Introduction: Navigating the Global Market for parts of an auto

Navigating the global market for auto parts can be a daunting challenge for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With an increasing demand for reliable components, understanding the intricacies of sourcing high-quality parts is crucial for maintaining competitive advantage. This comprehensive guide delves into the essential components of vehicles, from engines and transmissions to braking systems and electrical parts. Each section will explore various types of auto parts, their applications, and the pivotal role they play in vehicle performance and safety.

In addition to detailing the types of parts available, this guide will provide actionable insights into supplier vetting processes, helping you identify trustworthy manufacturers and distributors. It will also discuss cost factors, logistics considerations, and market trends that can influence your purchasing decisions. By equipping international B2B buyers with the knowledge to navigate the complexities of the auto parts market, this guide empowers you to make informed choices that enhance your supply chain efficiency and reduce operational risks.

Whether you’re based in Nigeria, Brazil, or anywhere in between, understanding the global landscape of auto parts sourcing will position your business for success. Dive into this resource to unlock the potential of strategic purchasing and ensure your operations run smoothly with the right components at your fingertips.

Inhaltsverzeichnis

- Top 3 Parts Of An Auto Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of an auto

- Understanding parts of an auto Types and Variations

- Key Industrial Applications of parts of an auto

- 3 Common User Pain Points for ‘parts of an auto’ & Their Solutions

- Strategic Material Selection Guide for parts of an auto

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of an auto

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of an auto’

- Comprehensive Cost and Pricing Analysis for parts of an auto Sourcing

- Alternatives Analysis: Comparing parts of an auto With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of an auto

- Navigating Market Dynamics and Sourcing Trends in the parts of an auto Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of an auto

- Strategic Sourcing Conclusion and Outlook for parts of an auto

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

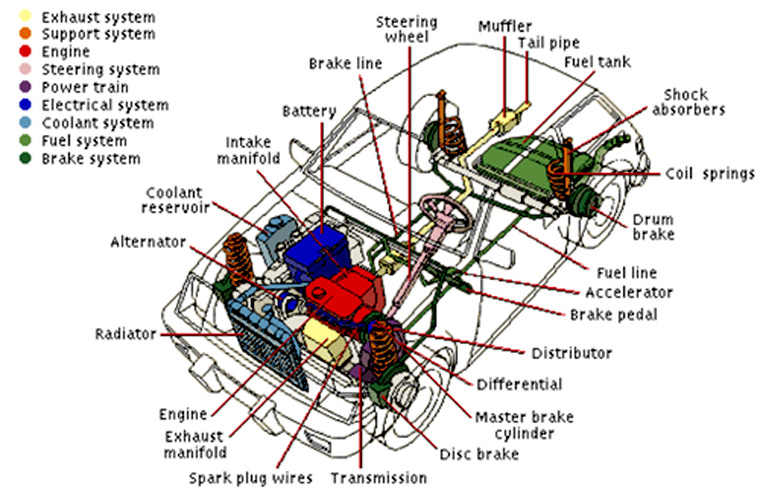

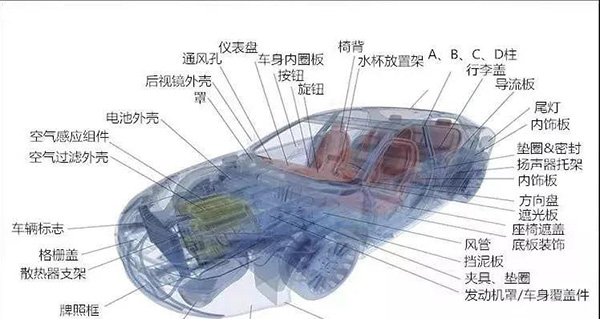

Understanding parts of an auto Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Verbrennungsmotor | Comprises cylinder block, pistons, crankshaft, and valves | Automotive manufacturing, aftermarket parts | Vorteile: High performance, established technology. Nachteile: Higher emissions, maintenance-intensive. |

| Übertragungssysteme | Includes automatic, manual, and CVT variations | Vehicle assembly, repairs, fleet management | Vorteile: Diverse options for efficiency and performance. Nachteile: Complexity may require specialized training for repairs. |

| Elektrische Systeme | Encompasses batteries, alternators, and wiring harnesses | Electric vehicle production, component suppliers | Vorteile: Essential for vehicle functionality, growing market for EVs. Nachteile: Rapid technological changes may affect compatibility. |

| Federungssysteme | Involves shocks, struts, and control arms | Vehicle performance enhancement, repairs | Vorteile: Verbessert die Fahrqualität und das Fahrverhalten. Nachteile: Quality varies by manufacturer, affecting reliability. |

| Auspuffanlagen | Comprises catalytic converters, mufflers, and tailpipes | Emission control compliance, aftermarket upgrades | Vorteile: Reduces emissions, enhances engine efficiency. Nachteile: Regulatory changes can impact design and requirements. |

Was sind die wichtigsten Merkmale von Verbrennungsmotoren?

Internal combustion engines (ICE) are the backbone of traditional vehicles, converting fuel into mechanical energy through a series of controlled explosions within the cylinders. B2B buyers should consider the engine’s displacement, power output, and fuel efficiency when sourcing components. With a focus on performance and reliability, understanding the specific applications—such as passenger vehicles versus heavy-duty trucks—can guide purchasing decisions. However, the shift towards electric vehicles may influence future investments in this segment.

Wie wirken sich unterschiedliche Getriebesysteme auf die Fahrzeugleistung aus?

Transmission systems, including automatic, manual, and continuously variable transmissions (CVT), play a critical role in managing engine power and vehicle speed. B2B buyers in automotive manufacturing or repair should evaluate the compatibility of transmissions with various engine types and vehicle models. While automatic transmissions offer ease of use, manual options may appeal to performance enthusiasts. Understanding the nuances of each system helps buyers select the right components to optimize vehicle performance and customer satisfaction.

Warum sind elektrische Systeme für moderne Fahrzeuge von entscheidender Bedeutung?

Electrical systems, which encompass batteries, alternators, and wiring harnesses, are vital for vehicle operation, especially in the growing electric vehicle market. B2B buyers must consider the latest technologies, such as lithium-ion batteries and smart wiring solutions, to stay competitive. The rapid evolution of electrical components necessitates a keen understanding of compatibility and regulatory standards. While investing in high-quality electrical systems can enhance vehicle performance, the fast-paced changes in technology may require ongoing education and adaptation.

What Role Do Suspension Systems Play in Vehicle Dynamics?

Suspension systems are essential for maintaining ride quality and handling characteristics in vehicles. They consist of various components like shocks, struts, and control arms that work together to absorb road irregularities. B2B buyers should assess the intended use of the vehicle—whether for comfort or performance—to determine the appropriate suspension components. While high-performance suspensions can enhance vehicle dynamics, they may also come with increased costs and complexity in installation and maintenance.

