Introduction: Navigating the Global Market for que es un alternador de carro

In the ever-evolving automotive industry, understanding the intricacies of vehicle components like the alternator is crucial for international B2B buyers. The alternator plays a vital role in a car’s electrical system by converting mechanical energy into electrical energy, ensuring that the battery remains charged and that essential systems operate effectively. However, sourcing reliable alternators for diverse markets poses challenges, particularly when it comes to quality assurance, compliance with local regulations, and cost-effectiveness.

This comprehensive guide explores the various types of alternators available in the market, their applications across different vehicle models, and key considerations for supplier vetting. From recognizing the signs of alternator failure to understanding the cost implications associated with different types, this resource is designed to empower B2B buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Brazil and Saudi Arabia. By providing actionable insights and expert recommendations, we enable informed purchasing decisions that enhance operational efficiency and reliability in vehicle maintenance and production.

Navigating the global market for alternators can be daunting, but with the right knowledge and resources, you can confidently select suppliers that meet your business needs while ensuring the longevity and performance of your automotive offerings.

Table Of Contents

- Top 2 Que Es Un Alternador De Carro Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for que es un alternador de carro

- Understanding que es un alternador de carro Types and Variations

- Key Industrial Applications of que es un alternador de carro

- 3 Common User Pain Points for ‘que es un alternador de carro’ & Their Solutions

- Strategic Material Selection Guide for que es un alternador de carro

- In-depth Look: Manufacturing Processes and Quality Assurance for que es un alternador de carro

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es un alternador de carro’

- Comprehensive Cost and Pricing Analysis for que es un alternador de carro Sourcing

- Alternatives Analysis: Comparing que es un alternador de carro With Other Solutions

- Essential Technical Properties and Trade Terminology for que es un alternador de carro

- Navigating Market Dynamics and Sourcing Trends in the que es un alternador de carro Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of que es un alternador de carro

- Strategic Sourcing Conclusion and Outlook for que es un alternador de carro

- Important Disclaimer & Terms of Use

Understanding que es un alternador de carro Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternator | Typically 12V, used in most conventional vehicles. | Passenger cars, light trucks. | Pros: Cost-effective, widely available. Cons: Limited power output for high-demand vehicles. |

| High-Output Alternator | Designed to deliver higher amperage for demanding systems. | Performance vehicles, off-road trucks. | Pros: Supports advanced electronics. Cons: Higher cost and may require modifications. |

| Diesel Alternator | Built to handle the unique demands of diesel engines. | Heavy-duty trucks, commercial vehicles. | Pros: Robust design for durability. Cons: Heavier and more expensive. |

| Smart Alternator | Incorporates advanced electronics for efficiency. | Hybrid and electric vehicles. | Pros: Improves fuel efficiency, reduces emissions. Cons: More complex, potentially higher repair costs. |

| Marine Alternator | Designed for marine environments, resistant to corrosion. | Boats, yachts, and marine equipment. | Pros: Durable and weather-resistant. Cons: Specialized design can limit availability. |

What Are the Characteristics of Standard Alternators?

Standard alternators are the most common type found in conventional vehicles, typically operating at 12 volts. They are designed to recharge the battery while the engine runs and power essential electrical systems like lights and infotainment. B2B buyers should consider their compatibility with a wide range of passenger and light truck models, making them a practical choice for automotive repair shops and parts suppliers. They offer a cost-effective solution, although their power output may not suffice for vehicles with high electrical demands.

