Introduction: Navigating the Global Market for alternator brands

In today’s competitive landscape, sourcing reliable alternator brands is a crucial challenge for international B2B buyers. As the backbone of generator functionality, alternators play a vital role in ensuring optimal power supply across various applications—from industrial machinery to automotive needs. However, navigating the myriad of options available can be daunting, especially for buyers in regions like Africa, South America, the Middle East, and Europe, where local market dynamics and standards vary significantly.

This comprehensive guide is designed to empower B2B buyers by providing an in-depth analysis of the leading alternator brands. It covers essential aspects such as types of alternators, their specific applications, and how to effectively vet suppliers. Additionally, the guide addresses cost considerations and potential ROI, ensuring that buyers can make informed decisions that align with their operational needs and budget constraints.

By equipping you with valuable insights into the strengths and specialties of various manufacturers, this guide aims to simplify the procurement process. Whether you’re looking for heavy-duty industrial alternators or automotive solutions, the information presented here will help you identify the right partners and products to enhance your business operations and drive efficiency.

Inhaltsverzeichnis

- Top 4 Alternator Brands Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator brands

- Understanding alternator brands Types and Variations

- Key Industrial Applications of alternator brands

- 3 Common User Pain Points for ‘alternator brands’ & Their Solutions

- Strategic Material Selection Guide for alternator brands

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator brands

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator brands’

- Comprehensive Cost and Pricing Analysis for alternator brands Sourcing

- Alternatives Analysis: Comparing alternator brands With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator brands

- Navigating Market Dynamics and Sourcing Trends in the alternator brands Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator brands

- Strategic Sourcing Conclusion and Outlook for alternator brands

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding alternator brands Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Industrielle Wechselstromgeneratoren | Heavy-duty construction, high power output, and durability | Manufacturing, construction, and large-scale energy generation | Vorteile: Long lifespan, reliable under heavy loads. Nachteile: Höhere Anfangsinvestitionen. |

| Kfz-Lichtmaschinen | Compact design, optimized for vehicle energy management | Automobilherstellung, Reparaturwerkstätten | Vorteile: Lightweight, efficient, and designed for specific vehicle models. Nachteile: Beschränkt auf Anwendungen in der Automobilindustrie. |

| Schiffsgeneratoren | Corrosion-resistant materials, high performance in harsh environments | Shipping, offshore platforms, recreational boating | Vorteile: Built to withstand marine conditions, reliable power supply. Nachteile: Can be costly due to specialized materials. |

| Wechselstromgeneratoren für erneuerbare Energien | Designed for solar, wind, and hybrid systems, often with integrated technology | Renewable energy projects, off-grid solutions | Vorteile: Supports sustainable energy initiatives, often energy-efficient. Nachteile: May require specialized installation and maintenance. |

| Tragbare Wechselstromgeneratoren | Lightweight, compact, and often generator-compatible | Events, construction sites, emergency backup | Vorteile: Easy transport and setup, versatile use. Nachteile: Lower power output compared to industrial models. |

What Are the Characteristics of Industrial Alternators?

Industrial alternators are engineered for heavy-duty applications, characterized by their robust construction and high power output, often exceeding 440 KW. They are essential in sectors like manufacturing and construction, where reliability under heavy loads is crucial. When purchasing, businesses should consider the alternator’s durability, warranty options, and compatibility with existing systems. While the initial investment may be higher, the long lifespan and reduced maintenance costs can provide significant long-term savings.

How Do Automotive Alternators Differ in Design and Function?

Automotive alternators are designed to be compact and efficient, optimizing vehicle energy management by charging the battery and powering electrical systems while the engine runs. They are widely used in automotive manufacturing and repair, making them essential for dealerships and repair shops. Buyers should focus on compatibility with specific vehicle models, ease of installation, and the alternator’s efficiency ratings. While automotive alternators are lightweight and efficient, their application is limited to vehicles, which may restrict their use in broader industrial contexts.

What Makes Marine Alternators Suitable for Harsh Environments?

Marine alternators are uniquely constructed with corrosion-resistant materials to ensure reliability in harsh marine environments. They are critical for applications in shipping, offshore platforms, and recreational boating, where consistent power supply is vital. When sourcing marine alternators, businesses must assess the materials used, power output, and certifications for marine use. Although these alternators can be more expensive due to specialized construction, their durability and performance in challenging conditions justify the investment.

Why Are Renewable Energy Alternators Important for Sustainable Projects?

Renewable energy alternators are specifically designed for integration with solar, wind, and hybrid systems, often featuring advanced technology for energy efficiency. They play a vital role in renewable energy projects and off-grid solutions, making them essential for businesses focused on sustainability. Key considerations for buyers include the alternator’s compatibility with renewable energy systems, efficiency ratings, and installation requirements. While they promote sustainable practices, the need for specialized installation and maintenance can pose challenges for some businesses.

What Are the Advantages of Portable Alternators for Temporary Applications?

Portable alternators are designed to be lightweight and compact, making them ideal for temporary applications such as events, construction sites, and emergency backup scenarios. Their versatility allows for easy transport and setup, appealing to businesses that require flexible power solutions. When selecting a portable alternator, buyers should evaluate power output, fuel efficiency, and ease of use. While they offer convenience, their lower power output compared to industrial models may limit their effectiveness for larger operations.

