Introduction: Navigating the Global Market for vehicle alternator parts

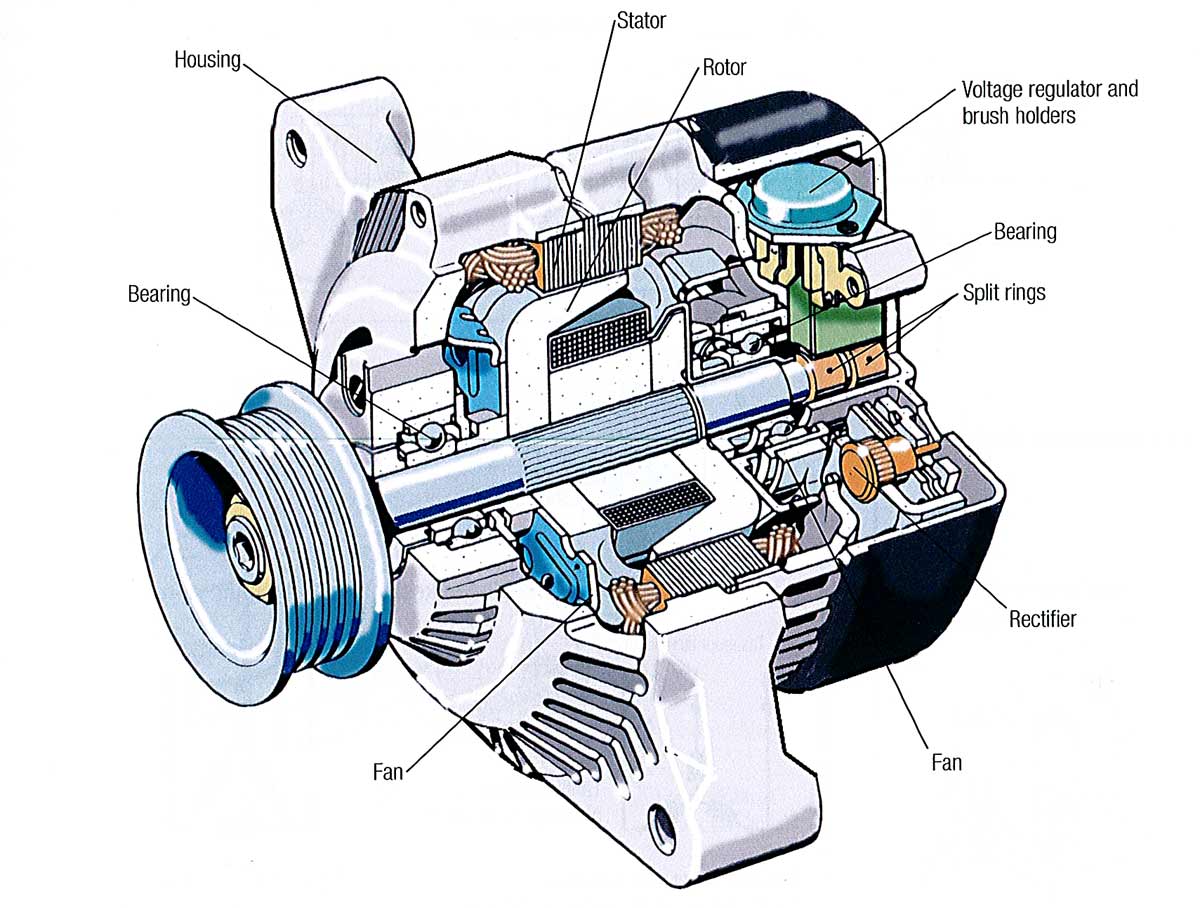

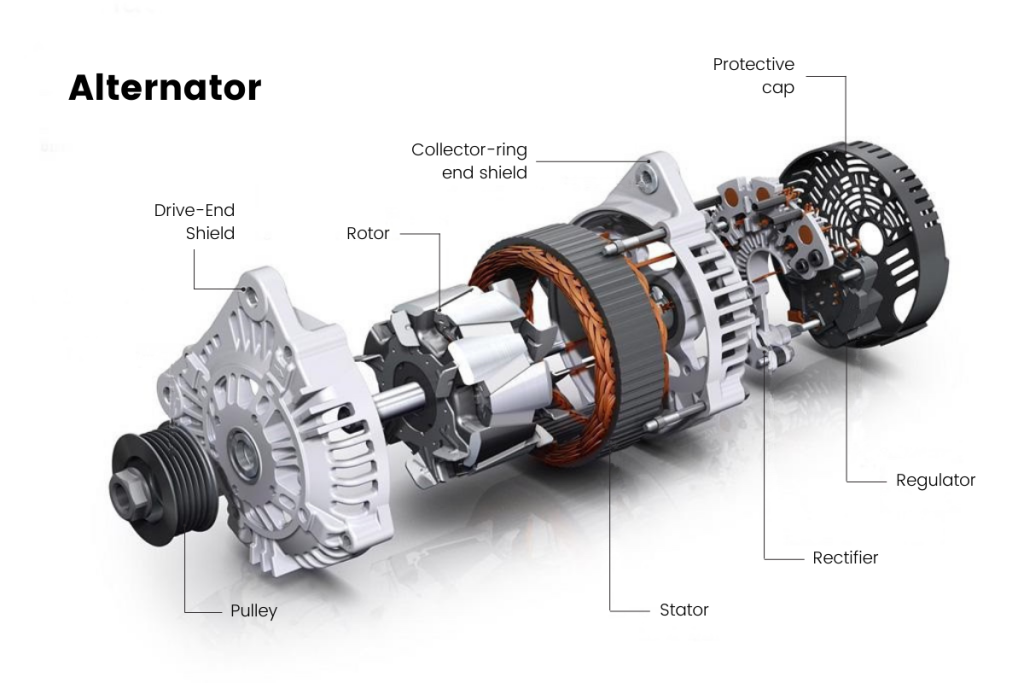

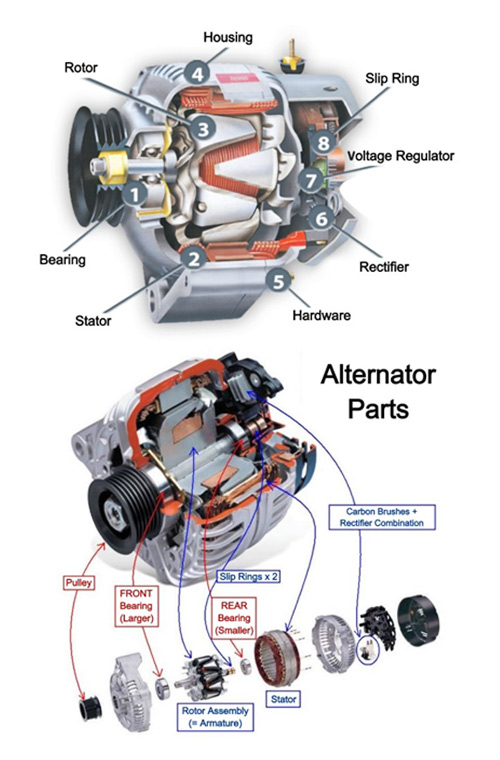

In today’s global marketplace, sourcing vehicle alternator parts presents a unique challenge for B2B buyers, particularly in dynamic regions like Africa, South America, the Middle East, and Europe. With the automotive industry evolving rapidly, understanding the intricacies of alternator components, their applications, and the various suppliers available is crucial for making informed purchasing decisions. This comprehensive guide delves into the essential elements of vehicle alternator parts, including their key components such as rotors, stators, rectifiers, and voltage regulators, as well as insights into their functionality and importance in vehicle performance.