How Do Exhaust Systems Contribute to Emission Control?

Exhaust systems, which include catalytic converters, mufflers, and tailpipes, are critical for controlling vehicle emissions and ensuring compliance with environmental regulations. B2B buyers in the automotive sector must stay informed about evolving emission standards and consider the implications for component sourcing. Investing in advanced exhaust technologies can improve engine efficiency and reduce harmful emissions. However, fluctuations in regulatory requirements may necessitate adjustments in product offerings, impacting long-term purchasing strategies.

Key Industrial Applications of parts of an auto

| Branche/Sektor | Specific Application of parts of an auto | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Engine components (e.g., pistons, crankshafts) | Enhances production efficiency and vehicle performance | Quality certifications, material specifications, lead times |

| Transportdienstleistungen | Suspension systems for commercial vehicles | Improves ride quality and safety for passengers | Compatibility with vehicle models, durability, cost-effectiveness |

| Ersatzteile | Brake systems and components (e.g., pads, rotors) | Gewährleistet die Fahrzeugsicherheit und die Einhaltung von Vorschriften | Availability of OEM vs aftermarket options, warranty terms |

| Erneuerbare Energien | Electric vehicle (EV) battery systems and components | Unterstützt nachhaltige Verkehrslösungen | Technology compatibility, sourcing of raw materials, lifecycle management |

| Flottenmanagement | Diagnostic tools and electronic control units (ECUs) | Optimizes maintenance schedules and reduces downtime | Integration capabilities, software support, scalability |

Wie werden Motorkomponenten im Automobilbau eingesetzt?

In automotive manufacturing, engine components such as pistons and crankshafts are critical for assembling high-performance vehicles. These parts are designed to withstand extreme conditions, ensuring reliability and efficiency. B2B buyers in this sector, particularly from regions like Africa and South America, must prioritize sourcing high-quality components that meet international standards. Problems such as engine failure due to subpar parts can lead to costly recalls, making it essential to verify suppliers’ certifications and material quality.

What Role Do Suspension Systems Play in Transportation Services?

Suspension systems are vital in commercial vehicles, enhancing ride quality and ensuring passenger safety. These systems absorb shocks from the road, providing stability and comfort during transit. For B2B buyers in transportation services, especially in the Middle East and Europe, sourcing durable and compatible suspension components is crucial. Buyers should consider the specific vehicle models in their fleet and the local road conditions, as these factors influence the performance and longevity of suspension parts.

Why Are Brake Systems Essential in the Aftermarket Parts Industry?

Brake systems, including pads and rotors, are essential for vehicle safety and regulatory compliance. In the aftermarket parts industry, these components must meet stringent safety standards to avoid liability issues. B2B buyers, especially in emerging markets, should assess whether they are purchasing OEM or aftermarket parts, as this can affect performance and warranty coverage. Furthermore, understanding local regulations regarding vehicle safety can guide buyers in selecting appropriate brake systems.

How Do EV Battery Systems Support Renewable Energy Initiatives?

Electric vehicle (EV) battery systems are at the forefront of renewable energy initiatives, facilitating the transition to sustainable transport solutions. These systems require advanced technology and high-quality materials to ensure efficiency and longevity. International B2B buyers, particularly in Europe and Africa, should consider the sourcing of raw materials, such as lithium and cobalt, which are critical for battery production. Additionally, understanding the lifecycle management of these components is essential for maximizing return on investment and minimizing environmental impact.

What Benefits Do Diagnostic Tools Offer Fleet Management?

Diagnostic tools and electronic control units (ECUs) are crucial in fleet management, helping businesses optimize maintenance schedules and reduce vehicle downtime. These tools provide real-time data on vehicle performance, enabling timely interventions that prevent costly repairs. B2B buyers in fleet management, especially in South America and Africa, should focus on sourcing tools that offer integration capabilities with existing systems. Scalability and software support are also vital considerations, as they ensure that the tools can adapt to the evolving needs of the fleet.

3 Common User Pain Points for ‘parts of an auto’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Auto Parts

Das Problem: B2B buyers often struggle to source high-quality auto parts due to a fragmented supply chain. This issue is exacerbated in regions like Africa and South America, where local suppliers may lack the necessary inventory or standards for quality. Buyers face the risk of receiving counterfeit or subpar components, which can lead to safety concerns and increased maintenance costs. The reliance on multiple suppliers can also create inconsistencies in product availability and pricing, making it challenging to maintain operational efficiency.

Die Lösung: To overcome these sourcing challenges, B2B buyers should establish relationships with reputable manufacturers and distributors known for their commitment to quality. Conducting thorough market research is essential. Buyers can leverage platforms like trade shows, industry forums, and online marketplaces to identify trusted suppliers. Additionally, implementing a vendor evaluation process that includes criteria such as product certifications, reviews, and warranty offerings will help in selecting reliable partners. Buyers should also consider forming strategic alliances with local distributors who have a proven track record and can provide consistent access to quality parts.

Illustrative image related to parts of an auto

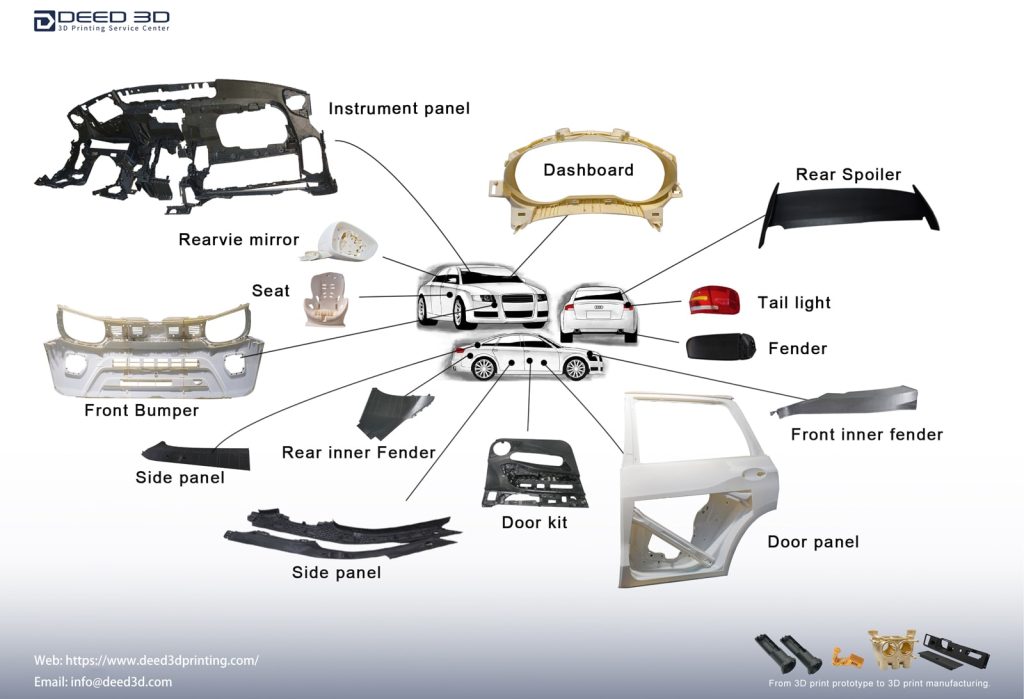

Scenario 2: Understanding Technical Specifications for Parts Compatibility

Das Problem: Many B2B buyers encounter difficulties in understanding the technical specifications required for parts compatibility with their vehicles. The automotive industry uses a complex system of specifications, including part numbers, dimensions, and material types. Misinterpretation of these details can lead to purchasing the wrong components, resulting in delays, increased costs, and potential vehicle downtime. This problem is particularly pronounced in regions where technical support may be limited, leaving buyers to navigate specifications on their own.

