Introduction: Navigating the Global Market for how long does alternator last

In the complex landscape of automotive parts procurement, understanding how long an alternator lasts is crucial for international B2B buyers. The alternator is a key component in a vehicle’s electrical system, responsible for charging the battery and powering essential functions. This guide delves into the lifespan of alternators, which typically ranges around seven years or 150,000 miles, while also exploring the variables that can influence this duration. By addressing the challenges of sourcing reliable alternators from diverse markets in Africa, South America, the Middle East, and Europe—including specific countries like Vietnam and Saudi Arabia—this comprehensive resource equips buyers with the insights necessary for making informed purchasing decisions.

Throughout this guide, we will cover critical aspects such as the different types of alternators available, their applications across various vehicle models, and essential considerations for supplier vetting. Additionally, we will discuss cost factors and maintenance tips that can extend the lifespan of alternators. By providing actionable insights and expert recommendations, this guide empowers B2B buyers to navigate the global market confidently, ensuring they select high-quality alternators that meet their operational needs while minimizing downtime and repair costs. With the right knowledge, international buyers can enhance their procurement strategies and optimize vehicle performance, ultimately driving business success.

Inhaltsverzeichnis

- Top 3 How Long Does Alternator Last Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long does alternator last

- Understanding how long does alternator last Types and Variations

- Key Industrial Applications of how long does alternator last

- 3 Common User Pain Points for ‘how long does alternator last’ & Their Solutions

- Strategic Material Selection Guide for how long does alternator last

- In-depth Look: Manufacturing Processes and Quality Assurance for how long does alternator last

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does alternator last’

- Comprehensive Cost and Pricing Analysis for how long does alternator last Sourcing

- Alternatives Analysis: Comparing how long does alternator last With Other Solutions

- Essential Technical Properties and Trade Terminology for how long does alternator last

- Navigating Market Dynamics and Sourcing Trends in the how long does alternator last Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long does alternator last

- Strategic Sourcing Conclusion and Outlook for how long does alternator last

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding how long does alternator last Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard-Lichtmaschinen | In der Regel 5–7 Jahre oder 100.000–150.000 Meilen. | Autowerkstätten, Flottenmanagement | Vorteile: Kostengünstig; weithin verfügbar. Nachteile: Limited lifespan; may require frequent replacement. |

| Hochleistungsgeneratoren | Designed for heavy-duty applications; extended lifespan of 10+ years. | Racing, heavy machinery, commercial vehicles | Vorteile: Higher durability; better performance. Nachteile: Higher initial cost; may require specialized installation. |

| Überholte Lichtmaschinen | Rebuilt from used parts; typically last 3-5 years. | Auto parts retailers, budget-conscious repairs | Vorteile: Cost-effective; eco-friendly option. Nachteile: Variable quality; shorter lifespan than new units. |

| OEM-Lichtmaschinen | Original equipment manufacturer parts; designed for specific vehicle models. | Dealerships, fleet operators | Vorteile: Guaranteed compatibility; high reliability. Nachteile: Higher price; limited availability for older models. |

| Ersatzteil-Lichtmaschinen | Third-party alternatives; often designed for performance or cost-saving. | Independent repair shops, DIY mechanics | Vorteile: Variety of options; competitive pricing. Nachteile: Quality can vary; may not fit all vehicles. |

What Are the Characteristics of Standard Alternators and Their Suitability for B2B Buyers?

Standard alternators are the most common type, typically lasting between 5 to 7 years or 100,000 to 150,000 miles. They are ideal for general automotive applications and are widely available, making them suitable for automotive repair shops and fleet management companies. Buyers should consider their cost-effectiveness and availability, but they should also be prepared for potential frequent replacements due to their limited lifespan.

How Do High-Performance Alternators Differ and What Are Their Key B2B Applications?

High-performance alternators are specifically designed for heavy-duty applications, offering an extended lifespan of over 10 years. They are primarily used in racing, heavy machinery, and commercial vehicles where reliability and performance are critical. While they provide higher durability, buyers must weigh the higher initial costs and ensure proper installation, which may require specialized expertise.

Was sollten Käufer über wiederaufgearbeitete Generatoren wissen?

Remanufactured alternators are rebuilt from used components and typically last between 3 to 5 years. They serve budget-conscious repairs and are often available at auto parts retailers. Buyers should consider the cost savings and environmental benefits of choosing remanufactured parts. However, they must be cautious about variable quality and the shorter lifespan compared to new units.

Why Are OEM Alternators Important for B2B Operations?

Original Equipment Manufacturer (OEM) alternators are made specifically for certain vehicle models, ensuring guaranteed compatibility and reliability. They are commonly used by dealerships and fleet operators who prioritize quality and performance. While they offer high reliability, buyers should be aware of the higher prices and limited availability for older models, which can affect procurement strategies.

Was sind die Vor- und Nachteile von Aftermarket-Generatoren?

Aftermarket alternators provide a wide variety of options, often at competitive pricing. They are suitable for independent repair shops and DIY mechanics looking for alternatives to OEM parts. While they offer flexibility and potential cost savings, buyers need to be cautious about quality variability and the possibility that certain models may not fit all vehicles, which can complicate inventory management.

