Introduction: Navigating the Global Market for starter location

In the fast-paced world of automotive parts sourcing, understanding the intricate details of starter location is crucial for international B2B buyers. Whether you’re navigating the complexities of locating a starter motor for a specific vehicle or evaluating the best suppliers, this guide serves as an essential resource. With a focus on diverse applications across various vehicle models, we will delve into the types of starters available, their specific locations within different engine configurations, and practical tips for efficient sourcing.

This comprehensive overview empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—like Nigeria and Germany—to make informed purchasing decisions. By addressing key challenges such as supplier vetting and cost considerations, we aim to streamline your procurement process. In addition, we will provide insights into the latest trends and technologies that influence starter motor performance and reliability.

Ultimately, this guide is designed to equip you with the knowledge necessary to navigate the global market effectively, ensuring that your sourcing efforts yield high-quality components that meet your operational needs. Let’s embark on this journey to uncover the essential aspects of starter location, enhancing your purchasing strategy in the competitive automotive landscape.

Table Of Contents

- Top 1 Starter Location Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter location

- Understanding starter location Types and Variations

- Key Industrial Applications of starter location

- 3 Common User Pain Points for ‘starter location’ & Their Solutions

- Strategic Material Selection Guide for starter location

- In-depth Look: Manufacturing Processes and Quality Assurance for starter location

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter location’

- Comprehensive Cost and Pricing Analysis for starter location Sourcing

- Alternatives Analysis: Comparing starter location With Other Solutions

- Essential Technical Properties and Trade Terminology for starter location

- Navigating Market Dynamics and Sourcing Trends in the starter location Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter location

- Strategic Sourcing Conclusion and Outlook for starter location

- Important Disclaimer & Terms of Use

Understanding starter location Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Front-Wheel Drive Starter | Positioned between engine and transmission, often on the driver’s side. | Passenger vehicles, compact cars | Pros: Easier access for replacement. Cons: Limited compatibility with some models. |

| Rear-Wheel Drive Starter | Typically located below the exhaust manifold on the passenger side. | Trucks, SUVs, performance vehicles | Pros: Robust design for heavy-duty applications. Cons: More complex access can increase labor costs. |

| Top-Mounted Starter | Found on some models on top of the engine, often under the intake manifold. | Specialty vehicles, certain high-performance cars | Pros: Centralized location can simplify installation. Cons: Often requires intake manifold removal for access. |

| Under-Intake Starter | Located beneath the intake manifold, common in various models. | Economy cars, sedans | Pros: Space-saving design. Cons: Difficult access can lead to higher service costs. |

| Side-Mounted Starter | Positioned at the side of the engine, varies by manufacturer. | Diverse range of vehicles including hybrids | Pros: Versatile placement across various models. Cons: Variability can complicate sourcing exact replacements. |

What Are the Characteristics of a Front-Wheel Drive Starter?

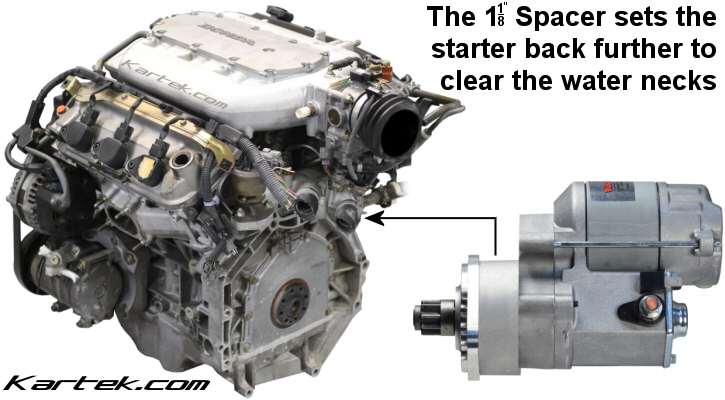

Front-wheel drive starters are typically found in passenger vehicles, particularly compact cars. Their location, nestled between the engine and transmission on the driver’s side, often allows for easier access during replacements. This accessibility is advantageous for workshops and parts suppliers, as it can lead to quicker service times and reduced labor costs. B2B buyers should consider the compatibility of these starters with various vehicle makes and models, as well as the availability of aftermarket options.

How Do Rear-Wheel Drive Starters Differ?

Rear-wheel drive starters are commonly located below the exhaust manifold on the passenger side of the vehicle. This positioning is prevalent in trucks, SUVs, and performance vehicles, which often require a more robust starter due to higher torque demands. While their durability is a significant advantage, the complexity of accessing these starters can lead to increased labor costs, making it essential for B2B buyers to factor in serviceability when sourcing parts.

What Makes Top-Mounted Starters Unique?

Top-mounted starters are found on specific high-performance and specialty vehicles, often situated underneath the intake manifold. This design can provide advantages in terms of space utilization and weight distribution. However, accessing these starters typically requires the removal of the intake manifold, which can complicate replacement and increase service time. Buyers should weigh the benefits of performance against the potential for higher maintenance costs when considering these starters.

Why Consider Under-Intake Starters?

Under-intake starters are often used in economy cars and sedans, offering a compact design that saves space within the engine bay. While their location can be advantageous for manufacturers looking to optimize engine layouts, it presents challenges for serviceability. B2B buyers should be aware that the difficulty in accessing these starters can result in higher service fees, necessitating careful evaluation of total ownership costs when selecting these components.

