Introduction: Navigating the Global Market for alternator issues symptoms

In the dynamic landscape of automotive maintenance, identifying alternator issues symptoms is crucial for international B2B buyers seeking reliable solutions. A malfunctioning alternator can lead to significant operational challenges, impacting the efficiency of fleets and individual vehicles alike. Whether you’re managing a logistics company in Nigeria or overseeing a car rental service in Germany, understanding the nuances of alternator performance is essential for sustaining productivity and minimizing downtime.

This comprehensive guide delves into the various types of alternator issues, their symptoms, and the potential implications for vehicle performance across different applications. From warning lights on dashboards to fluctuating electrical systems, we explore the telltale signs that indicate a failing alternator. Additionally, we provide insights into supplier vetting processes, helping you identify trusted manufacturers and service providers capable of delivering quality repairs and replacements.

By leveraging this guide, B2B buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions, ensuring that their vehicles are equipped with reliable alternators. With actionable insights into costs, maintenance practices, and troubleshooting techniques, this resource empowers you to enhance operational efficiency while mitigating risks associated with alternator failures. As you navigate the global market for automotive components, our guide serves as a vital tool in securing the performance and longevity of your fleet.

Table Of Contents

- Top 2 Alternator Issues Symptoms Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator issues symptoms

- Understanding alternator issues symptoms Types and Variations

- Key Industrial Applications of alternator issues symptoms

- 3 Common User Pain Points for ‘alternator issues symptoms’ & Their Solutions

- Strategic Material Selection Guide for alternator issues symptoms

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator issues symptoms

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator issues symptoms’

- Comprehensive Cost and Pricing Analysis for alternator issues symptoms Sourcing

- Alternatives Analysis: Comparing alternator issues symptoms With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator issues symptoms

- Navigating Market Dynamics and Sourcing Trends in the alternator issues symptoms Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator issues symptoms

- Strategic Sourcing Conclusion and Outlook for alternator issues symptoms

- Important Disclaimer & Terms of Use

Understanding alternator issues symptoms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Starting Issues | Difficulty starting the vehicle; clicking sound upon ignition | Automotive repair shops, fleet management | Pros: Immediate diagnosis; Cons: May require urgent repair. |

| Electrical System Malfunctions | Flickering or dimming lights; malfunctioning electronics | Vehicle maintenance services | Pros: Identifies broader issues; Cons: Can lead to increased downtime. |

| Warning Light Activation | Battery warning light illuminated on the dashboard | Automotive diagnostics, fleet operations | Pros: Easy to detect; Cons: May mislead if misinterpreted. |

| Unstable Power Supply | Variability in headlight brightness; inconsistent electronic features | Electrical system repairs, automotive parts suppliers | Pros: Indicates alternator issues early; Cons: Potential for cascading failures. |

| Unusual Noises | Grinding or whining sounds from the engine compartment | Mechanical repair services, parts distributors | Pros: Early warning of mechanical failure; Cons: May indicate serious damage. |

What Are the Characteristics of Starting Issues Related to Alternators?

Starting issues are often the first sign of alternator problems. Vehicles may struggle to start or produce a clicking sound when the ignition is turned. This symptom is critical for B2B buyers in the automotive repair sector, as it indicates a need for immediate attention. Fleet managers should prioritize these signs to minimize downtime and ensure operational efficiency. Purchasing reliable alternator components can prevent recurring issues and enhance vehicle reliability.

How Do Electrical System Malfunctions Indicate Alternator Problems?

