Introduction: Navigating the Global Market for headlight replacement cost

In the dynamic landscape of the global automotive industry, understanding the headlight replacement cost is essential for B2B buyers seeking reliable and cost-effective solutions. This guide delves into the multifaceted aspects of headlight replacement, addressing key challenges such as fluctuating prices, varying technologies, and the necessity for accurate supplier vetting. From the different types of headlight bulbs—ranging from economical halogen to advanced LED and HID options—to the complexities of installation and labor costs, this comprehensive resource equips international buyers with the insights needed to navigate the market effectively.

For businesses operating in regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Saudi Arabia, making informed purchasing decisions is paramount. The guide provides a thorough examination of headlight types and their applications, ensuring buyers understand the implications of their choices on vehicle safety and performance. By outlining cost structures, potential suppliers, and installation considerations, this resource empowers stakeholders to streamline their procurement processes and achieve better value for their investments.

With the right knowledge at their fingertips, B2B buyers can confidently approach headlight replacement, ensuring they select products that meet both safety standards and budget constraints while fostering long-term partnerships with suppliers.

Inhaltsverzeichnis

- Top 4 Headlight Replacement Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for headlight replacement cost

- Understanding headlight replacement cost Types and Variations

- Key Industrial Applications of headlight replacement cost

- 3 Common User Pain Points for ‘headlight replacement cost’ & Their Solutions

- Strategic Material Selection Guide for headlight replacement cost

- In-depth Look: Manufacturing Processes and Quality Assurance for headlight replacement cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘headlight replacement cost’

- Comprehensive Cost and Pricing Analysis for headlight replacement cost Sourcing

- Alternatives Analysis: Comparing headlight replacement cost With Other Solutions

- Essential Technical Properties and Trade Terminology for headlight replacement cost

- Navigating Market Dynamics and Sourcing Trends in the headlight replacement cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of headlight replacement cost

- Strategic Sourcing Conclusion and Outlook for headlight replacement cost

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding headlight replacement cost Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Halogen Headlights | Affordable, widely available, shorter lifespan | Fuhrparkmanagement, preisbewusste Käufer | Pros: Low initial cost; Cons: Frequent replacements needed |

| HID (Hochdruckentladung) | Bright, energy-efficient, longer lifespan | Luxury vehicles, commercial fleets | Pros: Better visibility; Cons: Higher cost, complex installation |

| LED (Leuchtdiode) | Long-lasting, energy-efficient, modern design | High-end vehicles, eco-friendly initiatives | Pros: Durability; Cons: Initial investment can be significant |

| Complete Headlight Assembly | Includes all components; varying complexity | Repair shops, vehicle refurbishing | Pros: Comprehensive solution; Cons: Higher upfront cost |

| DIY Headlight Replacement | Cost-effective, requires basic tools | Unabhängige Mechaniker, Heimwerker | Pros: Significant savings; Cons: Time-consuming, requires skill |

What are the Characteristics of Halogen Headlights for B2B Buyers?

Halogen headlights are the most common type used in vehicles today. They are relatively inexpensive, making them a popular choice for fleet management and budget-conscious buyers. However, they typically have a shorter lifespan, requiring more frequent replacements. B2B buyers should consider the long-term costs associated with maintenance and the need for regular replacements when opting for halogen headlights.

Illustrative image related to headlight replacement cost

How Do HID Headlights Stand Out for Commercial Applications?

HID headlights offer superior brightness and energy efficiency compared to halogen options, making them suitable for luxury vehicles and commercial fleets. Their longer lifespan reduces the frequency of replacements, which can be a significant advantage for businesses managing multiple vehicles. However, the higher initial cost and complex installation process may deter some buyers, necessitating careful consideration of the total cost of ownership.

