Introduction: Navigating the Global Market for price to replace starter

In the ever-evolving landscape of global automotive supply chains, understanding the price to replace a starter is crucial for B2B buyers. Sourcing reliable and cost-effective starter replacements can be a daunting challenge, particularly for businesses operating in regions like Africa, South America, the Middle East, and Europe. With variations in vehicle models, parts availability, and labor costs, making informed purchasing decisions is essential to maintaining operational efficiency and ensuring customer satisfaction.

This comprehensive guide delves into the multifaceted aspects of starter replacement pricing, offering insights into the types of starters available, their applications across different vehicle types, and key factors influencing costs. It also emphasizes the importance of supplier vetting to ensure quality and reliability. By equipping international buyers with detailed information on market trends, pricing structures, and potential pitfalls, this guide empowers businesses to navigate the complexities of sourcing automotive parts effectively.

Whether you’re in Nigeria seeking affordable options or in Saudi Arabia looking for premium parts for luxury vehicles, this guide serves as a valuable resource. It not only simplifies the decision-making process but also enhances your ability to negotiate better deals, ultimately leading to improved profitability and operational success in the competitive automotive market.

Inhaltsverzeichnis

- Top 6 Price To Replace Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for price to replace starter

- Understanding price to replace starter Types and Variations

- Key Industrial Applications of price to replace starter

- 3 Common User Pain Points for ‘price to replace starter’ & Their Solutions

- Strategic Material Selection Guide for price to replace starter

- In-depth Look: Manufacturing Processes and Quality Assurance for price to replace starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘price to replace starter’

- Comprehensive Cost and Pricing Analysis for price to replace starter Sourcing

- Alternatives Analysis: Comparing price to replace starter With Other Solutions

- Essential Technical Properties and Trade Terminology for price to replace starter

- Navigating Market Dynamics and Sourcing Trends in the price to replace starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of price to replace starter

- Strategic Sourcing Conclusion and Outlook for price to replace starter

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding price to replace starter Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Replacement Starter | Factory-manufactured, direct fit for specific vehicle models | Allgemeine Kfz-Werkstätten | Vorteile: Kostengünstig, weit verbreitet. Nachteile: Möglicherweise fehlen erweiterte Funktionen. |

| Überholter Anlasser | Rebuilt from used starters, often with new components | Fleet maintenance services | Vorteile: More affordable than new, environmentally friendly. Nachteile: Variable quality; warranty considerations. |

| Leistung Starter | Designed for enhanced durability and higher power output | Leistungsstarke Autowerkstätten | Vorteile: Verbesserte Zuverlässigkeit und Leistung. Nachteile: Höhere Anschaffungskosten. |

| Universal Starter | Versatile design that fits multiple vehicle types | Unabhängige Werkstätten | Vorteile: Flexibility for varied inventory. Nachteile: May require modifications for fit. |

| OEM (Original Equipment Manufacturer) Starter | Exact replica of original part, often with warranty | Dealerships and specialized repair services | Vorteile: Guaranteed fit and quality. Nachteile: Typically the most expensive option. |

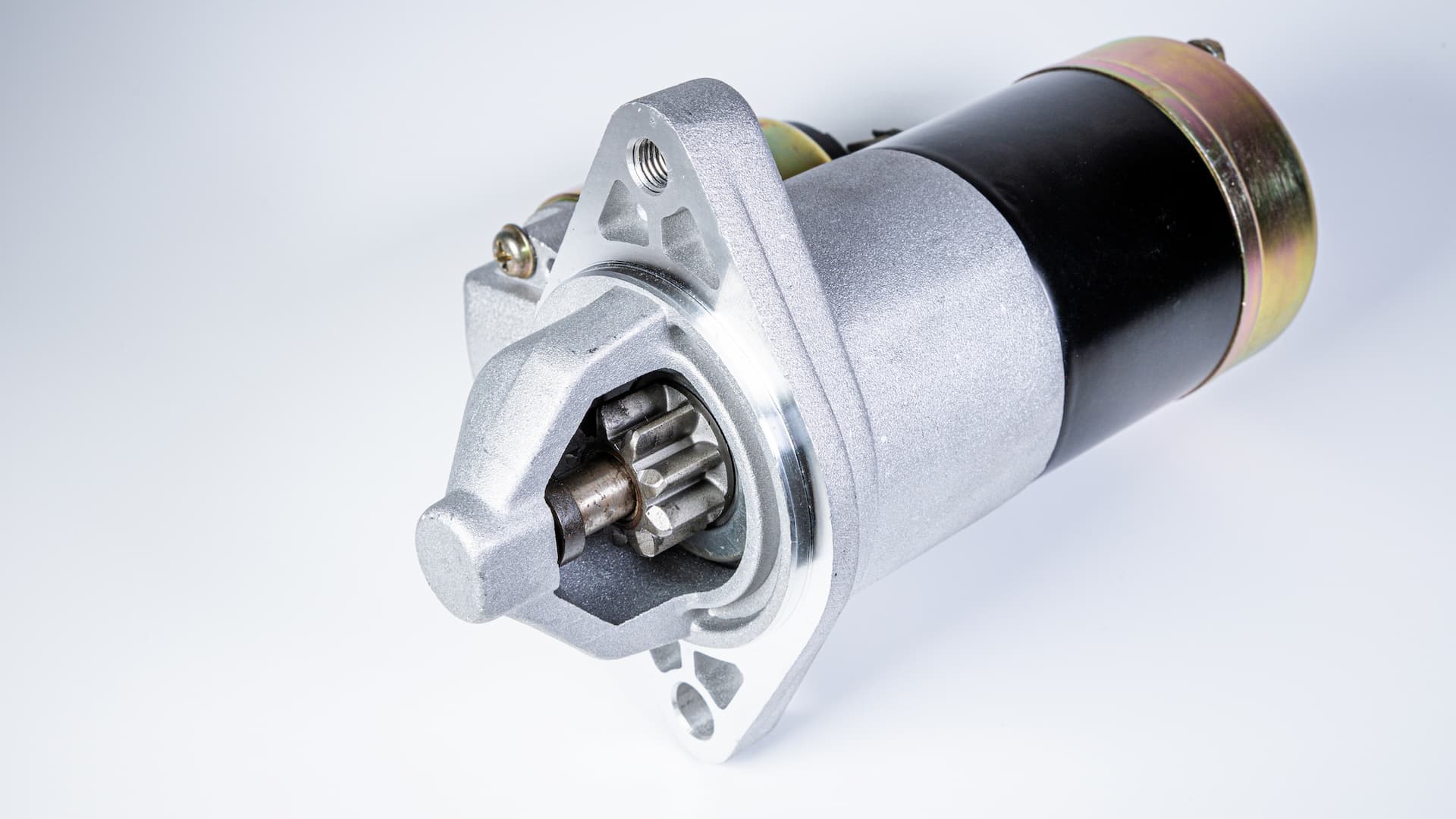

What Are the Key Characteristics of Standard Replacement Starters?

