Einleitung: Navigieren auf dem globalen Markt für Fahrzeuganlasser

In the rapidly evolving automotive landscape, sourcing reliable vehicle starter motors poses a significant challenge for international B2B buyers. Whether you’re operating in the emerging markets of Africa and South America or established regions like Europe and the Middle East, understanding the intricacies of starter motor procurement is crucial. This guide serves as an essential resource, detailing various types of starter motors, their applications across different vehicle models, and the factors that influence their performance and longevity.

As you navigate the complexities of the global market, it’s imperative to consider not only the technical specifications of starter motors but also the credibility of suppliers. This comprehensive guide offers insights into effective supplier vetting processes, cost considerations, and market trends, empowering you to make informed purchasing decisions. By examining the nuances of sourcing starter motors, from new to remanufactured options, this guide equips you with the knowledge needed to optimize your supply chain and enhance operational efficiency.

With a focus on actionable insights tailored for diverse international markets—including Vietnam and Germany—this resource aims to facilitate strategic partnerships and foster growth in your automotive ventures. By leveraging the information provided, you can confidently navigate the global starter motor market, ensuring that your business remains competitive and responsive to customer demands.

Inhaltsverzeichnis

- Top 1 Vehicle Starter Motor Manufacturers & Suppliers List

- Einleitung: Navigieren auf dem globalen Markt für Fahrzeuganlasser

- Fahrzeuganlasser Typen und Variationen verstehen

- Wichtige industrielle Anwendungen von Fahrzeuganlassern

- 3 häufige Schmerzpunkte von Benutzern für ‘Fahrzeuganlasser’ und ihre Lösungen

- Leitfaden für die strategische Materialauswahl für Fahrzeuganlasser

- Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für Fahrzeuganlasser

- Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘Fahrzeuganlasser’.’

- Umfassende Kosten- und Preisanalyse für die Beschaffung von Fahrzeuganlassern

- Analyse der Alternativen: Vergleich des Fahrzeuganlassers mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für Fahrzeuganlasser

- Marktdynamik und Beschaffungstrends im Bereich der Anlasser für Fahrzeuge

- Häufig gestellte Fragen (FAQs) für B2B-Käufer von Fahrzeuganlassern

- Strategische Beschaffung Schlussfolgerung und Ausblick für Fahrzeuganlasser

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Fahrzeuganlasser Typen und Variationen verstehen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| DC Starter Motors | Operates on direct current; typically compact. | Automotive, heavy machinery. | Vorteile: Zuverlässig, weit verbreitet. Nachteile: Limited torque compared to some alternatives. |

| Untersetzungsgetriebe-Starter | Uses gears to increase torque output. | High-performance vehicles, racing. | Vorteile: Enhanced torque, lightweight. Nachteile: More complex, potentially higher costs. |

| High Torque Starters | Designed for heavy-duty applications, robust build. | Commercial vehicles, trucks. | Vorteile: Superior power for larger engines. Nachteile: Bulkier, may require specific installation. |

| Permanentmagnet-Starter | Utilizes permanent magnets for efficiency. | Elektrofahrzeuge, Hybridfahrzeuge. | Vorteile: Energieeffizient, leicht. Nachteile: May have a higher upfront cost. |

| Solenoid-Activated Starters | Incorporates a solenoid to engage the motor. | Allgemeine Automobilanwendungen. | Vorteile: Simple design, reliable engagement. Nachteile: Vulnerable to electrical failures. |

What are the Characteristics of DC Starter Motors for B2B Buyers?

DC starter motors are the most common type used in vehicles, operating on direct current to initiate engine combustion. They are compact and lightweight, making them suitable for a wide range of applications, from passenger cars to heavy machinery. B2B buyers should consider their availability and compatibility with various vehicle models. However, while they are reliable, they may not deliver the high torque needed for larger engines, which can be a limitation in specific industrial applications.

How Do Gear Reduction Starters Benefit High-Performance Applications?

Gear reduction starters utilize a gear system to amplify torque output, making them ideal for high-performance vehicles and racing applications. Their design allows for lighter components without sacrificing power, which is crucial in competitive environments. B2B buyers should note that while these starters can enhance performance, they tend to be more complex and expensive than standard DC starters. Careful consideration of installation requirements and compatibility with vehicle specifications is essential.

What Makes High Torque Starters Ideal for Commercial Vehicles?

High torque starters are specifically engineered for heavy-duty applications, providing the necessary power to crank larger engines found in commercial vehicles and trucks. Their robust construction ensures durability under demanding conditions, making them a preferred choice for fleet operators. B2B buyers must weigh the benefits of superior power against the potential downsides of bulkier designs and installation challenges, ensuring that their selection aligns with operational needs.

Why Are Permanent Magnet Starters Preferred in Electric Vehicles?

Permanent magnet starters leverage the efficiency of permanent magnets to reduce energy consumption, making them a suitable choice for electric and hybrid vehicles. Their lightweight design contributes to improved overall vehicle performance and efficiency. B2B buyers should consider the initial investment, as these starters may come at a premium compared to traditional options. Understanding the long-term benefits of energy savings and reduced weight can justify the upfront costs.