Die Lösung: To address this issue, B2B buyers should invest time in training and resources that enhance their understanding of auto parts specifications. This could involve workshops or online courses focusing on automotive parts and their applications. Additionally, utilizing digital tools like parts catalog software can streamline the identification process. Many manufacturers provide detailed catalogs and compatibility charts; buyers should leverage these resources during the purchasing process. Engaging directly with suppliers’ technical support teams can also clarify uncertainties and ensure that the selected parts meet the necessary specifications for compatibility.

Scenario 3: Managing Inventory and Reducing Lead Times

Das Problem: Efficient inventory management and minimizing lead times are critical pain points for B2B buyers in the automotive parts industry. Inconsistent demand forecasting can lead to overstocking or stockouts, both of which can impact cash flow and operational efficiency. Moreover, long lead times for parts can disrupt service delivery and customer satisfaction, particularly in competitive markets where quick turnaround is essential. This challenge is intensified in regions with logistical constraints, where shipping delays are common.

Die Lösung: Implementing an advanced inventory management system can significantly alleviate these issues. B2B buyers should consider adopting software that integrates real-time data analytics for demand forecasting, inventory tracking, and supplier performance evaluation. Additionally, establishing a just-in-time (JIT) inventory strategy can help reduce excess stock while ensuring that parts are available when needed. Collaborating with local suppliers who can provide expedited shipping options can also decrease lead times. Finally, maintaining a flexible inventory that adapts to changing market demands will enable buyers to respond quickly to customer needs, ultimately enhancing service levels and profitability.

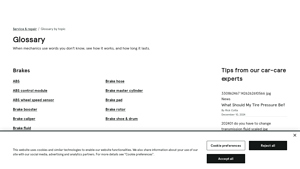

Strategic Material Selection Guide for parts of an auto

What Are the Key Materials Used in Automotive Parts?

When selecting materials for automotive parts, it is crucial to consider properties such as strength, weight, cost, and resistance to environmental factors. Here we analyze four common materials used in the automotive industry, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to parts of an auto

Wie verhält sich Stahl in Automobilanwendungen?

Steel is one of the most widely used materials in automotive manufacturing due to its excellent mechanical properties. It offers high tensile strength, making it suitable for structural components like frames and chassis. Steel can withstand high temperatures and pressures, which is essential for parts like engine blocks and transmission housings.

Vorteile: Steel is durable, cost-effective, and readily available. It can be easily formed and welded, allowing for complex shapes and designs.

Nachteile: However, steel is prone to corrosion, which can be a significant drawback in humid or saline environments. Additionally, its weight can negatively impact fuel efficiency.

Auswirkungen auf die Anwendung: Steel’s compatibility with various media, such as oil and fuel, makes it a reliable choice for many automotive applications.

Überlegungen für internationale Käufer: Buyers from regions like Africa and South America should be aware of local corrosion issues and may need to consider coatings or treatments to enhance steel’s resistance. Compliance with standards such as ASTM A36 is important for ensuring quality.

What Role Does Aluminum Play in Modern Vehicles?

Aluminum has gained popularity in the automotive industry due to its lightweight properties, making it an ideal choice for components where weight reduction is critical, such as body panels and engine parts.

Vorteile: Aluminum is resistant to corrosion and can improve fuel efficiency by reducing the overall weight of the vehicle. It also has good thermal conductivity, making it suitable for heat exchangers.

Nachteile: The primary drawback of aluminum is its higher cost compared to steel. Additionally, aluminum components can be more challenging to weld and may require specialized manufacturing processes.

Illustrative image related to parts of an auto

Auswirkungen auf die Anwendung: Aluminum’s compatibility with various environmental conditions makes it suitable for diverse automotive applications, particularly in regions with high humidity.

Überlegungen für internationale Käufer: Buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions and be aware of the local availability of aluminum alloys.

