Einleitung: Navigieren auf dem globalen Markt für durchschnittliche Kosten für den Austausch eines Starters

In der heutigen dynamischen Automobillandschaft kann es für internationale B2B-Einkäufer eine große Herausforderung sein, die durchschnittlichen Kosten für den Austausch eines Anlassers zu verstehen. Schwankende Preise, unterschiedliche Arbeitskosten und Unterschiede in der Verfügbarkeit von Teilen können den Beschaffungsprozess erschweren, insbesondere für Unternehmen, die in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, einschließlich Deutschland und Brasilien, tätig sind. Dieser umfassende Leitfaden geht auf diese Komplexität ein, indem er detaillierte Einblicke in die verfügbaren Startertypen, ihre Anwendungen bei verschiedenen Fahrzeugmarken und -modellen sowie effektive Strategien zur Lieferantenprüfung bietet.

Durch die Untersuchung der Kostenfaktoren, die mit dem Austausch des Anlassers verbunden sind - wie z. B. Arbeitsaufwand, Teiletypen und regionale Preisunterschiede - gibt dieser Leitfaden Entscheidungsträgern das nötige Wissen an die Hand, um fundierte Kaufentscheidungen zu treffen. Darüber hinaus bietet er praktische Ratschläge zur Identifizierung von Qualitätsteilen, zum Verständnis der Einbaubedingungen und zur Navigation durch die Feinheiten des Kfz-Reparaturmarktes.

Ganz gleich, ob Sie Fuhrparkleiter, Autoteilehändler oder Inhaber einer Kfz-Werkstatt sind, dieses Handbuch hilft Ihnen, Ihre Beschaffungsstrategien zu optimieren und hochwertige Anlasser zu wettbewerbsfähigen Preisen zu sichern. Mit dem Schwerpunkt auf umsetzbaren Erkenntnissen, die auf globale Einkäufer zugeschnitten sind, dient dieser Leitfaden als unverzichtbares Hilfsmittel, um die Komplexität der Kosten für den Austausch von Anlassern zu bewältigen und letztendlich die betriebliche Effizienz zu steigern und Ihr Endergebnis zu verbessern.

Inhaltsverzeichnis

- Top 5 Durchschnittliche Kosten für den Austausch des Anlassers Hersteller & Lieferanten Liste

- Einleitung: Navigieren auf dem globalen Markt für durchschnittliche Kosten für den Austausch eines Starters

- Verständnis der durchschnittlichen Kosten für den Austausch von Anlassern Typen und Variationen

- Wichtigste industrielle Anwendungen der durchschnittlichen Kosten für den Austausch eines Starters

- 3 häufige Schmerzpunkte von Nutzern für ‘durchschnittliche Kosten für den Austausch des Anlassers’ und ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für die durchschnittlichen Kosten für den Austausch des Starters

- Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für die durchschnittlichen Kosten für den Austausch eines Starters

- Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘durchschnittliche Kosten für den Austausch eines Starters’.’

- Umfassende Kosten- und Preisanalyse für die durchschnittlichen Kosten für den Ersatz eines Starters Beschaffung

- Analyse der Alternativen: Vergleich der durchschnittlichen Kosten für den Austausch des Starters mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für die durchschnittlichen Kosten für den Austausch des Anlassers

- Marktdynamik und Beschaffungstrends im Bereich der durchschnittlichen Kosten für den Austausch von Startern

- Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den durchschnittlichen Kosten für den Austausch des Anlassers

- Strategische Beschaffung Schlussfolgerung und Ausblick für die durchschnittlichen Kosten für den Austausch eines Starters

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Verständnis der durchschnittlichen Kosten für den Austausch von Anlassern Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard-Starter | Traditionelles Design; zuverlässig, aber weniger effizient | Allgemeine Kfz-Werkstätten | Vorteile: Kostengünstig; leicht zu beschaffen. Nachteile: Geringerer Wirkungsgrad; muss möglicherweise häufiger ausgetauscht werden. |

| Untersetzungsgetriebe-Anlasser | Effizienter; benötigt weniger Batteriestrom; kompaktes Design | Leistungsstarke Fahrzeuge; Fachgeschäfte | Vorteile: Höhere Effizienz, längere Lebensdauer. Nachteile: Höhere Anschaffungskosten; erfordert unter Umständen Fachkenntnisse für die Installation. |

| Hochleistungsstarter | Entwickelt für den Rennsport oder schwere Anwendungen; hochwertige Materialien | Motorsportteams; schwere Maschinen | Vorteile: Verbesserte Leistung; langlebig. Nachteile: Teuer; für Standardfahrzeuge möglicherweise nicht erforderlich. |

| OEM-Starter | Teile des Originalherstellers, die für bestimmte Modelle zugeschnitten sind | Autohäuser; Flottenmanagementunternehmen | Vorteile: Garantierte Kompatibilität; oft mit Garantie. Nachteile: Höhere Kosten; begrenzte Verfügbarkeit für ältere Modelle. |

| Überholter Anlasser | Wiederaufgebaute Anlasser aus gebrauchten Teilen; eine nachhaltigere Option | Kostensensible Reparaturwerkstätten | Vorteile: Kostengünstig und umweltfreundlich. Nachteile: Unterschiedliche Qualität; kürzere Lebensdauer im Vergleich zu neuen Anläufen. |

Was sind die Merkmale von Standardstartern?

Standardanlasser sind die gängigsten Typen, die heute in Fahrzeugen zu finden sind. Sie zeichnen sich in der Regel durch ein einfaches Design aus, das sie leicht austauschbar und weithin verfügbar macht. B2B-Einkäufer in allgemeinen Kfz-Werkstätten werden feststellen, dass diese Anlasser für die meisten Fahrzeuge eine kostengünstige Lösung darstellen. Ihr geringerer Wirkungsgrad kann jedoch dazu führen, dass sie häufiger ausgetauscht werden müssen, was für Unternehmen, die Wert auf langfristiges Kostenmanagement legen, ein Problem darstellen kann.

Wie unterscheiden sich Getriebestarter von Standardstartern?

Anlasser mit Untersetzungsgetriebe sind für ihre kompakte Bauweise und ihre Effizienz bekannt, was sie ideal für Hochleistungsfahrzeuge macht. Sie verbrauchen weniger Batteriestrom und werden häufig in speziellen Fahrzeuganwendungen eingesetzt. B2B-Einkäufer, insbesondere in leistungsstarken Kfz-Werkstätten, sollten diese Anlasser für Kunden in Betracht ziehen, die eine höhere Leistung wünschen. Sie sind zwar mit höheren Anschaffungskosten verbunden, aber ihre Langlebigkeit und Effizienz können die Investition rechtfertigen.

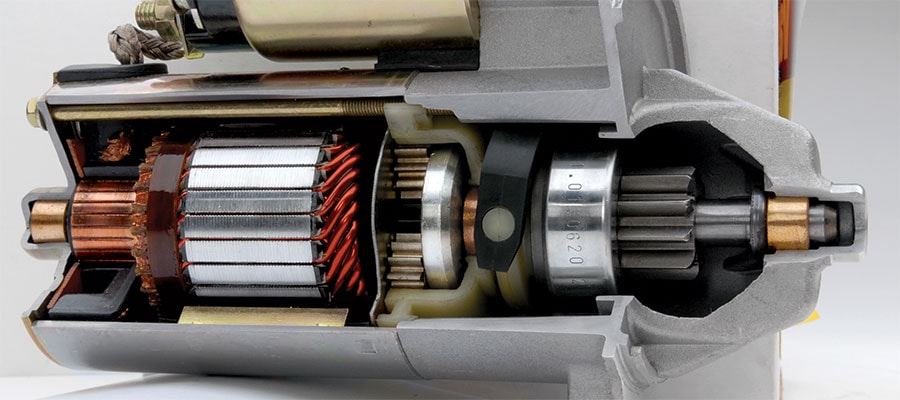

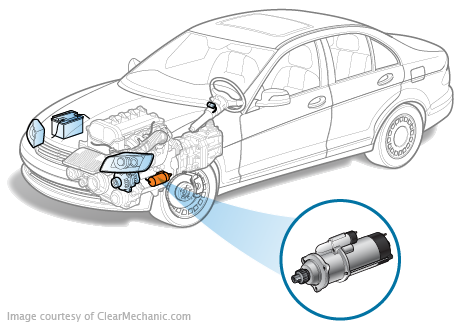

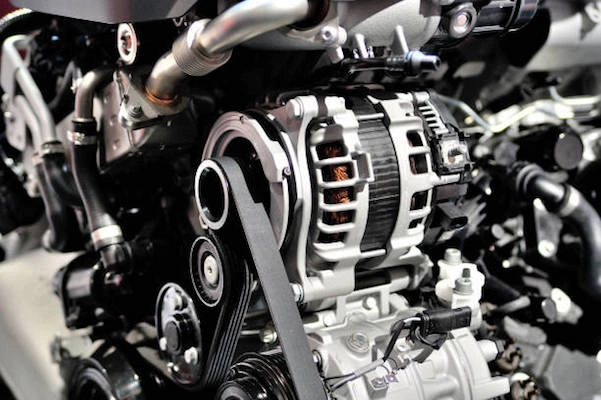

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Warum sollten Sie sich für Hochleistungsstarter entscheiden?

Hochleistungsanlasser sind speziell für den Rennsport oder Hochleistungsanwendungen entwickelt worden. Sie verwenden erstklassige Materialien und fortschrittliche Technologie, um überlegene Leistung und Zuverlässigkeit zu bieten. Diese Art von Anlassern wird häufig von Motorsportteams und Unternehmen, die mit schweren Maschinen arbeiten, nachgefragt. Obwohl sie die teuerste Option sind, können ihre Leistungsvorteile für Anwendungen, die maximale Zuverlässigkeit unter extremen Bedingungen erfordern, entscheidend sein.

Was sind die Vorteile von OEM-Startern?

OEM-Starter werden vom Originalhersteller entwickelt und auf bestimmte Fahrzeugmodelle zugeschnitten. Dies gewährleistet die Kompatibilität und ist oft mit einer Garantie verbunden, was sie zu einer zuverlässigen Wahl für Händler und Flottenmanagementunternehmen macht. Sie sind zwar in der Regel teurer als Aftermarket-Optionen, aber die Gewährleistung von Qualität und Passgenauigkeit kann Unternehmen vor zukünftigen Komplikationen beim Einbau oder bei der Leistung bewahren.

Welchen Wert haben wiederaufbereitete Anlasser?