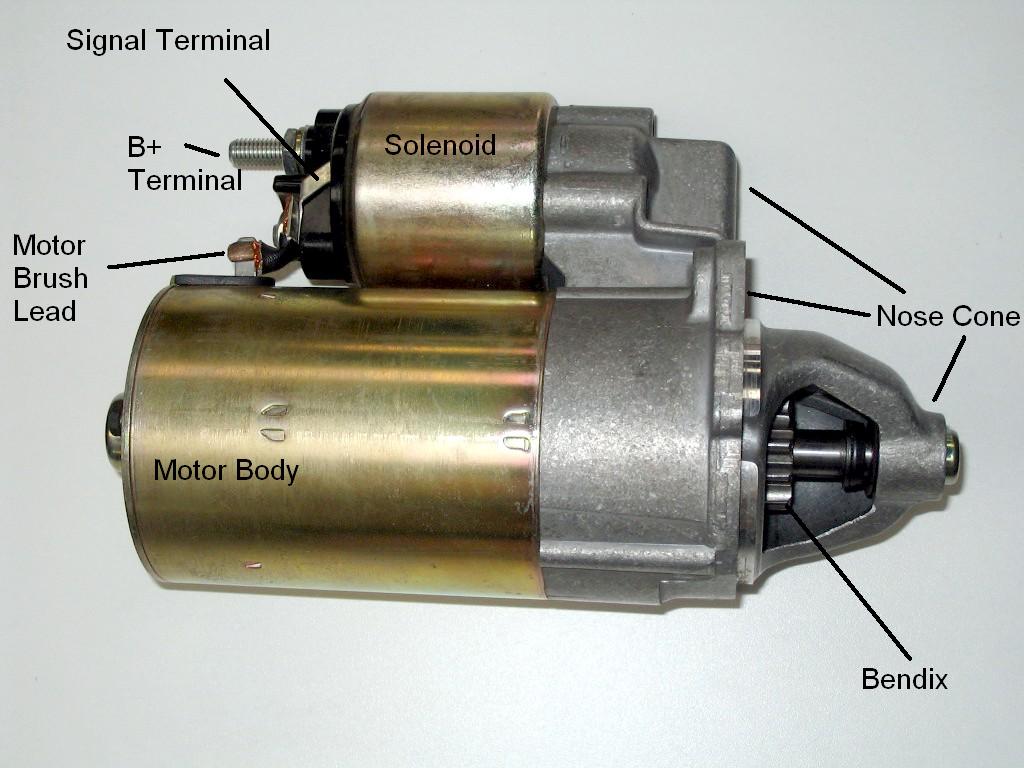

How Do Solenoid-Activated Starters Function in General Automotive Applications?

Solenoid-activated starters feature a solenoid that engages the motor when the ignition is turned on, providing a straightforward and reliable starting mechanism. This type of starter is commonly found in general automotive applications due to its simplicity and ease of installation. B2B buyers should be aware that while these starters are generally dependable, they can be susceptible to electrical failures, which may necessitate more frequent maintenance or replacement in high-use scenarios.

Wichtige industrielle Anwendungen von Fahrzeuganlassern

| Branche/Sektor | Spezifische Anwendung des Fahrzeuganlassers | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Assembly of passenger and commercial vehicles | Ensures reliable engine start-up, enhancing production efficiency | Quality control, compatibility with various vehicle models, and certifications |

| Landwirtschaft | Starting agricultural machinery (tractors, harvesters) | Improves operational uptime, critical for seasonal farming | Durability in harsh conditions, availability of replacement parts, and voltage specifications |

| Transport & Logistik | Fleet management for trucks and buses | Reduces downtime, ensuring timely deliveries and services | Bulk purchasing options, warranty terms, and technical support availability |

| Bergbau und Bauwesen | Starting heavy equipment (excavators, loaders) | Enhances productivity by minimizing equipment start failures | Rugged design requirements, environmental certifications, and service agreements |

| Marine | Starting marine engines for boats and vessels | Vital for safety and operational reliability at sea | Resistance to corrosion, compliance with maritime regulations, and sourcing for specialized marine applications |

How is the Vehicle Starter Motor Used in Automotive Manufacturing?

In automotive manufacturing, vehicle starter motors are integral to the assembly of both passenger cars and commercial vehicles. They are essential for ensuring that engines start reliably during production tests, which helps maintain production efficiency. Manufacturers must consider factors such as compatibility with various vehicle models, quality control processes, and necessary certifications to meet industry standards. International buyers should prioritize suppliers with a robust supply chain to ensure timely delivery and support.

What Role Does the Vehicle Starter Motor Play in Agriculture?

Agricultural machinery, including tractors and harvesters, relies heavily on starter motors for efficient operation. These motors enable quick engine starts, which is crucial during peak farming seasons when time is of the essence. Buyers in this sector should focus on sourcing durable starter motors capable of withstanding harsh environmental conditions, as well as ensuring the availability of replacement parts. Additionally, voltage specifications must align with the machinery to avoid operational disruptions.

How Do Vehicle Starter Motors Impact Transportation and Logistics?

In the transportation and logistics sector, vehicle starter motors are critical for fleet management, particularly for trucks and buses. A reliable starter motor minimizes downtime, ensuring that vehicles are ready for timely deliveries and services. For international B2B buyers, bulk purchasing options can lead to cost savings, while warranty terms and technical support availability are vital for long-term operational reliability. Companies should also evaluate suppliers based on their ability to provide consistent quality across large orders.

Why are Vehicle Starter Motors Important in Mining and Construction?

Heavy equipment used in mining and construction, such as excavators and loaders, requires robust starter motors to function effectively. These motors are essential for enhancing productivity by reducing the frequency of equipment start failures, which can lead to costly delays. Buyers in this sector should look for starter motors with rugged designs that can withstand extreme conditions, as well as environmental certifications to ensure compliance with safety standards. Service agreements that offer maintenance support can also add value.

How are Vehicle Starter Motors Utilized in Marine Applications?

