internationally, buyers must be aware of certification requirements that may vary by region. For instance, CE marking is required for products sold in the European Union, while different standards may apply in Africa or South America.

Understanding these nuances can help buyers navigate regulatory requirements and ensure that the alternators they procure are compliant with local laws. Additionally, maintaining open communication with suppliers about quality expectations and certifications can foster trust and ensure a smoother procurement process.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions that enhance the reliability and life expectancy of alternators, ultimately leading to better performance in their applications.

Illustrative image related to alternator life expectancy

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator life expectancy’

Introduction

Understanding alternator life expectancy is critical for B2B buyers looking to procure reliable automotive components. This guide provides a step-by-step checklist to help you evaluate suppliers and products effectively, ensuring you make informed decisions that enhance your operational efficiency and reduce unexpected downtime.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify your technical requirements for the alternators you need. Consider factors like voltage output, amperage, and compatibility with specific vehicle models or machinery. Having precise specifications allows you to filter suppliers who can meet your needs and helps prevent costly mistakes down the line.

Step 2: Research Market Standards and Lifespan Expectations

Familiarize yourself with the general lifespan of alternators, which typically ranges from 7 to 10 years or 80,000 to 150,000 miles. Understanding these benchmarks helps you set realistic expectations for your procurement and maintenance schedules. Additionally, research any regional variations in standards, especially if you’re sourcing from different continents like Africa or Europe.

Illustrative image related to alternator life expectancy

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers possess relevant industry certifications that validate their manufacturing processes and product quality. Look for ISO certifications, automotive industry standards, and compliance with local regulations. Certified suppliers are more likely to deliver reliable products, which directly impacts the longevity of the alternators you procure.

Step 4: Request Product Samples and Testing Data

Before finalizing your order, request samples of the alternators to assess their quality firsthand. Along with samples, ask for testing data that demonstrates the alternator’s performance under various conditions. This step is essential to verify that the products align with your specifications and expectations for durability and efficiency.

Step 5: Assess Warranty and Support Services

Review the warranty terms offered by suppliers, as they often reflect the manufacturer’s confidence in their product. A robust warranty can save you significant costs in the event of early failure. Additionally, inquire about the availability of technical support and after-sales services, which can be vital for troubleshooting and maintenance.

Step 6: Analyze Supplier Reputation and Reviews

Investigate the reputation of potential suppliers by seeking out reviews and testimonials from other B2B buyers in similar industries. Online platforms, industry forums, and trade shows can provide insights into supplier reliability and customer service. Engaging with existing customers can also offer valuable perspectives on the supplier’s responsiveness and product quality.

Step 7: Negotiate Terms and Conditions

Once you identify suitable suppliers, engage in negotiations to discuss pricing, delivery timelines, and payment terms. Clear communication regarding these elements is crucial to establishing a mutually beneficial relationship. Ensure that all agreements are documented to avoid misunderstandings and to facilitate smoother transactions.

By following this checklist, you can make informed decisions when sourcing alternators, ultimately leading to enhanced operational reliability and reduced maintenance costs in your fleet or machinery.

Comprehensive Cost and Pricing Analysis for alternator life expectancy Sourcing

When sourcing alternators, understanding the comprehensive cost structure is vital for making informed purchasing decisions. The total cost involved in acquiring alternators encompasses various components, which can significantly impact overall pricing.

What Are the Key Cost Components in Alternator Sourcing?

-

Materials: The primary materials used in alternators include copper, aluminum, and various plastics. The quality and sourcing of these materials can vary, influencing the final cost. Higher-grade materials often lead to better durability and performance, affecting the longevity of the alternator.

-

Labor: Labor costs are influenced by the complexity of the assembly process and the region where manufacturing occurs. Skilled labor in countries with higher wage standards will increase costs, while regions with lower labor costs may provide more competitive pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall cost of the alternator.

-

Tooling: The initial investment in tooling for production can be substantial, especially for custom or specialized alternators. These costs are typically amortized over the production run, affecting unit pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the alternators meet performance and safety standards. While this adds to the cost, it also reduces the risk of failures and warranty claims, which can be more costly in the long run.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the buyer’s destination. Import tariffs and customs duties also play a role in the total logistics cost, particularly for international buyers.

-

Margin: Suppliers will include a profit margin in their pricing. This can fluctuate based on market demand, competition, and perceived value of the product.

What Factors Influence Pricing in Alternator Sourcing?

Several factors can influence the pricing of alternators, particularly for B2B buyers in international markets:

Illustrative image related to alternator life expectancy

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to reduced per-unit costs. Buyers should negotiate for better pricing based on projected volumes.

-

Specifications and Customization: Custom alternators designed for specific applications can incur additional costs. Buyers need to clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Alternators that meet certain quality certifications (e.g., ISO, TS16949) may carry a higher price tag. Buyers should weigh the benefits of these certifications against their budget constraints.