Key Industrial Applications of alternator brands

| Branche/Sektor | Specific Application of alternator brands | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Fertigung | Power generation for machinery and equipment | Ensures consistent operation and reduces downtime | Reliability ratings, voltage compatibility, and efficiency standards |

| Landwirtschaft | Power supply for irrigation systems and farm equipment | Enhances productivity and resource management | Durability in harsh environments, maintenance support, and power output |

| Bauwesen | Powering heavy machinery and tools on-site | Increases operational efficiency and project timelines | Size compatibility, load capacity, and environmental resilience |

| Transport | Alternators for commercial vehicles and fleets | Improves vehicle reliability and reduces maintenance costs | OEM compatibility, performance under load, and warranty terms |

| Erneuerbare Energien | Integration in solar and wind energy systems | Supports sustainable practices and energy independence | Adaptability to renewable systems, efficiency ratings, and installation support |

How Are Alternator Brands Used in Manufacturing Industries?

In the manufacturing sector, alternators are crucial for powering machinery and equipment, ensuring that production lines operate smoothly without interruptions. High-quality alternators from reputable brands minimize the risk of equipment failure, thereby reducing downtime and improving overall productivity. Buyers in this sector must consider reliability ratings, voltage compatibility, and efficiency standards to ensure optimal performance in their specific applications.

What Role Do Alternator Brands Play in Agriculture?

In agriculture, alternators are essential for powering irrigation systems and various farm equipment, enhancing productivity and resource management. The ability to operate reliably in remote or harsh conditions is paramount, as farmers often rely on these systems for critical operations. When sourcing alternators, buyers should prioritize durability, maintenance support, and adequate power output to meet the specific demands of agricultural applications.

How Are Alternator Brands Applied in Construction?

Construction sites rely heavily on alternators to power heavy machinery and tools, which are vital for timely project completion. The efficiency of these alternators directly impacts operational timelines and project costs. Buyers should focus on size compatibility, load capacity, and environmental resilience when sourcing alternators to ensure that they can withstand the demanding conditions typically found on construction sites.

Why Are Alternator Brands Important for Transportation?

In the transportation sector, particularly for commercial vehicles and fleets, alternators are integral for maintaining vehicle reliability and performance. High-quality alternators reduce maintenance costs and enhance the longevity of vehicles. Sourcing considerations should include OEM compatibility, performance under load, and warranty terms to ensure that the chosen alternators meet the rigorous demands of commercial transportation.

How Do Alternator Brands Support Renewable Energy Initiatives?

Alternators are increasingly being integrated into renewable energy systems, such as solar and wind energy setups, to facilitate energy generation and storage. This application supports sustainable practices and energy independence, making it a critical consideration for businesses looking to invest in green technologies. Buyers should focus on adaptability to renewable systems, efficiency ratings, and installation support to ensure seamless integration into their energy solutions.

3 Common User Pain Points for ‘alternator brands’ & Their Solutions

Scenario 1: Struggling with Compatibility Issues in Alternators

Das Problem:

B2B buyers often face significant challenges when sourcing alternators that are compatible with their specific machinery or vehicles. Many alternators are designed with unique specifications, and mismatched units can lead to costly downtime or equipment failure. For example, a construction company in Nigeria may purchase a high-quality alternator, only to find that it does not integrate properly with their existing generator setup. This can lead to frustration, additional costs for modifications, and delays in project timelines.

Die Lösung:

To mitigate compatibility issues, buyers should conduct thorough compatibility assessments before purchasing. Start by gathering detailed specifications for both the existing equipment and the alternator you are considering. Utilize resources such as manufacturer databases and online catalogs to compare specifications like power ratings, sizes, and voltage requirements. When in doubt, consult directly with the manufacturer or distributor to ensure you are selecting an alternator that meets your specific needs. Additionally, consider investing in alternators from reputable brands like Leroy Somer or Marelli, which often offer a wider variety of models tailored for different industrial applications. This proactive approach will save time and money, ensuring seamless integration and optimal performance.

Scenario 2: Facing Quality and Reliability Concerns

Das Problem:

Many B2B buyers are concerned about the quality and reliability of alternators, especially when sourcing from international markets. In regions like South America, where supply chain disruptions are common, businesses may receive subpar products that fail prematurely. A mining operation in Brazil may rely on alternators for critical machinery, and any failure can lead to significant financial losses and safety hazards. These concerns can make buyers hesitant to commit to bulk purchases.

Die Lösung:

To ensure quality and reliability, buyers should prioritize sourcing from established and well-reviewed manufacturers. Look for brands like Bosch or Marathon Electric, known for their rigorous quality control processes and reliable performance. Request documentation such as quality certifications and performance test results for the alternators being considered. Additionally, engage in supplier audits or site visits when possible to assess manufacturing practices. Establishing long-term relationships with trusted suppliers can also help ensure consistent quality. Finally, consider warranty terms and after-sales support; a strong warranty can provide peace of mind and protection against unforeseen failures.

Scenario 3: Difficulty in Finding Cost-Effective Solutions

Das Problem:

B2B buyers often struggle to find cost-effective alternator solutions that do not compromise quality. In regions like Africa and the Middle East, where budgets may be tighter, the pressure to balance cost with performance can be overwhelming. For instance, a logistics company might need to replace multiple alternators for their fleet, but opting for the cheapest option can result in higher maintenance costs and reduced operational efficiency over time.

Die Lösung:

To navigate cost concerns without sacrificing quality, buyers should adopt a strategic sourcing approach. Start by conducting a total cost of ownership (TCO) analysis that considers not just the initial purchase price but also maintenance, energy efficiency, and lifespan. Look for manufacturers that offer competitive pricing without compromising on quality, such as Unitech Motor or Denso. Additionally, consider bulk purchasing agreements or long-term contracts that can provide discounts and stabilize costs. Engage in negotiations with suppliers to explore options for extended warranties or service agreements that can further enhance value. By taking a comprehensive view of costs and benefits, buyers can make informed decisions that lead to sustainable savings.

Strategic Material Selection Guide for alternator brands

What Are the Common Materials Used in Alternator Manufacturing?

