Introduction: Navigating the Global Market for how long do alternators typically last

In the competitive landscape of automotive parts procurement, understanding how long alternators typically last is crucial for B2B buyers. Alternators are essential components that power vehicle electrical systems, and their lifespan directly impacts operational efficiency and maintenance costs. This guide delves deep into the factors influencing alternator longevity, including quality variations, environmental conditions, and vehicle usage patterns.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Brazil), face unique challenges in sourcing reliable alternators. These challenges include navigating diverse supplier markets, assessing the quality of components, and understanding the implications of alternator failure on overall vehicle performance.

By providing a comprehensive overview of alternator types, applications, and critical maintenance tips, this guide equips B2B decision-makers with the insights needed to make informed purchasing decisions. Additionally, it covers supplier vetting processes and cost considerations, ensuring that buyers can balance quality and budget effectively. As a result, businesses can enhance their operational reliability while minimizing unexpected downtime and repair costs. With this guide in hand, you’ll be well-prepared to navigate the global market for alternators and secure the best options for your fleet or service needs.

Inhaltsverzeichnis

- Top 3 How Long Do Alternators Typically Last Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long do alternators typically last

- Understanding how long do alternators typically last Types and Variations

- Key Industrial Applications of how long do alternators typically last

- 3 Common User Pain Points for ‘how long do alternators typically last’ & Their Solutions

- Strategic Material Selection Guide for how long do alternators typically last

- In-depth Look: Manufacturing Processes and Quality Assurance for how long do alternators typically last

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long do alternators typically last’

- Comprehensive Cost and Pricing Analysis for how long do alternators typically last Sourcing

- Alternatives Analysis: Comparing how long do alternators typically last With Other Solutions

- Essential Technical Properties and Trade Terminology for how long do alternators typically last

- Navigating Market Dynamics and Sourcing Trends in the how long do alternators typically last Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long do alternators typically last

- Strategic Sourcing Conclusion and Outlook for how long do alternators typically last

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding how long do alternators typically last Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard-Lichtmaschinen | Average lifespan of 7 years or 150,000 miles | General automotive repair and maintenance | Vorteile: Kostengünstig, weit verbreitet. Nachteile: May not perform well under heavy electrical loads. |

| Hochleistungsgeneratoren | Designed for vehicles with extensive electronic systems | Leistungsstarke Fahrzeuge, Aftermarket-Upgrades | Vorteile: Increased power output, suitable for custom installations. Nachteile: Higher cost, potential compatibility issues. |

| Überholte Lichtmaschinen | Rebuilt versions of original alternators | Budget-conscious repairs and fleet maintenance | Vorteile: Lower cost than new, often reliable. Nachteile: Shorter lifespan than new parts, variable quality. |

| OEM-Lichtmaschinen | Original Equipment Manufacturer parts | New vehicle replacements, warranty services | Vorteile: Guaranteed compatibility, quality assurance. Nachteile: Erstklassige Preise im Vergleich zu Aftermarket-Optionen. |

| Schiffsgeneratoren | Designed for marine environments and conditions | Boats and marine vehicles | Vorteile: Corrosion-resistant, robust design. Nachteile: Specialized, often more expensive than standard. |

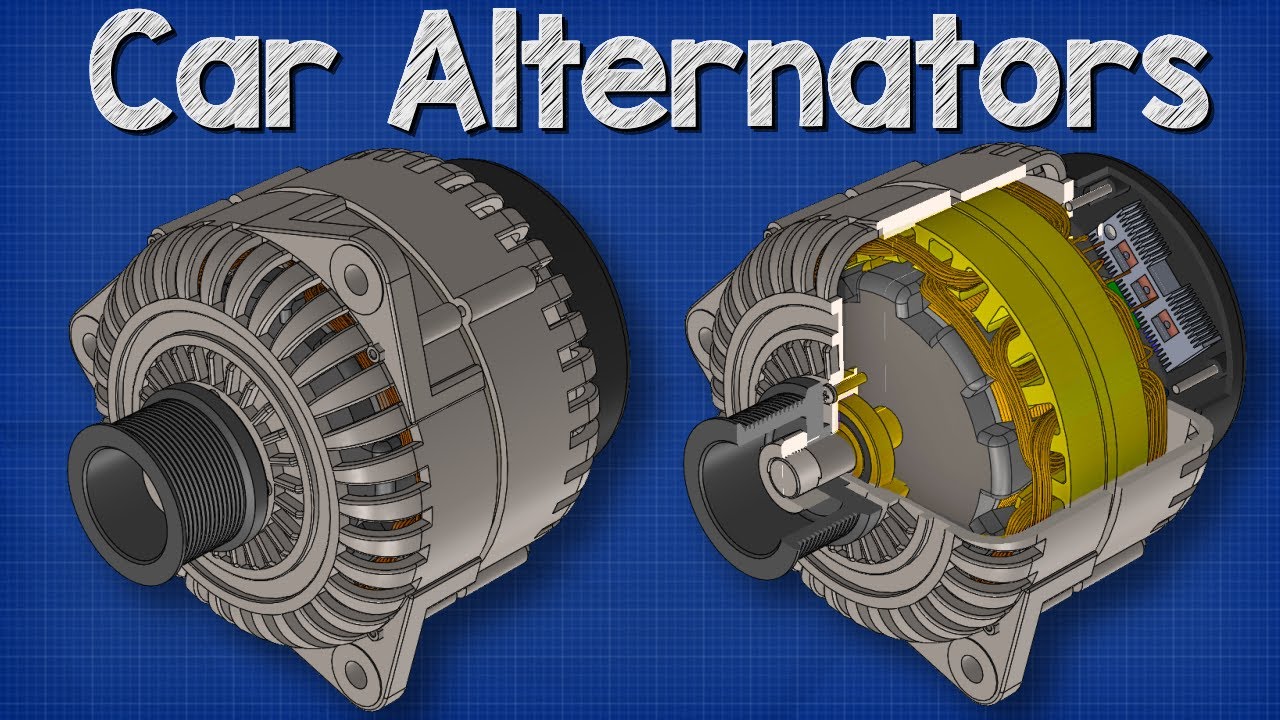

Was sind die Merkmale von Standard-Lichtmaschinen?

Standard alternators are typically designed to last around seven years or up to 150,000 miles, making them suitable for most everyday vehicles. They provide adequate power for basic electrical systems, making them a popular choice for general automotive repair and maintenance. When considering a standard alternator, B2B buyers should focus on quality assurance from suppliers and the part’s compatibility with various vehicle models. While they are cost-effective, businesses should be aware that they may not meet the power demands of vehicles with extensive electronic systems.

How Do High-Output Alternators Differ in Functionality?

High-output alternators are engineered to deliver more power, making them ideal for performance vehicles or those with numerous aftermarket electronic installations. These alternators can handle increased electrical loads, which is crucial for businesses involved in the customization of vehicles. When purchasing high-output alternators, buyers should consider the specific electrical requirements of the vehicle and potential compatibility with existing systems. While they offer superior performance, the higher price point and potential installation complexities may be a drawback for some buyers.

What Are the Advantages of Remanufactured Alternators?

Remanufactured alternators provide a cost-effective alternative for businesses looking to manage repair budgets without sacrificing reliability. These parts are rebuilt to meet OEM specifications, making them suitable for budget-conscious repairs and fleet maintenance. B2B buyers should evaluate the warranty and quality assurance offered by suppliers, as the lifespan may be shorter compared to new units. While remanufactured alternators can be a smart financial choice, variability in quality can be a concern, necessitating careful supplier selection.