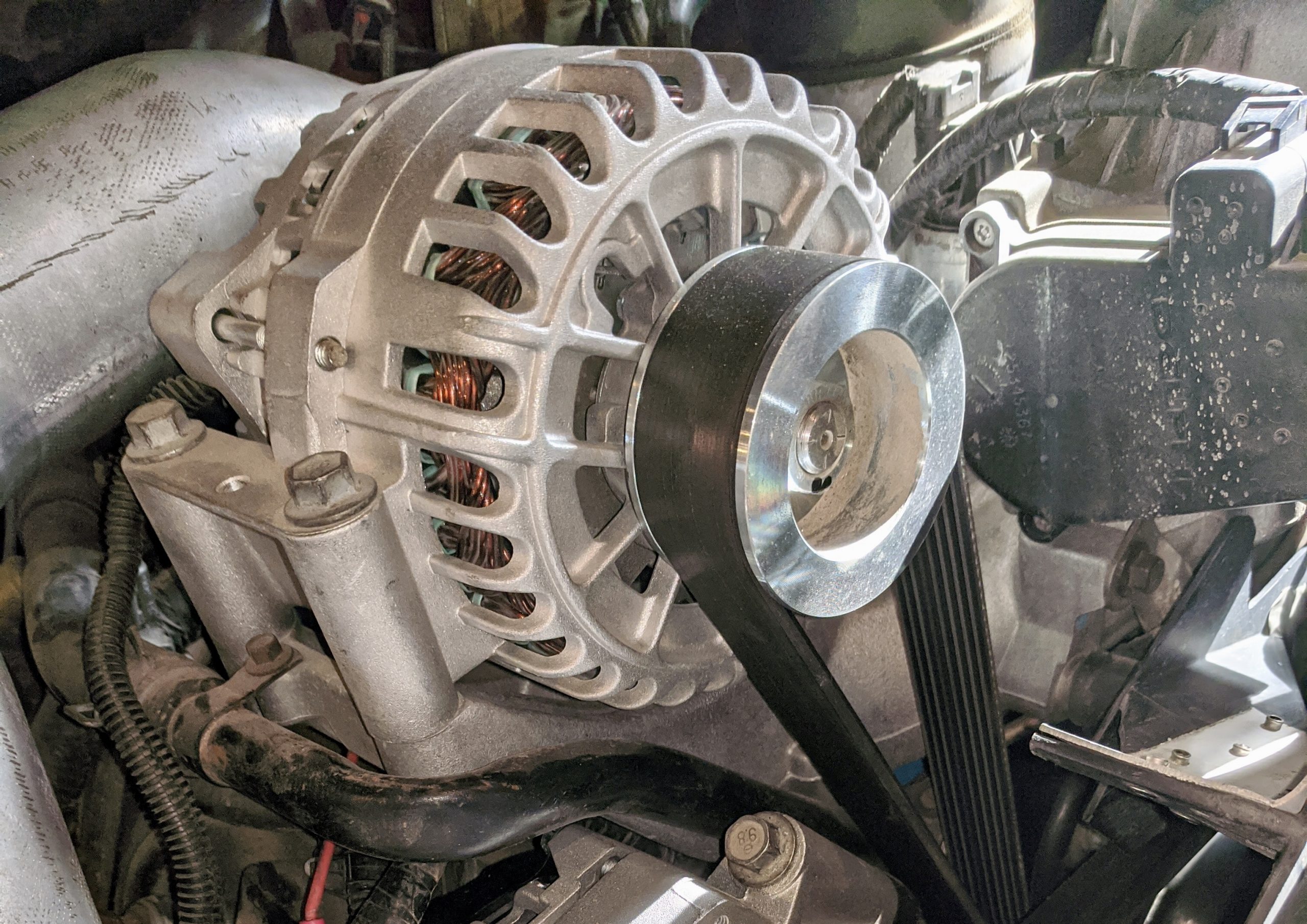

Illustrative image related to how long does alternator last

Key Industrial Applications of how long does alternator last

| Branche/Sektor | Specific Application of how long does alternator last | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Quality control in alternator production | Ensures longevity and reliability of vehicles | Supplier reputation, part quality, and warranty terms |

| Transport | Flottenmanagement für Nutzfahrzeuge | Reduziert Ausfallzeiten und Wartungskosten | Volume discounts, service agreements, and lead times |

| Erneuerbare Energien | Maintenance of hybrid and electric vehicles | Enhances operational efficiency and sustainability | Compatibility with existing systems and certifications |

| Landwirtschaft | Power supply for agricultural machinery | Increases productivity and reduces operational risks | Performance specifications and environmental conditions |

| Bergbau | Heavy machinery reliability in harsh environments | Minimizes equipment failure and operational delays | Durability under extreme conditions and sourcing local parts |

How is the Lifespan of an Alternator Critical in Automotive Manufacturing?

In the automotive manufacturing sector, understanding the lifespan of an alternator is essential for quality control. Manufacturers need to ensure that the alternators they produce can last at least seven years or 150,000 miles under normal conditions. This reliability is vital for customer satisfaction and brand reputation. Buyers should prioritize suppliers with a proven track record in producing high-quality alternators, as well as those who offer robust warranty terms to protect their investment.

Why is the Lifespan of an Alternator Important for Fleet Management?

For transportation companies managing fleets of commercial vehicles, knowing how long an alternator lasts can significantly impact operational efficiency. Fleet managers can schedule preventative maintenance to replace alternators before they fail, thus minimizing downtime and unexpected repair costs. When sourcing alternators, businesses should consider volume discounts and service agreements to optimize their procurement strategy and ensure timely replacements.

How Does Alternator Longevity Affect Renewable Energy Applications?

In the renewable energy sector, particularly with hybrid and electric vehicles, the lifespan of alternators is crucial for maintaining operational efficiency. A well-functioning alternator ensures that the vehicle’s battery remains charged, thus enhancing the overall performance and sustainability of the vehicle. Buyers in this sector should look for alternators that are compatible with their existing systems and come with necessary certifications to meet regulatory standards.

What Role Does Alternator Lifespan Play in Agriculture?

In agriculture, the alternators used in machinery such as tractors and harvesters must be reliable to avoid interruptions during critical operations. A failing alternator can lead to significant productivity losses. Therefore, understanding the expected lifespan helps farmers plan for timely replacements. Buyers should focus on performance specifications tailored to agricultural environments, including resistance to dust and moisture.

Why is Alternator Durability Essential in Mining Operations?

Mining operations often expose machinery to extreme conditions, making the durability and lifespan of alternators critical. A reliable alternator can prevent equipment failure, which can lead to costly operational delays. Companies should prioritize sourcing alternators that are designed to withstand harsh environments and consider local sourcing options to reduce lead times and ensure rapid replacements when necessary.

3 Common User Pain Points for ‘how long does alternator last’ & Their Solutions

Scenario 1: Understanding Alternator Lifespan in Diverse Conditions

Das Problem: B2B buyers, particularly those in regions with extreme weather conditions, often struggle to determine the expected lifespan of an alternator. Variability in temperature, humidity, and altitude can significantly affect alternator performance. For example, an alternator in a hot, humid climate may fail sooner than one in a temperate zone. This uncertainty can lead to unscheduled downtimes and increased operational costs, especially for businesses relying on fleet vehicles.

Die Lösung: To navigate these challenges, businesses should conduct thorough research into the specific environmental factors that affect alternator lifespan. Engaging with manufacturers who provide detailed specifications based on regional conditions can be invaluable. For instance, businesses can inquire about alternators designed for high-performance in extreme climates. Additionally, implementing regular maintenance schedules that include inspections of the electrical system can preemptively identify wear and tear. Educating drivers about the signs of alternator issues, such as fluctuating electrical performance or unusual sounds, can also mitigate risks and ensure timely replacements before critical failures occur.

Szenario 2: Beschaffung hochwertiger Lichtmaschinen für vielfältige Anwendungen

Das Problem: Many B2B buyers face challenges when sourcing alternators that meet the specific needs of their diverse vehicle fleets. With variations in vehicle types, engine sizes, and electrical demands, finding the right alternator can be a daunting task. This often leads to purchasing subpar products that do not last as long as expected, resulting in frequent replacements and increased operational costs.

Die Lösung: To effectively source quality alternators, businesses should establish relationships with reputable suppliers who specialize in automotive electrical systems. It’s essential to provide detailed specifications about the fleet’s needs, including vehicle make, model, engine type, and any aftermarket electrical accessories. Buyers can also request samples or performance data to assess the quality of the alternators before making bulk purchases. Additionally, understanding the warranty terms and service support from suppliers can provide peace of mind and a safety net for future replacements. By investing time in sourcing the right products, businesses can enhance their operational efficiency and reduce long-term costs.

Scenario 3: Managing Maintenance and Replacement Costs

Das Problem: One of the most significant pain points for B2B buyers is managing the costs associated with alternator maintenance and replacement. Many businesses underestimate the total cost of ownership related to alternators, including labor, unexpected breakdowns, and the impact on productivity. This often results in budget overruns and operational disruptions, particularly in industries where vehicles are critical to daily operations.

Die Lösung: To manage these costs effectively, businesses should implement a proactive maintenance strategy that includes regular inspections and performance assessments of the alternators. Utilizing fleet management software can help track alternator performance and schedule maintenance before issues arise. Additionally, investing in training for staff to recognize early signs of alternator failure can lead to timely interventions, reducing the likelihood of costly breakdowns. Establishing a budget that accounts for regular maintenance and potential replacements can also help businesses avoid financial surprises. By taking a strategic approach to alternator management, companies can improve their bottom line while ensuring reliable vehicle performance.