Wiederaufbereitete Anlasser werden aus gebrauchten Teilen zusammengebaut und bieten eine nachhaltigere und kostengünstigere Lösung für Werkstätten. Sie können eine praktikable Option für Unternehmen sein, die ein ausgewogenes Verhältnis zwischen Qualität und Preis suchen. Allerdings sollten Käufer wegen der schwankenden Qualität und der möglicherweise kürzeren Lebensdauer im Vergleich zu neuen Startern vorsichtig sein. Die Wahl eines zuverlässigen Lieferanten kann einige mit dieser Option verbundene Risiken mindern.

Wichtigste industrielle Anwendungen der durchschnittlichen Kosten für den Austausch eines Starters

| Branche/Sektor | Spezifische Anwendung der durchschnittlichen Kosten für den Austausch des Starters | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Schätzung der Kosten für den Austausch von Startern bei Kundenreparaturen | Stärkt das Vertrauen der Kunden durch transparente Preisgestaltung | Zugang zu zuverlässigen Ersatzteillieferanten und genauen Arbeitskostendaten |

| Flottenmanagement | Budgetierung für den Austausch von Anlasser in einer Fahrzeugflotte | Reduziert Ausfallzeiten durch Planung von Wartungsplänen | Großeinkaufsoptionen und Garantien für Teile |

| Baumaschinen | Bewertung der Kosten für den Austausch von Startern für schwere Maschinen | Sicherstellung der betrieblichen Effizienz durch Minimierung von Geräteausfällen | Spezialisierte Teilebeschaffung für einzigartige Maschinenmodelle |

| Transportdienstleistungen | Bewertung der Kosten für den Austausch von Startern in Logistikfahrzeugen | Verbessert die Zuverlässigkeit des Fuhrparks und reduziert Notreparaturen | Verständnis für regionale Unterschiede bei der Verfügbarkeit und Preisgestaltung von Teilen |

| Landwirtschaftliche Maschinen | Berechnung der Wiederbeschaffungskosten für Erstausrüstungen in der Landwirtschaft | Gewährleistet rechtzeitigen Betrieb während kritischer Pflanzzeiten | Kenntnisse über OEM- und Aftermarket-Teile für bestimmte Maschinen |

Wie hoch sind die durchschnittlichen Kosten für den Austausch von Anlassern in Kfz-Werkstätten?

Für Kfz-Werkstätten ist es wichtig, die durchschnittlichen Kosten für den Austausch eines Anlassers zu kennen, um den Kunden genaue Kostenvoranschläge unterbreiten zu können. Durch eine klare Preisgestaltung können die Werkstätten Vertrauen schaffen und Wiederholungsaufträge fördern. Dies erfordert den Zugang zu zuverlässigen Ersatzteillieferanten und die Kenntnis der lokalen Lohnkosten, die je nach Region sehr unterschiedlich sein können. Für internationale Einkäufer, insbesondere in Afrika und Südamerika, kann die Kenntnis der lokalen Marktbedingungen bei der effizienten und wettbewerbsfähigen Beschaffung von Teilen hilfreich sein.

Welche Rolle spielen die Kosten für den Austausch des Anlassers im Fuhrparkmanagement?

Für Fuhrparkmanagementunternehmen ist die Budgetierung des Anlasserwechsels von entscheidender Bedeutung für die Aufrechterhaltung der Zuverlässigkeit ihrer Fahrzeuge. Durch die Vorhersage dieser Kosten können die Manager die Wartung proaktiv planen und so die Wahrscheinlichkeit unerwarteter Ausfälle verringern. Diese Planung gewährleistet nicht nur die betriebliche Effizienz, sondern verlängert auch die Lebensdauer des Fuhrparks. Unternehmen müssen Großeinkaufsoptionen und Garantien in Betracht ziehen, um die Einsparungen zu maximieren und sicherzustellen, dass die Teile den erforderlichen Standards entsprechen.

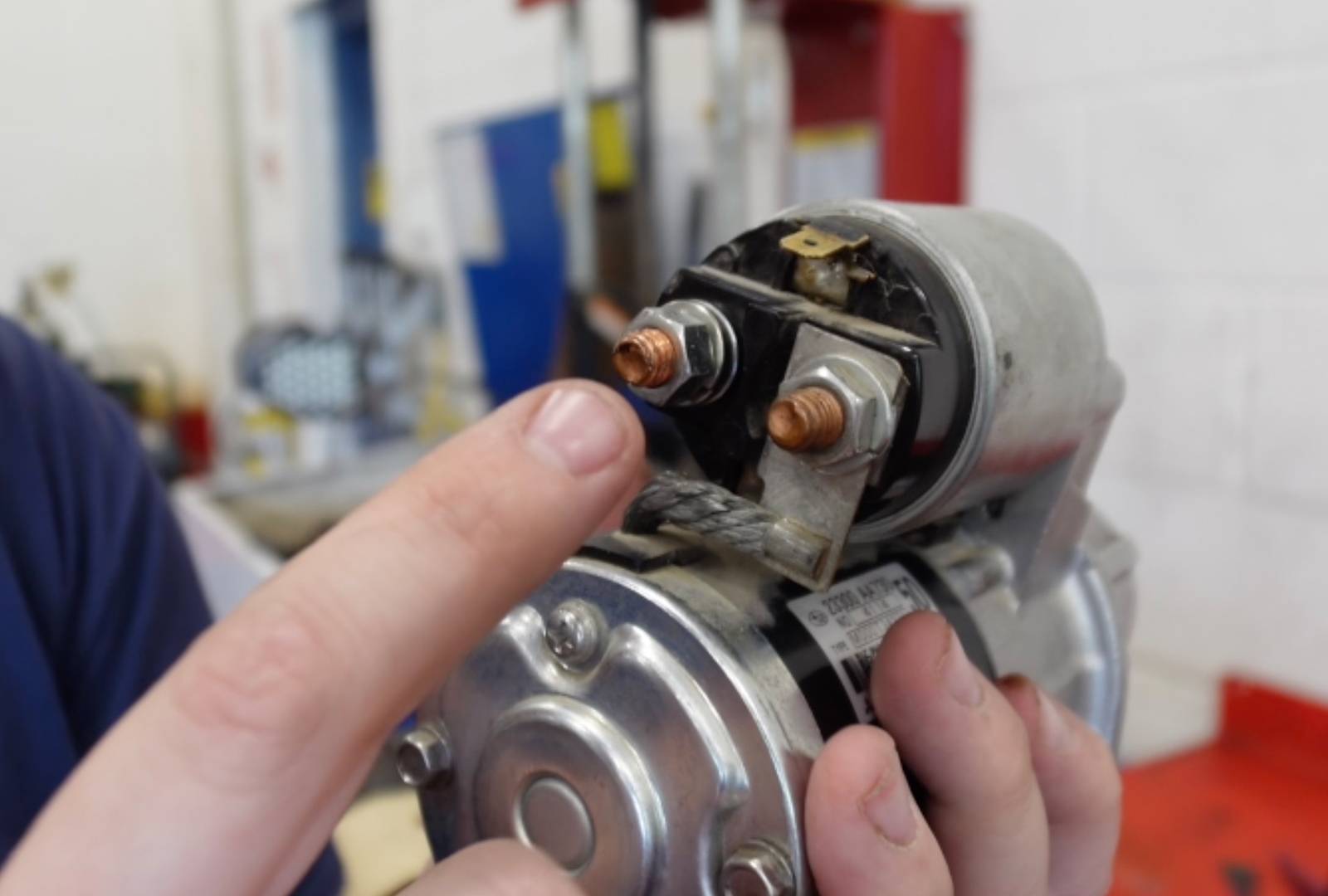

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Wie hoch sind die durchschnittlichen Kosten für den Austausch von Startern bei Baumaschinen?

In der Bauindustrie können Ausfallzeiten von Maschinen zu erheblichen finanziellen Verlusten führen. Die Bewertung der Kosten für den Austausch von Startern für schwere Maschinen hilft den Verantwortlichen, die betriebliche Effizienz zu erhalten. Es ist wichtig, spezielle Teile zu beschaffen, die zu den einzelnen Maschinenmodellen passen, da allgemeine Teile möglicherweise nicht die erforderliche Zuverlässigkeit bieten. Käufer sollten auch die Auswirkungen lokaler Lieferketten berücksichtigen, insbesondere in Regionen wie dem Nahen Osten, wo die Verfügbarkeit von Teilen schwanken kann.

Warum ist das Verständnis der Startersatzkosten für Transportdienste wichtig?

Transportdienstleister sind bei Logistik und Auslieferung stark auf ihre Fahrzeuge angewiesen. Die Ermittlung der durchschnittlichen Kosten für den Austausch von Startern ermöglicht es diesen Unternehmen, die Zuverlässigkeit ihrer Flotte zu verbessern und Notfallreparaturen zu minimieren. Für den internationalen Betrieb ist es wichtig, die regionalen Unterschiede in der Verfügbarkeit und Preisgestaltung von Ersatzteilen zu kennen. Unternehmen müssen auch die Gesamtbetriebskosten unter Berücksichtigung von Arbeitsaufwand und möglichen Verzögerungen bewerten, um ihre Budgetierungsstrategien zu optimieren.

Wie profitieren landwirtschaftliche Betriebe von der Kenntnis der Kosten für die Startersatzung?

In der Landwirtschaft müssen Maschinen während der kritischen Pflanz- und Erntesaison oft effizient arbeiten. Die Berechnung der Ersatzteilkosten für Starter in landwirtschaftlichen Geräten stellt sicher, dass der Betrieb reibungslos und termingerecht abläuft. Käufer in diesem Sektor sollten sich auf die Unterschiede zwischen OEM- und Aftermarket-Teilen konzentrieren, da die richtige Wahl sowohl die Leistung als auch die Langlebigkeit beeinflussen kann. Die Kenntnis der lokalen landwirtschaftlichen Praktiken und Gerätetypen ist für eine effektive Beschaffung der entsprechenden Komponenten unerlässlich.