Why Choose OEM Alternators for Vehicle Replacements?

Original Equipment Manufacturer (OEM) alternators are made specifically for individual vehicle makes and models, ensuring perfect compatibility and reliability. They are often recommended for new vehicle replacements and warranty services. B2B buyers should weigh the benefits of guaranteed quality against the higher price tag associated with OEM parts. While they provide peace of mind in terms of performance and longevity, the cost can be prohibitive for businesses operating on tight margins.

What Are the Unique Features of Marine Alternators?

Marine alternators are specifically designed to withstand harsh marine environments, featuring corrosion-resistant materials and robust construction. They are essential for powering the electrical systems of boats and other marine vehicles. When purchasing marine alternators, businesses should consider factors like voltage requirements and environmental durability. Although they offer specialized features that justify a higher price, their unique design makes them indispensable for marine applications, ensuring reliable operation in challenging conditions.

Key Industrial Applications of how long do alternators typically last

| Branche/Sektor | Specific Application of how long do alternators typically last | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Evaluating lifespan for vehicle assembly lines | Reduziert Ausfallzeiten und Wartungskosten | Qualitätssicherung und Kompatibilität mit verschiedenen Fahrzeugmodellen |

| Landwirtschaft | Powering machinery such as tractors and harvesters | Ensures reliable operation and prevents crop loss | Sourcing durable alternators suited for harsh environments |

| Transport | Fleet management for buses and trucks | Minimizes unexpected breakdowns and maintenance expenses | Focus on high-performance alternators with long warranties |

| Bergbau | Supporting heavy equipment like excavators and drills | Enhances operational efficiency and reduces repair costs | Consideration of alternator capacity and environmental resilience |

| Bauwesen | Powering construction vehicles and equipment | Ensures project timelines are met without electrical failures | Emphasis on sourcing robust alternators for heavy-duty applications |

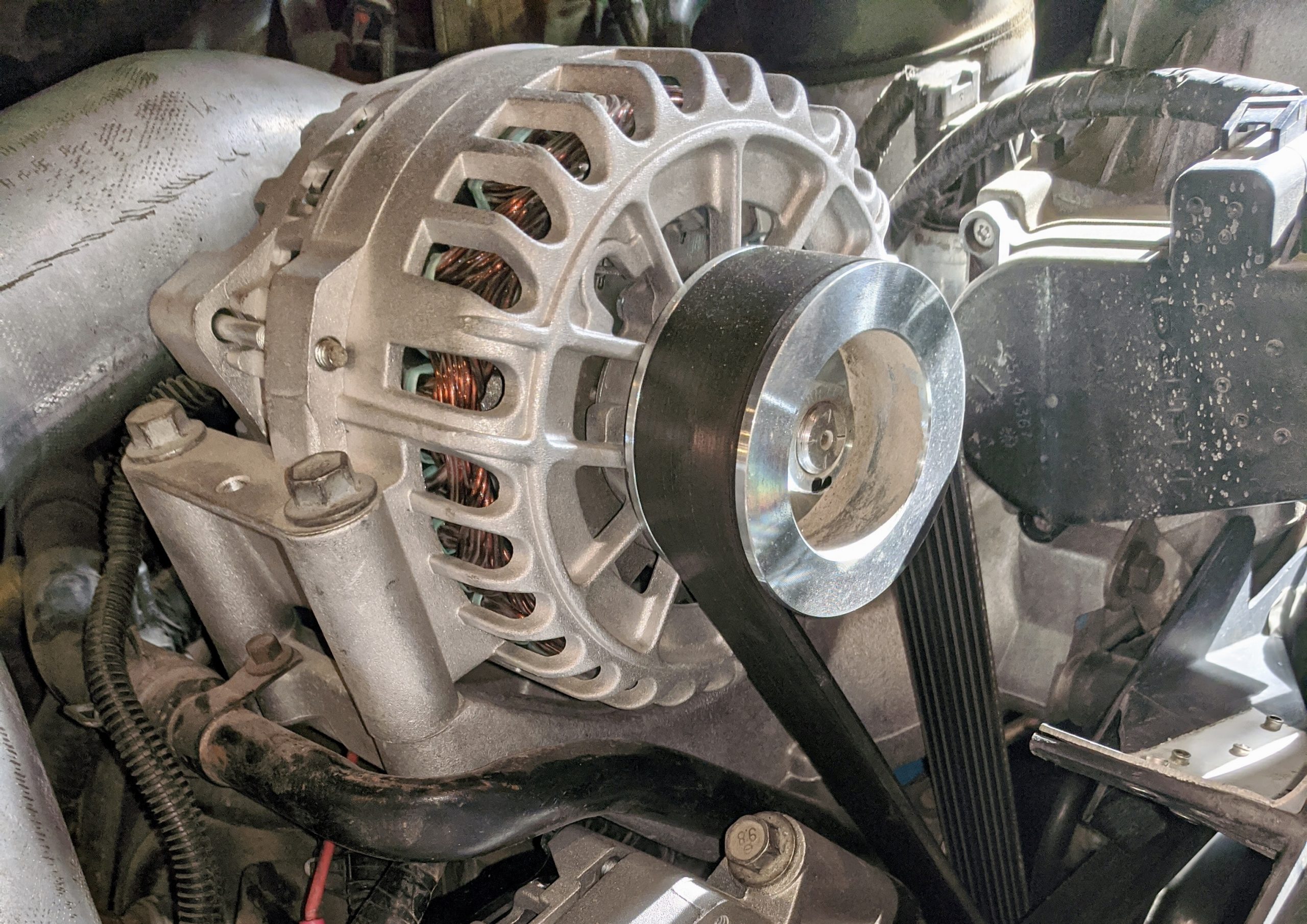

How is the lifespan of alternators relevant in automotive manufacturing?

In the automotive manufacturing sector, understanding the lifespan of alternators is crucial for production efficiency. Manufacturers rely on accurate estimates to schedule maintenance and minimize vehicle downtime. A typical lifespan of around seven years or 150,000 miles allows for strategic planning in assembly lines. Ensuring that sourced alternators meet quality standards is essential, as it directly impacts vehicle reliability and customer satisfaction. International buyers, particularly in regions like Germany and Brazil, should prioritize suppliers who offer extensive warranties and proven performance records.

What role do alternators play in agriculture and farming machinery?

In agriculture, alternators are vital for powering machinery such as tractors, harvesters, and irrigation systems. A reliable alternator ensures that these machines operate effectively, preventing downtime that could lead to crop loss. Given the harsh operating conditions in many agricultural settings, sourcing durable alternators that can withstand dust, moisture, and temperature variations is critical. Buyers from South America and Africa should seek suppliers who specialize in agricultural machinery to ensure that the alternators are tailored for optimal performance in challenging environments.

How does alternator lifespan impact transportation and fleet management?

In the transportation sector, particularly for fleets of buses and trucks, the longevity of alternators is directly linked to operational efficiency. A failing alternator can lead to unexpected breakdowns, resulting in costly repairs and service disruptions. Fleet managers must evaluate alternators that offer high performance and reliability to minimize maintenance expenses. When sourcing alternators, businesses should consider suppliers that provide comprehensive service agreements and support, particularly in regions like the Middle East where fleet operations are extensive and diverse.

Illustrative image related to how long do alternators typically last

Why is alternator durability important in mining operations?

Mining operations depend on heavy equipment like excavators and drills, which require dependable power sources. The lifespan of alternators in this context can significantly affect equipment performance and operational costs. A robust alternator can withstand extreme conditions, ensuring continuous operation and reducing repair expenses. International buyers in the mining industry should focus on sourcing high-capacity alternators that are specifically designed for heavy-duty applications, prioritizing suppliers who understand the unique challenges of mining environments.

