Introduction: Navigating the Global Market for parts of an alternator diagram

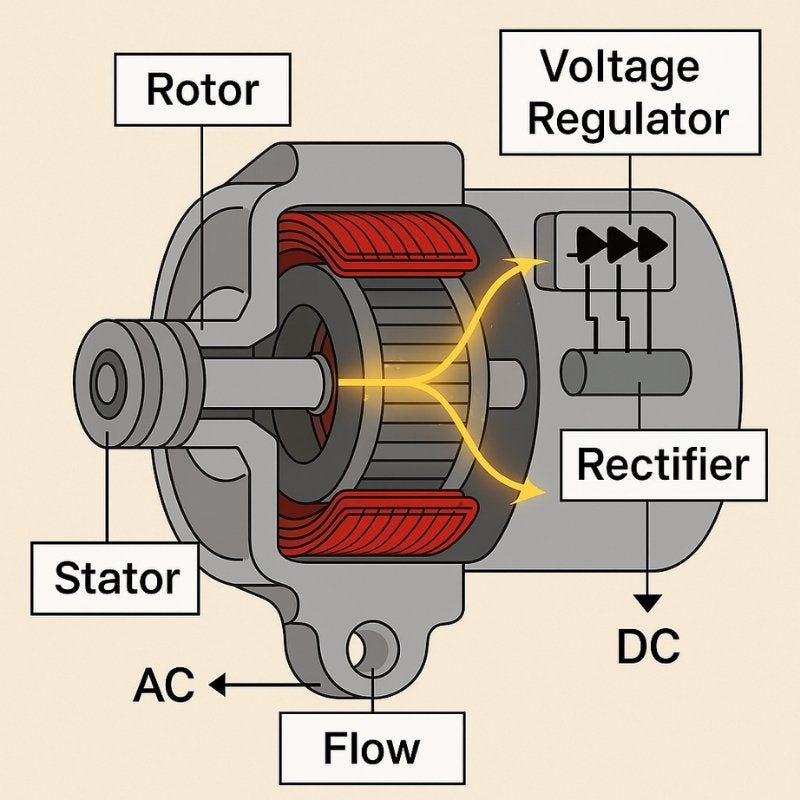

In today’s competitive landscape, navigating the global market for the parts of an alternator diagram presents a significant challenge for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, including countries such as Germany and Brazil. Understanding the intricate components of an alternator—such as the rotor, stator, rectifier, and voltage regulator—is crucial for ensuring the reliability and efficiency of automotive and industrial applications. This guide aims to demystify the complex world of alternator components, offering insights into various types, their applications, and the critical factors to consider when sourcing these essential parts.

Throughout this comprehensive resource, we will delve into the specifics of each component, explore their functions, and provide practical tips on supplier vetting, cost considerations, and quality assurance. By equipping international buyers with detailed diagrams and clear explanations, this guide empowers informed purchasing decisions, ultimately enhancing operational efficiency and reducing downtime in your business operations. Whether you are looking to optimize your supply chain or improve product quality, understanding the parts of an alternator diagram is essential for maintaining a competitive edge in your market.

Inhaltsverzeichnis

- Top 5 Parts Of An Alternator Diagram Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of an alternator diagram

- Understanding parts of an alternator diagram Types and Variations

- Key Industrial Applications of parts of an alternator diagram

- 3 Common User Pain Points for ‘parts of an alternator diagram’ & Their Solutions

- Strategic Material Selection Guide for parts of an alternator diagram

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of an alternator diagram

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of an alternator diagram’

- Comprehensive Cost and Pricing Analysis for parts of an alternator diagram Sourcing

- Alternatives Analysis: Comparing parts of an alternator diagram With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of an alternator diagram

- Navigating Market Dynamics and Sourcing Trends in the parts of an alternator diagram Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of an alternator diagram

- Strategic Sourcing Conclusion and Outlook for parts of an alternator diagram

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding parts of an alternator diagram Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Alternator Diagram | Basic representation with labeled components | Automotive manufacturing | Vorteile: Easy to understand; widely used. Nachteile: Lacks detail for advanced applications. |

| Electrical Circuit Diagram | Focuses on electrical connections and flow | Electrical engineering projects | Vorteile: Essential for troubleshooting; clear flow representation. Nachteile: May be complex for non-technical staff. |

| Exploded View Diagram | Detailed view showing assembly and parts separation | Parts manufacturing and assembly | Vorteile: Visual clarity of parts; aids in assembly. Nachteile: Can be overwhelming due to complexity. |

| Schematic Diagram | Simplified representation of electrical pathways | Design and repair services | Vorteile: Quick reference for electrical paths; easy to modify. Nachteile: Less detail on physical layout. |

| 3D Model Diagram | Interactive or visual 3D representation of parts | Training and simulation | Vorteile: Engaging for training; realistic view of components. Nachteile: Requires software for viewing; can be resource-intensive. |

What Are the Characteristics and Suitability of a Standard Alternator Diagram?

