Introduction: Navigating the Global Market for solenoide de arranque

In today’s competitive landscape, sourcing reliable solenoide de arranque (starter solenoids) is a critical challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive for operational efficiency, the need for dependable components that ensure robust engine performance becomes paramount. This guide is designed to navigate the complexities of the global market for starter solenoids, providing valuable insights into various types, applications, and sourcing strategies tailored to your unique business needs.

The comprehensive scope of this guide encompasses essential aspects such as different solenoid designs, their specific applications across various machinery, and a detailed analysis of the supplier vetting process. Additionally, we will explore cost considerations and market trends that influence purchasing decisions. By delving into these critical areas, this resource empowers you to make informed choices that enhance your operational capabilities and align with your strategic goals.

Whether you are a procurement manager in Saudi Arabia looking for high-performance automotive components or a distributor in Brazil seeking reliable suppliers, understanding the intricacies of the solenoide de arranque market is vital. This guide equips you with the knowledge to identify quality products, negotiate favorable terms, and build lasting partnerships with trusted suppliers, ultimately driving your business forward in a globalized economy.

Inhaltsverzeichnis

- Top 2 Solenoide De Arranque Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for solenoide de arranque

- Understanding solenoide de arranque Types and Variations

- Key Industrial Applications of solenoide de arranque

- 3 Common User Pain Points for ‘solenoide de arranque’ & Their Solutions

- Strategic Material Selection Guide for solenoide de arranque

- In-depth Look: Manufacturing Processes and Quality Assurance for solenoide de arranque

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘solenoide de arranque’

- Comprehensive Cost and Pricing Analysis for solenoide de arranque Sourcing

- Alternatives Analysis: Comparing solenoide de arranque With Other Solutions

- Essential Technical Properties and Trade Terminology for solenoide de arranque

- Navigating Market Dynamics and Sourcing Trends in the solenoide de arranque Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of solenoide de arranque

- Strategic Sourcing Conclusion and Outlook for solenoide de arranque

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding solenoide de arranque Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Electromagnetic Solenoid | Operates using electromagnetic force, reliable and common. | Automobilindustrie, Schwermaschinen | Vorteile: Hohe Zuverlässigkeit; Nachteile: Can be sensitive to electrical issues. |

| Permanent Magnet Solenoid | Utilizes permanent magnets for actuation, compact design. | Smaller engines, portable equipment | Vorteile: Energieeffizient; Nachteile: Limited power output. |

| Latching Solenoid | Maintains position without continuous power, energy-efficient. | Industrial automation, locking systems | Vorteile: Low power consumption; Nachteile: More complex control mechanism. |

| High-Voltage Solenoid | Designed for higher voltage applications, robust construction. | Schwere Nutzfahrzeuge, Industriemaschinen | Vorteile: Suitable for demanding environments; Nachteile: Höhere Kosten. |

| Dual Coil Solenoid | Features two coils for different functions, versatile operation. | Various automotive and industrial uses | Vorteile: Flexible functionality; Nachteile: More complex wiring requirements. |

What Are the Characteristics and Applications of Electromagnetic Solenoids?

Electromagnetic solenoids are the most commonly used type in various industries, particularly in automotive and heavy machinery applications. They function by converting electrical energy into mechanical movement through electromagnetic forces. B2B buyers should consider their reliability and ease of integration into existing systems. However, potential buyers must also account for their sensitivity to electrical issues, which may necessitate additional safeguards in high-demand environments.

How Do Permanent Magnet Solenoids Differ from Other Types?

Permanent magnet solenoids leverage the power of permanent magnets, making them compact and energy-efficient. They are particularly well-suited for smaller engines and portable equipment, where space and energy consumption are critical. B2B buyers should evaluate the specific power requirements of their applications, as these solenoids may have limitations in terms of power output compared to their electromagnetic counterparts. Their compact design can be a significant advantage in applications with size constraints.

What Are the Advantages of Latching Solenoids for Industrial Applications?

Latching solenoids are designed to maintain their position without continuous power, making them highly energy-efficient. They are ideal for applications in industrial automation and locking systems, where power conservation is essential. Buyers should consider the complexity of control mechanisms required for operation, as this can influence overall system design. While they provide significant energy savings, the additional complexity may require specialized knowledge for installation and maintenance.

In What Scenarios Are High-Voltage Solenoids Most Effective?

High-voltage solenoids are engineered to handle demanding environments, making them suitable for heavy-duty vehicles and industrial machinery. Their robust construction allows them to withstand high voltage applications, which is crucial in environments where reliability is paramount. B2B buyers should weigh the benefits of their durability and performance against the typically higher costs associated with these solenoids. This type is ideal for businesses that prioritize performance over initial investment.

How Do Dual Coil Solenoids Enhance Versatility in Operations?

Dual coil solenoids offer versatility by featuring two coils that can perform different functions, making them suitable for various automotive and industrial applications. This flexibility allows businesses to optimize their operations by integrating a single component for multiple uses. However, buyers must also consider the more complex wiring requirements that come with dual coil systems, which could lead to increased installation time and costs. Evaluating the specific operational needs will help in deciding if the benefits outweigh the complexities.