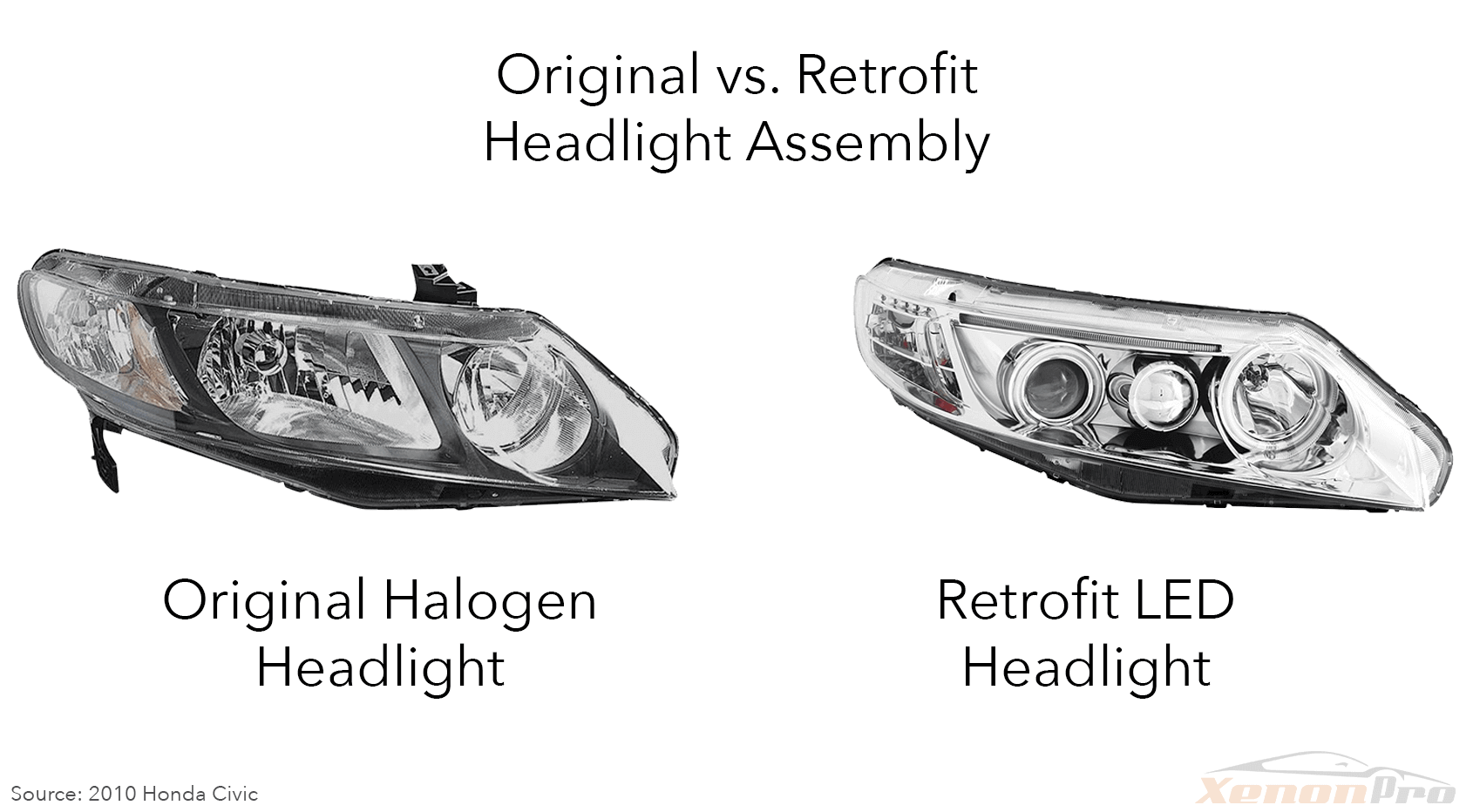

What Makes LED Headlights a Preferred Choice for Modern Vehicles?

LED headlights are becoming increasingly popular due to their longevity and energy efficiency. They are often found in high-end vehicles and are favored by businesses focused on sustainability. While they provide excellent visibility and require less frequent replacements, the upfront cost can be higher than traditional options. B2B buyers should evaluate their budget and the long-term benefits of LED technology before making a decision.

Why Should B2B Buyers Consider Complete Headlight Assemblies?

Complete headlight assemblies offer a comprehensive solution, including all necessary components for installation. This option is particularly appealing to repair shops and businesses involved in vehicle refurbishing. While the upfront cost may be higher, the all-in-one nature can save time and labor costs, making it a practical choice for B2B buyers who prioritize efficiency in their operations.

How Does DIY Headlight Replacement Benefit Independent Mechanics?

For independent mechanics and DIY enthusiasts, replacing headlights themselves can lead to significant cost savings. This approach requires basic tools and some technical know-how but can be time-consuming. B2B buyers should weigh the potential savings against the time investment and skill level required, ensuring they have the resources to effectively manage this type of maintenance.

Illustrative image related to headlight replacement cost

Key Industrial Applications of headlight replacement cost

| Branche/Sektor | Specific Application of headlight replacement cost | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Cost estimation for headlight bulb replacement | Accurate budgeting for maintenance and repair services | Availability of compatible parts and local labor rates |

| Flottenmanagement | Replacement scheduling for commercial vehicles | Enhanced safety and reduced liability for fleet operations | Bulk purchasing options and supplier reliability |

| Öffentliche Verkehrsmittel | Upgrading headlight systems for buses and taxis | Improved visibility and safety for passengers | Compliance with local regulations and quality standards |

| Baumaschinen | Headlight replacement for heavy machinery | Minimizes downtime and enhances operational safety | Sourcing durable parts suitable for harsh environments |

| Automobilbau | Cost analysis for headlight assembly production | Streamlined manufacturing processes and cost efficiency | Supplier capabilities and technological compatibility |

How is ‘headlight replacement cost’ relevant to the automotive repair industry?

In the automotive repair sector, understanding headlight replacement costs is crucial for service providers to offer accurate estimates to customers. This includes both the cost of the bulbs and the labor required for installation. Repair shops must consider the varying prices based on the vehicle model and the type of headlight technology—halogen, HID, or LED. For international buyers, particularly in regions like Africa and South America, sourcing affordable yet reliable parts is essential to remain competitive and maintain customer satisfaction.

What benefits does headlight replacement cost offer to fleet management?

For fleet management, effectively managing headlight replacement costs can significantly enhance operational safety. By scheduling timely replacements, fleet operators can reduce the risk of accidents caused by poor visibility. This proactive approach not only protects drivers but also mitigates potential liability issues for the company. Buyers in the Middle East and Europe should focus on suppliers who can provide bulk purchasing options to optimize costs while ensuring the availability of high-quality parts.

Why is headlight replacement cost important for public transportation?

In the public transportation sector, headlight replacement costs play a vital role in ensuring the safety of passengers. Upgrading headlight systems in buses and taxis can lead to improved visibility during nighttime operations or adverse weather conditions. This directly impacts the reliability of services offered. B2B buyers must consider local regulations regarding vehicle safety standards and seek suppliers that can guarantee compliance while providing cost-effective solutions.

Illustrative image related to headlight replacement cost

How does headlight replacement cost impact construction equipment operations?

For construction equipment, managing headlight replacement costs is critical to minimize downtime and enhance operational safety. Heavy machinery often operates in low-light conditions, making functional headlights essential. Sourcing durable parts that can withstand harsh environments is a key consideration for buyers in this sector. Ensuring quick access to replacement parts can keep projects on schedule and prevent costly delays, making it essential for international buyers to establish reliable supplier relationships.