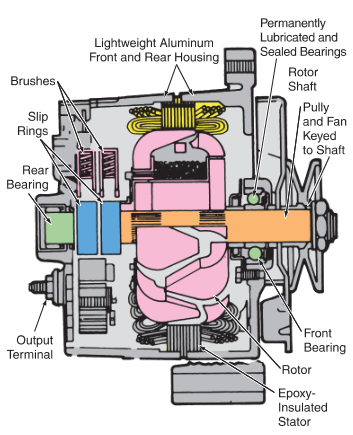

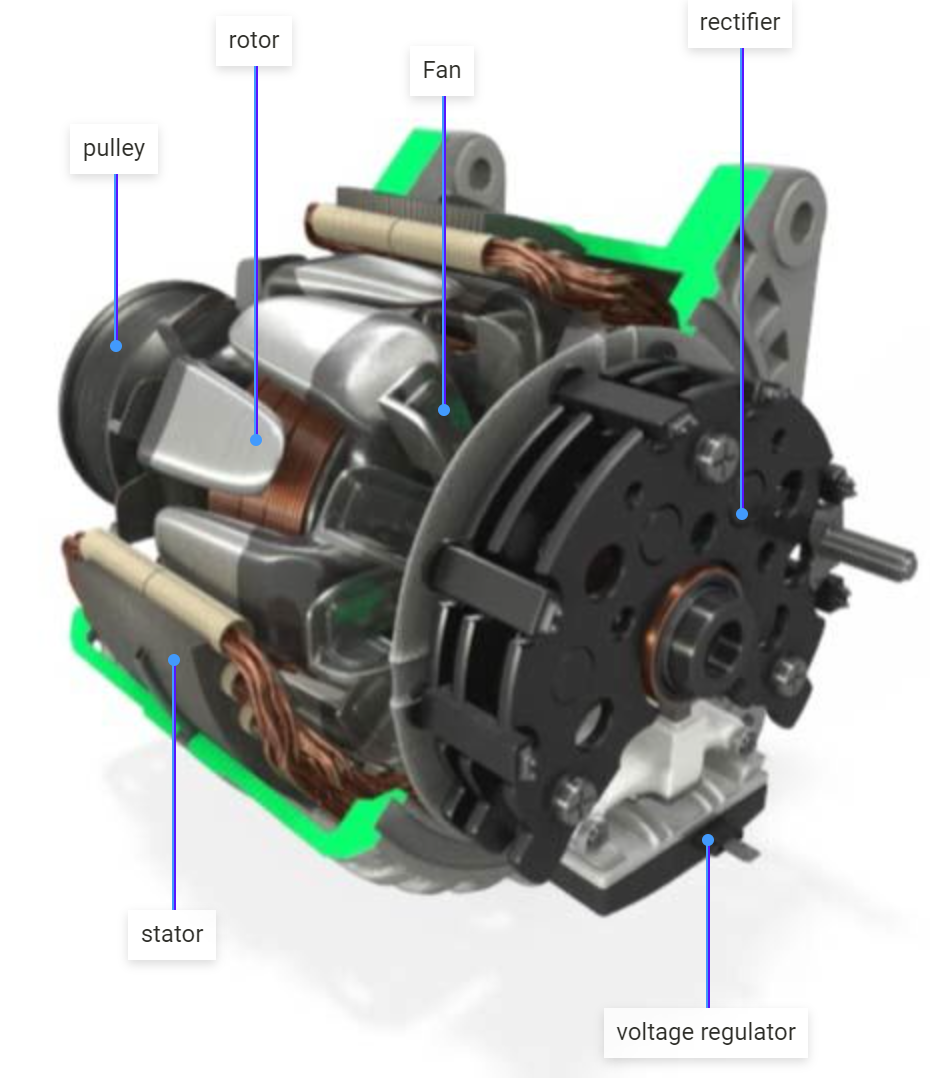

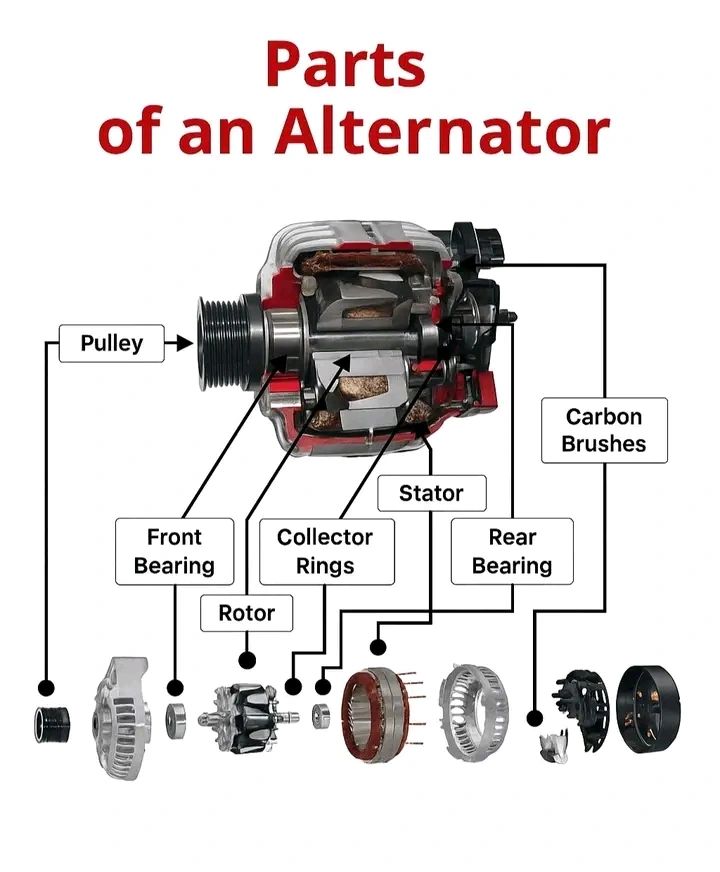

The standard alternator diagram offers a straightforward depiction of the alternator’s key components, such as the rotor, stator, and rectifier, often labeled for clarity. This type is particularly suitable for automotive manufacturers and training programs, as it provides a foundational understanding of how alternators function. B2B buyers should consider this diagram for educational purposes or initial design phases, as it facilitates discussions among engineers and technicians. However, it may not provide enough detail for complex engineering applications, limiting its utility for advanced technical projects.

How Does an Electrical Circuit Diagram Benefit B2B Applications?

An electrical circuit diagram emphasizes the electrical connections and flow within the alternator. This type is crucial for electrical engineering projects, especially during troubleshooting or system design. It helps engineers understand how power flows through the system, making it invaluable for maintenance and repair services. B2B buyers in sectors like automotive repair should prioritize this diagram for its clarity in illustrating potential issues. However, its complexity may pose a challenge for non-technical staff, necessitating additional training or support.

Why Choose an Exploded View Diagram for Parts Manufacturing?

The exploded view diagram provides a detailed perspective of the alternator’s assembly, showcasing how each part fits together. This type is highly beneficial for parts manufacturing and assembly lines, as it aids workers in understanding component relationships. B2B buyers in manufacturing should consider this diagram for its visual clarity, which can enhance training and reduce assembly errors. Nonetheless, its complexity may overwhelm some users, making it essential to provide adequate training resources alongside it.

What Are the Advantages of Using a Schematic Diagram?

Schematic diagrams offer a simplified representation of the electrical pathways within the alternator, making them ideal for design and repair services. They provide quick reference points for electrical paths, allowing engineers to modify designs efficiently. B2B buyers involved in product development or repair services should utilize schematic diagrams for their ease of use and adaptability. However, the lack of physical layout detail may limit their effectiveness in certain applications, requiring supplementary diagrams for comprehensive understanding.

How Does a 3D Model Diagram Enhance Training and Simulation?

3D model diagrams present an interactive or visual representation of the alternator’s components, making them particularly engaging for training and simulation purposes. This type is suitable for educational institutions and training programs aiming to provide hands-on learning experiences. B2B buyers in the training sector should invest in 3D model diagrams to enhance understanding and retention of complex concepts. However, these diagrams often require specialized software for viewing, which can be resource-intensive and may pose accessibility challenges for some users.