In the marine industry, vehicle starter motors are crucial for starting engines in boats and vessels. A reliable starter is vital for safety and operational reliability, particularly in emergency situations at sea. Buyers must consider factors such as resistance to corrosion and compliance with maritime regulations when sourcing starter motors for marine applications. Additionally, specialized sourcing for marine-grade components can enhance performance and longevity in salty environments.

3 häufige Schmerzpunkte von Benutzern für ‘Fahrzeuganlasser’ und ihre Lösungen

Scenario 1: Difficulty in Identifying Starter Motor Failures

Das Problem: B2B buyers, particularly those managing fleets or automotive workshops, often face the challenge of accurately diagnosing starter motor failures. Symptoms like a clicking noise without the engine starting can lead to confusion between battery and starter issues. This uncertainty not only wastes time but also results in unnecessary costs from replacing the wrong components. Misdiagnosis can further exacerbate operational downtime, affecting customer satisfaction and profitability.

Die Lösung: To effectively address this issue, buyers should invest in diagnostic tools that allow for thorough testing of starter motors and associated electrical systems. For instance, a multi-meter can be used to measure voltage at the starter while attempting to crank the engine. If the voltage drops significantly, it indicates a battery issue rather than a starter problem. Additionally, training staff on troubleshooting techniques can enhance their ability to identify issues accurately. Regular maintenance checks should also be implemented, ensuring connections are clean and tight to prevent intermittent failures. By establishing a standard operating procedure for diagnosing starter issues, businesses can minimize misdiagnoses and streamline repairs.

Scenario 2: Sourcing Quality Starter Motors in Diverse Markets

Das Problem: Sourcing reliable starter motors can be particularly challenging for B2B buyers operating in diverse markets like Africa and South America, where quality assurance may vary significantly between manufacturers. Buyers often encounter counterfeit products or substandard components, leading to high failure rates and increased replacement costs. This situation not only damages their reputation but also strains customer relationships due to frequent breakdowns.

Die Lösung: To navigate this challenge, B2B buyers should establish partnerships with reputable manufacturers and distributors known for quality assurance and support. Conducting thorough research into suppliers, including checking certifications and customer reviews, can help identify trustworthy partners. Implementing a vendor management system can also facilitate tracking the performance of suppliers and ensure consistency in product quality. Additionally, buyers should consider purchasing from manufacturers that provide warranties and after-sales support, offering peace of mind and reducing the risk of future failures. By prioritizing quality over cost, businesses can enhance their operational reliability and strengthen customer loyalty.

Scenario 3: Managing Inventory for Starter Motors

Das Problem: Efficient inventory management of starter motors is a common pain point for B2B buyers, particularly those with extensive vehicle fleets or repair operations. Overestimating demand can lead to excess stock that occupies valuable warehouse space, while underestimating can result in stockouts that delay repairs and service. This imbalance affects cash flow and can compromise the ability to meet customer demands promptly.

Die Lösung: Implementing an inventory management system that leverages data analytics can significantly improve forecasting accuracy. By analyzing historical sales data and vehicle repair trends, businesses can better predict which starter motors will be in demand. Additionally, adopting a just-in-time (JIT) inventory strategy can help minimize excess stock by aligning orders with actual usage rates. Collaborating closely with suppliers to maintain flexible agreements can also allow for quicker restocking, reducing the risk of stockouts. Furthermore, conducting regular inventory audits can help identify slow-moving items and inform future purchasing decisions. By optimizing inventory management practices, businesses can enhance operational efficiency and improve service delivery to their customers.

Leitfaden für die strategische Materialauswahl für Fahrzeuganlasser

What Materials Are Commonly Used in Vehicle Starter Motors?

When selecting materials for vehicle starter motors, several options are prevalent in the industry, each with its unique properties, advantages, and limitations. Understanding these materials can help international B2B buyers make informed decisions that align with their operational needs and regional standards.

Welchen Einfluss hat Kupfer auf die Leistung des Anlassers?

Wichtige Eigenschaften: Copper is known for its excellent electrical conductivity and thermal properties, making it ideal for components requiring efficient energy transfer. It can withstand temperature variations and has a low resistance, which is crucial for the high current demands of starter motors.

Vor- und Nachteile: The primary advantage of copper is its superior conductivity, which enhances the starter motor’s efficiency. However, copper is susceptible to corrosion, especially in humid or saline environments, which can lead to performance degradation over time. Additionally, copper is relatively expensive compared to other materials, which can impact overall production costs.

Anschauliches Bild zum Fahrzeuganlasser

Auswirkungen auf die Anwendung: Copper components are particularly effective in environments with stable temperatures and low humidity. However, in regions like Africa or South America, where humidity and temperature fluctuations are common, additional coatings or treatments may be necessary to prevent corrosion.

Considerations for Buyers: Buyers should ensure compliance with international standards such as ASTM B187 for copper and consider the local environmental conditions that may affect copper’s longevity.

Why Is Steel a Preferred Material for Starter Motor Components?

Wichtige Eigenschaften: Steel offers high tensile strength and durability, making it suitable for structural components of starter motors. It can withstand high pressure and temperature, which are common during engine start-up.

Vor- und Nachteile: The primary advantage of steel is its robustness and cost-effectiveness. It is less expensive than copper and can be produced in various grades to meet specific performance requirements. However, steel is heavier than other materials and may require additional energy to operate efficiently.

Auswirkungen auf die Anwendung: Steel components are well-suited for heavy-duty applications, particularly in trucks and industrial vehicles where durability is paramount. However, the weight may be a drawback in lightweight vehicles, where reducing mass is crucial for efficiency.

Considerations for Buyers: Buyers should look for steel that meets international standards like DIN 17100 or JIS G3101 to ensure quality and performance.

How Do Plastics Enhance Starter Motor Functionality?