How Do Side-Mounted Starters Fit Into the Market?

Side-mounted starters vary significantly by manufacturer and vehicle type, making them a versatile option across a diverse range of vehicles, including hybrids. This variability can be both an advantage and a challenge; while it allows for a broader application, it can complicate the sourcing of specific replacement parts. B2B buyers should prioritize understanding the specifications of the vehicles they service to ensure they procure the correct starter models, thereby minimizing downtime and enhancing customer satisfaction.

Key Industrial Applications of starter location

| Industry/Sector | Specific Application of starter location | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Design and assembly of vehicle starter systems | Enhanced reliability and performance of vehicles | Quality of materials, compatibility with vehicle models, and supplier certifications. |

| Heavy Machinery | Integration of starters in construction and agricultural equipment | Increased operational efficiency and reduced downtime | Sourcing durable starters that can withstand harsh environments and high torque demands. |

| Marine and Aerospace | Use of starters in marine engines and aircraft systems | Improved safety and reliability in critical applications | Compliance with industry regulations and availability of specialized starters for extreme conditions. |

| Renewable Energy | Installation of starters in wind turbines and solar trackers | Enhanced energy conversion efficiency and reliability | Availability of starters designed for variable loads and environmental resilience. |

| Transportation and Logistics | Utilization of starters in fleet vehicles and logistics equipment | Reduced maintenance costs and improved fleet uptime | Supplier reliability, service support, and pricing competitiveness. |

How Is Starter Location Integral to Automotive Manufacturing?

In automotive manufacturing, the location of the starter is crucial for the design and assembly of vehicle starter systems. Typically situated between the engine and transmission, the starter’s placement affects the overall vehicle design and performance. For international buyers in regions like Africa and South America, understanding the starter’s placement can lead to improved vehicle reliability and performance, which is essential in markets where vehicles may face challenging driving conditions. Buyers should consider the compatibility of starter systems with various vehicle models and the quality of materials used to ensure durability.

What Role Does Starter Location Play in Heavy Machinery?

In the heavy machinery sector, starter location is vital for the integration of starters in construction and agricultural equipment. These starters must be positioned to handle high torque and withstand harsh operational environments. For businesses in the Middle East and Africa, where machinery is often subjected to extreme conditions, sourcing durable starters is critical. Buyers should prioritize suppliers who offer products that meet industry standards for performance and durability, ensuring minimal downtime and enhanced operational efficiency.

How Is Starter Location Relevant in Marine and Aerospace Industries?

In marine and aerospace applications, the starter’s location is essential for both safety and reliability. Starters in these industries must be strategically placed to ensure they function optimally under extreme conditions, such as high humidity and varying temperatures. For international buyers, especially in Europe, compliance with industry regulations is a top consideration. Sourcing specialized starters that meet these stringent requirements is crucial for maintaining safety and reliability in critical applications.

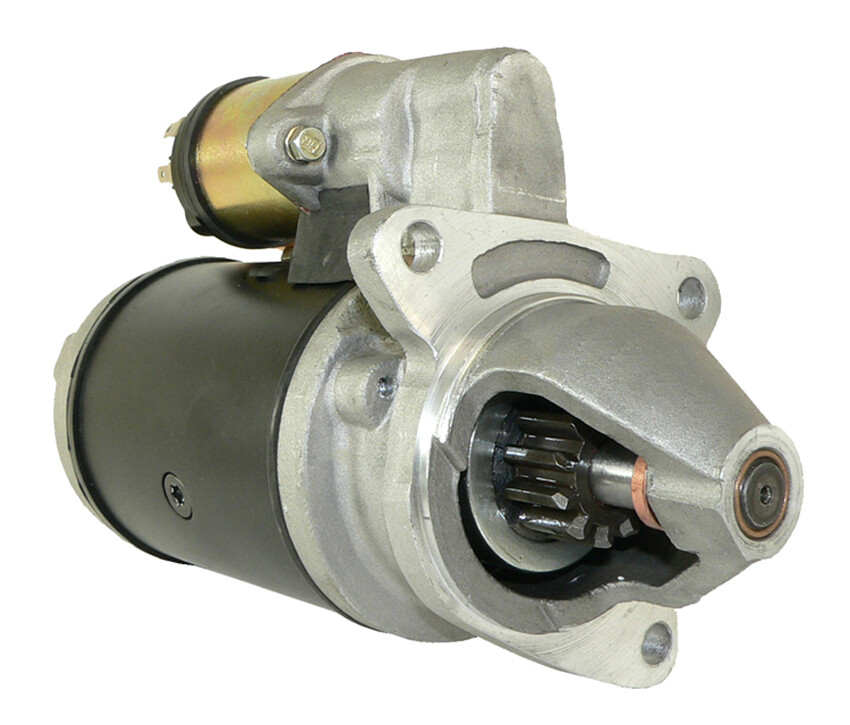

Illustrative image related to starter location

Why Is Starter Location Important for Renewable Energy Solutions?

In the renewable energy sector, particularly for wind turbines and solar trackers, the location of the starter influences energy conversion efficiency. Starters must be designed to handle variable loads and operate effectively in diverse environmental conditions. Buyers in emerging markets, such as those in South America and Africa, should focus on sourcing starters that are resilient and efficient. Ensuring availability and performance of these components can significantly impact the reliability of renewable energy systems.

