Introduction: Navigating the Global Market for electricity vs gas car

As international B2B buyers explore the complex landscape of sourcing vehicles, the decision between electricity vs gas cars poses a significant challenge. Understanding the nuances of electric vehicles (EVs) versus traditional gas-powered vehicles is critical for making informed purchasing decisions that align with both financial and environmental goals. This comprehensive guide delves into various aspects of this choice, including vehicle types, operational applications, supplier vetting processes, cost analyses, and the evolving market dynamics in regions such as Africa, South America, the Middle East, and Europe.

The shift towards electric vehicles is not merely a trend but a fundamental change in the automotive industry, driven by advancements in technology and increasing regulatory pressures. By equipping B2B buyers with actionable insights and detailed comparisons, this guide empowers them to navigate the global market effectively. Whether assessing total cost of ownership, evaluating local incentives, or understanding the implications of charging infrastructure, buyers will find crucial information tailored to their specific regional contexts.

In a world where sustainability and cost-efficiency are paramount, making the right choice between electric and gas vehicles can yield significant long-term benefits. This guide will serve as a valuable resource, ensuring that you are well-prepared to make strategic decisions that will impact your organization’s operational success.

Table Of Contents

- Top 3 Electricity Vs Gas Car Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for electricity vs gas car

- Understanding electricity vs gas car Types and Variations

- Key Industrial Applications of electricity vs gas car

- 3 Common User Pain Points for ‘electricity vs gas car’ & Their Solutions

- Strategic Material Selection Guide for electricity vs gas car

- In-depth Look: Manufacturing Processes and Quality Assurance for electricity vs gas car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘electricity vs gas car’

- Comprehensive Cost and Pricing Analysis for electricity vs gas car Sourcing

- Alternatives Analysis: Comparing electricity vs gas car With Other Solutions

- Essential Technical Properties and Trade Terminology for electricity vs gas car

- Navigating Market Dynamics and Sourcing Trends in the electricity vs gas car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of electricity vs gas car

- Strategic Sourcing Conclusion and Outlook for electricity vs gas car

- Important Disclaimer & Terms of Use

Understanding electricity vs gas car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Battery Electric Vehicle (BEV) | Fully electric, powered by batteries; no gasoline required. | Fleet vehicles, urban deliveries | Pros: Lower operating costs, minimal maintenance. Cons: Limited range, longer refueling time. |

| Plug-in Hybrid Electric Vehicle (PHEV) | Combines electric battery with a gasoline engine; can operate on both. | Delivery and logistics, corporate fleets | Pros: Flexibility in fuel use, reduced emissions. Cons: More complex maintenance, higher initial cost. |

| Hybrid Electric Vehicle (HEV) | Uses both gasoline and electric power but cannot be charged externally. | Ride-sharing services, taxis | Pros: Better fuel efficiency than traditional vehicles. Cons: Limited electric-only range, higher emissions than BEVs. |

| Compressed Natural Gas Vehicle (CNG) | Runs on compressed natural gas, often seen as a cleaner alternative to gasoline. | Public transportation, long-haul trucking | Pros: Lower fuel costs, reduced emissions. Cons: Limited infrastructure, less efficient than electric options. |

| Fuel Cell Electric Vehicle (FCEV) | Uses hydrogen to generate electricity, emitting only water vapor. | Long-distance freight, public transport | Pros: Quick refueling, long range. Cons: High infrastructure costs, limited availability of hydrogen stations. |

What are the Characteristics of Battery Electric Vehicles (BEVs)?

Battery Electric Vehicles (BEVs) are entirely powered by electric batteries, offering zero tailpipe emissions. They are ideal for urban environments where short distances are common, making them suitable for fleet operations and urban deliveries. B2B buyers should consider the total cost of ownership, including incentives for EVs and potential savings on fuel and maintenance. With advancements in battery technology, the range of BEVs is steadily increasing, addressing one of the primary concerns for businesses regarding range limitations.

How Do Plug-in Hybrid Electric Vehicles (PHEVs) Stand Out?

Plug-in Hybrid Electric Vehicles (PHEVs) offer a combination of electric and gasoline power, allowing for flexibility in fuel use. This feature makes PHEVs suitable for businesses that operate in diverse environments where charging infrastructure may be limited. While they provide lower emissions and potential fuel savings, B2B buyers should weigh the initial investment against the complexity of maintenance and the potential need for dual fueling strategies. PHEVs can be particularly beneficial for delivery services that require both short and long distances.

Illustrative image related to electricity vs gas car

What Makes Hybrid Electric Vehicles (HEVs) a Viable Option?

Hybrid Electric Vehicles (HEVs) utilize both gasoline engines and electric motors, automatically switching between them to maximize efficiency. They are particularly advantageous for ride-sharing services and taxis, where fuel efficiency can significantly impact operating costs. However, HEVs have a limited electric-only range and still produce emissions, which may be a consideration for companies focused on sustainability. B2B buyers should evaluate the balance between fuel savings and emissions when considering HEVs for their fleets.

Why Consider Compressed Natural Gas Vehicles (CNG)?

Compressed Natural Gas Vehicles (CNG) utilize natural gas as a cleaner alternative to gasoline, making them attractive for public transportation and long-haul trucking. They often have lower fuel costs and reduced emissions compared to traditional gasoline vehicles. However, the limited availability of refueling infrastructure can be a significant drawback for B2B buyers. Businesses should assess their operational routes and the feasibility of integrating CNG into their fleets, keeping in mind the potential environmental benefits.

What are the Advantages of Fuel Cell Electric Vehicles (FCEVs)?

Fuel Cell Electric Vehicles (FCEVs) generate electricity through hydrogen fuel cells, emitting only water vapor as a byproduct. They are particularly well-suited for long-distance freight and public transport due to their quick refueling capabilities and extended range. However, the high costs associated with hydrogen infrastructure can be a barrier for B2B buyers. Companies considering FCEVs should evaluate the availability of hydrogen stations and the overall investment required to transition their fleets, as well as the potential for significant emissions reductions.

