Introduction: Navigating the Global Market for replacing car starter cost

Navigating the complexities of sourcing replacement car starters can be a daunting task for international B2B buyers, particularly those operating in emerging markets across Africa, South America, the Middle East, and Europe, including regions like Nigeria and Saudi Arabia. Understanding the costs associated with replacing car starters is crucial, not only for effective budgeting but also for ensuring the longevity and reliability of vehicles in diverse environments. This guide delves into the various types of starters, their applications, and the intricacies involved in supplier vetting, allowing businesses to make well-informed purchasing decisions.

In an industry where the cost of replacing a car starter can range significantly—from $531 to over $1,400 depending on the vehicle and its location—having a comprehensive understanding of these variables is essential. Our guide will empower you with insights on labor costs, parts pricing, and the implications of choosing OEM versus aftermarket options. Additionally, we will address common issues that may arise during the replacement process and provide strategies for selecting reliable suppliers who align with your business needs. By equipping yourself with this knowledge, you can mitigate risks, optimize costs, and enhance operational efficiency in your automotive ventures.

Inhaltsverzeichnis

- Top 6 Replacing Car Starter Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for replacing car starter cost

- Understanding replacing car starter cost Types and Variations

- Key Industrial Applications of replacing car starter cost

- 3 Common User Pain Points for ‘replacing car starter cost’ & Their Solutions

- Strategic Material Selection Guide for replacing car starter cost

- In-depth Look: Manufacturing Processes and Quality Assurance for replacing car starter cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacing car starter cost’

- Comprehensive Cost and Pricing Analysis for replacing car starter cost Sourcing

- Alternatives Analysis: Comparing replacing car starter cost With Other Solutions

- Essential Technical Properties and Trade Terminology for replacing car starter cost

- Navigating Market Dynamics and Sourcing Trends in the replacing car starter cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of replacing car starter cost

- Strategic Sourcing Conclusion and Outlook for replacing car starter cost

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding replacing car starter cost Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard-Ersatz | Basic aftermarket starter, compatible with various models | Allgemeine Kfz-Werkstätten | Vorteile: Kostengünstig; weithin verfügbar. Nachteile: May lack OEM quality. |

| OEM-Ersatz | Original Equipment Manufacturer parts | Dealerships, high-end repair facilities | Vorteile: Guaranteed compatibility; high reliability. Nachteile: Höhere Kosten. |

| Überholter Anlasser | Refurbished starters, often with warranty | Fleet management, budget-conscious shops | Vorteile: Cost savings; eco-friendly. Nachteile: Reliability may vary. |

| Leistung Starter | Enhanced starters for high-performance vehicles | Specialty automotive shops, racing teams | Vorteile: Improved durability and efficiency. Nachteile: Premium-Preise. |

| DIY-Starter-Kits | Starter kits with all necessary components for replacement | Heimwerker, kleine Reparaturwerkstätten | Vorteile: Potentially lower costs; hands-on experience. Nachteile: Requires skill and tools. |

What are the characteristics of Standard Replacement starters?

Standard Replacement starters are aftermarket parts designed to fit a variety of vehicle models, making them a popular choice among general automotive repair shops. They offer a cost-effective solution for businesses looking to manage repair budgets without sacrificing quality. However, while they are widely available, the quality may not match that of OEM parts, which could lead to more frequent replacements. B2B buyers should consider their customer base’s expectations and the potential for warranty claims when opting for this type.

How do OEM Replacement starters differ from other options?

OEM Replacement starters are manufactured by the original equipment manufacturer, ensuring perfect compatibility with specific vehicle models. This type is often preferred by dealerships and high-end repair facilities that prioritize reliability and performance. While they come with a higher price tag, B2B buyers can justify this cost through customer satisfaction and reduced return rates. It’s crucial for businesses to assess whether their clientele values OEM quality over cost savings.

What are the advantages of Remanufactured Starters?

Remanufactured starters are refurbished components that often come with a warranty, making them an attractive option for fleet management companies and budget-conscious repair shops. They provide a balance between cost savings and reliability, appealing to businesses looking to minimize expenses while maintaining service quality. However, the reliability of remanufactured parts can vary, so B2B buyers should ensure they source from reputable suppliers to mitigate risks.

When should Performance Starters be considered?

Performance starters are designed for high-performance vehicles, offering enhanced durability and efficiency for demanding applications. They are typically sought after by specialty automotive shops and racing teams that require superior performance under extreme conditions. While they come at a premium price, the investment can be justified by the increased reliability and performance benefits. B2B buyers should evaluate their target market’s needs and readiness to invest in high-performance solutions.

What are the key considerations for DIY Starter Kits?

DIY Starter Kits provide all necessary components for a starter replacement, catering to DIY enthusiasts and small repair shops. These kits can offer significant cost savings but require a certain level of mechanical skill and the right tools. B2B buyers should assess their customer base’s capabilities and preferences before promoting these kits, as they may appeal more to those looking for hands-on repair experiences. Additionally, clear instructions and support can enhance customer satisfaction and reduce potential issues.

Key Industrial Applications of replacing car starter cost

| Branche/Sektor | Specific Application of replacing car starter cost | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparaturdienste | Cost estimation for starter replacements | Enables competitive pricing and improved service offerings | Quality of parts, labor costs, and local market demand |

| Flottenmanagement | Budgeting for fleet vehicle maintenance | Optimizes operational costs and minimizes downtime | Volume discounts, warranty terms, and reliable suppliers |

| Logistik und Transport | Assessing repair costs for delivery vehicles | Enhances budgeting accuracy and service reliability | Availability of parts, service turnaround time, and location |

| Autohäuser | Pricing strategies for starter replacements | Improves customer satisfaction and loyalty | OEM vs aftermarket parts, service packages, and customer feedback |

| Vertrieb von Automobilteilen | Inventory management for starters | Increases sales potential and reduces stock-outs | Supplier reliability, shipping costs, and regional demand |

How is ‘replacing car starter cost’ utilized in the Automotive Repair Services sector?

