Introduction: Navigating the Global Market for what is a starting motor

When it comes to sourcing a starting motor, B2B buyers face the challenge of navigating a complex global market filled with diverse options and suppliers. A starting motor is not just a component; it is the heartbeat of internal combustion vehicles, ensuring that engines ignite and run smoothly. This guide provides a comprehensive overview of starting motors, including types, applications, and critical factors for supplier vetting. By addressing cost considerations and performance metrics, we aim to equip international buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Nigeria and Brazil—with the insights necessary for informed purchasing decisions.

As the automotive industry evolves, understanding the intricacies of starting motors becomes essential for businesses looking to optimize their fleet operations or aftermarket services. This guide will delve into the mechanics of starting motors, the various types available, and their specific applications across different vehicle categories. Moreover, we will discuss the importance of selecting reputable suppliers to ensure quality and reliability, as well as how to evaluate costs effectively. By arming yourself with this knowledge, you can confidently navigate the global market, making choices that enhance operational efficiency and drive your business success.

Inhaltsverzeichnis

- Top 5 What Is A Starting Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is a starting motor

- Understanding what is a starting motor Types and Variations

- Key Industrial Applications of what is a starting motor

- 3 Common User Pain Points for ‘what is a starting motor’ & Their Solutions

- Strategic Material Selection Guide for what is a starting motor

- In-depth Look: Manufacturing Processes and Quality Assurance for what is a starting motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a starting motor’

- Comprehensive Cost and Pricing Analysis for what is a starting motor Sourcing

- Alternatives Analysis: Comparing what is a starting motor With Other Solutions

- Essential Technical Properties and Trade Terminology for what is a starting motor

- Navigating Market Dynamics and Sourcing Trends in the what is a starting motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is a starting motor

- Strategic Sourcing Conclusion and Outlook for what is a starting motor

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

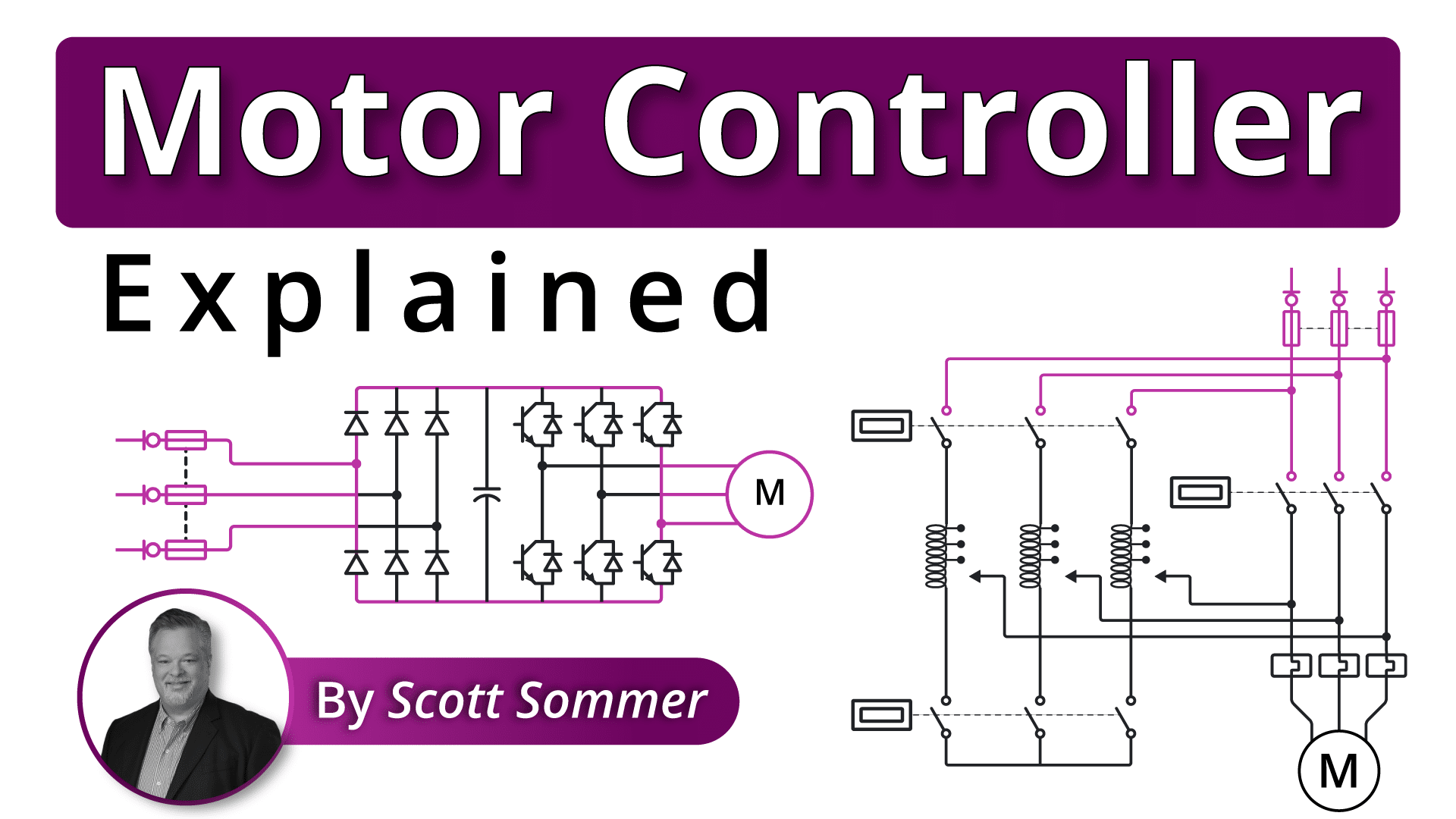

Understanding what is a starting motor Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| DC Starter Motors | Operate on direct current, high torque for brief periods. | Automotive, marine applications, heavy machinery. | Pros: High torque, reliable. Cons: Limited lifespan due to wear. |

| Untersetzungsgetriebe-Starter | Use a gear system to enhance torque output. | Heavy-duty vehicles, construction equipment. | Pros: Increased efficiency, compact design. Cons: More complex, higher initial cost. |

| Permanentmagnet-Starter | Utilize permanent magnets for increased efficiency. | Electric vehicles, hybrid vehicles. | Pros: Lightweight, high efficiency. Cons: Sensitive to heat, higher cost. |

| Bendix Drive Starters | Incorporate a drive mechanism to engage/disengage. | Allgemeine Automobilanwendungen. | Pros: Simple design, effective. Cons: Mechanical wear over time. |

| Leistungsstarke Anlasser | Designed for racing or high-demand applications. | Motorsports, performance vehicles. | Pros: Enhanced power, lightweight. Cons: Higher price, may require specific installation. |

What are DC Starter Motors and Their B2B Relevance?

