Introduction: Navigating the Global Market for an alternator

In today’s competitive landscape, sourcing high-quality alternators is a critical challenge for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. An alternator not only powers essential vehicle systems but also plays a pivotal role in ensuring operational efficiency and reliability across various applications. This comprehensive guide aims to equip buyers with the knowledge to navigate the complexities of the global alternator market, covering essential topics such as types of alternators, their applications in different industries, effective supplier vetting strategies, and a detailed analysis of cost factors.

Understanding the intricacies of alternators is crucial for making informed purchasing decisions. As buyers seek to optimize their supply chains and enhance product performance, this guide offers actionable insights tailored to the unique needs of regions like Brazil and Saudi Arabia. From recognizing the technical specifications that align with specific vehicle models to evaluating supplier reliability and after-sales support, this resource empowers buyers to mitigate risks and maximize value in their procurement processes. By demystifying the alternator market, this guide not only serves as a foundational tool for strategic sourcing but also positions businesses for sustained success in their operational endeavors.

Table Of Contents

- Top 3 An Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for an alternator

- Understanding an alternator Types and Variations

- Key Industrial Applications of an alternator

- 3 Common User Pain Points for ‘an alternator’ & Their Solutions

- Strategic Material Selection Guide for an alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for an alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘an alternator’

- Comprehensive Cost and Pricing Analysis for an alternator Sourcing

- Alternatives Analysis: Comparing an alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for an alternator

- Navigating Market Dynamics and Sourcing Trends in the an alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of an alternator

- Strategic Sourcing Conclusion and Outlook for an alternator

- Important Disclaimer & Terms of Use

Understanding an alternator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternator | Conventional design, typically 12V, utilizes a belt drive. | Automotive, light trucks, and buses. | Pros: Cost-effective, widely available. Cons: Limited power for high-demand applications. |

| High-Output Alternator | Enhanced output for demanding electrical systems. | Performance vehicles, heavy machinery. | Pros: Supports additional electrical loads. Cons: Higher cost, may require modifications. |

| Brushless Alternator | No brushes, reduced wear and maintenance needs. | Marine applications, industrial equipment. | Pros: Longer lifespan, higher efficiency. Cons: More expensive, complex design. |

| Smart Alternator | Integrated voltage regulation, adjusts output dynamically. | Hybrid and electric vehicles. | Pros: Optimizes battery charging, improves fuel efficiency. Cons: Higher initial investment. |

| Dual-Voltage Alternator | Capable of producing both 12V and 24V outputs. | Commercial vehicles, construction equipment. | Pros: Versatile for different applications. Cons: More complex and costly to install. |

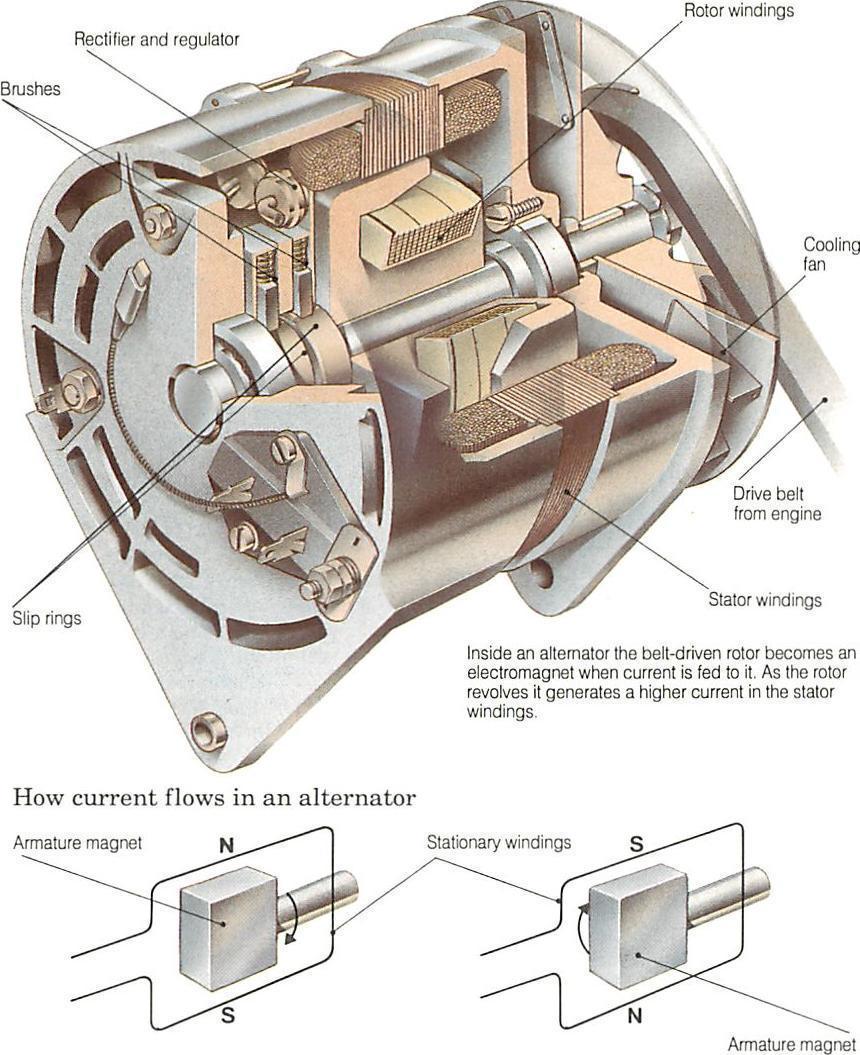

What Are the Characteristics of Standard Alternators?

Standard alternators are the most commonly used type, typically producing 12 volts of electricity. They operate on a belt-driven system, converting mechanical energy from the engine into electrical energy for vehicle systems. These alternators are well-suited for general automotive applications, including light trucks and buses, making them a reliable choice for fleet operations. B2B buyers should consider their availability and cost-effectiveness, as they are easily sourced and relatively inexpensive. However, businesses with higher electrical demands may find them lacking.

Why Choose High-Output Alternators for Performance Vehicles?

High-output alternators are designed to deliver increased electrical output, making them ideal for performance vehicles and heavy machinery that require more power. These alternators can support additional accessories like advanced sound systems or lighting. B2B buyers in sectors such as automotive performance or industrial applications should consider their unique power requirements when purchasing. While these units come at a premium price, the benefits of enhanced performance and reliability can justify the investment for high-demand applications.

What Advantages Do Brushless Alternators Offer?

Brushless alternators operate without brushes, resulting in reduced wear and maintenance needs. They are often used in marine applications and industrial equipment where reliability and efficiency are paramount. For B2B buyers, the longevity and reduced maintenance of brushless alternators can lead to lower operational costs over time. However, they typically come with a higher price tag and a more complex design, which may not be suitable for all businesses.

How Do Smart Alternators Improve Efficiency in Hybrid Vehicles?

