Introduction: Navigating the Global Market for where is an alternator located

In the complex landscape of automotive components, understanding where an alternator is located is crucial for international B2B buyers seeking reliable electrical systems for vehicles. The alternator, often positioned at the front of the engine, plays a pivotal role in generating electricity to charge the battery and power essential vehicle components. However, sourcing the right alternator can be challenging, especially with varying designs across different vehicle makes and models. This guide provides an in-depth exploration of alternator locations, highlighting the types, applications, and key factors to consider when selecting suppliers.

As you navigate the global market for alternators, you’ll gain insights into the critical aspects of supplier vetting, ensuring that you choose reliable manufacturers who meet quality standards. We’ll also cover cost considerations, helping you make informed purchasing decisions that align with your budget and operational needs. This comprehensive resource is tailored for B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Nigeria. By empowering you with knowledge about alternator specifications and sourcing strategies, this guide enables your organization to enhance vehicle performance while minimizing downtime and maintenance costs. With the right information at your fingertips, you can confidently approach the market and secure the best alternator solutions for your fleet.

Inhaltsverzeichnis

- Top 3 Where Is An Alternator Located Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for where is an alternator located

- Understanding where is an alternator located Types and Variations

- Key Industrial Applications of where is an alternator located

- 3 Common User Pain Points for ‘where is an alternator located’ & Their Solutions

- Strategic Material Selection Guide for where is an alternator located

- In-depth Look: Manufacturing Processes and Quality Assurance for where is an alternator located

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘where is an alternator located’

- Comprehensive Cost and Pricing Analysis for where is an alternator located Sourcing

- Alternatives Analysis: Comparing where is an alternator located With Other Solutions

- Essential Technical Properties and Trade Terminology for where is an alternator located

- Navigating Market Dynamics and Sourcing Trends in the where is an alternator located Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of where is an alternator located

- Strategic Sourcing Conclusion and Outlook for where is an alternator located

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding where is an alternator located Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Belt-Driven Alternator | Typically mounted on the front of the engine, connected via a serpentine belt. | Kfz-Werkstätten, Flottenwartung | Vorteile: Kostengünstig, weit verbreitet. Nachteile: May require more frequent replacement in older vehicles. |

| ECU-Controlled Alternator | Integrated with the vehicle’s ECU for optimized performance and efficiency. | Modern automotive manufacturing, electric vehicle production | Vorteile: Enhanced efficiency, reduced battery overcharging. Nachteile: Higher initial cost, complexity in replacement. |

| Internal Regulator Alternator | Contains an internal voltage regulator, simplifying installation and maintenance. | Auto parts distribution, repair services | Vorteile: Easier installation, less wiring complexity. Nachteile: Limited to specific vehicle models. |

| Hochleistungs-Lichtmaschine | Designed to produce more electricity for vehicles with high electrical demands. | Performance automotive, heavy-duty applications | Vorteile: Unterstützt zusätzliches elektrisches Zubehör. Nachteile: Higher cost, may require modifications for installation. |

| Kompakter Wechselstromgenerator | Smaller design for vehicles with limited engine bay space, often found in hybrids. | Electric vehicle manufacturers, compact car production | Vorteile: Platzsparend, leicht. Nachteile: Lower output capacity compared to standard models. |

What are the Key Characteristics of Belt-Driven Alternators?