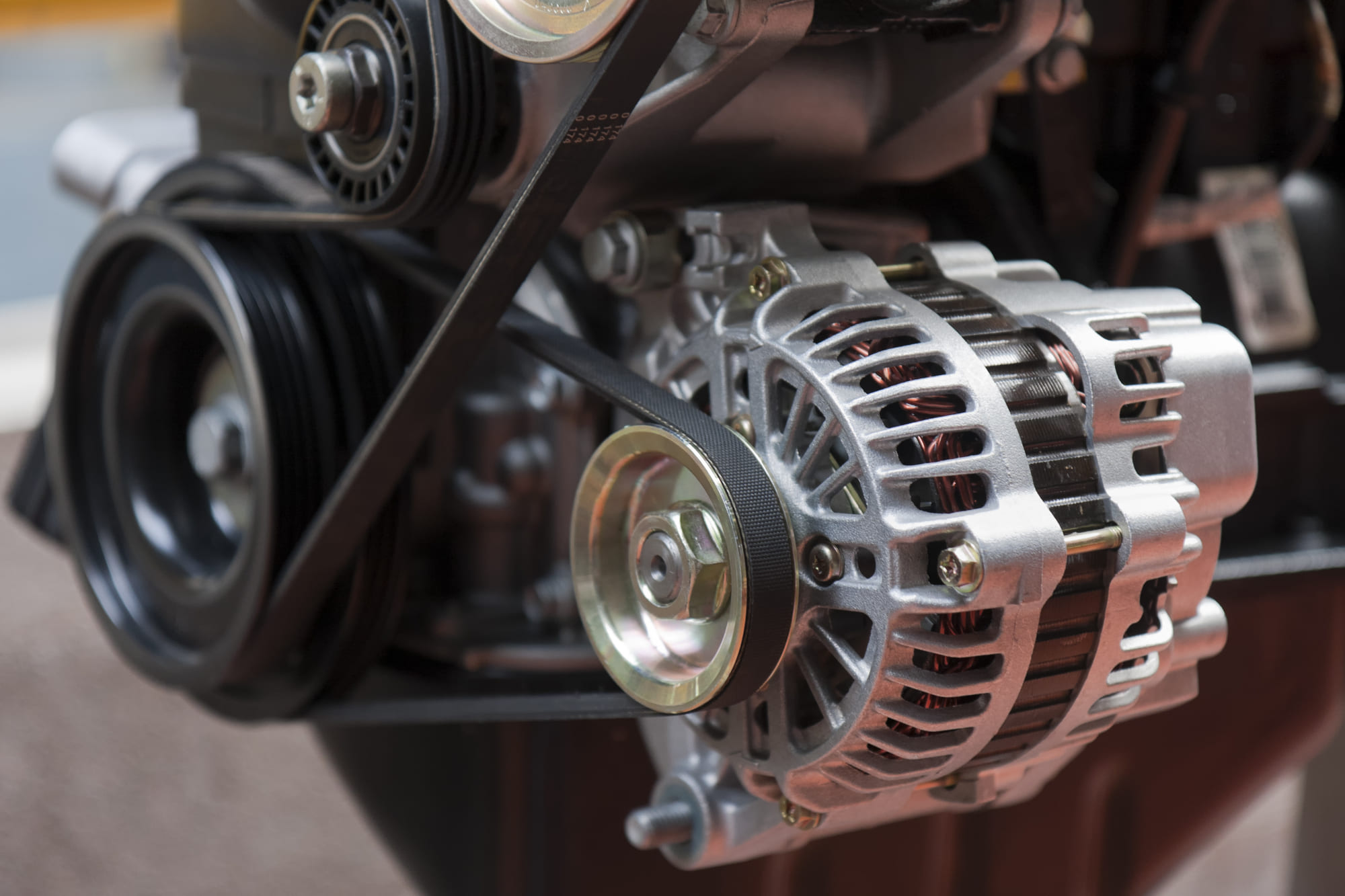

Illustrative image related to que es un alternador de carro

How Do High-Output Alternators Differ from Standard Ones?

High-output alternators are engineered to provide increased amperage, making them suitable for vehicles with significant electrical requirements, such as performance or off-road vehicles. These alternators can support advanced electronics, aftermarket sound systems, and additional lighting. B2B buyers in the automotive aftermarket should prioritize these alternators for customers seeking enhanced vehicle performance. However, the increased cost and potential need for installation modifications may be a consideration for some buyers.

What Makes Diesel Alternators Essential for Commercial Vehicles?

Diesel alternators are specifically designed to meet the rigorous demands of diesel engines, often found in heavy-duty trucks and commercial vehicles. They feature robust construction to withstand harsh operating conditions and ensure reliable performance. For B2B buyers in the commercial vehicle sector, investing in diesel alternators is crucial for maintaining fleet operations. While they are more expensive and heavier than standard models, their durability and reliability justify the investment.

Why Are Smart Alternators Becoming Popular in Modern Vehicles?

Smart alternators utilize advanced electronics to optimize charging efficiency and reduce emissions, making them particularly relevant for hybrid and electric vehicles. These alternators adjust their output based on real-time electrical demand, enhancing fuel efficiency. B2B buyers in the automotive sector should consider smart alternators as a forward-thinking option for eco-conscious clients. However, their complexity may lead to higher repair costs, which should be factored into purchasing decisions.

What Are the Key Features of Marine Alternators?

Marine alternators are built to withstand the corrosive conditions of marine environments, making them essential for boats and yachts. They often feature specialized coatings and materials to prevent rust and corrosion. B2B buyers in the marine industry should focus on these alternators for their durability and reliability in harsh conditions. While their specialized design can limit availability, the investment is justified for businesses catering to marine applications.

Key Industrial Applications of que es un alternador de carro

| Industry/Sector | Specific Application of que es un alternador de carro | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles and automotive components | Ensures reliable electrical systems, enhancing vehicle performance and customer satisfaction | Quality standards, compatibility with various vehicle models, and supply chain reliability |

| Automotive Repair Services | Maintenance and repair of vehicles | Provides essential service to customers, ensuring vehicle safety and performance | Access to OEM parts, expertise in alternator diagnosis, and competitive pricing |

| Fleet Management | Maintenance of commercial vehicle fleets | Reduces downtime and repair costs, ensuring operational efficiency | Bulk purchasing agreements, warranty terms, and after-sales support |

| Renewable Energy Solutions | Integration in hybrid and electric vehicles | Supports sustainable energy solutions, appealing to eco-conscious consumers | Compliance with environmental regulations and technology compatibility |

| Transportation and Logistics | Support for delivery and transport vehicles | Enhances reliability and efficiency in logistics operations | Durability and performance under various conditions, and sourcing from reputable manufacturers |

How is ‘que es un alternador de carro’ Applied in Automotive Manufacturing?

In the automotive manufacturing sector, alternators are critical components that ensure the electrical systems of vehicles function optimally. They convert mechanical energy from the engine into electrical energy, powering various systems such as lights, infotainment, and safety features. For international buyers, particularly in emerging markets like Africa and South America, sourcing high-quality alternators that meet specific vehicle models and performance standards is essential. Manufacturers must consider compatibility and adherence to quality certifications to maintain brand reputation and customer satisfaction.

Illustrative image related to que es un alternador de carro

What Role Does ‘que es un alternador de carro’ Play in Automotive Repair Services?

Automotive repair services rely heavily on alternators for vehicle maintenance. A malfunctioning alternator can lead to significant issues, including battery failure and compromised vehicle performance. Repair shops must be equipped to diagnose alternator problems accurately and provide timely repairs to minimize customer downtime. For B2B buyers in regions like the Middle East and Europe, sourcing OEM or high-quality aftermarket alternators is crucial to ensure reliability and safety in their service offerings. Competitive pricing and access to a wide range of parts are also key considerations.

How is ‘que es un alternador de carro’ Relevant in Fleet Management?

In fleet management, the performance of commercial vehicles is paramount. Alternators play a vital role in ensuring that vehicles are operational and efficient. A well-functioning alternator reduces the risk of electrical failures, thereby minimizing downtime and repair costs. For businesses operating in logistics and transportation, sourcing reliable alternators in bulk can lead to cost savings and improved operational efficiency. Additionally, establishing partnerships with manufacturers that offer warranties and after-sales support can further enhance fleet reliability.

In What Ways Does ‘que es un alternador de carro’ Contribute to Renewable Energy Solutions?