Key Industrial Applications of parts of an alternator diagram

| Branche/Sektor | Specific Application of parts of an alternator diagram | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Use of alternator parts in electric vehicle production | Enhances vehicle reliability and energy efficiency | Quality of components, compatibility with existing systems |

| Erneuerbare Energien | Integration of alternators in wind and solar systems | Provides stable power output and energy conversion | Environmental certifications, efficiency ratings |

| Schwere Maschinen | Alternators in construction and agricultural equipment | Improves operational efficiency and equipment uptime | Durability under harsh conditions, maintenance support |

| Marine and Aviation | Alternator components in ships and aircraft | Ensures reliable power supply for critical systems | Compliance with safety standards, weight considerations |

| Telekommunikation | Use of alternators in backup power systems | Guarantees continuous operation during outages | Availability of spare parts, service agreements |

How Are Parts of an Alternator Diagram Utilized in Automotive Manufacturing?

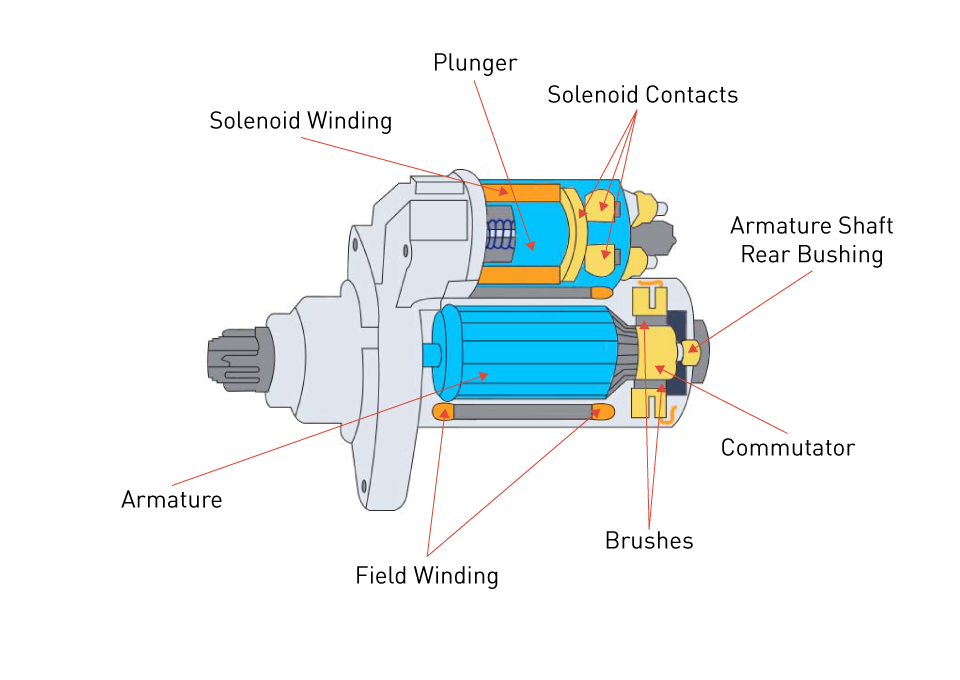

In automotive manufacturing, particularly for electric and hybrid vehicles, understanding the parts of an alternator is crucial for producing reliable and efficient power systems. The alternator converts mechanical energy into electrical energy, ensuring that vehicles operate seamlessly. Key components such as the rotor and stator must be precisely engineered to meet rigorous performance standards. Buyers in this sector should prioritize sourcing high-quality components that adhere to international automotive standards, ensuring compatibility and longevity.

What Role Do Alternator Parts Play in Renewable Energy Applications?

In the renewable energy sector, alternators are integral to wind and solar energy systems. They are used to convert mechanical energy from turbines or solar trackers into electrical energy. The efficiency of alternators directly impacts energy conversion rates, making knowledge of their parts essential. International buyers should focus on sourcing components that not only meet performance criteria but also possess environmental certifications, as sustainability is a key concern in this industry.

How Are Alternator Parts Essential for Heavy Machinery?

Heavy machinery, such as construction and agricultural equipment, relies on alternators to provide the electrical power necessary for operation. The robustness of alternator components is critical, as these machines often operate in demanding environments. Understanding the parts of an alternator diagram helps manufacturers ensure that their equipment remains operational even under extreme conditions. When sourcing, businesses should consider the durability and maintenance support of alternator parts to minimize downtime.

Why Are Alternator Components Important in Marine and Aviation Sectors?

In marine and aviation applications, alternators are vital for supplying power to critical systems, including navigation and communication equipment. The reliability of these components can affect safety and operational efficiency. Buyers in these sectors must ensure that the alternators comply with stringent safety and performance standards. Weight considerations are also important, as lighter components can enhance the overall efficiency of vessels and aircraft.

How Do Alternator Parts Support Telecommunications Infrastructure?

In telecommunications, alternators are used in backup power systems to ensure that networks remain operational during outages. The reliability of these systems is paramount, as any downtime can lead to significant financial losses. Understanding the parts of an alternator helps telecommunications companies select the right components to maintain continuous power supply. Buyers should prioritize sourcing from suppliers that offer robust service agreements and readily available spare parts to enhance operational resilience.

3 Common User Pain Points for ‘parts of an alternator diagram’ & Their Solutions

Scenario 1: Difficulty in Understanding Alternator Functionality Through Diagrams

Das Problem: Many B2B buyers, particularly those in sectors like automotive repair and manufacturing, often struggle to fully grasp how alternators function based on technical diagrams. The complexity of the components—like the rotor, stator, and rectifier—can be overwhelming, leading to misinterpretations and, consequently, costly mistakes in sourcing or repairing parts. This challenge is exacerbated in regions with less access to technical education, where the workforce may not have been formally trained in automotive systems.

Die Lösung: To overcome this challenge, buyers should seek out detailed training materials that break down the alternator’s components and their functions in a simplified manner. Investing in comprehensive workshops or online courses that utilize interactive diagrams can enhance understanding. Additionally, suppliers should provide annotated diagrams alongside parts listings, highlighting key functions and interconnections. This approach not only empowers buyers with knowledge but also promotes more informed purchasing decisions, reducing the risk of errors.

Scenario 2: Inaccurate Sourcing of Replacement Parts

Das Problem: B2B buyers often encounter difficulties when sourcing replacement parts for alternators due to the lack of clarity in diagrams. Misinterpretations of component specifications can lead to ordering incorrect parts, which can halt production lines or repair processes, causing delays and financial losses. This issue is particularly prevalent in regions with varying standards and specifications, where the same part might have different requirements.

Die Lösung: To mitigate this pain point, buyers should ensure they are using diagrams that are specific to their vehicle or equipment model. Collaborating closely with manufacturers and suppliers to obtain model-specific alternator diagrams is crucial. Additionally, implementing a robust quality control system to cross-reference part numbers and specifications before placing orders can significantly reduce errors. Suppliers should also be encouraged to offer customization options and technical support to clarify specifications based on the buyer’s needs.

