Introduction: Navigating the Global Market for starting motor

Navigating the intricate landscape of the global market for starting motors can be a daunting challenge for international B2B buyers. As demand for reliable and efficient vehicle ignition systems grows across regions such as Africa, South America, the Middle East, and Europe, sourcing high-quality starting motors has never been more critical. This guide is designed to address the complexities involved in procuring these essential components, from understanding the various types of starting motors to exploring their applications in different vehicle models.

Buyers will find insights on supplier vetting processes, ensuring that partnerships are established with reputable manufacturers and distributors. Additionally, we will delve into cost considerations, providing a framework for comparing pricing structures across diverse markets. Understanding the nuances of starting motor technology, including key components and their functions, will empower buyers to make informed purchasing decisions that align with their operational needs.

By equipping B2B buyers with essential knowledge and strategic insights, this guide not only simplifies the sourcing process but also enhances the potential for successful procurement outcomes. Whether you’re based in Germany, Brazil, or beyond, this comprehensive resource serves as a vital tool to navigate the global starting motor market with confidence and precision.

Inhaltsverzeichnis

- Top 2 Starting Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starting motor

- Understanding starting motor Types and Variations

- Key Industrial Applications of starting motor

- 3 Common User Pain Points for ‘starting motor’ & Their Solutions

- Strategic Material Selection Guide for starting motor

- In-depth Look: Manufacturing Processes and Quality Assurance for starting motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starting motor’

- Comprehensive Cost and Pricing Analysis for starting motor Sourcing

- Alternatives Analysis: Comparing starting motor With Other Solutions

- Essential Technical Properties and Trade Terminology for starting motor

- Navigating Market Dynamics and Sourcing Trends in the starting motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starting motor

- Strategic Sourcing Conclusion and Outlook for starting motor

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding starting motor Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Konventioneller Anlasser | Utilizes a DC motor and solenoid to engage the flywheel. | Automobilindustrie, Schwermaschinen | Vorteile: Zuverlässig, weit verbreitet. Nachteile: Prone to wear and tear over time. |

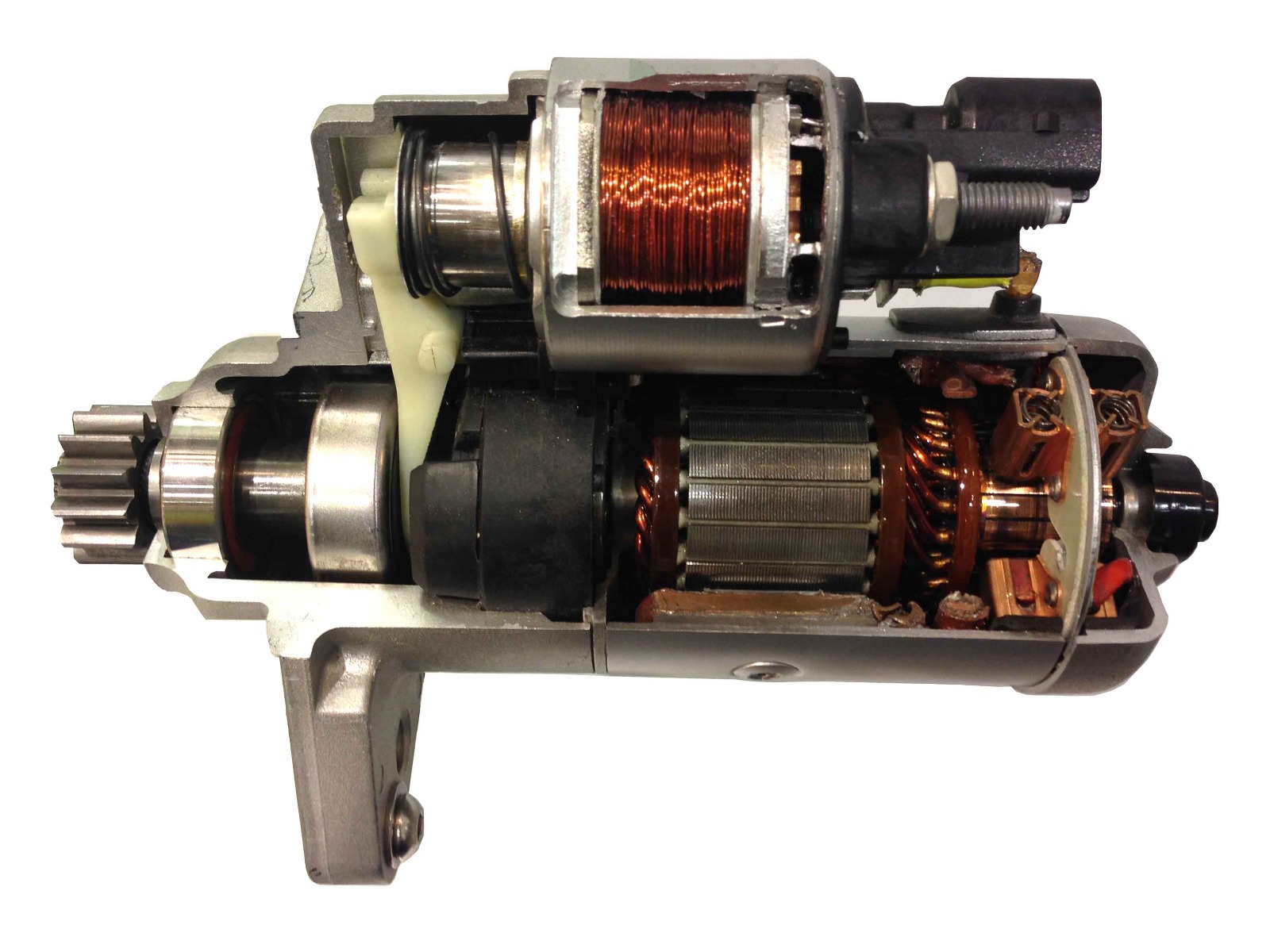

| Untersetzungsgetriebe Anlasser | Features a gear reduction system for increased torque. | High-performance vehicles, Commercial Vehicles | Vorteile: Higher torque, efficient. Nachteile: Komplexer, potenziell höhere Kosten. |

| Permanentmagnet-Startermotor | Uses permanent magnets instead of electromagnets. | Electric vehicles, Small engines | Vorteile: Compact, lightweight. Nachteile: Limited torque compared to conventional types. |

| Hochleistungs-Startermotor | Designed for racing and high-demand applications. | Motorsports, Performance vehicles | Vorteile: Superior performance, durable. Nachteile: Higher price point, specific use cases. |

| Bendix Drive Starter Motor | Incorporates a Bendix drive mechanism for engagement. | Standard-Automobilanwendungen | Vorteile: Simple design, easy replacement. Nachteile: Mechanical failure risk if not maintained. |

