Introduction: Navigating the Global Market for starter motor starter

In today’s competitive landscape, international B2B buyers face the critical challenge of sourcing reliable starter motor starters that meet diverse operational requirements while ensuring compliance with regional standards. Whether you’re operating in the bustling markets of Nigeria, the industrial sectors of Germany, or the emerging economies of South America and the Middle East, understanding the nuances of starter motor starters can significantly impact your purchasing decisions. This comprehensive guide delves into the various types of starter motor starters, their applications across different industries, and the essential criteria for supplier vetting.

By exploring the intricacies of cost structures, performance specifications, and regulatory compliance, this guide equips B2B buyers with the insights necessary to make informed decisions. We will discuss how to evaluate supplier reliability, assess product quality, and navigate the complexities of international shipping and tariffs. Furthermore, we will provide actionable tips on negotiating favorable terms and securing the best value for your investments.

With a focus on empowering businesses to enhance their operational efficiency, this resource is designed to streamline your sourcing process and ensure you select the right starter motor starters tailored to your specific needs. As you navigate the global market, let this guide be your trusted companion in achieving optimal performance and reliability in your motor operations.

Table Of Contents

- Top 2 Starter Motor Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor starter

- Understanding starter motor starter Types and Variations

- Key Industrial Applications of starter motor starter

- 3 Common User Pain Points for ‘starter motor starter’ & Their Solutions

- Strategic Material Selection Guide for starter motor starter

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor starter’

- Comprehensive Cost and Pricing Analysis for starter motor starter Sourcing

- Alternatives Analysis: Comparing starter motor starter With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor starter

- Navigating Market Dynamics and Sourcing Trends in the starter motor starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor starter

- Strategic Sourcing Conclusion and Outlook for starter motor starter

- Important Disclaimer & Terms of Use

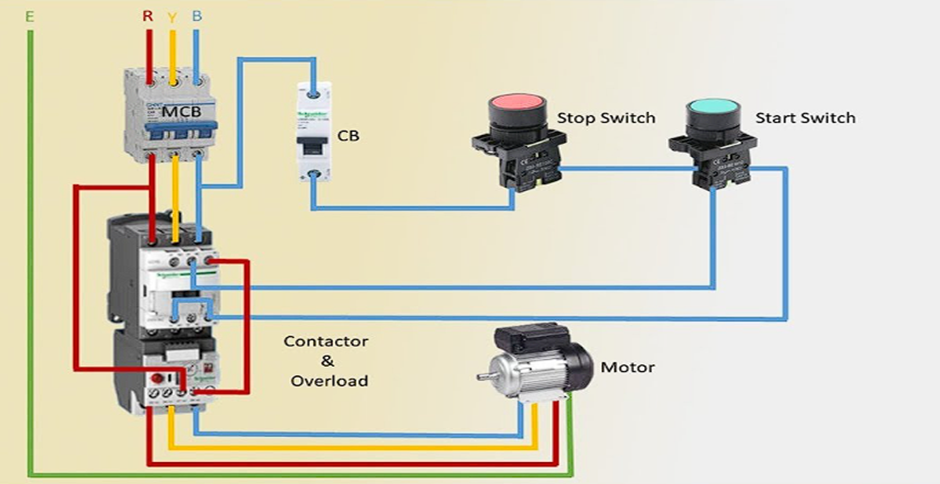

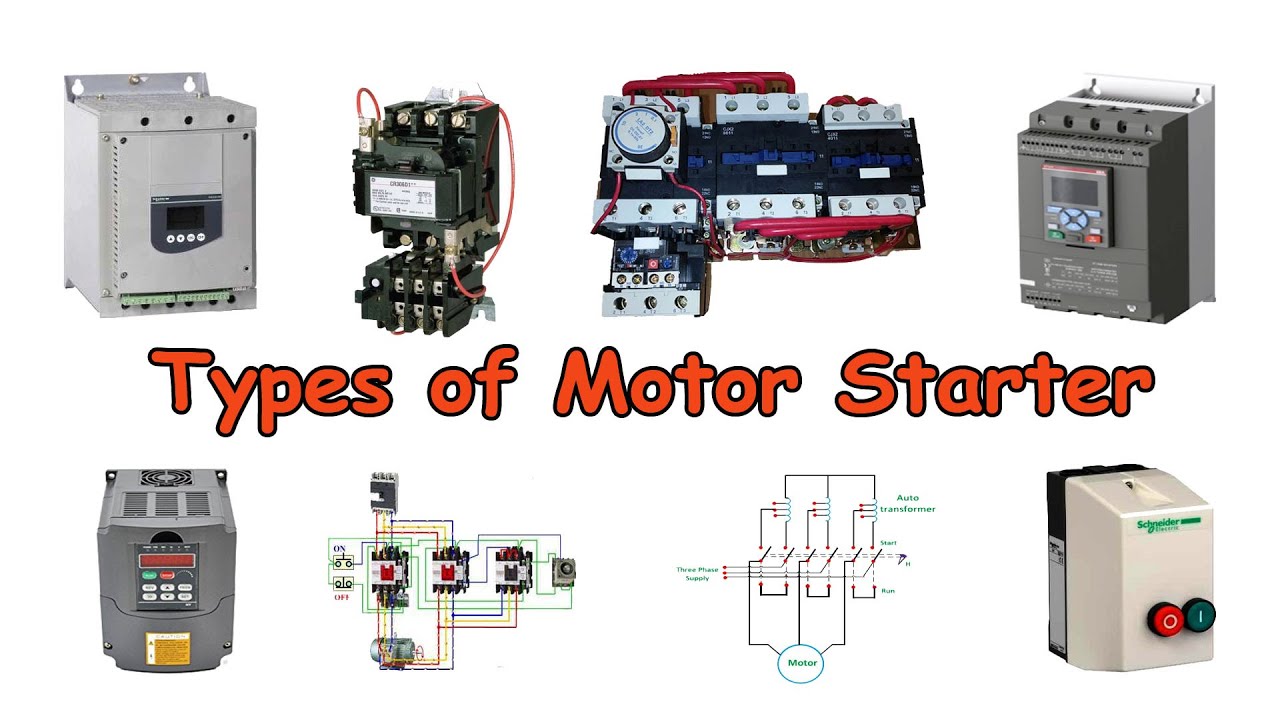

Understanding starter motor starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Motor Starters | Utilizes electromagnetic induction; robust and reliable. | Manufacturing, HVAC systems, agriculture | Pros: Cost-effective, easy maintenance. Cons: Limited speed control. |

