Introduction: Navigating the Global Market for how to tell if alternator or battery is bad

Understanding how to determine if an alternator or battery is bad is crucial for international B2B buyers, especially those operating in emerging markets such as Africa, South America, the Middle East, and Europe. The ability to accurately diagnose electrical issues not only minimizes downtime but also enhances operational efficiency. In this comprehensive guide, we delve into various symptoms and diagnostic methods for both batteries and alternators, ensuring that businesses can make informed decisions regarding repairs or replacements.

This guide encompasses a wide range of topics, including the specific signs of battery and alternator failure, testing techniques, and preventative maintenance strategies. Additionally, we provide insights on sourcing reliable suppliers and evaluating costs, which are key considerations for B2B buyers looking to optimize their procurement processes. Understanding the nuances of these components will empower businesses to mitigate risks associated with vehicle reliability and maintenance.

By equipping decision-makers with the knowledge to differentiate between battery and alternator issues, this guide supports effective troubleshooting and encourages proactive management of automotive resources. As a result, organizations can enhance their operational resilience, ensuring that their fleets remain dependable and efficient in various market conditions. Whether you are a fleet manager in Nigeria or a logistics provider in Vietnam, mastering these diagnostic skills is essential for maintaining the integrity of your transportation assets.

Table Of Contents

- Top 2 How To Tell If Alternator Or Battery Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to tell if alternator or battery is bad

- Understanding how to tell if alternator or battery is bad Types and Variations

- Key Industrial Applications of how to tell if alternator or battery is bad

- 3 Common User Pain Points for ‘how to tell if alternator or battery is bad’ & Their Solutions

- Strategic Material Selection Guide for how to tell if alternator or battery is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how to tell if alternator or battery is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to tell if alternator or battery is bad’

- Comprehensive Cost and Pricing Analysis for how to tell if alternator or battery is bad Sourcing

- Alternatives Analysis: Comparing how to tell if alternator or battery is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how to tell if alternator or battery is bad

- Navigating Market Dynamics and Sourcing Trends in the how to tell if alternator or battery is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to tell if alternator or battery is bad

- Strategic Sourcing Conclusion and Outlook for how to tell if alternator or battery is bad

- Important Disclaimer & Terms of Use

Understanding how to tell if alternator or battery is bad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Visual Inspection | Check for corrosion, loose connections, or physical damage. | Automotive repair shops, fleet maintenance | Pros: Quick and low-cost; Cons: May miss underlying issues. |

| Voltage Testing | Measure voltage output using a multimeter; healthy range is 13-14.5V. | Electrical component suppliers, auto parts retailers | Pros: Accurate; Cons: Requires proper equipment and knowledge. |

| Load Testing | Apply a load to the battery to assess performance under stress. | Battery distributors, automotive service centers | Pros: Comprehensive; Cons: Time-consuming and requires specialized equipment. |

| Jump Start Test | Jump start the vehicle; if it dies shortly after, suspect alternator. | Automotive diagnostics, roadside assistance | Pros: Simple; Cons: Not definitive, may misidentify issues. |

| Diagnostic Tools | Use advanced diagnostic tools to assess battery and alternator performance. | Automotive repair shops, fleet management systems | Pros: In-depth analysis; Cons: Higher investment cost. |

What is the Role of Visual Inspection in Diagnosing Battery and Alternator Issues?

Visual inspection is a foundational method for diagnosing battery and alternator problems. Technicians look for signs of corrosion, loose connections, or physical damage to components. This method is particularly beneficial for automotive repair shops and fleet maintenance operations where quick assessments are crucial. While it is cost-effective and straightforward, it may not reveal deeper electrical issues, making it essential to follow up with more thorough testing.

How Does Voltage Testing Help Identify Electrical Issues?

Voltage testing is a reliable technique that involves measuring the voltage output of the battery and alternator using a multimeter. A healthy battery should display a voltage between 12.6V (fully charged) and around 14.5V when the engine is running. This method is widely used by electrical component suppliers and auto parts retailers to ensure proper functionality. While voltage testing is accurate, it necessitates the right tools and a basic understanding of electrical systems.

What Are the Benefits of Load Testing for Batteries?

Load testing evaluates the battery’s ability to perform under stress, simulating real-world conditions. This technique is particularly useful for battery distributors and automotive service centers, as it provides a comprehensive assessment of battery health. Load testing can reveal weaknesses that other methods may overlook. However, it can be time-consuming and requires specialized equipment, which may not be feasible for all businesses.

Why is the Jump Start Test a Common Diagnostic Method?

The jump start test is a straightforward method where a vehicle is jump-started to see if it dies shortly after, indicating a potential alternator issue. This method is often used by automotive diagnostics professionals and roadside assistance teams for its simplicity and speed. However, while it can provide quick insights, it may not definitively identify the root cause of the problem, leading to potential misdiagnoses.

How Do Diagnostic Tools Enhance the Assessment of Battery and Alternator Performance?

Advanced diagnostic tools offer a detailed analysis of both battery and alternator performance, enabling technicians to pinpoint issues accurately. These tools are essential for automotive repair shops and fleet management systems that prioritize efficiency and accuracy in their diagnostics. While they provide in-depth insights, the initial investment in such tools can be significant, making them more suitable for businesses with high diagnostic demands.

Key Industrial Applications of how to tell if alternator or battery is bad

| Industry/Sector | Specific Application of how to tell if alternator or battery is bad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostic services for battery and alternator failures | Increases customer satisfaction and repeat business | Access to reliable diagnostic tools and training for technicians |

| Transportation & Logistics | Fleet maintenance and management | Reduces downtime and maintenance costs | Need for bulk purchasing of batteries and alternators |

| Agriculture | Equipment reliability in farming machinery | Ensures operational efficiency during critical seasons | Availability of heavy-duty batteries and alternators for agricultural equipment |

| Mining | Power supply reliability for mining vehicles | Minimizes operational disruptions | Sourcing robust components capable of handling extreme conditions |

| Construction | Ensuring reliable power for construction machinery | Enhances project timelines and productivity | Need for durable batteries and alternators suitable for harsh environments |

How is ‘how to tell if alternator or battery is bad’ applied in the Automotive Repair Sector?