Key Industrial Applications of electricity vs gas car

| Industry/Sector | Specific Application of electricity vs gas car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Transportation | Electric delivery vans for urban logistics | Reduced fuel costs and lower emissions enhance brand image | Availability of charging infrastructure and vehicle range |

| Public Transportation | Electric buses for city transit systems | Lower operational costs and improved air quality | Government incentives and local regulations on emissions |

| Construction & Mining | Electric vehicles for site transport | Decreased maintenance costs and quieter operations | Durability and battery life suitable for rugged environments |

| Agriculture | Electric utility vehicles for farm operations | Cost savings on fuel and reduced environmental impact | Compatibility with existing farm equipment and charging options |

| Tourism & Hospitality | Electric shuttles for eco-friendly transport services | Enhanced guest experience and alignment with sustainability goals | Availability of charging stations at key locations |

How Are Electric Vehicles Transforming Logistics and Transportation?

In the logistics and transportation sector, electric delivery vans are becoming increasingly popular for urban logistics. These vehicles help companies significantly reduce fuel costs and lower their carbon emissions, which can enhance their brand image in a market that values sustainability. For international buyers, particularly in regions like Africa and South America, sourcing vehicles requires consideration of the availability of charging infrastructure and the range of electric vehicles to ensure they can meet delivery demands.

What Benefits Do Electric Buses Offer Public Transportation Systems?

Electric buses are revolutionizing public transportation systems in cities across Europe and the Middle East. They provide lower operational costs through reduced fuel expenses and maintenance, while also contributing to improved air quality in urban areas. For B2B buyers in public transit, it is essential to evaluate government incentives for electric vehicles and local regulations on emissions, as these factors can significantly impact the total cost of ownership and operational feasibility.

Illustrative image related to electricity vs gas car

How Are Electric Vehicles Enhancing Construction and Mining Operations?

In the construction and mining industries, electric utility vehicles are increasingly used for site transport. These vehicles offer decreased maintenance costs and operate more quietly than their gas counterparts, making them suitable for urban construction sites. For buyers in these sectors, sourcing considerations include the durability of the vehicles and battery life, ensuring they can withstand the rugged conditions often found in construction and mining environments.

What Role Do Electric Vehicles Play in Agriculture?

Electric utility vehicles are finding applications in agricultural operations, providing cost savings on fuel and reducing environmental impact. These vehicles can perform various tasks, from transporting goods to assisting in fieldwork. Buyers in agriculture should consider the compatibility of electric vehicles with existing farm equipment and the availability of charging options, especially in rural areas where infrastructure may be limited.

How Can Electric Shuttles Enhance Tourism and Hospitality Experiences?

In the tourism and hospitality sector, electric shuttles are being used to provide eco-friendly transport services for guests. This not only enhances the guest experience but also aligns with sustainability goals that many hotels and resorts are adopting. For international buyers, key considerations include the availability of charging stations at key locations and the vehicle’s range, ensuring seamless transportation options for visitors.

3 Common User Pain Points for ‘electricity vs gas car’ & Their Solutions

Scenario 1: Navigating Initial Cost Concerns for Electric Vehicles

The Problem:

B2B buyers often grapple with the initial cost of electric vehicles (EVs) compared to gasoline cars. The perceived higher upfront investment can deter businesses from making the switch, especially in regions where budget constraints are prevalent. For instance, a logistics company in Brazil may find that while the average price of an EV is gradually decreasing, it still represents a significant capital outlay compared to traditional gas vehicles. This scenario is compounded by the lack of awareness about available incentives and long-term savings.

The Solution:

To effectively address initial cost concerns, buyers should conduct a comprehensive total cost of ownership (TCO) analysis. This analysis should encompass not only the sticker price but also fuel savings, maintenance costs, and potential state or local incentives. For example, in regions like South Africa, where government initiatives support EV adoption, businesses can leverage rebates and tax credits to offset the initial investment. Collaborating with local dealerships that specialize in EVs can also provide access to exclusive financing options. Additionally, creating a phased transition plan, where a portion of the fleet is converted to electric over time, can alleviate upfront financial pressure while allowing the business to gradually adapt to new technology.

Scenario 2: Understanding Charging Infrastructure Limitations

The Problem:

A prevalent concern for B2B buyers considering electric vehicles is the adequacy of charging infrastructure. Companies in regions like the Middle East may face challenges due to limited access to charging stations, which can hinder fleet operations and employee convenience. The unpredictability of charging availability can lead to anxiety over vehicle downtime and operational efficiency, particularly for businesses reliant on tight delivery schedules.

The Solution:

To tackle the issue of charging infrastructure, businesses should conduct a thorough assessment of existing charging options within their operational areas. This includes mapping out charging station locations, understanding charging speeds, and identifying any partnerships with local utility companies that may offer incentives for installing charging stations at company premises. Furthermore, investing in home or workplace charging solutions can significantly mitigate downtime. For companies operating in regions with limited public infrastructure, installing dedicated charging stations can enhance operational reliability and employee satisfaction. Exploring innovative solutions such as mobile charging units can also provide flexibility in managing fleet operations.

Scenario 3: Addressing Maintenance and Longevity Concerns

The Problem:

Many B2B buyers have lingering doubts regarding the maintenance and longevity of electric vehicles compared to traditional gasoline cars. For instance, a fleet manager in Europe may worry about the long-term reliability of EV batteries, as well as the availability of specialized maintenance services. This skepticism can be amplified by misconceptions about the durability of electric vehicles and their components, ultimately impacting purchasing decisions.

The Solution:

To overcome maintenance and longevity concerns, businesses should prioritize education and training about EV technology for their fleet management teams. Engaging with manufacturers and service providers who specialize in electric vehicles can provide valuable insights into the expected lifespan of battery systems and the overall maintenance requirements of EVs. Establishing relationships with certified EV service centers ensures that businesses have access to qualified technicians who can handle repairs and maintenance. Moreover, considering warranties that cover battery performance over extended periods can provide added assurance. Regularly scheduled maintenance, coupled with the adoption of telematics solutions to monitor vehicle health, will further enhance operational efficiency and longevity, allowing businesses to maximize their investment in electric vehicles.