How Does Starter Location Affect Transportation and Logistics?

For transportation and logistics, the starter’s location in fleet vehicles and logistics equipment directly impacts maintenance costs and fleet uptime. A well-positioned starter can enhance the overall reliability of vehicles, which is critical for businesses that rely on timely deliveries. Buyers in regions like Nigeria and Germany should consider supplier reliability and service support when sourcing starters. Competitive pricing and responsiveness from suppliers can lead to better fleet management and reduced operational costs.

3 Common User Pain Points for ‘starter location’ & Their Solutions

Scenario 1: Difficulty Accessing Starter for Replacement in Complex Engine Designs

The Problem: B2B buyers often encounter challenges when it comes to replacing starters in vehicles with complex engine designs. For instance, many modern vehicles have starters located in hard-to-reach areas, requiring significant disassembly of other components. This not only increases labor costs but also prolongs vehicle downtime, which can be especially detrimental for businesses relying on a fleet of vehicles for operations. Buyers need to be aware of these complexities to avoid underestimating the time and costs involved in maintenance.

Illustrative image related to starter location

The Solution: To overcome this challenge, buyers should prioritize thorough research on the specific vehicle models they are maintaining. This includes consulting detailed repair manuals or databases that provide precise starter locations and the necessary steps for access. Additionally, partnering with suppliers who offer comprehensive vehicle-specific starter kits can streamline the replacement process. These kits often include not just the starter, but also tools and components needed for easier access, which can significantly reduce repair time and labor costs.

Scenario 2: Misidentifying Starter Issues Leading to Incorrect Repairs

The Problem: Another common issue faced by B2B buyers is misdiagnosing starter problems due to a lack of understanding of starter functionality and location. For example, a vehicle may exhibit symptoms like clicking noises or failure to start, leading buyers to assume the starter is faulty when the actual issue could be related to battery problems or wiring issues. This misdiagnosis can result in unnecessary purchases and repairs, increasing operational costs.

The Solution: To mitigate this risk, buyers should invest in diagnostic tools that can accurately assess starter functionality and related components. Implementing a systematic troubleshooting process can help identify whether the starter or another component is at fault. Training staff on the specifics of starter systems, including location and common failure signs, is also beneficial. Providing your team with access to professional resources, such as online courses or workshops, can enhance their understanding, leading to more accurate diagnoses and cost-effective repairs.

Scenario 3: Inconsistent Starter Specifications Leading to Compatibility Issues

The Problem: B2B buyers frequently face compatibility issues when sourcing starters due to variations in specifications across different vehicle models and manufacturers. For instance, a buyer may order a starter based on a general description, only to find that the part does not fit the specific vehicle due to differences in mounting locations or electrical connections. This not only results in wasted time and resources but can also lead to delays in vehicle repairs, affecting overall business productivity.

The Solution: To avoid these compatibility issues, buyers should implement a meticulous part identification process before making purchases. Utilizing VIN (Vehicle Identification Number) decoding can help ensure that the correct part is sourced. Additionally, building strong relationships with reliable suppliers who provide detailed specifications and compatibility charts can be invaluable. Leveraging technology, such as parts lookup software, can also assist in verifying that the starter selected matches the exact requirements of the vehicle, thus minimizing the risk of errors and ensuring a smooth repair process.

By addressing these common pain points effectively, B2B buyers can enhance their operational efficiency, reduce costs, and ensure that their vehicles remain reliable and ready for use.

Strategic Material Selection Guide for starter location

What Are the Key Materials for Starter Location Components?

When selecting materials for components related to starter locations in vehicles, several factors must be considered, including performance properties, cost, and regional compliance. Below is a detailed analysis of four common materials used in this application: steel, aluminum, plastic composites, and copper alloys.

How Does Steel Perform in Starter Locations?

Key Properties: Steel is known for its high tensile strength and durability. It typically offers excellent temperature resistance, making it suitable for environments where heat from the engine is a concern. Steel can also withstand significant pressure, which is essential for components that engage with the engine’s flywheel.

Illustrative image related to starter location

Pros & Cons: The primary advantage of steel is its robustness and longevity, which translates into a longer service life for starter components. However, steel is heavier than other materials, which may affect overall vehicle weight and fuel efficiency. Additionally, steel is prone to corrosion if not properly treated, which can be a significant drawback in humid or coastal environments.

Impact on Application: Steel’s compatibility with high-temperature and high-pressure environments makes it ideal for starter locations. However, its weight may necessitate careful consideration in vehicle design.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the local climate and potential for corrosion. Compliance with standards such as ASTM for material quality is also crucial, particularly in Europe where regulations are stringent.

What Are the Benefits of Aluminum in Starter Applications?

Key Properties: Aluminum is lightweight yet maintains a good strength-to-weight ratio. It has excellent corrosion resistance due to the formation of a protective oxide layer, making it suitable for various environmental conditions.

Pros & Cons: The lightweight nature of aluminum can enhance fuel efficiency and overall vehicle performance. However, aluminum may not withstand as much pressure as steel, which could limit its use in high-stress applications. The cost of aluminum is generally higher than steel, which may affect budget considerations for manufacturers.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for starter components exposed to moisture and other corrosive elements. However, its lower pressure tolerance may restrict its use in certain engine designs.