-

Supplier Factors: Supplier reliability, reputation, and location can impact pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

-

Incoterms: Understanding shipping terms is crucial. FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) can affect cost calculations and risk management.

What Are the Best Buyer Tips for Cost-Efficient Alternator Sourcing?

-

Negotiation: Engage in price negotiations, especially when ordering in bulk. Building a long-term relationship with suppliers can also yield better pricing over time.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the initial purchase price. Consider factors like warranty, maintenance costs, and longevity when evaluating alternator options.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, it’s essential to factor in currency fluctuations, import duties, and shipping logistics. Establishing contracts in stable currencies can mitigate risks associated with exchange rates.

-

Research and Compare Suppliers: Utilize platforms that provide comprehensive supplier evaluations and comparisons. This will help identify the best value for money, ensuring a balance between cost and quality.

Disclaimer

Prices for alternators can vary widely based on the factors outlined above. It is advisable to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing alternator life expectancy With Other Solutions

Introduction: Exploring Alternatives to Alternator Life Expectancy

When considering the longevity and reliability of electrical systems in vehicles, understanding alternator life expectancy is crucial. However, B2B buyers should also evaluate alternative technologies and methods that fulfill similar roles in power generation and battery management. This analysis compares alternator life expectancy with two viable alternatives: Battery Management Systems (BMS) and Supercapacitors.

Comparison Table

| Comparison Aspect | Alternator Life Expectancy | Battery Management System (BMS) | Supercapacitors |

|---|---|---|---|

| Performance | 7-10 years / 80,000-150,000 miles | Highly efficient, extends battery life | Rapid charging, high power density |

| Cost | $100 – $800 (replacement) | $50 – $500 (system cost) | $10 – $200 (per unit) |

| Ease of Implementation | Requires mechanical knowledge | Moderate complexity, requires integration | Simple integration with existing systems |

| Maintenance | Regular checks needed | Minimal maintenance needed | Low maintenance |

| Best Use Case | Standard vehicle applications | Electric vehicles, renewable energy systems | High-performance applications, energy storage |

Detailed Breakdown of Alternatives

Battery Management Systems (BMS)

A Battery Management System optimizes battery usage, extending its lifespan by managing charge cycles and preventing overcharging. BMS technology is particularly beneficial in electric vehicles and hybrid systems, where battery performance directly impacts vehicle efficiency. The primary advantage of a BMS is its ability to enhance battery longevity and safety. However, BMS can be costly to implement, especially in older vehicles lacking integrated systems. While it requires moderate technical expertise for installation, the long-term savings on battery replacements can justify the initial investment.

Supercapacitors

Supercapacitors are energy storage devices that charge and discharge rapidly, providing a high power output for short durations. They are often used in applications requiring quick bursts of energy, such as regenerative braking in electric vehicles. One of the main benefits of supercapacitors is their ability to handle extreme charge and discharge cycles without degrading, offering a lifespan that can exceed traditional batteries and alternators. However, they typically have lower energy density compared to batteries, meaning they are not suited for long-term energy storage. Their installation is relatively simple, but integrating them into existing systems may require some modifications.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right power management solution hinges on specific operational requirements and cost considerations. Alternators offer a reliable and cost-effective solution for traditional combustion engine vehicles, while Battery Management Systems are ideal for electric and hybrid vehicles focused on energy efficiency. Supercapacitors serve a niche market, excelling in applications demanding rapid energy delivery. By carefully evaluating the performance, cost, and maintenance needs of each alternative, buyers can make informed decisions that align with their business objectives and operational needs.

Essential Technical Properties and Trade Terminology for alternator life expectancy

What Are the Key Technical Properties Affecting Alternator Life Expectancy?

Understanding the technical properties of alternators is crucial for B2B buyers seeking to enhance the longevity and reliability of their electrical systems. Here are some critical specifications to consider:

-

Material Grade

The materials used in alternator construction, such as aluminum or high-grade steel for the housing and copper for windings, significantly affect performance and durability. Higher-grade materials can withstand environmental stressors, reducing the likelihood of corrosion and wear. For buyers, investing in alternators made from superior materials can lead to lower maintenance costs and extended operational life. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions during manufacturing. Precise tolerances ensure that components fit together correctly and function efficiently, which is vital for the alternator’s performance. In B2B transactions, understanding tolerance levels can help buyers select products that meet their quality standards and reduce the risk of premature failure due to poor assembly. -

Power Output Rating

This specification indicates the maximum amount of electrical power the alternator can generate, usually measured in amperes (A). A higher power output is essential for vehicles with extensive electrical systems or additional accessories. Buyers should assess their electrical demands to ensure the alternator’s power output aligns with their needs, preventing overloading and potential damage. -

Heat Resistance

Alternators generate heat during operation, which can lead to component failure if not properly managed. Heat resistance ratings indicate how well an alternator can function under high-temperature conditions. For buyers in regions with extreme climates, selecting an alternator with superior heat resistance can significantly impact life expectancy and performance stability. -

Insulation Class

This property determines the alternator’s ability to withstand electrical and thermal stress. Insulation classes, such as Class B or Class F, indicate the maximum operating temperature the insulation can tolerate without degrading. Buyers should consider insulation class when selecting alternators, as higher classes typically translate to better longevity and reliability, especially in demanding operational environments.