Standard replacement starters are factory-manufactured parts designed to fit specific vehicle models directly. They are often the go-to choice for general automotive repair shops due to their cost-effectiveness and ease of sourcing. B2B buyers should consider their availability and the reputation of the manufacturer, as this can influence both reliability and performance. However, while they serve well for standard applications, these starters may not offer advanced features found in higher-end options.

Why Choose Remanufactured Starters for Fleet Maintenance?

Remanufactured starters are created from used units that have been refurbished, often incorporating new components to ensure reliability. This option is popular among fleet maintenance services looking to balance cost and performance. B2B buyers should evaluate the warranty and quality assurance provided by the remanufacturer, as this can vary widely. While these starters are generally more affordable and environmentally friendly, they can sometimes present inconsistencies in quality.

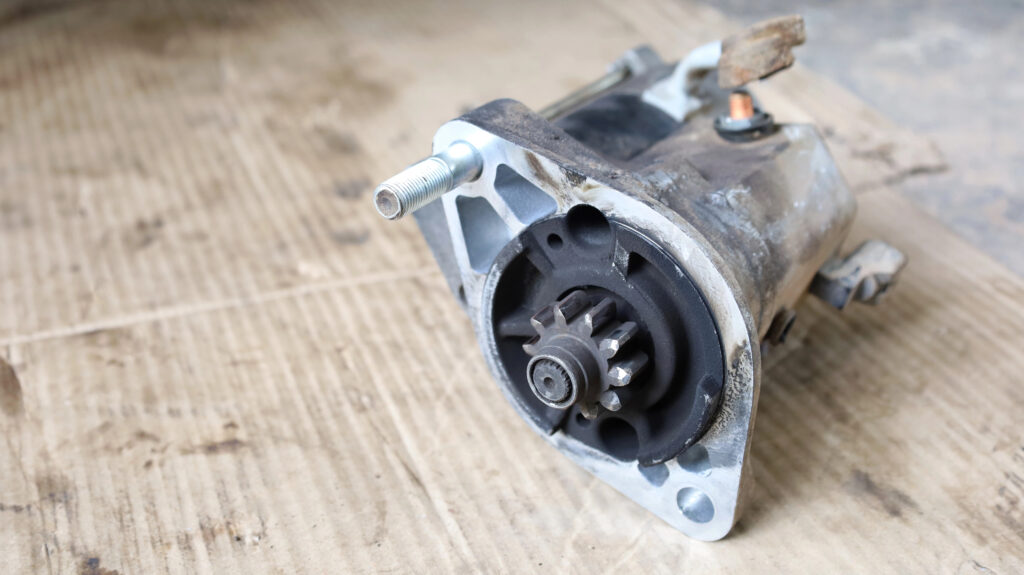

Illustrative image related to price to replace starter

How Do Performance Starters Differ from Other Types?

Performance starters are engineered for enhanced durability and higher power output, making them ideal for specialized applications such as racing or heavy-duty vehicles. Automotive performance shops frequently utilize these starters to meet the demands of high-performance engines. B2B buyers should assess the specific performance benefits and the initial investment required, as these starters typically come at a higher price point but can offer significant long-term advantages in reliability.

What Are the Advantages of Using Universal Starters?

Universal starters feature a versatile design that allows them to fit a wide range of vehicle types, making them a flexible option for independent repair shops. This adaptability can help manage inventory more effectively, especially in markets with diverse vehicle populations. However, B2B buyers must consider the potential need for modifications to ensure proper fit, which can lead to additional labor costs and time.

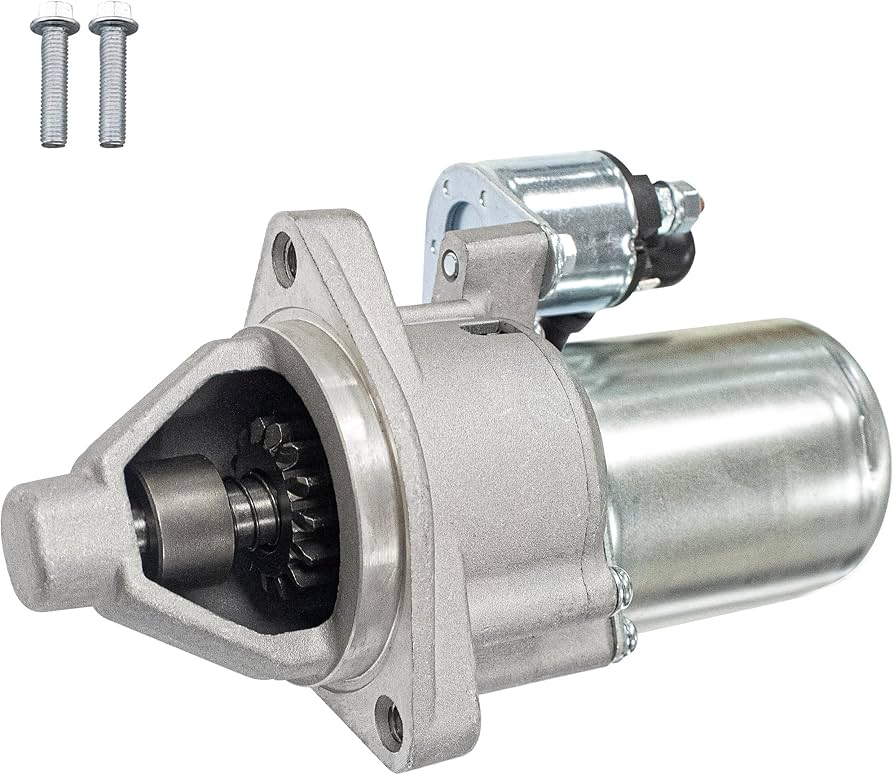

Why Are OEM Starters Considered the Best Quality?

OEM starters are exact replicas of the original parts, produced by the vehicle manufacturer. They are typically used by dealerships and specialized repair services, ensuring a guaranteed fit and performance. B2B buyers investing in OEM starters can be confident in their quality and reliability, although they often come with a higher price tag. It’s essential to weigh the benefits of guaranteed compatibility against the cost when making purchasing decisions.