Strategic Material Selection Guide for electricity vs gas car

What Materials Are Commonly Used in Electric and Gas Cars?

When considering the strategic selection of materials for electric versus gas vehicles, several key materials come into play. Each material has unique properties that affect performance, durability, and cost, which are essential factors for international B2B buyers.

How Does Aluminum Compare in Electric and Gas Vehicles?

Aluminum is widely used in both electric and gas vehicles due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating that can withstand high engine temperatures, making it suitable for various automotive applications.

Pros: Aluminum is durable and significantly reduces vehicle weight, enhancing fuel efficiency and range, particularly in electric vehicles. Its manufacturing process is relatively straightforward, allowing for complex shapes and designs.

Cons: The primary limitation of aluminum is its cost, which can be higher than steel. Additionally, while it is corrosion-resistant, it may require protective coatings in certain environments, particularly in coastal areas or regions with high humidity.

Impact on Application: Aluminum’s lightweight properties contribute to improved energy efficiency in electric vehicles, while its strength and durability make it suitable for structural components in gas vehicles.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local availability and cost fluctuations of aluminum. Compliance with standards such as ASTM or DIN is crucial, as is understanding the local market’s preference for lightweight materials.

What Role Does Steel Play in Vehicle Manufacturing?

Steel remains a staple in vehicle manufacturing, particularly for structural components and safety features. Its high strength-to-weight ratio and excellent impact resistance make it a reliable choice for both electric and gas vehicles.

Pros: Steel is cost-effective and widely available, with established manufacturing processes. It provides excellent crash protection, which is a critical factor for safety compliance.

Cons: Steel is heavier than aluminum, potentially reducing the efficiency of electric vehicles. Additionally, it is susceptible to corrosion unless treated, which can increase long-term maintenance costs.

Illustrative image related to electricity vs gas car

Impact on Application: Steel is often used in the chassis and body of gas vehicles, while its use in electric vehicles may be balanced with lighter materials to optimize performance.

Considerations for International Buyers: Buyers should be aware of the varying standards for steel quality and treatment in different regions. Compliance with local regulations and standards like JIS for Japan or EN for Europe is essential for ensuring product safety and reliability.

How Does Copper Influence Electrical Systems in Vehicles?

Copper is a critical material for electrical systems in both electric and gas vehicles. Its excellent conductivity makes it ideal for wiring, connectors, and battery components.

Illustrative image related to electricity vs gas car

Pros: Copper’s high electrical conductivity ensures efficient power transmission, which is vital for electric vehicle performance. It is also highly durable and resistant to corrosion.

Cons: The primary drawback of copper is its cost, which can fluctuate based on global market conditions. Additionally, its weight can be a concern in applications where reducing overall vehicle weight is a priority.

Impact on Application: In electric vehicles, copper is essential for battery connections and electric motors, while in gas vehicles, it is used for wiring and electronic components.

Considerations for International Buyers: Buyers should evaluate the availability and pricing of copper in their regions. Compliance with international standards for electrical components is crucial, especially in markets with stringent safety regulations.

What Is the Importance of Plastics in Modern Vehicle Design?

Plastics are increasingly used in both electric and gas vehicles for various components, including interior parts, dashboards, and exterior body panels.

Pros: Plastics are lightweight, which helps improve fuel efficiency and range in electric vehicles. They can also be molded into complex shapes, allowing for innovative designs.

Cons: While plastics can be cost-effective, their long-term durability may be a concern, particularly in harsh environments. Some plastics may also have lower temperature resistance compared to metals.

Impact on Application: In electric vehicles, plastics can help reduce weight and improve energy efficiency, while in gas vehicles, they can contribute to design flexibility and cost savings.

Considerations for International Buyers: Buyers should consider the environmental impact of plastics and the growing trend toward sustainable materials. Compliance with regulations regarding plastic use in automotive applications is increasingly important, particularly in Europe.

Summary Table of Material Properties and Considerations

| Material | Typical Use Case for electricity vs gas car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body panels, structural components | Lightweight, corrosion-resistant | Higher cost, requires coatings | High |

| Steel | Chassis, safety components | Cost-effective, strong | Heavier, susceptible to corrosion | Low |

| Copper | Electrical wiring, connectors, batteries | Excellent conductivity, durable | High cost, weight concerns | High |

| Plastics | Interior parts, body panels | Lightweight, design flexibility | Durability issues, lower temperature resistance | Medium |

This guide provides a comprehensive overview of the materials used in electric and gas vehicles, helping B2B buyers make informed decisions based on performance, cost, and compliance with international standards.

Illustrative image related to electricity vs gas car

In-depth Look: Manufacturing Processes and Quality Assurance for electricity vs gas car

What are the Main Stages of Manufacturing Electric and Gas Cars?

The manufacturing processes for electric vehicles (EVs) and gas-powered vehicles share several similarities, yet they diverge significantly in key areas due to their differing technologies. Understanding these processes is crucial for B2B buyers looking to engage with suppliers across various regions.

Material Preparation: What Raw Materials Are Used?

The first stage in manufacturing either type of vehicle involves material preparation. For gas cars, this typically includes metals like steel and aluminum for the body, along with various plastics for internal components. In contrast, EVs require additional materials, such as lithium, cobalt, and nickel for battery production. As demand for electric cars rises, the sourcing of these materials is becoming increasingly critical, with concerns over supply chain sustainability and ethical sourcing practices becoming prominent.

How Are Vehicles Formed During Manufacturing?

The forming stage involves shaping the raw materials into vehicle components. For gas cars, stamping and welding techniques are commonly employed to create the car body and chassis. In EV manufacturing, while these techniques are also used, additional processes like die-casting for battery enclosures and the assembly of battery packs are integral. The complexity of battery assembly necessitates specialized equipment and trained personnel to ensure quality and safety.

What Are the Key Techniques in Vehicle Assembly?

During the assembly phase, both types of vehicles undergo a series of steps to integrate their components. Gas cars typically focus on engine assembly, fuel system installation, and the incorporation of exhaust systems. In contrast, EV assembly prioritizes battery integration, electric motor installation, and advanced electronic systems. The use of automation and robotics has increased in both sectors, streamlining assembly lines and improving efficiency.

