Introduction: Navigating the Global Market for starting a car with a bad starter

Dealing with a car that won’t start can be a significant headache for businesses operating in diverse markets, particularly when a faulty starter is involved. Understanding how to effectively start a car with a bad starter is crucial for automotive companies, fleet managers, and service providers across Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil. This guide offers a comprehensive exploration of the various types of starters, their applications, and innovative solutions for overcoming starter issues, equipping B2B buyers with the knowledge needed to make informed decisions.

In this resource, you will find actionable insights on diagnosing starter problems, essential tools required for temporary fixes, and tips for sourcing reliable starter components from vetted suppliers. The guide also addresses cost considerations and the long-term implications of choosing quality over price. By understanding the nuances of starter issues and the available solutions, international B2B buyers can optimize their purchasing strategies, ensuring their operations remain smooth and efficient. Empower your business with the knowledge to tackle starter problems head-on and enhance your service offerings in the competitive global automotive market.

Table Of Contents

- Top 1 Starting A Car With A Bad Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starting a car with a bad starter

- Understanding starting a car with a bad starter Types and Variations

- Key Industrial Applications of starting a car with a bad starter

- 3 Common User Pain Points for ‘starting a car with a bad starter’ & Their Solutions

- Strategic Material Selection Guide for starting a car with a bad starter

- In-depth Look: Manufacturing Processes and Quality Assurance for starting a car with a bad starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starting a car with a bad starter’

- Comprehensive Cost and Pricing Analysis for starting a car with a bad starter Sourcing

- Alternatives Analysis: Comparing starting a car with a bad starter With Other Solutions

- Essential Technical Properties and Trade Terminology for starting a car with a bad starter

- Navigating Market Dynamics and Sourcing Trends in the starting a car with a bad starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starting a car with a bad starter

- Strategic Sourcing Conclusion and Outlook for starting a car with a bad starter

- Important Disclaimer & Terms of Use

Understanding starting a car with a bad starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Battery Jump Start | Utilizes jumper cables to connect to another vehicle’s battery | Automotive repair shops, roadside assistance services | Pros: Quick and inexpensive; Cons: Only a temporary fix. |

| Tapping the Starter | Gently striking the starter to free stuck components | DIY mechanics, auto parts retailers | Pros: No special tools required; Cons: Risk of further damage. |

| Cleaning Battery Connections | Removing corrosion from battery terminals | Maintenance service providers, fleet management | Pros: Simple and effective; Cons: Requires regular maintenance. |

| Manual Push Start (for Manual Cars) | Using physical force to start the vehicle | Automotive training programs, driving schools | Pros: Effective for manual vehicles; Cons: Not suitable for automatics. |

| Solenoid Repair | Fixing or replacing the solenoid for better connectivity | Auto repair shops, parts suppliers | Pros: Long-term solution; Cons: Requires technical expertise. |

What Are the Key Features of Battery Jump Starting?

Battery jump starting is a common method for addressing starting issues caused by a bad starter. This technique involves using jumper cables to connect the vehicle’s battery to another functioning battery, providing the necessary power to start the engine. This method is particularly useful for automotive repair shops and roadside assistance services, as it allows for quick, on-the-spot solutions. However, it’s important for buyers to understand that this is only a temporary fix; if the starter is indeed faulty, the vehicle will likely need further repairs.

How Does Tapping the Starter Work?

Tapping the starter is a traditional technique that involves gently striking the starter motor with a hammer or mallet to free any stuck components. This method can be particularly appealing to DIY mechanics and auto parts retailers, as it requires minimal tools and can often be performed on-site. While this approach may yield immediate results, it carries the risk of causing additional damage to the starter motor, making it essential for buyers to weigh the potential downsides against the urgency of the situation.

Why Is Cleaning Battery Connections Important?

Cleaning battery connections is a preventive measure that can help avoid starter issues caused by poor electrical connectivity. This process involves removing any corrosion from the battery terminals and ensuring secure connections. Maintenance service providers and fleet management companies can benefit from incorporating this practice into their routine checks. Although it is a simple and effective solution, it necessitates regular maintenance to ensure optimal vehicle performance, which should be factored into service contracts.

What Is Involved in Manual Push Starting?

Manual push starting is a technique used primarily for manual transmission vehicles, where the vehicle is rolled to gain momentum before the driver releases the clutch while turning the ignition key. This method can be an effective way to bypass a malfunctioning starter and is often taught in automotive training programs and driving schools. While it is a practical solution for manual cars, it is not applicable to automatic vehicles, limiting its utility. Buyers should also consider safety precautions when employing this method.

How Can Solenoid Repair Provide a Long-Term Solution?

Solenoid repair involves diagnosing and fixing issues with the solenoid, an essential component that facilitates the connection between the ignition switch and the starter motor. This approach is particularly relevant for auto repair shops and parts suppliers looking to provide comprehensive service options. While solenoid repair can lead to a long-term solution for starting problems, it requires technical expertise and may involve additional costs for parts and labor, making it important for buyers to consider their budget and the expertise of their service providers.

Key Industrial Applications of starting a car with a bad starter

| Industry/Sector | Specific Application of starting a car with a bad starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Temporary solutions for customers with faulty starters | Enhances customer satisfaction by providing quick fixes | Reliable tools, parts availability, and technician training |

| Fleet Management | Emergency starting solutions for fleet vehicles | Minimizes downtime and operational costs | Durable equipment, quick service options, and logistics support |

| Transportation Services | Start assistance for vehicles in transit | Ensures timely deliveries and reduces service interruptions | Portable tools, effective training, and safety measures |

| Car Rental Agencies | Quick fixes for rental cars with starter issues | Maintains fleet availability and customer trust | Comprehensive toolkits, staff training, and maintenance schedules |

| Construction Equipment | Starting solutions for construction vehicles | Keeps projects on schedule by minimizing equipment failure | Heavy-duty tools, compatibility with various machinery types |

How Can Automotive Repair Shops Benefit from Starting a Car with a Bad Starter?