When selecting alternators for various applications, the choice of materials plays a crucial role in determining performance, durability, and overall efficiency. Here, we analyze four common materials used in alternator brands, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

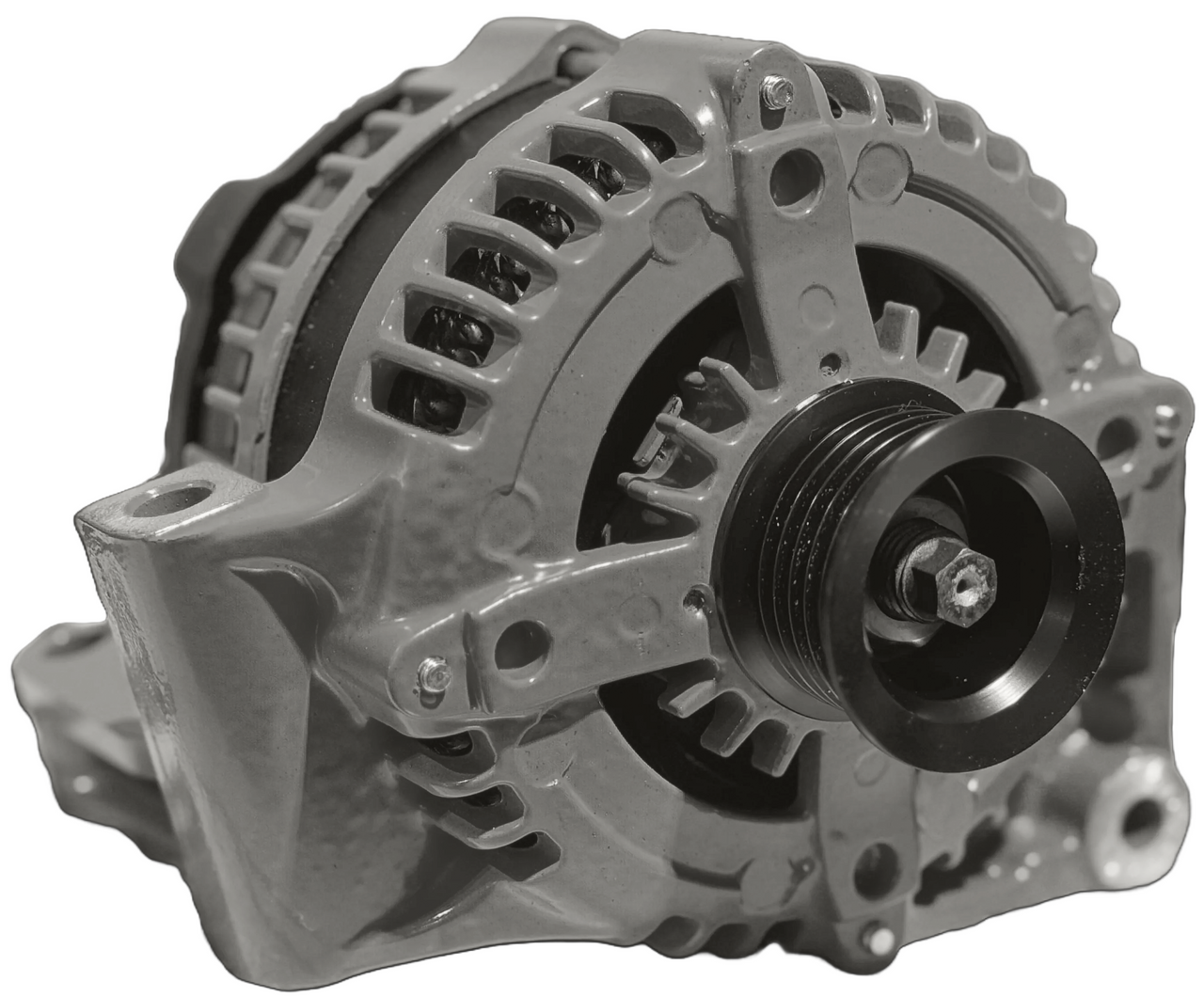

Illustrative image related to alternator brands

How Does Copper Impact Alternator Performance?

Copper is widely used in alternators, particularly for windings and electrical connections due to its excellent electrical conductivity. Key properties of copper include a high melting point (around 1,085°C) and good corrosion resistance, which make it suitable for high-temperature applications.

Vorteile: Copper offers superior conductivity, which enhances energy efficiency and reduces heat generation. It is durable and can withstand mechanical stress, making it ideal for demanding environments.

Nachteile: The primary drawback of copper is its cost, which is higher than alternatives like aluminum. Additionally, copper components can be heavier, potentially impacting the overall weight of the alternator.

Illustrative image related to alternator brands

Auswirkungen auf die Anwendung: Copper’s high conductivity ensures compatibility with various media, including automotive and industrial applications. However, its weight may be a consideration in lightweight design requirements.

Überlegungen für internationale Käufer: Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. In regions like Africa and South America, the availability of copper may vary, influencing procurement strategies.

Why Is Aluminum a Popular Choice for Alternators?

Aluminum is another common material used in alternator construction, particularly for housings and some winding applications. It is lightweight, with a melting point of about 660°C, and offers good corrosion resistance.

Illustrative image related to alternator brands

Vorteile: The primary advantage of aluminum is its low weight, which can enhance fuel efficiency in automotive applications. It is also cost-effective compared to copper, making it an attractive option for manufacturers.

Nachteile: While aluminum has decent conductivity, it is not as effective as copper. Additionally, it may require additional coatings or treatments to improve corrosion resistance in harsh environments.

Auswirkungen auf die Anwendung: Aluminum is suitable for applications where weight savings are critical, such as in automotive and aerospace sectors. However, its lower conductivity may limit its use in high-performance applications.