How do construction projects benefit from reliable alternators?

In construction, alternators power various vehicles and equipment, making their reliability essential for meeting project deadlines. A malfunctioning alternator can halt work, leading to delays and increased costs. By understanding the typical lifespan of alternators, construction firms can plan for replacements and maintenance proactively. Buyers should seek out alternators that are designed for heavy-duty use and inquire about warranty options to ensure they are making a sound investment in their equipment. This approach is particularly important in rapidly developing regions where construction activities are on the rise.

3 Common User Pain Points for ‘how long do alternators typically last’ & Their Solutions

Scenario 1: Understanding the Lifespan of Alternators for Fleet Management

Das Problem:

For fleet managers overseeing a diverse range of vehicles, understanding the lifespan of alternators is crucial for effective maintenance planning. Many fleet operators may face unexpected downtimes due to alternator failures, leading to costly repairs and disruptions in operations. With varying vehicle types and usage patterns, determining how long an alternator typically lasts can be challenging. This uncertainty may result in either premature replacements, causing unnecessary expenses, or delayed maintenance that could lead to breakdowns.

Die Lösung:

To effectively manage alternator lifespans within a fleet, implement a proactive maintenance schedule that includes regular inspections and diagnostics of the electrical systems. Utilize telematics to monitor battery health and alternator performance across the fleet. Establish a threshold based on average lifespans—typically around seven years or 150,000 miles—and create alerts for when vehicles approach this limit. Additionally, invest in high-quality alternators from reputable suppliers to ensure reliability. By understanding specific usage patterns and keeping detailed maintenance logs, fleet managers can optimize replacement schedules and minimize unplanned downtimes.

Szenario 2: Beschaffung von Qualitätsgeneratoren für internationale Märkte

Das Problem:

B2B buyers in regions such as Africa or South America often struggle to source reliable alternators that meet both quality and performance standards. Local markets may be saturated with low-cost alternatives that do not last as long or function as effectively, leading to increased replacement costs and vehicle downtime. This situation can be exacerbated by inconsistent supplier reliability and varying import regulations that complicate procurement processes.

Die Lösung:

To navigate these challenges, it is essential for buyers to establish partnerships with trustworthy suppliers who specialize in high-quality automotive parts. Conduct thorough research to identify manufacturers with a proven track record in producing durable alternators that comply with international standards. Leverage trade shows, automotive expos, or industry forums to connect with reputable suppliers. When negotiating contracts, emphasize warranties and return policies to safeguard against defective parts. Additionally, consider bulk purchasing agreements to reduce costs while ensuring a steady supply of alternators tailored for the specific demands of the regional market.

Scenario 3: Training Technicians on Alternator Maintenance and Replacement

Das Problem:

Businesses that rely on automotive repair services often encounter a gap in technician knowledge regarding alternator maintenance and replacement. A lack of understanding about the signs of a failing alternator can lead to delayed repairs, which may exacerbate issues and increase costs. Furthermore, technicians may not be fully aware of best practices for installation, which can affect the longevity of the alternator.

Die Lösung:

To address this gap, businesses should invest in comprehensive training programs for their technicians. Partner with automotive training institutions to provide workshops focusing on alternator diagnostics, maintenance, and installation techniques. Incorporate hands-on training with real-world scenarios to enhance learning outcomes. Additionally, create resource materials, such as manuals or quick-reference guides, that detail common symptoms of alternator failure and proper replacement procedures. Encouraging ongoing education and certification can empower technicians to confidently address alternator issues, ultimately improving service quality and customer satisfaction. By prioritizing technician training, businesses can reduce the frequency of alternator-related issues and enhance their operational efficiency.

Strategic Material Selection Guide for how long do alternators typically last

Welche Materialien werden üblicherweise in Wechselstromgeneratoren verwendet, und wie wirken sie sich auf die Langlebigkeit aus?

When considering how long alternators typically last, the materials used in their construction play a crucial role in determining their performance, durability, and overall lifespan. Here, we analyze four common materials used in alternators: aluminum, copper, steel, and plastic. Each material has distinct properties that influence the longevity and functionality of alternators, particularly in diverse international markets.

How Does Aluminum Impact the Lifespan of Alternators?

Aluminum is widely used in alternator housings due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 150°C, making it suitable for automotive applications where heat dissipation is essential.

Vorteile: Aluminum is resistant to corrosion, which is particularly advantageous in humid or saline environments often found in regions like Africa and coastal areas of South America. Its lightweight nature also contributes to overall vehicle efficiency.

Nachteile: While aluminum is durable, it can be prone to fatigue over time, especially under high-stress conditions. Additionally, the manufacturing process can be complex and costly, impacting the overall price of the alternator.

Auswirkungen auf die Anwendung: Aluminum’s thermal properties help maintain optimal operating temperatures, which can enhance the alternator’s lifespan. However, care must be taken in environments with extreme temperatures.

Illustrative image related to how long do alternators typically last

Überlegungen für internationale Käufer: Buyers in Europe, especially Germany, may prefer aluminum for its compliance with strict environmental regulations. Understanding local standards such as DIN can help ensure compatibility.

Welche Rolle spielt Kupfer für die Leistung von Lichtmaschinen?

Copper is a key material in the windings and electrical connections of alternators due to its superior electrical conductivity. It can handle high current loads effectively, which is crucial for the performance of modern vehicles equipped with numerous electronic systems.

Vorteile: Copper’s excellent conductivity translates to lower energy losses, enhancing the efficiency of the alternator. It is also highly durable and can withstand high temperatures.

Nachteile: The primary drawback of copper is its cost, which is higher compared to aluminum and steel. Additionally, copper is susceptible to corrosion if not properly insulated.

Auswirkungen auf die Anwendung: Copper’s conductivity is vital for ensuring that the alternator can efficiently charge the battery and power electrical components, especially in vehicles with extensive electronic systems.

Überlegungen für internationale Käufer: Buyers in South America and the Middle East should be aware of the varying quality standards for copper wiring. Compliance with ASTM standards can ensure reliability and performance.

Wie trägt Stahl zur Langlebigkeit von Lichtmaschinen bei?

Steel is often used in the construction of alternator brackets and internal components due to its strength and durability. It can withstand significant mechanical stress, making it suitable for heavy-duty applications.

Vorteile: Steel’s high tensile strength ensures that alternator components remain stable under high loads, contributing to longevity. It is also relatively inexpensive compared to aluminum and copper.

Nachteile: Steel is prone to rust and corrosion, especially in humid environments. This can lead to premature failure if protective coatings are not applied.

Auswirkungen auf die Anwendung: The use of steel in alternators can enhance their robustness, making them suitable for heavy-duty vehicles operating in challenging conditions.

Überlegungen für internationale Käufer: Buyers from regions with high humidity, such as parts of Africa and the Middle East, should prioritize corrosion-resistant coatings or treatments to extend the life of steel components.

What Is the Role of Plastic in Alternator Design?

Plastic is commonly used for non-structural components of alternators, such as covers and insulators. Its lightweight nature and resistance to corrosion make it a popular choice.

Vorteile: Plastic is cost-effective and can be molded into complex shapes, allowing for innovative designs. It also provides good electrical insulation, which is essential for safety.

Nachteile: Plastic is less durable than metals and can degrade over time due to UV exposure or high temperatures. This can lead to failure in critical components.

Auswirkungen auf die Anwendung: While plastic components can reduce weight and manufacturing costs, their longevity may be compromised in harsh environments.

