Introduction: Navigating the Global Market for how to know if your alternator is bad or battery

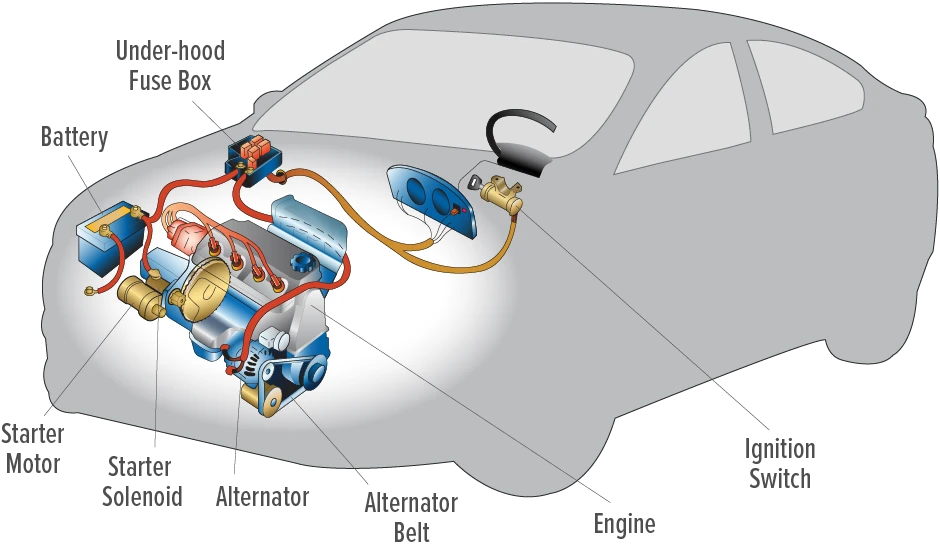

In the complex landscape of automotive maintenance, knowing how to determine if your alternator is bad or if the issue lies with your battery is crucial for businesses operating within the transportation sector. This guide offers a comprehensive resource for international B2B buyers, addressing common challenges faced in diagnosing electrical issues in vehicles. From understanding the signs of alternator failure to evaluating battery performance, this guide covers various types of alternators and batteries, their applications, and the latest diagnostic techniques.

By exploring the nuances of sourcing high-quality components and vetting reliable suppliers, businesses can make informed purchasing decisions that enhance their operational efficiency. Whether you’re navigating the markets in Nigeria, Brazil, or Europe, this guide empowers you with actionable insights to mitigate risks associated with faulty electrical systems. Additionally, it discusses cost considerations and the importance of selecting parts that meet international standards, ensuring long-term reliability and performance.

The automotive sector is increasingly competitive, and having the knowledge to distinguish between a failing alternator and a compromised battery can save time and resources. This guide not only equips you with the technical know-how but also reinforces the significance of strategic supplier partnerships, enabling your business to thrive in a global marketplace.

Table Of Contents

- Top 3 How To Know If Your Alternator Is Bad Or Battery Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to know if your alternator is bad or battery

- Understanding how to know if your alternator is bad or battery Types and Variations

- Key Industrial Applications of how to know if your alternator is bad or battery

- 3 Common User Pain Points for ‘how to know if your alternator is bad or battery’ & Their Solutions

- Strategic Material Selection Guide for how to know if your alternator is bad or battery

- In-depth Look: Manufacturing Processes and Quality Assurance for how to know if your alternator is bad or battery

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if your alternator is bad or battery’

- Comprehensive Cost and Pricing Analysis for how to know if your alternator is bad or battery Sourcing

- Alternatives Analysis: Comparing how to know if your alternator is bad or battery With Other Solutions

- Essential Technical Properties and Trade Terminology for how to know if your alternator is bad or battery

- Navigating Market Dynamics and Sourcing Trends in the how to know if your alternator is bad or battery Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to know if your alternator is bad or battery

- Strategic Sourcing Conclusion and Outlook for how to know if your alternator is bad or battery

- Important Disclaimer & Terms of Use

Understanding how to know if your alternator is bad or battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Visual Inspection | Look for physical signs of damage or corrosion | Automotive repair shops | Pros: Quick assessment; Cons: May miss hidden issues. |

| Multimeter Testing | Measures voltage output under various loads | Fleet management, automotive service | Pros: Accurate; Cons: Requires technical knowledge. |

| Load Testing | Tests battery and alternator under simulated load | Battery suppliers, automotive workshops | Pros: Comprehensive; Cons: Time-consuming. |

| Full Field Test | Bypasses regulator to check maximum output | Advanced automotive diagnostics | Pros: Identifies regulator issues; Cons: Risk of damage if not done correctly. |

| Battery Health Assessment | Analyzes battery capacity and health | Battery manufacturers, vehicle fleets | Pros: Preventive; Cons: Requires specialized equipment. |

What Are the Key Characteristics of Visual Inspection for Alternator and Battery Issues?

Visual inspection is the simplest method for identifying potential problems with alternators and batteries. This method involves checking for visible signs of wear, corrosion on terminals, or physical damage to components. While it is quick and requires no specialized tools, its effectiveness can be limited, as it may overlook underlying issues that could lead to system failure. B2B buyers, particularly in automotive repair shops, can utilize this method for initial diagnostics but should follow up with more comprehensive tests for accuracy.

How Does Multimeter Testing Enhance Diagnostic Accuracy?

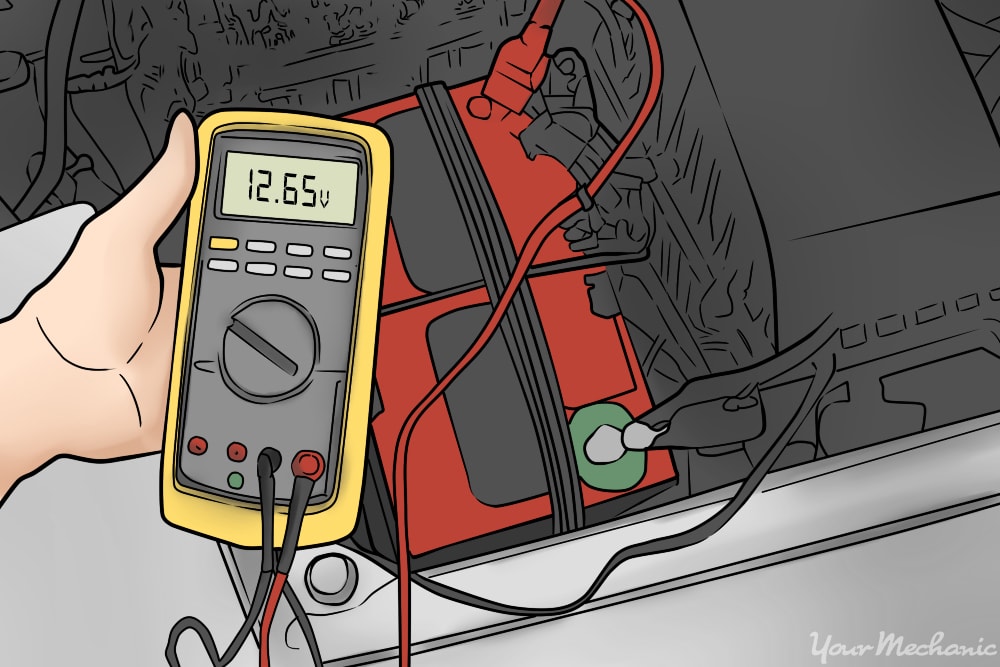

Multimeter testing involves measuring the voltage output of the alternator while the vehicle is running. A healthy alternator typically produces between 13.5 to 14.5 volts under load. This method is highly accurate and can help identify issues such as a failing alternator or battery. It is particularly beneficial for fleet management and automotive service businesses where quick and precise diagnostics can lead to reduced downtime. However, it requires technicians to have a certain level of expertise in electrical systems.

