Introduction: Navigating the Global Market for how do i test my starter

In the intricate landscape of automotive maintenance, understanding how to test a starter motor is crucial for international B2B buyers. A malfunctioning starter can lead to costly downtimes and operational inefficiencies, particularly in regions where reliable transportation is vital for business continuity. This guide addresses the pressing challenge of sourcing effective testing methods for starter motors, empowering companies to make informed purchasing decisions and minimize unnecessary expenditures.

Within these pages, we delve into various testing techniques, including auditory signals, visual inspections, and electrical assessments, ensuring that you have a comprehensive understanding of each method’s applications. We also explore the importance of supplier vetting to ensure that you are partnering with reliable manufacturers who provide quality components and support. Additionally, we will discuss the cost implications of testing tools and services, offering insights tailored for B2B buyers from diverse markets such as Africa, South America, the Middle East, and Europe, including key players like Saudi Arabia and Nigeria.

By equipping you with actionable knowledge on starter motor testing, this guide serves as a strategic resource to enhance your operational efficiency, reduce maintenance costs, and ultimately strengthen your supply chain resilience in a competitive global market.

Table Of Contents

- Top 3 How Do I Test My Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do i test my starter

- Understanding how do i test my starter Types and Variations

- Key Industrial Applications of how do i test my starter

- 3 Common User Pain Points for ‘how do i test my starter’ & Their Solutions

- Strategic Material Selection Guide for how do i test my starter

- In-depth Look: Manufacturing Processes and Quality Assurance for how do i test my starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do i test my starter’

- Comprehensive Cost and Pricing Analysis for how do i test my starter Sourcing

- Alternatives Analysis: Comparing how do i test my starter With Other Solutions

- Essential Technical Properties and Trade Terminology for how do i test my starter

- Navigating Market Dynamics and Sourcing Trends in the how do i test my starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do i test my starter

- Strategic Sourcing Conclusion and Outlook for how do i test my starter

- Important Disclaimer & Terms of Use

Understanding how do i test my starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Visual Inspection | Simple checks for physical damage, loose connections, or corrosion | Automotive repair shops, fleet services | Pros: Quick and easy; no special tools required. Cons: Limited diagnostic capability; may miss underlying issues. |

| Click Test | Listening for clicking sounds during ignition | Vehicle diagnostics, maintenance shops | Pros: Non-invasive; immediate feedback on solenoid status. Cons: Cannot confirm starter motor functionality; may confuse with battery issues. |

| Multimeter Voltage Test | Measures battery voltage and starter draw | Fleet management, automotive technicians | Pros: Accurate; helps differentiate between battery and starter issues. Cons: Requires knowledge of multimeter use; potential for misinterpretation. |

| Bench Testing | Directly connects starter to a battery for testing | Automotive repair, parts suppliers | Pros: Definitive results; isolates starter performance. Cons: Labor-intensive; requires removal of the starter. |

| Inductive Ammeter Test | Measures current draw during cranking | Automotive repair shops, diagnostics | Pros: Provides insight into starter efficiency; can detect short circuits. Cons: Requires specialized equipment; may be complex for novice users. |

What Are the Key Characteristics of Visual Inspection for Starter Testing?

Visual inspection is the most straightforward method of testing a starter motor. It involves checking for obvious physical damage, loose connections, or corrosion at the terminals. This method is suitable for automotive repair shops and fleet services where quick assessments are crucial. However, while it is simple and requires no specialized tools, it may overlook deeper issues that could lead to starter failure.

How Does the Click Test Provide Immediate Feedback on Starter Functionality?

The click test involves listening for a clicking sound when the ignition is turned. This sound indicates that the starter solenoid is receiving power, but it does not confirm the starter motor’s functionality. Commonly used in vehicle diagnostics and maintenance shops, this method offers immediate feedback but cannot differentiate between a faulty starter and other electrical issues, such as a weak battery.

Why Is the Multimeter Voltage Test Essential for Accurate Diagnosis?

Using a multimeter to test battery voltage and starter draw is a more precise method of diagnosing starter issues. This approach is vital for fleet management and automotive technicians, as it accurately identifies whether the problem lies with the battery or the starter motor itself. While it provides reliable data, it requires a certain level of expertise in multimeter operation, which may pose a challenge for less experienced users.

What Are the Advantages of Bench Testing for Starter Motors?

Bench testing involves removing the starter and connecting it directly to a battery. This definitive test allows for a clear assessment of the starter motor’s functionality. It is particularly useful in automotive repair and parts supply scenarios, where accurate diagnostics are critical. However, this method is labor-intensive and may not be practical for all buyers, especially those with limited technical skills.

How Does the Inductive Ammeter Test Enhance Starter Diagnostics?

The inductive ammeter test measures the current draw of the starter motor during cranking, providing insights into its efficiency and performance. This method is ideal for automotive repair shops and diagnostic centers, as it can detect issues like short circuits. However, it requires specialized equipment and knowledge, making it potentially complex for novice users. Understanding the current draw can be invaluable in making informed purchasing decisions regarding starter components.

Key Industrial Applications of how do i test my starter

| Industry/Sector | Specific Application of how do i test my starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostic testing of starter motors in vehicles | Reduces downtime and repair costs through accurate diagnostics | Availability of diagnostic tools and skilled technicians |

| Transportation Services | Ensuring reliability of starter motors in fleet vehicles | Enhances operational efficiency and minimizes breakdowns | Access to high-quality starter components and testing equipment |

| Agriculture | Testing starter motors in agricultural machinery | Increases productivity and reduces maintenance costs | Compatibility with various machinery models and local sourcing |

| Construction | Verifying starter functionality in heavy machinery | Prevents project delays and equipment failure | Local supplier relationships for quick access to parts |

| Mining | Assessing starter motors in mining equipment | Ensures continuous operation in critical environments | Robust testing solutions for harsh conditions and reliability |

How is ‘how do I test my starter’ applied in the Automotive Repair sector?