Überlegungen für internationale Käufer: Buyers should be aware of standards like ASTM B221 for aluminum extrusions. In regions with high humidity, additional protective measures may be necessary to prevent corrosion.

Wie trägt Stahl zur Langlebigkeit von Lichtmaschinen bei?

Steel is often used in the structural components of alternators, including frames and brackets, due to its strength and durability. Steel has a high melting point (around 1,370°C) and excellent mechanical properties.

Vorteile: Steel provides robust structural support, ensuring the alternator can withstand vibrations and mechanical stresses. It is also relatively inexpensive compared to other materials.

Nachteile: The main disadvantage of steel is its susceptibility to corrosion unless treated or coated. Additionally, it is heavier than aluminum, which may not be ideal for all applications.

Auswirkungen auf die Anwendung: Steel’s strength makes it suitable for heavy-duty applications, including industrial generators. However, corrosion resistance must be considered, especially in humid or coastal environments.

Überlegungen für internationale Käufer: Buyers should ensure compliance with standards like ASTM A36 for structural steel. In regions like the Middle East, where humidity is high, protective coatings may be necessary.

What Role Does Plastic Play in Alternator Components?

Plastic materials, particularly thermoplastics, are increasingly used in non-structural components of alternators, such as insulators and housings. Plastics offer a melting point range of 100-300°C, depending on the type.

Vorteile: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes, allowing for design flexibility. They also provide electrical insulation, which is critical in alternator applications.

Nachteile: The primary limitation of plastics is their lower mechanical strength compared to metals. They may also degrade under high temperatures or UV exposure, limiting their use in certain environments.

Auswirkungen auf die Anwendung: Plastics are suitable for applications where weight reduction and insulation are priorities. However, their mechanical limitations may restrict their use in high-stress areas.

Überlegungen für internationale Käufer: Buyers should be aware of standards like ASTM D638 for plastic materials. In regions with extreme temperatures, the choice of plastic type should be carefully considered to ensure performance.

Zusammenfassende Tabelle der materiellen Erwägungen

| Material | Typical Use Case for alternator brands | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Wicklungen und elektrische Anschlüsse | Hervorragende Leitfähigkeit | Hohe Kosten und hohes Gewicht | Hoch |

| Aluminium | Gehäuse und einige Wicklungen | Leicht und kostengünstig | Geringere Leitfähigkeit | Mittel |

| Stahl | Strukturelle Komponenten | Hohe Festigkeit und Haltbarkeit | Korrosionsanfällig | Niedrig |

| Kunststoff | Isolatoren und nicht-strukturelle Komponenten | Leicht und korrosionsbeständig | Geringere mechanische Festigkeit | Mittel |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions when sourcing alternators that meet specific performance and environmental requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator brands

What Are the Main Stages of Manufacturing Processes for Alternator Brands?

The manufacturing of alternators involves several critical stages that ensure the final product meets the high-performance and durability standards required by various industries. Understanding these stages can help B2B buyers make informed decisions when selecting alternators for their operations.

-

Materialvorbereitung: The first stage involves sourcing high-quality raw materials. Key components include copper for windings, steel for the rotor and stator, and various plastics for insulation. Manufacturers often conduct material tests to ensure compliance with international standards, assessing factors such as conductivity, tensile strength, and thermal stability.

-

Formung: In this stage, raw materials are shaped into the necessary components. Techniques such as stamping, forging, and casting are commonly used. For instance, the rotor is typically cast from high-grade aluminum or steel, while windings are formed from copper wire. Precision in this stage is crucial as it impacts the overall efficiency and functionality of the alternator.

-

Montage: Once the components are formed, they are assembled into the alternator. This involves precise alignment of the rotor and stator, connecting the windings, and integrating additional components like voltage regulators and cooling systems. Automation plays a significant role in this stage to ensure consistency and reduce human error.

-

Endbearbeitung: The final stage includes surface treatments such as painting or coating to enhance corrosion resistance and aesthetic appeal. Additionally, manufacturers may conduct balancing processes to ensure that the alternator operates smoothly without vibrations, which can lead to premature wear.

How Do Quality Assurance Processes Work for Alternator Brands?

Quality assurance (QA) is an integral part of the manufacturing process for alternators, ensuring that each unit meets rigorous performance and safety standards. B2B buyers must understand these QA processes to assess the reliability of their suppliers.

-

Einhaltung internationaler Normen: Most reputable alternator manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are often pursued, especially for alternators used in critical applications like automotive and industrial machinery.

-

Kontrollpunkte der Qualitätskontrolle: Quality control is typically segmented into various checkpoints during the manufacturing process:

-

Eingangsqualitätskontrolle (IQC): This initial stage involves inspecting raw materials to ensure they meet specified standards before production begins. Any non-compliant materials are rejected at this stage.

-

In-Process-Qualitätskontrolle (IPQC): During manufacturing, ongoing inspections are conducted to monitor the quality of components and assembly processes. This helps catch defects early, minimizing waste and rework.

-

Endkontrolle (FQC): After assembly, each alternator undergoes rigorous testing, including performance tests, electrical tests, and durability assessments. This ensures that the alternators meet the required specifications before they are shipped to customers.

- Gängige Prüfmethoden: Manufacturers utilize various testing methods, including:

- Elektrische Prüfung: Assessing voltage output, current, and efficiency under load conditions.

- Thermische Prüfung: Evaluating the alternator’s performance under high-temperature conditions to ensure reliability.

- Schwingungsprüfung: Ensuring that the alternator operates smoothly without excessive vibrations, which can lead to mechanical failures.

Wie können B2B-Einkäufer die Qualitätskontrollmaßnahmen von Lieferanten überprüfen?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential to ensure product reliability and compliance with local regulations.

