Introduction: Navigating the Global Market for whats a car starter

In today’s competitive automotive landscape, sourcing reliable car starters is a critical challenge for international B2B buyers. The starter motor, a pivotal component in vehicle functionality, plays an essential role in ensuring smooth engine ignition and overall vehicle performance. However, navigating the complexities of starter motor types, applications, and supplier reliability can overwhelm even the most seasoned procurement professionals. This guide aims to demystify the global market for car starters, providing actionable insights that will empower you to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore various starter motor types—ranging from traditional solenoid starters to advanced integrated systems found in hybrid vehicles. We will also discuss their specific applications across different vehicle models and markets, ensuring that you understand which products best meet your operational needs. Additionally, we will provide crucial information on supplier vetting processes, cost considerations, and maintenance best practices.

By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Saudi Arabia and Nigeria—with the knowledge necessary to assess and select high-quality starter motors, this guide will serve as an invaluable tool in your procurement strategy. With the right information at your fingertips, you can confidently navigate the complexities of the global automotive parts market and secure the best solutions for your business.

Table Of Contents

- Top 3 Whats A Car Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for whats a car starter

- Understanding whats a car starter Types and Variations

- Key Industrial Applications of whats a car starter

- 3 Common User Pain Points for ‘whats a car starter’ & Their Solutions

- Strategic Material Selection Guide for whats a car starter

- In-depth Look: Manufacturing Processes and Quality Assurance for whats a car starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘whats a car starter’

- Comprehensive Cost and Pricing Analysis for whats a car starter Sourcing

- Alternatives Analysis: Comparing whats a car starter With Other Solutions

- Essential Technical Properties and Trade Terminology for whats a car starter

- Navigating Market Dynamics and Sourcing Trends in the whats a car starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of whats a car starter

- Strategic Sourcing Conclusion and Outlook for whats a car starter

- Important Disclaimer & Terms of Use

Understanding whats a car starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Starter | Utilizes a DC electric motor, engages via solenoid | Automotive manufacturing, repairs | Pros: Widely available, cost-effective. Cons: Limited lifespan, sensitive to battery health. |

| High-Performance Starter | Designed for racing and heavy-duty applications | Performance vehicles, racing teams | Pros: High torque, durable under extreme conditions. Cons: Higher cost, may require specialized installation. |

| Gear Reduction Starter | Uses gears to increase torque output | Heavy machinery, commercial vehicles | Pros: Efficient power transfer, compact design. Cons: More complex, potential for gear wear. |

| Integrated Starter Generator (ISG) | Combines starter and generator functions | Hybrid vehicles, electric vehicles | Pros: Space-saving, improves fuel efficiency. Cons: Higher initial investment, specialized maintenance. |

| Bendix Starter | Features a unique drive mechanism for engagement | Classic car restoration, vintage vehicles | Pros: Reliable for older models, easy to source. Cons: Limited compatibility with modern vehicles. |

What are the Characteristics of Conventional Starters for B2B Buyers?