In the automotive repair industry, diagnosing battery and alternator issues is crucial for providing quality service. Mechanics utilize advanced diagnostic tools to identify whether a vehicle’s starting problems stem from the battery or the alternator. By accurately diagnosing these issues, repair shops can prevent unnecessary part replacements, thereby enhancing customer satisfaction and increasing the likelihood of repeat business. International buyers, especially in regions with fluctuating power supply, should consider sourcing reliable diagnostic equipment that can withstand various environmental conditions.

What role does battery and alternator diagnostics play in Transportation & Logistics?

In the transportation and logistics sector, maintaining a fleet’s operational efficiency is paramount. Regular checks on the battery and alternator systems help prevent unexpected breakdowns, which can lead to costly downtime. By implementing systematic diagnostic procedures, logistics companies can optimize their maintenance schedules and reduce overall operational costs. Buyers in this sector must prioritize sourcing high-quality, durable batteries and alternators that can support extensive daily use across diverse geographic locations.

Why is battery and alternator reliability essential in Agriculture?

Agricultural machinery relies heavily on batteries and alternators for uninterrupted operation, particularly during planting and harvesting seasons. Understanding how to diagnose battery and alternator issues enables farmers to maintain their equipment and avoid costly delays. For international buyers in agriculture, especially in developing regions, sourcing heavy-duty batteries and alternators that can withstand harsh conditions is critical to ensuring reliable power supply for essential farming activities.

Illustrative image related to how to tell if alternator or battery is bad

How does mining benefit from battery and alternator diagnostics?

In the mining industry, the reliability of power supplies for heavy machinery is vital for continuous operations. Diagnosing alternator and battery failures promptly can minimize downtime and enhance productivity. Mining companies require robust components that can endure extreme environmental conditions. Therefore, international buyers should focus on sourcing high-performance batteries and alternators that meet the unique demands of mining operations, ensuring their equipment remains functional under challenging circumstances.

What is the importance of battery and alternator diagnostics in Construction?

Construction projects often rely on machinery that requires consistent power to meet tight deadlines. Diagnosing battery and alternator issues helps ensure that construction equipment operates without interruptions. By proactively managing these components, construction firms can enhance productivity and adhere to project timelines. Buyers in this sector should consider sourcing durable and reliable batteries and alternators that are specifically designed for the rigorous demands of construction environments, ensuring minimal operational disruptions.

