Introduction: Navigating the Global Market for gas cars vs electric

In today’s rapidly evolving automotive landscape, international B2B buyers face a critical challenge: deciding between gas cars and electric vehicles (EVs) for their fleets. With the global market shifting towards sustainability, sourcing the right vehicle type has never been more complex. This comprehensive guide will delve into various aspects of gas cars versus electric vehicles, including their different types, applications, and the crucial factors for supplier vetting. We will also explore the cost implications, performance metrics, and long-term savings associated with both vehicle categories.

By providing actionable insights tailored specifically for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Vietnam—this guide empowers stakeholders to make informed purchasing decisions. Understanding the nuances of each vehicle type is essential not only for operational efficiency but also for aligning with regional regulations and sustainability goals.

With the automotive industry at a crossroads, this guide serves as a vital resource to navigate the complexities of the gas versus electric vehicle debate, ultimately supporting your business in achieving its strategic objectives while fostering a commitment to environmental stewardship.

Table Of Contents

- Top 3 Gas Cars Vs Electric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for gas cars vs electric

- Understanding gas cars vs electric Types and Variations

- Key Industrial Applications of gas cars vs electric

- 3 Common User Pain Points for ‘gas cars vs electric’ & Their Solutions

- Strategic Material Selection Guide for gas cars vs electric

- In-depth Look: Manufacturing Processes and Quality Assurance for gas cars vs electric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas cars vs electric’

- Comprehensive Cost and Pricing Analysis for gas cars vs electric Sourcing

- Alternatives Analysis: Comparing gas cars vs electric With Other Solutions

- Essential Technical Properties and Trade Terminology for gas cars vs electric

- Navigating Market Dynamics and Sourcing Trends in the gas cars vs electric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of gas cars vs electric

- Strategic Sourcing Conclusion and Outlook for gas cars vs electric

- Important Disclaimer & Terms of Use

Understanding gas cars vs electric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Internal Combustion Engine (ICE) | Runs on gasoline or diesel; established technology | Fleet vehicles, logistics | Pros: Lower initial cost, widespread availability. Cons: Higher long-term fuel and maintenance costs. |

| Battery Electric Vehicle (BEV) | Powered entirely by electricity; zero emissions | Delivery services, corporate fleets | Pros: Lower operating costs, tax incentives. Cons: Higher upfront cost, limited range for some models. |

| Plug-in Hybrid Electric Vehicle (PHEV) | Combines ICE with an electric motor; can run on both | Urban transport, short-range delivery | Pros: Flexibility in fuel choice, reduced emissions. Cons: Complexity in maintenance, potential for higher initial cost. |

| Fuel Cell Electric Vehicle (FCEV) | Uses hydrogen to generate electricity; longer range than BEVs | Heavy-duty transport, public transport | Pros: Fast refueling, zero emissions. Cons: Limited refueling infrastructure, higher costs. |

| Micro-Hybrid Vehicles | Combines traditional ICE with start-stop technology; improves fuel efficiency | Urban delivery, taxi services | Pros: Lower emissions than standard ICE, improved fuel economy. Cons: Limited benefits compared to full hybrids or EVs. |

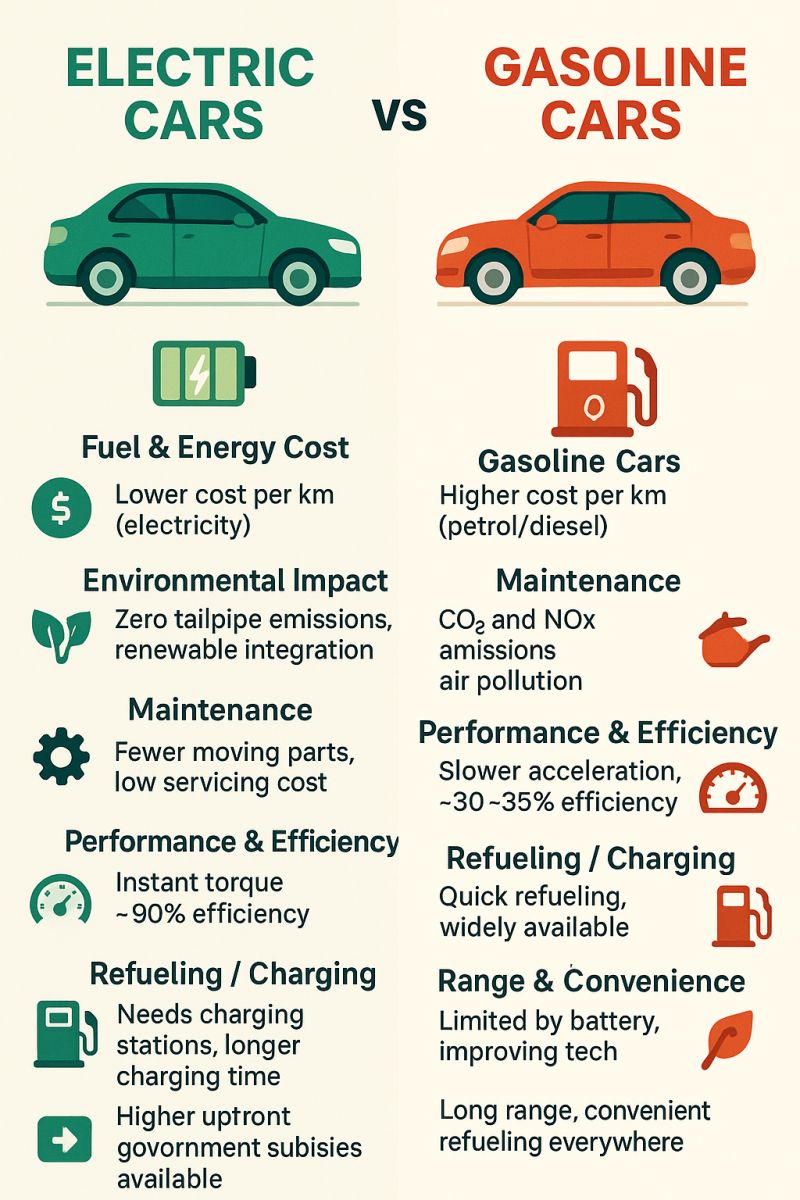

What are Internal Combustion Engine (ICE) Vehicles and Their B2B Relevance?

Internal combustion engine vehicles are the traditional choice for many businesses due to their established infrastructure and lower initial costs. They are suitable for a wide range of applications, including logistics and fleet operations where long-range travel is essential. However, B2B buyers should consider the rising fuel prices and maintenance costs associated with ICE vehicles over time, which may influence total cost of ownership.

Illustrative image related to gas cars vs electric

How Do Battery Electric Vehicles (BEVs) Benefit B2B Buyers?

Battery electric vehicles are gaining traction among businesses looking to reduce operating costs and their carbon footprint. With zero tailpipe emissions and significant savings on fuel, BEVs are ideal for delivery services and corporate fleets operating in urban areas. While the initial purchase price can be higher, the long-term savings from lower fuel and maintenance costs, coupled with available tax incentives, make them an attractive option for B2B buyers.

Why Consider Plug-in Hybrid Electric Vehicles (PHEVs) for Urban Applications?

Plug-in hybrid electric vehicles offer a balanced approach by combining both electric and gasoline power. This flexibility makes them suitable for urban transport and short-range delivery applications, where emissions can be minimized. While they provide the ability to switch between fuel types, B2B buyers should evaluate the complexity of maintenance and the potential higher upfront costs compared to traditional ICE vehicles.