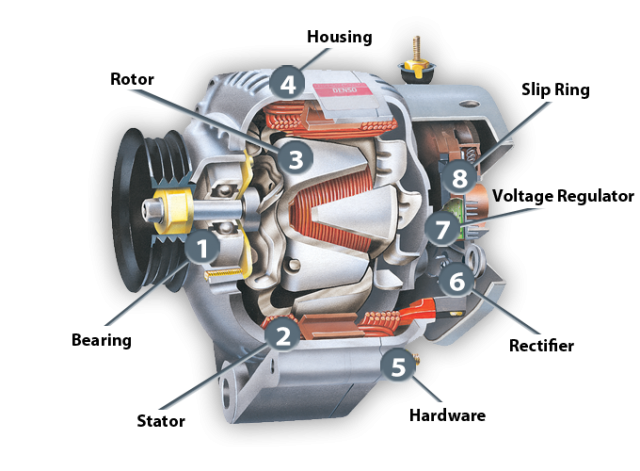

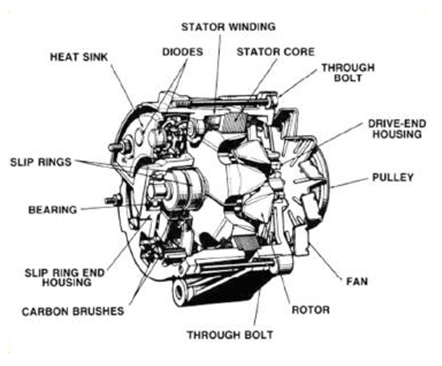

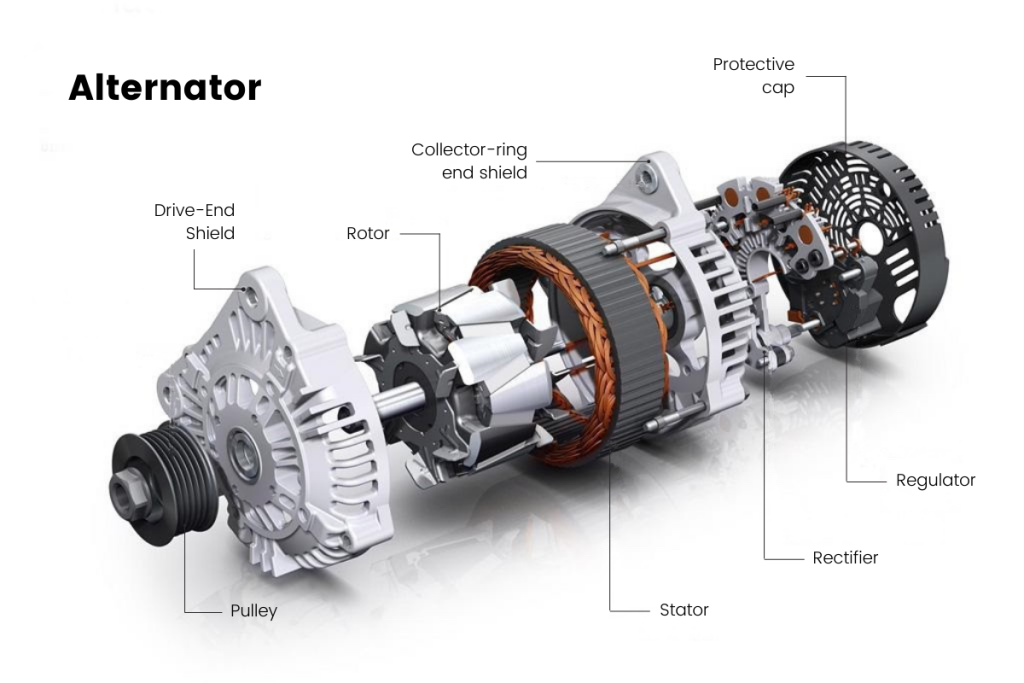

Belt-driven alternators are the most common type found in traditional internal combustion engine vehicles. They are mounted on the engine’s front, connected by a serpentine belt that drives the alternator when the engine runs. This design is straightforward, making them a favored choice among automotive repair shops and fleet maintenance services. When purchasing, buyers should consider the compatibility with their specific vehicle models and the typical lifespan of these alternators, which may vary based on driving conditions and maintenance practices.

How Do ECU-Controlled Alternators Enhance Vehicle Performance?

ECU-controlled alternators are integrated with the vehicle’s electronic control unit, allowing for precise regulation of electrical output. This type is increasingly popular in modern automotive manufacturing and electric vehicle production due to its efficiency. By adjusting the power output based on demand, these alternators prevent battery overcharging and enhance fuel efficiency. B2B buyers should assess the vehicle’s compatibility with this technology and consider the potential for reduced long-term maintenance costs despite a higher initial investment.

What Makes Internal Regulator Alternators a Practical Choice?

Internal regulator alternators simplify the installation process by incorporating the voltage regulator within the alternator itself. This design minimizes wiring complexity, making it an attractive option for auto parts distributors and repair services. They are typically used in older vehicle models, where retrofitting newer technology may not be feasible. Buyers should evaluate their inventory needs and the specific vehicles they service to ensure the right fit, as these alternators may be limited to certain applications.

Warum sollten Sie sich für Hochleistungsgeneratoren für Schwerlastanwendungen entscheiden?

High-output alternators are engineered to meet the electrical demands of vehicles with extensive accessory loads, such as sound systems or off-road lighting. They are commonly utilized in performance automotive markets and heavy-duty applications, where reliable power generation is crucial. While they offer significant benefits in terms of supporting additional electrical accessories, buyers must consider the higher upfront costs and the potential need for modifications during installation.

What Are the Advantages of Compact Alternators in Modern Vehicles?

Compact alternators are designed for vehicles with limited engine bay space, such as hybrids and small cars. Their smaller footprint allows manufacturers to optimize engine layouts, making them ideal for electric vehicle manufacturers and compact car production. While they provide the advantage of weight reduction and space efficiency, they typically have a lower output capacity. B2B buyers should weigh the trade-offs between size and electrical output when selecting compact alternators for their product offerings.

Key Industrial Applications of where is an alternator located

| Branche/Sektor | Specific Application of where is an alternator located | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Locating alternators in assembly lines for vehicle production | Ensures efficient assembly and quality control | Supplier reliability, component compatibility, and cost-effectiveness |

| Erneuerbare Energien | Integration of alternators in hybrid energy systems | Enhances energy efficiency and system reliability | Compliance with international standards, sourcing of durable materials |

| Transport & Logistik | Wartung der elektrischen Systeme von Flottenfahrzeugen | Reduziert Ausfallzeiten und Wartungskosten | Availability of spare parts, local service support, and warranty terms |

| Agriculture & Farming | Use of alternators in agricultural machinery | Improves equipment reliability and productivity | Access to local repair services, understanding of machinery specifications |

| Bergbau und Bauwesen | Deployment of alternators in heavy machinery | Increases operational efficiency and reduces failures | Durability under harsh conditions, sourcing of high-quality components |

How is ‘where is an alternator located’ utilized in the Automotive Manufacturing Industry?

In the automotive manufacturing sector, knowing the precise location of alternators is critical for assembly line efficiency. As vehicles are constructed, the alternator must be installed correctly to ensure that the electrical system functions effectively. This knowledge helps manufacturers streamline their assembly process, reduce errors, and maintain quality control. Buyers in this sector should consider the reliability of suppliers, the compatibility of components, and overall cost-effectiveness when sourcing alternators.

What role do alternators play in Renewable Energy Systems?

In renewable energy applications, particularly in hybrid systems, alternators are essential for converting mechanical energy into electrical energy. Their strategic location within these systems allows for effective energy generation and storage, enhancing overall system reliability. International buyers must ensure that their suppliers comply with relevant standards and provide durable materials that can withstand varying environmental conditions, which is particularly important in regions with extreme weather patterns.

How does the Transportation & Logistics Sector benefit from understanding alternator locations?

For the transportation and logistics industry, the location of alternators in fleet vehicles is crucial for maintaining the electrical systems that power essential operations. Knowing where the alternator is located facilitates easier maintenance and reduces vehicle downtime, ultimately lowering operational costs. B2B buyers should prioritize suppliers that offer readily available spare parts and local service support to ensure quick repairs and minimal disruptions.

Why is the location of alternators important in Agriculture & Farming Equipment?

In agriculture, alternators are often found in tractors and other machinery, where they play a vital role in powering electrical systems. Understanding their location allows for effective maintenance, ensuring that equipment remains operational during critical farming periods. Buyers in this sector should focus on sourcing from suppliers who provide access to local repair services and who understand the specific machinery requirements to enhance productivity.

How do Mining & Construction Industries leverage the knowledge of alternator locations?

In the mining and construction industries, alternators are integral to the functionality of heavy machinery. Their location impacts how easily maintenance can be performed, which is vital in reducing equipment failures and improving operational efficiency. Buyers in these sectors should look for high-quality components that can endure harsh working conditions, as well as suppliers who offer warranties and support services to minimize equipment downtime.

