Einleitung: Navigieren auf dem globalen Markt für alle Teile des Automobils

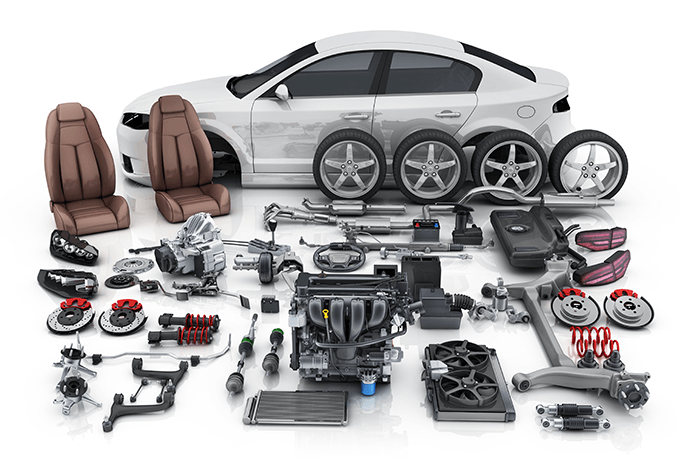

In der heutigen globalen Automobillandschaft stellt die effektive Beschaffung aller Autoteile eine große Herausforderung für internationale B2B-Einkäufer dar. Angesichts der Komplexität der Fahrzeugkomponenten, die von Motoren und Getrieben bis hin zu Bremssystemen und elektrischen Systemen reichen, ist das Verständnis der Nuancen jedes einzelnen Teils entscheidend. Dieser Leitfaden soll die Vielfalt der Automobilkomponenten entmystifizieren, indem er ihre Arten, Anwendungen und die kritischen Faktoren, die bei der Auswahl von Lieferanten zu berücksichtigen sind, detailliert beschreibt.

Von den geschäftigen Märkten Afrikas und Südamerikas bis hin zu den sich schnell entwickelnden Automobilindustrien im Nahen Osten und in Europa stehen Einkäufer vor einzigartigen Herausforderungen wie schwankenden Kosten, unterschiedlichen Qualitätsstandards und dem Bedarf an zuverlässigen Lieferanten. Dieser Leitfaden gibt B2B-Einkäufern wertvolle Einblicke in die Prozesse der Lieferantenprüfung, Kostenanalysen und Markttrends und hilft ihnen so, fundierte Kaufentscheidungen zu treffen.

Ausgestattet mit dem Wissen über die Feinheiten von Automobilteilen und deren Anwendungen können sich internationale Einkäufer sicher auf dem globalen Markt bewegen und sicherstellen, dass sie hochwertige Komponenten beschaffen, die ihren spezifischen Anforderungen entsprechen. Ganz gleich, ob Sie für eine Produktionsstätte oder ein Teilevertriebszentrum beschaffen, diese umfassende Ressource wird Ihnen als unverzichtbares Werkzeug für eine erfolgreiche Beschaffung im dynamischen Automobilsektor dienen.

Inhaltsverzeichnis

- Ein Blick auf alle Teile der Autohersteller und -lieferanten

- Einleitung: Navigieren auf dem globalen Markt für alle Teile des Automobils

- Alle Teile des Fahrzeugs verstehen Typen und Variationen

- Industrielle Schlüsselanwendungen für alle Teile des Fahrzeugs

- 3 häufige Schmerzpunkte der Benutzer für ‘alle Teile des Autos’ und ihre Lösungen

- Leitfaden zur strategischen Materialauswahl für alle Teile des Fahrzeugs

- Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für alle Teile des Fahrzeugs

- Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘alle Teile des Autos’

- Umfassende Kosten- und Preisanalyse für alle Teile des Fahrzeugs Beschaffung

- Analyse der Alternativen: Vergleich aller Teile des Fahrzeugs mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für alle Teile des Fahrzeugs

- Navigieren durch Marktdynamik und Beschaffungstrends in allen Bereichen des Automobilsektors

- Häufig gestellte Fragen (FAQs) für B2B-Käufer aller Autoteile

- Strategische Beschaffung Fazit und Ausblick für alle Teile des Autos

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Alle Teile des Fahrzeugs verstehen Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Verbrennungsmotor | Umfasst Komponenten wie Kolben, Kurbelwelle und Nockenwelle | Automobilherstellung, Reparaturwerkstätten | Vorteile: Hohe Ausgangsleistung, bewährte Technologie. Nachteile: Höhere Emissionen, komplexe Wartung. |

| Übertragungssysteme | Umfasst manuelle, automatische und CVT-Typen | Fahrzeugbau, Aftermarket-Teile | Vorteile: Abwechslungsreiche Fahrerlebnisse, Effizienz. Nachteile: Potenziell hohe Reparaturkosten, Komplexität bei automatischen Systemen. |

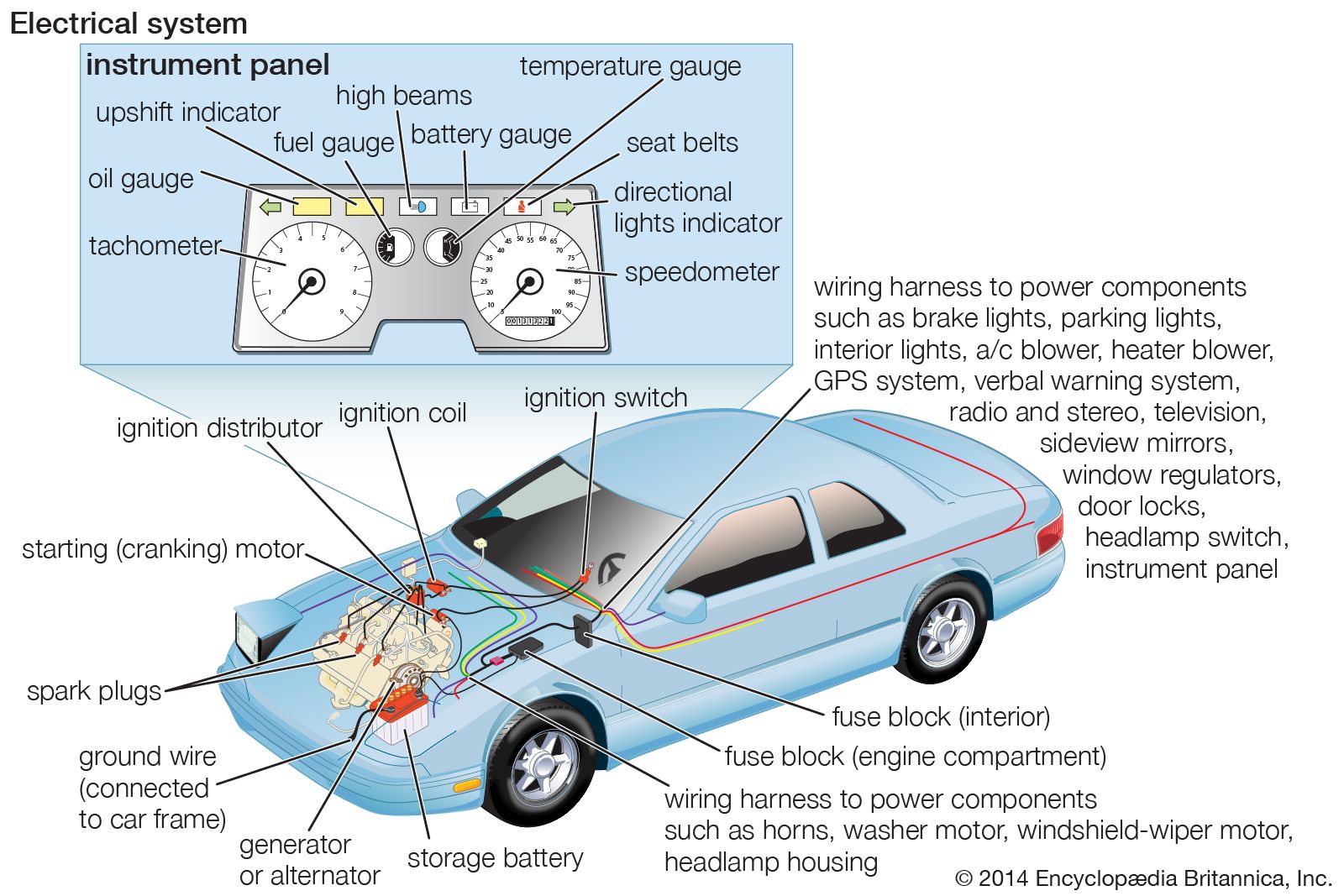

| Elektrische Systeme | Umfasst Batterien, Lichtmaschinen und Zündsysteme | Automobilzulieferer, Händler für elektrische Teile | Vorteile: Unverzichtbar für den Fahrzeugbetrieb, Innovation in der Technologie. Nachteile: Abhängigkeit von Qualitätskomponenten für die Zuverlässigkeit. |

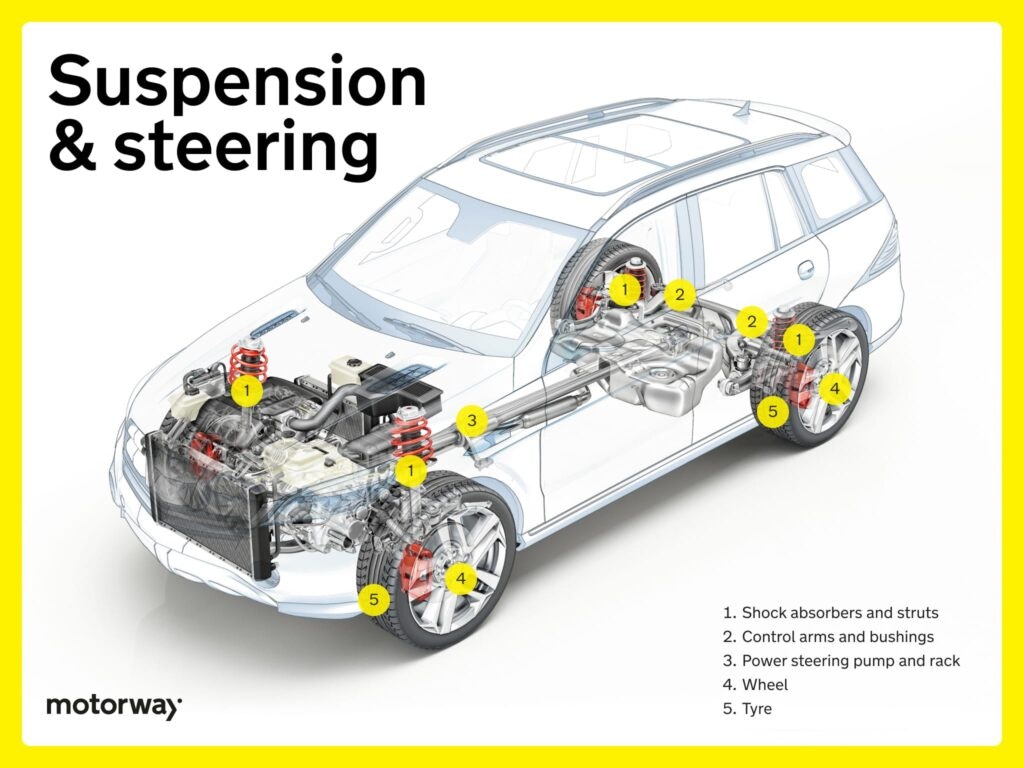

| Federungssysteme | Bestehend aus Stoßdämpfern, Federbeinen und Querlenkern | Lieferanten von Aufhängungsteilen, Reparaturdienste | Vorteile: Verbessert die Fahrqualität und die Sicherheit. Nachteile: Der Austausch kann kostspielig sein, die Qualität variiert von Hersteller zu Hersteller. |