Automotive repair shops can utilize techniques for starting a car with a bad starter to provide immediate solutions for customers. By offering temporary fixes, such as cleaning battery connections or using a mallet on the starter, they can enhance customer satisfaction through quick service. Repair shops should consider sourcing reliable tools and ensuring technicians are trained in these methods, as they can significantly reduce wait times and improve service quality.

Illustrative image related to starting a car with a bad starter

What Advantages Do Fleet Management Companies Gain from Emergency Starting Solutions?

Fleet management companies often face challenges when vehicles fail to start, impacting their operations. Implementing emergency starting solutions can minimize downtime and reduce operational costs. For these businesses, it is crucial to source durable equipment that can withstand frequent use, as well as ensure quick service options are available to address starter issues promptly. This approach enhances efficiency and maintains the overall productivity of the fleet.

How Do Transportation Services Ensure Timely Deliveries with Starting Assistance?

Transportation services can encounter delays due to vehicle starting issues. Having the ability to start vehicles with a bad starter ensures timely deliveries and reduces service interruptions. Companies in this sector should focus on portable tools and effective training for drivers to handle starter problems. Additionally, implementing safety measures during these processes is essential to protect both personnel and equipment.

What Role Does Quick Fixes Play for Car Rental Agencies?

Car rental agencies frequently deal with starter issues in their fleets. Implementing quick fixes for vehicles with bad starters allows these businesses to maintain fleet availability and customer trust. Sourcing comprehensive toolkits and ensuring staff are trained in emergency starting techniques can facilitate rapid responses to such issues, ultimately leading to higher customer satisfaction and loyalty.

How Can Construction Equipment Companies Benefit from Starting Solutions?

Construction equipment often experiences failures, including starting problems, which can halt projects. Having effective starting solutions for construction vehicles ensures that projects remain on schedule and do not incur additional costs due to equipment failure. Companies should prioritize sourcing heavy-duty tools that are compatible with various machinery types, allowing for quick resolutions to starting issues and minimizing project delays.

3 Common User Pain Points for ‘starting a car with a bad starter’ & Their Solutions

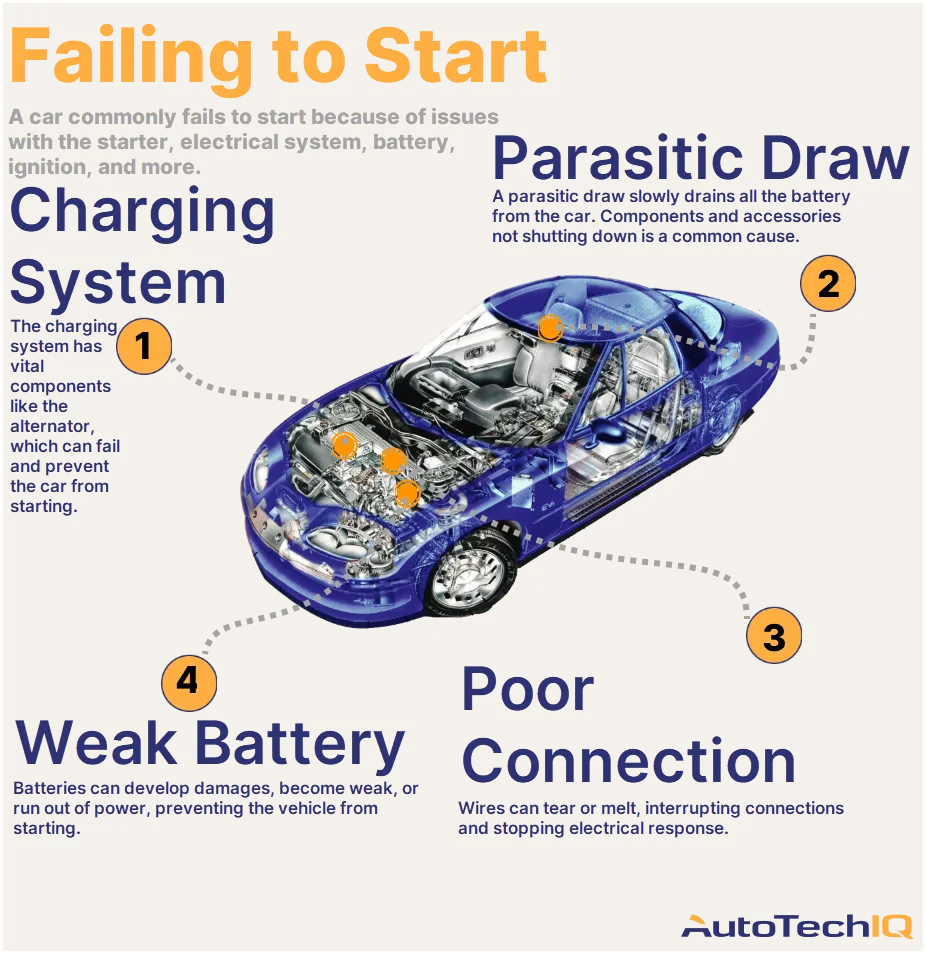

Scenario 1: Difficulty Diagnosing Starter Issues in Fleet Vehicles

The Problem: For B2B buyers managing a fleet of vehicles, the challenge of diagnosing a faulty starter can lead to significant downtime and operational inefficiencies. When a vehicle fails to start, it may not be immediately clear whether the issue lies with the starter, the battery, or another component such as the ignition system. This uncertainty can result in unnecessary repairs and increased costs, especially if vehicles are sent to the shop without proper diagnostics. Additionally, fleet managers may struggle with the logistical implications of having vehicles out of service, which can disrupt schedules and service commitments.