3 Common User Pain Points for ‘where is an alternator located’ & Their Solutions

Scenario 1: Difficulty Locating the Alternator in Complex Engine Bays

Das Problem:

Many B2B buyers, especially those in regions with diverse vehicle models, face significant challenges in locating the alternator due to the compact and intricate layouts of modern engine bays. In newer vehicles, the alternator can be buried beneath multiple components, making it difficult to access without detailed knowledge or guidance. This issue can lead to delays in repairs, increased labor costs, and frustration among mechanics and fleet managers who need to maintain vehicle uptime.

Die Lösung:

To effectively address this challenge, B2B buyers should invest in comprehensive repair manuals or access online databases that provide detailed diagrams and step-by-step guides for locating the alternator in specific vehicle models. Resources like Haynes Manuals or OEM service documentation can be invaluable. Additionally, utilizing tools such as mobile apps that offer visual guides or augmented reality features can enhance the ability to identify components quickly. Creating a network with local automotive parts suppliers can also facilitate faster access to specific parts, ensuring that any necessary replacements can be made promptly.

Scenario 2: Misdiagnosing Electrical Issues Related to the Alternator

Das Problem:

B2B buyers, particularly those managing fleets or automotive service centers, often encounter situations where symptoms of electrical failure (like dimming lights or battery warning lights) lead to misdiagnosis. Many technicians may assume the battery is at fault, overlooking the potential failure of the alternator. This can result in unnecessary battery replacements and further downtime, negatively impacting operational efficiency and customer satisfaction.

Die Lösung:

To mitigate misdiagnosis, it is crucial to implement a standardized troubleshooting protocol that includes testing the alternator’s output before concluding that the battery is the issue. Investing in diagnostic tools that can measure voltage output and identify alternator performance can enhance accuracy in assessments. Training staff on the electrical system’s interplay, including how to check the alternator’s health, will empower them to make informed decisions. Furthermore, utilizing diagnostic software that can interface with the vehicle’s onboard systems can provide real-time data on the alternator’s performance, helping to pinpoint issues more effectively.

Scenario 3: Challenges in Sourcing Quality Alternators

Das Problem:

B2B buyers face challenges in sourcing quality alternators, particularly in regions where the automotive parts market is flooded with counterfeit or subpar products. This not only affects vehicle performance but can also lead to warranty issues and increased long-term costs due to frequent replacements. Buyers need to ensure that they are obtaining reliable components that meet industry standards.

Die Lösung:

To navigate this sourcing challenge, B2B buyers should establish relationships with reputable suppliers and manufacturers known for their quality products. Conducting thorough research and leveraging platforms that provide ratings and reviews can help identify trustworthy sources. Implementing a vendor management system that tracks supplier performance and product quality will also enhance purchasing decisions. Additionally, buyers can consider joining industry associations or networks that provide access to certified suppliers and exclusive deals on high-quality alternators. This proactive approach not only secures reliable components but also fosters a strong supply chain that supports long-term operational efficiency.

Strategic Material Selection Guide for where is an alternator located

Welche Materialien werden üblicherweise beim Bau von Wechselstromgeneratoren verwendet?

When considering the materials used in alternators, several key options stand out due to their unique properties and performance characteristics. This analysis will focus on aluminum, steel, copper, and plastic, highlighting their advantages and disadvantages, especially for international B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Aluminum: A Lightweight and Corrosion-Resistant Choice

Aluminum is frequently used in alternator housings due to its lightweight nature and excellent corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for automotive applications. The main advantage of aluminum is its ability to reduce the overall weight of the vehicle, which can enhance fuel efficiency.