| Soft Starters | Gradually increases motor voltage; reduces inrush current. | Pumps, compressors, conveyor systems | Pros: Extends motor life, minimizes mechanical stress. Cons: Higher initial cost. |

| Direct-On-Line (DOL) Starters | Simple design; connects motor directly to the power supply. | Small motors in various industries | Pros: Low cost, straightforward installation. Cons: High starting current can damage motors. |

| Star-Delta Starters | Reduces starting current by initially connecting in star configuration. | Large industrial motors | Pros: Reduces electrical stress, energy-efficient. Cons: More complex installation. |

| Variable Frequency Drives (VFDs) | Allows precise control of motor speed and torque. | Automation, robotics, and energy sectors | Pros: Highly efficient, flexible control. Cons: Higher upfront investment and complexity. |

What are the Characteristics of Induction Motor Starters?

Induction motor starters are characterized by their use of electromagnetic induction to start and run electric motors. They are particularly suited for applications that require reliability and robustness, such as manufacturing and HVAC systems. B2B buyers should consider the ease of maintenance and cost-effectiveness of induction starters, but they should also be aware that these starters typically offer limited speed control, which may not suit all operational needs.

Illustrative image related to starter motor starter

How Do Soft Starters Work and Where Are They Used?

Soft starters are designed to gradually increase the voltage supplied to the motor, significantly reducing inrush current during startup. This feature is particularly beneficial in applications involving pumps, compressors, and conveyor systems, where mechanical stress can lead to premature equipment failure. While soft starters extend motor life and minimize wear, they come with a higher initial cost that buyers should factor into their purchasing decisions.

What Are the Advantages and Disadvantages of Direct-On-Line Starters?

Direct-On-Line (DOL) starters are one of the simplest types, connecting the motor directly to the power supply. This straightforward design makes DOL starters ideal for small motors across various industries. They are cost-effective and easy to install; however, the high starting current can potentially damage the motor or the electrical infrastructure, making it crucial for buyers to assess their system’s capacity before opting for this type.

Why Choose Star-Delta Starters for Large Motors?

Star-Delta starters are effective for large industrial motors, as they initially connect the motor in a star configuration to reduce starting current and then switch to a delta configuration for normal operation. This method not only reduces electrical stress but also enhances energy efficiency. However, the installation process is more complex, requiring careful consideration of the operational environment and the technical expertise available.

How Do Variable Frequency Drives (VFDs) Enhance Motor Control?

Variable Frequency Drives (VFDs) offer precise control over motor speed and torque by adjusting the frequency and voltage supplied to the motor. This capability makes VFDs suitable for applications in automation, robotics, and energy sectors, where efficiency and flexibility are paramount. While VFDs provide significant advantages in energy savings and operational control, the higher upfront investment and complexity may be a barrier for some buyers, necessitating a thorough evaluation of long-term benefits versus initial costs.

