Introduction: Navigating the Global Market for como saber si el alternador esta fallando

In the complex landscape of global vehicle maintenance, understanding how to identify whether an alternator is failing is paramount for businesses reliant on automotive performance. The ability to discern early warning signs of alternator issues can be a game-changer for B2B buyers, particularly those operating fleets in regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Vietnam. This guide, “como saber si el alternador esta fallando,” equips decision-makers with essential insights into alternator functionality, potential failure indicators, and the implications for vehicle operations.

This comprehensive resource covers the types of alternators, their various applications across different vehicle models, and critical supplier vetting strategies to ensure quality procurement. Additionally, we delve into cost considerations, providing a balanced perspective on investment versus long-term savings through proactive maintenance. By understanding the nuances of alternator performance and failure signs—such as dashboard warnings, unusual noises, and electrical issues—B2B buyers can make informed purchasing decisions that enhance operational efficiency and reduce downtime.

In a market characterized by diverse automotive needs and regional challenges, this guide empowers businesses to navigate the intricacies of alternator maintenance effectively, ensuring that vehicles remain reliable and efficient. Equip your organization with the knowledge to mitigate risks associated with alternator failures and enhance your fleet’s overall performance.

Table Of Contents

- Top 2 Como Saber Si El Alternador Esta Fallando Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for como saber si el alternador esta fallando

- Understanding como saber si el alternador esta fallando Types and Variations

- Key Industrial Applications of como saber si el alternador esta fallando

- 3 Common User Pain Points for ‘como saber si el alternador esta fallando’ & Their Solutions

- Strategic Material Selection Guide for como saber si el alternador esta fallando

- In-depth Look: Manufacturing Processes and Quality Assurance for como saber si el alternador esta fallando

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘como saber si el alternador esta fallando’

- Comprehensive Cost and Pricing Analysis for como saber si el alternador esta fallando Sourcing

- Alternatives Analysis: Comparing como saber si el alternador esta fallando With Other Solutions

- Essential Technical Properties and Trade Terminology for como saber si el alternador esta fallando

- Navigating Market Dynamics and Sourcing Trends in the como saber si el alternador esta fallando Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of como saber si el alternador esta fallando

- Strategic Sourcing Conclusion and Outlook for como saber si el alternador esta fallando

- Important Disclaimer & Terms of Use

Understanding como saber si el alternador esta fallando Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Visual Inspection | Check for physical signs of wear on the alternator | Fleet maintenance, vehicle servicing | Pros: Quick and easy; Cons: May miss hidden issues |

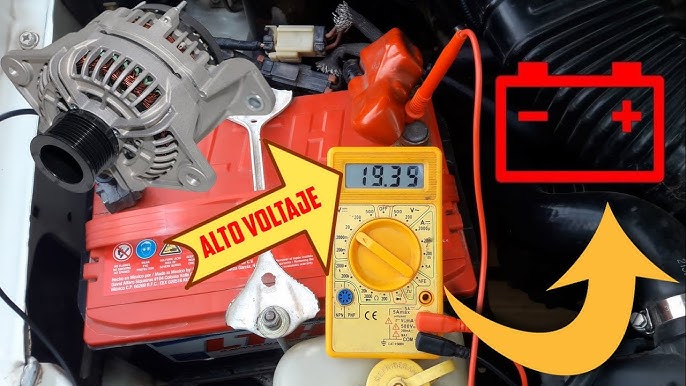

| Electrical Testing | Use of multimeters to assess voltage and current | Diagnostics for commercial vehicles | Pros: Accurate; Cons: Requires specialized equipment |

| Sound Diagnostics | Listening for unusual noises like grinding or whining | Mechanic workshops, repair shops | Pros: Non-invasive; Cons: Subjective interpretation |

| Accessory Performance Check | Monitoring performance of electrical components | Quality assurance in fleet vehicles | Pros: Real-time assessment; Cons: May not pinpoint cause |

| Battery Condition Assessment | Evaluating battery health in relation to alternator | Battery supply and maintenance | Pros: Comprehensive; Cons: Time-consuming |