Scenario 3: Inconsistent Voltage Regulation Issues

Das Problem: A common issue faced by businesses dealing with alternators is inconsistent voltage regulation due to misunderstandings of how the various components interact within the alternator system. This can result in electrical failures, damaging sensitive equipment and leading to expensive downtime. Buyers often lack a comprehensive understanding of the voltage regulator’s role and the impact of other components, such as the rectifier and stator, on overall performance.

Illustrative image related to parts of an alternator diagram

Die Lösung: To address this concern, it is essential for buyers to prioritize sourcing diagrams that illustrate not only the individual parts but also their operational relationships. This includes providing access to detailed guides on voltage regulation processes and troubleshooting tips. Suppliers can enhance their offerings by creating instructional content that explains common issues and solutions related to voltage regulation in alternators. Furthermore, establishing a feedback loop with buyers can help identify recurring problems, allowing suppliers to improve their educational resources and support systems. This proactive approach not only empowers buyers but also builds stronger supplier-buyer relationships.

Strategic Material Selection Guide for parts of an alternator diagram

What Are the Key Materials Used in Alternator Components?

When selecting materials for the various parts of an alternator, it is crucial to consider their unique properties and how they influence performance, durability, and overall application suitability. This guide analyzes four common materials used in alternator components: aluminum, copper, steel, and silicone rubber. Each material has distinct advantages and disadvantages that can impact international B2B buyers’ decisions.

How Does Aluminum Benefit Alternator Construction?

Aluminum is widely used for the outer housing of alternators due to its lightweight nature and excellent thermal conductivity. It does not magnetize, which is essential for dissipating heat generated during electrical power production. Aluminum typically has a temperature rating of around 150°C and offers good corrosion resistance, particularly when anodized.

Vorteile: Aluminum’s lightweight property reduces overall vehicle weight, enhancing fuel efficiency. It is also relatively low-cost and easy to manufacture, making it a popular choice.

Nachteile: While aluminum is durable, it can be less robust than other materials like steel, particularly in high-stress applications. It may also require additional treatments to improve corrosion resistance in harsh environments.

Auswirkungen auf die Anwendung: Aluminum is suitable for applications where weight reduction and heat dissipation are critical. However, it may not be ideal for environments with high mechanical stress.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM or DIN is essential. Buyers should ensure that aluminum components meet local regulations regarding manufacturing and environmental impact.

Illustrative image related to parts of an alternator diagram

Why Is Copper Essential for Electrical Conductivity?

Copper is the preferred material for windings and electrical connections in alternators due to its excellent electrical conductivity, which is significantly higher than that of aluminum. It can handle high temperatures, typically rated up to 200°C, and has good corrosion resistance when properly coated.

Vorteile: Copper’s high conductivity ensures efficient power transfer, reducing energy losses. It is also highly durable and can withstand thermal cycling without degrading.

Nachteile: Copper is more expensive than aluminum, which can increase the overall cost of alternator production. It is also heavier, which may not align with lightweight design goals.

Auswirkungen auf die Anwendung: Copper is ideal for high-performance applications where efficient electrical conductivity is paramount. However, its weight and cost can be limiting factors.

Überlegungen für internationale Käufer: Buyers should be aware of copper’s price volatility and ensure compliance with international standards for electrical components.

Illustrative image related to parts of an alternator diagram

How Does Steel Contribute to Structural Integrity?

Steel is often used in components like the rotor shaft and other structural parts of the alternator due to its high strength and durability. It can withstand high mechanical stresses and has a temperature rating of around 250°C, making it suitable for demanding environments.

Vorteile: Steel provides excellent structural integrity and resistance to wear and fatigue, ensuring long-term reliability. It is also relatively low-cost compared to other materials.

Nachteile: Steel is heavier than aluminum and can be prone to corrosion if not properly treated. This can lead to increased maintenance costs over time.

Auswirkungen auf die Anwendung: Steel is suitable for applications requiring high strength and durability but may not be ideal for lightweight designs.

Überlegungen für internationale Käufer: Compliance with material standards such as JIS or ASTM is critical. Buyers should also consider local manufacturing capabilities for steel components.

What Role Does Silicone Rubber Play in Alternator Components?

Silicone rubber is commonly used for seals and gaskets in alternators. It has excellent temperature resistance, typically rated up to 200°C, and offers good flexibility and durability.

Vorteile: Silicone rubber provides excellent sealing properties, preventing moisture and contaminants from entering the alternator. It is also resistant to aging and UV light.

Nachteile: While silicone rubber is effective in sealing applications, it may not provide the same level of mechanical strength as metals, limiting its use to non-structural components.

Auswirkungen auf die Anwendung: Silicone rubber is ideal for sealing applications where flexibility and temperature resistance are essential. However, it should not be used in load-bearing components.

Überlegungen für internationale Käufer: Buyers should ensure that silicone rubber components meet international standards for automotive applications, including compliance with health and safety regulations.

Illustrative image related to parts of an alternator diagram

Zusammenfassende Tabelle zur Materialauswahl für Lichtmaschinenbauteile

| Material | Typical Use Case for parts of an alternator diagram | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Outer housing | Leichtes Gewicht und gute Wärmeleitfähigkeit | Less robust under high stress | Niedrig |

| Kupfer | Wicklungen und elektrische Anschlüsse | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und höheres Gewicht | Hoch |

| Stahl | Rotor shaft and structural components | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Korrosion | Med |

| Silicone Rubber | Seals and gaskets | Excellent sealing properties | Begrenzte mechanische Festigkeit | Niedrig |

This guide provides a comprehensive overview of the materials commonly used in alternator components, enabling international B2B buyers to make informed decisions based on performance, durability, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of an alternator diagram

What Are the Main Stages of Manufacturing Parts of an Alternator?

The manufacturing process for alternator components involves several critical stages that ensure quality and performance. Understanding these stages is vital for B2B buyers who need reliable parts for their applications.

How Are Materials Prepared for Alternator Parts?

The first step in the manufacturing process is material preparation. This includes selecting high-quality materials that meet specific performance criteria. For alternators, common materials include aluminum for the housing due to its lightweight and non-magnetic properties, and copper for the windings, which is essential for electrical conductivity.

Before production, these materials undergo rigorous testing to verify their properties. For instance, aluminum is often checked for tensile strength and corrosion resistance, while copper may be assessed for purity and conductivity. Any deviation from the material specifications can lead to performance issues in the final product.