By addressing the diverse requirements and challenges faced by international buyers, this guide equips you with the knowledge needed to navigate the complexities of sourcing alternator parts. It outlines best practices for vetting suppliers, assessing quality standards, and understanding pricing structures across different markets. Whether you are looking to enhance your supply chain efficiency or ensure compliance with regional automotive standards, this resource serves as a valuable tool.

Empowered with actionable insights and detailed information, you can confidently engage with suppliers and make strategic decisions that drive your business forward. As you explore the intricacies of the alternator parts market, you will be better positioned to optimize your procurement processes and foster long-term partnerships in the automotive sector.

Inhaltsverzeichnis

- Top 3 Vehicle Alternator Parts Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for vehicle alternator parts

- Understanding vehicle alternator parts Types and Variations

- Key Industrial Applications of vehicle alternator parts

- 3 Common User Pain Points for ‘vehicle alternator parts’ & Their Solutions

- Strategic Material Selection Guide for vehicle alternator parts

- In-depth Look: Manufacturing Processes and Quality Assurance for vehicle alternator parts

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘vehicle alternator parts’

- Comprehensive Cost and Pricing Analysis for vehicle alternator parts Sourcing

- Alternatives Analysis: Comparing vehicle alternator parts With Other Solutions

- Essential Technical Properties and Trade Terminology for vehicle alternator parts

- Navigating Market Dynamics and Sourcing Trends in the vehicle alternator parts Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vehicle alternator parts

- Strategic Sourcing Conclusion and Outlook for vehicle alternator parts

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding vehicle alternator parts Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Herkömmliche Lichtmaschinen | Standard design, typically 12V output, includes rotor and stator | Automotive manufacturing, aftermarket parts | Pros: Widely available, cost-effective. Cons: Limited efficiency at low RPMs. |

| Hochleistungsgeneratoren | Increased amperage output, often includes upgraded cooling systems | Performance vehicles, heavy-duty applications | Pros: Supports high-demand electrical systems. Cons: Higher cost, may require modifications. |

| Bürstenlose Generatoren | No brushes or slip rings, reduced wear, and maintenance needs | Industrial machinery, marine applications | Pros: Longer lifespan, lower maintenance. Cons: More expensive upfront. |

| Intelligente Lichtmaschinen | Advanced voltage regulation, integrated with vehicle’s electronics | Modern vehicles, hybrid and electric systems | Pros: Optimizes energy usage, enhances fuel efficiency. Cons: Complex installation, higher repair costs. |

| Clutch Alternators | Equipped with a clutch mechanism to disengage under low demand | Commercial vehicles, trucks | Pros: Reduces engine load, improves fuel efficiency. Cons: More complex, potential for failure under high stress. |

Was sind die Merkmale herkömmlicher Lichtmaschinen?