-

Lieferantenaudits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. This can include reviewing their compliance with ISO standards and assessing their production facilities.

-

Qualitätssicherungsberichte: Requesting detailed quality assurance reports from suppliers can reveal their testing methodologies, inspection results, and any corrective actions taken for non-conformities. This documentation is crucial for understanding the supplier’s commitment to quality.

-

Inspektionen durch Dritte: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These services often conduct inspections at various stages of the production process and can provide certifications that enhance the buyer’s confidence in the product.

Was sind die Feinheiten der Qualitätskontrolle und Zertifizierung für internationale B2B-Einkäufer?

International B2B buyers must navigate various quality control and certification nuances that can impact their purchasing decisions.

-

Regional Regulations: Different regions may have specific regulations and standards for alternators, particularly in terms of safety and environmental impact. Buyers should be aware of these regulations to ensure compliance and avoid potential penalties.

-

Certification Authenticity: It is crucial for buyers to verify the authenticity of the certifications claimed by suppliers. This can be done by checking with certifying bodies or requesting copies of the certificates and associated audit reports.

-

Kulturelle Erwägungen: Understanding the business culture in the supplier’s country can also impact quality assurance. For instance, certain regions may prioritize different aspects of quality, such as cost over durability, which could affect the final product’s performance.

-

Unterstützung nach dem Kauf: Finally, buyers should consider the supplier’s post-purchase support, including warranty policies and service agreements. Reliable after-sales support can significantly enhance the overall value of the purchase.

By understanding the manufacturing processes and quality assurance measures in the alternator industry, B2B buyers can make informed decisions that ensure they select the right products for their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator brands’

In the competitive landscape of B2B procurement, sourcing high-quality alternators is vital for ensuring operational efficiency and reliability in power generation. This guide provides a structured approach to help international buyers navigate the complexities of selecting the right alternator brands for their needs.

Illustrative image related to alternator brands

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Establishing clear technical requirements is the foundation of successful procurement. Consider the voltage requirements, power ratings, and compatibility with existing systems. This clarity will help narrow down suitable alternator brands that meet your specific operational needs.

Schritt 2: Research Reputable Manufacturers

Identifying credible manufacturers is crucial in ensuring product quality and reliability. Look for brands with a strong market presence and positive reviews, such as Leroy Somer, John Deere, and Marelli. Focus on manufacturers known for their durability, efficiency, and compliance with industry standards to mitigate risks in your supply chain.

Schritt 3: Lieferantenzertifizierungen bewerten

Before making a decision, verify that potential suppliers hold relevant certifications. Check for ISO certifications, compliance with international quality standards, and any industry-specific accolades. This step ensures that the products you source will meet safety and performance benchmarks, essential for long-term operational success.

Schritt 4: Assess Product Range and Customization Options

Different projects may require various types of alternators, so ensure that the supplier offers a diverse product range. Ask about customization options to tailor the alternators to your specific requirements. A supplier that can provide both standard and customized solutions can better serve your unique operational demands.

Illustrative image related to alternator brands

Schritt 5: Request Samples and Conduct Quality Inspections

Before committing to a bulk order, request samples of the alternators for testing. Conduct thorough inspections to assess build quality, performance metrics, and compatibility with your existing systems. This hands-on evaluation can prevent costly mistakes and ensure the products meet your expectations.

Schritt 6: Review Pricing and Payment Terms

Understanding the pricing structure and payment terms is essential for budgeting and financial planning. Compare quotes from multiple suppliers while considering factors such as shipping costs, warranties, and after-sales support. Ensure that the payment terms align with your cash flow requirements to facilitate smoother transactions.

Schritt 7: Establish Communication and Support Channels

Effective communication with your chosen supplier is vital for ongoing support and relationship management. Confirm the availability of customer service and technical support to address any future queries or issues. Establishing a strong line of communication can enhance collaboration and ensure swift resolution of any challenges that arise.

By following this checklist, B2B buyers can confidently navigate the sourcing process for alternator brands, ensuring they make informed decisions that align with their operational goals and quality standards.

Illustrative image related to alternator brands

Comprehensive Cost and Pricing Analysis for alternator brands Sourcing

What Are the Key Cost Components in Alternator Brand Sourcing?

When sourcing alternators for B2B applications, understanding the cost structure is crucial for making informed purchasing decisions. The total cost of an alternator is influenced by various components, including materials, labor, manufacturing overhead, tooling, quality control, logistics, and supplier margins.

-

Materialien: The choice of materials significantly affects the cost of alternators. High-quality copper, aluminum, and specialized alloys are commonly used to enhance performance and durability. Sourcing raw materials from reputable suppliers can lead to higher initial costs but may result in better long-term reliability.

-

Arbeit: Labor costs vary by region and manufacturing practices. Countries with lower labor costs, like China, can offer competitive pricing but may compromise on quality. Conversely, manufacturers in Europe or the U.S. may charge higher rates due to skilled labor and stringent quality standards.

-

Fertigungsgemeinkosten: This includes expenses related to the production process, such as utilities, rent, and administrative costs. Efficient manufacturing processes can reduce overhead, impacting the final price of the alternators.

-

Werkzeuge: Custom tooling for specific alternator designs can lead to increased upfront costs. However, investing in high-quality tooling ensures precision and can lower production costs over time.

-

Qualitätskontrolle (QC): Rigorous QC processes are essential for ensuring the reliability of alternators. While this adds to the cost, it is a necessary investment to avoid failures and maintain customer satisfaction.

-

Logistik: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping methods, and customs duties can significantly affect the overall price.

-

Marge: Finally, suppliers will include a margin for profit, which can vary widely based on brand reputation and market demand.