Smart alternators feature integrated voltage regulation, allowing them to adjust their output based on the vehicle’s electrical needs. This technology is particularly beneficial in hybrid and electric vehicles, where optimizing battery charging can lead to improved fuel efficiency. B2B buyers in the automotive sector should weigh the higher initial investment against the potential long-term savings in fuel and maintenance costs. The dynamic nature of smart alternators makes them an attractive option for forward-thinking companies focused on sustainability.

Why Are Dual-Voltage Alternators Valuable for Commercial Applications?

Dual-voltage alternators can produce both 12V and 24V outputs, making them versatile for various commercial applications such as construction equipment and heavy-duty trucks. This adaptability is crucial for businesses that operate a mixed fleet or require different power systems. B2B buyers should consider the complexity and installation costs associated with dual-voltage systems. While they can be more expensive, the ability to serve multiple applications can provide significant value in the long run.

Key Industrial Applications of an alternator

| Industry/Sector | Specific Application of an alternator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Vehicle electrical systems in passenger and commercial vehicles | Ensures reliable power supply for vehicle operations and accessories | Quality, compatibility with vehicle models, and warranty terms |

| Renewable Energy | Off-grid solar power systems | Converts mechanical energy from generators into electrical energy for storage | Efficiency ratings, durability, and suitability for local climates |

| Marine | Power generation on boats and ships | Provides essential power for navigation, communication, and onboard systems | Resistance to corrosion, size constraints, and energy output |

| Construction Equipment | Powering heavy machinery | Supplies electrical energy for tools and equipment in remote locations | Load capacity, ruggedness, and compliance with safety standards |

| Agricultural Machinery | Irrigation systems and equipment | Powers pumps and other electrical devices essential for farming operations | Efficiency, reliability under load, and maintenance support |

How is an alternator used in the automotive sector, and what are the sourcing considerations?

In the automotive industry, alternators are crucial for powering the electrical systems of both passenger and commercial vehicles. They convert mechanical energy from the engine into electrical energy, ensuring that batteries are charged and that electrical components like lights, radios, and navigation systems function reliably. For international buyers, particularly in regions like Africa and South America, sourcing high-quality alternators that are compatible with specific vehicle models is essential. Buyers should prioritize suppliers that offer robust warranties and proven durability, given the varying road conditions and climates in these regions.

What role does an alternator play in renewable energy applications?

In renewable energy, particularly within off-grid solar power systems, alternators convert the mechanical energy produced by wind or other generators into usable electrical energy. This process is vital for charging batteries and providing a steady power supply to homes and businesses. For buyers in the Middle East and Europe, efficiency ratings and the ability to withstand local environmental conditions are critical factors in sourcing. Additionally, the durability of the alternator can greatly affect the overall reliability of the renewable energy system, making it a key consideration for long-term investments.

How do marine applications benefit from alternators?

In the marine sector, alternators are essential for generating power on boats and ships, supplying energy for navigation systems, communication devices, and onboard amenities. The unique environment of marine applications demands alternators that are resistant to corrosion and can operate efficiently in varying conditions. Buyers in Europe and the Middle East should focus on sourcing alternators that meet industry standards for marine equipment, ensuring reliability and safety while navigating harsh conditions.

Why are alternators important for construction equipment?

Construction equipment relies on alternators to provide power for various tools and machinery, especially in remote locations where traditional power sources are unavailable. By converting mechanical energy into electrical energy, alternators enable the operation of hydraulic systems, lighting, and other essential functions. Buyers in Africa and South America should consider the ruggedness and load capacity of alternators when sourcing for construction applications, as equipment often faces demanding operational conditions.

How does an alternator enhance agricultural machinery?

In agriculture, alternators are used to power irrigation systems and other machinery, ensuring efficient water management and crop production. By converting mechanical energy from tractors or other farming equipment into electrical energy, alternators facilitate the operation of pumps and electronic controls. For agricultural buyers in regions like Brazil and Saudi Arabia, sourcing alternators that offer high efficiency and reliability under load is paramount, as these factors directly impact productivity and operational costs.

3 Common User Pain Points for ‘an alternator’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Alternators for Fleet Maintenance

The Problem:

B2B buyers responsible for maintaining vehicle fleets often face challenges in sourcing high-quality alternators. This can be especially acute in regions like Africa and South America, where the availability of reliable automotive parts may be limited. Poor-quality alternators can lead to increased downtime, higher maintenance costs, and potential safety risks for drivers. Fleet managers may struggle to find suppliers that provide not only competitively priced alternators but also those that meet OEM specifications, resulting in a lack of trust in aftermarket parts.

The Solution:

To overcome sourcing challenges, buyers should establish relationships with trusted suppliers who specialize in automotive parts. Conduct thorough research on potential suppliers by assessing their reputation, customer reviews, and the quality certifications of the products they offer. Additionally, consider sourcing from manufacturers that provide a warranty and have a proven track record of supplying OEM-grade components. Utilizing local distributors who understand the specific needs and conditions of your region can also improve reliability. Implementing a supplier evaluation process, including criteria such as delivery times, service quality, and responsiveness, will ensure that the alternators sourced are not only reliable but also suitable for the specific demands of your fleet.

Scenario 2: Misdiagnosing Electrical Problems Related to Alternators

The Problem:

B2B buyers in industries that rely heavily on vehicle performance may experience frustration when their vehicles exhibit electrical issues. Often, these problems can be misdiagnosed as battery failures when, in fact, the alternator is the underlying issue. This misunderstanding can lead to unnecessary replacement costs and prolonged downtime as technicians may replace batteries without addressing the root cause. In regions with limited access to skilled technicians, this issue can be particularly problematic.

The Solution:

To mitigate misdiagnosis, it is essential for buyers to invest in training for their maintenance staff. Providing education on the signs of alternator failure—such as dimming lights, unusual noises, and dashboard alerts—can help technicians accurately identify issues. Additionally, implementing a systematic diagnostic protocol that includes checking the alternator’s output voltage and inspecting the connections can lead to quicker, more accurate assessments. Collaborating with professional automotive service providers for periodic training sessions can also enhance your team’s diagnostic skills. By fostering a culture of knowledge-sharing and continuous learning, businesses can reduce misdiagnosis rates and improve overall vehicle reliability.

Scenario 3: Understanding the Impact of Alternator Load on Performance

The Problem:

B2B buyers may overlook the impact of electrical load on alternator performance. In sectors where vehicles are equipped with numerous electrical accessories—such as refrigeration units in transport or advanced electronic systems in service vehicles—overloading the alternator can lead to premature failure. Buyers may not fully understand the specifications required for their specific applications, risking operational efficiency and increasing maintenance costs.

The Solution:

To address this issue, it is crucial for buyers to perform a comprehensive analysis of their vehicle’s electrical load requirements. This includes accounting for all accessories that draw power, such as lighting systems, climate control, and electronic devices. Collaborate with electrical engineers or automotive specialists to calculate the total amperage needed and ensure that the alternator can handle the load. When purchasing alternators, opt for those with a higher output rating than the calculated requirements to provide a buffer against unexpected demands. Additionally, regular maintenance checks should be scheduled to assess the alternator’s performance and ensure it operates within its designed limits. By understanding and managing the electrical load, buyers can prolong the life of their alternators and enhance overall vehicle performance.