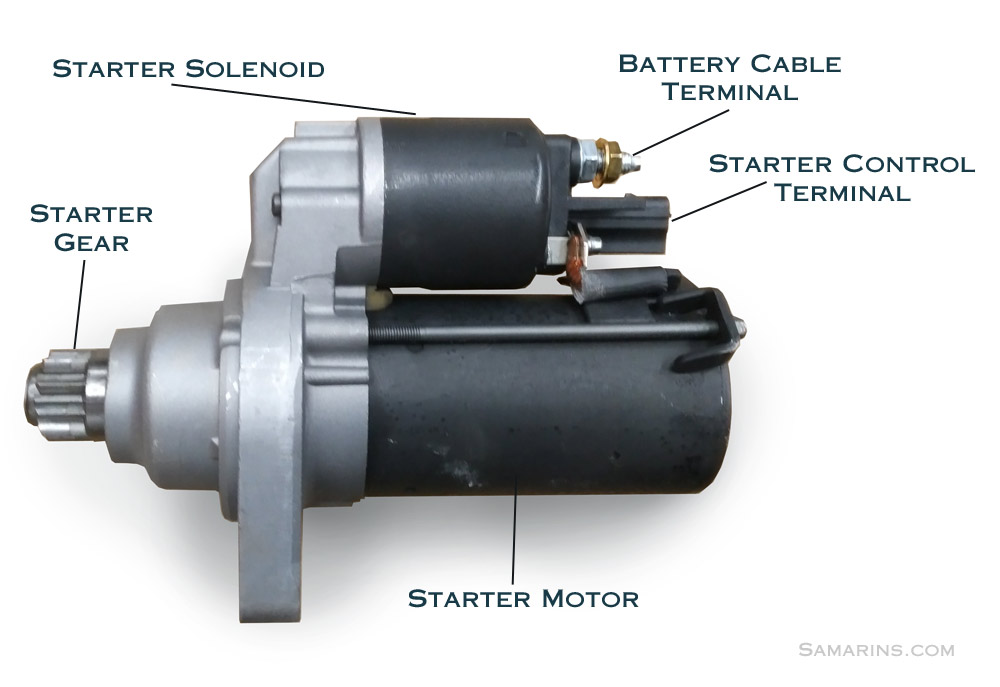

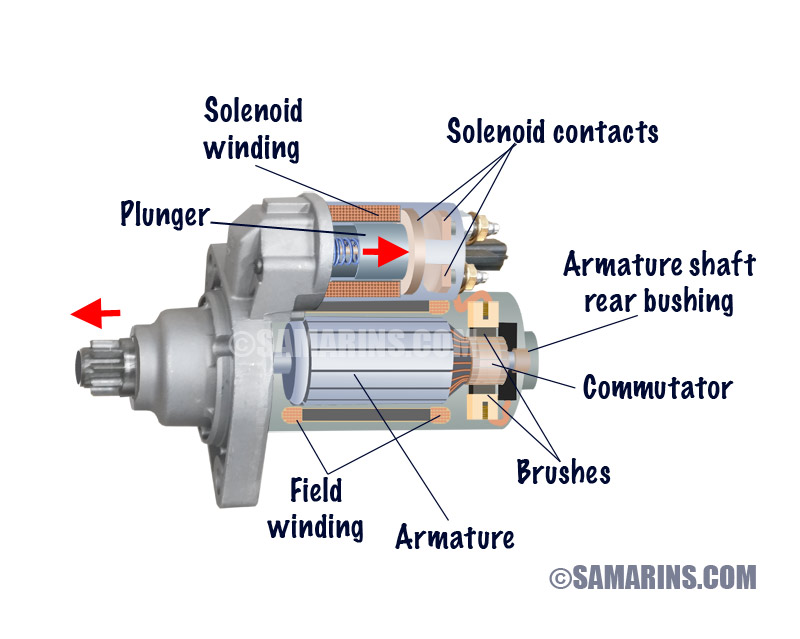

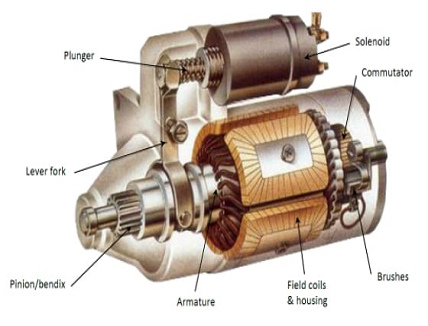

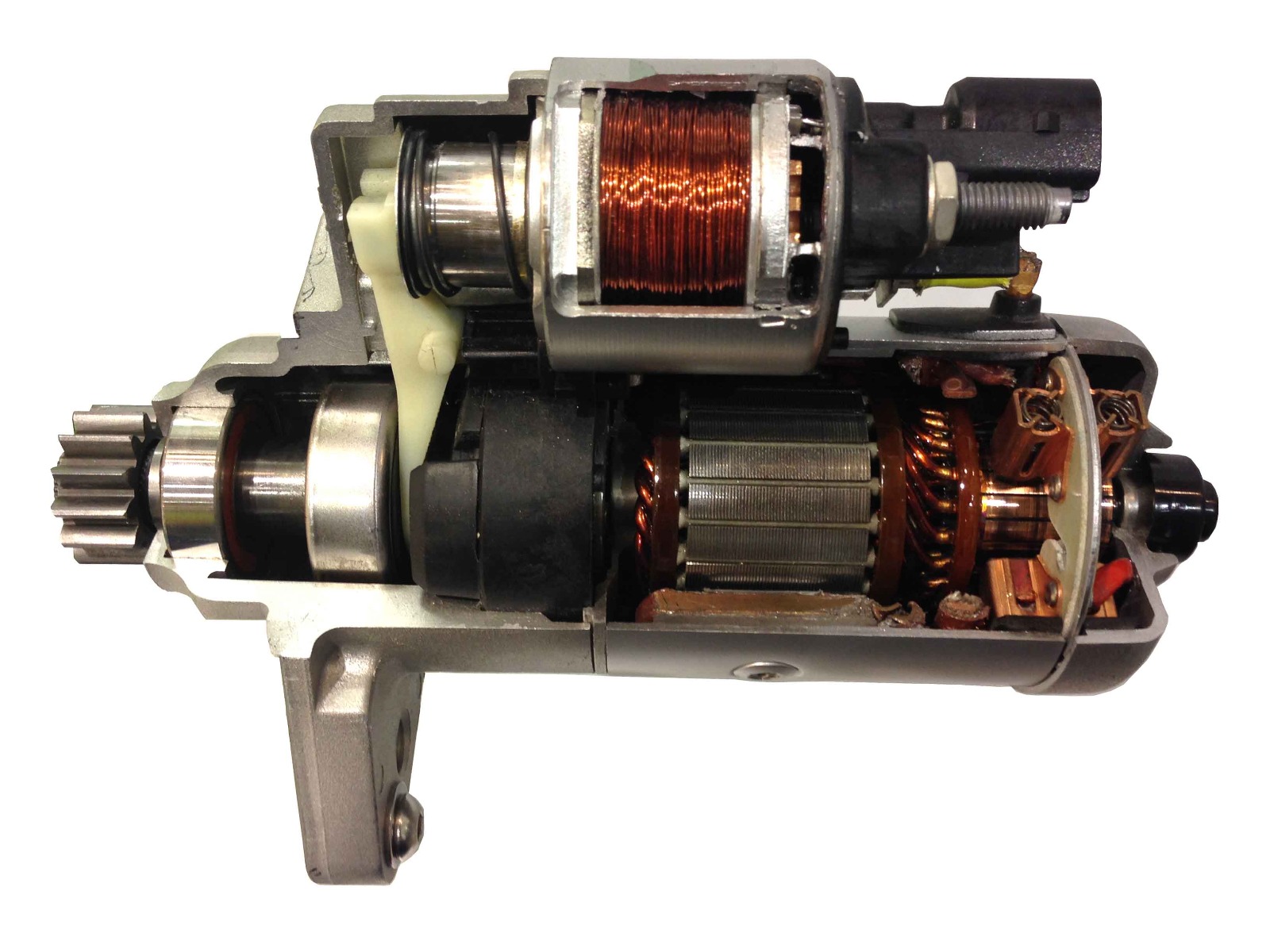

Conventional starters are the most common type used in modern vehicles. They operate using a DC electric motor, which is activated by a solenoid when the ignition key is turned. Their simplicity and widespread availability make them a staple in automotive manufacturing and repair sectors. B2B buyers should consider the compatibility with vehicle models, as well as the cost-effectiveness of sourcing these starters, particularly for high-volume applications.

How Do High-Performance Starters Benefit Racing and Heavy-Duty Applications?

High-performance starters are engineered to deliver superior torque and reliability, making them essential for racing and heavy-duty applications. These starters can withstand extreme conditions and repeated use, which is crucial in competitive environments. B2B buyers in the performance automotive sector should assess the torque specifications and durability ratings to ensure they meet the demands of their specific applications, despite the higher costs associated with these units.