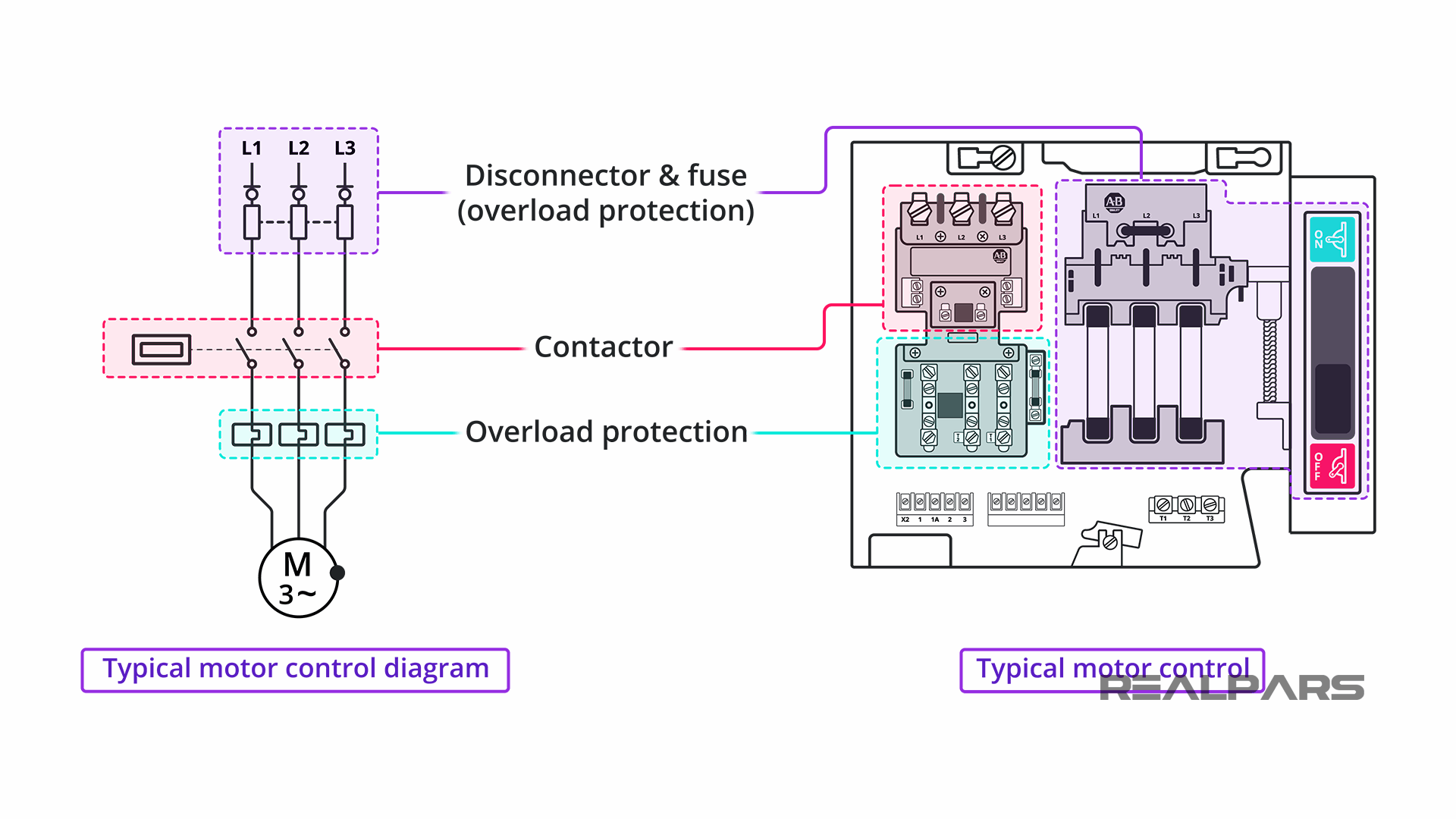

Key Industrial Applications of starter motor starter

| Industry/Sector | Specific Application of starter motor starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Machinery startup and shutdown control | Enhances operational efficiency and reduces downtime | Ensure compatibility with existing machinery; verify NEMA ratings; consider thermal overload protection. |

| Agriculture | Agricultural equipment ignition systems | Reliable starting in various weather conditions | Look for weather-resistant designs; assess power requirements for different machinery types. |

| Transportation | Heavy-duty vehicle engine starting | Ensures reliable vehicle operation and safety | Evaluate kW ratings suitable for vehicle types; consider remanufactured options for cost savings. |

| Construction | Power tool and equipment activation | Improves productivity and reduces project delays | Prioritize heavy-duty models; verify compliance with local electrical standards. |

| Renewable Energy | Wind turbine and solar panel system activation | Supports sustainable energy generation | Assess voltage compatibility; focus on durable designs for harsh environments. |

How is ‘starter motor starter’ Used in Manufacturing Machinery?

In manufacturing, starter motor starters are critical for controlling the startup and shutdown of heavy machinery. This application helps prevent equipment damage during operation, ensuring that machines function optimally. By implementing starters with thermal overload protection, manufacturers can safeguard their equipment against electrical faults. For international B2B buyers, especially in regions like Nigeria and Germany, sourcing starters that comply with local standards (such as UL508A and IEC) is essential to ensure safety and reliability.

What Role Does ‘starter motor starter’ Play in Agriculture?

In the agricultural sector, starter motor starters are employed in various equipment, including tractors and harvesters, to ensure reliable ignition. These starters are designed to operate effectively in diverse weather conditions, which is crucial for agricultural operations that cannot afford downtime. Buyers from South America and Africa should consider sourcing weather-resistant models that can handle the rigors of outdoor use, as well as verifying that the starters meet the necessary power requirements for different types of machinery.

How is ‘starter motor starter’ Essential for Transportation?

In the transportation industry, starter motor starters are vital for the reliable ignition of heavy-duty vehicles, including trucks and buses. A dependable starter ensures that vehicles can operate safely and efficiently, minimizing the risk of breakdowns. B2B buyers should assess the kW ratings of starters to ensure compatibility with specific vehicle types. Additionally, considering remanufactured options can provide significant cost savings without sacrificing quality, making it an attractive choice for companies looking to optimize their budgets.

Why is ‘starter motor starter’ Important in Construction?

Starter motor starters are essential in the construction industry for activating various power tools and equipment, enhancing productivity on job sites. The ability to quickly start and stop equipment reduces project delays and improves overall efficiency. When sourcing starters, construction companies should prioritize heavy-duty models that can withstand the demanding conditions of construction sites. Compliance with local electrical standards is also crucial to avoid potential safety hazards and ensure reliable operation.

Illustrative image related to starter motor starter

How Does ‘starter motor starter’ Support Renewable Energy Initiatives?

In renewable energy applications, such as wind turbines and solar panel systems, starter motor starters are used to activate and deactivate systems effectively. These starters contribute to the overall efficiency of energy generation, supporting sustainability goals. Buyers should focus on starters that offer durability and compatibility with the specific voltage requirements of renewable energy systems. Additionally, sourcing starters designed for harsh environmental conditions is crucial for ensuring long-term operational reliability.

3 Common User Pain Points for ‘starter motor starter’ & Their Solutions

Scenario 1: Inconsistent Performance and Reliability Issues

The Problem: Many B2B buyers, particularly those in industries relying on heavy machinery, face challenges with starter motor starters that exhibit inconsistent performance. For instance, a manufacturing plant in Germany may experience frequent failures during peak operational hours, leading to unexpected downtimes. This not only affects productivity but also incurs additional costs related to repairs and lost operational time. Buyers may find themselves questioning the reliability of their current suppliers, as poor-quality components can significantly disrupt business operations.