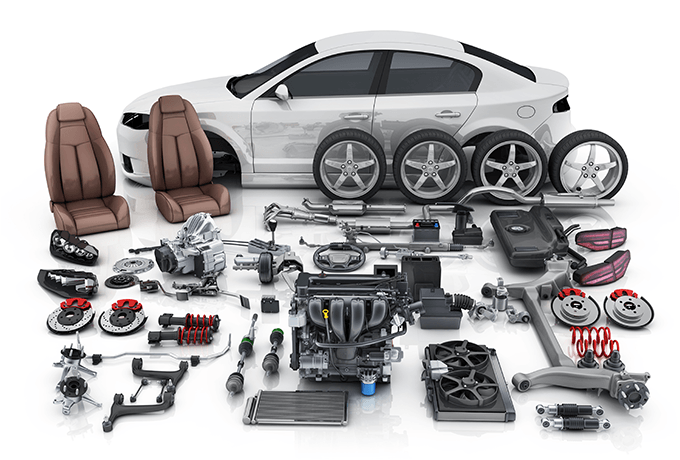

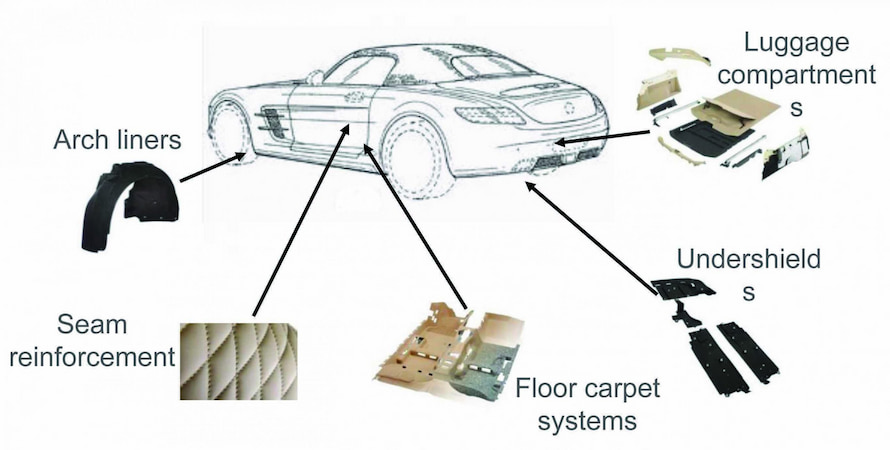

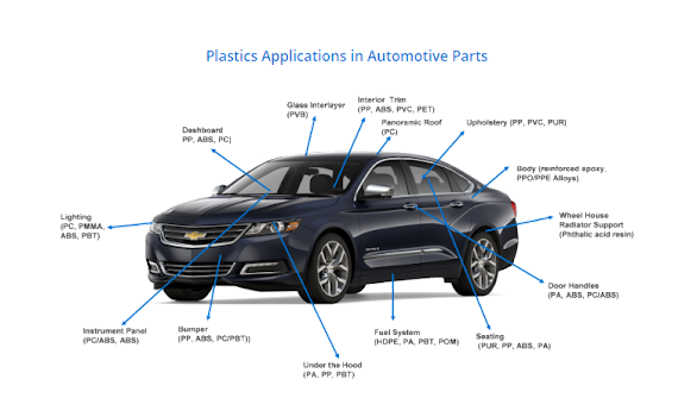

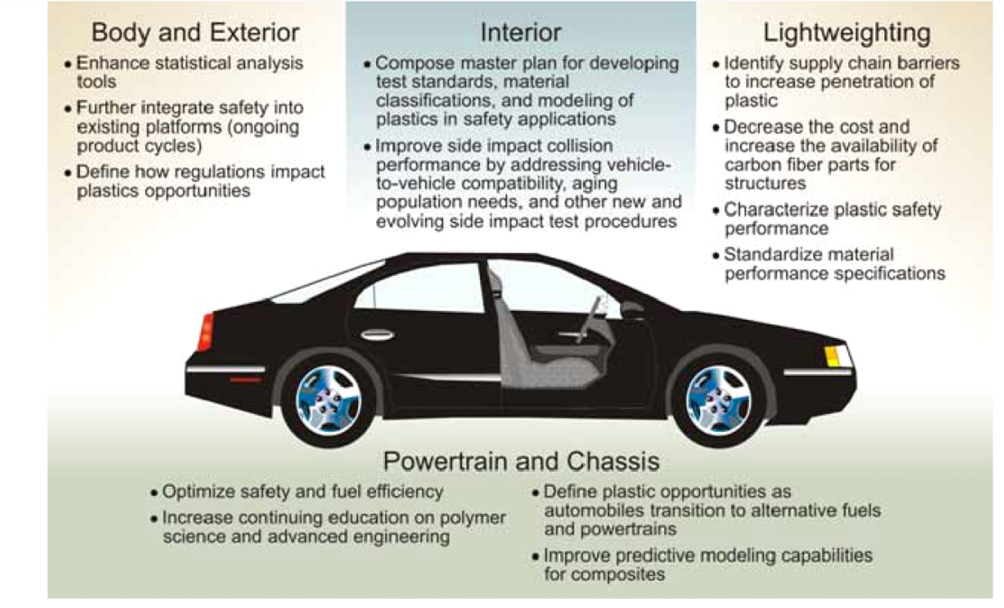

Wie trägt Kunststoff zum Automobildesign bei?

Plastics are increasingly used in automotive applications, particularly for interior components and non-structural parts. Various types of plastics, such as polypropylene and polycarbonate, offer unique properties suited for specific applications.

Vorteile: Plastics are lightweight, cost-effective, and can be molded into complex shapes. They also provide good resistance to chemicals and corrosion.

Illustrative image related to parts of an auto

Nachteile: However, plastics may not offer the same level of strength and durability as metals, which can limit their use in high-stress applications. They can also degrade under UV exposure unless treated.

Auswirkungen auf die Anwendung: Plastics are often used in interior trims, dashboards, and light covers, where aesthetics and weight savings are essential.

Überlegungen für internationale Käufer: Buyers should consider the specific plastic grades and their compliance with standards like ISO 9001. In regions with high UV exposure, selecting UV-stabilized plastics is advisable.

What Advantages Does Composite Material Offer?

Composite materials, such as carbon fiber and fiberglass, are becoming increasingly popular in high-performance automotive applications. They provide an excellent strength-to-weight ratio, making them ideal for sports cars and racing vehicles.

Vorteile: Composites are lightweight and can be tailored for specific performance characteristics. They also offer excellent corrosion resistance.

Illustrative image related to parts of an auto

Nachteile: The primary drawback is the high cost and complexity of manufacturing composite parts, which can limit their use in mass-market vehicles.

Auswirkungen auf die Anwendung: Composites are often used in body panels, structural components, and performance parts, where weight savings are critical.

Überlegungen für internationale Käufer: Buyers should be aware of the manufacturing capabilities in their region, as composites may require specialized equipment and expertise. Compliance with standards like ASTM D3039 for composite materials is crucial.

Übersichtstabelle zur Materialauswahl für Automobilteile

| Material | Typical Use Case for parts of an auto | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Fahrgestell, Motorblöcke | Hohe Festigkeit und Haltbarkeit | Korrosionsanfällig | Mittel |

| Aluminium | Body panels, engine components | Leicht und korrosionsbeständig | Higher cost and complex welding | Hoch |

| Kunststoff | Interior trims, dashboards | Leicht und kostengünstig | Limited strength in high-stress | Niedrig |

| Komposit | Body panels, performance parts | Ausgezeichnetes Verhältnis von Festigkeit zu Gewicht | Hohe Kosten und komplexe Herstellung | Hoch |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of an auto

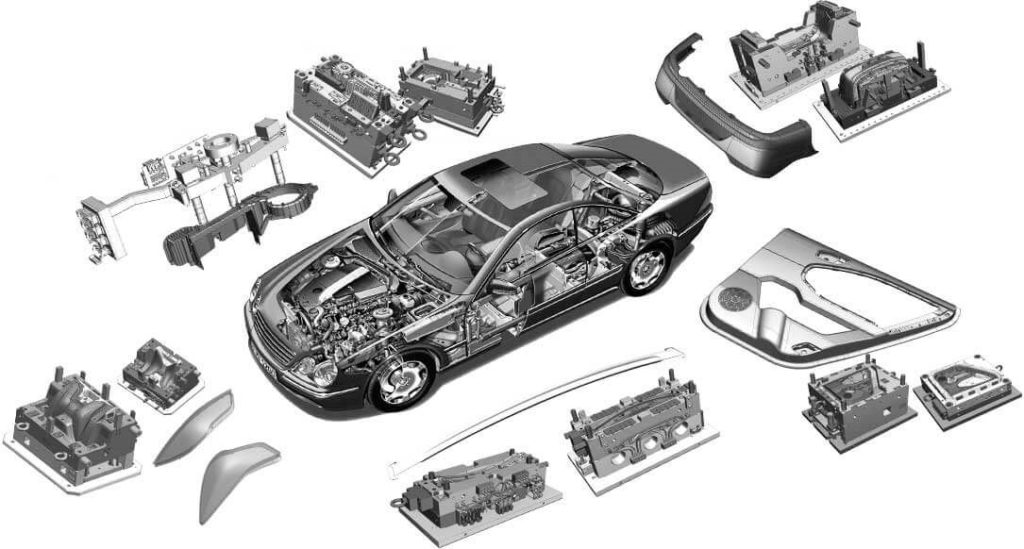

What Are the Key Stages of Manufacturing Auto Parts?