Strategic Material Selection Guide for how long does alternator last

What Materials Are Commonly Used in Alternator Manufacturing?

When considering the longevity and reliability of alternators, the choice of materials plays a crucial role. Here, we analyze several common materials used in alternator components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Was sind die wichtigsten Eigenschaften von Aluminium in Lichtmaschinen?

Aluminum is widely used in alternator housings and some internal components due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of around 150°C and can withstand moderate pressure levels. This property makes aluminum suitable for automotive applications where weight savings and resistance to environmental factors are critical.

Vorteile: Aluminum is durable, cost-effective, and easy to machine, making it suitable for mass production. Its lightweight nature contributes to improved fuel efficiency in vehicles.

Illustrative image related to how long does alternator last

Nachteile: While aluminum is resistant to corrosion, it can be less durable under extreme mechanical stress compared to heavier metals. Additionally, it may require anodizing or other treatments to enhance its surface properties.

Auswirkungen auf die Anwendung: Aluminum’s lightweight and corrosion-resistant properties make it ideal for alternators, particularly in regions with high humidity or saline environments, such as coastal areas in Africa and South America.

Überlegungen für internationale Käufer: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider local manufacturing capabilities and preferences for aluminum alloys.

Wie trägt Kupfer zur Leistung der Lichtmaschine bei?

Copper is predominantly used in the windings and electrical connections of alternators due to its superior electrical conductivity. It can handle high temperatures (up to 200°C) and offers excellent corrosion resistance when properly coated.

Vorteile: Copper’s high conductivity ensures efficient energy transfer, which is vital for the performance of the alternator. It also has a long lifespan when maintained properly.

Nachteile: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, copper is heavier, which may not be ideal for all applications.

Auswirkungen auf die Anwendung: Copper is critical for applications requiring high electrical performance, making it suitable for high-demand vehicles in regions with extreme climates, such as the Middle East.

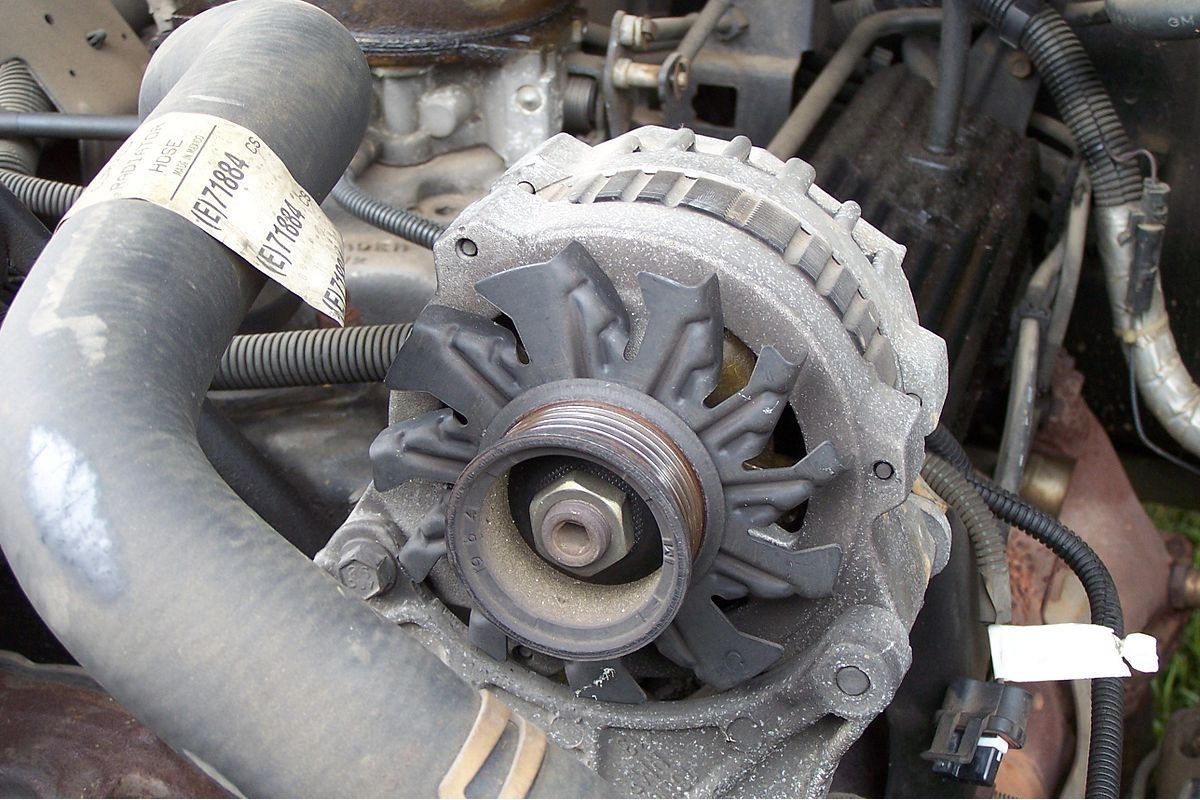

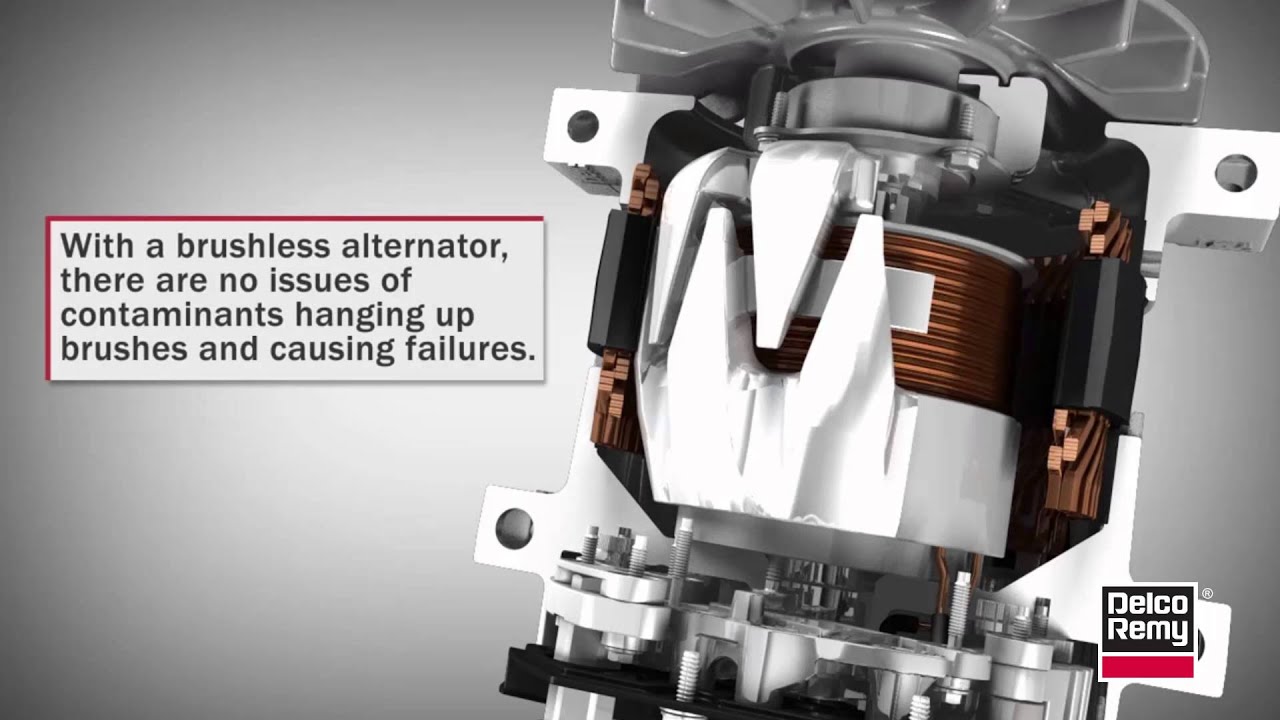

Illustrative image related to how long does alternator last

Überlegungen für internationale Käufer: Buyers should ensure compliance with electrical standards and consider the availability of copper in their local markets, as fluctuations in price can impact overall costs.