What Finishing Processes Are Common in Vehicle Manufacturing?

The final stage, finishing, involves painting and surface treatment to enhance durability and aesthetics. Gas vehicles may require additional processes for corrosion resistance due to their exposure to fuel and oil. EVs, however, need to ensure that electrical components are adequately insulated and protected from the elements. This stage also includes quality checks to confirm that all systems function correctly before the vehicle is shipped to dealers.

Illustrative image related to electricity vs gas car

How is Quality Assurance Implemented in Electric and Gas Car Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for both electric and gas vehicles. B2B buyers should be aware of the international standards and industry-specific regulations that govern these practices.

Which International Standards Are Relevant for Vehicle Quality Control?

The International Organization for Standardization (ISO) 9001 is a widely recognized standard for quality management systems across industries, including automotive manufacturing. Compliance with ISO 9001 ensures that manufacturers maintain a consistent level of quality in their processes and products. In addition to this, other industry-specific standards such as the European Union’s CE marking and the American Petroleum Institute (API) standards for engine components are essential for ensuring product safety and performance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to the manufacturing process. Incoming Quality Control (IQC) examines raw materials and components upon delivery, ensuring they meet specified standards. In-Process Quality Control (IPQC) monitors manufacturing processes to identify defects early on, while Final Quality Control (FQC) takes place before vehicles leave the factory. This last checkpoint involves comprehensive testing of all vehicle systems to verify functionality and safety.

What Common Testing Methods Are Used for Quality Assurance?

To ensure vehicles meet quality standards, various testing methods are employed. These include:

- Functional Testing: Verifying that all vehicle systems, such as brakes, lights, and electrical components, operate correctly.

- Durability Testing: Subjecting vehicles to extreme conditions to assess their performance and longevity.

- Safety Testing: Evaluating crashworthiness and compliance with safety regulations.

These methods are critical for both electric and gas vehicles but may differ in their application, particularly concerning battery safety and performance testing in EVs.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should adopt a proactive approach to verify the quality control processes of their suppliers. This can include:

- Audits: Conducting regular audits of suppliers to assess compliance with quality standards and operational practices.

- Quality Reports: Requesting detailed quality reports that outline testing results, defect rates, and corrective actions taken.

- Third-Party Inspections: Engaging independent third-party organizations to perform inspections and audits can provide unbiased assessments of a supplier’s quality management systems.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate additional complexities in quality control due to varying regulations and standards across regions. For instance, buyers from Africa and South America may face different compliance challenges compared to those in Europe or the Middle East. Understanding local regulations and aligning supplier practices with these requirements is essential for avoiding compliance issues.

How Can Regional Differences Impact Quality Assurance?

Regional differences can significantly impact the quality assurance processes employed by manufacturers. For example, some countries may have stricter environmental regulations that affect materials used in vehicle manufacturing. Additionally, understanding cultural differences in business practices can enhance communication and negotiation with suppliers, ensuring smoother transactions and better quality outcomes.

Conclusion: Why Understanding Manufacturing and Quality Assurance Is Crucial for B2B Buyers

For B2B buyers in the automotive sector, a comprehensive understanding of manufacturing processes and quality assurance is essential for making informed purchasing decisions. By focusing on material preparation, assembly techniques, and quality control measures, buyers can assess supplier capabilities effectively. As the market for electric vehicles continues to grow, aligning with suppliers who prioritize quality and sustainability will be key to remaining competitive in an evolving landscape.

Illustrative image related to electricity vs gas car

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electricity vs gas car’

Introduction

This guide serves as a comprehensive checklist for B2B buyers evaluating the procurement of electric versus gas vehicles. As global markets shift towards sustainable transportation, understanding the nuances between these two options is crucial for making informed purchasing decisions. This checklist will guide you through the essential steps to assess your requirements, evaluate suppliers, and ultimately choose the vehicle that best aligns with your business needs.

Step 1: Define Your Operational Requirements

Begin by outlining the specific operational needs of your business. Consider factors such as fleet size, vehicle usage patterns, and geographic range.

- Usage Patterns: Determine how frequently vehicles will be used and for what purposes.

- Range Requirements: Assess the distance your vehicles need to cover on a daily basis, as this will influence your choice between electric and gas options.

Step 2: Evaluate Total Cost of Ownership (TCO)

Understanding the total cost of ownership is critical for long-term budgeting. Compare the initial purchase price, fuel costs, maintenance expenses, and potential resale value of both electric and gas vehicles.

- Fuel Costs: Analyze the average fuel costs based on current market prices in your region. Electric vehicles often have lower fuel costs, but this can vary significantly by location.

- Maintenance Costs: Consider that electric vehicles generally incur lower maintenance costs due to fewer moving parts.

Step 3: Research Incentives and Tax Benefits

Investigate available government incentives and tax benefits for purchasing electric vehicles in your region. These can significantly reduce your upfront costs.

- Local Incentives: Check for state or local programs that offer rebates or tax credits for electric vehicle purchases.

- International Opportunities: Explore any international agreements or partnerships that might provide additional benefits for sustainable vehicle investments.

Step 4: Assess Supplier Capabilities

Thoroughly evaluate potential suppliers of electric and gas vehicles. A reliable supplier can influence the overall satisfaction with your vehicle procurement.

Illustrative image related to electricity vs gas car

- Supplier Experience: Look for suppliers with a proven track record in delivering vehicles suited for your industry and region.

- Product Range: Ensure they offer a range of models that meet your defined operational requirements.

Step 5: Verify Vehicle Specifications and Features

Review the technical specifications and features of the vehicles you are considering. This includes efficiency ratings, charging capabilities, and safety features.

- Efficiency Ratings: For electric vehicles, check the kWh/100 miles metric to understand energy consumption.

- Charging Options: Consider the availability of charging infrastructure in your area, including the speed and type of chargers compatible with the vehicles.

Step 6: Conduct a Comparative Analysis

Create a comparative analysis of the shortlisted vehicles. This should include a side-by-side evaluation of costs, features, and expected performance.

- Cost-Benefit Analysis: Use spreadsheets to visualize the differences in TCO, including initial costs, operational savings, and environmental impact.