The manufacturing processes for auto parts are intricate and multifaceted, involving several critical stages. Understanding these stages can help B2B buyers make informed decisions when sourcing components. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to parts of an auto

How Is Material Prepared for Auto Parts Manufacturing?

Material preparation is the first step in the manufacturing process. It involves selecting the appropriate raw materials, which may include metals like steel or aluminum, plastics, and composites. Suppliers often rely on advanced technology to ensure the materials meet specific requirements. This stage may also involve cutting and shaping the raw materials into manageable sizes, which is crucial for subsequent processes.

What Forming Techniques Are Commonly Used in Auto Parts Production?

Once materials are prepared, the next stage is forming, which shapes the materials into the desired component shapes. Common techniques include:

- Stempeln: Used primarily for flat parts like brackets and panels, this process involves pressing a sheet of metal into a die.

- Gießen: This technique is prevalent for plastic components, where heated plastic is poured into a mold to create complex shapes.

- Bearbeitungen: Precision machining is employed to create highly detailed parts, such as engine components, using tools like lathes and mills.

- Gießen: This method is used for parts that require intricate shapes, such as engine blocks, where molten metal is poured into a mold and allowed to solidify.

Each of these techniques has its strengths and is chosen based on the part’s design specifications and material properties.

How Are Auto Parts Assembled?

After forming, the assembly stage brings together various components into a complete unit. This stage may involve welding, fastening, or the use of adhesives, depending on the materials and design. Automation plays a significant role in modern assembly processes, enhancing efficiency and consistency.

Robotic assembly lines are increasingly utilized, particularly in large-scale production, to reduce human error and increase output. However, manual assembly is still common for more complex or sensitive parts where precision is paramount.

Illustrative image related to parts of an auto

What Finishing Processes Are Applied to Auto Parts?

Finishing processes enhance the aesthetic and functional qualities of auto parts. These processes may include:

- Beschichtung: Applying paints, powder coatings, or galvanization to protect against corrosion and wear.

- Polishing: This technique improves the surface finish of metal components, enhancing their appearance and reducing friction.

- Heat Treatment: Used to improve the mechanical properties of metals, this process can increase strength and durability.

These finishing touches are crucial for ensuring the longevity and performance of auto parts.

Welche Qualitätssicherungsstandards sollten B2B-Einkäufer kennen?

Quality assurance (QA) is paramount in the auto parts manufacturing process. It ensures that components meet international standards and are fit for use. For B2B buyers, understanding relevant QA standards is critical.

Which International Standards Are Relevant to Auto Parts Manufacturing?

ISO 9001 is a fundamental standard that outlines the requirements for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, specific industry standards such as:

Illustrative image related to parts of an auto

- ISO/TS 16949: Focuses on quality management systems for automotive production.

- CE-Kennzeichnung: Indicates conformity with European health, safety, and environmental protection standards.

- API-Zertifizierung: Relevant for manufacturers of oil and gas industry components.

These certifications can significantly impact the decision-making process for B2B buyers, particularly in regions with stringent regulations.

What Are the Key Quality Control Checkpoints in Auto Parts Manufacturing?

Quality control (QC) checkpoints are essential for ensuring that parts meet specified standards throughout the manufacturing process. The main QC checkpoints include:

- Eingangsqualitätskontrolle (IQC): This initial checkpoint verifies the quality of raw materials before they enter the manufacturing process.

- In-Process-Qualitätskontrolle (IPQC): Conducted during the manufacturing stages, IPQC ensures that each step adheres to quality standards.

- Endkontrolle (FQC): The last checkpoint before products are shipped, FQC involves comprehensive testing and inspection of finished products to ensure they meet specifications.

Each of these checkpoints helps mitigate risks associated with defects and ensures that the final product is reliable.

Welche Prüfverfahren werden üblicherweise zur Qualitätssicherung eingesetzt?

Various testing methods are employed to verify the quality of auto parts. Common methods include:

- Dimensional Inspection: Ensures that parts are manufactured to exact specifications using tools like calipers and gauges.

- Material Testing: Assesses the properties of materials, including tensile strength, hardness, and fatigue resistance.

- Leistungstests: Simulates real-world conditions to evaluate how parts will perform under stress.

These tests provide valuable data that can help B2B buyers assess the reliability of potential suppliers.

Wie können B2B-Käufer die Qualitätskontrollprozesse ihrer Lieferanten überprüfen?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are some strategies:

Illustrative image related to parts of an auto

- Audits: Conducting on-site audits allows buyers to assess a supplier’s quality management system firsthand.

- Berichte: Requesting documentation of quality control processes and results can provide insights into a supplier’s commitment to quality.

- Third-party Inspections: Engaging independent inspection services can offer an unbiased evaluation of the supplier’s quality standards.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Einkäufer?

When sourcing auto parts internationally, particularly from regions like Africa, South America, the Middle East, and Europe, there are unique nuances to consider. Differences in regulations, standards, and practices can affect quality assurance processes.

B2B buyers should be aware of:

- Local Standards: Familiarize themselves with local standards and certifications that may differ from international norms.

- Kulturelle Unterschiede: Understand how cultural factors influence manufacturing practices and quality perceptions.

- Logistische Herausforderungen: Be prepared for potential delays and complications in supply chain logistics that can affect quality and delivery times.

By navigating these nuances effectively, B2B buyers can establish reliable partnerships and ensure the quality of the auto parts they procure.

In conclusion, understanding the manufacturing processes and quality assurance protocols for auto parts is essential for B2B buyers. With a comprehensive grasp of these elements, buyers can make informed decisions, fostering successful international trade relationships.

Illustrative image related to parts of an auto

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of an auto’

To successfully procure automotive parts, B2B buyers must navigate a complex landscape that includes supplier vetting, technical specifications, and compliance requirements. This guide provides a step-by-step checklist to streamline the sourcing process, ensuring that you make informed decisions and secure high-quality components.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Understanding the specific technical requirements of the parts you need is essential. Different vehicle models and types have unique specifications that must be adhered to in order to ensure compatibility and performance. Document details such as part numbers, dimensions, materials, and any certifications required for the parts.

- Wichtige Überlegungen:

- Compatibility with existing vehicle systems.

- Industry standards and regulations applicable to your region.

Schritt 2: Führen Sie Marktforschung durch

Prior to engaging suppliers, conduct thorough market research to identify potential vendors and understand pricing trends. This step will help you gauge the availability of parts and the typical lead times associated with procurement.