What Are the Benefits of Load Testing for Batteries and Alternators?

Load testing assesses the performance of the battery and alternator under simulated conditions, providing a clear picture of their operational capacity. This method is especially useful for battery suppliers and automotive workshops that need to ensure reliability in their products. While it offers a comprehensive evaluation, load testing can be time-consuming and may require specialized equipment. Businesses should consider the balance between thoroughness and efficiency when incorporating this method into their service offerings.

Why Is the Full Field Test Important for Advanced Diagnostics?

The full field test is a more advanced diagnostic technique that involves bypassing the voltage regulator to check the alternator’s maximum output. This method can help identify specific issues with the regulator or alternator that may not be apparent through standard testing. While it provides valuable insights, it carries risks, including potential damage to the alternator if not performed correctly. This method is typically used by advanced automotive diagnostics professionals and should be approached with caution.

How Can Battery Health Assessment Prevent Future Failures?

Battery health assessment focuses on evaluating the overall condition and capacity of the battery, helping to predict its lifespan and performance. This method is essential for battery manufacturers and vehicle fleet operators, as it allows for proactive maintenance and replacement strategies. Although it requires specialized equipment, the investment can lead to significant cost savings by preventing unexpected failures and extending the life of the vehicle’s electrical system.

Key Industrial Applications of how to know if your alternator is bad or battery

| Industry/Sector | Specific Application of how to know if your alternator is bad or battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Regular diagnostics of vehicle electrical systems using multimeters | Reduces downtime by ensuring vehicles are operational and safe | Quality of diagnostic tools, availability of parts, training |

| Transportation & Logistics | Fleet management systems to monitor vehicle battery and alternator health | Enhances fleet reliability, minimizes repair costs | Real-time monitoring solutions, integration with existing systems |

| Agriculture | Maintenance of agricultural machinery like tractors and harvesters | Ensures equipment reliability during critical farming periods | Access to specialized agricultural service providers, local support |

| Mining | Monitoring of heavy machinery used in extraction processes | Prevents costly equipment failure and operational delays | Robust diagnostic equipment, local repair capabilities |

| Construction | Maintenance checks for construction vehicles and equipment | Increases project efficiency by minimizing machinery downtime | Availability of parts and service expertise in remote locations |

How is the Knowledge of Alternator and Battery Health Applied in the Automotive Repair Industry?

In the automotive repair sector, knowing how to diagnose alternator and battery issues is crucial for maintaining vehicle performance. Mechanics utilize multimeters to assess the voltage output of the alternator, ensuring it meets the required standards for vehicle operation. This proactive approach minimizes downtime and enhances customer satisfaction by providing reliable services. B2B buyers in this industry must consider the quality and precision of diagnostic tools, as well as the availability of spare parts to ensure effective repairs.

How is This Knowledge Essential for Transportation and Logistics Businesses?

In the transportation and logistics industry, fleet managers rely on understanding the health of their vehicles’ electrical systems to maintain operational efficiency. By implementing regular diagnostics of alternators and batteries, businesses can prevent unexpected breakdowns that could lead to costly delays. The integration of real-time monitoring systems is crucial for tracking the performance of each vehicle. B2B buyers should focus on sourcing monitoring solutions that are compatible with existing fleet management systems and provide timely alerts for maintenance needs.

What Role Does This Knowledge Play in Agriculture?

Agricultural machinery, such as tractors and harvesters, heavily depends on reliable electrical systems. Knowing how to diagnose alternator and battery issues ensures that these machines operate effectively during critical farming seasons. Farmers and agricultural businesses benefit from reduced risk of equipment failure, which can lead to significant productivity losses. Buyers in this sector should prioritize sourcing from suppliers who offer specialized services and support tailored to agricultural equipment maintenance.

How Does This Knowledge Impact Mining Operations?

In the mining industry, where heavy machinery is essential for extraction processes, understanding alternator and battery health can prevent operational disruptions. Regular diagnostics help identify potential failures before they occur, protecting against costly downtime. Mining companies must ensure they have access to robust diagnostic equipment and local repair capabilities to maintain their machinery efficiently. Sourcing considerations should include the durability of tools and the expertise of service providers familiar with mining equipment.

Why is This Knowledge Important for Construction Firms?

For construction companies, the reliability of vehicles and machinery is paramount to project timelines and budgets. Regular checks on alternators and batteries can significantly reduce the risk of equipment failure on-site. This proactive maintenance approach leads to increased efficiency and productivity. B2B buyers in the construction sector should focus on suppliers that can provide quick access to parts and services, particularly in remote locations where construction projects often take place.