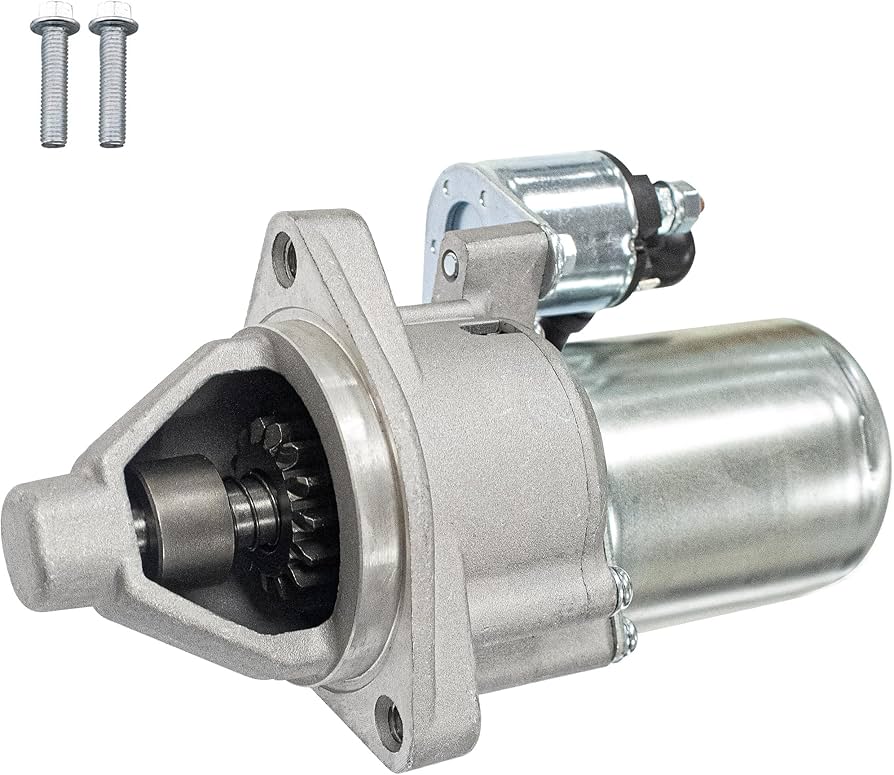

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

3 häufige Schmerzpunkte von Nutzern für ‘durchschnittliche Kosten für den Austausch des Anlassers’ und ihre Lösungen

Szenario 1: Verstehen der Kostenvariabilität in verschiedenen Märkten

Das Problem: B2B-Einkäufer stehen oft vor der Herausforderung, die Kosten für den Austausch von Startern zu schätzen, da die Preise in den verschiedenen Regionen stark variieren. So kann ein Unternehmen in Deutschland beispielsweise feststellen, dass die Arbeitskosten wesentlich höher sind als in Brasilien oder Südafrika. Diese Diskrepanz kann zu Budgetüberschreitungen und unerwarteten Ausgaben führen, insbesondere für Unternehmen, die einen Fuhrpark verwalten, bei dem eine genaue Budgetierung von entscheidender Bedeutung ist. Darüber hinaus können schwankende Teilepreise auf der Grundlage lokaler Zulieferer die Kostenabschätzung weiter erschweren, so dass es für Käufer schwierig ist, ein realistisches Reparaturbudget zu erstellen.

Die Lösung: Um diese Herausforderung zu meistern, sollten B2B-Einkäufer eine umfassende Marktanalyse durchführen, bevor sie sich für eine Reparatur entscheiden. Holen Sie zunächst detaillierte Angebote von mehreren lokalen Anbietern ein, um die Preisspanne für Teile und Arbeit in Ihrer Region zu ermitteln. Nutzen Sie Online-Tools, die faire Preiskalkulationen anbieten und auf Ihren Standort zugeschnittene Erkenntnisse liefern können. Ziehen Sie außerdem in Erwägung, Beziehungen zu zertifizierten Werkstätten oder Lieferanten aufzubauen, die wettbewerbsfähige Preise und zuverlässigen Service bieten können. Dieser Ansatz gewährleistet nicht nur eine genaue Budgetierung, sondern fördert auch langfristige Partnerschaften, die sich auf zukünftige Reparaturen und Wartungsarbeiten positiv auswirken können.

Szenario 2: Qualität vs. Kosten beim Startersatz

Das Problem: Ein weiterer häufiger Schmerzpunkt ist das Dilemma zwischen der Entscheidung für kostengünstige Lösungen und der Gewährleistung von Qualität. B2B-Einkäufer könnten versucht sein, billigere Ersatzteile für den Anlasser zu wählen, um Geld zu sparen, aber das kann zu höheren Kosten führen, wenn die Teile vorzeitig ausfallen. So kann die Verwendung von Nicht-OEM-Teilen zu Kompatibilitätsproblemen, Ineffizienz und letztlich zu einer negativen Beeinträchtigung der Fahrzeugleistung führen. Diese Situation ist besonders für Unternehmen bedenklich, die für ihren Betrieb stark auf ihre Fahrzeuge angewiesen sind, da Ausfallzeiten zu Umsatzeinbußen führen können.

Die Lösung: Um ein ausgewogenes Verhältnis zwischen Qualität und Kosten zu erreichen, sollten Käufer vorrangig hochwertige OEM-Teile (Original Equipment Manufacturer) kaufen. Diese sind zwar mit höheren Anschaffungskosten verbunden, bieten aber oft eine höhere Zuverlässigkeit und eine längere Lebensdauer. Wenn Sie mit Lieferanten verhandeln, sollten Sie sich über die Garantien informieren, die sowohl für OEM- als auch für Aftermarket-Teile angeboten werden. Auf diese Weise lassen sich die tatsächlichen Betriebskosten ermitteln, wobei mögliche Einsparungen durch eine geringere Austauschhäufigkeit berücksichtigt werden können. Ziehen Sie außerdem die Einführung eines präventiven Wartungsprogramms in Betracht, das regelmäßige Inspektionen und rechtzeitigen Austausch vorsieht, um die Wahrscheinlichkeit unerwarteter Ausfälle und damit verbundener Kosten zu verringern.

Szenario 3: Die Komplexität von DIY-Reparaturen

Das Problem: Viele B2B-Einkäufer ziehen in Erwägung, den Austausch von Startern intern zu erledigen, um Kosten zu sparen. Dies kann jedoch zu unvorhergesehenen Komplikationen führen, insbesondere wenn das Team nicht über die erforderlichen Fähigkeiten oder Werkzeuge verfügt. Eine Fehldiagnose des Problems, ein falscher Einbau oder das Versäumnis, damit zusammenhängende Probleme zu erkennen, können die Situation verschlimmern und zu weiteren Schäden und höheren Reparaturkosten führen. Darüber hinaus kann die Zeit, die für diese Heimwerkerprojekte aufgewendet wird, Ressourcen von den Kernfunktionen des Unternehmens abziehen, was die Gesamtproduktivität beeinträchtigt.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Die Lösung: Um dieses Szenario effektiv zu bewältigen, sollten B2B-Einkäufer ihre internen Fähigkeiten ehrlich einschätzen. Wenn es dem Team an Fachwissen im Bereich der Kfz-Reparaturen fehlt, kann es sinnvoller sein, den Austausch des Anlassers an qualifizierte Fachleute auszulagern. Dadurch wird nicht nur sichergestellt, dass die Arbeit korrekt ausgeführt wird, sondern auch, dass sich das Unternehmen weiterhin auf seine Haupttätigkeit konzentrieren kann. Diejenigen, die immer noch mit dem Gedanken spielen, den Anlasser selbst zu reparieren, sollten in umfassende Schulungsprogramme für ihre Mitarbeiter investieren oder vertrauenswürdige Mechanikerdienste für Beratungen in Anspruch nehmen, um die mit der Selbstreparatur verbundenen Risiken deutlich zu verringern. Die Erstellung eines klaren Protokolls für die Fahrzeugwartung, einschließlich der Suche nach zuverlässigen Reparaturdiensten, kann zu einem effizienteren Betrieb und niedrigeren Gesamtkosten führen.

Strategischer Leitfaden zur Materialauswahl für die durchschnittlichen Kosten für den Austausch des Starters

Wenn man die durchschnittlichen Kosten für den Austausch eines Anlassers betrachtet, spielt die Wahl der Materialien, die bei der Herstellung von Anlassern verwendet werden, eine entscheidende Rolle für Leistung, Haltbarkeit und Gesamtkosten. Im Folgenden analysieren wir vier gängige Materialien, die in Anlassern verwendet werden, und geben Einblicke, die für internationale B2B-Einkäufer zugeschnitten sind.

Was sind die wichtigsten Eigenschaften von Kupfer in Anlassern?

Kupfer ist ein weit verbreiteter Werkstoff in Anlassern, insbesondere für elektrische Anschlüsse und Wicklungen, da es eine ausgezeichnete elektrische Leitfähigkeit besitzt. Es kann hohen Temperaturen standhalten und bietet bei entsprechender Behandlung eine gute Korrosionsbeständigkeit.

Vor- und Nachteile: Der Hauptvorteil von Kupfer ist seine hervorragende Leitfähigkeit, die den Wirkungsgrad des Anlassers erhöht. Allerdings ist es im Vergleich zu Alternativen wie Aluminium relativ teuer, und sein Gewicht kann bei Anwendungen, bei denen eine Gewichtsreduzierung entscheidend ist, ein Nachteil sein.

Auswirkungen auf die Anwendung: Da Kupfer hohen elektrischen Belastungen standhält, eignet es sich für Anlasser in Schwerlastfahrzeugen. In Regionen mit hoher Luftfeuchtigkeit oder Salzbelastung können jedoch zusätzliche Schutzschichten erforderlich sein, um Korrosion zu verhindern.

Überlegungen für internationale Käufer: Käufer aus Regionen wie Europa und dem Nahen Osten sollten sich vergewissern, dass die lokalen elektrischen Normen wie IEC oder DIN eingehalten werden, die bestimmte Kupfersorten und -behandlungen vorschreiben können.

Wie schneidet Aluminium im Vergleich für Starteranwendungen ab?

Aluminium wird häufig für das Gehäuse und einige interne Komponenten von Anlassern verwendet. Es bietet ein gutes Gleichgewicht zwischen Festigkeit und Gewicht, was es zu einer attraktiven Option für Automobilanwendungen macht.

Vor- und Nachteile: Das geringe Gewicht von Aluminium kann die Gesamteffizienz von Fahrzeugen verbessern. Seine im Vergleich zu Kupfer geringere elektrische Leitfähigkeit kann jedoch zu erhöhtem Widerstand und potenzieller Wärmeentwicklung führen. Außerdem kann Aluminium bei unsachgemäßer Behandlung anfällig für Korrosion sein.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Auswirkungen auf die Anwendung: Aluminium ist besonders vorteilhaft für Anwendungen, bei denen Gewichtseinsparungen entscheidend sind, wie z. B. bei Elektrofahrzeugen. Für Hochleistungsstarter, die einen maximalen elektrischen Wirkungsgrad erfordern, ist es jedoch möglicherweise nicht geeignet.

Überlegungen für internationale Käufer: Einkäufer in Südamerika und Afrika sollten die lokalen Fertigungsmöglichkeiten für Aluminiumkomponenten sowie die Einhaltung von Normen wie ASTM für die Materialqualität berücksichtigen.