Illustrative image related to solenoide de arranque

Key Industrial Applications of solenoide de arranque

| Branche/Sektor | Specific Application of solenoide de arranque | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Starter motor activation in vehicles | Sorgt für einen zuverlässigen Motorstart und reduziert Ausfallzeiten | Quality certifications and compatibility with vehicle models |

| Baumaschinen | Engine ignition in heavy machinery | Enhances operational efficiency and productivity | Durability in harsh environments and resistance to vibrations |

| Schiffsindustrie | Starting systems for boats and vessels | Reliable performance in challenging marine conditions | Corrosion resistance and compliance with maritime standards |

| Landwirtschaftliche Geräte | Ignition systems in tractors and harvesters | Maximizes field productivity with minimal delays | Availability of parts for maintenance and support in remote areas |

| Erneuerbare Energien | Activation of generators in wind turbines | Supports sustainable energy production | Compatibility with different energy systems and scalability |

How is ‘solenoide de arranque’ used in the automotive manufacturing sector?

In the automotive manufacturing sector, the solenoide de arranque is pivotal for the activation of starter motors in vehicles. It enables the efficient start-up of engines, which is crucial for reducing downtime during assembly and testing phases. B2B buyers in this industry must consider the solenoide’s compatibility with various vehicle models and ensure it meets quality certifications to guarantee reliability and performance.

What role does the solenoide de arranque play in construction equipment?

In construction, the solenoide de arranque is essential for the ignition of engines in heavy machinery such as excavators and bulldozers. Its reliable performance directly impacts operational efficiency, allowing machinery to start promptly and operate without interruption. Buyers should focus on sourcing solenoides that demonstrate durability in harsh environments and are resistant to vibrations, as this ensures longevity and reduces maintenance costs.

How does the marine industry utilize solenoide de arranque?

The marine industry employs solenoides de arranque in the starting systems of boats and vessels. Given the challenging conditions at sea, these solenoides must perform reliably under various environmental factors, including moisture and salt exposure. Buyers should prioritize corrosion-resistant solenoides that comply with maritime standards to ensure the safety and reliability of their marine operations.

In what ways do agricultural equipment manufacturers benefit from solenoide de arranque?

In agriculture, solenoides de arranque are crucial for ignition systems in tractors and harvesters, enabling quick and efficient engine starts that maximize productivity in the field. This is particularly important during peak harvesting seasons. Buyers in this sector should consider the availability of parts for maintenance and support, especially in remote areas, to minimize downtime and ensure continuous operation.

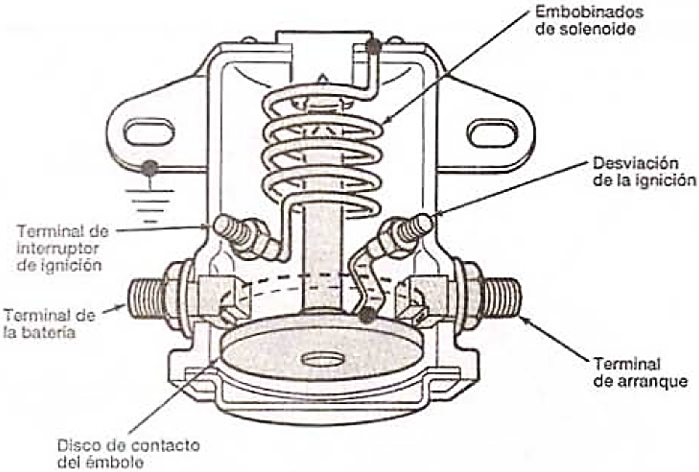

Illustrative image related to solenoide de arranque

How is the renewable energy sector impacted by solenoide de arranque?

The renewable energy sector utilizes solenoides de arranque in the activation of generators within wind turbines. This application is vital for supporting sustainable energy production and ensuring that turbines operate efficiently. B2B buyers should focus on sourcing solenoides that are compatible with different energy systems and scalable to meet future energy demands, ensuring long-term viability and performance in renewable energy projects.

3 Common User Pain Points for ‘solenoide de arranque’ & Their Solutions

Scenario 1: Unreliable Performance Under Harsh Conditions

Das Problem: For B2B buyers in sectors such as agriculture, construction, or mining, solenoide de arranque often operates in extreme environments, including high temperatures, humidity, or dust. This can lead to premature failure of the solenoid, resulting in costly downtime and operational inefficiencies. Buyers may face challenges in sourcing components that can withstand these harsh conditions, leading to frustration and increased maintenance costs.

Die Lösung: To ensure reliable performance, it is crucial to select solenoide de arranque that is specifically designed for extreme environments. Buyers should look for solenoids with protective coatings or seals that resist moisture and dust intrusion. Additionally, sourcing from reputable manufacturers who provide detailed specifications and testing results can help ensure the solenoid meets industry standards for durability. Regular maintenance checks, including cleaning and testing of the solenoid, can also prevent unexpected failures. Consider investing in solenoids with a proven track record in similar applications to mitigate risk.

Scenario 2: Difficulty in Sourcing Compatible Components

Das Problem: B2B buyers often struggle to find solenoide de arranque that is compatible with their existing machinery or systems. This can be particularly challenging in regions where certain brands or models are not readily available. Incompatibility issues can lead to increased procurement costs and extended lead times, disrupting the supply chain and affecting overall productivity.

Die Lösung: To alleviate this issue, it is advisable to conduct a thorough compatibility assessment before purchasing. This includes reviewing the specifications of the existing machinery and identifying any specific requirements for the solenoide de arranque, such as voltage ratings and physical dimensions. Building relationships with multiple suppliers can provide access to a broader range of products and help identify alternatives if specific models are unavailable. Utilizing online platforms that specialize in industrial parts can streamline the sourcing process and offer insights into compatible products.

Scenario 3: Lack of Technical Knowledge for Installation and Maintenance

Das Problem: Many B2B buyers may lack the technical expertise necessary for the proper installation and maintenance of solenoide de arranque. This knowledge gap can lead to improper installation, affecting the solenoid’s functionality and lifespan. Furthermore, without proper maintenance, even high-quality solenoids can fail, leading to increased costs and operational disruptions.