Welche Techniken werden bei der Umformung von Lichtmaschinenbauteilen eingesetzt?

Once the materials are prepared, the next stage is forming the various components of the alternator. This process includes techniques such as die casting for the aluminum housing and precision machining for internal components like the rotor and stator.

-

Druckguss: This technique is commonly used to create complex shapes with high precision. It involves pouring molten aluminum into a mold, allowing it to cool and solidify, thus forming the alternator’s outer casing.

-

Bearbeitungen: After forming, components like the rotor and stator undergo machining processes to achieve the necessary tolerances and surface finishes. CNC (Computer Numerical Control) machining is often employed for its accuracy and efficiency.

How Are Alternator Parts Assembled?

The assembly of alternator components is a crucial stage that requires meticulous attention to detail. This process typically involves:

-

Komponentenintegration: Each part, including the rotor, stator, rectifier, and voltage regulator, is assembled in a specific order to ensure proper functionality. The rotor is placed inside the stator, and electrical connections are established through terminals.

-

Qualitätskontrollen während der Montage: As components are integrated, quality checkpoints are established. These may include visual inspections and functional tests to ensure that each part fits correctly and functions as intended.

What Finishing Processes Are Applied to Alternator Parts?

Finishing processes are essential to enhance the durability and performance of alternator components. This includes:

-

Oberflächenbehandlung: Components often undergo anodizing or powder coating to improve corrosion resistance and aesthetics. Anodizing aluminum components increases their lifespan by providing a protective oxide layer.

-

Abschließende Prüfung: After finishing, each alternator undergoes rigorous testing. This may include electrical testing to verify output voltage and load testing to ensure the alternator can perform under various conditions.

Wie wird die Qualitätssicherung bei der Herstellung von Wechselstromgeneratoren umgesetzt?

Quality assurance (QA) is critical in ensuring that alternator components meet industry standards and customer expectations. B2B buyers should be familiar with the key aspects of quality assurance.

Welche internationalen Normen sollten B2B-Einkäufer berücksichtigen?

International standards such as ISO 9001 are fundamental to quality management systems across various industries. This standard emphasizes a process approach to quality management and encourages continuous improvement, which is vital for manufacturers of alternator parts.

In addition to ISO 9001, industry-specific standards such as CE marking (for products sold in Europe) and API (American Petroleum Institute) standards for automotive components should be considered. These certifications ensure that the products meet safety and performance requirements.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle während der Produktion?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

-

Eingangsqualitätskontrolle (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring that materials meet specified standards is crucial to preventing defects later in production.

-

In-Process-Qualitätskontrolle (IPQC): During the manufacturing process, regular inspections and tests are performed. This includes monitoring critical parameters like dimensions and electrical characteristics to identify issues early.

-

Endkontrolle (FQC): After assembly, the final inspection ensures that the product meets all specifications before shipment. This may involve comprehensive testing to simulate operational conditions.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

B2B buyers should take proactive measures to verify the quality control practices of their suppliers. This can include:

Illustrative image related to parts of an alternator diagram

-

Lieferanten-Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should assess their adherence to international standards and their internal QA procedures.

-

Überprüfung der Qualitätsberichte: Suppliers should provide documentation of their quality control processes, including test results and certification records. These reports can help buyers evaluate the reliability of the products.

-

Inspektionen durch Dritte: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality management practices. These organizations can conduct thorough inspections and provide detailed reports on compliance with standards.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

-

Einhaltung gesetzlicher Vorschriften: Different countries may have varying regulations regarding automotive parts. Buyers must ensure that the products they source comply with local regulations, including safety and environmental standards.

-

Kulturelle Unterschiede bei den Qualitätserwartungen: Understanding regional differences in quality perceptions can aid in establishing clear communication with suppliers. For example, European buyers may prioritize stringent quality controls compared to other regions.

-

Überlegungen zu Logistik und Lieferkette: Buyers should factor in the logistics of transporting alternator parts. This includes understanding how quality can be affected during shipping and storage, and ensuring that suppliers have measures in place to mitigate these risks.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing alternator parts, ensuring reliability and performance in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of an alternator diagram’

In the competitive landscape of automotive components, sourcing the right parts for an alternator is critical for ensuring performance and reliability. This guide will provide international B2B buyers with a structured approach to procuring parts of an alternator diagram, focusing on essential steps to streamline the process.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Understanding the specific requirements for your alternator parts is the foundation of effective sourcing. Outline the types of alternators you are working with, including make, model, and performance specifications. This clarity will help you communicate effectively with suppliers and ensure compatibility with your existing systems.

- Wichtige Überlegungen:

- Voltage and amperage ratings

- Physical dimensions and weight constraints

- Environmental conditions (e.g., temperature, humidity)

Schritt 2: Recherche über seriöse Anbieter

Finding trustworthy suppliers is paramount to maintaining quality and reliability in your supply chain. Conduct thorough research to identify manufacturers and distributors with a solid reputation in the automotive parts industry.

- Schwerpunkte:

- Supplier reviews and ratings

- Industry certifications (e.g., ISO, TS16949)

- Track record of delivery timelines and customer service

Schritt 3: Lieferantenzertifizierungen bewerten

Before finalizing any partnership, it’s crucial to verify that potential suppliers meet industry standards and regulations. Certifications not only ensure quality but also indicate that the supplier adheres to best practices in manufacturing and safety.

- Was Sie beachten sollten:

- Quality management systems

- Compliance with local and international regulations

- Evidence of continuous improvement practices

Schritt 4: Detaillierte Produktinformationen anfordern

Engage with suppliers to obtain comprehensive product specifications for the alternator parts you need. This includes datasheets, technical drawings, and performance benchmarks to ensure that the parts meet your requirements.

- Essential Documents:

- Technical datasheets

- Installation guides

- Warranty and service information

Schritt 5: Durchführung einer Kosten-Nutzen-Analyse

Evaluate the financial implications of sourcing from different suppliers. It’s not just about the lowest price; consider factors such as shipping costs, lead times, and potential discounts for bulk orders.

- Analytical Points:

- Total cost of ownership (TCO)

- Payment terms and conditions

- Long-term supplier relationships for better pricing

Schritt 6: Kundenbetreuung und Garantie bewerten

After-sales support is crucial for maintaining operational efficiency. Ensure that suppliers offer robust support services, including warranty terms and availability of replacement parts.

- Wichtige Aspekte:

- Length and coverage of warranty

- Availability of technical support

- Return and exchange policies

Schritt 7: Klare Kommunikationskanäle einrichten

Effective communication with your suppliers can enhance collaboration and expedite the procurement process. Establish clear protocols for updates, order tracking, and addressing any issues that may arise.