Welche Rolle spielt Stahl beim Bau von Anlassern?

Stahl wird in der Regel für die strukturellen Komponenten von Anlassern verwendet, z. B. für das Gehäuse und die Montagehalterungen. Seine Festigkeit und Haltbarkeit machen ihn zu einer zuverlässigen Wahl für den Schutz interner Komponenten.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Vor- und Nachteile: Stahl bietet eine hervorragende Haltbarkeit und Schlagfestigkeit, was für Automobilanwendungen unerlässlich ist. Sein Gewicht kann jedoch ein Nachteil sein, und er ist rostanfällig, wenn er nicht richtig beschichtet ist.

Auswirkungen auf die Anwendung: Die Robustheit von Stahl macht ihn ideal für den Einsatz in rauen Umgebungen, wie z. B. in Baufahrzeugen. In Regionen mit hoher Feuchtigkeit sind jedoch korrosionsbeständige Beschichtungen erforderlich, um die Lebensdauer zu verlängern.

Überlegungen für internationale Käufer: Die Käufer müssen sicherstellen, dass die Stahlteile den örtlichen Normen für Festigkeit und Korrosionsbeständigkeit entsprechen, insbesondere in feuchtem Klima, wie es in Teilen Afrikas und Südamerikas vorherrscht.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Wie verbessern Verbundwerkstoffe die Leistung von Anlassern?

Verbundwerkstoffe, einschließlich verstärkter Kunststoffe, werden in Anlassern zunehmend für nichtstrukturelle Komponenten verwendet. Diese Materialien können das Gewicht reduzieren und bieten gleichzeitig eine ausreichende Festigkeit.

Vor- und Nachteile: Verbundwerkstoffe können in komplexe Formen gegossen werden, was eine hohe Designflexibilität ermöglicht. Allerdings halten sie möglicherweise extremen Temperaturen nicht stand und können teurer sein als herkömmliche Materialien.

Auswirkungen auf die Anwendung: Verbundwerkstoffe eignen sich für Anwendungen, bei denen eine Gewichtsreduzierung von entscheidender Bedeutung ist, aber ihre thermischen Einschränkungen können den Einsatz in Hochleistungsbereichen einschränken.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Überlegungen für internationale Käufer: Käufer in Europa und im Nahen Osten sollten überprüfen, ob Verbundwerkstoffe den einschlägigen Automobilnormen wie der ISO entsprechen, um Zuverlässigkeit und Sicherheit zu gewährleisten.

Übersichtstabelle zur Materialauswahl für Anlasser

| Material | Typischer Anwendungsfall für durchschnittliche Kosten für den Austausch eines Starters | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Wicklungen und Anschlüsse | Hervorragende elektrische Leitfähigkeit | Hohe Kosten und hohes Gewicht | Hoch |

| Aluminium | Gehäuse und leichte Komponenten | Geringes Gewicht und gute Festigkeit | Geringere Leitfähigkeit und Korrosionsgefahr | Mittel |

| Stahl | Strukturelle Komponenten und Gehäuse | Ausgezeichnete Haltbarkeit und Festigkeit | Schwer und rostanfällig | Mittel |

| Verbundwerkstoffe | Nicht-strukturelle Komponenten | Flexibles Design und geringes Gewicht | Begrenzte Temperaturbeständigkeit | Mittel bis Hoch |

Diese Analyse bietet einen umfassenden Überblick über die in Anlassern verwendeten Materialien und hilft B2B-Einkäufern, fundierte Entscheidungen auf der Grundlage von Leistungs-, Kosten- und regionalen Erwägungen zu treffen.

Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für die durchschnittlichen Kosten für den Austausch eines Starters

Was sind die wichtigsten Phasen des Herstellungsprozesses für Starter?

Die Herstellung eines Anlassers umfasst mehrere kritische Phasen, von denen jede für die Leistung, Zuverlässigkeit und Kosteneffizienz des Endprodukts entscheidend ist. Zu den wichtigsten Phasen gehören die Materialvorbereitung, die Formgebung, die Montage und die Endbearbeitung.

-

Materialvorbereitung

Der Prozess beginnt mit der Beschaffung hochwertiger Rohstoffe, vor allem Metalle wie Stahl und Aluminium für das Gehäuse und Kupfer für die Wicklungen. Die Zulieferer führen oft strenge Tests durch, um sicherzustellen, dass die Materialien bestimmte mechanische und elektrische Normen erfüllen. Für B2B-Käufer ist es wichtig, die Rückverfolgbarkeit dieser Materialien zu verstehen, da sie sich auf die Gesamtlebensdauer und Effizienz des Anlassers auswirken. -

Formung

In dieser Phase werden die Rohmaterialien verschiedenen Umformungsprozessen unterzogen. Techniken wie das Stanzen und die maschinelle Bearbeitung werden zur Herstellung des Anlassergehäuses und der inneren Komponenten eingesetzt. Moderne Technologien wie die CNC-Bearbeitung (Computer Numerical Control) werden häufig eingesetzt, um eine hohe Präzision der Teile zu erreichen, die für die Betriebseffizienz des Anlassers entscheidend ist. Käufer sollten sich über die von den Zulieferern verwendeten Technologien informieren, da diese die Produktionsqualität und die Kosten erheblich beeinflussen können. -

Montage

Sobald die einzelnen Komponenten geformt sind, werden sie zusammengebaut. Dieser Prozess umfasst in der Regel die Integration des Ankers, der Feldspulen und der Magnetspule. Automatisierte Montagelinien werden immer häufiger eingesetzt, um die Konsistenz zu verbessern und die Arbeitskosten zu senken. Die manuelle Montage ist jedoch nach wie vor weit verbreitet, insbesondere bei komplexen Einheiten, die qualifizierte Techniker erfordern. B2B-Einkäufer sollten die Montageverfahren potenzieller Lieferanten prüfen, um sicherzustellen, dass sie die Qualitätsstandards erfüllen und die erforderlichen Fachkräfte bereitstellen können. -

Endbearbeitung

Die letzte Phase ist die Endbearbeitung, bei der die Bauteile behandelt werden, um ihre Haltbarkeit und Leistung zu verbessern. Dies kann Verfahren wie Lackierung, Beschichtung und die Anwendung von Korrosionsschutzbehandlungen umfassen. Qualitätssicherungskontrollen in dieser Phase sind entscheidend, um sicherzustellen, dass jeder Starter die Leistungsspezifikationen erfüllt, bevor er die Produktionsstätte verlässt. Käufer sollten sich vergewissern, dass die Zulieferer die Endbearbeitungsstandards einhalten, die Langlebigkeit und Zuverlässigkeit unter verschiedenen Betriebsbedingungen gewährleisten.

Wie wird die Qualitätssicherung in die Starter-Produktion integriert?

Die Qualitätssicherung (QS) ist ein grundlegender Aspekt des Herstellungsprozesses von Anlassern und umfasst verschiedene internationale Normen und branchenspezifische Vorschriften. Für B2B-Einkäufer ist es von entscheidender Bedeutung, sicherzustellen, dass die Produkte diese Normen erfüllen, insbesondere bei der Beschaffung auf verschiedenen Märkten in Afrika, Südamerika, dem Nahen Osten und Europa.

-

Einschlägige internationale Normen

Die Einhaltung internationaler Normen wie ISO 9001 ist für Hersteller von entscheidender Bedeutung. Diese Norm umreißt die Kriterien für ein Qualitätsmanagementsystem und betont die kontinuierliche Verbesserung. Darüber hinaus können spezifische Zertifizierungen wie CE (Conformité Européenne) für die europäischen Märkte und API (American Petroleum Institute) für erdölverwandte Produkte je nach Anwendungsbereich der Anlasser ebenfalls relevant sein. -

Kontrollpunkte der Qualitätskontrolle

Eine wirksame Qualitätskontrolle umfasst mehrere Kontrollpunkte während des gesamten Herstellungsprozesses:

– Eingangsqualitätskontrolle (IQC): In dieser Phase werden die Rohstoffe auf die Einhaltung der Spezifikationen geprüft, bevor sie in die Produktionslinie gelangen.

– In-Process-Qualitätskontrolle (IPQC): Während der Herstellung werden regelmäßige Kontrollen durchgeführt, um sicherzustellen, dass die Prozesse innerhalb der festgelegten Parameter bleiben.

– Endkontrolle (FQC): Nach Abschluss der Montage wird jeder Starter umfassenden Tests unterzogen, um die Funktionalität, Haltbarkeit und Einhaltung der Industrienormen zu überprüfen. -

Gängige Prüfmethoden für Anlasser

Um sicherzustellen, dass die Anlasser unter verschiedenen Bedingungen ordnungsgemäß funktionieren, werden verschiedene Prüfverfahren eingesetzt. Dazu gehören:

– Prüfstandstests: Simulation der Betriebsbedingungen zur Bewertung der Leistung des Anlassers.

– Elektrische Prüfung: Messung des Widerstands, der Stromaufnahme und der Ausgangsspannung, um sicherzustellen, dass der Anlasser den elektrischen Spezifikationen entspricht.

– Haltbarkeitsprüfung: Anlasser werden extremen Bedingungen ausgesetzt, um ihre Zuverlässigkeit im Laufe der Zeit zu messen.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

Für internationale B2B-Einkäufer ist die Überprüfung der Qualitätskontrollpraktiken der Lieferanten von entscheidender Bedeutung, um die Zuverlässigkeit und Leistungsfähigkeit ihrer Produkte zu gewährleisten. Im Folgenden finden Sie einige Strategien zur effektiven Bewertung der Lieferantenqualität:

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

-

Durchführung von Lieferantenaudits

Regelmäßige Audits bei den Lieferanten können Aufschluss über deren Herstellungsverfahren und Qualitätskontrollmaßnahmen geben. Diese Audits sollten sich auf die Einhaltung der internationalen Normen, die Produktionskapazitäten und die Effizienz der Qualitätsmanagementsysteme konzentrieren. -

Anforderung von Qualitätssicherungsberichten

Einkäufer sollten detaillierte Qualitätssicherungsberichte verlangen, in denen die angewandten Prüfmethoden, die Ergebnisse der verschiedenen Kontrollpunkte und die im Falle von Abweichungen ergriffenen Korrekturmaßnahmen dargelegt sind. Diese Dokumente dienen als wertvoller Nachweis für das Engagement des Lieferanten für Qualität. -

Einsatz von Inspektionen durch Drittparteien

Die Beauftragung von Inspektionsdiensten durch Dritte kann eine unvoreingenommene Bewertung der Qualitätskontrollverfahren eines Lieferanten bieten. Diese Inspektionen können in verschiedenen Phasen der Produktion durchgeführt werden und bieten eine zusätzliche Sicherheit für die Produktqualität.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

Internationale B2B-Einkäufer müssen bei der Beschaffung von Anlassern aus verschiedenen Regionen besondere Herausforderungen bewältigen. Ein Verständnis der Nuancen in den Qualitätskontrollpraktiken der verschiedenen Märkte kann Risiken mindern und die Produktzuverlässigkeit verbessern.