In the automotive repair services sector, accurately estimating the cost of replacing a car starter is vital for maintaining competitive pricing and customer satisfaction. Repair shops must provide transparent estimates that include both parts and labor to build trust with clients. Understanding local market pricing trends is essential for international buyers, especially in regions like Africa and South America, where economic conditions may vary significantly. Furthermore, incorporating high-quality parts can lead to repeat business and referrals.

What role does ‘replacing car starter cost’ play in Fleet Management?

For fleet management, replacing car starters is a significant maintenance consideration that impacts operational efficiency. Fleet managers need to budget for these costs to minimize vehicle downtime, which can affect service delivery. By analyzing historical data on starter failures and replacements, fleet managers can implement preventive maintenance strategies, thereby extending the lifespan of vehicles. International buyers should consider local labor rates and parts availability when sourcing starter replacements to ensure timely repairs.

How does ‘replacing car starter cost’ impact the Logistics and Transportation industry?

In the logistics and transportation industry, assessing the cost of starter replacements is crucial for budgeting and ensuring that delivery vehicles remain operational. Accurate cost assessments help logistics companies plan for unexpected repairs, reducing the risk of delays in service. Buyers in this sector, especially in the Middle East and Europe, should focus on sourcing reliable parts with quick turnaround times to maintain their service levels. Understanding the local repair landscape can also aid in negotiating better service contracts.

Why is ‘replacing car starter cost’ important for Car Dealerships?

Car dealerships benefit from understanding the cost of replacing starters as it allows them to develop effective pricing strategies for service packages. By offering competitive pricing on starter replacements, dealerships can enhance customer loyalty and satisfaction. Additionally, dealerships should weigh the advantages of using OEM parts against aftermarket options to provide the best value to customers. International buyers should be aware of regional preferences for parts and service quality, which can influence their sourcing decisions.

How does ‘replacing car starter cost’ affect Automotive Parts Distribution?

In the automotive parts distribution sector, managing inventory for starters is essential to meet market demand without overstocking. Understanding the cost of replacing starters helps distributors set competitive prices and avoid stock-outs. For international buyers, factors such as supplier reliability, shipping costs, and regional demand must be evaluated to optimize their supply chain. By maintaining a balanced inventory based on replacement costs, distributors can enhance their sales potential and customer satisfaction.

3 Common User Pain Points for ‘replacing car starter cost’ & Their Solutions

Scenario 1: Unexpected High Costs from Labor and Parts

Das Problem: B2B buyers often face challenges in managing the costs associated with replacing a car starter, particularly when unexpected high labor rates and parts prices arise. This situation is exacerbated when a vehicle is not easily accessible, requiring the disassembly of multiple components before the starter can be replaced. Such unforeseen expenses can strain budgets, especially for businesses operating fleets or managing vehicle maintenance on tight margins.

Die Lösung: To mitigate the risk of unexpected costs, buyers should conduct thorough market research and obtain multiple quotes from different service providers or parts suppliers. Utilizing digital platforms that allow for price comparisons can lead to more competitive pricing. Furthermore, leveraging relationships with trusted suppliers or mechanics can provide insights into fair pricing, potential discounts, or package deals for recurring services. It’s advisable to keep a detailed inventory of the vehicle’s maintenance history and anticipated repairs, which can help in negotiating better rates based on loyalty or volume of business. Implementing preventative maintenance schedules can also reduce the frequency of starter replacements, ultimately lowering overall costs.

Scenario 2: Difficulty in Finding Quality Parts

Das Problem: Another significant pain point for B2B buyers is the challenge of sourcing high-quality starter parts. In regions such as Africa or South America, the availability of OEM (Original Equipment Manufacturer) parts may be limited, leading to a reliance on generic or substandard alternatives. This can result in frequent replacements, increased downtime, and a negative impact on operational efficiency.

Die Lösung: To address this issue, buyers should prioritize establishing partnerships with reputable parts distributors that specialize in high-quality automotive components. Conducting due diligence on suppliers, including checking reviews and ratings, can help ensure the reliability of the parts being purchased. Additionally, buyers should consider investing in a relationship with local automotive repair shops that may have access to quality parts or can recommend trusted suppliers. Educating procurement teams about the importance of quality over price can also lead to more informed purchasing decisions. Implementing a rigorous testing and evaluation process for new suppliers can further safeguard against the risks associated with low-quality parts.

Scenario 3: Lack of Transparency in Pricing

Das Problem: Many B2B buyers encounter a lack of transparency in pricing for car starter replacements. Hidden fees, such as diagnostic charges or additional labor costs, can lead to confusion and frustration, especially when budgets are tight. This lack of clarity can erode trust between buyers and service providers, making it difficult to maintain long-term relationships.

Die Lösung: To combat this issue, B2B buyers should insist on receiving detailed estimates that break down all potential costs associated with starter replacement. This includes parts, labor, diagnostic fees, and any other charges that might arise. Buyers can also request a written agreement that specifies all terms and conditions before work begins. Utilizing technology, such as mobile apps or online platforms that offer transparent pricing models and customer reviews, can facilitate better decision-making. Establishing clear communication channels with service providers and encouraging them to explain their pricing structures can also foster transparency. By advocating for upfront pricing and comprehensive service agreements, buyers can ensure they are not caught off guard by unexpected charges.