Considerations for International Buyers: In Europe, aluminum components often need to meet specific DIN standards. Buyers should also consider the cost implications, especially in regions where aluminum is less readily available.

How Do Plastic Composites Fit into Starter Locations?

Key Properties: Plastic composites are lightweight and can be engineered for specific thermal and chemical resistance. They are often used in non-structural components where weight savings are critical.

Pros & Cons: The primary advantage of plastic composites is their low weight and resistance to corrosion. However, they may not provide the same level of durability and strength as metals, which could lead to a shorter lifespan in high-stress applications.

Impact on Application: Plastic composites are suitable for components that do not experience extreme pressure or temperature variations. They can offer design flexibility and reduced manufacturing costs.

Considerations for International Buyers: Compliance with international standards for plastics, such as ISO specifications, is essential. Buyers should also be aware of the environmental impact of plastic materials, particularly in regions with strict waste management regulations.

Illustrative image related to starter location

Why Are Copper Alloys Important for Starter Locations?

Key Properties: Copper alloys, particularly brass, are known for their excellent electrical conductivity and resistance to corrosion. They are often used in electrical connections and components within starter systems.

Pros & Cons: The key advantage of copper alloys is their ability to conduct electricity efficiently, which is vital for starter motors. However, they can be more expensive than other materials and may not be suitable for structural components due to lower strength.

Impact on Application: Copper alloys are ideal for electrical connections in starter systems, ensuring reliable performance. However, their cost and lower mechanical strength may limit their use in structural applications.

Considerations for International Buyers: Buyers should ensure compliance with electrical standards, such as IEC or UL, particularly in regions with stringent electrical safety regulations.

Summary Table of Material Selection for Starter Locations

| Material | Typical Use Case for Starter Location | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components in starter systems | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight starter housings | Excellent corrosion resistance | Lower pressure tolerance | High |

| Plastic Composites | Non-structural components | Lightweight and corrosion-resistant | Shorter lifespan in high-stress areas | Medium |

| Copper Alloys | Electrical connections in starters | Excellent electrical conductivity | Higher cost and lower mechanical strength | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for starter locations, emphasizing the importance of performance properties, regional compliance, and cost considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for starter location

What Are the Main Stages in the Manufacturing Process for Starters?

The manufacturing of starter motors involves several critical stages that ensure the final product meets performance and durability standards.

Material Preparation: What Materials Are Used?

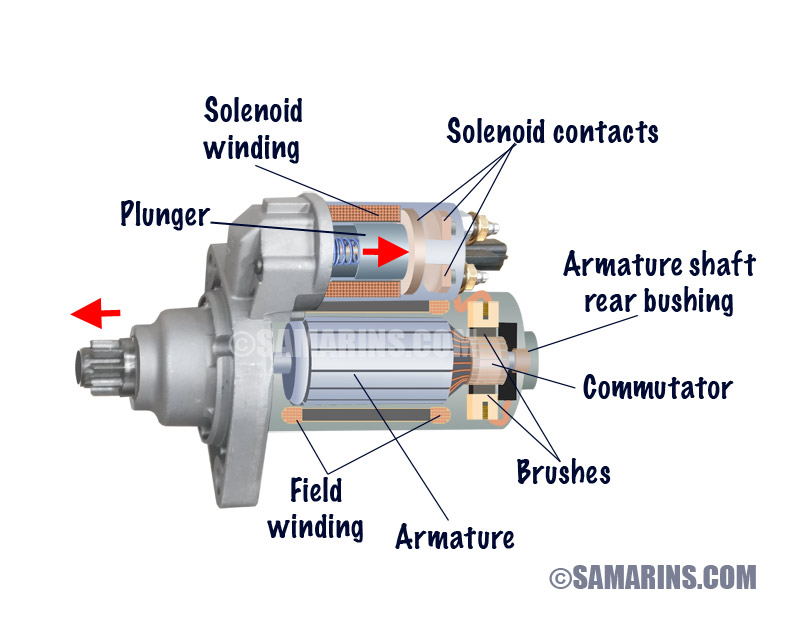

The primary materials used in starter manufacturing include high-grade steel, copper, and various alloys. High-grade steel is crucial for components like the casing and housing, providing strength and resistance to wear. Copper is predominantly used for the windings due to its excellent electrical conductivity. Additionally, plastic and rubber components are used for insulation and protection against environmental factors.

Before assembly, these materials undergo rigorous quality checks to ensure they meet the required specifications. This includes assessing their chemical composition, tensile strength, and resistance to corrosion.

How Is the Forming Process Executed?

The forming process involves several techniques, including stamping, machining, and forging.

-

Stamping: Metal sheets are stamped into specific shapes for components like the starter housing. This process ensures precise dimensions and reduces material waste.

-

Machining: After stamping, components may require further machining to achieve finer tolerances. CNC (Computer Numerical Control) machines are commonly used for this purpose, providing high accuracy and repeatability.

-

Forging: For parts that require exceptional strength, such as the pinion gear, forging techniques are applied. This process involves shaping heated metal using compressive forces, enhancing its structural integrity.

What Is Involved in the Assembly Process?

The assembly stage is where the various components come together. Typically, this includes:

-

Winding the Armature: Copper wire is wound around a core to form the armature, which is crucial for generating the magnetic field necessary for the starter’s operation.