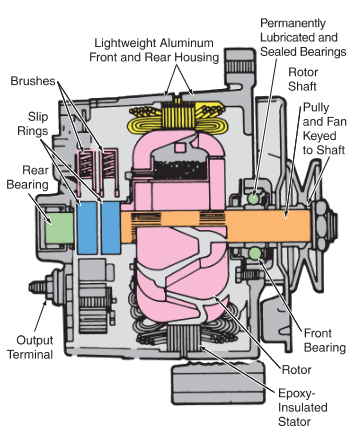

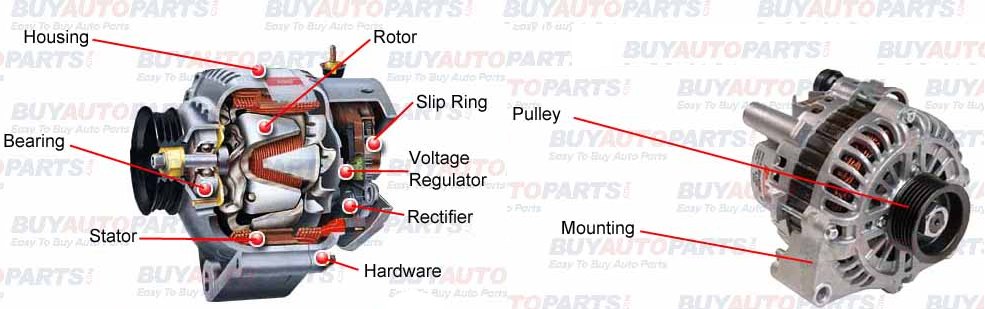

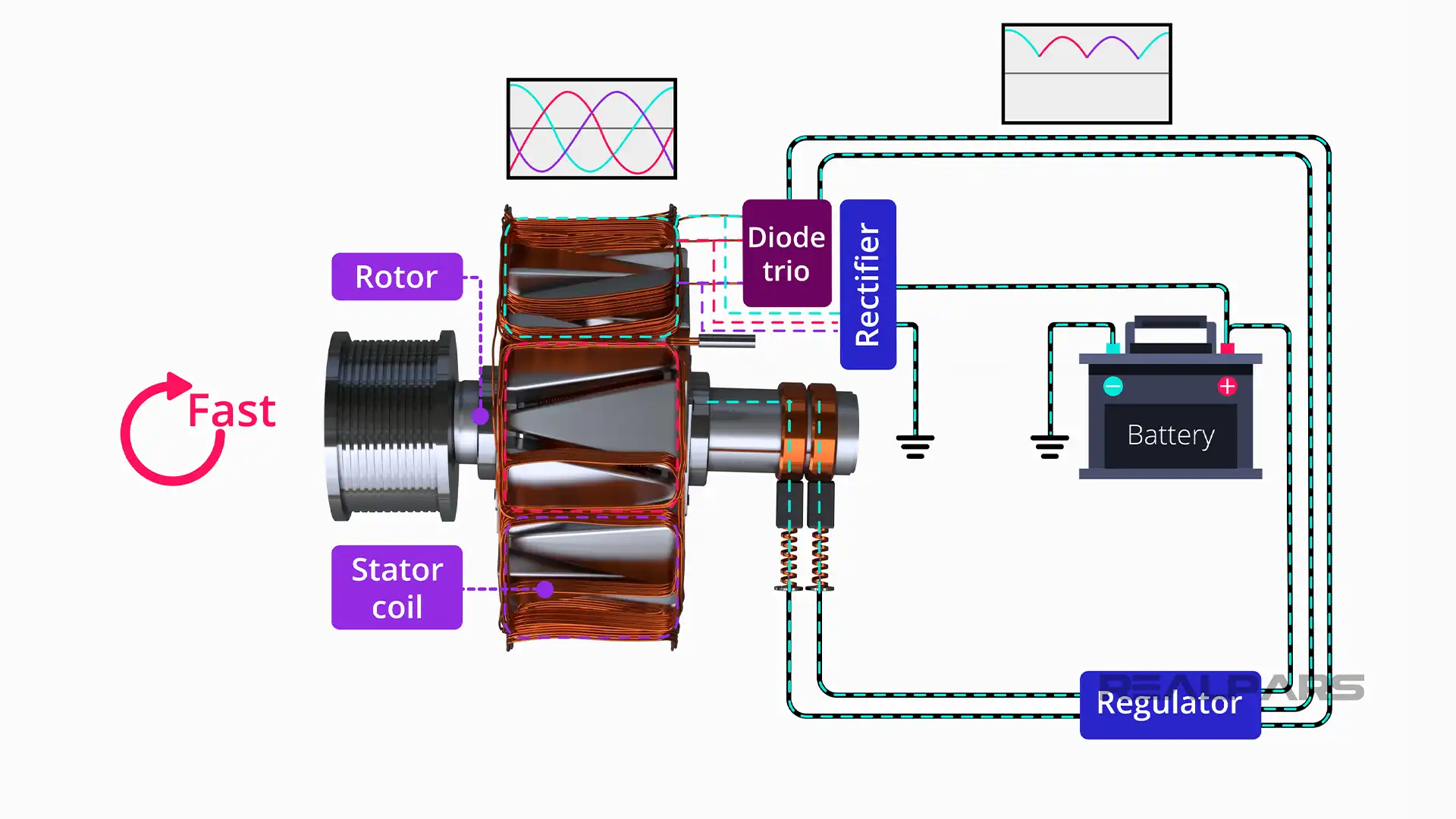

Conventional alternators are the standard choice for most vehicles, delivering a 12V output that suits typical automotive needs. They consist of a rotor and stator, which work together to convert mechanical energy into electrical energy. B2B buyers in automotive manufacturing often prefer these due to their availability and cost-effectiveness. However, they may not perform efficiently at low RPMs, which can be a consideration for buyers focused on performance or specific applications.

How Do High-Output Alternators Differ from Conventional Options?

High-output alternators are designed to provide increased amperage, catering to vehicles with high electrical demands, such as performance cars or heavy-duty trucks. These alternators often come with upgraded cooling systems to manage the heat generated by higher output levels. B2B buyers should consider these for applications requiring robust electrical support, though they come at a higher price point and may necessitate vehicle modifications.

Why Choose Brushless Alternators for Industrial Applications?

Brushless alternators eliminate brushes and slip rings, which reduces wear and maintenance needs, making them ideal for industrial machinery and marine applications. Their design enhances longevity and reliability, appealing to businesses that prioritize low maintenance costs. While they have a higher initial investment, the long-term savings on maintenance can make them an attractive option for B2B buyers in demanding environments.

What Are the Advantages of Smart Alternators in Modern Vehicles?

Smart alternators integrate advanced voltage regulation and communicate with the vehicle’s electronic systems to optimize energy usage. They are becoming increasingly popular in modern vehicles, including hybrids and electric models. B2B buyers should note their ability to enhance fuel efficiency and reduce emissions, although the complexity of installation and potential repair costs could be a drawback.

How Do Clutch Alternators Improve Fuel Efficiency?

Clutch alternators feature a mechanism that disengages the alternator under low electrical demand, reducing engine load and improving fuel efficiency. This design is particularly beneficial for commercial vehicles and trucks, where operational efficiency is critical. Buyers should weigh the potential complexities and failure risks against the fuel savings and performance benefits when considering these alternatives.

Key Industrial Applications of vehicle alternator parts

| Branche/Sektor | Specific Application of Vehicle Alternator Parts | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Production of electric vehicles and hybrids | Enhanced energy efficiency and reduced emissions | Quality standards, compatibility with various models |

| Schwere Ausrüstung | Power generation for construction machinery | Reliable operation under demanding conditions | Durability, resistance to harsh environments |

| Öffentliche Verkehrsmittel | Alternators for buses and commercial vehicles | Improved reliability and lower maintenance costs | Supplier reliability, parts availability |

| Schiffsindustrie | Power systems for boats and ships | Efficient energy management and safety | Einhaltung der maritimen Vorschriften, Korrosionsbeständigkeit |

| Landwirtschaftliche Geräte | Alternators in tractors and harvesters | Continuous power supply for essential operations | Performance in variable weather conditions, warranty terms |

How Are Vehicle Alternator Parts Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, vehicle alternator parts are critical for the production of electric and hybrid vehicles. These components convert mechanical energy into electrical energy efficiently, enabling the vehicle’s battery to recharge while supporting various electrical systems. The demand for energy-efficient solutions is rising, particularly in regions like Europe and South America, where regulatory pressures for reduced emissions are strong. Buyers must ensure that the alternator parts meet stringent quality standards and are compatible with diverse vehicle models to maintain production efficiency.

What Role Do Alternator Parts Play in Heavy Equipment?

Heavy equipment relies heavily on vehicle alternator parts for power generation, particularly in construction machinery such as excavators and bulldozers. These alternators must operate reliably under extreme conditions, ensuring that machinery remains functional during demanding tasks. For international buyers in Africa and the Middle East, sourcing durable and robust alternator components is vital to prevent downtime and maintain productivity. Considerations include the alternator’s resistance to dust, moisture, and temperature variations, as well as the availability of replacement parts.

How Are Vehicle Alternator Parts Essential for Public Transportation?

In the public transportation sector, alternators are vital for buses and commercial vehicles, where reliability directly impacts service quality and operational costs. Alternator parts ensure that these vehicles can continuously power essential systems, from lighting to passenger information displays. With a focus on reducing maintenance costs and improving reliability, buyers must prioritize sourcing from reputable suppliers who can guarantee the availability of high-quality parts and timely delivery, especially in regions with high public transport demand like Brazil.

Why Are Vehicle Alternator Parts Important in the Marine Industry?

In the marine industry, vehicle alternator parts are crucial for ensuring efficient power systems on boats and ships. These components help manage onboard electrical systems, contributing to safety and operational efficiency. Buyers in this sector must consider compliance with maritime regulations and the materials used, as corrosion resistance is critical due to exposure to saltwater environments. Ensuring that alternators can withstand harsh marine conditions can significantly enhance vessel reliability and longevity.

How Do Vehicle Alternator Parts Support Agriculture Equipment?

Agriculture equipment, such as tractors and harvesters, relies on vehicle alternator parts for a consistent power supply during operations. These components are essential for running various electrical systems that support farming activities, from GPS navigation to automated systems. International buyers in regions like Africa must focus on sourcing alternators that perform well in variable weather conditions and offer robust warranties. This ensures that equipment remains operational during critical planting and harvesting seasons, minimizing potential losses.

3 Common User Pain Points for ‘vehicle alternator parts’ & Their Solutions

Scenario 1: Difficulty Sourcing Reliable Alternator Components

Das Problem: B2B buyers often struggle to find reliable suppliers for vehicle alternator parts. This challenge is particularly acute in regions like Africa and South America, where local sourcing options may be limited, and international shipping can lead to delays and increased costs. Buyers may receive substandard parts that do not meet specifications, resulting in frequent failures and customer dissatisfaction. This situation not only affects operational efficiency but also damages the reputation of businesses that rely on quality automotive components.

Die Lösung: To mitigate sourcing issues, buyers should establish relationships with reputable suppliers who specialize in alternator parts. Conduct thorough research on potential vendors, checking for certifications and reviews from other B2B clients. Consider suppliers that offer detailed product specifications, including OEM compatibility, materials used, and warranty information. Utilizing platforms that aggregate reviews and ratings can also aid in making informed decisions. Furthermore, investing in local partnerships can help streamline logistics and ensure quicker turnaround times for parts procurement.

Scenario 2: Misunderstanding Alternator Specifications

Das Problem: Another common pain point for B2B buyers is the misunderstanding of technical specifications related to alternator parts. With various models and configurations available, buyers often face confusion over compatibility, output ratings, and component functionality. This can lead to purchasing incorrect parts, resulting in increased costs due to returns, reorders, and potential downtime in operations. In addition, the lack of technical knowledge can hinder effective communication with suppliers.