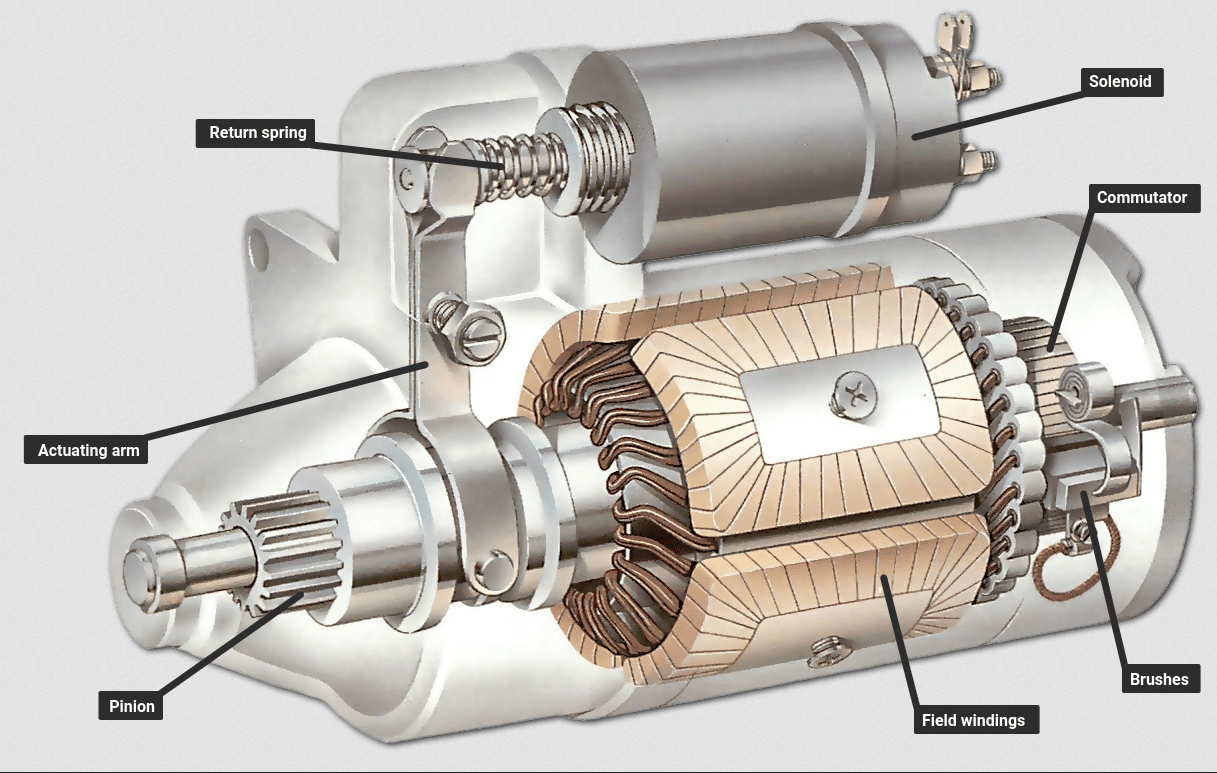

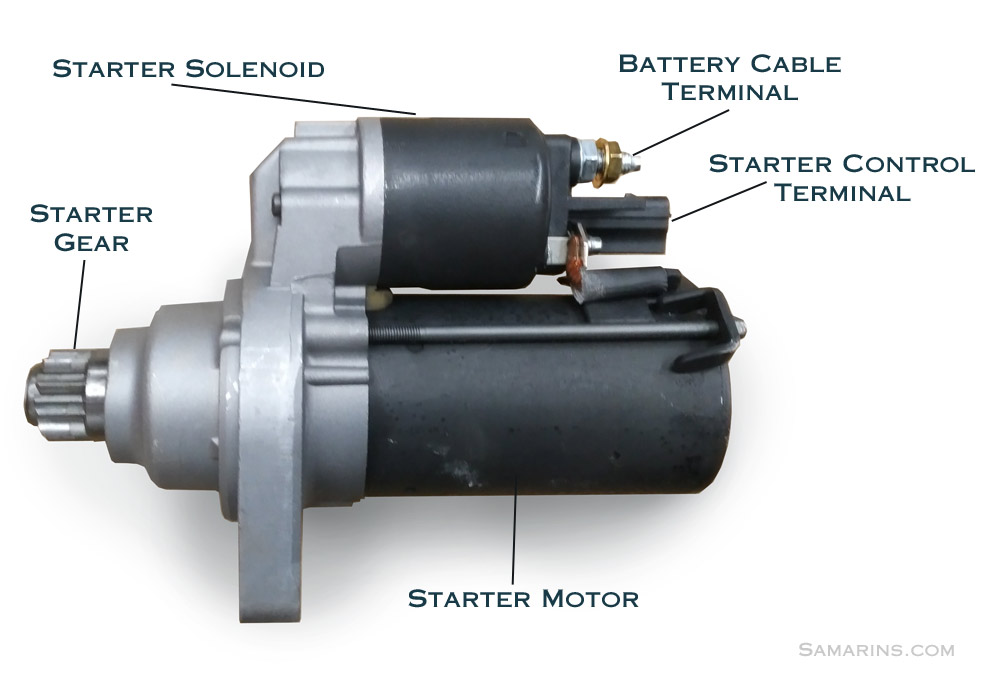

What are the Characteristics of Conventional Starter Motors?

Conventional starter motors are the most common type used in internal combustion engines. They employ a direct current (DC) motor and solenoid to engage the flywheel, initiating the engine’s combustion process. Their simplicity and reliability make them a standard choice for automotive applications, particularly in passenger vehicles and heavy machinery. B2B buyers should consider the availability of replacement parts and the ease of maintenance, as these motors can experience wear over time.

Wie verbessern Startermotoren mit Untersetzungsgetriebe die Leistung?

Gear reduction starter motors utilize a gear system to amplify torque, making them ideal for high-performance and commercial vehicles. This design allows for a smaller motor size while delivering the necessary power to start larger engines. For B2B buyers, the efficiency and durability of gear reduction starters can lead to reduced downtime and maintenance costs, making them a preferred choice for demanding applications.