The rise of hybrid and electric vehicles marks a significant shift in the automotive landscape. Alternators are being adapted for these vehicles to manage energy storage and distribution effectively. This integration supports the transition to sustainable energy solutions, appealing to environmentally conscious consumers. Buyers in the renewable energy sector must consider sourcing alternators that comply with environmental regulations and are compatible with advanced vehicle technologies. Ensuring that suppliers meet sustainability standards is vital for maintaining a competitive edge.

How Does ‘que es un alternador de carro’ Impact Transportation and Logistics?

For transportation and logistics companies, the reliability of delivery vehicles is crucial. Alternators ensure that vehicles remain operational by providing the necessary electrical power for various systems. This reliability translates to enhanced efficiency in logistics operations, reducing the risk of delays. B2B buyers in this sector should prioritize sourcing durable and high-performance alternators that can withstand diverse operational conditions. Establishing relationships with reputable manufacturers can also ensure consistent supply and support for vehicle maintenance needs.

3 Common User Pain Points for ‘que es un alternador de carro’ & Their Solutions

Scenario 1: Understanding Alternator Functionality for Fleet Management

The Problem:

B2B buyers managing fleets of vehicles often struggle with understanding the functionality and maintenance needs of alternators. Misunderstandings about how alternators work can lead to poor vehicle performance, unexpected downtime, and costly repairs. Fleet managers might not realize that the alternator is responsible for powering essential electrical systems when the vehicle is running, and if it fails, it can result in vehicles being inoperable. This lack of awareness can cause significant delays in operations and impact overall productivity.

The Solution:

To mitigate these issues, fleet managers should invest in comprehensive training sessions for their maintenance staff that cover the basics of alternator functionality and maintenance. This includes recognizing the signs of alternator failure, such as dimming lights, difficulty starting the vehicle, or unusual noises. Additionally, establishing a regular maintenance schedule that includes alternator checks can prevent unexpected failures. When sourcing alternators, opt for reputable suppliers who provide detailed specifications and warranties, ensuring that the components meet the specific requirements of your fleet vehicles. Utilizing diagnostic tools that can monitor the electrical system’s performance will also allow for proactive maintenance, ensuring that any potential issues are addressed before they escalate.

Scenario 2: Sourcing Reliable Alternators for Importation

The Problem:

Businesses in regions such as Africa and the Middle East often face challenges in sourcing high-quality alternators for vehicles. The market can be flooded with subpar products that fail to meet international standards, leading to increased maintenance costs and customer dissatisfaction. Buyers may find it difficult to verify the authenticity and quality of alternators, leading to uncertainty in their procurement processes.

The Solution:

To address these sourcing challenges, B2B buyers should establish strong relationships with certified manufacturers and suppliers who are known for their quality assurance practices. Conduct thorough research on potential suppliers, checking for certifications such as ISO standards, and seeking references from other businesses in the industry. It’s also beneficial to visit suppliers’ facilities, if possible, to observe their manufacturing processes and quality control measures. Additionally, consider leveraging technology such as blockchain for transparency in the supply chain, which can help verify the authenticity of the products. Implementing a robust procurement strategy that includes quality audits and setting specific performance benchmarks for alternators will further ensure that only reliable products are acquired.

Scenario 3: Troubleshooting Alternator Issues in Vehicle Repairs

The Problem:

Automotive repair shops frequently encounter difficulties when diagnosing and resolving alternator-related issues in vehicles. Without a clear understanding of how alternators function and the symptoms of their failure, technicians may misdiagnose problems, leading to unnecessary repairs and increased costs for both the shop and the customer. This can erode trust and damage the reputation of the repair shop.

The Solution:

To enhance troubleshooting capabilities, repair shops should invest in training programs focused on electrical systems, with a particular emphasis on alternators. Workshops and certifications can equip technicians with the necessary skills to accurately diagnose alternator failures and other related issues. Implementing advanced diagnostic tools that can analyze the vehicle’s electrical system in real-time will also aid in identifying problems more effectively. Additionally, establishing a systematic approach to troubleshooting can streamline the repair process—starting with visual inspections, testing battery voltage, and checking for any warning lights on the dashboard. By fostering a culture of continuous learning and equipping technicians with the right tools, repair shops can improve their service quality and customer satisfaction, ultimately leading to increased business success.

Strategic Material Selection Guide for que es un alternador de carro

What Are the Key Materials Used in Alternators for Vehicles?

When selecting materials for alternators, several factors come into play, including performance, durability, cost, and compatibility with specific applications. Here, we analyze four common materials used in the construction of alternators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Materials Are Commonly Used in Alternators?

1. Aluminum

Key Properties: Aluminum is lightweight, has excellent corrosion resistance, and offers good thermal conductivity. It typically withstands temperatures up to 150°C, making it suitable for automotive applications.

Pros & Cons: The lightweight nature of aluminum contributes to overall vehicle efficiency, enhancing fuel economy. However, while it is durable, aluminum may not withstand extreme mechanical stress as well as other metals, which could lead to deformation under high loads.

Impact on Application: Aluminum is often used in the casing and structural components of alternators. Its corrosion resistance makes it ideal for vehicles operating in humid or coastal environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider the availability of aluminum and its recyclability. Compliance with international standards such as ASTM B221 can be crucial for ensuring quality.

2. Copper

Key Properties: Copper has high electrical conductivity, thermal conductivity, and resistance to corrosion. It can operate effectively at temperatures up to 200°C, making it suitable for electrical components.

Pros & Cons: The primary advantage of copper is its superior electrical performance, which enhances the efficiency of the alternator. However, copper is relatively expensive and can be heavy, which may impact overall vehicle weight.

Impact on Application: Copper is predominantly used in windings and electrical connections within the alternator. Its excellent conductivity ensures efficient power generation and distribution.

Considerations for International Buyers: Buyers should be aware of copper’s fluctuating market prices and potential supply chain issues. Compliance with standards like ASTM B170 is essential for quality assurance.

3. Steel

Key Properties: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for structural components of alternators.

Pros & Cons: The strength of steel makes it ideal for components that experience significant mechanical stress. However, it is heavier than aluminum and can be prone to corrosion if not properly treated.

