Introduction: Navigating the Global Market for starter solenoid failure symptoms

In the dynamic landscape of automotive components, understanding starter solenoid failure symptoms is critical for international B2B buyers looking to enhance their sourcing strategies. A malfunctioning starter solenoid can lead to operational inefficiencies, impacting both productivity and profitability. This guide delves into the various types of starter solenoid failures, their applications across different vehicle models, and the common symptoms that signal potential issues.

By providing insights into supplier vetting processes, cost considerations, and maintenance practices, this comprehensive resource empowers businesses, particularly those in Africa, South America, the Middle East, and Europe, to make informed purchasing decisions. Buyers will learn how to identify reliable suppliers, assess product quality, and understand the implications of starter solenoid failures on vehicle performance.

Moreover, with a focus on actionable insights and practical solutions, this guide aims to equip businesses with the knowledge they need to mitigate risks associated with faulty components. Ultimately, navigating the complexities of starter solenoid failures will enable B2B buyers to optimize their supply chains and enhance the reliability of their automotive operations.

Inhaltsverzeichnis

- Top 4 Starter Solenoid Failure Symptoms Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter solenoid failure symptoms

- Understanding starter solenoid failure symptoms Types and Variations

- Key Industrial Applications of starter solenoid failure symptoms

- 3 Common User Pain Points for ‘starter solenoid failure symptoms’ & Their Solutions

- Strategic Material Selection Guide for starter solenoid failure symptoms

- In-depth Look: Manufacturing Processes and Quality Assurance for starter solenoid failure symptoms

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter solenoid failure symptoms’

- Comprehensive Cost and Pricing Analysis for starter solenoid failure symptoms Sourcing

- Alternatives Analysis: Comparing starter solenoid failure symptoms With Other Solutions

- Essential Technical Properties and Trade Terminology for starter solenoid failure symptoms

- Navigating Market Dynamics and Sourcing Trends in the starter solenoid failure symptoms Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter solenoid failure symptoms

- Strategic Sourcing Conclusion and Outlook for starter solenoid failure symptoms

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding starter solenoid failure symptoms Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Keine Antwort | Engine does not start; no sound or movement. | Autowerkstätten | Vorteile: Indicates a clear failure; easy diagnosis. Nachteile: May require extensive troubleshooting. |

| Single Click | A single clicking sound from the engine compartment. | Wartung von Fahrzeugen | Vorteile: Often signals a stuck solenoid; quick fix potential. Nachteile: Can be misdiagnosed as battery issues. |

| Repeated Clicking | Multiple clicking sounds, often indicative of low power. | Flottenmanagement | Vorteile: Highlights potential battery failure; prompts timely maintenance. Nachteile: May lead to unnecessary part replacement. |

| Intermittierender Start | Occasional successful starts, inconsistent behavior. | Heavy machinery and transport | Vorteile: Signals potential wear; allows for proactive replacement. Nachteile: Difficult to diagnose; may frustrate users. |

| Starter Engaging Unexpectedly | Starter engages without key in ‘start’ position. | Automotive manufacturers | Vorteile: Safety hazard prompt; immediate attention required. Nachteile: Can cause additional damage to the starter. |

What Are the Characteristics of No Response Symptoms?

The ‘No Response’ symptom is characterized by the absence of any sound or movement when the ignition key is turned. This could indicate a complete failure of the starter solenoid or related components. For B2B buyers, this symptom is crucial as it signals a definitive failure, simplifying the diagnostic process. However, it may require further investigation to rule out issues such as battery failure or wiring problems, which could complicate repair timelines and costs.

How to Identify a Single Click Sound?

A ‘Single Click’ sound occurs when the ignition is engaged but the engine does not turn over. This often means the solenoid is attempting to engage but is stuck. For automotive repair shops, this symptom can lead to a straightforward solution, as it typically requires minimal intervention. However, it can be misdiagnosed as a battery issue, leading to unnecessary part replacements if not properly assessed.

What Does Repeated Clicking Indicate?

‘Repeated Clicking’ is a symptom where multiple clicks are heard, indicating a struggle to provide sufficient power to the starter. This is often a sign of a low battery or a failing solenoid. For fleet management, recognizing this symptom is essential for timely maintenance, as it can prevent more significant issues down the line. However, it may lead to confusion if misinterpreted, potentially resulting in unnecessary repairs.

How to Recognize Intermittent Starting Issues?

Intermittent starting issues occur when the vehicle starts successfully at times and fails at others. This inconsistency may point to a failing starter solenoid or other electrical issues. Heavy machinery operators and transport companies should monitor this symptom closely, as it can indicate wear and tear. While it allows for proactive replacement, diagnosing the exact cause can be challenging and may require professional assessment.

What Are the Risks of Starter Engaging Unexpectedly?

The symptom of a starter engaging unexpectedly—where the engine starts without turning the key—poses significant safety risks. This issue typically indicates a faulty solenoid and requires immediate attention to prevent damage to the starter and engine. Automotive manufacturers must be aware of this symptom, as it could lead to safety recalls or warranty claims. While it prompts urgent action, it can also result in added costs if not addressed quickly.