DC starter motors are the most common type, widely used in traditional internal combustion engine vehicles. They operate on direct current and are designed to deliver a high torque output for short durations, making them ideal for starting engines. B2B buyers in automotive, marine, and heavy machinery sectors should consider their reliability and performance under typical operating conditions. However, the limited lifespan due to wear and tear can be a concern, necessitating regular maintenance and timely replacements.

How Do Gear Reduction Starters Enhance Performance?

Gear reduction starters utilize a gear system to amplify the torque produced by the motor. This feature makes them particularly suitable for heavy-duty vehicles and construction equipment that require significant starting power. For B2B buyers, the increased efficiency and compact design are key advantages, allowing for better space management in machinery. However, the complexity of their design can lead to higher initial costs, which should be weighed against the long-term benefits of performance and reliability.

Welche Vorteile bieten Permanentmagnet-Starter?

Permanent magnet starters are known for their high efficiency and lightweight design, making them increasingly popular in electric and hybrid vehicles. Their ability to provide consistent performance makes them appealing to B2B buyers focused on sustainability and energy efficiency. However, potential sensitivity to heat and a higher upfront cost can be drawbacks. Businesses should evaluate their operational environment and specific vehicle requirements when considering this type of starter motor.

Why Choose Bendix Drive Starters for General Applications?

Bendix drive starters incorporate a mechanism that allows for the engagement and disengagement of the starter gear with the engine flywheel. This design is prevalent in general automotive applications due to its simplicity and effectiveness. B2B buyers will appreciate the straightforward installation and maintenance, although mechanical wear over time can lead to failures. Understanding the operational demands and expected lifespan can guide purchasing decisions for fleets and service operations.

Was macht Hochleistungsstarter ideal für den Motorsport?

High-performance starters are specifically designed to meet the rigorous demands of racing and high-performance vehicles. They provide enhanced power and are typically lighter than standard starters, making them ideal for competitive environments. B2B buyers in the motorsports industry should consider the benefits of improved acceleration and reduced weight. However, the higher price point and potential need for specialized installation must be factored into the overall budget and project timelines.

Key Industrial Applications of what is a starting motor

| Branche/Sektor | Specific Application of what is a starting motor | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Engine assembly in vehicles | Ensures reliable vehicle startups, enhancing customer satisfaction | Quality certifications, compatibility with various engine types |

| Landwirtschaft | Starting motors in tractors and heavy farm equipment | Increases operational efficiency and reduces downtime | Durability in harsh environments, availability of spare parts |

| Bauwesen | Use in heavy machinery like excavators and cranes | Enhances productivity by ensuring quick machine startups | Load capacity, resistance to vibration and shock |

| Marine | Starting motors for boats and ships | Reliable engine ignition critical for safety and operation | Corrosion resistance, performance in varying temperatures |

| Erneuerbare Energien | Wind turbines and solar panel tracking systems | Facilitates efficient energy generation | Environmental certifications, compatibility with existing systems |

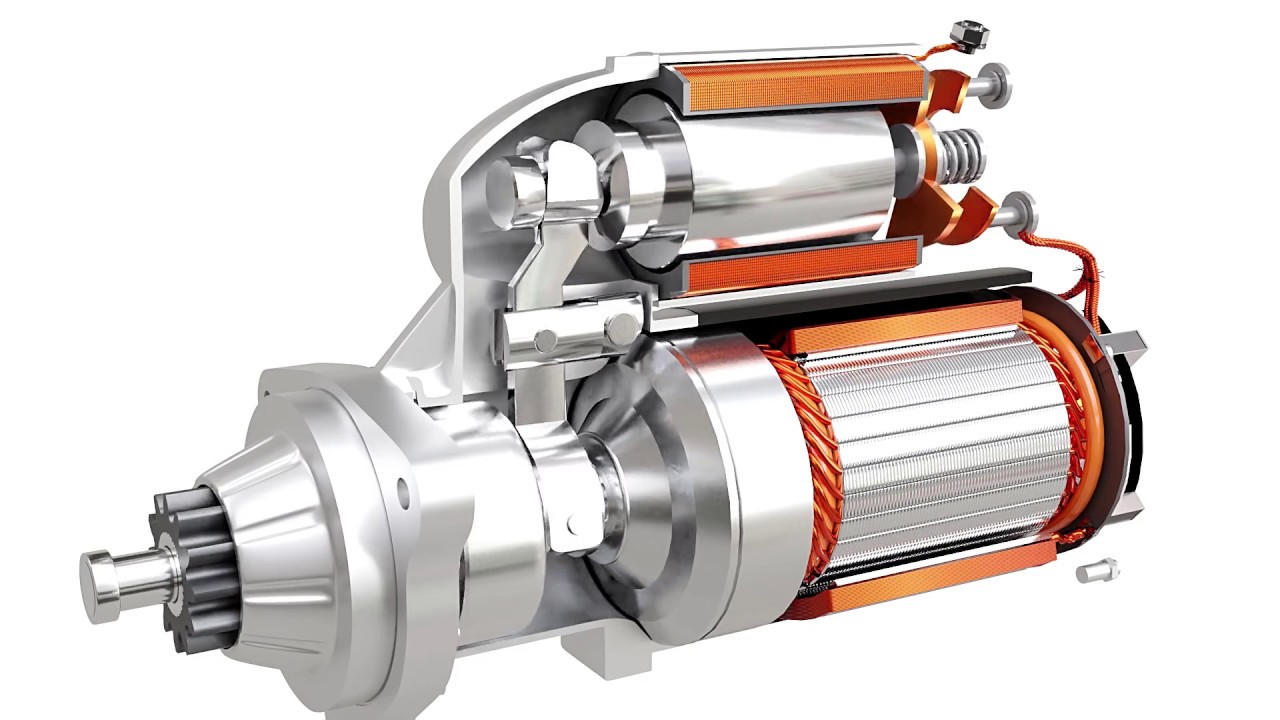

How is a Starting Motor Used in the Automotive Manufacturing Sector?

In the automotive manufacturing sector, starting motors play a crucial role in engine assembly. They are integral to ensuring that vehicles can start reliably, which is essential for meeting customer expectations. Automotive manufacturers must consider sourcing high-quality starter motors that are compatible with various engine types and configurations. Additionally, quality certifications are vital to guarantee performance and reliability, which can significantly affect the brand’s reputation.