Impact on Application: Steel is commonly used in the alternator’s frame and support structures. Its strength ensures that the alternator can endure the vibrations and shocks typical in automotive environments.

Considerations for International Buyers: For regions like the Middle East, where humidity can be high, buyers should opt for corrosion-resistant steel grades. Compliance with standards such as DIN 10130 can be important for ensuring product reliability.

4. Plastic Composites

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They typically operate well within a temperature range of -40°C to 120°C.

Pros & Cons: The lightweight nature of plastic composites can reduce the overall weight of the alternator, improving vehicle efficiency. However, they may not offer the same level of mechanical strength as metals, potentially leading to durability concerns.

Impact on Application: Plastic composites are often used for non-structural components, such as housings and covers, which require insulation from electrical components.

Considerations for International Buyers: Buyers should evaluate the environmental impact of plastics and ensure compliance with regulations in their respective countries. Standards such as ISO 9001 can help in assessing quality.

Summary Table of Material Selection for Alternators

| Material | Typical Use Case for que es un alternador de carro | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Casing and structural components | Lightweight and corrosion-resistant | Less durable under extreme stress | Medium |

| Copper | Windings and electrical connections | Superior electrical conductivity | Expensive and heavier | High |

| Steel | Frame and support structures | High tensile strength | Heavier and prone to corrosion | Medium |

| Plastic Composites | Housings and covers | Lightweight and moldable | Lower mechanical strength | Low |

This comprehensive analysis provides B2B buyers with critical insights into material selection for alternators, ensuring informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for que es un alternador de carro

What Are the Main Stages in the Manufacturing Process of a Car Alternator?

The manufacturing of a car alternator involves several key stages that ensure the final product meets the necessary performance and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with the selection of high-quality raw materials, primarily aluminum, copper, and various polymers. Aluminum is commonly used for the casing, while copper is essential for the windings. These materials must meet specific standards for conductivity and durability to ensure efficient performance.

-

Forming: This stage involves shaping the raw materials into components such as the rotor, stator, and housing. Techniques like die casting for aluminum parts and winding for copper coils are prevalent. Precision is crucial here, as any defects can lead to inefficiencies or failures in the alternator’s operation.

-

Assembly: After forming, the individual components are assembled. This includes inserting the rotor into the stator, connecting the rectifier, and integrating the voltage regulator. Skilled technicians often carry out this process, ensuring that each part is correctly aligned and secured. Automated assembly lines may also be utilized to improve efficiency and consistency.

-

Finishing: The final stage includes quality checks and surface treatments. Components may undergo anodizing or painting to enhance corrosion resistance. This stage is critical for aesthetic and functional purposes, as it can affect the alternator’s lifespan and performance.

How is Quality Assurance Implemented in Car Alternator Manufacturing?

Quality assurance is a vital aspect of the manufacturing process for car alternators, ensuring that each unit meets rigorous industry standards. Various international and industry-specific standards guide these practices.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which focuses on quality management systems. Compliance with this standard indicates a commitment to quality processes and customer satisfaction. Additionally, certifications such as CE (Conformité Européenne) are essential for products sold in Europe, ensuring they meet safety and environmental requirements.

-

Quality Control Checkpoints: Quality control is typically integrated at various stages of the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are performed to monitor the integrity of components. This can include dimensional checks, material inspections, and functional tests.

– Final Quality Control (FQC): Before packaging, each alternator undergoes a thorough inspection and testing process. This may involve electrical testing to ensure the alternator meets voltage and current specifications. -

Common Testing Methods: Various testing methods are employed to verify the performance and reliability of car alternators. These may include:

– Electrical Testing: Ensuring the output voltage and current meet specifications.

– Thermal Testing: Checking the alternator’s performance under different temperature conditions.

– Vibration Testing: Assessing the alternator’s durability against vibrations experienced during vehicle operation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are several methods to consider:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and overall operational capabilities of the supplier. This firsthand observation can provide insights into the supplier’s commitment to quality.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the supplier’s performance metrics. These reports should include data on defect rates, compliance with international standards, and results from various testing methods.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control processes. These agencies can conduct inspections at various stages of production and provide certification that can be crucial for international trade.

What Are the Quality Control and Certification Nuances for International Buyers?

When engaging with suppliers from different regions, international buyers must be aware of specific quality control and certification nuances:

-

Regional Standards: Different regions may have varying standards and certifications. For instance, while ISO 9001 is recognized globally, other certifications may be region-specific, such as the Brazilian INMETRO or Saudi Arabian SASO. Understanding these regional standards can help buyers ensure compliance and reliability.

-

Cultural Considerations: Cultural differences can impact quality control practices. For example, some regions may emphasize collective quality management practices, while others focus on individual accountability. Buyers should consider these cultural factors when evaluating potential suppliers.

-

Documentation and Traceability: Buyers should ensure that suppliers maintain thorough documentation of their quality control processes. This includes records of material certifications, inspection reports, and compliance with international standards. Such documentation not only ensures accountability but also facilitates traceability in the event of quality issues.

Conclusion

The manufacturing processes and quality assurance practices for car alternators are complex yet essential for ensuring product reliability and performance. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions when sourcing alternators. This knowledge is particularly vital for international buyers navigating diverse markets and standards across Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es un alternador de carro’

Introduction

In the automotive industry, understanding the components of a vehicle, such as the alternator, is crucial for B2B buyers involved in procurement. This guide provides a step-by-step checklist to assist you in sourcing high-quality alternators for your business needs. By following these steps, you can ensure that you choose the right product and supplier to meet your operational requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline the technical specifications of the alternators you require. Consider factors such as power output, size, and compatibility with specific vehicle models. Having detailed specifications helps in narrowing down your options and ensures that the products you procure meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in alternators. Look for suppliers with a strong reputation in the market and those who have experience supplying to businesses similar to yours. Utilize industry directories, trade shows, and online platforms to compile a list of potential candidates.