Wichtige Eigenschaften: Engineering plastics, such as polyamide (nylon) and polycarbonate, are increasingly used for non-structural components in starter motors due to their lightweight nature and resistance to chemicals and wear.

Vor- und Nachteile: The main advantage of using plastics is their low weight, which can contribute to overall vehicle efficiency. They also offer good electrical insulation properties. However, plastics may not withstand high temperatures as effectively as metals, leading to potential failure in extreme conditions.

Auswirkungen auf die Anwendung: Plastics are particularly beneficial in applications where weight reduction is critical, such as in electric vehicles. However, they may not be suitable for high-temperature environments without proper material selection.

Considerations for Buyers: It is essential to verify that the selected plastics meet relevant international standards such as ASTM D638 for tensile properties, especially in regions with varying temperature conditions.

Welche Rolle spielt Aluminium bei der Konstruktion von Anlassern?

Wichtige Eigenschaften: Aluminum is lightweight and has good corrosion resistance, making it an attractive option for starter motor housings and components. It also has decent thermal and electrical conductivity.

Vor- und Nachteile: The key advantage of aluminum is its weight-saving potential, which can enhance vehicle fuel efficiency. However, aluminum is generally more expensive than steel and can be less durable under high-stress conditions.

Auswirkungen auf die Anwendung: Aluminum is particularly effective in applications where reducing weight is essential, such as in performance vehicles. However, its lower strength compared to steel may limit its use in heavy-duty applications.

Considerations for Buyers: Buyers should ensure that aluminum components comply with standards such as ASTM B221 to guarantee quality, especially in regions with demanding operational conditions.

Übersichtstabelle zur Materialauswahl für Fahrzeuganlasser

| Material | Typischer Anwendungsfall für Fahrzeuganlasser | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse und Wicklungen | Hervorragende elektrische Leitfähigkeit | Korrosionsanfälligkeit | Hoch |

| Stahl | Strukturelle Komponenten | High strength and cost-effective | Heavier than other materials | Mittel |

| Kunststoffe | Nicht-strukturelle Komponenten | Leicht und gute Isolierung | Begrenzte Hochtemperaturbeständigkeit | Niedrig |

| Aluminium | Gehäuse und Leichtbaukomponenten | Weight-saving potential | Weniger haltbar bei Belastung | Mittel bis Hoch |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in vehicle starter motors, helping them make informed decisions that align with their operational requirements and regional standards.

Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für Fahrzeuganlasser

What Are the Key Stages in the Manufacturing Process of Vehicle Starter Motors?

The manufacturing process of vehicle starter motors is intricate, involving multiple stages that ensure the delivery of high-quality components. Understanding these stages can help B2B buyers assess suppliers more effectively.

Materialaufbereitung: Welche Materialien werden verwendet und wie werden sie aufbereitet?

The first step in manufacturing starter motors is material preparation. Common materials include high-grade steel for the housing, copper for electrical components, and various alloys for gears. Suppliers typically source these materials from certified vendors who adhere to international quality standards.

Material processing involves cutting, shaping, and treating the raw materials to meet specific design requirements. Techniques such as forging or stamping are used for metal components to enhance durability. For instance, high-strength steel is often cold-formed to achieve precise dimensions while maintaining structural integrity.

Wie werden Anlasser geformt und zusammengebaut?

Forming Techniques: What Methods Are Employed for Component Creation?

Forming techniques play a crucial role in producing the various parts of a starter motor. Key methods include:

-

Gießen: This technique is often used for the motor housing, which must withstand significant stress. Sand casting or die casting methods are commonly employed, depending on the volume and specifications.

-

Bearbeitung: Precision machining is utilized for critical components like the rotor and stator. CNC (Computer Numerical Control) machines ensure high accuracy and repeatability, which are vital for performance.

-

Wickeln: The electric windings are created using specialized machines that can precisely coil copper wire around the armature. This step is crucial for generating the magnetic field necessary for the motor’s operation.

Assembly Process: How Are Components Integrated?

Once all parts are formed, the assembly process begins. This typically involves:

-

Unterbaugruppe: Components such as the solenoid, armature, and housing are assembled separately before final integration.

-

Endmontage: Skilled technicians assemble the motor by integrating all sub-components. Automated assembly lines may be employed for efficiency, but critical stages often require manual oversight to ensure quality.

-

Qualitätskontrollen während der Montage: Key quality checkpoints, such as torque testing of bolted joints and alignment checks, are conducted at this stage to prevent future operational issues.

What Are the Finishing Processes for Vehicle Starter Motors?

Surface Finishing: Why Is It Important?

After assembly, the starter motors undergo surface finishing processes that enhance their durability and performance. Common techniques include:

-

Beschichtung: Application of protective coatings (e.g., zinc plating or powder coating) helps prevent corrosion, especially in harsh environments.

-

Reinigung: Thorough cleaning processes remove any debris or contaminants that could affect performance. This step often involves ultrasonic cleaning or solvent washing.

What International Standards Guide Quality Assurance in Starter Motor Manufacturing?

Quality assurance (QA) is crucial for ensuring that starter motors meet safety and performance standards. International standards, such as ISO 9001, provide a framework for consistent quality management systems. Compliance with these standards not only enhances product reliability but also builds trust with international buyers.

Industry-Specific Certifications: What Should B2B Buyers Look For?

In addition to ISO standards, various industry-specific certifications are relevant for starter motors:

-

CE-Kennzeichnung: Indicates compliance with European safety and environmental requirements, critical for suppliers targeting the European market.

-

API-Zertifizierung: Relevant for automotive components, ensuring that products meet specific performance criteria.

