Introduction: Navigating the Global Market for changing starter motor

In the fast-paced automotive industry, sourcing reliable solutions for changing starter motors poses a significant challenge for B2B buyers across global markets. A malfunctioning starter motor can lead to unexpected downtime, affecting operational efficiency and customer satisfaction. This guide is designed to empower international buyers from regions such as Africa, South America, the Middle East, and Europe, by providing a comprehensive overview of the starter motor replacement landscape.

Within these pages, you will find in-depth insights into various types of starter motors, their applications in diverse vehicle models, and the critical factors to consider when evaluating potential suppliers. We also delve into the costs associated with purchasing and installing starter motors, equipping you with the knowledge to make informed financial decisions. Additionally, this guide outlines best practices for vetting suppliers, ensuring you partner with reputable manufacturers who meet your quality and service expectations.

By understanding the nuances of changing starter motors, you will be better positioned to navigate the complexities of the global market. This resource not only enhances your purchasing strategy but also supports your commitment to providing high-quality automotive solutions, ultimately driving your business success in an increasingly competitive environment.

Table Of Contents

- Top 5 Changing Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for changing starter motor

- Understanding changing starter motor Types and Variations

- Key Industrial Applications of changing starter motor

- 3 Common User Pain Points for ‘changing starter motor’ & Their Solutions

- Strategic Material Selection Guide for changing starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for changing starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘changing starter motor’

- Comprehensive Cost and Pricing Analysis for changing starter motor Sourcing

- Alternatives Analysis: Comparing changing starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for changing starter motor

- Navigating Market Dynamics and Sourcing Trends in the changing starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of changing starter motor

- Strategic Sourcing Conclusion and Outlook for changing starter motor

- Important Disclaimer & Terms of Use

Understanding changing starter motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gear Reduction Starter | Uses gears to amplify torque, ideal for high-compression engines | Heavy machinery, performance vehicles | Pros: High torque output; Cons: More complex installation. |

| Permanent Magnet Starter | Compact design using permanent magnets for efficiency | Automotive, motorcycles | Pros: Lightweight; Cons: Limited torque compared to gear starters. |

| High-Performance Starter | Designed for racing and extreme conditions | Motorsports, custom builds | Pros: Enhanced performance; Cons: Higher cost and may require modifications. |

| Mini Starter | Smaller size for tight engine compartments | Classic cars, compact vehicles | Pros: Space-saving; Cons: May have lower power output. |

| Solenoid-Integrated Starter | Combines solenoid and starter motor in one unit | General automotive applications | Pros: Simplified installation; Cons: Potential for higher failure rates. |

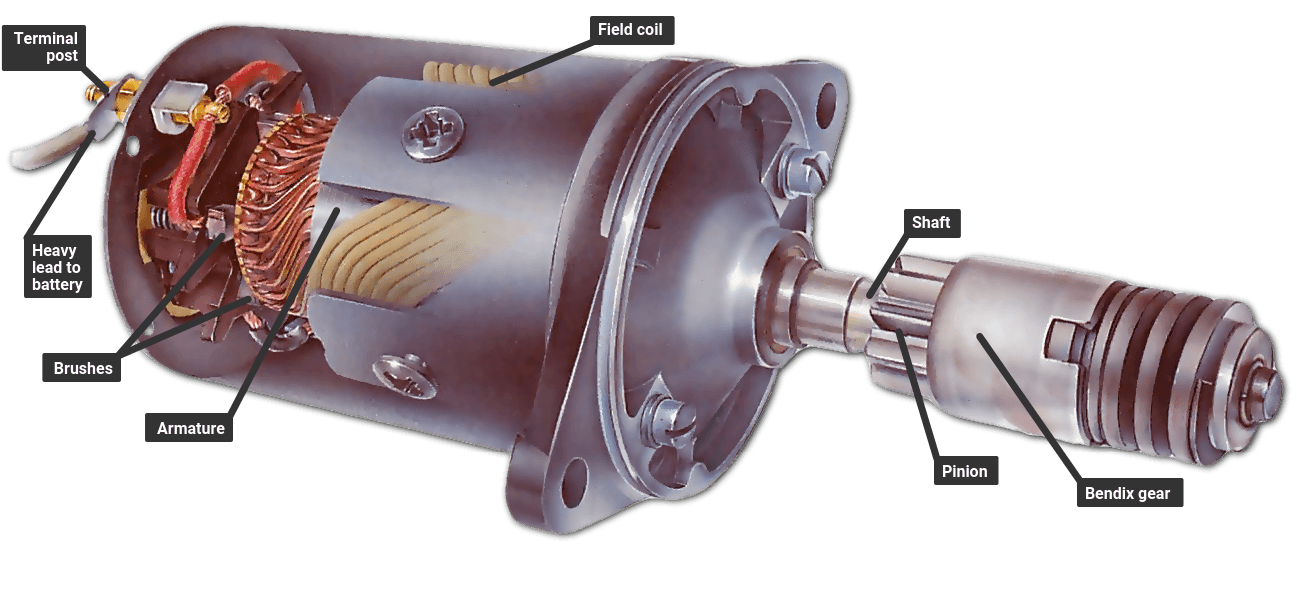

What Are Gear Reduction Starters and Their Key Applications?

Gear reduction starters leverage a system of gears to significantly increase the torque output, making them suitable for high-compression engines commonly found in heavy machinery and performance vehicles. These starters are ideal for applications where high torque is necessary to overcome engine resistance. When considering procurement, B2B buyers should evaluate the specific torque requirements of their vehicles and the complexity of installation, as these starters may require specialized knowledge for effective installation.

How Do Permanent Magnet Starters Differ in Performance?

Permanent magnet starters utilize magnets instead of coils to generate the magnetic field, which makes them more compact and efficient. They are predominantly used in standard automotive applications and motorcycles where weight savings are critical. B2B buyers should consider the balance between weight and torque requirements, as these starters may not deliver the same high torque as gear reduction models but are excellent for everyday use and smaller engines.

What Makes High-Performance Starters Suitable for Motorsports?

High-performance starters are engineered to withstand the rigors of racing and extreme conditions, offering superior cranking power and reduced weight. These starters are essential for motorsport applications where reliability and performance are paramount. Buyers in the B2B space should be prepared for a higher investment and potential modifications to their vehicles, as these products are typically designed for specific performance needs.

Why Choose Mini Starters for Space-Constrained Vehicles?

Mini starters are designed for applications where space is limited, such as in classic cars and compact vehicles. Their smaller size allows for easier installation in tight engine compartments, making them a popular choice among restoration shops and custom vehicle builders. However, B2B buyers should be cautious about the potential for lower power output and assess whether the reduced size meets their specific operational requirements.

What Are the Benefits and Drawbacks of Solenoid-Integrated Starters?

Solenoid-integrated starters combine the solenoid and starter motor into a single unit, simplifying installation and reducing the number of components. They are commonly used in general automotive applications, providing an efficient solution for many vehicles. However, B2B buyers should be aware of the potential for higher failure rates compared to traditional setups, and consider the long-term reliability of these integrated units in their purchasing decisions.