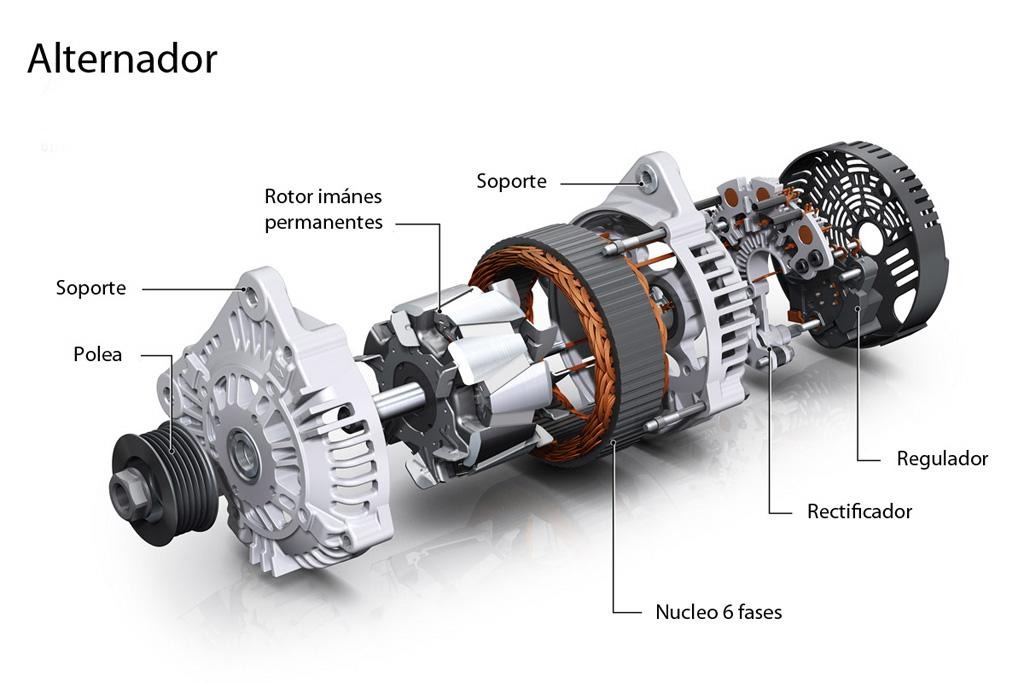

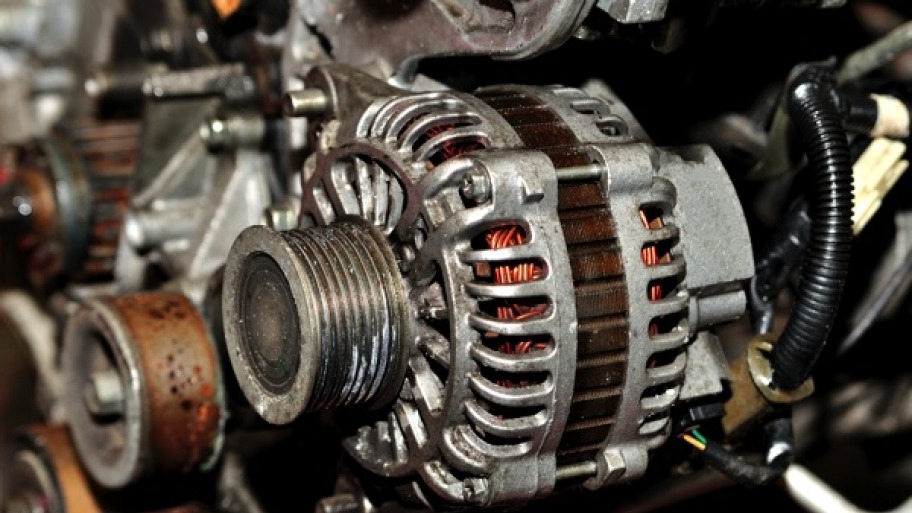

What are the Key Characteristics of Visual Inspection for Alternator Issues?

Visual inspection involves examining the alternator and its components for obvious signs of wear, such as cracks in the casing or frayed belts. This method is particularly suitable for businesses with fleets, as it allows for rapid assessments during routine maintenance checks. While this approach is quick and cost-effective, it may not uncover deeper electrical issues, making it essential to complement it with other diagnostic methods.

How Can Electrical Testing Help Identify Alternator Failures?

Electrical testing typically involves using a multimeter to measure the alternator’s output voltage and current. This technique is critical for automotive diagnostics in commercial settings, where ensuring the reliability of vehicles is paramount. Although it offers accurate insights into the alternator’s functionality, it requires trained personnel and specialized equipment, which can add to operational costs.

Why is Sound Diagnostics Important in Identifying Alternator Problems?

Sound diagnostics focuses on identifying unusual noises from the alternator, such as grinding or whining, which can indicate mechanical failure. This method is beneficial in mechanic workshops where technicians can quickly assess vehicle conditions. While it is non-invasive and cost-effective, the interpretation of sounds can be subjective and may require experienced technicians to avoid misdiagnosis.

What Role Does Accessory Performance Checking Play in Diagnosing Alternator Health?

Monitoring the performance of electrical accessories like lights, air conditioning, and the audio system can provide insights into the alternator’s health. This method is especially useful in quality assurance processes for fleet vehicles, where real-time performance data can reveal potential failures. However, while it can indicate issues, it may not pinpoint the exact cause, necessitating further investigation.

How Does Battery Condition Assessment Relate to Alternator Functionality?

Assessing the battery’s condition in conjunction with the alternator is vital for understanding the overall electrical system health. This evaluation is crucial for businesses involved in battery supply and maintenance, ensuring that both components are functioning optimally. Although this method provides a comprehensive view of the electrical system, it can be time-consuming and may require specialized knowledge to interpret results accurately.

Key Industrial Applications of como saber si el alternador esta fallando

| Industry/Sector | Specific Application of como saber si el alternador esta fallando | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Diagnostic services for fleet vehicles to identify alternator issues | Reduces downtime and maintenance costs, ensuring fleet reliability | Availability of diagnostic tools and trained technicians |

| Construction Equipment | Maintenance checks for heavy machinery alternators | Enhances operational efficiency and reduces unexpected failures | Access to specialized parts and skilled maintenance staff |

| Public Transportation | Routine inspections of public transport vehicles | Ensures safety and reliability for passengers | Compliance with local regulations and availability of parts |

| Agriculture Machinery | Monitoring alternator performance in agricultural equipment | Maximizes productivity during peak seasons | Understanding of agricultural machinery specifications |

| Renewable Energy Systems | Assessing alternator functionality in hybrid systems | Improves energy efficiency and system reliability | Knowledge of hybrid technology and sourcing of compatible parts |

How is ‘como saber si el alternador esta fallando’ Applied in the Automotive Repair Industry?