What Makes Gear Reduction Starters Suitable for Heavy Machinery?

Gear reduction starters utilize a gear system to amplify torque, making them ideal for heavy machinery and commercial vehicles. Their efficient power transfer allows for easier engine starts under load. B2B buyers should evaluate the specific power requirements of their machinery and consider the complexity of installation and potential gear wear when selecting these starters.

Illustrative image related to whats a car starter

Why are Integrated Starter Generators (ISG) Gaining Popularity in Hybrid Vehicles?

Integrated Starter Generators combine the functions of a starter and generator, making them increasingly popular in hybrid and electric vehicles. They provide a compact solution that enhances fuel efficiency by allowing for regenerative braking and smoother engine starts. B2B buyers should consider the initial investment costs and the need for specialized maintenance when integrating ISG into their fleets.

What is the Relevance of Bendix Starters in Classic Car Restoration?

Bendix starters are characterized by their unique drive mechanism, which allows for reliable engagement in older vehicle models. They are particularly relevant for classic car restoration projects where original parts are preferred. B2B buyers should focus on sourcing authentic Bendix starters that ensure compatibility with vintage vehicles, keeping in mind the limited availability and potential challenges in sourcing parts for modern applications.

Key Industrial Applications of whats a car starter

| Industry/Sector | Specific Application of whats a car starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicles | Ensures reliable engine start-up for quality assurance | Supplier reliability, compliance with international standards, and cost-effectiveness. |

| Fleet Management | Maintenance of commercial vehicle fleets | Reduces downtime and maintenance costs | Bulk purchasing options, warranty terms, and compatibility with various vehicle models. |

| Construction Equipment | Starting heavy machinery | Enhances operational efficiency on job sites | Durability under harsh conditions, availability of replacement parts, and service support. |

| Transportation Services | Operation of public transport vehicles | Improves service reliability and customer satisfaction | Quality certifications, adaptability to different vehicle types, and after-sales support. |

| Agriculture | Starting agricultural machinery | Increases productivity during critical planting seasons | Availability of specialized starters for various equipment, robustness, and supplier expertise. |

How is a Car Starter Used in Automotive Manufacturing?

In automotive manufacturing, car starters are essential for the assembly of vehicles. They ensure that each vehicle’s engine can be reliably started during testing and quality assurance processes. This reliability minimizes production delays and enhances the overall quality of the vehicles produced. For international buyers, particularly in regions like Africa and South America, sourcing starters that meet specific compliance standards is crucial to avoid penalties and ensure vehicles meet local regulations.

What Role Does a Car Starter Play in Fleet Management?

In fleet management, the efficient operation of commercial vehicles hinges on the functionality of car starters. A reliable starter minimizes vehicle downtime, which is critical for businesses that depend on timely deliveries and services. For B2B buyers in the Middle East and Europe, considerations such as bulk purchasing agreements, warranty terms, and compatibility with various vehicle models are vital for optimizing fleet maintenance and operational costs.

How Do Car Starters Impact Construction Equipment Operations?

Car starters are integral to the operation of heavy machinery in construction. They enable quick and efficient starting of equipment, which is crucial for maintaining productivity on job sites. In regions with challenging climates, such as the Middle East, sourcing starters that can withstand extreme temperatures and heavy usage is essential. Buyers should prioritize suppliers that offer durable products and reliable after-sales support to ensure minimal operational disruptions.

Illustrative image related to whats a car starter

Why Are Car Starters Important for Transportation Services?

For transportation services, particularly public transport, the reliability of car starters directly influences service quality and customer satisfaction. A malfunctioning starter can lead to delays, impacting the reputation of the service provider. B2B buyers in Europe and Africa should focus on sourcing starters that come with quality certifications and demonstrate adaptability to a range of vehicle types, ensuring seamless integration into their existing fleets.

How Are Car Starters Used in Agriculture?

In agriculture, starters are critical for the efficient operation of various machinery, especially during planting and harvesting seasons. A reliable starter allows farmers to maximize their productivity by ensuring that equipment is operational when needed. Buyers in agricultural sectors should consider the availability of specialized starters for different machinery types, their robustness in field conditions, and the supplier’s expertise in agricultural equipment to ensure they are making informed purchasing decisions.

3 Common User Pain Points for ‘whats a car starter’ & Their Solutions

Scenario 1: Difficulty Identifying Starter Motor Issues

The Problem:

B2B buyers often encounter challenges in diagnosing issues related to starter motors, especially in regions where vehicle maintenance knowledge may vary. A common scenario is a fleet manager receiving reports of vehicles that won’t start. The symptoms can range from a simple clicking sound to complete silence upon turning the ignition. Differentiating between a faulty starter and other potential issues, such as a dead battery or corroded cables, can lead to costly misdiagnoses and unnecessary repairs, impacting fleet operations and budgets.

The Solution:

To effectively identify starter motor problems, B2B buyers should invest in comprehensive diagnostic tools that can pinpoint issues with starters versus other electrical components. Encouraging routine maintenance checks can help prevent confusion; these should include testing battery voltage, checking connections for corrosion, and examining starter functionality. Additionally, providing training for maintenance staff on troubleshooting techniques can significantly reduce downtime. When sourcing starter motors, opt for suppliers who offer detailed specifications and support, ensuring compatibility with the fleet’s vehicles. This proactive approach minimizes misdiagnosis, saving both time and money.

Illustrative image related to whats a car starter

Scenario 2: Sourcing High-Quality Starter Motors

The Problem:

In many international markets, particularly in Africa and South America, B2B buyers often struggle to find reliable sources for high-quality starter motors. The availability of substandard parts can lead to frequent failures, risking both vehicle safety and operational efficiency. Buyers may find themselves overwhelmed by the sheer number of suppliers, each promising quality, but without the ability to verify those claims, leading to hesitation and potential losses.

