Introduction: Navigating the Global Market for how to test starter motor

When it comes to sourcing reliable methods for testing starter motors, international B2B buyers face the challenge of navigating varying standards, tools, and expertise across different regions. Ensuring the performance of starter motors is crucial for automotive operations, as a faulty starter can lead to unexpected downtime and increased repair costs. This comprehensive guide delves into the intricacies of testing starter motors, covering various types, applications, and diagnostic techniques that are essential for maintaining vehicle reliability.

Our guide provides a detailed overview of the diagnostic steps required to accurately assess starter motor functionality. From visual inspections to voltage tests, we outline best practices and the necessary tools, such as multimeters and battery testers, to facilitate effective troubleshooting. Additionally, we emphasize the importance of vetting suppliers who can provide quality components and services tailored to your specific market needs.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Brazil—this guide empowers you to make informed purchasing decisions. By understanding the nuances of starter motor testing, you can minimize risks, enhance operational efficiency, and ultimately drive profitability in your automotive operations. With the right knowledge at your fingertips, you can confidently navigate the global market and secure reliable solutions for your automotive needs.

Inhaltsverzeichnis

- Top 2 How To Test Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to test starter motor

- Understanding how to test starter motor Types and Variations

- Key Industrial Applications of how to test starter motor

- 3 Common User Pain Points for ‘how to test starter motor’ & Their Solutions

- Strategic Material Selection Guide for how to test starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for how to test starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to test starter motor’

- Comprehensive Cost and Pricing Analysis for how to test starter motor Sourcing

- Alternatives Analysis: Comparing how to test starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for how to test starter motor

- Navigating Market Dynamics and Sourcing Trends in the how to test starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to test starter motor

- Strategic Sourcing Conclusion and Outlook for how to test starter motor

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding how to test starter motor Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Sichtprüfung | Involves checking for physical damage and loose connections. | Kfz-Werkstätten, Flottenservices | Vorteile: Quick and easy; no special tools needed. Nachteile: Kann interne Probleme übersehen. |

| Spannungsprüfung | Measures voltage at starter terminals to assess performance. | Diagnostic centers, automotive manufacturers | Vorteile: Provides clear electrical status; identifies weak connections. Nachteile: Requires multimeter and knowledge of electrical systems. |

| Prüfung des Anlassermagneten | Checks the solenoid’s operation by listening for clicks. | Service centers, automotive technicians | Vorteile: Simple diagnostic method; quick results. Nachteile: Limited to solenoid issues; may need further testing. |

| Prüfstandstests | Dazu muss der Anlasser ausgebaut und unabhängig getestet werden. | Specialist repair shops, engine rebuilders | Vorteile: Comprehensive assessment of starter functionality. Nachteile: Time-consuming; requires specialized tools. |

| Spannungsabfallprüfung | Assesses resistance in the starter circuit during operation. | Automotive diagnostics, fleet maintenance | Vorteile: Identifies weak points in wiring; effective for troubleshooting. Nachteile: More complex; requires assistance for proper execution. |

What Are the Characteristics of Visual Inspection for Starter Motors?

Visual inspection is the most straightforward method for assessing starter motors. It involves checking for visible signs of wear, corrosion, or loose connections. This method is particularly suitable for automotive repair shops and fleet services where quick diagnostics are essential. While it offers the advantage of being quick and requiring no specialized tools, it may not uncover internal issues that could affect performance. B2B buyers should consider integrating visual inspection as a preliminary step before more in-depth testing.

How Does Voltage Testing Help in Diagnosing Starter Motors?

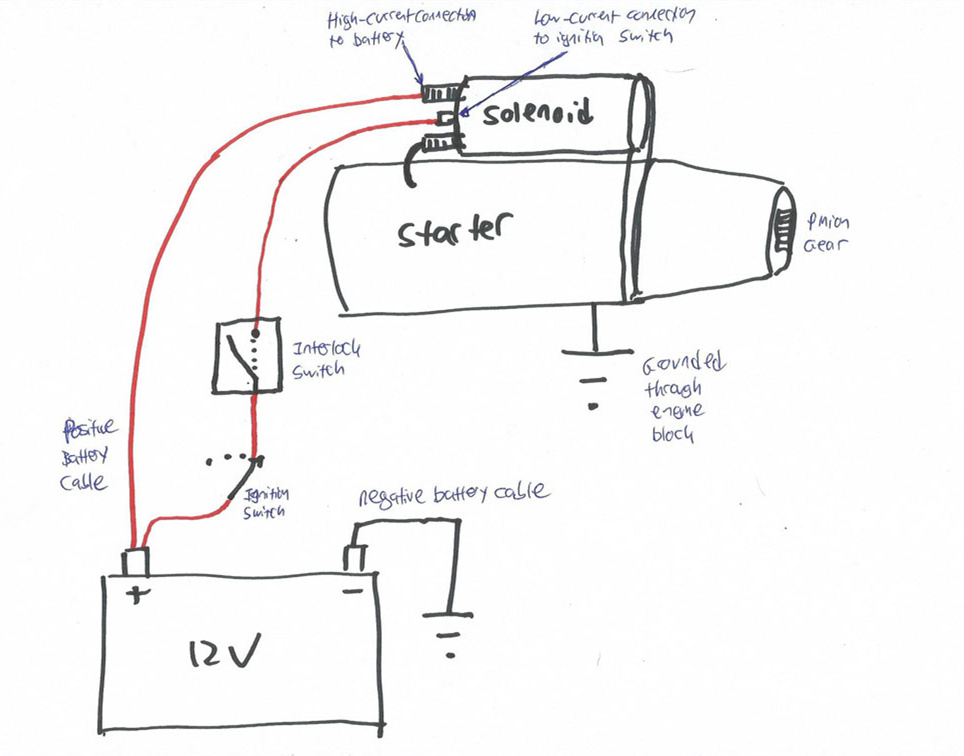

Voltage testing is a critical diagnostic technique that measures the electrical current reaching the starter motor. By using a multimeter, technicians can determine if the starter motor is receiving adequate voltage to function correctly. This method is essential for diagnostic centers and automotive manufacturers, as it provides clear insights into electrical status and identifies weak connections. Although it requires some technical knowledge and tools, the benefits far outweigh the cons, making it a valuable investment for B2B buyers focused on accuracy.

Why Is the Starter Solenoid Test Important for B2B Buyers?

The starter solenoid test checks whether the solenoid engages when the ignition key is turned. This method is particularly useful for service centers and automotive technicians who need quick diagnostic results. It is simple and effective, allowing for rapid identification of solenoid-related issues. However, its limitation lies in addressing only solenoid problems, which may necessitate further testing if the motor does not operate. B2B buyers should leverage this test for efficient troubleshooting in high-volume repair environments.