What Makes Permanent Magnet Starter Motors Suitable for Electric Vehicles?

Permanent magnet starter motors are compact and lightweight, making them particularly suitable for electric vehicles and small engines. They operate using permanent magnets rather than electromagnets, which enhances their efficiency and reduces power consumption. B2B buyers should evaluate the specific torque requirements of their applications, as these motors may not deliver the same torque levels as conventional starters, but their efficiency can lead to overall cost savings.

Why Choose High-Performance Starter Motors for Motorsports?

High-performance starter motors are engineered for racing and high-demand applications, where reliability and power are critical. These motors are built to withstand extreme conditions and provide superior starting performance. For B2B buyers in the motorsports industry, investing in high-performance starters can enhance vehicle reliability and performance, though the higher price point should be justified by the specific performance needs of the application.

What are the Benefits of Bendix Drive Starter Motors?

Bendix drive starter motors feature a simple mechanical engagement system that connects the motor to the flywheel. This design is prevalent in standard automotive applications and is known for its ease of replacement. However, B2B buyers should be aware of the potential for mechanical failures if these motors are not maintained properly. Regular servicing and inspections can mitigate risks and ensure optimal performance.

Key Industrial Applications of starting motor

| Branche/Sektor | Specific Application of starting motor | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Engine assembly for vehicles | Ensures reliable engine start-up, enhancing production efficiency | Quality assurance, compatibility with various vehicle models, and compliance with international standards |

| Landwirtschaft | Starting motors in tractors and harvesters | Facilitates reliable operation in remote areas, ensuring timely harvesting | Durability in harsh environments, ease of maintenance, and availability of spare parts |

| Marine | Starting motors in boats and ships | Critical for engine ignition, enhancing safety and operational readiness | Resistance to corrosion, performance in extreme conditions, and compliance with maritime regulations |

| Bauwesen | Schwermaschinen und -geräte | Ensures quick start-up for productivity on job sites | Robust design for reliability, adherence to safety standards, and support for various power configurations |

| Bergbau | Equipment start-up in mining operations | Essential for operational efficiency and minimizing downtime | Resistance to dust and moisture, compatibility with heavy-duty applications, and availability of technical support |

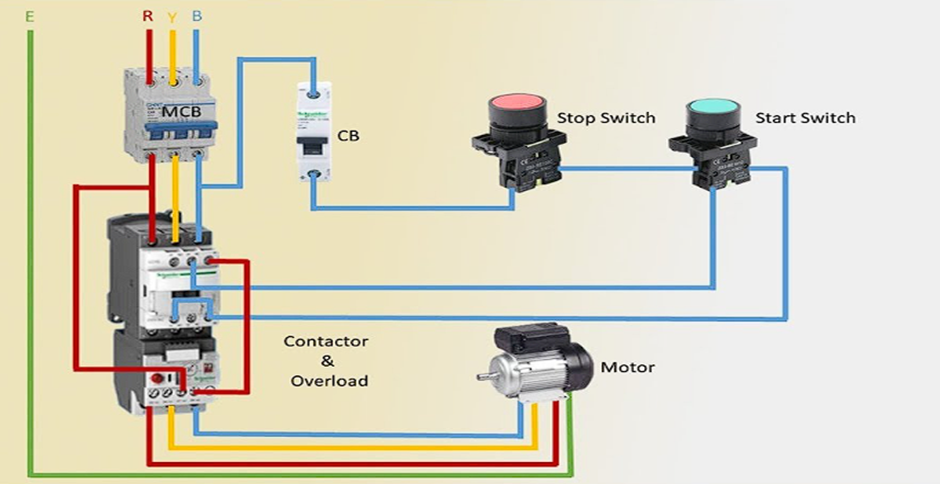

How is the Starting Motor Used in Automotive Manufacturing?

In automotive manufacturing, starting motors are vital components in the engine assembly process. They provide the necessary torque to crank engines, ensuring reliable start-up during production. This reliability translates into enhanced production efficiency and reduced downtime, which is critical for meeting demand in competitive markets. Buyers in this sector must prioritize sourcing high-quality starter motors that meet specific vehicle model requirements and adhere to international automotive standards, especially in regions like Europe and South America where regulations may vary.

What Role Do Starting Motors Play in Agriculture?

In the agriculture sector, starting motors are integral to the operation of tractors and harvesters, particularly in remote areas where reliability is crucial. They enable quick engine start-up, facilitating timely agricultural tasks such as planting and harvesting, which can significantly impact yield. Buyers should consider the durability of starting motors, as they must withstand harsh environmental conditions, and ensure easy maintenance and availability of spare parts to minimize operational interruptions.

How are Starting Motors Essential for Marine Applications?

Starting motors are essential for boats and ships, providing the ignition needed to start marine engines. This functionality is critical for safety and operational readiness, especially in commercial shipping and recreational boating. When sourcing starting motors for marine applications, buyers should focus on components that offer resistance to corrosion and reliable performance under extreme conditions, as well as compliance with maritime regulations to ensure safety and longevity.

Why are Starting Motors Important in Construction?

In construction, starting motors are crucial for heavy machinery and equipment, enabling quick start-up to enhance productivity on job sites. The ability to start machinery efficiently can significantly reduce downtime and improve project timelines. Buyers in this sector should look for robust starter motors designed for reliability and safety, ensuring they meet the specific power configurations required for various machines while also considering the availability of technical support and service.

What is the Importance of Starting Motors in Mining Operations?

Starting motors play a critical role in mining operations by facilitating the start-up of heavy equipment, which is essential for operational efficiency. Reliable ignition systems minimize downtime, allowing mining companies to maintain productivity levels. When sourcing starting motors for mining applications, buyers should focus on features like resistance to dust and moisture, compatibility with heavy-duty machinery, and the availability of local technical support to address any operational issues promptly.

3 Common User Pain Points for ‘starting motor’ & Their Solutions

Scenario 1: Frequent Starter Motor Failures in Fleet Vehicles

Das Problem: For B2B buyers managing fleets, such as transportation companies or logistics providers, frequent starter motor failures can lead to significant downtime and increased operational costs. When a starter motor fails, it not only halts vehicle operations but can also disrupt supply chains, leading to delayed deliveries and dissatisfied customers. Fleet managers may find themselves caught in a cycle of repairs and replacements, which can strain budgets and resources.