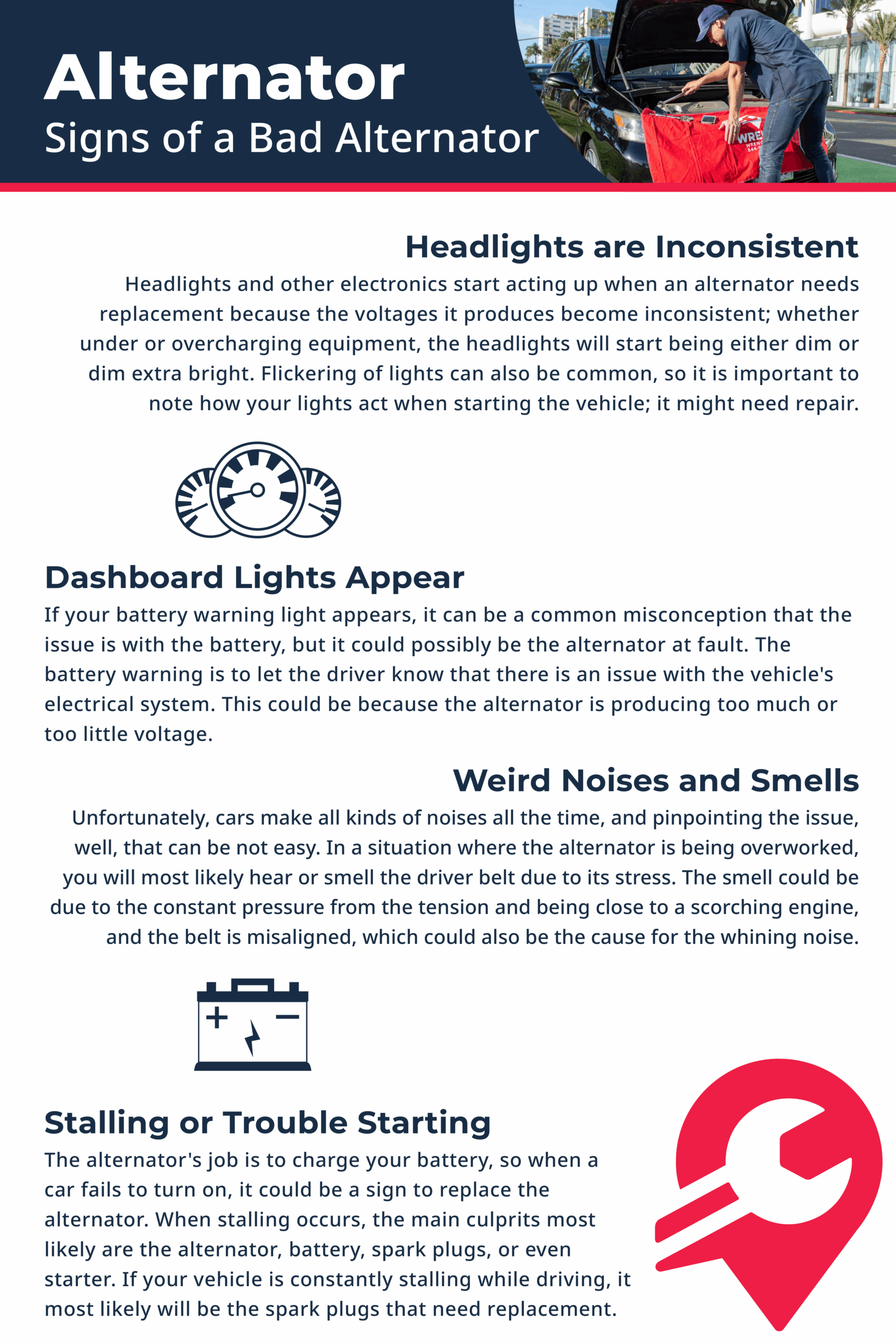

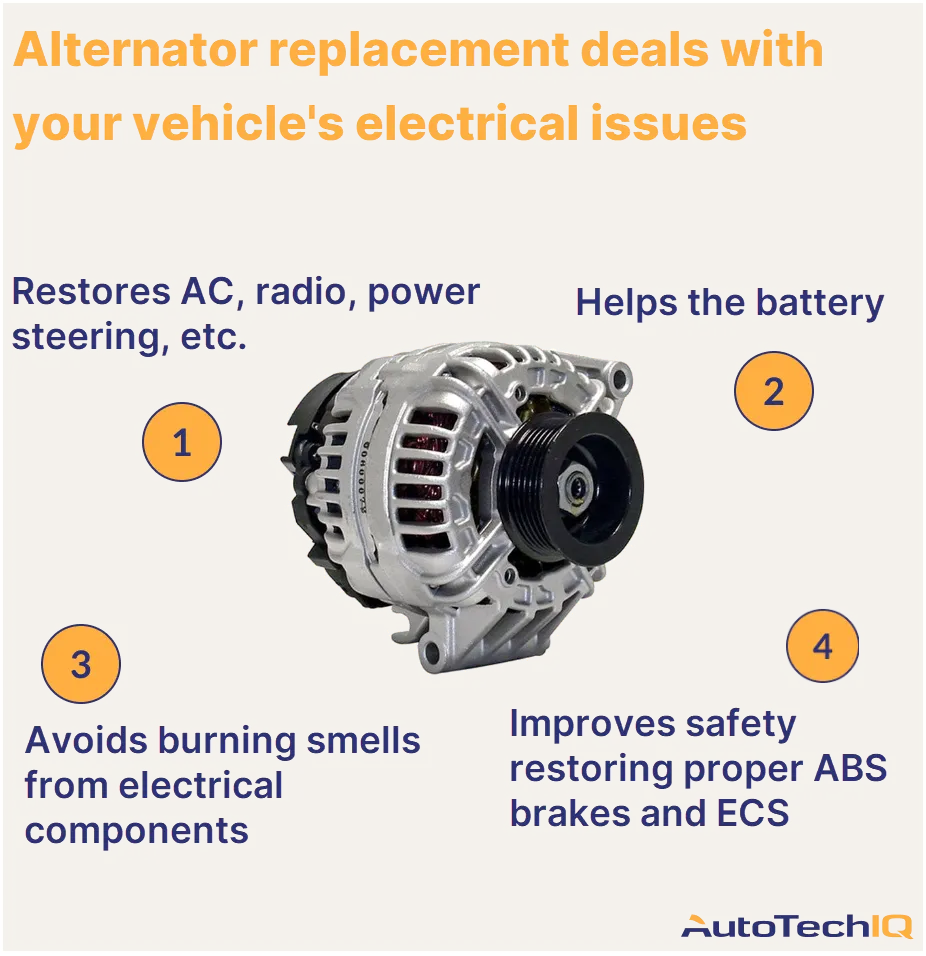

Electrical system malfunctions manifest as flickering lights or non-functioning electronic features, such as power windows or radio. These symptoms suggest that the alternator is not supplying adequate power. For B2B buyers in vehicle maintenance, recognizing these indicators can lead to prompt diagnosis and repair, reducing the risk of more extensive electrical system failures. Investing in high-quality alternators can mitigate these risks and improve customer satisfaction.

Why is Warning Light Activation a Key Indicator of Alternator Failure?

The battery warning light is a prominent feature on vehicle dashboards, signaling potential alternator issues. While it may suggest battery problems, it often points to broader electrical system failures. B2B buyers, especially in automotive diagnostics, should leverage this information to provide comprehensive service offerings. Understanding the nuances of warning light indicators can enhance service efficiency and customer trust.

What Does an Unstable Power Supply Reveal About Alternator Health?

An unstable power supply is characterized by inconsistent headlight brightness and erratic operation of electrical components. This symptom is crucial for automotive repair businesses, as it signals a failing alternator that could lead to further complications. B2B buyers should consider investing in advanced diagnostic tools to accurately assess these issues. Addressing unstable power supply symptoms early can prevent costly repairs and improve vehicle longevity.

How Do Unusual Noises Signal Potential Alternator Issues?

Unusual noises, such as grinding or whining, often indicate mechanical failure within the alternator. This symptom is vital for B2B buyers in mechanical repair services, as it can lead to significant engine damage if not addressed promptly. Recognizing these sounds can facilitate timely intervention and parts replacement. B2B buyers should prioritize sourcing high-quality alternators and components to ensure reliable performance and customer satisfaction.

Key Industrial Applications of alternator issues symptoms

| Industry/Sector | Specific Application of alternator issues symptoms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Diagnosing electrical failures in vehicles | Reduces downtime by ensuring timely repairs and maintenance | Quality of components, compatibility with existing systems, supplier reliability |

| Construction Equipment | Monitoring alternator performance in heavy machinery | Enhances operational efficiency and safety on job sites | Durability of parts, service support, and maintenance training |

| Transportation & Logistics | Ensuring fleet reliability through alternator checks | Minimizes breakdowns and improves delivery timelines | Availability of spare parts, warranty terms, and lead times |

| Mining Operations | Evaluating alternator health in mining vehicles | Prevents costly equipment failures and operational delays | Adaptability to harsh environments, technical support, and performance metrics |

| Renewable Energy | Assessing alternator issues in wind turbines | Optimizes energy production and reduces maintenance costs | Compliance with industry standards, energy efficiency, and supplier expertise |

How Are ‘Alternator Issues Symptoms’ Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, recognizing alternator issues is critical for maintaining vehicle performance. Symptoms such as dimming headlights or dashboard warning lights can indicate electrical failures that may lead to extensive downtime if not addressed promptly. Buyers in this sector must prioritize sourcing high-quality alternators that are compatible with their vehicle models, ensuring reliability in production lines and customer satisfaction.