- Best Practices:

- Regular check-ins and updates

- Designate point-of-contact personnel

- Utilize technology for real-time communication

By following this structured approach, B2B buyers can ensure they are making informed decisions when sourcing parts for alternators, ultimately leading to improved product quality and operational efficiency.

Comprehensive Cost and Pricing Analysis for parts of an alternator diagram Sourcing

What Are the Key Cost Components for Sourcing Parts of an Alternator?

When sourcing parts for an alternator, understanding the cost structure is vital for effective budgeting and decision-making. The primary cost components include:

-

Materialien: The raw materials for alternators typically include aluminum for the housing, copper for the windings, and various plastics for insulation. The quality of these materials significantly impacts the overall cost. For instance, high-purity copper and aerospace-grade aluminum will be more expensive but offer better performance and longevity.

-

Arbeit: Labor costs can vary significantly based on geographic location and the complexity of the manufacturing process. Skilled labor is essential for precision assembly, especially for components like the rotor and stator, where tolerances are critical.

-

Fertigungsgemeinkosten: This encompasses indirect costs such as utilities, rent, and administrative expenses associated with the production facilities. These costs can be significant, particularly in regions with high operational expenses.

-

Werkzeuge: Initial tooling costs can be substantial, especially for custom or specialized parts. Investing in high-quality tooling can reduce long-term costs by increasing efficiency and reducing waste.

-

Qualitätskontrolle (QC): Ensuring that parts meet specific standards is essential, especially for B2B buyers in regulated markets. QC processes can add to the cost but are crucial for maintaining product integrity and reliability.

-

Logistik: Transportation costs can vary widely based on the distance, method of shipping, and any tariffs or customs fees involved. Efficient logistics planning can help mitigate these costs.

-

Marge: Suppliers will add a markup to cover their costs and profit. Understanding the typical margins in your industry can help in negotiations.

How Do Price Influencers Affect Sourcing Decisions for Alternator Parts?

Several factors influence the pricing of alternator parts:

-

Volumen und Mindestbestellmenge (MOQ): Purchasing in bulk can significantly reduce per-unit costs. However, it’s essential to assess your inventory management capabilities to avoid excess stock.

-

Spezifikationen und Anpassung: Custom designs or specifications will typically incur higher costs. Standardized parts may be more cost-effective, so consider whether your requirements can be met with off-the-shelf components.

-

Materialqualität und Zertifizierungen: Parts that meet specific industry certifications (e.g., ISO, TS16949) may command higher prices but can lead to cost savings in the long run due to reduced failure rates.

-

Lieferantenfaktoren: The supplier’s reputation, experience, and location can affect pricing. Established suppliers may offer better reliability, which can justify a higher price.

-

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) is crucial, as they dictate who is responsible for shipping costs and risks. This can impact the total landed cost of parts.

What Buyer Tips Should Be Considered for Cost-Efficiency in Alternator Parts Sourcing?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Verhandlung: Always negotiate terms and pricing. Building a strong relationship with suppliers can lead to better deals and improved service.

-

Gesamtbetriebskosten (TCO): Evaluate the total cost of ownership rather than just the purchase price. Consider factors such as maintenance, durability, and warranty when assessing value.

-

Regional Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have different pricing structures compared to those in South America or Africa due to varying labor and material costs.

-

Marktforschung: Conduct thorough market research to understand the competitive landscape. This knowledge can empower you during negotiations and help identify the best suppliers.

-

Long-term Partnerships: Establish long-term relationships with reliable suppliers. This can lead to better pricing, priority service, and enhanced collaboration on future projects.

Haftungsausschluss für indikative Preise

It is important to note that prices for alternator parts can fluctuate based on market conditions, raw material costs, and geopolitical factors. Therefore, all indicative prices should be treated as such and verified through direct supplier engagement.

Illustrative image related to parts of an alternator diagram

Alternatives Analysis: Comparing parts of an alternator diagram With Other Solutions

Exploring Alternative Solutions to ‘Parts of an Alternator Diagram’

In the automotive industry, understanding the components and functionality of an alternator is essential for maintenance and repair. However, various alternative technologies and methods can achieve similar goals, such as power generation and electrical system management. This section will compare the ‘parts of an alternator diagram’ with other viable solutions to help B2B buyers make informed decisions.

| Vergleichsaspekt | Parts Of An Alternator Diagram | Alternative 1: Integrated Generator System | Alternative 2: Solarstromanlage |

|---|---|---|---|

| Leistung | High efficiency in converting mechanical to electrical energy | Excellent for continuous power supply, especially in hybrid systems | Variable performance, dependent on sunlight availability |

| Kosten | Moderate initial cost, potential long-term savings | Higher upfront investment but lower operational costs | Initial setup cost can be high, but low maintenance |

| Einfache Implementierung | Requires technical knowledge for installation and maintenance | More complex integration with existing systems | Installation can be straightforward but may require permits |

| Wartung | Regelmäßige Kontrollen für optimale Leistung erforderlich | Generally low maintenance after installation | Minimal maintenance, mainly cleaning panels |

| Bester Anwendungsfall | Conventional vehicles needing reliable electrical supply | Hybrid and electric vehicles requiring integrated solutions | Off-grid applications or supplementary power for homes |

Detaillierte Aufschlüsselung der Alternativen

Integrated Generator System

An integrated generator system combines various power generation methods into a single unit, often found in hybrid vehicles. These systems can produce power from multiple sources, ensuring a consistent energy supply. The primary advantage is their ability to function seamlessly with the vehicle’s existing electrical system, enhancing overall efficiency. However, the complexity of installation and integration can present challenges, especially for those unfamiliar with advanced automotive technologies.

Solarstromanlage

Solar power systems harness energy from the sun to generate electricity, making them an attractive alternative for off-grid applications or as supplementary power sources for residential use. The main benefit is their sustainability and minimal ongoing costs after the initial setup. However, solar systems can be heavily dependent on geographical location and weather conditions, which may lead to inconsistent power generation. Additionally, navigating local regulations for installation can complicate the setup process.

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

When selecting between the ‘parts of an alternator diagram’ and alternative solutions, B2B buyers should assess their specific requirements, including performance needs, budget constraints, and the intended application. For conventional vehicles, a robust understanding of alternator components is essential, while hybrid systems may benefit from integrated generators. Conversely, those considering renewable energy sources should evaluate the viability of solar power based on location and intended use. By aligning the chosen solution with operational needs and financial capabilities, buyers can ensure optimal performance and long-term satisfaction.

Illustrative image related to parts of an alternator diagram

Essential Technical Properties and Trade Terminology for parts of an alternator diagram

What Are the Key Technical Properties of Alternator Components?