What Makes Bench Testing a Comprehensive Method for Starter Motors?

Bench testing involves removing the starter motor from the vehicle and testing it independently to ensure it operates correctly. This method is ideal for specialist repair shops and engine rebuilders that require thorough assessments. Although it provides a comprehensive view of the starter’s functionality, it can be time-consuming and demands specialized tools and expertise. B2B buyers should weigh the benefits of detailed diagnostics against the operational costs associated with bench testing.

How Does Voltage Drop Testing Enhance Troubleshooting for Starter Motors?

Voltage drop testing assesses the resistance in the starter circuit while the engine attempts to start. This technique is particularly valuable for automotive diagnostics and fleet maintenance, as it helps identify weak points in wiring that may hinder starter performance. While it can yield effective troubleshooting results, it is more complex and often requires assistance for accurate execution. For B2B buyers, investing in training for this testing method can significantly enhance diagnostic capabilities and operational efficiency.

Key Industrial Applications of how to test starter motor

| Branche/Sektor | Specific Application of how to test starter motor | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Diagnostische Prüfung von Anlassern in Fahrzeugen | Reduces misdiagnosis, ensuring accurate repairs and customer satisfaction | Availability of specialized testing tools and trained technicians |

| Transport & Logistik | Maintenance of fleet vehicles to ensure operational efficiency | Minimizes downtime and enhances reliability of transportation services | Access to bulk purchasing of starter motors and diagnostic equipment |

| Landwirtschaftliche Maschinen | Testing starter motors in tractors and heavy machinery | Ensures machinery is operational, preventing delays in farming activities | Need for durable components that withstand harsh environments |

| Baumaschinen | Regular testing of starter motors in construction machinery | Increases machinery uptime, leading to better project timelines | Sourcing from suppliers with reliable service support and warranty |

| Schiffsindustrie | Testing starter motors in boats and marine equipment | Enhances safety and reliability of marine operations | Compliance with maritime regulations and availability of marine-grade parts |

How is ‘how to test starter motor’ applied in the automotive repair industry?

In automotive repair shops, testing starter motors is a critical diagnostic process. Technicians use various methods, such as visual inspections and voltage tests, to determine whether a starter motor is functioning correctly. Accurate testing reduces the risk of misdiagnosis, ensuring that customers only pay for necessary repairs. Given the competitive nature of the automotive repair industry, having reliable diagnostic tools and trained personnel is essential for maintaining customer trust and satisfaction.

What are the implications of starter motor testing in transportation and logistics?

In the transportation and logistics sector, regular testing of starter motors in fleet vehicles is vital for operational efficiency. By ensuring that starter motors are functioning properly, businesses can minimize vehicle downtime, which directly impacts service delivery and profitability. This sector often requires bulk purchasing of starter motors and diagnostic tools, so suppliers must provide competitive pricing and reliable delivery schedules to meet the demands of fleet maintenance.

How does starter motor testing benefit agricultural machinery?

Testing starter motors in agricultural machinery, such as tractors and harvesters, is crucial for maintaining productivity on farms. A malfunctioning starter motor can lead to significant delays during critical planting and harvesting periods. Buyers in this sector need to ensure that they source durable and reliable components that can withstand harsh agricultural environments. Additionally, suppliers should offer comprehensive support and quick turnaround times to address any issues that may arise.

Why is testing starter motors important in construction equipment?

In the construction industry, the reliability of machinery is paramount for meeting project timelines. Regular testing of starter motors in construction equipment helps identify issues before they lead to equipment failure. This proactive approach not only enhances machinery uptime but also contributes to overall project efficiency. Buyers in this sector should prioritize sourcing from suppliers that offer robust customer support and warranty options to safeguard their investments.

What role does starter motor testing play in the marine industry?

In the marine industry, testing starter motors in boats and other marine equipment is essential for ensuring safety and reliability during operations. A faulty starter motor can lead to operational failures, posing risks to both personnel and equipment. Buyers must consider suppliers that comply with maritime regulations and provide marine-grade parts to ensure optimal performance in challenging marine environments. Reliable sourcing is critical to maintaining the safety and efficiency of marine operations.

3 Common User Pain Points for ‘how to test starter motor’ & Their Solutions

Scenario 1: Difficulty Diagnosing Starter Motor Issues

Das Problem:

B2B buyers, particularly those in automotive repair or parts distribution, often encounter challenges in accurately diagnosing starter motor failures. Many technicians may initially misattribute starting problems to the battery or ignition system, leading to unnecessary part replacements and increased costs. This misdiagnosis can be particularly frustrating for businesses that rely on efficient turnaround times and customer satisfaction, as they may waste time troubleshooting the wrong components.

Die Lösung:

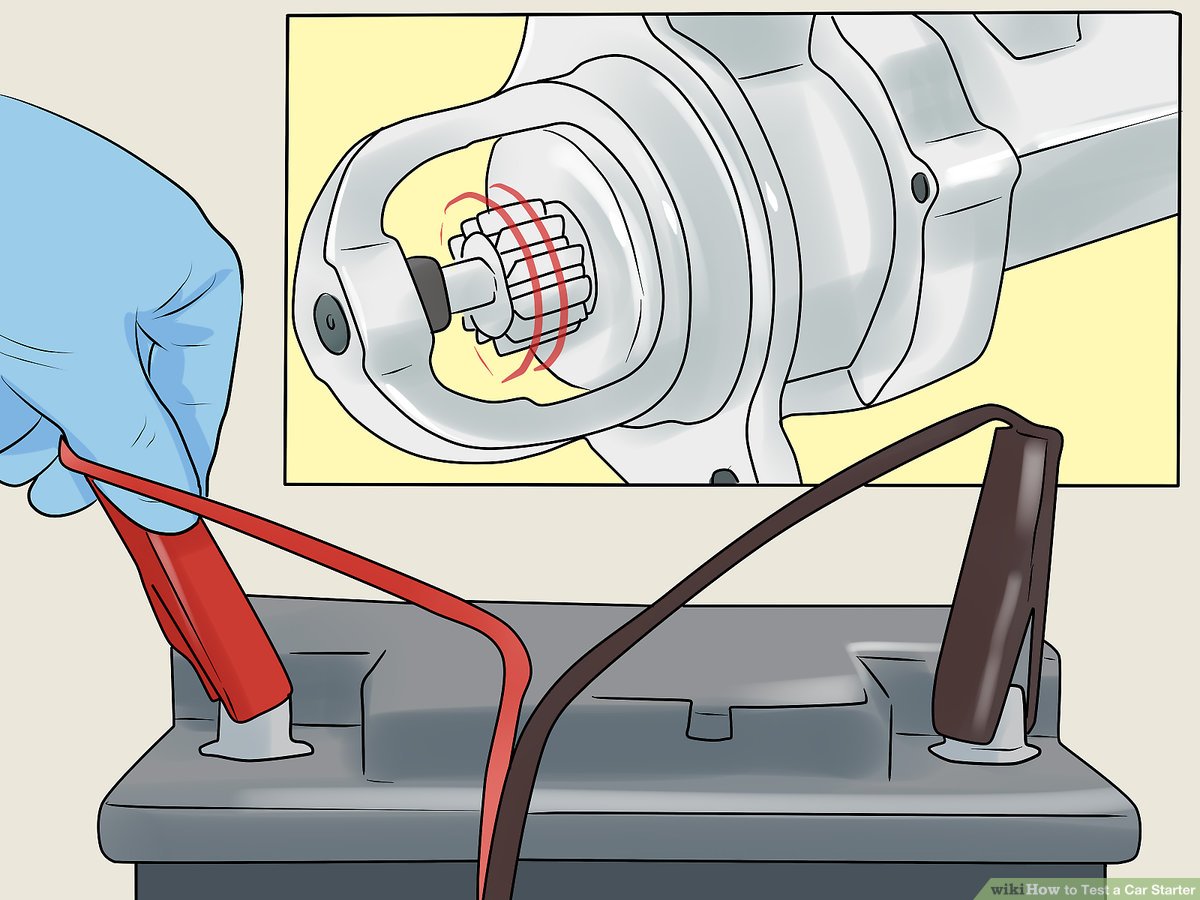

To effectively diagnose starter motor issues, it is essential to implement a systematic testing approach. Start by conducting a visual inspection of the starter motor and its connections. Look for signs of corrosion, loose wiring, or physical damage that could impede functionality. Next, use a multimeter to measure the voltage at the starter terminals. A reading below 12.25 volts indicates a potential issue with the battery or wiring, necessitating further inspection of those components.

Encourage your technicians to utilize a voltage drop test, connecting a multimeter between the battery and starter motor while attempting to start the engine. A significant voltage drop (greater than 0.5 volts) suggests excessive resistance in the circuit, requiring attention to the connections or wiring. This structured approach not only enhances diagnostic accuracy but also builds customer trust through transparent communication about the testing process.

Scenario 2: Inadequate Knowledge of Testing Equipment

Das Problem:

Many B2B buyers may struggle with understanding the appropriate tools and equipment required to test starter motors effectively. This knowledge gap can lead to inefficient testing procedures, delayed repairs, and increased operational costs. For businesses operating in regions with limited access to specialized automotive diagnostic tools, this can be a particularly pressing issue.

Die Lösung:

Investing in the right testing equipment is crucial for accurate starter motor diagnostics. Essential tools include a digital multimeter for measuring voltage and continuity, as well as a starter motor trigger for bench testing. Train your team on how to utilize these tools correctly. Provide resources such as manuals or online tutorials that outline step-by-step procedures for testing starter motors.

Consider establishing partnerships with reliable suppliers to ensure access to high-quality testing equipment. Additionally, hosting workshops or training sessions can enhance your team’s understanding of electrical systems and troubleshooting techniques. Empowering your workforce with the necessary knowledge and tools will streamline operations, reduce downtime, and ultimately improve customer satisfaction.

Scenario 3: Overcoming Safety Concerns During Testing

Das Problem:

Safety is a significant concern for B2B buyers when testing starter motors, especially in environments with multiple vehicles or heavy machinery. The potential for electrical hazards, injuries from improper handling, or accidents while testing can deter technicians from conducting thorough diagnostics. This concern is amplified in regions where safety regulations may not be strictly enforced, leading to increased risk for employees.

Die Lösung:

Establishing a robust safety protocol is essential for mitigating risks associated with starter motor testing. Start by implementing comprehensive training programs focused on electrical safety, proper tool usage, and emergency procedures. Ensure that all technicians are familiar with the safety guidelines specific to working with automotive electrical systems.

Provide personal protective equipment (PPE) such as gloves and safety goggles to reduce the risk of injury. Additionally, create a designated testing area that is well-ventilated and free from potential hazards. Encourage technicians to perform tests in pairs, promoting a culture of safety and accountability. By prioritizing safety in your operations, you not only protect your workforce but also foster a professional environment that can enhance productivity and build a positive reputation among clients.

Strategic Material Selection Guide for how to test starter motor

When selecting materials for testing starter motors, it is essential to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. Below are analyses of four common materials used in the testing of starter motors, emphasizing their relevance to the automotive sector.

What are the Key Properties of Copper in Starter Motor Testing?

Kupfer is widely used in electrical components due to its excellent conductivity. It has a high melting point of approximately 1,984°F (1,085°C) and can withstand significant electrical loads without degrading. Its corrosion resistance is moderate; however, it can oxidize over time, which may affect conductivity.

Vorteile: Copper’s superior electrical conductivity ensures efficient power transfer, making it ideal for starter motor applications. It is relatively easy to manufacture and shape, which supports complex designs.

Nachteile: The primary downside is its susceptibility to corrosion, particularly in humid environments, which can lead to performance issues. Additionally, copper is more expensive than some alternatives, which may impact cost-sensitive projects.

Auswirkungen auf die Anwendung: Copper is crucial for connections and wiring in starter motors, ensuring reliable performance. However, it requires careful handling and maintenance to prevent oxidation.

Überlegungen für internationale Käufer: Compliance with international standards such as ASTM B170 for copper wire is essential. Buyers from regions like Africa and South America should consider local environmental factors that may accelerate corrosion.

How Does Aluminum Compare for Testing Starter Motors?

Aluminium is another popular choice due to its lightweight nature and decent conductivity, approximately 61% that of copper. It has a melting point of about 1,221°F (660.3°C) and offers good corrosion resistance when anodized.

Vorteile: The lightweight property of aluminum makes it easier to handle and install, which can reduce labor costs. It is also less expensive than copper, making it a cost-effective choice for many applications.

Nachteile: While aluminum is resistant to corrosion, it can be less durable under high-stress conditions compared to copper. Its conductivity is lower, which may necessitate larger gauge wires to achieve the same performance.

Auswirkungen auf die Anwendung: Aluminum is suitable for starter motor applications where weight is a concern, but its lower conductivity can be a limiting factor in high-performance scenarios.