Key Industrial Applications of price to replace starter

| Branche/Sektor | Specific Application of price to replace starter | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Replacing starters in vehicles for maintenance | Ensures reliable vehicle operation and customer satisfaction | Quality of parts, availability of OEM vs aftermarket, warranty terms |

| Transport & Logistik | Flottenmanagement und Wartung | Reduces downtime, enhances fleet reliability | Bulk purchasing options, compatibility with various vehicle models |

| Baumaschinen | Starter replacement in heavy machinery | Minimizes project delays, maintains operational efficiency | Durability of parts, supplier reliability, local service support |

| Landwirtschaft | Starter replacements in farm machinery | Ensures timely planting and harvesting, reduces equipment failure | Availability of specialized parts, adaptability to different machinery types |

| Erneuerbare Energien | Replacing starters in wind turbines and solar equipment | Enhances energy production efficiency, reduces maintenance costs | Technical support for installation, sourcing sustainable materials |

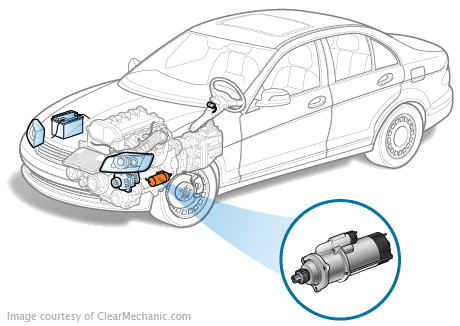

How is the ‘price to replace starter’ applied in the automotive repair industry?

In the automotive repair sector, understanding the price to replace a starter is crucial for workshops and service centers. This application is vital for vehicle maintenance, as a faulty starter can lead to significant downtime for customers. By offering competitive pricing and high-quality replacement starters, businesses can enhance customer satisfaction and loyalty. International B2B buyers must consider the quality of parts and whether to source OEM or aftermarket options, as these factors directly influence repair reliability and customer trust.

Illustrative image related to price to replace starter

What role does starter replacement play in transportation and logistics?

In transportation and logistics, fleet operators rely on efficient starter replacement to ensure their vehicles remain operational. The cost associated with starter replacement impacts overall fleet maintenance budgets and operational efficiency. By minimizing vehicle downtime through timely starter replacements, businesses can enhance their service delivery and reduce costs associated with delays. Buyers in this sector should focus on bulk purchasing agreements and compatibility with a diverse range of vehicle models, ensuring they have the right parts readily available.

How does starter replacement benefit the construction equipment sector?

For the construction industry, starters in heavy machinery are critical for maintaining productivity on job sites. The price to replace starters can significantly affect project timelines; hence, timely replacements are essential to avoid costly delays. Ensuring that machinery starts reliably enables construction companies to meet deadlines and maintain efficiency. Buyers should prioritize sourcing durable parts, assessing supplier reliability, and considering local service support to facilitate quick replacements and minimize downtime.

Why is starter replacement important for agricultural machinery?

In agriculture, the timely replacement of starters in farm machinery is essential for ensuring that planting and harvesting activities proceed without interruption. The cost of replacing starters directly impacts operational efficiency, as delays can lead to lost revenue during critical farming periods. Buyers in this sector should seek suppliers that offer specialized parts tailored to different machinery types, ensuring compatibility and performance. Availability of parts during peak seasons is also a crucial consideration to avoid operational disruptions.

How does starter replacement affect renewable energy systems?

In the renewable energy sector, particularly in wind turbines and solar equipment, the reliability of starters is vital for maintaining energy production efficiency. The price to replace starters can influence the overall maintenance budget and operational costs. Ensuring that these systems function optimally reduces long-term maintenance expenses and enhances energy output. Buyers should focus on sourcing sustainable materials and ensuring technical support for installation, as these factors contribute to the longevity and efficiency of renewable energy systems.

3 Common User Pain Points for ‘price to replace starter’ & Their Solutions

Scenario 1: Understanding the Total Cost of Starter Replacement

Das Problem: B2B buyers often face uncertainty when it comes to the total cost of replacing a starter. This confusion can arise from varying labor rates, parts prices, and the complexity of the vehicle models they manage. For example, a fleet manager in Nigeria may not be fully aware of how factors like vehicle make, model, and year influence replacement costs. They may find themselves with unexpected expenses that affect their budgeting and operational efficiency.

Die Lösung: To navigate this challenge, B2B buyers should conduct thorough market research to understand the average costs associated with starter replacements for different vehicle types. Creating a detailed inventory of the vehicles in their fleet, along with their respective starter specifications, can provide clarity. Additionally, it’s advisable to establish relationships with multiple local and international suppliers. Requesting quotes from various vendors and comparing prices can ensure that the buyer is getting the best deal. Utilizing an online cost estimator tailored to their vehicle types can also help in budgeting for replacement costs effectively.

Scenario 2: Sourcing Reliable Starter Parts at Competitive Prices

Das Problem: Another significant pain point for B2B buyers is sourcing reliable starter parts that are both high-quality and cost-effective. This is particularly important for businesses that depend on vehicles for logistics, such as those in South America or the Middle East. Poor quality starters can lead to frequent breakdowns and increased maintenance costs, ultimately affecting the bottom line.

Die Lösung: B2B buyers should prioritize establishing partnerships with reputable suppliers who specialize in automotive parts. They can attend trade shows, join industry associations, or utilize online platforms that connect them with verified parts manufacturers. It’s crucial to assess the suppliers based on their reviews and the warranties they offer on their products. Additionally, buyers can negotiate bulk purchase agreements to secure better pricing. Implementing a quality assurance process, such as requesting samples before making large orders, can further mitigate the risk of investing in subpar products.

Illustrative image related to price to replace starter

Scenario 3: Overcoming Labor Cost Variability in Starter Replacement

Das Problem: Labor costs associated with starter replacement can vary significantly based on geographic location and the complexity of the job. A fleet operator in Europe might face high labor rates, especially in urban areas where skilled mechanics are scarce. This variability can lead to discrepancies in overall repair costs and can disrupt financial planning.

Die Lösung: To tackle this issue, B2B buyers should consider investing in training for their in-house mechanics, enabling them to handle starter replacements efficiently. This not only reduces reliance on external labor but also ensures that repairs are done correctly and promptly. For those who still require external services, building relationships with multiple local garages can provide flexibility in choosing where to send vehicles for repairs. Additionally, buyers can explore online platforms that offer competitive labor rates from certified mechanics. Keeping a detailed log of labor costs for different repairs can help in forecasting future expenses and negotiating better rates with service providers.