Strategic Material Selection Guide for replacing car starter cost

When selecting materials for replacing car starters, B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Here, we analyze four common materials used in starter components, focusing on their properties, advantages, disadvantages, and implications for international markets.

What Are the Key Properties of Steel in Starter Components?

Steel is a widely used material in automotive applications, including starter motors. Its key properties include high tensile strength, good wear resistance, and the ability to withstand high temperatures. Steel can also be treated for corrosion resistance, which is crucial in environments with high humidity or exposure to road salts.

Vorteile: Steel’s durability makes it suitable for heavy-duty applications, ensuring longevity in starter performance. It is generally less expensive than other metals, making it a cost-effective choice for manufacturers.

Nachteile: While steel is strong, it is also heavier than alternatives like aluminum, which may affect the overall weight of the vehicle. Additionally, untreated steel can corrode, necessitating protective coatings that may increase manufacturing complexity.

Auswirkungen auf die Anwendung: Steel starters are well-suited for vehicles operating in diverse climates, but buyers should ensure that the steel used meets relevant standards for corrosion resistance, especially in regions like Africa and South America.

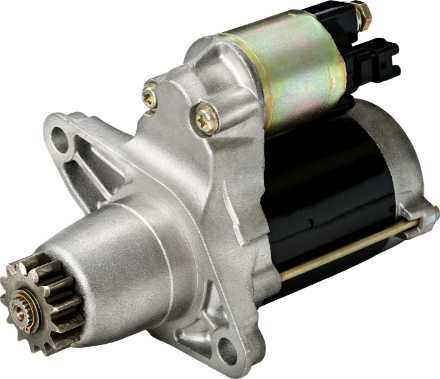

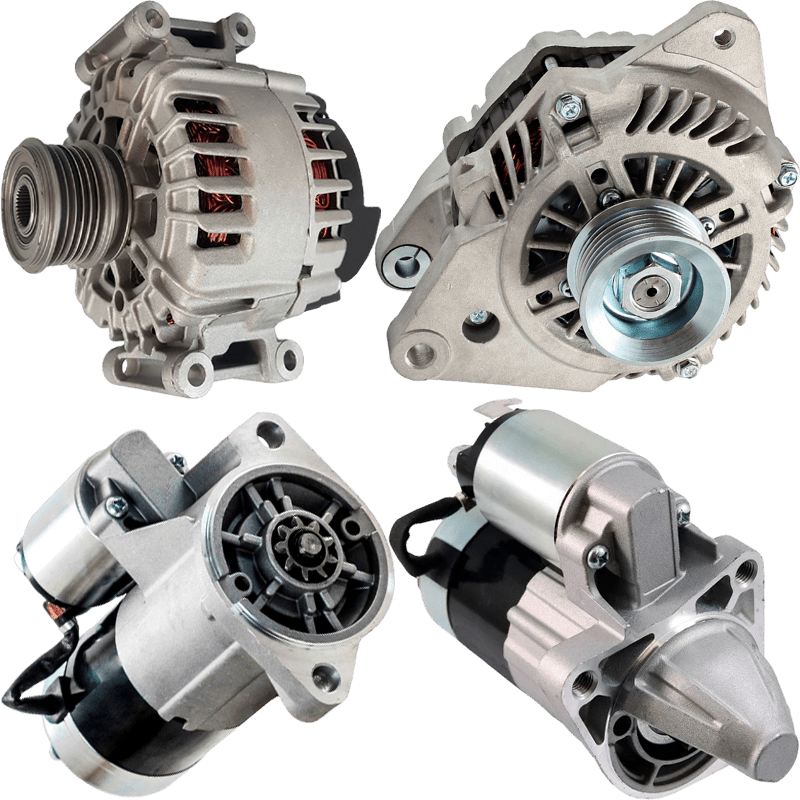

Illustrative image related to replacing car starter cost

Wie schneidet Aluminium im Vergleich bei Starterkomponenten ab?

Aluminum is another common material used in starter motors, particularly for its lightweight properties. It has good thermal conductivity and resistance to corrosion, making it a popular choice for automotive applications.

Vorteile: The primary advantage of aluminum is its weight, which can help improve fuel efficiency and performance in vehicles. Additionally, aluminum can be anodized to enhance its corrosion resistance.

Nachteile: While aluminum is resistant to corrosion, it is not as strong as steel, which may limit its use in high-stress applications. The manufacturing processes for aluminum can also be more complex, potentially increasing costs.

Auswirkungen auf die Anwendung: In regions with high humidity or coastal environments, aluminum starters can offer better performance due to their corrosion resistance. However, buyers must consider the strength requirements for specific vehicles, especially in markets with rugged terrain.

Illustrative image related to replacing car starter cost

Welche Rolle spielt Kupfer in Startersystemen?

Copper is predominantly used in electrical components of starters, such as windings and connectors, due to its excellent electrical conductivity. It also has good thermal properties, which can enhance the efficiency of starter motors.

Vorteile: The high conductivity of copper ensures efficient power transfer, which is critical for reliable starter operation. Copper is also relatively easy to work with, allowing for intricate designs in electrical components.

Nachteile: Copper is more expensive than steel and aluminum, which can increase the overall cost of starter assemblies. It is also susceptible to corrosion, requiring protective coatings or the use of alloys to improve durability.

Illustrative image related to replacing car starter cost

Auswirkungen auf die Anwendung: In regions with strict electrical standards, copper components are often preferred for their reliability. However, buyers in cost-sensitive markets may need to balance performance with budget constraints.

How Does Plastic Factor into Starter Design?

Plastic is increasingly being used in non-structural components of starters, such as housings and insulators. It offers lightweight properties and can be molded into complex shapes.