In the automotive repair industry, testing starter motors is critical for diagnosing vehicle starting issues. Technicians utilize various methods, such as visual inspections and multimeter tests, to identify problems early. By accurately diagnosing starter issues, repair shops can avoid unnecessary part replacements, ultimately saving costs for both the business and the customer. For international buyers, sourcing reliable diagnostic tools and skilled technicians is crucial to maintain service quality and customer satisfaction.

What role does starter testing play in Transportation Services?

For transportation services, especially those operating fleets, the reliability of starter motors is paramount. Regular testing of starters can prevent unexpected vehicle breakdowns that lead to costly delays and lost revenue. Implementing a proactive maintenance schedule that includes starter testing ensures that vehicles are always in optimal condition. B2B buyers in this sector should prioritize sourcing high-quality starter components and testing equipment to enhance fleet reliability and reduce operational disruptions.

How is starter testing crucial in Agriculture?

In the agriculture sector, machinery such as tractors and harvesters relies heavily on functional starter motors for efficient operation. Testing these components ensures that agricultural equipment is ready for use, especially during peak seasons. By identifying starter issues before they escalate, farmers can enhance productivity and reduce maintenance costs. Buyers in this sector should focus on compatibility with various machinery models and establish local sourcing relationships for timely access to parts.

Why is starter testing important in Construction?

In construction, heavy machinery is essential for project completion, making the reliability of starter motors critical. Testing these components helps prevent unexpected equipment failures that can cause project delays and increased costs. By ensuring that all machinery is in working order, construction firms can maintain productivity and adhere to project timelines. Businesses should consider local supplier relationships for quick access to testing tools and replacement parts to minimize downtime.

How does starter testing benefit the Mining industry?

The mining sector operates in demanding environments where equipment reliability is vital. Testing starter motors in mining equipment ensures continuous operation, which is crucial for maintaining output levels. Regular testing can prevent costly breakdowns in remote locations, where repairs can be time-consuming and expensive. B2B buyers should look for robust testing solutions that can withstand harsh conditions, ensuring that their equipment remains operational and efficient.

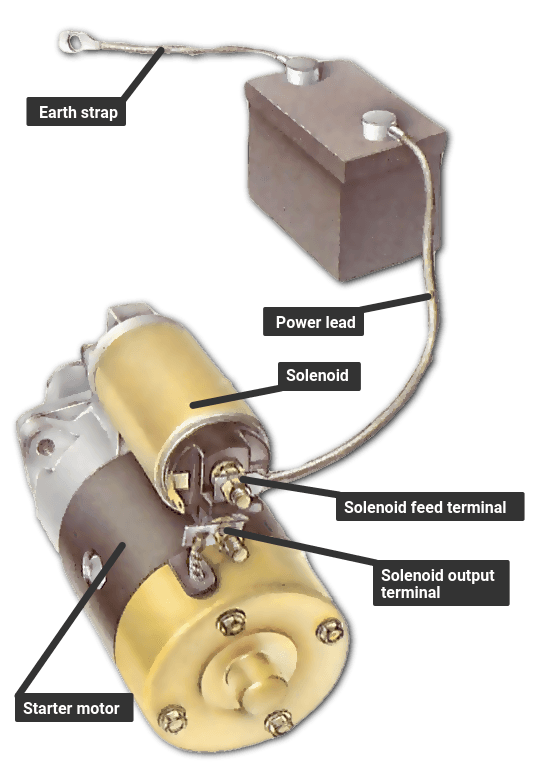

Illustrative image related to how do i test my starter

3 Common User Pain Points for ‘how do i test my starter’ & Their Solutions

Scenario 1: Misdiagnosing Starter Issues Leads to Unnecessary Costs

The Problem: A common challenge faced by B2B buyers, especially those managing fleets or vehicle maintenance services, is the misdiagnosis of starter issues. When a vehicle fails to start, the immediate assumption often falls on the starter motor. However, issues like a dead battery, faulty ignition switch, or corroded connections can also cause similar symptoms. This misdiagnosis can lead to unnecessary replacement costs and downtime, impacting overall operational efficiency.

The Solution: To effectively diagnose whether the starter motor is indeed the culprit, it’s crucial to follow a systematic approach. Start by listening for the typical click sound when the ignition is turned. If there’s no sound, first check the battery voltage using a multimeter; a healthy battery should read around 12.6 volts. If the battery is fine, proceed with a visual inspection of the starter and its connections for signs of wear or corrosion. This thorough checking can save costs by preventing unnecessary starter replacements and ensuring that only the faulty components are addressed.

Scenario 2: Lack of Technical Knowledge in Testing Starters

The Problem: Many B2B buyers, particularly in regions where technical expertise is limited, struggle with the lack of knowledge regarding the testing procedures for starter motors. This gap often results in reliance on external service providers, which can be costly and time-consuming. Furthermore, without understanding the testing process, buyers may feel vulnerable to being overcharged for repairs.