The Solution: To address these reliability issues, it is crucial for buyers to partner with reputable suppliers that offer high-quality starter motor starters. When sourcing, look for products that meet industry standards such as UL508A and IEC certifications, ensuring they have undergone rigorous testing for performance and safety. Additionally, consider investing in starters with built-in thermal overload protection and adjustable trip current features, as these can enhance operational reliability. Regular maintenance checks should also be implemented to identify potential issues before they escalate, and maintaining an inventory of essential spare parts can further minimize downtime.

Illustrative image related to starter motor starter

Scenario 2: Complexity in Installation and Compatibility Challenges

The Problem: B2B buyers often encounter difficulties with the installation and compatibility of starter motor starters, especially when dealing with diverse machinery setups. A business operating in South America may find that their existing electrical systems are not compatible with newly purchased starters, leading to delays in project timelines. The complexity of installation can also require specialized knowledge, which may not be readily available within the organization, resulting in increased labor costs and potential installation errors.

The Solution: To mitigate these installation challenges, buyers should prioritize sourcing starter motor starters that come with comprehensive installation manuals and technical support. Engage with suppliers who offer prewired options, as these can simplify the installation process and reduce the need for specialized skills. Furthermore, consider conducting a compatibility assessment of the electrical systems before making a purchase. This proactive approach can help ensure that the selected starter motor starters are suitable for the specific machinery in use, thereby avoiding compatibility issues down the line.

Scenario 3: Limited Customization and Scalability Options

The Problem: As businesses grow, their operational needs evolve, leading to a demand for starter motor starters that can adapt to varying requirements. For instance, a company in Nigeria may need to scale up its machinery to accommodate increased production demands, but find that their existing starter solutions do not offer the necessary flexibility or capacity. This limitation can hinder business growth and force companies to invest in entirely new systems, incurring additional costs.

Illustrative image related to starter motor starter

The Solution: To ensure scalability, buyers should seek starter motor starters that offer customizable features. Products that allow for adjustable settings, such as trip currents and phase loss sensitivity protection, can provide the flexibility needed for varying operational demands. Additionally, consider suppliers that offer a range of models with different horsepower ratings and voltage options, allowing businesses to scale their operations without complete overhauls of their electrical systems. Establishing a long-term relationship with a supplier that understands your growth trajectory can also facilitate better planning and inventory management, ensuring that you have the right components available as your needs change.

Strategic Material Selection Guide for starter motor starter

What Are the Key Materials Used in Starter Motor Starters?

When selecting materials for starter motor starters, it’s essential to consider various factors that impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of starter motor starters.

How Does Mild Steel Perform in Starter Motor Starters?

Key Properties: Mild steel is known for its excellent tensile strength and ductility. It can withstand moderate temperatures and is relatively easy to fabricate. However, it has limited corrosion resistance, which can be a drawback in harsh environments.

Pros & Cons: The primary advantage of mild steel is its cost-effectiveness and ease of machining, making it suitable for high-volume production. However, its susceptibility to rust and corrosion can lead to reduced lifespan, particularly in humid or corrosive environments.

Impact on Application: Mild steel is compatible with various media but may require protective coatings to enhance its durability in specific applications.

Considerations for International Buyers: For buyers in regions like Nigeria or Brazil, where humidity can be high, it’s crucial to consider additional protective measures. Compliance with standards such as ASTM A36 may be necessary to ensure quality.

What Role Does Stainless Steel Play in Starter Motor Starters?

Key Properties: Stainless steel offers superior corrosion resistance and can withstand higher temperatures compared to mild steel. It is also known for its aesthetic appeal and longevity.

Pros & Cons: The main advantage of stainless steel is its durability and resistance to rust, making it ideal for outdoor applications. However, it is more expensive than mild steel and can be more challenging to machine.

Impact on Application: Stainless steel is suitable for applications where moisture or corrosive substances are present. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer stainless steel due to stringent regulations regarding material quality and environmental impact. Compliance with DIN standards is essential.

How Does Aluminum Compare in Starter Motor Starters?

Key Properties: Aluminum is lightweight and has excellent thermal conductivity. It also exhibits good corrosion resistance, making it suitable for various applications.

Pros & Cons: The lightweight nature of aluminum allows for easier installation and reduced energy consumption. However, it is generally less durable than steel and may not withstand high-pressure environments as effectively.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in automotive or aerospace industries.

Considerations for International Buyers: In regions like the Middle East, where temperatures can soar, aluminum’s thermal properties can be advantageous. Compliance with JIS standards may be necessary for certain applications.

Illustrative image related to starter motor starter

What About Composite Materials in Starter Motor Starters?

Key Properties: Composite materials are engineered to provide specific properties, such as high strength-to-weight ratios and excellent corrosion resistance. They can be tailored for specific applications.

Pros & Cons: The primary advantage of composites is their versatility and ability to meet specific performance criteria. However, they can be more expensive and complex to manufacture.

Impact on Application: Composites can be used in specialized applications where traditional materials may fail, such as in extreme environments.

Considerations for International Buyers: For buyers in South America, understanding the specific requirements and certifications for composite materials is vital. Compliance with local standards will ensure product acceptance.

Summary Table of Material Selection for Starter Motor Starters

| Material | Typical Use Case for starter motor starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | General industrial applications | Cost-effective and easy to machine | Limited corrosion resistance | Low |

| Stainless Steel | Outdoor and corrosive environments | Superior corrosion resistance | Higher cost and machining difficulty | High |

| Aluminum | Automotive and aerospace applications | Lightweight and good thermal conductivity | Less durable under high pressure | Medium |

| Composite | Specialized applications in extreme environments | Tailored properties for performance | Higher cost and manufacturing complexity | High |

This guide serves as a strategic tool for international B2B buyers, helping them make informed decisions on material selection based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor starter

What Are the Main Stages of Manufacturing Starter Motor Starters?