-

Connecting Components: The armature, solenoid, and other parts are interconnected, ensuring proper functionality. This step often requires specialized tools to ensure secure connections.

-

Final Assembly: The assembled components are then placed inside the starter casing. This step is critical as it ensures that all parts fit correctly and function harmoniously.

What Quality Assurance Measures Are Applied During Manufacturing?

Quality assurance (QA) is a pivotal aspect of starter manufacturing, ensuring that each unit meets international standards and customer expectations.

Which International Standards Are Relevant?

For B2B buyers, it is essential to ensure that manufacturers comply with recognized international standards.

-

ISO 9001: This standard outlines the requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

-

CE Marking: Particularly relevant in the European market, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

-

API Certification: For starters used in heavy-duty applications, compliance with American Petroleum Institute (API) standards can also be crucial, especially in regions with stringent regulatory frameworks.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before they enter the production line. It ensures that all materials meet the required specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production quality. This includes checks on dimensions, assembly integrity, and electrical performance.

-

Final Quality Control (FQC): Once assembly is complete, each starter undergoes rigorous testing, including functional testing to ensure it operates correctly under various conditions.

What Common Testing Methods Are Used for Starters?

Testing methods are vital in validating the performance and reliability of starters. Common tests include:

-

Electrical Testing: This involves checking the starter’s voltage, current draw, and resistance to ensure it meets operational specifications.

-

Durability Testing: Starters are subjected to endurance tests, simulating real-world conditions to evaluate their performance over time.

-

Thermal Testing: Given the heat generated during operation, thermal testing is conducted to ensure that components can withstand high temperatures without failure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to mitigate risks associated with product reliability.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess quality control processes. Buyers should:

-

Request Documentation: Suppliers should provide documentation of their quality management systems, including certifications and audit reports.

-

On-Site Visits: If feasible, conducting on-site visits allows buyers to witness the manufacturing process and quality control measures firsthand.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

What Nuances Should International Buyers Consider?

When dealing with suppliers from diverse regions such as Africa, South America, the Middle East, and Europe, buyers should consider the following nuances:

-

Cultural Differences: Understanding cultural attitudes toward quality and customer service can impact negotiations and expectations.

-

Regulatory Compliance: Buyers must ensure that suppliers adhere to both local and international regulations, which can vary significantly across regions.

-

Logistical Challenges: International shipping can introduce complexities in quality assurance, such as damage during transit. Buyers should discuss return and warranty policies with suppliers to safeguard against such issues.

In conclusion, the manufacturing processes and quality assurance measures for starters are comprehensive and critical for delivering reliable products. By understanding these processes, B2B buyers can make informed decisions and establish strong partnerships with suppliers, ensuring that they receive high-quality starters that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter location’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure components related to starter locations in vehicles. Understanding the specific needs for starter components, especially in international markets such as Africa, South America, the Middle East, and Europe, is crucial for ensuring compatibility and reliability. This checklist will help you navigate the procurement process effectively, ensuring you make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the starter components you need. This includes specifications such as size, voltage, torque ratings, and compatibility with various vehicle models. Having precise specifications is essential to avoid mismatches and ensure optimal performance.

- Consider vehicle types: Different vehicles, such as SUVs, trucks, or compact cars, may require different starter configurations.

- Account for regional variations: Be aware that certain models may have unique specifications depending on the region they are manufactured for.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in automotive starter components. This step is vital to ensure that you source from reputable companies that can meet your needs reliably.

- Check industry reputation: Look for suppliers with positive reviews and testimonials from other international buyers.

- Assess product range: Ensure that the supplier offers a variety of starter components to match different vehicle models.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This is crucial for ensuring the quality and safety of the components you intend to purchase.

- ISO and other relevant certifications: Look for suppliers that hold ISO certifications or other relevant industry standards that validate their manufacturing processes.

- Quality assurance practices: Inquire about their quality control measures to ensure they consistently meet specified requirements.

Step 4: Request Samples and Technical Documentation

Ask suppliers for samples of the starter components, as well as technical documentation. This will help you assess the quality and compatibility of the products before making a bulk purchase.

- Inspect samples: Evaluate the physical quality, materials used, and overall craftsmanship of the samples.

- Review documentation: Ensure that the technical documentation includes installation instructions, warranty information, and maintenance guidelines.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. This step is crucial for establishing a mutually beneficial relationship.

- Discuss bulk pricing: Inquire about discounts for larger orders, which can significantly reduce costs.

- Clarify delivery timelines: Ensure that you have a clear understanding of when the components will be delivered, especially if you are operating under tight project deadlines.

Step 6: Establish a Communication Plan

Effective communication is key to successful procurement. Establish a clear communication plan with your supplier to facilitate smooth interactions throughout the sourcing process.

- Set regular check-ins: Schedule periodic updates to track the status of your order and address any potential issues promptly.

- Utilize multiple channels: Ensure you have various communication channels available (email, phone, messaging apps) for quick and efficient dialogue.

Step 7: Conduct Post-Purchase Evaluation

After the procurement process, evaluate the performance of the starter components and the supplier’s service. This will help you refine your sourcing strategy for future purchases.

- Gather feedback from your team: Assess how well the components performed in real-world applications and gather insights from technicians.

- Review supplier performance: Evaluate whether the supplier met delivery timelines, product quality, and customer service expectations.