Key Industrial Applications of changing starter motor

| Industry/Sector | Specific Application of changing starter motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Replacement of starter motors in vehicles | Restores vehicle functionality, minimizing downtime | Quality of parts, warranty terms, and installation support |

| Transportation | Fleet maintenance for commercial vehicles | Ensures reliability, reducing operational disruptions | Bulk purchasing options, compatibility with various vehicle models |

| Agriculture | Starting motors for agricultural machinery | Enhances productivity by ensuring equipment readiness | Availability of specialized starters for different machinery types |

| Construction | Heavy machinery starter replacements | Reduces equipment failure rates, ensuring project timelines are met | Durability under harsh conditions, sourcing from reliable suppliers |

| Mining | Starter motor replacements in mining equipment | Prevents costly delays due to equipment failure | Compliance with safety standards, sourcing from local suppliers for faster delivery |

How is ‘Changing Starter Motor’ Utilized in Automotive Repair?

In the automotive repair sector, changing starter motors is a routine yet critical service. As vehicles age, starter motors can fail due to wear and tear, affecting engine ignition. For repair shops, having access to quality starter motors can significantly reduce vehicle downtime, leading to higher customer satisfaction and repeat business. B2B buyers in this sector should prioritize sourcing reliable parts with good warranty terms to ensure longevity and performance.

What Role Does Changing Starter Motors Play in Transportation Fleet Management?

For businesses managing transportation fleets, maintaining operational efficiency is paramount. A faulty starter motor can lead to unexpected vehicle failures, disrupting schedules and increasing costs. By regularly changing starter motors in their fleet, businesses can enhance vehicle reliability and minimize operational disruptions. Buyers should consider bulk purchasing options and ensure compatibility with various vehicle models to streamline their maintenance processes.

How is ‘Changing Starter Motor’ Applied in Agriculture?

In agriculture, machinery like tractors and harvesters rely heavily on functional starter motors to ensure timely operations during planting and harvesting seasons. A malfunctioning starter can delay critical tasks, impacting productivity. By investing in high-quality starter motors, agricultural businesses can enhance the readiness of their equipment. Buyers should look for specialized starters that cater to different machinery types and ensure a reliable supply chain to avoid downtime.

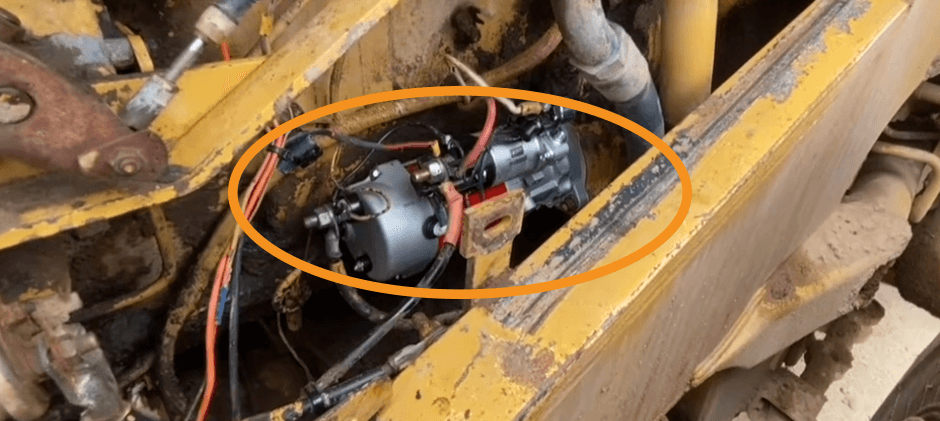

Why is Changing Starter Motors Important for Construction Equipment?

Heavy machinery in the construction industry often faces extreme conditions, leading to increased wear on starter motors. Regularly changing these components helps prevent equipment failures that could derail project timelines. For construction companies, sourcing durable starter motors that can withstand harsh environments is essential. Buyers should focus on suppliers who provide robust products and can guarantee timely delivery to support ongoing projects.

What are the Benefits of Changing Starter Motors in Mining Operations?

In mining, the reliability of equipment is critical for operational success. Starter motor failures can lead to significant delays and financial losses. Regularly changing starter motors in mining equipment ensures that operations run smoothly, minimizing downtime. B2B buyers in this sector should prioritize compliance with safety standards and consider sourcing from local suppliers to ensure fast delivery and support, especially in remote mining locations.

3 Common User Pain Points for ‘changing starter motor’ & Their Solutions

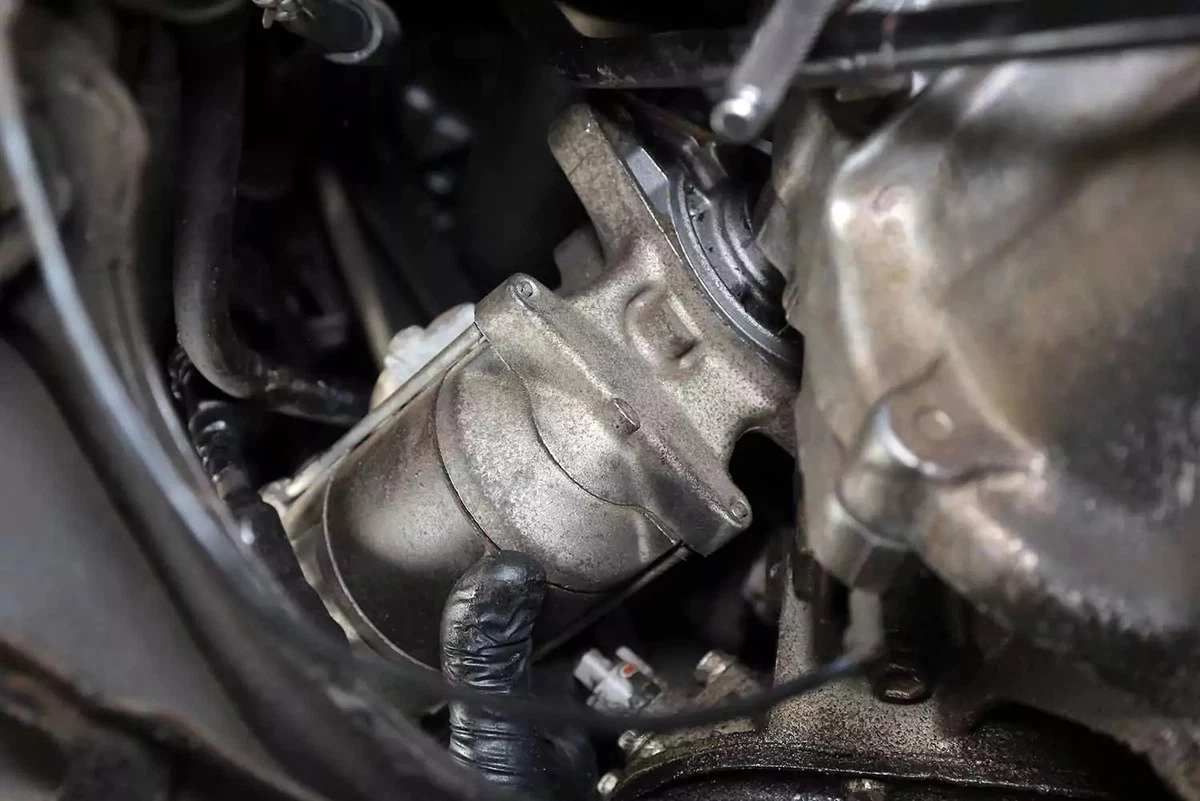

Scenario 1: Difficulty in Identifying a Failing Starter Motor

The Problem: Many B2B buyers, such as fleet managers or auto repair shop owners, encounter challenges when diagnosing starter motor issues. Symptoms like slow cranking, clicking sounds, or unusual noises can indicate problems, but these signs can also be attributed to other electrical failures or battery issues. This ambiguity often leads to misdiagnosis, wasted time, and unnecessary replacement of parts, resulting in higher operational costs and increased downtime for vehicles.