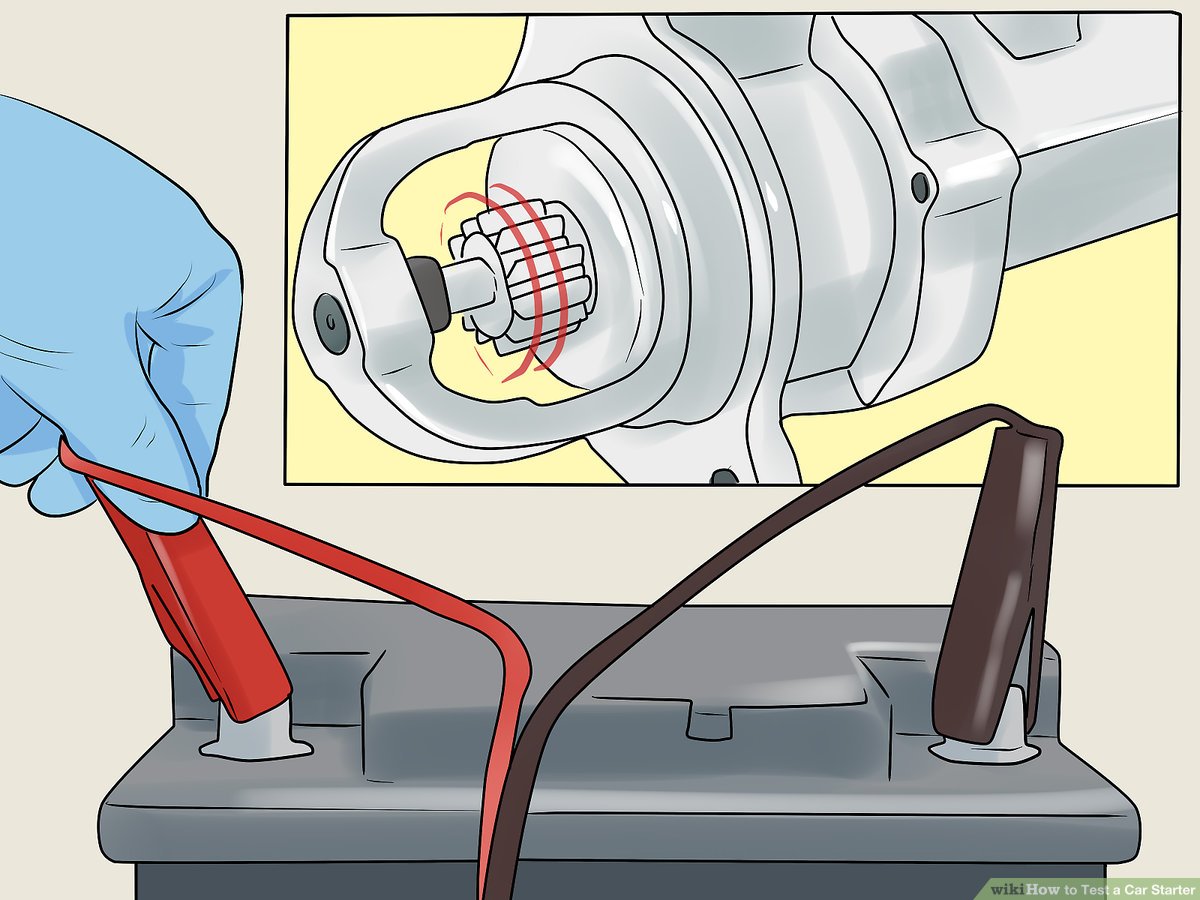

The Solution: To empower buyers, it’s essential to provide them with a clear, step-by-step guide on how to test a starter motor. Start by educating them on the basics of using a multimeter to measure voltage and continuity. Next, explain how to perform a bench test by removing the starter and connecting it directly to a battery with jumper cables. This method allows for direct observation of the starter’s functionality. Additionally, providing training sessions or workshops can enhance their understanding, enabling them to perform these tests independently and confidently, ultimately reducing their dependency on external services.

Scenario 3: Uncertainty About When to Replace the Starter

The Problem: Another significant pain point for B2B buyers is the uncertainty regarding when a starter motor should be replaced. Without a clear understanding of the symptoms indicating a failing starter, businesses risk operating vehicles with unreliable starting systems. This situation not only leads to potential breakdowns but also affects overall fleet management and customer service.

The Solution: Establishing a set of clear indicators for starter replacement can help businesses make informed decisions. Key signs include the presence of a clicking noise without engine cranking, difficulty starting the engine, or intermittent starting issues. Educate buyers on the importance of monitoring these symptoms and encourage them to keep records of any starting difficulties. Additionally, recommend regular maintenance checks to assess starter health, including checking the solenoid and battery connections. By creating a proactive maintenance schedule and developing a checklist for symptoms, businesses can minimize the risks associated with starter failures and enhance their operational efficiency.

By addressing these scenarios with actionable solutions, B2B buyers can improve their understanding of starter testing, reduce costs, and enhance their vehicle management strategies.

Illustrative image related to how do i test my starter

Strategic Material Selection Guide for how do i test my starter

What Materials Are Commonly Used in Starter Testing Tools?

When it comes to testing starter motors, the materials used in the tools and equipment can significantly influence performance and reliability. Here, we analyze four common materials that are essential for various testing methods, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Copper in Starter Testing Equipment?

Copper is widely used in electrical connections and wiring due to its excellent conductivity and thermal properties. It can withstand high temperatures and is relatively resistant to corrosion when properly insulated.

Pros:

– High electrical conductivity ensures minimal resistance.

– Good thermal conductivity allows for effective heat dissipation.

– Relatively easy to work with during manufacturing.

Cons:

– Prone to oxidation, which can affect performance if not properly coated.

– Higher cost compared to aluminum, which can impact overall product pricing.

Impact on Application:

Copper’s compatibility with various electrical systems makes it ideal for starter motor testing tools that require reliable electrical connections.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. In regions like Africa and South America, where electrical infrastructure may vary, the quality of copper used can significantly impact the longevity of the equipment.

How Does Aluminum Compare as a Material for Testing Starter Motors?

