Introduction: Navigating the Global Market for how long do alternators last in a car

In the dynamic landscape of the automotive industry, understanding the longevity of car alternators is crucial for international B2B buyers. With an average lifespan of around seven years or 150,000 miles, alternators are vital components that ensure the reliability and efficiency of vehicles. However, sourcing high-quality alternators that meet specific operational demands can pose significant challenges, particularly for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Germany and Saudi Arabia.

This comprehensive guide delves into the various types of alternators available, their applications across different vehicle models, and critical factors influencing their lifespan. We provide insights into effective supplier vetting processes, allowing buyers to identify trustworthy manufacturers that deliver quality products. Additionally, this guide addresses cost considerations, helping businesses make informed purchasing decisions that align with their budgetary constraints.

By equipping B2B buyers with essential knowledge about alternator maintenance, performance indicators, and the implications of poor-quality components, this resource empowers them to mitigate risks and enhance operational efficiency. Whether you are looking to optimize your supply chain or ensure your fleet remains reliable, understanding how long alternators last in a car is an essential piece of the puzzle for informed decision-making in the global market.

Table Of Contents

- Top 1 How Long Do Alternators Last In A Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long do alternators last in a car

- Understanding how long do alternators last in a car Types and Variations

- Key Industrial Applications of how long do alternators last in a car

- 3 Common User Pain Points for ‘how long do alternators last in a car’ & Their Solutions

- Strategic Material Selection Guide for how long do alternators last in a car

- In-depth Look: Manufacturing Processes and Quality Assurance for how long do alternators last in a car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long do alternators last in a car’

- Comprehensive Cost and Pricing Analysis for how long do alternators last in a car Sourcing

- Alternatives Analysis: Comparing how long do alternators last in a car With Other Solutions

- Essential Technical Properties and Trade Terminology for how long do alternators last in a car

- Navigating Market Dynamics and Sourcing Trends in the how long do alternators last in a car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long do alternators last in a car

- Strategic Sourcing Conclusion and Outlook for how long do alternators last in a car

- Important Disclaimer & Terms of Use

Understanding how long do alternators last in a car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternators | Typically last 5-7 years or 100,000-150,000 miles | General automotive repairs and replacements | Pros: Widely available, cost-effective. Cons: Limited lifespan, may require frequent replacement. |

| High-Output Alternators | Designed for vehicles with heavy electronic loads | Performance vehicles, aftermarket upgrades | Pros: Increased power output, suited for modified vehicles. Cons: Higher initial cost, potential compatibility issues. |

| Remanufactured Alternators | Rebuilt versions of original alternators | Budget-friendly options for repairs | Pros: Cost-effective, environmentally friendly. Cons: Variable quality, may not last as long as new units. |

| OEM Alternators | Original equipment manufacturer parts, tailored for specific models | Dealerships, fleet maintenance | Pros: High reliability, perfect fit. Cons: Higher price, limited to specific vehicle models. |

| Heavy-Duty Alternators | Built for larger vehicles or commercial applications | Trucks, buses, and heavy machinery | Pros: Extended lifespan, capable of handling high loads. Cons: Heavier and more expensive, not suitable for standard cars. |

What are the Characteristics of Standard Alternators?

Standard alternators are the most common type used in everyday vehicles, typically providing a lifespan of 5-7 years or 100,000-150,000 miles under normal operating conditions. They are designed to meet the average electrical demands of standard vehicles. B2B buyers in automotive repair and maintenance sectors often opt for these due to their cost-effectiveness and wide availability. However, frequent replacements may be necessary, which can lead to increased operational costs over time.

What are High-Output Alternators and Their Suitability?

High-output alternators are engineered for vehicles with significant electrical demands, such as those equipped with advanced audio systems, lighting, or other electronic accessories. They generally provide a higher amperage output, making them suitable for performance vehicles or those with aftermarket modifications. B2B buyers in performance automotive markets should consider these units for their enhanced capabilities, although they may come at a higher price point and require careful compatibility checks with the vehicle’s electrical system.