What role does headlight replacement cost play in automotive manufacturing?

In automotive manufacturing, analyzing headlight replacement costs is integral to streamlining production processes. Manufacturers need to account for the cost of various headlight assemblies when designing vehicles to remain competitive. This requires collaboration with suppliers who can deliver components that meet quality standards while also being cost-effective. For manufacturers in Europe and the Middle East, understanding the technological compatibility of parts is essential to avoid production delays and ensure product reliability.

3 Common User Pain Points for ‘headlight replacement cost’ & Their Solutions

Scenario 1: Unpredictable Costs of Headlight Replacement

Das Problem:

B2B buyers often face the challenge of unpredictable costs when it comes to headlight replacement. For businesses operating fleets, such as transportation or logistics companies, maintaining budget predictability is crucial. The cost to replace headlight bulbs can vary significantly based on the vehicle type, the complexity of the installation, and the type of bulbs used (halogen, HID, or LED). This variability can lead to unexpected expenses that disrupt financial planning and affect the bottom line.

Die Lösung:

To mitigate this issue, B2B buyers should invest time in establishing a comprehensive inventory management system that tracks headlight types and their associated costs for each vehicle in the fleet. By conducting thorough research on the specific headlight requirements for different models, buyers can preemptively budget for replacements. Additionally, partnering with reliable suppliers can ensure consistent pricing and availability of parts. Creating a maintenance schedule based on average bulb lifespan can further help in anticipating costs, allowing businesses to budget effectively over time. Regular training for fleet maintenance staff on DIY replacement processes can also reduce labor costs, further stabilizing expenses.

Scenario 2: Difficulty in Sourcing Quality Replacement Parts

Das Problem:

Another common pain point for B2B buyers is the difficulty in sourcing quality replacement parts. Many businesses rely on third-party suppliers for headlight components, but inconsistent quality can lead to recurring issues, such as frequent bulb failures or compatibility problems. This not only affects vehicle performance but also compromises safety, leading to potential liability issues for the company.

Illustrative image related to headlight replacement cost

Die Lösung:

To address this challenge, B2B buyers should develop relationships with reputable manufacturers or distributors known for high-quality automotive parts. Conducting thorough due diligence, including checking for certifications and quality assurances, can help ensure that the parts sourced meet industry standards. Implementing a vendor evaluation process to regularly assess supplier performance based on quality, delivery times, and pricing will also ensure that only reliable suppliers are used. Additionally, integrating a feedback loop from the maintenance team about part performance can help inform future purchasing decisions, ensuring that only the best products are selected for fleet maintenance.

Scenario 3: Lack of Knowledge About Installation Options and Costs

Das Problem:

Many B2B buyers, especially those new to vehicle maintenance or those managing diverse fleets, may lack the necessary knowledge about installation options and associated costs for headlight replacements. This lack of understanding can lead to over-reliance on external mechanics, resulting in inflated labor costs and delays in vehicle downtime.

Die Lösung:

To empower B2B buyers with the knowledge they need, it’s essential to invest in training for in-house maintenance teams. Providing access to online resources, such as instructional videos and detailed guides on headlight replacement for various vehicle models, can equip staff with the skills needed for DIY installations. Additionally, creating a cost-benefit analysis comparing DIY replacement versus professional services can help decision-makers understand the financial implications. Establishing partnerships with local automotive training institutions can also provide ongoing education for staff, ensuring they stay updated on best practices and new technologies in headlight systems. This proactive approach not only reduces costs but also increases operational efficiency by minimizing vehicle downtime.

Strategic Material Selection Guide for headlight replacement cost

What Are the Common Materials Used in Headlight Replacement and Their Costs?

When considering headlight replacement, the choice of materials significantly influences both performance and cost. Below are analyses of four common materials used in headlight assemblies and bulbs, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Polycarbonate Plastic

Wichtige Eigenschaften:

Polycarbonate is a highly durable thermoplastic known for its excellent impact resistance and optical clarity. It can withstand a wide temperature range, typically from -40°C to 120°C, making it suitable for automotive applications.

Illustrative image related to headlight replacement cost

Vor- und Nachteile:

The primary advantage of polycarbonate is its lightweight nature, which reduces the overall weight of the vehicle, potentially improving fuel efficiency. It is also less expensive compared to glass. However, polycarbonate can be prone to scratching and UV degradation over time, necessitating protective coatings to enhance longevity.

Auswirkungen auf die Anwendung:

Polycarbonate is compatible with various automotive lighting technologies, including halogen, HID, and LED systems. Its transparency allows for optimal light transmission, critical for safety.

Überlegungen für internationale Käufer:

B2B buyers in regions like Africa and South America should ensure that polycarbonate materials comply with local automotive safety standards. Certifications such as ISO or ASTM can provide assurance of quality.

2. Glas

Wichtige Eigenschaften:

Glass is known for its high temperature resistance and excellent optical clarity. It can withstand extreme temperatures and is less susceptible to scratching compared to polycarbonate.

Vor- und Nachteile:

The key advantage of glass is its durability and resistance to UV light, which helps maintain clarity over time. However, glass is heavier than polycarbonate, which can negatively impact vehicle weight and fuel efficiency. Additionally, glass components are generally more expensive and can be more complex to manufacture.

Auswirkungen auf die Anwendung:

Glass is typically used in high-end vehicles where performance and aesthetics are prioritized. It is compatible with various lighting technologies but may require more robust mounting systems due to its weight.