How Do Price Influencers Impact Alternator Costs?

Several factors influence the pricing of alternators, particularly for B2B buyers in diverse markets.

-

Menge/Mindestbestellmenge: Purchasing in bulk often leads to discounts, as manufacturers are more willing to negotiate prices for larger orders. Understanding the minimum order quantity (MOQ) is essential for optimizing costs.

-

Spezifikationen/Anpassung: Custom alternators designed for specific applications can incur higher costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materialien und Qualitätszertifizierungen: Brands that provide certifications for quality and performance, such as ISO or CE marks, may have higher prices. However, these certifications often ensure better reliability and lower long-term costs.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can influence pricing. Established brands may charge more due to their proven track record, while lesser-known manufacturers may offer lower prices but with increased risk.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms define the responsibilities of buyers and sellers, impacting overall costs related to shipping and insurance.

What Are the Best Tips for Buyers to Optimize Costs?

To achieve cost efficiency in sourcing alternators, consider the following strategies:

-

Negotiate: Don’t hesitate to negotiate prices, especially for larger orders. Suppliers often have flexibility in pricing, particularly if they value a long-term relationship.

-

Gesamtbetriebskosten (TCO) bewerten: Look beyond the initial purchase price. Consider factors like maintenance, warranty, and expected lifespan. A higher upfront cost may lead to lower overall expenses.

-

Preisnuancen für internationale Einkäufer verstehen: Different regions may have varying pricing structures. For example, buyers in Africa or South America should factor in potential tariffs and shipping costs that could affect the final price.

-

Forschung zu Markttrends: Staying informed about market trends and competitor pricing can provide leverage in negotiations and help identify the best sourcing opportunities.

-

Diversify Suppliers: Engaging multiple suppliers can create competition, leading to better prices and terms.

Schlussfolgerung

In summary, understanding the cost structure and pricing influencers in alternator sourcing is critical for B2B buyers. By focusing on key cost components, leveraging negotiation strategies, and considering the Total Cost of Ownership, businesses can make informed decisions that align with their operational needs and budget constraints. Remember, while price is essential, quality and reliability should never be compromised for the sake of cost.

Alternatives Analysis: Comparing alternator brands With Other Solutions

Exploring Alternatives to Alternator Brands: What Are the Options?

In the dynamic landscape of power generation and automotive solutions, understanding the available alternatives to traditional alternator brands is crucial for B2B buyers. While leading brands like Leroy Somer, John Deere, and Marelli offer proven reliability and performance, there are other technologies and methods that can also fulfill similar roles. This analysis will compare established alternator brands with battery management systems and hybrid power solutions, providing a comprehensive view of the options available.

| Vergleichsaspekt | Alternator Brands | Batterie-Management-Systeme | Hybrid Power Solutions |

|---|---|---|---|

| Leistung | High reliability and efficiency | Optimizes battery life and performance | Combines multiple energy sources for efficiency |

| Kosten | Generally higher initial investment | Moderate initial cost, potential savings long-term | Higher upfront costs, but long-term savings possible |

| Einfache Implementierung | Standardized installation | Requires integration with existing systems | Complex setup, requires specialized knowledge |

| Wartung | Regelmäßige Kontrollen für Langlebigkeit erforderlich | Low maintenance if properly configured | Varies by system; hybrid systems may require more upkeep |

| Bester Anwendungsfall | Industrial applications and heavy-duty use | Electric vehicles and renewable energy systems | Remote areas with unstable power supply |

What Are the Benefits and Drawbacks of Battery Management Systems?

Battery management systems (BMS) are integral to modern energy storage solutions, particularly in electric vehicles and renewable energy setups. They enhance battery performance and longevity by monitoring charge levels and health. The main advantage of BMS is their ability to maximize the efficiency of battery systems, ensuring optimal use of stored energy. However, BMS require integration with existing infrastructure, which can complicate initial setup. For businesses focused on sustainability and energy efficiency, investing in BMS can yield significant long-term benefits.

How Do Hybrid Power Solutions Compare?

Hybrid power solutions combine traditional power generation methods with renewable energy sources, such as solar or wind. This approach offers the flexibility of using multiple energy sources, reducing dependency on any single type of energy. The primary advantage is their ability to provide stable power in remote or unstable grid areas, making them ideal for businesses operating in such environments. However, the complexity of installation and maintenance can be a deterrent, as these systems often require specialized knowledge and ongoing management. For companies looking to innovate and ensure energy resilience, hybrid systems can be a compelling choice.

Making an Informed Decision: How Should B2B Buyers Choose?

When selecting between alternator brands and alternative solutions, B2B buyers should assess their specific operational needs and long-term goals. Factors such as the scale of operations, budget constraints, and the intended application should guide the decision-making process. For instance, businesses in industrial sectors may prioritize the reliability of established alternator brands, while those focused on sustainability may lean towards battery management systems or hybrid solutions. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make informed choices that align with their operational strategies and financial objectives.

Essential Technical Properties and Trade Terminology for alternator brands

What Are the Key Technical Properties of Alternators That B2B Buyers Should Consider?