What Role Do Alternator Issues Play in Construction Equipment?

In construction, heavy machinery relies heavily on efficient electrical systems. Symptoms of alternator failure can manifest as equipment stalling or malfunctioning electronic features, leading to safety hazards and project delays. Businesses must consider the durability and reliability of alternators, especially when sourcing for equipment that operates in rugged environments. Additionally, having access to service support and maintenance training can significantly enhance operational efficiency.

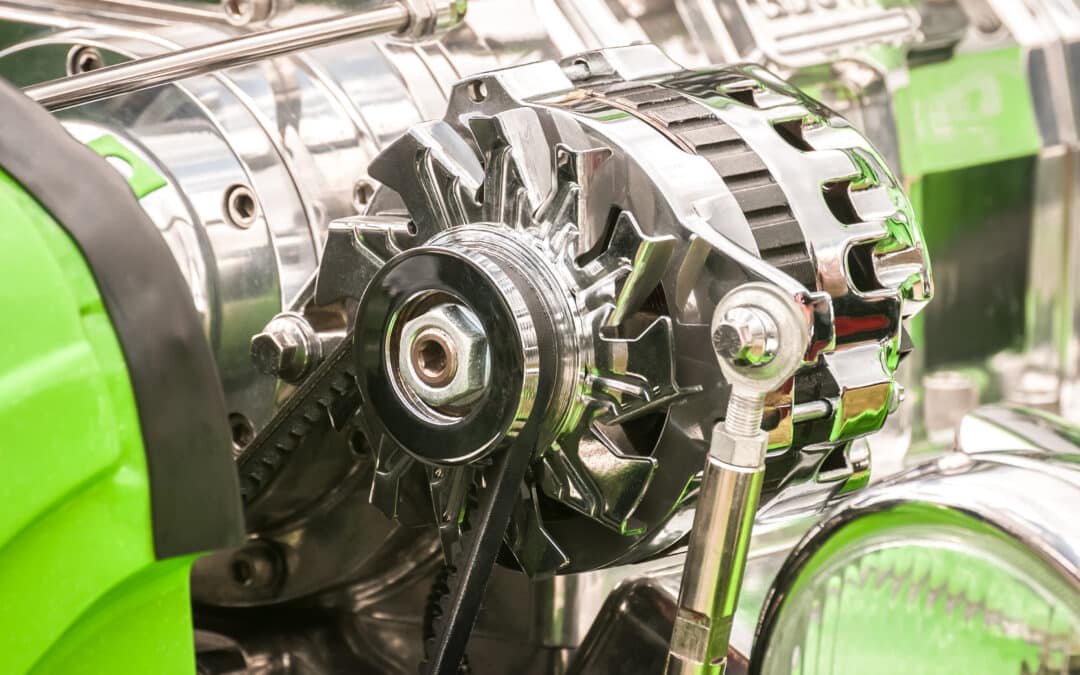

Illustrative image related to alternator issues symptoms

How Can Transportation & Logistics Benefit from Monitoring Alternator Health?

For companies in transportation and logistics, the reliability of their fleet is paramount. Alternator issues can lead to unexpected breakdowns, jeopardizing delivery schedules and customer trust. Regular diagnostics for symptoms such as starting problems or flickering lights can help prevent such occurrences. When sourcing alternators, businesses should evaluate the availability of spare parts and consider warranty terms that can safeguard their operations against potential failures.

Why Is It Important for Mining Operations to Address Alternator Symptoms?

In mining operations, vehicles endure extreme conditions, making the health of alternators vital for operational continuity. Symptoms like unusual noises or electrical malfunctions can indicate impending failures that could halt productivity. Buyers should focus on sourcing alternators designed to withstand harsh environments and provide robust performance metrics. Technical support from suppliers is also essential to ensure quick resolutions to any issues that arise.

How Do Renewable Energy Projects Utilize Knowledge of Alternator Issues?

In renewable energy, particularly with wind turbines, alternator performance directly affects energy output. Symptoms such as inconsistent power generation can signal potential problems that need immediate attention. For international buyers, understanding compliance with industry standards and energy efficiency is crucial when sourcing alternators. Partnering with suppliers that have proven expertise in renewable energy systems can optimize maintenance costs and enhance overall energy production efficiency.

3 Common User Pain Points for ‘alternator issues symptoms’ & Their Solutions

Scenario 1: Frequent Vehicle Stalling and Starting Issues

The Problem: A fleet manager in Nigeria has been facing frequent vehicle stalling and starting difficulties, particularly with older models in their fleet. This not only disrupts daily operations but also increases downtime, leading to inefficiencies and potential loss of revenue. The manager understands that an alternator issue might be the root cause but struggles to identify which vehicles require immediate attention and how to address the symptoms effectively.

The Solution: To tackle this problem, the fleet manager should implement a systematic approach to monitor and diagnose the electrical systems of the vehicles. First, they should invest in diagnostic tools that can measure battery voltage and alternator output, ensuring that each vehicle is operating within the recommended parameters. Regularly scheduled inspections should be established, focusing on signs of alternator failure such as difficulty in starting, stalling, and electrical malfunctions. Additionally, creating a maintenance log for each vehicle can help track patterns of issues, making it easier to identify which units may require alternator repairs or replacements. Partnering with local auto repair shops that specialize in electrical systems can also ensure timely repairs and minimize fleet downtime.

Scenario 2: Inconsistent Electrical Performance Across Fleet Vehicles

The Problem: A logistics company in Germany experiences inconsistent electrical performance in their fleet, where some vehicles have dimming headlights and malfunctioning electronic features. This inconsistency raises safety concerns and affects driver morale, as operators cannot rely on their vehicles’ electrical systems. The company needs a reliable method to pinpoint which vehicles are experiencing alternator issues before they lead to more significant problems.

The Solution: The logistics company should conduct a comprehensive electrical system audit across their fleet. This involves checking the battery warning lights, inspecting the condition of the alternator, and ensuring that all connections are secure and free from corrosion. Implementing a standardized checklist for drivers to report any electrical anomalies can provide valuable data for the fleet manager. Moreover, investing in advanced vehicle telematics systems can help monitor battery performance and alternator health in real-time, enabling proactive maintenance. Training drivers to recognize early warning signs of alternator issues will empower them to report problems immediately, facilitating timely interventions.