Die Lösung: To address specification challenges, buyers should prioritize education on alternator components and their functions. Engaging with suppliers who provide comprehensive technical support can be beneficial. Request detailed catalogs that include diagrams, specifications, and compatibility information for different vehicle models. Training sessions or workshops offered by suppliers can also enhance the buyer’s understanding of alternator technology. Additionally, creating a specification checklist that outlines the required parameters for each part can streamline the purchasing process and minimize errors.

Scenario 3: Navigating Warranty and Return Policies

Das Problem: Warranty and return policies for vehicle alternator parts can often be a source of confusion and frustration for B2B buyers. Many suppliers have varying terms, and buyers may be unaware of the implications of these policies until they encounter an issue with a purchased part. This lack of clarity can lead to unexpected costs if parts need to be returned or replaced, affecting the overall budget and project timelines.

Die Lösung: Buyers should proactively seek clarity on warranty and return policies before finalizing any purchase. This includes asking suppliers for explicit documentation outlining the terms of service, warranty duration, and conditions that may void a warranty. It’s advisable to negotiate terms that allow for returns or exchanges in the event of defective parts, and to ensure that this is documented. Establishing a good communication channel with suppliers can facilitate smoother transactions and create an environment where issues can be resolved quickly. Buyers may also benefit from implementing a quality assurance process to test parts upon arrival, reducing the likelihood of complications related to warranties down the line.

Strategic Material Selection Guide for vehicle alternator parts

What Materials Are Commonly Used in Vehicle Alternator Parts?

When selecting materials for vehicle alternator parts, it is crucial to consider their properties, advantages, and limitations. The choice of materials directly impacts the performance, durability, and cost-effectiveness of the alternator, making it essential for international B2B buyers to understand these factors.

How Does Aluminum Benefit Vehicle Alternator Components?

Aluminum is the predominant material used for the outer housing of alternators. Its lightweight nature allows for efficient heat dissipation, which is critical given the high temperatures generated during operation. Aluminum also does not magnetize, ensuring that the magnetic fields created by the rotor are not disrupted.

Vorteile: Aluminum is highly durable, resistant to corrosion, and relatively inexpensive compared to other metals. Its manufacturing processes are well-established, making it easy to source and fabricate.

Nachteile: While aluminum is robust, it may not withstand extreme mechanical stress as well as some other materials, such as steel. Additionally, it has a lower tensile strength, which could be a concern in high-load applications.

Auswirkungen auf die Anwendung: Aluminum’s thermal properties make it suitable for environments with significant temperature fluctuations, common in regions like Africa and the Middle East. However, buyers must ensure compliance with local standards, such as ASTM for the U.S. or DIN for Germany.

Welche Rolle spielt Kupfer in Lichtmaschinenkomponenten?

Copper is often used in the windings of the rotor and stator due to its excellent electrical conductivity. This property ensures efficient energy transfer, allowing the alternator to generate power effectively.

Vorteile: Copper’s high conductivity translates to lower energy losses, which is vital for optimal performance. It is also relatively easy to work with, making it a preferred choice for electrical components.

Nachteile: The primary drawback of copper is its susceptibility to corrosion, particularly in humid environments. Additionally, copper is more expensive than aluminum, impacting overall production costs.

Auswirkungen auf die Anwendung: In regions with high humidity, such as parts of South America, protective coatings or alloys may be necessary to prevent corrosion. Buyers should also consider the implications of fluctuating copper prices on their supply chain.

Why Is Steel Used in Certain Alternator Parts?

Steel is sometimes utilized for components like the rotor shaft and internal structural elements due to its high strength and durability. This material can withstand significant mechanical stress, making it ideal for parts that experience high rotational forces.

Vorteile: Steel’s high tensile strength provides excellent durability, making it suitable for heavy-duty applications. It also has good wear resistance, extending the lifespan of critical components.

Nachteile: Steel is heavier than aluminum and can lead to increased overall weight, which may affect vehicle efficiency. It is also more prone to rust and corrosion if not properly treated.

Auswirkungen auf die Anwendung: For buyers in Europe, where stringent regulations on vehicle emissions are in place, the increased weight of steel may be a concern. Compliance with environmental standards must be considered when selecting materials.

Wie verbessert Kunststoff die Funktionsfähigkeit von Lichtmaschinen?

Plastic materials, particularly high-performance polymers, are increasingly being used for non-structural components like covers and insulation. These materials offer excellent electrical insulation properties and are lightweight.

Vorteile: Plastics are resistant to corrosion and can be molded into complex shapes, allowing for design flexibility. They are also generally less expensive than metals.

Nachteile: The primary limitation of plastics is their lower thermal resistance compared to metals, which may restrict their use in high-temperature areas of the alternator.

Auswirkungen auf die Anwendung: In warmer climates, such as parts of Africa, the thermal properties of plastics must be carefully evaluated to ensure they can withstand operational temperatures. Buyers should also consider the recyclability of plastics in their sourcing decisions.

Summary of Material Selection for Vehicle Alternator Parts

| Material | Typical Use Case for vehicle alternator parts | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Outer housing | Leicht und korrosionsbeständig | Geringere Zugfestigkeit | Niedrig |

| Kupfer | Rotor- und Statorwicklungen | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Hoch |

| Stahl | Rotor shaft and structural elements | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Rost | Mittel |

| Kunststoff | Abdeckungen und Isolierung | Corrosion-resistant and moldable | Geringerer Wärmewiderstand | Niedrig |

This strategic material selection guide equips international B2B buyers with essential insights to make informed decisions when sourcing vehicle alternator parts, ensuring compliance with local standards and optimizing performance for various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for vehicle alternator parts

What Are the Main Stages in the Manufacturing Process of Vehicle Alternator Parts?