Strategic Material Selection Guide for price to replace starter

What Materials Are Commonly Used for Replacing Starters in Vehicles?

When considering the replacement of a starter, the choice of materials is critical to ensure durability, performance, and cost-effectiveness. Here, we analyze four common materials used in starter construction: steel, aluminum, copper, and composite materials.

Illustrative image related to price to replace starter

Welchen Einfluss hat Stahl auf die Leistung und die Kosten von Anlassern?

Steel is a widely used material for various components of automotive starters due to its strength and durability. It typically exhibits excellent temperature resistance and can withstand high pressures, making it suitable for high-performance applications.

Vorteile: Steel’s primary advantages include its high tensile strength and resistance to deformation under stress. This makes it ideal for components that experience significant mechanical forces. Additionally, steel is generally cost-effective and readily available, which is beneficial for manufacturers.

Nachteile: On the downside, steel is susceptible to corrosion if not properly treated, which can affect longevity, especially in humid or saline environments common in parts of Africa and the Middle East. The manufacturing complexity can also increase due to the need for protective coatings or treatments.

Auswirkungen auf die Anwendung: Steel starters are compatible with a wide range of vehicles but may require additional corrosion protection in regions with harsh climates.

Welche Rolle spielt Aluminium in der Starterherstellung?

Aluminum is another common material used in starter construction, particularly for housings and casings. It is known for its lightweight properties, which can enhance vehicle efficiency.

Illustrative image related to price to replace starter

Vorteile: The key advantage of aluminum is its excellent corrosion resistance, making it ideal for applications in coastal regions or areas with high humidity. Its lightweight nature contributes to overall vehicle performance and fuel efficiency.

Nachteile: However, aluminum is not as strong as steel, which can limit its use in high-stress components. It is also generally more expensive than steel, which may impact the overall cost of starter replacements.

Auswirkungen auf die Anwendung: Aluminum starters are particularly suitable for modern vehicles designed for fuel efficiency. Buyers in Europe and South America may prefer aluminum due to regulatory pressures for lighter vehicles.

Why Is Copper Important in Starter Components?

Copper is primarily used in the electrical components of starters, such as windings and connections. Its excellent electrical conductivity makes it an essential material for efficient starter operation.

Illustrative image related to price to replace starter

Vorteile: Copper’s high conductivity ensures that electrical signals are transmitted efficiently, reducing the risk of overheating and failure. It is also relatively durable, maintaining performance over time.

Nachteile: The main disadvantage of copper is its susceptibility to corrosion, especially when exposed to moisture. Additionally, copper is more expensive than other metals, which can increase the overall cost of starter assemblies.

Auswirkungen auf die Anwendung: Given its importance in electrical systems, copper is critical for starters in all regions, including Africa and the Middle East, where electrical reliability is paramount.

Illustrative image related to price to replace starter

How Do Composite Materials Affect Starter Design?

Composite materials, often a blend of plastics and fibers, are increasingly used in starter manufacturing. They offer unique properties that can enhance performance.

Vorteile: Composites are lightweight, corrosion-resistant, and can be molded into complex shapes, which can simplify manufacturing processes. Their thermal and electrical insulating properties can also enhance starter performance.

Nachteile: However, composites may not withstand high temperatures as effectively as metals, which can limit their application in high-performance vehicles. They can also be more expensive to produce.

Auswirkungen auf die Anwendung: In regions with moderate climates, composite starters can be a viable option, particularly for electric vehicles. Buyers in Europe may be more inclined to adopt these materials due to sustainability trends.

Zusammenfassung der Materialauswahl für den Starterwechsel

| Material | Typical Use Case for price to replace starter | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Strukturelle Komponenten von Startern | Hohe Festigkeit und Haltbarkeit | Korrosionsanfällig | Mittel |

| Aluminium | Anlassergehäuse und Verkleidungen | Leicht und korrosionsbeständig | Geringere Festigkeit im Vergleich zu Stahl | Hoch |

| Kupfer | Elektrische Wicklungen und Anschlüsse | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Hoch |

| Komposit | Lightweight components in starters | Leicht und formbar | Begrenzte Hochtemperaturbeständigkeit | Mittel |

This guide provides a comprehensive overview of material choices for starter replacements, helping B2B buyers make informed decisions based on performance requirements, cost considerations, and regional conditions.

Illustrative image related to price to replace starter

In-depth Look: Manufacturing Processes and Quality Assurance for price to replace starter

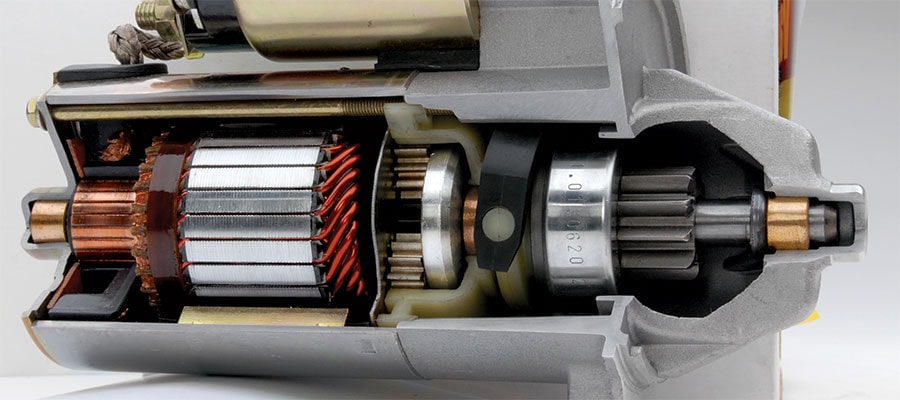

Was sind die wichtigsten Schritte im Herstellungsprozess von Startern?

The manufacturing of automotive starters is a complex process that involves several key stages, each designed to ensure that the final product meets stringent performance and quality standards. Understanding these stages can help B2B buyers make informed decisions when sourcing replacement starters.

1. Materialvorbereitung: Welche Materialien werden bei der Starterherstellung verwendet?

The first step in the manufacturing process is the preparation of raw materials. Automotive starters are typically made from a variety of metals, including steel for the housing, copper for the windings, and aluminum for components such as the solenoid.

Quality of materials is crucial; therefore, suppliers often source materials that meet specific industry standards. For instance, high-grade steel is preferred for its durability and strength, while copper must be of high conductivity to ensure efficient electrical performance.

Wie werden Vorspeisen geformt und zusammengebaut?