In the automotive repair sector, understanding how to identify alternator failures is crucial for maintaining fleet vehicles. Diagnostic services that focus on alternator health can significantly reduce downtime and maintenance costs, ensuring that vehicles remain operational. Businesses in this sector must prioritize sourcing quality diagnostic tools and employing trained technicians who can accurately assess and address alternator issues.

What Role Does ‘como saber si el alternador esta fallando’ Play in Construction Equipment Maintenance?

For construction companies, the performance of heavy machinery is vital. Regular maintenance checks that include alternator diagnostics help prevent unexpected failures, thereby enhancing operational efficiency. Businesses need to ensure access to specialized parts for various machinery types and have skilled maintenance staff who can quickly identify and resolve alternator-related issues, minimizing project delays.

How Does ‘como saber si el alternador esta fallando’ Benefit Public Transportation Systems?

Public transportation systems rely heavily on the reliability of their vehicles. Routine inspections that focus on alternator performance are essential for ensuring passenger safety and system reliability. Companies must navigate local regulatory requirements while ensuring that they have immediate access to parts and services that can address alternator problems swiftly to avoid service interruptions.

Why is ‘como saber si el alternador esta fallando’ Important for Agriculture Machinery?

In the agricultural sector, monitoring the performance of alternators in machinery is critical during peak seasons when productivity is paramount. Understanding how to diagnose alternator issues ensures that equipment operates efficiently, preventing costly downtime. Buyers in this sector should be knowledgeable about the specific requirements of agricultural machinery and ensure that they can source compatible parts quickly to maintain productivity.

How is ‘como saber si el alternador esta fallando’ Utilized in Renewable Energy Systems?

In the renewable energy sector, particularly with hybrid systems, assessing alternator functionality can significantly improve energy efficiency and system reliability. Companies must have a firm grasp of hybrid technology and ensure they can source compatible parts for maintenance. This focus on alternator health allows businesses to optimize performance and reduce the risk of energy supply interruptions.

3 Common User Pain Points for ‘como saber si el alternador esta fallando’ & Their Solutions

Scenario 1: Identifying Electrical Issues in Fleets

The Problem: For B2B buyers managing fleets of vehicles, understanding how to identify alternator failures can significantly impact operational efficiency. A failing alternator can lead to unexpected vehicle breakdowns, causing delays and increasing maintenance costs. Fleet managers may struggle with symptoms that overlap with battery issues, making it challenging to pinpoint the root cause of electrical failures. This confusion can result in unnecessary repairs or replacements, leading to wasted resources and reduced vehicle availability.

The Solution: To effectively diagnose alternator issues in fleet vehicles, it is essential to implement a systematic approach to vehicle maintenance. Start by training your team to recognize key symptoms of alternator failure, such as dashboard warning lights, unusual noises, and electrical accessory malfunctions. Encourage routine checks of the alternator belt for wear and tension. Additionally, invest in a multimeter to regularly measure battery voltage—both when the engine is off and running. A voltage reading below 13.5 volts when the engine is running may indicate a failing alternator. By establishing a preventative maintenance schedule that includes these diagnostics, fleet managers can ensure their vehicles remain operational, thereby minimizing downtime and maximizing productivity.

Scenario 2: Costly Repairs from Delayed Diagnosis

The Problem: B2B buyers often face the challenge of escalating repair costs due to delayed diagnosis of alternator problems. When the alternator is not functioning properly, it can lead to a chain reaction of failures in the vehicle’s electrical system. This can result in significant repair bills that could have been avoided with timely intervention. Companies may find themselves facing not only direct repair costs but also indirect costs related to lost business opportunities during vehicle downtime.

The Solution: To mitigate the risk of costly repairs, organizations should implement an early detection strategy for alternator issues. This includes setting up a protocol for regular inspections where technicians look for signs of wear, such as burnt smells or unusual sounds. Moreover, leveraging technology such as onboard diagnostics (OBD) systems can provide real-time data on vehicle performance, allowing for quicker identification of electrical problems. Training staff on how to interpret this data can further enhance their ability to detect issues before they escalate. By prioritizing timely diagnostics and utilizing technology, companies can significantly reduce repair costs and improve overall vehicle reliability.

Scenario 3: Impact on Safety and Compliance

The Problem: B2B buyers in industries such as transportation and logistics must prioritize safety and regulatory compliance. A malfunctioning alternator can compromise vehicle safety, leading to potential accidents and liability issues. The inability to ensure that all vehicles are operating efficiently can also result in non-compliance with industry regulations, risking penalties and reputational damage.

The Solution: To address safety concerns related to alternator functionality, businesses should integrate comprehensive safety checks into their vehicle maintenance programs. This should include regular assessments of the electrical system, focusing on the alternator’s performance and its impact on other critical safety systems like lighting and braking. Establishing a checklist that includes voltage checks, visual inspections of the alternator and its belt, and testing electrical accessories during routine maintenance can help ensure compliance and safety. Additionally, educating drivers on the importance of reporting any electrical issues immediately can create a culture of safety within the organization. By fostering an environment that emphasizes proactive maintenance and safety, companies can protect their employees and assets while ensuring compliance with industry standards.

Strategic Material Selection Guide for como saber si el alternador esta fallando

When assessing the materials relevant to understanding how to identify alternator failures, it is crucial to consider their properties, performance, and application suitability. The following analysis highlights four common materials that play a significant role in the context of alternators and their components.