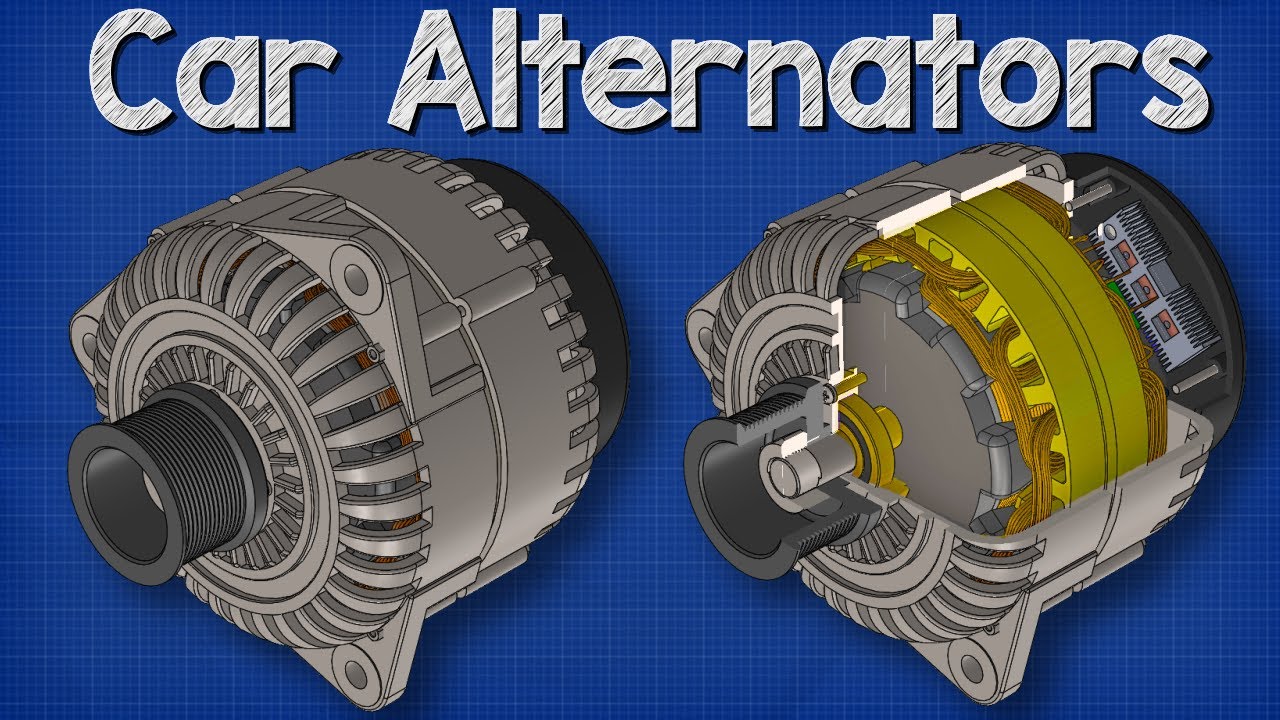

The manufacturing of vehicle alternator parts involves several key stages: material preparation, forming, assembly, and finishing. Each of these stages is critical to ensure the functionality and reliability of the alternator.

How is Material Prepared for Vehicle Alternator Parts?

Material preparation is the initial phase where raw materials, typically aluminum for the housing and copper for electrical components, are sourced and processed. Manufacturers often use high-grade aluminum alloys due to their lightweight and corrosion-resistant properties, which are essential for heat dissipation in alternators. Copper is utilized for windings and connections due to its excellent conductivity.

During this stage, materials undergo quality checks to ensure they meet specified standards. This may include verifying the tensile strength of aluminum and the conductivity of copper. Proper documentation is crucial, as it provides traceability for B2B buyers and confirms that materials meet international standards.

Welche Umformtechniken werden bei der Herstellung von Lichtmaschinen verwendet?

Once the materials are prepared, they move to the forming stage. This involves techniques such as die casting, machining, and stamping. Die casting is commonly used for creating the aluminum housing, allowing for complex shapes and precise dimensions. Machining may be employed to create the rotor and stator components, ensuring they meet tight tolerances.

Illustrative image related to vehicle alternator parts

Stamping is often used for producing flat components such as mounting brackets and other support structures. Each forming technique must be performed under strict control to maintain consistency and quality, aligning with international manufacturing standards.

How Are Vehicle Alternator Parts Assembled?

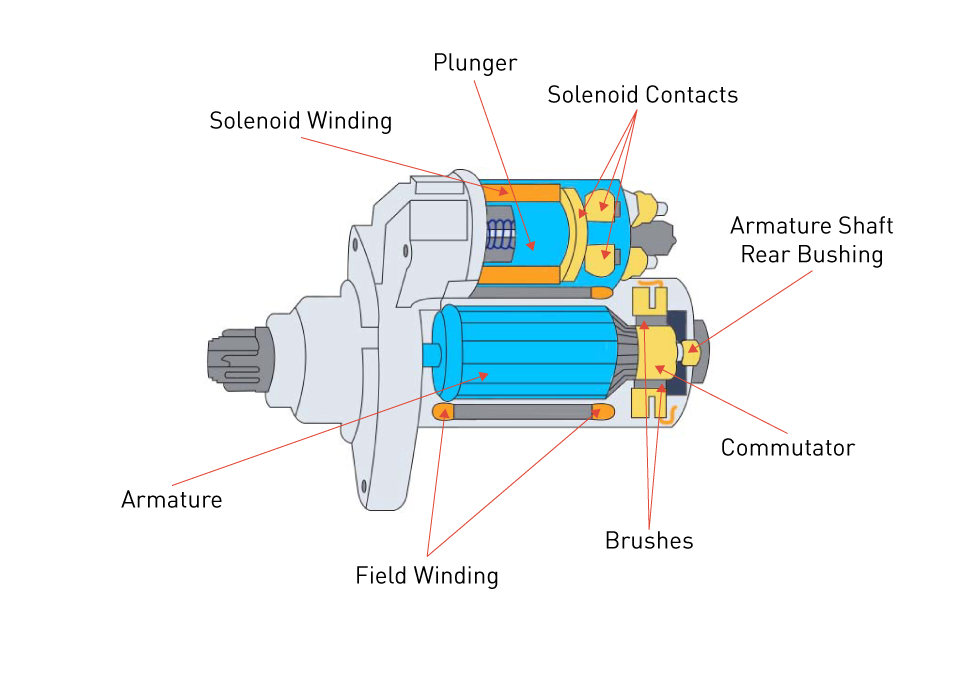

The assembly phase brings together all the components. This typically involves several sub-stages: initial assembly of the rotor and stator, followed by the integration of the rectifier, voltage regulator, slip rings, and brushes. Each component must fit together precisely to ensure optimal performance.

Automated assembly lines are increasingly common in this industry, utilizing robotics to improve efficiency and reduce human error. However, manual assembly is still prevalent for more complex tasks requiring a higher level of precision or customization.

What Finishing Processes Are Applied to Alternator Parts?

Finishing processes enhance the durability and performance of alternator parts. This includes treatments such as anodizing for aluminum components, which increases corrosion resistance and wear characteristics. Additionally, components may undergo surface treatments to reduce friction and improve electrical conductivity.

Quality control during finishing is critical. Manufacturers often perform inspections to ensure that coatings are applied uniformly and that no defects are present. This not only affects the performance of the alternator but also influences customer satisfaction and compliance with international quality standards.

What Are the Key Quality Assurance Standards for Vehicle Alternator Parts?

Quality assurance (QA) is essential in manufacturing alternator parts, ensuring they meet international and industry-specific standards. Common standards include ISO 9001 for general quality management and CE marking for compliance with European safety regulations.

How Do International Standards Influence Quality Control?

ISO 9001 provides a framework for manufacturers to establish effective quality management systems (QMS). This includes documentation of processes, continuous monitoring, and improvement initiatives. By adhering to these standards, manufacturers can assure B2B buyers of consistent quality and reliability.

In addition to ISO standards, alternator manufacturers may also comply with sector-specific standards such as API (American Petroleum Institute) for components used in automotive applications. This compliance ensures that parts can withstand the rigors of automotive use, particularly in diverse environments like those found in Africa, South America, and the Middle East.

What QC Checkpoints Are Important in the Manufacturing Process?

Quality control occurs at various checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Illustrative image related to vehicle alternator parts

What Is Incoming Quality Control (IQC)?

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This step is crucial for ensuring that only high-quality materials are used in production. Common checks include verifying material certifications and performing physical inspections.

Wie wird die prozessbegleitende Qualitätskontrolle (IPQC) durchgeführt?

IPQC takes place during the manufacturing process, where operators monitor production parameters and conduct tests on components at various stages. For example, dimensional checks may be performed during the machining of rotor and stator components, ensuring they meet specified tolerances.

What Is the Role of Final Quality Control (FQC)?

FQC occurs once the alternator is fully assembled. This stage often includes functional testing, where the alternator is subjected to electrical tests to confirm it meets output specifications. Additionally, visual inspections are conducted to identify any cosmetic defects that could affect customer perception.

Illustrative image related to vehicle alternator parts

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

B2B buyers must ensure that their suppliers adhere to stringent quality control practices. One effective way to verify this is through supplier audits, which provide an in-depth look at the manufacturing processes and QA measures in place.

What Should Buyers Look for in Supplier Audits?

During an audit, buyers should assess the supplier’s compliance with international standards and their internal quality management processes. Buyers may request documentation such as quality control reports, certificates of compliance, and records of previous audits.