Illustrative image related to starting a car with a bad starter

The Solution: Implementing a systematic approach to diagnosing starter issues can greatly enhance operational efficiency. Start by investing in diagnostic tools that allow for accurate battery and starter testing. A multimeter can help assess voltage levels, while a starter relay tester can quickly identify issues without removing the starter. Educating fleet personnel on how to perform basic checks—such as inspecting battery connections for corrosion—can also help rule out simpler problems before escalating to more costly repairs. Regular training sessions on vehicle maintenance can empower staff to identify potential issues early, ensuring that vehicles are only sent for professional diagnostics when absolutely necessary.

Scenario 2: High Repair Costs Due to Frequent Starter Failures

The Problem: Businesses relying on vehicles often face escalating repair costs due to recurring starter failures. This situation is particularly common in regions with harsh climates or where vehicles are subjected to heavy usage. The financial burden is not only from the direct costs of repairs but also from the indirect costs associated with lost productivity and the potential impact on customer service. Frequent breakdowns can lead to higher insurance premiums and a negative reputation if service delivery is affected.

The Solution: To mitigate these costs, B2B buyers should prioritize quality when sourcing starter components. Partnering with reputable suppliers who offer high-performance starters designed for durability can provide long-term savings. Additionally, implementing a preventative maintenance schedule that includes regular inspections of the starter and related electrical systems can help catch issues before they lead to failure. Educating the workforce on the importance of proper vehicle operation—such as avoiding short trips that can strain the battery and starter—can also prolong the life of these components. Consider investing in training programs that enhance the skills of maintenance personnel, enabling them to perform timely interventions that can prevent starter-related issues.

Scenario 3: Limited Knowledge of Temporary Solutions for Starting a Vehicle

The Problem: B2B buyers may find themselves in situations where they need to start a vehicle with a bad starter but lack the knowledge of effective temporary solutions. This knowledge gap can lead to frustration and wasted time, especially when immediate access to professional assistance is not available. Understanding how to perform temporary fixes can be crucial in maintaining operations, especially for businesses in remote areas or those with a tight schedule.

The Solution: Providing comprehensive training on temporary methods for starting a car with a bad starter can empower employees and minimize downtime. Techniques such as using jumper cables to test for battery issues or employing a mallet to tap the starter can be effective short-term solutions. It’s essential to have a toolkit readily available that includes jumper cables, a hammer, and basic diagnostic tools. Additionally, establishing a protocol for safe push-starting manual transmission vehicles can be invaluable. Documenting these methods in a user-friendly guide or manual, and distributing it to all drivers and maintenance personnel, can ensure that everyone is equipped to handle starter issues effectively. Regular refresher courses can help keep this knowledge fresh and ensure that staff remain confident in applying these techniques when necessary.

Strategic Material Selection Guide for starting a car with a bad starter

What Materials Are Best for Starting a Car with a Bad Starter?

When dealing with the challenge of starting a car with a bad starter, the selection of materials used in tools and components can significantly impact performance and reliability. Here, we analyze four common materials that are critical for this application: copper, aluminum, steel, and plastic. Each material has unique properties, advantages, and limitations that international B2B buyers should consider.

How Does Copper Perform in Starter Applications?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for battery cables and connections. It has a high melting point (1,984°F or 1,085°C) and offers good resistance to corrosion, especially when coated.

Pros: Copper’s superior conductivity ensures efficient energy transfer, which is crucial when jump-starting a vehicle. Its durability and resistance to oxidation enhance the longevity of connections.

Cons: The primary drawback of copper is its cost, which can be relatively high compared to alternatives. Additionally, copper is heavier, which may not be ideal for all applications.

Impact on Application: Copper’s compatibility with various automotive fluids and its ability to withstand high temperatures make it suitable for electrical connections in starter systems.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM B75 for copper wire. In countries like Brazil, local sourcing may reduce costs and improve supply chain efficiency.

Is Aluminum a Viable Option for Starter Components?

Aluminum is another common material used in automotive applications, especially for components like housings and brackets due to its lightweight nature and good corrosion resistance.

Pros: Aluminum is significantly lighter than copper, which can improve the overall weight of components. It is also less expensive than copper while still providing adequate electrical conductivity for many applications.

Cons: While aluminum resists corrosion, it can be less durable under high-stress conditions compared to steel. Additionally, its conductivity is lower than that of copper, which may affect performance in high-demand scenarios.

Impact on Application: Aluminum’s lightweight properties make it suitable for portable tools used to start vehicles, such as jump starters and battery clamps.

Considerations for International Buyers: Buyers should be aware of the specific grades of aluminum that comply with local standards, such as DIN EN 573 in Europe. In regions like Africa, sourcing aluminum locally can help mitigate import costs.

What Role Does Steel Play in Starter Tools?

Steel is often used in the construction of tools required for starting a car, such as wrenches and hammers. Its strength and durability make it an ideal choice for applications requiring high mechanical resistance.

Pros: Steel tools are robust and can withstand significant force, making them suitable for tasks like tapping a starter motor. Steel is also generally more affordable than both copper and aluminum.