What Are the Common Trade Terms Related to Alternator Life Expectancy?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to the manufacturer that produces parts that are identical to those originally installed in vehicles. Purchasing OEM alternators often guarantees compatibility and reliability. For buyers, understanding OEM products can help ensure they receive parts that meet the original specifications and performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it can affect inventory costs and supply chain management. Knowing the MOQ helps businesses plan their purchases effectively to avoid excess inventory or stock shortages. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products, such as alternators. This document is essential for comparing offers and negotiating favorable terms. For buyers, issuing an RFQ can streamline the procurement process and ensure they obtain the best value. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and delivery. Understanding these terms is vital for B2B buyers, especially when importing alternators from different regions, as they dictate cost responsibilities and risk management during transport. -

Warranty Period

This term indicates the duration for which the manufacturer guarantees the alternator’s performance. A longer warranty period can indicate confidence in the product’s durability and can be a significant factor for buyers when assessing the overall value of an alternator.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance the longevity and reliability of their electrical systems, ultimately leading to cost savings and improved operational efficiency.

Illustrative image related to alternator life expectancy

Navigating Market Dynamics and Sourcing Trends in the alternator life expectancy Sector

What are the Current Market Dynamics and Key Trends Influencing Alternator Life Expectancy?

The global alternator market is experiencing significant transformations driven by technological advancements and changing consumer expectations. One of the key trends is the increasing demand for high-efficiency alternators that enhance vehicle performance while optimizing energy consumption. As electric and hybrid vehicles gain traction, the need for alternators that can support higher electrical loads becomes crucial. This shift is particularly relevant for international buyers in regions like Africa and South America, where the adoption of electric vehicles is on the rise, fueled by government incentives and environmental awareness.

Moreover, the integration of smart technologies into automotive components is reshaping the sourcing landscape. B2B buyers are increasingly looking for suppliers that offer IoT-enabled alternators capable of real-time monitoring and diagnostics. This technology not only improves the longevity of alternators but also provides actionable insights for maintenance, thereby reducing operational costs. Additionally, manufacturers are focusing on advanced materials and innovative designs to enhance durability, which is vital for buyers in harsh climates, such as those in the Middle East, where extreme temperatures can significantly affect alternator life expectancy.

How is Sustainability and Ethical Sourcing Reshaping the Alternator Life Expectancy Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the alternator sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, is prompting buyers to prioritize ethical sourcing. Suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials or adhering to stringent environmental regulations, are more likely to attract international buyers.

The demand for ‘green’ certifications is also on the rise. Certifications such as ISO 14001 for environmental management systems signal a manufacturer’s commitment to reducing their ecological footprint. B2B buyers are increasingly seeking suppliers who can provide documentation of their sustainability efforts, which can enhance their own brand reputation and compliance with regulations.

Moreover, the focus on ethical supply chains is becoming essential. Buyers are encouraged to engage with suppliers that ensure fair labor practices and transparency in their sourcing processes. This not only mitigates reputational risks but also fosters long-term partnerships built on trust and shared values.

What is the Brief Evolution of the Alternator Life Expectancy Sector?

The alternator has evolved significantly since its inception in the early 20th century. Initially designed to convert mechanical energy into electrical energy, early models had limited lifespan and efficiency. As automotive technology advanced, so did the alternator. The introduction of solid-state electronics in the 1970s marked a turning point, enhancing performance and reliability.

In recent years, the focus has shifted towards increasing longevity and efficiency. Modern alternators are designed to withstand higher electrical demands and extreme operating conditions, significantly extending their life expectancy. This evolution is critical for B2B buyers, as the integration of advanced technologies and materials directly impacts the total cost of ownership and operational efficiency.

As the market continues to evolve, understanding these dynamics is essential for international B2B buyers to make informed sourcing decisions that align with both performance and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator life expectancy

-

How long does an alternator typically last in commercial vehicles?

The lifespan of an alternator in commercial vehicles generally ranges between 7 to 10 years or approximately 80,000 to 150,000 miles, depending on factors like driving conditions, load demands, and maintenance practices. For B2B buyers, understanding these metrics is crucial when assessing the longevity of alternators for fleet management. Regular inspections and proactive maintenance can significantly extend the lifespan, ensuring that your vehicles remain operational and reducing unexpected downtime. -

What are the key signs that indicate an alternator is failing?