Überlegungen für internationale Käufer: Buyers in Europe may need to ensure that plastics used comply with environmental regulations, such as REACH, to avoid issues with material safety.

Übersichtstabelle zur Materialauswahl für Generatoren

| Material | Typical Use Case for how long do alternators typically last | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Bauteile | Leicht und korrosionsbeständig | Prone to fatigue under stress | Mittel |

| Kupfer | Wicklungen und elektrische Anschlüsse | Ausgezeichnete Leitfähigkeit und Haltbarkeit | Höhere Kosten und Korrosionsanfälligkeit | Hoch |

| Stahl | Halterungen und interne Komponenten | High tensile strength and cost-effective | Prone to rust without protective coatings | Niedrig |

| Kunststoff | Abdeckungen und Isolatoren | Leicht und formbar | Less durable, can degrade over time | Niedrig |

This material selection guide provides insights into the various materials used in alternators and their implications for longevity and performance. Understanding these factors is crucial for B2B buyers looking to make informed purchasing decisions, especially in diverse international markets.

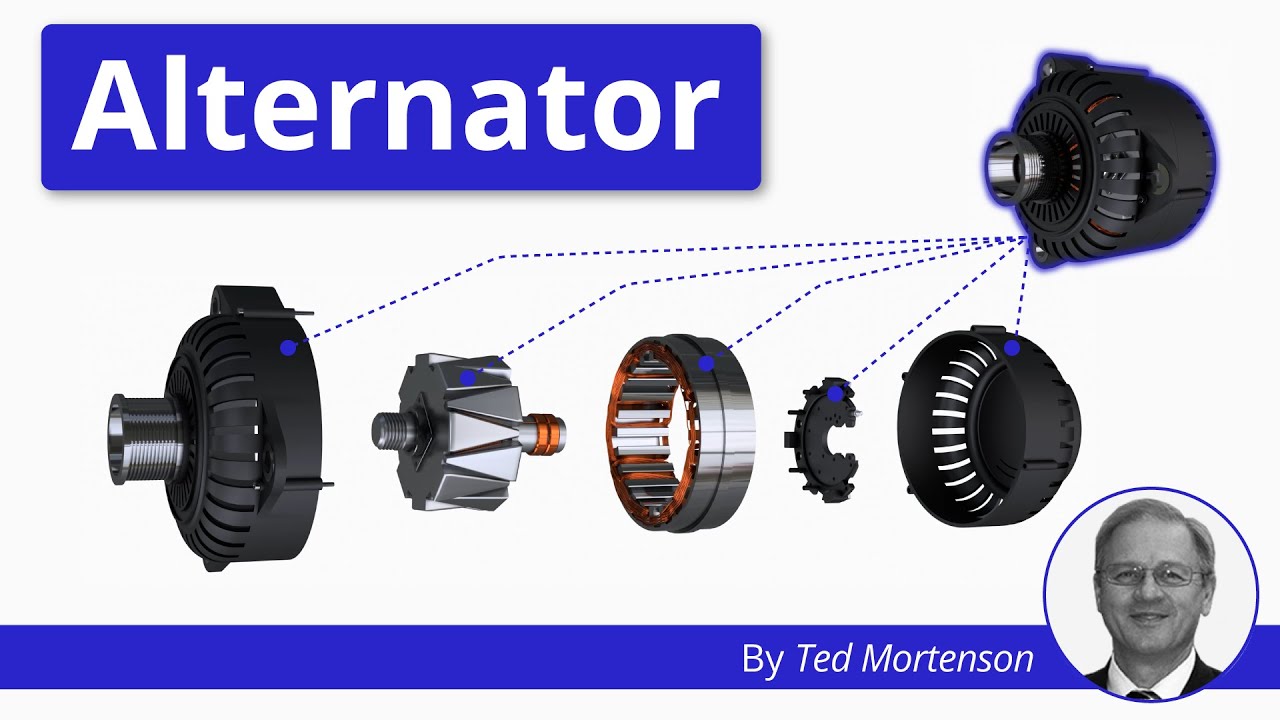

In-depth Look: Manufacturing Processes and Quality Assurance for how long do alternators typically last

Was sind die wichtigsten Phasen des Herstellungsprozesses von Lichtmaschinen?

The manufacturing of alternators involves several critical stages, each designed to ensure that the final product meets the rigorous demands of automotive applications. Understanding these stages can help B2B buyers assess the quality and reliability of the alternators they source.

Wie wird das Material für die Herstellung von Lichtmaschinen vorbereitet?

Material preparation is the foundational step in the manufacturing process. Common materials used in alternator production include high-grade aluminum for the housing, copper for the windings, and various alloys for the rotor. Suppliers must ensure that these materials meet specific mechanical and electrical standards.

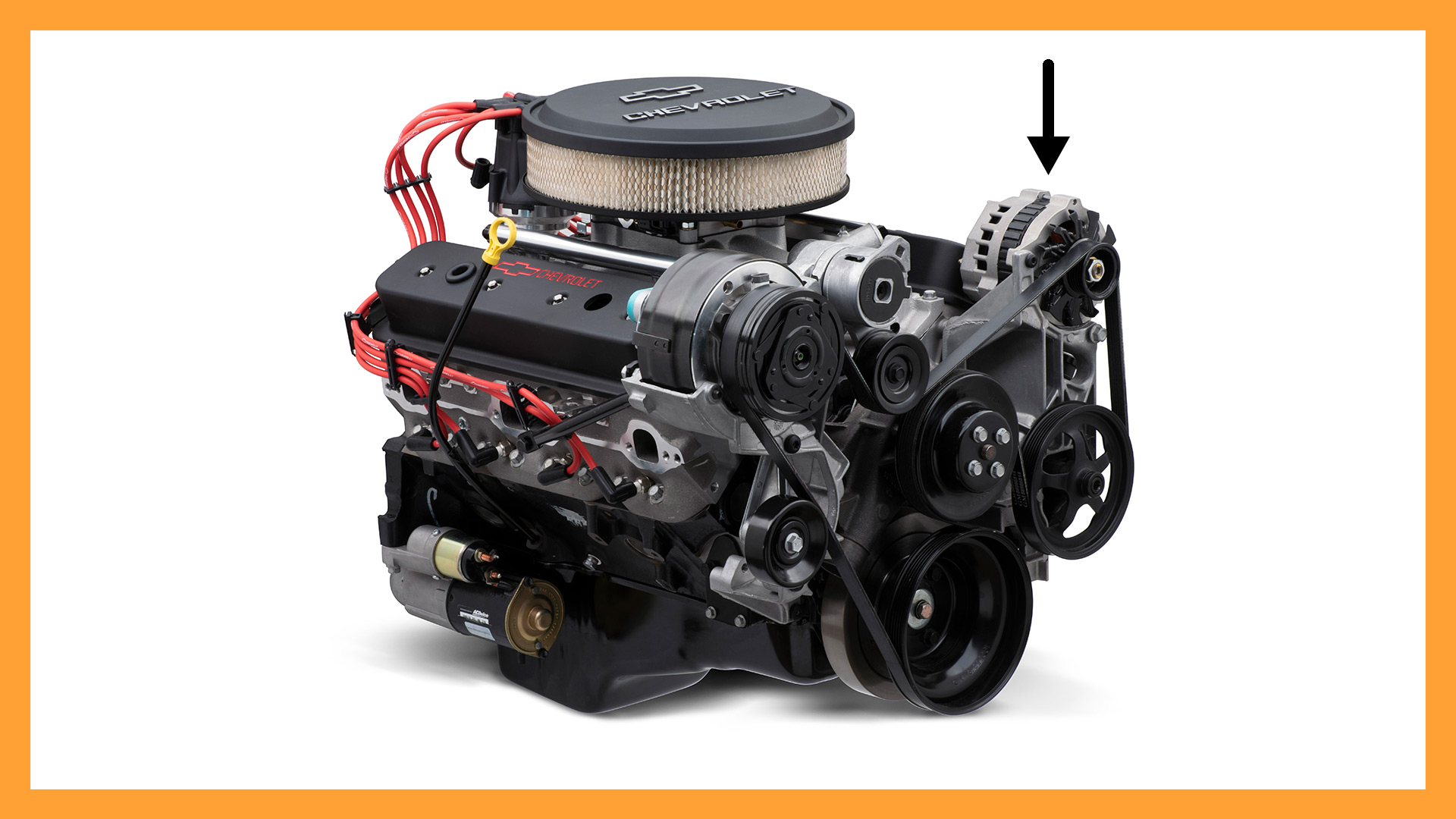

Illustrative image related to how long do alternators typically last

Typically, the preparation involves:

- Material Sourcing: Suppliers should provide documentation regarding the origin and quality of materials, which can impact performance and durability.

- Qualitätsprüfung: Incoming materials undergo inspections to verify compliance with specifications. This step often includes testing for material properties such as conductivity, tensile strength, and corrosion resistance.

What Techniques Are Used in the Forming Stage of Alternator Manufacturing?

The forming stage focuses on shaping the prepared materials into the necessary components of the alternator. Key techniques include:

- Gießen: Aluminum housings are often produced through die-casting, which provides uniform density and structural integrity. Quality assurance during this stage includes monitoring for defects such as air pockets or incomplete fills.

- Bearbeitungen: Precision machining is employed to create the rotor and stator components, ensuring accurate dimensions for efficient electrical performance. Techniques like CNC machining can enhance precision and repeatability.

- Wicklung: The winding process involves wrapping copper wire around the stator. This stage requires meticulous attention to detail, as inconsistencies can lead to decreased efficiency and increased heat generation.

Was wird bei der Montage von Generatoren beachtet?

The assembly of alternators is a critical phase where all individual components are brought together. This step typically includes:

- Komponentenintegration: After forming, the rotor, stator, and housing are assembled. This process is often automated to ensure consistency, but skilled technicians oversee the assembly to catch any potential errors.

- Elektrische Anschlüsse: Proper soldering and connections are vital for electrical efficiency. Manufacturers often use automated systems to ensure that connections are solid and minimize human error.

How Is Finishing Done in Alternator Manufacturing?

The finishing stage focuses on preparing the alternator for market readiness. It includes:

- Oberflächenbehandlung: Components may undergo anodizing or powder coating to enhance corrosion resistance and improve aesthetic appeal. This process also contributes to the durability of the alternator.

- Endkontrolle: Before packaging, each alternator typically goes through a final quality control check to ensure it meets specified tolerances and performance standards.

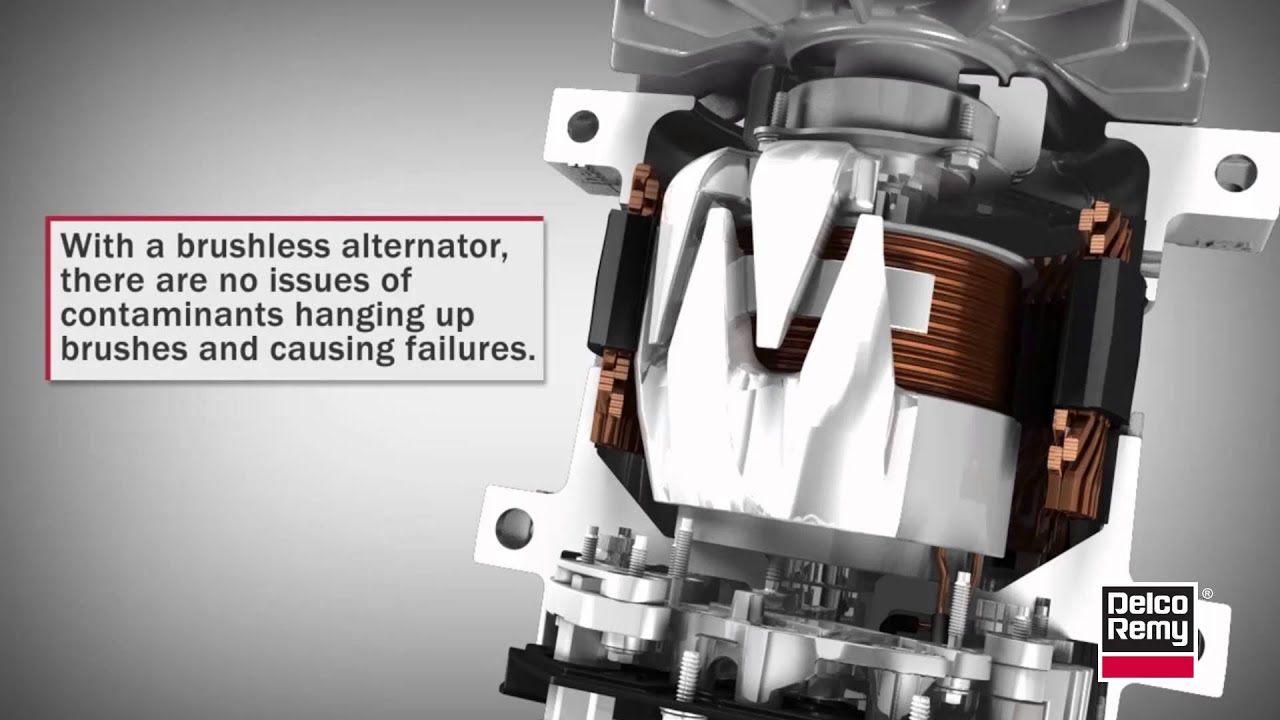

Welche Maßnahmen zur Qualitätskontrolle werden bei der Herstellung von Wechselstromgeneratoren ergriffen?

Quality control (QC) is paramount in the production of alternators, ensuring that each unit performs reliably under varying conditions. B2B buyers should be aware of the relevant international and industry-specific standards that guide these QC processes.

Welche internationalen Normen sind für die Qualitätssicherung von Generatoren relevant?

Manufacturers often adhere to international standards like ISO 9001, which outlines requirements for a quality management system. Compliance with these standards helps ensure consistent quality and customer satisfaction.

Illustrative image related to how long do alternators typically last

Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for specific automotive applications can enhance the credibility of alternator suppliers.

Was sind die wichtigsten Punkte der Qualitätskontrolle bei der Herstellung von Generatoren?

Quality control is typically segmented into several checkpoints throughout the manufacturing process:

- Eingangsqualitätskontrolle (IQC): This initial checkpoint assesses the quality of raw materials and components before production begins.

- In-Process-Qualitätskontrolle (IPQC): During the manufacturing stages, periodic inspections are conducted to ensure that components meet specifications and tolerances.

- Endkontrolle (FQC): Before shipment, each alternator undergoes comprehensive testing, including electrical performance tests and durability assessments. These tests help to identify potential failures and ensure reliability.

Welche gängigen Prüfverfahren werden zur Überprüfung der Qualität von Wechselstromgeneratoren eingesetzt?

Common testing methods employed in the quality assurance of alternators include:

- Elektrische Prüfung: This involves measuring voltage output, current flow, and resistance to ensure the alternator operates within specified parameters.

- Thermische Prüfung: Alternators are subjected to high-temperature environments to evaluate their performance under stress and to detect potential overheating issues.