The Solution:

To navigate the complexities of sourcing, B2B buyers should establish relationships with trusted suppliers who have a proven track record in the automotive parts industry. Conducting thorough market research to identify reputable manufacturers is key; look for certifications and customer reviews that attest to product quality. Additionally, participating in trade shows and automotive expos can provide direct access to manufacturers and the opportunity to ask questions about product warranties and quality control processes. Establishing a solid supply chain with quality assurance protocols will ensure that only reliable starter motors are procured, ultimately enhancing vehicle performance and longevity.

Scenario 3: Understanding Starter Motor Specifications

The Problem:

A significant pain point for B2B buyers is navigating the various specifications of starter motors. Different vehicles require different types of starters, including variations in size, power requirements, and engagement mechanisms. Buyers may feel overwhelmed by technical jargon and specifications, leading to the risk of purchasing incompatible parts that can disrupt vehicle operations and incur additional costs for returns or replacements.

The Solution:

B2B buyers can mitigate this issue by developing a clear understanding of the specifications required for their fleet. This can be achieved through a detailed inventory of all vehicles, including make, model, and existing starter motor specifications. Collaborating with technical experts or automotive engineers to create a comprehensive specification guide will help streamline the procurement process. Additionally, utilizing digital tools and databases that allow for easy comparison of starter motor specifications can empower buyers to make informed decisions. Training staff on the importance of accurate specification matching can further ensure that the right parts are sourced, reducing the likelihood of future compatibility issues and enhancing overall operational efficiency.

Strategic Material Selection Guide for whats a car starter

What Materials Are Commonly Used in Car Starters?

When selecting materials for car starters, several factors must be considered, including the operational environment, performance requirements, and cost-effectiveness. Below is an analysis of four common materials used in the manufacturing of car starters, focusing on their properties, advantages, limitations, and implications for international B2B buyers.

What Are the Key Properties of Copper in Car Starters?

Copper is widely used in electrical components of car starters due to its excellent electrical conductivity and thermal properties. It can handle high temperatures and provides reliable performance under varying conditions. Copper’s corrosion resistance is moderate, which is essential for components exposed to moisture or contaminants.

Pros: Copper offers superior conductivity, which enhances the efficiency of the starter motor. It is relatively easy to work with during manufacturing, allowing for intricate designs.

Cons: The primary limitation of copper is its susceptibility to corrosion, particularly in humid environments. Additionally, copper is generally more expensive than alternative materials like aluminum.

Impact on Application: Copper’s high conductivity makes it ideal for wiring and connections within the starter, ensuring minimal energy loss.

Considerations for International Buyers: Buyers in regions such as Africa and the Middle East should be aware of local corrosion challenges and may need to consider protective coatings or treatments. Compliance with international standards like ASTM B170 for copper wire may also be relevant.

How Does Aluminum Compare for Use in Car Starters?

Aluminum is increasingly being used in starter motors due to its lightweight nature and good corrosion resistance. It is particularly beneficial in applications where weight reduction is crucial for overall vehicle efficiency.

Illustrative image related to whats a car starter

Pros: Aluminum is lightweight, reducing the overall weight of the starter assembly. It also has good thermal conductivity and is resistant to corrosion, making it suitable for various environments.

Cons: While aluminum is less expensive than copper, it has lower electrical conductivity, which may affect performance in high-demand applications.

Impact on Application: Aluminum can be used for housings and casings, providing adequate protection while contributing to weight savings.

Considerations for International Buyers: Buyers should ensure that aluminum components meet standards such as ASTM B221 for structural aluminum, especially in regions with stringent regulations.

What Role Does Steel Play in the Manufacturing of Car Starters?

Steel is often used in the structural components of car starters, particularly in the housing and mounting brackets. Its strength and durability make it a reliable choice for mechanical parts.

Pros: Steel is highly durable and can withstand significant mechanical stress, making it ideal for structural applications. It is also relatively inexpensive compared to other metals.

Illustrative image related to whats a car starter

Cons: Steel’s weight can be a disadvantage in applications where weight savings are critical. Additionally, steel is prone to rust if not properly treated or coated.

Impact on Application: Steel’s strength ensures that the starter can endure the mechanical forces during operation without deforming or breaking.

Considerations for International Buyers: Steel components should comply with standards such as ASTM A36 for structural steel. Buyers in humid climates should consider corrosion-resistant coatings to enhance longevity.

How Is Plastic Used in Car Starters?

Plastics, particularly high-performance polymers, are used in non-structural components of car starters, such as insulation and covers. They provide electrical insulation and can help reduce weight.

Pros: Plastics are lightweight and can be molded into complex shapes, offering design flexibility. They also provide excellent electrical insulation.

Cons: Plastics may not withstand high temperatures as well as metals, which could limit their use in certain applications.

Impact on Application: Plastics are ideal for insulating electrical components, ensuring safety and efficiency in operation.

Considerations for International Buyers: Buyers should ensure that plastics used in starters meet relevant standards such as UL 94 for flammability, especially in markets with strict safety regulations.

Summary Table of Material Selection for Car Starters

| Material | Typical Use Case for whats a car starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections and wiring | Excellent conductivity | Susceptible to corrosion | High |

| Aluminum | Housings and casings | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Steel | Structural components | High durability | Heavier and prone to rust | Low |

| Plastic | Insulation and covers | Lightweight and moldable | Limited high-temperature resistance | Medium |

This analysis provides a comprehensive overview of the materials commonly used in car starters, highlighting their properties, advantages, and considerations for international buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for whats a car starter

What Are the Main Stages of Manufacturing a Car Starter?

The manufacturing process of a car starter involves several critical stages, each designed to ensure the final product meets performance and reliability standards. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

How is Material Prepared for Car Starters?

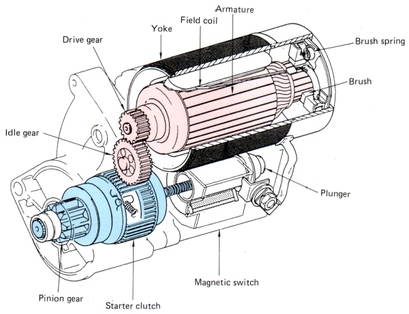

The first step in manufacturing a car starter is material preparation. High-quality materials such as copper, steel, and various alloys are selected based on their electrical conductivity and mechanical strength. The components typically include the starter motor housing, armature, solenoid, and pinion gear.