Illustrative image related to how to know if your alternator is bad or battery

3 Common User Pain Points for ‘how to know if your alternator is bad or battery’ & Their Solutions

Scenario 1: Difficulty in Distinguishing Alternator Issues from Battery Problems

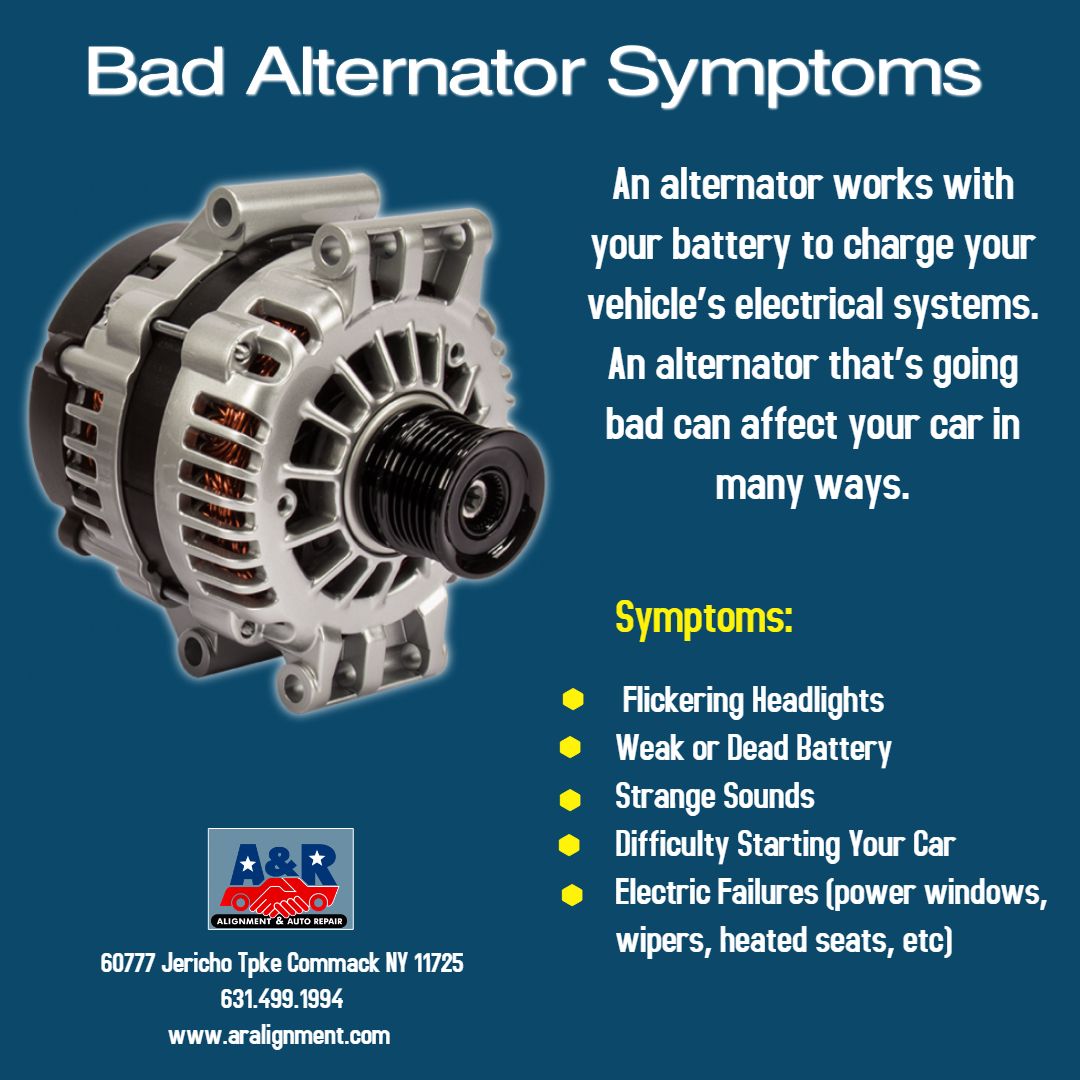

The Problem: B2B buyers, particularly fleet managers or auto parts retailers, often encounter vehicles that exhibit symptoms of electrical failure. These can include dimming headlights, starting issues, or even complete power loss. The challenge arises in accurately diagnosing whether the fault lies with the alternator or the battery. This uncertainty can lead to unnecessary costs, either by replacing components that are still functional or delaying repairs that could keep a vehicle out of service longer than necessary.

The Solution: Implementing a systematic diagnostic approach can help clarify the source of the issue. First, advise your clients to use a multimeter to check the battery voltage. A healthy battery should read around 12.6 volts when fully charged. Next, with the engine running, the voltage should ideally be between 13.8 to 14.5 volts, indicating the alternator is functioning properly. If the alternator output is lower than this, it may be failing. Provide training on how to perform these tests, or consider sourcing diagnostic tools that can simplify this process. Additionally, consider establishing partnerships with local auto parts suppliers for quick access to replacement components, which can expedite repairs.

Scenario 2: The Risk of Improper Testing Techniques

The Problem: In many regions, particularly in emerging markets like parts of Africa and South America, mechanics may resort to outdated or unsafe testing methods, such as disconnecting the battery while the engine is running. This not only poses a risk to the vehicle’s electronics but can also damage a good alternator or lead to erroneous conclusions about the vehicle’s health. B2B buyers in the automotive sector face the challenge of ensuring that their technicians are trained in safe, effective diagnostic methods.

The Solution: To mitigate this risk, it’s essential to provide educational resources and workshops that emphasize safe testing procedures. Encourage the use of appropriate diagnostic tools, such as load testers and multimeters, which can accurately assess battery and alternator performance without risking damage to the vehicle. Partnering with automotive training organizations to offer certification programs can also enhance the skill set of your workforce. Creating detailed instructional content that explains the dangers of improper techniques will not only protect their investments but also improve overall service quality.

Scenario 3: Understanding the Long-Term Implications of Electrical Failures

The Problem: For businesses that rely heavily on their vehicles, such as logistics companies or construction firms, electrical failures can have significant operational impacts. A faulty alternator or battery can lead to vehicle downtime, resulting in lost revenue and decreased productivity. However, many buyers may not fully understand the long-term implications of these failures, including potential damage to other electrical components and increased repair costs.

The Solution: Educating clients about the holistic impact of electrical system failures is crucial. Create comprehensive guides that explain how a faulty alternator can lead to battery drain and affect other systems within the vehicle, such as the ECU and electrical accessories. Offer preventive maintenance packages that include regular electrical system checks to ensure that both the alternator and battery are functioning optimally. Providing value-added services, such as fleet management software that tracks vehicle performance and alerts users to potential electrical issues before they escalate, can also enhance customer loyalty and satisfaction.

Strategic Material Selection Guide for how to know if your alternator is bad or battery

What Materials are Commonly Used for Testing Alternators and Batteries?

When assessing the functionality of alternators and batteries, the choice of materials used in testing equipment can significantly impact performance and reliability. Below, we analyze four common materials that are integral to the testing process, considering their properties, advantages, disadvantages, and the specific needs of international B2B buyers.

What Are the Key Properties of Copper in Electrical Testing?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for wiring and connectors in testing equipment. Its high thermal conductivity also allows for efficient heat dissipation, which is crucial during prolonged testing sessions.

Pros: Copper is durable and resistant to corrosion, especially when plated with tin or nickel. It is relatively easy to work with, allowing for straightforward manufacturing processes.

Cons: The primary downside is its cost, which can be higher than alternatives like aluminum. Additionally, copper is susceptible to oxidation if not properly protected, which can impact conductivity over time.

Impact on Application: Copper’s compatibility with various electrical media makes it ideal for testing alternators and batteries, ensuring accurate voltage readings.

Considerations for International Buyers: Compliance with standards such as ASTM B170 for copper wire is essential. Buyers in regions like Africa and South America should also consider local availability and cost fluctuations.

How Does Aluminum Compare for Electrical Testing Applications?

Aluminum is another common material used in electrical testing equipment, particularly for connectors and cables. It is lighter than copper, which can be advantageous for portable testing devices.