Überlegungen für internationale Käufer:

Buyers in Europe and the Middle East should be aware of specific regulations regarding glass use in automotive applications, such as ECE regulations, which dictate safety and performance standards.

Illustrative image related to headlight replacement cost

3. Aluminium

Wichtige Eigenschaften:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can handle a range of temperatures, making it suitable for various automotive applications.

Vor- und Nachteile:

The main advantage of aluminum is its strength-to-weight ratio, which can enhance vehicle performance. It is also recyclable, appealing to environmentally conscious buyers. However, aluminum can be more expensive than plastic alternatives, and its manufacturing processes can be complex.

Auswirkungen auf die Anwendung:

Aluminum is often used in headlight housings to provide structural integrity and heat dissipation for high-performance lighting systems. Its compatibility with both LED and HID technologies makes it a versatile choice.

Überlegungen für internationale Käufer:

B2B buyers should consider the availability of aluminum in their region and any tariffs or import duties that may apply. Compliance with international standards such as DIN or JIS can also be crucial.

4. Polypropylene

Wichtige Eigenschaften:

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight properties. It can operate effectively in temperatures ranging from -20°C to 100°C.

Illustrative image related to headlight replacement cost

Vor- und Nachteile:

Polypropylene is cost-effective and offers good impact resistance, making it suitable for budget-friendly applications. However, it may not provide the same level of optical clarity as polycarbonate or glass, which could affect performance.

Auswirkungen auf die Anwendung:

This material is often used in lower-cost headlight assemblies, where cost savings are prioritized over performance. It works well with halogen bulbs but may not be ideal for high-intensity lighting systems.

Überlegungen für internationale Käufer:

Buyers in regions with strict environmental regulations should ensure that polypropylene products meet local compliance standards. Additionally, understanding the local market for polypropylene can help in making informed purchasing decisions.

Summary Table of Material Selection for Headlight Replacement Cost

| Material | Typical Use Case for headlight replacement cost | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Polycarbonat | Headlight lenses and assemblies | Leicht und kostengünstig | Prone to scratching | Niedrig |

| Glas | High-end vehicle headlight assemblies | Excellent durability | Schwerer und teurer | Hoch |

| Aluminium | Headlight housings for performance lighting | Strong and lightweight | Higher manufacturing cost | Mittel |

| Polypropylene | Budget-friendly headlight assemblies | Cost-effective | Lower optical clarity | Niedrig |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for headlight replacement cost

What Are the Key Stages in the Manufacturing Process of Headlight Components?

The manufacturing of headlight components involves several critical stages that ensure the final product meets safety, performance, and aesthetic standards. These stages include material preparation, forming, assembly, and finishing.

-

Materialvorbereitung

This initial stage involves sourcing high-quality materials such as glass, plastic, and metal. The choice of materials is crucial as they must withstand varying environmental conditions, UV exposure, and thermal fluctuations. For example, polycarbonate is often used for lens covers due to its lightweight and impact-resistant properties. Suppliers typically conduct rigorous testing of raw materials to ensure compliance with industry standards. -

Formung

The forming stage includes processes such as injection molding and glass blowing. Injection molding is commonly used for plastic components, where heated plastic is injected into molds to create the desired shapes for the headlight housing and lens. Glass forming, on the other hand, involves shaping glass using high temperatures to produce durable and clear lenses. Each forming technique has its own set of parameters to maintain precision and quality. -

Montage

Once individual components are formed, they undergo assembly. This includes integrating the bulb sockets, wiring, and other electrical components into the housing. Automated assembly lines often enhance efficiency and accuracy, reducing the risk of defects. During this stage, manufacturers ensure that all components fit together seamlessly, which is vital for both functionality and safety. -

Endbearbeitung

The finishing stage involves applying coatings or treatments to enhance durability and aesthetics. For instance, UV-resistant coatings may be applied to protect against sun damage, while anti-fog treatments improve visibility in adverse weather conditions. Finishing processes also include quality checks for scratches, distortions, and other imperfections that could compromise performance.

Wie wird die Qualitätssicherung bei der Herstellung von Scheinwerfern umgesetzt?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that every headlight meets stringent safety and performance standards. Key international standards, such as ISO 9001, guide manufacturers in establishing effective QA systems.

-

International Standards and Industry-Specific Regulations

Compliance with international standards like ISO 9001 ensures that manufacturers maintain a systematic approach to quality management. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for certain automotive applications may also apply. These certifications signal adherence to safety and quality benchmarks recognized globally. -

Kontrollpunkte der Qualitätskontrolle

Various checkpoints throughout the manufacturing process are crucial for maintaining quality. These include:

- Eingangsqualitätskontrolle (IQC): At this stage, raw materials are inspected before production. This includes testing for material properties and dimensions to ensure they meet specifications.

- In-Process-Qualitätskontrolle (IPQC): During the manufacturing process, random samples are tested to detect defects early. This includes monitoring the injection molding process and checking for any variances in temperature or pressure.

- Endkontrolle (FQC): After assembly, each headlight undergoes a final inspection. This includes functional tests to ensure proper light output, alignment, and durability testing under simulated environmental conditions.

- Gängige Prüfmethoden

Manufacturers employ a variety of testing methods to ensure product reliability. These include photometric testing to measure light output, vibration testing to simulate road conditions, and thermal cycling tests to assess performance under extreme temperature changes. Additionally, manufacturers may use life-cycle testing to estimate how long a headlight will perform under normal usage conditions.