Die Lösung: To address this challenge, buyers should invest in training programs for their technical staff or seek support from manufacturers who offer installation guides and maintenance training. Many reputable suppliers provide detailed manuals and online resources, including video tutorials, that can assist in the proper installation and maintenance of solenoide de arranque. Additionally, engaging with service technicians who specialize in these components can provide valuable insights and hands-on assistance. Establishing a routine maintenance schedule can also help in identifying potential issues before they lead to failure, ensuring the solenoid operates efficiently over its lifespan.

Strategic Material Selection Guide for solenoide de arranque

When selecting materials for solenoide de arranque (starter solenoids), it is crucial to consider the specific operational requirements and environmental conditions in which these components will function. The choice of material directly influences performance, durability, and compliance with international standards. Below is a detailed analysis of four common materials used in the manufacturing of starter solenoids, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Copper in Starter Solenoids?

Copper is widely used in solenoide de arranque due to its excellent electrical conductivity and thermal properties. It typically has a high melting point (approximately 1,984°F or 1,085°C) and can withstand significant electrical loads without degrading. Additionally, copper offers good corrosion resistance, especially when alloyed with other metals.

Vor- und Nachteile: The primary advantage of copper is its superior conductivity, which enhances the solenoid’s efficiency and responsiveness. However, copper can be relatively expensive compared to other materials, and its susceptibility to corrosion in certain environments can necessitate protective coatings or treatments.

Auswirkungen auf die Anwendung: Given its excellent conductivity, copper is particularly suitable for applications requiring rapid actuation and high current flow. Buyers in regions with high humidity or corrosive environments, such as coastal areas in Brazil or the Middle East, should consider protective measures.

How Does Steel Perform in Starter Solenoids?

Steel, particularly carbon steel, is another common material used in solenoide de arranque. It is valued for its strength and durability, with a high tensile strength that can withstand the mechanical stresses encountered during operation.

Vor- und Nachteile: Steel’s primary advantage is its robustness, making it ideal for heavy-duty applications. However, it is prone to rust and corrosion if not properly treated, which can limit its lifespan in harsh environments. Additionally, the manufacturing complexity can be higher due to the need for additional coatings or treatments.

Illustrative image related to solenoide de arranque

Auswirkungen auf die Anwendung: Steel solenoids are well-suited for heavy machinery and industrial applications, especially where mechanical strength is paramount. International buyers should ensure compliance with local standards for corrosion resistance, particularly in humid climates.

What Role Does Aluminum Play in Starter Solenoid Construction?

Aluminum is increasingly used in solenoide de arranque due to its lightweight nature and good corrosion resistance. It typically has a lower melting point (approximately 1,221°F or 660°C) than copper and steel, making it easier to manufacture and shape.

Vor- und Nachteile: The main advantage of aluminum is its weight, which can lead to lighter overall equipment and improved fuel efficiency in automotive applications. However, its lower strength compared to steel may limit its use in high-stress environments, and it can be more expensive than steel.

Auswirkungen auf die Anwendung: Aluminum is particularly beneficial in automotive applications where weight reduction is critical. Buyers in Europe and South America, where automotive regulations increasingly favor lightweight materials, may find aluminum solenoids advantageous.

Why Choose Plastic or Composite Materials for Solenoids?

Plastic and composite materials are sometimes used for non-conductive components of solenoide de arranque, such as housings or insulation. These materials offer excellent resistance to corrosion and are lightweight.

Vor- und Nachteile: The primary advantage of plastics is their resistance to environmental factors, which can enhance the longevity of the solenoid. However, they may not withstand high temperatures or mechanical stress as well as metals, limiting their application scope.

Auswirkungen auf die Anwendung: Plastic components are suitable for applications where electrical insulation is critical. Buyers should consider the specific thermal and mechanical requirements of their applications, especially in regions with extreme temperatures.

Summary Table of Material Selection for Solenoide de Arranque

| Material | Typical Use Case for solenoide de arranque | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | High-performance automotive applications | Hervorragende elektrische Leitfähigkeit | Higher cost, corrosion susceptibility | Hoch |

| Stahl | Schwermaschinen und industrielle Anwendungen | Hohe Festigkeit und Haltbarkeit | Prone to corrosion, manufacturing complexity | Mittel |

| Aluminium | Automotive and lightweight applications | Leichtes Gewicht, gute Korrosionsbeständigkeit | Geringere Festigkeit im Vergleich zu Stahl | Mittel |

| Kunststoff/Komposit | Non-conductive components and insulation | Hervorragende Korrosionsbeständigkeit | Limited temperature and stress tolerance | Niedrig |

This guide provides a comprehensive overview of material options for solenoide de arranque, aiding international B2B buyers in making informed decisions based on performance, cost, and environmental considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for solenoide de arranque

The manufacturing of solenoide de arranque, or starter solenoids, involves a series of meticulously controlled processes to ensure the final product meets the stringent requirements of various industries, including automotive and heavy machinery. Understanding these processes and the associated quality assurance measures is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Main Stages of Manufacturing Solenoide de Arranque?

The manufacturing process of solenoide de arranque typically encompasses four primary stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in ensuring the solenoid’s performance and reliability.

How Is Material Prepared for Solenoide de Arranque Production?

Material preparation is foundational to the manufacturing process. It involves sourcing high-quality raw materials, such as copper for windings and durable metals for the housing. Suppliers often conduct rigorous tests on materials to verify their properties, including conductivity, tensile strength, and corrosion resistance. For B2B buyers, understanding the material sourcing process and ensuring that suppliers adhere to relevant international standards is essential to ensure product longevity and performance.