What Advantages Do Fuel Cell Electric Vehicles (FCEVs) Offer for Heavy-Duty Applications?

Fuel cell electric vehicles operate on hydrogen, providing a longer range than battery electric vehicles and fast refueling times. They are particularly advantageous for heavy-duty transport and public transport systems. However, the limited availability of hydrogen refueling infrastructure and higher vehicle costs can be significant considerations for B2B buyers looking to invest in this technology.

How Do Micro-Hybrid Vehicles Fit into the B2B Landscape?

Micro-hybrid vehicles utilize start-stop technology to enhance fuel efficiency while still relying on traditional combustion engines. They are a practical choice for urban delivery and taxi services where reducing emissions is a priority. Although they offer better fuel economy than standard ICE vehicles, B2B buyers should assess whether the benefits justify the investment compared to fully electric or hybrid options.

Key Industrial Applications of gas cars vs electric

| Industry/Sector | Specific Application of gas cars vs electric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Transportation | Fleet operations using gas vs. electric vehicles | Lower fuel and maintenance costs with EVs; reduced emissions | Availability of charging infrastructure; vehicle range; total cost of ownership |

| Construction | Heavy machinery and transport vehicles | Gas vehicles may offer better power for heavy loads; EVs lower running costs | Fuel availability; maintenance support; vehicle durability |

| Agriculture | Transporting goods and equipment | EVs reduce fuel costs and emissions; gas vehicles provide reliability | Terrain compatibility; charging stations; vehicle adaptability |

| Public Sector | Municipal services (e.g., waste collection) | Cost savings on fuel and maintenance; environmental impact reduction | Local incentives for EVs; fleet management; operational range |

| Tourism & Hospitality | Shuttle services and fleet vehicles | Enhanced customer experience with quieter, cleaner EVs; lower operational costs | Vehicle comfort; charging infrastructure; branding opportunities |

How Do Gas Cars and Electric Vehicles Apply in Logistics and Transportation?

In the logistics and transportation sector, businesses often operate large fleets for deliveries and goods movement. Gas vehicles have historically dominated this space due to their power and range; however, electric vehicles (EVs) are rapidly gaining traction due to significant long-term cost savings in fuel and maintenance. B2B buyers should consider the availability of charging infrastructure and the total cost of ownership when evaluating options. With the potential for reduced emissions, companies can also enhance their corporate social responsibility profiles.

What Are the Benefits of Using Gas vs. Electric Vehicles in Construction?

In the construction industry, both gas and electric vehicles play crucial roles in transporting materials and equipment. Gas vehicles are favored for their ability to handle heavy loads and rough terrain, making them ideal for job sites. Conversely, electric vehicles can provide substantial savings in fuel and maintenance costs over time, especially for shorter routes. Buyers need to assess the availability of fuel types, the durability of vehicles for various conditions, and support for maintenance to ensure operational efficiency.

How Is the Agriculture Sector Adopting Gas and Electric Vehicles?

The agriculture sector relies heavily on transportation for goods and equipment. Electric vehicles can significantly reduce fuel costs and emissions, making them an attractive option for eco-conscious farmers. However, gas vehicles may still be preferred for their reliability and ability to navigate challenging terrains. B2B buyers should focus on the adaptability of vehicles to local conditions, availability of charging stations, and the overall cost of ownership to maximize their investment.

Why Are Gas and Electric Vehicles Important for Public Sector Operations?

Municipal services, such as waste collection and public transportation, are increasingly exploring the use of gas and electric vehicles. Electric options can lead to substantial cost savings on fuel and maintenance while contributing to environmental goals. Buyers in this sector should consider local incentives for EV adoption, the management of fleet operations, and the operational range required to meet service demands. This shift not only enhances public image but also aligns with sustainability initiatives.

Illustrative image related to gas cars vs electric

How Can the Tourism and Hospitality Industry Benefit from Gas and Electric Vehicles?

In the tourism and hospitality sector, shuttle services and fleet vehicles are essential for providing quality customer experiences. Electric vehicles offer a quieter, cleaner alternative, which can enhance guest satisfaction while also reducing operational costs. For B2B buyers, it’s crucial to evaluate vehicle comfort, the availability of charging infrastructure, and branding opportunities associated with eco-friendly transportation options to attract environmentally conscious travelers.

3 Common User Pain Points for ‘gas cars vs electric’ & Their Solutions

Scenario 1: Budget Constraints and Cost Predictions

The Problem: B2B buyers often grapple with tight budgets and unpredictable costs when deciding between gas cars and electric vehicles (EVs). For companies operating in regions with fluctuating fuel prices, the total cost of ownership can be challenging to estimate. In markets such as Africa or South America, where economic conditions can be volatile, making a long-term investment in a vehicle—whether gas or electric—requires careful financial planning. Buyers need to understand not only the initial purchase price but also ongoing operational costs, including fuel and maintenance, to justify their investment.

The Solution: To navigate this issue, businesses should conduct a comprehensive Total Cost of Ownership (TCO) analysis that encompasses initial purchase costs, fuel costs, maintenance, and potential government incentives for electric vehicles. Using tools like the U.S. Department of Energy’s fuel-savings calculator can help estimate costs based on specific models and local electricity rates. Additionally, buyers should engage with local dealerships or fleet management companies that provide tailored financing options and leasing agreements, which can mitigate upfront costs. By leveraging incentives and financing solutions, companies can make informed decisions that align with their budget constraints while maximizing long-term savings.

Illustrative image related to gas cars vs electric

Scenario 2: Infrastructure Challenges for Electric Vehicles

The Problem: One of the significant barriers to adopting electric vehicles is the lack of sufficient charging infrastructure, particularly in developing regions. B2B buyers may hesitate to invest in EVs if their operations are located in areas where charging stations are scarce or where electricity supply is unreliable. This concern is particularly prevalent in Middle Eastern countries where the existing power grid may not support widespread EV use, causing anxiety about the practicality of transitioning fleets to electric.

The Solution: To address infrastructure concerns, businesses should conduct a thorough assessment of the charging network in their operational areas before committing to electric vehicle purchases. Collaborating with local governments or utility companies to explore potential partnerships can lead to investment in charging stations. Furthermore, companies can consider installing their own charging solutions at their facilities, which not only enhances control over charging logistics but can also qualify for government incentives. Incorporating renewable energy sources, such as solar panels, to power these charging stations can further reduce costs and improve sustainability, making the transition to electric vehicles more feasible.

Scenario 3: Maintenance and Longevity Concerns

The Problem: B2B buyers often worry about the long-term maintenance and longevity of electric vehicles compared to traditional gas cars. In industries where vehicles are subjected to rigorous use, such as logistics and transportation, the reliability of EVs is paramount. Concerns about battery lifespan, potential degradation, and the availability of specialized maintenance services can deter companies from making the switch to electric, especially in regions where service networks for EVs are still developing.

Illustrative image related to gas cars vs electric

The Solution: To alleviate maintenance concerns, businesses should invest in comprehensive training programs for their maintenance teams focused on electric vehicle technology. Partnering with manufacturers for training sessions can ensure that staff is well-equipped to handle EV-specific issues, such as battery management and software updates. Furthermore, buyers should look for electric models with extended warranties and robust service agreements that cover battery replacement and other critical components. By proactively addressing maintenance through training and service partnerships, companies can enhance the reliability of their electric fleets and ensure they are equipped to handle the unique challenges associated with EV upkeep.