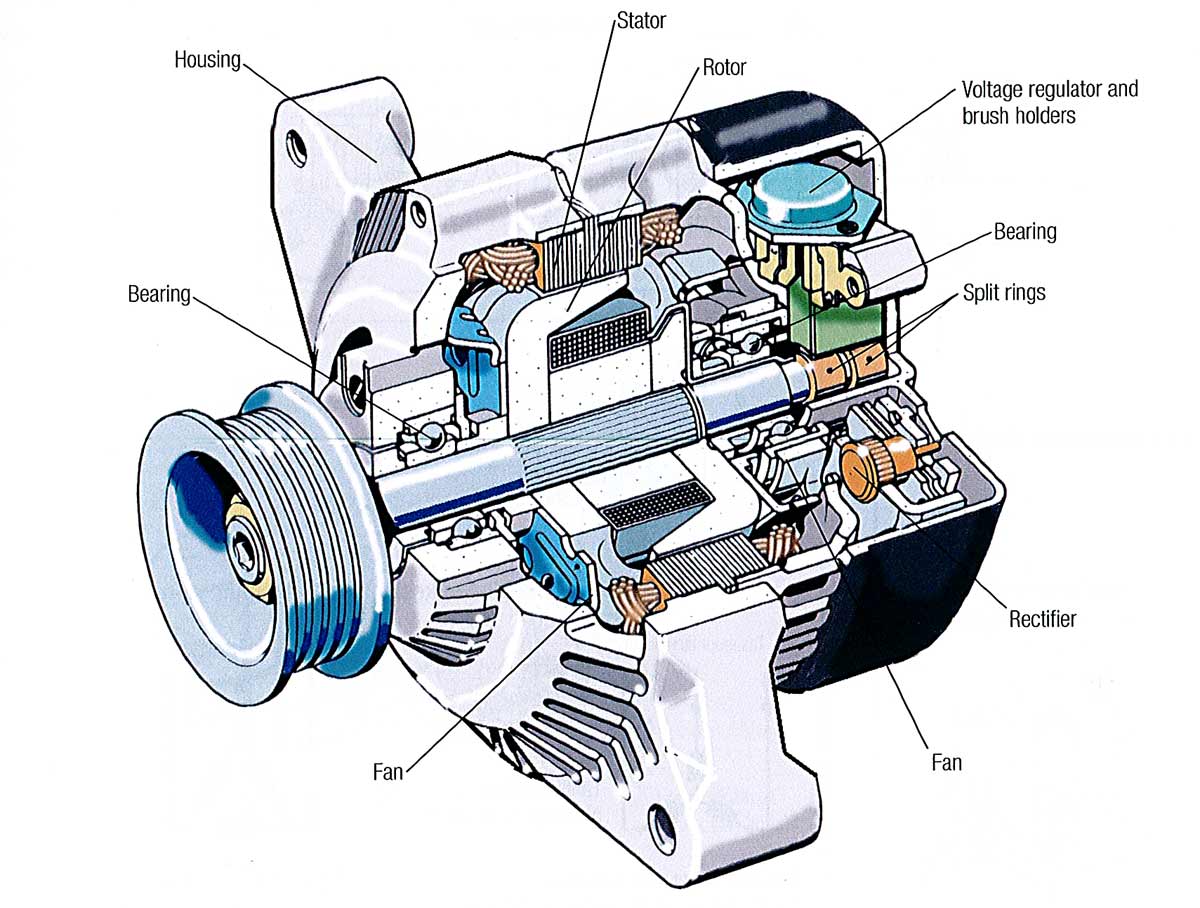

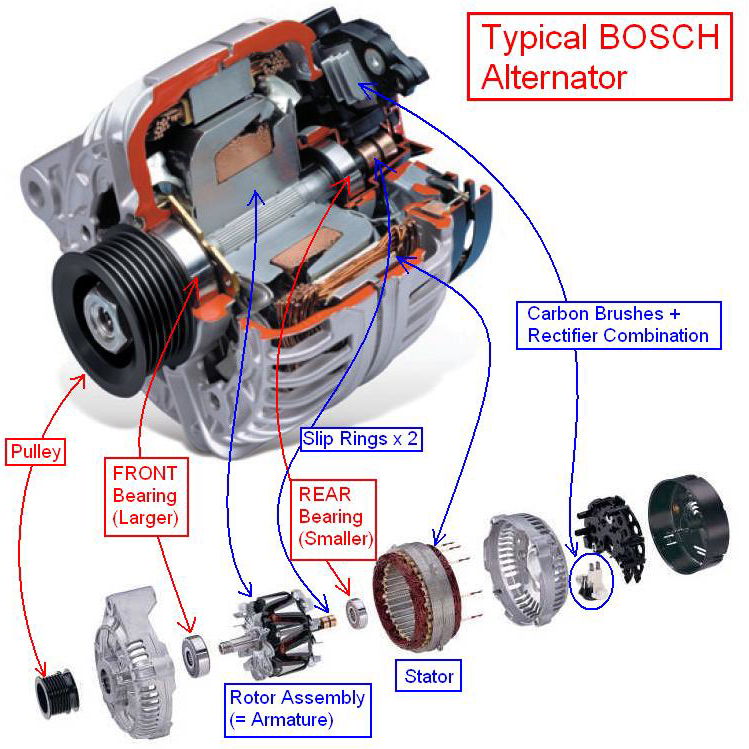

Illustrative image related to where is an alternator located

However, aluminum can be more expensive than other materials like steel, and its manufacturing process can be complex, requiring specialized techniques such as die casting. Additionally, while aluminum is durable, it may not withstand extreme mechanical stress as well as steel. For international buyers, compliance with standards like ASTM for aluminum alloys is essential, particularly in regions with stringent automotive regulations.

Stahl: Stärke und Langlebigkeit

Steel is another common material used in the construction of alternators, particularly for components that require high strength and durability, such as the frame and internal parts. Steel can handle higher temperatures and pressures compared to aluminum and is less prone to deformation under stress.

The primary disadvantage of steel is its weight, which can negatively impact vehicle performance and fuel efficiency. Additionally, steel is susceptible to corrosion unless treated with protective coatings. For buyers in humid or coastal regions, such as parts of Africa or the Middle East, corrosion resistance is a critical factor. Compliance with international standards like DIN can also affect material selection in these markets.

Copper: The Electrical Conductor

Copper is widely used in alternators for electrical windings due to its excellent conductivity. The material ensures efficient electricity generation and minimizes energy loss. Copper components can operate effectively at high temperatures, making them ideal for the demanding environment of an alternator.

However, copper is relatively expensive compared to aluminum and steel, which can raise overall production costs. Additionally, the weight of copper can contribute to the overall heft of the alternator, potentially affecting vehicle dynamics. International buyers should consider the fluctuating copper prices and ensure compliance with environmental regulations regarding copper mining and recycling, especially in regions focused on sustainability.

Kunststoff: Leicht und kosteneffektiv

Plastic is sometimes utilized in alternator components, particularly for non-structural parts such as covers or insulation. Its lightweight nature can contribute to overall vehicle weight reduction, and it is generally less expensive than metals. Plastic also offers good resistance to corrosion and can be molded into complex shapes.

The downside of plastic is its lower temperature and mechanical strength compared to metals, which may limit its application in high-stress areas of the alternator. Additionally, concerns regarding plastic waste and environmental impact are increasingly relevant for international buyers. Compliance with standards related to plastic materials, such as JIS in Japan or REACH in Europe, is crucial for ensuring product acceptance in various markets.

Übersichtstabelle zur Materialauswahl für Generatoren

| Material | Typical Use Case for where is an alternator located | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Bauteile | Leicht und korrosionsbeständig | Höhere Kosten und komplexe Herstellung | Mittel |

| Stahl | Frame and internal parts | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Korrosion | Mittel |

| Kupfer | Elektrische Wicklungen | Excellent conductivity and heat resistance | Teuer und schwer | Hoch |

| Kunststoff | Nicht-strukturelle Komponenten | Leicht und kostengünstig | Geringere Festigkeit und Temperaturbeständigkeit | Niedrig |

This analysis provides a comprehensive overview of the materials commonly used in alternator construction, helping B2B buyers make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for where is an alternator located

Was sind die wichtigsten Phasen im Herstellungsprozess von Lichtmaschinen?

The manufacturing process of alternators involves several critical stages that ensure the production of reliable and efficient electrical components. Each stage contributes to the overall quality and functionality of the alternator, which is vital for automotive applications.

Wie wird das Material für die Produktion von Wechselstromgeneratoren vorbereitet?

The first step in the manufacturing process is material preparation. High-quality materials are crucial for producing durable alternators. Common materials include aluminum for the casing, copper for the windings, and various steel alloys for internal components.

Manufacturers typically source these materials from reputable suppliers, ensuring compliance with international standards. They may conduct material inspections to verify that the specifications meet the required mechanical and electrical properties. This initial quality check is critical to avoid downstream issues.

Welche Umformtechniken werden bei der Herstellung von Wechselstromgeneratoren verwendet?