2. Forming: What Techniques Are Used to Shape Starter Components?

Once the materials are ready, the next stage is forming. This involves several techniques, including:

Illustrative image related to price to replace starter

-

Stanzen und spanende Bearbeitung: Metal components are stamped into shape using precision dies and then machined for accuracy. This is particularly important for parts like the starter housing and the armature.

-

Wickeln: Copper wire is wound around the armature to create electromagnetic coils. This process requires precision to ensure that the coils are evenly wound for optimal performance.

-

Gießen: Some components, like the solenoid housing, may be cast from aluminum. This allows for more intricate designs and reduces weight.

What Does the Assembly Process Look Like?

3. Assembly: How Are Different Parts of the Starter Put Together?

The assembly of a starter involves the integration of various components, including the solenoid, armature, and drive gear. This process typically includes:

-

Manual and Automated Assembly: Depending on the manufacturer, some assembly processes may be automated, while others are performed manually. This can enhance quality control as skilled workers can inspect components during assembly.

-

Integration of Electrical Systems: The electrical connections must be made with precision to ensure that the starter operates correctly. Any faults in these connections can lead to performance issues.

Welche Veredelungsprozesse sind für Einsteiger wichtig?

4. Finishing: How Are Starters Prepared for Market?

The final stage in the manufacturing process is finishing, which can include:

-

Oberflächenbehandlung: Components may undergo surface treatments such as galvanization or painting to prevent corrosion and improve aesthetics.

-

Endmontage und Prüfung: Once the starter is fully assembled, it undergoes final assembly checks and performance testing to ensure that it meets specifications.

What Quality Assurance Measures Are Essential in Starter Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for products like automotive starters that must perform reliably under various conditions.

5. What International Standards Are Relevant for Starter Manufacturers?

To ensure consistent quality, many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with these standards demonstrates a commitment to quality and continuous improvement.

Illustrative image related to price to replace starter

Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the region and application. These certifications ensure that products meet specific safety and performance criteria.

Wie werden die Qualitätskontrollpunkte implementiert?

6. What Are the Key Quality Control Checkpoints in Starter Manufacturing?

The quality control process typically includes several checkpoints, such as:

-

Eingangsqualitätskontrolle (IQC): Die Rohstoffe werden bei ihrer Ankunft kontrolliert, um sicherzustellen, dass sie den vorgegebenen Normen entsprechen.

-

In-Process-Qualitätskontrolle (IPQC): Throughout the manufacturing process, inspections are performed at various stages to identify any defects early on.

-

Endkontrolle (FQC): After assembly, each starter undergoes rigorous testing to ensure it operates correctly. This may include electrical testing, performance checks, and visual inspections.

Welche Prüfverfahren werden üblicherweise bei Startern angewandt?

7. What Testing Methods Ensure the Reliability of Starters?

Zu den gängigen Testmethoden gehören:

-

Elektrische Prüfung: This involves checking the starter’s electrical performance to ensure it operates within specified parameters.

-

Haltbarkeitsprüfung: Starters may be subjected to stress tests that simulate real-world operating conditions to ensure longevity and reliability.

-

Noise and Vibration Testing: These tests assess the operational noise and vibration levels of the starter, which can indicate potential issues.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

8. What Steps Should B2B Buyers Take to Verify Supplier QC?

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

-

Lieferantenaudits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can help identify any gaps in compliance with international standards.

-

Anforderung von Qualitätsberichten: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC testing.

-

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices. This is especially important for international buyers who may not have the resources to conduct audits themselves.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

9. How Do Quality Control Standards Differ by Region?

Quality control standards can vary significantly between regions. For instance, European manufacturers might be more stringent in their compliance with CE standards, while manufacturers in the Middle East may focus on specific regional regulations.

B2B buyers from Africa, South America, and the Middle East should be aware of these differences and ensure that their suppliers can meet the necessary quality standards for their specific markets. Understanding these nuances can help mitigate risks associated with sourcing automotive starters internationally.

Illustrative image related to price to replace starter

Conclusion: Why Is Quality Assurance Critical in the Starter Replacement Market?

In summary, the manufacturing processes and quality assurance measures for automotive starters are integral to ensuring that replacement products perform reliably and meet customer expectations. For B2B buyers, understanding these processes can provide a competitive edge when sourcing products for their markets. By focusing on suppliers that adhere to international quality standards and robust QC practices, buyers can ensure they receive high-quality starters that enhance their operations and meet regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘price to replace starter’

Einführung

In the automotive industry, sourcing replacement starters can be a complex process, particularly for B2B buyers operating across diverse markets such as Africa, South America, the Middle East, and Europe. This guide provides a structured checklist to help you navigate the procurement process efficiently, ensuring you acquire the right starter at the best price while maintaining quality and reliability.

Schritt 1: Assess Your Vehicle Requirements

Understanding the specific needs of your fleet is critical. Different vehicles require different starters based on make, model, and year. Compile a comprehensive list of your vehicles’ specifications to ensure that you source compatible starters.

- Consider factors such as:

- Engine size and type

- Starter accessibility and installation complexity

Schritt 2: Forschung Marktpreise

Before making any purchases, conduct thorough market research to understand the price range for starter replacements. Prices can vary significantly based on region, supplier, and brand.

- Look for:

- Average costs for both new and rebuilt starters

- Variations in pricing for different vehicle types, such as sedans versus trucks

Schritt 3: Lieferantenzertifizierungen bewerten

It’s essential to ensure that your suppliers adhere to industry standards and certifications. This not only guarantees product quality but also compliance with international regulations.

- Check for:

- ISO certifications

- Any relevant automotive industry certifications, such as IATF 16949

Schritt 4: Muster oder Demonstrationen anfordern

If possible, request samples or demonstrations of the starters from potential suppliers. This step allows you to assess the quality and compatibility of their products firsthand.

Illustrative image related to price to replace starter

- Focus on:

- Build quality and material used

- Performance metrics in real-world conditions

Schritt 5: Bestätigen Sie die Garantie- und Rückgaberichtlinien

A robust warranty and clear return policies are vital components of a solid procurement strategy. Ensure that your suppliers provide guarantees that protect your investment.

- Inquire about:

- Length and coverage of the warranty

- Procedures for returning defective products

Schritt 6: Zahlungsbedingungen aushandeln

Negotiating favorable payment terms can significantly impact your cash flow. Discuss terms that allow for flexibility and minimize financial risk.

- Consider options such as:

- Extended payment periods

- Discounts for bulk purchases

Schritt 7: Kommunikationskanäle einrichten

Effective communication with suppliers is key to a successful procurement process. Ensure that you have clear channels in place for discussing orders, deliveries, and any potential issues.