Strategic Material Selection Guide for gas cars vs electric

What Are the Key Materials Used in Gas Cars and Electric Vehicles?

In the automotive industry, material selection plays a crucial role in determining the performance, durability, and cost-effectiveness of vehicles. This section analyzes several common materials used in gas cars and electric vehicles (EVs), focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Impact Gas Cars and Electric Vehicles?

Key Properties: Aluminum is lightweight, with excellent corrosion resistance and good thermal conductivity. It can withstand moderate temperatures, making it suitable for various automotive applications.

Illustrative image related to gas cars vs electric

Pros & Cons: The primary advantage of aluminum is its weight-saving properties, which enhance fuel efficiency in gas cars and extend the range of EVs. However, aluminum can be more expensive than traditional steel and may require more complex manufacturing processes, such as welding or extrusion.

Impact on Application: In gas cars, aluminum is often used in engine blocks, transmission cases, and body panels. For EVs, it is critical in battery enclosures and structural components to reduce weight and improve range.

Specific Considerations for International Buyers: Buyers in regions like Africa and South America may need to consider local sourcing options to mitigate costs. Compliance with standards such as ASTM for material properties is essential, particularly in Europe, where stringent regulations exist.

What Role Does Steel Play in the Construction of Gas Cars and Electric Vehicles?

Key Properties: Steel is known for its high tensile strength, durability, and affordability. It can withstand high temperatures and pressures, making it suitable for critical components.

Pros & Cons: The cost-effectiveness of steel is a significant advantage, especially for mass production. However, its heavier weight compared to aluminum can negatively impact fuel efficiency in gas cars and range in EVs. Additionally, steel is prone to corrosion, requiring protective coatings.

Impact on Application: Steel is widely used in the chassis, frame, and body of both gas and electric vehicles. Its strength is crucial for safety features, while its weight can affect overall vehicle performance.

Specific Considerations for International Buyers: Compliance with international standards such as DIN and JIS is vital for ensuring quality and safety. Buyers in the Middle East may also need to consider the impact of high temperatures on steel performance.

How Do Composites Enhance Performance in Gas Cars and Electric Vehicles?

Key Properties: Composites, such as carbon fiber and fiberglass, offer high strength-to-weight ratios and excellent corrosion resistance. They can withstand varying temperatures and provide design flexibility.

Pros & Cons: The lightweight nature of composites significantly improves fuel efficiency and range for both gas and electric vehicles. However, they are generally more expensive and can complicate manufacturing due to their specialized processing requirements.

Impact on Application: Composites are often used in high-performance gas cars for body panels and structural components. In EVs, they are increasingly utilized in battery housings and lightweight frames to maximize efficiency.

Specific Considerations for International Buyers: Buyers should be aware of the availability and cost of composite materials in their region. Compliance with local and international standards is also crucial, especially in Europe, where regulations on material safety and recyclability are stringent.

What Is the Importance of Lithium-Ion Batteries in Electric Vehicles?

Key Properties: Lithium-ion batteries are known for their high energy density, long cycle life, and low self-discharge rates. They operate effectively within a wide temperature range.

Pros & Cons: The primary advantage of lithium-ion batteries is their ability to store large amounts of energy in a compact form, essential for EV performance. However, they are costly and require careful management to ensure safety and longevity.

Impact on Application: In electric vehicles, lithium-ion batteries are the primary energy source, directly impacting range, performance, and charging times.

Specific Considerations for International Buyers: Buyers must consider the availability of lithium and other materials used in battery production. Compliance with safety standards and recycling regulations is increasingly important in regions like Europe and North America.

Summary Table of Material Selection for Gas Cars vs Electric Vehicles

| Material | Typical Use Case for gas cars vs electric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine blocks, body panels, battery enclosures | Lightweight, enhances fuel efficiency | Higher cost, complex manufacturing | Medium |

| Steel | Chassis, frame, body | Cost-effective, high strength | Heavier, prone to corrosion | Low |

| Composites | Body panels, structural components | High strength-to-weight ratio | Expensive, complex manufacturing | High |

| Lithium-Ion Batteries | Primary energy source in EVs | High energy density, long cycle life | Costly, requires careful management | High |

This analysis provides a comprehensive overview of the materials used in gas cars and electric vehicles, offering valuable insights for international B2B buyers looking to make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for gas cars vs electric

What Are the Key Stages in the Manufacturing Process of Gas Cars vs. Electric Vehicles?

The manufacturing processes for gas cars and electric vehicles (EVs) share some similarities, yet they also exhibit distinct differences due to the inherent technology and components involved. Understanding these stages is crucial for B2B buyers looking to source vehicles or components.