Once materials are prepared, the next stage is forming. This involves shaping components through various techniques such as die casting, stamping, and machining.

- Druckguss: This method is often used for creating the alternator housing. Aluminum is melted and poured into molds to form the outer shell, ensuring a precise fit and lightweight structure.

- Stempeln: Steel components, such as the rotor and stator cores, are typically produced through stamping. This process involves pressing sheets of metal into specific shapes, which reduces waste and enhances production efficiency.

- Bearbeitungen: Precision machining is employed to create internal components, ensuring they fit together correctly and function optimally. CNC (Computer Numerical Control) machines are commonly used for this purpose, allowing for high precision and repeatability.

Wie werden Lichtmaschinen zusammengebaut?

The assembly stage is where all the manufactured components come together. This process involves several sub-steps, including:

-

Inspektion von Bauteilen: Before assembly, each part undergoes an inspection to ensure it meets quality standards. This includes checking dimensions and surface finishes.

-

Unterbaugruppe: Components like the rotor, stator, and voltage regulator are often assembled separately before being integrated into the main alternator body. This allows for easier handling and troubleshooting.

-

Endmontage: The sub-assembled parts are then brought together. The rotor is fitted into the stator, and the pulley is attached. Electrical connections are made, and the entire unit is secured in the outer casing.

Welche Endbearbeitungsverfahren werden bei Lichtmaschinen angewendet?

Finishing processes enhance the durability and aesthetic appeal of alternators. Common techniques include:

- Oberflächenbehandlung: Components may undergo treatments such as anodizing or powder coating to improve corrosion resistance.

- Testing and Calibration: After assembly, alternators are tested for electrical output and efficiency. Calibration ensures that the voltage regulator is functioning correctly, maintaining optimal performance under various load conditions.

Welche Qualitätssicherungsstandards sollten B2B-Käufer berücksichtigen?

Quality assurance is paramount in the manufacturing of alternators, particularly for international B2B buyers. Adhering to recognized standards ensures that the products meet safety and performance benchmarks.

Welche internationalen Normen sind für die Herstellung von Lichtmaschinen relevant?

ISO 9001 is the most widely recognized quality management standard and is essential for manufacturers aiming to demonstrate their commitment to quality. Compliance with this standard indicates that a manufacturer has established quality management systems that enhance customer satisfaction and operational efficiency.

For electrical components like alternators, additional standards such as CE marking (for European markets) and API standards (for industrial applications) may also be relevant. These certifications ensure that products meet specific safety and environmental criteria.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle bei der Herstellung von Lichtmaschinen?

Quality control (QC) checkpoints are vital at various stages of alternator manufacturing. Key checkpoints include:

-

Eingangsqualitätskontrolle (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. It ensures that all materials meet specified quality standards before production begins.

-

In-Process-Qualitätskontrolle (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of components and assembly. This may involve dimensional checks and functional tests to identify any defects early in the production cycle.

-

Endkontrolle (FQC): After assembly, the completed alternator undergoes a final inspection. This includes electrical testing to verify output voltage and performance under load. Any units that fail these tests are either repaired or discarded.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

B2B buyers need to ensure that their suppliers adhere to stringent quality control measures. Here are several ways buyers can verify supplier QC:

Was sind die besten Praktiken für Lieferantenaudits?

Conducting supplier audits is one of the most effective methods for assessing a manufacturer’s quality control practices. Buyers should:

- Schedule regular audits to evaluate compliance with ISO 9001 and other relevant standards.

- Review the supplier’s quality management documentation, including quality manuals and inspection reports.

- Observe the manufacturing processes in action to assess adherence to specified quality control procedures.

How Can Buyers Leverage Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality practices. These services can:

- Conduct random inspections during various stages of production.

- Verify compliance with international standards.

- Provide detailed reports that highlight any discrepancies and suggest corrective actions.

Welche Feinheiten sollten internationale B2B-Einkäufer beachten?

When sourcing alternators from manufacturers in different regions, B2B buyers must consider several nuances:

-

Kulturelle Unterschiede: Understanding cultural nuances can facilitate better communication and relationship-building with suppliers, particularly in regions like Africa and the Middle East.

-

Einhaltung gesetzlicher Vorschriften: Buyers should familiarize themselves with local regulations regarding electrical components in their target markets. This ensures that products not only meet international standards but also comply with local laws.

-

Supply Chain Challenges: International buyers must be aware of potential supply chain disruptions and logistics issues that can affect delivery times and costs.

By understanding the manufacturing processes and quality assurance measures involved in alternator production, B2B buyers can make informed decisions, ensuring that they partner with reputable suppliers who deliver high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘where is an alternator located’

To effectively source information about the location of an alternator, especially for international B2B buyers, it is essential to follow a structured approach. This guide provides a practical checklist to ensure a comprehensive understanding of alternators, which can assist in procurement, training, or technical support.

Illustrative image related to where is an alternator located

Schritt 1: Identify Your Vehicle Type and Model

Understanding the specific vehicle type and model is crucial since the location of the alternator can vary widely. Different manufacturers may design their engines differently, and knowing the exact model allows for precise sourcing of relevant information. Collect details such as the make, model, year, and engine type, as this will streamline your search for accurate alternator location data.

Schritt 2: Consult Technical Manuals

Technical manuals and service guides are invaluable resources that provide detailed diagrams and specifications regarding the alternator’s location. Look for manuals specific to your vehicle’s model, as these documents often include step-by-step instructions for locating and servicing the alternator. Consider sourcing these manuals from reliable suppliers, as they can also offer insights into maintenance and troubleshooting.

Schritt 3: Utilize Online Automotive Forums

Engaging with online automotive forums can provide real-time insights from mechanics and automotive enthusiasts. These communities often discuss specific issues related to alternators, including common locations and any unique challenges faced with particular models. Participate in discussions or search for threads related to your vehicle to gather firsthand information.

Schritt 4: Check OEM and Aftermarket Supplier Websites

Original Equipment Manufacturer (OEM) and reputable aftermarket suppliers often have detailed product listings that include installation guides and diagrams. These resources can clarify where the alternator is located in various vehicle models. Ensure that the suppliers you check are well-reviewed and recognized in the automotive industry to guarantee the reliability of their information.