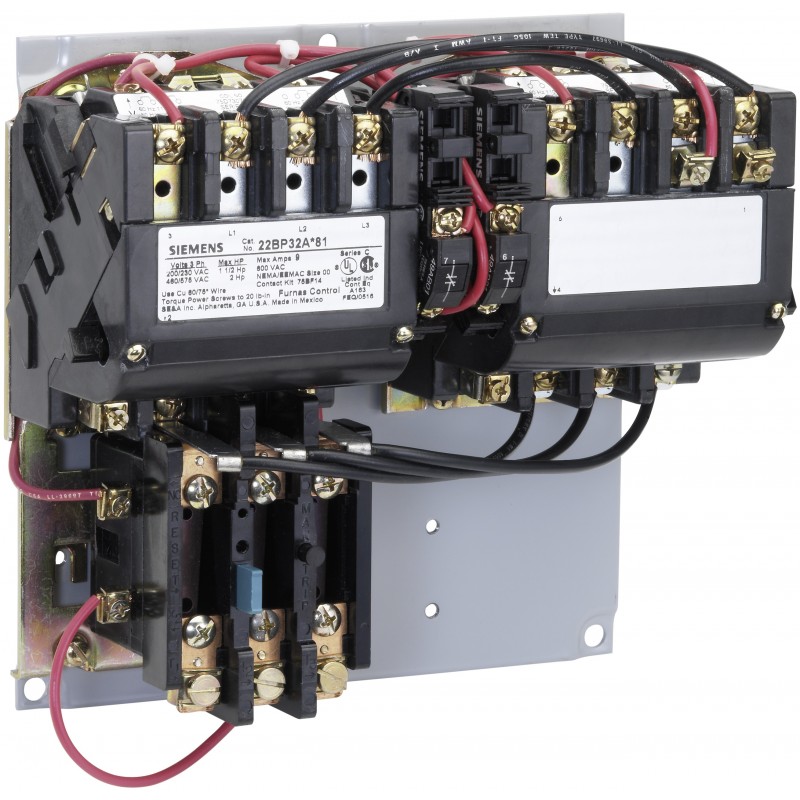

Illustrative image related to what is a starting motor

What Role Does a Starting Motor Play in Agriculture?

In agriculture, starting motors are commonly used in tractors and other heavy farm equipment. These motors are essential for ensuring that machinery starts quickly, thereby increasing operational efficiency and minimizing downtime during critical planting and harvesting seasons. Buyers in this sector should focus on sourcing durable starter motors that can withstand harsh environmental conditions, as well as ensuring the availability of spare parts to maintain equipment reliability.

How Are Starting Motors Utilized in the Construction Industry?

Starting motors are vital in the construction industry, particularly in heavy machinery such as excavators and cranes. These motors facilitate quick engine startups, enhancing productivity on job sites where time is often of the essence. When sourcing starting motors for construction equipment, companies need to prioritize components that can handle heavy loads and resist vibration and shock, ensuring that machinery operates smoothly in demanding conditions.

What is the Importance of Starting Motors in the Marine Sector?

In the marine industry, starting motors are critical for the operation of boats and ships. They ensure reliable engine ignition, which is crucial for safety and effective operation on water. Marine buyers should consider sourcing starter motors with corrosion resistance and the ability to perform under varying temperatures, as these factors significantly influence longevity and reliability in marine applications.

How Do Starting Motors Contribute to Renewable Energy Applications?

Starting motors are increasingly being used in renewable energy applications, such as wind turbines and solar panel tracking systems. They facilitate efficient energy generation by ensuring that systems start and operate effectively. When sourcing starting motors for these applications, businesses should look for environmental certifications and compatibility with existing systems to ensure seamless integration and compliance with sustainability goals.

3 Common User Pain Points for ‘what is a starting motor’ & Their Solutions

Scenario 1: Navigating Starter Motor Selection for Diverse Applications

Das Problem: B2B buyers often encounter difficulties in selecting the right starter motor for various applications, particularly when dealing with a fleet of vehicles that includes both passenger cars and commercial trucks. The challenge lies in understanding the specific requirements of each vehicle type, as different engines demand starter motors with varying torque outputs, dimensions, and electrical specifications. This misalignment can lead to costly downtime, increased maintenance expenses, and potential damage to the vehicles.

Die Lösung: To effectively source the correct starter motors, buyers should develop a comprehensive inventory management system that catalogs the specifications of each vehicle in their fleet. This system should include details such as engine size, type of fuel, and existing starter motor specifications. When approaching suppliers, buyers can provide this data to ensure compatibility and performance. Additionally, consulting with manufacturers for custom solutions can yield starter motors that meet unique operational requirements, thus avoiding performance issues and reducing the risk of premature failure.

Scenario 2: Understanding the Impact of Environmental Conditions on Starter Motor Performance

Das Problem: Buyers in regions with extreme environmental conditions—such as high humidity, excessive heat, or severe cold—often face challenges with starter motor reliability. For instance, in tropical climates, moisture can lead to corrosion, while in colder climates, battery performance may degrade, affecting starter functionality. This situation can result in unexpected vehicle failures, increased repair costs, and operational inefficiencies, especially for businesses reliant on consistent transportation.

Die Lösung: To mitigate these challenges, buyers should prioritize sourcing starter motors that are specifically designed for their operating environment. This can involve selecting motors with corrosion-resistant coatings and enhanced insulation to prevent moisture-related issues. Furthermore, regular maintenance checks should be instituted, focusing on battery health and electrical connections, which are critical for starter motor performance. Establishing relationships with local suppliers who understand regional challenges can also lead to tailored solutions that enhance durability and reliability.

Scenario 3: Dealing with Starter Motor Failure and Its Ripple Effects

Das Problem: When a starter motor fails, it not only impacts the specific vehicle but can also create a ripple effect throughout the business operations. For example, a breakdown in a delivery truck can lead to delayed shipments, dissatisfied customers, and potentially lost revenue. B2B buyers often find it difficult to determine the root cause of starter motor failures, which can result from poor quality parts, improper installation, or lack of maintenance.

Die Lösung: To address this issue, buyers should implement a proactive maintenance program that includes regular inspections and testing of starter motors as part of their overall vehicle maintenance strategy. This program should incorporate diagnostic tools to assess starter motor performance and identify early signs of wear or malfunction. Additionally, buyers should establish partnerships with reputable suppliers who provide high-quality starter motors and can offer support and advice on installation practices. Investing in quality parts and training for installation can significantly reduce failure rates and ensure operational continuity.