Illustrative image related to gas cars vs electric

Material Preparation and Sourcing

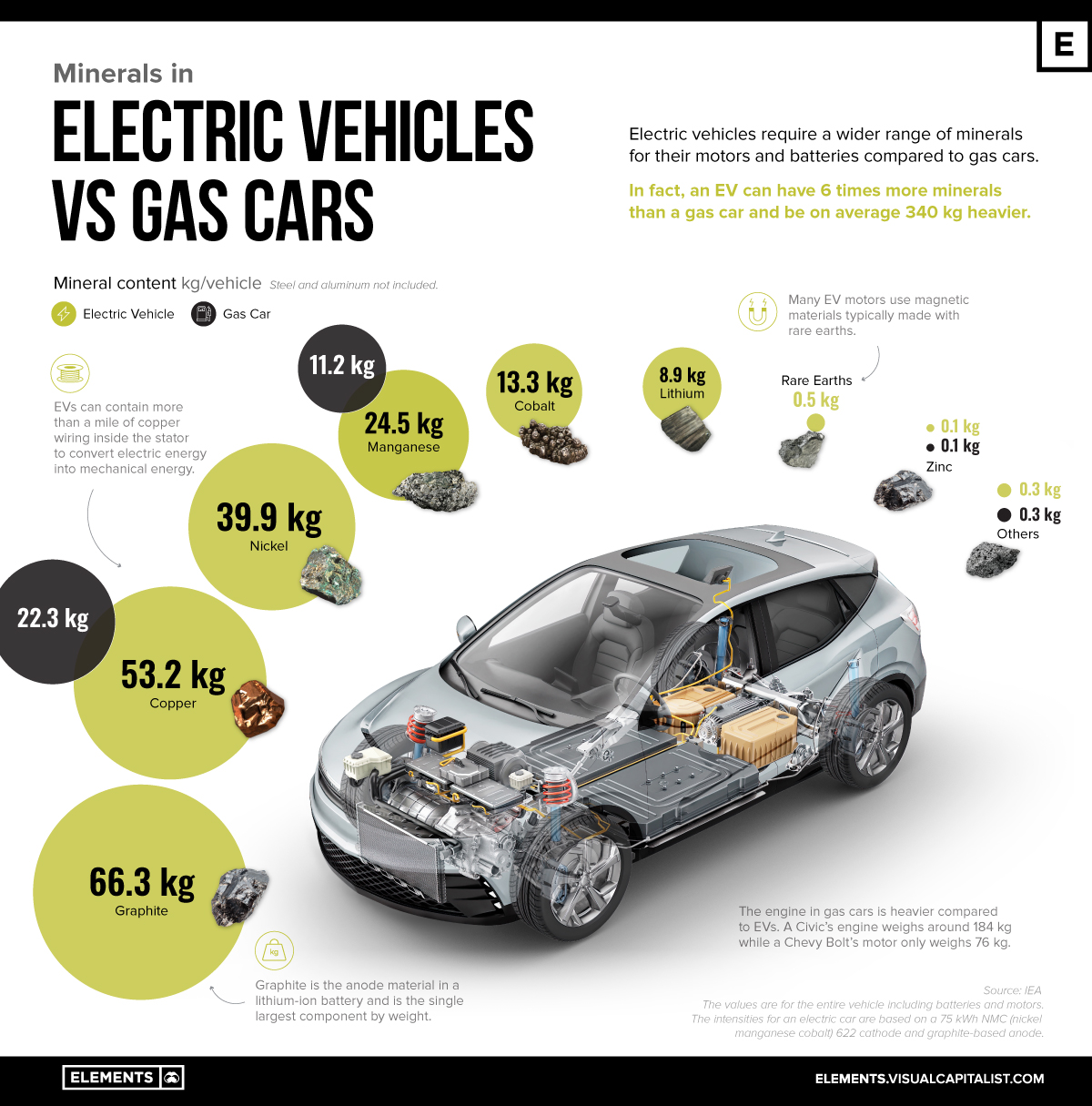

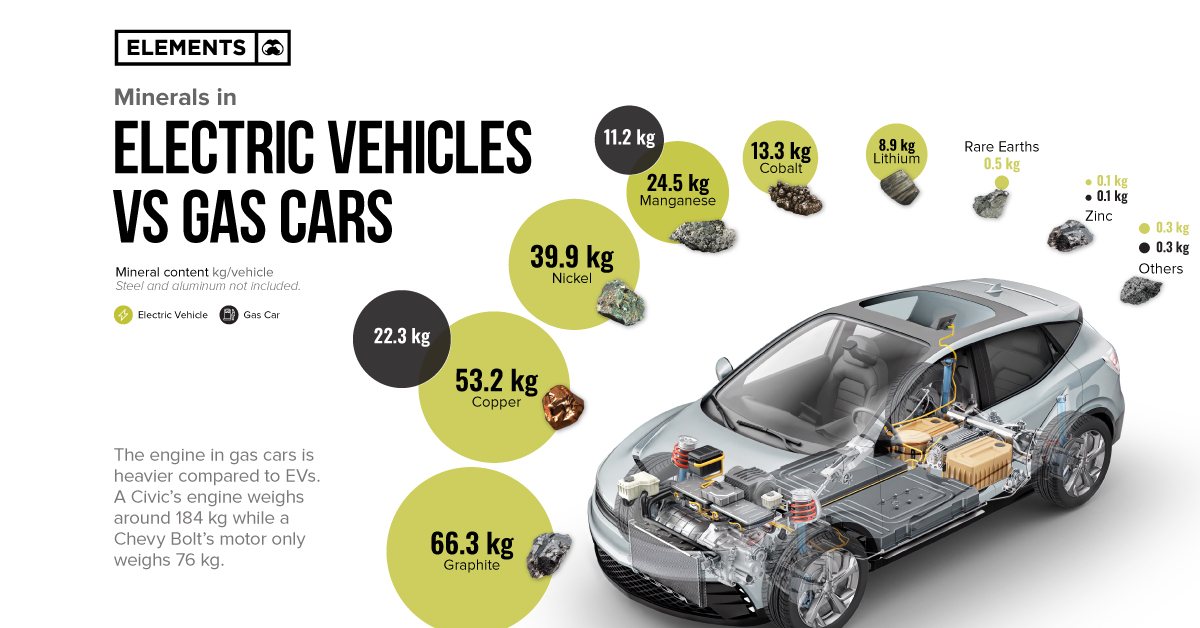

For both gas and electric vehicles, material preparation begins with the sourcing of raw materials. Gas vehicles typically require steel, aluminum, plastics, and rubber for various components, such as the engine, chassis, and tires. In contrast, electric vehicles necessitate additional materials, particularly for their battery systems. Lithium, cobalt, nickel, and graphite are critical for producing lithium-ion batteries, making the sourcing process more complex and dependent on global supply chains.

Forming Techniques: How Are Components Shaped?

The forming stage involves shaping materials into usable components. Gas cars often use traditional stamping and machining techniques for producing engine parts, body panels, and chassis components. Electric vehicles, however, utilize advanced manufacturing techniques such as die-casting and injection molding for battery enclosures and electric motor housings. These methods allow for reduced weight and improved structural integrity, which are vital for EV efficiency.

Assembly Processes: What Sets Them Apart?

The assembly of gas cars typically involves a sequential build process where components are added in a predetermined order. This can include the installation of the engine, transmission, and exhaust systems, which require specialized tools and skilled labor. Electric vehicle assembly is increasingly automated, particularly for battery installation. Robotics play a significant role in ensuring precision and speed, as the battery pack is one of the most critical components influencing vehicle performance and safety.

Finishing Techniques: How Is Quality Achieved?

Finishing processes, such as painting and surface treatment, are essential for both gas and electric vehicles. However, electric vehicles often undergo additional finishing processes to ensure that their battery systems are protected against environmental factors. For instance, corrosion-resistant coatings and thermal management systems are critical to prolong battery life and performance.

What International Standards Guide Quality Assurance in Vehicle Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that vehicles meet safety and performance standards. International standards such as ISO 9001 provide a framework for establishing a quality management system. Compliance with ISO standards is crucial for suppliers looking to operate in global markets, as it demonstrates a commitment to quality.

What Industry-Specific Standards Are Relevant?

In addition to general ISO standards, specific certifications are applicable to the automotive sector. For instance, the European Union mandates compliance with the CE marking, indicating that products meet safety, health, and environmental protection standards. In the U.S., automotive manufacturers often adhere to standards set by the American Petroleum Institute (API) for engine oils and fuels.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is implemented at various checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Ensures that materials and components meet specified requirements before they are used in production.

- In-Process Quality Control (IPQC): Monitors the manufacturing process to identify and rectify issues in real-time, minimizing defects.

- Final Quality Control (FQC): Conducts comprehensive testing and inspections of the completed vehicle to ensure it meets all quality and safety standards.

What Common Testing Methods Are Used in Vehicle Manufacturing?

Testing methods employed in the automotive industry include:

- Functional Testing: Evaluates the performance of various vehicle systems, including braking, steering, and electrical components.

- Durability Testing: Assesses how well vehicles withstand stress, temperature variations, and environmental conditions.

- Crash Testing: Simulates collisions to ensure that vehicles meet safety standards and provide adequate occupant protection.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control measures implemented by suppliers. This can include:

Illustrative image related to gas cars vs electric

- Conducting Audits: Periodic audits of suppliers can help assess compliance with international standards and internal quality protocols.

- Requesting Quality Reports: Suppliers should provide documentation detailing their quality assurance processes, testing results, and certifications.

- Engaging Third-Party Inspectors: Utilizing independent inspectors can provide an unbiased assessment of a supplier’s manufacturing and quality control practices.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of regional regulations and standards that may differ from their home countries. Understanding these nuances is essential for ensuring compliance and product acceptance in local markets. Buyers should engage with local regulatory bodies and industry associations to stay informed about specific requirements.