Illustrative image related to parts of an auto

- Research Tools:

- Industry reports and market analysis.

- Online B2B platforms and automotive trade shows.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing to a supplier, it is crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence will provide insights into their reliability and product quality.

- Was Sie beachten sollten:

- Supplier reviews and testimonials.

- Certifications (ISO, QS, etc.) that indicate quality assurance.

Schritt 4: Request Samples for Quality Assurance

Once you have shortlisted potential suppliers, request samples of the parts you intend to purchase. Evaluating samples allows you to assess the quality, fit, and performance of the parts before making a bulk order.

- Sample Evaluation Criteria:

- Material quality and durability.

- Compliance with your technical specifications.

Schritt 5: Verify Compliance with Regulatory Standards

Ensure that the parts meet all relevant local and international regulatory standards. This is particularly important in regions like Africa and South America, where compliance can vary significantly.

- Regulatory Aspects to Check:

- Emission standards for automotive components.

- Safety regulations specific to automotive parts.

Schritt 6: Verhandeln Sie Bedingungen und Preise

Once you have selected a supplier, engage in negotiations to finalize the terms of your purchase. Discuss pricing, payment terms, delivery schedules, and after-sales support to ensure a mutually beneficial agreement.

- Verhandlungstipps:

- Be clear about your budget constraints.

- Consider long-term partnership opportunities for better pricing.

Schritt 7: Establish a Quality Control Process

After placing your order, establish a quality control process to monitor the parts as they arrive. This step will help you identify any discrepancies early and ensure that the parts meet your quality expectations.

- Qualitätskontrollmaßnahmen:

- Conduct visual inspections upon receipt.

- Implement testing procedures for critical components.

By following this checklist, B2B buyers can streamline the sourcing process for automotive parts, reduce risks, and enhance their procurement outcomes.

Comprehensive Cost and Pricing Analysis for parts of an auto Sourcing

When sourcing auto parts for international markets, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers. The cost components and price influencers that shape the final price of auto parts can significantly impact procurement decisions, especially for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Auto Parts Sourcing?

-

Materialien: The quality and type of materials used directly influence the cost of auto parts. High-grade materials, such as aluminum and carbon fiber, often come at a premium but can offer better performance and longevity. Conversely, lower-quality materials may reduce upfront costs but could lead to higher failure rates and increased maintenance expenses.

-

Arbeit: Labor costs can vary greatly depending on the region of production. Countries with lower labor costs may offer competitive pricing, but it’s essential to consider the skill level of the workforce. Skilled labor may demand higher wages, but it can lead to better craftsmanship and fewer defects.

-

Fertigungsgemeinkosten: This encompasses the indirect costs associated with production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize overhead costs, which can be a significant component of the total cost structure.

-

Werkzeuge: The initial investment in tooling can be substantial, especially for custom parts. Tooling costs are often amortized over the production volume, making them a critical consideration for buyers looking at minimum order quantities (MOQs).

-

Qualitätskontrolle (QC): Implementing rigorous quality control processes ensures that parts meet specified standards, which can prevent costly returns and warranty claims. However, enhanced QC measures can increase overall costs.

-

Logistik: Transportation and handling fees can significantly affect the total cost of ownership. Buyers should consider freight costs, import duties, and insurance when evaluating the price of auto parts.

-

Marge: Suppliers will typically add a margin to cover their costs and profit. Understanding the supplier’s margin expectations can provide room for negotiation.

What Influences the Pricing of Auto Parts?

-

Volumen und Mindestbestellmenge (MOQ): Larger orders often qualify for volume discounts, which can be a significant cost-saving strategy for B2B buyers. Negotiating MOQs can also lead to better pricing, but it requires careful inventory management.

-

Spezifikationen und Anpassung: Custom parts tailored to specific vehicle models may incur additional costs due to specialized manufacturing processes. Buyers should weigh the benefits of customization against the increased expenses.

-

Auswahl der Materialien: The selection of materials can impact both the cost and performance of the parts. Understanding the trade-offs between different materials is essential for making informed purchasing decisions.

-

Qualitätszertifizierungen: Parts that meet industry standards or possess certifications (e.g., ISO, TS16949) may come at a higher price but offer assurances of quality and reliability, which can be crucial in regulated markets.

-

Lieferantenfaktoren: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but can provide better support and warranties.

-

Incoterms: The terms of delivery (Incoterms) can affect pricing by determining who bears the costs and risks during shipping. Buyers should familiarize themselves with these terms to avoid unexpected expenses.

What Are the Best Practices for International B2B Buyers?

-

Verhandlungsstrategien: Build strong relationships with suppliers and be prepared to negotiate terms and prices. Understanding market conditions can provide leverage in discussions.

-

Fokus auf Kosteneffizienz: Consider the total cost of ownership rather than just the purchase price. Factors such as maintenance, warranty, and replacement costs should be included in the overall evaluation.

-

Nuancen in der Preisgestaltung: International buyers should be aware of regional pricing differences and currency fluctuations that can affect costs. Establishing contracts in stable currencies can mitigate risks.

-

Lokale Verordnungen: Understanding import regulations and tariffs in the target market can prevent unforeseen costs and ensure compliance.

-

Due Diligence: Conduct thorough research on potential suppliers, including their financial stability, production capabilities, and customer reviews, to ensure a reliable partnership.

Haftungsausschluss für indikative Preise

Prices for auto parts can vary significantly based on numerous factors such as market demand, production costs, and regional economic conditions. Buyers are encouraged to conduct detailed market research and obtain quotes from multiple suppliers to achieve the best pricing.

Alternatives Analysis: Comparing parts of an auto With Other Solutions

Introduction: What Are the Alternatives to Auto Parts?

In the automotive industry, the traditional parts of an auto play a crucial role in vehicle performance and safety. However, emerging technologies and methodologies offer viable alternatives that can enhance functionality, reduce costs, or simplify maintenance. Understanding these alternatives allows B2B buyers to make informed decisions based on performance, cost-effectiveness, and specific operational needs.

Comparison Table of Auto Parts and Alternatives

| Vergleichsaspekt | Parts Of An Auto | Electric Vehicle (EV) Components | Modulare Fahrzeugsysteme |

|---|---|---|---|

| Leistung | High performance with mechanical efficiency | High torque and instant acceleration | Customizable performance based on needs |

| Kosten | Im Allgemeinen niedrigere Anfangskosten | Higher initial investment but potential savings on fuel | Variable costs depending on configuration |

| Einfache Implementierung | Widely available and standardized | Erfordert spezielle Kenntnisse für die Installation | Requires planning for integration |

| Wartung | Regular maintenance needed, parts replacement common | Lower maintenance with fewer moving parts | Maintenance can vary based on modular components |

| Bester Anwendungsfall | Conventional combustion vehicles | Urban environments with charging infrastructure | Fleet vehicles needing quick adaptation |

Detaillierte Aufschlüsselung der Alternativen

Electric Vehicle (EV) Components

Electric vehicles represent a significant shift in automotive technology, relying on electric motors and battery systems instead of traditional internal combustion engines. The performance of EVs is notable, as they provide high torque and instant acceleration, making them suitable for urban environments. While the initial cost can be higher due to battery technology, the long-term savings on fuel and maintenance make them an attractive option. However, implementing EV components requires specialized knowledge and infrastructure for charging, which may present challenges in regions with limited resources.