B2B buyers should inquire about these certifications when assessing potential suppliers, as they reflect a commitment to quality and safety.

What Are the Quality Control Checkpoints in Starter Motor Manufacturing?

Key Quality Control Checkpoints: How Are They Implemented?

Quality control (QC) is integrated into every stage of the manufacturing process, with specific checkpoints:

-

Eingangsqualitätskontrolle (IQC): Die Rohstoffe werden bei ihrer Ankunft kontrolliert, um sicherzustellen, dass sie den vorgegebenen Normen entsprechen.

-

In-Process-Qualitätskontrolle (IPQC): During assembly, random samples are tested for alignment, torque, and electrical resistance. This ongoing monitoring helps catch defects early.

-

Endkontrolle (FQC): After assembly, each starter motor undergoes comprehensive testing. This may include functional tests to ensure proper engagement and disengagement of the pinion gear, as well as endurance tests to simulate long-term use.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

What Steps Can Buyers Take to Ensure Quality?

To ensure that suppliers adhere to stringent quality control practices, B2B buyers can take several proactive steps:

Anschauliches Bild zum Fahrzeuganlasser

-

Lieferantenaudits: Conducting regular audits of potential suppliers allows buyers to evaluate their manufacturing processes, quality control systems, and compliance with international standards.

-

Anforderung von Qualitätsberichten: Buyers should request quality assurance documentation, including inspection reports and certifications, to verify a supplier’s claims.

-

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s operations and quality practices, ensuring that products meet the necessary standards before shipment.

What Are the QC Nuances for International B2B Buyers?

How Do Regional Differences Affect Quality Assurance?

International buyers, especially from diverse regions such as Africa, South America, the Middle East, and Europe, must be aware of regional differences in quality expectations. For instance:

- Europa: Emphasis on CE marking and stringent environmental regulations.

- Afrika und Südamerika: Local certifications may vary, and understanding these can help ensure compliance with market demands.

B2B buyers should familiarize themselves with regional standards and practices to navigate these nuances effectively.

By understanding the manufacturing processes and quality assurance practices for vehicle starter motors, B2B buyers can make informed decisions, minimize risks, and secure reliable partnerships with suppliers.

Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘Fahrzeuganlasser’.’

Einführung

Sourcing vehicle starter motors is a critical task for businesses in the automotive sector, especially for those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to streamline your procurement process, ensuring that you select the right products that meet your operational needs while optimizing costs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before initiating the sourcing process, it is essential to clearly outline the technical requirements for the starter motors. Consider factors such as voltage, power output (kW rating), and compatibility with specific vehicle models.

– Power Rating: Ensure the starter motor can handle the starting requirements of the vehicles in your fleet.

– Size and Weight: Confirm that the motor fits the designated space in the vehicle.

Anschauliches Bild zum Fahrzeuganlasser

Schritt 2: Recherche von Lieferantenoptionen

Conduct thorough research to identify potential suppliers who specialize in vehicle starter motors. Utilize online directories, industry publications, and trade shows to compile a list of reputable manufacturers and distributors.

– Global Reach: Look for suppliers with experience in international shipping, particularly in your target regions.

– Produktpalette: Ensure they offer a variety of starter motors, including new and remanufactured options.

Schritt 3: Lieferantenzertifizierungen bewerten

Verifying supplier certifications is crucial for ensuring quality and compliance with industry standards. Request documentation such as ISO certifications or other relevant quality assurance processes.

– Quality Control: Suppliers with robust quality control systems are less likely to provide defective products.

– Einhaltung gesetzlicher Vorschriften: Ensure that the products meet regional regulations and safety standards.

Schritt 4: Muster zum Testen anfordern

Before making a large order, request samples of the starter motors to evaluate their performance and compatibility. Testing samples allows you to assess quality firsthand and avoid costly mistakes.

– Compatibility Tests: Ensure the sample works seamlessly with your vehicles.

– Leistungsbewertung: Monitor how the starter motor performs under typical operating conditions.

Schritt 5: Check Supplier References and Reviews

Reputation matters in B2B sourcing. Reach out to previous customers or check online reviews to gauge supplier reliability and product quality.

– Case Studies: Look for examples of successful partnerships with businesses similar to yours.

– Feedback on Customer Service: Assess how the supplier handles issues like returns or warranty claims.

Anschauliches Bild zum Fahrzeuganlasser

Schritt 6: Verhandeln Sie die Allgemeinen Geschäftsbedingungen

Once you have shortlisted suppliers, engage in negotiations to finalize the terms of purchase. Discuss pricing, payment options, lead times, and warranty conditions to ensure mutual understanding.

– Volume Discounts: Inquire about pricing breaks for bulk orders.

– After-Sales-Unterstützung: Clarify the level of support you can expect post-purchase, including warranty coverage and service options.

Schritt 7: Bestellung abschließen und Lieferung überwachen

After agreeing on terms, place your order and closely monitor the delivery process. Stay in communication with the supplier to address any potential issues promptly.

– Shipping Documentation: Ensure all necessary documentation is provided for customs clearance, especially for international shipments.

– Inventory Management: Plan for inventory storage and management upon receipt to maintain operational efficiency.

By following this checklist, B2B buyers can navigate the complexities of sourcing vehicle starter motors effectively, ensuring they procure high-quality products that meet their needs.

Umfassende Kosten- und Preisanalyse für die Beschaffung von Fahrzeuganlassern

What Are the Key Cost Components in Vehicle Starter Motor Sourcing?

When sourcing vehicle starter motors, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materialien: The raw materials for starter motors, such as copper for windings, steel for casings, and various electronic components, significantly influence the final price. Fluctuations in commodity prices can directly affect sourcing costs, making it crucial for buyers to stay updated on market trends.