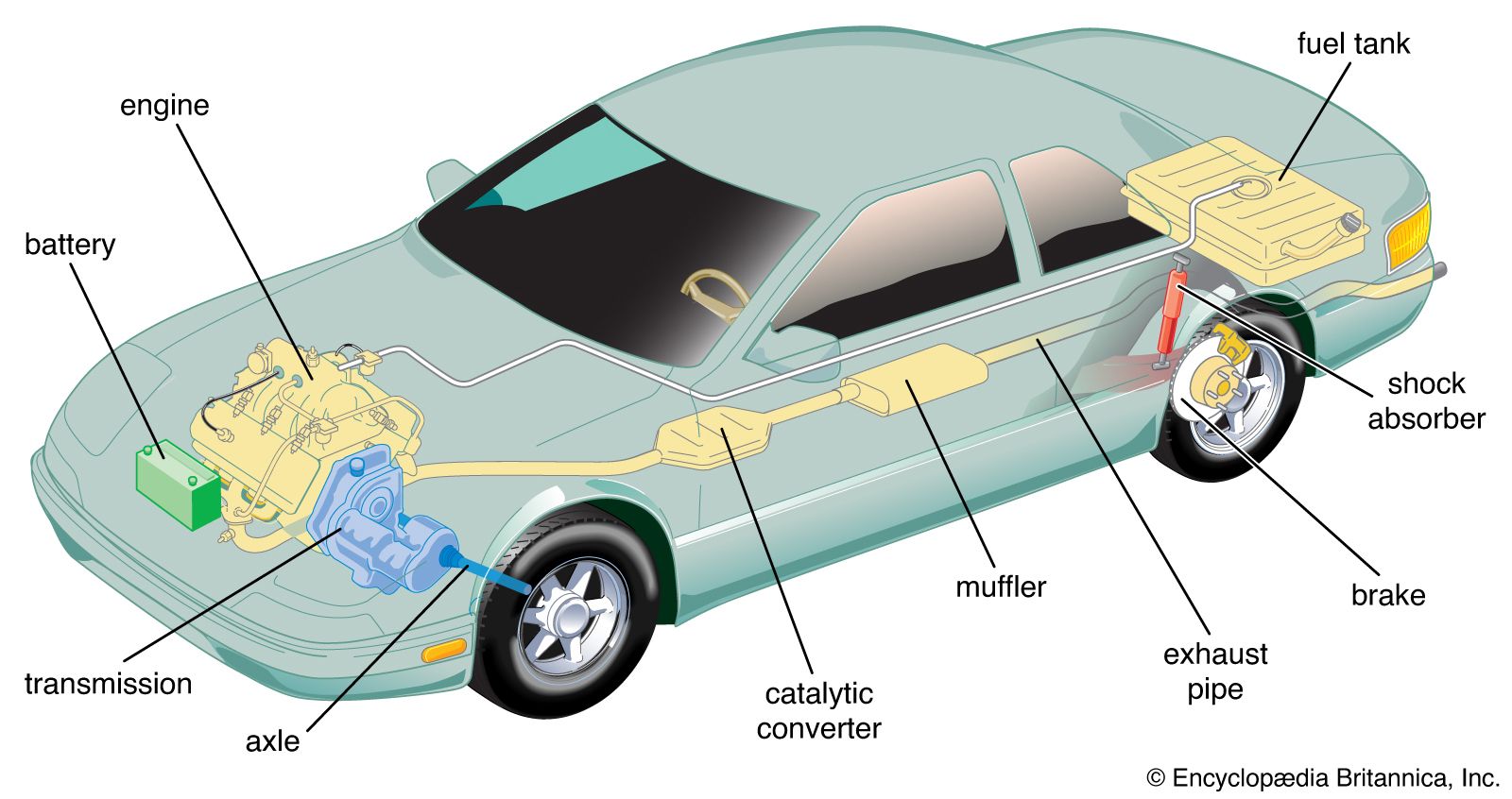

| Auspuffanlagen | Beinhaltet Katalysatoren, Schalldämpfer und Auspuffrohre | Emissionskontrollsysteme, Teile für den Ersatzteilmarkt | Vorteile: Reduziert die Emissionen und verbessert die Motorleistung. Nachteile: Wartung für die Effizienz erforderlich, Rostgefahr. |

Was sind die wichtigsten Merkmale von Verbrennungsmotoren?

Verbrennungsmotoren (ICE) sind das Herzstück herkömmlicher Fahrzeuge und wandeln Kraftstoff durch eine Reihe kontrollierter Explosionen in mechanische Energie um. Sie bestehen aus wichtigen Komponenten wie Kolben, Kurbelwellen und Nockenwellen, die zur Erzeugung von Energie zusammenarbeiten. B2B-Käufer sollten den Motortyp auf der Grundlage der Kraftstoffeffizienz, der Emissionsnormen und der Wartungsanforderungen auswählen. Die etablierte Technologie der Verbrennungsmotoren bietet Zuverlässigkeit, doch der wachsende Trend zu Elektrofahrzeugen kann künftige Kaufentscheidungen beeinflussen.

Wie wirken sich unterschiedliche Getriebesysteme auf die Fahrzeugleistung aus?

Getriebesysteme, einschließlich manueller, automatischer und stufenloser Getriebe (CVT), sind für die Fahrzeugleistung von zentraler Bedeutung. Manuelle Getriebe bieten dem Fahrer ein hohes Maß an Engagement, während Automatikgetriebe eine einfache Bedienung ermöglichen. CVT-Getriebe verbessern mit ihren sanften Schaltvorgängen die Kraftstoffeffizienz. B2B-Einkäufer sollten die Präferenzen ihrer Zielgruppe und die damit verbundenen Kosten für jeden Getriebetyp ermitteln. Wenn man die Auswirkungen der Getriebewahl auf die Fahrzeugleistung und -wartung versteht, kann man sich an Beschaffungsstrategien und Bestandsentscheidungen orientieren.

Warum sind elektrische Systeme für moderne Fahrzeuge von entscheidender Bedeutung?

Elektrische Systeme umfassen Komponenten wie Batterien, Lichtmaschinen und Zündsysteme, die für die Funktion des Fahrzeugs unerlässlich sind. Sie gewährleisten einen zuverlässigen Betrieb und unterstützen fortschrittliche Funktionen wie Start-Stopp-Technologie und Infotainment-Systeme. B2B-Einkäufer sollten bei der Beschaffung von elektrischen Komponenten auf hohe Qualität achten, da sich die Zuverlässigkeit auf die Gesamtleistung des Fahrzeugs auswirkt. Die rasante Entwicklung in der Elektrotechnik macht es erforderlich, immer auf dem neuesten Stand der Technik zu sein, was Beziehungen zu seriösen Lieferanten unerlässlich macht.

Welche Rolle spielen Federungssysteme für die Sicherheit und den Komfort eines Fahrzeugs?

Aufhängungssysteme, einschließlich Stoßdämpfern, Federbeinen und Querlenkern, sind entscheidend für die Fahrzeugstabilität, den Fahrkomfort und die Sicherheit. Diese Komponenten absorbieren Straßenunebenheiten und halten den Kontakt der Reifen mit der Straße aufrecht, was sich direkt auf das Fahrverhalten und die Bremsen auswirkt. B2B-Einkäufer sollten die Qualität und Haltbarkeit von Aufhängungsteilen prüfen, um die Sicherheit und Leistung des Fahrzeugs zu gewährleisten. Investitionen in seriöse Lieferanten können das Risiko kostspieliger Reparaturen mindern und die Kundenzufriedenheit durch eine bessere Fahrqualität erhöhen.

Wie tragen Abgassysteme zur Fahrzeugeffizienz und zur Einhaltung von Vorschriften bei?

Abgassysteme mit Komponenten wie Katalysatoren und Schalldämpfern spielen eine wichtige Rolle bei der Verringerung schädlicher Emissionen und der Verbesserung der Motoreffizienz. Sie sind für die Einhaltung von Umweltvorschriften unerlässlich. B2B-Einkäufer müssen bei der Beschaffung auf die Qualität und Technologie der Abgasteile achten, um sowohl die Leistungs- als auch die gesetzlichen Normen zu erfüllen. Da die Emissionsvorschriften weltweit verschärft werden, können Investitionen in fortschrittliche Abgassysteme einen Wettbewerbsvorteil auf dem Automobilmarkt verschaffen.

Industrielle Schlüsselanwendungen für alle Teile des Fahrzeugs

| Branche/Sektor | Spezifische Anwendung für alle Teile des Fahrzeugs | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Herstellung von Fahrzeugen mit verschiedenen Teilen wie Motoren und Getrieben | Rationalisierte Produktionsprozesse und verbesserte Qualität | Zuverlässigkeit der Lieferanten, Kompatibilität der Teile und Kosteneffizienz |

| Transport & Logistik | Flottenmanagement und Wartung von Lieferfahrzeugen | Verbesserte betriebliche Effizienz und geringere Ausfallzeiten | Verfügbarkeit von Teilen, Vorlaufzeiten und After-Sales-Support |

| Kfz-Reparaturdienste | Austausch und Reparatur von Autoteilen für verschiedene Fahrzeugmarken und -modelle | Höhere Kundenzufriedenheit und -treue | Qualitätssicherung, Garantiebedingungen und Flexibilität bei der Beschaffung |

| Erneuerbare Energien | Integration von Elektrofahrzeugkomponenten wie Batterien und Motoren | Zugang zum wachsenden EV-Markt und Nachhaltigkeitsziele | Technologiekompatibilität, Innovation bei Teilen und Skalierbarkeit |

| Export und Handel | Export von Gebrauchtteilen oder Fahrzeugen in Schwellenländer | Kapitalisierung der Nachfrage in Entwicklungsregionen | Einhaltung der internationalen Vorschriften und logistische Unterstützung |

Wie werden Autoteile in der Fertigung eingesetzt?

In der Automobilbranche sind verschiedene Teile wie Motoren, Getriebe und Aufhängungssysteme für den Bau von Fahrzeugen unerlässlich. Die Hersteller sind auf qualitativ hochwertige Teile angewiesen, um einen reibungslosen und effizienten Betrieb ihrer Montagelinien zu gewährleisten. Probleme wie Unterbrechungen der Lieferkette können zu Produktionsverzögerungen führen, weshalb die Beschaffung zuverlässiger Lieferanten von entscheidender Bedeutung ist. Internationale Einkäufer sollten Lieferanten den Vorzug geben, die nachweislich kompatible Teile liefern, die strengen Qualitätsstandards entsprechen.