The manufacturing process of starter motor starters involves several critical stages, each designed to ensure the final product meets the rigorous demands of industrial applications. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to starter motor starter

-

Material Preparation: The manufacturing process begins with the selection of high-quality materials such as mild steel for the enclosure and copper for electrical components. Materials are sourced from certified suppliers, ensuring compliance with international standards. In this phase, materials are inspected for defects and prepared for processing, which may involve cutting, shaping, or treating them for enhanced durability.

-

Forming: This stage involves shaping the prepared materials into their required forms. Techniques such as stamping, bending, and machining are employed to create components like enclosures, contactors, and thermal overload protectors. Precision is crucial here, as even minor discrepancies can affect the functionality of the starter motor.

-

Assembly: Once the individual components are formed, they are assembled into the final product. This process often includes the installation of electrical components, mechanical fastening, and integration of safety features such as overload protection. Automated assembly lines may be used for efficiency, but manual inspection is also vital to ensure correct assembly.

-

Finishing: The final stage involves applying protective coatings and surface treatments to enhance durability and resistance to environmental factors. This may include painting or galvanizing the metal parts. Quality checks are conducted to ensure that the finishing meets aesthetic and functional requirements.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for starter motor starters, ensuring that products meet both safety standards and performance expectations. Several international and industry-specific standards guide this process.

-

Relevant International Standards:

– ISO 9001: This widely recognized standard outlines the criteria for a quality management system. Compliance with ISO 9001 ensures that a manufacturer consistently meets customer and regulatory requirements.

– CE Marking: In Europe, products must meet specific health, safety, and environmental protection standards to earn the CE mark, indicating conformity with European directives. -

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial inspection phase checks raw materials and components for compliance with specifications before they enter production.

– In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves regular inspections and tests to monitor product quality and detect issues early. This may include measuring tolerances and assessing assembly integrity.

– Final Quality Control (FQC): The final inspection ensures that the completed starter motor starters meet all specifications and performance standards. Testing may involve electrical performance checks, mechanical stress tests, and safety assessments.

What Common Testing Methods Are Used in Quality Assurance?

To ensure that starter motor starters function effectively and safely, several testing methods are commonly employed:

-

Electrical Testing: This includes checking the motor’s voltage, current, and resistance to ensure it operates within specified limits. Load testing is often conducted to simulate real-world conditions.

-

Mechanical Testing: Durability tests assess the robustness of the assembly, particularly the enclosure and mechanical components, to withstand industrial environments.

-

Thermal Testing: This evaluates the thermal overload protection mechanisms to ensure they operate correctly under high-temperature conditions.

-

Environmental Testing: Products may undergo tests for resistance to moisture, dust, and corrosive elements, ensuring they perform reliably in various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing starter motor starters, B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and overall operational standards of suppliers. This can reveal insights into their commitment to quality.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality assurance processes, including results from IQC, IPQC, and FQC. These reports can help verify compliance with international standards and industry practices.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing processes and product quality. This is particularly important for buyers in regions where local standards may differ from international norms.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, face unique challenges when verifying quality control in starter motor starters. Here are key considerations:

Illustrative image related to starter motor starter

-

Regulatory Compliance: Each region may have specific regulations and standards that products must meet. Buyers should be familiar with local requirements and ensure that their suppliers comply with both local and international standards.

-

Cultural Differences: Understanding the cultural and business practices of suppliers in different regions can aid in communication and negotiation. Building strong relationships can facilitate better quality assurance practices.

-

Supply Chain Transparency: Buyers should seek suppliers who are transparent about their supply chains and quality control processes. This transparency can provide confidence in the integrity of the products being sourced.

In conclusion, understanding the manufacturing processes and quality assurance practices for starter motor starters is crucial for B2B buyers. By focusing on rigorous standards, effective quality control checkpoints, and thorough verification methods, buyers can ensure they source reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor starter’

Introduction

Sourcing a starter motor starter requires a systematic approach to ensure that you acquire the right product for your operational needs. This guide outlines essential steps to help B2B buyers navigate the procurement process, ensuring they make informed decisions that align with both technical specifications and business requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is paramount before initiating the sourcing process. Consider factors such as voltage requirements, horsepower ratings, and phase types (single or three-phase). This clarity will help narrow down options and ensure compatibility with your existing systems.

Illustrative image related to starter motor starter

- Voltage Options: Assess whether you need 120V, 240V, or 480V starters based on your electrical infrastructure.

- Horsepower Ratings: Determine the range of horsepower your motors will require, typically between 0.5HP to 10HP for most applications.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify reputable suppliers who specialize in starter motor starters. Look for companies with established market presence and positive customer reviews.

- Industry Experience: Prioritize suppliers with a track record in your specific industry.

- Geographic Considerations: Evaluate suppliers that can efficiently serve your region, particularly in Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This step is crucial to ensure product reliability and safety.

- UL and IEC Standards: Check if the products meet UL508A and IEC standards, which indicate adherence to safety and performance benchmarks.

- Quality Assurance Processes: Inquire about the supplier’s quality control measures and testing procedures.

Step 4: Request Detailed Product Information

Gather detailed product specifications and documentation from shortlisted suppliers. This includes manuals, installation guides, and data sheets.

- Technical Documentation: Ensure that you receive comprehensive product documentation that covers installation, maintenance, and troubleshooting.

- Warranty and Support: Clarify warranty terms and the availability of technical support for post-purchase assistance.

Step 5: Compare Pricing and Payment Terms

Obtain quotes from multiple suppliers to compare pricing structures and payment terms. This not only helps in budget planning but also provides leverage in negotiations.

- Bulk Discounts: Inquire about discounts for bulk purchases, which can significantly reduce overall costs.