- Vibrationsprüfung: This test assesses the alternator’s performance under dynamic conditions, ensuring that it can withstand the vibrations experienced during vehicle operation.

Wie können B2B-Käufer die Qualitätskontrollprozesse ihrer Lieferanten überprüfen?

B2B buyers can take several steps to ensure the quality control processes of their alternator suppliers:

- Audits durchführen: Regular audits of suppliers can provide insights into their manufacturing and quality assurance practices. This could involve on-site visits or reviewing quality management system documentation.

- Qualitätsberichte anfordern: Buyers should request detailed quality reports that outline the results of testing and inspections at various stages of production.

- Beauftragen Sie externe Prüfer: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing processes and quality control measures in place.

Was sind die Feinheiten der Qualitätskontrolle und Zertifizierung für internationale B2B-Einkäufer?

International buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be cognizant of several nuances:

Illustrative image related to how long do alternators typically last

- Einhaltung gesetzlicher Vorschriften: Different regions may have specific regulatory requirements for automotive components. Understanding these can help buyers avoid compliance issues.

- Kulturelle Erwägungen: Establishing strong relationships with suppliers often requires navigating cultural differences, which can impact communication and expectations regarding quality.

- Logistics and Supply Chain: Buyers must consider the logistics involved in sourcing alternators from various regions, as this can influence lead times and the ability to maintain consistent quality.

By understanding the manufacturing processes and quality assurance measures involved in alternator production, B2B buyers can make informed decisions that prioritize reliability and performance in their procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long do alternators typically last’

Einführung

Understanding the typical lifespan of alternators is essential for B2B buyers in the automotive industry. This guide provides a practical checklist to help you make informed decisions when sourcing alternators, ensuring you select products that meet your operational needs and quality standards.

Schritt 1: Assess Your Vehicle Specifications

Begin by gathering detailed specifications of the vehicles for which you need alternators. Understanding the make, model, and electrical requirements is vital, as alternators vary in output and compatibility. This information will help you identify suitable products that can efficiently power the vehicle’s electrical systems.

Schritt 2: Determine Your Quality Standards

Establish clear quality standards for the alternators you intend to procure. Consider factors such as durability, manufacturing processes, and material quality. High-quality alternators typically last longer and reduce the frequency of replacements, ultimately saving costs in the long run.

Schritt 3: Forschung Hersteller Reputation

Investigate the reputation of potential manufacturers. Look for companies with a proven track record in producing reliable alternators. Check online reviews, industry forums, and request feedback from other buyers to gauge the manufacturer’s reliability and product performance.

Illustrative image related to how long do alternators typically last

Schritt 4: Bewerten Sie Garantie- und Supportoptionen

Before finalizing your purchase, examine the warranty and customer support options offered by the supplier. A robust warranty indicates confidence in the product’s quality, while responsive customer support can assist with installation and maintenance issues. Ensure that the warranty covers significant aspects such as defects and performance guarantees.

Schritt 5: Produktmuster anfordern

Whenever possible, request samples of the alternators you are considering. Testing samples in real-world conditions can provide insight into their performance and durability. Pay attention to factors like noise levels, charging efficiency, and compatibility with your vehicles.

Schritt 6: Preisstrukturen vergleichen

Conduct a thorough analysis of pricing structures among different suppliers. While cost should not be the sole deciding factor, understanding the price range for quality alternators will enable you to make a more informed decision. Look for transparency in pricing and consider potential hidden costs, such as shipping or installation.

Schritt 7: Check Compliance with Industry Standards

Ensure that the alternators you are considering comply with relevant industry standards and regulations. Compliance with standards such as ISO or specific automotive certifications is crucial for ensuring safety and reliability. This step not only protects your business but also enhances your reputation in the market.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing alternators, ensuring they select high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for how long do alternators typically last Sourcing

Was sind die wichtigsten Kostenkomponenten bei der Beschaffung von Generatoren?

When evaluating the costs associated with sourcing alternators, several fundamental components come into play. Understanding these can aid international B2B buyers in making informed decisions.

Materialien: The primary materials in alternator production include high-grade metals, plastics, and magnets. The quality of these materials directly influences both the performance and longevity of the alternator. For instance, premium copper wiring and durable casings can lead to longer-lasting products, but they also increase costs.

Arbeit: Labor costs can vary significantly based on the region of manufacturing. In countries with higher labor costs, such as Germany, the expense will be more pronounced compared to regions like South America or parts of Africa. Skilled labor is essential for assembly and quality assurance, impacting overall pricing.

Illustrative image related to how long do alternators typically last

Fertigungsgemeinkosten: This includes utilities, facility expenses, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, leading to more competitive pricing for buyers.

Werkzeuge: The initial investment in tooling for production can be substantial. Custom tooling for specific alternator designs can lead to higher upfront costs but may be necessary for specialized applications.

Qualitätskontrolle (QC): Quality assurance processes are crucial for ensuring that alternators meet performance standards. Rigorous QC can add to the cost but is essential for maintaining reliability and customer satisfaction.

Logistik: Transportation costs also play a significant role in the total cost structure. International shipping, tariffs, and customs can affect the final price, particularly for buyers in Africa and the Middle East, where logistics may be more complex.

Marge: Suppliers typically add a margin to cover their operational costs and desired profit. This margin can fluctuate based on market demand, competition, and the supplier’s business model.

Was beeinflusst die Preisgestaltung von Wechselstromgeneratoren?

Several factors can influence the pricing of alternators in the B2B market.

Volumen und Mindestbestellmenge (MOQ): Purchasing in larger volumes often leads to discounts. Buyers should negotiate MOQs to optimize cost-efficiency, especially when sourcing for fleets or large projects.

Spezifikationen und Anpassung: Custom specifications can significantly impact pricing. Standardized products are usually more cost-effective, while customized alternators may come with a premium due to the additional design and manufacturing efforts required.

Illustrative image related to how long do alternators typically last

Materialqualität und Zertifizierungen: Alternators that come with certifications for quality (e.g., ISO, TS) may carry higher costs but provide assurance of reliability. Buyers should weigh the benefits of certified products against their budget constraints.

Lieferantenfaktoren: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their track record, while newer entrants may offer lower prices to gain market share.

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. This knowledge can help buyers negotiate better terms and avoid unexpected costs.

How Can Buyers Enhance Cost-Efficiency When Sourcing Alternators?

To maximize cost-efficiency, international B2B buyers should consider the following strategies:

Bedingungen aushandeln: Engaging in discussions about pricing, payment terms, and delivery schedules can lead to better deals. Suppliers may be open to negotiation, especially for long-term contracts.

Illustrative image related to how long do alternators typically last

Gesamtbetriebskosten (TCO) bewerten: Instead of focusing solely on the purchase price, consider the total cost of ownership, which includes maintenance, warranty, and replacement costs. Higher upfront costs for quality alternators can lead to lower overall expenses in the long run.

Understand Pricing Nuances in Different Markets: Buyers in Africa, South America, and the Middle East may face unique challenges, such as fluctuating exchange rates and import tariffs. Staying informed about local market conditions can help in making strategic purchasing decisions.

Recherche und Vergleich von Anbietern: Conduct thorough market research to compare different suppliers. Assess their product offerings, pricing structures, and customer service to find the best fit for your needs.

Illustrative image related to how long do alternators typically last

Haftungsausschluss für indikative Preise

Prices for alternators can vary widely based on the factors mentioned above. This analysis serves as a general guide; actual pricing may differ based on specific circumstances, market conditions, and the nature of the transaction. Always consult multiple suppliers for accurate quotes tailored to your specific requirements.