Illustrative image related to how to test starter motor

Überlegungen für internationale Käufer: Buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions. In regions with high humidity, additional protective coatings may be necessary to enhance longevity.

What Role Does Steel Play in Starter Motor Testing?

Stahl, particularly stainless steel, is often used in structural components of starter motors. It has a high tensile strength and can withstand high temperatures, with a melting point around 2,500°F (1,370°C) for stainless steel.

Vorteile: Steel’s durability and strength make it ideal for components that require structural integrity. It is also more resistant to deformation under stress compared to aluminum.

Nachteile: The downside is that steel is heavier than both copper and aluminum, which may not be suitable for all applications. It also has lower electrical conductivity, which limits its use in electrical connections.

Illustrative image related to how to test starter motor

Auswirkungen auf die Anwendung: Steel is excellent for housing and support structures in starter motors but is less effective for electrical components where conductivity is critical.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM A276 for stainless steel is crucial. Buyers in Europe may prefer materials that meet EU regulations regarding corrosion resistance and environmental impact.

How is Plastic Used in Testing Starter Motors?

Kunststoff, specifically high-grade thermoplastics, is used in non-structural components of starter motors, such as housing for electrical connectors. It has a melting point that varies widely depending on the type, typically around 300°F (150°C) for common automotive plastics.

Vorteile: Plastics are lightweight, corrosion-resistant, and can be molded into complex shapes, making them versatile for various applications. They are also cost-effective compared to metals.

Nachteile: Plastics may not withstand high temperatures or mechanical stresses as well as metals, which can limit their use in certain components. Additionally, they can degrade over time under UV exposure.

Illustrative image related to how to test starter motor

Auswirkungen auf die Anwendung: Plastics are suitable for insulating components and protecting electrical connections in starter motors, but care must be taken to choose the right type for high-temperature environments.

Überlegungen für internationale Käufer: Compliance with standards like ISO 9001 for quality management systems is essential. Buyers should also consider the thermal properties of plastics in regions with extreme temperatures.

Summary Table of Material Selection for Starter Motor Testing

| Material | Typical Use Case for how to test starter motor | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse und Verkabelung | Hervorragende Leitfähigkeit | Korrosionsanfällig | Hoch |

| Aluminium | Wiring and lightweight components | Leicht und kostengünstig | Geringere Leitfähigkeit als Kupfer | Mittel |

| Stahl | Strukturelle Komponenten und Gehäuse | Hohe Festigkeit und Haltbarkeit | Schwerer und geringere Leitfähigkeit | Mittel |

| Kunststoff | Insulating components and connectors | Corrosion-resistant and versatile | Begrenzte Temperaturbeständigkeit | Niedrig |

This analysis provides B2B buyers with actionable insights into material selection for testing starter motors, helping them make informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how to test starter motor

Was sind die wichtigsten Schritte im Herstellungsprozess von Anlassern?

The manufacturing process of starter motors involves several critical stages, each essential for ensuring the final product meets performance and reliability standards. The main stages include material preparation, forming, assembly, and finishing.

Wie wird das Material für die Anlasserproduktion vorbereitet?

The first step in manufacturing starter motors is the preparation of raw materials. This typically involves selecting high-quality metals such as steel and copper, which are essential for durability and conductivity. The materials undergo a rigorous quality check to ensure they meet the specified standards. Techniques like cutting, milling, and machining are utilized to shape the components, such as the housing, armature, and rotor, into precise dimensions.

Illustrative image related to how to test starter motor

Welche Umformtechniken werden bei der Herstellung von Anlassern verwendet?

Once the materials are prepared, forming techniques are employed to create the desired shapes. Common methods include stamping and forging for metal components, which help achieve the necessary strength and integrity. For electrical components, processes like winding are used to create coils that will generate the magnetic field necessary for the starter motor’s operation. These techniques are crucial, as any defects at this stage can lead to performance issues in the final product.

Wie werden Anlasser zusammengebaut?

The assembly stage is where various components come together to form the complete starter motor. Skilled technicians or automated systems assemble parts such as the solenoid, drive gear, and housing. Attention to detail is paramount, as improper assembly can lead to malfunction. During this stage, manufacturers often implement torque specifications and alignment checks to ensure that all components are correctly fitted and secured.

Welche Endbearbeitungsverfahren werden bei Anlassern angewandt?

Finishing processes include surface treatments like painting, plating, or coating to enhance durability and corrosion resistance. These treatments are not only aesthetic but also functional, as they protect the starter motor from environmental factors. Quality assurance at this stage involves checking for uniformity in coating and verifying that no surfaces are left exposed to potential damage.

What Quality Control Measures Are Essential for Starter Motor Manufacturing?

Quality control (QC) is integral to ensuring that starter motors meet international standards and customer expectations. Implementing a robust QC system helps manufacturers catch defects early and maintain product integrity.

Welche internationalen Normen sollten B2B-Einkäufer beachten?

For manufacturers aiming to sell internationally, adhering to standards such as ISO 9001 is crucial. This standard outlines requirements for a quality management system (QMS) and helps organizations ensure consistent quality in their products and services. Additionally, industry-specific certifications like CE (for the European market) or API (for automotive components) may be necessary depending on the target market.

Was sind die wichtigsten Punkte der Qualitätskontrolle in der Anlasserproduktion?

Die Qualitätskontrolle umfasst in der Regel mehrere Kontrollpunkte während des gesamten Herstellungsprozesses:

-

Eingangsqualitätskontrolle (IQC): Raw materials are inspected upon arrival to ensure they meet specifications. This includes checking for material properties and conducting initial tests.

-

In-Process-Qualitätskontrolle (IPQC): During manufacturing, continuous monitoring is performed at various stages. This includes dimensional checks and performance tests to identify any deviations from standards.

-

Endkontrolle (FQC): Once assembly is complete, the finished starter motors undergo comprehensive testing, including electrical tests, load tests, and functional tests to ensure they operate correctly.

Welche Prüfverfahren werden üblicherweise für Anlasser verwendet?