What Techniques Are Used in Forming Solenoide de Arranque Components?

The forming stage involves shaping the raw materials into specific components required for the solenoid. Techniques such as stamping, forging, and CNC machining are commonly employed. Precision is key in this stage, as any deviation can affect the solenoid’s operational efficiency. Advanced manufacturing technologies, like laser cutting and automated assembly lines, are increasingly used to enhance accuracy and reduce production time. Buyers should inquire about the technologies used by suppliers to ensure they meet the latest industry standards.

How Is the Assembly of Solenoide de Arranque Conducted?

In the assembly phase, individual components are meticulously assembled into the final product. This stage often involves both manual and automated processes. Skilled technicians perform critical tasks such as winding the coils and connecting the electrical components. The assembly process is typically designed to minimize human error and ensure consistent quality. For B2B buyers, understanding the assembly techniques employed by suppliers can provide insights into the expected reliability and performance of the solenoide de arranque.

Illustrative image related to solenoide de arranque

What Finishing Processes Are Involved in Solenoide de Arranque Production?

Finishing processes, such as surface treatment, coating, and packaging, are essential for enhancing the solenoid’s durability and aesthetic appeal. Treatments like galvanization or powder coating are often applied to protect against corrosion and wear. Packaging is equally important, especially for international shipping, as it must ensure that the solenoide de arranque reaches its destination without damage. B2B buyers should assess the finishing processes used by suppliers, as they can impact the long-term performance of the product.

What Quality Assurance Measures Are Essential for Solenoide de Arranque?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that every solenoide de arranque meets or exceeds the necessary standards. Key international standards, such as ISO 9001, provide a framework for quality management systems. Additionally, industry-specific certifications like CE and API are crucial for compliance in various markets.

How Do International Standards Influence Quality Control?

Compliance with international standards helps ensure that the manufacturing processes are efficient and the final products are reliable. For solenoide de arranque manufacturers, adherence to ISO 9001 signifies a commitment to continuous improvement and customer satisfaction. Buyers should verify that suppliers hold these certifications, as they reflect a rigorous approach to quality management.

Was sind die wichtigsten Qualitätskontrollpunkte in der Produktion?

Quality control checkpoints are strategically placed throughout the manufacturing process. These typically include:

Illustrative image related to solenoide de arranque

- Eingangsqualitätskontrolle (IQC): This stage involves the inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process-Qualitätskontrolle (IPQC): Continuous monitoring during production helps identify and rectify defects early in the process.

- Endkontrolle (FQC): A thorough examination of the finished product, including testing for electrical performance and physical integrity, ensures that only compliant units are shipped.

For B2B buyers, understanding these checkpoints can provide confidence in the quality of the solenoide de arranque being sourced.

What Testing Methods Are Commonly Used for Solenoide de Arranque?

Various testing methods are employed to ensure the functionality and reliability of solenoide de arranque. Common tests include:

- Elektrische Prüfung: Ensures that the solenoid operates correctly under specified voltage and current conditions.

- Mechanische Prüfung: Assesses the physical durability and strength of the solenoid components.

- Umweltprüfungen: Evaluates performance under different environmental conditions, such as temperature extremes and humidity.

Buyers should request documentation of these tests to verify that the products meet their operational requirements.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

To ensure that suppliers maintain high-quality standards, B2B buyers can implement several strategies:

- Lieferanten-Audits: Conducting on-site audits provides firsthand insight into the manufacturing processes and quality assurance practices of suppliers. This can be particularly useful for buyers in Africa, South America, the Middle East, and Europe, where understanding local manufacturing capabilities can be crucial.

- Qualitätsberichte: Requesting regular quality reports from suppliers can help monitor their compliance with quality standards and identify any recurring issues.

- Inspektionen durch Dritte: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control practices and product performance.

By leveraging these strategies, B2B buyers can mitigate risks and ensure they are sourcing reliable solenoide de arranque.