Scenario 3: High Repair Costs Due to Ignored Alternator Symptoms

The Problem: An auto parts distributor in South America has encountered a situation where several of their delivery trucks have suffered from costly repairs due to neglected alternator symptoms. Drivers frequently reported problems like flickering lights and starting issues, but these complaints were often dismissed as minor inconveniences. The distributor now faces unexpected repair costs that strain their budget and impact service delivery.

The Solution: To prevent further financial strain, the distributor should establish a clear protocol for addressing alternator symptoms as soon as they arise. This includes educating drivers on the importance of reporting even minor electrical issues and conducting regular training sessions on vehicle maintenance. Setting up a responsive maintenance schedule that aligns with reported symptoms can significantly reduce the risk of severe failures. Additionally, the distributor should consider collaborating with a specialized alternator supplier who can provide quality parts at competitive rates, ensuring that repairs are both efficient and cost-effective. By adopting a proactive maintenance approach and fostering open communication regarding vehicle performance, the distributor can minimize repair costs and enhance operational efficiency.

Illustrative image related to alternator issues symptoms

Strategic Material Selection Guide for alternator issues symptoms

What Are the Key Materials for Addressing Alternator Issues Symptoms?

When dealing with alternator issues, understanding the materials used in the components is crucial for effective diagnosis and repair. Here, we analyze four common materials that are integral to the performance and longevity of alternators, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Copper Influence Alternator Performance?

Key Properties: Copper is known for its excellent electrical conductivity, making it ideal for wiring and connections within the alternator. It can withstand a wide temperature range, typically from -200°C to 250°C, and has good corrosion resistance, especially when coated.

Pros & Cons: The primary advantage of copper is its superior conductivity, which ensures efficient power transfer. However, copper can be relatively expensive compared to alternatives like aluminum, and it is also heavier, which may impact the overall weight of the alternator.

Impact on Application: Copper is compatible with various electrical systems and is essential for high-performance applications. However, its susceptibility to corrosion in certain environments can lead to increased maintenance costs.

Considerations for International Buyers: Buyers in regions like Africa or South America should consider the local climate and potential for corrosion. Compliance with international standards such as ASTM B170 for copper wire is essential for ensuring quality.

Illustrative image related to alternator issues symptoms

What Role Does Aluminum Play in Alternator Components?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a temperature rating of up to 150°C. It is also less conductive than copper, but its weight advantage often compensates for this in automotive applications.

Pros & Cons: The lightweight nature of aluminum makes it suitable for applications where weight savings are critical. However, its lower conductivity can lead to inefficiencies in power transfer, necessitating larger wire gauges.

Impact on Application: Aluminum is often used in the casing and some internal components of alternators. Its compatibility with various media makes it a versatile choice, but it may require more frequent inspections for wear and tear.

Considerations for International Buyers: Compliance with standards like DIN EN 573 for aluminum alloys is crucial. Buyers in Europe, such as Germany, may prefer aluminum for its lightweight properties, particularly in electric vehicles.

How Do Plastics Enhance Alternator Durability?

Key Properties: Plastics, particularly thermoplastics like polycarbonate and nylon, offer excellent insulation properties and can withstand temperatures up to 120°C. They are also resistant to various chemicals and moisture.

Illustrative image related to alternator issues symptoms

Pros & Cons: The primary advantage of plastics is their lightweight and cost-effectiveness. However, they may not withstand high temperatures as well as metals, which can limit their application in high-stress areas.

Impact on Application: Plastics are often used for insulating components and housing parts of the alternator. Their compatibility with electrical systems makes them suitable for various automotive applications.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with international standards such as ISO 9001 for quality management. In regions like the Middle East, where temperatures can soar, selecting high-temperature-resistant plastics is vital.

What Benefits Does Steel Provide in Alternator Design?

Key Properties: Steel offers high strength and durability, with a temperature rating that can exceed 300°C. It is also resistant to wear and tear, making it suitable for heavy-duty applications.

Pros & Cons: The strength of steel provides excellent structural integrity, but it is heavier than aluminum and can be prone to rust if not properly treated. This can lead to increased maintenance costs over time.

Impact on Application: Steel is commonly used in the alternator’s frame and mounting components, providing stability and support. Its durability makes it suitable for demanding environments.

Considerations for International Buyers: Compliance with standards such as JIS G3101 for general structural steel is essential. Buyers from regions with high humidity, like parts of Africa, should prioritize galvanized or stainless steel options to prevent corrosion.

Summary Table of Material Selection for Alternator Issues Symptoms

| Material | Typical Use Case for alternator issues symptoms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical connections | Superior electrical conductivity | Higher cost and heavier weight | High |

| Aluminum | Casing and internal components | Lightweight and corrosion resistant | Lower conductivity | Medium |

| Plastics | Insulating components and housing parts | Cost-effective and lightweight | Limited high-temperature resistance | Low |

| Steel | Frame and mounting components | High strength and durability | Heavier and prone to rust | Medium |

This guide serves as a comprehensive resource for B2B buyers looking to understand the materials involved in alternator issues symptoms, enabling informed decisions that enhance product performance and reliability.

Illustrative image related to alternator issues symptoms

In-depth Look: Manufacturing Processes and Quality Assurance for alternator issues symptoms

What Are the Key Stages in the Manufacturing Process of Alternators?

The manufacturing process of alternators involves several critical stages that ensure high-quality production. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

What Are the Main Stages of Alternator Manufacturing?

-

Material Preparation

– The first stage involves sourcing and preparing materials, such as copper for windings, aluminum or steel for the casing, and various plastics for insulation. Quality control begins here, as the materials must meet specific standards for conductivity, durability, and thermal resistance.

– Suppliers typically conduct tests on raw materials to ensure they meet industry specifications, which is essential for the alternator’s performance. -

Forming

– In this stage, the raw materials are shaped into components. Techniques such as die-casting, stamping, and machining are used to create parts like the rotor, stator, and housing.

– Advanced technologies, including CNC (Computer Numerical Control) machining, are often employed to ensure precision and consistency. This accuracy is crucial for the alternator’s functionality and longevity. -

Assembly

– After forming, the components are assembled. This involves the integration of various parts, including bearings, brushes, and rectifiers. Automated assembly lines are common, allowing for high efficiency and reduced human error.

– Each assembled unit undergoes initial quality checks to ensure that all components fit correctly and function as intended. -

Finishing

– The final stage involves finishing processes such as painting, coating, or plating to protect against corrosion and enhance durability. This is particularly important for alternators that will be used in harsh environments.