Strategic Material Selection Guide for an alternator

What Materials Are Commonly Used in Alternators?

When selecting materials for alternators, several factors influence performance, durability, and cost. Here, we analyze four common materials used in the construction of alternators: aluminum, copper, steel, and plastic. Each material has unique properties that affect the overall functionality and reliability of the alternator.

How Does Aluminum Benefit Alternator Design?

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent thermal conductivity. Key properties of aluminum include a high strength-to-weight ratio and resistance to corrosion, making it an ideal choice for automotive applications.

Illustrative image related to an alternator

Pros: Aluminum’s lightweight characteristic enhances fuel efficiency in vehicles. It also resists corrosion, which is crucial for longevity, especially in humid or coastal environments.

Cons: While aluminum is durable, it can be more expensive than steel and may require specialized manufacturing techniques, which can complicate production processes.

Impact on Application: Aluminum’s compatibility with various media, including oils and coolants, makes it suitable for automotive use.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that aluminum components meet local standards, such as ASTM or ISO certifications, to guarantee quality and reliability.

What Role Does Copper Play in Alternator Functionality?

Copper is primarily used in the winding of the rotor and stator due to its excellent electrical conductivity. This material allows for efficient energy transfer, which is essential for the alternator’s performance.

Pros: Copper’s high conductivity ensures minimal energy loss during the conversion of mechanical to electrical energy, enhancing overall efficiency.

Cons: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum or steel. Additionally, copper is susceptible to corrosion if not properly insulated.

Impact on Application: Copper’s compatibility with electrical systems makes it indispensable in alternators, ensuring reliable performance under various operational conditions.

Considerations for International Buyers: Buyers must be aware of the copper market fluctuations and consider sourcing from suppliers who adhere to international standards like ASTM or DIN to ensure quality.

Why Is Steel Used in Alternator Manufacturing?

Steel is often employed in the construction of the alternator’s frame and mounting brackets due to its strength and durability.

Illustrative image related to an alternator

Pros: Steel provides robust structural integrity, ensuring that the alternator can withstand mechanical stresses and vibrations encountered in automotive environments.

Cons: The primary limitation of steel is its weight, which can negatively impact fuel efficiency. Additionally, steel is prone to rusting if not adequately coated or treated.

Impact on Application: Steel’s strength makes it suitable for supporting heavy components, but its weight must be managed to avoid hindering vehicle performance.

Considerations for International Buyers: Buyers in regions with high humidity or saline environments, like the Middle East, should prioritize corrosion-resistant steel options and ensure compliance with local standards.

Illustrative image related to an alternator

How Does Plastic Enhance Alternator Components?

Plastic is frequently used for non-structural components, such as covers and insulators, due to its lightweight and insulating properties.

Pros: Plastic components are lightweight, which contributes to overall vehicle efficiency. They also provide excellent electrical insulation, reducing the risk of short circuits.

Cons: Plastic may not be as durable as metal alternatives and can degrade over time, especially under high-temperature conditions.

Impact on Application: Plastic’s electrical insulation properties make it suitable for components that require protection from electrical interference.

Considerations for International Buyers: Buyers should ensure that plastic materials meet relevant safety and durability standards, particularly in markets that experience extreme temperatures.

Summary of Material Selection for Alternators

| Material | Typical Use Case for an alternator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housings and structural components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Copper | Rotor and stator windings | High electrical conductivity | Expensive and prone to corrosion | High |

| Steel | Frame and mounting brackets | Strong and durable | Heavy and susceptible to rust | Low |

| Plastic | Covers and insulators | Lightweight and excellent insulation | Less durable and temperature-sensitive | Low |

This guide provides a comprehensive overview of material selection for alternators, highlighting the importance of balancing performance, cost, and durability to meet the needs of international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for an alternator

What Are the Main Stages of Manufacturing an Alternator?

The manufacturing process for an alternator involves several key stages that ensure the final product meets the required performance and quality standards. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

Material Preparation: What Materials Are Used in Alternator Manufacturing?