Pros: Aluminum is cost-effective and has good corrosion resistance, especially when anodized. Its lightweight nature can reduce shipping costs, making it appealing for international buyers.

Cons: While aluminum has decent conductivity, it is not as effective as copper, which may lead to less accurate readings. Additionally, aluminum can be more challenging to work with due to its tendency to oxidize.

Impact on Application: Aluminum’s lower conductivity can affect performance in high-load applications, making it less suitable for critical testing scenarios.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B231 for aluminum wire. In regions with high humidity, such as parts of the Middle East, additional protective coatings may be necessary to prevent oxidation.

What Role Does Plastic Play in Testing Equipment?

Plastic materials, particularly high-grade polymers, are often used for insulation and housing in testing equipment. They provide excellent electrical insulation, which is critical for safety during testing.

Pros: Plastics are lightweight, cost-effective, and resistant to moisture and chemicals. They can be molded into complex shapes, allowing for versatile designs in testing devices.

Cons: Plastics can degrade over time when exposed to high temperatures or UV light, potentially compromising the integrity of the testing equipment.

Impact on Application: The use of plastic ensures that testing equipment remains safe and functional in various environments, although care must be taken to select the right type of plastic for specific temperature ranges.

Illustrative image related to how to know if your alternator is bad or battery

Considerations for International Buyers: Buyers should look for plastics that meet international standards such as ISO 9001 for quality management. In hot climates, materials with high thermal resistance should be prioritized.

How Important is Steel for Structural Integrity in Testing Devices?

Steel, particularly stainless steel, is often used in the structural components of testing equipment. Its strength and durability make it suitable for devices that may experience physical stress.

Pros: Steel offers excellent strength and resistance to wear, ensuring that testing devices can withstand rigorous use. Stainless steel is also resistant to corrosion, making it suitable for various environments.

Cons: The primary drawback is its weight, which can increase shipping costs and reduce portability. Additionally, steel can be more expensive than other materials.

Impact on Application: Steel’s robustness makes it ideal for heavy-duty testing equipment, ensuring longevity and reliability.

Illustrative image related to how to know if your alternator is bad or battery

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is critical. Buyers in Europe may also need to consider EU regulations regarding material safety.

Summary Table of Material Selection for Testing Alternators and Batteries

| Material | Typical Use Case for how to know if your alternator is bad or battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and connectors for multimeters and testing devices | Excellent electrical conductivity | Higher cost, oxidation risk | High |

| Aluminum | Connectors and cables in portable testing equipment | Lightweight and cost-effective | Lower conductivity than copper | Med |

| Plastic | Insulation and housing for testing devices | Lightweight and moisture-resistant | Can degrade under high temperatures | Low |

| Steel | Structural components of testing equipment | High strength and durability | Increased weight and cost | Med |

This material selection guide aims to assist international B2B buyers in making informed decisions regarding the materials used in testing equipment for alternators and batteries, ensuring both performance and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to know if your alternator is bad or battery

What Are the Key Stages in the Manufacturing Process for Alternators and Batteries?

The manufacturing processes for alternators and batteries involve several critical stages, each contributing to the overall quality and functionality of the final product.

Material Preparation: What Materials Are Used in Alternators and Batteries?

The first stage in manufacturing involves the selection and preparation of raw materials. For alternators, key materials include copper for windings, steel or aluminum for the casing, and various plastics for insulation. Batteries typically use lead, sulfuric acid, and various electrolyte solutions. Each material must meet specific industry standards to ensure durability and efficiency.

Forming: How Are Alternators and Batteries Shaped?

The forming stage involves shaping these materials into functional components. For alternators, this includes winding the copper wire into coils and forming the rotor and stator assemblies. In battery manufacturing, the lead plates are cast and assembled into cells. Precision in forming is vital, as any discrepancies can lead to inefficiencies and failures in the final product.

Assembly: What Techniques Are Employed in the Assembly Process?

Once components are formed, they undergo assembly. This stage often employs automated techniques to enhance efficiency and consistency. For alternators, this includes integrating the rotor, stator, and voltage regulator. In battery production, cells are assembled into modules and connected with safety features such as venting systems. Each assembly step is crucial, as it directly impacts the performance and reliability of the product.

Finishing: How Is Quality Achieved Through Finishing Processes?

The finishing stage involves final touches that enhance both performance and appearance. For alternators, this may include protective coatings and final electrical testing. Batteries undergo rigorous checks to ensure no leaks and proper electrolyte levels. Quality assurance during this stage is critical, as it ensures that products meet industry standards and customer expectations.

What Quality Control Measures Are Relevant in the Manufacturing of Alternators and Batteries?

Quality control (QC) is essential in ensuring that alternators and batteries perform reliably in various applications. The following are key QC measures and international standards relevant to B2B buyers.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for establishing quality management systems. Compliance with these standards ensures that manufacturers consistently meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for oil and gas applications add another layer of credibility.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor and verify quality.

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): During manufacturing, processes are monitored to detect any deviations from quality standards early.

- Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to verify that all specifications are met.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to ensure the functionality and safety of alternators and batteries. Common tests include:

- Electrical Testing: Voltage output and current draw are measured to assess performance.

- Load Testing: Batteries are subjected to load tests to simulate real-world conditions, ensuring they can handle the expected electrical demand.

- Environmental Testing: Products are exposed to extreme conditions (temperature, humidity) to evaluate their durability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of their suppliers.

What Are Effective Methods for Auditing Suppliers?

Conducting audits is an effective way to ensure compliance with quality standards. Buyers can request supplier audits to assess their quality management systems, manufacturing processes, and QC measures. This includes reviewing documentation, inspecting facilities, and assessing employee training programs.

How Can Buyers Utilize Reports and Third-Party Inspections?

Buyers should also request quality reports from suppliers, which provide insights into their testing results and compliance with standards. Involving third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality practices and product reliability.

What QC and Certification Nuances Should International Buyers Consider?

When sourcing alternators and batteries internationally, buyers must navigate various QC and certification nuances.

How Do Regional Standards Impact Quality Assurance?

Different regions may have specific standards and regulations that affect the manufacturing and sale of alternators and batteries. For instance, products sold in the European market must meet CE marking requirements, while those in the U.S. may need to comply with Underwriters Laboratories (UL) certifications. Understanding these requirements is crucial for avoiding compliance issues.

Illustrative image related to how to know if your alternator is bad or battery

What Are the Challenges in Ensuring Consistent Quality Across Borders?

Ensuring consistent quality across borders can be challenging due to variations in manufacturing practices, regulatory environments, and cultural approaches to quality management. B2B buyers should establish clear communication channels with suppliers and set expectations regarding quality standards to mitigate these challenges.