– Finishing also includes final assembly checks, where the completed alternator is tested for electrical performance and mechanical integrity before being packaged for shipment.

How Is Quality Assurance Implemented in Alternator Manufacturing?

Quality assurance (QA) is a vital aspect of alternator manufacturing, ensuring that the products meet both international and industry-specific standards.

What Are the Relevant International Standards for Quality Control?

- ISO 9001 Certification

-

This globally recognized standard focuses on quality management systems (QMS). Manufacturers certified under ISO 9001 demonstrate their commitment to continuous improvement and customer satisfaction. B2B buyers should prioritize suppliers with this certification, as it indicates a robust quality framework.

-

CE Marking

-

Particularly relevant in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. For B2B buyers in Europe, ensuring that alternators are CE marked can facilitate smoother import processes and compliance with local regulations.

-

API Standards

- For suppliers dealing with automotive applications, adherence to American Petroleum Institute (API) standards is essential. These standards address the performance and quality of automotive products, ensuring that they can withstand rigorous conditions.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC)

– This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. It ensures that all materials meet the specified standards before production begins. -

In-Process Quality Control (IPQC)

– During the manufacturing process, various checkpoints are established to monitor production quality. This includes regular inspections of formed components and assembled units to detect any defects early in the process. -

Final Quality Control (FQC)

– At this stage, completed alternators undergo comprehensive testing. This includes performance tests to assess electrical output, mechanical integrity, and environmental durability. Any units failing to meet quality standards are reworked or discarded.

What Common Testing Methods Are Used in Quality Control?

B2B buyers should be aware of the various testing methods employed to ensure alternator quality:

- Electrical Testing

-

This involves measuring voltage and current output to confirm that the alternator functions correctly under load conditions. Tests may include load testing and no-load testing.

-

Thermal Testing

-

Alternators are subjected to temperature variations to ensure performance stability under extreme conditions. This testing helps identify potential overheating issues.

-

Vibration Testing

- This assesses the alternator’s ability to withstand operational vibrations, ensuring that it remains functional in dynamic environments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying the quality control processes of potential suppliers is crucial for B2B buyers, especially in international markets.

What Audit Methods Can Be Used to Evaluate Suppliers?

- Supplier Audits

-

Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality management systems, and compliance with relevant standards. Audits should focus on both documentation and operational practices.

-

Quality Assurance Reports

-

Requesting detailed quality assurance reports can provide insights into the supplier’s QC processes, including defect rates, corrective actions taken, and performance metrics.

-

Third-Party Inspections

- Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. This can be particularly valuable for buyers from regions like Africa and South America, where local oversight may vary.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when sourcing alternators, particularly in regions with diverse regulatory environments.

- Understanding Local Regulations

-

Buyers must familiarize themselves with local regulations regarding automotive components in their respective markets. Compliance with these regulations is essential to avoid legal issues and ensure product acceptance.

-

Cultural and Operational Differences

-

Cultural nuances can affect manufacturing practices and quality expectations. B2B buyers should engage with suppliers to align on quality standards and operational expectations, ensuring mutual understanding.

-

Supply Chain Considerations

- International logistics can complicate quality assurance. Buyers should ensure that their suppliers have robust logistics and quality management systems to mitigate risks associated with transportation and handling.

In conclusion, understanding the manufacturing processes and quality assurance standards for alternators is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control measures, buyers can make informed decisions and ensure reliable product performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator issues symptoms’

This guide provides a structured approach for B2B buyers to identify and procure solutions related to alternator issues symptoms. Understanding these symptoms is critical for maintaining vehicle performance and ensuring the reliability of automotive operations, especially in regions where vehicle uptime is crucial.

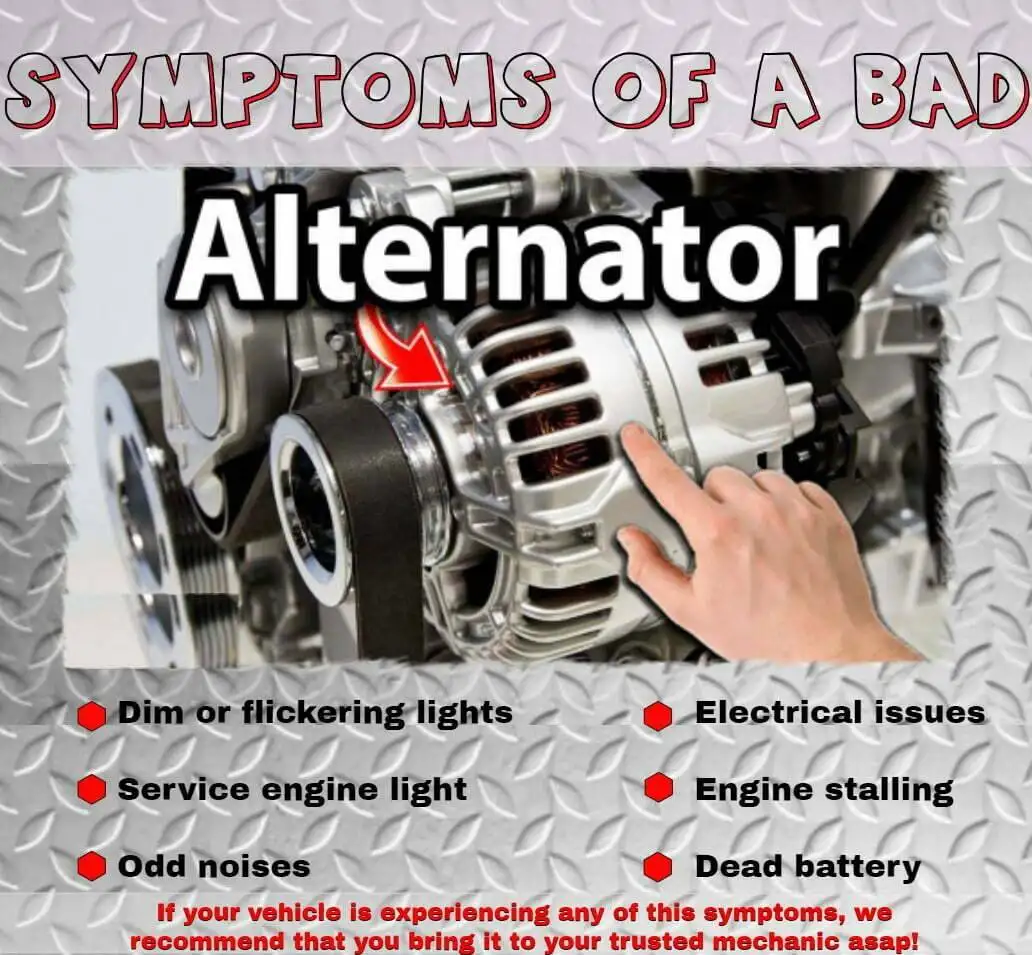

Step 1: Identify Key Symptoms of Alternator Issues

Begin by compiling a comprehensive list of symptoms associated with alternator failure. Common signs include starting problems, battery warning lights, flickering headlights, and unusual noises. Understanding these symptoms will help you pinpoint the specific issues you need to address when evaluating potential suppliers or repair services.