Modulare Fahrzeugsysteme

Modular vehicle systems offer flexibility by allowing manufacturers to customize vehicle configurations based on specific operational requirements. These systems can be tailored to various applications, from cargo transport to passenger services, making them ideal for fleet operations. The performance can be optimized for different uses, providing a competitive edge in diverse markets. However, the complexity of planning and integrating modular systems can be a drawback, as it requires careful consideration of design and compatibility. Additionally, costs can vary significantly based on the selected components and configuration.

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

When evaluating alternatives to traditional auto parts, B2B buyers must consider their specific operational needs, budget constraints, and the availability of support infrastructure. Electric vehicle components may be ideal for businesses looking to reduce long-term operational costs and align with sustainability goals, especially in urban settings. Conversely, modular vehicle systems are well-suited for companies that require flexibility and adaptability in their fleet operations. Ultimately, the right choice will depend on a thorough analysis of performance requirements, cost implications, and the ease of implementation in the buyer’s specific context.

Essential Technical Properties and Trade Terminology for parts of an auto

What Are the Key Technical Properties to Consider When Sourcing Auto Parts?

When sourcing auto parts, understanding the technical specifications is crucial for making informed purchasing decisions. Here are several critical specifications that B2B buyers should consider:

-

Werkstoffgüte

Material grade refers to the quality and type of material used in the manufacturing of auto parts. Common materials include steel, aluminum, and plastics, each with different strengths and weaknesses. Understanding material grade helps buyers assess durability, weight, and corrosion resistance, which are essential for performance and longevity. For instance, high-grade steel may be preferred for structural components due to its strength, while lightweight aluminum might be chosen for engine parts to enhance fuel efficiency. -

Toleranz

Tolerance indicates the allowable variation in dimensions during the manufacturing process. It is a critical factor in ensuring that parts fit together correctly and function as intended. Tight tolerances are necessary for components that require precise alignment, such as engine parts and transmission systems. Inaccurate tolerances can lead to malfunction, increased wear, and safety issues, making it vital for buyers to confirm tolerance specifications when procuring parts. -

Finish

The finish of a part affects both its aesthetic appeal and functional performance. Common finishes include anodizing, powder coating, and plating, which can enhance corrosion resistance and reduce friction. Buyers should consider the finish required based on the part’s application and environmental exposure, as this can significantly impact maintenance costs and part lifespan. -

Tragfähigkeit

Load capacity refers to the maximum weight or force that a component can safely bear. This specification is particularly important for parts such as axles, suspension components, and brakes. Understanding load capacity helps buyers select appropriate parts for different vehicle types and ensure safety and performance under various driving conditions. -

Kompatibilität

Compatibility indicates whether a part will fit and function correctly with a specific vehicle model or system. This includes considering OEM (Original Equipment Manufacturer) specifications versus aftermarket options. Buyers need to ensure that any part they source is compatible to avoid costly returns and installation issues.

What Are Common Trade Terms Used in the Auto Parts Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation with suppliers. Here are some common terms to know:

-

OEM (Originalgerätehersteller)

OEM parts are components made by the original manufacturer of the vehicle. These parts are designed to meet the exact specifications of the vehicle and are often preferred for their reliability and quality. Buyers should be aware that while OEM parts typically come at a premium price, they offer assurance in performance and fit. -

MOQ (Mindestbestellmenge)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs, especially if they are looking to test a new supplier or part type without committing to large quantities upfront. -

RFQ (Angebotsanfrage)

An RFQ is a formal process in which a buyer requests pricing and terms from suppliers for specific parts. This process helps buyers compare offers and negotiate better deals. Clearly defining requirements in the RFQ can lead to more accurate quotes and smoother procurement processes. -

Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and liability. Familiarity with these terms is vital for B2B buyers engaged in cross-border trade, as they clarify expectations and reduce the risk of disputes. -

Vorlaufzeit

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for effective supply chain management and inventory planning. Buyers should communicate their needs clearly to suppliers to ensure timely delivery and avoid production delays.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, enhance their purchasing strategies, and ultimately improve their operations in the competitive auto parts market.

Navigating Market Dynamics and Sourcing Trends in the parts of an auto Sector

What Are the Key Market Dynamics Impacting the Auto Parts Sector for B2B Buyers?

The global auto parts market is undergoing significant transformations driven by technological advancements, changing consumer preferences, and regulatory pressures. For international B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. One of the most notable trends is the rise of electric vehicles (EVs), which is reshaping the demand for traditional components while creating opportunities in new technologies such as batteries and electric drivetrains. This shift is further accelerated by government incentives promoting greener vehicles, pushing suppliers to adapt their offerings accordingly.

Additionally, the integration of Industry 4.0 technologies, including IoT, AI, and big data analytics, is revolutionizing sourcing and supply chain management. These technologies enhance efficiency and provide deeper insights into market trends, enabling B2B buyers to make informed decisions. For instance, predictive analytics can help anticipate demand fluctuations, allowing suppliers to optimize inventory levels and reduce costs. Moreover, the COVID-19 pandemic highlighted the vulnerabilities in global supply chains, prompting buyers to seek more localized sourcing options to mitigate risks associated with geopolitical tensions and logistics disruptions.

B2B buyers are also increasingly focused on transparency in the supply chain, pushing suppliers to adopt practices that enhance visibility and accountability. This trend underscores the importance of establishing strong relationships with suppliers who can provide reliable, high-quality parts that meet evolving standards.

How Is Sustainability and Ethical Sourcing Shaping the Auto Parts Industry?

Sustainability is becoming a critical consideration in the auto parts sector, influencing purchasing decisions among B2B buyers. The environmental impact of automotive manufacturing is significant, with traditional processes contributing to pollution and resource depletion. As a result, businesses are prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes the use of recyclable materials, reduced emissions in production, and adherence to environmental regulations.

Ethical sourcing has also gained traction, with buyers increasingly scrutinizing the supply chain for labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for suppliers aiming to establish credibility in the market. Additionally, the growing demand for “green” parts—such as those made from bio-based materials or featuring lower lifecycle emissions—presents an opportunity for suppliers to differentiate themselves.

Incorporating sustainability into the sourcing strategy not only meets regulatory requirements but also aligns with consumer expectations, particularly in markets where eco-consciousness is high. B2B buyers can leverage these trends to enhance their brand reputation and foster long-term relationships with suppliers who share their values.