Conclusion: How to Navigate Manufacturing and Quality Assurance in Gas Cars vs. Electric Vehicles

As the automotive landscape evolves, understanding the differences in manufacturing processes and quality assurance between gas cars and electric vehicles becomes increasingly important for B2B buyers. By focusing on supplier quality, leveraging international standards, and engaging in thorough verification processes, buyers can make informed decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas cars vs electric’

Introduction

Navigating the decision between procuring gas cars and electric vehicles (EVs) can be complex, especially for B2B buyers considering factors such as costs, efficiency, and sustainability. This practical sourcing guide outlines essential steps to help you make informed decisions tailored to your organization’s needs.

Step 1: Assess Your Operational Needs

Understanding your company’s specific operational requirements is crucial. Identify the primary use cases for the vehicles, including mileage, load capacity, and terrain types. This assessment will guide you in determining whether gas or electric vehicles better align with your logistics and transportation strategies.

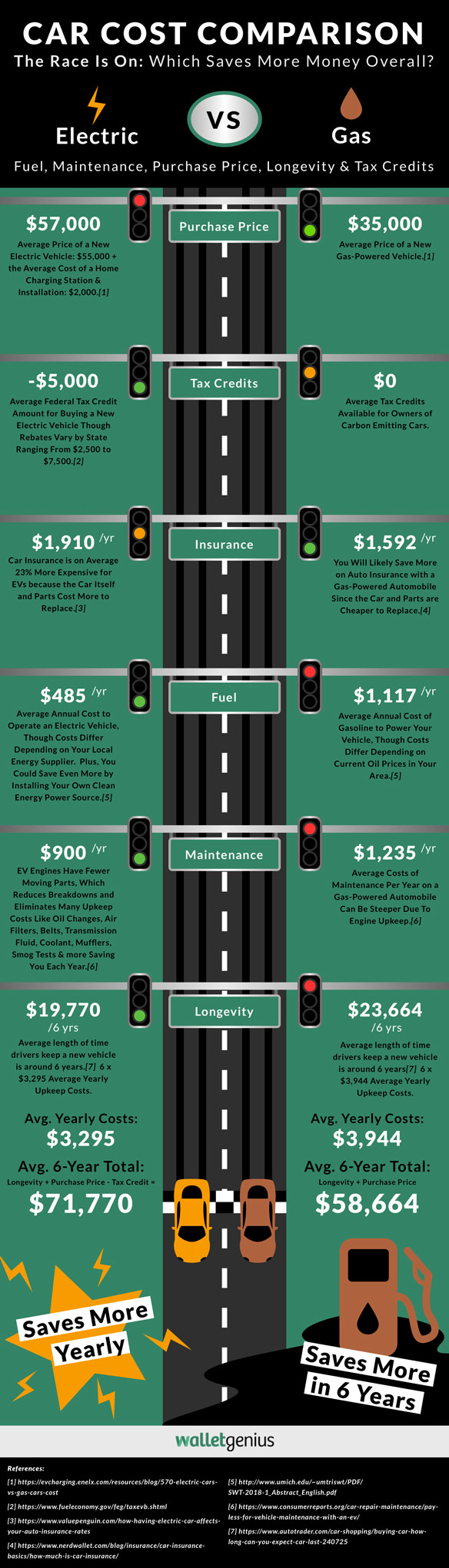

Step 2: Evaluate Total Cost of Ownership (TCO)

Calculating the total cost of ownership is vital for a comprehensive financial analysis. TCO includes initial purchase price, fuel costs, maintenance expenses, and potential tax incentives. Given that EVs typically offer lower fuel and maintenance costs, a TCO analysis can reveal significant long-term savings, especially in regions where electricity prices are stable.

Step 3: Identify Available Incentives and Subsidies

Research regional and federal incentives that may apply to your purchase. Many governments offer tax credits, rebates, or grants for EV purchases, which can significantly reduce upfront costs. Familiarizing yourself with these programs can also help in forecasting your budget and maximizing savings.

Step 4: Evaluate Supplier Certifications and Reputation

Before choosing a supplier, verify their certifications and industry reputation. Look for suppliers with proven track records in delivering high-quality vehicles and reliable service. Check for certifications that indicate adherence to environmental standards, which can be especially relevant for electric vehicle manufacturers.

Step 5: Consider Charging Infrastructure Needs

For electric vehicles, assessing your charging infrastructure is essential. Determine whether your location has access to charging stations and evaluate the feasibility of installing charging units. Consider the costs associated with installation, maintenance, and the potential need for upgrades to your electrical systems.

Step 6: Analyze Vehicle Performance and Efficiency

Review the performance specifications of both gas and electric vehicles. Key metrics include fuel efficiency for gas cars and energy consumption (kWh/100 miles) for EVs. Understanding these metrics will enable you to select vehicles that not only meet your operational needs but also enhance sustainability efforts.

Step 7: Plan for Future Scalability

Finally, consider your organization’s long-term growth and how your vehicle fleet may need to adapt. Evaluate the scalability of both gas and electric options in terms of available models, technology advancements, and infrastructure developments. Planning for future needs can help ensure that your investment remains viable over time, minimizing disruption to your operations.

Illustrative image related to gas cars vs electric

By following these steps, B2B buyers can make a more informed decision when choosing between gas and electric vehicles, ensuring alignment with both current and future business objectives.

Comprehensive Cost and Pricing Analysis for gas cars vs electric Sourcing

What Are the Key Cost Components for Gas Cars and Electric Vehicles?

When analyzing the cost structure of gas cars versus electric vehicles (EVs), several components must be considered.

-

Materials: The material costs differ significantly between gas and electric vehicles. Gas cars rely heavily on traditional automotive materials, such as steel and aluminum, while EVs require specialized materials for batteries, including lithium, cobalt, and nickel. The volatility in prices for these battery materials can affect the overall cost of EVs, especially as demand continues to rise.

-

Labor: Labor costs can also vary. Manufacturing gas vehicles typically involves more complex assembly processes due to the internal combustion engine, which may require more skilled labor. Conversely, EVs have fewer moving parts, leading to potentially lower labor costs in manufacturing. However, the need for skilled workers in battery technology and software integration for EVs can offset these savings.

-

Manufacturing Overhead: The overhead for both types of vehicles includes facilities, technology, and research and development costs. As automakers pivot to EV production, they may incur higher initial overhead due to the need for new manufacturing lines and technology investments.

-

Tooling and Quality Control (QC): Tooling costs are integral to both gas and electric vehicles, but the transition to EVs necessitates new tools for battery production and assembly. Quality control measures are also critical, especially for EVs, where battery performance and safety standards are paramount.

-

Logistics: The logistics of sourcing materials for gas cars and EVs can differ. EVs may involve longer supply chains due to the need for rare minerals, which are often sourced from specific regions worldwide. This can increase logistics costs, particularly if geopolitical factors disrupt supply routes.

-

Margin: Profit margins for manufacturers can differ between gas and electric vehicles. While gas cars have established markets, EVs are rapidly evolving, leading to competitive pricing pressures. Manufacturers may initially accept lower margins on EVs to gain market share.

How Do Price Influencers Affect Gas and Electric Vehicle Sourcing?

Several factors can influence the pricing structure for B2B buyers when sourcing gas and electric vehicles.

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing can often lead to significant cost reductions. Buyers looking to acquire a fleet should negotiate pricing based on volume, which can influence both upfront costs and long-term partnerships with suppliers.

-

Specifications and Customization: Customization can drive up costs. Buyers should clearly define specifications to avoid unnecessary expenses. EVs often come with various options for battery size, range, and features, which can impact pricing.