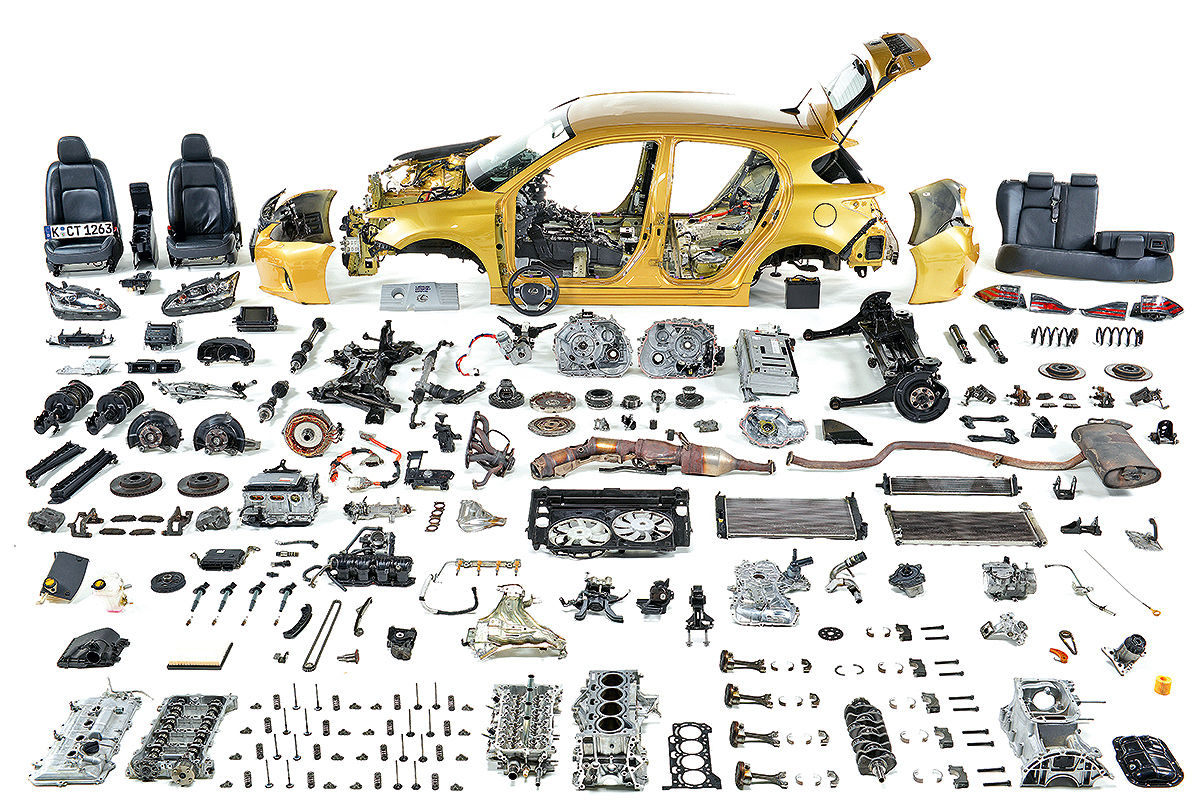

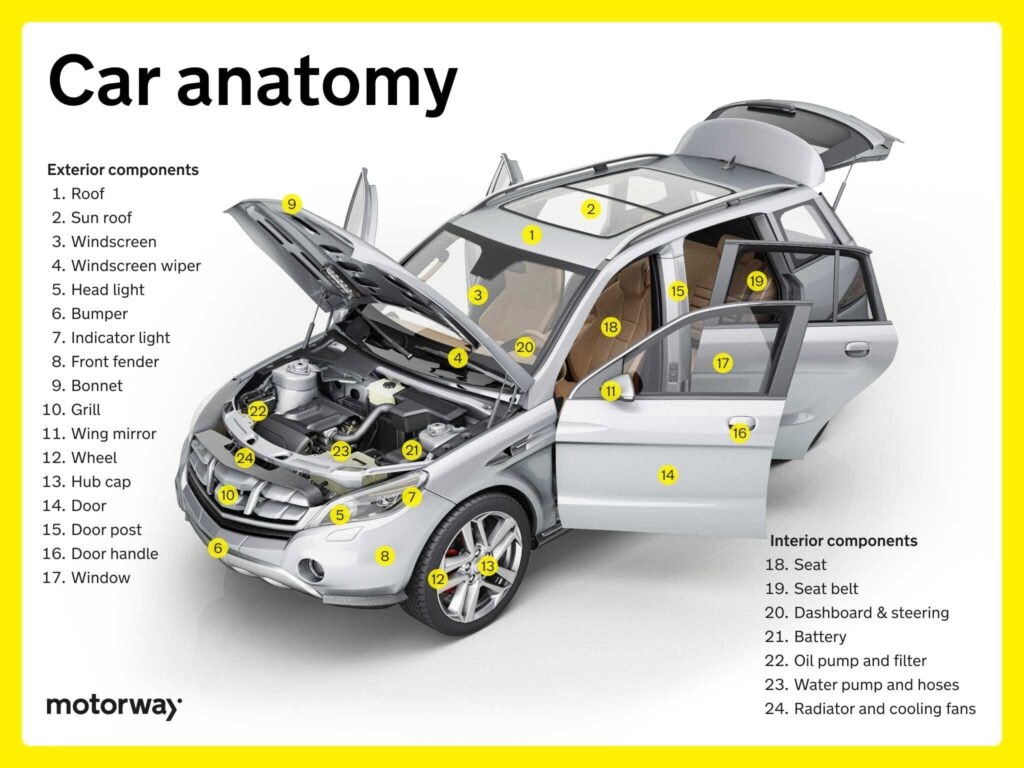

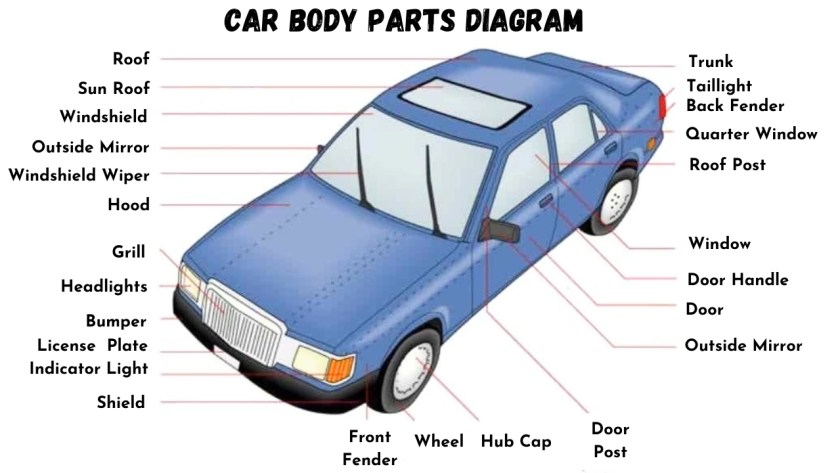

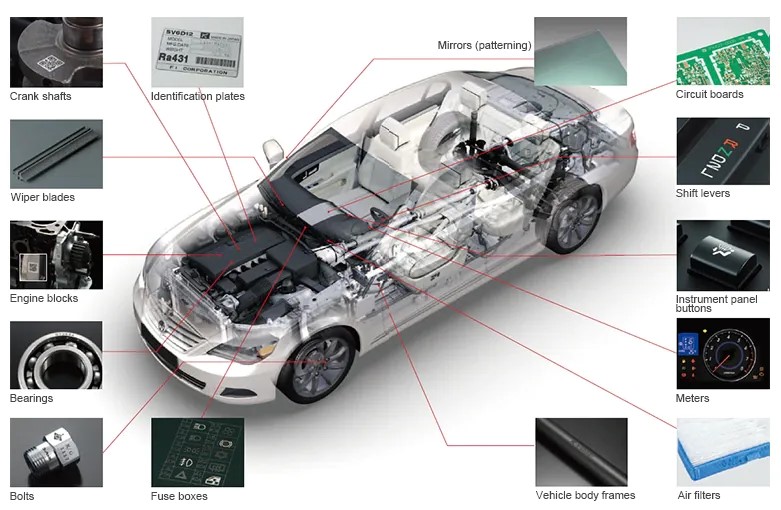

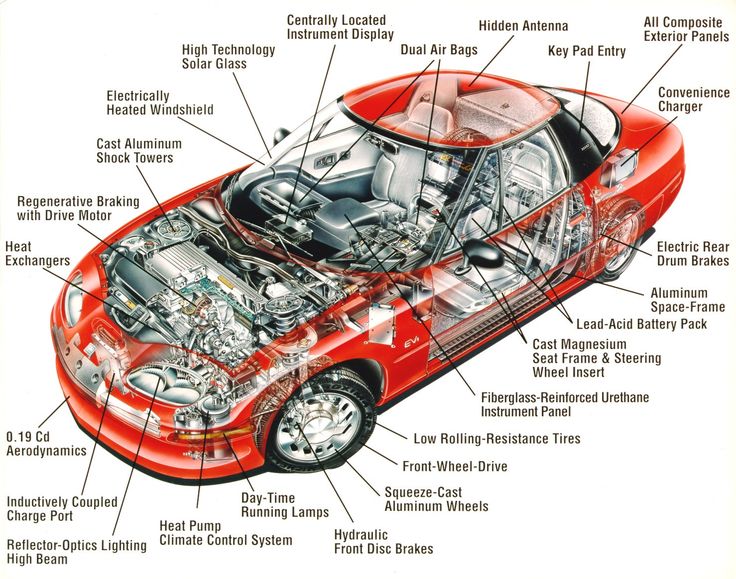

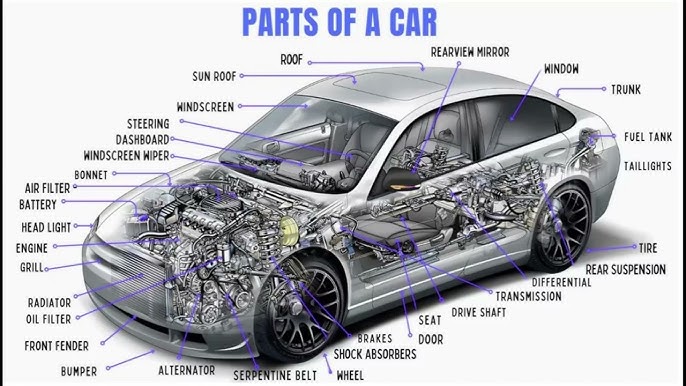

Illustratives Bild zu allen Teilen des Fahrzeugs

Was sind die Vorteile von Automobilteilen in Transport und Logistik?

In der Transport- und Logistikbranche hängt der effiziente Betrieb von Lieferflotten stark von gut gewarteten Fahrzeugen ab. Schlüsselkomponenten wie Bremsen, Reifen und Motoren müssen regelmäßig gewartet oder ausgetauscht werden, um Ausfallzeiten zu minimieren. Indem sie sicherstellen, dass sich alle Teile des Fahrzeugs in optimalem Zustand befinden, können Unternehmen die betriebliche Effizienz steigern und die mit Verspätungen verbundenen Kosten senken. Einkäufer in diesem Sektor sollten Lieferanten in Betracht ziehen, die kurze Lieferzeiten und einen soliden Kundendienst bieten, um rechtzeitige Reparaturen zu gewährleisten.

Wie nutzen Kfz-Reparaturdienste verschiedene Autoteile?

Kfz-Reparaturdienste sind auf eine breite Palette von Autoteilen angewiesen, um ihren Kunden effektive Wartungs- und Reparaturlösungen anbieten zu können. Dazu gehört alles von Motorkomponenten bis zu elektrischen Systemen. Ein gut sortierter Bestand an Qualitätsteilen erhöht nicht nur die Kundenzufriedenheit, sondern fördert auch die Loyalität der Kunden, da sie mit größerer Wahrscheinlichkeit für künftige Reparaturen wiederkommen. B2B-Einkäufer in diesem Bereich müssen sich auf die Beschaffung von Teilen konzentrieren, die mit Garantien versehen sind und von zuverlässigen Herstellern unterstützt werden, damit sie ihren Kunden den besten Service bieten können.

Welche Rolle spielen Automobilteile bei Initiativen für erneuerbare Energien?

Der Sektor der erneuerbaren Energien integriert zunehmend Komponenten für Elektrofahrzeuge (EV), wie Batterien und Elektromotoren, in sein Angebot. Dieser Wandel bietet Unternehmen die Möglichkeit, den wachsenden Markt für Elektrofahrzeuge zu erschließen und sich an den Zielen der Nachhaltigkeit auszurichten. Käufer müssen die neuesten technologischen Fortschritte bei Automobilteilen berücksichtigen und die Kompatibilität mit bestehenden Systemen sowie die Skalierbarkeit für zukünftige Entwicklungen sicherstellen. Zulieferer, die in innovative Lösungen investieren, können auf diesem sich schnell entwickelnden Markt erhebliche Vorteile bieten.

Illustratives Bild zu allen Teilen des Fahrzeugs

Welche Bedeutung haben Autoteile für Export und Handel?

Der Export und der Handel mit Kfz-Teilen, einschließlich gebrauchter Fahrzeuge, sind von entscheidender Bedeutung für die Deckung des Bedarfs der aufstrebenden Märkte, insbesondere in Regionen wie Afrika und Südamerika. Unternehmen können sich den Bedarf an erschwinglichen Transportlösungen zunutze machen, indem sie qualitativ hochwertige Gebrauchtteile oder Fahrzeuge beschaffen. Internationale Käufer sollten sich über die Einhaltung lokaler Vorschriften und die mit dem grenzüberschreitenden Transport von Teilen verbundene Logistik im Klaren sein. Die Zusammenarbeit mit Lieferanten, die diese Dynamik verstehen, kann zu erfolgreichen Handelsbeziehungen und größeren Marktanteilen führen.

3 häufige Schmerzpunkte der Benutzer für ‘alle Teile des Autos’ und ihre Lösungen

Szenario 1: Beschaffung von Qualitätsteilen inmitten von Unterbrechungen der Lieferkette

Das Problem: B2B-Einkäufer haben oft erhebliche Schwierigkeiten bei der Beschaffung hochwertiger Autoteile, weil die Lieferkette ständig unterbrochen wird. Faktoren wie geopolitische Spannungen, Handelshemmnisse und die jüngste Pandemie haben zu Verzögerungen, erhöhten Kosten und uneinheitlicher Qualität geführt. Käufer können sich in einer Situation wiederfinden, in der sie sich zwischen verspäteten Lieferungen oder minderwertigen Teilen entscheiden müssen, was sich letztlich auf den Ruf ihres Unternehmens und die betriebliche Effizienz auswirken kann.