Wie können Inspektionen durch Dritte die Qualitätssicherung verbessern?

Engaging third-party inspection agencies can further bolster confidence in supplier quality. These independent bodies can conduct random inspections and tests, ensuring that the products meet the required specifications before shipment.

Was sind die Besonderheiten der Qualitätskontrolle und Zertifizierung für internationale B2B-Einkäufer?

International B2B buyers must navigate various certification and quality assurance nuances when sourcing alternator parts. For instance, compliance with CE marking is essential for products sold within the European Union, while other regions may have their certification requirements.

Illustrative image related to vehicle alternator parts

How Do Regional Standards Affect Sourcing Decisions?

Understanding regional standards can significantly impact sourcing decisions. For example, buyers in Africa may prioritize suppliers who comply with local regulations and standards, while those in Europe may focus on ISO and CE compliance.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for vehicle alternator parts enables B2B buyers to make informed sourcing decisions. By emphasizing quality and compliance, businesses can establish lasting partnerships with reliable suppliers, ensuring they receive high-performance products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vehicle alternator parts’

To effectively source vehicle alternator parts, it’s essential to follow a systematic approach that ensures quality, reliability, and cost-effectiveness. This guide provides a step-by-step checklist tailored for B2B buyers focused on procuring alternator components.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Establishing clear technical specifications is the foundation of a successful procurement process. Determine the types of alternator parts you need, such as rotors, stators, rectifiers, and voltage regulators. Consider the specifications related to vehicle models, electrical output, and compatibility with existing systems to ensure optimal performance.

Illustrative image related to vehicle alternator parts

Schritt 2: Potenzielle Lieferanten recherchieren

Conduct thorough research to identify potential suppliers who specialize in alternator parts. Look for companies with a strong reputation in the automotive industry, particularly those that serve markets similar to yours, such as Africa, South America, and Europe. Utilize industry directories, trade shows, and online platforms to gather a list of suppliers.

Schritt 3: Lieferantenzertifizierungen bewerten

Before proceeding, verify the certifications of potential suppliers. Look for compliance with international quality standards such as ISO 9001, which indicates a commitment to quality management. Certifications ensure that the supplier adheres to industry regulations and can provide reliable, high-quality products.

Schritt 4: Muster für die Qualitätsbewertung anfordern

Obtaining samples is crucial to evaluate the quality of the alternator parts before making bulk purchases. Assess the materials, craftsmanship, and compatibility with your specifications. Testing samples allows you to identify any potential issues and gauge the supplier’s ability to meet your quality expectations.

Illustrative image related to vehicle alternator parts

Schritt 5: Preise und Zahlungsbedingungen analysieren

Compare pricing structures among shortlisted suppliers to ensure you receive competitive rates. Be mindful of the total cost of ownership, including shipping, taxes, and potential tariffs. Additionally, clarify payment terms and options; favorable terms can enhance cash flow and overall procurement efficiency.

Schritt 6: Prüfen Sie den Kundendienst und die Garantie

Assess the level of after-sales support and warranty offered by suppliers. A solid warranty demonstrates the supplier’s confidence in their products and provides assurance in case of defects or performance issues. Ensure that the supplier has a responsive customer service team to assist with any post-purchase inquiries.

Schritt 7: Eine langfristige Beziehung aufbauen

Finally, focus on building a long-term relationship with your chosen supplier. Consistent communication and collaboration can lead to better pricing, priority service, and access to new products. Regularly review the partnership to ensure it continues to meet your evolving needs and expectations.

Illustrative image related to vehicle alternator parts

By following this checklist, B2B buyers can streamline their sourcing process for vehicle alternator parts, ensuring they procure high-quality components that meet their operational requirements.

Comprehensive Cost and Pricing Analysis for vehicle alternator parts Sourcing

What Are the Key Cost Components for Sourcing Vehicle Alternator Parts?

When sourcing vehicle alternator parts, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materialien: The choice of materials significantly impacts the cost. Common materials used in alternator production include aluminum for the housing, copper for windings, and various alloys for internal components. Higher quality materials can enhance performance but also increase costs.

-

Arbeit: Labor costs vary by region and supplier. In areas with lower labor costs, such as parts of Africa or South America, the overall labor expense may be reduced, but this can also affect quality and production speed.

-

Fertigungsgemeinkosten: This encompasses costs related to factory operations, including utilities, equipment maintenance, and salaries of supervisory staff. Efficient manufacturing processes can help minimize these costs.

-

Werkzeuge: The initial investment in tooling can be substantial, especially for custom parts. Depending on the complexity of the alternator design, tooling costs can vary significantly.

-

Qualitätskontrolle (QC): Implementing stringent QC processes ensures that the alternator parts meet required specifications, which can incur additional costs. However, investing in quality control can reduce long-term costs related to returns and warranties.

-

Logistik: Transportation and warehousing costs must be considered, especially for international shipments. Incoterms will dictate who bears these costs and can influence the final price.

-

Marge: Supplier margins can vary widely based on market conditions and the level of competition. Understanding the typical margin in your supplier’s region can help in negotiations.

What Influences the Pricing of Vehicle Alternator Parts?

Several factors can influence the pricing of vehicle alternator parts:

-

Menge/Mindestbestellmenge: Bulk purchasing often leads to reduced costs per unit. Suppliers may offer better pricing for larger orders, which is advantageous for buyers looking to stock inventory.

-

Spezifikationen und Anpassung: Customized alternator parts may incur additional costs due to the need for specialized tooling or materials. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materialien: As mentioned earlier, the choice of materials affects pricing. Opting for high-grade materials can enhance performance but may lead to higher upfront costs.

-

Qualität und Zertifizierungen: Parts that meet international quality standards or have specific certifications may command a higher price. Buyers should weigh the benefits of certified parts against their budgets.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can also influence pricing. Established suppliers with a track record of quality may charge more but offer better service and reliability.

-

Incoterms: The chosen Incoterm affects logistics costs and responsibilities, impacting the overall price. Buyers should be familiar with terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) to make informed decisions.

How Can Buyers Negotiate for Better Prices on Vehicle Alternator Parts?

Effective negotiation strategies can lead to significant cost savings:

-

Forschung und Benchmarking: Understand market prices and benchmark against competitors to ensure you’re receiving a fair deal.

-

Beziehungen aufbauen: Establishing a strong relationship with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

-

Discuss Total Cost of Ownership (TCO): Emphasize the importance of TCO rather than just the initial purchase price. Highlighting the long-term savings from higher quality parts can justify a higher upfront cost.

-

Mengenrabatte ausnutzen: If you plan on purchasing in bulk, use this to your advantage during negotiations. Suppliers are often more willing to offer discounts for larger orders.

-

Achten Sie auf preisliche Nuancen: Understand the specific pricing dynamics in your region. For instance, in South America or Africa, local economic conditions may influence pricing structures differently than in Europe.

Conclusion: Pricing Insights for International B2B Buyers

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigating the complexities of sourcing vehicle alternator parts can be challenging. By understanding the cost components, pricing influencers, and effective negotiation tactics, buyers can optimize their procurement strategies and enhance their overall purchasing experience. Always remember that prices can vary significantly based on the factors discussed, and it is advisable to approach sourcing with a comprehensive strategy in mind.

Alternatives Analysis: Comparing vehicle alternator parts With Other Solutions

Introduction to Alternative Solutions for Vehicle Power Generation

In the automotive industry, the vehicle alternator plays a crucial role in converting mechanical energy from the engine into electrical energy to power various vehicle systems. However, there are alternative solutions available that can achieve similar outcomes. This section explores the comparison between traditional vehicle alternator parts and other viable technologies, enabling B2B buyers to make informed decisions.