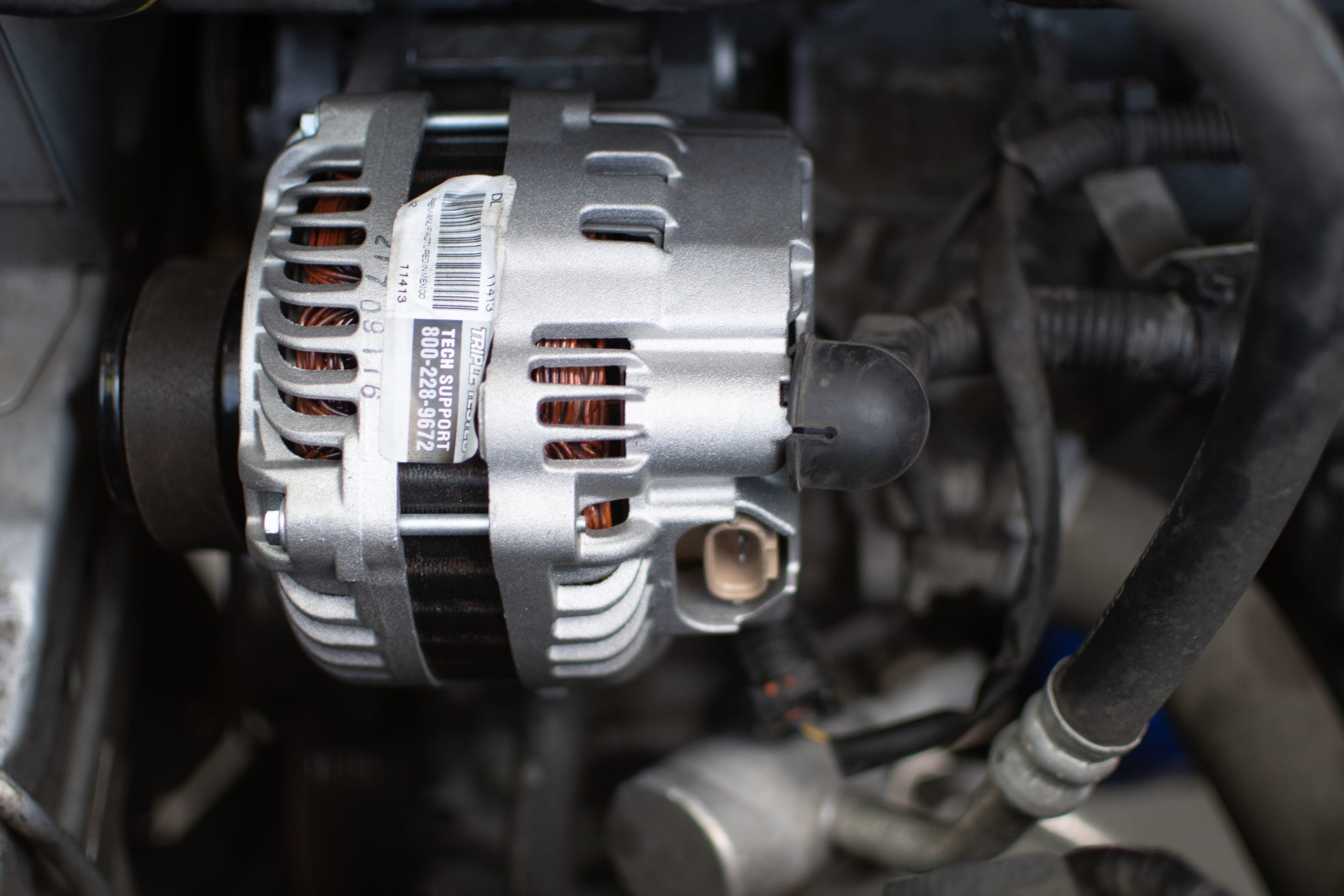

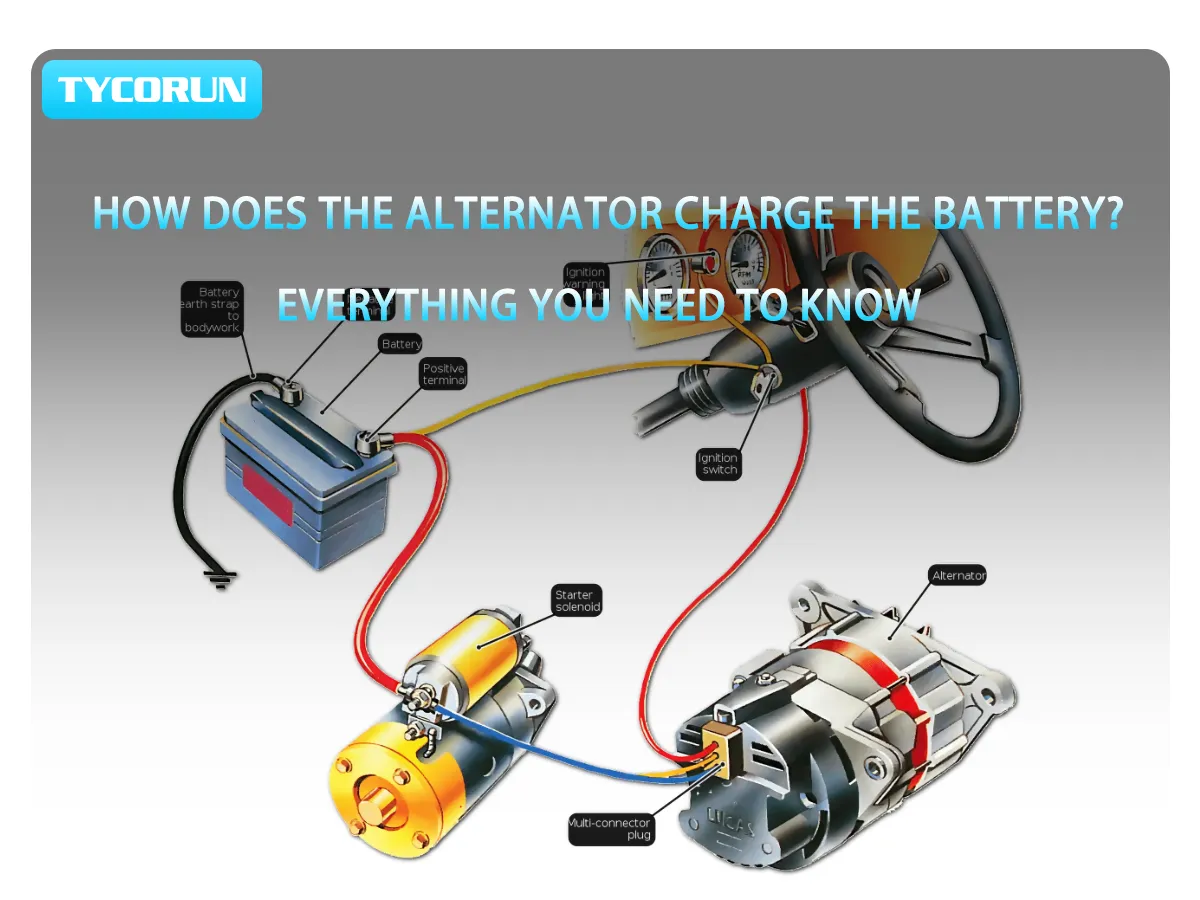

Illustrative image related to how long do alternators last in a car

Why Choose Remanufactured Alternators?

Remanufactured alternators are rebuilt versions of original units, offering a more budget-friendly alternative for repairs. They are often marketed as environmentally sustainable options since they reduce waste by reusing components. B2B buyers in fleet maintenance or independent repair shops may find these appealing due to their lower cost. However, the variable quality of remanufactured parts can be a concern, as they may not last as long as new units.

What are the Advantages of OEM Alternators?

OEM alternators are manufactured by the original equipment maker and are designed specifically for certain vehicle models. They offer high reliability and perfect fit, making them a preferred choice for dealerships and fleet maintenance operations. While B2B buyers appreciate the assurance of quality and performance, the higher price and limited availability to specific models can be drawbacks for some businesses.

How Do Heavy-Duty Alternators Perform?

Heavy-duty alternators are designed for larger vehicles, such as trucks, buses, and heavy machinery, where electrical demands are significantly higher. They typically have a longer lifespan and can handle substantial loads, making them suitable for commercial applications. B2B buyers in the transportation and logistics sectors should invest in these units for their durability and reliability; however, the increased weight and cost might be a consideration for those operating standard passenger vehicles.

Key Industrial Applications of how long do alternators last in a car

| Industry/Sector | Specific Application of how long do alternators last in a car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles with long-lasting alternators | Enhanced vehicle reliability and customer satisfaction | Quality control of alternator components and supplier certifications |

| Fleet Management | Maintenance scheduling for commercial vehicle fleets | Reduced downtime and maintenance costs | Bulk purchasing agreements and warranty terms |

| Automotive Aftermarket | Retail and distribution of replacement alternators | Increased sales through reliable product offerings | Sourcing from trusted manufacturers with performance guarantees |

| Transportation Services | Ensuring vehicle readiness for logistics and transport | Improved operational efficiency and safety | Evaluating alternator lifespan and compatibility with diverse vehicle types |

| Automotive Repair Services | Diagnostic and repair services for alternator issues | Enhanced service offerings and customer trust | Access to quality diagnostic tools and replacement parts |

How is ‘how long do alternators last in a car’ relevant in Automotive Manufacturing?

In the automotive manufacturing sector, understanding the lifespan of alternators is crucial for designing vehicles that offer durability and reliability. Manufacturers aim to produce vehicles with alternators that can last approximately seven years or 150,000 miles, which directly impacts customer satisfaction and brand reputation. Buyers in this sector should prioritize sourcing high-quality alternators that meet stringent performance standards and consider suppliers with robust quality control processes to ensure longevity and reliability.

What role does alternator lifespan play in Fleet Management?