Die Lösung: Um diese Herausforderungen effektiv zu meistern, sollten Einkäufer enge Beziehungen zu mehreren Lieferanten in verschiedenen Regionen aufbauen. Die Diversifizierung der Lieferanten mindert nicht nur die Risiken, die mit der Abhängigkeit von einer einzigen Bezugsquelle verbunden sind, sondern stärkt auch die Verhandlungsposition. Darüber hinaus kann der Einsatz von Technologieplattformen für die Echtzeit-Bestandsverwaltung den Einkäufern helfen, die Lagerbestände zu überwachen und potenzielle Engpässe zu erkennen, bevor sie kritisch werden. Strategische Partnerschaften mit lokalen Herstellern können ebenfalls einen schnelleren Zugang zu Qualitätsteilen ermöglichen, die Vorlaufzeiten verkürzen und die Zuverlässigkeit erhöhen. Die regelmäßige Bewertung von Lieferanten auf der Grundlage von Leistungskennzahlen wie Qualität, Lieferzeiten und Service kann außerdem sicherstellen, dass nur die besten Partner ausgewählt werden.

Illustratives Bild zu allen Teilen des Fahrzeugs

Szenario 2: Verständnis von Kompatibilitätsproblemen mit Autoteilen

Das Problem: Kompatibilitätsprobleme sind ein häufiges Problem für B2B-Einkäufer, die sich mit allen Teilen eines Fahrzeugs befassen. Beim Kauf von Teilen ist es für Einkäufer oft schwierig sicherzustellen, dass die von ihnen ausgewählten Komponenten ordnungsgemäß in bestehende Systeme passen. Dies kann zu kostspieligen Rücksendungen, Zeitverschwendung und Unzufriedenheit bei Kunden führen, die sich auf ihre Dienstleistungen verlassen. Missverständnisse in Bezug auf die Kompatibilität können auf das Fehlen klarer Spezifikationen oder Unterschiede zwischen den Fahrzeugmodellen zurückzuführen sein, was den Beschaffungsprozess erschwert.

Die Lösung: Um Kompatibilitätsprobleme zu vermeiden, sollten Käufer bei der Beschaffung von Teilen auf gründliche Recherche und genaue Spezifikationen Wert legen. Die Nutzung einer zentralen Datenbank oder eines Katalogs, der detaillierte Informationen über die Kompatibilität von Teilen mit verschiedenen Fahrzeugmodellen enthält, kann von unschätzbarem Wert sein. Die Investition in Schulungen für Beschaffungsteams zu den spezifischen Anforderungen der verschiedenen Fahrzeugmarken und -modelle kann die Entscheidungsfindung ebenfalls verbessern. Darüber hinaus kann die Erstellung einer Checkliste mit den wichtigsten Kompatibilitätsparametern - wie Teilenummern, Abmessungen und Leistungsspezifikationen - den Einkaufsprozess rationalisieren. Eine enge Zusammenarbeit mit den Herstellern, um Einblicke in bevorstehende Modellwechsel und neue Teileveröffentlichungen zu erhalten, kann außerdem sicherstellen, dass die Einkäufer Kompatibilitätsproblemen immer einen Schritt voraus sind.

Szenario 3: Bewältigung von Kostensteigerungen ohne Qualitätseinbußen

Das Problem: Steigende Kosten für Autoteile aufgrund von Inflation, gestiegenen Rohstoffpreisen und erhöhter Nachfrage können für B2B-Einkäufer eine finanzielle Belastung darstellen. Diese Einkäufer müssen ein Gleichgewicht zwischen der Verwaltung von Budgets und der Aufrechterhaltung der Qualität der Teile, die sie ihren Kunden liefern, finden. Kompromisse bei der Qualität, um Kosten zu sparen, können zu einer unzuverlässigen Leistung des Fahrzeugs führen, was zu Unzufriedenheit der Kunden und potenziellen Sicherheitsproblemen führt.

Die Lösung: Um die Kosten effektiv zu steuern und gleichzeitig die Qualität zu sichern, sollten Einkäufer bei der Beschaffung einen strategischen Ansatz verfolgen. Das Aushandeln von Großeinkaufsvereinbarungen mit Lieferanten kann zu erheblichen Preisnachlässen führen, insbesondere wenn die Nachfrage genau vorhergesagt wird. Darüber hinaus kann die Einführung eines Just-in-Time-Bestandssystems die Lagerkosten minimieren und den Abfall reduzieren. Die Suche nach alternativen Materialien oder Teilen von renommierten Ersatzteillieferanten kann ebenfalls kostengünstige Lösungen bieten, ohne dass die Qualität darunter leidet. Die regelmäßige Durchführung von Marktanalysen, um über Preistrends und alternative Beschaffungsmöglichkeiten informiert zu sein, gibt den Einkäufern die Möglichkeit, fundierte Kaufentscheidungen zu treffen. Die Einführung eines Qualitätssicherungsprotokolls zur Bewertung von Teilen, bevor sie zum Kunden gelangen, bietet einen weiteren Schutz vor Qualitätsproblemen und stellt sicher, dass die Einkäufer ihren Ruf als zuverlässige Lieferanten aufrechterhalten.

Leitfaden zur strategischen Materialauswahl für alle Teile des Fahrzeugs

Bei der Auswahl von Materialien für Automobilkomponenten müssen B2B-Einkäufer verschiedene Faktoren wie Leistung, Kosten und die Einhaltung internationaler Normen berücksichtigen. Im Folgenden analysieren wir vier gängige Materialien, die in der Automobilherstellung verwendet werden, und konzentrieren uns dabei auf ihre Eigenschaften, Vorteile, Nachteile und spezifischen Überlegungen für internationale Einkäufer.

Was sind die wichtigsten Eigenschaften von Stahl in der Automobilindustrie?

Stahl ist aufgrund seiner Festigkeit und Vielseitigkeit ein wichtiger Werkstoff im Automobilbau. Zu den wichtigsten Eigenschaften gehören eine hohe Zugfestigkeit, hervorragende Verformbarkeit und gute Schweißbarkeit, wodurch er sich für Strukturteile wie Fahrgestell und Karosserieteile eignet. Stahl kann hohen Temperaturen und Drücken standhalten, was für Teile wie den Motorblock und das Getriebegehäuse unerlässlich ist.

Vor- und Nachteile: Stahl ist aufgrund seiner Langlebigkeit und Kosteneffizienz eine beliebte Wahl, aber er ist anfällig für Korrosion, wenn er nicht richtig behandelt wird. Die Komplexität der Herstellung kann variieren, insbesondere bei hochfesten Stählen (AHSS), die spezielle Verarbeitungstechniken erfordern.

Auswirkungen auf die Anwendung: Die Verträglichkeit von Stahl mit verschiedenen Medien, einschließlich Schmier- und Kühlmitteln, ist für Motor- und Getriebekomponenten entscheidend. Sein Gewicht kann sich jedoch negativ auf die Kraftstoffeffizienz auswirken, was die Hersteller dazu veranlasst, nach leichteren Alternativen zu suchen.

Illustratives Bild zu allen Teilen des Fahrzeugs

Überlegungen für internationale Käufer: Die Einhaltung von Normen wie ASTM A36 (für Baustahl) und DIN 17100 (für allgemeine Baustähle) ist unerlässlich. Käufer sollten auch die lokale Verfügbarkeit und den möglichen Bedarf an korrosionsbeständigen Beschichtungen berücksichtigen, insbesondere in feuchten oder küstennahen Regionen.

Wie schneidet Aluminium als Material für Autoteile im Vergleich ab?

Aluminium wird wegen seiner leichten Eigenschaften, die die Kraftstoffeffizienz und die Leistung verbessern, immer beliebter. Es zeichnet sich durch eine hervorragende Korrosionsbeständigkeit und Wärmeleitfähigkeit aus und ist daher ideal für Komponenten wie Motorblöcke, Räder und Wärmetauscher.

Vor- und Nachteile: Der Hauptvorteil von Aluminium ist sein geringes Gewicht, das zu einer besseren Kraftstoffersparnis beiträgt. Allerdings ist es in der Regel teurer als Stahl und kann bei hoher Beanspruchung weniger haltbar sein. Der Herstellungsprozess für Aluminiumteile kann auch komplexer sein, da spezielle Schweißtechniken erforderlich sind.

Auswirkungen auf die Anwendung: Die Kompatibilität von Aluminium mit verschiedenen Kfz-Flüssigkeiten ist vorteilhaft, aber seine geringere Festigkeit im Vergleich zu Stahl kann seine Verwendung in hochbelasteten Anwendungen ohne Verstärkung einschränken.

Illustratives Bild zu allen Teilen des Fahrzeugs

Überlegungen für internationale Käufer: Käufer sollten sicherstellen, dass Normen wie ASTM B221 (für Aluminium-Strangpressprofile) und JIS H 4000 (für Aluminiumlegierungen) eingehalten werden. Darüber hinaus kann es von Vorteil sein, die lokalen Recyclingmöglichkeiten für Aluminium zu kennen, da es sich gut recyceln lässt.

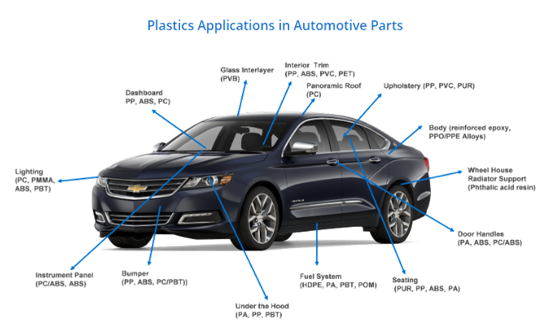

Was sind die Vorteile der Verwendung von Kunststoffen in der Automobilherstellung?

Kunststoffe werden aufgrund ihrer Vielseitigkeit und ihres geringen Gewichts in großem Umfang für Innen- und Außenbauteile von Kraftfahrzeugen verwendet. Zu den wichtigsten Eigenschaften gehören die Korrosionsbeständigkeit, die geringe Dichte und die leichte Formbarkeit für komplexe Formen.

Vor- und Nachteile: Die Hauptvorteile von Kunststoffen sind ihr geringes Gewicht und ihre Designflexibilität, was zu Kosteneinsparungen bei der Herstellung führen kann. Allerdings bieten sie bei hochbelasteten Anwendungen möglicherweise nicht das gleiche Maß an Haltbarkeit wie Metalle, und ihre Leistung kann durch extreme Temperaturen beeinträchtigt werden.

Auswirkungen auf die Anwendung: Kunststoffe sind mit verschiedenen Kfz-Chemikalien verträglich, ihre Leistung kann jedoch bei längerer Einwirkung von UV-Licht und extremen Temperaturen nachlassen.

Illustratives Bild zu allen Teilen des Fahrzeugs

Überlegungen für internationale Käufer: Die Einhaltung von Normen wie ISO 9001 für das Qualitätsmanagement und ASTM D638 für die Festigkeitseigenschaften ist entscheidend. Käufer sollten auch die Umweltauswirkungen von Kunststoffen und die wachsende Nachfrage nach recycelbaren Materialien berücksichtigen.

Wie verbessern Verbundwerkstoffe die Leistung von Kraftfahrzeugen?

Verbundwerkstoffe wie Kohlenstoff- und Glasfasern gewinnen in Hochleistungsanwendungen im Automobilbau zunehmend an Bedeutung. Sie bieten ein außergewöhnliches Verhältnis von Festigkeit zu Gewicht und eine hervorragende Ermüdungsbeständigkeit.

Vor- und Nachteile: Der Hauptvorteil von Verbundwerkstoffen ist ihr geringes Gewicht, das die Leistung und die Kraftstoffeffizienz von Fahrzeugen erheblich verbessert. Allerdings sind sie oft teurer und erfordern spezielle Fertigungstechniken, was die Produktion erschweren kann.

Auswirkungen auf die Anwendung: Verbundwerkstoffe eignen sich für Hochleistungsanwendungen wie Karosserieteile und Strukturbauteile, aber ihre Kompatibilität mit den üblichen Reparaturtechniken für Kraftfahrzeuge kann eine Einschränkung darstellen.