What Is the Historical Context of the Auto Parts Industry’s Evolution?

The auto parts industry has a rich history that has evolved significantly over the past century. Initially, the industry was characterized by a fragmented supply chain with local manufacturers producing specific components. However, the post-World War II era saw the rise of large automotive manufacturers who streamlined production processes and established global supply networks. This shift enabled economies of scale, allowing for mass production of vehicles and parts.

As the industry progressed, the introduction of just-in-time (JIT) manufacturing in the late 20th century transformed sourcing strategies, emphasizing efficiency and reducing waste. This method reshaped relationships between manufacturers and suppliers, fostering collaboration and innovation. In recent years, the focus has shifted towards integrating advanced technologies and sustainable practices, marking a new chapter in the industry’s evolution.

By understanding this historical context, B2B buyers can better appreciate the complexities of the current market and make informed decisions that align with future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of an auto

-

How do I solve supply chain disruptions when sourcing auto parts internationally?

Supply chain disruptions can significantly impact your ability to source auto parts. To mitigate this, establish strong relationships with multiple suppliers across different regions. Diversifying your supplier base can help reduce dependency on a single source. Additionally, consider implementing just-in-time inventory practices to minimize stock shortages. Regular communication with suppliers about potential delays and alternative logistics options can also aid in addressing any unforeseen issues quickly. -

What is the best way to vet suppliers for auto parts?

To effectively vet suppliers, start by assessing their industry reputation through reviews and testimonials from other B2B buyers. Request certifications that demonstrate compliance with international quality standards, such as ISO 9001. Conduct site visits or virtual inspections to evaluate their manufacturing capabilities and quality control processes. Lastly, establish clear communication and ask for samples to ensure that the parts meet your specifications before placing larger orders. -

What are the advantages of customizing auto parts for my business needs?

Customizing auto parts can provide significant advantages, including improved performance tailored to specific vehicle models and enhanced compatibility with existing systems. Custom parts can also differentiate your offerings in a competitive market, potentially attracting more customers. Additionally, customization can lead to cost savings in the long term by reducing the need for modifications during installation. It’s essential to communicate your requirements clearly with the supplier to achieve the desired results. -

What is the minimum order quantity (MOQ) for auto parts, and how does it vary by supplier?

Minimum order quantities (MOQs) for auto parts can vary widely depending on the supplier, type of part, and manufacturing processes. Typically, MOQs can range from a few units for standard parts to several hundred for custom or specialized components. Always discuss MOQs upfront with potential suppliers to understand their terms and how they can accommodate your purchasing needs. Negotiating lower MOQs may be possible, especially for long-term partnerships. -

What payment terms should I expect when sourcing auto parts internationally?

Payment terms can differ based on the supplier’s policies and the relationship you establish. Common terms include upfront payments, letters of credit, or net 30/60/90 days after invoice. It’s crucial to clarify payment conditions before finalizing contracts to avoid misunderstandings. Consider using secure payment methods such as escrow services to protect your investment, especially when dealing with new suppliers. -

How can I ensure quality assurance (QA) for the auto parts I source?

To ensure quality assurance, first, require suppliers to provide quality certifications and adhere to industry standards. Implement regular inspections throughout the manufacturing process, either through third-party services or in-house teams. Establish a clear return policy for defective parts and maintain an open line of communication with suppliers regarding quality issues. Additionally, consider conducting pre-shipment inspections to verify that the products meet your specifications before they leave the supplier’s facility. -

What logistics considerations should I keep in mind when importing auto parts?

When importing auto parts, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose between air freight for speed or sea freight for cost-effectiveness based on your needs. Familiarize yourself with the import duties and tariffs applicable in your country to avoid unexpected costs. Partnering with a logistics provider experienced in international trade can help streamline the shipping process and ensure compliance with regulations. -

How do I handle warranty claims for auto parts sourced internationally?

Handling warranty claims for internationally sourced auto parts requires clear communication and documented agreements with your suppliers. Ensure that warranties are explicitly stated in your purchase agreements, including coverage duration and conditions. Establish a straightforward claims process, detailing the steps for reporting issues and obtaining replacements. Additionally, maintain records of all transactions and communications to facilitate any warranty claims that may arise.

Top 3 Parts Of An Auto Manufacturers & Suppliers List

1. Moog – Steering Components

Domäne: moogparts.com

Registriert: 2005 (20 Jahre)

Einleitung: Steering Center Drag Links, Idler Arms, Pitman Arms, Steering Stabilizers, Complete Pre-Assembled Steering Linkage, Tie Rods, Solid Sway Bar Kits, Alignment Parts, Bushings, Coil Springs, Control Arms, Sway Bar Links, Ball Joints, Universal Joints, Couplers, Constant Velocity Axles, Complete Knuckle Assembly, Hub Assemblies.

2. Edmunds – Engine Components

Domäne: edmunds.com

Registriert: 1996 (29 Jahre)

Einleitung: 1. Engine: The engine is where combustion occurs, converting fuel into mechanical force to move the wheels. Key components include:

– Cylinder block and pistons: Houses cylinders for controlled explosions that drive pistons.

– Spark plugs: Generate a spark to ignite the fuel-air mixture in the cylinders.

– Cylinder head and valves: Control the flow of air and fuel into the cylinders.

-…

3. Cars.com – Brakes & Climate Controls

Domäne: autos.de

Registriert: 1998 (27 Jahre)

Einleitung: Brakes: ABS, ABS control module, ABS wheel speed sensor, Brake booster, Brake caliper, Brake fluid, Brake hose, Brake master cylinder, Brake pad, Brake rotor, Brake shoe & drum; Climate controls: AC compressor, AC condenser, AC evaporator, AC recharge, Air conditioning diagnosis, Cabin air filter, Heater blower motor, Heater blower motor resistor; Cooling systems: Coolant, Coolant leak diagnosis, …

Strategic Sourcing Conclusion and Outlook for parts of an auto

As the automotive industry continues to evolve, strategic sourcing of auto parts is becoming increasingly vital for international B2B buyers. Understanding the intricate composition of vehicles—ranging from engines to exhaust systems—enables buyers to make informed decisions that can enhance operational efficiency and profitability. By prioritizing reliable suppliers and investing in quality components, businesses can ensure not only compliance with stringent regulations but also the longevity and performance of their vehicles.

Moreover, the growing demand for sustainable and technologically advanced auto parts presents significant opportunities for sourcing innovations. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should leverage global partnerships to access cutting-edge technologies and eco-friendly solutions.

Looking ahead, the automotive market is poised for transformation, driven by advancements in electric vehicles and smart technologies. Now is the time to engage with trusted suppliers who can provide the necessary expertise and products to navigate this changing landscape. Embrace strategic sourcing as a pathway to not only enhance your supply chain resilience but also position your business for future growth.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to parts of an auto

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.