Introduction: Navigating the Global Market for tyc starter

In today’s competitive automotive landscape, sourcing a reliable TYC starter can pose significant challenges for international B2B buyers. With varying standards, regional preferences, and quality expectations, ensuring that you secure a starter motor that meets your specific needs is crucial. This guide aims to provide a comprehensive overview of TYC starters, covering various types, applications, and critical considerations for supplier vetting. By delving into essential factors such as cost analysis, product specifications, and market trends, we equip you with the knowledge to make informed purchasing decisions.

As a buyer from regions like Africa, South America, the Middle East, or Europe—including countries like Vietnam and Germany—you face unique obstacles, including logistical concerns and differing regulatory requirements. This guide not only addresses these challenges but also highlights best practices in sourcing and evaluating suppliers. Whether you are looking for starters for heavy-duty vehicles or passenger cars, understanding the nuances of the TYC starter market will empower you to negotiate better deals and establish long-term partnerships.

By the end of this guide, you will have a clear roadmap for navigating the complexities of the global TYC starter market, ensuring that you can confidently procure high-quality products that align with your operational needs.

Inhaltsverzeichnis

- Top 5 Tyc Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for tyc starter

- Understanding tyc starter Types and Variations

- Key Industrial Applications of tyc starter

- 3 Common User Pain Points for ‘tyc starter’ & Their Solutions

- Strategic Material Selection Guide for tyc starter

- In-depth Look: Manufacturing Processes and Quality Assurance for tyc starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tyc starter’

- Comprehensive Cost and Pricing Analysis for tyc starter Sourcing

- Alternatives Analysis: Comparing tyc starter With Other Solutions

- Essential Technical Properties and Trade Terminology for tyc starter

- Navigating Market Dynamics and Sourcing Trends in the tyc starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tyc starter

- Strategic Sourcing Conclusion and Outlook for tyc starter

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding tyc starter Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Untersetzungsgetriebe-Anlasser | Compact design, increased torque, and efficiency | Heavy-duty vehicles, trucks | Vorteile: High performance, reduced battery strain. Nachteile: May have a higher initial cost. |

| Direct Drive Starter | Simple design, typically lighter and cheaper | Light-duty vehicles, sedans | Vorteile: Kostengünstig, leicht zu ersetzen. Nachteile: Less torque, potential for more wear. |

| Hochleistungsstarter | Enhanced power output, often used in racing applications | Performance and racing vehicles | Vorteile: Superior starting power. Nachteile: May not be suitable for standard applications. |

| Überholter Anlasser | Rebuilt from used components, tested for reliability | Flottenfahrzeuge, preisbewusste Käufer | Vorteile: Geringere Kosten, umweltfreundlich. Nachteile: Variable quality, potential for shorter lifespan. |

| OEM Equivalent Starter | Designed to meet original equipment specifications | OEM replacements in various vehicles | Vorteile: Guaranteed compatibility, reliability. Nachteile: Often more expensive than aftermarket options. |

Was sind die Merkmale von Getriebestartern?

Gear reduction starters are designed to provide enhanced torque and efficiency, making them ideal for heavy-duty applications like trucks and other commercial vehicles. Their compact design allows for a lighter weight, which can contribute to overall vehicle efficiency. When purchasing, consider the specific torque requirements of the vehicle, as these starters can significantly reduce battery strain during the starting process. However, they may come with a higher initial cost, which could be a consideration for budget-conscious B2B buyers.

How Do Direct Drive Starters Compare to Other Types?

Direct drive starters are characterized by their simple design, which typically results in a lighter weight and lower cost compared to other types. They are commonly used in light-duty vehicles and sedans, making them a popular choice for fleet operators looking to minimize expenses. While they are easy to replace and maintain, direct drive starters may not provide the same level of torque as gear reduction starters, leading to potential wear issues over time. Buyers should weigh the cost savings against the performance needs of their vehicles.

What Makes High-Performance Starters Unique?

High-performance starters are engineered for superior power output, making them the preferred choice for racing and performance vehicles. These starters are built to handle the increased demands of high-revving engines, ensuring reliable starts under extreme conditions. For B2B buyers in the automotive racing industry, investing in high-performance starters can enhance vehicle reliability and performance on the track. However, their specialized nature means they may not be suitable for standard applications, and their cost can be significantly higher.