Copper: The Backbone of Electrical Conductivity

Key Properties: Copper is known for its excellent electrical conductivity, high thermal conductivity, and resistance to corrosion. It can withstand high temperatures, making it suitable for various electrical applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, which ensures efficient energy transfer within the alternator. However, it is relatively expensive compared to other conductive materials like aluminum, and its weight can be a disadvantage in applications where minimizing weight is critical.

Impact on Application: Copper is essential for wiring and connections within the alternator. Its compatibility with electrical systems makes it a preferred choice, but care must be taken to avoid galvanic corrosion when used with dissimilar metals.

Considerations for International Buyers: Buyers in regions such as Africa and South America should ensure compliance with international standards like ASTM B187 for copper products. In Europe, adherence to DIN standards is crucial, while buyers in the Middle East may prioritize suppliers who can meet local specifications.

Aluminum: A Lightweight Alternative

Key Properties: Aluminum is lightweight, has good corrosion resistance, and offers decent electrical conductivity, although not as high as copper. It can operate effectively in a range of temperatures.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which can enhance fuel efficiency in vehicles. However, its lower conductivity compared to copper can lead to increased energy losses, and it may require thicker wires to achieve the same performance.

Illustrative image related to como saber si el alternador esta fallando

Impact on Application: Aluminum is often used in alternator housings and some wiring applications. It is particularly suitable for automotive applications where weight reduction is a priority.

Considerations for International Buyers: Buyers should be aware of the different grades of aluminum and their corresponding standards, such as JIS H 4000 in Japan or EN AW in Europe. Compliance with local regulations regarding recycling and sustainability is also essential.

Steel: Strength and Durability

Key Properties: Steel is known for its strength and durability, with high tensile strength and resistance to wear. However, it is heavier than both copper and aluminum and can be prone to corrosion if not treated.

Pros & Cons: Steel’s primary advantage is its robustness, making it suitable for structural components of the alternator. The downside is its weight, which can negatively impact vehicle performance, and the need for protective coatings to prevent rust.

Impact on Application: Steel is commonly used in the framework and mounting brackets of alternators. Its durability ensures long-term reliability, but its weight must be managed in vehicle design.

Considerations for International Buyers: Buyers should ensure that the steel used meets international standards such as ASTM A36 or DIN 17100. Additionally, understanding local corrosion resistance requirements is vital, especially in humid or coastal regions.

Plastic: Insulation and Lightweight Design

Key Properties: Plastics are lightweight, corrosion-resistant, and provide excellent electrical insulation. They can withstand moderate temperatures but may not perform well under extreme heat.

Pros & Cons: The key advantage of plastic is its insulating properties, which protect electrical components from short circuits. However, plastics may not be as durable as metals and can degrade over time, especially when exposed to UV light.

Impact on Application: Plastics are often used for insulating covers and housings in alternators. They help reduce weight and improve safety by preventing electrical shock.

Considerations for International Buyers: Buyers should look for plastics that comply with relevant safety and environmental standards, such as RoHS in Europe or REACH regulations. Understanding the thermal and mechanical properties of the plastic used is also essential for ensuring long-term performance.

Summary Table

| Material | Typical Use Case for como saber si el alternador esta fallando | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and electrical connections in alternators | Superior electrical conductivity | High cost and weight | High |

| Aluminum | Alternator housings and wiring | Lightweight and good corrosion resistance | Lower conductivity than copper | Medium |

| Steel | Structural components and mounting brackets | High strength and durability | Heavy and prone to corrosion | Medium |

| Plastic | Insulating covers and housings | Excellent electrical insulation | Less durable and temperature sensitive | Low |

This analysis provides valuable insights for B2B buyers looking to understand material implications in alternator performance and failure identification. By considering the properties, advantages, and limitations of each material, international buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for como saber si el alternador esta fallando

What Are the Main Stages of Manufacturing for Alternators?

Manufacturing alternators involves several critical stages that ensure the final product meets the high standards required for optimal performance in vehicles. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

-

Material Preparation: The first step in alternator manufacturing is selecting high-quality raw materials, such as copper for windings and aluminum for the casing. These materials must meet specific international standards for conductivity and durability. Suppliers often conduct material inspections based on ISO standards to verify that they meet the necessary specifications.

-

Forming: The next stage involves forming the components of the alternator. This includes stamping the rotor and stator from sheets of metal, which are then shaped into the required dimensions. Advanced techniques like precision machining and laser cutting are often employed to ensure accuracy. The forming process must adhere to industry standards to maintain the integrity and performance of the components.

-

Assembly: After forming, the components are assembled. This includes winding the copper wire around the stator and installing the rotor, bearings, and rectifier. Automated assembly lines are commonly used to enhance efficiency and reduce human error. It is critical that assembly processes follow strict protocols to ensure that all parts fit correctly and function as intended.

-

Finishing: The finishing stage involves applying protective coatings, such as anti-corrosive treatments, and conducting final inspections. This stage is vital for ensuring the longevity of the alternator. Manufacturers may also perform balancing tests on the assembled alternators to eliminate vibrations during operation, which can lead to premature failure.

How Is Quality Assurance Implemented in Alternator Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for alternators. It encompasses a range of practices aimed at ensuring that each product meets the required specifications and performance standards.