3 Common User Pain Points for ‘how to tell if alternator or battery is bad’ & Their Solutions

Scenario 1: Inconsistent Power Supply Disrupting Operations

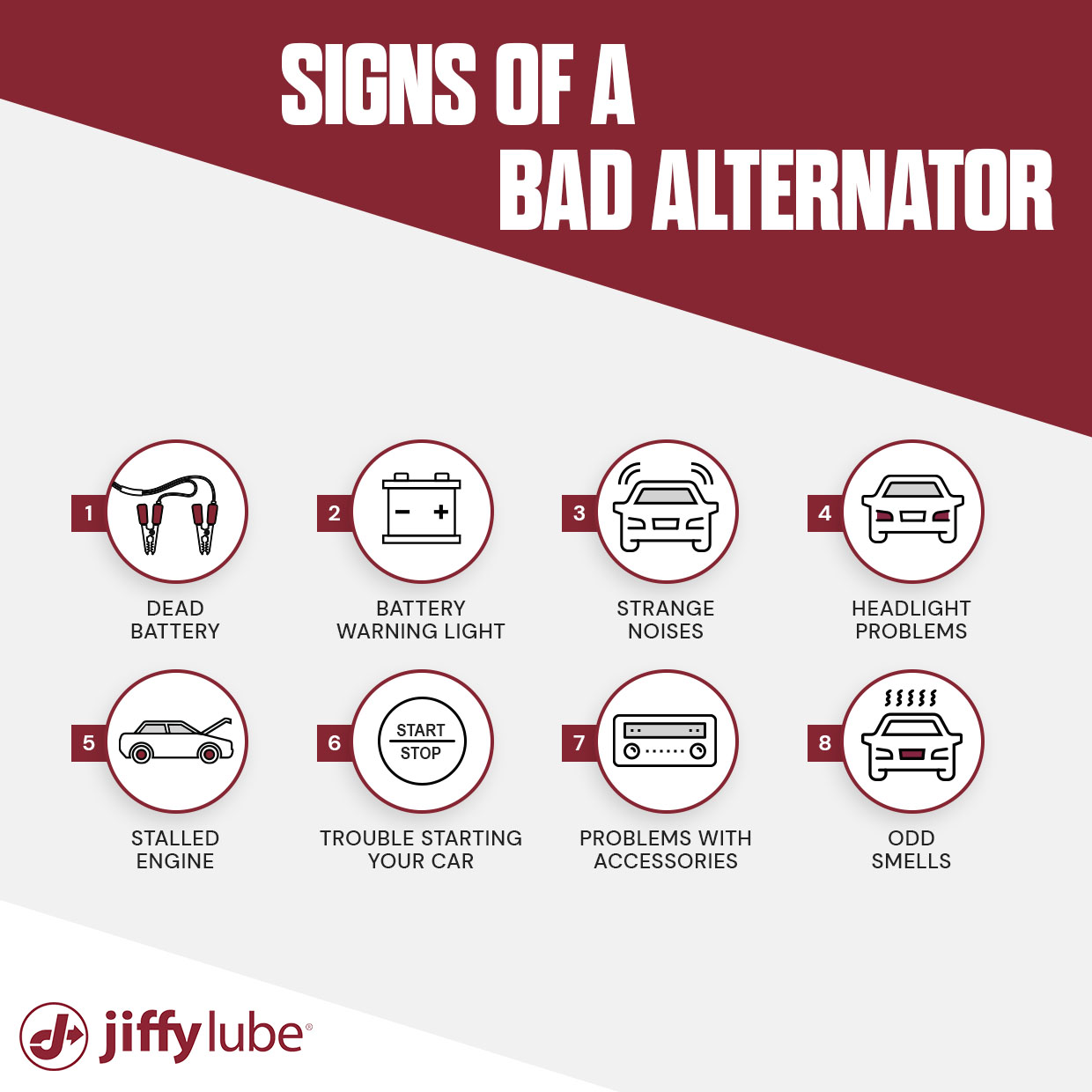

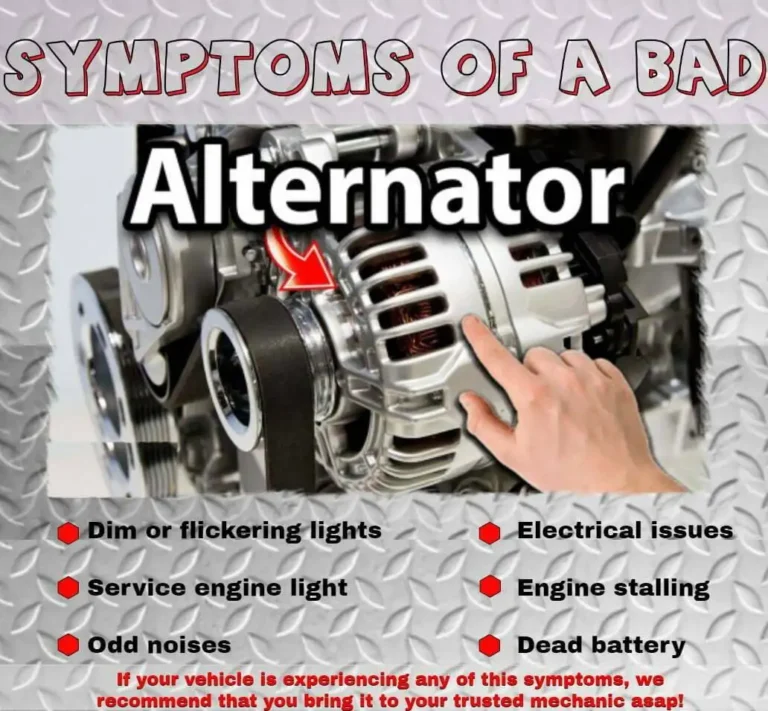

The Problem: For businesses that rely heavily on transportation, an unreliable vehicle can lead to significant operational disruptions. A common issue arises when employees report that vehicles either fail to start or experience inconsistent electrical performance, such as flickering headlights or malfunctioning onboard equipment. This uncertainty can create delays in deliveries or service provisions, resulting in lost revenue and dissatisfied customers. B2B buyers are often left wondering whether the problem lies with the battery or the alternator, complicating maintenance schedules and increasing downtime.

The Solution: To effectively diagnose whether the issue stems from the battery or the alternator, implement a systematic testing protocol. Start by educating your team on how to use a multimeter to check battery voltage. A healthy battery should read around 12.6 volts or higher when the vehicle is off. If the voltage drops below this, it indicates a battery issue. Next, while the engine is running, measure the voltage again; it should range between 13 to 14.5 volts. If the reading is lower, the alternator may not be charging the battery effectively. Providing your team with the necessary tools and knowledge not only minimizes downtime but also empowers them to address issues swiftly, ensuring that operations run smoothly.

Scenario 2: Increased Maintenance Costs Due to Misdiagnosis

The Problem: Misdiagnosing electrical issues can lead to unnecessary replacement of components, resulting in inflated maintenance costs. For instance, a company might replace a functioning alternator only to discover later that the real issue was a failing battery. This not only strains budgets but also diminishes trust in the maintenance team and the suppliers involved. B2B buyers often face the dilemma of ensuring their technical teams are well-informed to prevent such costly errors.

The Solution: To mitigate the risk of misdiagnosis, invest in training programs focused on electrical system diagnostics. Utilize workshops or online courses that cover the nuances of battery and alternator functionality, including symptoms and testing methods. Additionally, consider establishing a partnership with a local automotive training institution to provide on-site training for your maintenance staff. By fostering a knowledgeable workforce, businesses can ensure accurate diagnostics, reduce unnecessary expenses, and maintain a reliable fleet, ultimately enhancing overall operational efficiency.

Scenario 3: Limited Access to Diagnostic Tools in Remote Locations

The Problem: In many regions, particularly in developing countries or remote areas, access to sophisticated diagnostic tools can be limited. This presents a challenge for businesses that operate fleets in these locations, as technicians may struggle to identify whether a battery or alternator issue is causing vehicle failures. The inability to promptly diagnose and rectify these problems can lead to extended periods of inactivity for vehicles, affecting logistics and service delivery.

The Solution: To address this challenge, consider investing in portable diagnostic tools that are both affordable and easy to use. Look for handheld multimeters or simple battery testers that can be deployed in the field. Additionally, develop a standardized troubleshooting guide that technicians can refer to, which outlines step-by-step procedures for diagnosing battery and alternator issues without specialized equipment. This proactive approach not only empowers field technicians but also enhances vehicle uptime, allowing businesses to operate efficiently even in resource-limited environments. Establishing a reliable supply chain for these tools and guides can significantly improve your company’s response time to electrical issues, ultimately safeguarding your operational capabilities.

Strategic Material Selection Guide for how to tell if alternator or battery is bad

When diagnosing issues with alternators and batteries, the materials used in diagnostic tools and components play a critical role in performance and reliability. Here, we will analyze several common materials relevant to the tools and components used in determining whether an alternator or battery is malfunctioning.

What Materials Are Commonly Used in Diagnostic Tools?

1. Copper

Key Properties: Copper has excellent electrical conductivity, making it ideal for wiring and connectors. It can operate effectively in a temperature range from -200°C to 400°C and is resistant to corrosion when properly treated.

Pros & Cons: Copper is durable and offers low resistance, which enhances the performance of diagnostic tools. However, it is relatively expensive compared to alternatives like aluminum, and its weight can be a drawback in portable applications.

Illustrative image related to how to tell if alternator or battery is bad

Impact on Application: Copper wiring is essential for multimeters and other diagnostic tools that measure voltage and current. Its high conductivity ensures accurate readings, which is crucial for diagnosing battery and alternator issues.

Considerations for International Buyers: Compliance with international standards such as ASTM B170 for copper wire is essential. Buyers should also consider local sourcing options to mitigate costs and ensure availability.

2. Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a melting point of approximately 660°C. It offers moderate electrical conductivity, around 60% that of copper.

Pros & Cons: The primary advantage of aluminum is its lower cost and lighter weight, making it suitable for portable diagnostic tools. However, its lower conductivity means that longer lengths may be required, which can affect performance.

Impact on Application: Aluminum is often used in the construction of battery terminals and connectors. While it is suitable for many applications, its use in critical diagnostic tools may require careful consideration of performance trade-offs.

Illustrative image related to how to tell if alternator or battery is bad

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards such as ASTM B221. Additionally, they should be aware of regional preferences for material types, which can influence procurement decisions.