- Identify:

- Primary contacts for order management

- Preferred methods of communication (email, phone, etc.)

By following this checklist, B2B buyers can streamline the process of sourcing starters, ensuring they secure the best products at competitive prices while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for price to replace starter Sourcing

Understanding the cost structure and pricing for starter replacements is crucial for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. The total cost to replace a starter involves various components that can significantly affect pricing.

Was sind die wichtigsten Kostenfaktoren für den Austausch des Anlassers?

Materialien: The primary cost component is the starter itself, which can range from $50 for rebuilt units to over $350 for new starters, depending on the make and model of the vehicle. Additional materials may include wiring, connectors, and fuses, which can add to the overall cost.

Arbeit: Labor costs can vary widely based on the complexity of the installation. For straightforward replacements, labor may range from $50 to $150, but for more complex vehicles, it could reach $1,100 or more. This discrepancy is often due to the time required for disassembly and reassembly of engine components.

Fertigungsgemeinkosten: This includes costs related to production facilities, equipment, and technology used in the manufacturing process. Overhead can vary based on the supplier’s location and operational efficiency.

Werkzeuge: The cost of specialized tools needed for starter replacement can also factor into the overall expense. This is particularly relevant for workshops that may not have the required equipment for specific vehicles.

Qualitätskontrolle (QC): Ensuring the quality of starters involves inspection and testing processes that can add to the cost. Buyers should consider the quality certifications of suppliers, as higher standards may lead to increased costs but also enhanced reliability.

Logistik: Shipping costs can significantly impact pricing, especially for international buyers. Factors such as distance, shipping method, and customs duties play a crucial role in determining final costs.

Rand: Suppliers typically include a profit margin on the parts and services they provide. Understanding the average markup can help buyers negotiate better prices.

How Do Price Influencers Impact Starter Replacement Costs?

Volumen und Mindestbestellmenge (MOQ): Bulk purchasing often leads to lower prices per unit. Establishing a strong relationship with suppliers can also help negotiate better terms based on anticipated order volumes.

Spezifikationen und Anpassung: Customized starters for specific vehicle models may incur additional costs. Buyers should assess whether standard parts can suffice or if customization is necessary.

Materials Quality and Certifications: High-quality starters may come with certifications that ensure durability and performance. However, these may also come at a premium price. It’s essential for buyers to balance quality with budget constraints.

Illustrative image related to price to replace starter

Lieferantenfaktoren: Reliability and reputation of suppliers can influence pricing. Established suppliers with a history of quality and service may charge higher prices but can offer greater assurance of product performance.

Incoterms: Understanding shipping terms can save costs. For example, knowing whether the price includes shipping, insurance, and duties can help buyers calculate the total landed cost effectively.

What Are the Best Negotiation Strategies for International B2B Buyers?

-

Leverage Volume Purchases: If your business anticipates high demand, use this as leverage in negotiations to secure better pricing or terms.

-

Understand Total Cost of Ownership (TCO): Evaluate not only the initial cost of the starter but also the long-term implications, such as durability, warranty, and potential failure rates. A cheaper starter may lead to higher costs over time due to replacements.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide a clearer picture of market prices and help in negotiating better deals.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures influenced by local economies, supply chain dynamics, and currency fluctuations. Buyers in Africa and South America, for instance, should consider regional suppliers who may offer more competitive pricing compared to those in Europe or North America.

Haftungsausschluss für indikative Preise

The prices mentioned above are indicative and can fluctuate based on market conditions, exchange rates, and other external factors. Buyers should conduct thorough research and obtain updated quotes from suppliers to ensure accurate budgeting for starter replacements.

Alternatives Analysis: Comparing price to replace starter With Other Solutions

Erforschung alternativer Lösungen für die Kosten des Austauschs von Startermotoren

When considering the price to replace a vehicle starter, it’s essential to evaluate alternative solutions that may provide comparable benefits or even cost savings. Depending on the specific circumstances, such as the vehicle’s make and model, the nature of the starter issue, and the buyer’s budget constraints, alternative options may include rebuilding the starter, using a jump starter, or exploring advanced battery technologies. Below is a detailed comparison of these alternatives.

Illustrative image related to price to replace starter

| Vergleichsaspekt | Price To Replace Starter | Rebuild Starter | Starthilfe |

|---|---|---|---|

| Leistung | High reliability; OEM quality | Restores original performance; may not be as reliable as new | Provides temporary power; not a permanent solution |

| Kosten | $150 – $1.100 | $50 - $300 | $50 - $200 |

| Einfache Implementierung | Erfordert professionelle Installation | Can be DIY or professional; skill-dependent | Very easy; user-friendly devices available |

| Wartung | Minimal nach der Installation | Kann regelmäßige Kontrollen erfordern | Requires charging; limited lifespan |

| Bester Anwendungsfall | Long-term solution for vehicle reliability | Cost-effective for older vehicles or specific parts | Emergency situations or temporary fixes |

Rebuilding the Starter: Is It Worth It?

Rebuilding a starter can be a viable alternative for businesses looking to save costs while maintaining vehicle performance. This method involves disassembling the faulty starter, replacing worn components, and reassembling it. The primary advantage of rebuilding is cost; it typically ranges from $50 to $300, significantly lower than a full replacement. However, rebuilt starters may not offer the same reliability as new ones, especially if critical components are severely worn. This approach is best for older vehicles where new parts may be hard to find or prohibitively expensive.

Utilizing a Jump Starter: A Quick Fix for Starting Issues

Jump starters can be an effective temporary solution for starting issues, particularly in emergency situations. These portable devices can provide the necessary boost to start a vehicle without requiring any extensive repairs. The cost for a quality jump starter ranges from $50 to $200, making it a budget-friendly option. However, it is essential to note that a jump starter does not fix the underlying problem with the starter or battery; it merely serves as a stopgap solution. As such, it is most suitable for businesses that need immediate solutions without addressing the root cause of the issue.

Advanced Battery Technologies: A Long-Term Investment

Exploring advanced battery technologies, such as lithium-ion batteries, can provide a long-term solution to starter issues. These batteries tend to have higher efficiency, longer life spans, and better performance in various temperatures. While the initial investment is significantly higher, the cost-effectiveness over time—due to reduced maintenance and replacement needs—can make this option appealing for fleet operators or businesses relying on vehicle uptime. However, the complexity of implementation and integration into existing systems should be carefully considered.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

For B2B buyers, selecting the right solution for starter issues requires a thorough analysis of costs, performance, and long-term needs. While replacing the starter may provide immediate reliability, alternatives like rebuilding, jump starters, or investing in advanced battery technologies can offer varying benefits based on specific operational requirements. By carefully weighing these options, businesses can make informed decisions that align with their budgetary constraints and performance expectations, ultimately optimizing vehicle management strategies.