Welche Rolle spielt Stahl beim Bau von Lichtmaschinen?

Steel is often used for structural components of alternators, such as the rotor and stator cores. It provides strength and durability, with a temperature rating typically around 300°C.

Vorteile: Steel’s strength makes it suitable for high-stress applications, providing a robust framework that can endure operational wear and tear.

Nachteile: Steel is heavier than aluminum and can be prone to rust if not properly treated. This can be a significant disadvantage in humid environments.

Auswirkungen auf die Anwendung: Steel’s durability is beneficial for alternators used in heavy-duty vehicles, especially in regions with rough terrains, such as parts of Africa and South America.

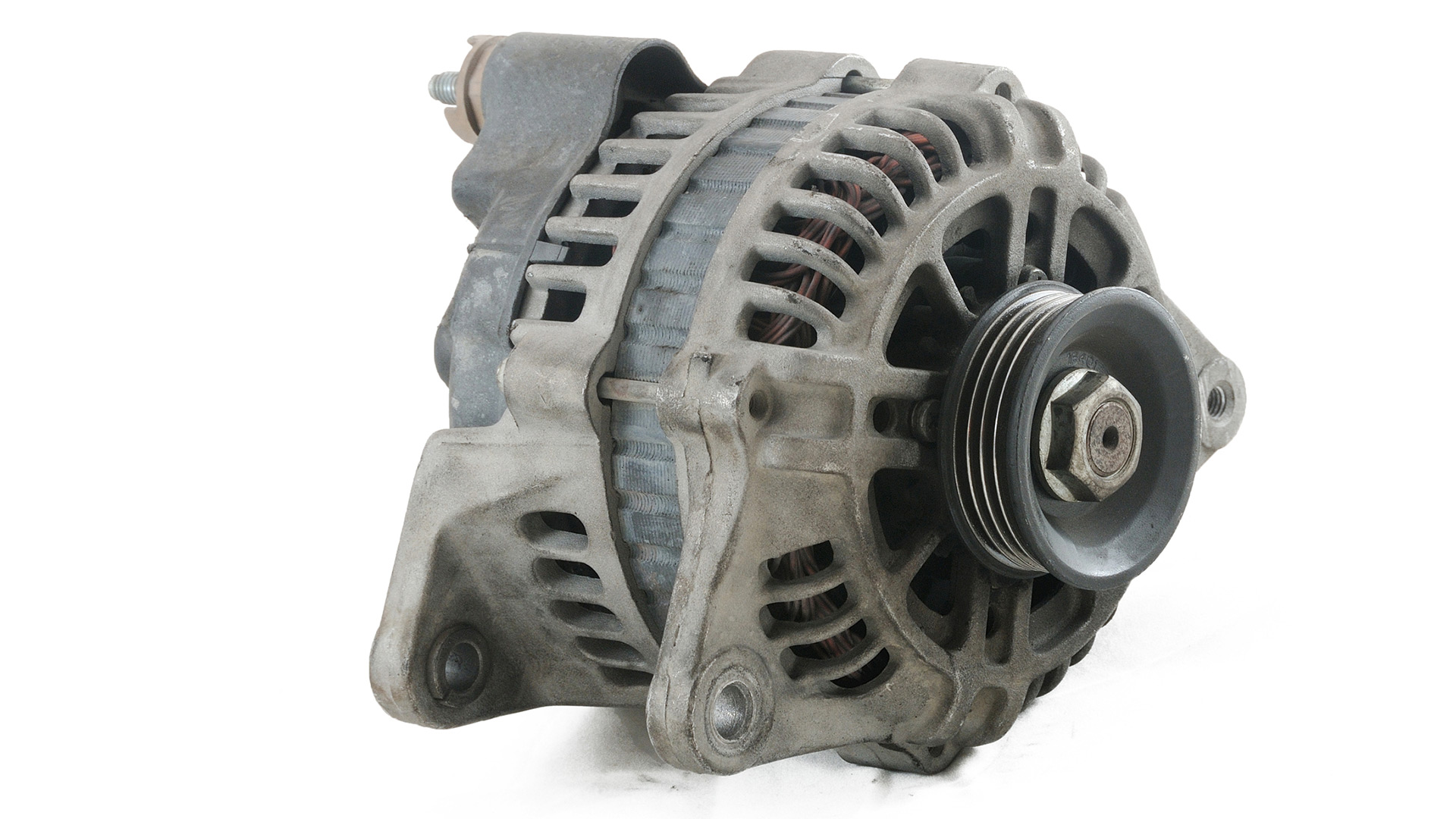

Illustrative image related to how long does alternator last

Überlegungen für internationale Käufer: Compliance with local standards for steel quality is crucial. Buyers should also evaluate the availability of treated steel to mitigate corrosion risks.

Why Is Plastic Used in Alternator Components?

Plastic is increasingly used in non-structural components of alternators, such as covers and insulation. It offers good electrical insulation properties and can withstand moderate temperatures (up to 120°C).

Vorteile: Plastic is lightweight, cost-effective, and can be molded into complex shapes, making it versatile for various applications.

Nachteile: Plastic may not provide the same level of durability or heat resistance as metals, potentially leading to a shorter lifespan in high-stress environments.

Illustrative image related to how long does alternator last

Auswirkungen auf die Anwendung: Plastic components can reduce overall weight, which is beneficial for fuel efficiency, but they may not be suitable for all climates, particularly in regions with extreme temperatures.

Überlegungen für internationale Käufer: Buyers should ensure that the plastics used meet relevant safety and performance standards, particularly in automotive applications.

Übersichtstabelle zur Materialauswahl für Generatoren

| Material | Typical Use Case for how long does alternator last | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und interne Komponenten | Leicht und korrosionsbeständig | Weniger haltbar bei extremer Belastung | Mittel |

| Kupfer | Wicklungen und elektrische Anschlüsse | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und höheres Gewicht | Hoch |

| Stahl | Rotor- und Ständerkerne | Stark und langlebig | Neigt ohne Behandlung zu Rost | Mittel |

| Kunststoff | Abdeckungen und Isolierung | Leicht und vielseitig | Limited durability in high-stress environments | Niedrig |

This analysis highlights the importance of material selection in the longevity and performance of alternators, offering valuable insights for international B2B buyers in diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for how long does alternator last

Was sind die wichtigsten Phasen des Herstellungsprozesses von Generatoren?

The manufacturing of alternators involves several key stages, each critical to ensuring the final product meets quality and performance expectations. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

Materialvorbereitung: Welche Materialien werden bei der Herstellung von Wechselstromgeneratoren verwendet?