Step 3: Evaluate Supplier Credentials

Once you have a list of potential suppliers, it’s important to evaluate their credentials. Verify their certifications, such as ISO 9001, which indicates a commitment to quality management standards. Additionally, assess their financial stability and history in the market to ensure they can meet your long-term supply needs.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the alternators from shortlisted suppliers. Testing samples allows you to evaluate the quality, performance, and compatibility of the products with your existing systems. This step is critical to avoid potential failures in your operations due to subpar components.

Step 5: Compare Pricing and Terms

After assessing the quality of the samples, compare the pricing and terms offered by each supplier. Consider not only the base price but also factors such as shipping costs, payment terms, and return policies. Understanding the total cost of ownership will help you make an informed decision that aligns with your budget.

Step 6: Check Customer References

Ask potential suppliers for references from other businesses that have purchased alternators from them. Contact these references to gather insights about their experiences, including product quality, delivery times, and customer service. This feedback can provide valuable context and help you gauge the reliability of the supplier.

Step 7: Negotiate Terms and Place Orders

Once you have selected the supplier that best meets your criteria, enter negotiations to finalize the terms of your purchase. Discuss aspects such as pricing, delivery schedules, and warranty conditions to ensure that both parties are clear on expectations. After reaching an agreement, proceed to place your order and establish a follow-up plan for delivery and performance evaluation.

By following this checklist, B2B buyers can systematically approach the procurement of alternators, minimizing risks and ensuring high-quality purchases that support their business operations.

Comprehensive Cost and Pricing Analysis for que es un alternador de carro Sourcing

What Are the Key Cost Components in Sourcing Car Alternators?

When sourcing car alternators, several cost components must be considered to establish a comprehensive pricing strategy. The primary cost components include:

-

Materials: This encompasses the raw materials needed for production, such as copper for windings, steel for the rotor and casing, and various plastics and metals for other components. The price of these materials can fluctuate based on market demand and availability.

-

Labor: Labor costs vary significantly by region and the complexity of the manufacturing process. Skilled labor is essential for assembly and quality control, and labor costs can be a significant portion of the total manufacturing expense.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient management of overhead can lead to significant cost savings.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized alternators. These costs are amortized over the production volume, so higher volumes can reduce the per-unit tooling cost.

-

Quality Control (QC): Ensuring that the alternators meet specified quality standards is crucial. This involves testing and inspection processes that add to the overall cost but are essential for maintaining reliability and customer satisfaction.

-

Logistics: Transportation costs for raw materials and finished goods can vary based on distance, shipping methods, and customs duties, particularly for international buyers. Efficient logistics can help minimize these costs.

-

Margin: Suppliers typically include a margin to cover their risks and ensure profitability. Understanding the expected margin can help buyers negotiate better pricing.

What Factors Influence Pricing for Car Alternators?

Several factors can influence the pricing of car alternators in a B2B context:

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can significantly impact the total cost.

-

Specifications and Customization: Custom alternators designed for specific vehicle models or performance requirements may incur additional costs. Buyers should evaluate whether the benefits of customization justify the higher price.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or OEM standards) can increase costs. However, investing in quality can reduce long-term failure rates and maintenance costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may command higher prices due to their quality assurance processes and service levels.

-

Incoterms: Understanding the Incoterms used in the transaction is critical. They determine who is responsible for shipping costs, insurance, and customs clearance, impacting the total landed cost.

How Can Buyers Negotiate Better Prices for Car Alternators?

Negotiating effectively can lead to more favorable pricing for car alternators:

-

Leverage Volume: If possible, consolidate orders or commit to long-term contracts to negotiate lower prices based on volume.

-

Assess Total Cost of Ownership (TCO): Evaluate the TCO, including maintenance and potential downtime costs, rather than just the initial purchase price. This perspective can provide leverage in negotiations.

-

Research Market Rates: Understanding market pricing trends can help buyers negotiate from a position of knowledge. Having comparative quotes from multiple suppliers can also strengthen negotiation positions.

-

Consider Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and lead times. This could also provide opportunities for better pricing.

-

Be Aware of Pricing Nuances: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of local market dynamics, currency fluctuations, and import duties that may affect pricing.

Disclaimer on Indicative Prices

It is important to note that the prices for car alternators can vary widely based on the aforementioned factors. This analysis provides a framework for understanding potential costs but does not guarantee specific pricing outcomes. Buyers should conduct thorough market research and engage with suppliers directly to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing que es un alternador de carro With Other Solutions

Exploring Alternative Solutions to ‘Que Es Un Alternador De Carro’

In the automotive industry, understanding the functionality and alternatives to the alternator is essential for B2B buyers looking to optimize vehicle performance and electrical systems. While the alternator plays a crucial role in generating electricity and recharging the battery, several alternative technologies exist that offer similar functionalities. This section provides a comparative analysis of the alternator against two alternative solutions: the DC Generator and Battery Management Systems (BMS).

Comparison Table

| Comparison Aspect | Que Es Un Alternador De Carro | DC Generator | Battery Management System (BMS) |

|---|---|---|---|

| Performance | Reliable energy generation while the engine runs | Provides stable DC power; less efficient at low speeds | Manages battery health and energy distribution |

| Cost | Moderate initial cost; long-term savings on maintenance | Generally lower cost but may require frequent maintenance | Higher upfront cost; long-term efficiency gains |

| Ease of Implementation | Standard installation in most vehicles | Requires custom setup; may not fit all vehicle types | Complex installation; needs integration with existing systems |

| Maintenance | Regular checks for wear and tear; low maintenance | Requires regular maintenance; brushes and commutators wear out | Minimal maintenance; software updates needed |

| Best Use Case | Ideal for conventional vehicles with combustion engines | Suitable for older vehicles or applications needing simple DC power | Best for electric vehicles and hybrid systems requiring optimal battery usage |

Detailed Breakdown of Alternatives

What Are DC Generators and Their Advantages?

DC generators serve as an alternative to alternators, primarily used in older vehicles or specific industrial applications. They convert mechanical energy into direct current (DC) electricity. The main advantage of DC generators is their simplicity and lower initial cost. However, they tend to be less efficient at lower speeds and may require more frequent maintenance due to wear on brushes and commutators.