When sourcing alternator parts, understanding the technical specifications is vital for ensuring quality, reliability, and performance. Here are several critical specifications to consider:

-

Werkstoffgüte: Alternators are typically constructed from aluminum due to its lightweight and non-magnetizing properties. This material efficiently dissipates heat generated during operation, which is crucial for maintaining performance and longevity. Buyers should ensure that suppliers adhere to international material standards, such as ASTM or ISO, to guarantee quality.

-

Toleranzwerte: Precision in manufacturing is paramount. Tolerance levels indicate the acceptable deviation in dimensions of alternator components, such as the rotor and stator. A tighter tolerance ensures better fit and function, reducing wear and tear over time. Buyers should specify tolerance requirements in their purchase orders to ensure compatibility with existing systems.

-

Elektrische Nennwerte: Alternators must be rated for specific voltage and current outputs, which are essential for compatibility with the vehicle’s electrical systems. Understanding the electrical ratings helps buyers select parts that meet their operational needs and avoid failures in the field.

-

Effizienz der Kühlung: The design of alternators includes components such as internal cooling fans and vents, which are crucial for preventing overheating. Buyers should evaluate the cooling mechanisms of alternators, particularly in regions with high ambient temperatures, to ensure optimal performance and reliability.

-

Dauerhaftigkeitsstandards: Components like the rectifier and voltage regulator should meet specific durability standards to withstand operational stresses. Buyers should inquire about the lifecycle and stress testing of these components to ensure they meet industry benchmarks.

-

Weight Specifications: The weight of alternators affects installation and vehicle performance. Lighter units can improve fuel efficiency, making weight specifications a critical consideration for buyers looking to enhance overall vehicle performance.

Welche gängigen Handelsbegriffe sollten B2B-Einkäufer verstehen?

Familiarity with industry terminology can facilitate smoother transactions and better negotiations. Here are several essential terms related to alternator parts sourcing:

-

OEM (Originalgerätehersteller): This term refers to parts made by the original manufacturer of the vehicle or equipment. OEM parts are often preferred due to their guaranteed compatibility and quality. Buyers should clarify whether they are sourcing OEM or aftermarket parts to ensure they meet their standards.

-

MOQ (Mindestbestellmenge): MOQ indicates the smallest number of units a supplier is willing to sell. Understanding the MOQ helps buyers plan their inventory and budget effectively, especially in markets where large orders may be necessary to secure favorable pricing.

-

RFQ (Angebotsanfrage): An RFQ is a document used to solicit price proposals from suppliers. Including detailed specifications in an RFQ can help buyers receive accurate quotes and choose the best supplier based on price, quality, and delivery time.

-

Incoterms (Internationale Handelsklauseln): These terms define the responsibilities of buyers and sellers in international shipping. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for managing shipping costs and risks effectively.

-

Vorlaufzeit: This term refers to the time it takes from placing an order to receiving the goods. Buyers should consider lead times when planning their procurement and inventory management to avoid production delays.

-

Warranty and Service Agreement: This refers to the terms under which a supplier will repair or replace defective parts. Understanding the warranty terms can protect buyers from unexpected costs and ensure they receive quality components.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring the reliability and efficiency of their alternator components.

Illustrative image related to parts of an alternator diagram

Navigating Market Dynamics and Sourcing Trends in the parts of an alternator diagram Sector

What Are the Key Market Drivers and Trends Impacting the Parts of an Alternator Diagram Sector?

The global market for automotive components, including alternator parts, is driven by several factors. Increasing vehicle production, particularly in emerging markets such as Brazil and South Africa, is a primary catalyst. The growing demand for electric vehicles (EVs) and hybrids is also reshaping the landscape, as these vehicles often require advanced alternator designs to manage their unique electrical demands. In Europe, particularly Germany, stringent emissions regulations are pushing manufacturers to innovate, leading to a greater focus on efficiency and performance in alternator components.

Emerging technologies such as digital twin simulations and advanced materials are becoming integral in the design and manufacturing of alternators. These technologies enable manufacturers to optimize performance while reducing waste and production costs. Additionally, the rise of Industry 4.0 is influencing sourcing strategies, with companies increasingly adopting automation and data analytics to enhance supply chain transparency and efficiency. B2B buyers should pay attention to suppliers who integrate these technologies, as they are likely to provide higher-quality, more reliable components.

Market dynamics are also shifting due to geopolitical factors and trade agreements that affect sourcing. For instance, buyers in the Middle East may encounter tariffs that influence the cost and availability of components sourced from Europe or Asia. Understanding these dynamics is crucial for international buyers aiming to mitigate risks and optimize their sourcing strategies.

How Can Sustainability and Ethical Sourcing Enhance Your Supply Chain for Alternator Parts?

Sustainability is becoming a significant consideration for B2B buyers in the automotive sector. The environmental impact of sourcing materials for alternator components, such as aluminum and copper, necessitates a focus on ethical supply chains. Sourcing from suppliers who prioritize sustainable practices can reduce the carbon footprint associated with production and transportation. For instance, manufacturers that use recycled materials or implement energy-efficient processes can offer products that align with global sustainability goals.

Moreover, buyers should look for suppliers that possess ‘green’ certifications, such as ISO 14001, which indicates adherence to effective environmental management systems. These certifications not only enhance a company’s reputation but also signify a commitment to responsible sourcing. By prioritizing suppliers with sustainable practices, B2B buyers can contribute to environmental conservation while ensuring compliance with increasing regulations concerning emissions and waste.

Incorporating sustainable sourcing into procurement strategies can also yield long-term cost benefits. For example, using alternative materials or innovative designs can lead to reduced energy consumption during the lifecycle of the alternator, ultimately lowering operational costs. Thus, integrating sustainability into the sourcing process is not only a moral obligation but also a smart business decision.

How Has the Parts of an Alternator Diagram Sector Evolved Over Time?

The evolution of alternator technology has significantly impacted the parts sector. Initially designed to provide basic electrical power for vehicles, alternators have transformed into complex systems that support advanced automotive technologies. The introduction of smart alternators with integrated voltage regulators and communication systems has enhanced their functionality, catering to the demands of modern vehicles.

Over the years, advancements in materials science have also played a crucial role. The shift from heavy metals to lightweight materials, such as aluminum, has improved efficiency and performance while reducing the overall weight of alternators. This evolution is particularly relevant as manufacturers strive to meet fuel efficiency standards and reduce emissions.

Illustrative image related to parts of an alternator diagram

As the automotive industry continues to evolve with the rise of electric and hybrid vehicles, the parts of an alternator diagram will likely undergo further transformations. Buyers must stay informed about these changes to ensure they are sourcing the most up-to-date and efficient components, positioning their businesses for future success.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of an alternator diagram

-

How do I source reliable suppliers for alternator parts?