Common symptoms of a failing alternator include dim or flickering lights, difficulty starting the vehicle, strange noises from the engine, and dashboard warning lights. For B2B buyers, recognizing these signs early can prevent costly repairs and downtime. It’s advisable to implement a routine check-up protocol to monitor alternator performance, especially in vehicles frequently used for heavy-duty operations. -

What factors influence the life expectancy of an alternator?

Several factors can affect an alternator’s lifespan, including driving habits (short trips vs. long distances), climate conditions (extreme heat or cold), electrical load from accessories, and overall vehicle maintenance. B2B buyers should consider these variables when selecting alternators for their fleets. Educating drivers on optimal driving habits and ensuring regular vehicle maintenance can mitigate the risks of premature alternator failure. -

How can I evaluate the quality of alternators from suppliers?

When sourcing alternators, it’s essential to assess supplier quality through certifications, customer reviews, and product warranties. Look for suppliers who provide detailed specifications and testing results for their alternators. Engaging in direct communication and requesting samples for testing can further ensure that the products meet your operational standards, ultimately leading to better performance and reliability. -

What are the minimum order quantities (MOQs) for purchasing alternators?

Minimum order quantities for alternators can vary widely based on the supplier and the specific product. Generally, MOQs can range from a few units for smaller suppliers to hundreds for larger manufacturers. B2B buyers should negotiate MOQs based on their needs and explore options for bulk purchasing discounts, which can enhance cost-effectiveness for fleet operations. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms can differ significantly based on the supplier and the nature of the transaction. Common terms include net 30, net 60, or even payment upon delivery. B2B buyers should clarify payment expectations upfront and consider using secure payment methods or letters of credit to minimize financial risk, particularly in international transactions. -

How do I ensure quality assurance for alternators from international suppliers?

To ensure quality assurance, B2B buyers should establish clear quality control protocols with their suppliers. This may include requiring certifications, conducting factory audits, and requesting regular quality reports. Additionally, implementing a testing phase upon receipt of goods can help identify any defects before the alternators are deployed in the field. -

What logistics considerations are important when importing alternators?

When importing alternators, key logistics considerations include shipping methods, customs regulations, and delivery timelines. B2B buyers should work with logistics providers familiar with international shipping to ensure compliance with local laws and efficient delivery. Additionally, evaluating the total landed cost, including tariffs and shipping fees, is crucial for accurate budgeting and financial planning.

Top 3 Alternator Life Expectancy Manufacturers & Suppliers List

1. Ford Fusion – Alternator Lifespan

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The average lifespan of a Ford Fusion alternator is around 180,000 miles, with some users reporting original alternators lasting up to 200,000 kilometers (approximately 124,000 miles) or more. Common issues leading to alternator failure include worn brushes in the voltage regulator, which typically last around 200,000 kilometers. Users suggest that instead of replacing the entire alternator, it ma…

2. Gurnee Chrysler Jeep Dodge Ram – Alternator Services

Domain: gurneechryslerjeepdodgeram.com

Registered: 2015 (10 years)

Introduction: The alternator is a crucial component of a vehicle that functions as a generator, using the engine as a source of energy to power the car’s electrical system. Common issues with alternators include the car not starting, devices not charging, dim headlights or interior lights, a burning rubber smell under the hood, an illuminated battery warning light, and whining or screeching noises after startin…

3. Tacoma – Alternator Lifespan Insights

Domain: tacomaworld.com

Registered: 2006 (19 years)

Introduction: Alternator life expectancy varies among Tacoma owners, with reported lifespans ranging from 112,000 miles to over 300,000 miles. Common issues include diode failure and bearing wear. Some users have replaced their alternators with remanufactured units from Napa or Denso. Maintenance tips include checking and potentially replacing brushes to extend alternator life.

Strategic Sourcing Conclusion and Outlook for alternator life expectancy

In navigating the complexities of alternator life expectancy, international B2B buyers should prioritize strategic sourcing to enhance operational efficiency and minimize costs. Understanding that alternators typically last between 7 to 10 years or 80,000 to 150,000 miles is crucial for planning maintenance schedules and budgeting for replacements. Factors such as driving habits, climate, and electrical load significantly influence longevity, making it essential to choose high-quality components that align with specific operational needs.

Effective sourcing strategies can lead to better supplier relationships, improved product quality, and lower total cost of ownership. By investing in reliable alternators and ensuring proper maintenance, companies can reduce downtime and avoid costly disruptions in their operations.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe should leverage data-driven insights and market trends to make informed purchasing decisions. Engage with trusted suppliers who provide transparency and support in understanding alternator specifications and performance. By doing so, businesses can secure a competitive edge and ensure their fleets remain operational, efficient, and ready for future challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to alternator life expectancy