Key Industrial Applications of starter solenoid failure symptoms

| Branche/Sektor | Specific Application of starter solenoid failure symptoms | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Diagnosing starting issues in vehicles | Reduces downtime, ensuring vehicles are operational quickly | Quality of components, availability of parts, and local service support |

| Schwere Maschinen | Maintenance of construction and agricultural equipment | Prevents unexpected breakdowns, ensuring project timelines are met | Robustness of parts, compatibility with existing machinery, and lead times |

| Transport & Logistik | Fleet management for delivery and transport vehicles | Enhances reliability and reduces costs associated with vehicle failures | Bulk purchasing options, warranty terms, and supplier reliability |

| Bergbau | Equipment operation in harsh environments | Minimizes operational disruptions, maintaining productivity | Durability, resistance to environmental factors, and after-sales support |

| Marine | Starting systems for boats and ships | Gewährleistet Sicherheit und Zuverlässigkeit im Schiffsbetrieb | Compliance with maritime standards, performance in saltwater conditions, and sourcing from specialized suppliers |

How Are Starter Solenoid Failure Symptoms Used in Automotive Repair?

In the automotive repair sector, identifying starter solenoid failure symptoms is crucial for diagnosing starting issues in vehicles. Symptoms like a single click or no response when turning the ignition key can indicate a faulty solenoid. By addressing these issues promptly, repair shops can minimize vehicle downtime, ensuring that clients can get back on the road quickly. For international B2B buyers, sourcing high-quality solenoids and related components is essential, emphasizing the need for reliable suppliers that can provide parts compatible with various vehicle models.

What Role Do Starter Solenoid Failure Symptoms Play in Heavy Machinery Maintenance?

In the heavy machinery industry, starter solenoid failure symptoms are vital for the maintenance of construction and agricultural equipment. A malfunctioning solenoid can lead to unexpected breakdowns, halting critical operations and delaying project timelines. Recognizing symptoms such as intermittent starting or failure to engage can help maintenance teams address issues before they escalate. Buyers in this sector should prioritize sourcing robust solenoids that can withstand harsh operating conditions and ensure compatibility with existing machinery to prevent future disruptions.

How Can Transportation & Logistics Benefit from Understanding Starter Solenoid Failure Symptoms?

For companies in transportation and logistics, understanding starter solenoid failure symptoms is key to effective fleet management. A reliable fleet ensures timely deliveries and minimizes costs associated with vehicle failures. Symptoms like erratic starting can be a precursor to more significant issues, enabling fleet managers to implement preventative maintenance. When sourcing starter solenoids, businesses should consider bulk purchasing options, warranty terms, and the reliability of suppliers to maintain their fleet’s operational efficiency.

Why Are Starter Solenoid Failure Symptoms Important in the Mining Industry?

In the mining sector, equipment often operates in harsh environments where reliability is paramount. Recognizing starter solenoid failure symptoms can help prevent operational disruptions that can significantly impact productivity. Symptoms such as failure to start or unusual noises can signal impending solenoid failure, allowing for timely maintenance. Buyers in this industry should focus on sourcing durable solenoids that can withstand extreme conditions and provide strong after-sales support to ensure continuous operation.

How Do Starter Solenoid Failure Symptoms Impact Marine Operations?

In the marine industry, the importance of starter solenoid failure symptoms cannot be overstated. Boats and ships rely on dependable starting systems for safety and operational efficiency. Symptoms like a non-responsive ignition can lead to critical failures at sea. Understanding these symptoms allows marine operators to conduct preventative maintenance, ensuring reliable performance. When sourcing components, compliance with maritime standards and the ability to perform in saltwater conditions are essential considerations for international buyers.

3 Common User Pain Points for ‘starter solenoid failure symptoms’ & Their Solutions

Scenario 1: Intermittent Starting Issues in Fleet Vehicles

Das Problem: A fleet manager in South America is facing significant downtime due to intermittent starting issues across multiple vehicles. Drivers report that some vehicles start without issue, while others fail to start, leading to frustration and delays in operations. This inconsistency complicates route planning and can result in customer dissatisfaction, ultimately affecting the company’s bottom line. The fleet manager suspects that the problem may stem from failing starter solenoids but lacks the precise knowledge to diagnose and address the issue effectively.

Illustrative image related to starter solenoid failure symptoms

Die Lösung: To tackle intermittent starting issues, the fleet manager should implement a systematic diagnostic approach. Begin by conducting a thorough inspection of the starter solenoids across the fleet. Look for common signs of failure such as clicking sounds when the ignition is engaged, which indicates that the solenoid is attempting to engage but failing to do so. It’s crucial to check the wiring and connections for corrosion or damage that could affect the solenoid’s performance.

Additionally, investing in quality diagnostic tools can expedite the troubleshooting process. Consider sourcing advanced multimeters or automotive diagnostic scanners that can assess the voltage and current reaching the starter solenoid. If a failing solenoid is confirmed, the fleet manager should prioritize sourcing high-quality replacement parts from reputable suppliers, ensuring compatibility with the specific vehicle models in the fleet. This proactive approach not only minimizes downtime but also enhances the overall reliability of the fleet.

Scenario 2: Unexpected Startup Failures in Heavy Machinery

Das Problem: A construction company operating in Nigeria experiences unexpected startup failures in their heavy machinery, which is crucial for ongoing projects. These failures cause project delays, leading to increased labor costs and potential penalties for late project completion. The machinery operators report hearing a single click sound but no engine turnover, indicating a possible solenoid failure. The company is at risk of losing contracts due to these operational inefficiencies.

Die Lösung: The construction company should establish a preventive maintenance program focused on the starter systems of their heavy machinery. First, they need to train their operators to recognize early signs of solenoid failure, such as unusual clicking sounds or intermittent starting behavior. Regularly scheduled inspections should include checks for loose connections, corroded wires, and the condition of the solenoids themselves.