Cons: The primary downside of steel is its susceptibility to rust and corrosion if not properly treated. This can limit its lifespan, especially in humid environments.

Impact on Application: Steel tools are essential for maintenance and emergency repairs, providing the necessary leverage and strength to manipulate starter components.

Considerations for International Buyers: Compliance with standards such as JIS G3101 in Japan or ASTM A36 in the U.S. is crucial for ensuring quality. Buyers in South America should also consider local regulations regarding tool manufacturing.

How Does Plastic Factor into Starter Solutions?

Plastic materials, particularly those that are heat-resistant, are often used in insulation and protective coverings for electrical components.

Pros: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes, making them ideal for insulation and protection of wiring.

Cons: Plastics may not withstand high temperatures as well as metals, which can lead to degradation over time. They also generally offer no electrical conductivity.

Impact on Application: Plastic is vital for ensuring safety and preventing electrical shorts in starter systems, especially in environments where moisture is a concern.

Considerations for International Buyers: Buyers should ensure that plastics comply with relevant safety and environmental standards, such as REACH in Europe. In regions like the Middle East, sourcing durable plastics that can withstand extreme temperatures is essential.

Summary Table of Material Selection for Starting a Car with a Bad Starter

| Material | Typical Use Case for starting a car with a bad starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Battery cables and electrical connections | Excellent electrical conductivity | High cost and weight | High |

| Aluminum | Housings and portable tools | Lightweight and cost-effective | Lower durability and conductivity than copper | Medium |

| Steel | Tools like wrenches and hammers | High strength and affordability | Prone to rust and corrosion | Low |

| Plastic | Insulation and protective coverings | Lightweight and corrosion-resistant | Limited temperature resistance | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to enhance their automotive service offerings, particularly in regions with varying environmental conditions and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for starting a car with a bad starter

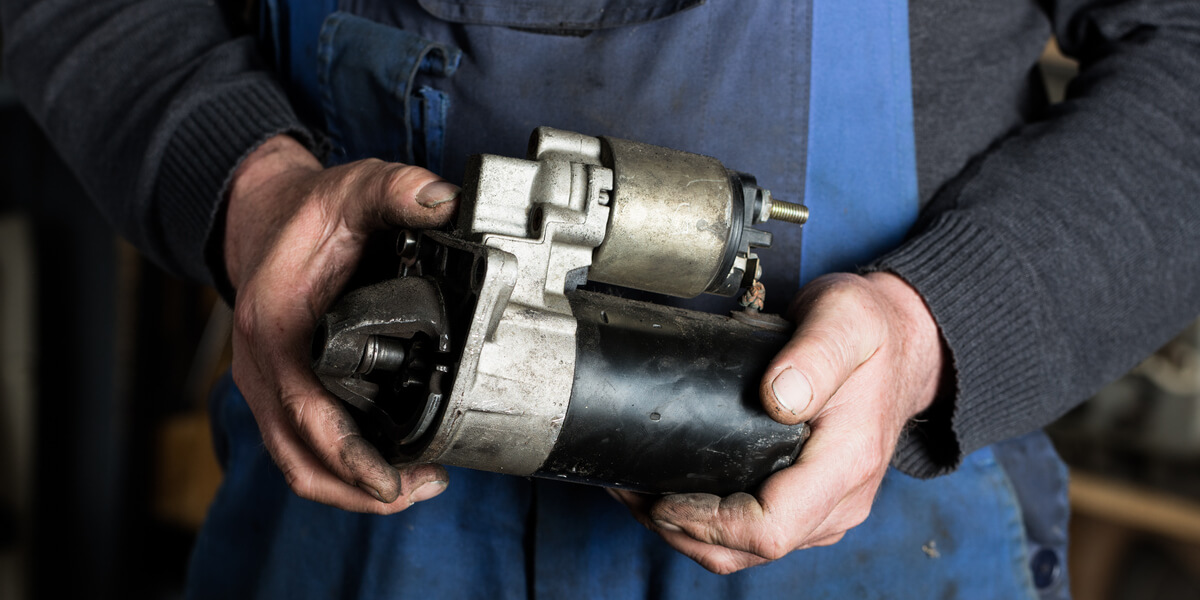

What Are the Main Stages in the Manufacturing Process of Starter Motors?

The manufacturing process for starter motors, essential components in automotive systems, involves several critical stages, each requiring precision and adherence to quality standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting high-quality raw materials, such as copper for windings, steel for the casing, and various alloys for components like gears and brushes. Suppliers must ensure that materials meet specific mechanical and electrical standards to enhance performance and durability. This stage often includes rigorous material testing to assess properties like tensile strength and conductivity.

-

Forming: The forming stage utilizes techniques such as stamping, forging, and machining to create the essential parts of the starter motor. Stamping is commonly used for producing the metal housings and end plates, while forging is employed for components that require high strength, such as the pinion gears. Precision machining is crucial for creating components like the armature and field coils, ensuring they fit together correctly and function efficiently.

-

Assembly: During assembly, the various components are brought together in a controlled environment. This process often employs automated assembly lines to enhance efficiency and reduce human error. Skilled workers oversee the assembly, ensuring that components are correctly aligned and securely fastened. This stage may also involve the installation of protective coatings to prevent corrosion and wear.

-

Finishing: The final stage includes quality checks and surface treatments. Components are coated to enhance corrosion resistance, and finishes may include painting or plating. This stage is critical, as it ensures that the starter motor can withstand harsh environmental conditions, especially in markets with extreme climates.