3. Plastic (Polymer Composites)

Key Properties: Plastics are lightweight and can be engineered for specific thermal and chemical resistance properties. They typically have a temperature tolerance between -40°C and 120°C.

Pros & Cons: The main advantage of plastic is its versatility and low cost. However, plastics can be less durable than metals and may degrade over time when exposed to heat or chemicals.

Impact on Application: Plastic housings for diagnostic tools protect sensitive electronic components from damage. They are also used in battery casings, where they provide insulation and protection from environmental factors.

Considerations for International Buyers: Compliance with environmental regulations such as RoHS (Restriction of Hazardous Substances) is critical when sourcing plastic materials. Buyers should also consider the availability of recycled options to meet sustainability goals.

Illustrative image related to how to tell if alternator or battery is bad

4. Steel

Key Properties: Steel is known for its strength and durability, with a melting point around 1370°C. It is resistant to deformation and can withstand high pressures.

Pros & Cons: Steel’s strength makes it ideal for structural components in diagnostic equipment. However, it is heavier than other materials and can be prone to corrosion if not properly treated.

Impact on Application: Steel is often used in the frames of diagnostic tools and equipment, providing stability and durability. Its robustness is essential for tools that may be subjected to rough handling in automotive environments.

Considerations for International Buyers: Buyers should ensure that steel components meet standards like ASTM A36 for structural steel. They should also consider local corrosion resistance treatments, especially in regions with high humidity or salt exposure.

Summary Table

| Material | Typical Use Case for how to tell if alternator or battery is bad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and connectors in multimeters | Excellent electrical conductivity | Relatively expensive | High |

| Aluminum | Battery terminals and lightweight diagnostic tools | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Plastic | Housings for diagnostic tools and battery casings | Versatile and low cost | Less durable under extreme conditions | Low |

| Steel | Structural components in diagnostic equipment | High strength and durability | Heavier and prone to corrosion | Medium |

This strategic material selection guide provides insights into the materials commonly used in diagnostic tools for alternators and batteries, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how to tell if alternator or battery is bad

What Are the Key Stages in the Manufacturing Process for Alternators and Batteries?

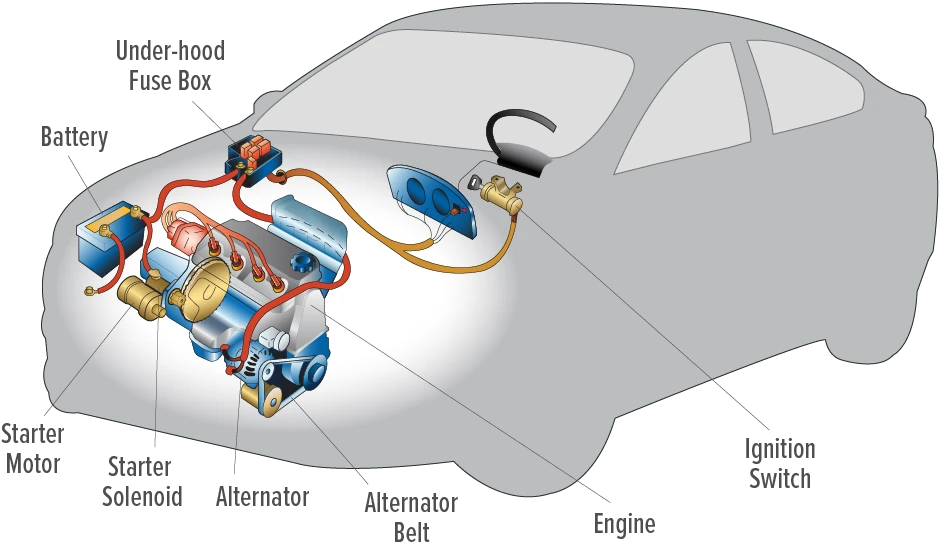

The manufacturing processes for alternators and batteries encompass several critical stages, each designed to ensure product reliability and performance. Understanding these stages can help B2B buyers make informed purchasing decisions.

What Is Involved in Material Preparation for Alternators and Batteries?

Material preparation is the foundational step in manufacturing alternators and batteries. For alternators, components such as copper wire, steel laminations, and plastic housings are sourced from certified suppliers. Battery manufacturing primarily involves lead, sulfuric acid, and advanced polymers.

Sourcing these materials involves rigorous supplier audits to ensure compliance with international standards. Buyers should verify that suppliers possess certifications like ISO 9001, which indicates adherence to quality management systems.

How Are Components Formed and Assembled in Alternator and Battery Manufacturing?

Once materials are prepared, they undergo forming processes. For alternators, copper wires are wound into coils, while steel laminations are stamped to create the rotor and stator. In battery manufacturing, lead plates are cast and assembled into cells.

The assembly stage is crucial, as it combines these components into a functional unit. Advanced robotics and automated systems are often employed to ensure precision and minimize human error. B2B buyers should inquire about the assembly techniques used, as this directly impacts the durability and efficiency of the final product.

What Are the Finishing Processes for Ensuring Quality in Alternators and Batteries?

Finishing processes include surface treatments, coatings, and packaging. For alternators, components may receive protective coatings to prevent corrosion, while batteries are sealed to ensure leak-proof performance.

Quality finishing not only enhances the product’s lifespan but also contributes to safety. Buyers should ensure that their suppliers follow stringent finishing standards and utilize materials that comply with environmental regulations, particularly for lead-acid batteries.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is integral to maintaining high standards in alternator and battery production. B2B buyers should be aware of the various checkpoints and testing methods used to ensure product reliability.

What International and Industry-Specific Standards Should B2B Buyers Consider?

International standards such as ISO 9001 and CE certification are vital for assessing supplier quality. These certifications indicate that the manufacturing processes meet globally recognized benchmarks.

Illustrative image related to how to tell if alternator or battery is bad

In addition, industry-specific standards such as API (American Petroleum Institute) for batteries used in oil and gas applications should be considered. B2B buyers can enhance their procurement strategies by prioritizing suppliers who demonstrate compliance with these standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) involves inspecting raw materials before they enter production. In-Process Quality Control (IPQC) ensures that assembly and forming processes meet specified tolerances. Finally, Final Quality Control (FQC) involves testing finished products for performance, safety, and compliance.