For fleet management companies, the longevity of alternators is vital for maintaining operational efficiency. These businesses rely on a fleet of vehicles, and any downtime due to alternator failure can lead to significant revenue losses. By scheduling regular maintenance based on the average lifespan of alternators, fleet managers can minimize unexpected breakdowns and optimize maintenance costs. When sourcing alternators, buyers should seek bulk purchasing options that provide favorable warranty terms to further reduce long-term expenses.

How does ‘how long do alternators last in a car’ impact the Automotive Aftermarket?

In the automotive aftermarket, knowledge of alternator longevity helps retailers and distributors stock the right replacement parts. Offering high-quality alternators that align with the expected lifespan can lead to increased sales and customer loyalty. Buyers in this sector must focus on sourcing from reputable manufacturers who provide performance guarantees, ensuring that the products meet or exceed the lifespan expectations of end-users.

Why is alternator lifespan critical for Transportation Services?

Transportation services depend on the reliability of their vehicles to ensure timely deliveries and passenger safety. Understanding how long alternators last helps these businesses maintain vehicle readiness and avoid disruptions in service. Buyers in this industry should evaluate the compatibility of alternators with various vehicle models and their expected lifespan to ensure operational efficiency. Additionally, sourcing durable components that can withstand the rigors of constant use is essential for minimizing vehicle downtime.

How does knowledge of alternator lifespan benefit Automotive Repair Services?

Automotive repair services benefit from understanding alternator longevity as it informs their diagnostic and repair offerings. Mechanics can better advise customers on when to replace alternators and provide preventative maintenance tips based on the average lifespan. Access to quality diagnostic tools and reliable replacement parts is crucial for these businesses to enhance service offerings and build customer trust. Repair shops should prioritize sourcing alternators that come with warranties to reassure customers of the quality and longevity of the replacement parts.

3 Common User Pain Points for ‘how long do alternators last in a car’ & Their Solutions

Scenario 1: Understanding the Lifespan of Alternators for Fleet Management

The Problem: B2B buyers managing fleets of vehicles often struggle with the unpredictable lifespan of alternators. This challenge is compounded by the diverse operating conditions of vehicles across different regions, such as the intense heat in the Middle East or the fluctuating climates in Europe and Africa. Fleet managers face the risk of unexpected vehicle breakdowns, which can lead to costly downtime, increased maintenance expenses, and diminished customer satisfaction. Additionally, they may not have a clear understanding of how long alternators typically last in their specific vehicle types, making it difficult to plan for replacements.

The Solution: To mitigate this issue, fleet managers should implement a proactive maintenance schedule that includes regular inspections of the alternators. Establishing a routine check-up every 6 to 12 months can help identify signs of wear or failure early. It’s advisable to document the lifespan of each alternator within the fleet, noting factors like mileage, load capacity, and environmental conditions. When sourcing alternators, opt for high-quality OEM (Original Equipment Manufacturer) parts that are designed for the specific vehicle models in your fleet. By investing in reliable alternators, you can extend their lifespan and reduce the frequency of replacements. Additionally, educating drivers about the importance of monitoring dashboard warning lights and addressing electrical issues promptly can further enhance the longevity of your fleet’s alternators.

Scenario 2: Dealing with Alternator Failure in Remote Areas

The Problem: B2B buyers operating in remote areas often encounter significant challenges when an alternator fails unexpectedly. In regions with limited access to automotive services, such as parts of South America and rural Africa, a malfunctioning alternator can lead to prolonged vehicle downtime, impacting logistics and supply chains. This unpredictability not only affects operational efficiency but also leads to increased costs due to emergency repairs or towing services.

The Solution: To address this pain point, companies should invest in training local staff or drivers on basic vehicle maintenance, specifically focusing on recognizing early signs of alternator failure. This includes monitoring for dimming headlights, unusual noises, or dashboard warning lights. Additionally, maintain a well-stocked inventory of critical spare parts, including alternators, in remote locations to facilitate quick repairs. Collaborating with local mechanics or establishing partnerships with service providers in these areas can ensure that assistance is readily available. Furthermore, consider implementing a telematics system that monitors vehicle health and alerts you to potential issues before they lead to failure, thus enhancing operational resilience.

Scenario 3: Managing Costs Associated with Alternator Replacements

The Problem: For B2B buyers, particularly those in manufacturing or transportation sectors, managing the costs associated with alternator replacements can be a significant concern. Frequent replacements can erode profit margins, especially if the business relies heavily on vehicle uptime. Buyers often grapple with the decision of whether to choose cheaper, lower-quality alternators or invest in more expensive but longer-lasting options, weighing the trade-offs between immediate costs and long-term reliability.

Illustrative image related to how long do alternators last in a car

The Solution: To navigate this dilemma, businesses should conduct a cost-benefit analysis comparing the total cost of ownership (TCO) for different alternator options. This analysis should factor in the initial purchase price, expected lifespan, and maintenance costs. Investing in high-quality alternators can result in lower total expenditures over time due to reduced failure rates and maintenance needs. Additionally, establishing relationships with multiple suppliers can provide competitive pricing and better warranty options. Consider implementing a predictive maintenance program that uses data analytics to forecast when alternators are likely to fail based on usage patterns. This proactive approach not only helps in budgeting for replacements but also allows for strategic planning of vehicle downtimes, ultimately leading to enhanced operational efficiency and cost savings.

Strategic Material Selection Guide for how long do alternators last in a car

What Materials Are Commonly Used in Alternators and How Do They Affect Longevity?

When considering the longevity of alternators in vehicles, the materials used in their construction play a crucial role. Understanding the properties, advantages, and limitations of these materials can guide international B2B buyers in making informed purchasing decisions. Below, we analyze four common materials used in alternators: aluminum, copper, steel, and plastic.

How Does Aluminum Impact the Lifespan of Alternators?

Aluminum is widely used in alternator housings due to its lightweight nature and excellent thermal conductivity. Its properties allow for efficient heat dissipation, which is critical in maintaining performance under high operational temperatures.

Pros & Cons: Aluminum is corrosion-resistant and offers good durability, making it suitable for various environments. However, its relatively lower strength compared to steel can be a limitation in high-stress applications. Additionally, while aluminum is generally cost-effective, prices can fluctuate based on market demand.

Impact on Application: Aluminum’s compatibility with electrical components is significant, as it helps minimize weight without compromising performance. This is particularly advantageous in vehicles designed for fuel efficiency.