-

Kulturelle und regulatorische Unterschiede

In verschiedenen Regionen können unterschiedliche Qualitätsstandards und -erwartungen gelten. So halten sich europäische Hersteller möglicherweise an strengere Umweltvorschriften als Hersteller in anderen Regionen. Einkäufer sollten sich mit diesen Unterschieden vertraut machen, um die Einhaltung der Vorschriften zu gewährleisten und den lokalen Erwartungen gerecht zu werden. -

Transparenz in der Lieferkette

In Regionen, in denen die Transparenz der Lieferkette möglicherweise nicht gegeben ist, sollten Einkäufer Lieferanten bevorzugen, die eine klare Dokumentation und Rückverfolgbarkeit von Materialien und Komponenten bieten. Diese Transparenz ist unerlässlich, um die Einhaltung internationaler Normen zu überprüfen und sicherzustellen, dass die Qualität in der gesamten Lieferkette gewährleistet ist. -

Langfristige Beziehungen aufbauen

Der Aufbau langfristiger Beziehungen zu zuverlässigen Lieferanten kann das Vertrauen stärken und eine bessere Qualitätskontrolle ermöglichen. Ein regelmäßiger Austausch über Qualitätserwartungen, Produktionskapazitäten und Marktveränderungen kann dazu beitragen, hohe Standards aufrechtzuerhalten und sicherzustellen, dass beide Parteien die gleichen Qualitätsziele verfolgen.

Indem sie sich auf diese Herstellungsverfahren und Qualitätssicherungspraktiken konzentrieren, können B2B-Einkäufer bei der Beschaffung von Anlassern fundierte Entscheidungen treffen und sicherstellen, dass sie qualitativ hochwertige Produkte erhalten, die ihren betrieblichen Anforderungen entsprechen.

Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘durchschnittliche Kosten für den Austausch eines Starters’.’

In der schnelllebigen Welt der Kfz-Wartung ist es für B2B-Einkäufer, die ihre Beschaffungsprozesse rationalisieren wollen, unerlässlich, die durchschnittlichen Kosten für den Austausch eines Anlassers zu kennen. Dieser Leitfaden enthält eine praktische Checkliste, die Sie bei der effizienten und kostengünstigen Beschaffung von Anlasser-Ersatzteilen unterstützt.

Schritt 1: Bewerten Sie die Spezifikationen Ihres Fahrzeugs

Beginnen Sie damit, die Marke, das Modell und das Jahr der Fahrzeuge in Ihrer Flotte zu bestimmen. Diese Informationen sind von entscheidender Bedeutung, da die Art des Anlassers je nach diesen Faktoren erheblich variieren kann. Die Kenntnis der Einzelheiten hilft bei der Beschaffung der richtigen Teile und vermeidet kostspielige Fehler.

- Wichtige Überlegungen:

- Für verschiedene Modelle sind möglicherweise spezielle Starter erforderlich, was sich auf die Verfügbarkeit und den Preis auswirkt.

- Unterschiede in der Art des Anlassers (Getriebeuntersetzung oder Direktantrieb) können Kosten und Leistung beeinflussen.

Schritt 2: Recherchieren Sie die durchschnittlichen Ersetzungskosten

Informieren Sie sich über die durchschnittlichen Kosten für den Austausch des Anlassers für Ihr Fahrzeug. Die Preise liegen in der Regel zwischen $531 und $1.200, je nach Arbeits- und Teilekosten.

- Warum das wichtig ist:

- Die Kenntnis des Marktangebots hilft Ihnen, Ihr Budget genau zu planen und mit den Lieferanten zu verhandeln.

- Sie legt die Erwartungen für Ihre Beschaffungsstrategie fest und hilft bei der Bewertung von Lieferantenangeboten.

Schritt 3: Identifizieren Sie seriöse Lieferanten

Stellen Sie eine Liste potenzieller Lieferanten zusammen, die sich auf Kfz-Teile spezialisiert haben. Suchen Sie nach Lieferanten, die einen guten Ruf für Zuverlässigkeit und Qualität haben.

- Aktionsschritte:

- Achten Sie auf Kundenrezensionen und Erfahrungsberichte.

- Vergewissern Sie sich, dass sie Erfahrung mit der Lieferung von Teilen für Ihre Fahrzeugtypen haben.

Schritt 4: Detaillierte Angebote anfordern

Sobald Sie potenzielle Lieferanten ausfindig gemacht haben, fordern Sie detaillierte Angebote an, in denen die Kosten für Teile und Arbeit aufgeschlüsselt sind. So erhalten Sie ein klareres Bild der Gesamtkosten.

- Was Sie beachten sollten:

- Vergewissern Sie sich, dass die Angebote Informationen zur Garantie und zu etwaigen zusätzlichen Gebühren enthalten.

- Vergleichen Sie die Arbeits- und Teilepreise verschiedener Anbieter, um das beste Angebot zu finden.

Schritt 5: Lieferantenzertifizierungen bewerten

Überprüfen Sie vor dem Kauf die Zertifizierungen und Qualitätssicherungsprozesse der von Ihnen gewählten Lieferanten. Dieser Schritt stellt sicher, dass Sie Teile beschaffen, die den Industriestandards entsprechen.

- Die Bedeutung der Zertifizierung:

- Zertifizierte Lieferanten liefern mit größerer Wahrscheinlichkeit qualitativ hochwertige Produkte, die das Risiko künftiger Ausfälle verringern.

- Zertifizierungen können auch ein Hinweis auf das Engagement eines Lieferanten für Kundenzufriedenheit und ethische Praktiken sein.

Schritt 6: Abwägen zwischen Aftermarket- und OEM-Teilen

Entscheiden Sie, ob Sie Originalteile des Herstellers (OEM) oder Alternativen auf dem Nachrüstungsmarkt verwenden wollen. Jede Option hat ihre Vor- und Nachteile in Bezug auf Kosten, Qualität und Verfügbarkeit.

- Zu beachtende Punkte:

- Erstausrüsterteile haben oft einen höheren Preis, gewährleisten aber Kompatibilität und Zuverlässigkeit.

- Aftermarket-Teile können kostengünstig sein, müssen aber sorgfältig ausgewählt werden, um Qualitätsprobleme zu vermeiden.

Schritt 7: Schließen Sie Ihren Kaufvertrag ab

Sobald Sie einen Lieferanten ausgewählt haben, schließen Sie den Kaufvertrag ab. Vergewissern Sie sich, dass alle Bedingungen, einschließlich der Lieferfristen und Rückgaberegeln, klar umrissen sind.

- Schlüsselelemente:

- Bestätigen Sie die Zahlungsbedingungen und eventuelle Rabatte für Großaufträge.

- Einrichtung eines klaren Kommunikationskanals für Aktualisierungen und Unterstützung während des Beschaffungsprozesses.

Anhand dieser strukturierten Checkliste können B2B-Einkäufer die Komplexität bei der Beschaffung von Ersatzteilnehmern effektiv bewältigen und sicherstellen, dass sie sich die bestmöglichen Angebote sichern und gleichzeitig hohe Qualitätsstandards einhalten.

Umfassende Kosten- und Preisanalyse für die durchschnittlichen Kosten für den Ersatz eines Starters Beschaffung

Für B2B-Einkäufer ist die Analyse der mit dem Austausch von Startern verbundenen Kosten von entscheidender Bedeutung, vor allem in unterschiedlichen Märkten wie Afrika, Südamerika, dem Nahen Osten und Europa. Das Verständnis der Kostenstruktur und der Preisdynamik kann es Unternehmen ermöglichen, fundierte Beschaffungsentscheidungen zu treffen, die ihre Gesamtbetriebskosten optimieren.

Was sind die wichtigsten Kostenfaktoren beim Austausch des Anlassers?

Die Hauptkomponenten, die zu den durchschnittlichen Kosten für den Austausch eines Starters beitragen, lassen sich in mehrere Bereiche unterteilen:

-

Materialien: Die Kosten für den Anlasser selbst liegen in der Regel zwischen $90 und über $400, je nach Marke und Modell des Fahrzeugs. Hochwertige Originalteile des Herstellers (OEM) sind aufgrund ihrer Zuverlässigkeit und Garantie in der Regel teurer.

-

Arbeit: Die Arbeitskosten können die Gesamtkosten erheblich beeinflussen und liegen zwischen $100 und $250 pro Stunde. Die Komplexität des Zugriffs auf den Anlasser variiert je nach Fahrzeug und beeinflusst die erforderlichen Arbeitsstunden. Bei einigen Modellen müssen zum Beispiel zusätzliche Komponenten entfernt werden, was die Arbeitszeit und die Kosten erhöht.

-

Fertigungsgemeinkosten: Dazu gehören Kosten im Zusammenhang mit Produktionsprozessen, Instandhaltung der Anlagen und Versorgungsleistungen. Die Hersteller verteilen diese Kosten oft auf die produzierte Stückzahl, was sich auf die Preisgestaltung auswirken kann.

-

Werkzeuge: Für den Einbau des Anlassers kann Spezialwerkzeug erforderlich sein, insbesondere bei Fahrzeugen mit schwierigem Grundriss. Dies kann zu zusätzlichen Kosten führen, wenn eine Werkstatt in spezielle Ausrüstung investieren oder diese mieten muss.

-

Qualitätskontrolle (QC): Um sicherzustellen, dass die Vorspeisen den Qualitätsstandards entsprechen, fallen Kosten für Tests und Kontrollen an. Lieferanten mit robusten Qualitätskontrollverfahren können höhere Preise verlangen, aber sie verringern auch das Risiko eines vorzeitigen Ausfalls.

-

Logistik: Die Transportkosten für die Lieferung von Teilen an Werkstätten oder Vertriebszentren können je nach Entfernung, Versandart und lokalen Logistikbedingungen stark variieren.

-

Marge: Lieferanten und Reparaturbetriebe schlagen ihre Gewinnspanne auf die Kosten auf, die je nach Wettbewerb, Markenpositionierung und Kundenbeziehungen variieren kann.