Common testing methods include electrical testing for alternators and capacity testing for batteries. B2B buyers should seek suppliers that provide detailed QC reports, including test results and compliance certificates.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is essential for ensuring product reliability. B2B buyers can conduct supplier audits, reviewing their manufacturing practices and quality assurance protocols. This may include assessing documentation, observing manufacturing processes, and interviewing key personnel.

Additionally, buyers should request third-party inspection reports. Engaging independent auditors can provide an unbiased assessment of a supplier’s adherence to quality standards.

What Nuances Should International B2B Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific challenges. Regulations and standards may vary significantly by region, impacting the compliance requirements for alternators and batteries.

B2B buyers should familiarize themselves with local regulations regarding the importation of electrical components, including any specific certifications required for automotive parts. Understanding these nuances can help avoid costly delays and ensure compliance with local laws.

Conclusion: The Importance of Understanding Manufacturing and Quality Assurance for B2B Buyers

For B2B buyers, particularly in international markets, a thorough understanding of the manufacturing processes and quality assurance practices for alternators and batteries is crucial. By focusing on supplier certifications, quality control checkpoints, and regional regulations, buyers can make informed decisions that enhance their procurement strategies and ensure the reliability of their products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to tell if alternator or battery is bad’

Introduction

This guide serves as a comprehensive checklist for B2B buyers aiming to procure the necessary tools and knowledge to diagnose issues related to vehicle batteries and alternators. Understanding how to differentiate between a failing battery and a malfunctioning alternator is essential for maintaining vehicle reliability and performance. This checklist will help you streamline your sourcing process, ensuring you acquire the right resources and expertise.

Step 1: Identify Your Diagnostic Needs

Before sourcing tools or services, assess the specific diagnostic capabilities required for your operations. Consider the types of vehicles you service and the common electrical issues encountered. Knowing whether you need basic testing tools like multimeters or advanced diagnostic equipment will guide your procurement process.

- Evaluate the vehicle types: Different vehicles may require different tools or techniques.

- Consider your service volume: Higher volumes may necessitate more advanced equipment.

Step 2: Research Reliable Diagnostic Tools

Investing in high-quality diagnostic tools is critical for accurate assessments. Look for reputable brands known for their durability and precision in automotive diagnostics.

- Check for user reviews: Customer feedback can provide insights into the tool’s effectiveness and reliability.

- Verify warranty information: A good warranty can indicate the manufacturer’s confidence in their product.

Step 3: Understand Battery and Alternator Functions

Equip your team with knowledge about the roles of batteries and alternators in a vehicle’s electrical system. This foundational understanding will enhance their diagnostic skills.

- Battery functions: Primarily responsible for starting the vehicle and powering accessories.

- Alternator roles: Generates electricity to recharge the battery and power the vehicle when the engine is running.

Step 4: Evaluate Testing Methods

Familiarize yourself with effective methods to test both batteries and alternators. This knowledge can significantly reduce misdiagnosis and improve service efficiency.

- Battery testing: Use a multimeter to check voltage levels—12.6 volts indicates a healthy battery.

- Alternator testing: Measure voltage output while the vehicle is running; it should fall between 13 and 14.5 volts.

Step 5: Source Quality Supplier Partnerships

Building relationships with trusted suppliers is essential for consistent quality and support. Look for suppliers who specialize in automotive diagnostics and offer comprehensive service packages.

- Request certifications: Ensure suppliers meet industry standards to guarantee the quality of their products.

- Seek testimonials: Connect with other businesses in your region to gather insights about their experiences with the supplier.

Step 6: Train Your Staff

Once you’ve procured the necessary tools, invest in training your staff on how to use them effectively. Proper training will ensure that your team can accurately diagnose issues and operate equipment safely.

Illustrative image related to how to tell if alternator or battery is bad

- Consider hands-on workshops: These can provide practical experience and enhance learning.

- Utilize online resources: Many suppliers offer instructional videos and manuals that can supplement training.

Step 7: Establish a Maintenance Routine

Regular maintenance of both diagnostic tools and vehicles is crucial for long-term efficiency. Create a routine for checking and calibrating your equipment to ensure accuracy.

- Schedule periodic checks: Regular assessments will help catch potential issues early.

- Document maintenance logs: Keep records of all maintenance activities for accountability and future reference.

By following this checklist, B2B buyers can ensure they are well-equipped to diagnose and resolve battery and alternator issues efficiently, ultimately improving service quality and customer satisfaction.

Comprehensive Cost and Pricing Analysis for how to tell if alternator or battery is bad Sourcing

What Are the Key Cost Components for Diagnosing Battery and Alternator Issues?

When assessing the costs involved in diagnosing whether a battery or alternator is faulty, several components must be considered. Materials include diagnostic tools such as multimeters, which can range in price based on quality and brand. Typically, a basic multimeter can cost between $10 to $50, while advanced models may exceed $100.

Labor costs are also a significant factor. Skilled technicians are required to perform accurate diagnostics, and their hourly rates can vary widely depending on the region and expertise, ranging from $20 to $100 per hour.

Manufacturing overhead and tooling costs come into play if diagnostic tools are produced in-house. This includes expenses related to production facilities, equipment maintenance, and utility costs, which can add a percentage to the overall pricing.

Illustrative image related to how to tell if alternator or battery is bad

Quality Control (QC) is essential for ensuring the reliability of diagnostic tools and methods. Implementing rigorous QC procedures can increase initial costs but results in better long-term performance and lower failure rates.

Logistics costs involve the transportation of diagnostic tools and spare parts, which can fluctuate based on distance, shipping method, and local regulations. For international buyers, understanding these logistics is crucial for accurate cost forecasting.

Margins are typically added by suppliers to cover their operating costs and profit expectations. In the B2B sector, margins can vary from 10% to 30% based on market demand and competition.

How Do Price Influencers Affect the Cost of Diagnosing Battery and Alternator Problems?

Several factors influence pricing in the sourcing of diagnostic tools and services. Volume and Minimum Order Quantity (MOQ) are critical considerations. Larger orders can lead to discounts, while smaller quantities may incur higher per-unit costs.

Specifications and customization can also affect pricing. Custom diagnostic tools tailored for specific vehicle types or applications may come at a premium compared to standard options.

Material quality and certifications play a role in determining cost. Tools made from high-grade materials or those that meet specific international standards (e.g., ISO certifications) typically command higher prices.