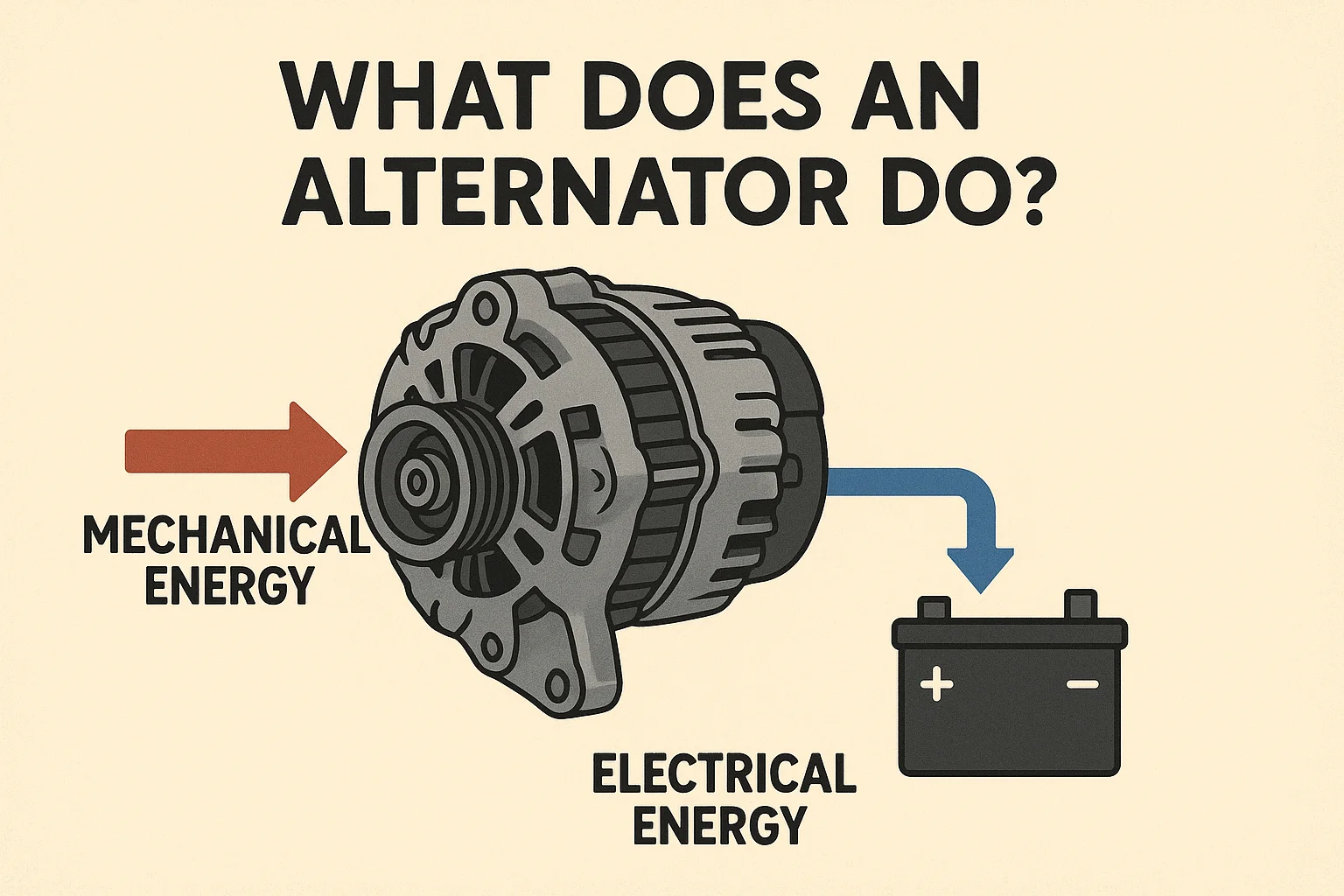

Illustrative image related to how long do alternators last in a car

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as DIN and ASTM for aluminum quality. In markets like Africa and South America, where environmental conditions can be harsher, selecting high-quality aluminum is essential for longevity.

Why Is Copper Essential for Alternator Performance?

Copper is the primary material for winding the alternator’s coils due to its exceptional electrical conductivity. This property allows for efficient energy transfer, which is crucial for the alternator’s functionality.

Pros & Cons: The high conductivity of copper translates to better performance and reduced energy losses. However, copper is more expensive than aluminum, which can impact the overall cost of the alternator. Additionally, copper is susceptible to corrosion, necessitating protective coatings.

Impact on Application: Copper’s compatibility with various electrical systems makes it ideal for high-performance vehicles. However, in regions with high humidity or exposure to corrosive elements, additional protective measures may be necessary.

Considerations for International Buyers: B2B buyers in Europe and the Middle East should prioritize copper that meets international standards for conductivity and corrosion resistance. In regions like Africa, sourcing copper from reputable suppliers can mitigate risks associated with inferior quality.

How Does Steel Contribute to Alternator Durability?

Steel is often used in the structural components of alternators, such as the frame and mounting brackets. Its high strength-to-weight ratio makes it an excellent choice for applications requiring durability.

Pros & Cons: Steel’s robustness ensures that the alternator can withstand mechanical stresses and vibrations. However, it is heavier than aluminum, which can affect the overall weight of the vehicle. Furthermore, steel is prone to rust if not properly coated.

Impact on Application: Steel’s durability is particularly beneficial in heavy-duty vehicles or those operating in rugged environments. Its strength allows for reliable performance even under challenging conditions.

Considerations for International Buyers: Buyers should look for steel that complies with ASTM or JIS standards to ensure quality. In regions like Saudi Arabia, where high temperatures can accelerate corrosion, selecting galvanized or coated steel is advisable.

What Role Does Plastic Play in Alternator Design?

Plastic is increasingly used in alternator components, such as covers and insulators, due to its lightweight and insulating properties.

Pros & Cons: Plastic can reduce the overall weight of the alternator, enhancing fuel efficiency. It is also resistant to corrosion and can be molded into complex shapes. However, plastic may not withstand high temperatures as well as metal materials, potentially limiting its use in high-performance applications.

Impact on Application: The use of plastic can enhance the design flexibility of alternators, allowing for innovative features. However, its thermal limitations may require careful consideration in high-temperature environments.

Considerations for International Buyers: B2B buyers should ensure that the plastic used meets relevant standards for heat resistance and durability. In markets with extreme weather conditions, selecting high-grade plastics can prevent premature failure.

Summary Table of Materials Used in Alternators

| Material | Typical Use Case for how long do alternators last in a car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and casings | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Copper | Coils and windings | Excellent electrical conductivity | Higher cost and corrosion susceptibility | High |

| Steel | Structural components | High strength and durability | Heavier and prone to rust | Medium |

| Plastic | Covers and insulators | Lightweight and corrosion-resistant | Limited thermal resistance | Low |

This analysis provides valuable insights for B2B buyers looking to understand the materials that influence the longevity and performance of alternators in vehicles. By considering these factors, buyers can make informed decisions that align with their specific operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how long do alternators last in a car

What Are the Main Stages of Alternator Manufacturing Processes?

The manufacturing of alternators involves several critical stages, each designed to ensure the final product meets performance and durability standards. Understanding these processes is essential for B2B buyers, as they can significantly impact the longevity and reliability of alternators.

How Are Materials Prepared for Alternator Production?

The first stage in alternator manufacturing is material preparation. High-quality materials such as aluminum, copper, and various insulating plastics are sourced from reliable suppliers. The choice of materials is crucial, as they directly influence the alternator’s efficiency and lifespan. Once the materials are selected, they undergo cleaning and inspection to eliminate any contaminants that could compromise performance.