- Performance Metrics: Rate vehicles based on efficiency, reliability, and customer reviews to gauge overall satisfaction.

Step 7: Make an Informed Decision

After thorough evaluation, consolidate your findings to make an informed decision. Ensure that your choice aligns with both your operational needs and sustainability goals.

- Stakeholder Input: Involve key stakeholders in the decision-making process to ensure that all perspectives are considered.

- Long-Term Strategy: Consider how your vehicle choice fits into your company’s long-term sustainability and operational strategy.

By following this checklist, B2B buyers can make informed decisions regarding the procurement of electric versus gas vehicles, ensuring alignment with both financial and environmental objectives.

Comprehensive Cost and Pricing Analysis for electricity vs gas car Sourcing

What Are the Key Cost Components for Electric vs. Gas Cars?

When analyzing the cost structure of electric vehicles (EVs) versus gas-powered cars, several components come into play.

-

Materials: The manufacturing of EVs typically incurs higher material costs, primarily due to the lithium-ion batteries that are essential for their operation. However, prices for battery materials have been declining, which may help balance the cost over time. In contrast, gas vehicles primarily rely on traditional metals and components, which have stable pricing but can be affected by oil market fluctuations.

-

Labor: Labor costs can vary significantly based on the complexity of the vehicle. EV production often requires more skilled labor due to the sophisticated technology involved. Conversely, gas vehicle production may be more labor-intensive in assembly due to the larger number of moving parts.

-

Manufacturing Overhead: This includes costs related to facilities, equipment, and utilities. EV manufacturers may face higher initial overhead as they invest in advanced technology and production methods. Gas vehicle manufacturers, with established processes, may benefit from economies of scale.

-

Tooling and Quality Control (QC): Tooling costs for EVs can be significant due to the specialized equipment needed for battery assembly and electric drivetrains. Quality control is crucial in both categories, but EVs may require more rigorous testing protocols to ensure safety and efficiency, adding to overall costs.

-

Logistics: Transportation and distribution costs can differ based on the supply chain infrastructure. EVs often require specialized logistics for battery transport, which can increase costs, particularly in regions with less developed logistics networks.

-

Margin: Profit margins for EVs may be lower initially as manufacturers seek to penetrate the market. However, as technology matures and production scales, margins are expected to stabilize.

How Do Price Influencers Impact Sourcing Decisions?

Several factors influence pricing in the B2B sourcing of electric and gas vehicles:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to significant discounts. Buyers should negotiate MOQ terms to optimize their procurement costs.

-

Specifications and Customization: Custom features can significantly impact pricing. Buyers should assess whether they require specialized configurations, which can raise costs.

-

Materials and Quality Certifications: The choice of materials and adherence to quality standards can affect the final price. Opting for higher-quality components may increase costs but can lead to greater durability and lower maintenance expenses.

-

Supplier Factors: The reliability and reputation of suppliers play a critical role. Established suppliers may offer better warranties or support, which can justify a higher price.

-

Incoterms: Understanding Incoterms is essential for international transactions. They determine who is responsible for shipping costs, insurance, and risks, all of which can influence the overall cost structure.

What Buyer Tips Can Help Optimize Cost-Efficiency?

-

Negotiate Effectively: Leverage bulk purchasing and long-term relationships with suppliers to negotiate better terms and pricing. Be prepared to discuss volume projections and payment terms.

-

Assess Total Cost of Ownership (TCO): Beyond initial purchase price, consider fuel efficiency, maintenance, and potential resale value. EVs generally offer lower TCO over their lifespan due to reduced fuel and maintenance costs.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should consider currency fluctuations, import tariffs, and local incentives that can affect overall costs.

-

Conduct Market Research: Stay informed about market trends, including shifts in material costs and technology advancements that may impact pricing.

-

Evaluate Infrastructure Needs: Especially for EVs, assess the local charging infrastructure, as this can influence operational costs and vehicle usability.

Conclusion

While the initial costs of electric vehicles may be higher than those of gas-powered cars, the long-term savings in fuel and maintenance often make them a more cost-effective option. International B2B buyers should carefully evaluate the various cost components and pricing influencers to make informed purchasing decisions. Keep in mind that prices can vary significantly based on market conditions, so always seek updated quotes and consider the total cost of ownership for a comprehensive analysis.

Alternatives Analysis: Comparing electricity vs gas car With Other Solutions

Exploring Viable Alternatives to Electricity and Gas Cars

In today’s evolving automotive landscape, businesses are increasingly considering various vehicle solutions beyond traditional electricity and gas-powered cars. This section examines alternatives that not only meet transportation needs but also align with sustainability and cost-effectiveness goals. By evaluating different methods, B2B buyers can make informed decisions that suit their operational requirements.

| Comparison Aspect | Electricity Vs Gas Car | Hydrogen Fuel Cell Vehicles | Plug-in Hybrid Electric Vehicles |

|---|---|---|---|

| Performance | High torque, quick acceleration; range varies (150-370 miles) | Comparable to gas cars; quick refueling (3-5 min) | Combines electric and gas; electric range (20-50 miles) |

| Cost | Lower fuel and maintenance costs; initial price higher but incentives available | High infrastructure and vehicle costs; limited incentives | Moderate initial costs; lower fuel costs than gas cars |

| Ease of Implementation | Requires charging infrastructure; home charging possible | Limited refueling stations; high initial investment | Easier to implement; can use existing gas stations |

| Maintenance | Lower maintenance costs; fewer moving parts | Moderate; hydrogen tanks require inspections | Higher than EVs but lower than gas cars |

| Best Use Case | Urban fleets, long-distance travel with charging access | Long-distance travel; areas with hydrogen infrastructure | Mixed driving environments; flexibility for short and long trips |

Hydrogen Fuel Cell Vehicles: Pros and Cons

Hydrogen fuel cell vehicles (FCVs) present a promising alternative to electricity and gas cars. They offer quick refueling times, similar to traditional gasoline vehicles, making them suitable for long-haul operations. However, the high costs associated with hydrogen production and the limited availability of refueling infrastructure present significant challenges. Businesses in regions where hydrogen stations are prevalent may find FCVs advantageous, particularly for fleets that require extended range without lengthy downtime.