Conclusion

Understanding the manufacturing processes and quality assurance measures for alternators and batteries is essential for B2B buyers. By focusing on the critical stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions and ensure they source reliable products that meet their operational needs. As the global market continues to evolve, maintaining a strong focus on quality will be paramount for success in the competitive landscape of automotive components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if your alternator is bad or battery’

In the fast-paced world of automotive procurement, understanding how to accurately diagnose alternator and battery issues is essential for maintaining operational efficiency. This guide provides B2B buyers with a practical checklist to determine whether an alternator is malfunctioning or if the battery is at fault, enabling informed purchasing decisions and effective supplier interactions.

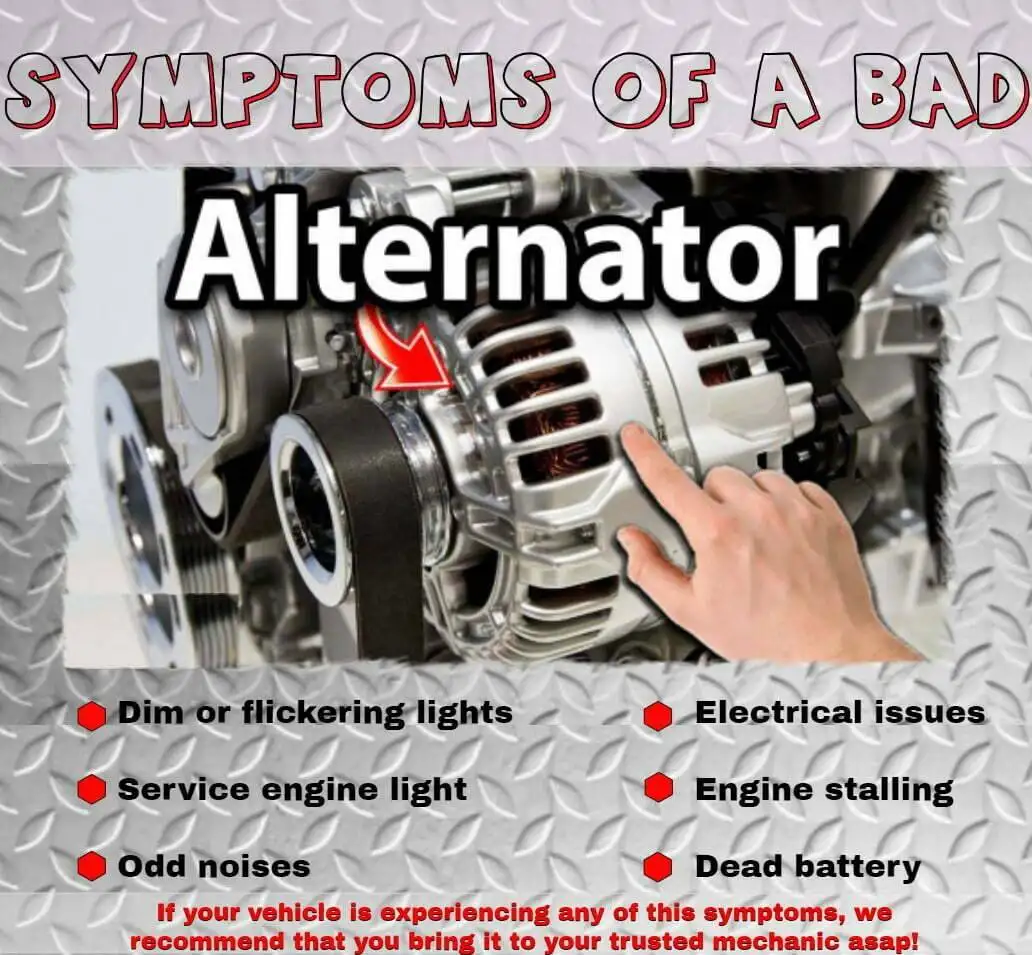

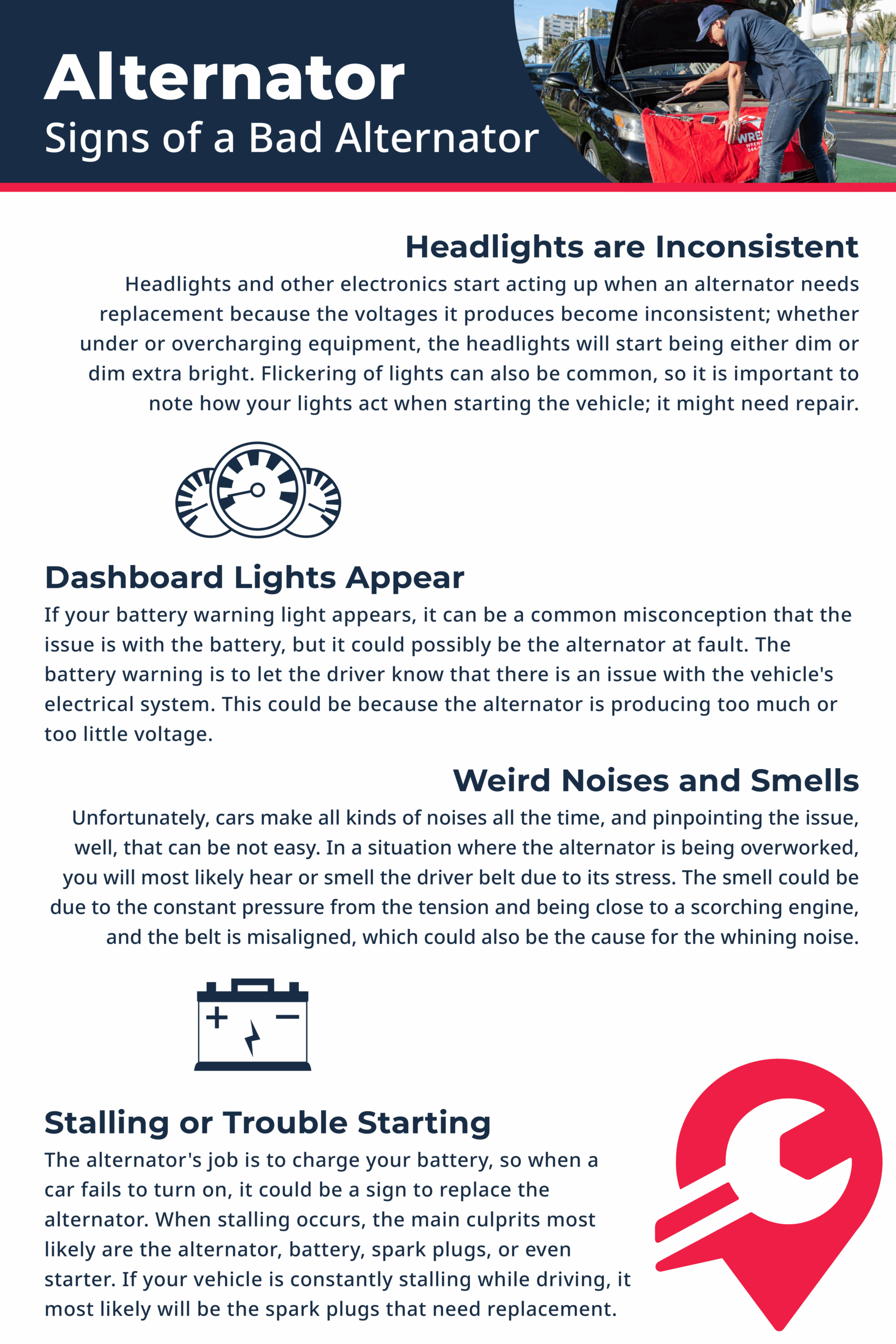

Step 1: Understand Common Symptoms

Begin by familiarizing yourself with the common signs of alternator and battery failure. This knowledge is critical for accurately diagnosing issues before seeking repairs or replacements. Symptoms may include dimming headlights, strange noises from the engine bay, or a warning light on the dashboard. Recognizing these indicators can save time and ensure you communicate effectively with suppliers.