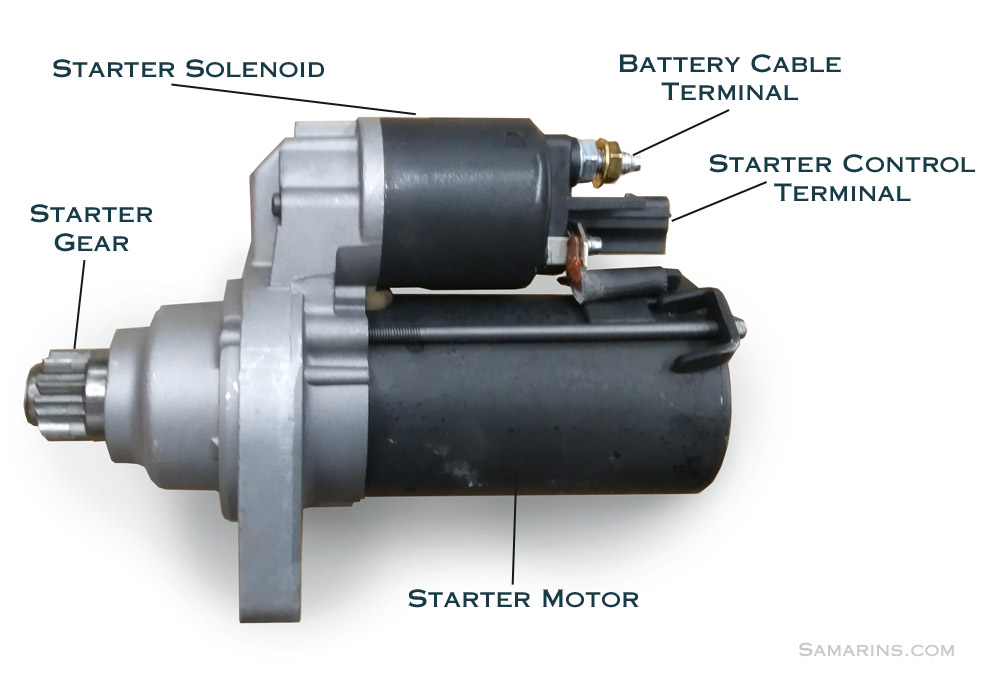

Strategic Material Selection Guide for what is a starting motor

Welche Materialien werden üblicherweise in Anlasser-Motoren verwendet?

When selecting materials for starter motors, it is essential to consider their properties, performance, and suitability for various applications. Here, we analyze four common materials used in the manufacturing of starter motors: steel, aluminum, copper, and plastic composites.

Wie verhält sich Stahl in Anlasseranwendungen?

Steel is a widely used material in starter motors, particularly for components that require high strength and durability. Its key properties include high tensile strength and excellent wear resistance, making it suitable for the mechanical stresses experienced during engine starts. Steel can withstand significant temperature variations, typically rated for high temperatures, which is crucial in automotive applications.

Vorteile: Steel components are durable and can handle the high torque demands of starter motors. They are also relatively cost-effective compared to other metals, making them a popular choice for manufacturers.

Nachteile: However, steel is prone to corrosion if not properly treated or coated, which can lead to premature failure in harsh environments. Additionally, the manufacturing process can be more complex due to the need for machining and finishing.

Auswirkungen auf die Anwendung: Steel is compatible with various media, including oil and fuel, which is essential for automotive applications.

Überlegungen für internationale Käufer: Buyers from regions like Africa and the Middle East should ensure that steel components comply with local standards for corrosion resistance, especially in humid or coastal environments.

Welche Rolle spielt Aluminium in Anlassern?

Aluminum is increasingly utilized in starter motor applications due to its lightweight nature and good thermal conductivity. It offers a lower weight alternative to steel, which can improve overall vehicle efficiency. Aluminum components typically have good corrosion resistance, especially when anodized.

Vorteile: The primary advantage of aluminum is its lightweight property, which can contribute to fuel efficiency in vehicles. It also has a lower thermal expansion coefficient, reducing the risk of component failure due to thermal cycling.

Illustrative image related to what is a starting motor

Nachteile: On the downside, aluminum is generally less strong than steel, which may limit its use in high-stress applications. Additionally, it can be more expensive to manufacture due to the required processing techniques.

Auswirkungen auf die Anwendung: Aluminum is suitable for applications where weight reduction is crucial, such as in electric or hybrid vehicles.

Überlegungen für internationale Käufer: Buyers should consider the specific aluminum grades and treatments that meet international standards, such as ASTM or DIN, to ensure performance and longevity.

Why is Copper Important in Starter Motor Design?

Copper is primarily used in starter motors for electrical connections and windings due to its excellent electrical conductivity. It ensures efficient power transfer from the battery to the starter motor, which is critical for reliable engine starting.

Vorteile: The key advantage of copper is its superior conductivity, which minimizes energy loss and improves the efficiency of the starter motor.

Nachteile: However, copper is more expensive than aluminum and can be prone to corrosion if not properly insulated or coated. This can lead to electrical failures over time.

Auswirkungen auf die Anwendung: Copper is compatible with various electrical media, making it ideal for high-performance applications.

Überlegungen für internationale Käufer: Buyers should ensure that copper components comply with international electrical standards and consider the environmental impact of copper mining and processing.

How Do Plastic Composites Enhance Starter Motor Performance?

Plastic composites are increasingly used in starter motors for non-structural components, such as housings and insulation. These materials are lightweight and can provide good thermal and electrical insulation.

Vorteile: The primary advantage of plastic composites is their resistance to corrosion and lightweight nature, which can contribute to overall vehicle efficiency.

Nachteile: However, they may not withstand high temperatures or mechanical stresses as well as metals, limiting their use in high-performance applications.

Auswirkungen auf die Anwendung: Plastic composites are suitable for applications where weight reduction and insulation are critical, but they may not be suitable for load-bearing components.

Überlegungen für internationale Käufer: Buyers should ensure that plastic composites meet relevant standards for thermal and mechanical performance in their specific regions.

Illustrative image related to what is a starting motor

Summary of Material Selection for Starter Motors

| Material | Typical Use Case for what is a starting motor | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Structural components like housings and gears | Hohe Festigkeit und Haltbarkeit | Ohne Behandlung korrosionsanfällig | Mittel |

| Aluminium | Lightweight components in high-efficiency vehicles | Leichtes Gewicht, gute Wärmeleitfähigkeit | Geringere Festigkeit als Stahl | Hoch |

| Kupfer | Elektrische Anschlüsse und Wicklungen | Hervorragende elektrische Leitfähigkeit | Teuer und anfällig für Korrosion | Hoch |

| Kunststoffverbundwerkstoffe | Nicht-strukturelle Komponenten wie Gehäuse | Korrosionsbeständig und leicht | Begrenzte Hochtemperaturleistung | Mittel |

This comprehensive analysis provides B2B buyers with valuable insights into material selection for starter motors, enabling informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a starting motor

Was sind die wichtigsten Schritte im Herstellungsprozess eines Anlassers?

The manufacturing process of a starter motor encompasses several critical stages, each contributing to the motor’s overall performance and reliability. Understanding these stages is essential for B2B buyers seeking to evaluate suppliers effectively.

Wie wird das Material für die Anlasserproduktion vorbereitet?

The first stage in manufacturing a starter motor involves the careful selection and preparation of materials. Typically, manufacturers use high-grade steel, aluminum, and copper for various components. The selection of these materials is crucial due to their impact on durability and performance.

Illustrative image related to what is a starting motor

After selection, the materials undergo treatment processes such as heat treatment and surface hardening to enhance their mechanical properties. This preparation ensures that components can withstand the high torque and electrical demands placed on the starter motor during operation.

What Forming Techniques Are Used in Starter Motor Production?

The forming stage involves shaping the prepared materials into the necessary components. This typically includes processes such as:

- Stanzen: Used for creating metal parts, like the housing and end plates, which form the outer structure of the starter motor.

- Bearbeitung: Precision machining is applied to components such as the armature and rotor to ensure they meet tight tolerances essential for effective operation.

- Gießen: Some parts may be cast using aluminum alloys to reduce weight while maintaining strength.