Testing is a crucial aspect of the quality assurance process. Various methods are employed to verify that starter motors function as intended:

-

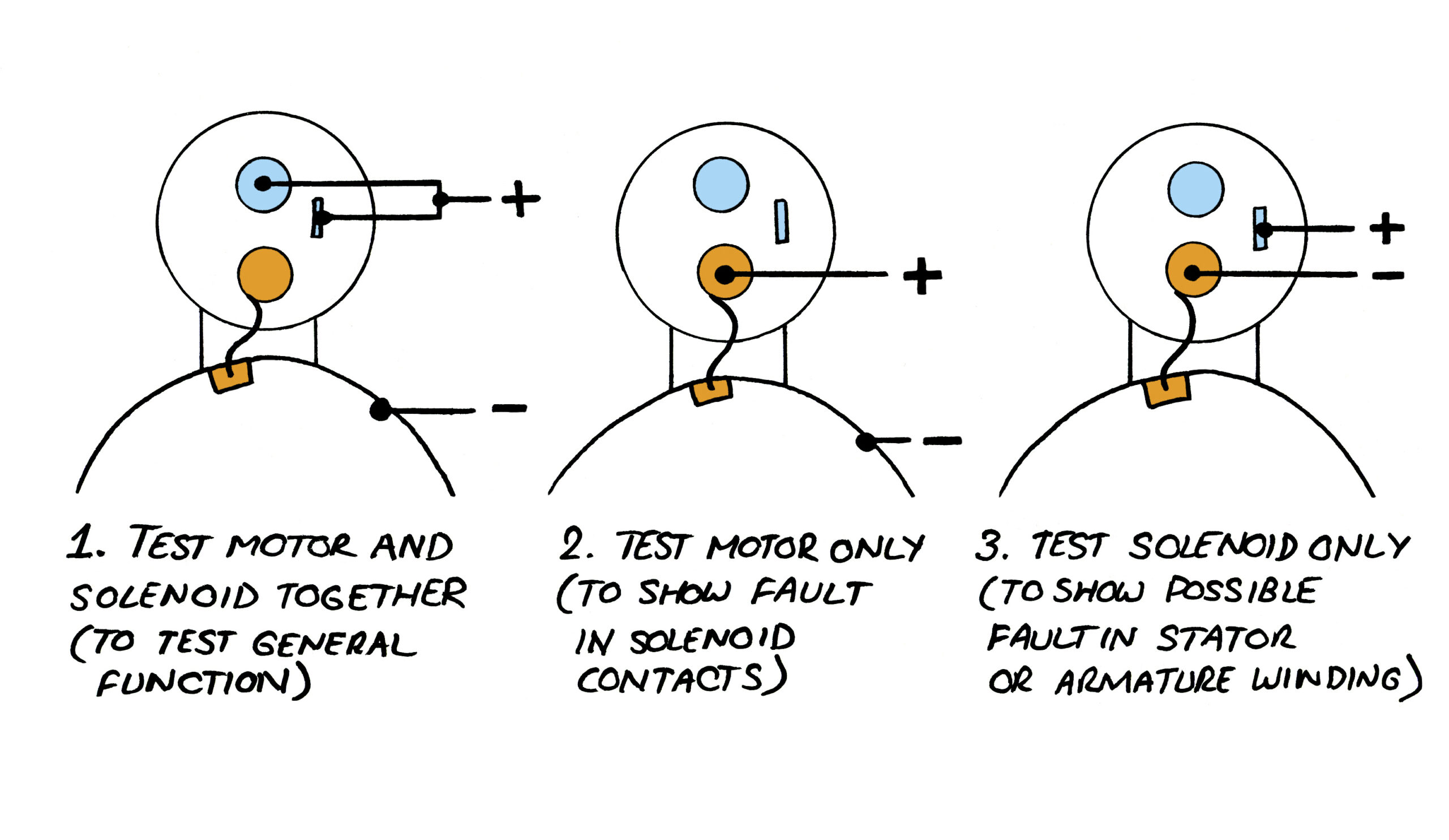

Voltage Tests: Multimeters are used to check voltage at different points in the starter motor. This helps identify issues like poor connections or insufficient power delivery.

-

Continuity Tests: These tests confirm that electrical pathways are intact, ensuring that the starter motor will engage properly when activated.

-

Bench Tests: For more detailed analysis, starter motors may be removed from the vehicle and tested under controlled conditions using specialized equipment. This allows for a thorough evaluation of performance characteristics.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

B2B buyers should be proactive in verifying the quality control measures of potential suppliers. Here are some effective strategies:

-

Durchführung von Lieferantenaudits: Regular audits can provide insights into a supplier’s manufacturing processes and QC practices. Buyers can assess compliance with international standards and identify areas for improvement.

-

Request QC Reports: Suppliers should provide documentation of their QC processes, including test results and compliance certifications. This transparency helps build trust and ensures that products meet required specifications.

-

Beauftragen Sie externe Prüfer: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These inspectors can conduct random checks, ensuring that products adhere to specified standards.

Was sind die Besonderheiten der Qualitätskontrolle und Zertifizierung für internationale B2B-Einkäufer?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control and certification requirements. Understanding local regulations and industry standards is crucial for successful market entry.

Buyers should also consider the logistics of shipping and potential customs regulations related to certifications. It is advisable to establish clear communication with suppliers regarding these requirements to avoid delays or compliance issues.

By focusing on robust manufacturing processes and stringent quality control measures, B2B buyers can ensure they receive reliable starter motors that meet their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to test starter motor’

In the automotive industry, understanding how to effectively test a starter motor is essential for maintaining vehicle performance and reliability. This guide provides a structured approach for B2B buyers looking to acquire the necessary tools and knowledge to perform starter motor diagnostics.

Schritt 1: Identify Your Testing Needs

Before proceeding with any procurement, clearly define the specific requirements for testing starter motors. Consider factors such as the types of vehicles you will be working with (e.g., cars, motorcycles, heavy machinery) and the frequency of testing needed. Understanding your needs will help you target the right suppliers and tools.

Schritt 2: Research Quality Testing Tools

Investing in high-quality testing equipment is crucial for accurate diagnostics. Look for tools like multimeters, battery testers, and starter motor test kits that are known for durability and precision. Ensure that these tools are compatible with the types of starter motors you will be testing, as this will streamline your operations and improve reliability.

Illustrative image related to how to test starter motor

- Multimeters: Choose models with a good reputation for accuracy and ease of use.

- Starter Motor Test Kits: Ensure they include all necessary components for both bench and in-vehicle testing.

Schritt 3: Lieferantenzertifizierungen bewerten

When sourcing tools and equipment, check for supplier certifications and compliance with international standards. Certifications can indicate the quality and safety of the products, which is particularly important in regions with varying regulatory requirements.

- ISO-Zertifizierungen: Look for suppliers with ISO 9001 or equivalent certifications.

- Lokale Compliance: Ensure suppliers adhere to local regulations that may affect product performance.

Schritt 4: Produktdemonstrationen anfordern

Before making a purchase, request demonstrations of the testing equipment from potential suppliers. This will allow you to assess the usability and effectiveness of the tools in real-world scenarios. Observing the equipment in action can also provide insights into its reliability and ease of integration into your existing workflow.