Plug-in Hybrid Electric Vehicles: Pros and Cons

Plug-in hybrid electric vehicles (PHEVs) provide a flexible alternative, combining an electric motor with a gasoline engine. This duality allows users to drive short distances on electric power alone, while also having the capability to travel longer distances using gasoline. PHEVs generally have a lower initial cost compared to full EVs and can utilize existing gas stations, making them easier to implement. However, they do require regular maintenance for both the electric and combustion systems, which can increase overall upkeep costs.

Making the Right Choice for Your B2B Needs

When deciding between electricity vs. gas cars and their alternatives, businesses should consider their specific operational requirements, including driving range, refueling infrastructure, and budget constraints. Factors like maintenance costs, ease of implementation, and performance characteristics will also influence the best choice. As the market for sustainable transportation continues to evolve, companies should remain informed about technological advancements and regional infrastructure developments to ensure they select the most efficient and cost-effective solution for their fleets.

Illustrative image related to electricity vs gas car

Essential Technical Properties and Trade Terminology for electricity vs gas car

What Are the Key Technical Properties of Electric and Gas Cars?

When evaluating electric vehicles (EVs) versus gas-powered vehicles, understanding critical specifications is essential for B2B buyers. The following properties play a significant role in assessing performance, cost, and long-term viability.

1. Battery Capacity (kWh)

Battery capacity, measured in kilowatt-hours (kWh), indicates how much energy an electric vehicle can store. A higher kWh rating typically translates to a longer driving range on a single charge. For B2B buyers, understanding battery capacity is crucial as it impacts operational efficiency, total cost of ownership, and potential customer satisfaction in fleet management.

2. Energy Efficiency (MPGe)

Energy efficiency is often expressed in miles per gallon equivalent (MPGe) for electric vehicles, measuring how far a vehicle can travel using the energy equivalent of one gallon of gasoline. This specification helps businesses project fuel costs and compare the economic viability of different vehicle types. Higher MPGe ratings indicate lower energy costs per mile, which can significantly influence operational budgets.

3. Charging Time (Hours)

Charging time refers to the duration required to recharge an electric vehicle’s battery fully. Charging options vary from Level 1 (standard home outlets) to Level 3 (DC fast chargers). For B2B operations, understanding charging times is essential for planning fleet usage and minimizing downtime, particularly in logistics and delivery services.

4. Maintenance Costs

Electric vehicles generally incur lower maintenance costs due to fewer moving parts and the absence of traditional engine components like oil and spark plugs. This property is significant for businesses evaluating total cost of ownership. Lower maintenance translates to reduced operational costs and less frequent vehicle downtime, enhancing overall efficiency.

5. Range (Miles)

The range of a vehicle indicates the maximum distance it can travel on a full tank or charge. For electric vehicles, this is particularly important as it affects the practicality of daily operations. Businesses must consider range when planning routes, especially in regions with limited charging infrastructure.

6. Towing Capacity (Pounds)

Towing capacity refers to the maximum weight a vehicle can safely tow. This specification is critical for businesses involved in logistics, construction, or any industry requiring transport of heavy loads. While traditional gas vehicles typically have higher towing capacities, advancements in electric vehicle technology are closing this gap.

What Are Common Trade Terms in the Electric and Gas Vehicle Industry?

Understanding industry terminology is crucial for effective communication and negotiation in the automotive sector. Here are several key terms relevant to electric and gas vehicles:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the automotive industry, OEMs design and manufacture vehicles or components. B2B buyers must consider OEM relationships to ensure quality and compatibility in vehicle sourcing.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For electric and gas vehicles, understanding MOQ is vital for procurement strategies, especially when acquiring fleet vehicles or parts. This can impact cash flow and inventory management for businesses.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. B2B buyers utilize RFQs to compare costs and negotiate terms effectively, ensuring they obtain the best value for electric or gas vehicle purchases.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Understanding these terms is essential for B2B transactions involving vehicle imports or exports, as they clarify delivery responsibilities, insurance, and risk management.

5. Lifecycle Cost

Lifecycle cost encompasses all costs associated with a vehicle over its entire lifespan, including acquisition, operation, maintenance, and disposal. For B2B buyers, evaluating lifecycle costs helps make informed decisions about vehicle investments, ensuring long-term profitability.

6. Telematics

Telematics refers to the integration of telecommunications and monitoring systems in vehicles, providing real-time data on performance, location, and maintenance needs. For businesses, leveraging telematics can enhance fleet management efficiency and optimize operational strategies.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational goals and financial constraints in the evolving landscape of electric and gas vehicles.

Navigating Market Dynamics and Sourcing Trends in the electricity vs gas car Sector

What Are the Current Market Dynamics and Key Trends in the Electricity vs. Gas Car Sector?

The global automotive landscape is undergoing a significant transformation driven by technological advancements, regulatory changes, and shifting consumer preferences. For international B2B buyers, particularly in emerging markets like Africa, South America, and the Middle East, understanding these dynamics is crucial. The demand for electric vehicles (EVs) is surging, with a notable shift from traditional gas-powered cars. According to recent market analyses, the average price of new EVs is dropping, making them more accessible to businesses looking to invest in sustainable fleets. This trend is further bolstered by governmental incentives aimed at reducing carbon emissions, which can significantly lower the total cost of ownership for businesses.

Moreover, the supply chain for EVs is evolving, with a focus on local sourcing of materials and components, particularly batteries. In regions such as Africa and South America, local mining of lithium and cobalt is gaining traction, providing opportunities for B2B partnerships that align with sustainability goals. Additionally, the integration of smart technology in vehicles is reshaping sourcing trends; features such as advanced telematics and connectivity are becoming essential, enhancing fleet management and operational efficiency.

As businesses navigate these changes, they must also consider the implications of fluctuating energy prices. The stability of electricity costs compared to the volatility of gas prices is a significant factor influencing the decision-making process for fleet management. Companies are increasingly evaluating their long-term energy strategies, considering both the economic benefits and environmental impact of their vehicle choices.