In terms of sourcing parts, the company should collaborate with local suppliers who specialize in heavy machinery parts to ensure they have immediate access to high-quality starter solenoids when needed. Moreover, they should consider investing in a comprehensive warranty for these parts to mitigate the financial impact of unexpected failures. By taking these steps, the construction company can minimize downtime and maintain project timelines, thereby safeguarding their reputation and financial stability.

Scenario 3: Costly Repairs Due to Misdiagnosis

Das Problem: An automotive repair shop in Europe faces challenges with misdiagnosing starter solenoid issues. Customers frequently report that their vehicles are not starting, and mechanics often mistakenly attribute the problem to dead batteries or faulty starters, leading to unnecessary repairs and costs. This misdiagnosis not only affects customer satisfaction but also strains the shop’s resources and profits.

Die Lösung: To reduce misdiagnosis rates, the automotive repair shop should invest in staff training focused on the electrical systems of vehicles, particularly the starter solenoid and relay systems. Workshops led by experienced technicians or online courses can enhance the team’s diagnostic skills, helping them to accurately identify solenoid failure symptoms.

Additionally, the shop should develop a standardized checklist for diagnosing starting issues, ensuring that technicians systematically evaluate potential causes, including battery health, wiring integrity, and solenoid functionality. Implementing diagnostic tools, such as battery testers and solenoid testers, can streamline the diagnostic process, allowing mechanics to quickly verify whether the solenoid is functioning correctly. By improving diagnostic accuracy, the shop can reduce unnecessary repairs, enhance customer trust, and ultimately increase profitability.

Strategic Material Selection Guide for starter solenoid failure symptoms

What Are the Key Materials Used in Starter Solenoid Applications?

When selecting materials for starter solenoids, understanding the properties, advantages, and limitations of common materials is crucial for ensuring optimal performance and longevity. Here, we analyze four prevalent materials used in the construction of starter solenoids, focusing on their key properties, pros and cons, and considerations for international B2B buyers.

How Does Copper Perform in Starter Solenoid Applications?

Wichtige Eigenschaften: Copper is renowned for its excellent electrical conductivity, making it an ideal choice for electrical components. It can withstand high temperatures and has a melting point of approximately 1,085°C.

Vor- und Nachteile: The primary advantage of copper is its superior conductivity, which ensures efficient power transfer. However, it is susceptible to corrosion, particularly in humid environments, which can lead to performance degradation over time. Additionally, copper is relatively expensive compared to other metals, impacting overall manufacturing costs.

Auswirkungen auf die Anwendung: Copper’s high conductivity makes it suitable for solenoids requiring rapid and reliable activation. However, its corrosion vulnerability necessitates protective coatings or treatments, especially in regions with high moisture, such as parts of Africa and South America.

Überlegungen für internationale Käufer: Buyers should ensure compliance with international standards like ASTM B187 for copper products. In regions like Europe and the Middle East, environmental regulations may also affect the choice of copper due to its recyclability and sustainability.

What Role Does Aluminum Play in Starter Solenoid Manufacturing?

Wichtige Eigenschaften: Aluminum is lightweight and has good thermal and electrical conductivity, with a melting point of about 660°C. It also exhibits excellent corrosion resistance due to the formation of a protective oxide layer.

Vor- und Nachteile: The lightweight nature of aluminum makes it easy to handle and install, reducing shipping costs. Its corrosion resistance is a significant advantage in humid climates. However, aluminum’s conductivity is lower than that of copper, which may necessitate larger or more complex designs to achieve the same performance.

Auswirkungen auf die Anwendung: Aluminum is suitable for solenoids in applications where weight is a critical factor, such as in automotive and aerospace industries. Its corrosion resistance makes it ideal for environments with high moisture levels.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM B221 is essential for aluminum products. Buyers in regions like Africa and South America may prefer aluminum for its cost-effectiveness and lightweight properties, especially in transportation applications.

How Does Steel Compare for Starter Solenoid Components?

Wichtige Eigenschaften: Steel, particularly stainless steel, offers high strength and durability, with a melting point around 1,370°C. It has moderate electrical conductivity and excellent resistance to wear and tear.

Vor- und Nachteile: The strength of steel makes it suitable for high-stress applications, ensuring longevity. However, its lower conductivity compared to copper and aluminum can lead to inefficiencies in electrical performance. Additionally, while stainless steel resists corrosion, it is heavier, which may not be suitable for all applications.

Auswirkungen auf die Anwendung: Steel is commonly used in structural components of solenoids where strength is crucial. However, its weight can be a disadvantage in applications where minimizing mass is essential.

Überlegungen für internationale Käufer: Buyers should be aware of various grades of stainless steel, such as ASTM A240, which may affect performance. In regions like Europe, adherence to environmental regulations regarding steel production and recycling is also important.

What About Plastics and Composites in Starter Solenoid Design?

Wichtige Eigenschaften: Engineering plastics and composites can offer high resistance to heat and chemicals, with varying electrical insulating properties depending on the type used.

Vor- und Nachteile: The main advantage of plastics is their lightweight and corrosion resistance. They can be molded into complex shapes, allowing for innovative designs. However, they generally lack the mechanical strength of metals and may not withstand high temperatures as effectively.