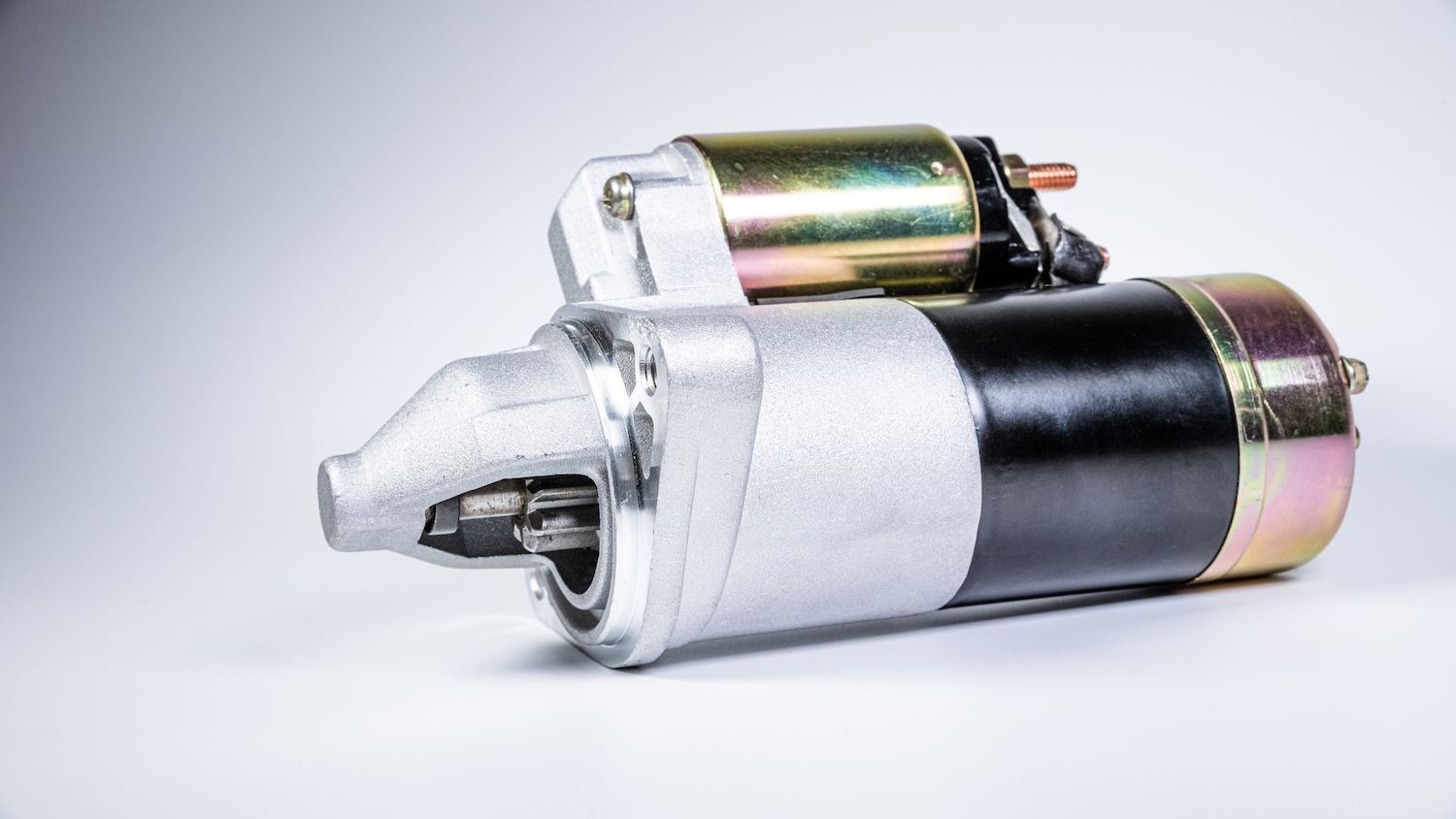

Illustrative image related to changing starter motor

The Solution: Implement a systematic diagnostic approach that combines visual inspection with electrical testing. Encourage your team to utilize a multimeter to check battery voltage and starter current draw. A healthy battery should read around 12.6 volts, while the starter draw should not exceed manufacturer specifications during cranking. By training technicians in these diagnostic techniques, you can reduce misdiagnosis rates. Additionally, consider investing in diagnostic tools that can analyze starter motor performance under load, helping to pinpoint issues accurately before deciding to replace the starter motor.