Material inspection is critical at this stage. Suppliers should conduct Incoming Quality Control (IQC) checks to ensure that all raw materials comply with specified standards. This may involve testing for impurities, mechanical properties, and dimensions to prevent defects in the final product.

Illustrative image related to whats a car starter

What Techniques Are Used for Forming Components of Car Starters?

Once materials are prepared, the next stage is forming the components. Techniques such as stamping, machining, and forging are commonly used.

- Stamping is often used for creating the starter motor housing and other flat components. High-speed presses shape the metal into required forms, ensuring precise dimensions.

- Machining is utilized for parts that require fine tolerances, such as the armature and pinion gear. CNC (Computer Numerical Control) machines are frequently employed for their accuracy and repeatability.

- Forging may be used for components that need to withstand high stress, such as the drive gear. This process enhances the material’s strength and durability.

Each forming process must adhere to strict tolerances, as any deviation can lead to performance issues in the starter motor.

How Are Car Starters Assembled?

After forming, the components move to the assembly stage. This process requires skilled labor to ensure that each part fits correctly and functions as intended.

Automated assembly lines are increasingly common, where robotic systems handle repetitive tasks like inserting the armature into the housing and attaching the solenoid. However, manual assembly is still essential for more complex tasks that require human dexterity, such as wiring connections.

Quality checks, known as In-Process Quality Control (IPQC), are integrated into the assembly line. These checks involve measuring dimensions, testing component fit, and ensuring that electrical connections are secure.

Illustrative image related to whats a car starter

What Finishing Processes Are Involved in Car Starter Manufacturing?

The final stage of manufacturing involves finishing processes that enhance the starter’s durability and aesthetics. This may include:

- Coating: Components often receive protective coatings to prevent corrosion and wear. Electroplating or powder coating techniques can be applied.

- Testing: Each completed starter undergoes rigorous testing to ensure it meets operational specifications. This includes performance tests under various load conditions, thermal cycling tests, and vibration tests to simulate real-world usage.

What Quality Assurance Standards Are Relevant for Car Starters?

Quality assurance is paramount in the automotive industry, where product reliability is non-negotiable. Various international standards guide the quality processes for car starters.

Which International Standards Should B2B Buyers Look For?

ISO 9001 is the leading standard for quality management systems and is widely recognized in the automotive sector. Suppliers certified to this standard demonstrate a commitment to consistent quality and continuous improvement.

In addition, B2B buyers should look for compliance with industry-specific standards such as:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for automotive components that interact with engine systems.

These certifications not only assure quality but also facilitate smoother trade across borders, particularly for buyers in Africa, South America, the Middle East, and Europe.

Illustrative image related to whats a car starter

What Are the Key Quality Control Checkpoints for Car Starters?

Quality control (QC) is implemented at various stages throughout the manufacturing process, focusing on specific checkpoints to ensure product integrity.

What Does Incoming Quality Control (IQC) Involve?

IQC involves checking the quality of materials received from suppliers. This step is crucial for preventing defects from the outset. Buyers should inquire about the supplier’s IQC procedures, including the types of tests conducted and the criteria for acceptance.

How Is In-Process Quality Control (IPQC) Conducted?

During the assembly process, IPQC is vital for monitoring the quality of the starter components. This may include:

- Visual inspections for defects.

- Dimensional checks using calipers or gauges.

- Functional tests to ensure components are assembled correctly.

Implementing IPQC helps to catch potential issues before they escalate into larger problems, reducing rework and ensuring timely delivery.

What Does Final Quality Control (FQC) Entail?

FQC occurs at the end of the manufacturing process, where each starter is tested for functionality and performance. Common methods include:

- Electrical Testing: Verifying the starter draws the correct current and engages properly.

- Load Testing: Assessing the starter’s ability to perform under simulated operational conditions.

- Durability Testing: Subjecting the starter to conditions that mimic extreme environments to evaluate longevity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability.

What Should Buyers Look For in Supplier Audits and Reports?

Buyers should request documentation that demonstrates a supplier’s adherence to quality standards. This includes:

- Audit Reports: These should detail the results of internal and external quality audits, highlighting areas of compliance and any corrective actions taken.

- Certificates: Proof of compliance with ISO 9001 and other relevant standards should be readily available.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can provide an additional layer of assurance. These services can conduct independent audits and quality checks at various stages of production, offering unbiased evaluations of the supplier’s capabilities.

What Are the Unique QC Considerations for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following nuances in quality control:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can help in selecting the right supplier.

- Regulatory Compliance: Different regions have varying regulations regarding automotive components, which can impact quality standards.

- Logistics and Supply Chain: Buyers must consider the reliability of the supplier’s logistics and whether they can consistently meet delivery timelines without compromising quality.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices involved in car starter production is essential for B2B buyers. By focusing on supplier qualifications, adherence to international standards, and effective quality control checkpoints, buyers can ensure they partner with reliable manufacturers that deliver high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘whats a car starter’

When procuring a car starter for your business, it’s essential to navigate the process systematically to ensure you receive high-quality components that meet your operational needs. This guide provides a step-by-step checklist designed for international B2B buyers, focusing on critical actions to take during the sourcing process.

Step 1: Define Your Technical Specifications

Before you begin sourcing, establish clear technical specifications for the car starters you need. This includes understanding the voltage, torque requirements, and compatibility with different vehicle models. Knowing the exact specifications helps in narrowing down potential suppliers and ensuring the components will perform as expected in your applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in automotive components, particularly starters. Look for suppliers with a solid reputation in the industry, and check their experience level, especially in the regions you are targeting, such as Africa, South America, the Middle East, and Europe. Utilize platforms like trade directories, industry forums, and trade shows to gather a comprehensive list of potential vendors.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess necessary certifications, such as ISO 9001, which indicates adherence to quality management standards. Certifications are crucial as they reflect a supplier’s commitment to quality and reliability. Additionally, check for compliance with regional automotive standards, especially if you are importing products from different countries.