The first stage involves sourcing high-quality materials essential for alternator production. Typically, manufacturers utilize copper for windings due to its excellent conductivity, aluminum for casings, and high-grade steel for the rotor and stator. Suppliers often conduct rigorous material testing to ensure that the components meet required specifications. This initial step is crucial, as the quality of raw materials directly influences the durability and performance of the alternator.

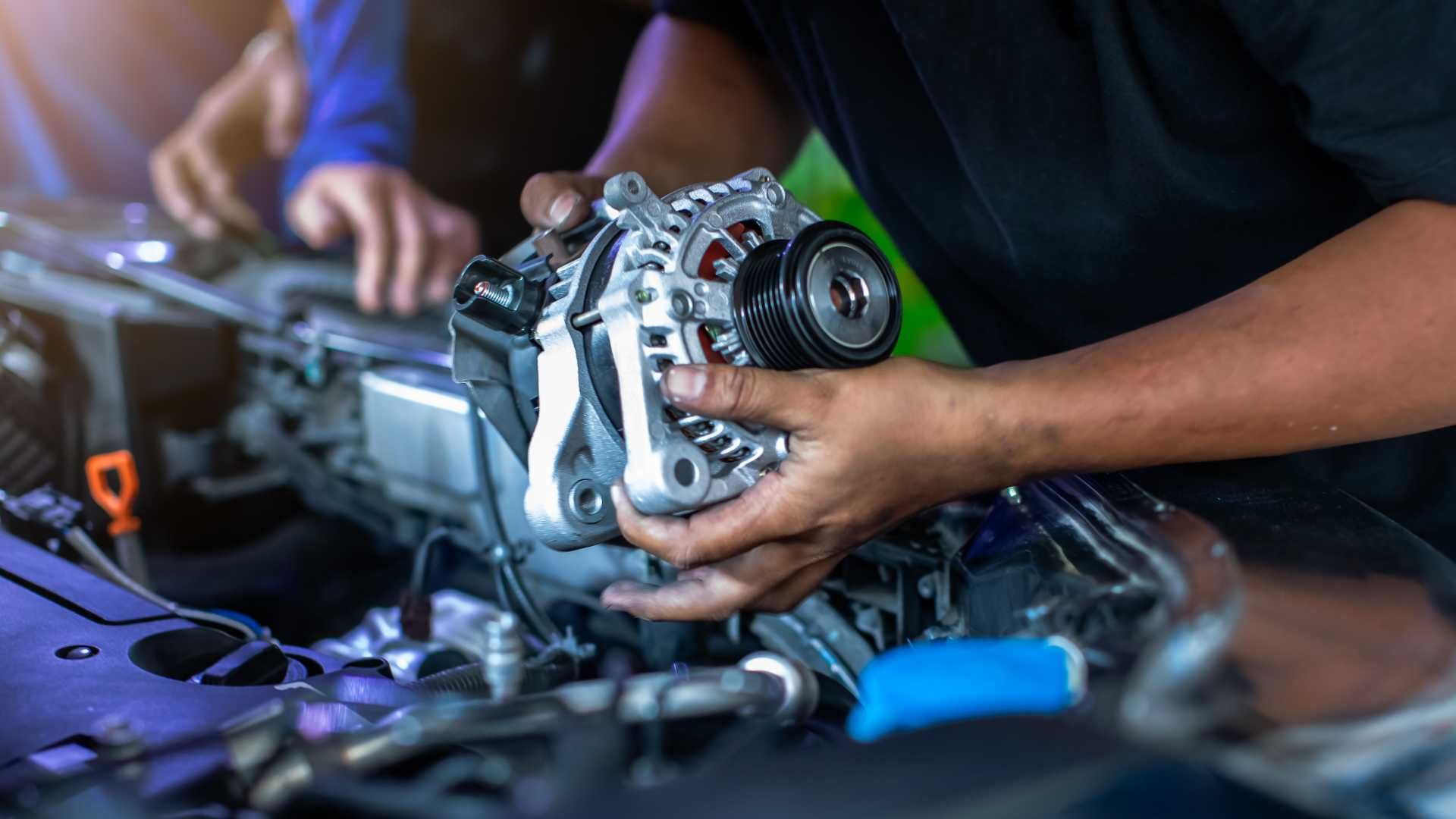

Illustrative image related to how long does alternator last

What Forming Techniques Are Commonly Used in Alternator Production?

Once materials are prepared, they undergo forming processes. Stamping is a prevalent technique used to create the stator and rotor components. This process involves using dies to cut and shape metal sheets into specific forms. Additionally, winding machines are utilized to coil copper wire around the stator, ensuring precise turns and spacing that are critical for efficient electrical performance.

How Is the Assembly Process Structured for Alternators?

The assembly stage is where the alternator components come together. This typically involves several key steps:

– Component Insertion: The rotor is inserted into the stator, and the bearings are placed.

– Elektrische Anschlüsse: The copper windings are connected to the rectifier and voltage regulator, ensuring that the alternator can effectively charge the vehicle’s battery.

– Endmontage: The casing is sealed, and any necessary hardware is attached.

During assembly, manufacturers often employ automated systems to enhance precision and reduce human error.

Illustrative image related to how long does alternator last

What Finishing Processes Are Applied to Ensure Quality?

Finishing processes are vital for enhancing the longevity and functionality of the alternator. Common techniques include:

– Oberflächenbehandlung: Coatings may be applied to resist corrosion and wear.

– Quality Inspections: Each unit undergoes visual inspections to ensure there are no defects or damages.

These finishing touches not only improve the product’s appearance but also its resistance to environmental factors, which is particularly important for buyers in regions with harsh climates.

How Is Quality Assurance Integrated Into Alternator Manufacturing?

Quality assurance is a crucial component of the manufacturing process, ensuring that each alternator meets established performance standards. This is particularly significant for B2B buyers who need reliable components for their operations.

What International Standards Are Relevant for Alternator Quality Assurance?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for an effective quality management system. Compliance with these standards indicates that a manufacturer has established processes to consistently deliver products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking for compliance with European health, safety, and environmental protection standards are vital for B2B buyers in Europe.

Was sind die wichtigsten Punkte der Qualitätskontrolle bei der Herstellung von Generatoren?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Eingangsqualitätskontrolle (IQC): This initial stage checks raw materials against specifications to ensure they are suitable for production.

- In-Process-Qualitätskontrolle (IPQC): During the assembly phase, periodic inspections are conducted to verify that components are being assembled correctly and meet quality standards.

- Endkontrolle (FQC): Before packaging, each alternator undergoes a comprehensive inspection to confirm that it functions correctly and meets all specifications.

These checkpoints are designed to catch defects early, reducing the risk of faulty products reaching the market.

What Common Testing Methods Are Used to Validate Alternator Performance?

Manufacturers employ a range of testing methods to ensure alternators perform as expected. Common tests include:

– Elektrische Prüfung: This assesses the alternator’s output voltage and current under various loads to ensure it meets performance specifications.

– Thermische Prüfung: Evaluating the alternator under high temperatures helps determine its durability in extreme conditions.

– Vibrationsprüfung: This simulates the operational environment of the alternator to ensure it can withstand the stresses of daily use.

These testing methodologies provide B2B buyers with assurance that the alternators they procure will operate effectively under real-world conditions.