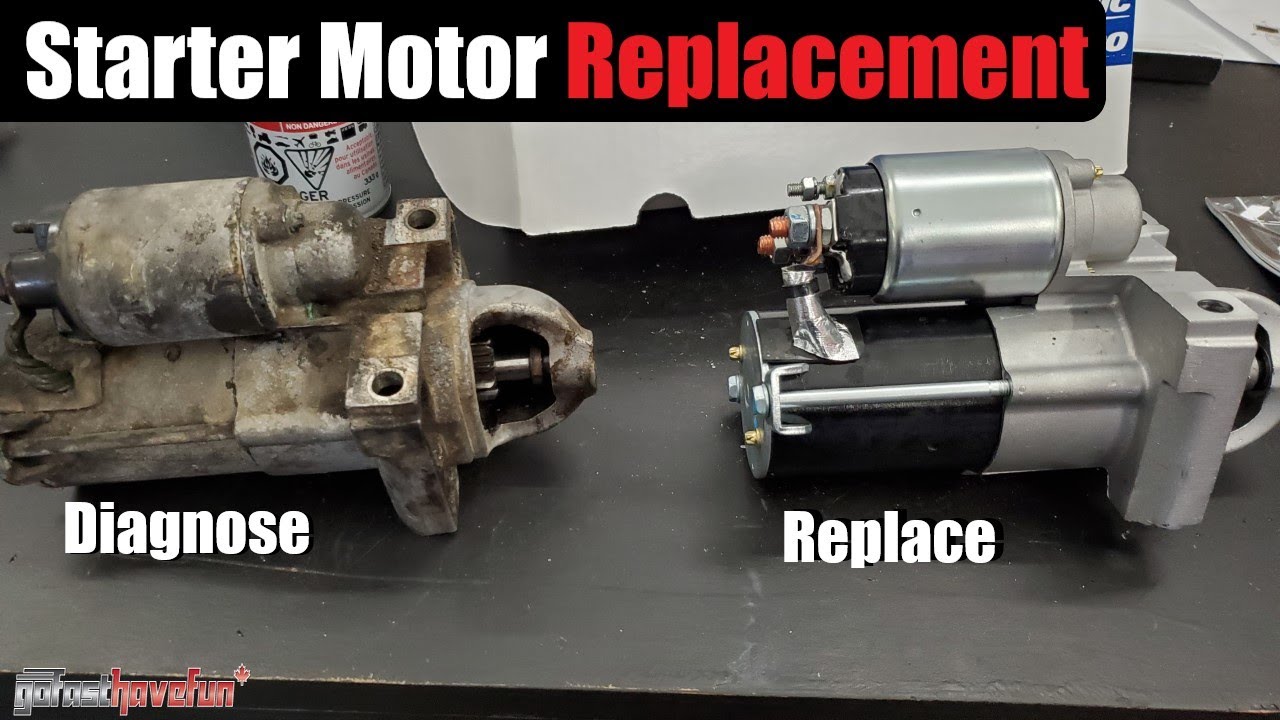

Scenario 2: Sourcing Quality Starter Motors Amidst Supply Chain Issues

The Problem: International buyers often face the challenge of sourcing reliable starter motors due to fluctuating supply chain dynamics, particularly in regions like Africa and South America where access to quality parts may be limited. Compounded by the fact that not all aftermarket parts meet OEM standards, businesses risk purchasing subpar products that could lead to premature failures, further complicating repairs and increasing costs.

The Solution: Build strong relationships with reputable suppliers who have a proven track record of providing quality starter motors. Conduct thorough research to identify manufacturers that offer warranties and have established quality control processes. Consider joining a buying group or cooperative to enhance your purchasing power and gain access to bulk discounts. Additionally, leverage online platforms that specialize in B2B auto parts to compare prices and reviews from other businesses, ensuring that you are making informed purchasing decisions. This proactive approach not only secures quality parts but also mitigates future supply disruptions.

Illustrative image related to changing starter motor

Scenario 3: Labor Costs and Time Constraints in Starter Motor Replacement

The Problem: B2B buyers often grapple with high labor costs and time constraints when it comes to changing starter motors. The replacement process can be time-consuming, sometimes taking several hours, depending on the vehicle model. For businesses operating with tight schedules, this can lead to significant downtime and loss of productivity, ultimately affecting the bottom line.

The Solution: Streamline the replacement process by investing in comprehensive training programs for your technicians. Provide them with hands-on experience through workshops and access to detailed service manuals that include vehicle-specific starter motor replacement procedures. Additionally, equip your service bays with high-quality tools and diagnostic equipment to expedite the process. Consider establishing a standard operating procedure (SOP) that outlines each step of the starter motor replacement, allowing for quicker onboarding of new technicians and minimizing errors. By enhancing your team’s skill set and providing the right tools, you can reduce labor times and costs, ultimately improving overall operational efficiency.

Strategic Material Selection Guide for changing starter motor

When selecting materials for changing starter motors, it is essential to consider the characteristics that will influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in starter motor components: steel, aluminum, copper, and composite materials. Each material has unique properties that can significantly affect the performance and longevity of the starter motor.

Illustrative image related to changing starter motor

What Are the Key Properties of Steel in Starter Motors?

Steel is widely used in starter motors due to its high strength and durability. It typically exhibits excellent temperature resistance and can withstand significant mechanical stress, making it suitable for the harsh conditions often encountered in automotive applications. Steel’s corrosion resistance can be improved through coatings or galvanization, but it is inherently prone to rust if exposed to moisture.

Pros and Cons of Steel:

– Pros: High strength, excellent wear resistance, relatively low cost, and good machinability.

– Cons: Heavier than alternative materials, potential for corrosion without protective coatings, and lower electrical conductivity compared to copper.

Impact on Application: Steel components can endure the high torque required to engage the starter motor, ensuring reliable performance. However, the weight may affect the overall vehicle efficiency.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or JIS G3101 is crucial. Buyers in regions like Africa and South America should consider the availability of corrosion-resistant coatings to enhance longevity in humid environments.

How Does Aluminum Perform in Starter Motor Applications?

Aluminum is another popular choice for starter motors, particularly for housing and brackets. It is lightweight and offers good corrosion resistance, making it ideal for applications where weight reduction is critical. Aluminum can also dissipate heat effectively, which is beneficial for maintaining operational efficiency.

Pros and Cons of Aluminum:

– Pros: Lightweight, good corrosion resistance, excellent thermal conductivity, and lower manufacturing complexity.

– Cons: Lower strength compared to steel, higher cost, and can be prone to deformation under extreme pressure.

Impact on Application: The lightweight nature of aluminum can improve vehicle fuel efficiency, while its thermal properties help manage heat generated during operation. However, its lower strength may limit its use in high-stress applications.

Considerations for International Buyers: Compliance with standards like ASTM B221 or DIN EN 573 is essential. Buyers in Europe may prefer aluminum due to stringent weight regulations in automotive design.

What Role Does Copper Play in Starter Motor Functionality?

Copper is primarily used for electrical connections and windings within starter motors due to its excellent electrical conductivity. It can handle high current loads, which is critical for the initial cranking of the engine.

Pros and Cons of Copper:

– Pros: Superior electrical conductivity, excellent thermal properties, and high ductility.

– Cons: Higher cost compared to aluminum and steel, and susceptible to corrosion without proper treatment.

Impact on Application: Copper’s conductivity ensures efficient energy transfer, which is vital for the starter’s performance. However, its cost may be a concern for budget-conscious buyers.

Considerations for International Buyers: Compliance with JIS H3100 or ASTM B170 is important. Buyers in regions with high humidity, such as the Middle East, should consider copper coatings to prevent oxidation.

Illustrative image related to changing starter motor

How Do Composite Materials Benefit Starter Motor Design?

Composite materials, often used in modern automotive applications, offer a balance between weight and strength. These materials can be engineered to provide specific properties, such as high resistance to heat and chemicals.

Pros and Cons of Composite Materials:

– Pros: Lightweight, customizable properties, excellent corrosion resistance, and potential for lower manufacturing costs.

– Cons: Higher initial material costs and potential challenges in recycling and disposal.

Impact on Application: Composites can enhance the overall performance of starter motors by reducing weight and improving resistance to environmental factors. However, the long-term durability may vary based on the specific composite used.

Considerations for International Buyers: Compliance with international standards such as ASTM D638 is necessary. In regions like Brazil, where environmental regulations are stringent, composites may be favored for their recyclability.