Auswirkungen auf die Anwendung: Plastics are often used for housing and insulating components in solenoids, providing protection against environmental factors. However, their use in high-stress areas is limited.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM D638 for plastics is crucial. Buyers in regions like the Middle East may favor plastics for their lightweight and corrosion-resistant properties, particularly in automotive applications.

Summary Table of Material Selection for Starter Solenoid Failure Symptoms

| Material | Typical Use Case for starter solenoid failure symptoms | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse in Magneten | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Hoch |

| Aluminium | Lightweight solenoid components | Leicht und korrosionsbeständig | Geringere Leitfähigkeit als Kupfer | Mittel |

| Stahl | Strukturelle Komponenten in Solenoiden | Hohe Festigkeit und Haltbarkeit | Heavier and lower electrical performance | Mittel |

| Kunststoffe | Insulation and housing for solenoids | Leicht und korrosionsbeständig | Begrenzte mechanische Festigkeit | Niedrig |

This analysis provides a comprehensive overview of the materials used in starter solenoid applications, equipping international B2B buyers with the insights needed to make informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for starter solenoid failure symptoms

What Are the Main Stages of Manufacturing Starter Solenoids?

The manufacturing process for starter solenoids involves several critical stages, ensuring that the end product meets stringent performance and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Starter Solenoids?

Material preparation begins with the selection of high-quality raw materials, typically copper for wiring, steel for the casing, and plastic for insulation. Suppliers must provide materials that conform to international standards, ensuring reliability and performance. Quality checks at this stage are crucial; suppliers should present certificates of compliance to verify that materials meet the required specifications.

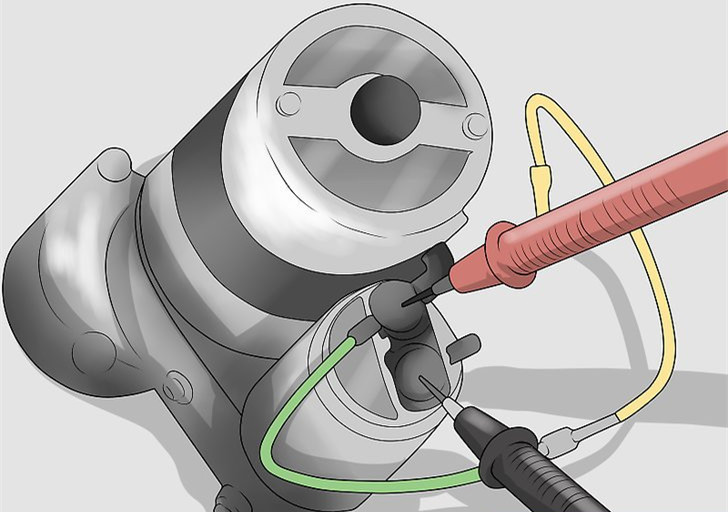

Illustrative image related to starter solenoid failure symptoms

Welche Techniken werden bei der Umformung eingesetzt?

The forming process generally involves stamping, machining, and molding. Stamping is used to create the solenoid casing and internal components, while precise machining is necessary for parts that require tight tolerances, such as the electromagnetic coil. Injection molding may be employed for producing plastic components. Each technique must adhere to strict dimensional tolerances to ensure the solenoid operates effectively.

Wie erfolgt die Montage von Startermagneten?

Assembly of starter solenoids is typically done through a combination of automated and manual processes. Automated machinery is often used for tasks such as winding the coils and inserting components, which enhances consistency and efficiency. Manual assembly may be necessary for final adjustments and quality inspections. To maintain quality, manufacturers should implement standardized assembly protocols, reducing the risk of defects.

What Are the Finishing Techniques Used in Starter Solenoid Production?

Finishing techniques involve applying protective coatings and conducting surface treatments to enhance durability. Common methods include electroplating, painting, or powder coating to prevent corrosion and wear. Quality assurance at this stage ensures that the finish meets industry standards and does not compromise the solenoid’s performance.

What International and Industry-Specific Standards Should B2B Buyers Be Aware Of?

When sourcing starter solenoids, B2B buyers should consider manufacturers that comply with international quality management standards such as ISO 9001. This certification indicates a commitment to quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for automotive applications can further validate a supplier’s credibility.

What Are the Key Quality Control Checkpoints in Manufacturing Starter Solenoids?

Quality control (QC) is a vital aspect of the manufacturing process for starter solenoids. Key checkpoints include:

Illustrative image related to starter solenoid failure symptoms

-

Eingangsqualitätskontrolle (IQC): This initial stage involves inspecting raw materials upon arrival. Suppliers should provide documentation, such as material test reports, to verify compliance with specifications.

-

In-Process-Qualitätskontrolle (IPQC): During the manufacturing process, periodic checks should be conducted to monitor parameters such as temperature, pressure, and dimensional accuracy. This ensures that any deviations are corrected immediately.

-

Endkontrolle (FQC): Before packaging and shipment, final inspections are performed to evaluate the overall functionality and safety of the starter solenoids. Testing methods may include electrical resistance tests, operational tests, and stress tests to simulate real-world conditions.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

B2B buyers can implement several strategies to verify a supplier’s quality control practices. Conducting on-site audits allows buyers to assess the manufacturing environment and QC procedures firsthand. Additionally, requesting quality reports that detail inspection results and compliance with standards can provide valuable insights into a supplier’s reliability.

Third-party inspections can also be beneficial. Independent auditors can evaluate the manufacturing processes and QC systems, offering an unbiased assessment of a supplier’s capabilities. Buyers should seek suppliers who are transparent and willing to share their QC documentation, as this indicates a commitment to quality.