Illustrative image related to alternator issues symptoms

Step 2: Define Your Technical Specifications

Clearly outline the technical requirements for the alternators or diagnostic tools you are sourcing. Consider factors such as voltage output, compatibility with various vehicle models, and necessary certifications for safety and efficiency. This step is vital to ensure that the products you procure meet the operational needs of your fleet.

Step 3: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in alternators and related diagnostic tools. Look for companies with a strong reputation in the industry, positive customer reviews, and a proven track record of reliability. This initial vetting can save time and resources in the long run by ensuring you partner with reputable suppliers.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers hold relevant certifications and comply with international quality standards. Certifications such as ISO 9001 or those specific to automotive parts indicate a commitment to quality and reliability. This step is essential for mitigating risks associated with poor-quality products that could lead to further vehicle issues.

Step 5: Request Samples or Demonstrations

Before making a bulk purchase, request samples or demonstrations of the alternators or diagnostic equipment. This allows you to assess the quality and performance of the products firsthand. Pay attention to the build quality, ease of installation, and how well they address the identified symptoms.

Step 6: Evaluate Warranty and Support Options

Investigate the warranty terms and after-sales support offered by your suppliers. A robust warranty can provide peace of mind, while reliable customer support can assist with any issues that arise post-purchase. This is particularly important for businesses that rely heavily on their vehicles, as downtime can have significant financial implications.

Step 7: Compare Pricing and Value

Finally, compare pricing among your shortlisted suppliers, but do not make decisions based solely on cost. Assess the overall value, considering factors such as product quality, warranty, and customer support. A slightly higher price may be justified if it comes with superior quality and service, ultimately reducing long-term operational costs.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing solutions for alternator issues, ensuring their vehicles remain operational and efficient in various markets around the globe.

Comprehensive Cost and Pricing Analysis for alternator issues symptoms Sourcing

What Are the Key Cost Components for Sourcing Alternator Issues Symptoms?

When considering the sourcing of components related to alternator issues, it is vital to understand the different cost components involved. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials, such as copper for windings, aluminum for housings, and other electronic components, significantly influences the overall price. Fluctuations in global metal prices can directly impact sourcing costs.

-

Labor: Labor costs vary by region and can influence pricing. For instance, countries with higher wage standards may have increased manufacturing costs compared to regions with lower labor costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead and, subsequently, the final price.

-

Tooling: The investment in tooling for custom or specialized parts can add to the initial costs. Customization often requires specific molds and tools, which can be costly but necessary for tailored solutions.

-

Quality Control: Ensuring that products meet international standards and certifications can incur additional costs. However, investing in quality control can lead to long-term savings by reducing returns and warranty claims.

-

Logistics: Transportation costs, including shipping and customs duties, play a crucial role, especially for international buyers. Understanding Incoterms and logistics options can help buyers navigate these costs effectively.

-

Margin: Suppliers will include a margin in their pricing to ensure profitability. The margin can vary based on market demand and competition.

How Do Price Influencers Affect the Cost of Alternator Components?

Several factors influence the pricing structure for alternator-related components:

-

Volume/MOQ: Bulk purchasing often leads to lower unit prices. Buyers should negotiate minimum order quantities (MOQs) to maximize cost savings.

-

Specifications and Customization: Custom specifications may lead to higher costs due to additional tooling and manufacturing complexities. Standardized components generally have lower prices due to economies of scale.

-

Materials and Quality Certifications: Higher quality materials and certifications can increase costs but are often justified by improved reliability and performance, reducing the total cost of ownership.

-

Supplier Factors: Relationships with suppliers can influence pricing. Long-term partnerships may lead to better pricing agreements and terms.

-

Incoterms: Understanding shipping terms can help buyers manage logistics costs. Choosing the right Incoterm can clarify responsibilities and reduce unexpected charges.

What Buyer Tips Can Help with Cost-Efficiency in Sourcing Alternator Components?

B2B buyers can adopt several strategies to ensure cost-efficiency when sourcing alternator components:

-

Negotiate Effectively: Always negotiate prices and terms. Understand the supplier’s pricing structure and be prepared to discuss volumes, payment terms, and delivery schedules to secure better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance costs, warranty terms, and potential downtime. A slightly higher initial cost may lead to lower long-term expenses.

-

Explore Local Suppliers: For buyers in regions such as Africa or South America, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall efficiency.

-

Stay Informed on Market Trends: Keeping abreast of market trends, such as material costs and global supply chain challenges, can empower buyers to make informed decisions regarding timing and sourcing strategies.

What Are the Pricing Nuances for International B2B Buyers?

International buyers face unique pricing challenges, particularly concerning fluctuating exchange rates and varying import duties. Buyers from regions like Nigeria or Germany should be aware of:

Illustrative image related to alternator issues symptoms

-

Currency Fluctuations: Changes in currency values can impact the final cost of components. Consider hedging strategies or pricing agreements to mitigate these risks.

-

Import Duties and Taxes: Understanding local regulations regarding import duties can prevent unexpected costs. Researching potential tariffs can help in budgeting effectively.

-

Cultural and Market Differences: Recognizing the cultural nuances in negotiation and purchasing behaviors can lead to more fruitful supplier relationships.