-

Materials and Quality Certifications: The choice of materials and the requirement for certifications can influence costs. For instance, EVs may need to meet stringent environmental standards, which can increase production costs. Buyers should ensure that suppliers can meet these standards without inflating prices.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established manufacturers may offer more stability but could charge a premium. New entrants might provide competitive pricing but could pose risks regarding quality and delivery.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk transfer. Misunderstanding these can lead to unexpected costs.

What Are the Best Negotiation Tips for B2B Buyers in the Automotive Sector?

-

Assess Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but the TCO, which includes maintenance, fuel costs, and depreciation. EVs often have lower operational costs, making them more economical over time.

-

Negotiate for Incentives: In regions where governments offer incentives for EV purchases, buyers should leverage these when negotiating prices. Understanding local regulations can help maximize savings.

-

Consider Regional Variations: Pricing nuances can vary greatly by region. Buyers in Africa, South America, the Middle East, and Europe should conduct market research to understand local pricing trends and negotiate accordingly.

-

Build Long-Term Relationships: Establishing a solid relationship with suppliers can lead to better pricing and terms over time. Regular communication and feedback can enhance collaboration and mutual benefit.

Disclaimer on Pricing

Prices can fluctuate due to market conditions, material costs, and geopolitical factors. Buyers should conduct due diligence and seek multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing gas cars vs electric With Other Solutions

Exploring Alternatives: Gas Cars vs. Electric Vehicles

In the evolving landscape of transportation, businesses are faced with numerous choices beyond traditional gas-powered vehicles and electric vehicles (EVs). Understanding the advantages and disadvantages of alternative solutions is crucial for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe where market conditions and infrastructure may vary significantly. This analysis will explore gas cars and electric vehicles in comparison to two viable alternatives: hydrogen fuel cell vehicles and plug-in hybrid electric vehicles (PHEVs).

Illustrative image related to gas cars vs electric

| Comparison Aspect | Gas Cars Vs Electric | Hydrogen Fuel Cell Vehicles | Plug-in Hybrid Electric Vehicles (PHEVs) |

|---|---|---|---|

| Performance | Good acceleration; limited range for EVs | Quick refueling; longer ranges than EVs | Good balance; can run on electric or gasoline |

| Cost | Lower initial costs for gas; higher fuel costs for gas cars | High initial costs; lower fuel costs | Moderate initial costs; mixed fuel costs |

| Ease of Implementation | Established infrastructure; EV charging growing | Limited refueling stations; emerging technology | Easier to adopt; dual charging options |

| Maintenance | Higher maintenance costs; regular service required | Lower maintenance; fewer moving parts | Moderate maintenance; similar to gas cars |

| Best Use Case | Long-distance travel; established markets | Long-haul transportation; specialized fleets | Urban commuting; flexibility in fuel choice |

What Are the Pros and Cons of Hydrogen Fuel Cell Vehicles?

Hydrogen fuel cell vehicles (FCVs) present a compelling alternative to traditional gas and electric vehicles. They offer quick refueling times comparable to gas cars, making them suitable for long-distance travel. Additionally, they emit only water vapor, contributing to lower emissions. However, the high initial cost of hydrogen vehicles and the limited availability of refueling infrastructure can be significant drawbacks. In regions where hydrogen stations are scarce, the practicality of FCVs is diminished, limiting their widespread adoption.

How Do Plug-in Hybrid Electric Vehicles (PHEVs) Compare?

Plug-in hybrid electric vehicles (PHEVs) provide a flexible option by combining an electric motor with a gasoline engine. This dual capability allows for electric-only driving for short distances, while the gasoline engine can take over for longer trips. PHEVs typically have a moderate initial cost compared to full EVs and can benefit from lower fuel costs when operating in electric mode. However, they still rely on gasoline, meaning they do not fully eliminate emissions. Their maintenance costs are also similar to gas vehicles, which may not provide the same long-term savings as fully electric models.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right vehicle solution requires a thorough assessment of specific business needs and operational contexts. B2B buyers should consider factors such as total cost of ownership, infrastructure availability, and the environmental impact of their choices. For businesses focused on sustainability and long-term savings, electric vehicles or hydrogen fuel cell vehicles may be more appealing, while those needing immediate flexibility might find PHEVs to be the best fit. Ultimately, understanding the nuances of each alternative will enable informed decisions that align with both financial and environmental goals.

Essential Technical Properties and Trade Terminology for gas cars vs electric

What Are the Key Technical Properties of Gas Cars and Electric Vehicles?

Understanding the technical specifications of gas and electric vehicles (EVs) is crucial for international B2B buyers, particularly when evaluating options for fleet purchases or partnerships in vehicle manufacturing and distribution.