When assessing alternator brands, understanding critical technical specifications is vital for making informed purchasing decisions. Here are several essential properties to keep in mind:

-

Werkstoffgüte

The material grade of alternators typically refers to the quality of metals used in their construction, such as copper for windings and aluminum for housings. High-grade materials enhance durability and reduce the likelihood of failures, which can significantly impact operational costs. For B2B buyers, investing in alternators made from superior materials translates to longer service life and lower maintenance needs. -

Power Output Rating

This specification indicates the maximum electrical power the alternator can generate, usually measured in kilowatts (kW). It’s crucial for buyers to match the power output of the alternator with their specific application requirements. A mismatch can lead to underperformance or damage to connected equipment. Understanding this rating helps businesses ensure reliable power supply for their operations. -

Spannungsregelung

Voltage regulation refers to the alternator’s ability to maintain a consistent voltage output despite variations in load. A reliable voltage regulator ensures that sensitive electronic components receive stable power, which is essential for preventing operational disruptions. For B2B buyers, knowing the voltage regulation specifications can aid in selecting alternators that provide consistent performance in critical applications. -

Cooling Systems

Effective cooling systems are vital for maintaining the performance and longevity of alternators. Overheating can lead to premature failure, especially in high-demand environments. Alternators equipped with advanced cooling technologies, such as air or liquid cooling, are more likely to sustain efficiency over time. B2B buyers should consider the cooling capabilities to ensure that the alternator can handle their operational demands without overheating. -

Effizienzbewertung

Efficiency ratings indicate how well the alternator converts mechanical energy into electrical energy. Higher efficiency ratings mean lower fuel consumption and reduced operational costs. For businesses looking to optimize their energy use and reduce expenses, understanding the efficiency of different alternators is essential.

What Common Trade Terms Should B2B Buyers Understand When Sourcing Alternators?

Familiarity with industry jargon can greatly enhance communication and negotiation with suppliers. Here are some key terms to know:

Illustrative image related to alternator brands

-

OEM (Originalgerätehersteller)

OEM refers to the company that produces parts or equipment that are sold under another company’s brand name. Understanding whether an alternator is an OEM product can help buyers gauge its quality and compatibility with existing systems. -

MOQ (Mindestbestellmenge)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively, avoiding overstocking or stockouts. -

RFQ (Angebotsanfrage)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. When sourcing alternators, submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive the best value. -

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping costs, risks, and responsibilities. Understanding these terms is essential for B2B buyers engaged in international transactions, as they dictate who is responsible for shipping and insurance. -

Vorlaufzeit

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time for alternators is critical for businesses with tight project schedules, allowing them to plan accordingly and avoid delays.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing alternators, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the alternator brands Sector

What Are the Key Market Trends Impacting Alternator Brands?

The alternator market is experiencing significant growth driven by various global factors. Increased demand for reliable power supply in industrial, automotive, and agricultural sectors, especially in emerging markets like Africa, South America, and the Middle East, is a primary driver. As urbanization progresses in these regions, the need for robust electrical systems that can support infrastructure development is critical. Additionally, the growing trend toward electric vehicles (EVs) is reshaping the alternator landscape, as manufacturers adapt to produce lighter, more efficient models suitable for hybrid and electric applications.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are also influencing sourcing strategies. B2B buyers are increasingly looking for alternators that incorporate smart technologies to enhance performance and diagnostic capabilities. This shift towards technology-driven products is prompting manufacturers to invest in R&D, leading to innovations that improve reliability and efficiency. Buyers should stay abreast of these trends to make informed purchasing decisions that align with their operational needs.

Furthermore, the competitive landscape is evolving, with new players entering the market, particularly from Asia. This influx is creating pricing pressure while also expanding the range of options available to buyers. Companies like Unitech Motor and Mitsubishi Electric are gaining traction due to their cost-effective solutions and reliable performance, making it essential for buyers to assess the total cost of ownership rather than just upfront costs.

How Is Sustainability Shaping the Sourcing of Alternator Brands?

Sustainability is becoming a paramount concern for B2B buyers in the alternator sector. Companies are increasingly prioritizing environmental impact when sourcing components, and this trend is notably strong in regions like Europe, where regulations are stringent. Buyers are encouraged to seek out alternator brands that demonstrate a commitment to sustainable practices, such as using recyclable materials and minimizing waste in their manufacturing processes.

Illustrative image related to alternator brands

Ethical sourcing is equally important, as businesses recognize the value of transparent supply chains. Buyers should consider brands that can provide certifications for their materials and processes, ensuring compliance with environmental and labor standards. Brands that invest in sustainability not only reduce their ecological footprint but also enhance their reputation, which can be a decisive factor for buyers committed to corporate social responsibility.

Moreover, the use of green certifications, such as ISO 14001, can serve as an important indicator of a brand’s commitment to sustainability. Buyers should prioritize manufacturers that are actively working to reduce emissions and improve energy efficiency in their product lines. By aligning with sustainable alternator brands, companies can not only meet regulatory demands but also resonate with environmentally conscious consumers, thereby driving long-term business success.

What Is the Historical Context of the Alternator Industry?

The alternator industry has evolved significantly since its inception in the early 20th century. Initially designed for automotive applications, alternators have expanded their role across various sectors, including industrial and agricultural markets. Major manufacturers like Leroy Somer and Marelli Motori have played pivotal roles in this evolution, pushing the boundaries of technology to enhance performance and reliability.

In recent decades, the rise of digital technology has further transformed the industry. Advanced engineering techniques have enabled the production of high-efficiency alternators that cater to the increasing power demands of modern machinery and vehicles. This historical context is crucial for B2B buyers to understand the trajectory of the market and the technological advancements that continue to shape product offerings today.

As the market progresses, staying informed about historical developments can provide valuable insights into current trends and future innovations, allowing buyers to make strategic sourcing decisions that align with their business objectives.

Illustrative image related to alternator brands

Frequently Asked Questions (FAQs) for B2B Buyers of alternator brands

-

How do I solve issues with alternator compatibility?

To ensure compatibility, first identify the specific requirements of your generator or vehicle, including power ratings, dimensions, and connection types. Research alternator brands that specialize in your sector, such as industrial or automotive, and consult their specifications. Additionally, reach out to suppliers for technical support to verify compatibility before making a purchase. Investing in high-quality alternators from reputable manufacturers can mitigate compatibility issues and enhance overall performance. -

What is the best alternator brand for industrial applications?