What Quality Assurance Processes Are Essential for Starter Motors?

Quality assurance (QA) in the manufacturing of starter motors is paramount to ensure reliability and performance. Adhering to international standards and implementing a robust quality control (QC) system can significantly reduce defects and improve customer satisfaction.

-

International Standards: Compliance with standards such as ISO 9001 is essential for manufacturers targeting international markets. ISO 9001 outlines the requirements for a quality management system (QMS), emphasizing customer satisfaction and continuous improvement. For automotive components, adherence to specific industry standards like the IATF 16949 is also critical, as it focuses on the automotive sector’s unique requirements.

-

QC Checkpoints: The QC process typically involves several key checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production line. Materials are tested for compliance with specifications, ensuring that only high-quality inputs are used.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to monitor production quality. This includes checking dimensions, tolerances, and assembly procedures to ensure that they meet established standards.

– Final Quality Control (FQC): After assembly, the finished starter motors undergo comprehensive testing. This includes functional tests to verify performance under various conditions, as well as durability tests to assess the lifespan of the product. -

Common Testing Methods: Various testing methods are employed during the QC process. Electrical testing checks for proper current flow and resistance, while mechanical testing assesses strength and durability. Vibration and thermal testing simulate real-world conditions to ensure reliability. Manufacturers may also conduct life cycle testing to predict the longevity of starter motors under typical usage scenarios.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets, verifying the quality control processes of suppliers is crucial to ensuring the reliability of starter motors. Here are some practical steps buyers can take:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to evaluate their manufacturing processes and QC measures firsthand. This includes reviewing documentation related to ISO certifications, quality management systems, and production workflows.

-

Quality Reports: Requesting detailed quality reports can provide insights into a supplier’s QC performance. These reports should include data on defect rates, testing outcomes, and corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing and quality assurance processes. These inspections can be particularly beneficial for buyers who are unable to visit suppliers in person, providing assurance that products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control to ensure they receive reliable products.

-

Regulatory Compliance: Understanding regional regulations and compliance requirements is essential. For example, European buyers should be aware of CE marking requirements, while buyers in the Middle East may need to consider local standards and certifications.

-

Cultural Differences: Cultural nuances can impact communication and expectations regarding quality. Buyers should establish clear lines of communication with suppliers and ensure that quality expectations are explicitly outlined in contracts.

-

Supply Chain Considerations: The complexity of international supply chains can introduce additional risks. Buyers should evaluate the entire supply chain, including logistics and transportation, to ensure that quality is maintained from manufacturing to delivery.

-

Post-Purchase Support: Establishing a strong relationship with suppliers can facilitate better post-purchase support. This includes warranty agreements, repair services, and the ability to address any quality concerns that may arise after the sale.

By understanding the manufacturing processes, quality assurance practices, and specific nuances relevant to international trade, B2B buyers can make informed decisions when sourcing starter motors and ensure they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starting a car with a bad starter’

To assist B2B buyers in effectively addressing the challenges of starting a car with a bad starter, this guide provides a practical checklist. By following these steps, you can ensure proper sourcing and execution of necessary actions to mitigate the issues caused by faulty starters.

Step 1: Identify the Symptoms of a Bad Starter

Understanding the symptoms of a bad starter is essential for accurate diagnosis. Common signs include a single click when turning the key or a series of rapid clicks, which may indicate a failing battery rather than the starter itself. Recognizing these symptoms early can save time and resources by directing your efforts towards the correct component.

Step 2: Gather Essential Tools for Troubleshooting

Before attempting any fixes, ensure you have the necessary tools on hand. Essential tools include jumper cables for potential battery issues, a mallet for tapping the starter, and a voltmeter to check battery voltage. Having the right tools readily available allows for quick troubleshooting, minimizing downtime and enhancing efficiency.

Illustrative image related to starting a car with a bad starter

Step 3: Clean Battery Connections Thoroughly

Corrosion on battery terminals can prevent proper electrical flow to the starter. Start by inspecting both the positive and negative terminals for signs of corrosion, which appears as a white or bluish-green buildup. Clean these connections with a wire brush and reconnect them securely to ensure a solid electrical connection, which might resolve the issue without further intervention.

Step 4: Inspect the Starter and Solenoid Connections

A visual inspection of the starter and its solenoid connections is crucial. Look for loose or corroded wires, which can hinder performance. If you identify any issues, clean or replace these connections as necessary. This step is vital to ensure that the starter receives the full current it needs to function.

Step 5: Utilize Temporary Fixes as Needed

In situations where immediate repair is not feasible, employ temporary fixes to start the vehicle. For example, gently tapping the starter with a hammer can sometimes free stuck components. Alternatively, consider push-starting a manual transmission vehicle as a quick solution to get it running until proper repairs can be scheduled.

Step 6: Evaluate Supplier Options for Replacement Parts

If the starter is determined to be faulty, sourcing a replacement is the next step. When evaluating suppliers, consider their reputation, product quality, and availability of parts specific to your vehicle model. Request certifications and warranties to ensure you are investing in reliable components that meet industry standards.

Step 7: Schedule Professional Diagnostics and Repairs

Finally, if the issue persists despite troubleshooting, it’s advisable to consult a professional mechanic. Schedule a diagnostic appointment to accurately assess the starter and related systems. Professional intervention can prevent further damage and ensure that the vehicle operates reliably in the long term, safeguarding your investment.

By following this checklist, B2B buyers can efficiently address issues with car starters, ensuring vehicles are operational while minimizing unnecessary costs and downtime.