-

Arbeit: Labor costs vary by region and the complexity of the manufacturing process. In countries with higher wage standards, such as Germany, the labor component will be more substantial than in regions like Vietnam or parts of Africa.

-

Fertigungsgemeinkosten: This includes costs associated with utilities, rent, and equipment maintenance. Efficient production facilities can minimize these overhead costs, impacting overall pricing.

-

Werkzeuge: Investment in tooling is necessary for producing starter motors. This upfront cost can be significant, especially for custom specifications, but it amortizes over high production volumes.

-

Qualitätskontrolle: Ensuring that starter motors meet international quality standards requires investment in testing and quality assurance processes. Certifications like ISO can add to the cost but are essential for markets that demand high-quality products.

-

Logistik: Shipping and handling costs can vary greatly depending on the distance, shipping method, and Incoterms used. Understanding these logistics can help buyers estimate total costs more accurately.

-

Marge: The profit margin for manufacturers typically ranges from 10% to 30%, depending on market competition and the unique value proposition of the product.

How Do Price Influencers Impact Vehicle Starter Motor Costs?

Several factors influence the pricing of vehicle starter motors, which can be crucial for B2B buyers to consider:

-

Menge/Mindestbestellmenge: Purchasing in bulk often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to maximize cost-efficiency.

-

Spezifikationen und Anpassung: Custom-engineered starter motors can significantly increase costs. Buyers should weigh the necessity of customization against potential cost savings from standard products.

-

Materialqualität und Zertifizierungen: Higher quality materials often lead to better performance and durability, justifying a higher price. Certifications may also be required in certain markets, affecting costs.

-

Lieferantenfaktoren: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge a premium for their products but often provide better quality assurance and service.

-

Incoterms: The choice of Incoterms can affect logistics costs and risks. Understanding who bears the cost and responsibility for transportation can help in budgeting and negotiating better deals.

What Are Essential Tips for B2B Buyers in Sourcing Starter Motors?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing effectiveness:

-

Verhandlung: Leverage your purchasing power to negotiate better terms. Building long-term relationships with suppliers can also lead to favorable pricing and terms.

-

Kosteneffizienz: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A cheaper starter motor may lead to higher long-term costs due to reliability issues.

-

Nuancen in der Preisgestaltung: Be aware of regional pricing differences and potential tariffs or trade barriers that may affect costs. Understanding local market conditions can provide a competitive edge.

-

Bewertung der Lieferanten: Conduct thorough due diligence on suppliers, including reviews of their financial stability, production capabilities, and quality control processes.

Schlussfolgerung

Navigating the complex landscape of vehicle starter motor sourcing requires a deep understanding of cost components, pricing influencers, and effective negotiation strategies. By considering these factors, B2B buyers can make informed decisions that not only meet their budgetary constraints but also align with their operational needs and quality expectations.

Haftungsausschluss: Prices and costs mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements.

Analyse der Alternativen: Vergleich des Fahrzeuganlassers mit anderen Lösungen

Alternativen zu Fahrzeuganlassern erforschen

In the automotive industry, the traditional vehicle starter motor has long been a reliable method for initiating engine operation. However, as technology evolves, several alternative solutions emerge that can potentially offer enhanced performance, cost efficiency, or ease of implementation. This analysis compares the vehicle starter motor with two viable alternatives: the Integrated Starter Generator (ISG) system and the manual starting method.

| Vergleichsaspekt | Fahrzeug-Startmotor | Integrierter Starter-Generator (ISG) | Manual Starting Method |

|---|---|---|---|

| Leistung | Hohes Drehmoment für schnelle Starts | Provides both starting and regenerative braking | Low torque; dependent on human effort |

| Kosten | Moderate initial investment; potential for high replacement costs | Higher upfront cost but reduced fuel consumption | Minimal cost; requires physical effort |

| Einfache Implementierung | Standardeinbau in die meisten Fahrzeuge | Requires specialized installation; not universally compatible | Simple; no installation required |

| Wartung | Regular checks needed; prone to wear | Generally low maintenance; integrated systems | Minimale Wartung; abhängig von den Fähigkeiten des Benutzers |

| Bester Anwendungsfall | Conventional vehicles; reliable performance in varied conditions | Hybrids and electric vehicles seeking efficiency | Vintage cars or situations lacking electric systems |

What Are the Advantages and Disadvantages of an Integrated Starter Generator (ISG)?

The Integrated Starter Generator (ISG) system represents a significant advancement in vehicle starting technology. It combines the functions of a starter motor and an alternator, allowing for engine start-up and energy recovery during braking. This dual functionality can lead to improved fuel efficiency and reduced emissions, making ISG systems ideal for hybrid and electric vehicles. However, the installation complexity and higher initial costs may deter some buyers, especially in markets where budget constraints are prevalent.

Anschauliches Bild zum Fahrzeuganlasser

How Does the Manual Starting Method Compare?

The manual starting method, often found in vintage vehicles or certain motorcycles, requires physical effort to initiate engine operation. While this method is cost-effective and eliminates the need for complex electrical systems, it lacks the reliability and convenience of electric starters. Moreover, it can be challenging for users, particularly in adverse weather conditions or when dealing with larger engines. This solution is best suited for niche markets or specific applications where simplicity and low cost are prioritized over performance.

How Should B2B Buyers Choose the Right Solution?

When selecting the most suitable starting solution, B2B buyers should assess their specific operational needs, budget constraints, and the types of vehicles in their fleet. For those operating conventional vehicles, the starter motor remains a dependable choice due to its established performance record. In contrast, buyers focused on reducing operational costs and improving sustainability may find ISG systems more appealing, despite the higher initial investment. Meanwhile, those dealing with vintage models or cost-sensitive environments may prefer the simplicity of manual starting methods. Ultimately, the decision should align with the buyer’s strategic goals and the unique demands of their market segment.