What Are the Common Testing Methods for Starter Solenoids?

Common testing methods used in the quality assurance of starter solenoids include:

-

Elektrische Prüfung: This involves measuring the resistance and continuity of the solenoid coil to ensure it meets electrical specifications.

-

Funktionsprüfung: Solenoids are subjected to operational tests to verify that they engage and disengage correctly under simulated starting conditions.

-

Umweltprüfungen: To assess durability, solenoids may undergo testing for resistance to temperature fluctuations, humidity, and vibration, simulating the conditions they will face in real-world applications.

Welche Nuancen der Qualitätskontrolle sollten internationale Einkäufer beachten?

For international B2B buyers, understanding the nuances of quality control is essential. Different regions may have varying standards and regulations that affect product specifications and certifications. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local compliance requirements to ensure that imported starter solenoids meet all necessary legal and safety standards.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear lines of communication and documentation processes can mitigate misunderstandings and help maintain quality assurance throughout the supply chain.

In summary, the manufacturing processes and quality assurance measures for starter solenoids are critical for ensuring reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter solenoid failure symptoms’

In the world of automotive maintenance and repair, understanding the symptoms of starter solenoid failures is crucial for ensuring vehicle reliability and operational efficiency. This guide serves as a practical checklist for B2B buyers, helping them to identify the key steps in sourcing reliable components and services related to starter solenoid issues.

Schritt 1: Identifizieren Sie Ihre spezifischen Bedürfnisse

Understanding the exact symptoms and requirements is the first step in the procurement process. Different vehicles may exhibit unique signs of starter solenoid failure, such as a single click when the ignition is turned or intermittent starting issues. Clearly defining these needs will help you communicate effectively with suppliers and ensure you acquire the right components.

Illustrative image related to starter solenoid failure symptoms

Schritt 2: Research Industry Standards and Specifications

Familiarize yourself with the industry standards and specifications relevant to starter solenoids. This includes understanding the voltage requirements, compatibility with various vehicle models, and performance benchmarks. Knowledge of these specifications will enable you to evaluate potential products more accurately and ensure compliance with safety regulations.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, case studies, and references from similar industries or regions. Pay attention to suppliers who can demonstrate experience in dealing with starter solenoid components specifically, as this can indicate reliability and expertise.

- Check for Certifications: Ensure that suppliers hold relevant certifications that guarantee quality and compliance with international standards.

- Review Feedback: Look for customer reviews and testimonials that highlight the supplier’s reliability and product quality.

Schritt 4: Produktmuster anfordern

Once you have narrowed down potential suppliers, request samples of their starter solenoid products. Testing samples allows you to assess the quality and functionality firsthand, which is critical for ensuring that the components meet your operational standards. Pay attention to the build quality and performance under simulated conditions.

Schritt 5: Analyze Pricing and Warranty Options

Pricing is a significant factor in procurement decisions, but it should not be the only consideration. Analyze the pricing structures of different suppliers and compare them with the quality of products offered. Additionally, inquire about warranty options and after-sales support, as these can provide crucial protection against future failures.

Schritt 6: Assess Delivery and Lead Times

Understanding the supplier’s delivery capabilities is vital for maintaining your operational timelines. Discuss lead times for orders and ensure that the supplier can meet your scheduling needs. Delays in receiving starter solenoid components can lead to increased downtime and operational inefficiencies.

Schritt 7: Aufbau einer langfristigen Partnerschaft

Once you have selected a supplier, consider establishing a long-term partnership. Building a relationship with a trusted supplier can lead to better pricing, priority service, and improved communication over time. Regularly review the partnership to ensure it continues to meet your evolving needs and expectations.

By following this checklist, B2B buyers can streamline their procurement process for starter solenoid components, ultimately enhancing the reliability of their automotive operations and reducing the likelihood of unexpected failures.

Comprehensive Cost and Pricing Analysis for starter solenoid failure symptoms Sourcing

What Are the Key Cost Components in Sourcing Starter Solenoid Components?

When sourcing components related to starter solenoid failure symptoms, understanding the cost structure is critical. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and margins.

Illustrative image related to starter solenoid failure symptoms

-

Materialien: The cost of raw materials such as copper, plastics, and metals significantly influences pricing. High-quality materials that meet industry standards often come at a premium, especially for solenoids designed for high-performance applications.

-

Arbeit: Labor costs vary by region and can impact the overall cost of manufacturing. Skilled labor is essential for quality assembly and testing, which is vital in ensuring the reliability of solenoid components.

-

Fertigungsgemeinkosten: This includes utilities, facility costs, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, which can be a competitive advantage in pricing.

-

Werkzeuge: The initial investment in tools and molds can be substantial but is amortized over production runs. Custom tooling for specialized solenoid designs will increase initial costs but may provide long-term savings through efficiency.

-

Qualitätskontrolle (QC): Ensuring product reliability through rigorous QC processes adds to costs but is crucial for maintaining supplier reputation and reducing returns or warranty claims.

-

Logistik: Shipping and handling costs can fluctuate based on distance, weight, and shipping method. International buyers must consider customs duties and tariffs, which can significantly affect total costs.

-

Marge: Suppliers typically apply a margin to cover their operational costs and profit. This margin can vary based on market conditions and competitive positioning.

How Do Price Influencers Affect the Cost of Starter Solenoid Components?