How Can Sustainability and Ethical Sourcing Impact the Electricity vs. Gas Car Sector?

Sustainability has become a cornerstone of modern business practices, particularly in the automotive sector. The environmental impact of vehicle emissions is a pressing concern, driving companies to consider greener alternatives. Electric vehicles offer a substantial reduction in greenhouse gas emissions compared to gas-powered cars, aligning with global climate goals. For B2B buyers, the transition to EVs not only reflects corporate responsibility but also meets the growing demand for sustainable practices from customers and stakeholders.

Ethical sourcing is integral to this transition, especially concerning the materials used in EV batteries, such as lithium, cobalt, and nickel. The extraction of these materials often raises ethical concerns regarding labor practices and environmental degradation. As a result, businesses are increasingly seeking suppliers that adhere to ethical standards and sustainability certifications. Engaging with manufacturers who prioritize transparent supply chains and environmentally friendly practices can enhance a company’s brand reputation and foster customer loyalty.

Moreover, certifications like ISO 14001 (Environmental Management) and the Responsible Cobalt Initiative are becoming critical in supplier evaluations. These certifications not only assure buyers of sustainable practices but also mitigate risks associated with supply chain disruptions and regulatory compliance, ultimately contributing to a more resilient business model.

What Has Been the Evolution of the Electricity vs. Gas Car Sector?

The evolution of the electricity vs. gas car sector dates back to the late 19th century, when electric vehicles were among the first to hit the roads. However, the rise of gasoline-powered cars in the early 20th century, fueled by mass production techniques, overshadowed their electric counterparts. Fast forward to the 21st century, and the narrative has changed dramatically.

With increasing awareness of climate change and advancements in battery technology, electric vehicles have gained renewed attention and investment. Legislative frameworks across Europe, Asia, and the Americas now favor EV adoption, with many countries setting ambitious targets for phasing out internal combustion engines. This evolution presents a unique opportunity for B2B buyers to adapt their sourcing strategies and embrace a future where electric vehicles play a dominant role in transportation, aligning their operations with global sustainability initiatives.

As businesses continue to navigate this dynamic landscape, they must remain agile and informed, leveraging emerging trends to enhance their competitive edge in the evolving automotive market.

Illustrative image related to electricity vs gas car

Frequently Asked Questions (FAQs) for B2B Buyers of electricity vs gas car

1. How do I determine whether to invest in electric or gas vehicles for my fleet?

To make an informed decision, analyze the total cost of ownership for both electric and gas vehicles. Consider factors such as upfront costs, maintenance expenses, fuel costs, and potential government incentives. Additionally, evaluate the operational requirements of your fleet, including range, charging infrastructure, and local electricity prices. Conduct a cost-benefit analysis over the expected lifespan of the vehicles to identify which option aligns better with your budget and sustainability goals.

2. What is the best electric vehicle for commercial use?

The best electric vehicle (EV) for commercial use largely depends on your specific business needs. Factors to consider include payload capacity, range, and charging time. Popular options for commercial fleets include the Tesla Model Y for its range and performance, the Ford E-Transit for cargo transport, and the Rivian R1T for versatility. Evaluate models based on their efficiency, local charging infrastructure, and available government incentives to maximize your investment.

