Einleitung: Navigieren auf dem globalen Markt für Probleme mit Anlasser und Lichtmaschine

In der komplizierten Landschaft der Kfz-Wartung ist es für internationale B2B-Einkäufer von entscheidender Bedeutung, die Nuancen zwischen Anlasser- und Lichtmaschinenproblemen zu verstehen. Unabhängig davon, ob Sie Zulieferer, Fuhrparkleiter oder Dienstleister sind, kann die effektive Diagnose und Beschaffung der richtigen Komponenten die betriebliche Effizienz und Kundenzufriedenheit erheblich beeinflussen. Dieser Leitfaden befasst sich mit der Komplexität dieser kritischen Fahrzeugkomponenten, mit häufigen Ausfallerscheinungen, mit den Auswirkungen auf die Wartung und mit den entscheidenden Unterschieden zwischen Anlasser und Lichtmaschine.

Während wir durch verschiedene Typen, Anwendungen und potenzielle Herausforderungen navigieren, erhalten Einkäufer Einblicke in Lieferantenprüfungsverfahren, Kostenüberlegungen und effektive Techniken zur Fehlerbehebung. Von den belebten Märkten Nigerias bis zu den industriellen Zentren Deutschlands finden Entscheidungsträger wertvolle Informationen, die auf ihre regionalen Gegebenheiten und spezifischen Bedürfnisse zugeschnitten sind. Der Leitfaden soll Ihnen das nötige Wissen vermitteln, um fundierte Kaufentscheidungen zu treffen und sicherzustellen, dass Ihre Flotte in einem zunehmend wettbewerbsorientierten globalen Markt zuverlässig und effizient bleibt.

Durch die Hervorhebung von umsetzbaren Strategien und Best Practices dient diese umfassende Ressource als wichtiges Hilfsmittel für Unternehmen, die ihre Beschaffung von Automobilkomponenten optimieren möchten, um letztlich ihr Dienstleistungsangebot und ihren Gewinn zu verbessern.

Inhaltsverzeichnis

- Top 3 Starter Vs Alternator Probleme Hersteller & Lieferanten Liste

- Einleitung: Navigieren auf dem globalen Markt für Probleme mit Anlasser und Lichtmaschine

- Verstehen von Problemen zwischen Anlasser und Lichtmaschine - Typen und Variationen

- Wichtige industrielle Anwendungen von Problemen zwischen Anlasser und Lichtmaschine

- 3 häufige Schmerzpunkte von Benutzern bei Problemen mit dem Anlasser oder der Lichtmaschine und deren Lösungen

- Leitfaden für die strategische Materialauswahl bei Problemen zwischen Anlasser und Lichtmaschine

- Eingehender Blick: Fertigungsprozesse und Qualitätssicherung bei Problemen mit Anlassern und Lichtmaschinen

- Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Probleme mit dem Anlasser oder der Lichtmaschine’

- Umfassende Kosten- und Preisanalyse für Probleme bei der Beschaffung von Anlassern und Lichtmaschinen

- Analyse der Alternativen: Vergleich von Anlasser- und Lichtmaschinenproblemen mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für Probleme zwischen Anlasser und Lichtmaschine

- Marktdynamik und Beschaffungstrends im Sektor Probleme mit Anlassern und Lichtmaschinen navigieren

- Häufig gestellte Fragen (FAQs) für B2B-Käufer bei Problemen mit Anlasser und Lichtmaschine

- Strategische Beschaffung Schlussfolgerung und Ausblick für Probleme mit Anlasser und Lichtmaschine

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Verstehen von Problemen zwischen Anlasser und Lichtmaschine - Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Ausfall des Anlassers | Zu den Symptomen gehören Klickgeräusche, kein Anlassen des Motors und Hitze. | Gewerbliche Flotten, Logistikunternehmen | Vorteile: Schnelle Diagnose; Nachteile: Möglicherweise längere Ausfallzeiten. |

| Ausfall der Lichtmaschine | Abgeschwächte Scheinwerfer, Störungen der elektrischen Anlage und Batterieprobleme. | Transport- und Lieferdienste | Vorteile: Verbesserte Zuverlässigkeit der Fahrzeuge; Nachteile: Möglicherweise ist ein vollständiger Austausch erforderlich. |

| Probleme mit der Batterieentladung | Langsames Anlassen, Anschwellen der Batterie und Ausfälle von elektrischen Komponenten. | Autowerkstätten, Flottenmanagement | Vorteile: Kostengünstige Lösungen verfügbar; Nachteile: Erfordert regelmäßige Wartungskontrollen. |

| Korrosionsprobleme | Sichtbare Korrosion an Klemmen, schlechte elektrische Verbindungen. | Anbieter von Fahrzeugwartung | Vorteile: Vorbeugende Maßnahmen können die Lebensdauer verlängern; Nachteile: Kann eine professionelle Reinigung erfordern. |

| Fehler bei der Installation | Fehlausrichtung, lose Verbindungen und Überspannung. | Fahrzeugmontage- und -reparaturbetriebe | Vorteile: Reduziert zukünftige Reparaturkosten; Nachteile: Die Ersteinrichtung kann zeitaufwändig sein. |

Was sind die Merkmale eines Anlasserschadens?