Several factors influence the pricing of starter solenoid components, particularly for international B2B buyers.

-

Menge/Mindestbestellmenge: Minimum order quantities (MOQ) can impact pricing. Larger orders often qualify for discounts, making it crucial to negotiate terms that align with your needs.

-

Spezifikationen und Anpassung: Custom specifications can increase costs. Buyers should be clear about their requirements to avoid unnecessary expenses related to re-engineering or modifications.

-

Materialien und Qualitätszertifizierungen: The choice of materials directly affects pricing. Additionally, certifications like ISO or TS16949 can increase costs but also enhance product reliability and market acceptance.

-

Lieferantenfaktoren: The supplier’s reputation, location, and production capacity can affect pricing. Engaging with reliable suppliers with proven track records can minimize risks and lead to better pricing.

-

Incoterms: Understanding Incoterms is essential for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence total landed costs, impacting budgeting and pricing strategies.

What Are the Best Buyer Tips for Negotiating Prices on Starter Solenoid Components?

B2B buyers can optimize their purchasing process through several strategies:

-

Effektiv verhandeln: Leverage volume purchases or long-term contracts to negotiate better pricing. Highlighting your position as a repeat customer can also strengthen your bargaining power.

-

Fokus auf Kosteneffizienz: Evaluate total cost of ownership rather than just upfront costs. Consider factors such as durability, warranty, and potential downtime associated with lower-quality components.

-

Verstehen Sie die Nuancen der Preisgestaltung für internationale Märkte: Be aware of economic conditions, currency fluctuations, and local regulations that may affect pricing in different regions, particularly in Africa, South America, the Middle East, and Europe.

-

Aufbau von Beziehungen zu Zulieferern: Establishing strong relationships can lead to better terms and pricing. Suppliers are often more willing to negotiate with customers they trust and have worked with previously.

-

Mehrere Angebote einholen: Obtaining quotes from various suppliers can provide a benchmark for pricing and help identify the best value for your specific needs.

Haftungsausschluss für indikative Preise

Pricing for starter solenoid components can vary widely based on the factors outlined above. It is essential for buyers to conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing information tailored to their specific requirements.

Alternatives Analysis: Comparing starter solenoid failure symptoms With Other Solutions

Understanding Alternatives to Starter Solenoid Failure Symptoms

In the context of automotive systems, recognizing starter solenoid failure symptoms is crucial for maintaining vehicle functionality. However, there are alternative solutions that can also help diagnose and resolve starting issues. This section compares the signs of a failing starter solenoid with other diagnostic technologies and methods that serve similar purposes.

| Vergleichsaspekt | Starter Solenoid Failure Symptoms | Batterie-Management-System | Electronic Control Unit (ECU) Diagnostics |

|---|---|---|---|

| Leistung | Directly indicates solenoid issues; reliable for older models | Monitors battery health, prevents starting issues | Ermöglicht umfassende Diagnosen über mehrere Systeme hinweg |

| Kosten | Low (manual checks, basic tools) | Moderate (initial investment for systems) | High (advanced technology and expertise required) |

| Einfache Implementierung | Simple checks can be performed by users | Erfordert professionelle Installation | Requires skilled technicians for setup and interpretation |

| Wartung | Minimal; mainly visual checks | Regular updates and checks needed | Periodic software updates and diagnostics |

| Bester Anwendungsfall | Older vehicles or basic troubleshooting | Fleets or vehicles with frequent starting issues | Modern vehicles with complex electrical systems |

What Are the Advantages and Disadvantages of Battery Management Systems?

Battery Management Systems (BMS) serve as an alternative to simply diagnosing starter solenoid issues. A BMS monitors the battery’s health, ensuring optimal performance and longevity. Its proactive approach can prevent starting problems before they occur. However, implementing a BMS typically requires a moderate investment and professional installation, which may not be feasible for all businesses. Additionally, ongoing maintenance and updates are necessary to keep the system functioning effectively.

Illustrative image related to starter solenoid failure symptoms

How Do Electronic Control Unit (ECU) Diagnostics Compare?

Electronic Control Unit diagnostics represent a more advanced alternative, providing a comprehensive overview of vehicle health, including the starter solenoid’s status. ECUs can detect a wide range of issues, offering insights into multiple systems within the vehicle. This technology is particularly beneficial for modern vehicles that rely on intricate electrical systems. However, it comes with a higher cost and requires skilled technicians to interpret the diagnostics effectively, making it less accessible for smaller operations or less experienced users.

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

For B2B buyers, the decision on whether to rely on diagnosing starter solenoid failure symptoms or adopting alternative solutions like Battery Management Systems or ECU diagnostics hinges on several factors, including vehicle type, operational scale, and budget. Businesses with older vehicles or those needing quick, cost-effective solutions may find manual symptom checks sufficient. Conversely, organizations managing fleets or modern vehicles may benefit from investing in advanced diagnostic systems that offer preventive measures and comprehensive data. Ultimately, aligning the choice with specific operational needs and financial constraints will ensure optimal vehicle performance and reliability.

Essential Technical Properties and Trade Terminology for starter solenoid failure symptoms

What Are the Key Technical Properties of Starter Solenoid Components?