By following this checklist, international B2B buyers can navigate the complexities of sourcing starter components effectively, ensuring they meet their operational requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for starter location Sourcing

In the competitive landscape of starter location sourcing, understanding the cost structure and pricing strategies is crucial for international B2B buyers. This section delves into the components that influence pricing and offers actionable insights tailored for buyers from diverse markets including Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Starter Location Sourcing?

Materials: The primary cost driver in starter sourcing is the materials used. High-quality metals and electrical components significantly impact the overall cost. Buyers should consider sourcing from suppliers who provide detailed specifications on material grades, as this affects durability and performance.

Illustrative image related to starter location

Labor: Labor costs encompass the workforce involved in manufacturing the starter. Regions with lower labor costs may offer more competitive pricing, but this can also correlate with quality. Buyers should evaluate the skill level of the workforce in the supplier’s location, as higher labor costs may be justified by superior craftsmanship.

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses. Effective management of these overheads can lead to more competitive pricing. Buyers should inquire about the supplier’s operational efficiencies and how they manage overhead to keep prices down.

Tooling: The initial investment in tooling can be substantial, especially for custom or specialized starters. Buyers looking for customization should be aware that tooling costs can be amortized over larger production volumes, potentially reducing the per-unit price.

Quality Control (QC): Ensuring that starters meet quality standards is essential. A robust QC process may increase initial costs but reduces the risk of failures, leading to lower Total Cost of Ownership (TCO) over time. Buyers should seek suppliers with certifications that guarantee quality, such as ISO standards.

Illustrative image related to starter location

Logistics: Transportation and warehousing costs can vary significantly based on the supplier’s location and the buyer’s market. Buyers should consider the total logistics costs, including shipping and customs duties, as they can dramatically affect the final price.

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the industry standard margins in different regions can help buyers negotiate better deals.

How Do Price Influencers Affect Starter Location Sourcing?

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. International buyers should assess their purchasing power and consider consolidating orders to meet MOQ requirements for discounts.

Specifications and Customization: Custom starters tailored to specific vehicle models can incur additional costs. Buyers should clearly communicate their requirements and understand the pricing implications of any customizations.

Quality and Certifications: Products with higher quality ratings or specific certifications can command a premium price. Buyers should weigh the benefits of investing in certified products against potential long-term savings from improved reliability.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of performance may charge more but offer better support and warranty options.

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding these terms can help buyers negotiate more favorable shipping arrangements, impacting the overall cost structure.

What Are the Best Negotiation Strategies for International B2B Buyers?

When negotiating prices, it’s essential to build a strong relationship with suppliers. Transparency about your needs and expectations can foster trust and lead to better pricing. Additionally, always consider the Total Cost of Ownership—factor in potential maintenance costs and the longevity of the starter when evaluating price.

Buyers should also be aware of pricing nuances in their respective regions. For instance, fluctuations in currency exchange rates can affect import costs, especially for buyers in Africa and South America. Staying informed about market trends can provide leverage during negotiations.

Conclusion and Disclaimer

In summary, a comprehensive understanding of the cost components and price influencers in starter location sourcing allows international B2B buyers to make informed purchasing decisions. It’s vital to approach negotiations strategically and consider the long-term implications of pricing choices. This analysis is indicative, and prices may vary based on market conditions and supplier negotiations. Always conduct thorough due diligence before finalizing any agreements.

Alternatives Analysis: Comparing starter location With Other Solutions

Understanding Alternatives to Starter Location in Automotive Solutions

In the automotive sector, the positioning and efficiency of the starter motor are crucial for optimal vehicle performance. However, there are alternative solutions and methods that can also be considered for enhancing engine ignition and starting processes. This section explores these alternatives, allowing B2B buyers to make informed decisions based on their specific needs and operational contexts.

| Comparison Aspect | Starter Location | Alternative 1: Push Button Start | Alternative 2: Remote Start System |

|---|---|---|---|

| Performance | Reliable ignition; dependent on physical installation and connections. | Quick and efficient; reduces wear on ignition key. | Convenient for pre-starting in cold weather; may require additional setup. |

| Cost | Moderate; depends on vehicle model and labor costs for installation. | Higher initial cost for installation; may require additional components. | Higher upfront costs; potential for increased insurance premiums. |

| Ease of Implementation | Requires specific tools and knowledge; accessibility can vary by vehicle model. | Generally straightforward installation for professionals; may need electrical modifications. | Installation can be complex; may require integration with existing security systems. |

| Maintenance | Low maintenance if installed correctly; may require occasional checks. | Minimal maintenance; primarily electrical components. | Regular checks necessary to ensure functionality; battery management is crucial. |

| Best Use Case | Ideal for traditional vehicles with standard ignition systems. | Best for modern vehicles prioritizing convenience and efficiency. | Suitable for climates where pre-conditioning of the vehicle is beneficial. |

Pros and Cons of Each Alternative

What Are the Advantages of a Push Button Start System?

The push button start system is designed for modern vehicles, offering enhanced convenience and efficiency. It eliminates the need for a physical key, reducing wear and tear on the ignition system. However, the installation costs can be higher than traditional starter locations, and it may require modifications to the vehicle’s electrical system. This solution is best suited for businesses that operate a fleet of newer vehicles, as it enhances user experience while maintaining reliability.

How Does a Remote Start System Compare?