What Techniques Are Used in the Forming Stage of Alternator Manufacturing?

In the forming stage, materials are shaped into specific components using techniques such as die-casting and stamping. Die-casting is particularly common for producing the alternator housing, which must withstand significant thermal and mechanical stress. For the rotor and stator, precision stamping ensures that the electrical components fit together flawlessly. Advanced CNC (Computer Numerical Control) machining may also be employed to achieve tight tolerances, crucial for the efficient operation of the alternator.

How Is Assembly Conducted in Alternator Manufacturing?

Assembly is a vital stage where various components are brought together. This process typically involves automated machinery along with skilled labor to ensure precision. Key steps include the installation of the rotor and stator, connection of the electrical wiring, and mounting of additional components like diodes and voltage regulators. Each connection is meticulously checked to ensure electrical continuity and mechanical stability.

What Finishing Processes Are Applied to Alternators?

Once assembled, alternators undergo finishing processes, which may include painting, coating, and final inspections. Coatings are applied to protect against corrosion and enhance durability. A thorough visual inspection and functional testing follow to confirm that each alternator meets the required specifications. This final stage is critical for ensuring that the alternator can operate efficiently under various conditions.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance (QA) is integral to the manufacturing process, particularly for components like alternators that play a crucial role in vehicle functionality. B2B buyers should be aware of various international standards and industry-specific certifications that indicate a manufacturer’s commitment to quality.

How Do International Standards Like ISO 9001 Impact Alternator Manufacturing?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate a commitment to continuous improvement and customer satisfaction. This standard encompasses all aspects of the manufacturing process, from material sourcing to final inspection, ensuring that every step is monitored and optimized for quality.

Illustrative image related to how long do alternators last in a car

What Other Industry-Specific Certifications Are Relevant for Alternator Quality?

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the market and application of the alternators. CE certification ensures that products meet European safety and environmental protection standards, while API certification is crucial for products used in the petroleum industry. These certifications not only enhance product credibility but also facilitate smoother international trade.

What Quality Control Checkpoints Are Essential in Alternator Manufacturing?

Implementing effective quality control (QC) checkpoints throughout the manufacturing process is critical for ensuring product reliability. Buyers should look for manufacturers that integrate several key QC checkpoints:

What Are the Key QC Checkpoints in the Manufacturing Process?

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects before they enter the production line. Ensuring that only high-quality materials are used sets a strong foundation for the final product.

-

In-Process Quality Control (IPQC): During the assembly phase, IPQC involves continuous monitoring of the manufacturing process to detect and correct defects in real time. This may include checking the accuracy of machine settings and the integrity of electrical connections.

-

Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the alternator’s performance, including functional tests to ensure proper voltage output and load handling. This stage is crucial for confirming that the alternator meets all operational specifications before it is shipped.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must perform due diligence to ensure that their suppliers adhere to rigorous quality control standards. Here are effective strategies for verification:

What Steps Can Buyers Take to Audit Supplier Quality Control?

-

Conduct Supplier Audits: Regular audits of the manufacturing facilities can provide insights into the supplier’s quality control processes. These audits should assess adherence to international standards, the effectiveness of QC checkpoints, and overall operational efficiency.

-

Request Quality Reports: Buyers should request documentation detailing the supplier’s quality control practices, including test results and inspection reports. These documents provide transparency and help buyers make informed decisions.

-

Engage Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These services can conduct random inspections, performance testing, and compliance checks, ensuring that the products meet the necessary standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific challenges related to quality control, particularly when sourcing from regions with varying manufacturing standards.

How Do Regional Differences Impact Quality Assurance in Alternator Manufacturing?

Cultural and regulatory differences can affect the manufacturing processes and quality assurance practices in various regions. For example, countries in Africa and South America may have different levels of access to advanced manufacturing technologies and quality control systems compared to Europe or the Middle East. Buyers should be aware of these differences and consider additional verification measures, such as:

-

Local Regulations and Standards: Understanding local regulations and standards can help buyers assess the credibility of suppliers and ensure compliance with their own market requirements.

-

Building Relationships: Establishing strong relationships with suppliers can lead to better communication and transparency regarding quality control practices. This is particularly important in regions where personal relationships play a crucial role in business.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance practices for alternators is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly processes, and finishing stages, buyers can better assess the reliability and durability of alternators. Additionally, by prioritizing manufacturers that adhere to international standards and implement robust quality control checkpoints, buyers can ensure they are sourcing high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long do alternators last in a car’

Introduction

This guide serves as a practical checklist for B2B buyers interested in understanding the lifespan of alternators in vehicles. Given the critical role alternators play in vehicle performance, knowing how long they last and the factors influencing their longevity is essential for informed purchasing decisions. This checklist will help you navigate the procurement process effectively, ensuring you choose quality products that meet your operational needs.

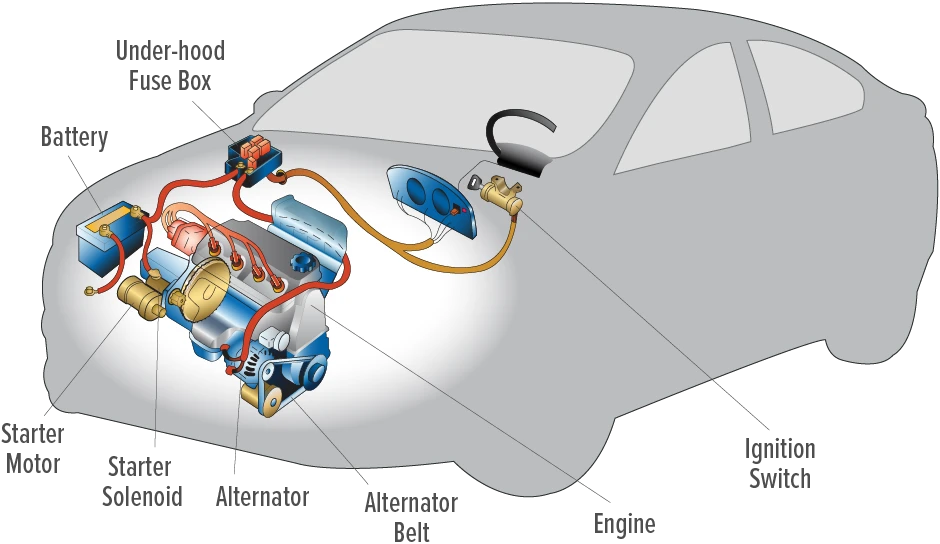

Illustrative image related to how long do alternators last in a car

Step 1: Understand the Average Lifespan of Alternators

Determine the standard lifespan of alternators, which averages around 7 years or 150,000 miles. Knowing this baseline helps in planning maintenance schedules and replacements. It’s important to factor in the specific vehicle types and usage conditions that may affect the alternator’s longevity, such as climate and driving habits.