Illustrative image related to whats a car starter

Step 4: Request Product Samples

Before making a large order, request samples of the car starters. Testing samples allows you to evaluate the quality, performance, and compatibility with your vehicles. This step is vital to avoid potential issues post-purchase and ensures that the starters meet your technical specifications.

Step 5: Assess Pricing and Terms of Sale

Gather quotes from multiple suppliers to compare pricing structures. Look beyond the base price; consider terms of sale, such as payment options, delivery timelines, and minimum order quantities. Understanding the total cost of ownership, including shipping and potential tariffs, is essential for making informed purchasing decisions.

Step 6: Check Reviews and References

Seek reviews and references from other businesses that have purchased from your shortlisted suppliers. This feedback can provide insight into the supplier’s reliability, customer service, and product quality. Engaging with other buyers in similar markets can also reveal any potential challenges to watch out for.

Step 7: Establish Communication Protocols

Once you have selected a supplier, establish clear communication protocols. Ensure that you have a designated point of contact for order updates, technical support, and any issues that may arise. Effective communication can significantly enhance the procurement process and help resolve any concerns swiftly.

By following this checklist, you can enhance your sourcing strategy for car starters, ensuring you select reliable suppliers that meet your business needs effectively.

Comprehensive Cost and Pricing Analysis for whats a car starter Sourcing

What Are the Key Cost Components in Sourcing Car Starters?

When sourcing car starters, understanding the cost structure is essential for B2B buyers. The main cost components include:

-

Materials: The primary materials used in car starters include copper for windings, steel for the casing, and various plastics for insulation and components. Fluctuations in raw material prices can significantly impact the overall cost.

-

Labor: Labor costs vary by region and manufacturing processes. Skilled labor is often required for assembly and quality control, which can increase the overall cost, particularly in countries with higher wage standards.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Initial setup costs for specialized tools and machinery can be substantial. However, these costs are amortized over production runs, making them less impactful on larger orders.

-

Quality Control (QC): Ensuring that each starter meets safety and performance standards incurs additional costs. Comprehensive QC processes are vital, particularly for markets with stringent regulations.

-

Logistics: Transportation costs must be factored in, including shipping and customs fees, especially when sourcing internationally. Proximity to suppliers can reduce these costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market competition and supplier reputation.

How Do Price Influencers Affect Car Starter Costs?

Several factors can influence the pricing of car starters:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their demand forecasts.

-

Specifications and Customization: Custom-built starters tailored to specific vehicle models or performance requirements can incur additional costs. Standardized products usually offer more competitive pricing.

-

Materials and Quality Certifications: Higher-quality materials and components may increase costs but can enhance performance and durability. Certifications like ISO or TS16949 can also add to the price but may be necessary for compliance in certain markets.

-

Supplier Factors: Supplier reliability, reputation, and geographic location can impact pricing. Established suppliers might charge a premium for their proven quality and service.

-

Incoterms: The terms of delivery, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), will influence the total landed cost. Understanding these terms is critical for effective budgeting.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Car Starters?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Building a strong relationship with suppliers can provide leverage in negotiations. Discussing long-term partnerships may yield better pricing and terms.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the initial purchase price. Factors such as durability, warranty, and maintenance costs can significantly affect long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local tariffs, which can impact costs. Establishing contracts in stable currencies or incorporating clauses to manage exchange rate risks can mitigate these effects.

-

Regional Considerations: Understand the specific requirements and market conditions in your region. For instance, certain regions may have preferences for specific starter types or features, which can affect pricing.

-

Supplier Diversification: Engaging multiple suppliers can create competitive pricing pressures and provide alternatives in case of supply chain disruptions.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier assessments to obtain the most accurate and relevant pricing information for your needs.

Alternatives Analysis: Comparing whats a car starter With Other Solutions

Exploring Alternatives to Traditional Car Starters

In the automotive industry, understanding the various options available for starting a vehicle is crucial for B2B buyers. While traditional car starters are widely used, alternative technologies and methods exist that may better suit specific needs, particularly in diverse markets across Africa, South America, the Middle East, and Europe. This analysis compares traditional car starters with two viable alternatives: the Integrated Starter Generator (ISG) and push-button start systems.

| Comparison Aspect | Whats A Car Starter | Integrated Starter Generator (ISG) | Push-Button Start System |

|---|---|---|---|

| Performance | High torque, reliable in starting engines | Provides smooth start and stop, energy recovery | Quick start with minimal effort |

| Cost | Generally low-cost, but varies by model | Higher initial investment but offers fuel savings | Moderate cost, dependent on vehicle model |

| Ease of Implementation | Standard installation in most vehicles | Requires advanced electrical systems | Easier installation in modern vehicles |

| Maintenance | Moderate, can fail over time | Low maintenance, fewer moving parts | Minimal, often integrated with vehicle systems |

| Best Use Case | Conventional vehicles, cost-sensitive applications | Hybrid and electric vehicles for efficiency | Luxury and newer vehicles for convenience |

What Are the Benefits and Drawbacks of the Integrated Starter Generator (ISG)?

The Integrated Starter Generator (ISG) combines the functions of a starter motor and an alternator into a single unit. This technology is particularly advantageous in hybrid and electric vehicles, where energy efficiency is paramount. The ISG allows for regenerative braking, which captures energy during deceleration and uses it to recharge the battery. However, the initial cost of implementing ISG technology can be higher compared to traditional starters, which may deter budget-conscious B2B buyers. Additionally, ISG systems require sophisticated electrical architecture, making them less suitable for older vehicle models.

How Does a Push-Button Start System Compare?

Push-button start systems are increasingly popular in modern vehicles, offering convenience and ease of use. This technology enables drivers to start their vehicles with the push of a button, typically using a key fob that communicates wirelessly with the vehicle. The primary advantage of this system is its user-friendly nature, appealing to buyers in markets where convenience is a significant factor. However, the installation costs can vary, and not all vehicles are compatible with this technology, which may limit its adoption in certain segments of the market.