- Payment Flexibility: Look for suppliers that offer flexible payment terms to accommodate your cash flow needs.

Step 6: Assess After-Sales Support and Service

Evaluate the after-sales support provided by potential suppliers. Reliable support can enhance your operational efficiency and minimize downtime.

Illustrative image related to starter motor starter

- Technical Support Availability: Ensure that the supplier offers accessible technical support for installation and troubleshooting.

- Replacement Parts Availability: Confirm that the supplier can provide replacement parts and accessories easily.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, negotiate the final terms of the purchase agreement. Ensure all details, including delivery timelines, payment schedules, and warranties, are clearly documented.

- Contract Review: Have legal counsel review the purchase agreement to protect your interests.

- Delivery and Installation Logistics: Coordinate with the supplier on delivery schedules and installation support to ensure a seamless integration into your operations.

By following these steps, you can make informed decisions in sourcing starter motor starters that meet your technical and operational requirements.

Comprehensive Cost and Pricing Analysis for starter motor starter Sourcing

What Are the Key Cost Components in Starter Motor Starter Manufacturing?

Understanding the cost structure of starter motor starters is essential for B2B buyers, especially when sourcing from international markets. The primary cost components include:

Illustrative image related to starter motor starter

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include mild steel for enclosures and copper for electrical components. High-quality materials can enhance durability but may also increase the price.

-

Labor: Labor costs vary significantly depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this could compromise quality if not managed properly.

-

Manufacturing Overhead: This includes utilities, facility costs, and other indirect expenses associated with production. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial investment in molds and tools for production can be substantial. Custom tooling for specialized designs may also lead to higher upfront costs but can result in better product performance.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet international standards, which is particularly critical for buyers in Europe and the Americas. These processes add to the cost but are essential for maintaining product reliability.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the chosen Incoterms. International shipping may also include customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary based on competition, market demand, and the supplier’s reputation.

How Do Price Influencers Affect Starter Motor Starter Costs?

Several factors influence the pricing of starter motor starters, making it essential for buyers to consider these when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Understanding the supplier’s MOQ can help in planning purchases effectively.

-

Specifications and Customization: Tailoring products to specific requirements can increase costs. While customized solutions may offer better fit and performance, they may also lead to longer lead times and higher prices.

-

Materials and Quality Certifications: Higher quality materials and certifications (like UL or IEC) can drive up costs. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can affect pricing. Established suppliers may charge more for their products due to perceived quality and service reliability.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is crucial, as they determine who is responsible for shipping costs and risks. This can significantly influence the total landed cost of the product.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Starter Motor Starters?

To optimize sourcing strategies, B2B buyers should consider the following tips:

-

Negotiate Effectively: Building a good relationship with suppliers can lead to better pricing and terms. Leverage volume orders and long-term contracts to negotiate favorable rates.

-

Focus on Total Cost of Ownership (TCO): Assess not just the initial purchase price but also maintenance, operational efficiency, and potential downtime costs. A slightly higher upfront cost may yield savings over the product’s lifecycle.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations, import duties, and local regulations that may impact total costs. This is particularly relevant for buyers in Africa and South America, where these factors can be more pronounced.

-

Consider Local Suppliers: When possible, sourcing from local suppliers can reduce shipping costs and lead times. It may also simplify compliance with local regulations.

-

Evaluate Supplier Stability: Investigate the financial health and operational stability of suppliers, especially in regions with economic volatility. A reliable supplier will provide better long-term value.

Conclusion

Navigating the complexities of sourcing starter motor starters requires an understanding of various cost components and pricing influencers. By applying strategic buyer tips, businesses can enhance their procurement processes, ensuring they acquire high-quality products at competitive prices. Always remember that indicative prices may fluctuate based on market conditions, so staying informed and adaptable is crucial for successful sourcing.

Alternatives Analysis: Comparing starter motor starter With Other Solutions

Introduction: Exploring Alternatives to Starter Motor Starters

When evaluating solutions for operating and protecting electric motors, understanding the alternatives to starter motor starters is crucial for B2B buyers. Different technologies can offer varying benefits in terms of performance, cost, and maintenance. This analysis aims to provide insights into viable alternatives, helping businesses make informed decisions based on their unique operational needs.

Comparison Table

| Comparison Aspect | Starter Motor Starter | Variable Frequency Drive (VFD) | Soft Starter |

|---|---|---|---|

| Performance | Reliable for single-speed operations | Adjustable speed control enhances efficiency | Reduces inrush current, prolongs motor life |

| Cost | $199.95 – $275.95 | $232.95 – $2,314.05 | $150 – $1,000 |

| Ease of Implementation | Simple installation with prewired components | Requires technical expertise for setup | Moderate complexity, often needing configuration |

| Maintenance | Low maintenance; robust design | Moderate, needs occasional recalibration | Low maintenance; less wear on motor |

| Best Use Case | Basic motor applications in industrial settings | Applications requiring variable speed control | Applications needing smooth starts and reduced torque |

Detailed Breakdown of Alternatives

Variable Frequency Drive (VFD)

Variable Frequency Drives are advanced motor controllers that allow for precise control over motor speed and torque. The primary advantage of VFDs is their ability to adjust the speed of the motor, which leads to improved energy efficiency and reduced operational costs. They are ideal for applications where variable speed operation is crucial, such as in HVAC systems or conveyor belts. However, VFDs can be more expensive and may require specialized knowledge for installation and configuration, making them less accessible for some businesses.

Soft Starter

Soft starters are devices designed to gradually ramp up the power supplied to an electric motor, minimizing inrush current during startup. This feature significantly reduces mechanical stress on the motor and extends its lifespan. Soft starters are particularly beneficial in applications where smooth acceleration is important, such as in pumps and fans. While they are generally more affordable than VFDs, they do not provide speed control and are limited to applications that require only a single speed.