Step 2: Assess Quality Standards

Verify the quality certifications of the alternators you are considering. Look for products that meet international standards such as ISO 9001 or equivalent. Quality certifications ensure that the alternators are manufactured to stringent quality control measures, which can significantly impact their performance and durability.

Step 3: Evaluate Supplier Reputation

Research potential suppliers thoroughly. Check for customer reviews, case studies, and testimonials from other businesses in your industry. A reputable supplier is more likely to provide high-quality alternators and reliable after-sales support, which is crucial for minimizing downtime in your operations.

Step 4: Consider the Impact of Electronics

Analyze the electrical load requirements of your vehicles. Modern vehicles with numerous electronic systems may place additional strain on alternators. Ensure that the alternators you are sourcing can handle the specific electrical demands of the vehicles they will be used in, preventing premature failure.

Step 5: Review Warranty and Support Terms

Examine the warranty and customer support options provided by suppliers. A solid warranty indicates the manufacturer’s confidence in their product. Look for terms that cover both parts and labor, as well as the availability of technical support to assist with installation and troubleshooting.

Step 6: Inquire About Maintenance Recommendations

Ask suppliers for maintenance guidelines and best practices. Understanding how to maintain alternators can significantly extend their lifespan. Suppliers who offer clear maintenance instructions and support show commitment to customer satisfaction and product longevity.

Step 7: Analyze Cost vs. Performance

Evaluate the balance between cost and performance. While it may be tempting to go for the lowest price, consider the long-term implications. Higher-quality alternators may come at a premium but can save costs in repairs and replacements over time due to their durability and reliability.

Illustrative image related to how long do alternators last in a car

By following this checklist, B2B buyers can make informed decisions when sourcing alternators, ensuring they invest in products that meet their operational requirements and deliver optimal performance.

Comprehensive Cost and Pricing Analysis for how long do alternators last in a car Sourcing

What Are the Key Cost Components for Alternators in Automotive Sourcing?

When evaluating the sourcing of alternators, it is essential to understand the various cost components that contribute to the final pricing. The primary elements include:

-

Materials: The quality and type of materials used in alternator production significantly affect the cost. Common materials include aluminum for the housing, copper for the windings, and various types of plastics and rubber for insulation and seals. Higher-grade materials often enhance durability and performance, which can be pivotal for international markets where conditions may vary.

-

Labor: Labor costs can fluctuate based on geographic location and the complexity of the manufacturing process. In regions with lower labor costs, such as parts of Africa and South America, manufacturers may have a cost advantage. Conversely, labor in Europe, particularly in countries like Germany, can be higher due to stringent labor regulations and standards.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and administrative expenses. Efficient production facilities that leverage automation may achieve lower overhead costs, allowing for more competitive pricing.

-

Tooling: Investment in specialized tooling for manufacturing specific alternator models can be substantial. Custom tooling is often a one-time cost but can significantly affect the initial pricing of new designs or specifications.

-

Quality Control (QC): Implementing rigorous quality control measures is crucial to ensure reliability and safety. Companies that prioritize QC may incur higher costs, but this can lead to reduced warranty claims and enhanced customer satisfaction, particularly in markets with high expectations for product quality.

-

Logistics: Transportation costs play a significant role, especially for international B2B transactions. Factors like shipping routes, packaging, and customs duties can impact overall pricing. Understanding Incoterms can help buyers better manage these logistics costs.

-

Margin: Manufacturers will typically add a markup to cover profit margins. This can vary widely based on market competition and brand positioning. Established brands may command higher margins due to perceived reliability and reputation.

What Influences Pricing for Alternators in International Markets?

Several factors can influence the pricing structure of alternators, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their demand forecasts to optimize pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the need for specialized manufacturing processes. Buyers should assess the necessity of custom features against potential price increases.

-

Materials and Quality Certifications: Alternators made from premium materials or those that comply with international quality standards (like ISO certifications) typically command higher prices. Buyers should evaluate whether the added cost aligns with their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers may charge a premium for their products due to consistent quality and reliable delivery.

What Should Buyers Consider for Cost Efficiency in Alternator Sourcing?

To achieve cost efficiency and optimize Total Cost of Ownership (TCO), buyers should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate better terms, especially for larger volumes. Building long-term relationships can lead to favorable pricing adjustments over time.

-

Total Cost of Ownership: Evaluate not only the purchase price but also the long-term implications of alternator performance, including maintenance costs and potential downtime. A slightly higher upfront cost for a more reliable alternator can result in significant savings over time.

-

Pricing Nuances for International Markets: Be aware of currency fluctuations, tariffs, and import duties that can affect the overall cost. Understanding local market conditions and regulations in regions such as Africa, South America, the Middle East, and Europe is crucial for effective budgeting.

Disclaimer for Indicative Prices

Pricing for alternators can vary widely based on the factors outlined above. The information provided is intended for guidance and may not reflect current market conditions or specific supplier quotes. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how long do alternators last in a car With Other Solutions

Exploring Alternatives to Traditional Car Alternators

In the automotive industry, understanding the longevity of traditional alternators is crucial for B2B buyers looking to optimize vehicle performance and reliability. However, several alternative technologies can also serve similar functions, such as providing electrical power and charging batteries. This analysis will compare the lifespan and effectiveness of traditional alternators with two viable alternatives: Smart Alternators and Battery Management Systems (BMS).

| Comparison Aspect | How Long Do Alternators Last In A Car | Smart Alternators | Battery Management Systems (BMS) |

|---|---|---|---|

| Performance | Approximately 7 years or 150,000 miles | Enhanced energy efficiency; variable output based on demand | Optimizes battery usage, prolongs lifespan |

| Cost | $300 – $800 for replacement | $400 – $1,000, higher initial cost | $200 – $600, depending on complexity |

| Ease of Implementation | Standard installation process | Requires specialized installation | Requires integration with existing systems |

| Maintenance | Regular inspections recommended | Minimal maintenance needed, but monitoring required | Low maintenance, but software updates may be needed |

| Best Use Case | Conventional vehicles with standard electrical demands | Modern vehicles with high electronic loads | Electric and hybrid vehicles requiring efficient energy management |

What Are Smart Alternators and Their Benefits?

Smart alternators represent an evolution in automotive technology. Unlike traditional alternators that provide a constant output, smart alternators adjust their output based on the vehicle’s electrical demand. This capability leads to improved fuel efficiency and reduced strain on the engine. The initial cost is higher than standard alternators, but the long-term savings in fuel consumption and battery longevity can offset this investment. However, the installation process may require specialized skills, making it less accessible for all buyers.

Illustrative image related to how long do alternators last in a car

How Do Battery Management Systems (BMS) Function?

Battery Management Systems (BMS) are primarily designed for electric and hybrid vehicles. They monitor and manage battery charge levels, optimizing energy usage and extending battery life. While BMS can be less expensive than smart alternators, they serve a different purpose by focusing on battery health rather than directly supplying power. BMS installations can be complex, as they often need to be integrated with existing vehicle systems, which may pose challenges for some B2B buyers. Nonetheless, their ability to enhance battery performance makes them an attractive option for businesses investing in electric vehicle technology.