Conclusion: How Should B2B Buyers Choose the Right Starting Solution?

When evaluating alternatives to traditional car starters, B2B buyers should consider factors such as performance requirements, budget constraints, and vehicle compatibility. For businesses operating in regions where fuel efficiency is critical, investing in Integrated Starter Generators may yield long-term savings. Conversely, for buyers focused on cost-effectiveness or retrofitting existing vehicles, traditional starters remain a reliable choice. Ultimately, understanding the specific needs of the target market and vehicle applications will guide decision-makers in selecting the most appropriate starting solution.

Essential Technical Properties and Trade Terminology for whats a car starter

What Are the Key Technical Properties of a Car Starter?

When sourcing car starters, understanding their technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties to consider:

Illustrative image related to whats a car starter

1. Material Grade

The materials used in car starters can significantly affect durability and performance. Common materials include high-grade steel for the casing and copper for wiring. High-quality materials ensure resistance to wear and tear, especially in demanding environments, which is vital for B2B buyers looking for longevity in their products.

2. Torque Rating

Torque is the rotational force generated by the starter motor to turn the engine over. A higher torque rating means the starter can handle larger engines and more demanding conditions. For buyers, selecting starters with appropriate torque ratings is essential to ensure reliable engine start-up, particularly in regions with extreme weather conditions.

3. Voltage and Amperage Specifications

Most automotive starters operate on a 12V system, but the amperage can vary. A typical starter may require between 150 to 300 amps during operation. Understanding these specifications helps buyers ensure that their vehicle’s battery and electrical system can support the starter’s demands, avoiding potential electrical failures.

4. Engagement Mechanism

The engagement mechanism, often a solenoid, is crucial for the starter’s function. It connects the starter to the engine’s flywheel when activated. Buyers should consider the design and reliability of this mechanism, as it can affect the starter’s lifespan and performance under various conditions.

5. Temperature Range

Car starters must operate effectively across a range of temperatures. Some starters are designed to function in extreme heat or cold, which can be particularly important for international buyers in diverse climates. Knowing the temperature range ensures that the starter will perform reliably regardless of environmental conditions.

6. Warranty Period

A comprehensive warranty period indicates the manufacturer’s confidence in the starter’s quality and durability. Buyers should pay attention to warranty details, as a longer warranty can mean lower long-term costs and assurance of product reliability.

Illustrative image related to whats a car starter

What Are Common Trade Terms in the Car Starter Industry?

Navigating the automotive parts market requires familiarity with specific trade terminology. Here are some key terms relevant to car starters:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the manufacturer of the vehicle. When sourcing car starters, buyers often prefer OEM parts for their guaranteed compatibility and quality. Understanding the difference between OEM and aftermarket parts is vital for making informed purchasing decisions.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory management, ensuring they do not overstock or understock essential components.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This is a common practice for B2B buyers to compare offers from different manufacturers, helping them secure the best deal for car starters.

Illustrative image related to whats a car starter

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can help buyers understand shipping costs and risks associated with importing car starters.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is critical for planning inventory and ensuring timely availability of car starters, particularly in markets with high demand.

6. Aftermarket

Aftermarket parts are components made by companies other than the original manufacturer. While often cheaper, buyers must evaluate the quality and compatibility of aftermarket starters to ensure they meet the necessary performance standards for their vehicles.

Understanding these technical properties and trade terms is essential for B2B buyers looking to make informed decisions when sourcing car starters, ensuring they meet their operational needs and market demands effectively.

Navigating Market Dynamics and Sourcing Trends in the whats a car starter Sector

What Are the Current Market Dynamics and Key Trends in the Car Starter Sector for B2B Buyers?

The global car starter market is experiencing significant growth driven by several factors, including the increasing demand for automotive vehicles, advancements in automotive technology, and a rising focus on vehicle performance and efficiency. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these market dynamics is crucial.

One key trend is the shift towards electric vehicles (EVs), which are becoming more prevalent as governments worldwide push for greener alternatives. As a result, traditional starter motors are evolving to accommodate hybrid and electric systems, which often integrate starter functions within the vehicle’s electrical architecture. This transition presents an opportunity for B2B buyers to source innovative starter solutions that align with modern automotive engineering.

Moreover, the rise of online platforms for sourcing automotive components is reshaping procurement strategies. B2B buyers can now leverage digital tools to compare products, review supplier ratings, and streamline their purchasing processes. This tech-savvy approach allows for more informed decisions, especially when sourcing from diverse international markets.

Additionally, the global supply chain landscape is facing challenges such as material shortages and fluctuating prices, which can affect the availability and cost of starter motors. Buyers should consider establishing relationships with multiple suppliers to mitigate risks and ensure consistent access to quality components.

How Is Sustainability Influencing Sourcing Trends in the Car Starter Sector?

Sustainability is increasingly becoming a focal point for B2B buyers in the car starter market. The environmental impact of automotive components, including starter motors, is prompting companies to seek suppliers that prioritize eco-friendly practices. This includes sourcing materials that are recyclable or produced with minimal environmental degradation.

Ethical sourcing is also gaining traction, with buyers showing preference for suppliers who adhere to fair labor practices and sustainable manufacturing processes. Certifications such as ISO 14001, which relates to effective environmental management systems, and the use of green materials are becoming essential criteria in supplier selection. These certifications not only help in reducing the carbon footprint but also enhance brand reputation, making it a strategic advantage in the competitive automotive market.

Incorporating sustainability into sourcing decisions can lead to cost savings in the long run, as companies that adopt greener practices may benefit from reduced waste and improved energy efficiency. For B2B buyers, aligning with suppliers that share a commitment to sustainability can foster long-term partnerships and contribute to a more responsible supply chain.

What Is the Brief History of Car Starters Relevant to B2B Buyers?