Aluminum is another common material used in starter motor testing equipment, particularly for components like housings and connectors. Its lightweight nature and resistance to corrosion make it a popular choice.

Pros:

– Lightweight, which reduces overall tool weight.

– Good corrosion resistance, especially when anodized.

– Cost-effective compared to copper.

Cons:

– Lower electrical conductivity than copper, which may affect performance in high-load situations.

– More susceptible to mechanical wear and tear.

Impact on Application:

Aluminum is suitable for applications where weight savings are critical, but its lower conductivity may limit its use in high-performance testing scenarios.

Considerations for International Buyers:

Buyers in the Middle East and Europe should be aware of the European Union’s RoHS compliance for aluminum products. Additionally, ensuring that aluminum components meet local standards for durability is essential.

What Role Does Steel Play in Starter Testing Tools?

Steel is often used in the structural components of testing equipment, such as frames and supports. Its strength and durability make it an excellent choice for heavy-duty applications.

Pros:

– High tensile strength provides durability and stability.

– Cost-effective for large-scale manufacturing.

– Resistant to deformation under load.

Cons:

– Heavier than aluminum, which can increase the overall weight of the tool.

– Susceptible to rust and corrosion if not properly treated.

Impact on Application:

Steel is ideal for applications where structural integrity is paramount, but its weight may be a consideration for portable testing equipment.

Considerations for International Buyers:

Buyers should ensure that steel components comply with international standards such as ASTM A36. In regions like Nigeria and Saudi Arabia, where environmental conditions can lead to corrosion, selecting galvanized or stainless steel may be necessary.

Why is Plastic Used in Some Starter Testing Equipment?

Plastic materials, particularly high-grade polymers, are often used for insulation and non-conductive parts in starter testing equipment. Their lightweight and insulating properties make them suitable for various applications.

Pros:

– Excellent electrical insulation properties.

– Lightweight and easy to mold into complex shapes.

– Cost-effective for mass production.

Cons:

– Limited temperature resistance compared to metals, which may restrict use in high-heat applications.

– Can degrade over time when exposed to UV light or harsh chemicals.

Impact on Application:

Plastics are ideal for components that require electrical insulation, but their limitations in heat resistance may restrict their use in high-load testing scenarios.

Considerations for International Buyers:

International buyers should be aware of compliance with safety standards such as UL 94 for flammability. Understanding the specific environmental conditions in regions like Africa and South America can influence material selection.

Summary Table of Material Selection for Starter Testing

| Material | Typical Use Case for how do i test my starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical connections and wiring | High electrical conductivity | Prone to oxidation | High |

| Aluminum | Housings and connectors | Lightweight and corrosion-resistant | Lower conductivity | Medium |

| Steel | Structural components | High tensile strength | Susceptible to rust | Low |

| Plastic | Insulation and non-conductive parts | Excellent electrical insulation | Limited temperature resistance | Low |

This analysis provides B2B buyers with critical insights into material selection for starter testing tools, emphasizing the importance of understanding material properties, advantages, and limitations in the context of their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how do i test my starter

What Are the Key Stages in Manufacturing Starter Testing Equipment?

The manufacturing process for starter testing equipment involves several critical stages, ensuring that the final product meets performance and reliability standards. Here’s a breakdown of the main stages:

Material Preparation: How Are Materials Selected for Starter Testing Equipment?

The first step in manufacturing starter testing equipment is the careful selection of materials. Manufacturers typically choose high-quality metals and plastics that can withstand electrical loads and mechanical stress. Common materials include copper for wiring due to its excellent conductivity, and durable plastics or composites for housing components to resist environmental factors. This stage also involves sourcing materials that comply with international standards to facilitate global trade and acceptance.

Forming: What Techniques Are Used to Shape Components?

After material preparation, the forming process shapes these materials into functional components. Techniques such as stamping, machining, and injection molding are commonly employed. For instance, metal components may be stamped into shape, while plastic parts are often produced via injection molding. Precision is crucial at this stage, as any defects can affect the performance of the testing equipment.

Assembly: How Are Components Integrated into a Functional System?

The assembly stage integrates all components into a cohesive unit. This process may involve manual assembly or the use of automated machinery. Each component, including the multimeter, connectors, and housing, is carefully fitted together. Manufacturers often employ modular designs to simplify repairs and replacements, thereby enhancing the longevity of the equipment.

Finishing: What Final Touches Ensure Quality and Durability?

The final stage involves finishing processes that enhance the equipment’s durability and aesthetics. This may include surface treatments to prevent corrosion, painting, or applying protective coatings. Additionally, labels and markings are added to ensure that users can easily identify functions and safety warnings. Quality assurance checks are often integrated into this stage to ensure that every unit meets the required specifications before it leaves the production line.

What Quality Control Measures Are Essential in Starter Testing Equipment Manufacturing?

Quality control (QC) is a fundamental aspect of the manufacturing process, particularly for equipment used in critical applications like starter testing. Here’s a detailed overview of relevant international standards and QC checkpoints.

Which International Standards Should B2B Buyers Be Aware Of?

International standards, such as ISO 9001, play a crucial role in ensuring the quality of manufacturing processes. ISO 9001 focuses on quality management systems, helping organizations consistently meet customer requirements and enhance satisfaction. Additionally, industry-specific certifications, such as CE marking for products sold in Europe or API standards for equipment used in the petroleum industry, are also vital. These standards help B2B buyers ensure that the products they are purchasing are compliant with regional regulations and safety requirements.

What QC Checkpoints Should Be Implemented During Manufacturing?

Quality control checkpoints are critical to maintaining product integrity throughout the manufacturing process. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected before they enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested to ensure that production is proceeding according to specifications. This may involve checking dimensions, electrical properties, and functionality at various stages.