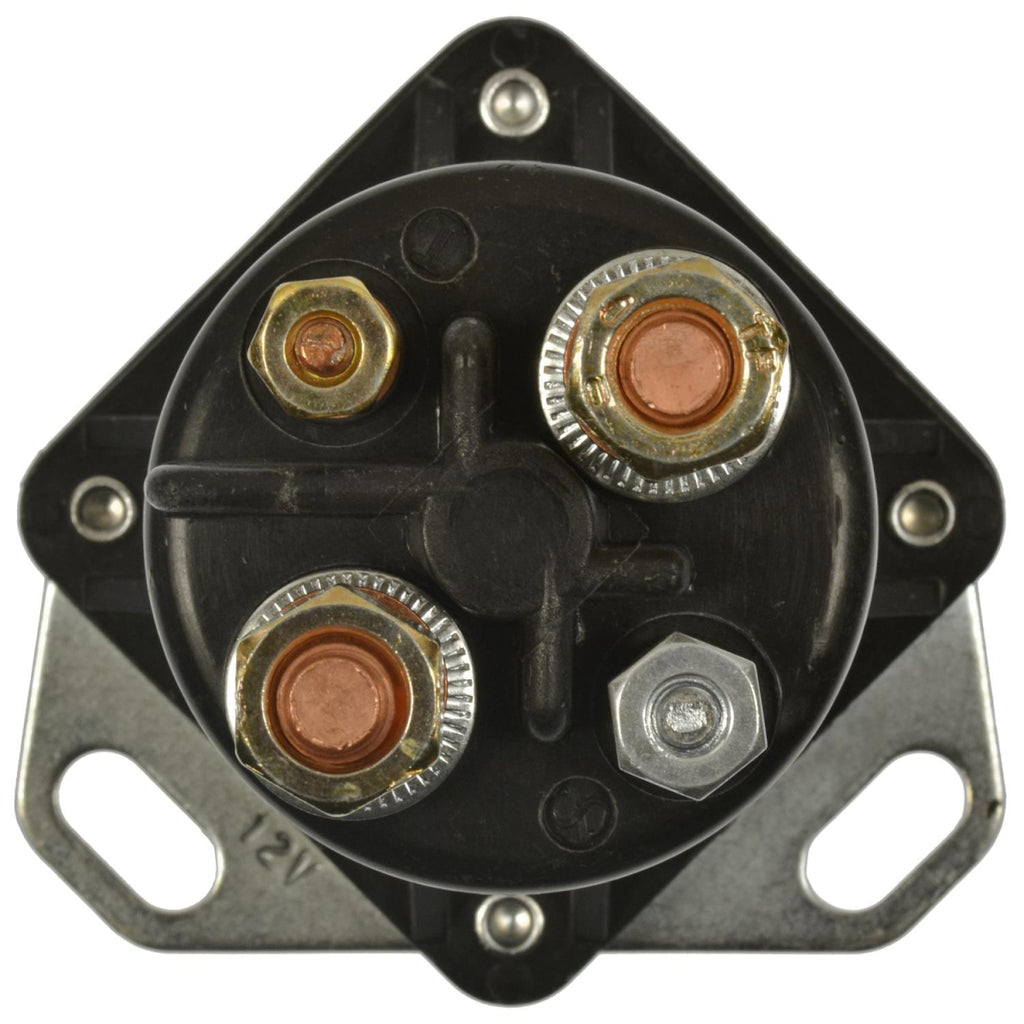

Illustrative image related to solenoide de arranque

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

International B2B buyers must be aware of specific nuances when it comes to quality control. Different regions may have varying standards and regulations, making it essential to understand local compliance requirements. For instance, CE marking is crucial for products sold in Europe, while certain certifications may be required in the Middle East and Africa.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear channels of communication and utilizing bilingual representatives can facilitate better understanding and collaboration between buyers and suppliers.

By navigating these complexities and focusing on robust quality assurance measures, B2B buyers can successfully source high-quality solenoide de arranque that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solenoide de arranque’

When sourcing solenoide de arranque, a systematic approach can enhance your procurement process and ensure that you select the best suppliers and products. This guide provides a comprehensive checklist to help B2B buyers navigate the complexities of sourcing these critical components effectively.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Understanding your specific requirements is the first step in sourcing solenoide de arranque. Consider the voltage, size, and compatibility with existing equipment. It’s vital to document these specifications to communicate effectively with potential suppliers.

- Voltage ratings (e.g., 12V, 24V) must align with your machinery.

- Dimensions and mounting configurations should match your application.

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research to identify suppliers that specialize in solenoide de arranque. Utilize industry directories, trade shows, and online platforms to create a list of reputable manufacturers and distributors.

- Look for suppliers with a strong presence in your target regions, such as Africa or South America.

- Consider their experience in supplying similar products to your industry.

Schritt 3: Lieferantenzertifizierungen bewerten

Supplier certifications are critical indicators of quality and compliance. Verify that suppliers have relevant certifications such as ISO 9001, which demonstrates a commitment to quality management systems.

- Check for industry-specific certifications that may be required in your region.

- Ensure that the supplier adheres to international standards for safety and reliability.

Schritt 4: Produktmuster anfordern

Before making large orders, request samples of the solenoide de arranque to evaluate their quality and performance. This step can help you avoid costly mistakes and ensure that the products meet your technical specifications.

- Assess the materials used and the overall construction of the solenoide.

- Test the sample in your operational environment to gauge performance.

Schritt 5: Review Pricing and Payment Terms

Once you’ve identified potential suppliers, request detailed quotations that include pricing, payment terms, and delivery timelines. Compare these factors to ensure you get the best value without compromising on quality.

- Look for transparent pricing structures that include shipping and handling costs.

- Negotiate payment terms that align with your cash flow needs.

Schritt 6: Kundenbetreuung und Garantie bewerten

Inquire about the after-sales support and warranty policies offered by suppliers. A robust support system can significantly impact your operations, especially if technical issues arise after purchase.

- Determine the duration and coverage of the warranty.

- Check if the supplier offers technical support or replacement parts.

Schritt 7: Finalize the Contract and Place Your Order

After evaluating all factors and ensuring that the supplier meets your requirements, finalize the contract. Ensure that all agreed terms are documented, including delivery schedules and penalties for non-compliance.

- Clarify any ambiguities before signing.

- Maintain open lines of communication with the supplier throughout the order process.

By following this checklist, B2B buyers can streamline their sourcing process for solenoide de arranque, ensuring they secure high-quality products from reliable suppliers while meeting their operational needs.

Comprehensive Cost and Pricing Analysis for solenoide de arranque Sourcing

What Are the Key Cost Components for Sourcing Solenoide de Arranque?

When evaluating the cost structure of sourcing solenoide de arranque (starter solenoids), buyers must consider several critical components that contribute to the final price. The primary cost components include:

-

Materialien: The choice of materials significantly impacts pricing. Solenoids typically consist of copper wire, steel, and various plastics. The fluctuating prices of these raw materials can lead to variations in the final product cost.