Was beeinflusst die Preisgestaltung beim Startersatz?

Mehrere Faktoren können den Preis eines Startersatzes beeinflussen, insbesondere für internationale B2B-Käufer:

-

Menge/Mindestbestellmenge: Bei Großeinkäufen können die Käufer oft bessere Preise aushandeln. Lieferanten können bei größeren Bestellungen Rabatte gewähren, was für Flottenbetreiber oder Kfz-Dienstleister von Vorteil sein kann.

-

Spezifikationen und Anpassung: Spezifische Anforderungen, wie z. B. kundenspezifische Starter oder solche, die besonderen Zertifizierungen entsprechen, können die Kosten erhöhen. Käufer sollten ihre Spezifikationen klar kommunizieren, um unerwartete Kosten zu vermeiden.

-

Materialqualität und Zertifizierungen: Qualitativ hochwertigere Materialien und zertifizierte Teile (z. B. solche, die ISO- oder OEM-Normen erfüllen) sind zwar mit höheren Anschaffungskosten verbunden, können aber zu niedrigeren Ausfallraten und geringeren langfristigen Kosten führen.

-

Lieferantenfaktoren: Die Zuverlässigkeit und der Ruf des Lieferanten können sich auf den Preis auswirken. Etablierte Anbieter bieten möglicherweise bessere Garantien und Unterstützung, was einen höheren Preis rechtfertigt.

-

Incoterms: Bei internationalen Käufen ist es wichtig, die Lieferbedingungen zu kennen. Käufer sollten klären, wer für Versand, Versicherung und Zölle verantwortlich ist, um versteckte Kosten zu vermeiden, die den Gesamtpreis in die Höhe treiben können.

Welche Tipps können Käufern helfen, bessere Preise zu verhandeln?

Für internationale B2B-Einkäufer, insbesondere in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, kann eine effektive Verhandlungsführung zu erheblichen Kosteneinsparungen führen:

-

Hebelwirkung auf die Gesamtbetriebskosten (TCO): Achten Sie nicht nur auf den Anschaffungspreis, sondern auch auf die langfristigen Auswirkungen von Qualität und Zuverlässigkeit. Ein höherer Anschaffungspreis kann durch einen geringeren Wartungsbedarf im Laufe der Zeit gerechtfertigt sein.

-

Forschung Marktpreise: Das Wissen um die durchschnittlichen Kosten in verschiedenen Regionen kann bei Verhandlungen von Vorteil sein. Nutzen Sie Online-Ressourcen und Branchenberichte, um Preise zu vergleichen.

-

Aufbau von Beziehungen zu Zulieferern: Der Aufbau starker Partnerschaften kann zu günstigeren Bedingungen und Preisen führen. Regelmäßige Kommunikation und Vertrauen können auch einen besseren Service und Support ermöglichen.

-

Lokale Anbieter erkunden: Die Suche nach lokalen Herstellern oder Lieferanten kann die Versandkosten und Vorlaufzeiten reduzieren und so die Gesamteffizienz steigern.

Schlussfolgerung

Für B2B-Einkäufer ist es von entscheidender Bedeutung, die umfassende Kostenstruktur und die preisbeeinflussenden Faktoren bei der Ersatzteilbeschaffung zu verstehen. Durch die Berücksichtigung der Feinheiten der Beschaffung, von der Materialqualität bis zu den Lieferantenbeziehungen, können Unternehmen ihre Einkaufsstrategien optimieren und bessere finanzielle Ergebnisse erzielen. Denken Sie daran, dass es sich bei den angegebenen Zahlen um Richtpreise handelt und dass die tatsächlichen Kosten je nach den spezifischen Umständen und Marktbedingungen variieren können.

Analyse der Alternativen: Vergleich der durchschnittlichen Kosten für den Austausch des Starters mit anderen Lösungen

Einführung in Alternativen für den Austausch von Startern

Bei der Betrachtung der durchschnittlichen Kosten für den Ersatz eines Starters kann es für Unternehmen von Vorteil sein, alternative Lösungen zu prüfen, mit denen ähnliche Ziele erreicht werden können. Diese Alternativen können von Reparaturmöglichkeiten bis hin zu technologischen Upgrades reichen und haben jeweils ihre eigenen Vor- und Nachteile. In dieser Analyse werden wir die durchschnittlichen Kosten für den Austausch eines Anlassers mit anderen praktikablen Methoden vergleichen, um B2B-Käufern eine fundierte Entscheidung zu ermöglichen.

Vergleichstabelle

| Vergleichsaspekt | Durchschnittliche Kosten für den Austausch des Anlassers | Alternative 1: Starter-Reparatur | Alternative 2: Aufgerüstete Startertechnologie |

|---|---|---|---|

| Leistung | Behebt in der Regel Startprobleme wirksam. | Sie können kleinere Probleme beheben, sind aber möglicherweise keine langfristige Lösung. | Verbesserte Effizienz und Zuverlässigkeit, weniger zukünftige Ausfälle. |

| Kosten | $531 - $773 (einschließlich Arbeit). | $100 - $300 (je nach Thema). | $500 - $1.000 (für fortgeschrittene Technologie). |

| Einfache Implementierung | Erfordert professionelle Installation und Werkzeuge. | Im Allgemeinen einfacher, vielleicht auch DIY-freundlich. | Professionelle Installation empfohlen, da es sich um komplexe Systeme handelt. |

| Wartung | Standardwartung des Anlassers. | Bei anhaltenden Problemen sind möglicherweise häufige Kontrollen erforderlich. | Wartungsarm und auf Langlebigkeit ausgelegt. |

| Bester Anwendungsfall | Am besten bei Totalausfall oder erheblichem Verschleiß. | Ideal für kleinere Probleme oder ältere Fahrzeuge. | Geeignet für moderne Fahrzeuge, die einen hohen Wirkungsgrad benötigen. |

Detaillierte Aufschlüsselung der Alternativen

Alternative 1: Starter-Reparatur

Bei der Anlasserreparatur werden spezifische Probleme im Anlasser diagnostiziert und behoben, anstatt die gesamte Einheit auszutauschen. Diese Option kann kostengünstig sein und liegt je nach Art des Problems oft zwischen $100 und $300. Der Hauptvorteil dieser Methode besteht darin, dass die Funktionsfähigkeit wiederhergestellt werden kann, ohne dass ein vollständiger Austausch erforderlich ist, was sie für Unternehmen mit knappem Budget interessant macht. Allerdings werden bei der Reparatur möglicherweise die zugrunde liegenden Abnutzungserscheinungen nicht behoben, was zu künftigen Ausfällen führen kann.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Alternative 2: Aufgerüstete Startertechnologie

Die Investition in eine modernere Anlassertechnologie kann die Leistung und Zuverlässigkeit des Fahrzeugs verbessern. Diese fortschrittlichen Anlasser sind effizienter und verwenden oft eine Untersetzungsgetriebe-Technologie, die weniger Batteriestrom benötigt. Die Kosten für diese Aufrüstung liegen in der Regel zwischen $500 und $1.000. Die Anfangsinvestition ist zwar höher, doch die langfristigen Vorteile sind geringere Wartungskosten und eine längere Lebensdauer des Fahrzeugs. Allerdings erfordert diese Lösung möglicherweise einen professionellen Einbau und ist für ältere Fahrzeugmodelle nicht geeignet.

Schlussfolgerung: Wie man die richtige Lösung wählt

Bei der Bewertung der durchschnittlichen Kosten für den Austausch eines Anlassers im Vergleich zu alternativen Lösungen sollten B2B-Käufer ihre spezifischen Bedürfnisse, Budgetbeschränkungen und den Fahrzeugzustand berücksichtigen. Für Unternehmen, die ihre Ausgaben kurzfristig minimieren wollen, kann eine Anlasserreparatur eine praktikable Option sein. Umgekehrt könnten Unternehmen, die auf langfristige Zuverlässigkeit und Effizienz Wert legen, feststellen, dass sich die Investition in eine verbesserte Anlassertechnologie mit der Zeit auszahlt. Letztendlich wird das Verständnis der einzigartigen Anforderungen jedes Fahrzeugs und der betrieblichen Ziele den Käufern bei der Auswahl der am besten geeigneten Lösung helfen.

Wesentliche technische Eigenschaften und Fachterminologie für die durchschnittlichen Kosten für den Austausch des Anlassers

Was sind die wichtigsten technischen Eigenschaften, die sich auf die Kosten für den Austausch des Anlassers auswirken?

Bei der Ermittlung der durchschnittlichen Kosten für den Austausch eines Anlassers spielen mehrere kritische technische Eigenschaften eine wichtige Rolle. Die Kenntnis dieser Spezifikationen kann B2B-Einkäufern helfen, fundierte Entscheidungen über die Beschaffung und Budgetierung von Kfz-Teilen zu treffen.

1. Werkstoffgüte

Die Materialqualität eines Anlassers hat erheblichen Einfluss auf seine Haltbarkeit und Leistung. Anlasser werden in der Regel aus hochwertigen Metallen wie Aluminium oder Stahl hergestellt, die Festigkeit und Beständigkeit gegen Verschleiß und Korrosion bieten. B2B-Einkäufer sollten bei der Beurteilung der langfristigen Zuverlässigkeit eines Anlassers die Materialqualität berücksichtigen, da höherwertige Materialien die Häufigkeit des Austauschs und die damit verbundenen Kosten verringern können.

2. Elektrische Nennwerte

Die elektrischen Nennwerte, einschließlich Spannung und Stromstärke, sind wichtige Spezifikationen für Anlasser. Die meisten Kfz-Starter arbeiten mit 12 Volt, aber ihre Stromaufnahme kann erheblich variieren, was sich auf die Wahl der Verkabelung und der Steckverbinder auswirkt. Die Kenntnis dieser Werte gewährleistet die Kompatibilität mit dem elektrischen System des Fahrzeugs und minimiert das Risiko elektrischer Ausfälle, die zu zusätzlichen Reparaturkosten führen könnten.

3. Drehmoment Leistung

Das abgegebene Drehmoment ist ein Maß für die Fähigkeit des Anlassers, den Motor zu starten. Es ist wichtig, dass die Drehmomentanforderungen mit den Spezifikationen des Fahrzeugmotors übereinstimmen. Ein unzureichendes Drehmoment kann zum Ausfall des Anlassers oder zu Problemen beim Anlassen des Motors führen. B2B-Käufer müssen sicherstellen, dass der gewählte Anlasser die Drehmomentanforderungen des jeweiligen Fahrzeugmodells erfüllt oder übertrifft, um Leistungsprobleme zu vermeiden.