These techniques are vital for ensuring that the components fit together seamlessly, which is essential for the motor’s functionality and efficiency.

What Does the Assembly Process Entail for a Starter Motor?

Assembly is a crucial phase where individual components come together to create the finished product. This process typically involves:

- Komponentenintegration: The motor’s core components, such as the armature, rotor, and solenoid, are carefully assembled. Each part must be aligned accurately to ensure optimal performance.

- Verdrahtung und elektrische Anschlüsse: Electrical connections are made to integrate the starter motor with the vehicle’s electrical system. This step requires precision to avoid future failures.

- Qualitätskontrollen während der Montage: Quality Control (QC) checkpoints are established during assembly to ensure that components meet specifications before final assembly.

The assembly process is often performed in a cleanroom environment to minimize contamination, which can affect performance.

How Is the Finishing Process Completed for a Starter Motor?

The finishing stage of manufacturing is where the starter motor receives its final touches. This includes:

- Oberflächenbehandlung: Parts may undergo additional treatments such as painting or powder coating to enhance corrosion resistance and aesthetic appeal.

- Endmontage und Prüfung: Once the finishing touches are applied, the starter motor undergoes final assembly. This includes installing protective covers and ensuring all components are securely fastened.

What International Quality Standards Are Relevant for Starter Motor Manufacturing?

Quality assurance in starter motor manufacturing is critical, especially for international B2B buyers. Several standards ensure that products meet safety and performance criteria:

- ISO 9001: This international standard outlines criteria for a quality management system (QMS). Adhering to ISO 9001 demonstrates a commitment to quality and customer satisfaction.

- CE-Kennzeichnung: Required for products sold in the European Economic Area, the CE mark indicates compliance with EU safety, health, and environmental protection standards.

- API-Standards: In regions where automotive components must meet specific performance standards, API (American Petroleum Institute) certifications may be relevant.

These standards help B2B buyers ensure that their suppliers maintain high-quality manufacturing processes.

What QC Checkpoints Are Essential in Starter Motor Production?

Quality Control (QC) checkpoints are critical in ensuring that each starter motor meets the required specifications. Key checkpoints include:

- Eingangsqualitätskontrolle (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility. Materials that do not meet specifications are rejected.

- In-Process-Qualitätskontrolle (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This includes measuring tolerances and checking assembly accuracy.

- Endkontrolle (FQC): The finished starter motors undergo a series of tests to verify functionality, including electrical testing and torque performance assessments.

These checkpoints ensure that only high-quality products reach the market, reducing the risk of failures in the field.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

For B2B buyers, verifying a supplier’s quality control practices is essential. Here are actionable steps:

Illustrative image related to what is a starting motor

- Durchführung von Lieferantenaudits: Regular audits can assess compliance with quality standards and manufacturing processes. This allows buyers to identify any potential weaknesses in the supplier’s QC system.

- Qualitätsberichte anfordern: Suppliers should provide documentation detailing their QC processes, including inspection reports and compliance certifications. This information is crucial for ensuring that the supplier meets industry standards.

- Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and QC processes. This is particularly valuable for international buyers who may face language or cultural barriers.

What Are Common Testing Methods for Starter Motors?

Testing is a fundamental aspect of the quality assurance process. Common testing methods for starter motors include:

- Funktionelle Prüfung: This checks the operational performance of the starter motor under simulated conditions to ensure it meets torque and speed specifications.

- Elektrische Prüfung: Voltage and current tests assess the electrical integrity of the motor, ensuring it can handle the demands of starting an engine.

- Haltbarkeitsprüfung: This involves subjecting the motor to repeated start cycles to evaluate its longevity and performance under stress.

These testing methods help confirm that the starter motor will perform reliably in real-world applications.

What Nuances Should International Buyers Consider Regarding QC and Certification?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding QC and certification:

- Regional Standards Compliance: Different regions may have varying requirements for certification. Understanding these requirements is crucial to ensure compliance and avoid regulatory issues.

- Transparenz in der Lieferkette: Buyers should seek suppliers who are transparent about their manufacturing processes and QC practices. This transparency builds trust and reduces the risk of supply chain disruptions.

- Kulturelle Erwägungen: Engaging with suppliers from different cultural backgrounds may require adjustments in communication and negotiation styles. Being aware of these differences can foster better relationships and smoother transactions.

By understanding these nuances, B2B buyers can make informed decisions when selecting suppliers for starter motors, ensuring they receive high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a starting motor’

In the competitive landscape of automotive components, sourcing a quality starter motor is crucial for ensuring reliable vehicle performance. This guide offers a structured checklist to help B2B buyers navigate the procurement process effectively, focusing on key considerations that will optimize their purchasing decisions.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Clearly outline the specifications required for the starter motor, including voltage, torque rating, and compatibility with vehicle models. This step is essential as it ensures that the starter motor meets the specific needs of the engine it will serve. Take into account the vehicle’s make, model, and engine type to avoid compatibility issues.

Schritt 2: Marktentwicklungen und Innovationen erforschen

Stay informed about the latest trends in starter motor technology, such as advancements in efficiency and integration with hybrid systems. Understanding these trends can provide insights into the best options available and help you identify suppliers that offer cutting-edge products. This knowledge can also lead to better negotiation positions and more favorable pricing.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering quality starter motors and excellent customer service.

- Check for industry certifications: Ensure that the supplier complies with relevant automotive standards and regulations, which is a strong indicator of quality.

- Assess their production capabilities: Investigate whether the supplier can meet your volume requirements and delivery timelines.

Schritt 4: Muster zum Testen anfordern

Before finalizing your order, request samples of the starter motors for testing. This allows you to evaluate their performance in real-world conditions and ensure they meet your technical specifications. Testing can reveal potential issues such as torque performance, durability, and compatibility.

Schritt 5: Verhandeln Sie die Allgemeinen Geschäftsbedingungen

Once you’ve selected a potential supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear communication of expectations is vital to establishing a mutually beneficial agreement. Ensure that all terms are documented to avoid misunderstandings later in the procurement process.

Schritt 6: Establish Quality Control Processes

Implement quality control measures to monitor the performance of the starter motors upon delivery. This may include inspections and testing protocols to verify that the products meet the agreed-upon specifications. Establishing these processes helps mitigate risks associated with defective components and ensures customer satisfaction.

Schritt 7: Planen Sie den After-Sales-Support

Consider the level of after-sales support provided by the supplier. Access to technical support and warranty services can be invaluable for addressing issues that may arise post-purchase. Confirm the supplier’s policies on returns, replacements, and maintenance to ensure comprehensive support throughout the product lifecycle.

By following this checklist, B2B buyers can effectively navigate the sourcing process for starter motors, ensuring they select high-quality components that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for what is a starting motor Sourcing

What Are the Key Cost Components for Sourcing a Starter Motor?

When sourcing a starter motor, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materialien: The composition of the starter motor significantly influences its cost. Typically, materials such as copper for windings, iron for the casing, and various alloys for gears and internal components are used. The quality and sourcing of these materials can vary, impacting the overall price.