Summary Table of Material Selection for Starter Motors

| Material | Typical Use Case for changing starter motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Starter housing and structural components | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Housing and brackets | Lightweight and corrosion-resistant | Lower strength | High |

| Copper | Electrical connections and windings | Superior electrical conductivity | Higher cost | High |

| Composite | Various components for weight reduction | Customizable properties | Higher initial material costs | Medium |

This analysis provides a comprehensive overview of material selection for changing starter motors, highlighting key properties, advantages, and considerations for international B2B buyers. Understanding these factors will enable buyers to make informed decisions that align with their operational needs and regional regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for changing starter motor

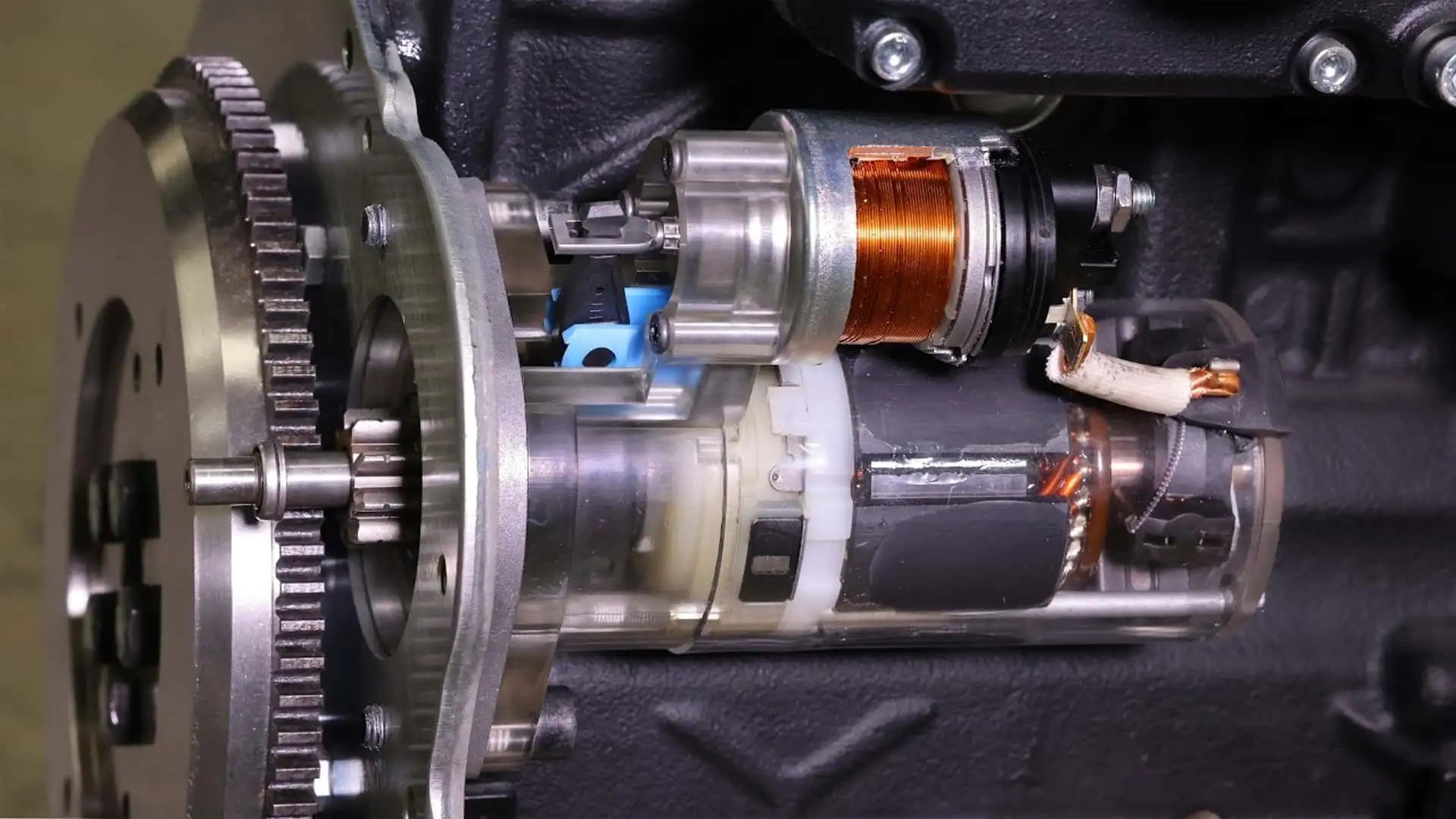

What Are the Key Stages in the Manufacturing Process of Starter Motors?

The manufacturing process for starter motors is complex, involving several crucial stages that ensure the product meets high-performance standards. Understanding these stages is vital for B2B buyers aiming to source reliable components.

Material Preparation: What Materials Are Used in Starter Motor Manufacturing?

The first stage of manufacturing involves the preparation of raw materials. Starter motors typically utilize high-grade steel for the casing, copper for windings, and various alloys for components like the pinion gear and solenoid. The selection of materials is critical as it directly impacts durability and performance. Suppliers often source materials from certified vendors to ensure compliance with international standards.

Illustrative image related to changing starter motor

Forming: How Are Components Shaped and Assembled?

Once materials are prepared, the forming stage begins. Techniques such as stamping, forging, and machining are employed to shape components precisely. For instance, the stator and rotor are machined to exact specifications to ensure optimal electrical performance. Advanced CNC (Computer Numerical Control) machines are often used for precision, significantly reducing tolerances and improving part uniformity.

Assembly: What Are the Steps Involved in Assembling a Starter Motor?

After forming, the assembly process takes place. This stage involves fitting components like the armature, field coils, and solenoid into the casing. Assembly is often done in a controlled environment to minimize contamination and defects. Skilled technicians utilize specific torque settings and assembly jigs to ensure that each part is securely fastened and aligned correctly.

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage includes processes like painting, plating, or coating to protect the starter motor from environmental factors and corrosion. Quality checks are performed at this stage to ensure that the aesthetic and functional aspects meet the required standards.

What Quality Assurance Measures Are Essential for Starter Motors?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each starter motor meets or exceeds industry standards.

Illustrative image related to changing starter motor

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are crucial for assessing the quality management systems of suppliers. This certification indicates that a manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, CE marking is relevant for products sold in Europe, signifying compliance with health, safety, and environmental protection standards.

What Are the Key QC Checkpoints During Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step ensures that all raw materials and components meet specified quality standards before production begins. Suppliers are often required to provide material certification.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are conducted to monitor the quality of the parts being produced. This includes dimensional checks and functional tests to ensure that components are being formed and assembled correctly.

-

Final Quality Control (FQC): After assembly, the finished product undergoes rigorous testing. This can involve electrical performance tests, load testing, and durability assessments to ensure the starter motor operates as intended.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is vital for ensuring reliable product performance.

What Methods Are Available for Supplier Audits?

Buyers can conduct audits of potential suppliers to assess their manufacturing processes and quality control measures. This includes reviewing documentation such as quality manuals, inspection records, and certifications.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services often include pre-shipment inspections, where samples are tested for compliance with specified standards before shipment. This step is crucial for mitigating risks associated with purchasing low-quality components.

Illustrative image related to changing starter motor

What Testing Methods Are Commonly Used in Quality Assurance for Starter Motors?