-

Arbeit: Labor costs vary by region and supplier. For instance, manufacturing in countries with lower wage standards can provide cost advantages, but may also raise concerns about quality and consistency.

-

Fertigungsgemeinkosten: This encompasses utilities, rent, and other indirect costs associated with production. Efficient operations can lower overhead costs, making products more competitively priced.

-

Werkzeuge: The initial investment in tooling can be substantial, especially for customized solenoids. This cost is often amortized over the production run, affecting pricing based on order volume.

-

Qualitätskontrolle (QC): Implementing robust QC processes ensures product reliability, but adds to the overall cost. Buyers should evaluate the supplier’s QC standards and certifications, as these can influence both price and performance.

-

Logistik: Transportation and handling costs can significantly affect the total cost. International shipping, customs duties, and local distribution expenses need to be factored into the sourcing decision.

-

Marge: Suppliers typically add a profit margin to cover their costs and generate revenue. Understanding the supplier’s margin expectations can provide negotiation leverage.

How Do Price Influencers Affect the Cost of Solenoide de Arranque?

Several factors influence the pricing of solenoide de arranque, particularly for international buyers:

-

Volumen/MOQ (Mindestbestellmenge): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers plan their purchases more effectively and optimize costs.

-

Spezifikationen und Anpassung: Custom-designed solenoids generally come at a premium. Buyers should assess whether standard models suffice or if custom features are necessary, balancing cost against operational needs.

-

Materialien und Qualität: Higher quality materials and certifications (e.g., ISO standards) can increase costs but often result in enhanced product reliability and longer lifespans.

-

Lieferantenfaktoren: The supplier’s reputation, experience, and reliability can affect pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: The choice of Incoterms (International Commercial Terms) dictates who bears the costs and risks during shipping. Familiarity with Incoterms can prevent unexpected expenses and simplify negotiations.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

To maximize cost efficiency when sourcing solenoide de arranque, international buyers should consider the following strategies:

-

Effective Negotiation: Engaging in open discussions about pricing, especially regarding volume discounts and payment terms, can lead to better deals. Building long-term relationships with suppliers often results in more favorable pricing.

-

Verständnis der Gesamtbetriebskosten (TCO): Buyers should evaluate the TCO, which includes purchase price, maintenance, and operational costs over the product’s lifespan. A lower initial price may lead to higher TCO if the product has a shorter lifespan or higher failure rates.

-

Regional Market Insights: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional market trends and pricing norms. Local economic conditions, currency fluctuations, and trade regulations can all impact sourcing costs.

-

Qualität vs. Preis: While it may be tempting to choose the lowest-priced option, it is essential to assess quality and supplier reliability. Investing in higher-quality solenoids can reduce long-term costs associated with failures and replacements.

Final Thoughts

While indicative prices for solenoide de arranque can vary significantly based on the aforementioned factors, understanding the cost structure and pricing influencers allows buyers to make informed decisions. By leveraging effective negotiation strategies and considering the total cost of ownership, international B2B buyers can enhance their sourcing strategies and achieve better value for their investments.

Illustrative image related to solenoide de arranque

Alternatives Analysis: Comparing solenoide de arranque With Other Solutions

Introduction to Alternatives in Starter Solenoids

When considering the best solution for starting engines in various applications, B2B buyers often face a choice between different technologies. The solenoide de arranque, or starter solenoid, is a popular option, but there are other viable alternatives that can also meet specific needs. Understanding the comparative strengths and weaknesses of each solution is crucial for making informed purchasing decisions.

Vergleichstabelle

| Vergleichsaspekt | Solenoide De Arranque | Relay Starter System | Push Button Start System |

|---|---|---|---|

| Leistung | High reliability and quick engagement | Moderate reliability; slower engagement | High reliability; instant engagement |

| Kosten | Generally low to moderate | Low cost; budget-friendly | Höhere Anfangskosten aufgrund der Komplexität |

| Einfache Implementierung | Simple installation; standard wiring | Requires additional components for installation | More complex; requires integration with existing systems |

| Wartung | Low maintenance; durable | Moderate maintenance; relay can fail | Geringer Wartungsaufwand; weniger bewegliche Teile |

| Bester Anwendungsfall | Heavy machinery, automotive applications | Light vehicles, budget-sensitive applications | High-end vehicles, modern machinery |

Detaillierte Aufschlüsselung der Alternativen

Relay Starter System

The relay starter system is a cost-effective alternative that utilizes a relay to control the starter motor. It is particularly suitable for light vehicles and applications where budget constraints are paramount. However, while it may be more affordable upfront, the relay can have a shorter lifespan compared to a solenoide de arranque, potentially leading to more frequent replacements. Furthermore, the engagement speed is slower, which may not be ideal for all applications. Overall, it serves well in budget-sensitive scenarios but may lack the reliability needed in heavy-duty settings.

Push Button Start System

The push button start system represents a modern advancement in starting technology. This system offers high reliability with instant engagement, making it ideal for high-end vehicles and advanced machinery. However, it typically involves a higher initial investment due to its complexity and the need for integration with existing electrical systems. While maintenance is minimal, the initial setup can be more challenging than traditional solenoids. This solution is best suited for buyers looking for cutting-edge technology and are willing to invest in a more complex system.

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

Selecting the right starting solution hinges on understanding your specific application requirements, budget constraints, and performance expectations. The solenoide de arranque remains a strong choice for its reliability and low maintenance, particularly in heavy machinery and automotive use. Alternatively, if cost is a primary concern, the relay starter system may suffice for lighter applications. For those seeking modern technology with quick engagement, the push button start system offers a compelling, albeit pricier, option. By carefully evaluating these alternatives against your operational needs, you can make a more informed decision that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for solenoide de arranque

What Are the Key Technical Properties of a Solenoide de Arranque?