Understanding the critical specifications of starter solenoids is essential for B2B buyers to ensure they procure reliable components. Here are some key properties:

-

Werkstoffgüte

Starter solenoids are typically made from materials such as copper and high-grade aluminum. Copper is essential for its excellent electrical conductivity, which is crucial for efficient performance. The choice of material affects not only the solenoid’s performance but also its durability under various environmental conditions, which is particularly important in regions with extreme temperatures. -

Aktuelle Bewertung

The current rating of a starter solenoid indicates the maximum electrical current it can handle without overheating or failing. This rating is critical for ensuring compatibility with the vehicle’s electrical system. For B2B buyers, selecting solenoids with appropriate current ratings ensures reliable vehicle operation and reduces the risk of electrical failures. -

Betriebsspannung

Most automotive starter solenoids operate at either 12V or 24V, depending on the vehicle type. Knowing the required operating voltage is essential for compatibility with various engine types. Buyers must confirm voltage specifications to prevent operational issues, especially in markets with diverse vehicle models. -

Toleranzwerte

Tolerance levels refer to the allowable deviation in dimensions and electrical performance of the solenoid. High tolerance levels ensure consistent performance across different units, which is vital for mass production. For B2B buyers, understanding tolerance specifications helps in maintaining quality control and reducing the likelihood of product returns. -

Activation Time

This property indicates how quickly the solenoid can engage and disengage. Faster activation times are crucial for performance, especially in high-demand applications. Buyers should consider activation times when evaluating solenoid efficiency, particularly for heavy-duty vehicles that require quick start capabilities.

What Are Common Trade Terms Related to Starter Solenoids?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Originalgerätehersteller)

OEM parts are manufactured by the vehicle’s original manufacturer or a certified supplier. These components often meet the highest quality standards and are crucial for maintaining warranty coverage. B2B buyers should prioritize OEM parts to ensure compatibility and reliability in their applications. -

MOQ (Mindestbestellmenge)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is vital for buyers to manage inventory costs and ensure they meet supplier requirements. Negotiating lower MOQs can be beneficial for small to medium-sized businesses looking to reduce upfront investment. -

RFQ (Angebotsanfrage)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. It is a critical step in the procurement process, allowing buyers to compare offers and make informed purchasing decisions. Crafting a clear RFQ helps to streamline communication and ensure accurate quotes. -

Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and risk management. Familiarity with these terms is essential for B2B buyers engaged in cross-border trade, as they help clarify obligations and reduce misunderstandings. -

Vorlaufzeit

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is critical for inventory management and production scheduling. Buyers should factor in lead times when planning their supply chain operations to ensure timely availability of starter solenoids.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the starter solenoid failure symptoms Sector

What Are the Current Market Dynamics in the Starter Solenoid Sector?

The starter solenoid sector is undergoing significant transformations influenced by various global factors. One primary driver is the increasing demand for efficient automotive solutions, especially in emerging markets across Africa, South America, the Middle East, and Europe. With growing populations and vehicle ownership, the need for reliable automotive components, including starter solenoids, is critical. The expansion of electric vehicles (EVs) is also reshaping the landscape, as these vehicles utilize different starting mechanisms that may influence traditional starter solenoid demand.

Current trends indicate a surge in technology integration, with manufacturers adopting advanced manufacturing techniques such as automation and IoT (Internet of Things) for improved quality control and production efficiency. B2B buyers are increasingly looking for suppliers who can provide not only high-quality products but also innovative solutions, such as predictive maintenance tools that can signal potential starter solenoid failures before they occur. Additionally, the advent of online marketplaces is facilitating easier sourcing options, allowing international buyers to access a broader range of suppliers and products.

Emerging markets are also witnessing a shift towards localized production to minimize import costs and lead times. This trend is particularly evident in regions like Nigeria and Vietnam, where local manufacturers are increasingly able to meet the quality standards set by international buyers. As the market evolves, businesses must stay attuned to these dynamics to capitalize on emerging opportunities while navigating challenges such as fluctuating raw material prices and supply chain disruptions.

How Can Sustainability and Ethical Sourcing Impact the Starter Solenoid Sector?

In today’s B2B landscape, sustainability and ethical sourcing have become paramount. The environmental impact of production processes related to starter solenoids, such as energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, including the use of eco-friendly materials and processes. This shift is especially relevant in regions like Europe, where regulatory frameworks mandate higher sustainability standards.

Illustrative image related to starter solenoid failure symptoms

Ethical supply chains are also critical for building trust and brand reputation. Buyers are looking for transparency in sourcing practices, ensuring that materials are sourced responsibly, and that labor practices are fair and ethical. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as essential indicators of a supplier’s commitment to these principles.

The trend towards ‘green’ certifications and materials is gaining traction, with many manufacturers exploring alternative materials that reduce environmental impact without compromising quality. By sourcing from suppliers who prioritize sustainability, B2B buyers can not only comply with regulations but also appeal to a growing segment of environmentally conscious consumers.

What Is the Historical Context Behind Starter Solenoid Technology?

The starter solenoid has evolved significantly since its inception, reflecting broader advancements in automotive technology. Initially developed in the early 20th century, solenoids were a revolutionary solution to the challenges of starting internal combustion engines. Their ability to convert low-voltage electrical signals into the high torque required to initiate engine movement was a game-changer.

As automotive technology advanced, so did the design and function of starter solenoids. The integration of electronics into vehicles led to more sophisticated solenoid designs capable of handling increased electrical loads and providing better performance. Today, starter solenoids are not only critical components for traditional vehicles but are also adapting to the needs of hybrid and electric vehicles, showcasing their versatility and importance in the automotive sector.