Wie können B2B-Käufer die Qualitätskontrollprozesse ihrer Lieferanten überprüfen?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

Illustrative image related to how long does alternator last

Welche Schritte können Einkäufer bei der Durchführung von Lieferantenaudits unternehmen?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control practices. Buyers should consider:

– On-site Visits: Physically visiting the manufacturing facility allows buyers to observe processes and conduct discussions with management about quality assurance protocols.

– Reviewing Quality Documentation: Requesting access to quality control reports, certifications, and audit histories can provide insights into a supplier’s commitment to maintaining high standards.

– Third-party Inspections: Engaging independent auditors to assess a supplier’s facilities and practices can offer an objective evaluation of quality compliance.

What QC and Certification Nuances Should International Buyers Be Aware Of?

International buyers should be mindful of specific regional regulations and certification requirements that may differ from their own. For instance, while ISO standards are widely recognized, specific markets may have additional certifications that are critical for compliance. Understanding these nuances can help buyers navigate the complexities of international trade and ensure that the products they procure align with local regulations.

Schlussfolgerung

Understanding the manufacturing processes and quality assurance protocols for alternators is vital for B2B buyers looking to make informed purchasing decisions. By knowing what to look for in terms of manufacturing stages, quality control standards, and verification methods, buyers can ensure they procure reliable products that will meet their operational needs. This knowledge not only helps in selecting the right suppliers but also enhances the overall efficiency and reliability of their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long does alternator last’

Einführung

This practical sourcing guide aims to provide B2B buyers with a structured approach to understanding the lifespan of alternators and the key factors influencing their procurement. By following this checklist, international buyers can ensure they make informed decisions that align with their operational needs and minimize the risk of premature alternator failure.

Schritt 1: Assess Your Application Requirements

Understanding the specific demands of your application is critical. Different vehicles and machinery require alternators with varying output capacities, sizes, and specifications. Identify the electrical load your alternator will need to support, including any aftermarket electronics, to ensure compatibility and longevity.

Illustrative image related to how long does alternator last

Schritt 2: Research Alternator Lifespan

On average, alternators last between 7 to 10 years or approximately 150,000 miles, but this can vary significantly based on usage and environmental factors. Consider the conditions in which your vehicles operate—such as extreme temperatures or heavy loads—which may influence the alternator’s longevity. This knowledge helps in setting realistic expectations and planning for future replacements.

Schritt 3: Bewertung der Zuverlässigkeit von Lieferanten

Before committing, it’s crucial to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their reputation in the market for delivering high-quality products that meet industry standards, as this can significantly affect the performance and durability of the alternators.

Schritt 4: Verify Product Certifications

Ensure that the alternators you are considering comply with international quality standards and certifications. Look for certifications such as ISO 9001 or specific automotive standards relevant to your region. These certifications can provide assurance of quality and performance, ultimately reducing the risk of premature failure.

Schritt 5: Erkundigen Sie sich nach Garantie und Support

A robust warranty can be an indicator of a supplier’s confidence in their product. Ask potential suppliers about their warranty terms and the support they offer in case of defects or early failures. Understanding the warranty coverage will help you mitigate potential losses and ensure you have recourse should issues arise.

Schritt 6: Consider Maintenance and Support Services

Inquire about the availability of maintenance and support services from the supplier. Regular maintenance can extend the lifespan of your alternators, so it’s beneficial to partner with suppliers who offer guidance and services for upkeep. Assess whether they provide training or resources to help your team maintain the alternators effectively.

Schritt 7: Musterprodukte anfordern

Before making a bulk purchase, consider requesting samples for evaluation. Testing the alternators in your specific operational context allows you to assess their performance firsthand. This step can help identify any compatibility issues and ensure that the products meet your expectations before committing to a larger order.

By following this step-by-step checklist, B2B buyers can confidently navigate the complexities of procuring alternators, ensuring they select the right products for their needs while optimizing performance and longevity.

Comprehensive Cost and Pricing Analysis for how long does alternator last Sourcing

Was sind die wichtigsten Kostenkomponenten bei der Beschaffung von Lichtmaschinen?

When sourcing alternators, B2B buyers must consider various cost components that contribute to the overall price. The primary elements include:

-

Materialien: The choice of materials used in the alternator significantly impacts costs. High-quality copper windings, robust housing materials, and durable bearings increase longevity but also raise production costs.

-

Arbeit: Labor costs vary by region and manufacturing practices. In countries with higher labor costs, such as those in Europe, the overall pricing may be elevated compared to regions like South America or Southeast Asia, where labor is generally more cost-effective.

-

Fertigungsgemeinkosten: This includes utilities, facility maintenance, and administrative costs. Efficient production processes can mitigate these expenses, allowing suppliers to offer competitive pricing.

-

Werkzeuge: Initial tooling costs can be substantial, especially for custom or high-volume orders. These costs are typically amortized over the production run, affecting unit pricing.

-

Qualitätskontrolle (QC): Implementing stringent QC measures ensures that the alternators meet industry standards, which can add to the overall cost but is essential for maintaining reliability and safety.

-

Logistik: Shipping costs vary significantly based on distance, mode of transport, and Incoterms. Buyers should factor in logistics when calculating total sourcing costs, especially for international orders.

-

Marge: Suppliers will include a profit margin in their pricing, which can fluctuate based on market demand, competition, and overall economic conditions.

Wie wirken sich Preisfaktoren auf die Kosten von Lichtmaschinen aus?

Several factors can influence the pricing of alternators, which are crucial for B2B buyers to understand:

-

Volumen und Mindestbestellmenge (MOQ): Purchasing in bulk often results in lower per-unit costs. Suppliers may offer discounts for larger orders, which can significantly reduce the total cost.

-

Spezifikationen und Anpassung: Customized alternators tailored to specific vehicle models or requirements may incur higher costs due to additional engineering and production complexity.

-

Materialqualität und Zertifizierungen: Higher-quality materials and adherence to industry certifications (like ISO or TS certifications) can increase costs but provide assurance of durability and performance.

-

Lieferantenfaktoren: The reliability, reputation, and experience of the supplier can affect pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: Understanding the shipping terms can influence the total landed cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, impacting overall pricing.

Welche Tipps sollten Käufer für Kosteneffizienz berücksichtigen?

To maximize value when sourcing alternators, buyers should implement several strategic practices:

-

Klug verhandeln: Engage suppliers in discussions about pricing and terms. Leverage bulk purchasing and long-term relationships to negotiate better deals.

-

Bewertung der Gesamtbetriebskosten (TCO): Beyond the initial purchase price, consider maintenance, replacement frequency, and warranty options. A lower-priced alternator may lead to higher costs in the long run if it fails prematurely.

-

Verstehen Sie die Nuancen der Preisgestaltung für die internationale Beschaffung: For buyers in Africa, South America, the Middle East, and Europe, currency fluctuations, tariffs, and import duties can significantly affect costs. Ensure a comprehensive understanding of these elements when budgeting for purchases.

-

Evaluate Supplier Proximity: Sourcing from nearby suppliers can reduce logistics costs and lead times, enhancing the supply chain’s responsiveness.

Haftungsausschluss für indikative Preise

Pricing for alternators can vary widely based on the factors mentioned above. It is advisable for buyers to request detailed quotes from multiple suppliers to obtain accurate pricing tailored to their specific needs and circumstances. This approach will help ensure that buyers make informed decisions that align with their operational goals.

Alternatives Analysis: Comparing how long does alternator last With Other Solutions

Exploring Alternatives to Alternators: How Long Do They Last Compared to Other Solutions?