Wie können B2B-Käufer die Qualitätskontrollprozesse ihrer Lieferanten überprüfen?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are several strategies:

-

Lieferantenaudits

Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Audits allow buyers to assess compliance with international standards, the effectiveness of quality checks, and the overall manufacturing environment. -

Qualitätssicherungsberichte

Requesting documentation such as quality assurance reports and certifications can help buyers verify that suppliers adhere to required standards. These documents should outline testing methods, results, and any certifications obtained. -

Inspektionen durch Dritte

Engaging third-party inspection services can add an extra layer of confidence. Independent inspectors can evaluate products before shipment, ensuring they meet specified quality and safety standards. This is particularly important for buyers in regions where local compliance may vary. -

Understanding Certification Nuances

Different regions may have varying requirements for certifications. For example, a CE mark is essential for products sold in Europe, while other regions might rely on local standards. Buyers should familiarize themselves with these nuances to ensure compliance and avoid potential legal issues.

What Challenges Do B2B Buyers Face Regarding Quality Assurance?

B2B buyers must navigate several challenges related to quality assurance when sourcing headlight components internationally. These include:

-

Variability in Standards

Different countries may have distinct quality standards, leading to inconsistencies in product quality. Buyers must ensure that their suppliers meet not only local regulations but also the standards required in their own markets. -

Communication Barriers

Language differences and cultural nuances can complicate discussions about quality expectations. Establishing clear communication channels is vital for ensuring that all parties understand the quality requirements. -

Transparenz in der Lieferkette

Ensuring transparency within the supply chain is critical for maintaining quality. Buyers should seek suppliers who provide detailed information about their sourcing, manufacturing processes, and quality control measures. -

Logistische Herausforderungen

International shipping can introduce risks related to product handling and transport conditions. Buyers should work with suppliers who have robust logistics plans in place to protect products during transit.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing headlight replacement parts, ensuring they select suppliers that prioritize quality and compliance.

Illustrative image related to headlight replacement cost

Practical Sourcing Guide: A Step-by-Step Checklist for ‘headlight replacement cost’

Einführung

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in understanding and managing headlight replacement costs. Whether you’re a vehicle fleet manager, an auto parts distributor, or a repair shop owner, having a clear strategy will help you optimize your procurement process and ensure that you are getting the best value for your investment.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before starting your procurement process, it’s crucial to identify the specific requirements for the headlight bulbs or assemblies you need. Consider factors such as vehicle make and model, bulb type (halogen, HID, or LED), and any compatibility issues. This step ensures that you avoid costly returns or replacements later on.

Schritt 2: Forschung Marktpreise

Conduct thorough market research to understand the price ranges for different types of headlight replacements. Prices can vary significantly based on geographic location, supplier, and bulb type. Knowing the average costs, which typically range from $30 to over $4,000 for assemblies, will empower you to negotiate better deals with suppliers.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering quality products and reliable service, as this can significantly impact your operational efficiency.

Schritt 4: Lieferantenzertifizierungen überprüfen

Ensure that your suppliers have the necessary certifications and adhere to international quality standards. Certifications can indicate compliance with safety regulations and can reflect the quality of the products. For instance, suppliers with ISO certifications are often seen as more reliable, which can reduce the risk of defective parts.

Illustrative image related to headlight replacement cost

Schritt 5: Assess Delivery and Lead Times

Understanding the delivery timelines is essential for maintaining your operations. Inquire about the average lead times for headlight replacements and whether the supplier can accommodate your schedule. Delays can lead to increased downtime, so it’s vital to choose a supplier known for prompt delivery.

Schritt 6: Muster oder Probestellungen anfordern

Whenever possible, request samples or trial orders before making a bulk purchase. This allows you to assess the quality of the headlight bulbs or assemblies firsthand. Evaluating the product’s performance in real-world conditions can help you avoid future issues and ensure satisfaction with your procurement.

Schritt 7: Verhandeln Sie die Allgemeinen Geschäftsbedingungen

Finally, don’t hesitate to negotiate the terms and conditions of your purchase. This includes pricing, payment terms, warranty policies, and return policies. A well-negotiated agreement can save you money and provide peace of mind, knowing that you have support in case of any product failures or issues.

By following these steps, B2B buyers can effectively navigate the complexities of headlight replacement costs, ensuring they make informed decisions that align with their operational needs and budget.

Comprehensive Cost and Pricing Analysis for headlight replacement cost Sourcing

What Are the Key Cost Components in Headlight Replacement?

The cost structure for headlight replacement encompasses several crucial components. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

Illustrative image related to headlight replacement cost

-

Materialien: The most variable cost component, materials include the headlight bulb itself (halogen, HID, or LED) and the headlight assembly. Prices can range significantly, from as low as $10 for basic halogen bulbs to over $100 for high-end HID or LED options. The complexity and technology of the bulb or assembly directly influence material costs.

-

Arbeit: Labor costs can vary by region and skill level. In many cases, professional installation can add $100 to $400 to the total cost, depending on the vehicle’s make and model. Businesses should consider whether they will outsource installation or invest in training for in-house technicians.

-

Fertigungsgemeinkosten und Werkzeugbau: These costs cover expenses related to production facilities, equipment, and technology used in manufacturing headlight components. A higher degree of automation may reduce these costs over time.

-

Qualitätskontrolle (QC): Ensuring that headlight products meet safety and performance standards is crucial. This may involve additional testing and certification processes, particularly for high-tech lighting solutions.

-

Logistik: Shipping costs can vary based on the origin of the materials and the destination markets. International buyers should consider tariffs and customs duties that may apply when importing headlight components.

-

Marge: Die Lieferanten schlagen in der Regel eine Marge auf, um ihre Kosten zu decken und die Rentabilität zu gewährleisten. Diese Marge kann je nach Marktnachfrage und Wettbewerb schwanken.