Illustrative image related to starter motor starter

Conclusion: Choosing the Right Solution for Your Needs

When selecting between starter motor starters and their alternatives, consider your specific operational requirements. If your application involves basic on/off control without the need for variable speed, a starter motor starter may be the most cost-effective and straightforward choice. However, if you require flexibility in speed control to enhance energy efficiency, a VFD could be the better investment, despite the higher upfront cost. For applications needing a gentle start to reduce mechanical wear, a soft starter might be the ideal solution. Ultimately, understanding your operational goals and constraints will guide you to the most suitable choice for your business.

Essential Technical Properties and Trade Terminology for starter motor starter

What Are the Key Technical Properties of Starter Motor Starters?

Understanding the essential technical specifications of starter motor starters is crucial for B2B buyers seeking reliable and efficient equipment. Here are several critical specifications that should be considered:

-

Material Grade

The material grade indicates the quality and durability of the starter motor starter. Common materials include mild steel for enclosures, which can withstand industrial conditions. High-grade materials ensure longevity and reliability, reducing replacement costs and downtime in operations. -

Power Rating (kW)

Power rating, measured in kilowatts (kW), reflects the starter’s capability to handle various motor sizes. For instance, a starter rated at 1 kW can effectively power smaller motors, while a 5 kW starter is suitable for larger applications. Selecting the appropriate power rating is essential to ensure optimal performance and avoid equipment failures. -

Voltage Rating

Voltage ratings, such as 120 VAC, 240 VAC, or 480 VAC, specify the electrical input required for the starter motor to operate. Understanding voltage requirements is vital for compatibility with existing electrical systems, ensuring efficiency and safety in operations. -

NEMA Rating

The National Electrical Manufacturers Association (NEMA) rating indicates the enclosure’s suitability for specific environmental conditions. For example, a NEMA 1 rating denotes protection against indoor dust and light contact. Selecting the right NEMA rating helps in maintaining operational integrity in diverse environments. -

Thermal Overload Protection

This feature is designed to prevent overheating, which can lead to equipment failure. Thermal overload protection automatically disconnects the motor when it exceeds a certain temperature, safeguarding both the starter and the connected motor. This is particularly important for industries where motors run continuously under heavy loads. -

Phase Configuration

Starters can be configured for single-phase or three-phase motors. Understanding the phase configuration is essential to ensure compatibility with the motor type being used, as this affects both performance and efficiency.

What Are Common Trade Terms in the Starter Motor Industry?

Familiarity with industry jargon can streamline negotiations and purchasing processes. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. OEM parts are often preferred for their compatibility and reliability, making them a crucial consideration for buyers looking to maintain or upgrade existing equipment. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs and ensure that they meet supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products. It is a vital tool for B2B buyers to compare costs and features, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is critical for international buyers to ensure clarity and avoid disputes during transactions. -

Lead Time

This term refers to the time taken from placing an order to the delivery of goods. Understanding lead times helps buyers plan their operations and manage expectations regarding product availability. -

Warranty Terms

Warranty terms outline the conditions under which a product can be repaired or replaced. Awareness of warranty specifics is essential for buyers to safeguard their investments and ensure support in case of product failure.

In conclusion, understanding these technical properties and trade terms enables B2B buyers to make informed decisions, ensuring they select the right starter motor starters for their operational needs while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the starter motor starter Sector

What Are the Current Market Dynamics and Key Trends in the Starter Motor Sector?

The global starter motor market is experiencing significant growth driven by the increasing demand for electric vehicles (EVs) and the expansion of industrial automation. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing a shift towards more energy-efficient starter motors. This transition is fueled by technological advancements, such as the integration of variable frequency drives (VFDs) that offer better control over motor speeds and reduce energy consumption.

Another emerging trend is the rise of smart technologies in motor starters, enabling remote monitoring and diagnostics. This capability enhances operational efficiency and minimizes downtime, making it a valuable feature for industrial buyers. Furthermore, as industries strive for greater sustainability, the demand for starters that comply with international standards, like UL508A and IEC regulations, is increasing.

In terms of sourcing strategies, international buyers are increasingly looking for suppliers who can provide comprehensive technical support and customization options. This is particularly relevant in markets such as Nigeria, where local manufacturers are gaining traction but still require expertise from established brands. Consequently, forging partnerships with reliable manufacturers can be a strategic move for B2B buyers aiming to navigate these market dynamics effectively.

How Is Sustainability Influencing the Sourcing of Starter Motors?

Sustainability has become a cornerstone of sourcing strategies in the starter motor sector. The environmental impact of manufacturing processes and the importance of ethical supply chains are now paramount considerations for B2B buyers. This shift is reflected in the increasing demand for products made from recyclable materials and those that minimize energy consumption during operation.

Buyers are actively seeking suppliers who prioritize green certifications and materials. For example, choosing starter motors that incorporate recyclable components not only reduces waste but also enhances brand reputation among environmentally conscious consumers. Furthermore, suppliers who adhere to ethical labor practices and transparent sourcing contribute to a more sustainable supply chain, aligning with the values of today’s businesses.

The push for sustainability also extends to the lifecycle of products. Buyers are looking for solutions that offer durability and longevity, reducing the frequency of replacements and, consequently, the environmental footprint. Engaging with suppliers that emphasize sustainable practices can provide a competitive edge in the market while contributing to broader environmental goals.

Illustrative image related to starter motor starter

What Is the Historical Context of the Starter Motor Sector?

The starter motor sector has evolved significantly since its inception in the early 20th century. Initially designed to enable the quick start of internal combustion engines, starter motors were mechanical in nature and required manual effort. The introduction of electric starter motors in the 1910s revolutionized the automotive industry, enhancing user convenience and reliability.