-

Final Quality Control (FQC): After assembly, final inspections are conducted to verify that the finished product meets all quality standards. This includes functional testing of the starter testing equipment to ensure it operates correctly.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

For B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some effective methods:

What Role Do Audits and Reports Play in Ensuring Quality?

Conducting supplier audits is an essential step for B2B buyers. These audits can assess the supplier’s manufacturing processes, quality control measures, and adherence to international standards. Buyers should request detailed reports on previous audits and quality checks performed by the supplier to gain insights into their reliability and commitment to quality.

How Important Are Third-Party Inspections in the Supply Chain?

Third-party inspections provide an unbiased evaluation of a supplier’s quality control processes. Engaging an independent inspection agency to conduct checks at various stages of production can help ensure that the equipment meets the required specifications and standards. This additional layer of verification is particularly valuable for international buyers, as it mitigates risks associated with cross-border transactions.

What Specific QC and Certification Nuances Should International Buyers Consider?

When sourcing starter testing equipment from international suppliers, buyers must be aware of certain nuances that can impact quality assurance:

How Do Regional Regulations Affect Quality Standards?

Different regions may have varying regulations and standards that affect product certification. For instance, while CE marking is essential for products sold in Europe, it may not be relevant in other markets. B2B buyers should familiarize themselves with local regulations to ensure compliance and avoid potential legal issues.

What Are the Implications of Cultural Differences on Quality Expectations?

Cultural differences can influence perceptions of quality and reliability. Buyers should communicate their quality expectations clearly and understand the supplier’s quality assurance practices. Building strong relationships with suppliers can also help bridge any gaps in understanding and ensure that both parties are aligned on quality standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for starter testing equipment is essential for B2B buyers. By focusing on key stages of manufacturing, relevant quality control standards, and effective verification methods, buyers can make informed decisions and source reliable equipment that meets their operational needs.

Illustrative image related to how do i test my starter

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do i test my starter’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to understand the process of testing a starter motor. Ensuring that your starter motor is functioning correctly is crucial for vehicle reliability and performance, especially in regions where vehicle downtime can significantly impact operations. By following these steps, you can effectively assess and verify the condition of starter motors before making a procurement decision.

Step 1: Understand the Testing Requirements

Before proceeding with any testing, it’s essential to clarify the specific requirements for your starter motor tests. Consider the vehicle types and the environmental conditions in which they operate. This understanding will guide your choice of testing methods and equipment.

- Identify Vehicle Models: Different vehicles may have varying starter motor designs and specifications.

- Consider Environmental Factors: Conditions such as extreme temperatures can affect starter performance.

Step 2: Gather Necessary Tools and Equipment

Assemble the appropriate tools required for testing starter motors. This may include a multimeter, jumper cables, and safety equipment.

- Multimeter: Essential for checking battery voltage and starter performance.

- Safety Gear: Gloves and goggles are critical to ensure safety during electrical tests.

Step 3: Perform a Visual Inspection

Conducting a visual inspection of the starter motor and its connections is a vital first step. Look for signs of wear, damage, or loose connections.

- Check Connections: Ensure all terminals are secure and free of corrosion, which can impede electrical flow.

- Inspect for Damage: Look for any physical damage to the motor housing that could affect performance.

Step 4: Test the Battery Voltage

A weak battery can often be mistaken for a faulty starter. Use a multimeter to check the battery’s voltage before testing the starter.

- Voltage Reading: A fully charged battery should read around 12.6 volts. If the reading is significantly lower, consider charging or replacing the battery first.

- Test Under Load: If possible, perform a load test to ensure the battery can maintain voltage when starting.

Step 5: Evaluate the Starter Solenoid

The starter solenoid plays a critical role in the starting process. Testing it can help identify whether the issue lies with the solenoid or the starter motor itself.

- Bypass Test: Using a screwdriver or jumper cables, temporarily bypass the solenoid to see if the starter engages. If it does, the solenoid may be faulty.

- Listen for Sounds: A clicking sound indicates the solenoid is receiving power, but it does not confirm the motor’s engagement.

Step 6: Conduct a Bench Test on the Starter Motor

For a definitive assessment, perform a bench test by removing the starter motor from the vehicle and testing it directly with a battery.

- Connect Properly: Use jumper cables to connect the starter to a battery, ensuring the positive and negative connections are secure.

- Monitor Functionality: Observe the starter’s operation, checking for any unusual smells or sounds that may indicate internal failure.

Step 7: Document Findings and Make Informed Decisions

After completing the tests, document all findings meticulously. This documentation will be invaluable when making procurement decisions or communicating with suppliers.

- Create a Report: Summarize the results of each test, noting any issues discovered during the process.

- Supplier Communication: Share your findings with potential suppliers to ensure they understand your requirements and can provide suitable products.

Following this checklist will equip B2B buyers with the knowledge and tools necessary to effectively test starter motors, ensuring reliable vehicle performance and informed purchasing decisions.

Comprehensive Cost and Pricing Analysis for how do i test my starter Sourcing

What Are the Key Cost Components in Testing a Starter Motor?

When analyzing the costs associated with testing a starter motor, several key components come into play. The primary cost elements include:

-

Materials: Basic tools such as multimeters, jumper cables, and screwdrivers are essential for testing. The quality of these tools can vary significantly, affecting overall costs. For example, a reliable multimeter may cost between $20 to $100, while jumper cables can range from $10 to $50.