Comparison Table of Vehicle Alternator Parts and Alternatives

| Vergleichsaspekt | Vehicle Alternator Parts | Regenerative Braking Systems | Lithium-ion Battery Systems |

|---|---|---|---|

| Leistung | High efficiency, reliable power generation under various loads. | Converts kinetic energy to electrical energy, enhancing efficiency. | Provides high energy density and quick discharge capabilities. |

| Kosten | Generally affordable, but varies with quality and brand. | Higher initial investment due to complex systems and integration. | Moderate to high cost, depending on technology and capacity. |

| Einfache Implementierung | Simple integration in conventional vehicles. | Requires additional components and modifications to braking systems. | Needs specific vehicle design and compatibility with existing systems. |

| Wartung | Regular checks needed for wear and tear, particularly brushes and bearings. | Low maintenance once installed, but requires monitoring of battery health. | Requires periodic checks and potential replacement after several cycles. |

| Bester Anwendungsfall | Ideal for traditional combustion engine vehicles. | Best for hybrid and electric vehicles to maximize energy efficiency. | Suitable for electric vehicles and applications needing high energy storage. |

Detaillierte Aufschlüsselung der Alternativen

Regenerative Braking Systems

Regenerative braking systems are an innovative approach that captures kinetic energy generated during braking and converts it into electrical energy. This energy can then be used to power the vehicle’s electrical systems or recharge the battery. The key advantage of regenerative braking is its ability to improve overall energy efficiency, especially in hybrid and electric vehicles. However, the initial installation cost can be high, and it requires significant modifications to the vehicle’s braking system, which may not be feasible for all applications.

Lithium-ion Battery Systems

Lithium-ion battery systems are increasingly being used as a primary power source in electric vehicles. These systems provide a high energy density, allowing vehicles to travel longer distances on a single charge. They also offer fast discharge capabilities, which can be crucial for performance in electric vehicles. While lithium-ion batteries are becoming more affordable, the initial investment remains moderate to high, and they require careful management and monitoring to ensure longevity and safety. Their integration into traditional combustion vehicles may also pose challenges.

Schlussfolgerung: Die Wahl der richtigen Stromerzeugungslösung

When selecting the right power generation solution for vehicles, B2B buyers must consider various factors such as performance, cost, and ease of implementation. Vehicle alternator parts remain the go-to choice for traditional combustion engine vehicles due to their reliability and affordability. However, for buyers looking to enhance energy efficiency or transition to electric vehicles, exploring alternatives like regenerative braking systems or lithium-ion battery systems may prove beneficial. Ultimately, the decision should align with the specific needs of the vehicle application and the buyer’s long-term strategic goals.

Essential Technical Properties and Trade Terminology for vehicle alternator parts

What Are the Key Technical Properties of Vehicle Alternator Parts?

When sourcing vehicle alternator parts, understanding specific technical properties is crucial for ensuring compatibility and performance. Here are several critical specifications that B2B buyers should prioritize:

-

Werkstoffgüte

– Definition: This refers to the type and quality of materials used in the construction of alternator components, such as aluminum for housings and copper for windings.

– Bedeutung: High-grade materials enhance durability and efficiency, which are essential for performance in demanding environments. For instance, aluminum housings are lightweight and heat-dissipating, making them ideal for automotive applications. -

Elektrische Nennleistung

– Definition: Measured in amperes (A), this rating indicates the maximum electrical current the alternator can produce.

– Bedeutung: Understanding the output rating is vital for ensuring that the alternator can meet the electrical demands of the vehicle’s systems. Insufficient output can lead to battery drain and electrical failures. -

Voltage Regulation Range

– Definition: This specification indicates the voltage range that the alternator can maintain during operation, typically around 13.5 to 14.5 volts.

– Bedeutung: A reliable voltage regulation range ensures that the vehicle’s electrical systems receive consistent power, preventing damage from voltage spikes or drops. -

Bearing Type and Load Capacity

– Definition: Alternators typically use ball or roller bearings, and their load capacity determines how much weight they can support.

– Bedeutung: The right bearing type and load capacity affect the alternator’s lifespan and operational smoothness. Poor bearing choices can lead to increased friction and premature failure. -

Toleranzwerte

– Definition: Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process.

– Bedeutung: Tight tolerances are critical for ensuring that components fit together correctly, which is essential for performance and longevity. Poor tolerances can lead to mechanical failures.

What Are Common Trade Terminology and Jargon in the Alternator Parts Industry?

Familiarity with industry terminology can streamline communication and negotiation processes. Here are several key terms that B2B buyers should know:

-

OEM (Originalgerätehersteller)

– Definition: Refers to companies that produce parts that are used in the manufacturing of new vehicles.

– Bedeutung: OEM parts are often preferred for their guaranteed compatibility and reliability, making them a safe choice for repairs and replacements. -

MOQ (Mindestbestellmenge)

– Definition: Die kleinste Menge eines Produkts, die ein Anbieter zu verkaufen bereit ist.

– Bedeutung: Understanding the MOQ is essential for inventory management and cost control. Buyers need to ensure that they can meet minimum requirements without overstocking. -

RFQ (Angebotsanfrage)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Bedeutung: An RFQ helps buyers compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (Internationale Handelsklauseln)

– Definition: A set of international rules for shipping and freight that define the responsibilities of buyers and sellers.

– Bedeutung: Familiarity with Incoterms is crucial for understanding shipping logistics, costs, and risk management, especially in international transactions. -

Ersatzteile

– Definition: Parts made by companies other than the OEM that can serve as replacements.

– Bedeutung: Aftermarket parts can offer cost savings and alternatives to OEM parts, but buyers should evaluate quality and compatibility to avoid potential issues.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing vehicle alternator parts, ensuring they select components that meet their operational needs and standards.

Navigating Market Dynamics and Sourcing Trends in the vehicle alternator parts Sector

What Are the Current Market Dynamics and Key Trends in Vehicle Alternator Parts?

The global vehicle alternator parts market is witnessing significant shifts driven by technological advancements, evolving consumer preferences, and regulatory changes. One of the primary drivers is the increasing demand for fuel-efficient and environmentally friendly vehicles. As automotive manufacturers pivot towards electric and hybrid models, there is a corresponding rise in demand for advanced alternator components that can efficiently support these systems. This trend is particularly relevant for B2B buyers in Africa, South America, the Middle East, and Europe, where local markets are rapidly modernizing.

Emerging technologies such as smart alternators, which can optimize energy usage and integrate with vehicle management systems, are gaining traction. Additionally, the rise of e-commerce platforms is transforming sourcing strategies, allowing buyers to access a wider range of suppliers and parts with greater ease. For international B2B buyers, understanding local market dynamics, such as currency fluctuations and import tariffs, is crucial for making informed purchasing decisions.

Furthermore, the market is experiencing a shift towards modular parts, which simplify repairs and reduce downtime. This trend is particularly beneficial for fleet operators seeking to minimize operational disruptions. Overall, B2B buyers should stay attuned to these trends to capitalize on opportunities and make strategic sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact the Vehicle Alternator Parts Supply Chain?

Sustainability is increasingly becoming a focal point in the vehicle alternator parts sector. The environmental impact of manufacturing processes, including the extraction of raw materials and energy consumption, has prompted buyers to seek sustainable sourcing options. Ethical supply chains are not just a regulatory necessity but a market differentiator, with consumers increasingly favoring brands that prioritize sustainability.