When evaluating the longevity and effectiveness of alternators, it’s essential to consider alternative technologies that serve similar purposes in powering vehicle electrical systems. As businesses in various regions like Africa, South America, the Middle East, and Europe make purchasing decisions, understanding these alternatives can provide valuable insights into their operational efficiency and cost-effectiveness.

| Vergleichsaspekt | How Long Does Alternator Last | Batterie-Management-Systeme (BMS) | Solarstromanlagen |

|---|---|---|---|

| Leistung | 7 Jahre / 150.000 Meilen | Up to 10 years, depending on usage | Indefinite lifespan with proper maintenance |

| Kosten | $300 – $700 for replacement | $150 – $500 for installation and components | $1,000 – $5,000 for installation |

| Einfache Implementierung | Moderate, requires professional installation | Moderate, requires technical expertise | High, needs substantial space and expertise |

| Wartung | Requires regular inspections; can fail suddenly | Low, periodic checks; can last longer with good care | Moderate, requires maintenance of panels and batteries |

| Bester Anwendungsfall | Standard vehicles, traditional combustion engines | Elektro- und Hybridfahrzeuge | Off-grid or renewable energy applications |

What Are the Advantages and Disadvantages of Battery Management Systems (BMS)?

Battery Management Systems are designed to monitor and manage battery performance in electric and hybrid vehicles. They extend battery life by optimizing charging and discharging cycles. The advantages include a longer lifespan (up to 10 years) and lower maintenance needs compared to traditional alternators. However, the initial installation cost can be significant, and they require a level of technical expertise for optimal performance. This makes BMS particularly suitable for businesses that are transitioning to electric fleets or looking to enhance the efficiency of their existing battery systems.

Illustrative image related to how long does alternator last

Wie unterscheiden sich Solarstromsysteme von herkömmlichen Wechselstromgeneratoren?

Solar power systems harness renewable energy to power vehicle electronics, offering an indefinite lifespan as long as the panels are maintained properly. They are particularly advantageous for off-grid applications or where traditional power sources are unreliable. However, the initial investment is considerably higher, and implementation can be complex, requiring adequate space for installation and knowledge of solar technology. Solar systems are best suited for businesses focused on sustainability and looking to reduce dependency on fossil fuels.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding between alternators and alternative solutions like Battery Management Systems or Solar Power Systems, B2B buyers should consider their specific operational needs and context. For traditional vehicles, understanding the average lifespan of an alternator and ensuring timely replacements can prevent costly downtimes. Conversely, businesses transitioning to electric vehicles may find BMS more aligned with their goals, providing enhanced battery longevity and reduced maintenance. Lastly, companies with a focus on sustainability might invest in solar power systems, despite the higher upfront costs, for long-term savings and energy independence. Each solution has its unique advantages and potential drawbacks, so aligning the choice with the company’s operational strategy is crucial for optimal results.

Essential Technical Properties and Trade Terminology for how long does alternator last

What Are the Key Technical Properties That Affect Alternator Longevity?

Understanding the technical specifications of alternators is essential for B2B buyers involved in the automotive sector. Here are critical specifications that influence the durability and performance of alternators:

-

Werkstoffgüte

The quality of materials used in the construction of an alternator significantly affects its lifespan. High-grade metals such as aluminum and copper are commonly used for windings and casings, providing resistance to corrosion and heat. Selecting alternators made from superior materials ensures better performance and longevity, which is vital for reducing maintenance costs in fleet operations. -

Power Output (Amperage Rating)

The amperage rating indicates the maximum electrical current an alternator can produce. Most standard alternators range from 70 to 150 amps. Understanding this specification is crucial when sourcing alternators, as choosing a unit with insufficient output can lead to battery drain and electrical failures, especially in vehicles loaded with high-demand electronics. -

Lagertyp

Alternators typically use either ball or roller bearings, which affect their efficiency and noise levels. Ball bearings offer smoother operation and reduced friction, contributing to a longer service life. This specification is particularly important for commercial vehicles, where longevity and reliability are paramount. -

Spannungsregelung

The voltage regulator is critical for maintaining consistent voltage output, preventing overcharging or undercharging the battery. A robust voltage regulation system enhances the alternator’s performance and extends its lifespan. For B2B buyers, ensuring the alternator has a reliable regulator is essential to minimize potential damage to the vehicle’s electrical system. -

Toleranzwerte

Tolerance levels define the acceptable limits of variation in the alternator’s components, such as winding resistance and physical dimensions. High-tolerance specifications ensure that parts fit correctly and function effectively, which is crucial for minimizing wear and tear. This is particularly significant for manufacturers and distributors who require reliable components for assembly lines.

Which Trade Terms Should B2B Buyers Know When Sourcing Alternators?

Familiarity with industry terminology can streamline the procurement process. Here are essential trade terms relevant to sourcing alternators:

-

OEM (Originalgerätehersteller)

OEM alternators are produced by the same manufacturer that made the original parts for a vehicle. They are often preferred due to their guaranteed compatibility and performance. For B2B buyers, understanding the difference between OEM and aftermarket parts can significantly influence purchasing decisions. -

MOQ (Mindestbestellmenge)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers, as understanding MOQ helps in budgeting and inventory management. It can also affect negotiations with suppliers, particularly for bulk orders. -

RFQ (Angebotsanfrage)

An RFQ is a formal document that a buyer sends to suppliers to request pricing information for specific products or services. For B2B buyers, issuing an RFQ is an essential step in comparing costs and ensuring they receive competitive pricing on alternators. -

Incoterms (Internationale Handelsklauseln)

Incoterms are internationally recognized standard trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers manage shipping logistics and costs effectively, ensuring a smooth procurement process. -

Garantiezeitraum

This term refers to the time frame during which a buyer can claim repairs or replacements for defective products. Understanding warranty terms is vital for B2B buyers, as it impacts long-term maintenance costs and supplier reliability. -

Vorlaufzeit

Lead time is the amount of time between placing an order and receiving the product. In the automotive sector, where timely availability can influence operations, knowing the lead time for alternators is crucial for maintaining service levels and customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their automotive businesses.

Navigating Market Dynamics and Sourcing Trends in the how long does alternator last Sector

What are the Global Drivers Affecting the Alternator Lifespan Market?

The global alternator market is witnessing significant shifts driven by various factors, including technological advancements, increased vehicle electrification, and the growing demand for electric vehicles (EVs). As vehicles become more reliant on electronic systems, the alternator’s role in maintaining battery health and powering these systems becomes critical. For B2B buyers, understanding these dynamics is essential for sourcing reliable alternator components that meet evolving industry standards.

In regions such as Africa and South America, where vehicle ownership is on the rise, the demand for durable and long-lasting alternators is increasing. International B2B buyers in these markets must consider sourcing from manufacturers that prioritize quality and longevity, as these regions often experience harsh driving conditions that can accelerate wear and tear on automotive components. Additionally, the Middle East and Europe are witnessing a surge in EV adoption, leading to innovations in alternator design that cater to hybrid and fully electric vehicles.

Illustrative image related to how long does alternator last

Emerging trends in sourcing also include the integration of smart technologies into alternators, enabling real-time monitoring of performance metrics. This trend is particularly relevant for fleet operators looking to optimize maintenance schedules and reduce downtime. By investing in alternators equipped with advanced features, international buyers can enhance operational efficiency and ensure vehicle reliability.

How Does Sustainability and Ethical Sourcing Impact the Alternator Market?