Die Lösung: To mitigate these issues, it is crucial to establish a proactive maintenance program that includes regular diagnostics and inspections of starter motors across the fleet. Invest in high-quality starter motors from reputable suppliers known for their durability and performance. Consider sourcing starter motors with warranties or guarantees that allow for returns or exchanges if issues arise shortly after installation. Additionally, educate your maintenance team on the signs of starter motor wear, such as unusual noises or slow engine cranking, to catch problems before they escalate. Implementing a standard operating procedure for regular checks, especially before peak operational periods, can significantly reduce the incidence of unexpected failures.

Scenario 2: Incompatibility Issues with Diverse Vehicle Models

Das Problem: B2B buyers in sectors like construction or agriculture often deal with a variety of vehicle models and types. This diversity can lead to challenges when sourcing starter motors that are compatible with different machines. Incorrect specifications or model mismatches can result in costly delays in repairs or replacements, as well as wasted inventory.

Die Lösung: To overcome compatibility issues, it’s essential to maintain a comprehensive inventory management system that tracks the specifications of starter motors for each vehicle model in use. Work closely with suppliers to ensure they provide detailed product information, including compatibility charts and technical specifications. When placing orders, always double-check vehicle VINs (Vehicle Identification Numbers) to confirm that the starter motor matches the requirements. Building strong relationships with a few trusted suppliers can also facilitate quicker access to the correct parts and enable better negotiation on bulk orders, ensuring that you have the right starter motors on hand when needed.

Scenario 3: High Costs of Starter Motor Replacement

Das Problem: Many B2B buyers are concerned about the high costs associated with starter motor replacements, particularly in industries where equipment downtime can lead to substantial financial losses. The price of quality starter motors can vary widely, and without a strategic sourcing approach, companies may end up overpaying or purchasing subpar products that fail prematurely.

Die Lösung: To manage costs effectively, consider implementing a strategic sourcing strategy that evaluates both quality and price. Conduct a thorough market analysis to identify reliable manufacturers that offer competitive pricing without compromising on quality. Establish long-term partnerships with these suppliers to leverage volume discounts or favorable terms. Additionally, consider investing in refurbished or remanufactured starter motors from reputable vendors as a cost-effective alternative. Ensure that any refurbished products come with a warranty to protect your investment. Regularly review and analyze your purchasing data to identify trends and adjust your sourcing strategy accordingly, ensuring you remain cost-efficient while maintaining the reliability of your fleet.

Strategic Material Selection Guide for starting motor

What are the Key Materials Used in Starter Motors?

When selecting materials for starter motors, it is essential to consider properties that directly influence performance, durability, and compatibility with various operating environments. Here, we analyze four common materials used in starter motor construction: steel, aluminum, copper, and plastic composites.

Wie verhält sich Stahl in Anlasseranwendungen?

Steel is a primary material used in the construction of starter motor housings and components due to its strength and durability. Key properties include high tensile strength and excellent wear resistance, making it suitable for high-pressure applications. However, steel can be prone to corrosion, particularly in humid or saline environments, which may lead to premature failure if not properly coated.

Pro und Kontra:

– Vorteile: High durability, cost-effective, readily available.

– Nachteile: Heavier than alternatives, potential for corrosion without protective coatings.

For international buyers, particularly in regions with high humidity like parts of Africa and South America, selecting corrosion-resistant coatings (like galvanization) is critical. Compliance with standards such as ASTM A36 can ensure quality and performance.

Why is Aluminum a Preferred Choice for Starter Motors?

Aluminum is increasingly favored in starter motor applications due to its lightweight nature and excellent corrosion resistance. It has a lower density compared to steel, which contributes to reduced overall weight, enhancing fuel efficiency in vehicles. Aluminum also has good thermal conductivity, which helps dissipate heat generated during operation.

Pro und Kontra:

– Vorteile: Lightweight, corrosion-resistant, good thermal properties.

– Nachteile: Generally more expensive than steel, lower tensile strength.

For buyers in Europe, especially Germany, where lightweight materials are prioritized for efficiency, aluminum can meet the stringent automotive standards (DIN EN 573). However, the higher cost may be a consideration for budget-conscious buyers in developing markets.

Illustrative image related to starting motor

Welche Rolle spielt Kupfer in Anlasser-Motoren?

Copper is predominantly used in the electrical components of starter motors, such as windings and connections, due to its excellent electrical conductivity. This material ensures efficient energy transfer, which is crucial for the quick engagement of the starter motor. Copper also has good thermal properties, allowing it to handle the heat generated during operation.

Pro und Kontra:

– Vorteile: High electrical conductivity, good thermal resistance, reliable performance.

– Nachteile: Higher cost, prone to oxidation if not protected.

International buyers should consider the implications of copper pricing fluctuations, which can affect overall costs. Compliance with standards like ASTM B170 for copper wire can assure quality. In regions like the Middle East, where temperatures can be extreme, ensuring proper insulation and protection against oxidation is vital.

Illustrative image related to starting motor

Wie verbessern Kunststoff-Verbundwerkstoffe die Funktionalität von Anlasser-Motoren?

Plastic composites are increasingly used in non-structural components of starter motors, such as housings and insulators. They offer excellent resistance to corrosion and are lightweight, contributing to overall energy efficiency. Additionally, plastics can be molded into complex shapes, allowing for innovative designs that optimize space and functionality.

Pro und Kontra:

– Vorteile: Lightweight, corrosion-resistant, versatile in design.

– Nachteile: Lower mechanical strength compared to metals, limited temperature resistance.

For B2B buyers, especially in regions like South America, where manufacturing processes may vary, it is essential to ensure that the selected plastic composites meet relevant standards (like ASTM D638). Understanding the temperature and chemical exposure in specific applications is crucial for ensuring longevity.

Übersichtstabelle zur Materialauswahl für Anlasser

| Material | Typical Use Case for starting motor | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Gehäuse und Bauteile | Hohe Lebensdauer | Korrosionsanfällig | Niedrig |

| Aluminium | Lightweight housings and components | Hervorragende Korrosionsbeständigkeit | Higher cost than steel | Med |

| Kupfer | Elektrische Wicklungen und Steckverbinder | Hohe elektrische Leitfähigkeit | Anfällig für Oxidation | Hoch |

| Kunststoffverbundwerkstoffe | Nicht-strukturelle Komponenten | Leicht und korrosionsbeständig | Geringere mechanische Festigkeit | Med |

This strategic material selection guide provides insights into the various materials used in starter motors, emphasizing their properties, advantages, and limitations. Understanding these factors is crucial for international B2B buyers to make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for starting motor

What Are the Main Stages of Manufacturing a Starting Motor?