Supplier factors such as reputation, reliability, and customer service can influence pricing. Established suppliers with a proven track record may charge more but provide better assurance of quality and support.

Incoterms (International Commercial Terms) are vital for international transactions, impacting overall costs related to shipping responsibilities, insurance, and tariffs. Understanding these terms can help buyers anticipate additional costs in their sourcing strategy.

What Buyer Tips Can Help Optimize Costs in Sourcing Diagnostic Tools?

When negotiating prices for diagnostic tools and services, buyers should consider leveraging volume discounts by committing to larger orders. Building long-term relationships with suppliers can also lead to better pricing and terms.

To achieve cost-efficiency, buyers should conduct thorough market research to compare prices and quality across different suppliers. This helps in identifying the best value propositions.

Focusing on the Total Cost of Ownership (TCO) is essential. While initial costs may be lower with cheaper tools, consider the longevity, reliability, and potential repair costs associated with them.

For international B2B buyers, understanding the pricing nuances in their specific regions is crucial. Economic conditions, local demand, and import regulations can significantly impact costs. Buyers from Africa, South America, the Middle East, and Europe should be aware of these factors when sourcing.

Illustrative image related to how to tell if alternator or battery is bad

Conclusion

While the costs associated with diagnosing battery and alternator issues can vary widely, understanding the breakdown of these costs and the factors influencing pricing can empower B2B buyers. By employing strategic sourcing practices, buyers can optimize their investments in diagnostic tools and services, ensuring they make informed purchasing decisions tailored to their specific needs.

Alternatives Analysis: Comparing how to tell if alternator or battery is bad With Other Solutions

Introduction to Evaluating Alternatives for Diagnosing Battery and Alternator Issues

When faced with vehicle electrical problems, distinguishing between a faulty alternator and a dead battery is crucial for effective repair and maintenance. While traditional diagnostic methods involve direct testing of these components, alternative solutions may offer additional insights or efficiencies. This section evaluates how to tell if an alternator or battery is bad compared to other viable methods, enabling B2B buyers to make informed decisions about their vehicle maintenance strategies.

Comparison Table

| Comparison Aspect | How To Tell If Alternator Or Battery Is Bad | Battery Load Tester | Professional Diagnostic Tools |

|---|---|---|---|

| Performance | Reliable voltage and amperage testing | Tests battery under load | Comprehensive diagnostics |

| Cost | Low-cost tools (multimeter) | Moderate cost (around $30-$100) | Higher cost (ranging from $200+) |

| Ease of Implementation | Requires basic knowledge | Simple to use | May require trained personnel |

| Maintenance | Minimal (occasional recalibration) | Requires battery maintenance | Regular software updates needed |

| Best Use Case | Quick diagnosis for DIY enthusiasts | Assessing battery health | Detailed analysis for fleet management |

Detailed Breakdown of Alternatives

What is a Battery Load Tester and its Advantages?

A battery load tester is a device specifically designed to evaluate a battery’s ability to hold a charge under load conditions. It provides a clear indication of battery health by simulating the demands placed on the battery during engine start-up. The primary advantage of this tool is its straightforward operation, allowing even those with limited technical knowledge to perform tests. However, it is limited to battery diagnostics and cannot assess alternator functionality, necessitating additional tools for comprehensive evaluations.

How Do Professional Diagnostic Tools Enhance Vehicle Maintenance?

Professional diagnostic tools offer a sophisticated approach to assessing vehicle electrical systems, including batteries and alternators. These devices connect to the vehicle’s onboard diagnostic system, providing real-time data and comprehensive insights into various components’ health. The main benefit is their ability to deliver detailed information, which is invaluable for fleet managers or automotive businesses. However, the initial investment is significantly higher, and their usage often requires trained personnel, making them less accessible for small-scale operations.

Conclusion: Choosing the Right Solution for Your Needs

In selecting the appropriate method for diagnosing alternator or battery issues, B2B buyers should consider their specific operational needs and technical capabilities. For businesses with limited resources or those looking for quick assessments, using basic tools like multimeters or battery load testers may suffice. Conversely, for larger enterprises or those managing extensive fleets, investing in professional diagnostic tools could provide long-term benefits through enhanced accuracy and efficiency. By aligning the chosen solution with operational demands, businesses can ensure optimal vehicle performance and minimize downtime.

Essential Technical Properties and Trade Terminology for how to tell if alternator or battery is bad

What Are the Key Technical Properties to Assess When Diagnosing Alternator or Battery Issues?

In the automotive industry, understanding the technical specifications of batteries and alternators is crucial for effective diagnosis and maintenance. Here are several critical properties that B2B buyers should consider:

-

Voltage Output

Batteries typically have a nominal voltage of 12 volts, while alternators should produce between 13 to 14.5 volts when the engine is running. Monitoring voltage output helps determine if the alternator is functioning properly and if the battery is receiving adequate charge. A consistent voltage within this range indicates a healthy electrical system, which is essential for the longevity of vehicle components. -

Amperage Rating

The amperage output of an alternator can range from 130 to 400 amps, depending on the vehicle’s requirements. This rating is crucial for businesses that utilize vehicles with high electrical demands, such as those equipped with powerful audio systems or heavy-duty lighting. Understanding this property helps in selecting the right alternator for specific applications, ensuring optimal performance without overloading the system. -

Cold Cranking Amps (CCA)

CCA measures a battery’s ability to start an engine in cold temperatures, indicating how much current the battery can deliver for 30 seconds at 0°F (-18°C). For B2B buyers operating in regions with extreme weather, a battery with a high CCA rating is essential. This specification ensures reliability and reduces the likelihood of battery failure during critical times. -

State of Charge (SOC)

The SOC is a percentage representing the current charge level of the battery compared to its full capacity. Maintaining an optimal SOC is vital for battery health; a battery that consistently operates below 50% SOC may suffer from sulfation, leading to decreased performance and lifespan. Regular monitoring of SOC can prevent unexpected failures, allowing businesses to plan maintenance schedules effectively. -

Cycle Life

This term refers to the number of complete charge and discharge cycles a battery can undergo before its capacity significantly diminishes. Understanding cycle life is essential for businesses that rely on vehicles for daily operations, as it directly affects the total cost of ownership. A battery with a longer cycle life reduces replacement frequency and ensures consistent vehicle availability.

What Are Common Trade Terms Relevant to Battery and Alternator Diagnostics?