Understanding Battery Management Systems (BMS)

Battery Management Systems are sophisticated solutions designed to monitor and manage the charging and discharging of batteries, particularly in electric and hybrid vehicles. A BMS optimizes battery life and performance, ensuring that energy is efficiently distributed among vehicle systems. While BMS installations can be complex and more expensive upfront, they offer significant long-term benefits, especially in reducing operational costs and enhancing battery longevity.

Conclusion: How Should B2B Buyers Choose the Right Solution?

For B2B buyers evaluating vehicle electrical systems, the choice between an alternator, a DC generator, and a Battery Management System depends on specific operational needs and vehicle types. If the focus is on reliability and standard vehicle applications, an alternator remains the most suitable option. Conversely, for older models or specific use cases requiring simple DC power, a DC generator may suffice. In contrast, businesses investing in electric or hybrid vehicles should consider a Battery Management System for its advanced management capabilities and long-term cost savings. By aligning the choice with operational requirements, buyers can make informed decisions that enhance vehicle performance and reliability.

Essential Technical Properties and Trade Terminology for que es un alternador de carro

What Are the Key Technical Properties of a Car Alternator?

When considering the procurement of car alternators, understanding the technical specifications is crucial for B2B buyers. Here are some critical properties to keep in mind:

-

Output Voltage and Current Rating

– Definition: The output voltage of an alternator typically ranges from 12V to 14.5V, while current ratings can vary from 30A to over 200A, depending on the vehicle’s electrical requirements.

– Importance: Adequate voltage and current ratings ensure that the alternator can efficiently power all electrical systems in the vehicle, from headlights to infotainment systems. Choosing an alternator with insufficient ratings can lead to electrical failures or battery drain. -

Efficiency Rating

– Definition: This refers to the alternator’s ability to convert mechanical energy from the engine into electrical energy, usually expressed as a percentage.

– Importance: Higher efficiency ratings mean less energy is wasted as heat, resulting in better fuel economy and reduced strain on the engine. B2B buyers should prioritize high-efficiency alternators to enhance overall vehicle performance. -

Temperature Range

– Definition: The operational temperature range specifies the conditions under which the alternator can function effectively, typically from -40°C to +125°C.

– Importance: Understanding the temperature range is critical for applications in extreme climates. An alternator that can withstand high temperatures will have a longer lifespan and require less frequent replacements, which is a significant cost consideration for fleet operators. -

Material Composition

– Definition: Common materials used in alternators include aluminum for the housing and copper for the windings.

– Importance: The choice of materials affects the alternator’s weight, durability, and heat dissipation capabilities. B2B buyers should ensure that the alternators they source use high-quality materials to enhance reliability and performance. -

Mounting Configuration

– Definition: This refers to how the alternator is affixed to the engine, which can vary between different vehicle models.

– Importance: Compatibility with existing vehicle designs is essential for seamless integration and installation. Buyers must confirm that the mounting configuration matches their vehicle specifications to avoid costly modifications.

What Are Common Trade Terms Related to Car Alternators?

Navigating the procurement landscape for car alternators involves familiarizing yourself with industry-specific terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to companies that manufacture products that are sold under another company’s brand, typically the original manufacturer of the vehicle.

– Relevance: OEM alternators are often preferred for their reliability and compatibility with specific vehicle models. B2B buyers should be aware of whether they are sourcing OEM or aftermarket products. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell in a single order.

– Relevance: Understanding the MOQ is vital for budget planning and inventory management. Buyers should negotiate MOQs that align with their purchasing capabilities to avoid excess stock. -

RFQ (Request for Quotation)

– Definition: A formal process where buyers request price quotes from suppliers for specified products or services.

– Relevance: An RFQ is essential for obtaining competitive pricing and understanding supplier capabilities. B2B buyers should prepare detailed RFQs to ensure they receive accurate and comprehensive responses. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of sellers and buyers in the delivery of goods.

– Relevance: Familiarity with Incoterms is crucial for international transactions, as they clarify shipping responsibilities, risk management, and cost allocation. Buyers should specify the appropriate Incoterms in contracts to avoid misunderstandings. -

Lead Time

– Definition: The time taken from placing an order to the delivery of goods.

– Relevance: Understanding lead times is critical for inventory planning and ensuring that production schedules are met. Buyers should communicate clearly with suppliers about lead times to avoid delays in vehicle assembly or repairs.

In conclusion, grasping the essential technical properties and trade terminology related to car alternators is vital for B2B buyers. This knowledge not only aids in making informed purchasing decisions but also enhances overall supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the que es un alternador de carro Sector

What Are the Key Market Dynamics Affecting the Alternator Sector?

The global alternator market is witnessing significant growth driven by the increasing demand for vehicles and advancements in automotive technology. Key drivers include the rising popularity of electric vehicles (EVs) and hybrids, which require efficient alternators to manage energy consumption and battery performance. Emerging markets in Africa and South America, particularly Brazil, are expanding their automotive industries, resulting in heightened demand for reliable alternators. The Middle East is also seeing a surge in automotive sales, influenced by urbanization and economic growth, making it a vital region for B2B buyers.

Current B2B sourcing trends emphasize the integration of advanced technologies such as IoT and AI in alternator manufacturing. These technologies facilitate predictive maintenance and enhance product efficiency, allowing suppliers to offer more value to their clients. Additionally, international buyers are increasingly looking for suppliers that provide transparency in their production processes, ensuring that they can meet regulatory standards and consumer expectations.

Furthermore, the shift towards sustainability is shaping sourcing strategies. B2B buyers are now prioritizing partnerships with manufacturers that focus on sustainable production practices and innovative materials. This trend is particularly evident in Europe, where stringent environmental regulations push suppliers to adapt their operations to remain competitive.

How Is Sustainability Influencing Sourcing Decisions in the Alternator Market?