Comprehensive Cost and Pricing Analysis for starting a car with a bad starter Sourcing

What Are the Key Cost Components for Starting a Car with a Bad Starter?

When analyzing the cost structure associated with starting a car that has a faulty starter, several key components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to starting a car with a bad starter

-

Materials: The most significant material costs are often linked to the starter motor itself, which varies based on vehicle specifications. Other materials may include cables, connectors, and cleaning agents for maintenance. Quality of materials can greatly influence durability and performance, impacting long-term costs.

-

Labor: Labor costs encompass both direct labor for repairs and indirect labor for diagnostics. Skilled technicians are necessary for accurately diagnosing starter problems and performing repairs. Labor rates can vary significantly depending on the region, with higher costs typically seen in Europe compared to Africa and South America.

-

Manufacturing Overhead: This includes costs related to the production of starter motors, such as utilities, equipment maintenance, and factory wages. Overhead can fluctuate based on the location of manufacturing and the efficiency of production processes.

-

Tooling: Specific tools are required for installation and maintenance, including wrenches, voltmeters, and cleaning supplies. The initial investment in these tools can be significant, particularly for businesses that service a variety of vehicle types.

-

Quality Control (QC): Implementing robust QC measures ensures that components meet industry standards. This could involve testing starter motors for performance and reliability, which adds to overall costs but is essential for minimizing future warranty claims.

-

Logistics: Transportation and warehousing costs for both parts and finished products should be considered. These costs can vary widely based on the distance from suppliers and the chosen shipping methods.

-

Margin: Businesses must also factor in their desired profit margins, which can differ based on market competition and demand for services.

How Do Price Influencers Affect Sourcing for a Bad Starter?

Several factors influence the pricing of components and services related to starting a car with a bad starter.

-

Volume/MOQ: Purchasing in bulk often leads to lower unit costs, making it essential for businesses to negotiate minimum order quantities (MOQ) that balance their needs with cost efficiency.

-

Specs/Customization: Custom specifications for starters, such as variations for specific car models, can significantly affect pricing. Customization often leads to increased costs, which should be justified by the anticipated demand.

-

Materials: The choice of materials directly impacts both durability and cost. High-quality materials may incur higher upfront costs but can reduce total ownership costs through increased longevity and performance.

-

Quality/Certifications: Components that meet stringent quality certifications may command higher prices but can lead to reduced failures and warranty claims, ultimately benefiting the buyer.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may charge a premium but offer assurance of quality and service reliability.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers in shipping. Different terms can influence overall costs, including duties and shipping fees.

What Are Key Buyer Tips for Cost-Efficiency in Sourcing Starter Solutions?

To navigate the complexities of sourcing components for starting a car with a bad starter, buyers should consider the following tips:

-

Negotiation: Engage suppliers in negotiations to secure better pricing based on volume purchases or long-term contracts. Building strong relationships can also lead to better terms.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO) rather than just initial purchase prices. Consider factors like maintenance, durability, and warranty when evaluating options.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, European markets may have stricter regulations and higher labor costs, affecting overall pricing compared to markets in Africa or South America.

-

Supplier Evaluation: Assess potential suppliers not only on price but also on their ability to provide quality products and reliable service. This can lead to long-term savings through fewer failures and reduced warranty claims.

-

Market Trends: Stay informed about industry trends and innovations that could affect sourcing strategies, such as advancements in starter technology that may offer better performance at competitive prices.

By understanding these cost structures and pricing influencers, international B2B buyers can make informed decisions that enhance their sourcing strategies for starter solutions.

Alternatives Analysis: Comparing starting a car with a bad starter With Other Solutions

Introduction to Alternative Solutions for Starting a Car

When faced with the challenge of starting a car with a bad starter, it’s crucial for B2B buyers to explore all viable alternatives. Understanding different methods not only aids in making informed decisions but also ensures optimal operational efficiency, especially for fleet managers and automotive businesses in diverse markets. Here, we will compare the conventional approach of starting a car with a faulty starter against other solutions that may offer advantages in performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | Starting A Car With A Bad Starter | Jump Starting with Cables | Push Starting a Manual Transmission |

|---|---|---|---|

| Performance | Limited; may not work consistently | High; often reliable | Moderate; only for manual vehicles |

| Cost | Low to moderate (tools needed) | Low (cables and battery) | No cost (requires no tools) |

| Ease of Implementation | Moderate; requires some technical knowledge | Easy; basic knowledge needed | Moderate; requires physical effort |

| Maintenance | Requires future repairs | Minimal; check battery health | None; just requires physical fitness |

| Best Use Case | Temporary fix for emergencies | Quick start for a dead battery | Manual cars in a pinch |

Detailed Breakdown of Alternatives

Jump Starting with Cables

Jump starting is a common method for reviving a vehicle when the battery is weak. This approach involves using jumper cables to connect the dead battery to a functioning one. The primary advantage is its reliability; if the battery is the issue, this method often provides an immediate solution. However, it does require access to another vehicle and proper handling of the cables to avoid electrical damage. Additionally, if the starter is indeed faulty, jump starting won’t resolve the underlying issue, necessitating further repairs.

Push Starting a Manual Transmission

For manual transmission vehicles, push starting can be an effective method to bypass a faulty starter. This technique involves rolling the vehicle and engaging the clutch while turning the ignition. Its main advantage is that it incurs no financial cost and can be executed with minimal tools. However, it requires physical effort from multiple people and is only applicable to manual cars. Furthermore, it may not be a viable option in urban settings or areas with heavy traffic, as safety becomes a concern.