3. What are the key differences in maintenance costs between electric and gas vehicles?

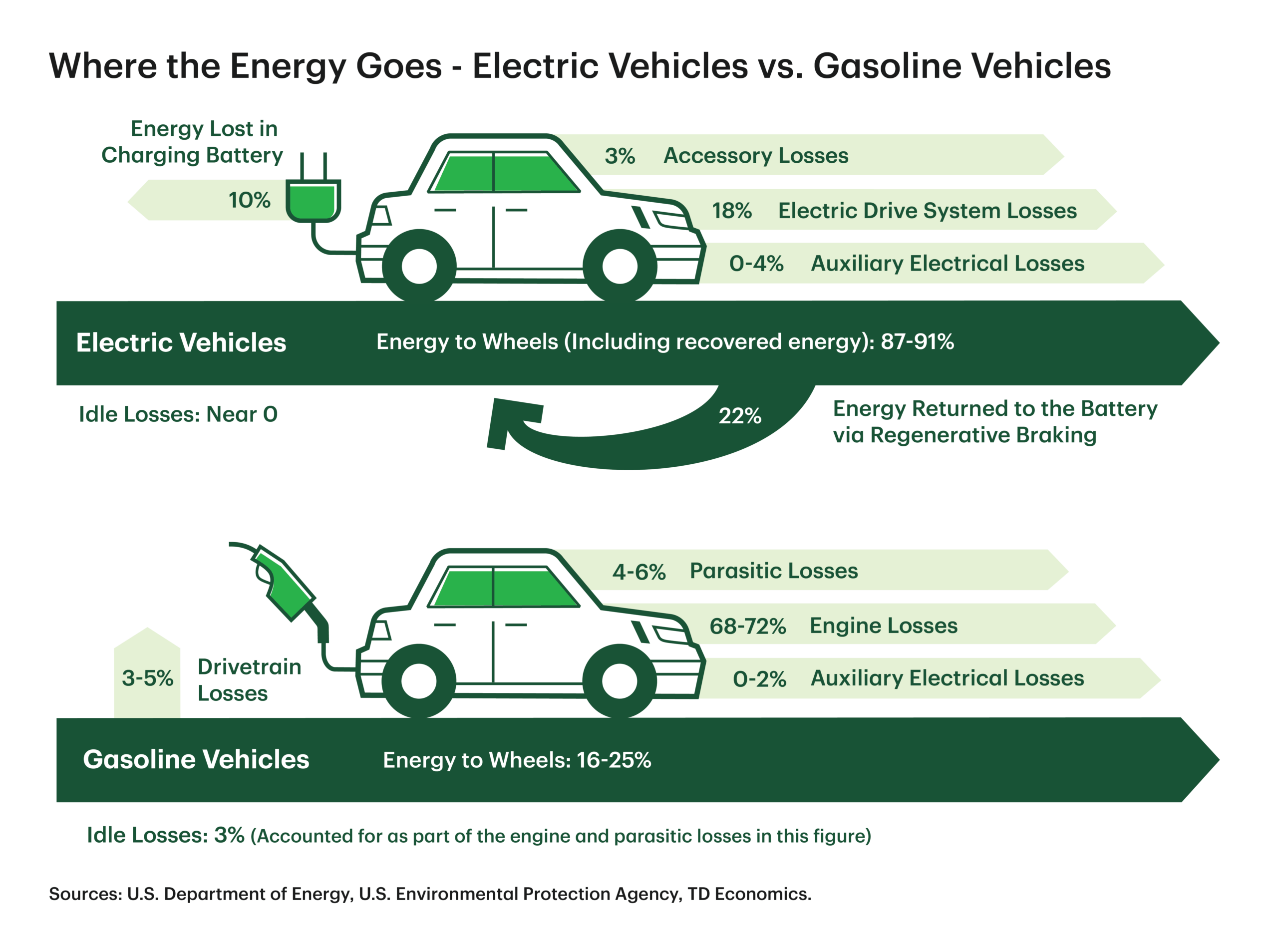

Electric vehicles generally have lower maintenance costs compared to gas vehicles. They do not require oil changes, have fewer moving parts, and feature regenerative braking, which extends brake life. Studies indicate that maintenance costs for EVs can be up to 40% lower than for comparable gas vehicles. However, it’s essential to factor in battery replacement costs, which can be significant, depending on the vehicle’s age and warranty.

4. How do I evaluate suppliers for electric vehicles?

When vetting suppliers for electric vehicles, assess their reputation, experience in the market, and compliance with local regulations. Request references from previous clients and examine their after-sales support and warranty terms. Additionally, inquire about the availability of charging infrastructure and their ability to provide customization options tailored to your fleet’s needs. Conducting site visits to supplier facilities can also provide insights into their operational capabilities.

Illustrative image related to electricity vs gas car

5. What payment terms are typical when sourcing electric vehicles internationally?

Payment terms for international purchases of electric vehicles can vary widely. Common arrangements include letters of credit, advance payments, or payment upon delivery. It’s crucial to negotiate terms that align with your cash flow and risk tolerance. Additionally, consider currency exchange rates and potential tariffs that could affect overall costs. Always ensure that payment terms are documented clearly in the purchase agreement to avoid disputes.

6. What minimum order quantities (MOQ) should I expect when sourcing electric vehicles?

Minimum order quantities (MOQ) can differ based on the supplier and the specific model of the vehicle. Some manufacturers may have strict MOQs, particularly for customized orders, while others may accommodate smaller orders, especially for new entrants in the market. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms that suit your fleet size and budget.

7. How can I ensure quality assurance (QA) for electric vehicles purchased internationally?

To ensure quality assurance for your international electric vehicle purchases, establish clear specifications and standards in your purchase agreement. Request certifications and compliance documentation that demonstrate adherence to local and international safety and environmental standards. Additionally, consider engaging third-party inspection services to assess vehicles before shipment. Regular communication with your supplier throughout the production process can also help address any quality concerns promptly.

8. What logistics considerations should I keep in mind when importing electric vehicles?

When importing electric vehicles, consider logistics factors such as shipping methods, customs clearance, and local regulations regarding vehicle emissions and safety standards. Work with experienced logistics providers familiar with the automotive industry to navigate these complexities. Ensure you account for lead times, potential delays at ports, and the costs associated with transportation and insurance. Additionally, understand the import duties and taxes applicable in your destination country to manage your budget effectively.

Top 3 Electricity Vs Gas Car Manufacturers & Suppliers List

1. Gas vs Electric Cars – Key Comparison Points

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Gas vs Electric Cars comparison highlights: 1. Material weight: Gas cars use 3800 lbs of materials, while electric cars use 6000 lbs. 2. Range: Electric cars have limited range with long charging times, whereas gas cars offer almost unlimited range. 3. Operating costs: Year-over-year costs of gas and electric are becoming similar, with recent calculations showing the difference per mile is minimal…

2. Constellation – Electric vs. Gas Cars Comparison

Domain: constellation.com

Registered: 1996 (29 years)

Introduction: Electric Cars vs. Gas Cars comparison focuses on several key aspects: 1. Cost Considerations: Beyond the sticker price, factors like power and maintenance costs are crucial. 2. Tax Credits: Eligible for a tax credit of 30% on labor for EV charger installation, up to $1,000. 3. Fuel Costs: Charging an EV versus filling a gas car varies based on local fuel prices and driving habits. EVs generally co…

3. Premium Autos Inc – Electric vs Gas Cars Guide

Domain: premiumautosinc.com

Registered: 2015 (10 years)

Introduction: Electric vs Gas Cars: True Cost of Ownership Guide, Locations: Norco, CA and El Monte, CA, Contact: (951) 220-8952, Inventory includes: Used Toyota, Used Tesla, Electric SUVs, Sports Cars, Trucks. Featured vehicles: 2021 Jeep Wrangler Unlimited Sport 80th Anniversary – $23,759, 2022 Dodge Charger SRT Hellcat Widebody – $67,996, 2019 Tesla Model S – $25,900, 2023 Toyota GR Corolla – $32,900, 2020 D…

Strategic Sourcing Conclusion and Outlook for electricity vs gas car

As the global automotive landscape evolves, B2B buyers must strategically evaluate the benefits of electric vehicles (EVs) versus gas-powered cars. The long-term cost savings associated with EVs are significant, driven by lower fuel and maintenance costs. With the average price of EVs decreasing and incentives still available, now is the opportune time for businesses to invest in electric fleets.

Strategic sourcing not only enhances operational efficiency but also aligns with corporate sustainability goals. By transitioning to electric vehicles, companies can reduce their carbon footprint, contributing positively to environmental efforts while also capitalizing on cost-effective mobility solutions.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, the shift towards electric vehicles is not merely a trend but a critical business decision. Leveraging the financial and environmental advantages of EVs can position companies as leaders in their markets. As you explore options, consider the specific incentives and infrastructure available in your region to maximize your investment. The future is electric—embrace it to drive innovation and sustainability in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to electricity vs gas car

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.