-

What International Standards Guide Quality Assurance?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO standards helps ensure consistency in production and customer satisfaction. Additionally, industry-specific certifications, such as CE marking in Europe and API specifications for automotive components, may also apply. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically segmented into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During manufacturing, inspections are conducted at various stages to monitor the quality of the components being produced.

– Final Quality Control (FQC): Once the alternator is assembled, a comprehensive evaluation is performed. This may include functional testing, visual inspections, and performance assessments against industry benchmarks. -

What Common Testing Methods Are Used?

Manufacturers often employ various testing methods to ensure the alternator’s reliability and efficiency. Common tests include:

– Electrical Testing: Measuring voltage output and current to verify that the alternator is functioning correctly under load.

– Thermal Testing: Assessing how the alternator performs under high temperatures to ensure it can withstand operational stresses.

– Vibration Testing: Determining if the alternator operates smoothly and without excessive vibration, which can indicate potential issues.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial. Here are some strategies to ensure that you partner with manufacturers who maintain high standards:

-

What Should Buyers Look for in Supplier Audits?

Conducting supplier audits is an effective way to evaluate their manufacturing processes and quality assurance protocols. Buyers should request documentation that outlines the supplier’s quality management system, including certifications, inspection reports, and testing results. -

How Can Buyers Utilize Reports and Third-Party Inspections?

Regularly reviewing quality reports from suppliers provides insights into their operational consistency. Additionally, engaging third-party inspection services can offer an unbiased evaluation of the supplier’s adherence to quality standards. These inspections often include audits of manufacturing practices and product testing. -

What Are the QC and Certification Nuances for International Markets?

Different regions may have varying requirements and standards for alternator manufacturing. For example, European markets may prioritize CE certification, while buyers in Africa or South America may focus on compliance with local regulations. It is essential for buyers to understand these nuances and ensure that their suppliers meet the necessary certifications for their target market.

Conclusion: Ensuring Quality in Alternator Manufacturing

Understanding the manufacturing processes and quality assurance measures for alternators is essential for B2B buyers seeking reliable suppliers. By focusing on the main stages of production, quality control checkpoints, and the verification of supplier standards, businesses can make informed decisions that enhance their operations and ensure the reliability of their vehicle fleets. In an international market, staying informed about certifications and compliance requirements is vital for successful partnerships and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘como saber si el alternador esta fallando’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to understand the signs of alternator failure in vehicles. Recognizing early indicators of alternator issues can save time and money by preventing extensive damage to the vehicle’s electrical system. This guide will help you identify key steps in sourcing reliable information and suppliers to ensure optimal vehicle performance.

Step 1: Identify Key Symptoms of Alternator Failure

Understanding the symptoms of a failing alternator is crucial. Common indicators include dashboard warning lights, unusual noises, and dimming headlights. Familiarizing yourself with these signs allows you to quickly address potential issues and seek professional help when necessary.

Step 2: Assess Your Vehicle’s Electrical System Needs

Evaluate the specific electrical requirements of your vehicles. Different models may have varying demands based on their age, type, and usage. Consider factors such as the number of electronic components and their power consumption to ensure any alternator sourced meets these specifications.

Step 3: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical specifications. This includes the voltage output, amperage rating, and compatibility with your vehicle models. Providing detailed specifications helps suppliers offer precise solutions that fit your operational needs, reducing the risk of mismatched components.

Step 4: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers specializing in automotive electrical components. Look for suppliers with a strong track record in your region, particularly those familiar with the specific requirements of vehicles used in Africa, South America, the Middle East, and Europe. Check for online reviews, ratings, and testimonials to gauge their reliability.

Step 5: Verify Supplier Certifications and Quality Assurance

Ensure that your chosen suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO and compliance with automotive safety regulations are indicators of quality. Request documentation to confirm that their products undergo rigorous testing for performance and durability.

Step 6: Request Samples and Conduct Testing

Before making a bulk purchase, request samples of the alternators. Testing these samples in real-world conditions can help identify any performance issues early on. Ensure that the samples align with your technical specifications and meet the quality standards expected for your fleet.

Step 7: Establish Clear Terms and Conditions

Once you select a supplier, establish clear terms and conditions regarding pricing, warranty, and return policies. A well-defined agreement can protect your interests and ensure that any potential issues are addressed promptly. Pay attention to delivery timelines and after-sales support, which are critical for maintaining your fleet’s operational efficiency.

Illustrative image related to como saber si el alternador esta fallando

By following this step-by-step checklist, B2B buyers can effectively navigate the process of understanding and sourcing solutions for alternator issues, ultimately ensuring the reliability and safety of their vehicles.

Comprehensive Cost and Pricing Analysis for como saber si el alternador esta fallando Sourcing

What Are the Key Cost Components in Sourcing for ‘como saber si el alternador esta fallando’?

When sourcing components related to the functionality of alternators, several cost components come into play. Understanding these elements is crucial for B2B buyers looking to make informed purchasing decisions.

-

Materials: The primary materials for alternators include copper for windings, aluminum for casings, and various plastics for insulation. The cost of these raw materials fluctuates based on global market conditions, affecting overall sourcing costs. Buyers should monitor material prices and consider sourcing from regions where these materials are abundant.

-

Labor: Labor costs vary significantly across different regions. In countries with lower labor costs, such as those in South America and parts of Africa, the manufacturing costs may be reduced. However, it’s essential to ensure that the workforce is skilled in electrical assembly to maintain quality standards.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and equipment depreciation. Buyers should seek manufacturers that can optimize overhead costs through efficient processes, which can translate into lower prices.