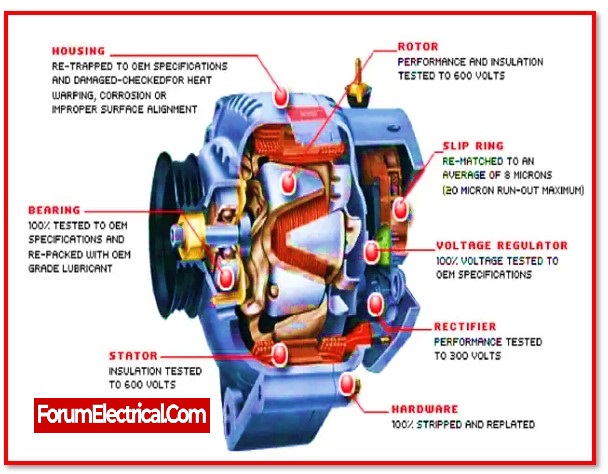

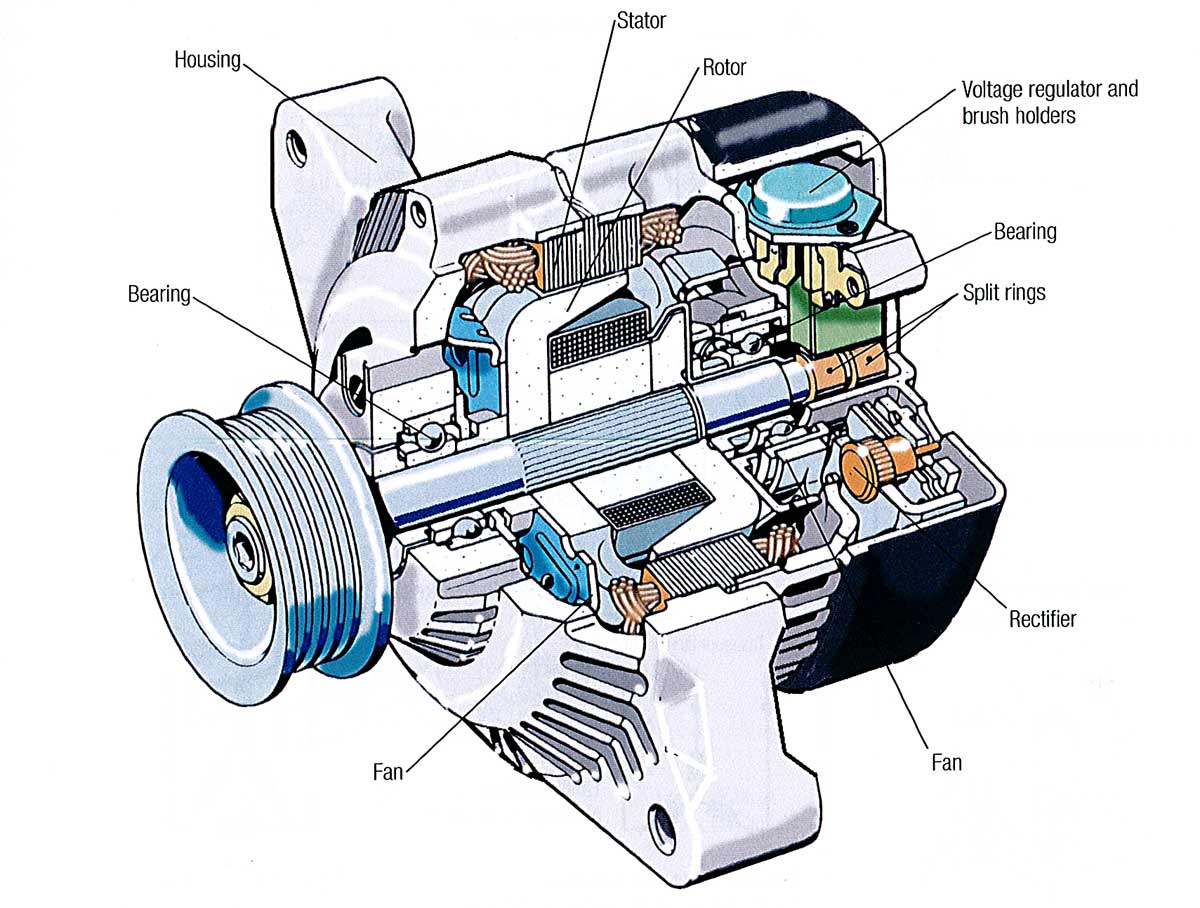

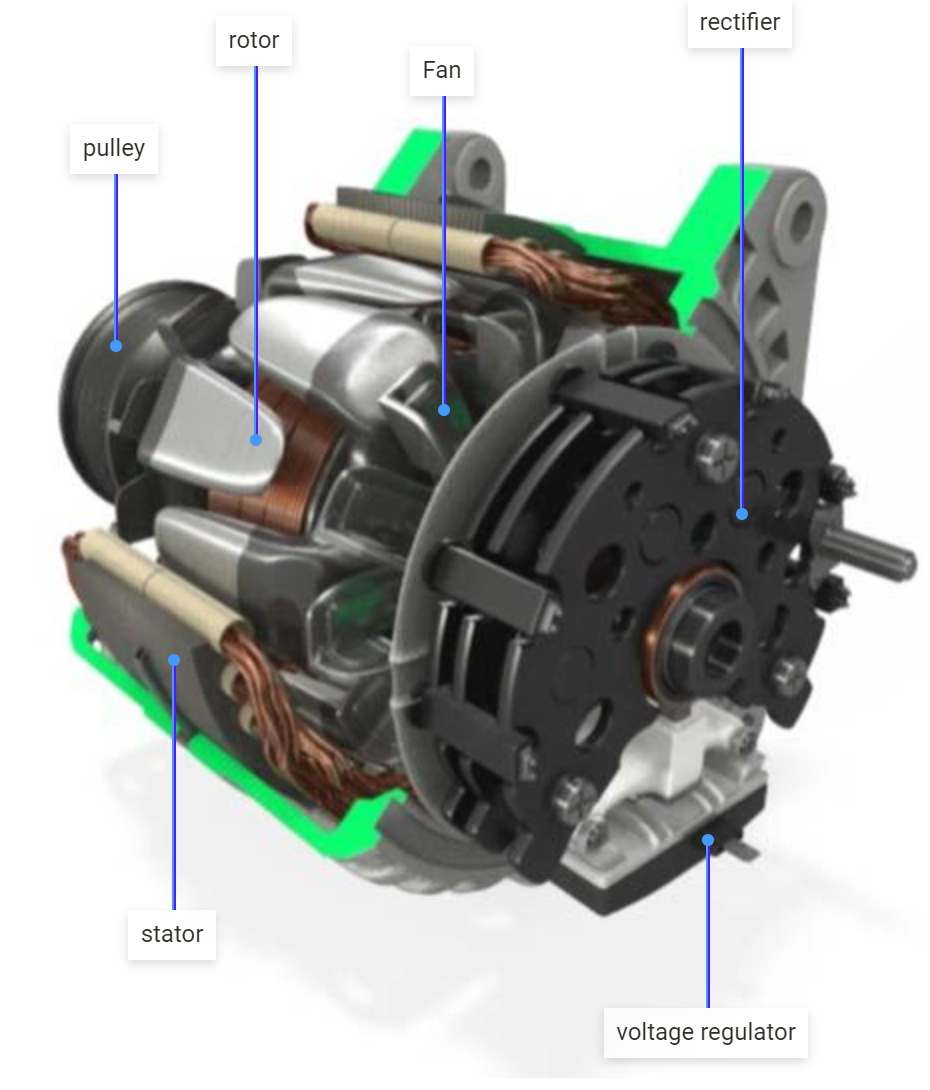

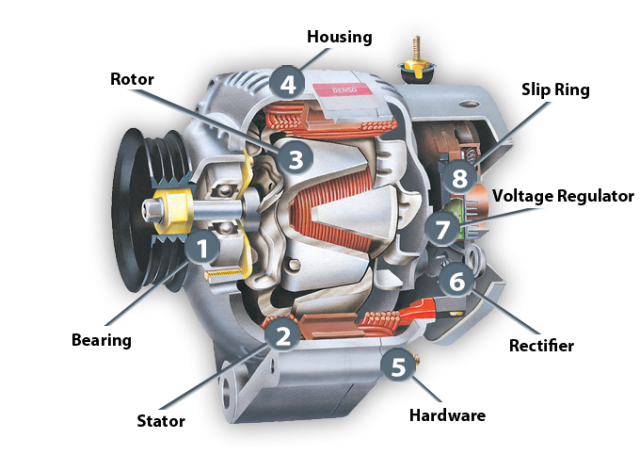

The primary materials used in alternator manufacturing include high-grade aluminum for the housing, copper for the windings, and various alloys for the rotor and stator components. The quality of these materials significantly impacts the performance and longevity of the alternator. Suppliers typically source materials from certified vendors who meet international quality standards, ensuring that the raw materials are free from impurities and defects.

Illustrative image related to an alternator

How Are Components Formed in Alternator Production?

Once the materials are prepared, the next stage is forming. This includes processes such as die-casting for the aluminum housing and stamping for the rotor and stator components. Advanced techniques like CNC machining are often employed to achieve precise dimensions and tolerances. The effectiveness of these forming techniques directly influences the alternator’s efficiency and reliability, making it crucial for B2B buyers to inquire about the manufacturing technologies used by suppliers.

What Does the Assembly Process Look Like for Alternators?