Illustrative image related to gas cars vs electric

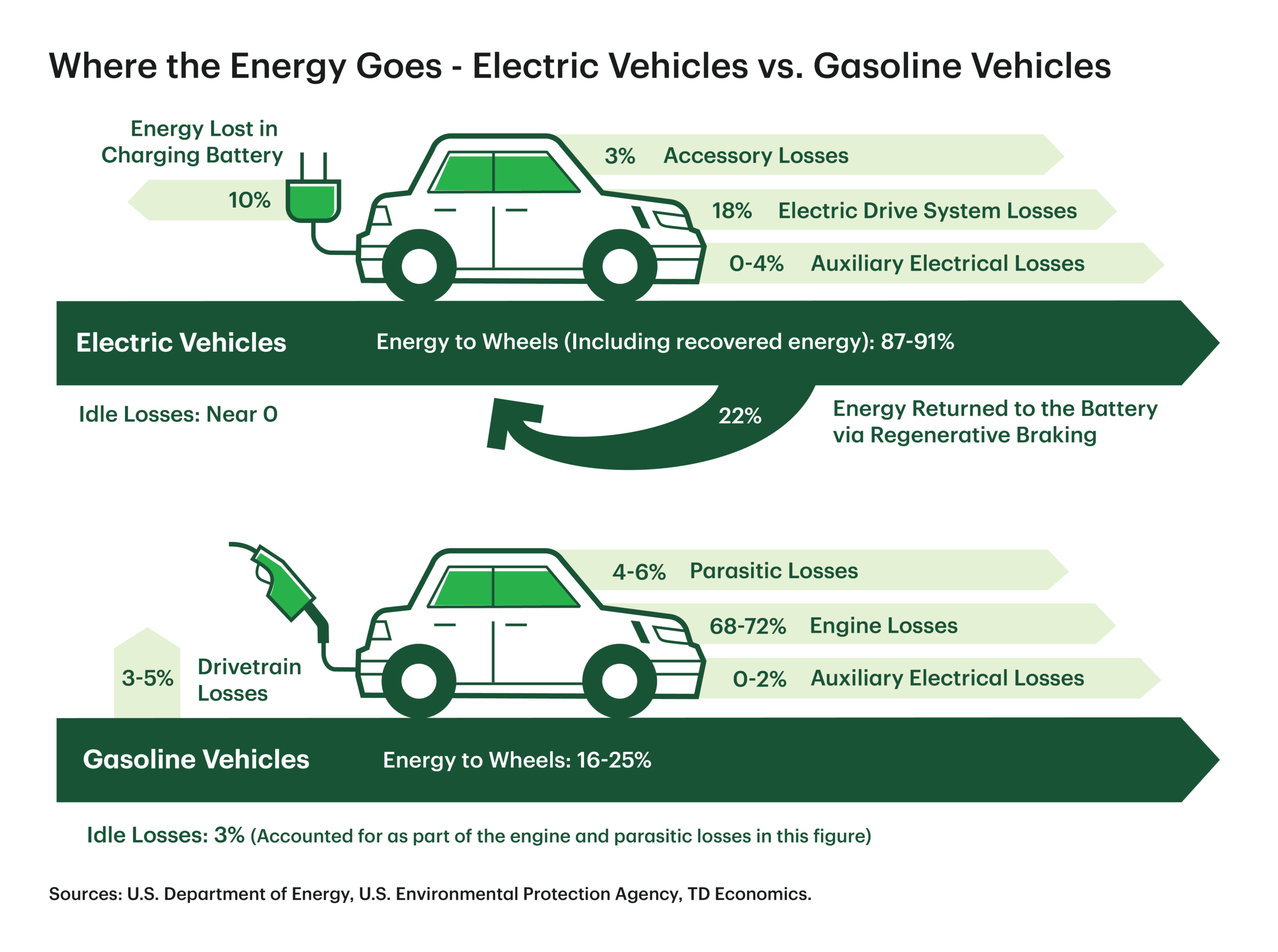

1. Powertrain Efficiency

Powertrain efficiency refers to how effectively an engine converts fuel into usable energy for movement. For gas cars, this is typically measured in miles per gallon (MPG), while for EVs, it is expressed in kilowatt-hours per 100 miles (kWh/100 miles). Higher efficiency ratings indicate lower operational costs and better performance. For B2B buyers, knowing these metrics aids in calculating the long-term cost of ownership and operational efficiency, which can significantly influence fleet management decisions.

2. Battery Capacity and Range

Battery capacity, measured in kilowatt-hours (kWh), is a critical specification for electric vehicles. It determines how far an EV can travel on a single charge. For instance, a vehicle with a 75 kWh battery may have a range of 250 miles, while a 100 kWh battery could offer 350 miles. This specification is vital for businesses that require vehicles for logistics or transportation, as it impacts route planning and charging infrastructure needs.

3. Maintenance Costs

Maintenance costs encompass all expenses related to vehicle upkeep, including parts replacement and service fees. Electric vehicles generally incur lower maintenance costs due to fewer moving parts and no need for oil changes. For B2B operations, understanding these costs can influence budgeting and financial planning, particularly for businesses operating large fleets.

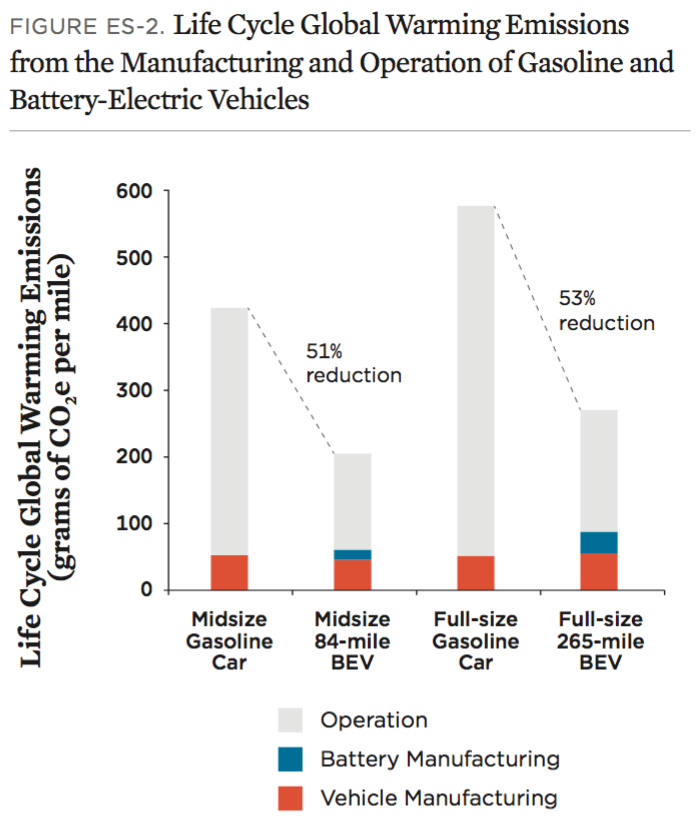

4. Carbon Emissions

Carbon emissions are a critical environmental metric, especially as global regulations tighten around vehicle emissions. Gas cars typically produce higher CO2 emissions compared to EVs, which are often considered zero-emission at the tailpipe. For companies focused on sustainability and corporate social responsibility, this specification is essential for aligning with eco-friendly initiatives and improving public relations.

Illustrative image related to gas cars vs electric

5. Charging Time and Infrastructure

Charging time is the duration required to recharge an electric vehicle’s battery. This can vary based on the charging station type: Level 1 chargers are slower, while Level 2 and DC fast chargers offer quicker options. Understanding charging times and the availability of charging infrastructure is critical for B2B buyers who need to ensure that their operations can accommodate EVs without significant downtime.

What Are Common Trade Terms in the Gas vs. Electric Vehicle Market?

In the automotive industry, certain trade terms frequently arise that can influence purchasing decisions and negotiations.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of gas and electric vehicles, OEMs are critical partners for B2B buyers looking to source quality components. Understanding OEM relationships helps businesses ensure they are obtaining reliable and compliant parts for vehicle assembly or maintenance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is particularly relevant for B2B buyers when negotiating bulk purchases of vehicles or parts. Knowing the MOQ can affect inventory management and financing decisions, as it often determines the scale of a buyer’s initial investment.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific goods or services. For B2B buyers, issuing RFQs is a strategic way to gather pricing information and evaluate suppliers based on cost and service offerings, ensuring they make informed purchasing decisions.

Illustrative image related to gas cars vs electric

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. For B2B buyers in different regions, understanding Incoterms is essential for clarifying shipping responsibilities, risks, and costs associated with the delivery of vehicles, whether gas or electric.

5. TCO (Total Cost of Ownership)

TCO is a financial estimate that helps buyers assess the direct and indirect costs of owning a vehicle over its entire lifecycle. This includes purchase price, financing, insurance, maintenance, and fuel or charging costs. For B2B buyers, evaluating TCO can guide strategic decisions regarding fleet purchases and operational budgeting.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals in the evolving automotive landscape.

Navigating Market Dynamics and Sourcing Trends in the gas cars vs electric Sector

What Are the Key Market Dynamics in the Gas Cars vs. Electric Vehicle Sector?

The global automotive landscape is undergoing a significant transformation, driven by technological advancements, regulatory changes, and shifting consumer preferences. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The electric vehicle (EV) market is experiencing rapid growth, propelled by declining battery costs, improved charging infrastructure, and government incentives aimed at reducing carbon emissions. In contrast, gas-powered vehicles still dominate in many markets due to established supply chains and lower initial purchase costs.

Illustrative image related to gas cars vs electric

Emerging trends indicate a growing shift towards hybrid models that combine the benefits of both gas and electric systems. This trend reflects the need for flexibility in diverse markets, where charging infrastructure may not yet be widespread. Additionally, advancements in autonomous driving technology and connected vehicle systems are reshaping sourcing strategies, emphasizing the importance of tech partnerships and collaborations. B2B buyers must stay agile, adapting to these trends while considering local market conditions and regulatory environments that can vary significantly by region.

How Does Sustainability Influence B2B Sourcing Decisions in the Automotive Sector?