Illustrative image related to where is an alternator located

Schritt 5: Review Video Tutorials

Video tutorials can be a helpful visual aid in understanding where the alternator is located. Platforms like YouTube host countless instructional videos where mechanics demonstrate the process of locating and replacing alternators in various vehicles. Look for videos that are specific to your vehicle model for the most accurate guidance.

Schritt 6: Evaluate Local Mechanic Insights

Local mechanics or automotive specialists can provide personalized insights based on their experience. If possible, consult with professionals who have worked extensively with your vehicle type. They can offer practical advice on locating the alternator and may highlight common issues or tips that are not available in manuals or online resources.

Schritt 7: Document Findings for Future Reference

As you gather information, document your findings meticulously. Create a reference guide that includes diagrams, specifications, and any unique observations regarding the alternator’s location in your vehicle. This documentation will be a valuable resource for future maintenance or when discussing issues with suppliers or mechanics.

By following this structured checklist, B2B buyers can effectively source and understand where an alternator is located, ensuring informed procurement and maintenance decisions.

Comprehensive Cost and Pricing Analysis for where is an alternator located Sourcing

Was sind die wichtigsten Kostenkomponenten bei der Beschaffung von Generatoren?

When sourcing alternators, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materialien: The primary materials for an alternator include metals like aluminum and copper, which are essential for electrical conductivity and durability. Depending on the design and specifications, alternative materials might be used, which can influence costs.

-

Arbeit: Labor costs vary significantly based on the region of production. Countries with lower labor costs may offer competitive pricing, but this could also affect the quality of workmanship and the final product.

-

Fertigungsgemeinkosten: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce these costs, impacting the overall pricing.

-

Werkzeuge: The costs associated with molds and machinery required for production can be substantial, especially for custom alternators. This is particularly relevant for buyers requiring specific configurations or features.

-

Qualitätskontrolle (QC): Implementing stringent QC measures ensures product reliability but adds to the cost. Certifications like ISO 9001 can enhance trust but may also increase sourcing expenses.

-

Logistik: Shipping costs can vary based on the supplier’s location, chosen Incoterms, and the volume of the order. For international buyers, understanding freight options and customs duties is essential for budgeting.

-

Marge: Suppliers will build a profit margin into their pricing, which can vary based on market demand and competition.

Wie beeinflussen Preiseinflüsse die Beschaffung von Generatoren?

Several factors can influence the pricing of alternators, which B2B buyers should be aware of:

-

Volumen und Mindestbestellmenge (MOQ): Larger orders typically secure better pricing due to economies of scale. Buyers should negotiate MOQs to optimize costs.

-

Spezifikationen und Anpassung: Unique specifications or custom designs can significantly increase costs. Buyers should assess whether customization is essential or if standard models suffice.

-

Materialqualität und Zertifizierungen: Higher quality materials and recognized certifications often lead to increased costs but can enhance performance and longevity, providing a better total cost of ownership.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium, but they often provide better quality assurance and after-sales support.

-

Incoterms: Understanding the chosen Incoterms is crucial for international buyers as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can all impact total costs.

What Are Some Effective Buyer Tips for Cost-Efficiency in Alternator Sourcing?

To ensure cost-efficiency when sourcing alternators, buyers should consider the following strategies:

-

Preise aushandeln: Leverage volume purchasing to negotiate better rates. Building long-term relationships with suppliers can also yield additional discounts.

-

Gesamtbetriebskosten (TCO) bewerten: Assess not just the purchase price but also the costs associated with installation, maintenance, and potential downtime. Investing in a higher-quality alternator may save money in the long run.

-

Research International Pricing Nuances: Prices can vary significantly across regions like Africa, South America, the Middle East, and Europe. Understanding local market dynamics can help buyers make informed decisions.

-

Bleiben Sie über Markttrends auf dem Laufenden: Keeping abreast of industry trends, material costs, and emerging technologies can provide insights into potential price fluctuations and help buyers plan their sourcing strategies accordingly.

-

Lokale Lieferanten in Betracht ziehen: Sourcing from local suppliers can reduce logistics costs and lead times. This is particularly beneficial in regions with underdeveloped infrastructure.

Haftungsausschluss zu Preisen

Pricing for alternators can fluctuate based on market conditions, material availability, and geopolitical factors. Therefore, it’s advisable for buyers to obtain multiple quotes and conduct thorough due diligence before making procurement decisions.

Alternatives Analysis: Comparing where is an alternator located With Other Solutions

Understanding Alternatives to ‘Where Is an Alternator Located’

In the automotive industry, understanding the location and function of the alternator is crucial for effective vehicle maintenance and repair. However, there are alternative solutions and technologies that serve similar purposes in vehicle electrical systems. This analysis will compare the traditional alternator with two alternatives: the integrated starter-generator (ISG) and the flywheel generator system (FGS).

Vergleichstabelle

| Vergleichsaspekt | Where Is An Alternator Located | Integrierter Starter-Generator (ISG) | Flywheel Generator System (FGS) |

|---|---|---|---|

| Leistung | Reliable electricity generation for battery charging and vehicle systems | Enhanced efficiency with regenerative braking capabilities | High power output and quick response time |

| Kosten | Moderate (replacement costs range from $200 to $350) | Higher initial investment but potential long-term savings | High setup costs due to specialized equipment |

| Einfache Implementierung | Generally straightforward in older models; may be complex in newer designs | Requires modifications to the engine and electrical system | Complex installation requiring specialized knowledge |

| Wartung | Regular checks needed; can be replaced relatively easily | Geringerer Wartungsaufwand durch weniger bewegliche Teile | High maintenance due to mechanical wear over time |

| Bester Anwendungsfall | Standard combustion engine vehicles | Hybrid vehicles seeking improved fuel efficiency | High-performance applications where rapid power is needed |

Detaillierte Aufschlüsselung der Alternativen

Integrierter Starter-Generator (ISG)

The ISG system combines the functions of starting the engine and generating electricity in one unit. This technology is particularly beneficial in hybrid vehicles, where it enhances efficiency by capturing energy during braking and using it to assist the engine during acceleration. The main advantage of ISG is its ability to reduce fuel consumption and emissions, making it suitable for environmentally conscious markets. However, the complexity and higher initial costs can be prohibitive for some buyers, especially in regions where budget constraints are prevalent.