-

Tooling: Initial costs for tooling can be substantial, especially for custom alternator designs. This is a crucial investment for manufacturers, impacting the price per unit for low-volume orders. Buyers may negotiate for shared tooling costs if they are ordering larger quantities.

-

Quality Control (QC): Implementing robust QC processes ensures that the alternators meet performance standards. While this adds to costs, it can prevent expensive returns and warranty claims. Buyers should inquire about the QC measures taken by suppliers to ensure reliability.

-

Logistics: Shipping costs can vary significantly based on the Incoterms agreed upon. Factors such as distance, shipping mode, and customs duties all play a role in logistics expenses. Buyers should evaluate different shipping options and negotiate terms that align with their budget and operational timelines.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the typical margin within the industry can help buyers gauge whether they are receiving a fair price.

What Influences Pricing for Alternator Components?

Several factors can influence the pricing of alternator components, particularly for international buyers.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should assess their purchasing capabilities and negotiate MOQs that fit their needs without overcommitting.

-

Specifications and Customization: Customized alternators may incur higher costs due to the need for specialized materials or production processes. Buyers should clearly define their specifications upfront to avoid unexpected costs later.

-

Supplier Factors: Supplier reputation, reliability, and history can influence pricing. Established suppliers may charge a premium, but their products often come with better warranties and service.

-

Quality Certifications: Components that meet international quality standards (e.g., ISO certifications) may be priced higher. However, these certifications often correlate with better performance and longevity, making them a wise investment.

What Tips Can B2B Buyers Use to Optimize Their Purchasing Strategy?

-

Negotiation: Always negotiate pricing and terms with suppliers. Understanding the cost structure can provide leverage during discussions.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance and operational costs over the product’s lifespan.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and trade agreements that may affect costs. Establishing long-term relationships with suppliers can also yield better pricing and terms.

-

Due Diligence: Conduct thorough research on potential suppliers, including their financial stability and reputation in the market. This can help mitigate risks associated with international sourcing.

Conclusion

Understanding the cost structure and pricing influencers for alternator components is essential for B2B buyers. By considering the aforementioned factors, businesses can enhance their sourcing strategies and make informed purchasing decisions that align with their operational needs. Always remember that while price is a critical factor, quality and reliability should not be compromised for short-term savings.

Alternatives Analysis: Comparing como saber si el alternador esta fallando With Other Solutions

Introduction to Alternative Solutions for Diagnosing Alternator Issues

Understanding how to determine if an alternator is failing is essential for maintaining the reliability of commercial vehicles. However, there are several alternative methods and technologies available that can serve similar purposes. This analysis compares the traditional approach of diagnosing alternator issues against other viable solutions, allowing B2B buyers to make informed decisions based on performance, cost, and implementation ease.

Illustrative image related to como saber si el alternador esta fallando

Comparison Table

| Comparison Aspect | Como Saber Si El Alternador Esta Fallando | Diagnostic Tools (e.g., Multimeter) | Professional Diagnostic Services |

|---|---|---|---|

| Performance | Effective for early detection | High accuracy in voltage readings | Comprehensive diagnostics |

| Cost | Low to moderate (self-inspection) | Moderate (tool purchase) | High (service fees) |

| Ease of Implementation | Simple and quick checks | Requires some technical knowledge | No effort required from the buyer |

| Maintenance | No ongoing maintenance needed | Low (occasional recalibration) | None (handled by professionals) |

| Best Use Case | Regular vehicle maintenance | Quick troubleshooting | Complex or persistent issues |

Detailed Breakdown of Alternatives

Diagnostic Tools (e.g., Multimeter)

Using a multimeter or similar diagnostic tool is an effective alternative for assessing the health of the alternator. This method allows users to measure voltage levels directly from the battery and alternator while the engine is running. The primary advantage of this approach is its accuracy; it can provide precise readings that indicate whether the alternator is functioning correctly. However, it does require some technical knowledge and familiarity with electrical systems, which may not be feasible for all users. The initial investment in tools can also be a consideration, but once acquired, they can be used for various applications beyond just diagnosing alternator issues.

Professional Diagnostic Services

Engaging professional diagnostic services is another alternative for determining alternator health. This approach involves taking the vehicle to a qualified technician who can perform a comprehensive assessment of the electrical system. The main advantage of this method is the expertise and thoroughness that professionals bring, often identifying issues that may not be apparent through basic inspections or DIY methods. However, this option tends to be the most expensive due to service fees. Additionally, it requires time for scheduling and may lead to vehicle downtime, which could impact business operations.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the best method for diagnosing alternator issues, B2B buyers should consider their specific operational needs and resources. For businesses with a strong technical background or those looking for cost-effective solutions, DIY methods like using a multimeter can be beneficial. Conversely, companies that prioritize thoroughness and have the budget for it may prefer professional diagnostic services for more complex issues. Ultimately, understanding the strengths and limitations of each alternative will empower buyers to choose the solution that best aligns with their operational requirements and ensures their vehicles remain in optimal condition.

Essential Technical Properties and Trade Terminology for como saber si el alternador esta fallando

What Are the Critical Technical Properties to Consider When Diagnosing Alternator Failure?