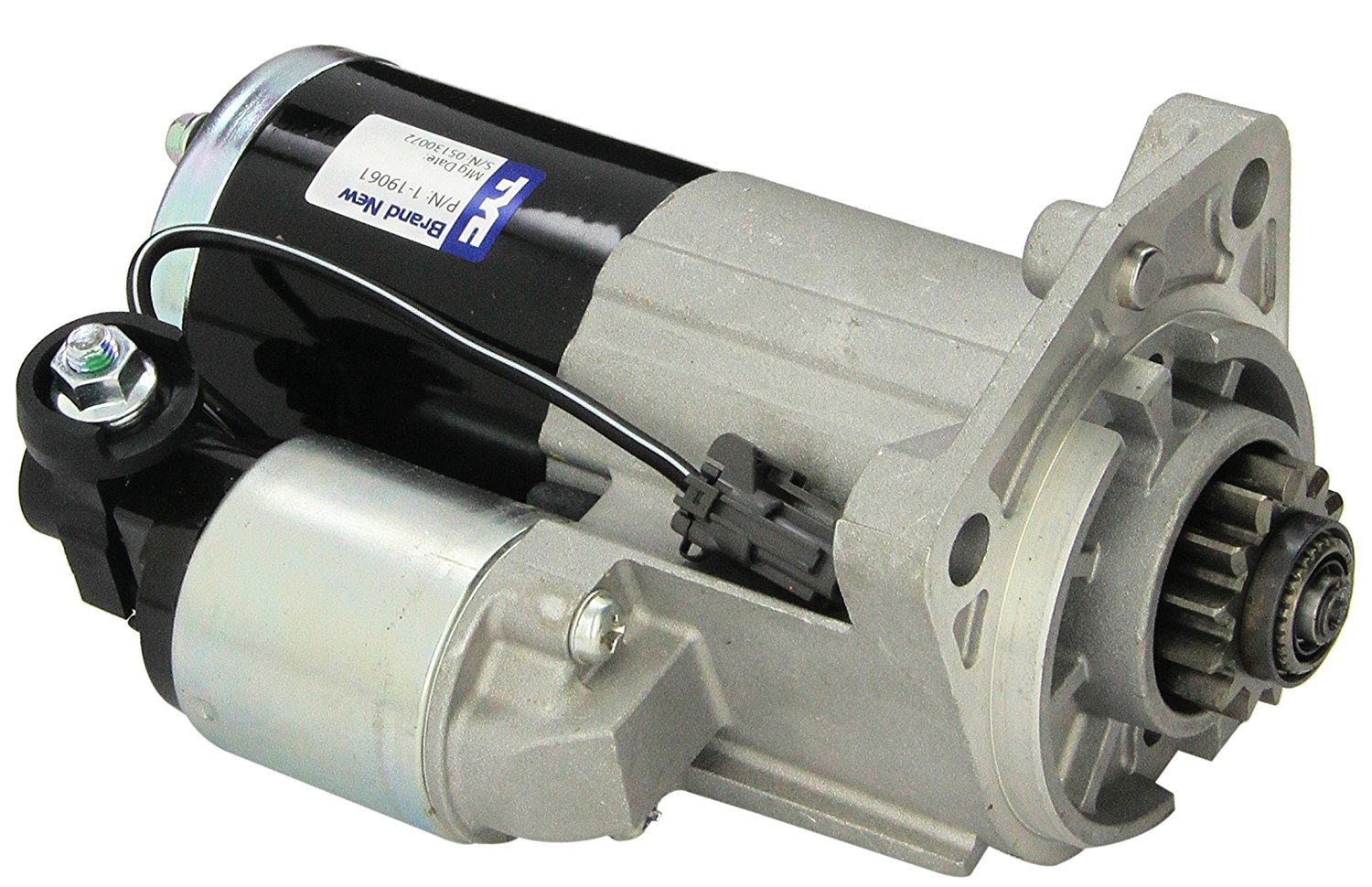

Illustrative image related to tyc starter

Why Consider Remanufactured Starters for Fleet Use?

Remanufactured starters offer a cost-effective solution for fleet vehicles, as they are rebuilt from used components and rigorously tested for reliability. This option is particularly appealing to budget-conscious buyers who need to maintain a fleet without incurring high costs. However, the quality of remanufactured starters can vary, so it’s essential to source them from reputable suppliers to ensure reliability. While they are eco-friendly, offering a sustainable alternative to new parts, buyers should be aware of the potential for a shorter lifespan.

What Are the Advantages of OEM Equivalent Starters?

OEM equivalent starters are designed to meet the specifications set by original equipment manufacturers, ensuring compatibility and reliability in various vehicles. They are often the go-to choice for businesses looking to replace faulty starters in a fleet or for maintenance in service centers. While OEM starters guarantee performance and fit, they typically come at a premium price compared to aftermarket options. B2B buyers should consider the balance between cost and quality when selecting starters for their operations.

Key Industrial Applications of tyc starter

| Branche/Sektor | Specific Application of tyc starter | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Replacement for OEM starters in assembly lines | Ensures reliable vehicle start-up, reducing downtime | Quality assurance certifications, compatibility with models |

| Schwere Maschinen | Starter motors for construction and agricultural equipment | Enhances operational efficiency in rugged environments | Langlebigkeit unter extremen Bedingungen, Garantiebedingungen |

| Transport & Logistik | Fleet vehicle maintenance and repair | Minimizes operational disruptions, ensuring timely deliveries | Bulk purchasing options, lead times for international shipping |

| Schifffahrt & Offshore | Starter motors for marine vessels | Reliable performance in harsh marine conditions | Resistance to corrosion, compliance with maritime regulations |

| Bergbauarbeiten | Heavy-duty starters for mining equipment | Increases reliability and reduces maintenance costs | Performance in high-load applications, technical support availability |

How is the TYC Starter Used in Automotive Manufacturing?

In the automotive manufacturing sector, TYC starters are primarily used as replacement components in assembly lines. These starters provide a cost-effective solution for manufacturers looking to maintain high production efficiency. By ensuring reliable vehicle start-up, TYC starters help reduce downtime, allowing for a smoother assembly process. International buyers should consider sourcing options that guarantee compatibility with specific vehicle models and ensure quality assurance certifications to meet industry standards.

What Role Does the TYC Starter Play in Heavy Machinery?

In the heavy machinery industry, TYC starters are integral to construction and agricultural equipment. These starters are designed to operate efficiently in rugged environments, where reliability is crucial. They enhance operational efficiency by ensuring that machinery starts promptly, even under challenging conditions. Buyers in this sector must prioritize durability and performance specifications, as well as warranty terms to safeguard their investment in demanding applications.

Why is the TYC Starter Important for Transportation and Logistics?

In transportation and logistics, TYC starters are vital for the maintenance and repair of fleet vehicles. Reliable starting mechanisms minimize operational disruptions, which is essential for ensuring timely deliveries. Businesses should look for bulk purchasing options that can help reduce costs while considering lead times for international shipping to ensure that replacements are available when needed. This is particularly relevant for companies operating in regions with logistical challenges.

How Does the TYC Starter Benefit Marine and Offshore Applications?

In marine and offshore industries, TYC starters are used in various vessels to ensure reliable performance in harsh marine conditions. The ability to withstand corrosion and extreme weather is critical for marine applications. Buyers should prioritize starters that comply with maritime regulations and offer robust performance metrics, as the reliability of these components directly impacts vessel operations and safety.

What Advantages Does the TYC Starter Offer in Mining Operations?