The assembly of an alternator is a critical phase that combines all the formed components. This typically involves:

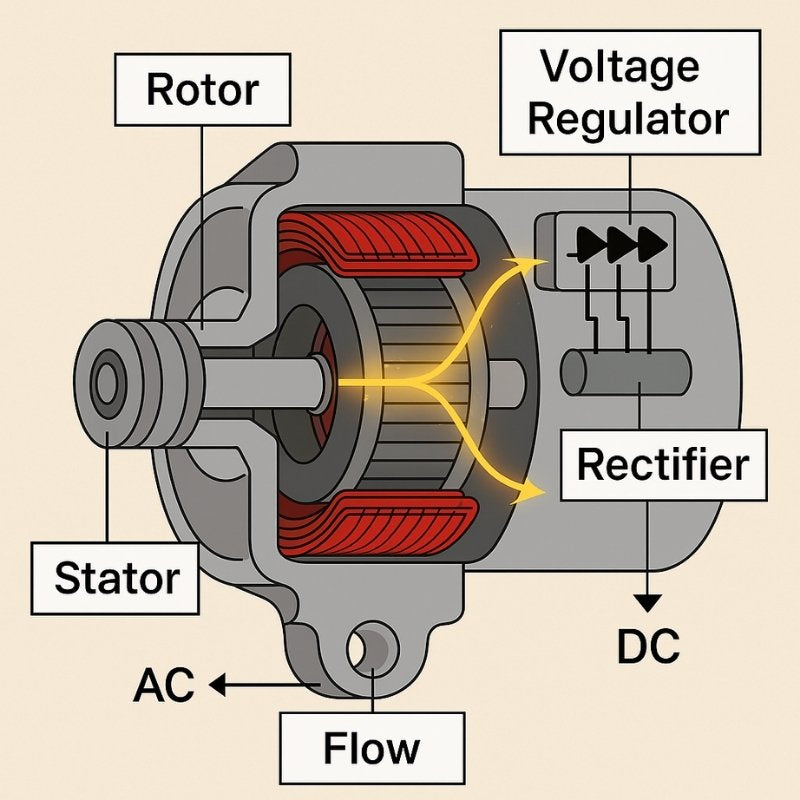

- Windings: Copper wire is wound around the stator to create electromagnetic fields.

- Rotor Installation: The rotor, which contains permanent magnets or windings, is placed within the stator.

- Integration of Diodes and Voltage Regulators: These components are crucial for converting AC to DC and regulating voltage output.

- Final Assembly: All parts, including the cooling fan and housing, are assembled, ensuring that each component fits correctly.

Quality control at this stage is vital, as any misalignment or improper installation can lead to failures during operation.

Illustrative image related to an alternator

What Quality Assurance Measures Are Employed in Alternator Manufacturing?

Quality assurance (QA) is essential in ensuring that alternators meet performance and safety standards. Various international and industry-specific standards guide QA processes.

What Are the Relevant International Standards for Alternator Quality Assurance?

B2B buyers should look for suppliers who adhere to internationally recognized quality management systems such as ISO 9001. This standard ensures that manufacturers implement effective quality management practices across their operations. Additionally, specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for industrial applications may also apply, depending on the intended use of the alternator.

What Are the Key Quality Control Checkpoints in Alternator Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to identify and rectify defects. Common checkpoints include:

Illustrative image related to an alternator

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, inspections occur at various stages to monitor compliance with design specifications.

- Final Quality Control (FQC): Once the assembly is complete, a thorough inspection and testing are conducted to verify that the alternator functions correctly and meets all performance criteria.

How Are Testing Methods Used to Ensure Alternator Quality?

Testing methods are crucial for validating the performance and durability of alternators. Common testing methods include:

- Electrical Testing: This involves measuring voltage output, current draw, and efficiency under different load conditions to ensure the alternator operates within specified parameters.

- Thermal Testing: Alternators are subjected to temperature extremes to assess their performance and reliability in varying environmental conditions.

- Vibration Testing: This is done to simulate real-world operating conditions and identify potential weaknesses in the assembly.

B2B buyers should inquire about the specific testing protocols used by suppliers to ensure comprehensive quality assessments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of potential suppliers is crucial for B2B buyers to ensure they receive reliable products. Here are actionable steps to consider:

- Conduct Audits: Regular audits of manufacturing facilities can provide insight into the supplier’s adherence to quality standards. Buyers should request audit reports or consider third-party audits for an objective assessment.

- Request Quality Control Reports: Suppliers should provide detailed quality control documentation, including results from IQC, IPQC, and FQC inspections.

- Third-Party Inspections: Engaging third-party inspection agencies can offer additional assurance of quality, especially for international transactions. These agencies can conduct on-site inspections and testing before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances when sourcing alternators. These include:

- Compliance with Local Standards: Different countries have varying regulations and standards for automotive components. Buyers should ensure that their suppliers are compliant with local market requirements.

- Cultural Differences in Quality Expectations: Understanding regional expectations regarding quality can help in establishing better communication and alignment with suppliers.

- Logistical Considerations: Buyers should also consider the logistics of transporting alternators, as improper handling can lead to quality issues. Suppliers should have robust packaging and shipping practices to mitigate risks.

By understanding the manufacturing processes and quality assurance measures associated with alternators, B2B buyers can make informed decisions that align with their operational needs and quality expectations. This comprehensive approach ensures that they invest in reliable components that enhance their product offerings and maintain customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘an alternator’

Introduction

Navigating the procurement of alternators for your business can be complex, especially with varying specifications and supplier capabilities. This guide offers a systematic approach to sourcing high-quality alternators, ensuring that you meet both technical requirements and budget constraints. By following this checklist, you will be better equipped to make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements for the alternators you need. Consider factors such as voltage output, current rating, size, and compatibility with existing systems.

– Tip: Collaborate with your engineering team to ensure all specifications align with your operational needs.

Step 2: Research Market Trends and Standards

Stay informed about the latest trends and standards in alternator technology. Understanding the industry landscape will help you identify the most reliable and efficient products available.

– Tip: Look for innovations such as improved energy efficiency and durability that could provide long-term benefits for your operations.

Illustrative image related to an alternator

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in alternators. Focus on companies with a proven track record in your specific industry, as they will be more familiar with your needs.

– Tip: Utilize online marketplaces, trade shows, and industry associations to expand your supplier list.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers possess the necessary certifications and quality assurances. This step is crucial for guaranteeing that the alternators meet international standards and regulations.

– Tip: Request documentation for ISO certifications or other relevant quality management systems to ensure product reliability.

Step 5: Evaluate Supplier Reputation and Experience

Before finalizing any agreements, assess the reputation and experience of your potential suppliers. Look for reviews, testimonials, and case studies from other businesses in your region or industry.

– Tip: Engage with current clients of the suppliers to gather insights into their service levels and product performance.

Illustrative image related to an alternator

Step 6: Request Samples and Conduct Testing

Once you have narrowed down your choices, request samples of the alternators for testing. This allows you to assess performance, compatibility, and quality firsthand.