4. Kompatibilität und Passform

Die Kompatibilität bezieht sich darauf, wie gut ein Anlasser in ein bestimmtes Fahrzeugmodell passt. Verschiedene Fahrzeuge können Anlasser mit einzigartigen Konfigurationen oder Befestigungspunkten erfordern. Die Gewährleistung der richtigen Passform ist entscheidend für die Effizienz des Einbaus und die Betriebssicherheit. Dieser Aspekt ist für B2B-Käufer von entscheidender Bedeutung, um Installationszeit und -kosten zu reduzieren und gleichzeitig eine optimale Leistung zu gewährleisten.

5. Lebenszyklus und Garantie

Die Lebensdauer eines Anlassers kann zusammen mit der vom Hersteller gewährten Garantie die Gesamtkosten erheblich beeinflussen. Eine längere Lebensdauer, die in der Regel durch eine Garantiezeit gekennzeichnet ist, deutet auf eine bessere Qualität und eine geringere Austauschhäufigkeit hin. B2B-Einkäufer sollten Produkten mit robusten Garantien den Vorzug geben, da diese oft das Vertrauen des Herstellers in die Haltbarkeit und Zuverlässigkeit seines Produkts widerspiegeln.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Was sind die gebräuchlichen Fachausdrücke im Zusammenhang mit den Kosten für den Austausch des Anlassers?

Um sich in der Komplexität der Kosten für den Ersatz von Startern zurechtzufinden, muss man mit dem Fachjargon vertraut sein. Hier sind einige wichtige Begriffe, die B2B-Einkäufer verstehen sollten:

1. OEM (Originalgerätehersteller)

OEM bezieht sich auf Teile, die vom Originalhersteller des Fahrzeugs hergestellt wurden. Erstausrüster werden oft wegen ihrer garantierten Kompatibilität und Qualität bevorzugt. B2B-Käufer sollten die Vorteile von OEM- gegenüber Aftermarket-Optionen abwägen, da Erstere in der Regel eine höhere Zuverlässigkeit bieten, aber auch teurer sind.

2. MOQ (Mindestbestellmenge)

MOQ bezeichnet die Mindestanzahl von Einheiten, die ein Lieferant benötigt, um eine Bestellung zu erfüllen. Das Verständnis der MOQ ist für Einkäufer von entscheidender Bedeutung, vor allem wenn sie über den Kauf großer Mengen von Vorspeisen verhandeln. Dieser Begriff kann sich auf die Bestandsverwaltung und den Cashflow auswirken und ist daher für eine kosteneffiziente Beschaffung unerlässlich.

3. RFQ (Angebotsanfrage)

Eine Anfrage ist ein formelles Dokument, das an Lieferanten geschickt wird, um Preise und Verfügbarkeit bestimmter Produkte zu erfragen. Dieser Prozess ist für B2B-Einkäufer, die wettbewerbsfähige Preise für Vorprodukte suchen, von entscheidender Bedeutung. Eine gut strukturierte Anfrage kann zu besseren Verhandlungsergebnissen und Preisstrategien führen.

4. Incoterms

Incoterms (International Commercial Terms) sind vordefinierte Handelsbedingungen, die die Verantwortlichkeiten von Käufern und Verkäufern im internationalen Handel klären. Die Vertrautheit mit den Incoterms, wie z. B. FOB (Free On Board) oder CIF (Cost, Insurance, and Freight), hilft B2B-Käufern dabei, die Versandkosten und die Haftung während des Transports zu verstehen, was sich auf die Gesamtkosten für den Austausch des Starters auswirken kann.

5. Ersatzteile

Aftermarket-Teile sind Komponenten, die von Dritten und nicht von den ursprünglichen Fahrzeugherstellern hergestellt werden. Sie können zwar Kosteneinsparungen bieten, aber die Qualität kann erheblich schwanken. B2B-Käufer sollten Aftermarket-Optionen sorgfältig prüfen und dabei die Kosten gegen das Risiko möglicher Leistungsprobleme abwägen.

Durch das Verständnis dieser technischen Eigenschaften und der Fachterminologie können B2B-Einkäufer die Komplexität der Kosten für den Ersatz von Anfängern besser bewältigen und so sicherstellen, dass sie fundierte Kaufentscheidungen treffen, die mit ihren betrieblichen Anforderungen übereinstimmen.

Marktdynamik und Beschaffungstrends im Bereich der durchschnittlichen Kosten für den Austausch von Startern

Welche Marktdynamik beeinflusst derzeit die durchschnittlichen Kosten für den Austausch von Startern?

In der sich wandelnden Landschaft der Kfz-Reparaturen werden die durchschnittlichen Kosten für den Austausch eines Anlassers zunehmend von der globalen Marktdynamik beeinflusst. Ein wichtiger Faktor ist die zunehmende Komplexität und Technologie der Fahrzeuge, insbesondere durch die Integration fortschrittlicher elektronischer Systeme in modernen Fahrzeugen. Diese Komplexität erfordert oft spezielle Kenntnisse und Werkzeuge für Diagnose und Reparatur, was die Arbeitskosten in die Höhe treibt. Für internationale B2B-Einkäufer, insbesondere in Afrika, Südamerika, dem Nahen Osten und Europa, ist das Verständnis dieser Nuancen entscheidend für Budgetierungs- und Beschaffungsentscheidungen.

Auch die aufkommenden Trends in der B2B-Technologie verändern die Beschaffungslandschaft. Das Aufkommen von Online-Plattformen und mobilen Apps erleichtert Preisvergleiche in Echtzeit und ermöglicht es Käufern, fundierte Entscheidungen auf der Grundlage lokaler Marktbedingungen zu treffen. Darüber hinaus führt die Verbreitung von Elektrofahrzeugen (EVs) neue Startertechnologien ein, wie z. B. hocheffiziente Getriebestarter, die sich sowohl auf die Teilepreise als auch auf die Arbeitskosten auswirken können, da eine spezielle Schulung erforderlich ist.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Die Marktdynamik wird auch durch regionale Faktoren beeinflusst. So gibt es auf den europäischen Märkten möglicherweise strengere Vorschriften für Kfz-Reparaturen, die sich auf die Kostenstrukturen für Teile und Arbeit auswirken. Umgekehrt können in den Entwicklungsmärkten die Verfügbarkeit von Ersatzteilen und unterschiedliche Arbeitslöhne zu erheblichen Kostenunterschieden führen. Einkäufer müssen diese Komplexität beherrschen, um ihre Beschaffungsstrategien zu optimieren und sicherzustellen, dass sie Lieferanten auswählen, die sowohl Qualität als auch wettbewerbsfähige Preise bieten können.

Wie wirken sich Nachhaltigkeit und ethische Beschaffung auf die durchschnittlichen Kosten für den Austausch von Startern aus?

Der Automobilsektor legt zunehmend Wert auf Nachhaltigkeit und ethische Beschaffung, was sich erheblich auf die durchschnittlichen Kosten für den Austausch von Anlassern auswirkt. Umweltbedenken hinsichtlich der Entsorgung von Kfz-Teilen, einschließlich Startern, haben die Hersteller dazu veranlasst, umweltfreundlichere Verfahren anzuwenden. Dazu gehören die Verwendung recycelbarer Materialien und die Reduzierung des Abfalls während der Produktion. Für B2B-Einkäufer kann die Beschaffung bei Lieferanten, die der Nachhaltigkeit Priorität einräumen, ihr soziales Verantwortungsprofil verbessern und sie möglicherweise für grüne Zertifizierungen qualifizieren.

Darüber hinaus rücken ethische Lieferketten immer mehr in den Mittelpunkt, insbesondere in Regionen wie Europa und Nordamerika, wo Verbraucher und Unternehmen gleichermaßen Transparenz fordern. Die Beschaffung bei Herstellern, die sich an ethische Arbeitspraktiken halten, mindert nicht nur das Reputationsrisiko, sondern kann auch zu zuverlässigeren Lieferketten führen. Einkäufer sollten Partnerschaften mit Lieferanten bevorzugen, die die Einhaltung von Umweltstandards und ethischen Beschaffungspraktiken nachweisen können.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Die Integration der Nachhaltigkeit in die Beschaffungsstrategien kann anfänglich die Kosten erhöhen, führt aber oft zu langfristigen Einsparungen, da weniger Abfall anfällt und die Produktqualität verbessert wird. Einkäufer können auch die Verfügbarkeit von ‘grünen’ zertifizierten Materialien prüfen, die möglicherweise Leistungsvorteile bieten, die höhere Anschaffungskosten rechtfertigen. Da sich der Markt weiter entwickelt, wird die Ausrichtung der Beschaffungsstrategien auf Nachhaltigkeit für die Aufrechterhaltung der Wettbewerbsfähigkeit und die Erfüllung der gesetzlichen Anforderungen von entscheidender Bedeutung sein.

Wie entwickeln sich die Kosten für den Austausch von Anlassern in der Automobilindustrie?

Die Kosten für den Austausch von Anlassern haben sich im Laufe der Jahrzehnte beträchtlich entwickelt, bedingt durch die Fortschritte in der Automobiltechnik und die veränderte Nachfrage der Verbraucher. In der Vergangenheit waren Anlasser relativ einfache Bauteile, deren Austauschverfahren die Kosten niedrig hielten. Da die Fahrzeuge jedoch immer ausgefeiltere und komplexere elektrische Systeme enthalten, sind die durchschnittlichen Austauschkosten erheblich gestiegen.

In den letzten Jahren hat sich diese Landschaft durch die Einführung von Elektro- und Hybridfahrzeugen weiter verändert. Diese Fahrzeuge nutzen oft fortschrittliche Anlassertechnologien, die spezielle Kenntnisse für den Einbau und die Reparatur erfordern, was die Arbeitskosten in die Höhe treiben kann. Darüber hinaus hat der zunehmende Trend zur Nachhaltigkeit die Art der in der Anlasserproduktion verwendeten Materialien beeinflusst, was sich auf die Gesamtkosten auswirkt.

Folglich müssen internationale B2B-Einkäufer über diese Trends informiert sein, um strategische Entscheidungen bei der Beschaffung und Budgetierung von Starter-Ersatzprodukten treffen zu können. Das Verständnis der Entwicklung der Startertechnologie und der damit verbundenen Kosten kann wertvolle Einblicke in die Marktdynamik liefern und letztlich zu einem effektiveren Lieferkettenmanagement beitragen.

Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den durchschnittlichen Kosten für den Austausch des Anlassers

-

Wie ermittle ich die durchschnittlichen Kosten für den Austausch eines Anlassers für meine Flottenfahrzeuge?