Überlegungen für internationale Käufer: Die Einhaltung einschlägiger Normen wie der ASTM D7264 für Verbundwerkstoffe ist von entscheidender Bedeutung. Käufer sollten auch die Verfügbarkeit von Fachkräften für die Herstellung von Verbundwerkstoffen in ihren Regionen prüfen.

Illustratives Bild zu allen Teilen des Fahrzeugs

Übersichtstabelle zur Materialauswahl für Automobilteile

| Material | Typischer Anwendungsfall für alle Teile des Fahrzeugs | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Fahrgestell, Motorblöcke, Karosserieteile | Hohe Festigkeit und Haltbarkeit | Korrosionsanfällig | Mittel |

| Aluminium | Motorkomponenten, Räder, Wärmetauscher | Leicht und korrosionsbeständig | Höhere Kosten und geringere Festigkeit | Hoch |

| Kunststoffe | Innenausstattung, Stoßstangen, Verkleidung | Designflexibilität und geringes Gewicht | Weniger haltbar bei Belastung | Niedrig |

| Verbundwerkstoffe | Hochleistungs-Karosserieteile, Strukturkomponenten | Außergewöhnliches Verhältnis von Stärke zu Gewicht | Hohe Kosten und komplexe Herstellung | Hoch |

Dieser Leitfaden für die strategische Materialauswahl bietet einen umfassenden Überblick für internationale B2B-Einkäufer und ermöglicht fundierte Entscheidungen, die mit den Leistungsanforderungen, Kostenerwägungen und Konformitätsstandards in den jeweiligen Märkten übereinstimmen.

Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für alle Teile des Fahrzeugs

Was sind die wichtigsten Phasen des Herstellungsprozesses von Autoteilen?

Die Herstellung von Autoteilen umfasst mehrere kritische Phasen, von denen jede dazu dient, Präzision, Effizienz und Qualität zu gewährleisten. Ein Verständnis dieser Phasen kann B2B-Einkäufern helfen, fundierte Entscheidungen bei der Beschaffung von Komponenten zu treffen.

Wie wird das Material für die Herstellung von Autoteilen vorbereitet?

Die Materialvorbereitung ist der erste Schritt im Herstellungsprozess. Dazu gehört die Auswahl von hochwertigen Rohstoffen wie Stahl, Aluminium und Kunststoffen, die für Haltbarkeit und Leistung unerlässlich sind. Die Zulieferer führen häufig eine gründliche Materialanalyse durch, bei der auch die chemische Zusammensetzung und die mechanischen Eigenschaften geprüft werden, um sicherzustellen, dass die Materialien den Industriespezifikationen entsprechen.

Illustratives Bild zu allen Teilen des Fahrzeugs

Sobald die Materialien geprüft sind, werden sie verschiedenen Verfahren wie Schneiden, Scheren oder Bearbeitung unterzogen, um die gewünschten Formen und Größen zu erhalten. Moderne Technologien wie Laserschneiden und CNC-Bearbeitung werden häufig eingesetzt, um die Präzision zu erhöhen und den Ausschuss zu verringern.

Welche Umformtechniken werden bei der Herstellung von Autoteilen üblicherweise verwendet?

Umformverfahren sind entscheidend für die Formung der Rohmaterialien zu den gewünschten Komponenten. In der Automobilindustrie sind verschiedene Techniken verbreitet:

-

Stanzen: Bei diesem Verfahren werden Bleche mit Hilfe von Matrizen in bestimmte Formen geschnitten und geformt. Es wird häufig für die Herstellung von Karosserieteilen und Halterungen verwendet.

-

Gießen: Für Bauteile wie Motorblöcke und Getriebegehäuse werden Gießverfahren wie Sand- oder Druckguss eingesetzt. Diese Verfahren ermöglichen komplexe Formen und eine hervorragende Materialintegrität.

-

Spritzgießen: Bei dieser Technik, die hauptsächlich für Kunststoffteile verwendet wird, wird geschmolzener Kunststoff in Formen gespritzt, um Gegenstände wie Armaturenbretter und Innenverkleidungen herzustellen.

-

Schmieden: Bei diesem Verfahren wird das Metall durch Druckkräfte geformt, wodurch seine Festigkeit erhöht wird. Es wird üblicherweise für kritische Komponenten wie Kurbelwellen und Pleuelstangen verwendet.

Wie erfolgt die Montage von Autoteilen?

In der Montagephase werden die einzelnen Komponenten zu einem vollständigen System zusammengefügt. Dieser Prozess kann je nach Komplexität der zu montierenden Teile sehr unterschiedlich sein.

In den meisten Fällen werden Montagelinien eingesetzt, in denen die Teile nach und nach in die Fahrzeugstruktur eingebaut werden. Die Automatisierung spielt hier eine entscheidende Rolle, wobei Robotersysteme Aufgaben wie Schweißen, Befestigen und Qualitätskontrollen übernehmen, um Geschwindigkeit und Konsistenz zu verbessern.

Darüber hinaus werden häufig die Grundsätze der schlanken Produktion angewandt, um die Verschwendung zu minimieren und die Arbeitsabläufe zu optimieren, was für die Aufrechterhaltung einer wettbewerbsfähigen Preisgestaltung auf den globalen Märkten von entscheidender Bedeutung ist.

Illustratives Bild zu allen Teilen des Fahrzeugs

Welche Veredelungstechniken gibt es für Autoteile?

Veredelungsverfahren verbessern das Aussehen und die Haltbarkeit von Autoteilen. Zu den gängigen Veredelungstechniken gehören:

-

Anstriche und Beschichtungen: Teile werden häufig mit Schutzschichten überzogen, um sie vor Korrosion zu schützen und ihr Aussehen zu verbessern. Dies kann eine Pulverbeschichtung oder eine galvanische Beschichtung sein.

-

Polieren und Schwabbeln: Diese Verfahren werden eingesetzt, um eine glatte Oberfläche auf sichtbaren Teilen zu erzielen und deren optische Attraktivität zu erhöhen.

-

Wärmebehandlung: Bestimmte Metallteile werden einer Wärmebehandlung unterzogen, um ihre physikalischen Eigenschaften wie Härte und Zugfestigkeit zu verändern, damit sie den betrieblichen Beanspruchungen standhalten.

Welche Qualitätssicherungsmaßnahmen sind in der Autoteilefertigung unerlässlich?

Die Qualitätssicherung (QS) ist von entscheidender Bedeutung, wenn es darum geht, dass Autoteile den strengen Sicherheits- und Leistungsstandards entsprechen. B2B-Einkäufer müssen sich der verschiedenen Qualitätssicherungsmaßnahmen bewusst sein, die im Herstellungsprozess eingesetzt werden.

Welche internationalen Normen sollten B2B-Einkäufer berücksichtigen?

Internationale Normen wie ISO 9001 bieten einen Rahmen für Qualitätsmanagementsysteme und gewährleisten eine gleichbleibende Qualität in allen Fertigungsprozessen. Darüber hinaus sind branchenspezifische Zertifizierungen wie CE (Conformité Européenne) für in Europa verkaufte Produkte oder API (American Petroleum Institute) für Kfz-Schmierstoffe wichtige Qualitätsindikatoren.

B2B-Einkäufer sollten Lieferanten bevorzugen, die sich an diese Normen halten, da die Einhaltung dieser Normen ein Zeichen für Qualität und Zuverlässigkeit ist.

Was sind die wichtigsten Qualitätskontrollpunkte in der Produktion?

Qualitätskontrollpunkte sind ein wesentlicher Bestandteil der Aufrechterhaltung hoher Standards während des gesamten Herstellungsprozesses. Die folgenden Kontrollpunkte werden in der Regel durchgeführt:

-

Eingangsqualitätskontrolle (IQC): Bei dieser ersten Kontrolle werden die Rohstoffe und Komponenten bei ihrem Eintreffen in der Produktionsstätte geprüft, um sicherzustellen, dass sie den Spezifikationen entsprechen.

-

In-Process-Qualitätskontrolle (IPQC): Während des Herstellungsprozesses werden regelmäßig Kontrollen durchgeführt, um die Qualität der laufenden Produktion zu überwachen. Dazu können Maßkontrollen und Funktionsprüfungen gehören.

-

Endkontrolle (FQC): Nach der Montage wird eine Endkontrolle durchgeführt, um zu überprüfen, ob die fertigen Teile alle Spezifikationen und Leistungskriterien erfüllen, bevor sie an die Kunden ausgeliefert werden.

Welche Prüfverfahren werden in der Qualitätssicherung üblicherweise eingesetzt?

Um die Unversehrtheit und Leistungsfähigkeit von Autoteilen zu gewährleisten, werden verschiedene Prüfverfahren eingesetzt:

-

Mechanische Prüfung: Tests wie Zugfestigkeit, Härte und Ermüdungsprüfungen helfen bei der Bewertung der physikalischen Eigenschaften von Materialien.

-

Zerstörungsfreie Prüfung (NDT): Techniken wie Ultraschallprüfung, Magnetpulverprüfung und Röntgenuntersuchung werden eingesetzt, um innere Fehler zu erkennen, ohne die Bauteile zu beschädigen.

-

Funktionelle Prüfung: Bei montierten Teilen wird durch Funktionsprüfungen sichergestellt, dass sie unter Betriebsbedingungen wie erwartet funktionieren, z. B. bei der Prüfung von Bremssystemen oder Motorkomponenten.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

Um sicherzustellen, dass die Lieferanten hohe Qualitätsstandards einhalten, sollten B2B-Einkäufer verschiedene Überprüfungsstrategien anwenden:

-

Lieferantenaudits: Die Durchführung regelmäßiger Audits in den Produktionsstätten der Lieferanten kann dazu beitragen, die Einhaltung von Qualitätsstandards und -praktiken zu überprüfen.

-

Überprüfung von Qualitätsberichten: Das Anfordern von detaillierten Qualitätsberichten und -zertifikaten von Lieferanten kann einen Einblick in deren Qualitätssicherungsprozesse und Leistungsgeschichte geben.

-

Inspektionen durch Dritte: Die Beauftragung von externen Prüfstellen kann eine unvoreingenommene Bewertung der Qualitätspraktiken und der Produktintegrität des Lieferanten bieten.

Was sind die Feinheiten der Qualitätskontrolle für internationale Käufer?

Internationale B2B-Einkäufer, insbesondere aus verschiedenen Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, sollten sich der besonderen Nuancen bei der Qualitätskontrolle bewusst sein:

-

Kulturelle Unterschiede: Das Verständnis des kulturellen Kontextes der Lieferanten kann dazu beitragen, eine wirksame Kommunikation und Erwartungen hinsichtlich der Qualitätsstandards zu schaffen.

-

Einhaltung gesetzlicher Vorschriften: In verschiedenen Regionen können unterschiedliche Vorschriften und Normen gelten. Die Einkäufer sollten sicherstellen, dass ihre Lieferanten sowohl die lokalen als auch die internationalen Vorschriften einhalten.

-

Logistische Überlegungen: Die Qualitätssicherung kann auch durch Transport- und Handhabungspraktiken beeinflusst werden. Die Käufer sollten diese Aspekte mit den Lieferanten besprechen, um die mit dem Transport und der Lagerung verbundenen Risiken zu mindern.

Durch ein umfassendes Verständnis der Herstellungsverfahren und Qualitätssicherungsmaßnahmen für Autoteile können B2B-Einkäufer fundierte Entscheidungen treffen und sicherstellen, dass sie qualitativ hochwertige Komponenten beziehen, die ihren betrieblichen Anforderungen entsprechen.

Praktischer Leitfaden für die Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘alle Teile des Autos’

In der wettbewerbsintensiven Landschaft der Beschaffung von Automobilteilen müssen sich internationale B2B-Einkäufer in einer komplexen Reihe von Komponenten und Lieferanten zurechtfinden. Dieser Leitfaden dient als praktische Checkliste zur Rationalisierung des Beschaffungsprozesses für ‘alle Teile des Autos’ und stellt sicher, dass Einkäufer fundierte und effektive Kaufentscheidungen treffen.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Die Festlegung klarer technischer Spezifikationen ist entscheidend für die Gewährleistung von Kompatibilität und Leistung. Ermitteln Sie die benötigten spezifischen Teile, einschließlich Details wie Abmessungen, Materialien und Einhaltung der örtlichen Vorschriften. Dieser Schritt minimiert Missverständnisse und bildet die Grundlage für alle nachfolgenden Beschaffungsaktivitäten.