In mining operations, heavy-duty TYC starters are essential for starting large mining equipment. These starters are designed to handle high-load applications, ensuring that machinery can operate efficiently without frequent breakdowns. Buyers should focus on the technical support available from suppliers and the performance specifications that align with their operational needs. This focus on reliability can lead to significant reductions in maintenance costs, making TYC starters an attractive option for mining companies.

3 Common User Pain Points for ‘tyc starter’ & Their Solutions

Scenario 1: Difficulty in Finding Reliable Sources for TYC Starters

Das Problem: B2B buyers often face challenges in sourcing TYC starters from reliable suppliers. This issue is particularly acute in regions like Africa and South America, where local markets may be flooded with counterfeit or substandard products. Buyers may struggle with the risk of purchasing from vendors who do not offer warranties or proper product information, leading to potential operational disruptions in their businesses. The financial implications of sourcing the wrong starter can be significant, impacting not only repair costs but also vehicle downtime.

Illustrative image related to tyc starter

Die Lösung: To mitigate these risks, B2B buyers should establish relationships with authorized distributors or manufacturers of TYC starters. Conducting thorough research to verify supplier credentials can help ensure the quality of the products. Buyers should look for suppliers who provide detailed product specifications, performance data, and customer testimonials. Additionally, leveraging online platforms that specialize in automotive parts can help locate trusted vendors. It’s also advisable to request samples or test units before placing larger orders, which will allow buyers to assess the product quality firsthand.

Scenario 2: Concerns Over Performance and Reliability of TYC Starters

Das Problem: Another common pain point for B2B buyers is the concern regarding the performance and reliability of TYC starters. Buyers may have heard mixed reviews about the brand, leading to hesitance in making a commitment. This is especially true for businesses operating in demanding environments, where the reliability of starter motors is crucial for their fleet’s performance. The fear of frequent replacements or failures can lead to increased operational costs and logistical headaches.

Die Lösung: To address these concerns, B2B buyers should conduct a performance analysis based on their specific operational needs. This includes understanding the typical conditions under which the vehicles will operate, such as temperature extremes and load requirements. Engaging with industry forums and communities can provide insights from other users who have successfully integrated TYC starters into their fleets. Buyers should also consider implementing a warranty policy that allows for returns or exchanges if the product does not meet performance expectations. Additionally, investing in a periodic review of starter performance can help identify potential issues early, ensuring proactive replacements before failures occur.

Scenario 3: Navigating Technical Specifications and Compatibility Issues

Das Problem: B2B buyers often encounter difficulties when it comes to understanding the technical specifications and compatibility of TYC starters with their vehicles. Given the diversity of models and configurations, selecting the wrong starter can lead to installation challenges and additional costs. This is particularly challenging for buyers in regions where technical support may be limited, leading to uncertainty and potential project delays.

Die Lösung: To effectively navigate these technical challenges, B2B buyers should invest time in understanding the compatibility requirements of TYC starters with their existing vehicle models. Utilizing TYC’s online resources, such as installation manuals and compatibility charts, can provide valuable information. It’s also beneficial to involve qualified technicians during the selection process, as their expertise can ensure that the correct starter is chosen. Buyers should maintain open communication with suppliers regarding technical queries and seek guidance on installation best practices. Creating a checklist of required specifications and vehicle compatibility can streamline the selection process and reduce the risk of errors.

Strategic Material Selection Guide for tyc starter

What Materials Are Commonly Used in TYC Starters and How Do They Affect Performance?

When selecting materials for TYC starters, it is essential to consider various factors that influence performance, durability, and cost. The following analysis focuses on four common materials used in TYC starters: aluminum, steel, copper, and plastic composites. Each material has unique properties and implications for international B2B buyers.

How Does Aluminum Impact TYC Starters?

Aluminum is a popular choice for TYC starter housings due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 150°C, making it suitable for automotive applications where heat dissipation is crucial.

Vorteile: Aluminum is durable yet lightweight, reducing the overall weight of the starter, which can enhance vehicle performance. It is also resistant to rust and corrosion, extending the lifespan of the component.

Nachteile: While aluminum is generally cost-effective, it may not withstand high-impact forces as well as steel. Additionally, the manufacturing process can be more complex, requiring specialized techniques such as die-casting.

Auswirkungen auf die Anwendung: Aluminum starters are compatible with various automotive environments, particularly in humid or corrosive conditions.

Überlegungen für internationale Käufer: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding aluminum use in automotive parts, as standards may vary.

What Role Does Steel Play in TYC Starters?

Steel is often utilized for components requiring high strength and durability, such as the starter’s internal gears. Steel can handle high pressure and has a temperature rating that can exceed 200°C, making it suitable for demanding applications.

Vorteile: Steel is incredibly strong and resistant to wear, making it ideal for components that experience significant mechanical stress. It is also relatively inexpensive compared to other materials.

Nachteile: Steel is heavier than aluminum and may be prone to rust if not properly treated. The manufacturing process can also be more energy-intensive, impacting overall sustainability.

Auswirkungen auf die Anwendung: Steel starters are well-suited for high-performance vehicles and heavy-duty applications, where strength and reliability are paramount.

Illustrative image related to tyc starter

Überlegungen für internationale Käufer: Compliance with ASTM standards is crucial for buyers in Europe and the Middle East, where quality assurance is highly emphasized.

How Does Copper Enhance Electrical Performance in TYC Starters?

Copper is primarily used in electrical contacts and windings within TYC starters due to its excellent electrical conductivity. It can handle high currents and has a temperature rating of around 200°C.

Vorteile: Copper’s high conductivity ensures efficient energy transfer, which is critical for reliable starter performance. It also has good corrosion resistance when properly coated.

Nachteile: Copper is more expensive than aluminum and steel, which can increase the overall cost of the starter. Additionally, it is heavier, which may affect the weight distribution in some applications.

Auswirkungen auf die Anwendung: Copper is ideal for electrical components, ensuring quick and reliable starting in various environmental conditions.

Überlegungen für internationale Käufer: Buyers should be aware of the regulations regarding copper use, particularly in regions with strict environmental controls, such as Germany.

How Do Plastic Composites Contribute to TYC Starters?