In summary, understanding the market dynamics, sustainability considerations, and historical context surrounding starter solenoids can empower international B2B buyers to make informed sourcing decisions that align with current trends and future opportunities.

Illustrative image related to starter solenoid failure symptoms

Frequently Asked Questions (FAQs) for B2B Buyers of starter solenoid failure symptoms

-

How do I identify starter solenoid failure symptoms in vehicles?

To identify starter solenoid failure symptoms, look for specific indicators such as the engine not starting at all, a single clicking sound when turning the key, or intermittent starting issues. If the solenoid is malfunctioning, you may also hear repeated clicking sounds, which could suggest inadequate electrical contact. Additionally, if the engine starts without turning the key or fails to disengage after starting, these are strong signs of solenoid failure. Regular diagnostics can help pinpoint the issue accurately. -

What is the best way to source reliable starter solenoids for my business?

Sourcing reliable starter solenoids involves researching potential suppliers through trade directories, industry exhibitions, and online platforms. Check supplier credentials, customer reviews, and certifications to ensure quality. Establish relationships with manufacturers who provide detailed product specifications and warranties. Additionally, consider suppliers who offer customization options to meet specific vehicle requirements and regulatory standards in your target markets. -

What are the common causes of starter solenoid failure?

Common causes of starter solenoid failure include electrical issues such as corroded connections, blown fuses, and damaged wiring. Overheating due to excessive current draw can also lead to solenoid failure. Environmental factors, like moisture and dirt ingress, may contribute to corrosion and malfunction. Regular maintenance and inspections can help mitigate these risks and extend the lifespan of the starter solenoid. -

How can I verify the quality of starter solenoids from suppliers?

To verify the quality of starter solenoids, request samples for testing and review product certifications such as ISO or TS standards. Implement a quality assurance process that includes inspections during production and pre-shipment checks. Additionally, establish clear communication with suppliers about quality control measures and warranty policies. Engaging third-party inspection services can provide an unbiased assessment of product quality before purchase. -

What are the minimum order quantities (MOQ) for starter solenoids?

Minimum order quantities (MOQ) for starter solenoids can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from a few dozen to several hundred units. When negotiating with suppliers, consider your business’s needs and inventory capacity. Some manufacturers may offer flexible MOQs, especially for long-term partnerships or bulk purchases, so it’s beneficial to communicate your requirements clearly. -

What payment terms should I expect when sourcing starter solenoids internationally?

Payment terms for international sourcing of starter solenoids typically include options like advance payment, letter of credit, or payment upon delivery. Many suppliers may request a deposit upfront, especially for larger orders. It’s essential to discuss and agree on payment terms that are mutually beneficial, considering factors like currency exchange rates and transaction fees. Ensure that all terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

Welche logistischen Überlegungen sollte ich bei der Einfuhr von Anlassermagneten anstellen?

When importing starter solenoids, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose reliable freight forwarders who understand the regulations of your target market. Ensure compliance with local import laws to avoid delays and additional costs. Additionally, factor in warehousing needs and distribution logistics to streamline operations once the products arrive. -

How can I customize starter solenoids to meet specific vehicle requirements?

Customizing starter solenoids involves collaborating with manufacturers who offer design flexibility. Discuss your specific needs regarding dimensions, electrical specifications, and material requirements. Request prototypes to evaluate performance before finalizing production. Establish a clear communication channel with your supplier to ensure that the customization process aligns with your operational timelines and quality standards.

Top 4 Starter Solenoid Failure Symptoms Manufacturers & Suppliers List

1. Reddit – Starter Solenoid Troubleshooting

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: This company, Reddit – Starter Solenoid Troubleshooting, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. LinkedIn – Starter Solenoid

Domäne: linkedin.com

Registriert: 2002 (23 Jahre)

Einleitung: A starter solenoid is an electromagnetic switch that engages the starter motor when the ignition key is turned to the ‘start’ position. Its primary function is to control the high current needed to operate the starter motor safely, ensuring clean engagement and disengagement to reduce wear. Symptoms of a bad starter solenoid include clicking noises, failure to crank, difficulty starting, decreased…

3. Eric’s Car Care – Starter Solenoid Solutions

Domäne: ericscarcare.com

Registered: 2021 (4 years)

Einleitung: This company, Eric’s Car Care – Starter Solenoid Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Can-Am – Starter Solenoid Symptoms

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Can-Am Renegade and Outlander; symptoms of a bad starter solenoid

Strategic Sourcing Conclusion and Outlook for starter solenoid failure symptoms

In the realm of automotive components, understanding starter solenoid failure symptoms is crucial for international B2B buyers. Recognizing the signs—such as a non-responsive ignition, unusual clicking sounds, or intermittent starting—can save time and reduce costs associated with vehicle downtime. Ensuring that your supply chain includes reliable sourcing of high-quality starter solenoids and components is essential for maintaining operational efficiency and customer satisfaction.

Strategic sourcing not only mitigates risks associated with component failure but also fosters long-term partnerships with suppliers who can provide insights into emerging trends and technologies. By prioritizing quality and reliability in your sourcing decisions, you can enhance the performance of your fleet and ensure that your operations remain uninterrupted.

As you navigate the global marketplace, consider leveraging local suppliers in regions such as Africa, South America, the Middle East, and Europe to optimize your supply chain. This strategic approach will not only reduce lead times but also support local economies. Engage with trusted suppliers today to future-proof your operations against starter solenoid failures and ensure your vehicles remain roadworthy and efficient.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.