– Tip: Develop a testing protocol that measures key performance indicators relevant to your application, such as efficiency and longevity.

Step 7: Negotiate Terms and Finalize Contracts

Finally, negotiate pricing, delivery schedules, and warranty terms before signing contracts. Clear agreements will protect your interests and ensure that both parties have aligned expectations.

– Tip: Consider including clauses for after-sales support and maintenance services, as these can be crucial for long-term operational success.

By following this checklist, you will enhance your procurement strategy for alternators, ensuring that you select the best products to meet your business needs while minimizing risks associated with sourcing.

Comprehensive Cost and Pricing Analysis for an alternator Sourcing

What Are the Key Cost Components in Alternator Sourcing?

When sourcing alternators, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The raw materials used in alternators, such as copper for windings, aluminum for housings, and various magnets, significantly impact costs. Fluctuations in global commodity prices can affect material costs, necessitating careful monitoring.

-

Labor: Labor costs vary by region and influence the overall pricing. Regions with lower labor costs may offer competitive pricing, but this should be balanced against quality standards and expertise.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, leading to lower prices for buyers.

-

Tooling: Custom tooling is often required for specialized alternators, which can increase initial costs. However, these costs may be amortized over larger production runs, making it essential to negotiate tooling costs effectively.

-

Quality Control (QC): QC processes are vital for ensuring the reliability of alternators. Enhanced QC measures may increase production costs, but they also reduce the risk of failures and warranty claims, providing long-term savings.

-

Logistics: Transportation and storage costs can vary widely based on location and shipping methods. Buyers should consider these logistics costs, especially when sourcing from overseas suppliers.

-

Margin: Supplier margins can vary based on market dynamics and competition. Understanding the typical margins in your market can help in negotiating better deals.

How Do Price Influencers Affect Alternator Sourcing?

Several factors influence the pricing of alternators, and recognizing these can lead to smarter purchasing decisions:

Illustrative image related to an alternator

-

Volume and Minimum Order Quantity (MOQ): Purchasing larger quantities typically results in lower per-unit costs. Buyers should assess their needs to negotiate favorable MOQs that align with their inventory management strategies.

-

Specifications and Customization: Customized alternators with specific features or performance metrics can command higher prices. Buyers need to clearly define their specifications to avoid unnecessary customization costs.

-

Material Quality and Certifications: High-quality materials and compliance with international standards (like ISO certifications) can increase costs. However, investing in quality can lead to lower failure rates and extended product lifespans.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may offer higher prices but provide better warranties and customer service, which can be beneficial in the long run.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) is essential, as they dictate who is responsible for various costs during shipping. This can significantly affect total costs, especially in international transactions.

What Buyer Tips Can Help Optimize Alternator Sourcing Costs?

To optimize costs in sourcing alternators, consider the following strategies:

-

Negotiation: Effective negotiation can yield significant savings. Prepare to discuss all aspects of pricing, including volume discounts, payment terms, and shipping costs.

-

Focus on Cost-Efficiency: Look beyond the initial price to evaluate the Total Cost of Ownership (TCO), which includes maintenance, reliability, and potential downtime costs. A higher upfront investment may lead to lower long-term expenses.

-

Understand Pricing Nuances for International Transactions: International buyers should be aware of tariffs, import duties, and currency fluctuations that can affect pricing. Engaging a local expert or logistics partner can help navigate these complexities.

-

Research Market Trends: Keeping abreast of market trends and pricing fluctuations can empower buyers to make informed purchasing decisions and time their orders to take advantage of lower prices.

-

Consider Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Suppliers are often more willing to negotiate with reliable, repeat customers.

In summary, a comprehensive understanding of the cost structure, pricing influencers, and strategic negotiation can significantly enhance the sourcing experience for alternators, particularly for international B2B buyers in diverse regions.

Alternatives Analysis: Comparing an alternator With Other Solutions

Understanding Alternatives to an Alternator

When evaluating energy generation and management solutions for vehicles and machinery, it’s essential to consider the various alternatives available alongside traditional alternators. Each option comes with its own set of advantages and challenges, making it crucial for B2B buyers to select the right fit based on specific operational requirements.

Comparison Table of Alternator and Alternatives

| Comparison Aspect | An Alternator | Battery Management System (BMS) | Solar Power System |

|---|---|---|---|

| Performance | Efficiently converts mechanical energy to electrical energy, maintaining battery charge. | Monitors and controls battery health and efficiency; optimizes energy usage. | Converts solar energy to electrical power; effective in sunny regions. |

| Cost | Moderate initial investment with low maintenance costs. | Higher initial setup cost; long-term savings on energy. | High upfront costs; potential for long-term savings on electricity bills. |

| Ease of Implementation | Simple integration into existing vehicle systems; minimal additional components required. | Requires integration with existing battery systems; may need specialized installation. | Installation complexity varies; requires space for solar panels and battery storage. |

| Maintenance | Generally low; occasional checks needed for wear and tear. | Moderate; regular software updates and hardware checks required. | Moderate to high; regular cleaning of solar panels and battery maintenance needed. |

| Best Use Case | Ideal for conventional vehicles and machinery requiring reliable power generation. | Best for systems where battery longevity and efficiency are critical. | Optimal for remote locations or where electricity costs are high, and sunlight is abundant. |

In-Depth Analysis of Alternatives

Battery Management System (BMS)

A Battery Management System enhances the efficiency and lifespan of batteries by monitoring their state, controlling the charging and discharging processes, and ensuring safety. The primary advantage of a BMS is its ability to prolong battery life and improve performance, which is especially beneficial for electric vehicles or systems relying heavily on battery storage. However, it requires a higher initial investment and more complex integration with existing systems, which may not be feasible for all users.

Solar Power System

Solar power systems harness renewable energy from the sun, converting it into electrical power. This technology is particularly advantageous for businesses located in sunny regions, as it can significantly reduce electricity costs and reliance on fossil fuels. While the environmental benefits are considerable, the initial setup cost can be high, and the system’s effectiveness is heavily dependent on geographic location and weather conditions. Additionally, maintenance can be more intensive, requiring regular cleaning and checks of solar panels and batteries.

Choosing the Right Solution for Your Needs

When selecting the appropriate energy generation solution, B2B buyers must consider their specific operational requirements, budget constraints, and environmental factors. An alternator remains a reliable choice for traditional vehicles and machinery, offering efficiency and low maintenance. However, for businesses looking to enhance battery longevity or reduce energy costs through renewable sources, evaluating a Battery Management System or a Solar Power System may provide valuable long-term benefits. Each option presents unique advantages; thus, understanding the operational context will guide informed decision-making tailored to specific energy needs.

Essential Technical Properties and Trade Terminology for an alternator

What Are the Essential Technical Properties of an Alternator?

Understanding the technical specifications of an alternator is crucial for B2B buyers, especially when considering the performance and reliability of automotive systems. Here are some key properties to consider:

What Is the Role of Material Grade in Alternators?