The environmental impact of automotive manufacturing, particularly regarding components like alternators, has become a critical consideration for B2B buyers. Manufacturers are under pressure to minimize their carbon footprint, leading to an increased focus on sustainable practices throughout the supply chain. This includes utilizing eco-friendly materials, reducing waste, and optimizing production processes to lower energy consumption.

Ethical sourcing has also gained prominence, as buyers seek to align with suppliers that adhere to fair labor practices and responsible resource extraction. Certifications such as ISO 14001 for environmental management and other green certifications are becoming essential for suppliers aiming to attract international clients. These certifications not only enhance a supplier’s reputation but also provide assurance to buyers that their sourcing decisions are contributing to a more sustainable future.

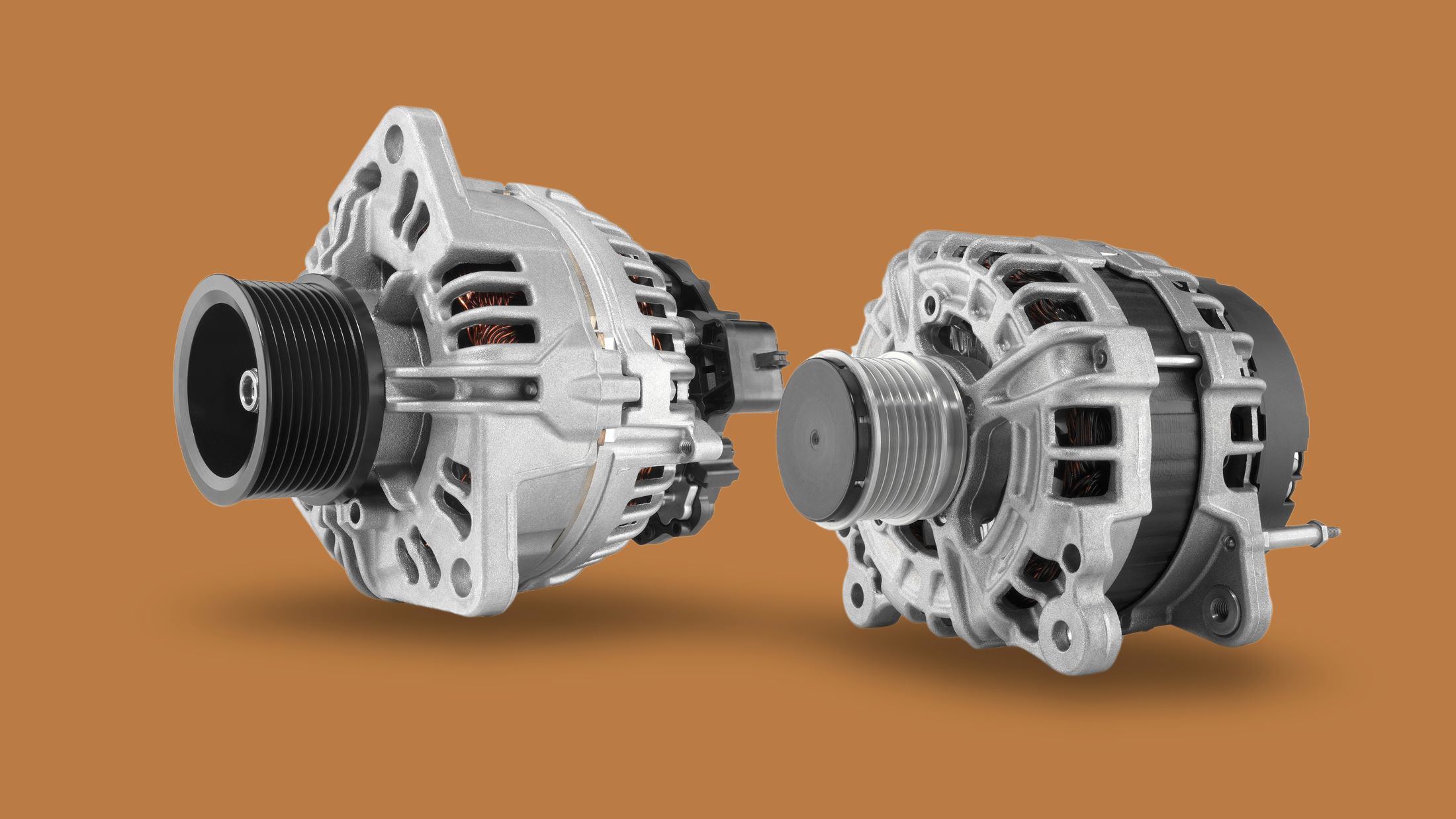

Illustrative image related to que es un alternador de carro

In the context of alternators, innovations in materials, such as the use of recycled metals and biodegradable components, are emerging. This shift not only reduces environmental impact but also appeals to a growing segment of eco-conscious consumers and businesses.

What Is the Evolution of the Alternator and Its Relevance to Today’s Market?

The alternator has evolved significantly since its inception in the early 20th century. Originally designed as a simple generator, modern alternators are complex devices that integrate advanced technologies for improved efficiency and reliability. The introduction of digital controls and microprocessors has transformed alternators into smart components capable of optimizing vehicle performance and energy management.

This evolution is particularly relevant for B2B buyers as they seek suppliers that not only provide traditional alternators but also innovative solutions that align with current automotive trends, including electrification and smart vehicle technologies. Understanding the historical context of alternator development can help buyers make informed decisions when sourcing products that will meet the demands of the future automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of que es un alternador de carro

-

How do I determine the right alternator for my vehicle?