Finding trustworthy suppliers for alternator parts begins with thorough research. Utilize B2B platforms like Alibaba or ThomasNet to identify potential manufacturers. Verify their credentials by checking for certifications, customer reviews, and their history in the industry. It’s beneficial to request samples before placing large orders, allowing you to assess quality firsthand. Additionally, consider attending trade shows or industry exhibitions to meet suppliers in person and establish relationships that can lead to better terms and reliability in future transactions. -

What is the best way to customize alternator parts for specific applications?

To customize alternator parts effectively, start by communicating your specific requirements clearly with your supplier. Provide detailed specifications, such as dimensions, material preferences, and performance criteria. Many manufacturers offer design services or can modify existing parts to fit your needs. Collaborate closely during the prototype phase, and ensure that you conduct thorough testing to validate performance before mass production. This approach ensures that the final product meets your application’s demands while maintaining quality. -

What are the minimum order quantities (MOQ) for alternator parts?

Minimum order quantities (MOQ) for alternator parts can vary significantly based on the supplier and the specific components required. Typically, MOQs can range from 100 to several thousand units. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your business model. Some manufacturers may offer lower MOQs for custom parts, especially if you are willing to pay a premium for smaller runs. Understanding your market demand will help you make informed decisions regarding order sizes. -

What payment terms are common in international B2B transactions for alternator parts?

Common payment terms in international B2B transactions for alternator parts include options like upfront payments, letters of credit, or net terms (e.g., net 30 or net 60). Many suppliers prefer a partial upfront payment to mitigate risk, especially for large orders. Always clarify payment methods accepted, whether through bank transfers, PayPal, or other platforms. It is crucial to review terms carefully to ensure they are favorable and to protect against potential risks associated with international trade. -

Wie kann ich die Qualitätssicherung (QA) für Generatorenteile sicherstellen?

Implementing a robust quality assurance (QA) process involves several steps. First, establish clear quality standards and specifications with your supplier. Request certifications and conduct factory audits to ensure compliance with these standards. Additionally, consider third-party inspection services to evaluate the products before shipment. Developing a strong relationship with your supplier can also facilitate better communication regarding quality expectations, leading to fewer defects and higher overall satisfaction with the parts received. -

What logistics considerations should I keep in mind when sourcing alternator parts?

When sourcing alternator parts, logistics play a critical role in ensuring timely delivery and cost-effectiveness. Consider factors such as shipping methods (air freight vs. sea freight), customs regulations in your country, and potential tariffs that may apply. Collaborate with your supplier to choose the most efficient shipping option based on your urgency and budget. Additionally, establish a clear timeline for production and delivery to avoid disruptions in your supply chain. -

How do I handle discrepancies in alternator part specifications upon delivery?

To address discrepancies in specifications upon delivery, first, document the differences with clear photographs and notes. Immediately notify your supplier, providing evidence of the issue and referencing your original order specifications. Most reputable suppliers will have procedures in place to rectify such problems, whether through replacements, refunds, or adjustments in future orders. Maintaining open communication and a professional tone will facilitate a smoother resolution process. -

What are the trends in alternator technology that I should be aware of?

Staying updated on trends in alternator technology is crucial for making informed purchasing decisions. Current trends include advancements in smart alternators that optimize energy output based on vehicle demands and the integration of lightweight materials for improved efficiency. Additionally, there is a growing focus on sustainability, with manufacturers exploring environmentally friendly production methods. Keeping abreast of these trends can help you choose parts that enhance performance and align with market demands.

Top 5 Parts Of An Alternator Diagram Manufacturers & Suppliers List

1. Electude – Alternator Components

Domäne: electude.com

Registriert: 2005 (20 Jahre)

Einleitung: Eine Lichtmaschine ist ein wichtiges Bauteil in einem Kraftfahrzeug, das mechanische Energie in elektrische Energie umwandelt und so Strom für die elektrischen Verbraucher und die Batterie des Fahrzeugs erzeugt. Zu den wichtigsten Komponenten gehören:

– Pulley: Transfers mechanical energy from the engine to the alternator.

- Rotor: Erzeugt das Magnetfeld zur Erzeugung des Wechselstroms.

– Stator: The static part where voltage is generat…

2. HowStuffWorks – Lichtmaschinen

Domäne: auto.wie-das-funktioniert.com

Registriert: 1998 (27 Jahre)

Einleitung: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation. Key components include: 1. Drive pulley – attached to the rotor shaft, converts mechanical energy to electrical power. 2. Terminals – S terminal (senses battery voltage), IG terminal (ignition switch), L terminal (warning lamp circuit), B terminal (main output to b…

3. Pinterest – Exploded View of an Alternator

Domäne: pinterest.com

Registriert: 2009 (16 Jahre)

Einleitung: Explosionszeichnung einer Lichtmaschine

4. Facebook – Car Alternator Diagram

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: A detailed diagram showing the internal structure of a car alternator, with labeled components such as the rotor, stator windings, brushes, rectifier.

5. Scribd – Automotive Alternator Components

Domäne: scribd.com

Registriert: 2006 (19 Jahre)

Einleitung: The document discusses the main parts and functions of an automotive alternator, describing 8 key parts: 1) the pulley that rotates the rotor assembly via the engine belt, 2) the housing that protects internal components, 3) bearings that allow the rotor to spin freely, 4) the rotor assembly that generates a magnetic field, 5) the stator assembly that uses this field to generate electricity, 6) th…

Strategic Sourcing Conclusion and Outlook for parts of an alternator diagram

As international B2B buyers increasingly seek efficient and reliable components for automotive applications, understanding the critical parts of an alternator becomes paramount. Each component—from the rotor and stator to the rectifier and voltage regulator—plays an integral role in transforming mechanical energy into electrical power. This knowledge not only aids in making informed purchasing decisions but also enhances the potential for optimizing supply chains.

Strategic sourcing of alternator components can lead to significant cost savings and improved product reliability. By establishing partnerships with reputable suppliers, buyers can ensure they are acquiring high-quality parts that meet industry standards, ultimately reducing maintenance costs and enhancing vehicle performance. This is particularly vital for markets in Africa, South America, the Middle East, and Europe, where reliable automotive components are essential for sustaining growth in the automotive sector.

Looking ahead, the demand for advanced alternator technologies is expected to rise, driven by the shift towards electric vehicles and more efficient power management systems. Buyers are encouraged to stay ahead of industry trends and leverage strategic sourcing to secure the best components for their needs. Engage with trusted suppliers today to explore innovative solutions that will enhance your competitive edge in the global marketplace.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.