How Do Price Influencers Affect Headlight Replacement Costs?

Several factors influence the pricing of headlight replacements, which international B2B buyers must consider:

-

Volumen und Mindestbestellmenge (MOQ): Bulk purchasing can significantly reduce unit costs. Buyers should negotiate volume discounts, especially when sourcing for fleets or large-scale operations.

-

Spezifikationen und Anpassung: Custom headlight solutions may incur additional costs. Buyers should evaluate whether they need specialized products or if standard offerings will suffice.

-

Materialqualität und Zertifizierungen: Higher quality materials often come at a premium. Certifications for safety and environmental standards can also affect pricing, particularly in regulated markets.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can impact costs. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding shipping terms is vital. Incoterms dictate responsibilities for shipping, insurance, and tariffs. Choosing the right Incoterm can optimize logistics costs and risks.

What Are the Best Buyer Tips for Cost-Efficiency in Headlight Replacement?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, implementing strategic purchasing practices can lead to significant savings:

-

Effektiv verhandeln: Leverage bulk orders and establish long-term relationships with suppliers to negotiate better pricing. Be prepared to discuss your expected order volumes and payment terms.

-

Berücksichtigen Sie die Gesamtbetriebskosten (Total Cost of Ownership, TCO): Evaluate not just the initial purchase price but also long-term costs, such as installation, maintenance, and the lifespan of the headlight products. Higher upfront costs may be justified by lower maintenance needs or longer-lasting products.

-

Bleiben Sie über die Nuancen der Preisgestaltung informiert: Fluctuations in material costs, currency exchange rates, and shipping prices can affect overall costs. Regularly review market trends to make informed purchasing decisions.

-

Utilize Local Knowledge: Engage with local distributors who understand regional market conditions. They can provide insights into the best products for specific needs and help navigate import regulations.

Haftungsausschluss für indikative Preise

The prices discussed in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. It is essential for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Illustrative image related to headlight replacement cost

Alternatives Analysis: Comparing headlight replacement cost With Other Solutions

Introduction to Alternative Solutions for Headlight Replacement Costs

When considering the cost of headlight replacement, B2B buyers must evaluate various alternatives to ensure they are making informed decisions that align with their operational needs. While traditional headlight replacement involves the purchase of bulbs or entire assemblies, alternative solutions may provide comparable results with varying costs, installation requirements, and maintenance needs. This analysis will compare headlight replacement costs against two viable alternatives: headlight restoration and aftermarket LED conversion kits.

Vergleichstabelle

| Vergleichsaspekt | Headlight Replacement Cost | Headlight Restoration | Aftermarket LED Conversion Kit |

|---|---|---|---|

| Leistung | Standard visibility | Improved clarity | Enhanced brightness and longevity |

| Kosten | $30 – $4,000 | $15 – $50 | $100 - $300 |

| Einfache Implementierung | Mäßig | Einfach | Moderate to High |

| Wartung | Periodic replacement | Rarely needed | Requires occasional checks |

| Bester Anwendungsfall | Vehicle with burnt-out bulbs | Oxidized or cloudy lenses | Upgrading to modern lighting |

Detaillierte Aufschlüsselung der Alternativen

What Are the Benefits of Headlight Restoration?

Headlight restoration is a cost-effective solution aimed at improving the clarity of worn or oxidized lenses. This method typically involves using a restoration kit that can cost between $15 and $50. One of the significant advantages of restoration is that it enhances the performance of existing headlights without the need for replacement, thus extending their lifespan. Additionally, the process is relatively easy and can often be completed by users with minimal mechanical experience. However, it is essential to note that restoration may not be suitable for severely damaged lenses, and the results can vary based on the condition of the headlight.

How Do Aftermarket LED Conversion Kits Compare?

Aftermarket LED conversion kits present an innovative alternative to traditional headlight replacement. These kits can cost between $100 and $300 and provide superior brightness and longevity compared to halogen bulbs. LED headlights can last significantly longer, often exceeding 30,000 hours, which translates to less frequent replacements. However, installation can be more complex, and it may require additional adjustments to the vehicle’s electrical system, which could incur further costs. The primary drawback is that not all vehicles are compatible with aftermarket kits, potentially leading to issues with the electrical system or legal compliance.

Illustrative image related to headlight replacement cost

Conclusion: Choosing the Right Solution for Headlight Needs

Selecting the appropriate solution for headlight issues depends on specific operational requirements and vehicle conditions. For businesses prioritizing budget and simplicity, headlight restoration may be the ideal choice, offering a straightforward way to enhance visibility without significant investment. Conversely, companies looking to modernize their vehicle fleets and improve safety may find aftermarket LED conversion kits worth the upfront costs due to their long-term benefits and efficiency. Ultimately, B2B buyers should consider their vehicle types, budget constraints, and desired performance levels when making decisions regarding headlight solutions.

Essential Technical Properties and Trade Terminology for headlight replacement cost

What Are the Key Technical Properties of Headlight Replacement Costs?

When considering headlight replacement costs, it’s essential to understand several technical properties that can significantly influence pricing and product selection. These properties include:

-

Glühbirnen-Typ: Headlights typically come in three main types: Halogen, HID (High-Intensity Discharge), and LED (Light Emitting Diode). Halogen bulbs are the most affordable and easy to replace, while HID and LED options offer better brightness and longevity but come at a higher cost. Understanding the differences helps B2B buyers select the right product based on their needs and budget.

-

Wattleistung: The wattage of a headlight bulb affects its brightness and energy consumption. Standard halogen bulbs usually range from 55 to 65 watts, while HIDs can range from 35 to 55 watts. For B2B buyers, knowing the wattage helps in ensuring compliance with vehicle specifications and regulations in different markets.