Plastic composites are increasingly used in TYC starters, particularly for housings and insulation. These materials can withstand temperatures up to 120°C and offer good chemical resistance.

Vorteile: Plastic composites are lightweight and can be molded into complex shapes, reducing manufacturing costs. They also provide excellent insulation, enhancing electrical safety.

Nachteile: While they are resistant to corrosion, plastic composites may not be as durable as metal options under extreme mechanical stress.

Auswirkungen auf die Anwendung: Plastic composites are suitable for non-structural components where weight reduction is a priority.

Überlegungen für internationale Käufer: Compliance with JIS standards is important for buyers in Asia, where plastic materials must meet specific quality benchmarks.

Summary Table of Material Selection for TYC Starters

| Material | Typical Use Case for TYC Starter | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Starter housing | Leicht und korrosionsbeständig | Less impact resistance than steel | Mittel |

| Stahl | Internal gears | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Rost | Niedrig |

| Kupfer | Electrical contacts | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und höheres Gewicht | Hoch |

| Kunststoffverbundwerkstoffe | Gehäuse und Isolierung | Leicht und formbar | Less durable under mechanical stress | Mittel |

This guide provides valuable insights into material selection for TYC starters, helping international B2B buyers make informed decisions that align with their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tyc starter

What Are the Key Manufacturing Processes for TYC Starters?

The manufacturing process for TYC starters is designed to ensure high performance and durability, aligning with the demands of the automotive industry. The process can be broken down into several main stages: material preparation, forming, assembly, and finishing.

Materialvorbereitung

The first step involves sourcing high-quality raw materials, which typically include steel, copper, and various alloys. These materials are selected based on their electrical and mechanical properties. The preparation phase includes cutting and shaping the materials to the required specifications. Advanced machining techniques, such as CNC (Computer Numerical Control) machining, are often employed to achieve precise dimensions and tolerances. This accuracy is crucial for the starter’s performance and longevity.

Forming Techniques Used in TYC Starter Production

Once the materials are prepared, they undergo various forming processes. Stamping is a common technique used to create the starter’s housing and other components. This method allows for mass production while maintaining consistent quality. Additionally, die-casting is employed for certain parts, ensuring that components are robust and can withstand the operational stresses of automotive applications.

Assembly of TYC Starters

The assembly phase is where individual components come together to form the final product. Automated assembly lines are often utilized, enhancing efficiency and reducing the risk of human error. During this phase, components such as the armature, commutator, and solenoid are integrated. Each starter is then subjected to a series of checks to ensure that all parts fit correctly and function as intended.

Finishing Processes for Enhanced Durability

The finishing stage includes surface treatments to enhance corrosion resistance and overall durability. Techniques such as powder coating or plating are commonly used to protect the starter from environmental factors. These treatments not only improve the aesthetic appeal of the product but also extend its operational lifespan, which is a crucial consideration for international buyers who operate in diverse environments.

How Is Quality Assurance Implemented in TYC Starter Production?

Quality assurance is integral to the manufacturing of TYC starters, ensuring that each product meets international standards and customer expectations. The quality control process is governed by various international and industry-specific standards, including ISO 9001, CE certification, and API standards.

What International Standards Are Relevant for TYC Starters?

ISO 9001 is a widely recognized quality management system that emphasizes customer satisfaction and continuous improvement. Compliance with this standard indicates that TYC follows a structured approach to quality management, which is crucial for B2B buyers seeking reliable products. CE certification is essential for products sold within the European market, ensuring they meet safety and environmental requirements.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle?

The quality assurance process includes several critical checkpoints:

-

Eingangsqualitätskontrolle (IQC): This initial stage verifies the quality of raw materials before they are used in production. Suppliers must provide certificates of compliance and other documentation to confirm that their materials meet specified standards.

-

In-Process-Qualitätskontrolle (IPQC): During manufacturing, ongoing inspections are conducted at various stages. This ensures that any defects are identified and rectified immediately, preventing them from progressing to the next phase.

-

Endkontrolle (FQC): Once assembly is complete, each starter undergoes rigorous testing. This includes electrical tests, functional tests, and performance evaluations to ensure that they meet or exceed industry standards.

What Common Testing Methods Are Used?

Common testing methods for TYC starters include load testing, which assesses the starter’s ability to perform under operational conditions, and thermal cycling tests, which evaluate performance under varying temperature conditions. Vibration tests are also conducted to simulate real-world operational stresses. These comprehensive testing protocols are vital for ensuring that the starters perform reliably in diverse environments.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. There are several strategies to ensure that suppliers meet the necessary quality standards.

What Are Effective Verification Methods?

1. Lieferantenaudits: Conducting on-site audits allows buyers to directly assess the manufacturing processes and quality control systems in place. This firsthand observation can provide insights into the supplier’s commitment to quality.

Illustrative image related to tyc starter

-

Anforderung von Qualitätsberichten: Suppliers should provide detailed quality control reports, including data from IQC, IPQC, and FQC stages. These reports offer transparency and assurance regarding the quality of the products being supplied.

-

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These organizations can conduct independent tests and provide certification that the products meet specified standards.

What Nuances Should International Buyers Consider?

Buyers from different regions may face unique challenges related to quality assurance. For instance, understanding local regulations and compliance requirements is crucial for importing automotive components. Additionally, varying levels of infrastructure and manufacturing capabilities in different regions can impact quality. Therefore, maintaining open communication with suppliers regarding expectations and standards is essential.

Schlussfolgerung

In summary, the manufacturing processes and quality assurance protocols for TYC starters are designed to meet high industry standards. By understanding these processes, international B2B buyers can make informed decisions, ensuring they procure reliable and high-quality automotive components. By leveraging quality control checkpoints and verification methods, buyers can mitigate risks and foster successful partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tyc starter’

In the competitive landscape of B2B procurement, sourcing a reliable TYC starter motor is critical for ensuring operational efficiency and minimizing downtime. This practical guide provides a step-by-step checklist to streamline your sourcing process, ensuring you make informed decisions that align with your business needs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Establishing precise technical specifications is essential for selecting the right TYC starter for your application. Consider factors such as the engine model, voltage requirements, and starter type (gear reduction vs. direct drive). This clarity will help you communicate your needs effectively to suppliers and avoid mismatches.