-

Arbeit: Labor costs encompass the expenses associated with skilled workers who assemble the starter motors. This includes wages, benefits, and training. In regions with higher labor costs, such as Europe, the overall price of the starter motor may increase.

-

Fertigungsgemeinkosten: This includes costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes and economies of scale can help reduce these costs, but they still represent a significant portion of the total cost.

-

Werkzeuge: The need for specialized tools and equipment can add to the initial investment required for production. Tooling costs are often amortized over production runs, making them a critical factor for buyers considering bulk orders.

-

Qualitätskontrolle (QC): Ensuring the reliability of starter motors involves rigorous testing and quality assurance processes. The costs associated with QC can vary based on the level of certification required, such as ISO standards, which may be crucial for international buyers.

-

Logistik: Shipping, handling, and storage costs can vary widely depending on the location of the supplier and the destination. Buyers should consider Incoterms that dictate responsibilities and costs associated with transportation.

-

Marge: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand and competition.

Wie wirken sich Preiseinflussfaktoren auf die Beschaffung von Anlassern aus?

Several factors can influence the pricing of starter motors:

-

Volumen und Mindestbestellmenge (MOQ): Larger orders often qualify for bulk discounts, reducing the per-unit cost. International buyers should negotiate MOQs to optimize cost-effectiveness.

-

Spezifikationen und Anpassung: Custom starter motors designed for specific applications may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Materialqualität und Zertifizierungen: Higher-quality materials and certifications can raise costs but also enhance reliability and performance. Buyers in regions with stringent automotive standards should prioritize these aspects.

-

Lieferantenfaktoren: The reputation and reliability of the supplier can impact pricing. Established suppliers may command higher prices due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the implications of various Incoterms (e.g., FOB, CIF) is essential for international buyers. These terms dictate who is responsible for shipping costs, insurance, and liability, which can affect overall pricing.

What Negotiation Tips Can Help in Sourcing Starter Motors?

B2B buyers can employ several strategies to negotiate better deals on starter motors:

-

Hebelwirkung Volumen: Buyers should highlight their purchasing power by negotiating prices based on larger order quantities. This can lead to significant cost savings.

-

Gesamtbetriebskosten (TCO): Consider not just the purchase price but also the TCO, which includes installation, maintenance, and potential downtime costs. Presenting a TCO analysis can provide leverage in negotiations.

-

Competitive Bidding: Solicit quotes from multiple suppliers to foster competition. This can help secure more favorable terms and pricing.

-

Quality Assurance Discussions: Engage in discussions about quality assurance processes and certifications. Emphasizing the importance of reliability can justify a higher price point if necessary.

-

Cultural Sensitivity: Understanding the cultural context of suppliers, especially in regions like Africa and South America, can facilitate better relationships and negotiations.

Disclaimer Regarding Indicative Prices

Prices for starter motors can vary significantly based on numerous factors, including market conditions, supplier relationships, and specific buyer requirements. Therefore, it is advisable to obtain quotes from multiple suppliers to ensure competitive pricing and to consider the aforementioned factors for a comprehensive evaluation of total costs.

Alternatives Analysis: Comparing what is a starting motor With Other Solutions

Exploring Alternatives to the Starting Motor

When considering the best solutions for initiating engine operation, it is essential to evaluate various technologies that can serve similar functions to the traditional starter motor. This analysis aims to compare the starter motor with alternative methods, providing B2B buyers with insights into which option might best suit their operational needs and constraints.

| Vergleichsaspekt | What Is A Starting Motor | Alternative 1 Name: Integrierter Startergenerator (ISG) | Alternative 2 Name: Manual Crank Start |

|---|---|---|---|

| Leistung | Hohes Drehmoment für schnellen Motorstart | Moderate torque; efficient in hybrid systems | Low torque; requires physical effort |

| Kosten | Moderate (depends on vehicle type) | Higher initial investment due to complexity | Low cost; minimal parts required |

| Einfache Implementierung | Standardmäßiger Einbau in Fahrzeuge | Requires advanced integration into vehicle systems | Simple installation, but labor-intensive |

| Wartung | Regular checks; prone to wear | Requires minimal maintenance; integrated systems | High maintenance due to wear on manual components |

| Bester Anwendungsfall | Ideal for conventional gasoline/diesel engines | Best suited for hybrid and electric vehicles | Suitable for older vehicles or emergency backups |

What Are the Benefits and Drawbacks of Integrated Starter Generators?

The Integrated Starter Generator (ISG) combines the functions of a starter motor and an alternator into a single unit, primarily used in hybrid and electric vehicles. One of its key advantages is efficiency, as it recovers energy during deceleration and stores it for later use, improving overall fuel economy. However, the ISG comes with a higher upfront cost and requires more complex installation, making it less attractive for traditional combustion engines. Additionally, while maintenance is minimal, the technology’s complexity may lead to higher repair costs if issues arise.

How Does the Manual Crank Start Compare?

The manual crank start is a traditional method of starting engines, primarily found in older vehicles. Its advantages include a low cost and minimal reliance on electrical systems, making it suitable for emergency situations or in regions with limited access to modern technology. However, the manual crank method requires physical effort, making it impractical for everyday use, especially in commercial applications where efficiency is paramount. Furthermore, it may lead to higher wear and tear on components, increasing maintenance demands.

Conclusion: Choosing the Right Engine Starting Solution

For B2B buyers, selecting the appropriate engine starting solution hinges on specific operational needs, vehicle types, and budget constraints. The starter motor remains the most reliable choice for conventional vehicles, offering a balance of performance and cost. In contrast, those operating hybrid or electric fleets may benefit from the efficiency of Integrated Starter Generators, despite their higher initial investment. Meanwhile, businesses with vintage vehicles or those in remote areas might find the manual crank start to be a practical, albeit labor-intensive, option. Ultimately, a thorough analysis of these alternatives will empower buyers to make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for what is a starting motor

What Key Technical Properties Should Buyers Understand About Starter Motors?