-

Lebenserwartung: The lifespan of a headlight bulb varies by type, with halogen bulbs typically lasting between 500 to 1,000 hours, while HID bulbs can last between 2,000 to 10,000 hours and LEDs up to 40,000 hours. B2B buyers should consider lifespan when evaluating total cost of ownership and frequency of replacements, which can impact operational costs.

-

Materialzusammensetzung: The materials used in the construction of headlight assemblies, such as polycarbonate for lenses and various metals for fixtures, impact durability and performance. Buyers should assess material quality to ensure that they are investing in products that will withstand environmental factors and provide reliable service.

-

Kompatibilität: Each vehicle model has specific requirements for headlight size and fitting. Compatibility details are crucial for B2B buyers to avoid returns and ensure seamless integration into their inventory or service offerings. Checking compatibility can save time and resources in the long run.

-

Komplexität der Installation: The ease or difficulty of installation can greatly influence labor costs. Some headlight replacements may require specialized tools or extensive disassembly of the vehicle, while others can be installed quickly with basic tools. For businesses, understanding installation complexity can aid in pricing labor services accurately.

What Are the Common Trade Terminology and Jargon Used in Headlight Replacement Costs?

Familiarity with industry jargon is vital for B2B buyers to communicate effectively and make informed purchasing decisions. Here are several key terms:

Illustrative image related to headlight replacement cost

-

OEM (Originalgerätehersteller): This term refers to parts made by the vehicle’s manufacturer. OEM headlights generally guarantee a perfect fit and performance, which can be crucial for maintaining warranty coverage. B2B buyers often prefer OEM parts for reliability.

-

MOQ (Mindestbestellmenge): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory levels and cost-effectiveness when placing bulk orders for headlights.

-

RFQ (Angebotsanfrage): An RFQ is a document sent to suppliers asking for pricing on specific products. It’s essential for B2B buyers to use RFQs to gather competitive pricing and terms from multiple suppliers, facilitating informed purchasing decisions.

-

Incoterms: These international commercial terms define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is essential for B2B buyers, particularly in regions like Africa, South America, and the Middle East, as they clarify shipping, insurance, and risk responsibilities.

-

Ersatzteilmarkt: Aftermarket parts are replacements made by third-party manufacturers. While often cheaper than OEM parts, aftermarket headlights may vary in quality and fit. B2B buyers must weigh the pros and cons of using aftermarket components versus OEM options.

-

Garantiezeitraum: This term refers to the duration for which a product is guaranteed to be free from defects. A longer warranty period can indicate a higher quality product, which is a vital consideration for B2B buyers looking to reduce returns and maintain customer satisfaction.

By understanding these essential technical properties and trade terminology, B2B buyers can navigate the complexities of headlight replacement costs more effectively, ensuring better purchasing decisions and improved operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the headlight replacement cost Sector

What Are the Key Market Dynamics and Trends Affecting Headlight Replacement Costs?

The headlight replacement market is experiencing significant shifts driven by several global factors. One of the primary drivers is the increasing focus on vehicle safety and compliance with international standards, which is particularly relevant in regions like Europe and the Middle East. Enhanced regulations surrounding automotive lighting systems are pushing manufacturers to innovate and provide higher quality products, often leading to increased costs. Furthermore, the rise in electric vehicles (EVs) is reshaping the market dynamics as these vehicles frequently utilize advanced headlight technologies, such as LEDs and adaptive lighting systems, which are more expensive to replace than traditional halogen bulbs.

Emerging technologies are also influencing sourcing strategies. B2B buyers are increasingly leveraging digital platforms for procurement, enabling them to compare prices, quality, and supplier reliability more effectively. Online marketplaces tailored for auto parts are becoming essential tools for buyers in Africa and South America, where traditional supply chains may be less established. Additionally, trends toward localization of supply chains are becoming prominent, driven by the need for reduced shipping times and costs, as well as the desire for more resilient sourcing strategies in the face of global disruptions.

Illustrative image related to headlight replacement cost

How Does Sustainability Impact Sourcing in the Headlight Replacement Sector?

The environmental impact of headlight production and disposal is becoming a significant concern for B2B buyers. As awareness of climate change grows, there is an increasing emphasis on sustainability in sourcing practices. Buyers are now more inclined to partner with suppliers that prioritize ethical manufacturing processes and environmental stewardship. This includes the use of sustainable materials in headlight production, such as recyclable plastics and low-impact manufacturing techniques.

Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential criteria for evaluating suppliers. These certifications not only assure buyers of compliance with environmental regulations but also demonstrate a commitment to reducing ecological footprints. In addition, the trend towards “green” headlights, which consume less energy and have longer lifespans, is driving demand for more innovative products. This shift toward sustainability is not just beneficial for the planet; it also aligns with the corporate social responsibility goals of many companies, enhancing their brand reputation and customer loyalty.

What Is the Evolution of the Headlight Replacement Market?

The headlight replacement market has evolved significantly over the decades. Initially dominated by simple halogen bulbs, the market has transitioned through various phases, including the introduction of high-intensity discharge (HID) systems and more recently, light-emitting diode (LED) technology. These advancements have not only improved visibility and safety but have also contributed to longer-lasting products, reducing the frequency of replacements.

The evolution has been driven by consumer demand for better performance and energy efficiency, alongside stricter regulatory frameworks that promote higher safety standards. As technology continues to advance, the market is expected to further innovate, with trends such as adaptive lighting systems and smart headlights becoming more mainstream. For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with current and future market demands.