Schritt 2: Recherche über seriöse Anbieter

Conduct thorough research to identify reputable suppliers of TYC starters. Look for suppliers with a solid track record, positive customer reviews, and industry recognition. Utilize platforms like trade directories and industry forums to gather insights into supplier reliability and product quality.

Schritt 3: Lieferantenzertifizierungen bewerten

Before finalizing your supplier, verify their certifications and compliance with industry standards. Key certifications to look for include ISO 9001 for quality management and any specific automotive standards relevant to your region. Ensuring that your supplier adheres to these standards can significantly reduce the risk of receiving subpar products.

Schritt 4: Produktmuster anfordern

Requesting product samples can be a pivotal step in the sourcing process. This allows you to assess the quality, durability, and performance of the TYC starter firsthand. During this evaluation, check for any documentation like testing reports or quality assurance certifications that accompany the samples.

Schritt 5: Preise und Konditionen vergleichen

Once you’ve identified potential suppliers, compare their pricing structures and payment terms. Ensure that the pricing reflects the quality of the product and includes all additional costs such as shipping and customs duties. Look for flexible payment options that align with your budget and cash flow needs.

Schritt 6: Bewertung des After-Sales-Supports

Strong after-sales support is crucial for ongoing satisfaction and operational continuity. Investigate the warranty terms, return policies, and customer service responsiveness of each supplier. A supplier that offers robust support can provide peace of mind and assistance should any issues arise post-purchase.

Schritt 7: Gather References and Reviews

Finally, seek references and reviews from other businesses that have sourced TYC starters. Engaging with current or past customers can provide valuable insights into the supplier’s reliability, product performance, and overall service quality. This step can help mitigate risks and ensure you’re making a sound investment.

By following this checklist, you can confidently navigate the sourcing process for TYC starters, ensuring that you select a product that meets your technical requirements and aligns with your business objectives.

Comprehensive Cost and Pricing Analysis for tyc starter Sourcing

In the competitive landscape of automotive components, understanding the cost structure and pricing dynamics of TYC starters is crucial for international B2B buyers. This analysis delves into the various cost components, price influencers, and practical buyer tips, especially relevant for markets in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components of TYC Starters?

The cost structure of TYC starters is influenced by several critical components:

-

Materialien: High-quality raw materials are essential for the production of durable starters. Costs vary based on metal prices (e.g., copper and aluminum) and the quality of insulating materials used.

-

Arbeit: Labor costs play a significant role, especially in regions with varying wage standards. Skilled labor is necessary for assembly and quality control, impacting the overall pricing.

-

Fertigungsgemeinkosten: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can help keep these costs in check.

-

Werkzeuge: Initial investments in tooling for starter production can be substantial. These costs may be amortized over large production runs, influencing unit pricing.

-

Qualitätskontrolle (QC): Rigorous QC processes ensure the reliability and performance of starters. This involves testing and certification, which can add to the overall cost but is critical for market acceptance.

-

Logistik: Transportation and warehousing costs vary significantly based on geographic location. Import duties and tariffs can further complicate logistics costs for international buyers.

-

Marge: Suppliers typically add a margin to cover their costs and generate profit. The margin can vary based on supplier reputation, market demand, and competition.

How Do Price Influencers Impact TYC Starter Pricing?

Several factors can influence the pricing of TYC starters, particularly in a B2B context:

-

Volumen und Mindestbestellmenge (MOQ): Larger orders often attract discounts due to economies of scale. Understanding MOQ requirements can lead to cost savings for buyers.

-

Spezifikationen und Anpassung: Custom specifications can increase costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Materialien und Qualitätszertifizierungen: The choice of materials and compliance with international quality standards (e.g., ISO certifications) can impact pricing. Higher-quality starters often come at a premium but can offer better longevity and performance.

-

Lieferantenfaktoren: Relationships with suppliers can lead to more favorable pricing. Long-term partnerships may yield better terms and flexibility in negotiations.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is essential for cost management. These terms define responsibilities for shipping, insurance, and tariffs, affecting the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for TYC Starters?

For international buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes:

-

Forschung und Benchmarking: Conduct thorough market research to benchmark prices against competitors. Having data on average costs can strengthen negotiation positions.

-

Gesamtbetriebskosten (TCO): Consider the TCO rather than just the purchase price. Evaluate factors such as expected lifespan, warranty, and maintenance costs to assess overall value.

-

Leverage Volume Purchases: If feasible, consolidate orders across multiple products to meet MOQ requirements and negotiate bulk pricing.

-

Flexible Payment Terms: Negotiating favorable payment terms can ease cash flow and provide financial flexibility. Consider options like staggered payments or discounts for early payment.

-

Understanding Local Market Nuances: Recognize that pricing may be influenced by local economic conditions, currency fluctuations, and trade policies. Tailoring negotiation strategies to these factors can lead to better outcomes.