B2B buyers should consider suppliers that adhere to international sustainability standards, such as ISO 14001 for environmental management systems. Additionally, certifications like LEED and Green Seal can indicate a supplier’s commitment to environmentally friendly practices. The use of recycled materials in alternator components, such as aluminum casings and copper windings, not only reduces the carbon footprint but also offers cost advantages in sourcing.

Moreover, transparency in the supply chain is critical. Buyers should engage with suppliers who can provide traceability for their materials, ensuring that they are sourced ethically and sustainably. This not only enhances the brand’s reputation but also fosters consumer trust. As regulations around sustainability tighten globally, prioritizing ethical sourcing will be essential for maintaining competitiveness in the vehicle alternator parts market.

What Historical Context Should B2B Buyers Understand About Vehicle Alternator Parts?

The evolution of vehicle alternator parts has been shaped by technological advancements and changing consumer demands over the decades. Initially, alternators were primarily mechanical devices designed to convert mechanical energy into electrical energy for vehicles. The introduction of the modern alternator in the 1960s marked a significant milestone, as these devices became more efficient and compact, allowing for better integration into vehicle designs.

With the growing emphasis on fuel efficiency and emissions reduction, alternators have evolved to accommodate the needs of modern vehicles, including hybrids and electric cars. This historical context is crucial for B2B buyers, as understanding the trajectory of alternator technology can inform sourcing strategies and highlight the importance of selecting suppliers who are not only keeping pace with innovation but are also capable of meeting future demands.

Illustrative image related to vehicle alternator parts

As the industry continues to evolve, staying informed about historical trends will empower buyers to make strategic decisions that align with both current market dynamics and future developments in vehicle technology.

Frequently Asked Questions (FAQs) for B2B Buyers of vehicle alternator parts

-

How do I identify the right alternator parts for my vehicle?

To find the correct alternator parts, start by referencing your vehicle’s manual or OEM specifications, which will provide part numbers and compatibility information. Utilize online databases or supplier catalogs that filter parts by vehicle make, model, and year. Additionally, reach out to suppliers with detailed requirements to ensure that the parts meet your specific needs. Consider factors like power output, size, and configuration when making your selection. -

What is the best way to evaluate potential suppliers for alternator parts?

When evaluating suppliers, look for established companies with a solid reputation in the industry. Check customer reviews, testimonials, and case studies to gauge their reliability. Verify certifications and compliance with international quality standards, such as ISO 9001. Engage in direct communication to assess their responsiveness and willingness to customize products according to your specifications. Request samples to evaluate the quality of their alternator parts firsthand. -

What customization options are available for alternator parts?

Many suppliers offer customization options for alternator parts, including size, power output, and specific materials used in construction. Customization may also extend to branding, packaging, and labeling to align with your company’s marketing strategy. Discuss your specific requirements with potential suppliers to explore available options, timelines, and any associated costs. Ensure that they have the capability to deliver custom parts consistently without compromising quality. -

What is the typical minimum order quantity (MOQ) for vehicle alternator parts?

Minimum order quantities (MOQs) for vehicle alternator parts can vary significantly by supplier and product type. Generally, MOQs range from 50 to 500 units, depending on the complexity and customization of the parts. For bulk orders, many suppliers are willing to negotiate MOQs to accommodate larger orders. It’s advisable to communicate your specific needs and potential future orders to find a mutually beneficial arrangement. -

What payment terms should I expect when sourcing alternator parts internationally?

Payment terms can vary based on the supplier and the nature of the transaction. Common arrangements include advance payment, letter of credit, or net 30/60/90 days, depending on your credit history with the supplier. Ensure that you clarify all payment terms, including currency, payment methods, and any associated fees. Negotiating favorable terms can help manage cash flow while ensuring timely delivery of your parts. -

How can I ensure quality assurance when sourcing alternator parts?

To guarantee quality assurance, request certifications from suppliers that demonstrate adherence to international standards, such as ISO 9001. Implement a quality inspection process, either through third-party services or in-house teams, to evaluate parts upon arrival. Consider establishing a clear return policy for defective items and ensure that the supplier is responsive to quality issues. Building a strong relationship with the supplier can also facilitate better quality control. -

What are the best practices for logistics when importing alternator parts?

Effective logistics for importing alternator parts involves careful planning and coordination. Choose a reliable freight forwarder experienced in handling automotive components to navigate customs regulations and shipping routes. Ensure proper packaging to prevent damage during transit. Monitor shipment tracking closely and maintain communication with your supplier regarding delivery timelines. Consider using incoterms that clearly define responsibilities for shipping, insurance, and tariffs. -

How can I stay updated on changes in the alternator parts market?

Staying informed about the alternator parts market requires regular engagement with industry publications, trade shows, and online forums. Subscribe to newsletters from reputable automotive parts organizations and follow market analysis reports that highlight trends and innovations. Networking with industry peers and participating in relevant associations can also provide insights into emerging technologies and shifts in supply chain dynamics.

Top 3 Vehicle Alternator Parts Manufacturers & Suppliers List

1. HowStuffWorks – Alternators

Domäne: auto.wie-das-funktioniert.com

Registriert: 1998 (27 Jahre)

Einleitung: Alternators are small and lightweight, roughly the size of a coconut, and constructed with an aluminum outer housing to dissipate heat and avoid magnetization. Key components include:

– Drive pulley attached to the rotor shaft, which converts mechanical energy from the engine into electrical power.

– Several terminals on the back:

– S terminal: Senses battery voltage

– IG terminal: Ignition sw…

2. Alternator – OEM-Quality Options

Domäne: shop.advanceautoparts.com

Registriert: 1997 (28 Jahre)

Einleitung: Alternator – Advance Auto Parts offers OEM-quality alternators from brands like Carquest, ACDelco, and Bosch. The alternator is a key component of a vehicle’s electrical charging system, converting mechanical energy into electricity to power the vehicle’s electrical system and maintain battery charge. A failing alternator can lead to battery depletion and engine failure. Various models available i…

3. Electude – Alternator Essentials

Domäne: electude.com

Registriert: 2005 (20 Jahre)

Einleitung: An alternator is a crucial automotive component that converts mechanical energy into electrical energy, generating power for the vehicle’s electrical consumer units and battery. Key components include: 1. Pulley – Transfers mechanical energy from the engine. 2. Rotor – Creates the magnetic field for generating alternating current. 3. Stator – The static part where voltage is generated. 4. Rectifie…

Strategic Sourcing Conclusion and Outlook for vehicle alternator parts

In conclusion, strategic sourcing of vehicle alternator parts is essential for international B2B buyers seeking to enhance their supply chain efficiency and product reliability. By understanding the intricate components—such as rotors, stators, rectifiers, and voltage regulators—buyers can make informed decisions that improve performance and reduce operational costs. Leveraging partnerships with reputable suppliers not only ensures quality but also fosters innovation in product development.

As the automotive industry evolves, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for high-quality alternator parts will continue to rise. Buyers are encouraged to adopt a proactive approach to sourcing, focusing on suppliers who prioritize sustainability and technological advancements. Embracing these practices will position businesses to meet the growing expectations of consumers and regulatory standards effectively.

Illustrative image related to vehicle alternator parts

Looking ahead, the future of vehicle alternator parts sourcing is promising, marked by advancements in manufacturing and materials that enhance durability and efficiency. International buyers should actively explore opportunities to collaborate with forward-thinking suppliers to stay ahead in this competitive market. By prioritizing strategic sourcing, businesses can drive growth and ensure their long-term success in the automotive sector.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.