-

Labor: Labor costs depend on whether the testing is conducted in-house or outsourced. Skilled technicians may charge hourly rates that vary by region, typically ranging from $30 to $100 per hour. In areas with a higher cost of living, such as Europe and parts of the Middle East, labor costs can be on the higher end.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with operating a workshop or facility where testing occurs. These costs are often spread over multiple projects, affecting the pricing structure.

-

Tooling: Specialized equipment for testing, such as diagnostic machines, can be a significant investment. The initial purchase price might range from $500 to several thousand dollars, depending on the complexity and capabilities of the equipment.

-

Quality Control (QC): Ensuring that testing procedures are reliable and accurate adds to the overall cost. Implementing QC measures can include regular calibration of tools and equipment, which may require additional investment.

-

Logistics: If testing services are provided on-site or require transportation of equipment, logistics costs can be a factor. This includes shipping fees for tools and equipment, which can vary widely based on distance and shipping method.

-

Margin: Companies will typically add a profit margin to their pricing, which can range from 10% to 30% depending on the market and competition.

How Do Price Influencers Affect Testing Services for Starters?

Various factors influence pricing in the context of testing starter motors. Understanding these can help buyers make informed decisions:

-

Volume/MOQ: Bulk purchases of testing tools or services often come with discounts. International buyers, particularly those in regions like Africa and South America, may benefit from negotiating lower prices based on volume.

-

Specifications and Customization: Custom testing solutions or specialized tools tailored to specific vehicle types may incur higher costs. Buyers should assess whether standard solutions suffice or if customization is essential for their operations.

-

Materials: The choice of materials and tools can impact pricing significantly. Investing in higher-quality tools can lead to long-term savings by reducing the frequency of replacements.

-

Quality and Certifications: Suppliers offering certified products may charge a premium, but this often guarantees reliability and compliance with international standards. For international buyers, especially in regulated markets, such certifications can be crucial.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer better warranties and support, which can justify higher costs.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate shipping responsibilities, costs, and risks, influencing the overall cost structure for buyers.

What Tips Can Help Buyers Optimize Costs in Testing Starters?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing costs when testing starter motors can yield significant savings:

-

Negotiation: Don’t hesitate to negotiate pricing, especially for bulk orders. Suppliers may be willing to offer discounts to secure larger contracts.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the purchase price. Consider maintenance, durability, and the potential need for replacements over time.

-

Pricing Nuances: Be aware of regional pricing variations and currency fluctuations that may affect costs. Local market conditions can lead to significant differences in pricing for similar services.

-

Research Local Suppliers: Establishing relationships with local suppliers can reduce logistics costs and lead to faster service response times.

Disclaimer

Prices and costs mentioned are indicative and may vary based on location, supplier, and market conditions. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing how do i test my starter With Other Solutions

Understanding Alternatives for Testing Starter Motors

When it comes to diagnosing issues with starter motors, various methods and technologies exist. Each option offers unique benefits and drawbacks, which can significantly influence decision-making for B2B buyers in the automotive sector. Understanding these alternatives allows businesses to choose the most suitable solution based on their specific needs, capabilities, and budget constraints.

Comparison Table

| Comparison Aspect | How Do I Test My Starter | Multimeter Testing | Professional Diagnostic Tools |

|---|---|---|---|

| Performance | Effective for basic checks; identifies common issues. | Accurate for electrical diagnostics; can pinpoint voltage issues. | Comprehensive; provides detailed analysis of starter and related systems. |

| Cost | Low; requires minimal tools (screwdriver, jumper cables). | Moderate; costs for a multimeter range from $20 to $100. | High; professional tools can cost hundreds to thousands of dollars. |

| Ease of Implementation | Simple; requires basic knowledge of electrical systems. | Requires understanding of electrical measurements; moderate complexity. | Typically requires professional training; complex to operate without expertise. |

| Maintenance | Low; occasional tool upkeep needed. | Low; multimeters are durable and require little maintenance. | High; professional tools may require calibration and servicing. |

| Best Use Case | Quick diagnostics for DIY mechanics or small workshops. | Ideal for detailed electrical diagnostics in larger repair shops. | Best suited for dealerships or specialized automotive repair centers needing in-depth analysis. |

Detailed Breakdown of Alternatives

What is Multimeter Testing and Why Should You Consider It?

Using a multimeter to test starter motors is a method focused on measuring electrical parameters such as voltage and current. This technique allows users to assess battery health and voltage drops in the starter circuit. The primary advantage of this method is its accuracy; it can help identify whether the problem lies with the starter motor itself or the battery. However, it requires a certain level of electrical knowledge and understanding of the readings, which might be a barrier for some users. Additionally, while the cost of a multimeter is reasonable, it may still represent a higher initial investment compared to basic DIY testing.

How Do Professional Diagnostic Tools Enhance Starter Testing?

Professional diagnostic tools provide a comprehensive approach to testing starters and other vehicle systems. These tools can connect to the vehicle’s onboard computer, offering insights beyond just the starter motor, such as fault codes and performance data. The main advantage of professional tools is their ability to provide a detailed analysis that includes testing multiple components simultaneously. However, these tools come at a high cost and often require trained technicians to operate them effectively. For businesses looking to maximize efficiency and accuracy in repairs, investing in such equipment may be worthwhile, but it does require significant financial commitment.

Conclusion: Choosing the Right Starter Testing Solution

For B2B buyers, selecting the appropriate starter testing solution hinges on several factors, including budget, expertise, and operational needs. If quick, cost-effective diagnostics are required, the basic DIY method of testing the starter motor may suffice. However, for businesses aiming for precision and thorough analysis, investing in a multimeter or professional diagnostic tool could yield better long-term results. Ultimately, understanding the strengths and limitations of each method will empower automotive businesses to make informed decisions that enhance service quality and operational efficiency.