Understanding the essential technical properties of alternators is crucial for B2B buyers in the automotive sector. Here are some of the key specifications to consider:

1. Output Voltage

Output voltage is a critical specification that indicates the electrical power produced by the alternator. Most automotive alternators provide between 12 to 14.5 volts, which is necessary for charging the battery and powering the vehicle’s electrical systems. Monitoring this parameter helps in diagnosing alternator performance issues. In B2B scenarios, reliable output voltage ensures that vehicles remain operational, thus minimizing downtime.

2. Ampere Rating

The ampere rating defines the maximum electrical current that the alternator can supply. Typically, this ranges from 40 to 250 amps, depending on the vehicle’s requirements. Understanding the ampere rating is vital for fleet managers and automotive suppliers to ensure that the alternators they procure can meet the energy demands of various vehicle systems. Inadequate amperage can lead to battery drain or failure of electrical components.

3. Efficiency Rating

The efficiency rating of an alternator refers to how effectively it converts mechanical energy into electrical energy. High-efficiency alternators (typically above 70%) are preferred in commercial applications as they reduce fuel consumption and emissions, offering a more sustainable solution. For businesses, investing in high-efficiency models can lead to long-term cost savings and improved vehicle performance.

Illustrative image related to como saber si el alternador esta fallando

4. Temperature Tolerance

Temperature tolerance is a specification that indicates the operating temperature range of the alternator. Alternators designed for extreme conditions can operate efficiently in temperatures ranging from -40°C to 120°C. This is particularly important for businesses operating in diverse climates, ensuring that their vehicles remain functional under various conditions.

5. Material Grade

The material grade of an alternator impacts its durability and longevity. Components made from high-grade materials, such as aluminum and copper, are preferred for their strength and resistance to corrosion. In B2B transactions, understanding material specifications can help buyers select reliable products that will minimize maintenance and replacement costs.

What Are the Common Trade Terms Related to Alternator Diagnosis?

Familiarity with industry jargon is essential for effective communication and negotiation in the automotive sector. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the assembly of vehicles. When purchasing alternators, opting for OEM parts can ensure compatibility and reliability, as they are made to the same specifications as the original components used in vehicle manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory levels and costs. For alternators, purchasing in bulk can lead to significant savings and ensure a steady supply for vehicle maintenance.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities of products. B2B buyers should prepare detailed RFQs for alternators to receive accurate quotes that reflect their needs, enabling better budgeting and planning for procurement.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers during the shipping process. Familiarity with these terms helps businesses understand shipping costs, risks, and delivery timelines for alternators, which is vital for efficient supply chain management.

Illustrative image related to como saber si el alternador esta fallando

5. Aftermarket

The aftermarket refers to the market for parts and accessories that are not sourced from the original vehicle manufacturer. Understanding the aftermarket is essential for businesses looking to source cost-effective alternators while ensuring quality and compatibility.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when diagnosing alternator issues, ensuring operational efficiency and reducing costs in their automotive fleets.

Navigating Market Dynamics and Sourcing Trends in the como saber si el alternador esta fallando Sector

What Are the Current Market Dynamics for Understanding Alternator Failures in B2B?

The global automotive market is witnessing a significant shift towards advanced diagnostics and maintenance solutions, particularly concerning critical components like alternators. This trend is driven by increasing demand for vehicle uptime, operational efficiency, and the rising cost of vehicle downtime. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are seeking reliable sources for high-quality alternators and diagnostic tools. Emerging technologies, such as IoT-enabled diagnostics, are gaining traction, allowing for real-time monitoring of vehicle systems, including alternators. This enables businesses to proactively address potential failures, minimizing repair costs and enhancing fleet management efficiency.

In Europe, for instance, there is a strong emphasis on integrating smart technologies that facilitate predictive maintenance. In contrast, markets in Africa and South America are increasingly focused on cost-effective solutions, prioritizing affordable yet reliable parts and services. Furthermore, suppliers are adapting to local market needs by offering tailored solutions that consider the unique operating conditions of vehicles in these regions, such as climate and road conditions. As a result, international buyers are encouraged to engage with suppliers who not only provide quality products but also possess expertise in local market dynamics.

How Can Sustainability and Ethical Sourcing Impact the Alternator Supply Chain?

Sustainability and ethical sourcing are becoming paramount in the automotive sector, particularly in the context of alternator production and maintenance. The environmental impact of manufacturing processes, including the extraction of raw materials and energy consumption, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as utilizing recycled materials and minimizing waste throughout their supply chains.

Moreover, ethical sourcing is essential in ensuring that raw materials used in alternators are obtained responsibly, without contributing to human rights abuses or environmental degradation. Buyers are now looking for suppliers with certifications that demonstrate a commitment to sustainability, such as ISO 14001 for environmental management systems or certifications for ethical labor practices. This trend is particularly relevant for buyers in Europe, where regulations around sustainability are stringent, but it is also gaining traction in other regions like Africa and South America, where consumers are becoming more environmentally conscious.

By aligning with sustainable and ethical suppliers, B2B buyers can not only enhance their brand reputation but also contribute to a greener automotive industry. This strategic approach to sourcing can lead to long-term partnerships and greater resilience in supply chains, ensuring that businesses remain competitive in an evolving market landscape.

What Is the Historical Context for Alternator Technology in the Automotive Industry?

The evolution of alternator technology has significantly shaped the automotive landscape, particularly in the B2B sector. Initially, vehicles relied on direct current (DC) generators, which were less efficient and required frequent maintenance. The introduction of the alternator in the 1960s marked a pivotal moment, offering greater efficiency and reliability in charging vehicle batteries and powering electrical systems.