- Hands-On Testing: If possible, test the equipment yourself to gauge performance.

- Technical Support Availability: Inquire about the support provided for the tools post-purchase.

Schritt 5: Gather User Reviews and Testimonials

Research user reviews and testimonials from businesses similar to yours to gain insights into the performance of the testing tools. Feedback from other B2B buyers can highlight any potential issues or advantages that may not be evident from product specifications alone.

- Industry-Specific Feedback: Seek reviews from businesses within your region or industry to ensure relevance.

- Long-Term Performance: Pay attention to comments about the durability and maintenance requirements of the tools.

Schritt 6: Assess Cost vs. Value

While cost is an important factor, it should not be the sole consideration. Assess the value that the testing tools bring to your operations, including potential savings from accurate diagnostics and reduced downtime. A slightly higher investment in quality tools may yield significant long-term benefits.

- Gesamtbetriebskosten: Consider not just the purchase price but also maintenance, warranty, and repair costs.

- Return on Investment (ROI): Analyze how improved testing capabilities can lead to better service and customer satisfaction.

Schritt 7: Finalize Supplier Agreements

Once you have selected a supplier, ensure that all terms of the agreement are clearly defined. This includes delivery timelines, warranty details, and return policies. A well-structured agreement protects both parties and ensures that expectations are met.

- Service Level Agreements (SLAs): Define clear expectations for product performance and support.

- Zahlungsbedingungen: Negotiate favorable payment terms that align with your cash flow needs.

By following this practical sourcing guide, B2B buyers can make informed decisions when acquiring tools and knowledge necessary for testing starter motors, ultimately enhancing their operational efficiency and service quality.

Comprehensive Cost and Pricing Analysis for how to test starter motor Sourcing

What Are the Key Cost Components for Testing Starter Motors?

When sourcing equipment and services for testing starter motors, understanding the cost structure is crucial. The primary cost components include:

-

Materialien: This encompasses the raw materials required for testing equipment such as multimeters, starter motor trigger kits, and wiring harnesses. The quality and specifications of these materials can significantly influence the overall cost.

-

Arbeit: Labor costs include the wages for skilled technicians or mechanics performing the tests. The complexity of testing procedures may require specialized knowledge, which can increase labor costs.

-

Fertigungsgemeinkosten: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. These costs are typically allocated across all products and services offered by a supplier.

-

Werkzeuge: Investment in specialized tools and equipment for testing starter motors can be substantial. This includes diagnostic tools, battery testers, and bench testing setups. The initial capital expenditure is a significant factor for buyers to consider.

-

Qualitätskontrolle (QC): Ensuring that testing processes meet industry standards requires investment in quality control measures. This may involve testing equipment calibration and compliance with safety regulations.

-

Logistik: Shipping costs, customs duties, and insurance for transporting testing equipment and components can add to the total cost. International buyers must account for these factors, especially when sourcing from different continents.

-

Marge: Suppliers will add a markup to cover their operational costs and profit margins. Understanding typical margins within the industry can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Testing Starter Motors?

Several factors can influence pricing in the starter motor testing market:

-

Volumen und Mindestbestellmenge (MOQ): Bulk orders often lead to reduced pricing per unit. Buyers should negotiate MOQs to maximize cost efficiency.

-

Spezifikationen und Anpassung: Customized testing solutions tailored to specific vehicle types or regions may incur additional costs. Clearly defining requirements can help manage expenses.

-

Materialqualität und Zertifizierungen: Higher quality materials and certifications (e.g., ISO standards) typically result in higher costs. Buyers should weigh the benefits of quality against budget constraints.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better support and service, which can enhance long-term value.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. These terms dictate who is responsible for shipping, insurance, and tariffs, impacting overall costs.

What Buyer Tips Can Help Optimize Costs for Testing Starter Motors?

-

Verhandlung: Engage suppliers in discussions about pricing and terms. Leveraging your purchasing power can lead to better deals, especially for larger orders.

-

Kosteneffizienz: Assess all potential costs, including maintenance and operational expenses, to determine the Total Cost of Ownership (TCO). This holistic view can highlight the most cost-effective solutions.

-

International Pricing Nuances: Be aware that pricing structures may vary significantly across regions. Factors like local market conditions, currency fluctuations, and import taxes can affect overall costs for buyers in Africa, South America, the Middle East, and Europe.

-

Forschung und Vergleich: Conduct thorough market research to compare offerings from different suppliers. This can help identify competitive pricing and ensure you are getting the best value for your investment.

-

Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into market trends. Consider establishing partnerships for ongoing needs.

Schlussfolgerung

Understanding the comprehensive cost and pricing structure for testing starter motors is essential for B2B buyers looking to optimize their sourcing strategies. By being informed about cost components, price influencers, and practical buyer tips, businesses can make strategic decisions that align with their operational goals and budgetary constraints. Always consider the broader context of international trade when engaging with suppliers across different regions.

Alternatives Analysis: Comparing how to test starter motor With Other Solutions

Exploring Alternatives to Testing a Starter Motor

When it comes to diagnosing starter motor issues, several methods exist beyond traditional testing. Each alternative has its strengths and weaknesses, making it essential for international B2B buyers to evaluate these options based on specific operational needs, budget constraints, and technological capabilities. Below is a comparison of the conventional method of testing a starter motor against two viable alternatives: using a professional diagnostic tool and employing remote diagnostics through specialized apps.

| Vergleichsaspekt | How To Test Starter Motor | Professionelles Diagnosewerkzeug | Remote Diagnostic Apps |

|---|---|---|---|

| Leistung | Effective for identifying starter-related issues directly on-site. | Highly accurate; can detect multiple vehicle issues, not just starter problems. | Convenient; provides quick diagnostics without physical inspection. |

| Kosten | Relatively low cost, mainly requiring basic tools (multimeter, cables). | Higher initial investment for the tool, but can save on future diagnostics. | Often subscription-based; may have variable costs depending on services used. |

| Einfache Implementierung | Requires mechanical knowledge and specific tools; can be complex for non-experts. | Requires training to operate effectively; can be cumbersome for small operations. | User-friendly; accessible via mobile devices; minimal training required. |

| Wartung | Low maintenance; requires occasional tool upkeep. | Moderate maintenance; tools may require updates and calibration. | Low maintenance; app updates are automatic. |

| Bester Anwendungsfall | Ideal for DIY mechanics and small workshops with limited budgets. | Best suited for larger repair shops or fleet services needing comprehensive diagnostics. | Perfect for mobile mechanics or businesses with remote operations needing quick assessments. |

Professional Diagnostic Tools: Pros and Cons

Professional diagnostic tools, such as OBD-II scanners, provide an in-depth analysis of a vehicle’s systems, including the starter motor. These devices are known for their accuracy and ability to detect multiple issues simultaneously, making them invaluable for larger repair shops or fleet services. However, they come with a higher upfront cost and require proper training to ensure effective use. Maintenance can also be moderate, as these tools may need regular updates to stay compatible with newer vehicle models.