When sourcing a solenoide de arranque, understanding its technical properties is crucial for ensuring compatibility and performance. Here are several essential specifications to consider:

-

Nennspannung

The voltage rating, typically 12V or 24V for solenoides de arranque, indicates the electrical potential required for operation. This specification is vital as it must align with the vehicle or machinery’s electrical system. An incorrect voltage rating can lead to malfunction or damage. -

Materialzusammensetzung

The materials used in the solenoid construction, such as copper for the windings and high-grade steel for the housing, affect durability and performance. Copper provides excellent conductivity, while robust materials ensure the solenoid can withstand environmental stressors, which is particularly important in harsh operating conditions found in regions like Africa and the Middle East. -

Spulenwiderstand

Measured in ohms, coil resistance is a measure of how much the solenoid will resist the flow of electrical current. This property is essential for assessing energy efficiency and the overall functionality of the solenoid. A high resistance can lead to insufficient power being supplied, affecting engine start-up. -

Betriebstemperaturbereich

This specification indicates the temperature limits within which the solenoid can operate effectively. A broader range is necessary for applications in extreme climates, ensuring reliability under various environmental conditions. Buyers in regions with extreme temperatures should prioritize solenoides with appropriate temperature ratings. -

Toleranzwerte

Tolerance levels refer to the allowable deviation from specified dimensions during manufacturing. High precision in these tolerances ensures proper fit and function, reducing the likelihood of failures. For B2B buyers, knowing the tolerance levels helps in assessing the quality and reliability of the product.

What Are Common Trade Terms Related to Solenoide de Arranque?

Navigating the procurement process requires familiarity with specific industry terminology. Here are some key terms that B2B buyers should know:

-

OEM (Originalgerätehersteller)

An OEM refers to companies that produce components that are used in another company’s end products. When sourcing solenoides de arranque, understanding whether a component is OEM can indicate quality and compatibility with existing systems. -

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B transactions as it can impact inventory costs and cash flow. Buyers should assess their needs against the supplier’s MOQ to avoid excess stock. -

RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Including detailed specifications for the solenoide de arranque in an RFQ can lead to more accurate quotes and better negotiation outcomes. -

Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery obligations. Understanding these terms can help buyers in different regions, such as Europe and South America, manage logistics and avoid unexpected costs. -

Vorlaufzeit

Lead time refers to the amount of time between placing an order and receiving the product. This term is critical for planning inventory and production schedules. Buyers should inquire about lead times to ensure they can meet operational demands. -

Garantiezeitraum

The warranty period is the timeframe during which the manufacturer guarantees the product’s performance and quality. Understanding warranty terms can provide buyers with confidence in the product’s reliability and facilitate after-sales support.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when procuring solenoides de arranque, ensuring that they select components that meet their operational requirements and standards.

Navigating Market Dynamics and Sourcing Trends in the solenoide de arranque Sector

What Are the Current Trends and Dynamics in the Solenoide de Arranque Market?

The solenoide de arranque sector is experiencing significant growth driven by advancements in automotive technology and increasing demand for efficient starting systems. Key market drivers include the rise in electric and hybrid vehicles, which require sophisticated solenoid designs to manage energy consumption effectively. Additionally, the global push towards automation and smart technologies is influencing the development of more integrated solenoid solutions. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for suppliers that can provide innovative, reliable, and cost-effective solenoid solutions to meet their specific operational needs.

Emerging sourcing trends include a shift towards just-in-time manufacturing and digital procurement processes, which enhance supply chain efficiency. Buyers are leveraging platforms that enable real-time tracking of inventory and shipments, reducing lead times and improving overall operational agility. Furthermore, the integration of IoT (Internet of Things) technologies is allowing for predictive maintenance and improved product life cycles, which are particularly valuable for businesses in dynamic markets.

As international buyers assess potential suppliers, they should prioritize companies that demonstrate a robust understanding of regional market dynamics and can offer tailored solutions that address local challenges. This includes evaluating the supplier’s ability to adapt to changing regulations and their responsiveness to fluctuating demand patterns.

Illustrative image related to solenoide de arranque

How Is Sustainability Shaping Sourcing Decisions in the Solenoide de Arranque Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the solenoide de arranque market. As global awareness of environmental issues increases, B2B buyers are placing greater emphasis on ethical sourcing practices. This includes evaluating the environmental impact of manufacturing processes, such as energy consumption and waste management, as well as the sourcing of raw materials.

Suppliers are increasingly obtaining ‘green’ certifications to validate their commitment to sustainability. These certifications may include ISO 14001 for environmental management systems or similar standards that demonstrate compliance with eco-friendly practices. B2B buyers should consider partnering with manufacturers that not only comply with these standards but also actively engage in reducing their carbon footprint through innovative production techniques and materials.

Moreover, the use of recycled materials in the manufacturing of solenoides is gaining traction, offering buyers the opportunity to support circular economy initiatives. By prioritizing suppliers with sustainable practices, businesses can enhance their brand reputation while contributing to global sustainability goals.

What Is the Historical Context of Solenoide de Arranque Development?

The evolution of solenoide de arranque technology has been marked by significant advancements since its inception. Initially developed for basic starter functions in internal combustion engines, solenoids have transformed into complex components that play a critical role in modern automotive systems. The transition from mechanical to electrical systems in vehicles has necessitated more reliable and efficient solenoid designs.