As vehicles became more complex, the demand for advanced alternators grew, leading to innovations in design and technology. Modern alternators are now equipped with features such as smart regulators and enhanced cooling systems, enabling them to support the increasing electrical loads of contemporary vehicles. This historical progression has important implications for B2B buyers, who must navigate a market that is not only focused on quality and performance but also on the integration of new technologies that enhance vehicle functionality.

Illustrative image related to como saber si el alternador esta fallando

Understanding this evolution allows B2B buyers to make informed decisions regarding sourcing and maintenance, ensuring they select alternators that meet current demands while considering future advancements in automotive technology.

Frequently Asked Questions (FAQs) for B2B Buyers of como saber si el alternador esta fallando

-

How do I identify if my vehicle’s alternator is failing?

To determine if your vehicle’s alternator is malfunctioning, look for key indicators such as dashboard warning lights, unusual sounds (like grinding or whining), and issues with electrical components. Additionally, check the voltage output using a multimeter; a reading below 13.8 volts while the engine is running may indicate a problem. Regular inspections of the alternator belt for wear and proper tension can also help in early detection of issues. -

What are the common symptoms of a failing alternator?

Common symptoms of a failing alternator include dimming or flickering lights, difficulty starting the vehicle, and malfunctioning electrical accessories like the radio or air conditioning. You may also notice a burning smell or unusual noises from the alternator area. If these symptoms occur, it’s advisable to conduct further diagnostics or seek professional assistance to prevent potential vehicle breakdowns. -

How can I ensure the quality of alternator suppliers?

When sourcing alternators, vet suppliers by checking their certifications, industry reputation, and customer reviews. Request samples and inquire about their quality assurance processes. Additionally, it’s beneficial to verify their compliance with international standards, especially if you are importing from different regions. Building relationships with suppliers who offer warranties can also provide peace of mind regarding product quality. -

What is the minimum order quantity (MOQ) for alternators from suppliers?

Minimum order quantities (MOQs) for alternators can vary significantly depending on the supplier and the type of alternator. Typically, MOQs can range from 10 to 100 units for bulk orders. Always discuss MOQs upfront with potential suppliers to ensure they align with your purchasing needs and inventory management practices. -

What payment terms should I expect when sourcing alternators internationally?

Payment terms when sourcing alternators can vary by supplier and region, but common options include advance payment, letters of credit, or net payment terms (like 30/60/90 days). It is crucial to negotiate payment terms that protect your interests while also accommodating the supplier’s requirements. Be sure to clarify any additional fees, such as transaction costs or currency conversion charges. -

How do I handle logistics and shipping for imported alternators?

Handling logistics for imported alternators involves selecting a reliable freight forwarder who understands the complexities of international shipping. Ensure you account for customs clearance, duties, and taxes when budgeting. Providing accurate shipping information and documentation will facilitate smoother transit. It’s also wise to consider insurance for your shipment to mitigate risks associated with loss or damage during transport. -

Can I customize alternators for specific applications?

Many suppliers offer customization options for alternators, allowing you to tailor specifications such as voltage output, size, and mounting configurations to suit specific applications. When discussing customization, provide detailed requirements and ensure that the supplier has the capability and experience to meet your needs. Keep in mind that custom orders may have longer lead times and higher costs. -

What quality assurance measures should I look for in alternators?

When evaluating alternators, look for suppliers who implement rigorous quality assurance measures, such as testing for performance, durability, and compliance with international standards. Certifications like ISO 9001 can indicate a supplier’s commitment to quality. Additionally, inquire about warranty policies and return procedures, as these can provide insights into the supplier’s confidence in their products and customer service commitment.

Top 2 Como Saber Si El Alternador Esta Fallando Manufacturers & Suppliers List

1. Endurance Warranty – Vehicle Protection Plans

Domain: endurancewarranty.com

Registered: 2009 (16 years)

Introduction: Endurance Warranty ofrece planes de protección vehicular que ayudan a ahorrar en reparaciones de vehículos. Se destaca la importancia de una garantía extendida para protegerse de fallas inesperadas en componentes como el alternador. El alternador es un generador eléctrico crucial que convierte energía cinética en energía eléctrica, alimentando los sistemas eléctricos del coche y manteniendo la bat…

2. Facebook – Alternador Cargando Truco

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Truco para saber si el alternador esta cargando o no

Strategic Sourcing Conclusion and Outlook for como saber si el alternador esta fallando

In conclusion, understanding how to identify potential alternator failures is crucial for maintaining the efficiency and reliability of commercial vehicles. Early detection of symptoms—such as dashboard warning lights, unusual noises, and voltage inconsistencies—can prevent costly downtime and repairs. For B2B buyers, strategic sourcing of high-quality alternators and related components is essential to ensure operational continuity and vehicle performance.

Investing in reliable suppliers who provide comprehensive support and maintenance services can significantly enhance the longevity of your fleet. As international buyers from regions such as Africa, South America, the Middle East, and Europe consider their sourcing strategies, prioritizing partnerships that emphasize quality, innovation, and customer service will yield substantial long-term benefits.

Looking forward, the evolution of automotive technology presents new opportunities for enhanced vehicle performance and efficiency. By staying informed and proactive, businesses can adapt to these changes, ensuring they remain competitive in a dynamic market. Embrace these insights and take the next step in optimizing your fleet’s performance by exploring partnerships with reputable suppliers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.