Disclaimer for Indicative Prices

It is important to note that the prices discussed in this analysis are indicative and can vary based on specific circumstances such as supplier negotiations, market conditions, and regional factors. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing alternator issues symptoms With Other Solutions

Understanding Alternatives to Alternator Issues Symptoms

In the automotive industry, diagnosing problems accurately is crucial for effective maintenance and repair. While recognizing alternator issues symptoms is essential for vehicle functionality, there are alternative diagnostic methods and technologies that can also address electrical system problems. This section compares the traditional symptom identification of alternator issues with two viable alternatives: advanced diagnostic tools and battery monitoring systems.

| Comparison Aspect | Alternator Issues Symptoms | Advanced Diagnostic Tools | Battery Monitoring Systems |

|---|---|---|---|

| Performance | Direct identification of specific alternator failures | Provides comprehensive diagnostics across multiple systems | Monitors battery health and performance continuously |

| Cost | Low cost (visual inspection and basic tests) | Higher initial investment for tools/software | Moderate cost for monitoring devices |

| Ease of Implementation | Requires basic mechanical knowledge | Requires training to interpret diagnostic data | Generally easy to install and use |

| Maintenance | Minimal maintenance required | Software updates and calibration needed | Periodic checks and battery replacement |

| Best Use Case | Quick checks during routine maintenance | In-depth diagnostics for professional mechanics | Continuous monitoring for fleets or high-use vehicles |

What Are the Pros and Cons of Advanced Diagnostic Tools?

Advanced diagnostic tools offer a sophisticated approach to identifying vehicle issues. These tools can provide insights into various electrical system components, not just the alternator. The pros include comprehensive diagnostics that can help prevent misdiagnosis and save time. However, the cons are significant; these tools often require a substantial investment and can necessitate specialized training for effective use. For businesses managing a fleet, the initial cost may be justified by the long-term savings on repairs.

How Do Battery Monitoring Systems Work?

Battery monitoring systems are designed to continuously track the health and performance of a vehicle’s battery. They provide real-time data on battery voltage, charge cycles, and overall health. The advantages include their ability to predict battery failures before they occur, thereby minimizing downtime. However, while they are user-friendly, these systems may not diagnose alternator issues directly. Instead, they focus on the battery’s condition, which can be misleading if the alternator is the primary problem.

Illustrative image related to alternator issues symptoms

Conclusion: How Should B2B Buyers Choose the Right Solution?

When considering the best approach to diagnosing electrical issues in vehicles, B2B buyers should evaluate their specific needs, budget, and operational scale. For businesses focused on routine maintenance and cost-effective solutions, understanding alternator issues symptoms may suffice. However, for those seeking to enhance their diagnostic capabilities or manage large fleets, investing in advanced diagnostic tools or battery monitoring systems could yield better long-term value. Ultimately, the choice depends on balancing the cost against the potential for improved vehicle reliability and reduced downtime.

Essential Technical Properties and Trade Terminology for alternator issues symptoms

What Are the Key Technical Properties of Alternators That Impact Performance?

When evaluating alternators, it is essential to understand several critical specifications that influence their performance and reliability. These properties are crucial for B2B buyers looking to source alternators that meet specific operational requirements.

-

Material Grade

The materials used in alternator construction, such as copper for windings and aluminum for housings, significantly affect efficiency and durability. High-grade materials enhance conductivity and thermal resistance, which can lead to longer service life and lower maintenance costs. Buyers should prioritize alternators made from superior materials to ensure optimal performance in various environmental conditions. -

Tolerance Levels

Tolerance refers to the allowable deviation from a specified dimension in alternator components. Tight tolerances ensure that parts fit correctly and function smoothly, reducing the risk of mechanical failure. In B2B transactions, understanding tolerance levels is vital for compatibility with existing systems and for ensuring reliable performance, particularly in high-demand applications. -

Output Voltage and Current Rating

The output voltage (typically 12V or 24V) and current rating (measured in amperes) determine how effectively the alternator can charge the battery and power electrical systems. A higher output rating is particularly important for vehicles with numerous electronic components. B2B buyers should match these specifications to their vehicle requirements to avoid performance issues. -

Efficiency Rating

Efficiency is a measure of how well an alternator converts mechanical energy from the engine into electrical energy. High-efficiency alternators minimize energy loss as heat, which can lead to improved fuel economy and reduced emissions. For businesses operating fleets, selecting high-efficiency alternators can translate into significant cost savings over time. -

Cooling Mechanism

The cooling mechanism of an alternator, whether passive or active, plays a crucial role in preventing overheating during operation. Alternators with better cooling systems can maintain optimal performance levels longer, reducing the likelihood of failure. This aspect is especially important in regions with extreme temperatures or high operational demands.

What Are Common Trade Terms Associated with Alternator Procurement?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions involving alternators. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers that produce parts that are identical to those used in the original assembly of vehicles. Sourcing OEM alternators ensures compatibility and reliability, which is crucial for businesses looking to maintain fleet performance. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of alternators that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to plan their inventory and budget. Suppliers may set MOQs based on production costs and inventory management strategies. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific alternator models. This document outlines the buyer’s requirements and helps facilitate competitive bidding, ensuring that buyers receive the best possible terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping, including costs and risk management. Familiarity with these terms is crucial for B2B buyers engaged in global trade, as they dictate who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the period between placing an order and receiving the alternators. Understanding lead times is critical for businesses that rely on timely delivery to avoid operational disruptions. -

Warranty Period

The warranty period is the duration during which the manufacturer guarantees the alternator against defects. A longer warranty period often indicates greater confidence in product quality and can be a crucial factor in purchasing decisions for B2B buyers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they choose products that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the alternator issues symptoms Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Issues Symptoms Sector?

The global alternator market is witnessing significant shifts, driven by an increase in automotive production and a growing demand for electric vehicles (EVs). As countries across Africa, South America, the Middle East, and Europe ramp up their automotive industries, the need for reliable alternators and their components becomes paramount. This demand is further fueled by the rising number of vehicles on the road, leading to an increased focus on vehicle maintenance and repair services.

Illustrative image related to alternator issues symptoms

Emerging technologies, such as advanced diagnostics and predictive maintenance tools, are transforming how B2B buyers approach sourcing alternator components. These innovations enable mechanics and service centers to identify alternator issues more efficiently, enhancing customer satisfaction and reducing downtime. For instance, the integration of IoT (Internet of Things) technology in vehicles allows for real-time monitoring of electrical systems, providing early warnings of alternator failures.

Additionally, international buyers are increasingly looking for suppliers who can offer comprehensive solutions, including installation services and after-sales support. This shift emphasizes the importance of establishing long-term partnerships with manufacturers and distributors who can provide not just products but also value-added services.

How Is Sustainability Shaping the Sourcing of Alternator Components in B2B?

Sustainability has become a critical consideration in the B2B sourcing landscape, particularly in the automotive sector. The environmental impact of manufacturing processes and the sourcing of materials for alternators is under scrutiny as businesses aim to reduce their carbon footprint. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or adopting energy-efficient manufacturing processes.