In conclusion, navigating the complexities of the headlight replacement market requires a keen understanding of the underlying trends, including technology advancements and sustainability concerns. By focusing on these factors, international B2B buyers can make strategic sourcing decisions that not only meet their operational needs but also align with broader market dynamics.

Illustrative image related to headlight replacement cost

Frequently Asked Questions (FAQs) for B2B Buyers of headlight replacement cost

-

How do I determine the cost of headlight replacement for different vehicle models?

To accurately assess the headlight replacement cost for various vehicle models, consider both parts and labor. The cost of headlight bulbs can range from $10 for halogen bulbs to over $100 for HID or LED options. Additionally, if the entire headlight assembly needs replacement, prices can vary significantly based on the vehicle’s make and model. For a comprehensive estimate, consult local suppliers, check online databases, or utilize cost estimation tools specific to your region. -

What factors influence the price of headlight replacement components?

Several factors impact the pricing of headlight replacement components, including bulb type (halogen, HID, or LED), the complexity of installation, and the vehicle’s make and model. High-tech vehicles with advanced lighting systems typically have higher replacement costs. Additionally, geographic location and supplier pricing strategies can affect overall costs. B2B buyers should evaluate multiple suppliers to compare prices and ensure they are getting the best value. -

How can I effectively vet suppliers for headlight replacement parts?

To vet suppliers for headlight replacement parts, consider their reputation, industry experience, and product quality. Look for suppliers who provide certifications and warranties for their products. Request samples to assess quality and ensure compatibility with your vehicle models. Additionally, check for customer reviews and testimonials, and consider suppliers who offer responsive customer service and technical support. -

What are the common minimum order quantities (MOQs) for headlight components?

Minimum order quantities (MOQs) for headlight components can vary widely depending on the supplier and the type of product. Typically, MOQs can range from as low as 50 units for standard bulbs to several hundred units for specialized components. It’s advisable to discuss MOQs upfront with suppliers, as many may be flexible based on order size or establish tiered pricing based on volume. -

What payment terms are standard for international headlight parts suppliers?

Standard payment terms for international suppliers often include options such as advance payment, letters of credit, or payment upon delivery. Commonly, suppliers may request a deposit upfront, with the remaining balance due upon shipment or delivery. It’s essential to negotiate terms that protect your investment while ensuring a smooth transaction process. Consider using escrow services for larger orders to mitigate risks. -

How do I ensure quality assurance (QA) for headlight replacement products?

To ensure quality assurance for headlight replacement products, establish clear specifications with your supplier, including testing standards and certifications. Request documentation such as ISO certification or compliance with local regulations. Conduct regular quality checks upon receiving shipments and consider third-party inspections for bulk orders. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What logistics considerations should I keep in mind when sourcing headlight replacements internationally?

When sourcing headlight replacements internationally, consider logistics aspects such as shipping methods, customs regulations, and import duties. Choose reliable shipping partners with experience in automotive parts to ensure timely delivery. Be aware of lead times and plan your inventory accordingly to avoid disruptions. Additionally, familiarize yourself with the regulations governing the import of automotive components in your region to avoid compliance issues. -

How can I customize headlight replacement products for my business needs?

To customize headlight replacement products, communicate your specific requirements clearly to potential suppliers. This may include custom packaging, branding, or even specific bulb configurations. Many manufacturers offer customization options, but it typically requires a minimum order quantity. Discuss lead times and costs associated with customization to ensure it aligns with your business objectives and budget.

Top 4 Headlight Replacement Cost Manufacturers & Suppliers List

1. Ford – Headlight Replacement

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: 2014 Ford Fusion, front left headlight bulb replacement, estimated labor cost $300, requires extensive labor including lifting the vehicle and removing several body panels.

2. Honda Clarity - Austausch von Scheinwerfern

Domäne: insideevsforum.com

Registriert: 2017 (8 Jahre)

Einleitung: Headlight replacement for Honda Clarity costs $1500 per headlight, totaling $3000 for both front headlights. The headlights use a sealed assembly with no replaceable bulbs, likely consisting of surface-mounted LEDs. Some users suggest alternatives like polishing hazy lenses or checking voltage, but caution against increasing voltage due to potential damage.

3. Toyota Camry – Low Beam Bulb Replacement

Domäne: community.cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: 2016 Toyota Camry SE, 2.5L 4-cylinder, Low Beam Bulb Replacement, Halogen bulbs, $35 each, $445 total quote from dealer, includes labor and bumper removal.

4. Kia – Headlight Assembly Replacement

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Expect to pay anywhere from $203 to $1,400 for the entire replacement for each headlight assembly at a Kia dealership, depending on the type of headlights.

Strategic Sourcing Conclusion and Outlook for headlight replacement cost

The complexities surrounding headlight replacement costs underscore the importance of strategic sourcing for international B2B buyers. Understanding the price variations—from basic halogen bulbs priced around $10 to advanced HID or LED systems exceeding $100—enables businesses to make informed purchasing decisions. Labor costs can also significantly impact total expenses, with estimates ranging from $30 to $400 depending on the vehicle model and installation complexity.

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can optimize supply chain efficiency and enhance cost management. By evaluating multiple suppliers, negotiating favorable terms, and considering bulk purchasing options, companies can secure high-quality products at competitive prices.

As the automotive industry evolves with technological advancements in lighting, staying informed about market trends and potential cost fluctuations will be crucial. We encourage buyers to engage with trusted suppliers and continuously explore innovative solutions to ensure their fleets remain compliant and safe. Embrace the opportunity to streamline your headlight sourcing strategy and position your business for future growth in this dynamic market.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to headlight replacement cost

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.