For industrial applications, brands like Leroy Somer and Stamford are highly regarded due to their focus on heavy-duty performance and reliability. Leroy Somer offers customized solutions tailored to specific industrial needs, while Stamford is known for its robust quality and high power output capabilities. When selecting an alternator, consider factors such as power requirements, environmental conditions, and the specific operational demands of your industry to ensure optimal performance. -

How can I vet alternator suppliers effectively?

Begin by researching the supplier’s reputation within the industry. Look for reviews, testimonials, and case studies that highlight their reliability and customer service. Verify certifications and compliance with international quality standards, such as ISO, to ensure product quality. Additionally, request references from other B2B buyers in your region and inquire about their experiences. A supplier with a transparent supply chain and strong after-sales support is crucial for building a lasting business relationship. -

Was sind die Mindestbestellmengen (MOQ) für Lichtmaschinen?

Minimum order quantities can vary significantly between manufacturers and suppliers. Some may offer flexible MOQs, especially for well-known brands, while others may require bulk orders to ensure cost-effectiveness. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your purchasing strategy. Consider forming partnerships with other businesses to meet MOQ requirements if necessary, which can also lead to better pricing. -

Mit welchen Zahlungsbedingungen muss ich bei der Beschaffung von Lichtmaschinen rechnen?

Payment terms can differ based on the supplier and the nature of the transaction. Common terms include partial upfront payments, net 30 or net 60 days, and letters of credit for larger orders. Always clarify payment methods accepted, such as wire transfers or credit terms, and ensure you understand any associated fees. Negotiating favorable payment terms can improve cash flow and reduce financial risk, so don’t hesitate to discuss options with your suppliers. -

Wie kann ich die Qualitätssicherung (QA) für Lichtmaschinen gewährleisten?

To guarantee quality assurance, partner with suppliers who have stringent QA processes in place. Request detailed information on their testing protocols, certifications, and manufacturing practices. Conduct regular quality audits or inspections during production runs, if possible. Establishing a clear communication channel with your supplier will also help address any quality concerns promptly and ensure that the alternators meet your expectations before shipment. -

Welche logistischen Aspekte sollte ich beim Import von Lichtmaschinen beachten?

Logistics plays a crucial role in ensuring timely delivery and minimizing costs. Consider the shipping methods available, including air freight for urgency or sea freight for cost savings. Ensure that your supplier can handle export documentation and customs clearance efficiently. Additionally, factor in lead times and potential delays due to customs regulations, especially in regions like Africa and South America. A reliable logistics partner will help streamline the process and provide updates throughout the shipment journey. -

Can alternators be customized for specific applications?

Yes, many manufacturers offer customization options for alternators to meet specific application requirements. Customization can include modifications in voltage output, size, and connection types. When seeking custom alternators, clearly communicate your specifications to the supplier and inquire about their capabilities in producing tailored solutions. Customization can enhance performance and efficiency, making it a worthwhile consideration for businesses with unique operational demands.

Top 4 Alternator Brands Manufacturers & Suppliers List

1. Denso – Quality Automotive Parts

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: This company, Denso – Quality Automotive Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Alternators – Key Manufacturers and Power Ratings

Domäne: genpowerusa.com

Registriert: 2001 (24 Jahre)

Einleitung: Alternators by Manufacturer: LEROY SOMER, STAMFORD, CUMMINS, MARATHON, KOHLER, MAGNAPLUS, MARELLI, MECC ALTE, NEWAGE, SDMO. Alternators by Power Rating: 10 KW to 40 KW, 45 KW to 95 KW, 100 KW to 175 KW, 200 KW to 350 KW, 400 KW to 600 KW, 650 KW to 2000 KW, 10 KVA to 40 KVA, 45 KVA to 100 KVA, 110 KVA to 200 KVA, 250 KVA to 400 KVA, 440 KVA to 750 KVA, 800 KVA to 2500 KVA. Alternators by Frequency…

3. D2U Alternators – Best in Business

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, D2U Alternators – Best in Business, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Meccalte – Synchronous Alternators

Domäne: meccalte.com

Registriert: 1998 (27 Jahre)

Einleitung: Main brand offers synchronous alternators 4 pole from 3.5kVA to 5,000kVA and 2 pole alternators from 5kVA to 2,000kVA. Products include: 1 phase brushless – capacitor for light towers, Slipring/Compound in 2 and 4 pole up to 24kVA, Brushless compound in 2 and 4 pole to 98.5kVA with AVR option, Brushless AVR in 2 and 4 pole to 5,000kVA, 400Hz up to 200kVA, 6 pole alternators, Variable speed Permane…

Strategic Sourcing Conclusion and Outlook for alternator brands

In the dynamic landscape of alternator brands, the importance of strategic sourcing cannot be overstated. International B2B buyers should prioritize partnerships with reputable manufacturers such as Leroy Somer, John Deere, Marelli, and Stamford, known for their commitment to quality and reliability. These brands not only enhance the longevity of generators but also ensure optimal performance, which is crucial for industries operating in demanding environments.

As markets in Africa, South America, the Middle East, and Europe evolve, the demand for high-quality alternators is expected to rise. Buyers should leverage technology and innovation from leading manufacturers to meet specific operational needs, ensuring compatibility and efficiency. Furthermore, understanding the unique requirements of local markets will allow businesses to make informed decisions that align with their operational goals.

Looking ahead, the future of alternator sourcing will be shaped by advancements in technology and increased focus on sustainability. B2B buyers are encouraged to stay ahead of trends and consider strategic alliances that prioritize quality, efficiency, and environmental responsibility. By doing so, businesses can enhance their operational resilience and drive long-term success in an increasingly competitive marketplace.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.