Flywheel Generator System (FGS)

The flywheel generator system offers a unique approach to energy generation, storing kinetic energy in a rotating flywheel. This energy can be converted back into electricity when needed, providing high power output and rapid response times. FGS is often utilized in applications requiring high performance, such as racing or heavy machinery. While it excels in power efficiency, the system’s high setup costs and ongoing maintenance needs can deter potential buyers, particularly in developing markets where cost-effectiveness is paramount.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

For B2B buyers, selecting the right electrical system solution hinges on specific operational requirements and budget considerations. If reliability and ease of maintenance are priorities, the traditional alternator remains a solid choice for most standard vehicles. In contrast, for those focused on sustainability and efficiency, the integrated starter-generator may provide long-term savings despite higher upfront costs. Lastly, if performance is the main concern, the flywheel generator system can deliver exceptional power but will require a greater investment in both installation and maintenance. Evaluating these aspects will help buyers make informed decisions aligned with their operational goals and market conditions.

Essential Technical Properties and Trade Terminology for where is an alternator located

What Are the Key Technical Properties of an Alternator’s Location in a Vehicle?

Understanding the technical specifications associated with alternators is crucial for B2B buyers in automotive parts and repair sectors. Here are some critical properties to consider:

Illustrative image related to where is an alternator located

-

Materialzusammensetzung:

The alternator is primarily constructed from aluminum and steel. Aluminum is lightweight, enhancing fuel efficiency, while steel provides durability. B2B buyers should prioritize suppliers that offer high-grade materials to ensure longevity and reliability, especially in harsh environments common in regions like Africa and the Middle East. -

Mechanismus der Kühlung:

Most alternators feature built-in cooling fans to dissipate heat generated during operation. This is vital for maintaining optimal performance and preventing damage. Buyers should inquire about the efficiency of cooling designs, as this can affect the alternator’s lifespan and overall performance in extreme temperatures. -

Elektrische Nennleistung:

Alternators are rated by their output capacity, usually expressed in amperes (A). Understanding this rating helps buyers select the right alternator for specific vehicle models and electrical demands. Higher output is essential for vehicles with extensive electrical systems, such as those equipped with advanced infotainment systems or multiple lighting options. -

Mounting Specifications:

The alternator’s mounting style varies among vehicle models and is crucial for installation. Specifications like bolt pattern and orientation can affect compatibility. B2B buyers should ensure that they are sourcing alternators that fit specific models to avoid costly installation issues. -

Reglertyp:

The type of voltage regulator (internal or external) can significantly impact the alternator’s performance. Internal regulators are standard in modern vehicles, providing more precise control over voltage output. Understanding the differences can help buyers make informed decisions about replacements or upgrades.

What Common Trade Terms Should B2B Buyers Know When Sourcing Alternators?

Navigating the automotive parts industry requires familiarity with specific jargon. Here are some key terms relevant to alternators:

-

OEM (Originalgerätehersteller):

OEM parts are made by the vehicle’s manufacturer or authorized suppliers. These components often guarantee compatibility and quality, making them a preferred choice for many buyers. Understanding the distinction between OEM and aftermarket parts is crucial for maintaining vehicle integrity. -

MOQ (Mindestbestellmenge):

This term refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can help in budgeting and inventory planning, especially when sourcing alternators in bulk for retail or service operations. -

RFQ (Angebotsanfrage):

An RFQ is a document sent to suppliers to request pricing and terms for specific products, like alternators. Crafting a clear RFQ is essential for obtaining accurate and competitive pricing, aiding in cost management for procurement. -

Incoterms:

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is vital for B2B transactions, especially when sourcing alternators from international suppliers. They clarify who is responsible for shipping, insurance, and tariffs, thus avoiding potential disputes. -

Ersatzteilmarkt:

This term refers to parts not made by the OEM but designed to fit the vehicle. Aftermarket alternators can provide cost-effective alternatives but may vary in quality and compatibility. Buyers should evaluate the reputation of aftermarket suppliers to ensure reliability. -

Garantiebedingungen:

Warranty terms specify the conditions under which a product, such as an alternator, is guaranteed against defects. Understanding these terms is essential for assessing the risk associated with purchases and ensuring long-term reliability.

By comprehending these technical properties and industry terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they meet the specific needs of their customers and enhance their operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the where is an alternator located Sector

What Are the Key Market Dynamics and Trends Influencing Alternator Sourcing?

The global market for automotive alternators is evolving rapidly, driven by technological advancements and changing consumer preferences. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for more efficient and durable alternators due to the rising complexity of modern vehicles. The integration of advanced technologies such as electric vehicles (EVs) and hybrid systems is reshaping sourcing strategies, with a focus on components that can support regenerative braking and energy efficiency.

Illustrative image related to where is an alternator located

Moreover, the increasing emphasis on performance and reliability in automotive components has led to a notable trend toward sourcing high-quality alternators that meet stringent industry standards. Buyers are increasingly seeking manufacturers that offer tailored solutions, including customized alternators designed to fit specific vehicle models. This trend is particularly evident in emerging markets, where a diverse range of vehicles requires adaptable sourcing strategies.

Additionally, the rise of e-commerce platforms is streamlining the procurement process for B2B buyers. Online sourcing allows for better price comparison, access to a wider range of suppliers, and efficient logistics management. As buyers in regions like Nigeria and Saudi Arabia look to optimize their supply chains, understanding the location and specifications of alternators becomes crucial for effective inventory management and cost control.

How Is Sustainability and Ethical Sourcing Impacting the Alternator Market?

Sustainability is becoming a critical consideration for B2B buyers in the automotive sector, influencing sourcing decisions for alternators. The environmental impact of manufacturing processes, especially concerning the extraction of raw materials, is under increased scrutiny. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or adopting energy-efficient manufacturing techniques.

Ethical sourcing is also gaining traction, with buyers seeking suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential benchmarks for evaluating potential suppliers. These certifications not only enhance the credibility of the supplier but also align with the buyers’ corporate social responsibility (CSR) goals.

Furthermore, the shift towards green technologies, including the use of alternators in electric and hybrid vehicles, underscores the importance of sourcing components that minimize environmental impact. Buyers are encouraged to seek out suppliers who are investing in innovative materials and technologies that contribute to a circular economy, thereby reducing waste and promoting sustainability in the automotive supply chain.