Um die durchschnittlichen Kosten für den Austausch von Anlassern in Ihrem Fuhrpark zu ermitteln, müssen Sie Faktoren wie Fahrzeugmarke und -modell, die Lohnkosten in Ihrer Region und die benötigten Teile berücksichtigen. Im Allgemeinen können die Kosten zwischen $531 und $1.200 pro Fahrzeug liegen. Es ist von Vorteil, mehrere Werkstätten zu konsultieren oder Online-Kostenvoranschläge zu nutzen, um einen umfassenden Überblick über die Kosten zu erhalten. Darüber hinaus kann die Analyse historischer Reparaturrechnungen Ihres Fuhrparks wertvolle Einblicke in typische Ausgaben liefern. -

Welche Faktoren beeinflussen die Kosten für den Austausch des Starters in den verschiedenen Ländern?

Die Kosten für den Austausch des Anlassers können je nach Land aufgrund von Lohnkosten, Steuern, Einfuhrzöllen und der Verfügbarkeit von Ersatzteilen erheblich variieren. In europäischen Ländern können die Arbeitskosten zum Beispiel höher sein als in Regionen in Afrika oder Südamerika. Auch die lokale Nachfrage nach bestimmten Fahrzeugteilen kann die Preise beeinflussen. Es ist ratsam, sich über regionale Anbieter zu informieren und Währungsschwankungen bei der Budgetierung von Reparaturen zu berücksichtigen. -

Worauf sollte ich bei der Auswahl von Lieferanten für Starterteile achten?

Prüfen Sie bei der Auswahl von Zulieferern für Anlasserteile deren Zuverlässigkeit, Ruf und Qualitätszertifizierungen. Suchen Sie nach Anbietern, die Erfahrung mit Kfz-Teilen haben, und prüfen Sie deren Kundenrezensionen. Vergewissern Sie sich, dass sie Erstausrüster- oder hochwertige Aftermarket-Teile anbieten, um das Risiko eines vorzeitigen Ausfalls zu verringern. Erkundigen Sie sich außerdem nach den Garantierichtlinien, den Rückgabeverfahren und der Fähigkeit, technischen Support zu leisten, was für Ihr Unternehmen entscheidend sein kann. -

Wie kann ich die Qualität der von internationalen Lieferanten bezogenen Vorspeisen sicherstellen?

Um die Qualität der Vorspeisen von internationalen Lieferanten zu gewährleisten, sollten Sie detaillierte Produktspezifikationen und Zertifizierungen verlangen, die die Einhaltung der Industrienormen belegen. Ziehen Sie Audits oder Inspektionen der Fertigungsprozesse des Lieferanten in Betracht, falls dies möglich ist. Legen Sie außerdem einen klaren Qualitätssicherungsprozess fest, der auch die Prüfung der Teile bei der Ankunft und vor dem Einbau umfasst, um das Risiko zu verringern, dass minderwertige Komponenten Ihren Betrieb beeinträchtigen. -

Was sind die typischen Mindestbestellmengen (MOQs) für Starterteile?

Die Mindestbestellmengen (MOQs) für Starterteile können je nach Lieferant und Hersteller stark variieren. Während einige Lieferanten MOQs von nur 10 Stück anbieten, können andere Bestellungen von 50 oder mehr verlangen. Berücksichtigen Sie bei Ihren Verhandlungen Ihre Lagerkapazitäten und Ihren Cashflow, und besprechen Sie mit den Lieferanten flexible Bestelloptionen, um Ihren Einkaufsanforderungen gerecht zu werden. Der Aufbau einer guten Beziehung kann auch zu besseren Bedingungen und Preisen führen. -

Welche Zahlungsbedingungen sollte ich mit Lieferanten für Starterteile aushandeln?

Wenn Sie mit Ihren Lieferanten Zahlungsbedingungen aushandeln, sollten Sie sich um Konditionen bemühen, die Ihren Cashflow unterstützen und das Risiko minimieren. Zu den üblichen Bedingungen gehören Netto 30, Netto 60 oder sogar Konsignationsvereinbarungen, bei denen Sie für Teile erst nach deren Verkauf bezahlen. Vergewissern Sie sich, dass Sie alle Strafen für verspätete Zahlungen kennen, und streben Sie günstige Bedingungen an, die Flexibilität zulassen, insbesondere wenn Sie große Mengen einkaufen. Ziehen Sie außerdem Akkreditive für internationale Transaktionen in Betracht, um Ihre Investition zu sichern. -

Wie wickle ich die Logistik für den Import von Ersatzteilen ab?

Um die Logistik für den Import von Starterteilen zu bewältigen, sollten Sie mit einem zuverlässigen Spediteur zusammenarbeiten, der mit Kfz-Teilen vertraut ist. Prüfen Sie Versandmethoden, Laufzeiten und Kosten, um die besten Optionen für Ihre Bedürfnisse zu ermitteln. Vergewissern Sie sich, dass alle erforderlichen Unterlagen, einschließlich Zollerklärungen und Rechnungen, genau vorbereitet sind, um Verzögerungen zu vermeiden. Berücksichtigen Sie bei der Berechnung der Gesamtimportkosten auch die lokalen Vorschriften und Zölle, die für Kfz-Teile gelten können. -

Was sind die häufigsten Anzeichen für einen defekten Anlasser, die ich in meinem Fuhrpark überwachen sollte?

Häufige Anzeichen für einen defekten Anlasser sind ungewöhnliche Geräusche wie Klicken oder Schleifen beim Versuch, den Motor zu starten, intermittierende Startprobleme oder ein kompletter Ausfall des Anlassers. Die Überwachung dieser Symptome kann bei der proaktiven Wartung helfen und Ausfallzeiten und Reparaturkosten reduzieren. Führen Sie einen regelmäßigen Inspektionsplan für Ihren Fuhrpark ein, um frühe Anzeichen von Anlasserproblemen zu erkennen, und halten Sie eine klare Kommunikation mit Ihren Mechanikern aufrecht, um etwaige Probleme sofort zu beheben.

Top 5 Durchschnittliche Kosten für den Austausch des Anlassers Hersteller & Lieferanten Liste

1. Facebook - Autoreparaturkosten

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Kosten für die Fahrt zur Werkstatt und den Austausch des Anlassers

2. AAA - Kosten für den Austausch des Autoanlassers

Domäne: aaa.com

Registriert: 1990 (35 Jahre)

Einleitung: Die durchschnittlichen Kosten für den Austausch eines Autoanlassers liegen zwischen $700 und $1.200, je nach Marke und Modell des Fahrzeugs und den erforderlichen Arbeitsstunden. Die Kosten für das Anlasserteil selbst liegen zwischen weniger als $100 und über $400. Die Arbeitspreise innerhalb des AAA Approved Auto Repair Network liegen zwischen $100 und $250 pro Stunde. Zu den Faktoren, die die Kosten beeinflussen, gehören Marke und Modell des Fahrzeugs, Art des Anlassers (Untersetzungsgetriebe)...

3. CarTalk – Leitfaden zum Austausch des Anlassers

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: Kosten für den Austausch eines Anlassers: $600 bis $900 für normale Fahrzeuge; $900 bis $1.400 für Luxusmodelle. Zu den Symptomen eines defekten Anlassers gehören Klickgeräusche, Quietschen und intermittierende Funktion. Anlasser können neu, wiederaufbereitet oder repariert sein, wobei wiederaufbereitete Anlasser am häufigsten verwendet werden. Moderne Fahrzeuge mit Stopp-Start-Systemen verfügen über neu gestaltete Anlasser, um ein vorzeitiges Versagen zu verhindern.

4. Denso - Anlasser-Ersatz für 2007 Toyota Tundra CrewMax

Domäne: tundras.com

Registriert: 2000 (25 Jahre)

Einleitung: Kosten für den Austausch des Anlassers: $1500 (Arbeit: $900, Teil: $650). Teil Nummer: Denso 428000-4640. Fahrzeug: 2007 Toyota Tundra CrewMax mit 174k Meilen.

5. CarBuzz - Kosten für den Austausch des Anlassers

Domäne: carbuzz.de

Registriert: 2003 (22 Jahre)

Einleitung: Die Kosten für den Austausch des Anlassers liegen im Durchschnitt zwischen $450 und $600, wobei bestimmte Modelle wie der Toyota Tundra (2000-2005) aufgrund der komplexen Installation zwischen $650 und $900 und der Honda Civic zwischen $490 und $760 kosten. Die Arbeitszeit für die meisten Austauscharbeiten beträgt in der Regel 1,5 bis 2,5 Stunden, kann aber bei bestimmten Motorkonfigurationen bis zu vier Stunden betragen. Die Kosten für Aftermarket-Anlasser liegen bei...

Strategische Beschaffung Schlussfolgerung und Ausblick für die durchschnittlichen Kosten für den Austausch eines Starters

Zusammenfassend lässt sich sagen, dass die durchschnittlichen Kosten für den Austausch eines Anlassers in der Regel zwischen $531 und $1.200 liegen und von Faktoren wie Fahrzeugmarke und -modell, Arbeitskosten und der Art des erforderlichen Anlassers abhängen. Für B2B-Einkäufer kann das Verständnis dieser Variablen erhebliche Auswirkungen auf Beschaffungsstrategien und Budgetzuweisungen haben. Strategische Beschaffung ist wichtig, um zuverlässige Lieferanten zu finden und günstige Konditionen auszuhandeln, was zu erheblichen Kosteneinsparungen führen kann.

Darüber hinaus ist mit der Entwicklung der Automobilmärkte die Nachfrage nach hochwertigen Komponenten, die Zuverlässigkeit und Leistung gewährleisten, von größter Bedeutung. Internationale Einkäufer, insbesondere aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, sollten Einblicke in die lokalen Marktbedingungen und die Fähigkeiten der Zulieferer nutzen, um fundierte Kaufentscheidungen zu treffen.

Mit Blick auf die Zukunft wird die Landschaft der Kfz-Reparaturen durch technologische Fortschritte und veränderte Verbraucherpräferenzen wahrscheinlich noch komplexer werden. Durch einen proaktiven Ansatz bei der Beschaffung und die ständige Information über Branchentrends können B2B-Einkäufer nicht nur ihre betriebliche Effizienz steigern, sondern sich auch auf den umkämpften Märkten günstig positionieren. Wenden Sie sich an vertrauenswürdige Lieferanten, erforschen Sie innovative Lösungen und investieren Sie in Qualitätskomponenten, um Ihren langfristigen Erfolg in der Automobilindustrie zu sichern.

Illustratives Bild zu den durchschnittlichen Kosten für den Austausch des Starters

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.