Conclusion: Selecting the Right Solution for Your Needs

In conclusion, when deciding how to address the problem of starting a car with a bad starter, B2B buyers must weigh the pros and cons of each alternative solution. Jump starting is often the quickest fix, while push starting can be a cost-effective method for manual vehicles. Each option has its unique set of advantages and limitations, depending on the context of use. Ultimately, evaluating the specific operational environment, vehicle type, and available resources will guide buyers in selecting the most suitable approach for their needs.

Essential Technical Properties and Trade Terminology for starting a car with a bad starter

What Are the Key Technical Properties for Starting a Car with a Bad Starter?

Understanding the essential technical properties related to starting a car with a bad starter is crucial for B2B buyers, particularly those in the automotive parts and service industry. Here are some key specifications to consider:

Illustrative image related to starting a car with a bad starter

1. Voltage Rating

The starter motor typically operates at 12 volts, which is standard for most automotive applications. Ensuring that components like the battery and wiring can maintain this voltage is vital for reliable performance. In a B2B context, suppliers must provide voltage ratings that meet or exceed OEM specifications to ensure compatibility and reliability.

2. Current Draw (Amperage)

When starting a vehicle, the starter motor can draw between 100 to 200 amps. Understanding the current draw is important for electrical system compatibility. Businesses should ensure that cables, fuses, and relays can handle this load to prevent overheating and failure. This knowledge helps in selecting appropriate components that can withstand high current during operation.

3. Material Composition

Starter motors are typically made from high-grade steel and copper to ensure durability and efficient electrical conductivity. The choice of materials affects the starter’s longevity and performance. B2B buyers should prioritize suppliers that offer components made from these materials to guarantee reliability in harsh operating conditions, particularly in regions with extreme weather.

Illustrative image related to starting a car with a bad starter

4. Torque Specifications

Torque is crucial for the effective engagement of the starter motor with the engine flywheel. The typical torque range for automotive starters is between 100 to 300 Nm (Newton-meters). Understanding torque specifications helps in selecting the right starter for specific vehicle models, ensuring proper fit and function, which is essential for automotive repair businesses.

5. Temperature Resistance

Starter motors should be able to withstand high temperatures, especially in hot climates. The ability to operate effectively at temperatures ranging from -40°C to +125°C is often specified. This property is vital for buyers in regions with extreme weather conditions, ensuring that the starter will perform consistently without failure.

What Are Common Trade Terms Used in the Automotive Starter Industry?

Familiarity with industry terminology can facilitate smoother transactions and communication between B2B buyers and suppliers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the original vehicle. These components are often preferred for their guaranteed compatibility and quality. B2B buyers should consider OEM parts when seeking reliability in repairs and maintenance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers, as it affects inventory management and purchasing strategies. Buyers should negotiate MOQs to align with their sales forecasts and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific parts or services. B2B buyers should utilize RFQs to compare prices and negotiate better terms, ensuring they receive competitive offers for automotive components.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and freight. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk, and delivery obligations, which are critical for international transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the automotive industry, understanding lead times is essential for inventory planning and customer service. Buyers should communicate clearly with suppliers to manage expectations and maintain operational efficiency.

6. Warranty Period

The warranty period is the timeframe during which the manufacturer guarantees the performance of their parts. Understanding warranty terms is essential for B2B buyers to assess product quality and make informed purchasing decisions, ultimately protecting their investment.

By grasping these technical properties and trade terms, B2B buyers in the automotive sector can enhance their purchasing strategies, ensuring they select the right components for starting vehicles with faulty starters.

Navigating Market Dynamics and Sourcing Trends in the starting a car with a bad starter Sector

What Are the Key Trends Impacting the Market for Starting a Car with a Bad Starter?

The market for starting a car with a bad starter is shaped by several global drivers that influence B2B buyer behavior. One of the most significant trends is the increasing reliance on technology for diagnostics and repairs. Advanced diagnostic tools are becoming essential for automotive businesses, allowing for quicker and more accurate identification of starter issues. This shift is particularly relevant for international buyers from regions like Africa and South America, where access to reliable repair services can be limited.

Illustrative image related to starting a car with a bad starter

Another emerging trend is the growth of e-commerce platforms dedicated to automotive parts and accessories. B2B buyers are increasingly turning to online suppliers for convenience and competitive pricing. This trend is especially pronounced in Europe, where established online marketplaces are expanding their offerings to include specialized components for starter systems. Additionally, the demand for DIY solutions and temporary fixes, such as jump-starting techniques or using mallets to tap the starter, is growing among consumers, creating opportunities for suppliers to offer educational resources and tools.

Market dynamics are also influenced by the increasing emphasis on vehicle longevity and maintenance. As the cost of new vehicles rises, buyers are seeking cost-effective solutions to extend the life of existing cars. This trend leads to a greater focus on sourcing high-quality starter components and related tools, ensuring that repairs are both effective and sustainable.

How Is Sustainability and Ethical Sourcing Relevant to the Starter Components Market?

In today’s B2B landscape, sustainability and ethical sourcing are becoming crucial considerations for buyers in the automotive sector. The environmental impact of automotive components, including starters, has led to a growing demand for eco-friendly materials and practices. Buyers are increasingly looking for suppliers who prioritize sustainability in their production processes, such as using recycled materials or implementing energy-efficient manufacturing techniques.

Ethical supply chains are also gaining importance, particularly in regions with stringent regulations. Buyers are more inclined to partner with manufacturers who demonstrate transparency in their sourcing practices and uphold labor rights. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming benchmarks for companies aiming to differentiate themselves in the market.