Schlussfolgerung

Navigating the cost and pricing landscape of TYC starters requires a thorough understanding of the various components and influencing factors. By leveraging insights into cost structures, engaging in strategic negotiations, and considering the Total Cost of Ownership, international B2B buyers can make informed purchasing decisions that align with their operational needs and market conditions. Always remember that prices can vary significantly based on the aforementioned factors, and it’s advisable to seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing tyc starter With Other Solutions

Understanding Alternatives to the TYC Starter

In today’s competitive market, B2B buyers must evaluate various options when selecting automotive starter solutions. The TYC starter has gained recognition for its affordability and performance, but several alternatives may better suit specific operational needs. This analysis compares the TYC starter with two viable alternatives: the Denso Starter and the Bosch Starter.

| Vergleichsaspekt | TYC Starter | Denso Starter | Bosch Starter |

|---|---|---|---|

| Leistung | Reliable with good torque; suitable for standard applications. | High efficiency; known for quick starts and durability. | Excellent power output; ideal for heavy-duty applications. |

| Kosten | Generally lower-priced ($68) with no core fee. | Mid-range pricing; often more expensive due to quality. | Premium pricing; reflects superior engineering and technology. |

| Einfache Implementierung | Straightforward installation; comes with installation tips. | Requires specific knowledge for installation; generally user-friendly. | Installation can be complex; often necessitates professional help. |

| Wartung | Low maintenance; typically robust but check battery health regularly. | Minimal maintenance; reliable long-term performance. | Low maintenance; built to withstand harsh conditions. |

| Bester Anwendungsfall | Ideal for cost-sensitive projects or older vehicles. | Best for modern vehicles needing reliable performance. | Optimal for commercial vehicles and high-demand applications. |

What Are the Pros and Cons of Using a Denso Starter?

The Denso starter is renowned for its efficiency and reliability, making it a popular choice among B2B buyers. Its performance is often superior, providing quick starts even in challenging conditions. However, the cost can be significantly higher than the TYC starter, which may be a consideration for budget-conscious buyers. Denso starters are generally user-friendly, but their installation can require specific knowledge, which may lead to additional labor costs if professional help is needed.

Why Consider a Bosch Starter as an Alternative?

Bosch starters are engineered for heavy-duty applications, offering excellent power output and reliability. They are particularly well-suited for commercial vehicles that operate in demanding environments. While Bosch products are typically priced at a premium, their durability can justify the investment over time. However, installation can be complex, often requiring professional expertise, which can add to the total cost of ownership. Buyers should weigh these factors carefully, especially if their operations involve high usage and potential wear and tear.

How to Choose the Right Starter for Your Needs

When evaluating the TYC starter against alternatives like the Denso and Bosch starters, B2B buyers should consider their specific operational requirements. Factors such as budget constraints, vehicle type, and anticipated usage intensity will heavily influence the decision. For those prioritizing cost-effectiveness, the TYC starter presents a viable option. However, for businesses requiring higher reliability and performance, investing in a Denso or Bosch starter may yield better long-term results. Ultimately, the right choice will align with operational demands and financial considerations, ensuring optimal performance and value.

Essential Technical Properties and Trade Terminology for tyc starter

What Are the Key Technical Properties of TYC Starters?

When considering TYC starters, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

1. Materialzusammensetzung

TYC starters are typically made from high-grade materials such as aluminum and reinforced plastics. The aluminum casing provides durability and heat resistance, which is vital in preventing overheating during operation. In a B2B context, selecting a starter with robust material composition ensures longevity and reliability, reducing the frequency of replacements.

2. Drehmoment

Torque rating indicates the starting power of the starter motor, measured in Newton-meters (Nm). A higher torque rating means the starter can effectively start larger or more demanding engines. For businesses, understanding torque ratings is essential when matching starters with specific engine types, ensuring optimal performance and reducing the risk of starter failure.

Illustrative image related to tyc starter

3. Elektrische Spezifikationen

Electrical specifications, including voltage (typically 12V or 24V) and current draw (measured in amps), are critical for compatibility with vehicle electrical systems. A starter that operates efficiently within these parameters can improve vehicle performance and reduce battery strain. Buyers should prioritize starters with low current draw to enhance battery life, especially in remote or high-demand environments.

4. Gear Reduction Design

Many TYC starters utilize a gear reduction design that enhances starting efficiency and reduces wear on the starter motor. This design allows for higher torque output at lower RPMs, making it particularly beneficial for heavy-duty applications. Businesses should consider gear reduction starters for their ability to provide reliable starting power in various conditions, reducing maintenance costs over time.

5. Testing and Quality Assurance

TYC starters come with comprehensive testing protocols, including performance tests to ensure each unit meets industry standards before shipment. This quality assurance is crucial for B2B buyers, as it minimizes the risk of receiving defective products and helps maintain operational efficiency in their fleets.

What Are Common Trade Terms Related to TYC Starters?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some commonly used terms in the context of TYC starters:

1. OEM (Originalgerätehersteller)

OEM refers to products made by the original manufacturer that are intended to fit specific vehicles as replacements. TYC starters are often considered OEM-equivalent, meaning they are designed to meet or exceed the specifications of original parts. Understanding OEM terminology helps buyers ensure compatibility and performance.

2. MOQ (Mindestbestellmenge)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. In the context of TYC starters, knowing the MOQ is essential for businesses to plan their inventory and budget effectively. This term is particularly relevant for bulk purchases, which can lead to cost savings.

3. RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. When sourcing TYC starters, submitting an RFQ allows buyers to compare prices, delivery times, and payment terms, ensuring they receive the best value for their investment.

4. Incoterms (Internationale Handelsklauseln)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers sourcing TYC starters from overseas, as they clarify shipping costs, insurance, and liability, facilitating smoother cross-border transactions.

5. Garantiebedingungen

Warranty terms specify the duration and conditions under which a product is guaranteed against defects. For TYC starters, understanding warranty coverage is critical for businesses to protect their investments and ensure they receive support for any potential issues.

In summary, grasping both the technical properties and trade terminology associated with TYC starters empowers B2B buyers to make informed, strategic purchasing decisions that align with their operational needs and goals.

Navigating Market Dynamics and Sourcing Trends in the tyc starter Sector

Market Overview & Key Trends

The global market for TYC starters is shaped by several key drivers that influence sourcing decisions for B2B buyers. One significant factor is the growing demand for reliable automotive components in emerging markets across Africa, South America, the Middle East, and Europe. As economies expand and vehicle ownership increases, the need for high-quality, cost-effective starter motors becomes essential. In regions like Vietnam and Germany, buyers are increasingly prioritizing suppliers that offer competitive pricing without compromising on quality.