Schritt 2: Erforschung von Markttrends und Preisgestaltung

Um wettbewerbsfähige Angebote machen zu können, ist es wichtig, die aktuellen Markttrends und Preise zu kennen. Analysieren Sie aktuelle Marktberichte, die Preise der Wettbewerber und Nachfrageschwankungen, um faire Preise für die von Ihnen benötigten Teile zu ermitteln. Dieses Wissen hilft bei der Aushandlung besserer Angebote und der Vermeidung von Überbezahlung.

Schritt 3: Identifizierung und Bewertung potenzieller Zulieferer

Bevor Sie sich binden, sollten Sie die Lieferanten gründlich prüfen. Suchen Sie nach etablierten Herstellern oder Händlern mit einem guten Ruf in der Branche. Fordern Sie Unternehmensprofile, Fallstudien und Referenzen von Käufern in einer ähnlichen Branche oder Region an, um deren Zuverlässigkeit und Servicequalität zu beurteilen.

- Lieferanten-Zertifizierungen: Überprüfen Sie, ob die Lieferanten über die erforderlichen Zertifizierungen (z. B. ISO, IATF) verfügen, um Qualitätsstandards zu gewährleisten.

- Produktionskapazität: Erkundigen Sie sich nach den Produktionskapazitäten des Unternehmens, um sicherzustellen, dass es Ihre Mengenanforderungen erfüllen kann.

Schritt 4: Anforderung von Mustern und Qualitätssicherungsprüfungen

Die Beschaffung von Mustern ist ein wichtiger Schritt, um die Qualität der Teile zu beurteilen, bevor Sie eine Großbestellung aufgeben. Vergewissern Sie sich, dass die Muster Ihren technischen Spezifikationen und Qualitätserwartungen entsprechen. Fordern Sie außerdem Unterlagen über die an den Teilen durchgeführten Qualitätssicherungsprüfungen an.

- Prüfnormen: Erkundigen Sie sich nach den Prüfstandards, die der Lieferant einhält, und stellen Sie sicher, dass sie den Anforderungen der Branche entsprechen.

- Rückgabebedingungen: Verstehen Sie die Rückgabebestimmungen des Lieferanten für defekte oder nicht konforme Teile.

Schritt 5: Aushandeln von Bedingungen und Konditionen

Sobald Sie potenzielle Lieferanten in die engere Wahl gezogen haben, sollten Sie Verhandlungen über Preise, Zahlungsbedingungen und Liefertermine aufnehmen. Die Festlegung klarer Bedingungen im Vorfeld hilft, spätere Streitigkeiten zu vermeiden und sorgt für einen reibungsloseren Ablauf der Transaktion.

- Zahlungsbedingungen: Besprechen Sie die für beide Seiten geeigneten Zahlungsmöglichkeiten, z. B. Akkreditive oder Zahlung bei Lieferung.

- Vorlaufzeiten: Bestätigen Sie die Vorlaufzeiten für Produktion und Versand, um sie mit Ihrem Lagerbedarf in Einklang zu bringen.

Schritt 6: Erstellen Sie einen Kommunikationsplan

Ein solider Kommunikationsplan ist entscheidend für die Aufrechterhaltung der Transparenz und die unverzügliche Behandlung von Problemen. Benennen Sie einen Ansprechpartner für die laufende Kommunikation mit dem Lieferanten, um schnelle Antworten auf Anfragen oder Bedenken zu ermöglichen.

- Regelmäßige Updates: Planen Sie regelmäßige Updates zum Auftragsstatus und zu möglichen Verzögerungen.

- Krisenmanagement: Entwicklung eines Protokolls für Notfälle oder Unterbrechungen der Lieferkette.

Schritt 7: Überwachung der Leistung nach dem Kauf

Überwachen Sie nach dem Beschaffungsprozess kontinuierlich die Leistung des Lieferanten in Bezug auf Qualität, Lieferung und Service. Sammeln Sie Feedback von Ihrem Team, um die allgemeine Zufriedenheit mit den gelieferten Teilen zu bewerten.

- Leistungsmetriken: Legen Sie wichtige Leistungsindikatoren (KPIs) fest, um die Zuverlässigkeit und Qualität der Lieferanten im Laufe der Zeit zu bewerten.

- Rückkopplungsschleife: Schaffen Sie eine Feedback-Schleife, um dem Lieferanten Erkenntnisse über seine Leistung zu vermitteln und so Verbesserungen und Zusammenarbeit zu fördern.

Anhand dieser umfassenden Checkliste können B2B-Einkäufer die Komplexität der Beschaffung von Kfz-Teilen effektiv bewältigen und sicherstellen, dass sie qualitativ hochwertige Komponenten erhalten und gleichzeitig die Kosten und Lieferantenbeziehungen optimieren.

Illustratives Bild zu allen Teilen des Fahrzeugs

Umfassende Kosten- und Preisanalyse für alle Teile des Fahrzeugs Beschaffung

Für B2B-Einkäufer, die fundierte Beschaffungsentscheidungen treffen wollen, ist es von entscheidender Bedeutung, die Kostenstruktur und Preisdynamik von Automobilteilen zu verstehen. Dieser Leitfaden befasst sich mit den wichtigsten Komponenten, die die Kosten von Kfz-Teilen beeinflussen, sowie mit Strategien zur Optimierung der Beschaffung.

Was sind die wichtigsten Kostenelemente bei der Herstellung von Automobilteilen?

Die Gesamtkosten von Kraftfahrzeugteilen setzen sich aus mehreren Schlüsselkomponenten zusammen:

-

Materialien: Die Wahl der Materialien wirkt sich erheblich auf den Preis aus. Hochwertige Materialien erhöhen zwar die Anschaffungskosten, können aber zu einer besseren Leistung und Haltbarkeit führen und so die langfristigen Kosten senken.

-

Arbeit: Die Arbeitskosten variieren je nach Region und können von den lokalen Lohnsätzen und der Verfügbarkeit von Fachkräften beeinflusst werden. Länder mit niedrigeren Arbeitskosten können wettbewerbsfähige Preise bieten, aber dies muss gegen Qualität und Fachwissen abgewogen werden.

-

Fertigungsgemeinkosten: Hierunter fallen Ausgaben für den Betrieb der Fabrik, z. B. für Versorgungsleistungen, Miete und Abschreibung der Anlagen. Effiziente Herstellungsverfahren können dazu beitragen, die Gemeinkosten zu senken, was wiederum zu niedrigeren Preisen führt.

-

Werkzeuge: Für bestimmte Teile sind oft maßgeschneiderte Werkzeuge erforderlich, was die Anfangskosten in die Höhe treiben kann. Die Investition in effiziente Werkzeuge kann jedoch die Produktionsgeschwindigkeit erhöhen und die Stückkosten im Laufe der Zeit senken.

-

Qualitätskontrolle (QC): Die Aufrechterhaltung von Qualitätsstandards ist in der Automobilindustrie von entscheidender Bedeutung. Strenge Qualitätskontrollverfahren können die Kosten erhöhen, sind aber für die Gewährleistung der Zuverlässigkeit und die Einhaltung der Sicherheitsvorschriften unerlässlich.

-

Logistik: Die Transport- und Bearbeitungskosten sind erheblich, insbesondere bei internationalen Sendungen. Faktoren wie die Entfernung, die Versandart und die Zollgebühren können die Logistikkosten beeinflussen.

-

Marge: Die Lieferanten werden in der Regel eine Gewinnspanne einkalkulieren, die je nach Marktbedingungen, Wettbewerb und dem wahrgenommenen Wert der Teile variiert.

Wie beeinflussen Preiseinflussfaktoren die Beschaffung von Automobilteilen?

Mehrere Faktoren können die Preisgestaltung für Kfz-Teile beeinflussen:

-

Menge/Mindestbestellmenge: Der Kauf größerer Mengen führt oft zu Preisnachlässen. Die Festlegung einer Mindestbestellmenge (MOQ) kann bei Verhandlungen ein Druckmittel sein.

-

Spezifikationen/Anpassung: Kundenspezifische Teile können aufgrund zusätzlicher Design- und Produktionsanforderungen höhere Kosten verursachen. Klare Spezifikationen können zu einer effektiven Kostenkontrolle beitragen.

-

Materialien: Die Wahl der Materialien beeinflusst nicht nur die Leistung, sondern auch den Preis. Käufer sollten auf ein ausgewogenes Verhältnis zwischen Kosten und Qualität achten.

-

Qualität/Zertifizierungen: Für Teile, die bestimmte Industrienormen oder Zertifizierungen erfüllen, können höhere Preise verlangt werden. Die Käufer müssen unbedingt prüfen, ob die zusätzlichen Kosten mit ihren Qualitätsanforderungen übereinstimmen.

-

Lieferantenfaktoren: Der Ruf und die Zuverlässigkeit der Lieferanten spielen eine entscheidende Rolle. Etablierte Anbieter verlangen zwar mehr, können aber auch bessere Unterstützung und Qualitätssicherung bieten.

-

Incoterms: Das Verständnis der Incoterms ist für internationale Transaktionen unerlässlich. Sie legen die Verantwortlichkeiten von Käufern und Verkäufern in Bezug auf Versand, Versicherung und Zölle fest, was die Gesamtkosten erheblich beeinflussen kann.

Was sind wirksame Tipps für die Preisverhandlung von Autoteilen?

Zur Optimierung der Beschaffungskosten sollten Sie die folgenden Strategien in Betracht ziehen:

-

Mengenrabatte ausnutzen: Wenn möglich, konsolidieren Sie Aufträge, um Mengenrabatte zu erhalten. Dies senkt nicht nur die Kosten pro Einheit, sondern kann auch die Beziehungen zu den Lieferanten stärken.

-

Fokus auf Gesamtbetriebskosten (TCO): Bewerten Sie die Teile auf der Grundlage ihrer langfristigen Kosten, einschließlich Wartung und Austausch. Die Investition in höherwertige Teile kann im Laufe der Zeit zu Einsparungen führen.

-

Klug verhandeln: Informieren Sie sich über die Marktbedingungen und seien Sie bereit zu verhandeln. Eine Recherche über die Preisgestaltung der Konkurrenz kann bei Gesprächen wertvolle Erkenntnisse liefern.

-

Lokale Beschaffung in Betracht ziehen: Für Einkäufer in Afrika, Südamerika, dem Nahen Osten und Europa kann die lokale Beschaffung Logistikkosten und Vorlaufzeiten reduzieren. Bewerten Sie die Kompromisse zwischen lokalen und internationalen Lieferanten.

Schlussfolgerung

Um die Komplexität der Beschaffung von Automobilteilen zu bewältigen, ist ein gründliches Verständnis der Kostenkomponenten und der Einflussfaktoren auf die Preisgestaltung erforderlich. Durch den Einsatz strategischer Verhandlungstechniken und die Konzentration auf die Gesamtbetriebskosten können B2B-Einkäufer fundierte Entscheidungen treffen, die mit ihren betrieblichen Anforderungen und Budgetvorgaben in Einklang stehen. Denken Sie daran, dass Preise je nach Marktbedingungen schwanken können. Holen Sie daher immer aktuelle Angebote ein und bleiben Sie bei Verhandlungen flexibel.

Analyse der Alternativen: Vergleich aller Teile des Fahrzeugs mit anderen Lösungen

Alternativen bei Automobillösungen verstehen

In der Automobilindustrie stehen die Käufer oft vor einer Vielzahl von Wahlmöglichkeiten, wenn es um Fahrzeugkomponenten und -systeme geht. Die Erkundung von Alternativen zu herkömmlichen Autoteilen kann zu Leistungssteigerungen, Kosteneinsparungen und höherer Zuverlässigkeit führen. Diese Analyse konzentriert sich auf den Vergleich von ‘allen Teilen des Autos’ mit zwei praktikablen Alternativen: Elektrofahrzeugsysteme und modulares Fahrzeugdesign. Jede dieser Alternativen bietet einzigartige Vorteile und Herausforderungen, die die Kaufentscheidungen von B2B-Käufern in verschiedenen Märkten beeinflussen können.