Remote Diagnostic Apps: Advantages and Limitations

Remote diagnostic apps represent a modern approach to vehicle troubleshooting. They offer the convenience of quick assessments from a mobile device, allowing users to diagnose issues without needing a physical inspection. This method is particularly beneficial for mobile mechanics operating in remote areas or those requiring rapid diagnostics. Despite their user-friendly nature, these apps may have subscription costs that vary based on the services provided. Additionally, while they can quickly identify starter motor problems, they might not offer the comprehensive analysis that a professional tool would.

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, selecting the right method for testing starter motors hinges on specific operational demands and budget considerations. If cost-effectiveness and hands-on diagnostics are priorities, traditional methods may suffice. Conversely, for businesses aiming for efficiency and a broader diagnostic scope, investing in professional tools or utilizing remote diagnostic apps could yield significant long-term benefits. Assessing the unique requirements of your operations will ensure that you select the most suitable solution for your starter motor testing needs.

Essential Technical Properties and Trade Terminology for how to test starter motor

What Are the Critical Technical Properties for Testing Starter Motors?

When evaluating starter motors, understanding their technical properties is essential for ensuring reliability and performance. Here are some critical specifications to consider:

-

Werkstoffgüte:

The materials used in starter motors, such as copper for windings and steel for housings, significantly affect their durability and efficiency. High-grade materials can withstand higher temperatures and provide better conductivity, which is crucial in regions with extreme weather conditions, such as parts of Africa and South America. -

Nennspannung:

Most automotive starter motors operate at 12 volts, while some heavy-duty applications may require 24 volts. Ensuring that the starter motor matches the voltage requirements of the vehicle is vital for optimal performance. A mismatch can lead to inefficiency or damage to the motor. -

Drehmoment-Spezifikationen:

Torque is a measure of rotational force, and starter motors must provide sufficient torque to crank the engine. Specifications typically range from 100 to 400 Nm, depending on the engine size. Understanding these specifications helps buyers select the right starter motor for their specific applications, ensuring reliable engine starts. -

Toleranzwerte:

Tolerances refer to the permissible limits of variation in dimensions and performance characteristics. For starter motors, these tolerances can affect the fit and engagement of the starter gear with the flywheel. Precise tolerances are crucial for maintaining the longevity of both the starter motor and the engine it serves. -

Isolationsklasse:

The insulation class indicates the temperature ratings for the motor’s windings. Common classes include B (130°C), F (155°C), and H (180°C). Selecting a starter motor with the appropriate insulation class is essential for ensuring performance in high-heat environments, which is particularly relevant for buyers in warmer climates. -

Einschaltdauer:

The duty cycle specifies how long a starter motor can operate under load before it requires a cooldown period. This is critical for applications with frequent starts, such as in commercial vehicles. Understanding duty cycles helps businesses select motors that can handle their operational demands without failure.

Which Industry Terms Are Important for Understanding Starter Motor Testing?

Familiarity with industry terminology can facilitate smoother transactions and clearer communication among B2B buyers and suppliers. Here are some essential terms:

-

OEM (Originalgerätehersteller):

This term refers to companies that produce parts that are used in the manufacturing of vehicles. For buyers, sourcing OEM starter motors ensures compatibility and reliability, as these parts are designed specifically for the vehicle’s specifications. -

MOQ (Mindestbestellmenge):

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and purchasing decisions, especially for businesses looking to maintain cost-effective stock levels. -

RFQ (Angebotsanfrage):

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is an essential tool for buyers to compare offerings and negotiate better deals, helping them make informed purchasing decisions regarding starter motors. -

Incoterms (Internationale Handelsklauseln):

These are international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping costs, risks, and responsibilities, particularly when sourcing parts from different regions. -

Prüfstandstests:

This term refers to the process of testing a starter motor outside of the vehicle to ensure it functions correctly. Understanding bench testing procedures can help buyers assess the quality and reliability of starter motors before installation. -

Ersatzteilmarkt:

The aftermarket refers to the secondary market where parts and accessories are sold after the original sale. Understanding this term is important for buyers looking to source replacement starter motors that may not be OEM, as it can affect quality and compatibility.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when testing and sourcing starter motors, ultimately enhancing their operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the how to test starter motor Sector

What Are the Key Market Dynamics Impacting the Starter Motor Testing Sector?

The starter motor testing sector is experiencing dynamic shifts driven by technological advancements and changing consumer expectations. One significant trend is the increasing integration of digital diagnostic tools that streamline the testing process. This trend is particularly relevant for B2B buyers in regions such as Africa, South America, and the Middle East, where the demand for efficient and reliable automotive solutions is growing. The rise of mobile diagnostic applications allows mechanics and businesses to quickly identify starter motor issues, reducing downtime and improving service efficiency.

Moreover, the market is witnessing a surge in demand for eco-friendly and sustainable automotive components. As environmental regulations tighten globally, companies are increasingly prioritizing products that adhere to green standards. This trend is evident in the sourcing of materials for testing equipment, with a growing emphasis on recyclable and non-toxic components. B2B buyers are encouraged to seek suppliers who are not only compliant with international quality standards but also demonstrate a commitment to sustainability.

Additionally, the economic landscape, characterized by fluctuating raw material prices and supply chain disruptions, has compelled buyers to adopt more strategic sourcing practices. Emphasizing relationships with reliable suppliers who can guarantee product availability and quality is crucial. For international buyers, understanding local market conditions and establishing partnerships with regional suppliers can lead to more effective sourcing strategies.

How Does Sustainability Influence Sourcing in the Starter Motor Testing Sector?

Sustainability has become a pivotal concern in the B2B landscape, especially within the automotive sector, where the environmental impact of products is under scrutiny. For businesses involved in testing starter motors, sourcing materials and components that align with sustainability goals is essential. Ethical supply chains not only mitigate environmental harm but also enhance brand reputation, fostering customer loyalty among increasingly eco-conscious consumers.

Incorporating ‘green’ certifications and materials is becoming a competitive advantage in the market. Buyers should look for suppliers who provide documentation on the environmental impact of their products, including certifications such as ISO 14001 or other relevant eco-labels. These credentials assure B2B buyers that their sourcing choices contribute positively to environmental sustainability.