Illustrative image related to how to know if your alternator is bad or battery

Step 2: Conduct a Visual Inspection

Perform a thorough visual inspection of the battery and alternator. Look for signs of corrosion on battery terminals, frayed wires, or physical damage to the alternator housing. These issues can often lead to performance problems and may indicate the need for replacement parts. Document any findings to discuss with potential suppliers for more targeted recommendations.

Step 3: Utilize a Multimeter for Voltage Testing

Testing the voltage output is a straightforward method to assess both components. With a multimeter, measure the voltage at the battery terminals while the engine is running. A healthy alternator should produce between 13.5V and 14.5V. If the reading is lower, this may suggest alternator failure, while a significantly low reading at rest may indicate a weak battery.

Step 4: Evaluate Load Performance

Evaluate the performance under load by turning on electrical accessories such as headlights, radio, and air conditioning. Observe any fluctuations in voltage readings. A stable voltage indicates a functioning alternator, while significant drops may suggest it is unable to handle the electrical load, necessitating further action.

Step 5: Check for Battery Health

Assess the battery’s health using a load tester. This tool can simulate the demands placed on the battery during operation. A battery that fails to hold charge under load may need replacement. Understanding battery performance is crucial for ensuring that the alternator is not being held responsible for issues that stem from battery failure.

Step 6: Research Supplier Expertise

When sourcing replacement parts, prioritize suppliers with expertise in automotive electrical systems. Look for vendors who provide detailed product specifications, warranties, and technical support. Engaging with knowledgeable suppliers can help you find the right solutions tailored to your specific needs.

Illustrative image related to how to know if your alternator is bad or battery

Step 7: Request Samples and Performance Data

Before finalizing any procurement decisions, request samples or detailed performance data from suppliers. This could include case studies or testimonials from similar businesses in your industry. Analyzing this information will provide insights into the reliability and effectiveness of the parts you are considering.

By following these steps, B2B buyers can ensure they make informed decisions when diagnosing and addressing alternator or battery issues, ultimately leading to improved operational efficiency and cost savings.

Comprehensive Cost and Pricing Analysis for how to know if your alternator is bad or battery Sourcing

When assessing the costs and pricing for understanding whether an alternator or battery is malfunctioning, a comprehensive approach is necessary. This includes evaluating the cost components, understanding price influencers, and offering valuable tips for buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Testing Equipment?

-

Materials: The primary components for testing equipment, such as multimeters or specialized diagnostic tools, can vary significantly based on quality and brand. Costs can range from economical basic models to high-end devices that offer advanced features. Expect to spend anywhere from $10 for a basic multimeter to $500 for professional-grade equipment.

-

Labor: Skilled technicians are essential for accurate diagnostics. Labor costs can fluctuate based on geographic location and the complexity of the test. For instance, labor rates in Europe may differ from those in Nigeria or Brazil, influencing overall project costs.

-

Manufacturing Overhead: This includes expenses related to the production of testing tools, such as utilities, rent, and administrative costs. These overheads can vary by region and impact pricing.

-

Tooling: Specialized tools for thorough testing might require upfront investment. This cost is often amortized over the production volume, making it crucial to consider volume when negotiating prices.

-

Quality Control (QC): Implementing stringent QC processes ensures the reliability of testing equipment. These costs are vital to maintaining product quality and can influence pricing structures.

-

Logistics: International shipping, customs duties, and local taxes can add significant costs. Buyers should factor in these logistics expenses when budgeting.

-

Margin: Suppliers typically add a profit margin on top of the total costs, which can vary widely depending on market demand and competition.

How Do Price Influencers Impact Your Purchasing Decisions?

-

Volume/MOQ: Bulk purchasing often leads to discounts. Understanding the minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Customized equipment designed for specific testing needs can increase costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certified products usually come at a premium. However, investing in quality can reduce long-term costs associated with replacements or inaccuracies.

-

Supplier Factors: The reliability and reputation of suppliers play a critical role in pricing. Established suppliers may charge more due to their proven track record but can offer better service and warranty options.

-

Incoterms: Understanding the Incoterms applicable to your transaction can help manage costs associated with shipping and delivery. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the risk and costs at various stages of shipping.

What Buyer Tips Can Enhance Cost-Efficiency?

-

Negotiation Skills: Cultivating strong negotiation skills can lead to significant savings. Buyers should research market prices and be prepared to discuss terms and conditions to secure favorable deals.

-

Total Cost of Ownership (TCO): Beyond initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. Investing in high-quality equipment may reduce long-term costs.

-

Pricing Nuances for International Buyers: Buyers in regions like Africa and South America should be aware of currency fluctuations, import duties, and shipping delays that can affect pricing. Building relationships with local suppliers can also facilitate better terms.

-

Disclaimer for Indicative Prices: Prices can fluctuate based on market conditions, supplier availability, and economic factors. Always seek updated quotes and consider multiple suppliers to ensure competitive pricing.

By understanding these components and dynamics, B2B buyers can make informed decisions regarding their purchases for testing alternators and batteries, ultimately leading to better operational efficiency and cost management.