Vergleichstabelle

| Vergleichsaspekt | Alle Teile des Fahrzeugs | Elektrische Fahrzeugsysteme | Modularer Fahrzeugbau |

|---|---|---|---|

| Leistung | Hohe Zuverlässigkeit und Effizienz; gut verstandene Mechanik. | Sofortiges Drehmoment; geringere Emissionen; leiser Betrieb. | Anpassbare Leistung je nach Bedarf; Flexibilität bei der Gestaltung. |

| Kosten | Die Anfangsinvestitionen können hoch sein; die laufenden Wartungskosten sind hoch. | Höhere Anfangskosten; mögliche langfristige Einsparungen bei Kraftstoff und Wartung. | Kann Kosten durch Standardisierung senken; Skalierbarkeit kann Produktionskosten senken. |

| Einfache Implementierung | Etablierte Lieferketten; leicht verfügbare Teile. | Erfordert spezielle Kenntnisse für Installation und Wartung. | Kann eine Schulung für die Montage erforderlich machen; kann Produktionsprozesse rationalisieren. |

| Wartung | Regelmäßige Wartung erforderlich; die Verfügbarkeit von Ersatzteilen ist hoch. | Geringerer Wartungsbedarf; weniger bewegliche Teile, aber der Austausch der Batterie kann kostspielig sein. | Die Wartung hängt von der Wahl der Komponenten ab; modulare Teile können Reparaturen vereinfachen. |

| Bester Anwendungsfall | Geeignet für traditionelle Märkte mit etablierter Infrastruktur. | Ideal für städtische Umgebungen mit Ladeinfrastruktur; umweltbewusste Verbraucher. | Am besten geeignet für spezialisierte Anwendungen, bei denen eine individuelle Anpassung wichtig ist, wie z. B. beim Flottenmanagement. |

Detaillierte Aufschlüsselung der Alternativen

Elektrische Fahrzeugsysteme

Elektrofahrzeuge stellen einen bedeutenden Wandel in der Automobiltechnologie dar und bieten Vorteile wie geringere Emissionen und niedrigere Kraftstoffkosten. Mit elektrischen Systemen können Unternehmen von staatlichen Anreizen für grüne Technologien profitieren, was sie zu einer attraktiven Option für Flottenbetreiber macht, die ihr Profil im Bereich der sozialen Verantwortung von Unternehmen verbessern wollen. Allerdings können die Anfangsinvestitionen beträchtlich sein, und der Bedarf an Ladeinfrastruktur kann in Regionen, in denen diese noch nicht weit verbreitet ist, eine Herausforderung darstellen.

Illustratives Bild zu allen Teilen des Fahrzeugs

Modularer Fahrzeugbau

Die modulare Bauweise von Fahrzeugen ermöglicht es den Herstellern, Fahrzeuge mit austauschbaren Teilen zu entwickeln, was die individuelle Anpassung und Flexibilität fördert. Dieser Ansatz ist besonders vorteilhaft für Unternehmen, die spezielle Fahrzeuge benötigen, wie z. B. Lieferflotten oder Baufahrzeuge. Durch eine modulare Bauweise können Unternehmen ihre Produktionskosten senken und die Wartungseffizienz erhöhen, da bestimmte Komponenten leicht ausgetauscht oder aufgerüstet werden können. Allerdings kann es erforderlich sein, die traditionellen Fertigungsverfahren zu ändern und das Personal an die neuen Montagemethoden zu gewöhnen.

Schlussfolgerung: Wie Sie die richtige Automotive-Lösung auswählen

Wenn B2B-Einkäufer Lösungen für die Automobilindustrie in Betracht ziehen, sollten sie ihre spezifischen betrieblichen Anforderungen, Budgetbeschränkungen und langfristigen Ziele bewerten. Herkömmliche Autoteile bieten Zuverlässigkeit und Vertrautheit, während elektrische Fahrzeugsysteme und modulare Designs innovative Alternativen darstellen, die zu größerer Effizienz und Kosteneinsparungen führen können. Durch eine sorgfältige Abwägung der Vor- und Nachteile der einzelnen Optionen in Bezug auf den jeweiligen Geschäftskontext können Einkäufer fundierte Entscheidungen treffen, die mit ihren strategischen Zielen und betrieblichen Anforderungen übereinstimmen.

Wesentliche technische Eigenschaften und Fachterminologie für alle Teile des Fahrzeugs

Was sind die wichtigsten technischen Eigenschaften von Autoteilen?

Bei der Beschaffung von Autoteilen ist die Kenntnis spezifischer technischer Eigenschaften entscheidend für die Gewährleistung von Qualität, Leistung und Kompatibilität. Hier sind einige wesentliche Spezifikationen:

-

Werkstoffgüte

Die Materialqualität eines Autoteils bestimmt seine Festigkeit, Haltbarkeit und Eignung für verschiedene Anwendungen. So werden beispielsweise Stahlsorten wie 304 und 316 aufgrund ihrer Korrosionsbeständigkeit und Zugfestigkeit häufig für Motorenteile verwendet. Bei B2B-Geschäften ist die Angabe der richtigen Materialsorte entscheidend, um kostspielige Ausfälle zu vermeiden und die Einhaltung der Industrienormen zu gewährleisten. -

Toleranz

Die Toleranz bezieht sich auf die zulässige Grenze der Abweichung in einer physikalischen Dimension. Bei Motorkomponenten beispielsweise können enge Toleranzen (z. B. ±0,01 mm) erforderlich sein, um eine einwandfreie Passform und Funktion zu gewährleisten. Das Verständnis von Toleranzen ist für Käufer von entscheidender Bedeutung, da sie den Montageprozess und die Gesamtleistung des Fahrzeugs beeinflussen. Geringe Toleranzen können zu höheren Herstellungskosten und einem erhöhten Fehlerrisiko führen. -

Härte

Die Härte gibt an, wie widerstandsfähig ein Material gegen Verformung und Verschleiß ist. Verschiedene Teile, wie Bremsbeläge oder Zahnräder, erfordern bestimmte Härtegrade, um den betrieblichen Belastungen standzuhalten. B2B-Einkäufer müssen sicherstellen, dass die Härtespezifikationen mit den Anforderungen ihrer Anwendung übereinstimmen, um vorzeitigen Verschleiß zu verhindern und Sicherheit zu gewährleisten. -

Wärmeleitfähigkeit

Diese Eigenschaft misst die Fähigkeit eines Materials, Wärme zu leiten, was für Bauteile wie Kühler und Auspuffanlagen entscheidend ist. Materialien mit hoher Wärmeleitfähigkeit können Wärme effizient ableiten und so eine Überhitzung verhindern. Käufer müssen die thermischen Eigenschaften berücksichtigen, wenn sie Teile für Hochleistungsfahrzeuge oder unter extremen Betriebsbedingungen beschaffen. -

Korrosionsbeständigkeit

Teile, die rauen Umgebungen ausgesetzt sind, wie z. B. Aufhängungskomponenten und Auspuffanlagen, sollten eine hohe Korrosionsbeständigkeit aufweisen. Diese Eigenschaft wird oft durch Beschichtungen oder die Wahl des Materials (z. B. Edelstahl) erreicht. Die Kenntnis der Korrosionsbeständigkeit ist für Käufer in Regionen mit hoher Luftfeuchtigkeit oder salzhaltigen Bedingungen von entscheidender Bedeutung, da sie sich auf Langlebigkeit und Wartungskosten auswirkt.

Was sind gängige Handelsbegriffe in der Automobilindustrie?

Die Vertrautheit mit der Branchenterminologie kann Einkaufsprozesse rationalisieren und die Kommunikation zwischen Einkäufern und Lieferanten verbessern. Hier sind die wichtigsten Fachbegriffe, die Sie kennen sollten:

-

OEM (Originalgerätehersteller)

OEM bezieht sich auf Teile, die vom Originalhersteller des Fahrzeugs hergestellt wurden, um Kompatibilität und Qualität zu gewährleisten. B2B-Käufer bevorzugen OEM-Teile oft wegen ihrer Zuverlässigkeit und der Einhaltung der Herstellerspezifikationen, was auch den Wiederverkaufswert beeinflussen kann. -

MOQ (Mindestbestellmenge)

MOQ gibt die kleinste Stückzahl an, die ein Lieferant zu verkaufen bereit ist. Die Kenntnis der MOQ ist für Einkäufer wichtig, um den Bestand effektiv zu verwalten und bessere Preise auszuhandeln. Die Einhaltung der MOQ kann sich auch auf die Versandkosten und die allgemeine Beschaffungsstrategie auswirken. -

RFQ (Angebotsanfrage)

Eine Anfrage ist ein formeller Prozess, bei dem Einkäufer Preise und Bedingungen von Lieferanten einholen. Dieser Begriff ist für B2B-Einkäufer von entscheidender Bedeutung, da er ihnen hilft, Angebote zu vergleichen und Verträge auszuhandeln. Eine gut strukturierte Anfrage kann zu einer besseren Preisgestaltung und günstigeren Bedingungen führen. -

Incoterms (Internationale Handelsklauseln)

In den Incoterms werden die Pflichten von Käufern und Verkäufern in Bezug auf Versand, Versicherung und Zölle festgelegt. Die Vertrautheit mit den Incoterms ist für internationale Käufer unerlässlich, um Risiken zu minimieren und ihre Verpflichtungen zu verstehen. Die Verwendung klarer Incoterms kann Streitigkeiten verhindern und die Logistik rationalisieren. -

Vorlaufzeit

Unter Vorlaufzeit versteht man die Zeit, die von der Auftragserteilung bis zum Erhalt der Ware vergeht. Dieser Begriff ist für B2B-Einkäufer entscheidend für die Planung von Lagerbeständen und Produktionsplänen. Die Kenntnis der Durchlaufzeiten hilft den Unternehmen, die betriebliche Effizienz zu erhalten und die Kundenanforderungen zu erfüllen.

Wenn internationale B2B-Einkäufer diese technischen Eigenschaften und Handelsbedingungen kennen, können sie fundierte Entscheidungen treffen und sicherstellen, dass sie die richtigen Autoteile beschaffen, die ihren betrieblichen Anforderungen und Compliance-Anforderungen entsprechen.

Illustratives Bild zu allen Teilen des Fahrzeugs

Navigieren durch Marktdynamik und Beschaffungstrends in allen Bereichen des Automobilsektors

Was sind die aktuelle Marktdynamik und die wichtigsten Trends im Autoteile-Sektor?

Der globale Markt für Kfz-Teile befindet sich in einem tiefgreifenden Wandel, der durch verschiedene Faktoren angetrieben wird, darunter technologischer Fortschritt, veränderte Verbraucherpräferenzen und verstärkter gesetzlicher Druck. Internationale B2B-Einkäufer, insbesondere aus den aufstrebenden Märkten in Afrika, Südamerika, dem Nahen Osten und Europa, müssen sich mit dieser Dynamik auseinandersetzen, um ihre Beschaffungsstrategien zu optimieren.

Einer der bemerkenswertesten Trends ist die zunehmende digitale Transformation der Beschaffungsprozesse. E-Commerce-Plattformen und digitale Marktplätze erfreuen sich zunehmender Beliebtheit und ermöglichen den Käufern den Zugang zu einer größeren Auswahl an Lieferanten und Teilen. Dieser Wandel erleichtert Preisvergleiche und Transparenz und ermöglicht es den Käufern, fundierte Kaufentscheidungen zu treffen. Darüber hinaus verbessert die Integration von künstlicher Intelligenz und maschinellem Lernen in das Lieferkettenmanagement die Bedarfsprognose und das Bestandsmanagement, wodurch Unternehmen ihre Kosten senken und ihre Effizienz steigern können.

Ein weiterer wichtiger Faktor ist die steigende Nachfrage nach Elektro- und Hybridfahrzeugen, die die Art der nachgefragten Teile verändert. Komponenten wie Batterien, Elektromotoren und fortschrittliche elektronische Systeme gewinnen an Bedeutung, was die Lieferanten dazu veranlasst, ihre Angebote zu erneuern und anzupassen. Darüber hinaus beeinflusst das weltweite Streben nach Nachhaltigkeit die Beschaffungspraktiken, wobei die Käufer Lieferanten bevorzugen, die umweltfreundliche Praktiken anwenden.

Illustratives Bild zu allen Teilen des Fahrzeugs

Wie wirken sich Nachhaltigkeit und ethische Beschaffung auf die Autoteileindustrie aus?