Essential Technical Properties and Trade Terminology for price to replace starter

What are the Key Technical Properties Relevant to Starter Replacement Costs?

When evaluating the price to replace a starter, several technical properties significantly influence the overall costs and performance. Understanding these properties can help B2B buyers make informed decisions.

1. Material Klasse

The material grade of a starter is critical as it affects durability and performance. Starters are typically made from high-strength steel or aluminum alloys, which provide the necessary rigidity and resistance to wear. Higher-grade materials can lead to increased longevity and reliability, which is essential for businesses that rely on their vehicles for operations.

2. Toleranzschwellen

Tolerance levels refer to the allowable variations in the dimensions of starter components. Precise tolerances are crucial for ensuring proper fit and functionality. Starters with tighter tolerances may cost more but can enhance performance and reduce the risk of failure. For B2B buyers, understanding tolerance levels helps in assessing the quality of parts and ensuring compatibility with specific vehicle models.

3. Nennspannung

Most automotive starters operate on a 12V system, but understanding the voltage rating is vital for ensuring compatibility with the vehicle’s electrical system. Variations in voltage can lead to performance issues or even damage. B2B buyers should verify the voltage rating of starters, especially when dealing with diverse vehicle fleets across different regions.

4. Torque Specifications

Torque specifications indicate the amount of rotational force a starter can exert. This is vital for turning over larger engines, particularly in commercial vehicles. Higher torque ratings generally correlate with more powerful starters, which can be essential for businesses with heavy-duty vehicles. Buyers must consider torque requirements based on their vehicle’s specifications to avoid issues related to insufficient starting power.

5. Weight and Size

The weight and size of a starter can impact installation and operational efficiency. Lighter and more compact starters can be easier to handle and install, reducing labor costs. Additionally, for businesses that maintain a fleet, understanding size specifications ensures that the starter fits within the vehicle’s design without necessitating additional modifications.

What Common Trade Terms Should B2B Buyers Understand When Discussing Starter Replacement?

Navigating the terminologies used in the automotive parts industry is essential for effective communication and decision-making. Below are common terms that B2B buyers should familiarize themselves with.

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the same manufacturer that produced the original components of the vehicle. Using OEM parts is often recommended as they meet the original specifications, ensuring optimal performance and reliability. B2B buyers should consider OEM starters for their fleets to maintain quality and consistency.

2. MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can influence purchasing decisions and inventory management. If a buyer requires a smaller quantity than the MOQ, they may need to negotiate or seek alternative suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. B2B buyers often use RFQs to compare pricing and terms from different vendors before making purchasing decisions. Crafting a clear RFQ can help ensure that suppliers provide comprehensive and competitive quotes.

4. Incoterms (Internationale Handelsklauseln)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps B2B buyers understand shipping costs, insurance responsibilities, and the transfer of risk during the shipping process. Knowing the applicable Incoterms can assist in negotiating better terms with suppliers.

5. Aftermarket-Teile

Aftermarket parts are components made by manufacturers other than the original vehicle manufacturer. While often less expensive, the quality and compatibility of aftermarket starters can vary significantly. B2B buyers should weigh the pros and cons of aftermarket options against OEM parts to ensure they meet their operational needs.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions regarding starter replacement, ultimately leading to better procurement strategies and operational efficiencies.

Navigating Market Dynamics and Sourcing Trends in the price to replace starter Sector

What Are the Current Market Dynamics Affecting the Price to Replace Starters?

The market for starter replacements is influenced by several global drivers, including the increasing vehicle population and the growing demand for reliable automotive services. With significant growth in regions such as Africa, South America, the Middle East, and Europe, international B2B buyers must navigate various dynamics. Notably, the rise of e-commerce platforms has transformed sourcing methods, allowing buyers to access a broader range of suppliers and products. This shift toward digital sourcing is bolstered by advancements in logistics technology, which enhance supply chain efficiency and reduce lead times.

Emerging trends also highlight the importance of transparency in the supply chain. Buyers are increasingly seeking suppliers that provide detailed product specifications and sourcing practices, fostering trust and reliability. Additionally, as vehicle technologies evolve, the complexity of starter systems has increased. This complexity necessitates specialized knowledge among mechanics, influencing the cost of labor and the availability of skilled technicians, which buyers should consider when estimating total replacement costs.

Illustrative image related to price to replace starter

Moreover, the fluctuation of raw material prices, driven by geopolitical tensions and economic shifts, directly impacts the pricing structure of starter components. B2B buyers must remain vigilant about these fluctuations to optimize their purchasing strategies and negotiate better deals.

How Is Sustainability and Ethical Sourcing Shaping the Price to Replace Starters?

As the automotive industry increasingly prioritizes sustainability, the sourcing of starter components is experiencing a shift towards ethical practices. Buyers are now more aware of the environmental impacts associated with traditional manufacturing processes, such as emissions and waste generation. Therefore, sourcing from manufacturers that implement sustainable practices is becoming crucial. This includes using recycled materials or adopting green manufacturing technologies that minimize environmental footprints.

In addition, certifications such as ISO 14001 (Environmental Management) and other ‘green’ labels are gaining traction in the market. Buyers are encouraged to look for suppliers who possess these certifications, ensuring that their sourcing decisions align with global sustainability goals. Ethical supply chains not only mitigate environmental impact but also enhance brand reputation, an essential factor for companies operating in competitive markets.

Furthermore, the demand for sustainable products is driving innovation in the starter replacement sector. Manufacturers are exploring alternatives such as lightweight materials that improve energy efficiency, which can ultimately reduce the cost of ownership for end-users. By investing in sustainable sourcing, B2B buyers can contribute to a circular economy while also benefiting from potential cost savings in the long run.

How Has the Price to Replace Starters Evolved Over Time?

The evolution of starter replacement pricing is closely tied to advancements in automotive technology and shifts in consumer behavior. Historically, starters were simple devices, leading to lower replacement costs. However, with the introduction of more sophisticated engines and electrical systems, the complexity of starters has increased, resulting in higher manufacturing and replacement costs.

In recent years, the proliferation of electric vehicles (EVs) has also influenced the market. As the automotive landscape transitions toward electrification, traditional starter systems are being re-evaluated, leading to innovations that may alter pricing structures. Additionally, as more vehicles are equipped with advanced driver-assistance systems (ADAS) and other technologies, the importance of reliable starting systems has become paramount, further impacting the perceived value of starter replacements.