Various testing methods are employed during the QC process:

-

Electrical Testing: This assesses the motor’s performance under load conditions to ensure it meets the required specifications.

-

Vibration Testing: This method evaluates the motor’s durability and its ability to withstand operational stresses.

-

Thermal Testing: Assessing how the motor operates under different temperature conditions is vital for ensuring reliability, especially in extreme climates.

How Do Regional Regulations Affect Quality Control for International Buyers?

Regional regulations can significantly impact the quality assurance processes for starter motors. For instance, in Europe, compliance with the REACH regulation concerning chemical substances is mandatory. Similarly, buyers in the Middle East may need to consider local certifications that affect product acceptance.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Critical for B2B Buyers?

For B2B buyers, particularly those in emerging markets, understanding the manufacturing processes and quality assurance practices is essential for making informed purchasing decisions. By ensuring that suppliers adhere to international standards and implement robust QC measures, buyers can mitigate risks and enhance the reliability of their starter motor sourcing. This knowledge not only aids in selecting the right supplier but also strengthens long-term business relationships built on trust and quality assurance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘changing starter motor’

To assist B2B buyers in the procurement process of changing starter motors, this guide provides a structured checklist that outlines essential steps for a successful sourcing experience. Ensuring the quality and reliability of starter motors is vital for maintaining vehicle performance, minimizing downtime, and optimizing operational efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the starter motor is the first step in the sourcing process. Consider factors such as compatibility with vehicle makes and models, voltage requirements, and torque ratings. This clarity will help in identifying the right products and avoiding mismatches that could lead to operational inefficiencies.

Illustrative image related to changing starter motor

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of starter motors. Look for companies with a proven track record in the industry, especially those that specialize in your specific vehicle types. Utilize online platforms, industry directories, and trade shows to gather a list of reputable suppliers.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it’s crucial to vet suppliers thoroughly. Ensure that they hold relevant certifications, such as ISO or other industry-specific standards, which indicate compliance with quality management systems. Additionally, inquire about their manufacturing processes to ensure they adhere to best practices.

Step 4: Request Product Samples

To assess the quality of the starter motors, request product samples from shortlisted suppliers. This step allows you to evaluate the materials, craftsmanship, and overall performance of the starters. Pay attention to factors such as weight, durability, and compatibility with your specifications.

Step 5: Analyze Pricing and Payment Terms

Once you have narrowed down your options, analyze the pricing structures and payment terms offered by each supplier. Look for a balance between cost-effectiveness and quality. Additionally, inquire about bulk purchase discounts, warranty options, and return policies to ensure favorable conditions for your business.

Step 6: Check References and Reviews

Request references from suppliers and follow up with previous clients to gain insights into their experiences. Look for reviews and testimonials online to assess the reputation of the supplier within the industry. Positive feedback from other businesses, particularly in your region, can indicate reliability and customer service quality.

Illustrative image related to changing starter motor

Step 7: Finalize the Contract and Logistics

Once you have selected a supplier, finalize the contract by clearly outlining all terms, including delivery timelines, payment schedules, and product specifications. Discuss logistics for shipping and handling, ensuring that the supplier can meet your timelines and that the delivery method aligns with your operational needs.

By following this checklist, B2B buyers can navigate the complexities of sourcing starter motors effectively, ensuring they make informed decisions that enhance their operational efficiency and vehicle performance.

Comprehensive Cost and Pricing Analysis for changing starter motor Sourcing

What Are the Key Cost Components for Changing a Starter Motor?

When evaluating the costs associated with changing a starter motor, several components contribute to the total expenditure. The primary cost components include:

-

Materials: The cost of the starter motor itself typically ranges from $100 to $400, depending on the make and model of the vehicle. Additional materials may include electrical connectors, bolts, and potentially new wiring harnesses.

-

Labor: Labor costs can vary significantly based on geographical location and the complexity of the job. On average, labor charges can range from $100 to $300. This cost can be minimized if the buyer opts for a DIY approach, provided they have the necessary skills and tools.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses that manufacturers incur. These costs are often factored into the pricing of starter motors.

-

Tooling: Specialized tools may be required for installation or removal of the starter motor. If a workshop does not have these tools, renting or purchasing them can add to the overall cost.

-

Quality Control (QC): Ensuring that starter motors meet industry standards involves QC measures, which can increase manufacturing costs. Products with higher certifications or guarantees may carry a premium price.

-

Logistics: Shipping costs can vary widely based on the distance from the supplier and the shipping method used. International buyers must consider additional tariffs, customs fees, and import taxes.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding the margin can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of Starter Motors?

Several factors influence the pricing of starter motors, particularly for international B2B buyers:

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Buyers should inquire about minimum order quantities (MOQs) and potential savings from larger orders.

-

Specifications and Customization: Customized starter motors designed for specific vehicle models or performance enhancements may incur higher costs due to specialized manufacturing processes.

-

Materials: The choice of materials (e.g., copper vs. aluminum) impacts both performance and price. High-quality materials generally result in a longer-lasting product, which can reduce the total cost of ownership over time.

-

Quality and Certifications: Motors that come with industry certifications (e.g., ISO, CE) may have a higher upfront cost but can provide assurance of reliability and performance.

-

Supplier Factors: The reputation, reliability, and geographical location of the supplier can influence pricing. Established suppliers with a history of quality may charge a premium.

-

Incoterms: The terms of shipping and delivery can significantly impact the overall cost. Understanding who is responsible for freight, insurance, and customs clearance is crucial for accurate budgeting.

What Tips Can Help B2B Buyers Optimize Costs for Changing Starter Motors?

-

Negotiate Pricing: Don’t hesitate to negotiate with suppliers. Leverage bulk orders or long-term contracts to secure better pricing.

-

Focus on Total Cost of Ownership (TCO): Consider factors beyond the initial purchase price, such as installation costs, expected lifespan, and potential maintenance expenses. A higher-quality starter motor may have a higher upfront cost but could save money in the long run.

-

Understand Pricing Nuances for International Buyers: Familiarize yourself with local market conditions, currency fluctuations, and import regulations in your region (e.g., Africa, South America, the Middle East, Europe). This knowledge can lead to better purchasing decisions.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and exclusive deals. Consider establishing partnerships with local suppliers in target regions like Vietnam or Brazil for cost-effective sourcing.

-

Stay Informed About Market Trends: Keep an eye on market trends and pricing fluctuations in the automotive parts industry to make timely purchasing decisions.