Essential Technical Properties and Trade Terminology for how do i test my starter

What are the Critical Technical Properties to Consider When Testing a Starter?

When evaluating a starter motor, several critical technical properties play a significant role in determining its performance and reliability. Understanding these specifications can help B2B buyers make informed decisions when sourcing starter motors or components.

-

Voltage Rating

The voltage rating indicates the electrical potential that the starter motor is designed to operate within, typically 12V for most automotive applications. Ensuring compatibility with the vehicle’s electrical system is crucial; incorrect voltage can lead to insufficient power or damage to the motor. -

Current Draw (Amperage)

Current draw refers to the amount of electrical current the starter motor consumes during operation, measured in amperes (A). A typical starter motor may draw between 100 to 200 amps. Understanding the current draw is vital for assessing the starter’s capability to crank the engine under various conditions, such as cold starts. -

Torque Output

Torque output measures the rotational force the starter can provide to crank the engine, usually expressed in Newton-meters (Nm) or foot-pounds (ft-lb). A higher torque rating indicates better performance, particularly in larger or high-compression engines. This specification is essential for B2B buyers dealing with diverse engine types. -

Material Composition

The materials used in a starter motor, such as the housing, windings, and gears, affect its durability and thermal resistance. Common materials include aluminum for the housing and copper for the windings. High-quality materials lead to a longer lifespan and better performance, crucial for B2B buyers focused on reliability. -

Temperature Rating

Temperature ratings indicate the operational limits of the starter motor, often specified in degrees Celsius. A starter designed to operate in extreme temperatures (both hot and cold) is essential for vehicles in diverse climates, particularly in regions like Africa and the Middle East. -

Weight

The weight of the starter motor can impact installation and vehicle performance. Lighter starters may be preferred in performance applications, while heavier units may offer more robust construction. B2B buyers should consider the weight in relation to the overall vehicle design and intended use.

What are Common Trade Terms Related to Starter Testing?

Navigating the world of automotive components requires familiarity with specific industry jargon. Here are some common terms that B2B buyers should understand when discussing starter motors.

-

OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are often preferred due to their guaranteed compatibility and quality, making them a reliable choice for businesses focused on maintaining high standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively and ensure they meet their purchasing needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This process is vital for B2B buyers to compare offers and negotiate better deals, ensuring they receive competitive pricing for starter motors. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and risk transfer. Familiarity with Incoterms is crucial for B2B transactions, particularly for buyers importing starter motors from different regions. -

Warranties and Guarantees

Warranties and guarantees are commitments from manufacturers regarding the quality and performance of their products. Understanding these terms helps B2B buyers assess the risk associated with their purchases, ensuring they have recourse in case of defects. -

Aftermarket

The aftermarket refers to parts and accessories sold after the original sale of the vehicle. B2B buyers often seek aftermarket options for cost-effective solutions, but they must ensure these parts meet quality and compatibility standards to avoid performance issues.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of starter motor testing and sourcing more effectively, ultimately making better purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the how do i test my starter Sector

What Are the Global Drivers Influencing the Starter Testing Market?

The market for testing starter motors is witnessing robust growth, driven by several global trends. The increasing demand for reliable automotive parts and services is one of the primary factors. As vehicles become more complex, the necessity for accurate diagnostics has surged, prompting businesses to invest in advanced testing technologies. Moreover, the rise of electric and hybrid vehicles has created a need for specialized testing equipment that can assess both traditional and new starter systems effectively.

Internationally, B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers that offer comprehensive diagnostic solutions. In markets such as Saudi Arabia and Nigeria, where automotive repair services are expanding, there is a growing trend toward adopting digital tools and automation in diagnostics. This shift is facilitating quicker service times and enhancing customer satisfaction, making it a crucial consideration for B2B buyers.

Illustrative image related to how do i test my starter

Furthermore, the COVID-19 pandemic has accelerated the need for remote diagnostics and online sourcing of automotive parts, compelling suppliers to enhance their digital platforms. As a result, international buyers are now more inclined to seek out suppliers who can provide both physical products and digital solutions, ensuring a seamless experience in testing and sourcing starter motors.

How Can Sustainability and Ethical Sourcing Impact the Starter Testing Sector?

Sustainability has become a pivotal concern within the automotive sector, influencing how international B2B buyers approach sourcing. The environmental impact of automotive components, including starter motors, is prompting businesses to seek out suppliers who adhere to sustainable practices. This includes the use of recycled materials and the adoption of energy-efficient manufacturing processes, which not only reduce carbon footprints but also appeal to eco-conscious consumers.

Ethical sourcing is equally important, with buyers increasingly demanding transparency in supply chains. Suppliers that can provide certifications demonstrating their commitment to sustainable practices, such as ISO 14001 for environmental management, are gaining a competitive edge. This focus on ethical sourcing is particularly pronounced in regions like Europe, where regulatory frameworks are stringent and consumer awareness is high.

Moreover, as the push for greener technologies grows, businesses are exploring partnerships with suppliers who specialize in ‘green’ starter components. These innovations can include the use of biodegradable materials and advanced recycling techniques, which not only mitigate environmental impact but also enhance brand reputation in a market that values sustainability.

What Is the Historical Context of Starter Testing Technologies?

The evolution of starter testing technologies has significantly influenced the automotive repair industry. Initially, testing was a manual and time-consuming process, often relying on basic observational techniques. As vehicles became more sophisticated in the late 20th century, the introduction of electronic ignition systems necessitated more advanced diagnostic tools.

The 1990s saw the emergence of specialized diagnostic equipment, allowing technicians to assess starter motors with greater accuracy. This shift was further accelerated by the advent of onboard diagnostics (OBD) systems, which provided real-time data on vehicle performance, including starter functionality.