Making the Right Choice for Your Automotive Needs

When evaluating alternatives to traditional alternators, B2B buyers must consider their specific operational requirements. For businesses managing conventional fleets, standard alternators might suffice due to their reliability and ease of installation. However, for those investing in modern vehicles with higher electrical demands, smart alternators offer enhanced performance and efficiency. Conversely, companies focused on electric or hybrid vehicles should prioritize Battery Management Systems to ensure optimal battery health and performance.

In conclusion, choosing the right solution hinges on a thorough assessment of your vehicle types, usage patterns, and long-term operational goals. Understanding these alternatives allows B2B buyers to make informed decisions that align with their business strategies and technological advancements.

Essential Technical Properties and Trade Terminology for how long do alternators last in a car

What Are the Key Technical Properties of Alternators in Cars?

Understanding the technical properties of alternators is crucial for B2B buyers in the automotive industry, especially when considering the lifespan and performance of these components. Here are some essential specifications to keep in mind:

-

Material Grade

The construction materials used in alternators, such as aluminum and copper, significantly affect their durability and efficiency. High-grade materials can withstand harsher conditions, thereby extending the alternator’s lifespan. B2B buyers should prioritize suppliers that offer alternators made from premium materials to ensure long-term performance. -

Electrical Output Rating

Alternators are rated by their electrical output, typically measured in amperes (A). Most standard alternators deliver between 70 to 150 amps, depending on the vehicle’s requirements. Buyers must match the alternator’s output with the vehicle’s electrical demands to avoid premature failure or underperformance, especially for vehicles with high-power electronics. -

Bearing Type and Quality

The bearings in an alternator reduce friction and wear during operation. High-quality ball bearings can enhance the lifespan of the alternator by ensuring smoother operation. Understanding the type and quality of bearings used is critical for buyers who want to reduce maintenance costs and improve reliability. -

Cooling Mechanism

Alternators can generate significant heat during operation, and effective cooling mechanisms are essential for preventing overheating. Some alternators feature built-in cooling fans or heat sinks. Buyers should consider the design and efficiency of these cooling systems to ensure optimal performance under demanding conditions. -

Tolerance Levels

Tolerance levels refer to the allowable deviations in the manufacturing process that can affect the alternator’s fit and function. Precision in these tolerances is vital for ensuring that the alternator operates seamlessly within the vehicle’s electrical system. Suppliers that maintain strict tolerance standards contribute to better product reliability and longevity.

What Are Common Trade Terms Related to Alternators?

Familiarity with industry jargon is essential for effective communication and decision-making in the B2B automotive sector. Here are some common terms related to alternators:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are often preferred for their guaranteed compatibility and quality. B2B buyers should consider OEM alternators when looking for reliable replacements that meet the specifications of the original vehicle. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding the MOQ is crucial for buyers, especially in regions where demand may fluctuate. This term helps buyers negotiate better purchasing agreements, ensuring they have enough stock while managing costs effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products, such as alternators. It is a vital tool for buyers to compare costs and terms from multiple suppliers. A well-prepared RFQ can lead to better pricing and favorable terms for large orders. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers involved in cross-border procurement, as they clarify shipping responsibilities, costs, and risks. -

Lifespan

The lifespan of an alternator typically ranges from 70,000 to 150,000 miles, or approximately 7 to 10 years, depending on usage and maintenance. B2B buyers should assess the expected lifespan when selecting alternators, as this will influence long-term cost-efficiency and customer satisfaction.

By equipping themselves with knowledge about the technical properties and trade terminology associated with alternators, B2B buyers can make informed purchasing decisions that enhance their operational efficiency and product reliability.

Illustrative image related to how long do alternators last in a car

Navigating Market Dynamics and Sourcing Trends in the how long do alternators last in a car Sector

What Are the Current Trends Influencing the Lifespan of Car Alternators?

The global automotive sector is experiencing significant shifts that impact the longevity and sourcing of alternators. With an average lifespan of around seven years or 150,000 miles, the demand for high-quality alternators is on the rise, particularly in emerging markets like Africa and South America, where vehicle ownership is increasing. Buyers are increasingly focusing on the quality and reliability of alternators, prompting manufacturers to innovate. Enhanced manufacturing techniques and materials are being developed to create more durable alternators that can withstand harsh conditions, such as extreme temperatures and varied driving environments, common in regions like the Middle East and Africa.

Another trend is the integration of technology into automotive components. Smart alternators equipped with sensors can provide real-time data on performance and health, allowing for predictive maintenance. This is particularly beneficial for fleet operators in Europe and the Middle East, who require efficient management of their vehicles to minimize downtime. Additionally, the rise of electric vehicles (EVs) is reshaping the alternator market, as manufacturers explore alternatives that can accommodate the unique energy demands of hybrid and fully electric vehicles.

How Is Sustainability Shaping the Sourcing of Alternators?

Sustainability is becoming a crucial factor for international B2B buyers in the automotive sector. The environmental impact of manufacturing processes and the materials used in alternators are under scrutiny. Ethical sourcing practices are increasingly prioritized, with buyers seeking suppliers who can provide transparency about their supply chains and the environmental footprint of their products.

Illustrative image related to how long do alternators last in a car

Materials used in alternators, such as rare earth metals, are often mined in ways that can be detrimental to local ecosystems. As a result, there is a growing emphasis on ‘green’ certifications and the use of recycled materials. Manufacturers that adopt sustainable practices not only meet regulatory requirements but also appeal to a more environmentally conscious consumer base. This trend is particularly relevant in Europe, where strict environmental regulations and consumer demand for sustainable products drive sourcing decisions.

What Is the Historical Context of Car Alternators for B2B Buyers?

The alternator has evolved significantly since its inception in the early 20th century, transitioning from simple generators to complex electronic components that are integral to modern vehicles. Initially designed to power vehicle lighting and ignition systems, today’s alternators are responsible for powering a wide array of electronic features, including infotainment systems and advanced driver-assistance technologies.

This evolution has influenced sourcing strategies, as B2B buyers must now consider not only the mechanical reliability of alternators but also their compatibility with increasingly sophisticated automotive technologies. Understanding the historical context of alternators aids buyers in identifying reliable suppliers that have adapted to technological advancements and can provide high-quality, durable products suited for contemporary automotive needs.