Disclaimer on Indicative Prices

The prices mentioned are indicative and can vary significantly based on various factors such as location, market conditions, and specific vehicle requirements. Buyers should conduct thorough market research and obtain multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing changing starter motor With Other Solutions

Understanding Alternatives to Changing a Starter Motor

When it comes to addressing starter motor issues, various alternatives can provide different solutions based on performance, cost, and complexity. Businesses need to evaluate these options carefully to determine the best fit for their operational requirements. Below, we compare the traditional method of changing a starter motor with two viable alternatives: using a high-performance starter upgrade and employing a jump-starting solution.

| Comparison Aspect | Changing Starter Motor | High-Performance Starter Upgrade | Jump-Starting Solution |

|---|---|---|---|

| Performance | Restores original functionality; effective for most vehicles. | Enhances starting power, durability, and efficiency. | Provides temporary power; effective for short-term use. |

| Cost | $100 – $400 for parts; labor costs vary. | $200 – $600, often higher initial investment. | $20 – $100 for portable jump starters. |

| Ease of Implementation | Requires mechanical skills; can be complex based on vehicle design. | More straightforward installation but requires compatibility checks. | Simple; can be performed by anyone with basic knowledge. |

| Maintenance | Regular checks needed to ensure longevity. | Minimal maintenance; designed for higher durability. | Requires battery maintenance and charging. |

| Best Use Case | Ideal for long-term vehicle reliability and restoration. | Best for high-performance vehicles or frequent use in demanding conditions. | Suitable for emergency situations or infrequent use. |

What Are the Advantages and Disadvantages of High-Performance Starter Upgrades?

High-performance starter upgrades provide a significant boost in starting power and overall efficiency, particularly beneficial for vehicles that operate in extreme conditions or require quick starts. These starters are designed to withstand higher loads and can enhance the vehicle’s performance, especially in racing or heavy-duty applications. However, the initial cost is higher, and businesses must ensure compatibility with their vehicle models. Additionally, while they offer long-term benefits, they may not be necessary for standard vehicles, making them a potentially unnecessary expense.

How Can Jump-Starting Solutions Serve as an Alternative?

Jump-starting solutions, such as portable jump starters, are an excellent alternative for businesses looking for a quick fix without the commitment of a full starter motor replacement. These devices can temporarily provide the power needed to start a vehicle, making them ideal for emergency situations or infrequent use. They are cost-effective and easy to use, requiring minimal technical knowledge. However, they are not a permanent solution and should not be relied upon for regular operation, as they do not address underlying starter motor issues.

Conclusion: How Should B2B Buyers Decide Between These Solutions?

When selecting the right solution for starter motor issues, B2B buyers should consider their specific operational needs and budget constraints. If long-term reliability and performance are paramount, changing the starter motor or opting for a high-performance upgrade may be the best route. However, for businesses that need quick fixes or operate in environments where starter failures are infrequent, jump-starting solutions might provide sufficient support without significant investment. Ultimately, assessing vehicle use, operational demands, and cost-effectiveness will guide businesses in making informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for changing starter motor

What Are the Key Technical Properties of a Starter Motor?

When considering the replacement of a starter motor, understanding its technical properties is crucial for ensuring compatibility and performance. Here are some essential specifications to consider:

-

Material Grade

The material grade refers to the quality and type of materials used in the construction of the starter motor. Common materials include high-grade steel and aluminum alloys, which provide durability and resistance to wear and corrosion. In a B2B context, selecting a starter motor with the appropriate material grade can affect the longevity and reliability of the product, directly impacting maintenance costs and operational efficiency. -

Torque Rating

The torque rating indicates the amount of rotational force the starter motor can produce to crank the engine. This specification is vital, as a starter with insufficient torque may struggle to start the engine, especially in cold climates or with larger engines. B2B buyers should ensure the torque rating aligns with the engine requirements to prevent premature failure and enhance customer satisfaction. -

Voltage Rating

Most starter motors operate at a standard voltage of 12 volts, but some heavy-duty or specialized applications may require different voltage ratings. Understanding the voltage requirements is critical for compatibility with the vehicle’s electrical system. Ensuring the correct voltage rating helps avoid electrical failures and contributes to the overall safety of the vehicle. -

Current Draw

The current draw specification indicates the amount of electrical current the starter motor requires during operation. A high current draw can lead to battery drain, especially in vehicles that are used frequently. For B2B buyers, selecting a starter with an optimal current draw ensures efficiency, prolongs battery life, and minimizes the risk of electrical issues. -

Mounting Configuration

The mounting configuration refers to how the starter motor is attached to the engine. This can vary significantly between vehicle models, affecting installation processes and compatibility. B2B buyers must be aware of the specific mounting configuration required for their applications to avoid costly installation errors or misalignments.

Which Trade Terms Are Commonly Used in the Starter Motor Industry?

Understanding industry terminology is essential for effective communication and negotiations in the B2B marketplace. Here are some common trade terms related to starter motors:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts produced by the original manufacturer of the vehicle. These parts are designed to meet the exact specifications of the vehicle’s original components. For B2B buyers, sourcing OEM parts can ensure high compatibility and performance, which is often crucial for maintaining warranties and customer trust. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is significant in B2B transactions, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their sales forecasts to optimize inventory levels without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to request pricing and terms from suppliers for specific products. Issuing an RFQ can help buyers compare offers and negotiate better deals. For businesses, a well-structured RFQ process can streamline procurement and enhance supplier relationships. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B transactions, as they determine shipping costs, risk management, and delivery responsibilities, thereby reducing the potential for disputes. -

Warranty Period

The warranty period is the duration during which a product is guaranteed to be free from defects. In the context of starter motors, a longer warranty period can indicate higher confidence in product durability. For B2B buyers, evaluating warranty terms can be critical in assessing the risk associated with their purchases.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing and replacing starter motors, ultimately leading to better operational efficiency and customer satisfaction.

Illustrative image related to changing starter motor

Navigating Market Dynamics and Sourcing Trends in the changing starter motor Sector

What Are the Key Trends Shaping the Starter Motor Market?

The starter motor market is experiencing significant transformations driven by technological advancements, evolving consumer preferences, and broader economic factors. Globally, there is a heightened focus on electric vehicles (EVs) as they gain traction in various regions, including Africa, South America, the Middle East, and Europe. This shift is prompting manufacturers to innovate starter motor designs that are compatible with hybrid and fully electric vehicles, emphasizing energy efficiency and performance.

Moreover, the demand for higher torque and durability in starter motors is on the rise, attributed to increasing vehicle sizes and more powerful engines. This trend is particularly relevant for international B2B buyers who are sourcing components for heavy-duty vehicles or specialized machinery. Additionally, the integration of smart technology in starter motors, such as diagnostic features that monitor performance and predict failures, is becoming increasingly popular.

Supply chain dynamics are also evolving, with a push towards local sourcing to mitigate risks associated with global supply disruptions. Buyers are increasingly prioritizing suppliers who can provide transparent and agile supply chains, ensuring timely delivery and quality assurance. In regions like Brazil and Vietnam, where manufacturing capabilities are expanding, partnerships with local suppliers can enhance competitiveness by reducing lead times and costs.

How Is Sustainability Influencing Sourcing in the Starter Motor Sector?

Sustainability and ethical sourcing are becoming crucial considerations for B2B buyers in the starter motor sector. The environmental impact of manufacturing processes and materials is under scrutiny, leading to a demand for greener alternatives. Companies are increasingly looking for starter motors made from recyclable materials and those that have lower carbon footprints during production.

The importance of ethical supply chains cannot be overstated. Buyers are now more vigilant about the origins of their components and the labor practices involved in their production. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential for suppliers aiming to attract conscientious buyers.