Remote start systems provide the ability to start the vehicle from a distance, which is particularly useful in extreme weather conditions. This technology allows users to pre-condition their vehicles, ensuring a comfortable temperature before entering. However, the complexity of installation can be a downside, as it often requires integration with existing vehicle systems and may necessitate ongoing maintenance to ensure functionality. This option is ideal for businesses operating in regions with harsh climates or for fleet managers looking to enhance driver comfort.

Making the Right Choice for Your Automotive Needs

When evaluating solutions such as starter location, push button start systems, or remote start systems, it’s essential for B2B buyers to consider their specific operational requirements. Factors such as vehicle age, climate, budget constraints, and user experience should guide the decision-making process. By analyzing the pros and cons of each alternative, businesses can select the solution that not only meets their immediate needs but also aligns with their long-term operational goals.

Essential Technical Properties and Trade Terminology for starter location

What Are the Key Technical Properties of Starter Location?

In the context of automotive components, understanding the technical specifications related to the starter location is crucial for B2B buyers looking to make informed purchasing decisions. Here are several essential properties:

1. Material Grade

The starter motor is typically constructed from materials like steel and aluminum alloys. Material grade is vital as it affects durability, weight, and resistance to heat and corrosion. For example, a higher-grade aluminum alloy can provide a lighter and more corrosion-resistant starter, which is especially important in regions with harsh climates.

2. Torque Specifications

Torque specifications indicate the amount of force required to secure the starter to the engine. This is critical for ensuring proper engagement with the flywheel. Incorrect torque can lead to improper functioning or damage. B2B buyers must ensure they are aware of the torque requirements for specific vehicle models to maintain performance and safety standards.

3. Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in the starter design. High tolerance levels are essential for ensuring the starter fits correctly within the engine compartment. For manufacturers, maintaining tight tolerances is crucial for quality control and can significantly reduce the risk of defects.

4. Electrical Ratings

The electrical ratings of a starter, including voltage and amperage, are crucial for its performance. Most starters operate at 12 volts, but the amperage can vary significantly between models. Understanding these ratings helps buyers select the appropriate starter for their vehicles, ensuring reliable ignition under different conditions.

5. Thermal Resistance

Given that starters operate in high-temperature environments, thermal resistance is an essential property. Materials and designs that can withstand elevated temperatures will prolong the life of the starter and prevent premature failure. B2B buyers should consider this property, especially for vehicles used in extreme conditions.

What Are Common Trade Terms in the Starter Location Industry?

Familiarity with industry-specific terminology can greatly enhance communication and negotiation between buyers and suppliers. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the vehicle’s original manufacturer. These components typically meet strict quality standards and are often preferred for replacements. B2B buyers should weigh the benefits of OEM parts against aftermarket options based on quality and warranty considerations.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their inventory and budget effectively. This term often affects pricing and can dictate whether a buyer can access a particular product.

Illustrative image related to starter location

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request price quotations for specific products. This term is crucial in the procurement process, enabling buyers to compare costs and terms from multiple suppliers effectively.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. They clarify who is responsible for shipping costs, insurance, and tariffs. B2B buyers must be well-versed in these terms to avoid misunderstandings in cross-border transactions.

5. Aftermarket Parts

Aftermarket parts are components produced by manufacturers other than the original vehicle maker. These parts can be less expensive and more readily available than OEM parts but vary in quality. Buyers should assess the reliability of aftermarket suppliers to ensure they meet necessary specifications.

In summary, understanding the technical properties and trade terminology related to starter locations is essential for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances communication with suppliers, ultimately leading to better procurement strategies and vehicle performance.

Illustrative image related to starter location

Navigating Market Dynamics and Sourcing Trends in the starter location Sector

What Are the Current Market Dynamics and Key Trends in the Starter Location Sector?

The global starter location sector is experiencing significant transformations influenced by various market dynamics. A primary driver is the increasing demand for efficient automotive components as manufacturers strive for enhanced vehicle performance and reliability. This trend is particularly pronounced in emerging markets across Africa and South America, where vehicle ownership is rising. International B2B buyers must be aware of the growing emphasis on electric vehicles (EVs) and hybrid technologies, which are reshaping sourcing strategies for starter motors. Companies are investing in advanced manufacturing technologies, such as automation and AI, to streamline production processes and improve quality control.

Furthermore, partnerships between OEMs and aftermarket suppliers are becoming more strategic, focusing on innovation and shared resources. Buyers should look for suppliers that can offer not only competitive pricing but also technological advancements and customization options tailored to local market needs. In Europe, for instance, there is a push towards integrating smart technologies into vehicle components, including starters, which requires suppliers to stay ahead of the curve in terms of R&D investments.

How Is Sustainability and Ethical Sourcing Being Integrated into the Starter Location Sector?

Sustainability has emerged as a critical concern for B2B buyers in the starter location sector, driven by increasing regulatory pressures and consumer demand for environmentally responsible practices. The environmental impact of sourcing materials and manufacturing processes is a focal point, prompting companies to adopt greener alternatives. Buyers should prioritize suppliers who utilize eco-friendly materials, such as recycled metals and non-toxic coatings, and those who adhere to environmental management systems like ISO 14001.