The manufacturing process of a starter motor involves several critical stages, each designed to ensure the final product meets performance and quality standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Starter Motor Manufacturing?

Material preparation begins with the selection of high-quality raw materials. Key components of a starter motor, such as the armature, solenoid, and housing, are typically made from materials like laminated soft iron, copper, and various types of plastic.

The materials are subjected to rigorous quality checks to ensure they meet specific international standards. This includes verifying their composition and mechanical properties. Once approved, the materials are cut, shaped, and treated as necessary to prepare them for the forming stage.

What Techniques Are Used in the Forming Stage of Starter Motors?

The forming process often involves techniques such as stamping, machining, and casting. For instance, the armature is usually manufactured through a combination of stamping and winding processes. Stamping is used to create the core, while copper wire is wound around it to form the coils.

In the case of the housing, die casting is a common technique, allowing for precise shapes and a high-quality surface finish. The components are then treated with coatings to enhance their durability and resistance to corrosion, which is crucial for the longevity of the starter motor in various environmental conditions.

How Is the Assembly of Starter Motors Conducted?

The assembly of the starter motor is a meticulous process that requires precision and attention to detail. This stage typically involves the integration of several components, including the armature, commutator, brushes, and solenoid.

During assembly, each part is tested for compatibility and functionality. Automated assembly lines are often utilized to enhance efficiency and consistency. Skilled technicians may also be involved in critical assembly stages to ensure that everything is fitted correctly, particularly in areas where precision is paramount, such as the alignment of the pinion gear with the flywheel.

What Finishing Processes Are Involved in Starter Motor Manufacturing?

Once assembled, starter motors undergo finishing processes that include quality inspections, painting, and packaging. Quality checks at this stage involve visual inspections and functionality tests to ensure that the motor operates correctly under simulated conditions.

Finishing also includes applying protective coatings that enhance the motor’s resistance to environmental factors, such as moisture and dust. This is particularly important for markets in Africa and South America, where climatic conditions can be harsh.

Welche Qualitätssicherungsnormen sind für Anlasser relevant?

Quality assurance is critical in the manufacturing of starter motors, and international standards play a significant role. Adherence to ISO 9001 standards ensures that manufacturers maintain consistent quality management systems throughout their operations.

In addition to ISO standards, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) are also essential for compliance in various markets. These certifications not only guarantee product safety and reliability but also help in building trust with international buyers.

Wie werden die Qualitätskontrollpunkte während der Herstellung festgelegt?

Quality control (QC) checkpoints are strategically integrated into the manufacturing process to ensure that each component meets quality standards. These checkpoints typically include:

Illustrative image related to starting motor

-

Eingangsqualitätskontrolle (IQC): Dabei werden die Rohstoffe und Komponenten bei ihrer Ankunft kontrolliert, um sicherzustellen, dass sie den vorgegebenen Standards entsprechen, bevor die Produktion beginnt.

-

In-Process-Qualitätskontrolle (IPQC): Throughout the manufacturing process, various inspections and tests are performed to monitor the quality of components at different stages, ensuring any issues are identified and rectified early.

-

Endkontrolle (FQC): Before the starter motors are packaged and shipped, they undergo final testing to verify their functionality and safety. This may include electrical testing, performance assessment, and environmental simulations.

Welche gängigen Prüfverfahren werden verwendet, um die Qualität von Anlassern sicherzustellen?

Testing methods for starter motors can vary but often include:

-

Elektrische Prüfung: This checks for proper voltage and current flow, ensuring the motor operates as intended.

-

Leistungsprüfung: Assessing the motor under load conditions to simulate real-world usage. This helps to identify any potential failures during operation.

-

Haltbarkeitsprüfung: Subjecting the starter motor to extreme conditions, such as high temperatures or humidity, to ensure reliability over time.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

For B2B buyers, especially those sourcing from international markets, verifying the quality control practices of suppliers is essential. Here are several strategies to ensure the quality of starter motors:

-

Lieferantenaudits: Conducting regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes. This can be done through on-site visits or by reviewing their quality management systems.

-

Anforderung von Qualitätsberichten: Suppliers should be able to provide documentation of their quality control processes, including IQC, IPQC, and FQC results.

-

Inspektionen durch Dritte: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures.

Welche Nuancen sollten internationale Einkäufer bei der Qualitätskontrolle beachten?

International buyers, particularly from regions like Africa, South America, and the Middle East, should be aware of several nuances in quality control:

-

Kulturelle Unterschiede: Understanding the cultural context of suppliers can help in building effective communication and cooperation regarding quality expectations.

-

Einhaltung gesetzlicher Vorschriften: Different regions may have specific regulatory requirements, and it’s crucial for buyers to ensure that suppliers are compliant with local laws and international standards.

-

Logistics and Supply Chain Issues: Quality can also be affected by logistics, so buyers should consider how transportation and storage conditions can impact the performance of starter motors.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing starter motors, ensuring they partner with reliable suppliers who meet their quality expectations.

Illustrative image related to starting motor

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starting motor’

To assist B2B buyers in the procurement of starter motors, this practical sourcing guide provides a structured checklist. This guide is designed to streamline the sourcing process, ensuring that you make informed decisions that align with your operational needs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before reaching out to suppliers, clearly outline your technical requirements for the starter motor. Consider factors such as voltage, power output, and compatibility with various engine types. Precise specifications help avoid misunderstandings and ensure that the product meets your operational demands.

- Voltage and Power Output: Confirm the voltage requirements (typically 12V or 24V) and the power output necessary for your engines.

- Kompatibilität: Ensure the starter motor is compatible with the specific vehicle models or machinery you are using.

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research to identify potential suppliers who specialize in starter motors. Look for companies with a solid reputation in the industry, particularly those with experience in your region, such as Africa, South America, the Middle East, or Europe.

- Branchenerfahrung: Evaluate suppliers’ experience, focusing on their history in manufacturing or supplying starter motors.

- Customer Reviews: Seek testimonials or reviews from other businesses that have previously engaged with the suppliers.

Schritt 3: Lieferantenzertifizierungen überprüfen

Ensure that the suppliers possess relevant certifications, such as ISO 9001 or quality management certifications. This step is essential to confirm that the products meet international quality standards and are safe for use.

- Qualitätssicherung: Certifications indicate adherence to quality control processes, minimizing the risk of defective products.

- Compliance: Check for compliance with regional regulations regarding automotive components.

Schritt 4: Muster zum Testen anfordern

Before placing a bulk order, request samples of the starter motors you are considering. Testing samples allows you to evaluate the quality and performance under real operational conditions.