Material Grade: Alternators are typically constructed from high-grade aluminum and steel alloys. The choice of materials affects durability, weight, and thermal conductivity. For example, aluminum is lightweight and resistant to corrosion, making it ideal for components exposed to heat and moisture. High-grade materials ensure longevity and reduce the risk of premature failure, which is particularly important for businesses that rely on fleet vehicles.

Why Is Tolerance Important in Alternator Manufacturing?

Tolerance: This refers to the allowable variation in dimensions and performance specifications. Tight tolerances are essential for the rotor and stator assembly to ensure efficient electromagnetic interactions. In B2B contexts, maintaining strict tolerances can minimize vibrations, improve energy conversion efficiency, and enhance overall performance. This is crucial for industries where reliability is paramount, such as transportation and logistics.

How Does Voltage Output Affect Alternator Functionality?

Voltage Output: Alternators typically produce between 12V to 14.5V of electrical current. This output is vital for charging the battery and powering electrical systems within vehicles. Buyers should ensure that the alternator meets the voltage requirements of the specific vehicle applications they are sourcing for. Inadequate voltage output can lead to electrical failures, affecting operational efficiency.

Illustrative image related to an alternator

What Is the Significance of Amperage Rating?

Amperage Rating: This indicates the maximum current the alternator can provide. A higher amperage rating is essential for vehicles with extensive electrical systems, such as those with advanced infotainment systems or additional lighting. For B2B buyers, selecting an alternator with the appropriate amperage ensures that all electrical components function optimally without risking damage or performance issues.

Why Is a Cooling Fan Integrated into Alternators?

Cooling Fan: Many alternators are equipped with a cooling fan to dissipate heat generated during operation. Effective cooling extends the life of the alternator and prevents overheating, which can cause component failure. B2B buyers should consider the cooling mechanisms when sourcing alternators, especially for vehicles operating in high-temperature environments.

What Are the Common Trade Terms Related to Alternators?

Familiarity with industry jargon can facilitate smoother transactions and better negotiations in the B2B landscape.

What Does OEM Stand For in the Automotive Industry?

OEM (Original Equipment Manufacturer): This term refers to products made by the original manufacturer of the vehicle. OEM alternators are designed to meet specific vehicle standards and are often preferred for their compatibility and reliability. B2B buyers should prioritize OEM parts when seeking long-term performance and warranty support.

Why Is MOQ Important When Sourcing Alternators?

MOQ (Minimum Order Quantity): This term signifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they are purchasing in quantities that align with their inventory needs without incurring excess costs.

What Is an RFQ and How Does It Benefit Buyers?

RFQ (Request for Quotation): This is a document sent to suppliers asking for prices on specified products. An RFQ allows B2B buyers to compare prices and terms from multiple vendors, ensuring they obtain the best deal for alternators.

How Do Incoterms Affect International Shipping of Alternators?

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping costs, insurance, and risk during transport. For B2B buyers, understanding Incoterms is essential to manage logistics and costs effectively when sourcing alternators from different regions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they select products that meet their operational needs while optimizing costs and performance.

Illustrative image related to an alternator

Navigating Market Dynamics and Sourcing Trends in the an alternator Sector

What Are the Key Market Drivers for the Alternator Sector?

The global alternator market is currently experiencing significant growth, driven by several factors. The rise in automotive production, particularly in emerging economies in Africa, South America, and the Middle East, is a primary catalyst. Countries like Brazil and Saudi Arabia are investing heavily in infrastructure and vehicle manufacturing, leading to increased demand for reliable power generation systems like alternators. Additionally, the growing trend toward electric and hybrid vehicles is reshaping the alternator market, as these vehicles require advanced alternator designs for efficient energy management.

Emerging technologies such as smart alternators equipped with sensors and IoT capabilities are also influencing sourcing trends. These innovations enhance the performance and efficiency of alternators, making them more appealing to B2B buyers looking for sustainable solutions. Furthermore, the demand for aftermarket alternators is on the rise due to increasing vehicle age and the need for replacement parts, particularly in regions with challenging road conditions.

As international B2B buyers navigate these market dynamics, understanding local regulations and compliance standards is crucial. In addition, forming strategic partnerships with manufacturers that emphasize quality and innovation will be vital for maintaining a competitive edge in this evolving sector.

How Does Sustainability Impact Sourcing Trends in the Alternator Sector?

Sustainability has become a focal point in the alternator sector, with environmental impacts and ethical sourcing increasingly influencing B2B purchasing decisions. The production of alternators can involve significant resource consumption and waste generation; thus, companies are prioritizing suppliers who adhere to sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and waste reduction initiatives.

The importance of ethical supply chains cannot be overstated, especially in markets like Africa and South America, where transparency and corporate responsibility are paramount. B2B buyers are now looking for ‘green’ certifications, such as ISO 14001, which demonstrate a commitment to environmental management. Furthermore, sourcing from manufacturers that utilize eco-friendly materials and processes not only reduces environmental impact but also enhances brand reputation among increasingly eco-conscious consumers.

By integrating sustainability into their sourcing strategies, international B2B buyers can not only meet regulatory requirements but also tap into new market opportunities, positioning themselves as leaders in the transition to greener technologies.

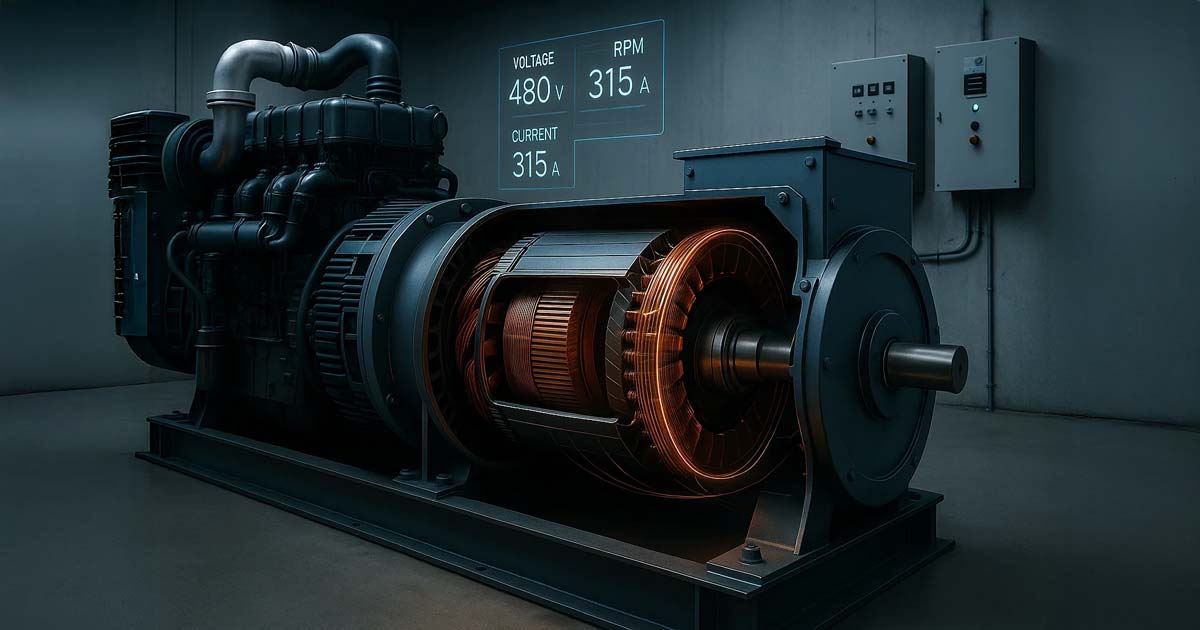

What Is the Evolution of the Alternator and Its Relevance Today?