To select the appropriate alternator, consider the specifications of your vehicle, including the make, model, and engine size. It’s essential to check the amperage rating of the alternator to ensure it meets the electrical demands of your vehicle’s systems, such as lights, infotainment, and other electrical components. Consult with your supplier for compatibility and performance standards. Additionally, reviewing OEM specifications can help in choosing a high-quality alternator that will provide reliable service. -

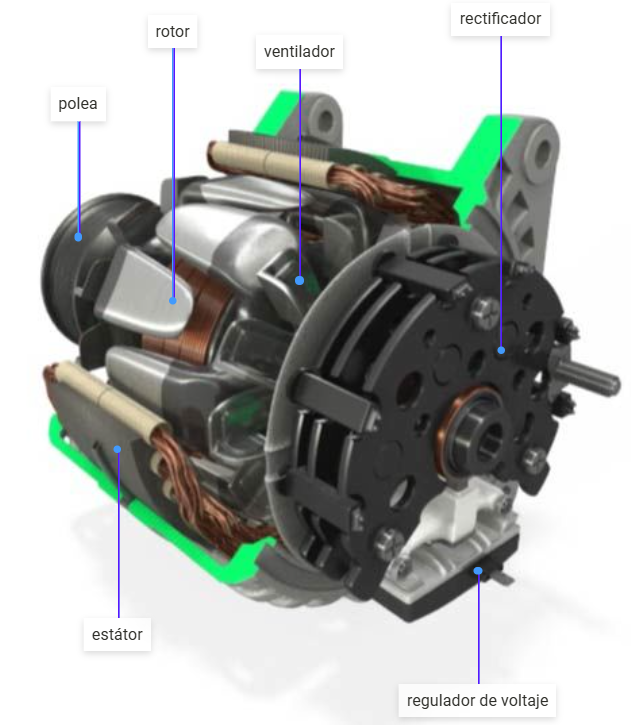

What are the key components of a car alternator?

A car alternator consists of several critical components, including the rotor, stator, rectifier, voltage regulator, and cooling fan. The rotor generates magnetic fields, while the stator converts this magnetic energy into electrical energy. The rectifier then changes alternating current (AC) to direct current (DC) for the battery and vehicle systems. Understanding these components can aid in troubleshooting and maintenance, ensuring you select the best alternator for your needs. -

What should I consider when sourcing alternators internationally?

When sourcing alternators internationally, assess the supplier’s reputation, quality certifications, and production capabilities. Verify that they comply with international standards such as ISO or CE. Additionally, consider the logistics of shipping, including lead times, customs regulations, and potential tariffs. It’s also beneficial to establish clear communication regarding specifications, warranties, and after-sales support to mitigate risks associated with international procurement. -

How can I verify the quality of alternators from a supplier?

To ensure the quality of alternators, request samples for testing and review the supplier’s quality assurance processes. Look for certifications such as ISO 9001 that indicate adherence to quality management standards. Additionally, seek references or testimonials from other clients and consider third-party inspections before finalizing orders. Conducting thorough due diligence will help you avoid subpar products and ensure long-term reliability. -

What are typical minimum order quantities (MOQs) for alternators?

Minimum order quantities (MOQs) for alternators can vary significantly depending on the supplier and the type of alternator required. Typically, MOQs can range from 50 to 500 units. Discussing your specific needs with suppliers can sometimes lead to flexibility in MOQs, especially if you are willing to establish a long-term partnership. Consider your inventory management and market demand when negotiating MOQs. -

What payment terms should I expect when purchasing alternators?

Payment terms for purchasing alternators can vary by supplier but often include options such as upfront payment, partial payment upon order confirmation, or payment upon delivery. Some suppliers may also offer credit terms, allowing you to pay within a specified period after receiving the goods. Clarifying these terms upfront will help manage cash flow and ensure a smooth transaction process. -

How do I handle logistics and shipping for alternators?

When arranging logistics for alternators, consider factors such as shipping method, cost, and transit times. Collaborate with your supplier to determine the best shipping options, whether by air or sea, based on urgency and budget. Ensure that all necessary documentation, such as bills of lading and customs declarations, is prepared to facilitate smooth customs clearance. Additionally, consider using a freight forwarder for expertise in international shipping. -

What common issues should I be aware of when using car alternators?

Common issues with car alternators include failure to charge the battery, unusual noises, and electrical system fluctuations. Regular maintenance checks can help identify problems early, such as worn bearings or faulty voltage regulators. Understanding the signs of alternator failure, such as dashboard warning lights or dimming lights, can prompt timely repairs, thereby prolonging the lifespan of your vehicle’s electrical system.

Top 2 Que Es Un Alternador De Carro Manufacturers & Suppliers List

1. Infinity Auto – Alternador

Domain: infinityauto.com

Registered: 2002 (23 years)

Introduction: El alternador es un generador que distribuye electricidad al auto y recarga la batería. Funciona convirtiendo energía mecánica en energía eléctrica, impulsado por el cigüeñal del motor a través de una correa serpentina. Sus componentes incluyen:

– Rotor: pieza cilíndrica rodeada de imanes que gira dentro del estator.

– Estator: parte fija que contiene cables de cobre conductores.

– Rectificador…

2. Race – Alternador de Coche

Domain: race.es

Introduction: El alternador es un componente del coche que produce electricidad y la acumula en la batería. Funciona mediante el giro rotativo del motor, generando electricidad alterna que se convierte en continua de 12 voltios a través de una placa de diodos. El voltaje generado debe estar entre 13,5 V y 14,5 V. En coches antiguos, el alternador era una pieza independiente, mientras que en coches modernos incl…

Strategic Sourcing Conclusion and Outlook for que es un alternador de carro

In summary, understanding the role of the alternator in vehicle operations is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The alternator not only recharges the battery but also powers essential electrical systems while the engine runs. Recognizing the critical components—such as the rotor, stator, and rectifier—can lead to informed purchasing decisions and better maintenance strategies.

Strategic sourcing of high-quality alternators enhances operational efficiency and reduces downtime for vehicles, which is vital in markets that rely heavily on transportation. By partnering with reputable suppliers who prioritize innovation and quality, businesses can ensure they are equipped with reliable components that meet their specific needs.

Illustrative image related to que es un alternador de carro

As the automotive industry evolves, the demand for efficient and durable alternators will only increase. International buyers are encouraged to proactively engage with suppliers, focusing on sustainability and technological advancements. This approach will not only enhance product offerings but also support long-term growth in a competitive market. Investing in strategic sourcing today will position your business for success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.