When sourcing starter motors for automotive applications, understanding their critical technical properties can significantly influence purchasing decisions. Here are several essential specifications:

Illustrative image related to what is a starting motor

-

Drehmoment

Torque is the measure of rotational force provided by the starter motor. It is crucial for overcoming the engine’s inertia during startup. A high torque rating is vital, especially for larger engines or in regions with extreme weather conditions. B2B buyers must ensure that the selected starter motor meets or exceeds the torque requirements of the specific vehicle to ensure reliable engine cranking. -

Werkstoffgüte

The materials used in manufacturing starter motors affect their durability and performance. Common materials include high-grade steel for the housing and copper for the windings. High-quality materials can enhance resistance to wear and thermal fatigue, which is essential for long-term reliability. Buyers should consider the material grades specified by manufacturers, as they often reflect the product’s overall quality and lifespan. -

Betriebsspannung

Most starter motors operate on a standard voltage, typically 12V for passenger vehicles and 24V for commercial applications. Understanding the voltage requirements is crucial for compatibility with vehicle electrical systems. Choosing the wrong voltage can lead to inefficiencies or damage, making it imperative for buyers to confirm the specifications before purchase. -

Stromaufnahme (Stromstärke)

The current draw indicates how much electrical power the starter motor will consume during operation. A higher amperage can lead to faster engine cranking, but it also requires a robust battery and wiring system. B2B buyers should assess their electrical systems’ capabilities to ensure they can handle the starter motor’s current demands without risking failure. -

Engagement-Mechanismus

The engagement mechanism refers to how the starter motor connects with the engine’s flywheel. Common types include solenoid-driven and permanent magnet engagement systems. Understanding the engagement type is essential for ensuring compatibility with the engine design and for assessing the reliability of the starting process. -

Temperaturtoleranz

Starter motors must function effectively across a range of temperatures. Buyers should look for specifications indicating operational temperature ranges, especially in regions prone to extreme heat or cold. A starter motor with a wider temperature tolerance will be more reliable in diverse environmental conditions.

What Common Trade Terms Should B2B Buyers Know in the Starter Motor Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Originalgerätehersteller)

This term refers to companies that produce parts that are used in the assembly of vehicles. An OEM starter motor is designed to meet the exact specifications of the original vehicle manufacturer. Buyers looking for high-quality parts often prefer OEM components to ensure compatibility and reliability. -

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, particularly when sourcing starter motors in bulk. This knowledge helps in planning inventory and managing costs effectively. -

RFQ (Angebotsanfrage)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. When purchasing starter motors, issuing an RFQ can help buyers compare prices, specifications, and terms from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (Internationale Handelsklauseln)

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is crucial for B2B buyers, as they clarify who is responsible for shipping, insurance, and tariffs, thereby reducing potential misunderstandings during the procurement process. -

Ersatzteilmarkt

The aftermarket refers to the market for parts and accessories that are not supplied by the OEM. Buyers often consider aftermarket starter motors for cost-effective alternatives or for performance upgrades. However, it’s important to assess the quality and compatibility of aftermarket options thoroughly. -

Garantiezeitraum

This term defines the duration for which the manufacturer guarantees the performance of the starter motor. A longer warranty period can indicate confidence in the product’s quality. Buyers should consider warranty terms when evaluating potential suppliers, as it can affect long-term operational costs.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing starter motors for their operations, ensuring they select products that meet their needs effectively.

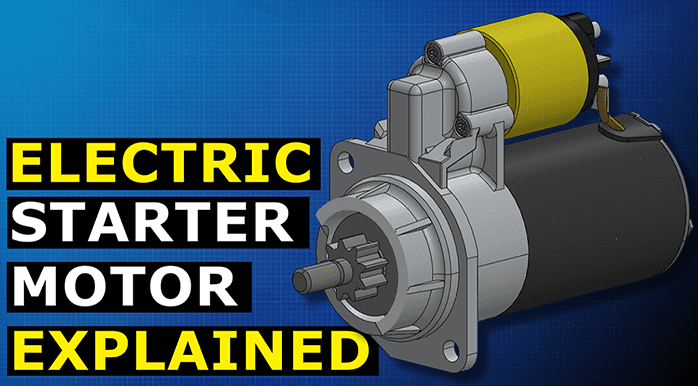

Navigating Market Dynamics and Sourcing Trends in the what is a starting motor Sector

Market Overview & Key Trends: What Are the Current Dynamics in the Starter Motor Sector?

The global starter motor market is experiencing significant growth, driven by the increasing demand for automotive vehicles, particularly in emerging markets such as Nigeria, Brazil, and other regions in Africa and South America. The rise of electric vehicles (EVs) has also introduced new dynamics, where traditional starter motors are being replaced by integrated starter-generator systems, reflecting a shift towards hybrid technology. This transformation is not just limited to passenger vehicles; commercial and industrial applications are also adopting advanced starter motor technologies to improve efficiency and reduce emissions.

Illustrative image related to what is a starting motor

In terms of sourcing trends, international B2B buyers are increasingly focusing on suppliers that can offer innovative solutions, such as lightweight materials and advanced electronic controls, to enhance performance and reduce energy consumption. The trend towards digitalization and smart manufacturing is reshaping supply chains, with data-driven insights enabling businesses to optimize procurement processes and enhance inventory management. Furthermore, buyers are prioritizing partnerships with manufacturers that can provide reliable after-sales support and service, which is critical for maintaining operational uptime in various industries.

How Is Sustainability Influencing Sourcing Decisions in the Starter Motor Sector?

Sustainability is becoming a crucial factor in the sourcing of starter motors. Buyers are increasingly aware of the environmental impact of their procurement choices and are seeking suppliers who prioritize ethical sourcing and sustainable practices. This includes the use of recyclable materials in manufacturing and the implementation of energy-efficient production methods.

The importance of ethical supply chains cannot be overstated, particularly in regions where compliance with labor and environmental regulations may vary. Buyers are encouraged to look for suppliers with certifications that demonstrate their commitment to sustainability, such as ISO 14001 for environmental management or certifications for using green materials in production. By choosing to source from environmentally responsible suppliers, businesses not only enhance their corporate social responsibility (CSR) credentials but also mitigate risks associated with potential regulatory changes and market shifts toward sustainability.

What Is the Historical Context of the Starter Motor’s Evolution?

The starter motor has a rich history that dates back to its invention by Charles Kettering in 1911, revolutionizing the automotive industry by replacing hand-cranked engines with electric starters. This innovation significantly improved vehicle usability and safety, paving the way for mass automotive production. Over the decades, advancements in technology have led to the development of more efficient and reliable starter motors, including the incorporation of solenoids and electronic controls.

The evolution of starter motors continues today, particularly with the increasing prevalence of hybrid and electric vehicles, which utilize integrated starter-generator systems. This historical context is vital for B2B buyers as it highlights the importance of staying informed about technological advancements and their implications for sourcing decisions in the automotive sector. Understanding the trajectory of starter motor technology allows buyers to make informed choices that align with current market demands and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a starting motor

-

How do I identify a failing starter motor?

A failing starter motor often exhibits symptoms such as a clicking noise when the ignition is turned, slow cranking, or complete failure to start the engine. If the battery is fully charged and connections are clean, the starter may be at fault. Conducting a voltage drop test can help determine if the starter is drawing excessive power. Additionally, if the starter works intermittently, it may indicate internal wear or a failing solenoid. Regular maintenance checks can help catch issues early, preventing downtime in your operations. -

What are the key specifications to consider when sourcing a starter motor?

When sourcing a starter motor, key specifications include voltage (commonly 12V or 24V), torque rating, size, and mounting configuration. Ensure compatibility with the engine type and vehicle make. It’s also crucial to consider the starter’s duty cycle, especially for commercial applications requiring high reliability. Request technical datasheets from suppliers to confirm these specifications align with your operational needs. Additionally, inquire about warranty periods and expected lifespans to ensure you receive a quality product. -

What is the best starter motor for heavy-duty applications?