In the context of starting a car with a bad starter, the focus on sustainability can drive innovation in product design. For example, manufacturers are exploring alternative materials that reduce environmental impact while maintaining performance. This shift not only appeals to environmentally conscious buyers but also aligns with global sustainability goals, making it a vital consideration for B2B buyers in Africa, South America, the Middle East, and Europe.

Illustrative image related to starting a car with a bad starter

What Is the Evolution of the Starter Component Market?

The evolution of the starter component market reflects broader changes in the automotive industry. Initially, starter motors were simple mechanical devices that relied on direct electrical connections to function. Over time, advancements in technology led to the development of more sophisticated starter systems, including the integration of solenoids and electronic controls. This transformation has improved the efficiency and reliability of starters, catering to the growing demand for high-performance vehicles.

As vehicles became more complex, the need for specialized knowledge in diagnosing and repairing starter issues emerged. This shift has prompted the rise of training programs and certification processes for technicians, ensuring that they are equipped with the latest skills and knowledge. For B2B buyers, this evolution highlights the importance of sourcing from suppliers who not only provide quality products but also offer technical support and training resources.

Today, the market is characterized by a blend of traditional repair methods and modern technology, with B2B buyers increasingly seeking innovative solutions that enhance vehicle performance and reliability. As the automotive landscape continues to evolve, understanding these historical trends will be crucial for making informed sourcing decisions in the starter components sector.

Frequently Asked Questions (FAQs) for B2B Buyers of starting a car with a bad starter

-

How do I diagnose a car with a bad starter?

To diagnose a bad starter, begin by observing the symptoms when attempting to start the vehicle. If you hear rapid clicking sounds, the issue may be with the battery rather than the starter. If there’s a single click or no sound at all, it indicates a potential starter failure. Check the battery connections for corrosion and ensure they are secure. If the battery is functional but the starter still fails to engage, further testing or professional evaluation may be necessary. -

What tools do I need to start a car with a bad starter?

Essential tools for starting a car with a bad starter include jumper cables for testing the battery, a mallet or hammer for gently tapping the starter, a voltmeter to check battery voltage, and wrenches for disconnecting terminals. Optional tools may include a starter relay tester to assess electrical connections. Having protective gear, such as gloves and goggles, is also recommended to ensure safety during troubleshooting. -

What are the common signs of a failing starter motor?

Common signs of a failing starter motor include a clicking sound when turning the key, the engine not turning over, or intermittent starting issues. If the dashboard lights illuminate but the engine remains silent, the starter is likely the issue. Additionally, if the vehicle starts after tapping the starter lightly, it may indicate worn components within the starter. Regular maintenance and inspections can help identify these signs early. -

Can I jump-start a car with a bad starter?

Jump-starting a car with a bad starter may help if the battery voltage is low. If the battery is functioning properly, jump-starting may not resolve the issue, as the starter itself could be faulty. It’s advisable to first check the battery’s voltage and connections before attempting to jump-start. If the vehicle starts after a jump, it may indicate that the battery was the problem rather than the starter. -

What payment terms should I consider when sourcing starter motors internationally?

When sourcing starter motors, consider payment terms that align with your cash flow and risk tolerance. Common options include Letter of Credit (LC), which provides security for both parties, and PayPal or wire transfers for faster transactions. Ensure to negotiate clear terms regarding payment timelines, deposits, and final payments upon delivery. Understanding the supplier’s payment preferences can facilitate smoother transactions. -

How can I ensure quality assurance when purchasing starter motors?

To ensure quality assurance when purchasing starter motors, establish clear specifications and standards with your suppliers. Request samples for testing before placing bulk orders, and inquire about their manufacturing processes and certifications. Conducting factory audits or using third-party inspection services can provide additional assurance of product quality. Setting up a robust communication channel with suppliers can also help address any quality concerns promptly. -

What logistics considerations should I keep in mind when importing starter motors?

When importing starter motors, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with automotive parts to navigate international shipping requirements. Additionally, assess the costs associated with duties and tariffs, and ensure compliance with local regulations to avoid delays. Proper documentation, such as bills of lading and commercial invoices, is crucial for smooth customs clearance. -

What customization options are available for starter motors?

Customization options for starter motors can vary based on the supplier. You may request modifications such as different voltage ratings, specific mounting configurations, or enhanced performance features. Discuss your requirements upfront to determine if the supplier can accommodate your needs. Be aware that customization might affect minimum order quantities (MOQ) and lead times, so plan accordingly to meet your project timelines.

Top 1 Starting A Car With A Bad Starter Manufacturers & Suppliers List

1. Facebook – Starter Troubleshooting Tips

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Starter Troubleshooting Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for starting a car with a bad starter

In conclusion, navigating the challenges of starting a car with a bad starter requires not only a solid understanding of automotive issues but also effective strategic sourcing of components and services. International B2B buyers should prioritize partnerships with reliable suppliers who offer quality starter motors and related components, ensuring that they can swiftly address vehicle issues while minimizing downtime.

Investing in diagnostic tools and training can empower businesses to efficiently identify starter problems, enhancing service offerings in markets across Africa, South America, the Middle East, and Europe. Additionally, implementing preventive maintenance strategies can significantly reduce the frequency of starter failures, ultimately improving customer satisfaction and loyalty.

As the automotive industry continues to evolve, the demand for efficient and cost-effective solutions will only increase. By proactively sourcing high-quality starters and fostering strong supplier relationships, businesses can position themselves for success in a competitive marketplace. Engage with your suppliers today to explore innovative solutions that will not only meet current demands but also anticipate future challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.