Moreover, the use of recycled materials in manufacturing starter motor testing equipment can significantly reduce the carbon footprint associated with production. It is also vital for buyers to engage with suppliers who prioritize ethical labor practices and fair trade, ensuring that the entire supply chain reflects their commitment to sustainability.

How Has the Starter Motor Testing Sector Evolved Over Time?

The evolution of the starter motor testing sector has been marked by significant technological advancements and shifts in consumer expectations. Historically, testing starter motors relied heavily on manual processes and rudimentary diagnostic methods, often leading to inefficiencies and inaccuracies. Over the years, the introduction of electronic diagnostic tools and software has revolutionized the way mechanics assess starter motor functionality, making the process faster and more reliable.

As vehicles have become more complex, so too have the systems that support them. The shift towards integrated automotive electronics has necessitated more sophisticated testing methods that can accurately diagnose issues within the starter motor and its associated components. This evolution reflects the broader trend of increasing reliance on technology in the automotive industry, highlighting the importance of staying updated with the latest diagnostic tools and techniques for B2B buyers in the sector.

In conclusion, navigating the starter motor testing sector requires an understanding of the current market dynamics, the importance of sustainability in sourcing, and an appreciation for the historical evolution of testing methods. By focusing on these aspects, international B2B buyers can make informed decisions that align with their operational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of how to test starter motor

-

Wie kann ich einen defekten Anlasser diagnostizieren?

To diagnose a faulty starter motor, start with a visual inspection of the motor and its connections for any visible damage, corrosion, or loose wires. Next, use a multimeter to check the voltage at the starter terminals; a reading below 12.25 volts may indicate an issue. Perform a voltage drop test during engine cranking to identify resistance in the circuit. If you suspect the starter solenoid is faulty, listen for a clicking sound when the ignition is turned on. If all else fails, a bench test can provide a definitive diagnosis. -

What tools do I need to test a starter motor effectively?

Essential tools for testing a starter motor include a digital multimeter for voltage measurements and continuity tests, jumper cables for bench testing, and basic hand tools for disassembly. A fully charged battery is crucial to ensure accurate testing. Additionally, having safety gear on hand, such as gloves and goggles, is important to protect against electrical hazards. Depending on the specific vehicle type, you may also need specialized tools or diagnostic equipment. -

What are common symptoms of a bad starter motor?

Common symptoms of a bad starter motor include a clicking sound when the ignition is turned, the engine failing to crank, or unusual noises such as grinding or whirring. If the starter motor is freewheeling, it may not be engaging the flywheel properly. Additionally, intermittent starting issues could suggest electrical problems. Identifying these symptoms early can save time and costs associated with unnecessary replacements. -

How can I ensure quality when sourcing starter motors from international suppliers?

To ensure quality when sourcing starter motors internationally, conduct thorough supplier vetting. Request certifications, such as ISO 9001, and review customer feedback to gauge reliability. Consider asking for product samples to assess quality firsthand. Establish clear quality assurance protocols, including specifications for materials and performance standards. Regular audits and inspections can also help maintain product quality throughout the supply chain. -

What are the typical payment terms for purchasing starter motors in bulk?

Typical payment terms for bulk purchases of starter motors vary by supplier but often include options like net 30, net 60, or payment upon shipment. Some suppliers may require a deposit upfront, especially for custom orders. It’s advisable to negotiate terms that suit your cash flow while ensuring the supplier’s security. Using secure payment methods and escrow services can help mitigate risks in international transactions. -

Wie hoch ist die Mindestbestellmenge (MOQ) für Anlasser von Lieferanten?

The minimum order quantity (MOQ) for starter motors can vary significantly based on the supplier and the type of motor. Many manufacturers have MOQs ranging from 50 to several hundred units to justify production costs. It’s important to communicate your needs clearly and explore options for lower MOQs, especially if you are testing a new market or product line. Some suppliers may be willing to accommodate smaller orders for first-time customers or through negotiation. -

How do I handle logistics when importing starter motors?

Handling logistics when importing starter motors involves selecting a reliable freight forwarder familiar with international shipping regulations. Ensure compliance with import duties and customs documentation to avoid delays. Consider shipping methods—air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Track shipments closely and maintain communication with your supplier to address any issues promptly during transit. -

Welche Anpassungsmöglichkeiten gibt es für Anlasser?

Customization options for starter motors may include modifications to voltage specifications, size, and mounting configurations to fit specific vehicle models. Some suppliers may offer branding or labeling options to align with your company’s identity. Discuss your requirements upfront to ensure the supplier can meet your specifications. Be prepared for potential MOQ adjustments or additional lead times when requesting custom features.

Top 2 How To Test Starter Motor Manufacturers & Suppliers List

1. Moto Electrical – Starter Motor Testing Guide

Domäne: motoelectrical.co.uk

Registriert: 2012 (13 Jahre)

Einleitung: Testing a starter motor on a motorcycle, ATV, or UTV involves checking its electrical and mechanical components to ensure it is functioning properly. Tools needed include a digital multimeter and a fully charged battery. Steps include ensuring safety precautions, locating the starter motor, performing a visual inspection, checking battery voltage, conducting a voltage drop test, checking solenoid …

2. Starter Replacement – Options and Tools

Domäne: instructables.com

Registriert: 2005 (20 Jahre)

Einleitung: Tools/Supplies Needed: multimeter, socket set and ratchet, battery load tester, wrenches, screwdriver set. Options for starter replacement: rebuild it yourself, have a specialist rebuild it, purchase a rebuilt unit, or purchase a new unit. Used replacement option exists but is not recommended due to uncertainty of life expectancy.

Strategic Sourcing Conclusion and Outlook for how to test starter motor

How Can Effective Testing of Starter Motors Enhance Your Procurement Strategy?

In conclusion, understanding how to test starter motors is crucial for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By implementing systematic diagnostic procedures—such as visual inspections, voltage tests, and continuity checks—businesses can ensure they procure reliable starter motors. This not only minimizes downtime and repair costs but also enhances customer satisfaction through improved product reliability.

Strategic sourcing plays a pivotal role in this process. By partnering with reputable suppliers and leveraging local expertise, businesses can streamline procurement, reduce lead times, and ensure they acquire high-quality components that meet their specific needs. As the automotive sector continues to evolve, the ability to source and test starter motors effectively will remain a competitive advantage.

Looking ahead, we encourage B2B buyers to invest in training and tools that enhance their testing capabilities. Consider collaborating with local experts and utilizing technology for more accurate diagnostics. By prioritizing these strategies, you can secure your supply chain and position your business for sustained success in a dynamic marketplace.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.