Illustrative image related to how to know if your alternator is bad or battery

Alternatives Analysis: Comparing how to know if your alternator is bad or battery With Other Solutions

Introduction: Exploring Alternatives for Diagnosing Alternator and Battery Issues

In the automotive sector, accurately diagnosing issues related to the alternator and battery is critical for operational efficiency and cost management. While many methods exist, understanding the benefits and drawbacks of each can help B2B buyers make informed decisions. This analysis will compare traditional methods of diagnosing alternator and battery problems with alternative solutions that offer varying levels of performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | How To Know If Your Alternator Is Bad Or Battery | Multimeter Testing | Professional Diagnostic Tools |

|---|---|---|---|

| Performance | Reliable for identifying the faulty component | High accuracy; measures voltage and current | Comprehensive diagnostics; includes various vehicle systems |

| Cost | Low (basic knowledge and tools required) | Moderate (cost of multimeter) | High (investment in specialized equipment) |

| Ease of Implementation | Requires basic knowledge and skills | Requires some technical know-how | Requires professional training to operate |

| Maintenance | Minimal (occasional checks) | Low (just the multimeter) | High (requires regular updates and calibration) |

| Best Use Case | Quick troubleshooting for minor issues | Accurate diagnostics for voltage issues | In-depth analysis for complex problems |

Detailed Breakdown of Alternatives

1. Multimeter Testing

Using a multimeter is a highly effective method for diagnosing alternator and battery issues. By measuring the voltage output, one can determine if the alternator is functioning correctly. A healthy alternator typically outputs between 13.5 to 14.5 volts when the engine is running. While this method requires some technical understanding, it is relatively cost-effective and provides accurate results. However, users must be cautious, as improper use can lead to misdiagnosis or further complications.

2. Professional Diagnostic Tools

Investing in professional diagnostic tools offers a comprehensive solution for identifying issues with the alternator and battery. These tools can analyze various vehicle systems and provide detailed reports, making them invaluable for automotive service centers. While the initial cost is high, they save time and increase efficiency in diagnosing complex problems. On the downside, these tools require professional training to operate effectively, and regular maintenance may be necessary to keep them up to date.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the best method for diagnosing alternator and battery issues, B2B buyers must consider their specific operational needs, budget constraints, and technical capabilities. For quick and cost-effective troubleshooting, basic methods like multimeter testing may suffice. However, for businesses that require in-depth analysis and a more systematic approach, investing in professional diagnostic tools could yield better long-term value. Ultimately, the right choice will depend on balancing immediate requirements with the potential for future operational efficiency.

Illustrative image related to how to know if your alternator is bad or battery

Essential Technical Properties and Trade Terminology for how to know if your alternator is bad or battery

What Are the Key Technical Properties for Assessing Alternator and Battery Health?

Understanding the technical properties of alternators and batteries is essential for B2B buyers involved in automotive maintenance or manufacturing. Here are critical specifications that can help determine whether an alternator is functioning correctly or if a battery needs replacement:

-

Voltage Output: Alternators typically output between 13.5V and 14.5V when the engine is running. This voltage range is crucial for charging the battery while powering electrical systems. For B2B buyers, knowing the voltage output can help in selecting the right alternator for specific vehicle models or applications.

-

Current Rating (Amperage): The amperage rating of an alternator indicates its capacity to deliver electrical current. A standard automotive alternator ranges from 40A to 200A, depending on the vehicle’s electrical demands. Understanding current ratings is vital for businesses to ensure compatibility with various vehicle systems, especially in commercial fleets.

-

Regulator Type: Alternators use either external or internal voltage regulators to manage voltage output. Internal regulators are more common in modern vehicles, offering better protection against voltage spikes. For suppliers, knowing the type of regulator can influence inventory decisions and compatibility with customer needs.

-

Diode Configuration: The diodes in an alternator convert AC power to DC. The number and quality of diodes can affect the alternator’s efficiency and longevity. B2B buyers should consider diode configuration when sourcing alternators, as higher quality diodes can lead to reduced failure rates and lower warranty claims.

-

Material Composition: The materials used in alternator construction, such as aluminum or copper, can impact performance and durability. Aluminum is lightweight and resistant to corrosion, while copper offers better conductivity. Buyers should assess material specifications to ensure they are sourcing products that meet their quality and performance requirements.

-

Temperature Rating: Alternators and batteries have specific temperature ratings that indicate their operational limits. High temperatures can lead to premature failure. Understanding these ratings is crucial for businesses operating in extreme climates, as it can influence purchasing decisions and warranty considerations.

What Are Common Trade Terms Related to Alternators and Batteries?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms that buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to parts made by the original manufacturer of the vehicle. OEM parts are often preferred for their quality and compatibility. Understanding OEM specifications is crucial for businesses that prioritize reliability in their product offerings.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ can aid in inventory management and budgeting, ensuring that they do not overcommit to stock that may not sell.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Businesses often use RFQs to compare pricing and terms from different vendors, making it a key part of the procurement process.

-

Incoterms: International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade, including shipping costs, risk, and delivery points. Understanding these terms helps businesses navigate logistics and shipping agreements effectively.

-

Aftermarket Parts: These are parts not made by the OEM but are designed to fit and function in the same way. For buyers, knowing the difference between OEM and aftermarket parts can influence purchasing decisions based on cost and quality considerations.

-

Testing Standards: Specifications like ISO or SAE standards ensure that alternators and batteries meet specific performance criteria. Familiarity with these standards can help buyers ensure compliance and reliability in their product offerings.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, optimize their supply chains, and enhance customer satisfaction in the automotive sector.

Illustrative image related to how to know if your alternator is bad or battery

Navigating Market Dynamics and Sourcing Trends in the how to know if your alternator is bad or battery Sector

What Are the Current Trends in the Market for Assessing Alternator and Battery Issues?

The automotive sector is witnessing transformative shifts driven by technological advancements and evolving consumer preferences, especially concerning how to diagnose alternator and battery issues. Key market drivers include the growing demand for electric vehicles (EVs) and hybrid models, which necessitate a deeper understanding of battery management systems and alternator functionality. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking reliable diagnostic tools and equipment. This demand is fueled by the need for efficient vehicle maintenance practices that minimize downtime and reduce operational costs.

Emerging trends show a significant uptake in diagnostic technologies, such as advanced multimeters and onboard diagnostic (OBD) tools, which provide real-time data on battery health and alternator performance. These tools not only enhance accuracy in identifying issues but also streamline the repair process, making them essential for automotive technicians and service providers. Moreover, the rise of digital platforms for parts procurement and service management is reshaping how B2B buyers source diagnostic equipment, emphasizing speed and efficiency.

Market dynamics are also influenced by the rise of remote diagnostics and telematics. These technologies enable fleet operators to monitor vehicle systems proactively, minimizing risks associated with alternator and battery failures. As international markets continue to grow, buyers must be aware of the regional variances in vehicle types and maintenance practices, tailoring their sourcing strategies accordingly.

Illustrative image related to how to know if your alternator is bad or battery

How Can Sustainability and Ethical Sourcing Impact the Battery and Alternator Sector?

Sustainability and ethical sourcing are becoming increasingly significant in the automotive industry, particularly concerning battery and alternator components. The environmental impact of battery production, including resource extraction and waste management, has prompted stakeholders to prioritize sustainable practices. Buyers are now seeking suppliers who employ eco-friendly materials and processes, which can include using recycled metals and reducing carbon footprints in production.

Ethical supply chains are also critical, especially for B2B buyers operating in regions with varying regulatory standards. Ensuring that suppliers adhere to ethical labor practices and environmental regulations not only mitigates risks but also enhances brand reputation. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as benchmarks for assessing suppliers’ commitment to sustainability.