Alternatives Analysis: Comparing how long do alternators typically last With Other Solutions

Introduction: Exploring Alternatives to Traditional Alternators

When considering how long alternators typically last, it is essential to recognize the variety of alternative solutions that can fulfill similar roles in automotive applications. These alternatives may provide different benefits regarding performance, cost, and maintenance. Understanding these options will help international B2B buyers make informed decisions based on their specific operational needs and market conditions.

Comparison Table: Evaluating Alternators Against Alternative Solutions

| Vergleichsaspekt | How Long Do Alternators Typically Last | Lithium-ion Battery Systems | Solar-Powered Generators |

|---|---|---|---|

| Leistung | 7 Jahre / 150.000 Meilen | High efficiency, longer lifespan (up to 10 years) | Variable; depends on sunlight availability |

| Kosten | Moderate Anschaffungskosten; Ersatz kann teuer sein | High initial cost; long-term savings possible | Varies widely; potential for high initial investment |

| Einfache Implementierung | Typically straightforward installation | Erfordert eine spezielle Installation | Installation complexity varies; may need professional help |

| Wartung | Regular checks and possible replacements | Minimal, though battery management systems are needed | Regular cleaning and maintenance required |

| Bester Anwendungsfall | Standard vehicles and fleet management | Electric vehicles and energy storage solutions | Off-grid applications and renewable energy systems |

Detaillierte Aufschlüsselung der Alternativen

Lithium-ion Battery Systems

Lithium-ion batteries have emerged as a prominent alternative to traditional alternators, especially in electric vehicles (EVs) and hybrid models. One of the significant advantages of lithium-ion technology is its longevity, often lasting up to ten years with proper management. However, the initial investment can be significantly higher than that of conventional alternators. Additionally, while maintenance is generally minimal, these systems require effective battery management to ensure optimal performance. For businesses focused on sustainability and long-term energy savings, lithium-ion batteries represent a compelling choice.

Illustrative image related to how long do alternators typically last

Solar-Powered Generators

Solar-powered generators offer a unique approach to energy generation that can supplement or replace traditional alternators in specific applications, particularly in off-grid scenarios. Their performance is heavily contingent upon sunlight availability, which can be a disadvantage in regions with inconsistent weather. While the initial setup cost can be substantial, solar generators can provide long-term savings on fuel and maintenance. Regular maintenance involves cleaning panels and checking connections, which can be manageable for businesses equipped to handle these tasks. Companies looking to reduce their carbon footprint or operate in remote areas may find solar-powered solutions advantageous.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

Selecting the right energy generation or management solution requires careful consideration of your operational context, budget, and long-term goals. Traditional alternators offer reliability and ease of replacement, making them suitable for standard vehicles and fleet operations. In contrast, lithium-ion systems and solar-powered generators provide innovative alternatives with distinct advantages in efficiency and sustainability. B2B buyers should assess their specific requirements, including operational conditions and financial constraints, to determine the most effective solution for their needs. By doing so, they can ensure optimal performance and cost-effectiveness in their automotive operations.

Essential Technical Properties and Trade Terminology for how long do alternators typically last

What Are the Key Technical Properties of Alternators and Their Importance in B2B Purchases?

When considering the lifespan and performance of alternators, understanding their technical properties is crucial for B2B buyers, particularly those involved in automotive procurement and maintenance. Here are essential specifications that influence how long alternators typically last:

-

Werkstoffgüte

– Alternators are often constructed from a combination of metals, including aluminum and copper. The quality of these materials affects durability, heat resistance, and overall performance. For B2B buyers, investing in alternators made from higher-grade materials can lead to longer-lasting products and reduce the frequency of replacements, ultimately saving costs. -

Power Output (Amperage)

– The power output of an alternator, measured in amperes, indicates its capacity to charge the battery and power electrical systems. A higher amperage rating often translates to better performance, especially in vehicles with numerous electronic components. Understanding this specification helps buyers match the alternator to their vehicle’s electrical demands, ensuring reliability and efficiency. -

Lagertyp

– Alternators typically use either ball bearings or sleeve bearings. Ball bearings provide better longevity and can withstand higher RPMs, while sleeve bearings may offer quieter operation but with a shorter lifespan. For B2B buyers, selecting the right bearing type can impact maintenance schedules and operational efficiency, making it essential to align bearing specifications with usage conditions. -

Spannungsregelung

– Voltage regulation is critical for maintaining a consistent electrical output. Most modern alternators use electronic voltage regulators that enhance performance and reliability. Understanding the regulation mechanism allows B2B buyers to select alternators that will deliver stable power, thus preventing potential damage to sensitive electronic components in vehicles. -

Toleranzwerte

– Tolerance levels refer to the acceptable range of variation in the alternator’s specifications, such as dimensions and electrical output. Stricter tolerances typically indicate higher manufacturing quality and performance consistency. Buyers should prioritize alternators with tight tolerances to ensure compatibility and minimize operational issues.

Was sind gängige Handelsbegriffe im Zusammenhang mit Lichtmaschinen?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are several key terms relevant to alternators:

-

OEM (Originalgerätehersteller)

– OEM parts are made by the original manufacturer of the vehicle and are often preferred for their guaranteed compatibility and quality. B2B buyers should be aware that while OEM parts may come at a premium, they usually offer better performance and longevity. -

MOQ (Mindestbestellmenge)

– MOQ refers to the smallest quantity of products that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Understanding MOQ helps businesses negotiate better purchasing agreements. -

RFQ (Angebotsanfrage)

– An RFQ is a document sent to suppliers to request pricing information for specific products, including alternators. This process helps buyers compare costs and terms effectively, facilitating informed purchasing decisions. -

Incoterms (Internationale Handelsklauseln)

– Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers to mitigate risks associated with global procurement. -

Garantiezeitraum

– The warranty period specifies the duration for which the manufacturer guarantees the alternator’s performance. A longer warranty often indicates confidence in the product’s durability. B2B buyers should consider warranty terms as part of their evaluation criteria to protect against potential defects. -

Ersatzteile

– Aftermarket parts are produced by manufacturers other than the original vehicle manufacturer. While they can offer cost savings, B2B buyers should assess the quality and compatibility of aftermarket alternators to ensure they meet operational requirements.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding the purchase and maintenance of alternators, ensuring optimal performance and longevity for their vehicles.

Navigating Market Dynamics and Sourcing Trends in the how long do alternators typically last Sector

What are the Current Market Trends Influencing the Lifespan of Alternators?

The global alternator market is experiencing significant shifts driven by technological advancements and evolving consumer preferences. Key trends include the increasing integration of electronic components in vehicles, which places greater demands on alternators. As vehicles become more equipped with advanced driver-assistance systems (ADAS), infotainment technologies, and electric power steering, the alternator’s role in maintaining battery health and vehicle performance has become paramount. This surge in electrical demands can lead to a shorter lifespan for standard alternators, often necessitating the adoption of more robust solutions.

Moreover, emerging markets in Africa and South America are witnessing a rise in vehicle ownership, leading to heightened demand for both new and replacement alternators. In regions such as the Middle East, where extreme temperatures can affect alternator performance, buyers are increasingly looking for high-quality products that can withstand challenging conditions. B2B buyers from Europe, particularly Germany and Brazil, are also prioritizing suppliers that offer products meeting stringent quality standards, as well as those that can provide detailed information on alternator lifespan and maintenance.