The alternator has evolved significantly since its inception in the early 20th century, transitioning from a simple mechanical device to a sophisticated electrical component integral to modern vehicles. Initially designed to provide a steady current for basic electrical systems, contemporary alternators now incorporate advanced technologies that enhance performance, efficiency, and reliability.

Illustrative image related to an alternator

Today’s alternators are engineered to support a wide array of electrical demands, especially in vehicles equipped with numerous electronic systems. This evolution is particularly relevant for B2B buyers, as the complexity and demands of modern vehicles necessitate sourcing high-quality, durable alternators that can withstand rigorous operational conditions. Understanding this historical context allows buyers to appreciate the advancements in alternator technology and the importance of selecting suppliers that are at the forefront of these innovations.

In summary, the alternator sector is marked by rapid evolution and significant market dynamics that international B2B buyers must navigate carefully. By focusing on sustainability, technological advancements, and understanding market trends, businesses can position themselves for success in this competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of an alternator

-

How do I solve issues with a failing alternator?

To address a failing alternator, first, check for common symptoms such as dimming headlights, dashboard warning lights, or unusual noises. Conduct a multimeter test to measure the voltage output; it should be between 13.8 to 14.5 volts when the engine is running. If it falls outside this range, consider replacing the alternator. Additionally, ensure all connections are secure and free from corrosion. Engaging a qualified technician for a thorough diagnostic can help pinpoint the issue and avoid misdiagnosis. -

What is the best alternator for heavy-duty vehicles?

For heavy-duty vehicles, such as trucks and construction equipment, look for high-output alternators that can provide at least 150 amps or more. Brands like Delco Remy and Bosch are renowned for their durability and efficiency. Ensure the alternator is compatible with the vehicle’s electrical system, including the voltage regulator. Customization options are often available to suit specific power requirements, so consult with suppliers for tailored solutions. -

What should I consider when vetting alternator suppliers?

When vetting alternator suppliers, assess their reputation, production capacity, and quality assurance processes. Look for suppliers that provide OEM specifications and certifications, ensuring their products meet international standards. Request samples to evaluate product quality and performance. Additionally, inquire about their experience in your market region, as local knowledge can be crucial for navigating customs and regulatory requirements. -

What are the typical minimum order quantities (MOQ) for alternators?

Minimum order quantities for alternators can vary significantly based on the supplier and product type. Generally, MOQs can range from 50 to several hundred units. Discuss your needs with potential suppliers, as many are willing to accommodate lower quantities for new buyers or ongoing partnerships. Be mindful that larger orders often come with cost benefits, so consider your inventory needs and market demand when negotiating MOQs. -

What payment terms should I expect when purchasing alternators internationally?

Payment terms for international alternator purchases typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for custom orders. It’s essential to negotiate terms that suit both parties, balancing risk and cash flow. Ensure you understand the currency used and any potential foreign exchange implications when dealing with suppliers from different regions. -

How can I ensure quality assurance (QA) for my alternator orders?

To ensure quality assurance for alternator orders, request detailed product specifications and certifications from suppliers. Implement a quality control process that includes pre-shipment inspections and testing to verify performance standards. Establish clear communication channels with the supplier for feedback during production. Additionally, consider third-party inspection services to validate product quality before shipment, especially for large orders. -

What logistics considerations should I keep in mind when sourcing alternators?

Logistics is crucial when sourcing alternators internationally. Consider shipping methods, lead times, and customs regulations for your target regions. Opt for suppliers with experience in export logistics to streamline the process. It’s also essential to plan for potential delays in customs clearance and ensure proper documentation is in place. Discuss incoterms with your supplier to clarify responsibilities for shipping costs and risks. -

Can alternators be customized for specific applications?

Yes, many suppliers offer customization options for alternators to meet specific applications and performance requirements. Customizations may include adjustments to output voltage, size, and additional features like integrated cooling systems. When discussing customization, provide detailed specifications and performance expectations. Collaborating closely with the supplier during the design phase can lead to a product that perfectly fits your operational needs.

Top 3 An Alternator Manufacturers & Suppliers List

1. Reddit – Alternator Functionality Explained

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Alternator Functionality Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Advance Auto Parts – Alternator

Domain: shop.advanceautoparts.com

Registered: 1997 (28 years)

Introduction: Alternator – Advance Auto Parts

Key Features:

– The alternator is part of the vehicle’s electrical charging system, along with the battery and voltage regulator.

– Converts mechanical energy from the engine’s crankshaft pulley into electricity.

– Powers the vehicle’s electrical system and maintains battery charge.

– A failing alternator can lead to battery depletion and engine failure.

Brands Av…

3. Nationwide – Alternator Overview

Domain: blog.nationwide.com

Registered: 1994 (31 years)

Introduction: The alternator is a generator that produces electricity for the vehicle and recharges the battery. It is about the size of a coconut and is mounted to the front of the engine, connected by a belt. Key components include: 1. Rotor and Stator: The rotor spins inside the stator, creating electricity through the movement of magnets over conductive copper wiring. 2. Voltage Regulator: Monitors and mana…

Strategic Sourcing Conclusion and Outlook for an alternator

As the global automotive market continues to evolve, the strategic sourcing of alternators becomes increasingly crucial for international B2B buyers. Understanding the vital role of alternators in vehicle performance and reliability allows businesses to make informed procurement decisions. Key takeaways include the importance of selecting high-quality components that meet industry standards, recognizing the potential impact of alternator failure on operational efficiency, and prioritizing suppliers who offer robust warranties and support services.

Strategic sourcing not only enhances supply chain resilience but also contributes to cost-effectiveness and improved vehicle uptime. By fostering relationships with reputable manufacturers, businesses can ensure access to advanced technologies and innovative solutions that cater to their specific needs, especially in diverse markets like Africa, South America, the Middle East, and Europe.

Looking ahead, it is essential for B2B buyers to stay proactive in monitoring market trends and emerging technologies in alternator production. By prioritizing strategic partnerships and investing in quality components, companies can position themselves for success in an increasingly competitive landscape. Engage with trusted suppliers today to secure a reliable and efficient supply of alternators that will drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to an alternator