Another trend is the integration of advanced technology in manufacturing processes. The rise of automation and smart manufacturing techniques is enhancing production efficiency and product quality. B2B buyers are now more inclined to partner with manufacturers that adopt these technologies, as they can ensure consistent performance and reliability in starter motors. Additionally, the trend towards online sourcing platforms is gaining momentum, enabling international buyers to access a wider range of products and suppliers, thus streamlining procurement processes.

Sourcing dynamics are also evolving due to geopolitical factors and trade agreements. For instance, fluctuating tariffs and trade policies can impact pricing and availability, making it crucial for buyers to stay informed about global trade developments. Moreover, the increasing focus on local sourcing is prompting businesses to explore regional suppliers, reducing lead times and transportation costs while supporting local economies.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are becoming paramount in the procurement of TYC starters. The environmental impact of manufacturing processes, particularly in the automotive sector, has garnered attention from consumers and regulatory bodies alike. B2B buyers are now seeking suppliers who prioritize sustainable practices, such as reducing waste, minimizing carbon emissions, and utilizing eco-friendly materials.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices to ensure compliance with labor laws and fair trade standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria for selection. These certifications not only demonstrate a supplier’s commitment to sustainability but also enhance their credibility in the market.

Furthermore, the use of ‘green’ materials in the production of TYC starters is gaining traction. Suppliers that invest in sustainable materials, such as recycled metals and non-toxic coatings, are likely to attract environmentally-conscious buyers. This shift not only contributes to a healthier planet but also aligns with the corporate social responsibility goals of many companies.

Brief Evolution/History

The TYC brand has established itself as a reputable player in the automotive components market, particularly known for its starter motors. Initially founded to supply high-quality parts for the aftermarket, TYC has evolved significantly over the years. The brand has integrated advanced manufacturing techniques and quality control measures to ensure that its products meet stringent industry standards.

Over time, TYC has expanded its product line and geographical reach, catering to a diverse international clientele. This evolution has been driven by the increasing demand for reliable and affordable automotive components, prompting TYC to enhance its production capabilities and sourcing strategies. Today, TYC starters are recognized for their quality and performance, making them a preferred choice among B2B buyers looking for dependable automotive solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of tyc starter

-

How do I ensure the quality of TYC starters when sourcing internationally?

To ensure the quality of TYC starters, conduct thorough supplier vetting. Look for manufacturers with ISO certifications, positive customer reviews, and a solid track record in the automotive parts industry. Request product samples to assess quality firsthand and consider third-party quality assurance checks. It’s also beneficial to inquire about warranty terms and return policies, which can provide insights into the manufacturer’s confidence in their product quality. -

What is the best TYC starter for heavy-duty vehicles?

The best TYC starter for heavy-duty vehicles often depends on the specific engine model and vehicle application. For example, TYC starters designed for 7.3L Power Stroke Diesel engines are popular due to their gear reduction design, which enhances starting power. Review product specifications and consult with your supplier to ensure compatibility with your fleet’s vehicles. Additionally, consider the starter’s durability and performance ratings in demanding conditions. -

What are the typical payment terms when sourcing TYC starters from international suppliers?

Payment terms can vary significantly among suppliers. Common arrangements include advance payment, letter of credit, or net 30/60/90 days after delivery. It’s crucial to clarify these terms during negotiations and ensure they align with your cash flow management. Additionally, consider using secure payment methods that offer buyer protection, such as PayPal or escrow services, especially when dealing with new suppliers. -

What are the minimum order quantities (MOQs) for TYC starters?

Minimum order quantities (MOQs) for TYC starters can vary based on the supplier and your specific requirements. Typically, MOQs may range from a few units to several dozen. Discuss your needs with the supplier to see if they can accommodate smaller orders, especially if you are a new buyer or testing a new market. Some suppliers may offer flexibility based on your purchasing history or the potential for future orders. -

How can I navigate logistics when importing TYC starters?

Navigating logistics for importing TYC starters involves understanding shipping options, customs regulations, and potential duties. Choose a reliable freight forwarder who is experienced in automotive parts logistics and familiar with the regulations of your destination country. Ensure all documentation, such as bills of lading and commercial invoices, is accurately completed to prevent delays at customs. Additionally, consider the shipping method that best balances cost and delivery speed for your needs. -

What is the warranty policy for TYC starters?

TYC typically offers a limited warranty on their starters, which usually covers defects in materials and workmanship for a specified period. It’s important to review the warranty details before purchase, as policies can differ by region and supplier. Ensure you understand the process for claims, including any requirements for documentation and the conditions under which the warranty is valid. This information is critical for mitigating risks associated with product failures. -

How can I customize TYC starters for my specific applications?

Customization of TYC starters may be possible depending on the supplier’s capabilities. Discuss your specific application requirements, such as voltage, size, or performance enhancements, with your supplier. Some manufacturers may offer tailored solutions or modifications to meet unique needs. Be prepared to provide detailed specifications and discuss potential costs and lead times associated with custom orders. -

What factors should I consider when evaluating suppliers of TYC starters?

When evaluating suppliers of TYC starters, consider factors such as their experience in the automotive industry, product range, and customer service reputation. Check for certifications like ISO 9001, which indicates adherence to quality management standards. Additionally, look for suppliers who offer transparent communication and support throughout the purchasing process, including post-sale service. Establishing a strong relationship with your supplier can enhance collaboration and ensure better procurement experiences.

Top 5 Tyc Starter Manufacturers & Suppliers List

1. TYC – Starter Motors

Domäne: tycamericas.com

Registered: 2022 (3 years)

Einleitung: This company, TYC – Starter Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. TYC – Starter for 2.7L Tacoma

Domäne: tacomaworld.com

Registriert: 2006 (19 Jahre)

Einleitung: TYC brand starter for 2.7L 4-cylinder Tacoma, priced at $90. User experiences vary, with some positive feedback on performance and warranty, while others express concerns about reliability and recommend alternatives like DENSO rebuilt starters. One user reported issues with bearings in a TYC alternator after 6 months of normal use.