Overall, B2B buyers must consider these historical trends when evaluating current market prices for starter replacements. Understanding the evolution of the market can provide valuable insights for making informed purchasing decisions and strategic sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of price to replace starter

-

How do I determine the correct starter replacement for my vehicle?

To identify the right starter replacement for your vehicle, consult the owner’s manual for specifications, including the make, model, and year. Additionally, you can reach out to suppliers with detailed information about your vehicle. They can assist you in finding compatible starter options. If available, provide the vehicle identification number (VIN) to ensure accuracy. This will help in sourcing the right parts, preventing costly errors and delays in procurement. -

Welche Faktoren beeinflussen den Preis für den Austausch eines Starters?

The price of a starter replacement can vary based on several factors, including the vehicle’s make and model, the complexity of installation, and whether you opt for a new or refurbished starter. Generally, luxury or larger vehicles may incur higher costs due to specialized parts and labor. Additionally, geographical location and local market conditions can impact pricing. Always compare quotes from multiple suppliers to ensure competitive pricing and assess the total cost of ownership, including shipping and installation. -

Was sind die häufigsten Anzeichen dafür, dass ein Anlasser ausgetauscht werden muss?

Common signs of a failing starter include unusual noises when starting, erratic cranking, and a complete lack of response when turning the ignition key. If you notice any of these symptoms, it’s essential to diagnose the issue promptly to avoid further damage. Conducting a thorough inspection or consulting with a mechanic can help confirm whether the starter is the root cause or if other components are contributing to the problem. -

What payment terms should I negotiate with suppliers for starter replacements?

When sourcing starter replacements, consider negotiating favorable payment terms that align with your cash flow needs. Common options include net 30 or net 60 terms, which allow you to pay for the parts after a set period. Some suppliers may also offer discounts for early payment or bulk orders. Always clarify payment methods accepted, including credit terms, wire transfers, or letters of credit, especially for international transactions. -

How can I vet suppliers for starter replacements?

To effectively vet suppliers, start by researching their reputation through online reviews and industry references. Request detailed product specifications and certifications to ensure quality standards are met. Engaging in direct communication can provide insights into their customer service and responsiveness. Additionally, consider ordering samples or small quantities to evaluate the product quality before committing to larger orders, particularly if you are sourcing from international markets. -

What is the minimum order quantity (MOQ) for starter replacements?

The minimum order quantity (MOQ) for starter replacements varies by supplier and is often influenced by the type of product and shipping costs. Some suppliers may require a MOQ to ensure cost-effectiveness and efficiency in production. It’s advisable to discuss your specific needs with potential suppliers, as they may offer flexibility in MOQs, especially for repeat customers or bulk orders. -

How can I ensure quality assurance (QA) for starter replacements?

To ensure quality assurance for starter replacements, request detailed product specifications and compliance certifications from suppliers. Implement a quality control process that includes inspecting parts upon arrival for defects or discrepancies. Establish clear communication channels with suppliers to address any issues promptly. Consider utilizing third-party inspection services, especially for international shipments, to verify quality before products are delivered to your facility. -

What logistics considerations should I keep in mind when sourcing starters internationally?

When sourcing starters internationally, consider logistics aspects such as shipping costs, customs duties, and delivery timelines. Partner with reliable freight forwarders who understand the regulations in your target markets. Ensure that all shipping documentation is accurate to avoid delays in customs clearance. Additionally, factor in the potential for tariffs or trade restrictions based on your location and the supplier’s country, which could affect overall costs and delivery schedules.

Top 6 Price To Replace Starter Manufacturers & Suppliers List

1. Reddit - Kosten für den Austausch des Anlassers

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Starter replacement, labor charges, diagnostics fees, OEM starter pricing, price markup.

2. Facebook – Starter Replacement Cost

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Kosten für die Fahrt zur Werkstatt und den Austausch des Anlassers

3. Starter Replacement – Cost Guide

Domäne: aaa.com

Registriert: 1990 (35 Jahre)

Einleitung: Average cost to replace a starter: $700 – $1,200. Replacement part cost: under $100 to over $400. Labor rates: $100 – $250 per hour. Factors influencing cost: car make and model, type of starter (gear reduction or direct drive), accessibility of starter. Symptoms of starter issues: slow cranking, car won’t start, clicking or grinding noises, starter running after engine starts, smoke from engine, …

4. Tundras – Starter Replacement

Domäne: tundras.com

Registriert: 2000 (25 Jahre)

Einleitung: Starter replacement for a 2007 Toyota Tundra CrewMax; quoted cost: $1500 ($900 labor + $650 part); part number: Denso 428000-4640; vehicle mileage: 174k; discussion includes opinions on pricing and difficulty of replacement.

5. Letzte Chance Autoreparaturen - Kosten für den Austausch des Anlassers

Domäne: letztechanceautoreparaturen.com

Registriert: 2009 (16 Jahre)

Einleitung: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Factors affecting cost: Vehicle type & model, New vs Re-Manufactured starters, Additional repairs. DIY costs: Parts only: $100 – $400, Tools & equipment: $20 – $100, Time invest…

6. Peterbilt – New Starter Costs

Domäne: thetruckersreport.com

Registriert: 2003 (22 Jahre)

Einleitung: New starter for a truck can cost around $550 from Peterbilt. Installation by a mechanic may cost an additional $300. Road service fees can range from $300 to $800 depending on the situation. Some users report being able to purchase a new starter for under $300 or rebuild one for under $150. Prices can vary based on location and availability.

Strategic Sourcing Conclusion and Outlook for price to replace starter

As the global automotive landscape evolves, understanding the intricacies of starter replacement costs becomes essential for B2B buyers in regions such as Africa, South America, the Middle East, and Europe. Strategic sourcing of starter components not only enables businesses to optimize procurement costs but also enhances operational efficiency. By analyzing the factors influencing replacement prices—such as vehicle type, complexity of installation, and availability of parts—buyers can make informed decisions that align with their budgetary constraints and technical requirements.

Moreover, fostering relationships with reliable suppliers can lead to better pricing agreements, ensuring that businesses remain competitive in their markets. As the demand for vehicle maintenance and repair services grows, especially in emerging markets, leveraging strategic sourcing will be crucial for businesses looking to thrive.

Looking ahead, it is vital for international B2B buyers to stay informed about market trends, technological advancements, and regional supply chain dynamics. By doing so, companies can not only anticipate changes in starter replacement costs but also position themselves favorably within their respective industries. Take action now by evaluating your sourcing strategies and establishing partnerships that will drive success in the evolving automotive marketplace.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.