- Leistungstests: Assess the starting performance, durability, and noise levels of the samples.

- Fit and Compatibility: Ensure that the samples fit correctly within your engine systems.

Schritt 5: Bewerten Sie Preisgestaltung und Zahlungsbedingungen

Analyze the pricing structure of the starter motors while considering the overall value rather than just the cost. Additionally, negotiate favorable payment terms that suit your cash flow needs.

- Mengenrabatte: Inquire about discounts for bulk orders, which can significantly reduce costs.

- Flexibilität bei der Zahlung: Look for suppliers that offer flexible payment terms, such as credit options or installment plans.

Schritt 6: Kundenbetreuung und Garantie bewerten

Inquire about after-sales support and warranty policies provided by the supplier. A strong warranty and responsive customer service can save you time and costs associated with repairs or replacements.

- Dauer der Garantie: Check the duration and coverage of the warranty offered on the starter motors.

- Support Availability: Ensure that the supplier provides accessible support channels for troubleshooting and technical assistance.

Schritt 7: Finalize the Contract and Place Your Order

Once all evaluations are complete and you are satisfied with your chosen supplier, finalize the contract. Ensure that all terms, including delivery timelines and specifications, are clearly outlined to avoid future disputes.

Illustrative image related to starting motor

- Vertragsüberprüfung: Carefully review the contract for any hidden clauses or fees.

- Order Confirmation: Confirm the order details in writing to maintain clarity and accountability.

By following these steps, you can effectively source starter motors that meet your operational needs while ensuring quality and reliability in your procurement process.

Comprehensive Cost and Pricing Analysis for starting motor Sourcing

Understanding the cost structure and pricing of starter motors is crucial for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. This analysis will break down the components that influence costs, the factors affecting pricing, and provide actionable insights for buyers looking to optimize their sourcing strategies.

What Are the Key Cost Components for Starter Motors?

The total cost of sourcing starter motors can be categorized into several key components:

-

Materialien: The primary materials used in starter motors include copper for wiring, steel for the housing, and various alloys for gears and other components. Prices for these materials fluctuate based on global supply and demand, which can significantly impact overall costs.

-

Arbeit: Labor costs vary widely by region. In countries with higher labor costs, such as Germany, the manufacturing expenses will be higher compared to countries in Africa or South America. Skilled labor is often required for assembly and quality control, which can add to costs.

-

Fertigungsgemeinkosten: This includes expenses related to factory operation, utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead, but these savings may not always be passed on to the buyer.

-

Werkzeuge: Custom tooling for specific starter motor designs or modifications can represent a significant upfront investment. Buyers should consider whether the tooling costs can be amortized over a large production volume to reduce per-unit costs.

-

Qualitätskontrolle (QC): Ensuring the reliability and performance of starter motors involves rigorous testing and quality assurance processes. The costs associated with QC are essential to mitigate risks of defects, especially for critical automotive components.

-

Logistik: Shipping and handling costs can vary based on the geographical location of suppliers and buyers. Understanding the Incoterms (International Commercial Terms) that govern these transactions can help buyers manage these costs effectively.

-

Marge: Suppliers typically add a markup to cover their costs and earn a profit. This margin can vary based on supplier reputation, market demand, and competition.

What Influences the Pricing of Starter Motors?

Several factors play a role in determining the final price of starter motors:

-

Menge/Mindestbestellmenge: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders usually benefit from economies of scale, leading to lower per-unit costs.

-

Spezifikationen und Anpassung: Custom-built starter motors or those with specific performance characteristics may incur higher costs due to unique design and manufacturing requirements.

-

Materialqualität und Zertifizierungen: Higher-quality materials and components often lead to better performance and durability, but they come at a premium. Certifications (e.g., ISO, TS16949) can also add costs but are critical for ensuring compliance with international standards.

-

Lieferantenfaktoren: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more due to their brand value and reliability.

Welche Tipps können Käufern helfen, bessere Preise zu verhandeln?

-

Verhandlung: Engage suppliers in discussions about pricing, especially when placing bulk orders. Be clear about your expectations and explore options for discounts based on order size or long-term contracts.

-

Kosteneffizienz: Evaluate the total cost of ownership (TCO), which includes initial purchase price, installation costs, and potential maintenance expenses. A higher upfront cost may be justified if the product offers greater reliability and lower long-term maintenance.

-

Understanding Pricing Nuances: International buyers should be aware of how exchange rates, local tariffs, and import duties can affect pricing. It’s essential to consider these factors when comparing prices from different regions.

-

Beziehungen zu den Lieferanten: Building strong relationships with suppliers can lead to better pricing and terms. Consider long-term partnerships rather than one-off transactions.

Haftungsausschluss zu Preisen

It is important to note that the prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Buyers are encouraged to conduct thorough market research and seek multiple quotes to ensure competitive pricing.

By understanding the cost structure, pricing influencers, and negotiation strategies, international B2B buyers can make informed decisions when sourcing starter motors, ensuring they receive the best value for their investments.

Alternatives Analysis: Comparing starting motor With Other Solutions

Understanding Alternatives to Starting Motors

When considering vehicle ignition systems, it’s crucial for B2B buyers to explore alternatives to traditional starting motors. While starting motors are widely used in internal combustion engines, advancements in technology have introduced alternative solutions that may offer unique benefits depending on specific applications and operational requirements.

Vergleichstabelle

| Vergleichsaspekt | Starting Motor | Alternative 1: Electric Starter Systems | Alternative 2: Compressed Air Start Systems |

|---|---|---|---|

| Leistung | Reliable for cranking engines; effective in various climates | High torque output; minimal maintenance required | Quick engagement; suitable for heavy machinery |

| Kosten | Moderate initial cost; long-term reliability | Higher upfront investment; lower operating costs | Variable costs depending on air compressor quality |

| Einfache Implementierung | Standard in most vehicles; straightforward installation | Requires integration with battery systems | Needs an air supply infrastructure; more complex |

| Wartung | Regular checks needed; wear and tear possible | Low maintenance; few moving parts | Regular checks on air compressor and hoses |

| Bester Anwendungsfall | Ideal for traditional vehicles and machinery | Best for electric vehicles and hybrid models | Suitable for industrial applications and large engines |

Detaillierte Aufschlüsselung der Alternativen

Electric Starter Systems

Electric starter systems are becoming increasingly popular, particularly in electric and hybrid vehicles. These systems utilize electric motors to turn the engine and can provide high torque output, which is essential for starting larger engines. The main advantage is their minimal maintenance requirements, as they typically have fewer moving parts compared to traditional starting motors. However, they come with a higher upfront investment, which may deter some buyers. These systems are best suited for modern vehicles that prioritize efficiency and sustainability.