What Is the Historical Context of Alternator Development and Its Relevance to Today’s B2B Market?

The alternator has evolved significantly since its introduction in the early 20th century. Originally designed as a simple generator, advancements in technology have transformed it into a sophisticated component essential for modern vehicles. The transition from DC generators to AC alternators in the 1960s marked a pivotal moment, enhancing efficiency and reliability.

In recent decades, the evolution of automotive technology, including the shift towards electric and hybrid vehicles, has further influenced the design and functionality of alternators. Today’s alternators are equipped with smart technology, allowing them to communicate with a vehicle’s electronic control unit (ECU) to optimize performance and energy management.

This historical context is vital for B2B buyers as it highlights the need for sourcing partners who understand the complexities of modern alternators. Buyers should seek suppliers with a proven track record in innovation and adaptation to emerging technologies, ensuring that their sourcing strategies align with the latest advancements in automotive engineering. Understanding this evolution not only informs purchasing decisions but also positions buyers to anticipate future trends in the automotive sector.

Frequently Asked Questions (FAQs) for B2B Buyers of where is an alternator located

-

How do I locate the alternator in my vehicle?

To find the alternator, first open the hood and locate the engine. The alternator is typically mounted on the front side of the engine, connected to a serpentine belt that drives it. It is a cylindrical component, often silver or grey, with a fan at one end for cooling. If the vehicle has a tightly packed engine bay, you may need to look closely among other components. Refer to your vehicle’s service manual for specific diagrams and details to assist in locating it. -

What are the common signs that an alternator needs replacement?

Signs of a failing alternator include dimming or flickering headlights, electrical malfunctions, and difficulty starting the vehicle. If the battery warning light on the dashboard illuminates, it may indicate that the alternator isn’t charging the battery properly. Additionally, unusual noises, such as grinding or whining, can signal internal issues with the alternator. Regular maintenance checks can help identify these issues before they lead to complete failure. -

What factors should I consider when sourcing alternators from international suppliers?

When sourcing alternators internationally, consider the supplier’s reputation, quality certifications, and compliance with industry standards. Evaluate their production capacity, lead times, and ability to meet your specific requirements, such as customization options. Additionally, assess their logistics capabilities and the availability of after-sales support to ensure a smooth procurement process. Conducting thorough due diligence will help mitigate risks associated with international trade. -

How can I verify the quality of alternators from suppliers?

To verify the quality of alternators, request samples and conduct performance tests to assess their functionality and durability. Look for certifications such as ISO and compliance with local automotive standards. Additionally, inquire about the supplier’s quality assurance processes and any warranty or guarantee they offer. Customer reviews and testimonials can also provide insights into the supplier’s reliability and the quality of their products. -

What customization options are typically available for alternators?

Many suppliers offer customization options such as varying voltage outputs, design specifications, and finishes. Depending on your requirements, you may also request specific mounting configurations or electrical connections. Discuss your needs with potential suppliers to understand the range of customization they can provide, as well as any associated costs and lead times. This ensures that the alternators meet the unique demands of your applications. -

Was ist die Mindestbestellmenge (MOQ) für Lichtmaschinen?

The MOQ for alternators can vary significantly between suppliers, often influenced by production capabilities and the specific model requested. Some suppliers may set MOQs as low as 50 units, while others may require higher quantities. It’s essential to clarify MOQs during negotiations and consider your budget and inventory needs. If you’re unsure about meeting a supplier’s MOQ, discuss options for partial orders or consolidating orders with other buyers. -

What payment terms are commonly offered by alternator suppliers?

Payment terms can vary widely depending on the supplier and your relationship with them. Common terms include upfront payments, 30-day net terms, or payment upon delivery. Some suppliers may offer discounts for early payments or larger orders. It’s crucial to negotiate favorable terms that align with your cash flow and business needs. Ensure that all payment terms are clearly outlined in the contract to avoid any misunderstandings. -

How can I manage logistics and shipping when sourcing alternators internationally?

Efficient logistics management is vital when sourcing alternators internationally. Collaborate with suppliers to understand their shipping methods, delivery times, and costs. Consider using freight forwarders who specialize in international shipments to streamline the process. It’s also important to factor in customs regulations and duties for your destination country. Establishing a clear communication line with your supplier can help address any potential issues that may arise during shipping.

Top 3 Where Is An Alternator Located Manufacturers & Suppliers List

1. Haynes – Alternators

Domäne: us.haynes.com

Registriert: 1996 (29 Jahre)

Einleitung: This company, Haynes – Alternators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Paulins Tire – Alternators

Domäne: paulinstire.com

Registriert: 2010 (15 Jahre)

Einleitung: Alternators are a part of your vehicle’s charging system, which includes the battery, voltage regulator, and the alternator itself. They generate electrical currents to power all electrical components in the car, such as headlights and dashboard lights. Located at the front of the engine, alternators are powered by the engine’s serpentine belt and use the crankshaft’s power to create electrical cu…

3. Family Handyman – Alternator Replacement Guide

Domäne: familyhandyman.com

Registriert: 1996 (29 Jahre)

Einleitung: Total Time: 1 to 3 hours, Complexity: Intermediate, Cost: $200 to $350, Tools Required: Car battery charger, Digital multimeter, Rags, Socket/ratchet set, Wrench set, Materials Required: Alternator, Disposable gloves.

Strategic Sourcing Conclusion and Outlook for where is an alternator located

In summary, understanding the location and function of an alternator is vital for B2B buyers involved in automotive sourcing and maintenance. The alternator, typically situated at the front of the engine and connected via a serpentine belt, plays a crucial role in generating electricity to power a vehicle’s electrical systems and charge the battery. Identifying the alternator’s position can streamline repair processes and enhance vehicle maintenance strategies, ultimately reducing downtime and operational costs.

For international buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, strategic sourcing of high-quality alternators and automotive parts is essential. Leveraging local suppliers or establishing relationships with international manufacturers can lead to improved supply chain efficiency and cost-effectiveness.

Looking ahead, as automotive technology continues to evolve, staying informed about alternator advancements and their implications on vehicle performance will be critical. We encourage B2B buyers to explore partnerships that prioritize quality and reliability in sourcing alternators, ensuring their fleets remain operational and efficient. Embrace these insights to enhance your sourcing strategies and drive your business forward.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.