Incorporating ‘green’ certifications into sourcing decisions is essential for businesses aiming to align with global sustainability goals. This commitment can attract environmentally conscious customers and enhance competitiveness in an increasingly eco-aware market.

What Is the Historical Context Behind Alternator and Battery Diagnostics?

The evolution of alternator and battery diagnostics has undergone significant changes since the introduction of the automotive electrical system. Initially, vehicles relied on simple generators that provided limited electrical output. As automotive technology advanced, the alternator became the standard due to its higher efficiency and ability to charge batteries while powering vehicle electrical systems.

Illustrative image related to how to know if your alternator is bad or battery

In the late 20th century, the introduction of onboard diagnostic systems revolutionized how vehicle issues were identified and addressed. These systems enabled technicians to access detailed information about the vehicle’s performance, including the status of the alternator and battery. Today, the integration of digital technologies continues to enhance diagnostic capabilities, offering real-time data analysis and predictive maintenance solutions.

As the automotive landscape evolves, understanding the historical context of alternator and battery diagnostics provides valuable insights for B2B buyers. It highlights the importance of investing in advanced diagnostic tools and technologies to remain competitive and responsive to market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of how to know if your alternator is bad or battery

-

1. How can I determine if my vehicle’s alternator is functioning correctly?

To ascertain if your alternator is working properly, utilize a multimeter to measure the voltage at the battery terminals while the engine is running. A healthy alternator should produce a voltage reading between 13.5V and 14.5V. If the voltage is below this range, it indicates that the alternator may be failing to charge the battery adequately. Additionally, look for signs such as dimming lights or electrical issues within the vehicle, which may further suggest alternator problems. -

2. What symptoms indicate a failing battery versus a bad alternator?

Common symptoms of a failing battery include slow engine crank, electrical failures, and a battery warning light on the dashboard. In contrast, a bad alternator might manifest as flickering dashboard lights, unusual noises from the engine, or a battery that continuously discharges despite being charged. It is essential to conduct a thorough diagnosis to differentiate between the two, as they can exhibit overlapping symptoms. -

3. What is the best method for testing an alternator and battery together?

The most effective method to test both the alternator and battery is to perform a voltage test. Start the vehicle and measure the battery voltage with a multimeter. Then, turn on the headlights and other electrical accessories to see if the voltage remains stable. If it drops significantly under load, it could indicate an issue with either the battery or the alternator. This method provides a comprehensive overview of both components’ health. -

4. How should I vet suppliers for automotive parts like batteries and alternators?

When sourcing automotive parts, it’s crucial to research potential suppliers thoroughly. Look for manufacturers with established reputations, positive customer reviews, and certifications that ensure quality standards. Request samples to evaluate product quality and engage in discussions about their production processes, warranty policies, and customer service responsiveness. Establishing clear communication channels can also help in assessing reliability and trustworthiness. -

5. What are typical minimum order quantities (MOQs) for alternators and batteries in international trade?

MOQs for alternators and batteries can vary significantly by supplier and product type. Generally, MOQs can range from 50 to 500 units, depending on the manufacturer’s capabilities and the specific item. It’s advisable to negotiate MOQs with suppliers based on your purchasing needs and to explore options for smaller trial orders to evaluate product quality before committing to larger quantities. -

6. What payment terms should I consider when purchasing automotive components?

When negotiating payment terms, consider options such as letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60). These terms can help mitigate risk in international transactions. It’s also wise to inquire about the supplier’s preferred payment methods and any associated fees. Establishing clear terms upfront can facilitate smoother transactions and help build a trusting relationship with your supplier. -

7. How can I ensure quality assurance (QA) for automotive parts sourced internationally?

To ensure quality assurance for automotive parts, establish a comprehensive QA process that includes supplier audits, product inspections, and testing protocols. Request certificates of compliance and quality standards relevant to your region. Engaging third-party inspection services can further validate product quality before shipment. Regular communication with suppliers about quality expectations can help mitigate potential issues. -

8. What logistics considerations should I keep in mind when importing alternators and batteries?

When importing automotive parts, consider factors such as shipping methods, customs clearance procedures, and local regulations regarding battery transportation due to safety concerns. Collaborate with experienced freight forwarders to navigate these complexities efficiently. Additionally, plan for potential delays in shipping and ensure proper insurance coverage for your shipments to safeguard against loss or damage during transit.

Top 3 How To Know If Your Alternator Is Bad Or Battery Manufacturers & Suppliers List

1. Reddit – Automotive Battery Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The battery provides power to all electronics, including the starter. The alternator charges the battery when the engine is running. The starter uses battery power to turn over the engine. Symptoms of a dead battery include no power at all, while a failing alternator may show a battery light on the dash when the engine is running. A parasitic draw could also drain the battery.

2. Nationwide – Alternator Insights

Domain: blog.nationwide.com

Registered: 1994 (31 years)

Introduction: Alternator: Powers the car when the engine is running, charges the battery, typically lasts the lifetime of the car but can require repair or replacement due to wear and tear. Signs of a bad alternator include dim interior lights, dim or overly bright headlights, growling noises, and burning smells. Battery: Stores power, starts the engine, delivers electricity to the ignition system, works with t…

3. Alternator Testing – Risks of Battery Disconnect

Domain: mechanics.stackexchange.com

Registered: 2009 (16 years)

Introduction: The text discusses a method to test an alternator by disconnecting the battery while the vehicle is running. It highlights that this method is not recommended as it can damage the vehicle’s electronics and the alternator itself. The alternator is internally regulated, and removing the battery can lead to voltage spikes that may harm sensitive components. A safer alternative is to use a multimeter …

Strategic Sourcing Conclusion and Outlook for how to know if your alternator is bad or battery

How Can You Effectively Diagnose Alternator and Battery Issues?

In summary, diagnosing whether your vehicle’s issues stem from a failing alternator or a dead battery is crucial for maintaining operational efficiency. Key diagnostic techniques include utilizing a multimeter to measure voltage outputs, understanding the symptoms of battery failure, and recognizing the signs of alternator malfunction. By ensuring that your vehicle’s electrical system is functioning properly, you can prevent costly downtime and enhance productivity.

Illustrative image related to how to know if your alternator is bad or battery

Strategic sourcing plays a vital role in securing high-quality automotive parts and services. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, must prioritize partnerships with reliable suppliers. This ensures access to genuine components and expert technical support, which are essential for effective vehicle maintenance.

Looking ahead, the automotive industry is poised for advancements in technology and sustainability. As electric vehicles gain traction, understanding the intricacies of alternators and batteries will become even more critical. By staying informed and fostering strong supplier relationships, businesses can navigate these changes effectively and remain competitive in the global marketplace. Engage with your suppliers today to ensure your fleet remains operational and efficient for the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to know if your alternator is bad or battery

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.