Compressed Air Start Systems

Compressed air start systems leverage pneumatic power to crank engines, making them particularly useful in industrial settings and for heavy machinery. Their quick engagement allows for efficient starting, especially in environments where electrical systems may be less reliable. However, the implementation of such systems can be complex, requiring a reliable air supply infrastructure, which may increase setup costs. Additionally, while they provide advantages in specific applications, they might not be suitable for standard passenger vehicles.

Schlussfolgerung: Wie man die richtige Lösung wählt

For B2B buyers evaluating ignition solutions, the choice between a starting motor and its alternatives should hinge on specific operational needs and cost considerations. If reliability and ease of maintenance are paramount, traditional starting motors remain a strong choice. However, for organizations looking to invest in future-proof technology, electric starter systems might provide better long-term benefits. Conversely, for applications involving heavy machinery or where air systems are already in place, compressed air start systems can offer significant advantages. Ultimately, understanding the unique requirements of your operation will guide you in selecting the most appropriate solution.

Essential Technical Properties and Trade Terminology for starting motor

What Are the Key Technical Properties of a Starting Motor?

Understanding the essential technical properties of a starting motor is crucial for B2B buyers, especially those sourcing components for automotive applications. Here are some critical specifications to consider:

Illustrative image related to starting motor

1. Material Klasse

The material used in starter motors typically includes high-grade steel for the housing and copper for electrical components. The choice of materials affects durability, weight, and performance. For example, high-grade steel can resist corrosion, which is particularly important in humid or coastal environments, while copper ensures optimal conductivity.

2. Torque Rating

The torque rating indicates the rotational force the starter motor can exert to crank the engine. This specification is vital as it directly impacts the ability to start engines of varying sizes and types. A higher torque rating is essential for larger engines, such as diesel engines, which require more power to initiate the combustion process.

3. Nennspannung

Most starter motors operate at 12V or 24V systems. The voltage rating determines compatibility with vehicle electrical systems. Buyers must ensure that the starter motor matches the vehicle’s voltage to avoid electrical failures or performance issues.

Illustrative image related to starting motor

4. Gear Reduction Ratio

The gear reduction ratio signifies the relationship between the motor’s speed and the output speed delivered to the flywheel. A higher gear reduction ratio means more torque at the output, which is critical for successfully starting larger engines. This specification is particularly relevant for industries dealing with commercial vehicles or heavy machinery.

5. Temperature Tolerance

Starter motors need to operate effectively across a range of temperatures. The temperature tolerance specification indicates the extremes within which the motor can function without failure. This is particularly important in regions with harsh climates, ensuring reliability and longevity.

6. Duty Cycle

The duty cycle refers to the duration a starter motor can operate continuously without overheating. It is crucial for applications where frequent starts are required, such as in fleet vehicles or machinery. Understanding this specification helps buyers select motors that can handle their operational demands without risking damage.

Was sind gängige Fachbegriffe im Zusammenhang mit Anlassern?

Familiarity with industry jargon can streamline the procurement process. Here are several essential trade terms relevant to starter motors:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold under another company’s brand name. In the context of starter motors, purchasing OEM components ensures compatibility and reliability since they are designed to meet specific vehicle standards.

2. MOQ (Mindestbestellmenge)

MOQ represents the smallest quantity a supplier is willing to sell. Understanding MOQ is vital for buyers, especially when managing budgets and inventory levels. It helps in negotiating bulk orders that can reduce per-unit costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. In the case of starter motors, a well-prepared RFQ will include specifications such as torque rating, material grade, and voltage, allowing suppliers to provide accurate quotes.

4. Incoterms (Internationale Handelsklauseln)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers. They clarify who is responsible for shipping costs, insurance, and customs duties. Understanding these terms is essential for international B2B transactions, particularly when sourcing starter motors from different regions.

5. Vorlaufzeit

Lead time is the amount of time it takes from placing an order to receiving the product. For businesses relying on starter motors, understanding lead times can help in planning inventory and ensuring timely project completion.

6. Garantie

A warranty is a guarantee provided by the manufacturer regarding the product’s performance over a specified period. Knowing the warranty terms for starter motors can provide assurance of quality and protect against defects, which is particularly important for B2B buyers investing in bulk components.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and support strategic procurement practices.

Navigating Market Dynamics and Sourcing Trends in the starting motor Sector

What Are the Key Trends Influencing the Global Starting Motor Market?

The global starting motor market is witnessing robust growth driven by several factors, including the rise in vehicle production, increasing demand for electric and hybrid vehicles, and advancements in automotive technology. In regions like Africa and South America, where automotive markets are expanding, there is a significant push for modern starting motor systems that enhance efficiency and reliability. Meanwhile, in Europe, particularly Germany, stringent emission regulations are prompting manufacturers to innovate and integrate more advanced technologies within starting motors.

Emerging trends such as the incorporation of IoT (Internet of Things) technology into starting motors are changing the landscape. This tech enables real-time diagnostics and predictive maintenance, helping businesses reduce downtime and improve operational efficiency. B2B buyers are increasingly seeking suppliers that can offer these advanced features, as they align with the growing emphasis on performance and efficiency.

Additionally, the ongoing shift towards electric vehicles (EVs) is reshaping sourcing strategies. Starting motors for EVs differ significantly from those in traditional internal combustion engines, necessitating a reevaluation of supply chains. Buyers must navigate these changes by establishing relationships with suppliers who are well-versed in the unique specifications and components required for electric and hybrid vehicle applications.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Starting Motor Sector?

Sustainability and ethical sourcing have become paramount in the automotive industry, including the starting motor sector. The environmental impact of manufacturing processes, particularly in regions with lax regulations, can be significant. B2B buyers must prioritize suppliers that adhere to sustainable practices, focusing on reducing waste and energy consumption during production.

An essential aspect of ethical sourcing is ensuring transparency throughout the supply chain. Buyers should seek out suppliers who can provide documentation regarding their sourcing of materials, particularly metals and rare earth elements used in electric vehicle components. Certifications such as ISO 14001 for environmental management systems or materials sourced from conflict-free zones can provide assurance of responsible sourcing practices.