Wesentliche technische Eigenschaften und Fachterminologie für Fahrzeuganlasser

What Are the Key Technical Properties of Vehicle Starter Motors?

When selecting a vehicle starter motor, understanding its technical specifications is crucial for ensuring compatibility and performance. Here are some critical specs to consider:

1. Drehmoment

Torque rating is the measure of the rotational force that the starter motor can provide. It is typically expressed in Newton-meters (Nm) or foot-pounds (ft-lbs). For B2B buyers, understanding torque ratings is essential because they directly impact the starter’s ability to turn over different engine sizes. A higher torque rating is necessary for larger engines or those with higher compression ratios.

2. Power Consumption

Power consumption is usually measured in kilowatts (kW) and indicates the amount of electrical power the starter motor uses during operation. This property is vital for ensuring that the vehicle’s battery and electrical system can handle the demands of the starter. Buyers must consider this aspect to avoid battery drain issues, especially in regions with extreme temperatures where starter performance can be affected.

3. Werkstoffgüte

The materials used in the construction of the starter motor, such as copper for windings and high-grade steel for housings, affect durability and performance. Understanding material grades helps buyers assess the longevity of the starter motor under various operating conditions. High-quality materials can withstand heat and wear, reducing the likelihood of premature failure, which is particularly important for fleet operators in challenging environments.

4. Betriebstemperaturbereich

The operating temperature range specifies the ambient temperatures within which the starter motor can function effectively. This is particularly critical for B2B buyers in regions with extreme climates, as a starter motor that cannot operate within the required temperature range may lead to failures. Ensuring the right operating temperature range can prevent costly downtime and repairs.

5. Übersetzungsverhältnis

The gear ratio determines how the rotational speed of the starter motor translates to the flywheel. A suitable gear ratio is essential for maximizing efficiency and ensuring the engine starts reliably. Buyers should consider the gear ratio when matching a starter motor to specific engine types, as it affects both performance and fuel efficiency.

Anschauliches Bild zum Fahrzeuganlasser

What Are Common Trade Terms Used in the Starter Motor Industry?

Understanding trade terminology is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms relevant to vehicle starter motors:

1. OEM (Originalgerätehersteller)

OEM refers to parts that are made by the manufacturer of the original vehicle. These components are often preferred for their guaranteed compatibility and reliability. B2B buyers should be aware of OEM parts to ensure they are sourcing high-quality products that meet factory specifications.

2. MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for buyers to manage inventory levels and reduce costs. A high MOQ might necessitate larger upfront investment, which can be a consideration for smaller businesses or those with limited budgets.

3. RFQ (Angebotsanfrage)

An RFQ is a document used to invite suppliers to submit price proposals for specific products or services. This term is crucial for buyers seeking competitive pricing and ensuring they receive the best possible deal for starter motors.

Anschauliches Bild zum Fahrzeuganlasser

4. Incoterms (Internationale Handelsklauseln)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk transfer, and delivery obligations, which are critical for managing supply chain logistics.

5. Remanufactured

Remanufactured starter motors are used components that have been restored to like-new condition. This term is important for buyers looking for cost-effective solutions without compromising on quality. Understanding the remanufacturing process can help buyers evaluate whether such options meet their operational needs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing vehicle starter motors, ensuring they select the right components for their specific applications and requirements.

Marktdynamik und Beschaffungstrends im Bereich der Anlasser für Fahrzeuge

What Are the Global Drivers Influencing the Vehicle Starter Motor Market?

The vehicle starter motor market is witnessing significant growth driven by several global factors. The increasing demand for efficient and reliable automotive components, particularly in emerging markets such as Africa and South America, is a key driver. As vehicle ownership rises in these regions, the need for high-quality starter motors becomes imperative to ensure reliability and performance. Additionally, the shift towards electric vehicles (EVs) and hybrid technologies is reshaping the starter motor landscape, with manufacturers innovating to create integrated starter-generator systems that cater to this new demand.

Emerging technologies such as automation and digitalization are also influencing sourcing trends. B2B buyers are now leveraging advanced analytics and IoT to optimize their supply chains, ensuring timely procurement and reducing downtime in automotive operations. The emphasis on remanufactured parts is growing, as businesses seek cost-effective solutions without compromising on quality. This trend is particularly relevant in regions like Europe and the Middle East, where sustainability and cost-efficiency are paramount.

How Are Sustainability and Ethical Sourcing Shaping the Vehicle Starter Motor Industry?

Sustainability and ethical sourcing have become central to the vehicle starter motor sector, reflecting a broader shift in B2B procurement strategies. The environmental impact of automotive manufacturing is under scrutiny, prompting buyers to prioritize suppliers who adhere to sustainable practices. This includes the use of recyclable materials in starter motor production and the implementation of energy-efficient manufacturing processes.

Ethical supply chains are critical, especially in regions with less stringent regulations. Buyers are increasingly seeking suppliers with certifications such as ISO 14001, which indicates a commitment to environmental management. The integration of green materials, such as eco-friendly lubricants and non-toxic components, is also gaining traction, appealing to environmentally conscious consumers and businesses alike. By aligning their sourcing strategies with sustainability goals, B2B buyers can enhance their brand reputation while contributing to global environmental efforts.

What Is the Historical Context of the Vehicle Starter Motor Development?