The car starter motor has a rich history that dates back to its invention by Charles Kettering in 1911, revolutionizing the automotive industry by replacing hand-cranked engines. Initially integrated with other electrical functions, starters have evolved significantly, particularly with the advent of modern automotive technologies. The development of the solenoid mechanism allowed for quick engagement and disengagement, enhancing reliability and performance.

As vehicles transitioned from mechanical to electrical systems, starters became more sophisticated, incorporating features that improved efficiency and durability. The rise of hybrid and electric vehicles has further transformed the starter landscape, prompting manufacturers to innovate and adapt to new automotive demands. For B2B buyers, understanding this evolution is essential for making informed sourcing decisions, as it highlights the importance of selecting advanced, compatible starter technologies that meet contemporary vehicle standards.

Frequently Asked Questions (FAQs) for B2B Buyers of whats a car starter

-

1. How do I identify a faulty car starter?

Identifying a faulty car starter typically involves observing specific symptoms. Common indicators include the engine not cranking when the key is turned, a clicking sound without engine turnover, or the starter working intermittently. Additionally, if the battery is fully charged and connections are secure, yet the vehicle fails to start, the starter may be at fault. To verify, testing the starter at an auto parts store can confirm its condition, helping you avoid unnecessary purchases and ensuring you’re sourcing the right component. -

2. What is the best starter motor for various vehicle types?

The best starter motor varies by vehicle type, engine size, and intended use. For high-performance vehicles, look for starters with higher torque ratings to ensure reliable starts. For everyday consumer vehicles, OEM (Original Equipment Manufacturer) starters are often recommended for compatibility and reliability. When sourcing, consider the specific requirements of the vehicles you service, including brand, model, and engine specifications to ensure optimal performance and longevity. -

3. How can I vet suppliers for car starters in international markets?

Vetting suppliers for car starters involves several key steps. Start by checking their credentials and certifications, ensuring they comply with international quality standards such as ISO. Request references or case studies from previous clients, particularly those in similar markets. Additionally, consider visiting their facilities or utilizing third-party inspection services. Engaging in direct communication regarding product specifications, lead times, and after-sales support will also provide insight into their reliability and professionalism. -

4. What are the typical minimum order quantities (MOQ) for car starters?

Minimum order quantities (MOQ) for car starters can vary significantly based on the supplier and the type of starter. Generally, MOQs can range from 50 to several hundred units, particularly for customized or specialty starters. When negotiating with suppliers, clarify if the MOQ can be adjusted based on your purchasing capacity or if there are benefits for larger orders. Understanding these terms upfront can help you manage inventory and cash flow effectively. -

5. What payment terms should I expect when sourcing car starters internationally?

Payment terms for international sourcing of car starters typically range from 30% upfront with the balance due upon shipment, to net 30 or net 60 days after receipt of goods. However, terms can vary based on supplier policies, transaction volume, and buyer-supplier relationships. It’s crucial to negotiate clear payment terms before finalizing orders, including potential discounts for early payment or penalties for late payment. Utilizing secure payment methods such as letters of credit can also mitigate risks. -

6. How do I ensure quality assurance for car starters?

Ensuring quality assurance for car starters involves implementing a comprehensive QA process. Begin by requiring suppliers to provide quality certifications and test reports for their products. Consider establishing specific quality benchmarks that align with your market’s standards. Additionally, conducting random inspections during production and upon delivery can help verify compliance. Collaborating with third-party inspection agencies can also provide an objective assessment of product quality before acceptance. -

7. What logistics considerations should I keep in mind when importing car starters?

When importing car starters, logistics considerations include shipping methods, customs regulations, and delivery timelines. Assess whether air freight or sea freight is more cost-effective based on the urgency of your needs. Familiarize yourself with import duties and taxes that may apply to automotive parts in your region. Collaborating with a reliable freight forwarder can simplify the process, ensuring compliance with local regulations and timely delivery to your warehouse or distribution center. -

8. How can I customize car starters to meet specific market needs?

Customizing car starters involves collaborating closely with manufacturers to tailor specifications to your market’s requirements. Consider factors such as torque, dimensions, and connector types that may differ based on regional vehicle models. Provide clear design specifications and volume estimates to facilitate the customization process. Additionally, engage in prototyping and testing phases to ensure the modified starters meet performance standards and customer expectations before mass production.

Top 3 Whats A Car Starter Manufacturers & Suppliers List

1. Morris Bros Auto – Car Starters

Domain: morrisbrosauto.com

Registered: 2017 (8 years)

Introduction: Car starters are electrical motors responsible for starting a vehicle’s engine. They receive a significant amount of electricity from the battery. When the ignition key is turned, the battery sends an electrical current to the starter solenoid on the starter motor, which powers the starter. A small gear extends from the starter to engage the vehicle’s flywheel, turning it and subsequently the cran…

2. Reddit – Car Starter Mechanism

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The car starter is powered by the battery and engages a smaller gear to quickly spin and engage the main gear, starting the engine. Once the engine reaches speed, it becomes self-sufficient, and the starter motor disengages. The process involves a precisely timed sequence of igniting fuel in the cylinders to keep the engine running.

3. Haynes – Starter Motors

Domain: us.haynes.com

Registered: 1996 (29 years)

Introduction: This company, Haynes – Starter Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for whats a car starter

The importance of strategic sourcing in the automotive sector, particularly for components like car starters, cannot be overstated. A well-functioning starter is crucial for engine operation, making it essential for B2B buyers to prioritize quality and reliability in their sourcing decisions. Understanding the nuances of starter motor functionality, potential failure symptoms, and the implications of sourcing inferior products can lead to significant operational efficiencies and cost savings.

By engaging with reputable suppliers, companies can ensure they receive high-quality starters that enhance vehicle performance and longevity. Moreover, establishing strong relationships with manufacturers allows for better negotiation terms, access to the latest technologies, and insights into emerging market trends.

As the global automotive market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, international buyers must remain proactive. Investing in strategic sourcing now will position your business to capitalize on future opportunities and ensure a competitive edge in the ever-changing landscape of automotive components. Take action today by evaluating your current supply chain and exploring partnerships that align with your long-term business goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.