In recent decades, the advent of electronic control units (ECUs) has further revolutionized the solenoid sector, allowing for improved precision in engine starting mechanisms. This historical progression has laid the groundwork for the current focus on integrating solenoides into smarter, more energy-efficient vehicles, aligning with the broader trends of automotive innovation and sustainability.

Understanding this historical context is essential for B2B buyers as it highlights the trajectory of technological advancements and informs future sourcing decisions. Buyers can leverage this knowledge to assess suppliers based on their innovation capabilities and adaptability to ongoing market changes.

Frequently Asked Questions (FAQs) for B2B Buyers of solenoide de arranque

-

How do I select the right solenoide de arranque for my equipment?

Choosing the right solenoide de arranque involves understanding the specifications of your equipment, such as voltage requirements, size, and operational environment. Review technical documentation and consult with manufacturers or suppliers to ensure compatibility. Additionally, consider the application’s demands, such as frequency of use and environmental factors like temperature and moisture. Engaging with a knowledgeable supplier can also provide insights into the best options available for your specific needs. -

What are the common voltage ratings for solenoide de arranque?

Solenoides de arranque typically come in various voltage ratings, with 12V and 24V being the most common in the market. The choice of voltage often depends on the equipment they are designed to support. For heavy machinery or larger vehicles, 24V solenoides are more prevalent, while 12V is commonly used in smaller vehicles. It’s crucial to select a solenoid that matches the voltage rating of your system to ensure optimal performance and prevent damage. -

What should I consider when vetting suppliers for solenoide de arranque?

When vetting suppliers, evaluate their reputation, experience in the industry, and customer reviews. Check for certifications and compliance with international quality standards. Request product samples to assess quality firsthand and inquire about their manufacturing processes. Additionally, consider their ability to provide timely support, customization options, and their responsiveness to inquiries, which can be indicative of their overall service quality. -

What customization options are available for solenoides de arranque?

Many suppliers offer customization options for solenoides de arranque, including specific voltage ratings, sizes, and materials based on operational requirements. Customization can also extend to features such as connectors and mounting configurations. Discuss your specific needs with suppliers to understand the range of modifications they can provide, ensuring the solenoid perfectly fits your equipment’s requirements. -

What are the typical minimum order quantities (MOQ) for solenoide de arranque?

Minimum order quantities for solenoides de arranque can vary significantly based on the supplier and the complexity of the product. Generally, standard items may have lower MOQs, while customized solenoids might require larger orders. It’s advisable to clarify MOQs upfront with suppliers to align your purchasing strategy with their requirements, ensuring you can meet your operational needs without incurring excess inventory costs. -

What payment terms should I expect when purchasing solenoides de arranque internationally?

Payment terms can vary by supplier and region but generally include options such as upfront payment, net 30/60 days, or letters of credit for larger orders. When engaging in international transactions, consider factors such as currency exchange rates and potential transaction fees. It is crucial to negotiate terms that protect both parties and ensure timely delivery of products while maintaining cash flow for your business. -

How can I ensure quality assurance for solenoides de arranque?

To ensure quality assurance, request documentation regarding the supplier’s quality management systems, such as ISO certifications. Many suppliers conduct rigorous testing on their products, so inquire about the testing procedures and quality control measures in place. You may also consider third-party inspections before shipment to verify product specifications and quality standards, ensuring that the solenoides meet your operational requirements. -

What logistics considerations should I be aware of when importing solenoides de arranque?

When importing solenoides de arranque, consider shipping methods, lead times, and customs regulations specific to your country. Engage with logistics providers who are experienced in handling industrial components to streamline the process. Be aware of potential tariffs and duties that may apply to your imports. Additionally, ensure proper documentation is in place to facilitate smooth customs clearance, reducing delays and additional costs.

Top 2 Solenoide De Arranque Manufacturers & Suppliers List

1. NAPA Echlin – ST81 Starter Solenoid Switch

Domäne: bo.ebay.com

Registriert: 1995 (30 Jahre)

Einleitung: Solenoide de arranque eléctrico para equipo pesado. Productos destacados incluyen: NAPA Echlin ST81 Starter Solenoid Switch (Bs. 275.33), Sparex S.61057 Solenoid 311007 para Ford (Bs. 236.57), 8N11450 Starter Solenoid Ford 8n 3 Post 6 Volt (Bs. 151.68), y solenoides para tractores Mahindra. Tipos de voltaje: 6 V, 12 V, 24 V. Estado: Nuevo, Restaurado, Usado. Marcas populares: A&I, Ford, John Deere…

2. Autodoc – Solenoide de Arranque

Domäne: autodoc.es

Einleitung: This company, Autodoc – Solenoide de Arranque, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for solenoide de arranque

In summary, effective strategic sourcing for solenoide de arranque is essential for international B2B buyers aiming to optimize their procurement processes. Understanding the unique demands of diverse markets in Africa, South America, the Middle East, and Europe will empower businesses to make informed purchasing decisions. Key takeaways include the importance of evaluating supplier reliability, ensuring compliance with local regulations, and considering the total cost of ownership, which encompasses not just the purchase price but also maintenance and operational efficiency.

Moreover, leveraging technology and data analytics can enhance decision-making, allowing companies to identify trends and forecast demand more accurately. As markets evolve, staying ahead of innovations in solenoide de arranque technology will provide a competitive edge.

Looking forward, international buyers should prioritize building strategic partnerships with suppliers that align with their operational goals. This proactive approach will not only streamline sourcing processes but also foster resilience against market fluctuations. Engage with local distributors and manufacturers to unlock new opportunities and drive growth in your respective regions. Embrace the future of procurement by investing in strategic sourcing today.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to solenoide de arranque

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.