The vehicle starter motor has undergone significant evolution since its inception in the early 20th century. Invented by Charles Kettering in 1911, the electric starter revolutionized automotive design, making cars more accessible and easier to operate. Initially integrated with ignition and generating systems, the starter motor has since evolved into a standalone component, reflecting advancements in technology and automotive engineering.

The introduction of advanced materials and designs has enhanced the efficiency and reliability of starter motors, catering to the diverse needs of modern vehicles. The modern landscape now includes high-performance and hybrid starter motors that align with the growing trend toward electrification in the automotive industry. This historical context is crucial for B2B buyers, as understanding the evolution of starter motor technology can inform sourcing decisions and highlight the importance of selecting suppliers who are at the forefront of innovation.

Häufig gestellte Fragen (FAQs) für B2B-Käufer von Fahrzeuganlassern

-

How do I determine if a starter motor is the right fit for my vehicle?

To ensure the correct starter motor is selected for your vehicle, you should first consult the vehicle’s specifications, including the make, model, and year. Additionally, consider the starter motor’s power rating (kW) and whether it meets the torque requirements for your engine. It’s also advisable to verify compatibility with your vehicle’s electrical system. If available, manufacturer part numbers can be cross-referenced to ensure accuracy. Engaging with your supplier about these specifications will help mitigate compatibility issues. -

What is the best starter motor brand for heavy-duty applications?

For heavy-duty applications, reputable brands like Bosch, ACDelco, and Powermaster Performance are often considered the best options due to their high-quality construction and reliability. These brands have a proven track record in demanding environments, ensuring durability and performance. When sourcing, look for specific models designed for heavy-duty use, as they typically feature enhanced torque and robust materials. Always check for warranty and support options, as they can be indicative of brand reliability. -

What should I consider when vetting international suppliers for starter motors?

When vetting international suppliers, consider their manufacturing capabilities, certifications (ISO, TS), and reputation in the industry. Request references or testimonials from previous clients to gauge reliability. Additionally, verify their compliance with international quality standards and regulations, especially regarding safety and environmental practices. It’s also prudent to assess their logistics capabilities and delivery timelines to ensure they align with your operational needs. -

What are the minimum order quantities (MOQs) for vehicle starter motors?

Minimum order quantities can vary significantly based on the supplier and the specific starter motor models. Typically, MOQs for vehicle starter motors range from 50 to 500 units. Larger orders may qualify for better pricing or discounts. Always discuss MOQs with your supplier, as some may offer flexibility for first-time buyers or smaller businesses. Understanding the MOQ can help you plan your inventory and budget accordingly. -

What payment terms should I expect when sourcing starter motors internationally?

Payment terms can vary widely among suppliers, but common practices include partial payments upfront (30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer credit terms based on your business relationship and payment history. It’s essential to clarify these terms before finalizing any agreement to avoid misunderstandings. Consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. -

How can I ensure quality assurance (QA) for the starter motors I import?

To ensure quality assurance, request detailed product specifications and manufacturing processes from your supplier. Consider conducting third-party inspections at the factory before shipment, which can help identify any defects or non-compliance with your standards. Additionally, inquire about the supplier’s quality control measures, including testing procedures for their starter motors. Establishing a clear return policy for defective products is also crucial for mitigating risks. -

Welche logistischen Überlegungen sollte ich beim Import von Anlassern anstellen?

When importing starter motors, consider shipping costs, delivery timelines, and customs regulations in your country. Work with your supplier to determine the best shipping method (air vs. sea) based on urgency and cost. Ensure you have all necessary import documentation to avoid delays at customs. It’s also wise to discuss insurance options for your shipment to protect against loss or damage during transit. -

What are common causes of starter motor failure, and how can I address them?

Common causes of starter motor failure include worn bearings, electrical connection issues, and insulation breakdown. To address these, ensure regular maintenance checks on the starter motor and surrounding electrical systems. If a starter motor exhibits symptoms like clicking without turning, check the battery and connections first. For preventive measures, consider investing in high-quality starter motors from reputable suppliers, which often come with warranties and support for troubleshooting issues.

Top 1 Vehicle Starter Motor Manufacturers & Suppliers List

1. 1A Auto – Starters

Domäne: 1aauto.de

Registriert: 1999 (26 Jahre)

Einleitung: Starters are small electric motors that engage with the engine’s flywheel to crank the engine and start the combustion cycle. There are different types of starters including inertia starters, pre-engaged starters, and gear reduction starters. Inertia starters engage the ring gear through a threaded pinion that spins out as the motor runs. Pre-engaged starters use a solenoid to push the pinion out …

Strategische Beschaffung Schlussfolgerung und Ausblick für Fahrzeuganlasser

In summary, effective strategic sourcing of vehicle starter motors is essential for international B2B buyers aiming to enhance operational efficiency and reduce costs. Key takeaways include the importance of selecting reliable manufacturers, understanding the technical specifications required for different vehicle models, and being aware of the potential for both new and remanufactured starter motors. Buyers should prioritize suppliers that offer comprehensive testing and quality assurance processes to mitigate the risk of premature failure and associated costs.

As the automotive industry evolves, particularly with the rise of hybrid and electric vehicles, the demand for high-quality starter motors will only increase. Buyers must stay ahead of market trends, leveraging strategic partnerships to ensure access to the latest technologies and innovations.

Looking forward, international B2B buyers from Africa, South America, the Middle East, and Europe should actively engage with suppliers who can deliver both value and reliability. By prioritizing strategic sourcing, businesses can not only optimize their supply chains but also position themselves for sustainable growth in a rapidly changing market. Embrace the opportunity to enhance your procurement strategies today and secure a competitive edge in the automotive sector.

Anschauliches Bild zum Fahrzeuganlasser

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.