Sourcing trends are shifting towards partnerships with manufacturers that offer comprehensive warranties and support services. This trend is crucial for international buyers looking to ensure long-term reliability and minimize operational disruptions caused by alternator failures. Furthermore, the rise of digital platforms and e-commerce in the automotive parts sector is making it easier for businesses to compare products and suppliers, streamlining the sourcing process.

How is Sustainability Impacting the Sourcing of Alternators?

Sustainability is becoming a critical factor in the sourcing of alternators, with B2B buyers increasingly seeking suppliers who prioritize environmentally responsible practices. The production and disposal of automotive parts, including alternators, have significant environmental impacts, from resource extraction to manufacturing emissions. As a result, many companies are now emphasizing the importance of ethical supply chains and the utilization of ‘green’ certifications.

Buyers are looking for alternators that not only meet performance standards but are also manufactured using sustainable practices. This includes the use of recycled materials, energy-efficient production processes, and reduced waste. Certifications such as ISO 14001 for environmental management systems are becoming a benchmark for evaluating potential suppliers. Furthermore, companies are expected to demonstrate transparency in their supply chains, ensuring that all materials are sourced ethically and responsibly.

The push for sustainability extends to end-of-life considerations as well. B2B buyers are increasingly interested in products that can be easily recycled or repurposed, reducing the overall environmental footprint. By prioritizing suppliers who align with these values, businesses can enhance their brand reputation and meet the growing consumer demand for environmentally friendly products.

Welche historischen Entwicklungen haben den Lichtmaschinenmarkt geprägt?

The alternator has undergone significant evolution since its inception in the early 20th century. Originally, vehicles were equipped with generators, which were less efficient and relied on mechanical connections to produce electricity. The introduction of the alternator in the 1960s marked a pivotal shift, allowing for more reliable and efficient power generation.

Illustrative image related to how long do alternators typically last

As automotive technology advanced, so too did the alternator’s design and functionality. Innovations such as the introduction of smart alternators, which can adjust their output based on real-time electrical demands, have further extended the lifespan and performance of these components. This evolution has been critical for B2B buyers, who now have access to a range of high-performance alternators tailored to modern vehicle requirements.

In summary, understanding the market dynamics and sourcing trends in the alternator sector is essential for international B2B buyers. By focusing on quality, sustainability, and technological advancements, companies can make informed decisions that enhance their operational efficiency and contribute to long-term success.

Frequently Asked Questions (FAQs) for B2B Buyers of how long do alternators typically last

-

Wie lange halten Lichtmaschinen in der Regel?

On average, alternators last between 7 to 10 years or approximately 150,000 kilometers (93,205 miles). However, several factors can influence this lifespan, including the quality of the alternator, the vehicle’s overall condition, and the electrical load from added accessories. For B2B buyers, it’s crucial to consider the operational environment and vehicle usage patterns when assessing alternator longevity, as harsher conditions can lead to faster wear. -

What signs indicate a failing alternator?

Common signs of a failing alternator include difficulty starting the vehicle, dimming headlights, unusual noises from the engine, and dashboard warning lights. Buyers should train their technicians to recognize these symptoms early to avoid unexpected breakdowns. Regular inspections and maintenance can also help in identifying potential issues before they escalate. -

Can I customize the alternators I purchase?

Yes, many manufacturers offer customization options for alternators to meet specific requirements. This can include variations in output capacity, size, and design features. When sourcing alternators, discuss your needs with suppliers to ensure they can provide tailored solutions that suit your fleet or equipment specifications. -

Was sind die Mindestbestellmengen (MOQ) für Lichtmaschinen?

Minimum order quantities can vary significantly between suppliers and regions. Generally, larger orders may lead to more favorable pricing. For B2B buyers, it’s essential to negotiate MOQs with potential suppliers to find a balance between meeting demand and managing inventory costs. -

Wie kann ich die Lieferanten von Lichtmaschinen überprüfen?

To vet suppliers effectively, consider their industry reputation, certifications, and experience in manufacturing alternators. Request references and case studies from previous clients, and verify their compliance with international standards. Additionally, visiting their manufacturing facility, if possible, can provide insights into their quality control processes. -

What payment terms are common for purchasing alternators internationally?

Payment terms can vary widely, but common practices include advance payments, letters of credit, or payment upon delivery. B2B buyers should clarify payment structures with suppliers early in negotiations to avoid misunderstandings. It’s advisable to establish a secure method of payment that protects both parties. -

What quality assurance measures should I expect from alternator suppliers?

Quality assurance measures can include rigorous testing of alternators under different conditions, adherence to international standards, and certification processes. Buyers should inquire about the supplier’s quality control protocols, warranty policies, and after-sales support to ensure they receive reliable products. -

Welche logistischen Aspekte sollte ich beim Import von Lichtmaschinen beachten?

When importing alternators, consider shipping times, customs regulations, and potential tariffs. It’s crucial to work with logistics providers familiar with the automotive parts industry to streamline the process. Additionally, ensure that your supply chain can handle the volume and that you have contingency plans in place for potential delays.

Top 3 How Long Do Alternators Typically Last Manufacturers & Suppliers List

1. Ford Fusion – Alternator Lifespan Insights

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Alternator average lifespan for Ford Fusion: typically around 180,000 miles, with some users reporting up to 200,000 km (approximately 124,274 miles) for the lifespan of brushes in the voltage regulator. Users suggest that alternators may last significantly longer if well-maintained and protected from dirt and debris.

2. Savannah Toyota – Alternators

Domäne: savannahtoyota.com

Registriert: 1996 (29 Jahre)

Einleitung: Die Lichtmaschine versorgt die gesamte Elektronik eines Fahrzeugs mit Strom, während der Motor läuft, und fungiert als Generator, der den Gasmotor als Energiequelle nutzt. Ihre Lebensdauer beträgt normalerweise zwischen 80.000 und 150.000 Meilen (etwa sieben Jahre). Die durchschnittlichen Kosten für eine neue Lichtmaschine liegen zwischen $500 und $1.000, je nach Fahrzeugtyp. Anzeichen für eine defekte Lichtmaschine sind eine Batteriewarnleuchte, schwache Scheinwerfer, b...

3. Pilots of America – Alternator Maintenance Guide

Domäne: pilotenvonamerika.com

Registriert: 2005 (20 Jahre)

Einleitung: Alternators typically last around 20 years or 1400 hours of operation. Internal inspections are recommended every 500 hours, with brushes often needing replacement after 1000-1500 hours depending on usage. Night flying increases load and wear on alternators. Alternator brushes are made of graphite and are crucial for current transmission. Failure to replace worn brushes can lead to costly alternat…

Strategic Sourcing Conclusion and Outlook for how long do alternators typically last

What Are the Key Takeaways for B2B Buyers Regarding Alternator Lifespan?

Understanding the typical lifespan of alternators—around seven years or 150,000 miles—can significantly impact procurement strategies for businesses reliant on vehicle fleets. Factors such as quality, vehicle condition, and electrical load play crucial roles in determining how long an alternator will last. Consequently, strategic sourcing of high-quality components can mitigate unexpected failures, ensuring operational efficiency and reducing maintenance costs.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, prioritizing reliable suppliers of alternators and related automotive parts is essential. Building relationships with manufacturers that offer warranties and robust customer support can enhance your supply chain resilience. Additionally, investing in regular maintenance and inspections can extend the lifespan of alternators, leading to improved vehicle performance and reduced downtime.

As the automotive landscape evolves, staying informed about advancements in alternator technology and best practices in maintenance will be crucial. Embrace the opportunity to enhance your procurement strategies by focusing on quality and reliability. Engage with trusted suppliers today to secure the longevity and performance of your vehicle fleet for tomorrow.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.