Sustainability is becoming a critical factor for B2B buyers in the automotive sector, influencing sourcing decisions and supply chain management. The environmental impact of gas vehicles compared to electric vehicles is substantial, with EVs typically emitting lower levels of greenhouse gases over their lifecycle. This shift towards sustainable practices is not just a regulatory requirement but also a market expectation, particularly in regions like Europe, where stringent emissions standards are in place.

Ethical sourcing is equally important, as consumers and businesses alike increasingly prioritize transparency and environmental responsibility. Buyers should look for suppliers that offer ‘green’ certifications and materials, which can enhance their brand reputation and align with corporate sustainability goals. These certifications can include adherence to international standards for emissions, energy consumption, and the use of recycled materials. By prioritizing ethical supply chains, B2B buyers can contribute to a more sustainable automotive industry while also meeting growing consumer demand for environmentally responsible products.

What Is the Historical Context of Gas Cars vs. Electric Vehicles?

The history of the automotive industry is marked by the rivalry between gas-powered and electric vehicles. Initially, electric vehicles were prominent in the early 20th century, but the rise of internal combustion engines, driven by lower costs and greater range, led to their dominance. The oil crisis of the 1970s rekindled interest in alternative fuels, but it wasn’t until the 21st century that electric vehicles began to reclaim market share.

The advent of modern battery technology, coupled with increasing environmental awareness, has transformed electric vehicles into a viable alternative. Today, major automakers are investing heavily in EV production, signaling a significant shift in consumer preferences and regulatory frameworks. For B2B buyers, this historical context is essential in understanding current market trends and making informed sourcing decisions that align with future automotive landscapes.

Frequently Asked Questions (FAQs) for B2B Buyers of gas cars vs electric

-

How do I determine the total cost of ownership between gas cars and electric vehicles?

To calculate the total cost of ownership (TCO) for gas cars versus electric vehicles (EVs), consider several factors: the initial purchase price, available incentives, fuel costs, maintenance expenses, and expected lifespan. While EVs may have a higher upfront cost, they typically incur lower fuel and maintenance expenses over time. Utilize online TCO calculators specific to your region to account for local fuel prices, electricity rates, and potential tax credits or rebates. This comprehensive approach will help you make an informed decision based on long-term savings. -

What are the key considerations when sourcing electric vehicles internationally?

When sourcing electric vehicles internationally, consider factors such as local regulations, import duties, and available charging infrastructure. Ensure the supplier complies with international quality standards and certifications. Evaluate the supplier’s ability to provide after-sales support and spare parts availability. Additionally, investigate the local market demand for EVs in your target region, as this may influence your purchasing strategy. Engaging with local industry experts can further enhance your sourcing decisions and mitigate risks. -

How can I vet suppliers for gas and electric vehicles effectively?

Effective supplier vetting involves several steps: researching potential suppliers’ backgrounds, checking references, and reviewing their product quality and delivery performance. Request certifications, such as ISO standards, to ensure compliance with international manufacturing practices. Conduct factory visits or audits if possible, and assess their financial stability through credit checks. Utilize platforms that offer supplier ratings and reviews to gauge their reputation in the industry. Establish clear communication to discuss your specific needs and expectations to gauge their responsiveness and reliability. -

What customization options should I consider when purchasing vehicles for my fleet?

When considering customization options for your fleet, evaluate factors such as vehicle specifications, branding, and technology features. For electric vehicles, consider battery capacity, charging capabilities, and range to suit your operational needs. Additionally, assess whether the supplier can integrate telematics systems for fleet management. For gas vehicles, inquire about engine types, fuel efficiency, and safety features. Ensure that any customization aligns with local regulations and market preferences to enhance the utility and appeal of your fleet. -

What are the minimum order quantities (MOQ) for gas cars and electric vehicles?

Minimum order quantities (MOQ) for gas cars and electric vehicles can vary significantly by supplier and market conditions. Typically, manufacturers may require a MOQ to ensure production efficiency and cost-effectiveness. For larger fleets, negotiating a lower MOQ may be possible, especially if you demonstrate a strong purchasing potential. Engage with multiple suppliers to compare MOQ terms and assess their flexibility in accommodating your needs. Understanding your budget and operational requirements will help you navigate MOQ discussions effectively. -

What payment terms are common in international vehicle transactions?

Common payment terms in international vehicle transactions include letters of credit, advance payments, and payment upon delivery. Each method has its advantages and risks; for instance, letters of credit offer security but may incur additional fees. Advance payments can secure better pricing but pose risks if the supplier fails to deliver. It is essential to negotiate payment terms that balance risk with cash flow needs. Establishing clear terms in a written agreement can help prevent misunderstandings and protect both parties’ interests. -

How can I ensure quality assurance (QA) for vehicles sourced internationally?

To ensure quality assurance for vehicles sourced internationally, implement a rigorous QA process that includes pre-shipment inspections, compliance with international standards, and documentation verification. Collaborate with third-party inspection services to assess vehicle quality before shipment. Request detailed specifications and test reports from suppliers to verify compliance with safety and performance standards. Additionally, establish a clear return policy for defective vehicles and ensure your contract includes quality benchmarks to safeguard against subpar products. -

What logistics considerations should I keep in mind when importing vehicles?

When importing vehicles, logistics considerations include shipping methods, customs clearance processes, and transportation costs. Evaluate whether to use container shipping or roll-on/roll-off (RoRo) methods based on your budget and the type of vehicles. Understand the import regulations specific to your country, including tariffs and required documentation. Partnering with a reliable logistics provider can streamline the shipping process and ensure compliance with customs regulations. Additionally, plan for potential delays and establish contingency plans to mitigate risks associated with international shipping.

Top 3 Gas Cars Vs Electric Manufacturers & Suppliers List

1. Reddit – Energy Density Comparison

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Energy Density Comparison, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Constellation – Electric vs. Gas Cars Comparison

Domain: constellation.com

Registered: 1996 (29 years)

Introduction: Electric cars vs. gas cars comparison includes considerations of cost, convenience, and environmental impact. Key points include: 1. Cost: Evaluate not just the sticker price but also the cost of powering and maintaining the vehicle. 2. Tax Credits: Eligible for a tax credit of 30% of labor for EV charger installation, up to $1,000. 3. Fuel Costs: Calculate monthly charging costs for EVs based on …

3. Yahoo Autos – Fuel Cost Insights

Domain: autos.yahoo.com

Registered: 1995 (30 years)

Introduction: This company, Yahoo Autos – Fuel Cost Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for gas cars vs electric

In evaluating the long-term implications of gas cars versus electric vehicles (EVs), B2B buyers must consider not only the upfront costs but also the total cost of ownership, including fuel and maintenance. Electric vehicles consistently demonstrate lower lifetime costs due to their significantly reduced fuel expenses and maintenance needs. Furthermore, with the declining prices of EVs and ongoing incentives in various regions, the financial gap between gas and electric vehicles is narrowing, making EVs an increasingly attractive option.

Strategic sourcing plays a crucial role in this transition. By leveraging partnerships with suppliers who specialize in electric vehicle technology and infrastructure, businesses can optimize their procurement processes and ensure they are equipped for the future of transportation. Additionally, considering regional factors—such as local electricity costs and government incentives—can enhance cost savings and operational efficiency.

As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential for international B2B buyers to adopt a forward-thinking approach. Embracing electric vehicles not only aligns with sustainability goals but also positions businesses favorably in an increasingly competitive landscape. Engage with suppliers now to capitalize on the electric vehicle revolution and drive your organization towards a more sustainable and cost-effective future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to gas cars vs electric

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.