Illustrative image related to starter location

Ethical sourcing practices are equally important, with a growing emphasis on supply chain transparency. B2B buyers are encouraged to seek out partners who demonstrate a commitment to fair labor practices and ethical sourcing of raw materials. Certifications such as Fair Trade and the Global Reporting Initiative (GRI) can serve as indicators of a supplier’s dedication to sustainability and ethical practices. Emphasizing these values not only enhances brand reputation but also aligns with global sustainability goals, making it a strategic advantage in competitive markets.

What Is the Brief Evolution of the Starter Location Sector and Its Significance for B2B Buyers?

The evolution of the starter location sector reflects broader trends in automotive technology and manufacturing. Initially, starter motors were simple mechanical devices, but advancements in electrical engineering have transformed them into sophisticated components crucial for engine ignition and operation. The integration of microprocessor technology has improved the efficiency and reliability of starters, making them pivotal in modern vehicles, especially with the rise of hybrid and electric models.

For B2B buyers, understanding this evolution is vital for making informed sourcing decisions. As the sector continues to innovate, buyers must adapt to these changes by seeking suppliers that not only provide high-quality products but also demonstrate a forward-thinking approach to technology and sustainability. Engaging with suppliers who are at the forefront of these developments can provide a competitive edge in an increasingly complex automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of starter location

-

How do I determine the correct starter location for my vehicle model?

To determine the correct starter location for a specific vehicle model, consult the manufacturer’s service manual or an online automotive database. The starter is generally located between the engine and transmission, but the exact position can vary based on the vehicle’s design—front-wheel drive models typically have it on the driver’s side, while rear-wheel drives may have it on the passenger’s side. For complex models, consider reaching out to a certified technician for precise guidance. -

What is the best way to identify quality starters from suppliers?

To identify quality starters from suppliers, look for manufacturers that adhere to international standards like ISO 9001. Request detailed specifications, certifications, and samples to evaluate quality. Additionally, consider suppliers with positive customer reviews and a history of reliability. Engaging in direct communication can also provide insights into their production processes and quality assurance measures. -

What are the common signs of a bad starter I should watch for?

Common signs of a failing starter include a clicking noise when turning the ignition, the engine not cranking, or intermittent starting issues. If the dashboard lights dim significantly when attempting to start the vehicle, this could indicate a weak starter or battery. Monitoring these signs can help in timely diagnosis and replacement, thus avoiding unexpected downtimes. -

How can I ensure compliance with international trade regulations when sourcing starters?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws of both your country and the supplier’s country. Ensure that the products meet any necessary safety and environmental standards. It is advisable to work with a freight forwarder or customs broker who can guide you through the paperwork and regulations to avoid potential legal issues. -

What payment terms are typically acceptable when sourcing from international suppliers?

Common payment terms in international B2B transactions include Letters of Credit, wire transfers, and payment upon delivery. Negotiating favorable terms is crucial; consider discussing partial payments upfront to secure the order while offering the remaining balance upon successful delivery. Always ensure that payment methods are secure and provide some level of buyer protection. -

What should I consider regarding minimum order quantities (MOQ) when sourcing starters?

When evaluating MOQs, consider your inventory needs and the supplier’s capabilities. Suppliers may set higher MOQs to offset production costs, so it’s essential to discuss your requirements upfront. If the MOQ is too high, inquire about the possibility of lower quantities at a higher price per unit or explore group purchasing options with other buyers to meet the MOQ. -

How can I effectively vet suppliers for starter motors?

To effectively vet suppliers for starter motors, conduct thorough background checks, including company history, financial stability, and customer testimonials. Request references from previous clients and investigate their reputation in the industry. Visiting the supplier’s facility, if possible, can provide first-hand insights into their manufacturing processes and quality controls. -

What logistics considerations should I keep in mind when importing starters?

When importing starters, consider shipping options, costs, and delivery timelines. Evaluate whether air freight or sea freight is more suitable based on urgency and budget. Additionally, factor in customs clearance times, storage facilities, and local distribution channels. Collaborating with experienced logistics partners can streamline the process and ensure timely delivery of products to your location.

Top 1 Starter Location Manufacturers & Suppliers List

1. Honda – High Torque Starter Motor

Domain: 2carpros.com

Registered: 1999 (26 years)

Introduction: 1995 Honda Accord, 234,575 miles; Starter motor is a high torque motor that utilizes a small pinion gear to contact the flywheel and a starter solenoid to initiate the electrical connection. Specific starter location varies by engine type (4-cylinder or V6).

Strategic Sourcing Conclusion and Outlook for starter location

In the ever-evolving automotive landscape, understanding the strategic sourcing of starter locations is paramount for international B2B buyers. Key takeaways highlight the variability in starter motor positioning across different vehicle models, influenced by factors such as drivetrain configuration and design. This insight is crucial for making informed purchasing decisions, whether you are sourcing components for repair services or aftermarket sales.

By strategically sourcing starters from reputable manufacturers, businesses can ensure reliability and performance, ultimately enhancing customer satisfaction. It is essential to consider not only the geographical location of suppliers but also their adherence to quality standards and technological advancements in starter design.

Illustrative image related to starter location

Looking ahead, the growing demand for electric vehicles and advancements in automotive technology present new opportunities for B2B buyers to innovate their sourcing strategies. As markets in Africa, South America, the Middle East, and Europe continue to expand, establishing partnerships with reliable suppliers will be key to navigating these changes successfully. Engage actively with your sourcing network today to leverage these insights, ensuring your business remains competitive and responsive to future automotive trends.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.