Vorteile: The primary advantage of plastic is its weight reduction, which can contribute to overall vehicle efficiency. Additionally, plastics can be engineered for specific thermal and electrical properties, enhancing performance.

Nachteile: Plastic components may not withstand high temperatures or mechanical stress as well as metals, which can limit their application in critical areas of the starter. The long-term durability of plastics can also be a concern in harsh environments.

Auswirkungen auf die Anwendung: In regions with extreme temperatures, the choice of plastic must be carefully considered to ensure it meets performance requirements. Compliance with international standards for materials is essential to avoid failures in the field.

Summary Table of Material Selection for Replacing Car Starters

| Material | Typical Use Case for replacing car starter cost | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Strukturelle Komponenten von Startern | Hohe Haltbarkeit und Festigkeit | Schwerer als Alternativen | Mittel |

| Aluminium | Lightweight housings and components | Leicht und korrosionsbeständig | Geringere Festigkeit als Stahl | Mittel |

| Kupfer | Elektrische Wicklungen und Steckverbinder | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und Korrosionsrisiko | Hoch |

| Kunststoff | Nicht-strukturelle Komponenten und Isolatoren | Leicht und formbar | Begrenzte thermische und mechanische Beständigkeit | Niedrig |

This analysis offers B2B buyers a comprehensive overview of material options for replacing car starters, emphasizing the importance of selecting the right materials based on performance, cost, and regional considerations.

Illustrative image related to replacing car starter cost

In-depth Look: Manufacturing Processes and Quality Assurance for replacing car starter cost

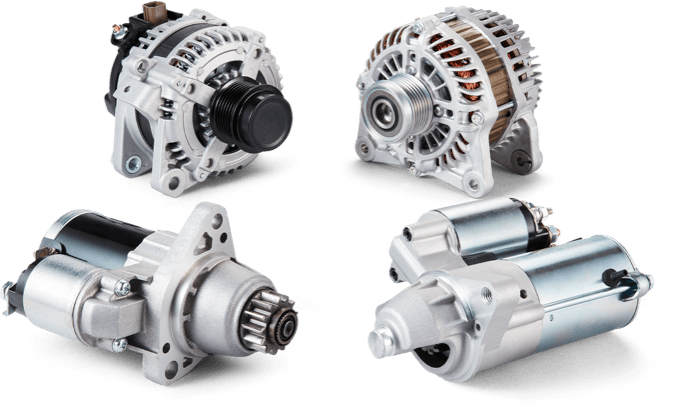

What Are the Main Stages of Manufacturing Car Starters?

The manufacturing of car starters involves several critical stages, each integral to ensuring the final product meets performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Wie wird das Material für die Starterproduktion vorbereitet?

The first step in manufacturing car starters is the selection and preparation of raw materials. Typically, high-grade steel and various alloys are used due to their strength and durability. The materials undergo rigorous quality checks to ensure they meet specific mechanical properties required for automotive applications. This can include tensile strength tests and fatigue testing to ascertain the material’s performance under stress.

Welche Umformtechniken werden in der Starterproduktion üblicherweise eingesetzt?

Once the materials are prepared, they are subjected to various forming techniques. Common methods include stamping, forging, and die-casting. Stamping is often used for creating the starter’s outer casing, while forging is utilized for components that require high strength, such as the armature. Die-casting is frequently used for producing intricate parts with tight tolerances, such as the solenoid housing. Each technique is chosen based on the component’s design specifications and performance requirements.

How Does Assembly of Starters Take Place?

After forming, the components move to the assembly stage. This process often involves automated machinery for precision and efficiency, although skilled labor is also critical for tasks requiring a high degree of expertise, such as wiring and connection of the electrical components. During assembly, technicians must ensure that all parts fit together seamlessly to prevent future failures. Common practices include the use of torque specifications and visual inspections to confirm that each component is correctly installed.

Welche Veredelungsverfahren werden bei Autostartern angewandt?

The finishing stage involves several processes to enhance the starter’s durability and aesthetics. This can include painting, coating, or plating to prevent corrosion and wear. Additionally, components may undergo surface treatment processes like anodizing or phosphating, which improve resistance to environmental factors. Quality checks during this stage ensure that the finishing meets industry standards and specifications.

Illustrative image related to replacing car starter cost

What Are the Key Quality Assurance Standards for Car Starters?

Quality assurance is paramount in the automotive industry, especially for components like starters that are crucial for vehicle operation. International standards such as ISO 9001 are often adopted to ensure consistent quality management systems. Additionally, industry-specific standards like CE marking in Europe or API standards in North America may apply, depending on the starter’s application.

Wie werden die Qualitätskontrollpunkte festgelegt?

Qualitätskontrollpunkte (QC) sind strategisch über den gesamten Fertigungsprozess verteilt, um Fehler frühzeitig zu erkennen. Zu den üblichen Kontrollpunkten gehören:

-

Eingangsqualitätskontrolle (IQC): This stage involves inspecting raw materials before they are used in production. It ensures that all materials meet the required specifications and standards.

-

In-Process-Qualitätskontrolle (IPQC): Throughout the manufacturing process, periodic checks are performed to monitor the quality of the components being produced. This includes dimensional checks and functional tests of components like solenoids and armatures.

-

Endkontrolle (FQC): After assembly, the entire starter undergoes comprehensive testing to ensure it meets performance criteria. Common tests include electrical performance tests, thermal cycling, and durability tests to simulate real-world conditions.

What Testing Methods Are Employed in Starter Manufacturing?

Several testing methods are essential in verifying the quality of manufactured starters. These include:

-

Elektrische Prüfung: Ensuring that the starter operates correctly under various conditions, including voltage and load tests.

-

Haltbarkeitsprüfung: Simulating conditions that the starter will face in real-world applications, including temperature extremes and vibration tests.