Ethical sourcing is also gaining traction, with international buyers seeking transparency in their supply chains. This includes ensuring that the materials used in alternator components are sourced responsibly, without exploiting labor or harming communities. Certifications such as ISO 14001 for environmental management and other green certifications are becoming essential for suppliers looking to enter or expand in the B2B market.

Moreover, companies that embrace sustainability not only improve their brand image but also tap into a growing consumer base that values eco-friendly practices. This trend is particularly relevant in regions like Europe, where stringent environmental regulations drive demand for greener alternatives in automotive components.

What Is the Evolution of the Alternator and Its Impact on B2B Sourcing?

The alternator has evolved significantly since its inception in the early 20th century. Initially, vehicles relied on generators, which were less efficient and required more maintenance. The shift to alternators in the 1960s marked a turning point, as these devices provided a more reliable and efficient way to generate electrical power for vehicles.

As automotive technology has advanced, so too have the designs and capabilities of alternators. Modern alternators are more compact, lightweight, and capable of handling the increasing electrical demands of contemporary vehicles, including advanced infotainment systems and safety features. This evolution has implications for B2B buyers, who must stay informed about the latest advancements to ensure they are sourcing compatible and high-quality components.

The growing trend toward electrification in the automotive industry is also reshaping the alternator landscape. With hybrid and fully electric vehicles becoming more prevalent, understanding the specific alternator requirements for these vehicles is crucial for B2B buyers aiming to remain competitive in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator issues symptoms

-

How do I solve starting problems related to a faulty alternator?

To address starting issues caused by a faulty alternator, first, check the battery’s voltage using a multimeter. A reading below 12.4 volts indicates insufficient charge. If the voltage is low, inspect the alternator for signs of wear, such as loose connections or damaged wiring. It may be necessary to replace the alternator if it fails to produce between 13.7 and 14.7 volts while the engine is running. Promptly resolving these issues can prevent further electrical system damage and ensure reliable vehicle operation. -

What is the best way to identify alternator issues in vehicles?

The most effective method for identifying alternator issues is through a combination of visual inspections and electrical tests. Look for dim or flickering headlights, dashboard warning lights, and unusual noises from the engine. Conduct a battery test to check voltage levels, and inspect the alternator belt for wear. If problems persist, consult with a qualified technician for a thorough assessment. Early detection can save costs on repairs and minimize downtime for vehicles in your fleet. -

What are common symptoms of alternator failure that I should watch for?

Common symptoms of alternator failure include difficulty starting the vehicle, flickering or dimming headlights, and malfunctioning electrical components such as windows and locks. Additionally, a burning smell or strange noises from the engine can indicate overheating or bearing failure. If you notice any of these symptoms, it’s critical to have the alternator inspected and serviced to prevent more significant electrical issues or breakdowns. -

How can I vet suppliers for alternator parts in international trade?

Vetting suppliers involves researching their reputation, checking customer reviews, and evaluating their certifications and quality control processes. Request samples of alternator parts to assess quality and compatibility with your specifications. Additionally, inquire about their experience in international trade, including their understanding of logistics, customs, and payment terms. Establishing clear communication and expectations can ensure a successful partnership. -

What customization options are typically available for alternator parts?

Many suppliers offer customization options for alternator parts, including specific voltage ratings, amperage outputs, and physical dimensions. You can also request modifications based on your vehicle specifications or operational requirements. Discuss these options with potential suppliers to determine their flexibility in meeting your needs and the lead times associated with custom orders. -

What is the minimum order quantity (MOQ) for alternator components?

The minimum order quantity (MOQ) for alternator components can vary significantly between suppliers. Some may have a MOQ as low as 10 units, while others may require orders of 100 or more. It’s advisable to communicate your needs upfront and negotiate terms that align with your purchasing strategy. Understanding the MOQ can help you manage inventory and cash flow effectively. -

What payment terms should I consider when sourcing alternator parts?

Payment terms can vary by supplier and may include options such as upfront payment, net 30/60/90 days, or letter of credit arrangements. Consider factors such as your cash flow, the supplier’s reputation, and the value of the order when negotiating terms. Establishing favorable payment terms can enhance your purchasing power and financial stability in international transactions. -

How do logistics impact the sourcing of alternator parts internationally?

Logistics play a crucial role in the timely delivery of alternator parts. Factors such as shipping methods, customs clearance processes, and lead times can affect your supply chain efficiency. Work with suppliers who have established logistics capabilities and a clear understanding of international shipping regulations. Ensure that you account for potential delays, especially when sourcing from regions with varying infrastructure and customs processes.

Top 2 Alternator Issues Symptoms Manufacturers & Suppliers List

1. Nissan – Alternator Symptoms

Domain: nissanofstockton.com

Registered: 2004 (21 years)

Introduction: Symptoms of a failing Nissan alternator include dimming headlights, dashboard warning lights (especially the battery warning light), electrical issues (like flickering interior lights and malfunctioning power windows), and strange noises (grinding or whining). To address a failing alternator, check the battery, inspect the alternator for physical damage, test the alternator’s voltage output, and r…

2. Alternator Replacement – Cost in the UK

Domain: rac.co.uk

Introduction: Alternator replacement cost in the UK ranges from £250 to £800, with an average price of £535.05 for parts and labor. Specific average replacement costs by manufacturer include: Audi £628.59, BMW £603.37, Citroen £629.99, Ford £494.90, Mercedes £614.57, MINI £549.36, Nissan £482.06, Peugeot £663.06, Renault £587.78, Toyota £477.93, Vauxhall £477.93, Volkswagen £507.07, Volvo £539.62.

Strategic Sourcing Conclusion and Outlook for alternator issues symptoms

As we conclude our exploration of alternator issues and their symptoms, it is crucial for international B2B buyers to recognize the significant impact of a well-functioning alternator on vehicle performance and reliability. Key takeaways include the importance of promptly addressing signs of alternator failure, such as starting problems, warning lights, and electrical malfunctions. By understanding these symptoms, businesses can mitigate downtime and enhance operational efficiency.

Strategic sourcing plays a pivotal role in ensuring access to high-quality alternators and related components. Establishing relationships with reliable suppliers can lead to better pricing, improved availability, and enhanced product performance, which are critical for maintaining a fleet’s operational readiness.

Looking ahead, businesses in Africa, South America, the Middle East, and Europe should proactively engage with suppliers who understand the regional nuances of automotive maintenance and repair. By prioritizing strategic sourcing and supplier collaboration, companies can safeguard their investments and ensure their vehicles remain in optimal condition. Take action today by evaluating your supply chain and exploring partnerships that align with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.