Familiarity with industry jargon is essential for effective communication in the B2B automotive space. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the original vehicle components. Sourcing OEM batteries and alternators ensures compatibility and performance standards that meet or exceed vehicle specifications, which is critical for businesses that prioritize reliability and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ helps B2B buyers negotiate better terms, manage inventory levels, and ensure they have sufficient parts on hand to avoid downtime in vehicle operations. -

RFQ (Request for Quotation)

An RFQ is a formal process used to solicit price offers from suppliers. For businesses looking to procure batteries or alternators, issuing an RFQ can help compare costs, quality, and delivery timelines, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is crucial for B2B buyers engaged in cross-border procurement of automotive parts, as they dictate shipping costs, risk levels, and delivery responsibilities. -

Aftermarket

This term refers to parts made for vehicles that are not sourced from the OEM. Aftermarket batteries and alternators can often provide cost savings, but buyers must ensure they meet quality standards to avoid potential issues in performance and reliability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding battery and alternator diagnostics, ultimately enhancing their operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the how to tell if alternator or battery is bad Sector

What Are the Global Drivers Influencing the Battery and Alternator Diagnostics Market?

The market for diagnosing battery and alternator issues is evolving rapidly, driven by several global trends. As vehicle electrification increases, particularly with the rise of electric and hybrid vehicles, the demand for reliable diagnostics has surged. This trend is especially pertinent in regions like Africa and South America, where the automotive market is expanding, and consumers are increasingly looking for efficient, cost-effective solutions for vehicle maintenance. Additionally, the Middle East and Europe are seeing an uptick in demand for advanced automotive technology, which requires sophisticated diagnostic tools to identify battery and alternator failures accurately.

Emerging technologies such as mobile diagnostics apps and cloud-based platforms are revolutionizing how businesses approach vehicle maintenance. These innovations allow for real-time data analysis and remote diagnostics, providing B2B buyers with actionable insights and reducing downtime. Furthermore, the availability of comprehensive training programs on battery and alternator diagnostics is becoming essential, enabling technicians to stay abreast of the latest methodologies and tools.

How Are Sustainability and Ethical Sourcing Impacting the Battery and Alternator Sector?

Sustainability is becoming a pivotal concern in the battery and alternator diagnostics market. The environmental impact of lead-acid batteries and the mining of materials for lithium-ion batteries has prompted a shift towards more sustainable practices. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmental responsibility. This includes utilizing recycled materials, reducing waste, and adopting green manufacturing processes.

Illustrative image related to how to tell if alternator or battery is bad

Moreover, certifications such as ISO 14001 for environmental management and other ‘green’ certifications are gaining importance among international buyers. These certifications not only assure compliance with environmental standards but also enhance brand reputation. Suppliers who can showcase their sustainability efforts are more likely to gain a competitive edge in markets that value corporate social responsibility, particularly in regions like Europe where consumers are more environmentally conscious.

What Historical Developments Have Shaped the Battery and Alternator Diagnostics Market?

Historically, the methods for diagnosing battery and alternator issues have evolved from rudimentary manual checks to sophisticated electronic diagnostics. Early automotive repair relied heavily on visual inspections and basic tools, which often led to misdiagnosis and inefficient repairs. With the advent of digital multimeters and advanced diagnostic scanners in the late 20th century, technicians gained the ability to measure voltage, amperage, and overall system performance more accurately.

The introduction of onboard diagnostics (OBD) systems in vehicles in the 1980s further transformed the landscape, allowing for real-time monitoring of electrical systems and providing critical data to technicians. This evolution has set the stage for the current market, where B2B buyers can leverage advanced diagnostic tools and technologies to enhance service efficiency and customer satisfaction. As the industry continues to adapt to new technologies and sustainability demands, understanding this historical context will be crucial for making informed sourcing decisions.

Illustrative image related to how to tell if alternator or battery is bad

Conclusion

In summary, the battery and alternator diagnostics market is characterized by rapid technological advancements, an increasing focus on sustainability, and a historical evolution that has paved the way for modern practices. International B2B buyers, particularly those from emerging markets, must stay informed about these trends to optimize their sourcing strategies and remain competitive in a dynamic landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of how to tell if alternator or battery is bad

-

How do I determine if my vehicle’s battery or alternator is failing?

To identify whether a battery or alternator issue is at play, start by checking the battery’s voltage with a multimeter. A healthy battery should read around 12.6 volts. If the vehicle starts but dies shortly after, the alternator may not be charging the battery. Look for dimming lights or erratic electrical performance, which could indicate alternator problems. Regular maintenance and testing can help prevent these issues and ensure efficient operation. -

What are the common symptoms of a bad battery?

Common symptoms of a failing battery include difficulty starting the vehicle, slow cranking, or a clicking sound when trying to start. Additionally, if you notice corrosion around the battery terminals or if the battery fails to hold a charge after a jump start, these are strong indicators of battery failure. Frequent short trips can also deplete the battery’s ability to recharge, leading to premature failure. -