-

Funktionsprüfung: Assessing the starter’s performance when engaged with an actual vehicle battery to confirm that it starts the engine without issues.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are several strategies:

-

Lieferanten-Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and QC practices. This can include reviewing their quality management systems and compliance with international standards.

-

Qualitätssicherungsberichte: Requesting detailed QA reports can help buyers understand the specific tests conducted and their results. This information can provide confidence in the supplier’s ability to deliver reliable products.

-

Inspektionen durch Dritte: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. This is particularly beneficial when dealing with new suppliers or when entering new markets.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

International buyers must navigate various nuances in quality control based on regional standards and practices. For instance, while CE marking is crucial in Europe, it may not hold the same significance in other regions. Buyers should be aware of local regulations and standards that might affect the product’s acceptance in their market.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear guidelines and expectations upfront can help mitigate misunderstandings and ensure that the final product meets the buyer’s quality standards.

In conclusion, understanding the manufacturing processes and quality assurance practices involved in car starter production is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside robust quality control measures, buyers can ensure they partner with reliable suppliers who deliver high-quality automotive components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacing car starter cost’

Einführung

This guide serves as a practical checklist for B2B buyers seeking to navigate the complexities of sourcing replacement car starters. Understanding the associated costs and identifying reliable suppliers are critical to ensuring that your procurement process is efficient and cost-effective. The following steps will help you streamline your sourcing efforts, evaluate potential suppliers, and make informed purchasing decisions.

Illustrative image related to replacing car starter cost

Schritt 1: Assess Your Vehicle Specifications

Before initiating the sourcing process, gather detailed information about the specific vehicles requiring starter replacements. This includes the make, model, and year of the vehicle, as well as any unique electrical specifications. Having this information on hand ensures that you procure the correct starter type, minimizing the risk of compatibility issues.

Schritt 2: Forschung Marktpreise

Conduct thorough research to understand the average costs associated with replacing car starters in your region. Utilize resources such as automotive repair websites, industry reports, and local mechanic estimates to gather price ranges. Being aware of the market pricing will empower you to negotiate better deals with suppliers and avoid overpaying.

Schritt 3: Potenzielle Lieferanten identifizieren

Compile a list of potential suppliers specializing in automotive parts, particularly starters. Consider suppliers who have a strong reputation in the market and are known for their reliability. Look for online reviews, industry certifications, and recommendations from other businesses within your network to gauge the credibility of these suppliers.

Schritt 4: Evaluate Supplier Quality and Certifications

When selecting suppliers, prioritize those who provide high-quality parts and are compliant with industry standards. Check for certifications such as ISO 9001 or other relevant quality management systems. Quality parts not only ensure better performance but also reduce the likelihood of returns and warranty claims.

Illustrative image related to replacing car starter cost

Schritt 5: Request and Compare Quotes

Reach out to your shortlisted suppliers to request quotes for the replacement starters. Ensure that the quotes include detailed breakdowns of costs, including parts, labor, and any additional fees. Comparing these quotes will help you identify the most cost-effective options while maintaining quality standards.

Schritt 6: Überprüfen Sie die Garantie- und Rückgabebedingungen

Before finalizing your purchase, confirm the warranty and return policies of the suppliers. A robust warranty indicates the supplier’s confidence in their products and provides you with peace of mind regarding future issues. Understanding the return process is equally important, as it protects you in case the parts do not meet your expectations or specifications.

Schritt 7: Aufbau einer langfristigen Beziehung

Once you have successfully sourced replacement starters, consider establishing a long-term relationship with your chosen suppliers. Regular communication and collaboration can lead to better pricing, priority service, and access to new products. Building strong partnerships can significantly enhance your procurement process for future automotive needs.

Illustrative image related to replacing car starter cost

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing replacement car starters, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for replacing car starter cost Sourcing

What Are the Key Cost Components for Replacing a Car Starter?

When considering the cost of replacing a car starter, multiple components contribute to the overall expenditure. The primary cost elements include:

-

Materialien: The starter motor itself is the most significant material cost, typically ranging from $356 to $516, depending on the vehicle model and specifications. Quality and brand can also influence the price, with OEM (Original Equipment Manufacturer) parts generally costing more due to their reliability and warranty offerings.

-

Arbeit: Labor costs for installation can range from $175 to $257, depending on the mechanic’s hourly rate and the complexity of the starter’s location within the vehicle. In some cases, accessing the starter may require the removal of additional components, which can increase labor time and cost.

-

Fertigungsgemeinkosten: This includes the costs associated with production, such as utilities, rent, and salaries of staff involved in the manufacturing process. Overhead costs can vary significantly between suppliers, especially when sourcing from different regions.

-

Werkzeuge: If specialized tools are required for installation or if the starter is custom-made, tooling costs can add to the overall price. This is particularly relevant for vehicles with unique designs or older models.

-

Qualitätskontrolle (QC): Ensuring that the starter meets industry standards involves quality checks during manufacturing. This cost is often passed on to the buyer and can vary based on the supplier’s QC processes.

-

Logistik: Shipping and handling costs can fluctuate, especially for international buyers. Factors such as distance, transportation mode, and customs duties play a significant role in logistics costs.

-

Marge: Suppliers typically add a margin to cover their operating expenses and profit. This margin can vary widely based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Impact Starter Replacement Costs?

Several factors influence the pricing of starter replacements, particularly for international B2B buyers:

-

Volumen/MOQ (Mindestbestellmenge): Bulk purchases can lead to lower per-unit costs. Suppliers are often willing to negotiate better pricing for larger orders, which can significantly reduce overall expenses.