Nachhaltigkeit ist zu einem Eckpfeiler der Automobilindustrie geworden und beeinflusst die Beschaffung von Teilen auf allen Ebenen. Die Umweltauswirkungen herkömmlicher Herstellungspraktiken werden von Verbrauchern, Aufsichtsbehörden und Investoren gleichermaßen kritisch beäugt. Infolgedessen ist die ethische Beschaffung keine Option mehr, sondern eine Notwendigkeit für Unternehmen, die sich einen Wettbewerbsvorteil verschaffen wollen.

B2B-Einkäufer müssen den gesamten Lebenszyklus von Automobilteilen berücksichtigen, von der Rohstoffgewinnung bis zur Entsorgung am Ende des Lebenszyklus. Dazu gehört auch die Bewertung der Zulieferer auf der Grundlage ihrer Umweltpraktiken, wie Abfallmanagement, Energieverbrauch und CO2-Fußabdruck. Die Nachfrage nach “grünen” Zertifizierungen und Materialien steigt, da die Käufer zunehmend nach Teilen aus recycelten oder nachhaltig beschafften Materialien suchen. Zertifizierungen wie ISO 14001 (Umweltmanagement) und LEED (Leadership in Energy and Environmental Design) können als Indikatoren für das Engagement eines Lieferanten für Nachhaltigkeit dienen.

Indem sie ethischen Lieferketten Vorrang einräumen, verbessern Unternehmen nicht nur ihren Ruf als Marke, sondern mindern auch die Risiken, die mit der Einhaltung von Vorschriften und Lieferunterbrechungen verbunden sind. Die Betonung der Nachhaltigkeit kann auch zu Kosteneinsparungen durch verbesserte Effizienz und Abfallreduzierung führen.

Wie sieht die historische Entwicklung der Autoteileindustrie aus?

Die Automobilzulieferindustrie hat sich seit der Einführung des Automobils im späten 19. Jahrhundert dramatisch entwickelt. Ursprünglich durch einfache mechanische Komponenten gekennzeichnet, hat sich die Branche zu einem komplexen Netz von Zulieferern entwickelt, die eine breite Palette von Spezialteilen herstellen. Die Einführung von Massenproduktionstechniken im frühen 20. Jahrhundert, verkörpert durch Henry Fords Fließband, revolutionierte den Herstellungsprozess und senkte die Kosten erheblich.

In den letzten Jahrzehnten hat die Globalisierung die Landschaft verändert und die Auslagerung der Teileproduktion in Regionen mit niedrigeren Arbeitskosten ermöglicht. Diese Verlagerung hat nicht nur die Lieferbasis erweitert, sondern auch den Wettbewerb unter den Zulieferern verschärft. Mit dem fortschreitenden technologischen Fortschritt steht die Branche nun vor einer neuen Welle der Umwälzung, insbesondere durch den Aufstieg von Elektrofahrzeugen und intelligenten Technologien. Diese kontinuierliche Entwicklung unterstreicht, wie wichtig es für B2B-Einkäufer ist, über Trends und Innovationen, die sich auf die Beschaffungsstrategien auswirken, informiert zu bleiben.

Illustratives Bild zu allen Teilen des Fahrzeugs

Schlussfolgerung

Zusammenfassend lässt sich sagen, dass die Autoteileindustrie bedeutende Veränderungen durchmacht, die durch technologische Fortschritte, Nachhaltigkeitsanforderungen und sich verändernde Marktanforderungen geprägt sind. B2B-Einkäufer müssen ihre Beschaffungsstrategien anpassen, um diese Komplexität zu bewältigen und sicherzustellen, dass sie wettbewerbsfähig bleiben und mit globalen Trends Schritt halten können. Durch die Nutzung digitaler Tools, die Priorisierung ethischer Beschaffung und das Verständnis des historischen Kontextes können sich Unternehmen für den Erfolg in einem sich schnell entwickelnden Markt positionieren.

Häufig gestellte Fragen (FAQs) für B2B-Käufer aller Autoteile

-

Wie kann ich die Qualität der Autoteile bei der internationalen Beschaffung sicherstellen?

Um die Qualität bei der internationalen Beschaffung von Autoteilen zu gewährleisten, ist eine gründliche Überprüfung der Lieferanten unerlässlich. Beginnen Sie damit, Zertifizierungen wie ISO und Qualitätssicherungsdokumente anzufordern. Nehmen Sie direkten Kontakt mit potenziellen Lieferanten auf, um deren Reaktionsfähigkeit und Bereitschaft zur Bereitstellung von Produktmustern zu prüfen. Ziehen Sie außerdem in Erwägung, wenn möglich die Produktionsstätten zu besuchen oder Inspektionsdienste von Dritten in Anspruch zu nehmen, um die Qualität vor dem Versand zu überprüfen. Der Aufbau einer Beziehung zu zuverlässigen Lieferanten kann ebenfalls das Vertrauen und eine konsistente Qualitätssicherung fördern. -

Wie finde ich am besten zuverlässige Lieferanten für Autoteile?

Um zuverlässige Lieferanten für Autoteile zu finden, müssen Sie mehrere Kanäle nutzen. Online B2B-Marktplätze wie Alibaba oder TradeIndia können Sie mit verschiedenen Herstellern in Verbindung bringen. Die Teilnahme an Branchenmessen und Ausstellungen bietet die Möglichkeit, Lieferanten persönlich zu treffen. Auch die Vernetzung in Foren oder Verbänden der Automobilbranche kann zu Empfehlungen führen. Außerdem sollten Sie Plattformen nutzen, die sich auf Lieferantenbewertungen und -rezensionen spezialisiert haben, um die Glaubwürdigkeit potenzieller Partner zu beurteilen. -

Was sind die üblichen Mindestbestellmengen (MOQ) für Autoteile?

Die Mindestbestellmengen (MOQ) für Autoteile können je nach Lieferant und Art des Teils erheblich variieren. Im Allgemeinen reichen die MOQs von 50 Stück für kleinere Komponenten bis zu mehreren hundert für größere oder spezialisierte Teile. Wenn Sie Ihre spezifischen Anforderungen mit den Lieferanten besprechen, kann dies manchmal zu einer Flexibilität bei den MOQs führen, vor allem, wenn Sie eine Verpflichtung für künftige Aufträge nachweisen können. Klären Sie MOQs immer im Voraus, um unerwartete Kosten zu vermeiden. -

Welche Zahlungsbedingungen sind im internationalen Autoteilehandel üblich?

Zu den Standardzahlungsbedingungen für internationale Geschäfte gehören oft Optionen wie Akkreditiv, Vorauszahlung oder Zahlung bei Lieferung. Viele Lieferanten ziehen eine teilweise Vorauszahlung vor, wobei der Restbetrag vor dem Versand oder bei Erhalt der Ware fällig wird. Die Aushandlung von Zahlungsbedingungen, die beiden Parteien Schutz bieten, ist von entscheidender Bedeutung; ziehen Sie bei Transaktionen mit hohem Wert die Inanspruchnahme von Treuhanddiensten in Betracht. Achten Sie stets darauf, dass die Zahlungsbedingungen im Vertrag klar definiert sind, um Streitigkeiten zu vermeiden. -

Wie kann ich Autoteile für spezifische Marktbedürfnisse maßschneidern?

Die Anpassung von Autoteilen an spezifische Marktanforderungen erfordert in der Regel eine enge Zusammenarbeit mit den Lieferanten. Beginnen Sie mit einer klaren Definition der Spezifikationen und Anforderungen auf der Grundlage regionaler Präferenzen oder Vorschriften. Besprechen Sie mit Ihren Zulieferern Optionen für Änderungen bei Materialien, Abmessungen oder Funktionen. Fordern Sie Prototypen an, um die Passform und Funktionalität zu beurteilen, bevor Sie größere Aufträge vergeben. Denken Sie daran, dass sich Anpassungen auf Vorlaufzeiten und Kosten auswirken können, planen Sie also entsprechend. -

Was sind die wichtigsten logistischen Aspekte beim Import von Autoteilen?

Zu den logistischen Überlegungen für die Einfuhr von Autoteilen gehören Versandmethoden, Zollabfertigung und lokale Vorschriften. Beurteilen Sie anhand der Dringlichkeit und der Kosten, ob Luftfracht oder Seefracht besser geeignet ist. Vergewissern Sie sich, dass Ihr Lieferant alle erforderlichen Unterlagen für den Zoll bereitstellt, z. B. Rechnungen und Packlisten. Informieren Sie sich über die in Ihrem Land anfallenden Einfuhrzölle und Steuern und ziehen Sie die Zusammenarbeit mit einem auf Kfz-Teile spezialisierten Logistikdienstleister in Betracht, um den Prozess zu optimieren. -

Wie gehe ich mit Streitigkeiten mit internationalen Lieferanten um?

Der Umgang mit Streitigkeiten mit internationalen Lieferanten erfordert ein strukturiertes Vorgehen. Beginnen Sie damit, den Vertrag zu prüfen, um die vereinbarten Bedingungen zu verstehen. Kommunizieren Sie offen und professionell mit dem Lieferanten, um Ihre Bedenken zu äußern. Kommt keine Lösung zustande, sollten Sie die Einschaltung eines Schlichters oder einer Schlichtungsstelle in Erwägung ziehen, wie in Ihrem Vertrag festgelegt. Das Führen von Aufzeichnungen über alle Kommunikationen und Transaktionen kann von unschätzbarem Wert sein, um Streitigkeiten wirksam beizulegen. -

Was sind die besten Praktiken für die Verwaltung des Bestands an Autoteilen?

Zu den bewährten Verfahren für die Verwaltung der Bestände an Autoteilen gehört die Einführung eines Bestandsverwaltungssystems, das die Lagerbestände in Echtzeit verfolgt. Die regelmäßige Überprüfung von Verkaufsdaten kann helfen, die Nachfrage vorherzusagen und die Bestellungen entsprechend anzupassen. Legen Sie Nachbestellungspunkte fest, um Fehlbestände zu vermeiden, und erwägen Sie Just-in-Time-Bestandsstrategien, um die Lagerkosten zu senken. Darüber hinaus kann die Pflege enger Beziehungen zu den Lieferanten eine schnellere Wiederauffüllung der Bestände ermöglichen und die Effizienz der Lieferkette insgesamt verbessern.

Ein Blick auf alle Teile der Autohersteller und -lieferanten

Ich konnte nicht genügend Lieferanten für alle Teile des Fahrzeugs verifizieren, um eine Liste zu erstellen.

Strategische Beschaffung Fazit und Ausblick für alle Teile des Autos

Die Beschaffungslandschaft für Kfz-Teile entwickelt sich ständig weiter, angetrieben von technologischen Fortschritten und Verschiebungen auf den globalen Märkten. Für B2B-Einkäufer, vor allem in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, ist die strategische Beschaffung von Fahrzeugteilen nicht nur eine Transaktionsaktivität, sondern ein entscheidender Aspekt für die Erhaltung der Wettbewerbsfähigkeit und die Gewährleistung der betrieblichen Effizienz. Die Priorisierung von Qualität, Zuverlässigkeit und Kosteneffizienz bei Beschaffungsentscheidungen kann die Leistung der Fahrzeuge und die Kundenzufriedenheit erheblich verbessern.

Das Verständnis der komplexen Zusammenhänge zwischen verschiedenen Autoteilen - wie Motoren, Getrieben und Bremssystemen - ermöglicht es Einkäufern, fundierte Entscheidungen zu treffen, die die Integrität des Fahrzeugs insgesamt verbessern. Durch die Nutzung von Datenanalysen und den Aufbau starker Partnerschaften mit Zulieferern können Unternehmen Markttrends vorhersehen, Risiken verwalten und ihre Lieferketten optimieren.

Mit Blick auf die Zukunft werden Nachhaltigkeit und Innovation die Zukunft der Beschaffung von Automobilteilen prägen. Internationale Einkäufer werden ermutigt, mit Lieferanten zusammenzuarbeiten, die umweltfreundliche Praktiken und Spitzentechnologien in den Vordergrund stellen. Auf diese Weise stellen Sie nicht nur eine stabile Lieferkette sicher, sondern tragen auch zu einer nachhaltigeren Automobilbranche bei. Ergreifen Sie noch heute Maßnahmen, um Ihre strategischen Beschaffungskapazitäten zu verbessern und im Wettbewerb der Automobilbranche die Nase vorn zu haben.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

Illustratives Bild zu allen Teilen des Fahrzeugs

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.