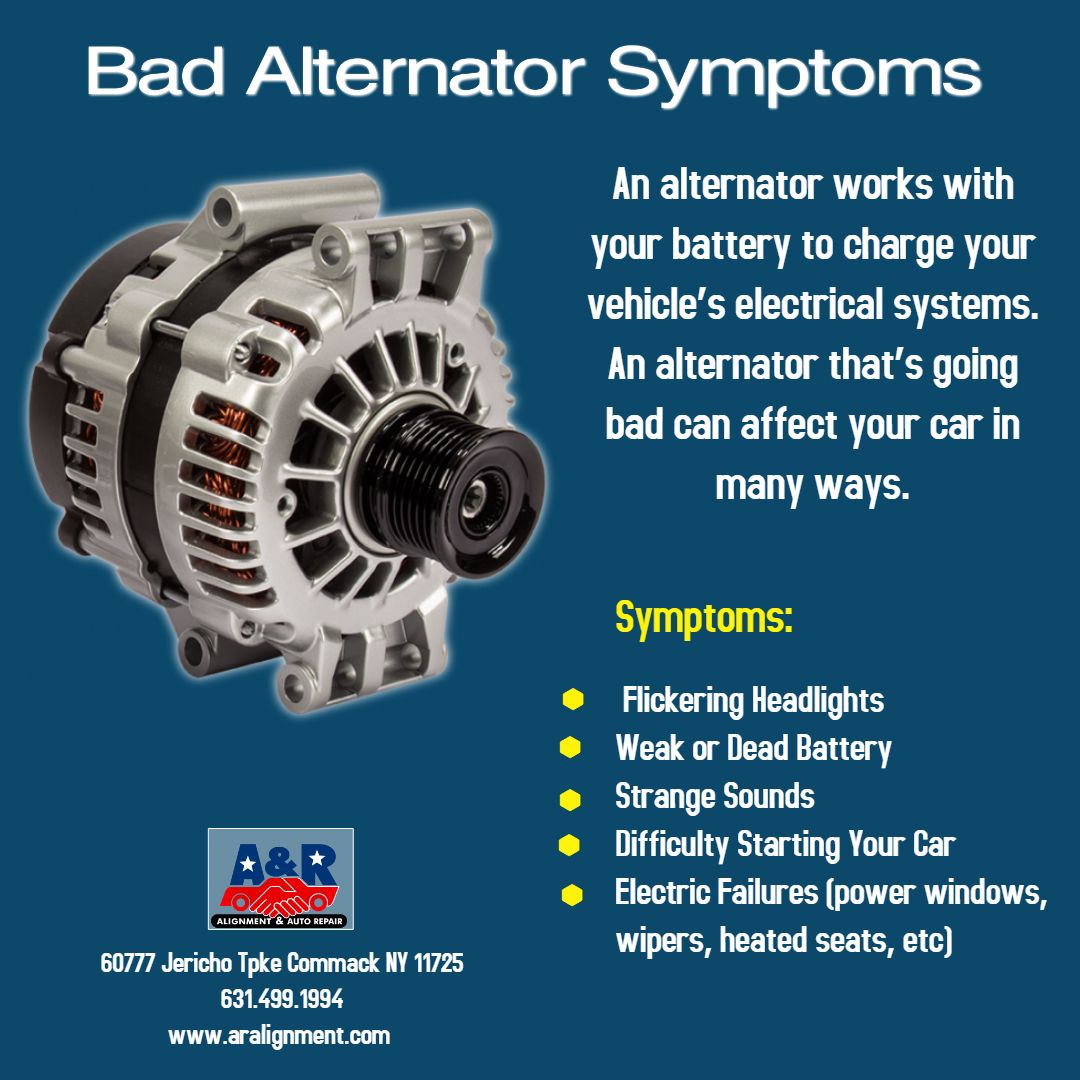

What signs indicate a faulty alternator?

Signs of a faulty alternator include dim or flickering headlights, dashboard warning lights, and electrical accessories malfunctioning. If the vehicle’s engine dies after being jump-started, it’s often a sign that the alternator is not recharging the battery properly. Additionally, a burning smell or unusual noises from the alternator area may indicate internal damage or wear. -

How can I test the alternator’s output effectively?

To test the alternator, use a multimeter while the vehicle is running. Measure the voltage across the battery terminals; a reading between 13 and 14.5 volts indicates that the alternator is functioning properly. If the voltage is below this range or fluctuates significantly, further diagnostics may be required. It’s advisable to have a professional perform a load test if you suspect alternator issues. -

What should I consider when sourcing batteries and alternators internationally?

When sourcing batteries and alternators from international suppliers, consider factors like quality certifications, warranty policies, and compliance with local regulations. Ensure that the supplier has a proven track record and positive reviews from other B2B buyers. Additionally, assess their ability to meet your specific needs regarding product customization and availability of various brands. -

What minimum order quantities (MOQ) should I expect for batteries and alternators?

Minimum order quantities can vary widely depending on the supplier and region. Generally, you might encounter MOQs ranging from 50 to 200 units for batteries and alternators. It’s advisable to negotiate these terms based on your purchasing needs and to confirm whether the supplier can accommodate smaller orders, especially if you’re testing the market. -

How can I ensure quality assurance (QA) when purchasing automotive parts?

To ensure quality assurance when purchasing automotive parts, request product samples or certifications from potential suppliers. Look for ISO certifications and inquire about their QA processes. Conducting factory audits or working with third-party inspection services can also help verify the quality of the products before committing to larger orders. -

What payment terms are typical for international orders of batteries and alternators?

Payment terms for international orders often include options such as letters of credit, advance payments, or payment upon delivery, depending on the trust level between buyer and supplier. Standard practices may involve a 30-50% deposit upfront, with the balance due upon shipment. Always clarify terms before placing an order to avoid misunderstandings and ensure a smooth transaction process.

Top 2 How To Tell If Alternator Or Battery Is Bad Manufacturers & Suppliers List

1. Vehicle Battery, Alternator, and Starter Diagnosis – Key Points

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around diagnosing issues related to a vehicle’s battery, alternator, and starter. Key points include: 1. The battery provides power to all electronics and the starter. 2. The alternator charges the battery when the engine is running. 3. The starter uses battery power to turn over the engine. 4. Symptoms of a dead battery include no power or lights. 5. A failing alternator m…

2. Alternator Testing – Risks and Recommendations

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: The text discusses a technique to test an alternator by removing a 12V battery lead while the vehicle is running. It highlights that this method is not recommended due to potential damage to the vehicle’s electronics and the alternator itself. The alternator is described as being internally regulated, and disconnecting the battery can cause spikes and transients that may harm sensitive electronic …

Strategic Sourcing Conclusion and Outlook for how to tell if alternator or battery is bad

In summary, understanding the differences between a faulty alternator and a dead battery is crucial for maintaining vehicle performance and minimizing downtime. Key indicators such as dimming lights, slow cranking, and warning lights can provide valuable insights into the health of your vehicle’s electrical system. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic sourcing of high-quality automotive components is essential. Investing in reliable batteries and alternators ensures not only optimal vehicle performance but also enhances customer satisfaction and operational efficiency.

As you navigate your sourcing strategy, consider leveraging local suppliers who can provide timely support and quality assurance tailored to your market’s unique demands. Engaging with trusted manufacturers and distributors fosters long-term partnerships that can lead to better pricing, availability, and service.

Looking forward, prioritize proactive maintenance and timely replacements to avoid costly disruptions. By doing so, you will empower your business to thrive in competitive landscapes, ensuring your fleet remains operational and your customers remain satisfied. Take action now by evaluating your sourcing options and aligning with partners who can support your automotive needs effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.