-

Spezifikationen und Anpassung: Custom starters tailored for specific vehicle models or unique operational requirements may incur additional costs. Standardized parts typically offer better pricing due to economies of scale.

-

Materialien und Qualitätszertifizierungen: The choice of materials can affect durability and performance, influencing price. High-quality starters with certifications may command higher prices but can lead to lower total cost of ownership due to reduced failure rates.

-

Lieferantenfaktoren: The reliability and reputation of the supplier can impact pricing. Established suppliers may charge more but often provide better warranties, customer support, and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can affect the total cost, as they determine who is responsible for shipping, insurance, and tariffs.

What Are the Best Buyer Tips for Sourcing Starters Internationally?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to optimize costs when sourcing starters:

-

Bedingungen aushandeln: Always negotiate pricing, especially if purchasing in bulk. Suppliers may offer discounts for larger orders or flexible payment terms.

-

Gesamtbetriebskosten bewerten: Consider not only the initial purchase price but also the long-term costs associated with installation, maintenance, and potential replacements. Higher-quality starters may have a higher upfront cost but can lead to savings over time.

-

Preisdifferenzen verstehen: Be aware of regional pricing differences and market dynamics. Factors such as currency fluctuations and local demand can impact costs significantly.

-

Recherche und Vergleich von Anbietern: Take the time to compare multiple suppliers. Look for reviews, certifications, and warranty offerings to gauge reliability and quality.

-

Plan for Logistics: Factor in shipping times and costs when sourcing internationally. Delays in supply chains can impact your operations, so having a reliable logistics partner is essential.

Haftungsausschluss für indikative Preise

The prices mentioned in this analysis are indicative and can vary based on numerous factors, including vehicle make and model, geographic location, and market conditions. Always consult with local suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing replacing car starter cost With Other Solutions

Exploring Alternatives to Replacing Car Starter Cost

When it comes to vehicle maintenance, the cost of replacing a car starter is a significant consideration for B2B buyers, especially in regions with varying economic conditions. Understanding the alternatives available can help businesses make informed decisions that align with their operational needs and budget constraints. Below is a comparative analysis of replacing a car starter against alternative solutions.

| Vergleichsaspekt | Replacing Car Starter Cost | Alternative 1: Austausch der Batterie | Alternative 2: Starter-Reparatur |

|---|---|---|---|

| Leistung | Restores full functionality to the vehicle’s starting system. | Improves starting performance if the battery is the issue. | Can restore functionality at a lower cost if the starter is repairable. |

| Kosten | Average cost ranges from $531 to $773, depending on the vehicle. | Battery replacement typically costs between $100 and $300. | Repairing a starter can cost between $100 and $300, depending on the issue. |

| Einfache Implementierung | Requires professional installation, often needing multiple components to be removed. | Generally straightforward, with many businesses able to perform it in-house. | Can be performed by skilled mechanics, but may require diagnostic testing. |

| Wartung | New starters require minimal maintenance but should be monitored for signs of wear. | Regular battery checks are essential, especially in extreme climates. | A repaired starter may require ongoing monitoring for future issues. |

| Bester Anwendungsfall | Ideal for vehicles with confirmed starter failures. | Best for vehicles showing symptoms of battery failure rather than starter issues. | Suitable when the starter shows signs of malfunction but is not completely failed. |

What Are the Benefits and Drawbacks of Battery Replacement?

Battery replacement is a viable alternative that can often solve starting issues without the need for a full starter replacement. When a vehicle fails to start, it’s essential to consider the battery as a potential culprit, especially if it is older or has been subjected to extreme temperatures. The cost of replacing a battery is significantly lower, typically ranging from $100 to $300, and many businesses have the capability to perform this service in-house, making it a cost-effective and efficient solution. However, if the starter is indeed at fault, merely replacing the battery will not resolve the underlying issue.

How Does Starter Repair Compare?

Starter repair serves as a middle ground between replacing a starter and replacing a battery. If diagnostics reveal that the starter is not completely failed, repairing it can restore functionality at a fraction of the cost of a full replacement, generally between $100 and $300. This option is particularly appealing for older vehicles where the starter is still in good condition but may need minor repairs. However, the effectiveness of this solution depends on the nature of the problem; in some cases, a repair may only be a temporary fix, leading to further costs down the line.

Illustrative image related to replacing car starter cost

How Should B2B Buyers Choose the Right Solution?

In making a decision, B2B buyers should assess the specific context of their fleet or vehicle use. Factors such as vehicle age, typical operating conditions, and the history of previous repairs can influence the choice between replacing the starter, opting for a battery replacement, or considering starter repair. Conducting thorough diagnostics is crucial to identifying the root cause of starting issues and ensuring that the selected solution provides both immediate relief and long-term reliability. Ultimately, understanding the total cost of ownership and the potential for future repairs will guide buyers towards the most cost-effective and efficient choice for their operations.

Essential Technical Properties and Trade Terminology for replacing car starter cost

What Are the Key Technical Properties When Considering Starter Replacement Costs?