3. TYC – Car & Truck Starter Motors

Domäne: ebay.de

Registriert: 1995 (30 Jahre)

Einleitung: TYC Car & Truck Starter Motors available on eBay. Key details include:

– Brand: TYC

– Condition options: New, New other (see details), Remanufactured, Used, For parts or not working

– Manufacturer Warranty: Options range from 1 month to lifetime

– Voltage ratings available from 1-85 V

– Price range: Under $125, $125 to $160, Over $160

– Delivery options: Free Shipping, Free Local Pickup

– P…

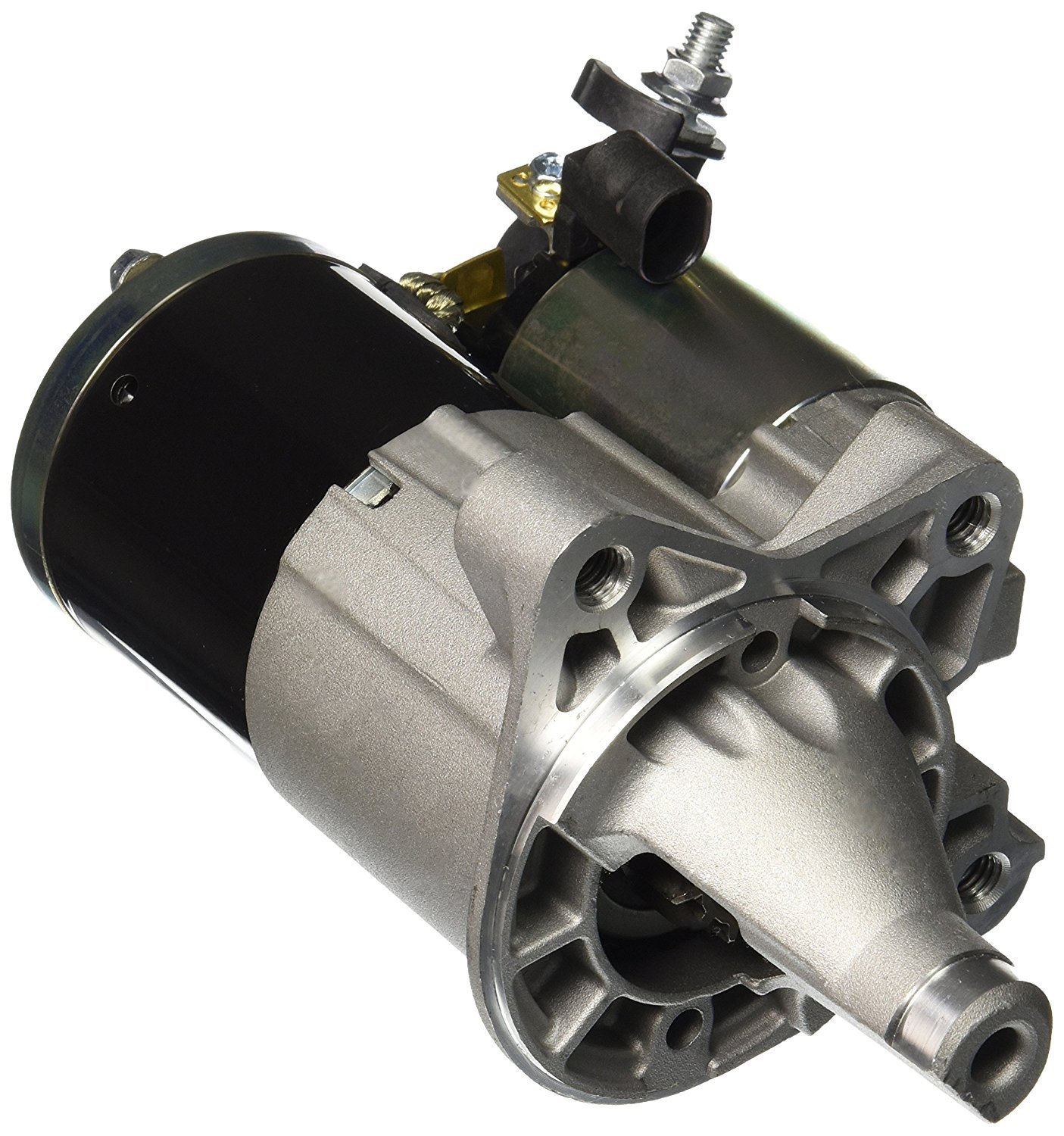

4. TYC – Starter for Ford 7.3L Power Stroke Diesel

Domäne: ford-trucks.com

Registriert: 1997 (28 Jahre)

Einleitung: TYC Starter for Ford 7.3L Power Stroke Diesel, priced at $68 with no core fee. It is a gear reduction starter, compatible with late-01 models that require only two bolts for installation. The product comes with a test sheet indicating it has passed various tests before shipping. It is noted for being well-machined and not a typical low-quality knockoff. The starter is made in China but is describe…

5. TYC – Electrical Parts

Domäne: rockauto.com

Registriert: 1999 (26 Jahre)

Einleitung: This company, TYC – Electrical Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tyc starter

In conclusion, the strategic sourcing of TYC starters presents a compelling opportunity for international B2B buyers seeking reliable automotive components. The TYC brand is recognized for its cost-effectiveness and quality, making it a viable option for businesses across Africa, South America, the Middle East, and Europe. By leveraging TYC starters, buyers can enhance their supply chain efficiency while ensuring that they meet the growing demand for durable and efficient automotive parts.

The importance of strategic sourcing cannot be overstated, especially in today’s competitive marketplace. Companies that prioritize sourcing high-quality products at competitive prices will not only improve their operational efficiency but also strengthen their market position. As the automotive industry continues to evolve, staying ahead with reliable suppliers like TYC will be crucial for sustained growth and customer satisfaction.

Looking ahead, it is essential for international buyers to evaluate their sourcing strategies continuously. Engage with suppliers, explore new markets, and ensure that you are equipped to meet future demands. By doing so, you will position your business for success in an increasingly interconnected global economy. Embrace the opportunity to source TYC starters and drive your business forward.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.