Illustrative image related to starting motor

Moreover, the use of ‘green’ materials in manufacturing starting motors is gaining traction. Suppliers who invest in eco-friendly materials, such as recycled metals or biodegradable components, align with the growing consumer and regulatory demand for sustainable products. Buyers can enhance their brand reputation and appeal to environmentally conscious customers by partnering with manufacturers committed to sustainability.

What Historical Developments Have Shaped the Starting Motor Market?

The evolution of starting motors dates back to the early 20th century when electric starters replaced manual crank systems, revolutionizing vehicle ignition. Initially, these motors were rudimentary, primarily designed for functionality. However, as automotive technology advanced, so did the complexity and efficiency of starting motors. The introduction of solenoids and improved electrical components in the mid-20th century significantly enhanced performance and reliability.

In recent decades, the shift towards more fuel-efficient and cleaner energy vehicles has further influenced the design and manufacturing of starting motors. The rise of electric and hybrid vehicles has prompted manufacturers to innovate continuously, focusing on lightweight materials and advanced technologies. This historical context is crucial for B2B buyers, as it underscores the importance of selecting suppliers who are not only aware of the past but are also forward-thinking in their approach to the evolving automotive landscape.

By understanding these dynamics, international B2B buyers can make informed decisions that align with market trends, sustainability goals, and technological advancements in the starting motor sector.

Frequently Asked Questions (FAQs) for B2B Buyers of starting motor

-

Wie kann ich Probleme mit einem defekten Anlasser lösen?

To address problems with a faulty starter motor, first check the battery’s condition, as a weak battery is often the primary cause of starting issues. Inspect connections for corrosion or loose wires, and ensure the ignition switch is functioning properly. If these components are in good condition, the starter motor itself may need testing or replacement. Engage a qualified technician to diagnose the specific fault, whether it’s a solenoid issue, mechanical failure, or electrical fault. Regular maintenance can help prevent these problems in the future. -

What is the best type of starter motor for commercial vehicles?

The best starter motor for commercial vehicles typically depends on the vehicle’s engine size and type. Heavy-duty vehicles often require robust starter motors designed to handle higher torque demands and frequent starts. Look for starter motors with higher amperage ratings and durable materials to withstand harsh operating conditions. Consulting with manufacturers or suppliers who specialize in commercial vehicle components can provide insights into the most reliable options available in your region. -

Wie kann ich die Qualität der von mir gekauften Anlasser sicherstellen?

To ensure the quality of starter motors, select suppliers that provide detailed specifications and certifications, such as ISO or TS certifications. Request samples for testing and consider suppliers who offer warranties or guarantees. It’s also beneficial to read customer reviews and case studies to assess the performance of their products. Implementing a quality assurance process, including testing for compatibility and durability, will help verify that you are purchasing reliable components. -

What is the typical minimum order quantity (MOQ) for starter motors?

The minimum order quantity (MOQ) for starter motors can vary significantly depending on the manufacturer and your specific requirements. Generally, MOQs range from 50 to 500 units, especially for customized orders. When sourcing, inquire about the MOQ upfront and explore options for bulk purchasing to negotiate better pricing. Additionally, some suppliers may offer lower MOQs for standard models, which can be advantageous for smaller businesses or first-time buyers. -

What payment terms should I expect when sourcing starter motors internationally?

Payment terms for international purchases of starter motors often include options like letter of credit, advance payment, or net 30/60 days terms. Many suppliers prefer partial upfront payments to mitigate risks. It’s essential to clarify these terms during negotiations and ensure they align with your cash flow capabilities. Additionally, consider using secure payment platforms that offer buyer protection for international transactions to safeguard your investments. -

Wie überprüfe ich potenzielle Lieferanten für Anlasser?

Vetting suppliers for starter motors involves assessing their reputation, experience, and reliability. Start by checking for industry certifications and customer testimonials. Conduct background research to verify their business history and financial stability. Request references from other clients and inquire about their manufacturing processes, quality control measures, and delivery timelines. Engaging in direct communication can also provide insights into their responsiveness and customer service quality. -

Welche logistischen Überlegungen sollte ich beim Import von Anlassern anstellen?

When importing starter motors, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose freight forwarders experienced in automotive parts to navigate complex regulations and ensure compliance with import duties. Evaluate shipping options (air vs. sea) based on cost and urgency. Additionally, prepare for potential delays by allowing extra time for customs clearance and logistics planning, especially when dealing with international suppliers. -

Can starter motors be customized for specific applications?

Yes, starter motors can often be customized for specific applications based on engine type, size, and operational conditions. Many manufacturers offer customization options that include changes in torque ratings, housing materials, and electrical specifications. When considering customization, provide detailed requirements to the supplier, including performance expectations and environmental factors. Collaborating closely with the manufacturer can help ensure that the customized starter motor meets your specific operational needs effectively.

Top 2 Starting Motor Manufacturers & Suppliers List

1. RAC – Starter Motors

Domäne: rac.co.uk

Registriert: 1996 (29 Jahre)

Einleitung: Starter motor is an electric component essential for starting internal combustion vehicles. It engages the engine’s rotation when the ignition is activated. Common causes of failure include broken solenoids, mechanical issues, electrical faults, overheating, and wear and tear. The starter motor is typically located at the back of the engine, and it should not continuously drain the battery. It usu…

2. Haynes - Handbuch Zündanlage

Domäne: us.haynes.com

Registriert: 1996 (29 Jahre)

Einleitung: Dieses Unternehmen, Haynes - Ignition System Guide, ist ein namhaftes Unternehmen auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

Strategic Sourcing Conclusion and Outlook for starting motor

In the realm of automotive components, the strategic sourcing of starter motors stands as a critical factor for international B2B buyers. Understanding the intricate workings of starter motors—from their essential role in engine ignition to the potential causes of failure—enables buyers to make informed procurement decisions. By partnering with reliable suppliers who offer high-quality starter motors, businesses can enhance their operational efficiency and ensure customer satisfaction.

Moreover, recognizing the diverse needs across regions such as Africa, South America, the Middle East, and Europe is vital. Tailoring sourcing strategies to accommodate regional market demands not only strengthens supply chains but also promotes competitive advantage. Buyers are encouraged to prioritize suppliers that demonstrate innovation and adaptability in their offerings, ensuring they can meet evolving automotive standards.

Looking ahead, the global push towards electric vehicles and sustainable practices will reshape the starter motor landscape. As technology advances, staying ahead of these trends will be crucial. Engage with suppliers who are committed to innovation and quality, and position your business for success in this dynamic market. Make strategic sourcing a priority to unlock the full potential of your automotive operations.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

Illustrative image related to starting motor

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.