When evaluating the cost of replacing a car starter, it’s crucial to understand specific technical properties that influence both the quality of the replacement parts and the overall expense. Here are some essential specifications to consider:

-

Werkstoffgüte

The material grade of a starter motor significantly impacts its durability and performance. Common materials include high-grade steel and aluminum alloys, which offer strength and resistance to wear. B2B buyers should prioritize starters made from robust materials to reduce the likelihood of premature failure, which can lead to additional costs and downtime. -

Elektrischer Widerstand

This property measures how well the starter can conduct electricity. A starter with low electrical resistance will operate more efficiently, resulting in better performance and lower energy consumption. Understanding this property is critical for procurement decisions, as higher efficiency can translate into cost savings over time. -

Drehmoment

The torque rating indicates the rotational force that the starter can generate to crank the engine. Different vehicles require different torque levels based on engine size and type. B2B buyers must ensure that the replacement starter meets or exceeds the original equipment specifications to ensure reliable engine starts and avoid potential issues. -

Compatibility Specifications

Compatibility specifications include the number of electrical connections and the mounting configuration. Each vehicle model may have unique requirements, and using a starter that does not match the existing setup can lead to installation challenges or operational failures. This is particularly important for B2B buyers dealing with diverse vehicle fleets. -

Lifecycle and Warranty Period

The lifecycle of a starter refers to its expected operational lifespan, often indicated by manufacturer warranties. A longer lifecycle means reduced costs in terms of replacements and repairs. B2B purchasers should consider products with solid warranties as they can provide insights into quality and manufacturer confidence.

What Are Common Trade Terms Relevant to Starter Replacement?

Understanding industry jargon is essential for effective negotiation and procurement in the automotive parts sector. Here are some key terms to be familiar with:

-

OEM (Originalgerätehersteller)

OEM parts are made by the same manufacturer that produced the original parts for the vehicle. These parts often come with a guarantee of fit and function, making them a safer choice for businesses looking to maintain quality. B2B buyers should weigh the benefits of OEM parts against aftermarket options, especially for critical components like starters. -

MOQ (Mindestbestellmenge)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and ensure that they are not over-committing on purchases that might not align with their operational needs. -

RFQ (Angebotsanfrage)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. Utilizing RFQs allows businesses to compare costs and conditions from various suppliers, ensuring they get the best value for their starter replacement needs. -

Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly concerning shipping and delivery. Familiarity with these terms is vital for B2B buyers involved in cross-border procurement, as they clarify who bears the risk at various stages of the shipment process. -

Vorlaufzeit

Lead time is the time taken from placing an order to receiving the goods. In the automotive industry, understanding lead times is essential for planning maintenance schedules and ensuring that vehicles are not out of service longer than necessary.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when navigating the complexities of starter replacement costs, ensuring they choose the right parts and suppliers for their needs.

Navigating Market Dynamics and Sourcing Trends in the replacing car starter cost Sector

Market Overview & Key Trends in the Replacing Car Starter Cost Sector

The global automotive sector is experiencing dynamic shifts driven by several factors, particularly impacting the cost and sourcing of car starters. One of the primary drivers is the increasing complexity of vehicles, where advanced technologies such as start-stop systems and hybrid engines require more sophisticated starter motors. This complexity leads to a broader range of replacement costs, with estimates ranging from $531 to $773, depending on the vehicle make and model. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these cost dynamics is crucial for effective budget planning.

Emerging technologies are also reshaping sourcing trends. The rise of digital platforms and e-commerce has enabled buyers to access a wider array of suppliers, facilitating competitive pricing and faster procurement. Countries like Nigeria and Saudi Arabia are leveraging these platforms to streamline their sourcing processes, while European buyers are increasingly focused on local suppliers to reduce lead times and shipping costs. Furthermore, the growing trend towards online repair guides and diagnostic tools empowers buyers to make informed decisions, reducing reliance on traditional mechanics and allowing for more direct purchasing.

The market is also influenced by the shift towards sustainability. As buyers become more environmentally conscious, there is a rising demand for eco-friendly starters and components that meet stringent emissions regulations. This trend is particularly relevant in Europe, where regulatory frameworks promote green initiatives, thus impacting sourcing strategies for car starters globally.

How Does Sustainability & Ethical Sourcing Impact the Replacing Car Starter Cost Sector?

Sustainability has become a key consideration in the sourcing of car starters, with significant implications for B2B buyers. The environmental impact of manufacturing processes, particularly in the automotive sector, is under scrutiny. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recycled materials and minimizing waste. As a result, the cost of sourcing these environmentally friendly components may initially be higher, but the long-term benefits include reduced liability and enhanced brand reputation.

Ethical sourcing is equally important, as buyers are more inclined to partner with manufacturers who adhere to fair labor practices and responsible sourcing of materials. This shift is particularly vital in regions like Africa and South America, where ethical supply chains can significantly influence purchasing decisions. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can help buyers identify suppliers committed to sustainability and ethical practices.

Moreover, as the demand for electric and hybrid vehicles grows, the focus on sourcing ‘green’ materials becomes paramount. Components like starters that are designed for energy efficiency and longevity can reduce the overall lifecycle costs for B2B buyers, making them an attractive option despite potentially higher upfront costs.

Illustrative image related to replacing car starter cost

Brief Evolution/History of the Replacing Car Starter Sector

The evolution of car starters has been closely linked to advancements in automotive technology. Initially, hand-cranked starters were common in early vehicles, but the introduction of electric starters in the 1910s revolutionized the industry. Over the decades, starters have evolved to incorporate more sophisticated features, including solenoids and brushless designs, which enhance efficiency and reliability.

As vehicles became more technologically advanced, the complexity of starter systems increased, necessitating more precise engineering and manufacturing processes. The move towards electric vehicles and hybrids in recent years has further accelerated innovation within the sector, leading to the development of starters that can operate in diverse conditions and support advanced vehicle functionalities. For B2B buyers, this historical context underscores the importance of partnering with suppliers who are at the forefront of these technological advancements, ensuring they have access to the latest and most reliable starter systems available on the market.