For heavy-duty applications, look for starter motors specifically designed for high-torque and high-performance environments. Brands like Bosch, Delco Remy, and Denso offer robust starter motors that can withstand the demands of larger vehicles and machinery. Ensure the starter has a higher amperage rating and is built with durable materials. Consulting with manufacturers or industry experts can also provide insights on the most suitable models based on your specific needs and conditions. -

Wie kann ich bei der internationalen Beschaffung von Anlassern die Qualität sicherstellen?

To ensure quality when sourcing starter motors internationally, perform thorough supplier vetting. Verify certifications such as ISO 9001 for quality management systems. Request samples to evaluate the product firsthand and check for compliance with international standards. Establish a quality assurance process, including periodic inspections during production. Building a strong relationship with suppliers can also facilitate better communication regarding quality expectations and concerns. -

What are typical minimum order quantities (MOQs) for starter motors?

Minimum order quantities (MOQs) for starter motors can vary widely depending on the supplier and the specific product. Generally, MOQs can range from 50 to 500 units for standard models. However, custom or specialized starter motors may have higher MOQs. When negotiating with suppliers, clarify their MOQ policies and explore options for lower quantities if necessary. Some suppliers might be open to flexible terms based on your business relationship and future order potential. -

What payment terms are common in international starter motor transactions?

Common payment terms for international transactions of starter motors include wire transfers, letters of credit, and payment upon delivery. Suppliers may request a deposit (usually 30% to 50%) before production, with the balance due upon shipment. Ensure that payment terms are clearly outlined in the purchase agreement to prevent misunderstandings. It’s advisable to conduct transactions through secure payment methods to protect against fraud and ensure the legitimacy of the supplier. -

Welche logistischen Überlegungen sollte ich beim Import von Anlassern anstellen?

When importing starter motors, consider logistics factors such as shipping methods (air vs. sea), customs regulations, and lead times. Ensure that the supplier provides proper documentation for customs clearance, including invoices, packing lists, and certificates of origin. It’s beneficial to work with logistics providers experienced in handling automotive parts to ensure compliance with regulations and minimize delays. Additionally, consider warehousing options in your region to facilitate quicker distribution once the motors arrive. -

How can I customize a starter motor for specific applications?

Customizing a starter motor typically involves specifying torque requirements, size constraints, and electrical specifications tailored to your application. Collaborate with manufacturers who offer customization services, providing detailed requirements and use cases. Discuss options such as different mounting styles, gear ratios, and materials that can enhance performance. It’s essential to review prototypes and conduct testing to ensure the custom starter motor meets your operational standards and performance expectations.

Top 5 What Is A Starting Motor Manufacturers & Suppliers List

1. Haynes – Starter Motor

Domäne: us.haynes.com

Registriert: 1996 (29 Jahre)

Einleitung: Dieses Unternehmen, Haynes - Starter Motor, ist eine bemerkenswerte Einheit auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

2. RAC – Anlasser

Domäne: rac.co.uk

Registriert: 1996 (29 Jahre)

Einleitung: Starter Motor: An essential electric component in internal combustion vehicles that initiates engine rotation when the ignition is engaged. It operates by receiving an electrical signal that activates the starter solenoid, sending a charge to the battery and engaging the starter motor to crank the engine. Common causes of failure include broken solenoids, mechanical issues, electrical faults, over…

3. Reddit – Starter Motor Explained

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: This company, Reddit – Starter Motor Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. AutoElectro – Starter Motors

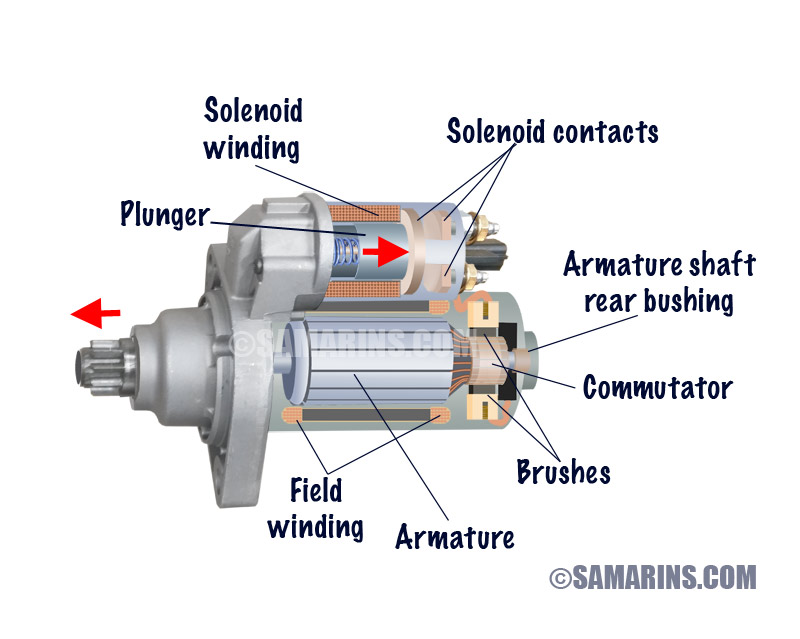

Domäne: autoelectro.de

Registriert: 1999 (26 Jahre)

Einleitung: Anlasser sind dafür verantwortlich, dass der Motor bei der Zündung anspringt und Luft und Kraftstoff zur Verbrennung eintreten können. Zu den wichtigsten Komponenten gehören:

- Anker: Ein auf der Antriebswelle montierter Elektromagnet, der mit Leiterschleifen umwickelt ist.

- Kommutator: Ein Teil der Welle, der den Strom durch Bürsten leitet.

- Bürsten: Leiten Strom durch Kontakt mit dem Kommutator.

- Magnetspule: ...

5. Frontier Toyota – Starter Motor

Domäne: frontiertoyota.com

Registriert: 1996 (29 Jahre)

Einleitung: This company, Frontier Toyota – Starter Motor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for what is a starting motor

In conclusion, understanding the essential role of the starter motor in automotive applications is crucial for international B2B buyers. This component is not merely a part of the engine; it is the linchpin that ensures reliable vehicle operation. As highlighted, strategic sourcing of starter motors can significantly impact operational efficiency, maintenance costs, and overall vehicle reliability. Buyers should prioritize sourcing from reputable manufacturers who adhere to quality standards, ensuring longevity and performance.

Furthermore, recognizing the signs of starter motor failure—such as difficulty starting or unusual noises—can lead to timely interventions, minimizing downtime and repair costs. As markets evolve and the demand for reliable transportation solutions increases, the need for quality starter motors will remain paramount.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe should leverage this knowledge to forge partnerships with trustworthy suppliers. By investing in quality and reliability today, businesses can secure their operations and enhance their competitive edge in the global market. Embrace the opportunity to optimize your sourcing strategies for starter motors and drive your business towards greater success.

Illustrative image related to what is a starting motor

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.