Today, the landscape is dominated by digital solutions that integrate software with hardware, enabling remote diagnostics and predictive maintenance. This evolution not only enhances the efficiency of testing procedures but also aligns with the growing demand for sustainable and ethical practices within the automotive sector. B2B buyers are now encouraged to consider suppliers who are not only adept in traditional testing methods but are also pioneers in adopting cutting-edge technologies that cater to the modern automotive landscape.

Illustrative image related to how do i test my starter

Frequently Asked Questions (FAQs) for B2B Buyers of how do i test my starter

-

How do I diagnose a faulty starter motor?

To diagnose a faulty starter motor, begin with a visual inspection of the starter and its connections for signs of wear or corrosion. Listen for the click sound when turning the ignition key; this indicates the solenoid is receiving power. Use a multimeter to test the battery voltage; a healthy battery should read around 12.6 volts. If the battery is functional, you can perform a bench test by removing the starter and connecting it directly to a battery using jumper cables. This will confirm whether the starter itself is operational. -

What tools do I need to test a starter motor?

Essential tools for testing a starter motor include a multimeter for checking voltage, jumper cables for bench testing, a screwdriver for bypassing the solenoid, and basic hand tools for removing the starter from the vehicle. If you’re unfamiliar with electrical components, having a manual or a guide can be beneficial. Investing in an inductive ammeter can also help measure current draw during testing, providing further insights into starter performance. -

What are the common signs of a bad starter motor?

Common signs of a bad starter motor include a clicking sound when turning the ignition key, the engine not cranking, or intermittent starting issues. Additionally, if you notice smoke or a burning smell from the starter area, this could indicate severe failure. Other indicators include dimming lights when attempting to start the vehicle and a grinding noise if the starter engages but fails to turn the engine. -

How can I ensure the quality of the starter motor I’m purchasing?

To ensure the quality of a starter motor, source from reputable suppliers who provide warranties and quality certifications. Request product samples to evaluate performance before placing a bulk order. Also, ask for references or customer testimonials to gauge the supplier’s reliability. Implement a quality assurance process, including testing a portion of the inventory upon arrival to verify that they meet your standards. -

What payment terms should I negotiate with my starter motor supplier?

When negotiating payment terms, consider factors like the order size, relationship with the supplier, and industry norms. Common terms include net 30 or net 60 days, which allow you time to generate revenue from sales before payment is due. For larger orders, you might negotiate a deposit upfront with the balance due upon delivery. It’s crucial to establish clear terms to avoid misunderstandings and ensure smooth transactions. -

What is the minimum order quantity (MOQ) for starter motors?

Minimum order quantities (MOQ) for starter motors can vary significantly between suppliers and manufacturers. Typically, MOQs range from 50 to several hundred units, depending on the supplier’s production capacity and your specific requirements. Discussing your needs upfront can sometimes allow for lower MOQs, especially if you are a first-time buyer or if you establish a long-term partnership with the supplier. -

How can I facilitate logistics for sourcing starter motors internationally?

To facilitate logistics for international sourcing of starter motors, engage with freight forwarders who can handle customs clearance and shipping regulations in your region. Plan your logistics well in advance, considering lead times for production and shipping. Use reliable shipping methods and track your orders to ensure timely delivery. Having a clear communication channel with your supplier can also help address any logistics challenges that may arise. -

What should I consider when vetting suppliers for starter motors?

When vetting suppliers for starter motors, assess their reputation, years in business, and customer reviews. Verify their certifications and compliance with international quality standards. Evaluate their production capabilities and delivery timelines to ensure they can meet your demand. Additionally, consider their communication responsiveness and willingness to accommodate your specific needs, as these factors can greatly impact your overall experience and satisfaction.

Top 3 How Do I Test My Starter Manufacturers & Suppliers List

1. Reddit – Car Starter Testing Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: To check if a car starter is working correctly, you can use a multimeter or jumper cables. A multimeter can help diagnose electrical issues, while jumper cables can be used to bench test the starter by connecting them to the starter’s terminals. Additionally, tapping on the starter while a friend turns the ignition key may help if the starter is stuck.

2. WikiHow – Car Starter Testing Guide

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: This article provides a step-by-step guide on how to test a car starter, including checking the pinion, testing the electrical system, and bench testing the starter. Key components involved in the process include the starter motor, pinion stub, solenoid, battery, and multimeter. The guide emphasizes the importance of inspecting battery terminals for corrosion, testing battery voltage, and ensuring…

3. Advance Auto Parts – New Starter

Strategic Sourcing Conclusion and Outlook for how do i test my starter

In conclusion, understanding how to test a starter motor is essential for businesses involved in automotive maintenance and repair, especially in regions like Africa, South America, the Middle East, and Europe. By employing techniques such as visual inspections, multimeter testing, and bench tests, B2B buyers can effectively diagnose starter issues, reducing unnecessary costs and downtime.

Strategic sourcing plays a pivotal role in ensuring that businesses have access to high-quality starter components and diagnostic tools. Establishing relationships with reliable suppliers can enhance operational efficiency and improve service delivery. Furthermore, having a well-informed procurement strategy allows companies to adapt to market demands and technological advancements, thereby staying competitive.

As the automotive industry continues to evolve, international buyers should remain proactive in seeking innovative solutions and partnerships. Embrace the opportunity to leverage advanced testing methodologies and reliable sourcing practices to enhance your service offerings. Engage with trusted suppliers and invest in training for your teams to ensure that they are equipped to handle the complexities of modern automotive diagnostics. Your commitment to quality and efficiency will not only benefit your business but also set a benchmark in the industry.

Illustrative image related to how do i test my starter

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.