Frequently Asked Questions (FAQs) for B2B Buyers of replacing car starter cost

-

1. How do I determine the appropriate starter replacement cost for my vehicles?

To accurately estimate the starter replacement cost, consider factors such as the make and model of the vehicle, labor rates in your region, and the availability of parts. Generally, parts can range from $356 to $516, while labor costs can be between $175 and $257. It’s advisable to obtain multiple quotes from local mechanics or suppliers to ensure competitive pricing. For international purchases, factor in shipping and customs duties, which may affect the overall cost. -

2. What is the best type of starter for various vehicle models?

The best type of starter depends on the specific vehicle model and its requirements. OEM (Original Equipment Manufacturer) starters are recommended for their compatibility and reliability. However, high-quality aftermarket options can also be effective, often at a lower cost. Ensure that any starter you consider has the same specifications and ratings as the original to avoid installation issues and potential damage to the vehicle. -

3. How can I ensure the quality of the starter I purchase internationally?

To guarantee quality, vet suppliers thoroughly by checking for certifications, customer reviews, and their experience in the automotive parts industry. Request samples or detailed product specifications before placing bulk orders. Additionally, consider suppliers who provide warranties or guarantees, as this can indicate confidence in their products. Establishing strong communication channels will also help address any quality concerns before they arise. -

4. What are the typical minimum order quantities (MOQs) for starter parts?

Minimum order quantities can vary significantly based on the supplier and the specific starter model. Generally, MOQs can range from 10 to 100 units for aftermarket parts. When sourcing internationally, inquire about the supplier’s flexibility with MOQs, as some may accommodate smaller orders, especially for new clients or first-time purchases. This can be crucial for businesses looking to manage inventory costs effectively. -

5. What payment terms should I negotiate when sourcing starters internationally?

Payment terms can vary widely between suppliers, but it’s common to negotiate terms such as 30% upfront and 70% upon delivery. Consider using secure payment methods like letters of credit or escrow services to minimize risk. Always clarify the currency of payment and any potential transaction fees. Additionally, ensure that payment terms are documented in your contract to avoid misunderstandings later. -

6. How do logistics and shipping impact the cost of starter replacements?

Logistics and shipping can significantly affect the total cost of sourcing starters, especially when importing from overseas. Consider factors like shipping method (air vs. sea), delivery times, and customs duties. Engaging a reliable logistics partner can help streamline the process and reduce costs. Always factor in potential delays and additional fees that may arise during customs clearance to avoid surprises. -

7. What are the common challenges faced in international sourcing of automotive parts?

Challenges in international sourcing can include language barriers, varying quality standards, and regulatory compliance issues. Understanding local regulations in both your country and the supplier’s country is crucial. It’s also important to have contingency plans for potential delays or quality discrepancies. Establishing strong relationships with suppliers and logistics partners can mitigate many of these risks. -

8. How can I effectively communicate my specifications and requirements to international suppliers?

Effective communication is key when dealing with international suppliers. Clearly outline your specifications, including part numbers, dimensions, and performance criteria in a detailed document. Utilize visual aids like diagrams or photos to minimize misunderstandings. Regular follow-ups and open lines of communication will help ensure that both parties are aligned and that your requirements are met accurately.

Top 6 Replacing Car Starter Cost Manufacturers & Suppliers List

1. Reddit – Starter Package

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: This company, Reddit – Starter Package, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Facebook – Autoreparaturkosten

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Kosten für die Fahrt zur Werkstatt und den Austausch des Anlassers

3. Car Talk – Starter Replacement Costs and Symptoms

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: Cost to replace a starter: $600 to $900 for common vehicles; $900 to $1,400 for luxury models. Symptoms of a failing starter include clicking sounds, screeching noises, and intermittent functionality. Starters can be new, remanufactured, or repaired, with remanufactured parts being common. Modern vehicles with stop-start systems are designed to prevent premature starter failures.

4. Starter Replacement Costs – Key Factors

Domäne: letztechanceautoreparaturen.com

Registriert: 2009 (16 Jahre)

Einleitung: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Average total cost ranges from $250 – $1,000+. Factors affecting cost include vehicle type and model, new vs remanufactured starters, and potential additional repairs. Symptoms …

5. Carfax – Starter Motor Replacement Costs

Domäne: carfax.de

Registriert: 1997 (28 Jahre)

Einleitung: Dieses Unternehmen, Carfax - Anlasserwechselkosten, ist ein namhaftes Unternehmen auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

6. Starter Replacement – Cost & Types Guide

Domäne: aaa.com

Registriert: 1990 (35 Jahre)

Einleitung: Average cost to replace a starter: $700 – $1,200; Replacement part cost: $100 – $400; Labor cost: $100 – $250 per hour; Types of starters: Gear reduction (more efficient, more expensive) and Direct drive (less efficient, cheaper); Common symptoms of starter issues: slow cranking, car won’t start, clicking or grinding sounds, starter running after engine starts, smoke from engine, dashboard warning…

Strategic Sourcing Conclusion and Outlook for replacing car starter cost

How Can B2B Buyers Optimize Costs for Replacing Car Starters?

In conclusion, the cost of replacing car starters can significantly impact the operational budgets of businesses, especially in international markets like Africa, South America, the Middle East, and Europe. Understanding the average costs, which typically range from $531 to $773, and the factors influencing these prices—such as labor complexity and part availability—enables buyers to make informed decisions.

Strategic sourcing plays a vital role in managing these costs effectively. By developing strong relationships with reputable suppliers and leveraging bulk purchasing agreements, businesses can secure high-quality starter replacements at competitive prices. Additionally, considering OEM parts can reduce the risk of further failures, thereby minimizing long-term expenses.

As the automotive landscape continues to evolve, it is crucial for B2B buyers to stay proactive. Embrace a data-driven approach to sourcing and evaluate new suppliers regularly to ensure you remain competitive. By prioritizing strategic sourcing, you not only enhance your bottom line but also position your business for sustainable growth in the automotive sector. Take action today to explore your sourcing options and optimize your replacement starter costs.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.