Over the decades, advancements in materials science and electrical engineering have led to the development of more compact and efficient starter motors. The transition to electronic ignition systems and the advent of hybrid and electric vehicles have further transformed the landscape. Today, starter motors are integral to various applications beyond automotive, including industrial machinery and renewable energy systems, reflecting their adaptability and importance in modern technology.

This historical perspective highlights the sector’s resilience and capacity for innovation, which is essential for B2B buyers to consider when sourcing products that meet current and future market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor starter

-

How do I choose the right starter motor starter for my application?

Choosing the right starter motor starter involves assessing several factors, including the motor’s horsepower, voltage, and phase requirements. Determine the specific application—industrial, commercial, or automotive—as different environments may demand unique specifications. Additionally, consider features like thermal overload protection, which safeguards the motor during high-stress conditions. Consulting with manufacturers about your specific needs can also help ensure you select a starter that meets both operational efficiency and safety standards. -

What certifications should I look for when sourcing starter motor starters?

When sourcing starter motor starters, look for certifications such as UL508, IEC standards, and NEMA ratings, which indicate compliance with safety and performance guidelines. These certifications ensure that the products have been tested for reliability and safety in various environments. In international trade, checking for region-specific certifications is also crucial, as regulations may vary between markets like Africa, Europe, and South America. Always verify the authenticity of these certifications with the supplier. -

What are the common payment terms in international B2B transactions for starter motor starters?

Common payment terms in international B2B transactions typically include options like Letter of Credit (LC), advance payment, or net terms (e.g., net 30 or net 60). Many suppliers may require a deposit upfront, especially for larger orders or custom products. It’s essential to discuss payment terms early in negotiations to ensure clarity and avoid potential disputes. Additionally, consider payment methods that offer protection, such as escrow services or trade finance solutions, especially when dealing with new suppliers. -

How can I vet a supplier for starter motor starters?

Vetting a supplier involves conducting thorough due diligence. Start by checking their business credentials, including registration, years in operation, and industry reputation. Request references from previous clients and review their product quality through samples or certifications. It’s beneficial to visit their facility if possible or utilize third-party inspection services to evaluate their production capabilities. Additionally, assess their responsiveness and willingness to communicate, as this can indicate their commitment to customer service. -

What is the minimum order quantity (MOQ) for starter motor starters?

The minimum order quantity (MOQ) for starter motor starters can vary significantly between suppliers, ranging from a few units to several hundred. Factors influencing MOQ include the type of starter, customization options, and production capabilities of the manufacturer. If you have a lower demand, consider negotiating the MOQ or exploring suppliers that specialize in small-batch production. Understanding the supplier’s pricing structure related to MOQ can help you make informed purchasing decisions. -

Can I customize starter motor starters to fit specific requirements?

Yes, many manufacturers offer customization options for starter motor starters to meet specific application needs. Customizations may include adjustments in voltage, horsepower ratings, enclosure types, or additional features like integrated control systems. When discussing custom orders, provide detailed specifications and requirements to the supplier. Be aware that customizations may affect lead times and pricing, so factor these into your project timelines and budget. -

What logistics considerations should I be aware of when importing starter motor starters?

When importing starter motor starters, consider logistics factors such as shipping methods, customs regulations, and potential tariffs or taxes. Select a reliable freight forwarder familiar with shipping electrical components to ensure compliance with international shipping laws. Additionally, factor in lead times for production and shipping when planning your inventory. Understanding the documentation required for customs clearance will also help streamline the import process and prevent delays. -

How do I ensure quality assurance for the starter motor starters I purchase?

To ensure quality assurance, request detailed product specifications and quality control processes from the supplier. Look for manufacturers that adhere to ISO standards or have their own quality assurance certifications. Conduct pre-shipment inspections or consider third-party quality assurance services to verify product quality before shipment. Establishing clear communication regarding quality expectations and potential penalties for non-compliance can also help maintain standards throughout the supply chain.

Top 2 Starter Motor Starter Manufacturers & Suppliers List

1. Cook MFG – Motor Starter

Domain: cookmfg.com

Registered: 2020 (5 years)

Introduction: {“name”: “Motor Starter”, “price_range”: “$199.95 – $275.95”, “description”: “Motor starters are used to operate and protect electric motors. The heavy duty and compact design is ideal for industrial environments.”, “enclosure_material”: “Steel”, “NEMA_rating”: “NEMA 1”, “features”: [“Heavy Duty Steel Enclosure”, “Motor Start / Stop Push Button”, “Motor Reset Push Button”, “Built In Thermal Overlo…

2. Haynes – Starter Motor

Domain: us.haynes.com

Registered: 1996 (29 years)

Introduction: This company, Haynes – Starter Motor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for starter motor starter

In the competitive landscape of the starter motor industry, strategic sourcing is pivotal for international B2B buyers aiming to optimize procurement processes and enhance operational efficiency. By leveraging key insights on product specifications, supplier reliability, and pricing structures, businesses can make informed decisions that align with their unique needs. The ability to source high-quality motor starters, equipped with essential features such as thermal overload protection and phase loss sensitivity, directly impacts the performance and longevity of electric motors across diverse applications.

As the market continues to evolve, buyers from regions like Africa, South America, the Middle East, and Europe must remain vigilant about emerging trends and technological advancements. Building strong relationships with reputable suppliers will not only ensure access to the latest innovations but also foster resilience against supply chain disruptions.

Looking ahead, now is the time for international buyers to enhance their sourcing strategies by prioritizing partnerships that deliver value and reliability. Embrace the opportunity to streamline your procurement processes and invest in quality starter motors that drive your business success. Engage with trusted suppliers today to secure the best solutions for your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to starter motor starter

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.