Sustainability is becoming a non-negotiable aspect of supply chain management in the automotive sector. For B2B buyers, understanding the environmental impact of alternator production is crucial. Traditional manufacturing processes often involve significant energy consumption and the use of non-renewable resources. However, there is a growing emphasis on ethical sourcing and the use of sustainable materials in alternator manufacturing.

Buyers should prioritize suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001 or adherence to circular economy principles. These certifications indicate that manufacturers are actively working to minimize their ecological footprint, which can enhance a buyer’s brand reputation and appeal to environmentally conscious consumers.

Moreover, the use of recycled materials in alternator production is gaining traction. Suppliers that incorporate recycled metals and plastics can not only reduce waste but also provide cost-effective solutions for B2B buyers. As the market shifts towards greener practices, investing in sustainably sourced alternators can yield long-term benefits, both economically and environmentally.

Illustrative image related to how long does alternator last

Wie hat sich der Lichtmaschinenmarkt im Laufe der Zeit entwickelt?

The alternator has undergone significant evolution since its inception, transitioning from mechanical generators to sophisticated electronic components. Initially, alternators were primarily designed to charge batteries and power basic electrical systems. However, with the advent of advanced automotive technologies, modern alternators now incorporate smart features that monitor battery health and optimize energy distribution.

This evolution has been particularly pronounced in regions with stringent emissions regulations, where manufacturers are compelled to develop more efficient alternators to meet regulatory standards. Additionally, the rise of electric and hybrid vehicles has spurred innovation in alternator design, leading to lighter, more efficient units that support the complex electrical demands of contemporary vehicles.

For B2B buyers, this historical context underscores the importance of sourcing alternators that are not only compatible with current technologies but are also adaptable to future advancements. By aligning with manufacturers that have a proven track record of innovation, buyers can ensure that they are investing in products that will stand the test of time in an increasingly competitive marketplace.

Illustrative image related to how long does alternator last

Frequently Asked Questions (FAQs) for B2B Buyers of how long does alternator last

-

1. How long does an alternator typically last?

The average lifespan of an alternator is about 7 years or approximately 150,000 miles, although this can vary based on several factors. Quality of the part, vehicle condition, and the extent of electronic usage all play significant roles in determining longevity. Regular inspections and maintenance can help extend the lifespan of your alternator. B2B buyers should consider sourcing high-quality alternators from reputable suppliers to ensure durability and reliability. -

2. What signs indicate a failing alternator?

A failing alternator may exhibit several warning signs, including difficulty starting the vehicle, frequent stalling, dim or flickering headlights, and unusual noises from the engine. Buyers should educate their teams on these symptoms to facilitate timely inspections and replacements. Early detection can prevent more significant electrical issues and costly repairs, thus maintaining operational efficiency in fleet management. -

3. How do I choose the right alternator supplier for my business?

Selecting the right alternator supplier involves assessing their reputation, product quality, and customer service. Conduct thorough market research, request samples, and check references. It’s also beneficial to evaluate their manufacturing processes and certifications to ensure compliance with international standards. Engaging in long-term partnerships with reliable suppliers can lead to consistent quality and favorable pricing. -

4. What customization options are available for alternators?

Many suppliers offer customization options for alternators, including modifications to meet specific electrical requirements or designs tailored for unique vehicle models. When sourcing, inquire about the supplier’s ability to accommodate specific needs, such as output capacity or mounting configurations. Customization can enhance performance and ensure compatibility with your fleet’s specifications. -

5. What are the typical minimum order quantities (MOQs) for alternators?

Minimum order quantities (MOQs) can vary widely among suppliers, often depending on the type of alternator and the supplier’s production capabilities. Some suppliers may set MOQs as low as 10 units, while others may require larger orders to optimize production efficiency. B2B buyers should negotiate MOQs based on their purchasing needs and consider establishing agreements for recurring orders to secure better pricing. -

6. What payment terms are commonly offered by alternator suppliers?

Payment terms can vary significantly among suppliers, typically ranging from upfront payments to net 30, 60, or even 90 days. It’s crucial to discuss and agree on payment terms that align with your cash flow and procurement strategy. Consider suppliers who offer flexible payment options, as this can enhance your financial management and procurement processes. -

7. How can I ensure quality assurance (QA) for alternators?

To ensure quality assurance for alternators, implement a rigorous supplier evaluation process that includes quality checks and compliance with industry standards. Request documentation of testing and certifications from suppliers. Additionally, conducting periodic audits and inspections can help maintain quality throughout the supply chain, ensuring the reliability of the products you source. -

8. What logistics considerations should I keep in mind when sourcing alternators internationally?

When sourcing alternators internationally, logistics considerations such as shipping methods, customs regulations, and lead times are critical. Evaluate the supplier’s ability to handle international shipping and their experience with customs documentation to avoid delays. Additionally, consider local regulations regarding automotive parts to ensure compliance. Establishing a clear logistics plan can streamline the import process and ensure timely delivery of products.

Top 3 How Long Does Alternator Last Manufacturers & Suppliers List

1. Ford Fusion – Lebensdauer der Lichtmaschine

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Alternator average lifespan for Ford Fusion is generally around 180,000 miles, with some users reporting original alternators lasting up to 200,000 km (approximately 124,274 miles) or more. Common issues leading to alternator failure include worn brushes in the voltage regulator, which typically last around 200,000 km. Users suggest that replacing just the brushes or the voltage regulator can exte…

2. Savannah Toyota - Austausch der Lichtmaschine

Domäne: savannahtoyota.com

Registriert: 1996 (29 Jahre)

Einleitung: The alternator in a vehicle powers all electronics while the engine is running, acting as a generator using the gas engine as its energy source. It typically lasts between 80,000 and 150,000 miles (about seven years). The average cost for a new alternator ranges from $500 to $1,000, depending on the vehicle type. Signs of a failing alternator include a battery warning light, dim headlights, burnin…

3. Toyota – Alternator Insights

Domäne: toyotaofeasley.com

Registriert: 1996 (29 Jahre)

Einleitung: The alternator is an electrical generator in a vehicle’s engine that converts mechanical energy into electrical energy, powering the battery, onboard computer, and other electrical components. Its lifespan varies based on wear, aftermarket components, and climate. Signs of a broken alternator include fluctuating headlights, burning electronics smell, illuminated warning lights, and malfunctioning …

Strategic Sourcing Conclusion and Outlook for how long does alternator last

In conclusion, understanding the lifespan and maintenance of alternators is crucial for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. With an average lifespan of approximately seven years or 150,000 miles, the longevity of alternators can vary significantly based on factors such as quality, vehicle condition, and electrical load. Recognizing early signs of alternator failure—like dimming headlights or unusual noises—can prevent costly downtime and ensure vehicle reliability.

Strategic sourcing plays a vital role in procuring high-quality alternators and related components. By partnering with reputable suppliers, businesses can enhance their operational efficiency and reduce maintenance costs. As the automotive landscape evolves, staying informed about the latest advancements in alternator technology will empower buyers to make informed decisions that align with their long-term objectives.

Looking ahead, it is essential for B2B buyers to prioritize quality and reliability in their sourcing strategies. By investing in robust alternator systems and fostering strong supplier relationships, businesses can navigate the complexities of the automotive industry with confidence and resilience. Engage with trusted suppliers today to ensure your fleet remains operational and efficient in the future.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

Illustrative image related to how long does alternator last

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.