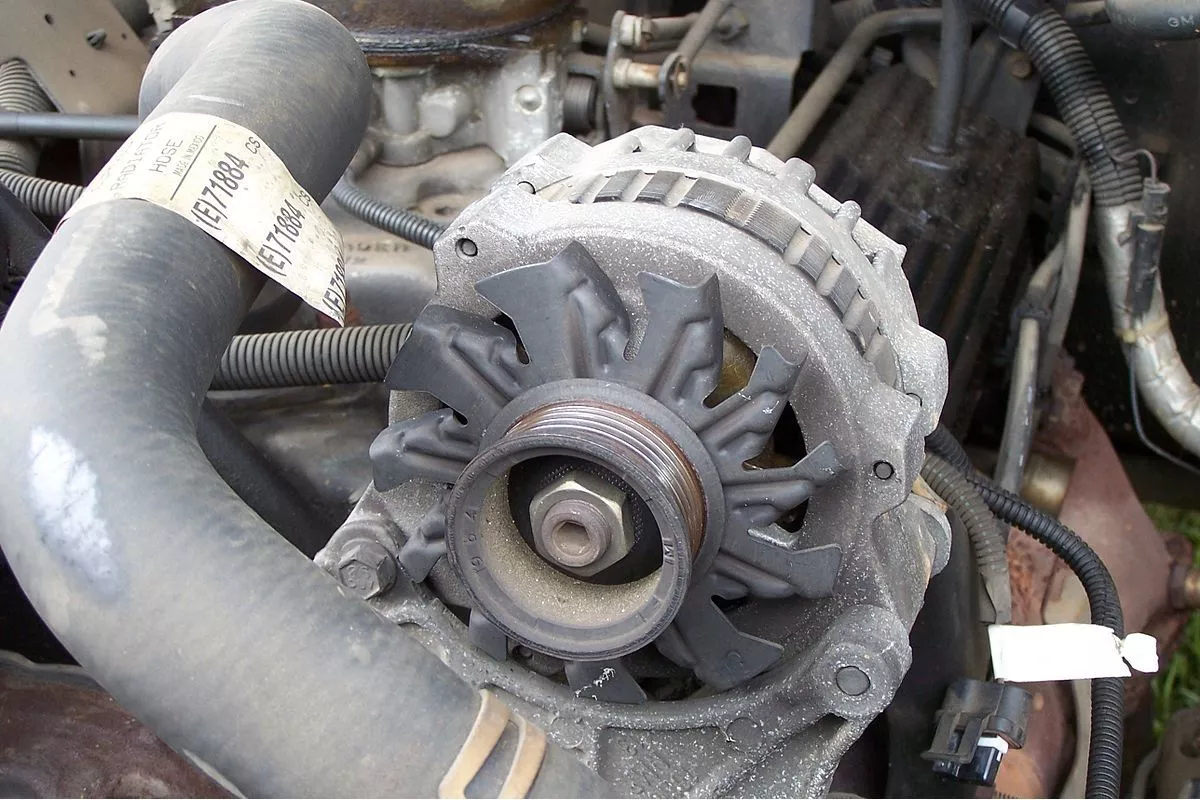

Illustrative image related to how long do alternators last in a car

In summary, as the automotive landscape continues to evolve, B2B buyers must remain vigilant about market dynamics, sustainability trends, and the historical context of alternator development to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of how long do alternators last in a car

-

1. How long do alternators typically last in a car?

The average lifespan of an alternator is around seven years or approximately 150,000 miles, depending on various factors such as vehicle usage, environmental conditions, and the quality of the alternator itself. In regions with extreme temperatures or heavy usage of electrical systems, alternators may wear out faster. Regular maintenance and inspections can help extend their lifespan, making it essential for B2B buyers to consider the quality of the alternator when sourcing parts for resale or fleet management. -

2. What are the signs of a failing alternator?

Common indicators of a failing alternator include dimming headlights, dashboard warning lights, difficulty starting the vehicle, and unusual sounds from the engine. If electrical components such as windows or audio systems malfunction intermittently, it could also signal an alternator issue. Recognizing these signs early can help prevent costly repairs and downtime, making it crucial for businesses to educate their teams about these warning signs when managing vehicle fleets. -

3. How can I ensure the quality of the alternators I purchase?

To ensure quality, it is essential to source alternators from reputable suppliers with a proven track record. Look for certifications and quality assurance processes in place. Request samples for testing and evaluate their performance under real-world conditions. Additionally, consider suppliers who provide warranties and after-sales support, which can enhance your business’s reliability in the market. -

4. What customization options are available for alternators?

Many manufacturers offer customization options for alternators, including specific voltage outputs, sizes, and mounting configurations. When sourcing alternators for diverse vehicle models or applications, inquire about these options to meet your specific needs. Customization can also extend to branding and packaging, allowing businesses to differentiate their products in competitive markets. -

5. What are the minimum order quantities (MOQs) for alternators?

Minimum order quantities can vary significantly among suppliers. Some manufacturers may require MOQs of several units, while others may accommodate smaller orders, particularly for specialty or customized alternators. When negotiating with suppliers, discuss your anticipated demand and seek flexibility in MOQs to optimize your inventory and cash flow management. -

6. What payment terms should I expect when sourcing alternators?

Payment terms can vary widely depending on the supplier and the nature of the business relationship. Common arrangements include upfront payments, net 30 or net 60 terms, and payment upon delivery. It’s advisable to negotiate terms that align with your cash flow needs while considering the supplier’s policies. Establishing a solid payment plan can help foster a long-term partnership and smooth transaction processes. -

7. How can I effectively vet suppliers for alternators?

To vet suppliers, conduct thorough research, including checking their industry reputation, customer reviews, and certifications. Request references from previous clients and assess their production capabilities and lead times. Additionally, consider visiting the manufacturing facilities if possible, as this can provide insights into their quality control processes and overall operational standards, ensuring you select a reliable partner. -

8. What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider shipping methods, customs duties, and import regulations specific to your region. Ensure that you have a clear understanding of the lead times involved and plan accordingly to avoid delays in your supply chain. Working with experienced logistics partners can help streamline the process, from transportation to customs clearance, ultimately ensuring timely delivery of your products to the market.

Top 1 How Long Do Alternators Last In A Car Manufacturers & Suppliers List

1. Ford Fusion – Alternator Lifespan Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Alternator average lifespan for Ford Fusion is generally around 180,000 miles, with some users reporting up to 200,000 kilometers (approximately 124,000 miles) for the lifespan of the brushes in the voltage regulator. Users have noted that alternators can last significantly longer if well protected, with some achieving up to 400,000 kilometers (approximately 248,548 miles) with proper maintenance….

Strategic Sourcing Conclusion and Outlook for how long do alternators last in a car

In conclusion, understanding the lifespan of alternators—typically around seven years or 150,000 miles—is crucial for B2B buyers in the automotive sector. Regular maintenance and prompt attention to warning signs can significantly extend the life of this essential component, thereby reducing overall operational costs. By strategically sourcing high-quality alternators and components, businesses can mitigate risks associated with unexpected failures and enhance their service offerings.

For international buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe, the importance of reliable partnerships cannot be overstated. Collaborating with reputable suppliers ensures access to durable parts that meet regional standards and demands.

As the automotive industry continues to evolve, staying informed about product innovations and maintenance best practices will be key to maintaining a competitive edge. We encourage you to engage with trusted suppliers and invest in quality parts to ensure your fleet remains operational and efficient. Your proactive sourcing decisions today will pave the way for sustained success in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.