Incorporating ‘green’ certifications and materials not only meets regulatory requirements but also enhances brand reputation. For international buyers, particularly in regions with stringent environmental regulations, sourcing from manufacturers who prioritize sustainability can be a competitive advantage. By aligning with suppliers who share these values, businesses can contribute to a more sustainable future while meeting market demands.

What Is the Historical Context of the Starter Motor Industry?

The evolution of starter motors traces back to the early 20th century when they were first introduced as a means to replace hand cranking engines. Initially, starter motors were simple mechanical devices powered by lead-acid batteries. Over the decades, advancements in electrical engineering and materials science have significantly enhanced their efficiency and reliability.

Illustrative image related to changing starter motor

The introduction of high-torque starter motors in the 1970s revolutionized the industry, allowing for easier engine starts in increasingly powerful vehicles. The shift towards electronic control systems in the late 1990s further propelled innovation, enabling more sophisticated designs that integrate seamlessly with modern vehicle electronics.

Today, the starter motor industry stands at a crossroads, driven by the dual forces of electrification and sustainability. As the automotive landscape continues to evolve, understanding this historical context is vital for B2B buyers to appreciate the technological advancements and market dynamics shaping the current landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of changing starter motor

-

How do I identify signs of a failing starter motor?

A failing starter motor can manifest through several symptoms. Common indicators include slow or labored cranking, unusual clicking sounds when attempting to start, or a grinding noise after the engine attempts to start. Additionally, if the starter engages but the engine does not turn over, this could signal a problem. Monitoring these signs is crucial for timely intervention, which can prevent more extensive vehicle damage and costly repairs. -

What is the best way to source starter motors for international markets?

When sourcing starter motors for international markets, consider suppliers with a strong reputation for quality and reliability. Look for manufacturers that adhere to international standards such as ISO certifications. Additionally, evaluate suppliers based on their ability to provide comprehensive product specifications, warranties, and after-sales support. Establishing a long-term relationship with suppliers who understand local market needs can also be beneficial. -

What are the typical lead times for ordering starter motors from suppliers?

Lead times can vary significantly based on the supplier’s location, manufacturing capacity, and order volume. Generally, you can expect lead times ranging from two to eight weeks. However, it’s essential to communicate directly with suppliers to confirm their current timelines and any potential delays due to logistics or production schedules. This proactive approach helps ensure timely delivery and minimizes disruptions in your supply chain. -

How can I ensure the quality of starter motors from suppliers?

To ensure quality, request samples before placing a bulk order. Verify that the products meet your specifications through rigorous testing. Additionally, inquire about the supplier’s quality assurance processes, such as inspections and certifications. Establishing clear communication about quality standards and expectations can help align both parties and reduce the risk of receiving subpar products. -

What customization options are available for starter motors?

Many suppliers offer customization options for starter motors, which may include modifications in terms of size, voltage, and connectors. Discuss your specific requirements with potential suppliers to understand the range of customization available. Custom solutions can enhance compatibility with your vehicle models and improve overall performance, making it crucial to choose a supplier that can accommodate your needs. -

What are the minimum order quantities (MOQ) for starter motors?

Minimum order quantities vary by supplier and can range from a few units to several hundred. It’s essential to clarify the MOQ during negotiations, especially if you’re a smaller buyer. Some suppliers may be willing to accommodate lower MOQs for first-time orders or if you establish a long-term partnership. Understanding these quantities can help you manage inventory and cash flow effectively. -

What payment terms should I expect when sourcing starter motors internationally?

Payment terms can differ widely based on the supplier’s policies and the buyer’s relationship. Common terms include upfront payments, deposits, or net payment terms (e.g., net 30 or net 60 days). Ensure that you discuss and agree upon payment terms before placing an order to avoid misunderstandings. Using secure payment methods and establishing clear invoicing practices can also protect your interests in international transactions. -

How do I handle logistics and shipping for international orders of starter motors?

Managing logistics for international orders requires careful planning. Work with suppliers who have experience in shipping to your region and can provide insights on customs clearance and duties. Consider using freight forwarders to streamline the shipping process. Additionally, ensure that you have a clear understanding of shipping costs, delivery timelines, and any potential risks involved in transporting starter motors across borders. This preparation can help mitigate delays and ensure a smooth supply chain.

Top 5 Changing Starter Motor Manufacturers & Suppliers List

1. WikiHow – Car Starter Installation Guide

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: The article provides a step-by-step guide on how to install a car starter, including removing a faulty starter and installing a new one. Key steps include disconnecting the battery, locating the starter, disconnecting wiring, removing retaining bolts, comparing the new starter with the old one, sliding the new starter into place, inserting retainer bolts, and reconnecting wiring to the starter sol…

2. Toyota – Starter Replacement Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2007 Toyota Corolla starter replacement; relatively simple process depending on accessibility; requires two bolts, a connector, and possibly a ground lug; estimated time for replacement is about 30 minutes if accessible; cost for a new starter around $150; troubleshooting may involve checking battery terminals.

3. Everything Euro – Starter Replacement Guide

Domain: everythingeuro.com

Registered: 2011 (14 years)

Introduction: Tools and Materials Needed: Socket wrench, Replacement starter, Extension cord (optional). Steps: 1. Disconnect the Negative Battery Cable. 2. Locate the Starter. 3. Remove the Starter (disconnect wires, remove bolts). 4. Install the New Starter (connect wires to terminals, bolt into place). 5. Reconnect the Negative Battery Cable. Tips: Ensure battery is fully charged, disconnect negative termina…

4. Electric Starter – High-Performance Motor

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Project Duration: 1 to 2 hours; Skill Level: Intermediate; Starter Type: Electric starter (starter motor); Typical Lifespan: At least 10 years; Weight: 20 pounds or more; Required Tools: Floor jack, jack stands, ramps or wheel cribs, wrenches, sockets, ratchet; Special Notes: Use correct starter bolts (not regular grade 8 bolts); Inspect battery cables for corrosion or damage; Check flexplate/flyw…

5. Haynes – Starter Motor Replacement Guide

Domain: us.haynes.com

Registered: 1996 (29 years)

Introduction: This company, Haynes – Starter Motor Replacement Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for changing starter motor

The importance of strategic sourcing in the changing starter motor landscape cannot be overstated. By prioritizing supplier relationships, international B2B buyers can ensure they have access to high-quality components while navigating the complexities of global markets. Understanding the nuances of starter motor performance, installation processes, and maintenance can empower buyers to make informed decisions that enhance operational efficiency and reduce downtime.

Moreover, leveraging data analytics and market intelligence can help identify the most reliable suppliers, facilitate cost-effective procurement, and mitigate risks associated with supply chain disruptions. As the automotive industry continues to evolve, embracing these strategic sourcing principles will be crucial for maintaining competitiveness in regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to changing starter motor

Looking ahead, it is essential for B2B buyers to stay proactive in their sourcing strategies, exploring innovative technologies and sustainable practices. By doing so, they can not only meet the immediate demands of their businesses but also contribute to a more resilient and efficient automotive supply chain. Engage with trusted suppliers today to secure the future of your operations and enhance your market position.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.