Ein Ausfall des Anlassers macht sich oft durch hörbare Klickgeräusche beim Versuch, das Fahrzeug zu starten, durch einen nicht anspringenden Motor oder sogar durch Rauch aufgrund von Überhitzung bemerkbar. Diese Art des Ausfalls tritt häufig in kommerziellen Flotten und Logistikunternehmen auf, wo Fahrzeuge für den Betrieb entscheidend sind. Für B2B-Kunden kann die Kenntnis der Anzeichen von Anlasserproblemen zu schnelleren Reparaturen führen und die Ausfallzeiten minimieren. Das Vertrauen in einen defekten Anlasser kann jedoch zu einem längeren Stillstand des Fahrzeugs führen und die Produktivität beeinträchtigen.

Wie erkennt man den Ausfall der Lichtmaschine in Fahrzeugen?

Ein Ausfall der Lichtmaschine macht sich durch Abblenden der Scheinwerfer, unregelmäßiges Verhalten des elektrischen Systems und häufige Probleme mit der Batterie bemerkbar. Dieses Problem ist besonders für Transport- und Lieferdienste von Bedeutung, bei denen Zuverlässigkeit an erster Stelle steht. Das frühzeitige Erkennen von Lichtmaschinenproblemen kann unerwartete Fahrzeugausfälle verhindern. B2B-Käufer sollten erwägen, in qualitativ hochwertige Lichtmaschinen zu investieren, um die Leistung des Fahrzeugs zu verbessern, auch wenn ein möglicher Komplettaustausch mit höheren Kosten verbunden sein kann.

Was sind die Ursachen für Probleme mit der Batterieentladung?

Probleme mit der Batterieentladung zeigen sich durch langsames Anlassen des Motors, aufgequollene Batterien und ausfallende elektrische Komponenten. Dieses Problem tritt häufig in Kfz-Werkstätten und im Fuhrparkmanagement auf, wo die Zuverlässigkeit des Fahrzeugs entscheidend ist. Eine rasche Behebung von Batterieproblemen kann langfristig Kosten sparen. Käufer sollten sich jedoch darüber im Klaren sein, dass regelmäßige Wartungsarbeiten notwendig sind, um unerwartete Ausfälle zu vermeiden.

Wie wirken sich Korrosionsprobleme auf die Fahrzeugleistung aus?

Korrosionsprobleme äußern sich häufig in Form von sichtbaren Schäden an Batteriepolen und schlechten elektrischen Verbindungen. Dieses Problem ist für Anbieter von Fahrzeugwartung von entscheidender Bedeutung, da es die Zuverlässigkeit des Fahrzeugs erheblich beeinträchtigen kann. Vorbeugende Maßnahmen, wie regelmäßige Inspektionen, können die Lebensdauer der Komponenten verlängern. Käufer sollten sich jedoch auf mögliche Kosten einstellen, die mit einer professionellen Reinigung und Wartung verbunden sind.

Warum sind Installationsfehler ein Problem für den Fahrzeugbetrieb?

Einbaufehler, wie z. B. eine falsche Ausrichtung oder lose Verbindungen, können zu erheblichen Problemen am Fahrzeug führen. Dies ist besonders für Fahrzeugmontage- und -reparaturbetriebe von Bedeutung, bei denen Genauigkeit entscheidend ist. Die Behebung von Einbaufehlern kann künftige Reparaturkosten senken und die betriebliche Effizienz steigern. B2B-Einkäufer müssen jedoch die Zeit einkalkulieren, die für die ordnungsgemäße Einrichtung erforderlich ist und die den Arbeitsablauf zunächst stören kann.

Wichtige industrielle Anwendungen von Problemen zwischen Anlasser und Lichtmaschine

| Branche/Sektor | Spezifische Anwendung von Problemen zwischen Anlasser und Lichtmaschine | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Diagnose von elektrischen Fehlern in Fahrzeugen für Reparaturdienste | Reduziert Ausfallzeiten und erhöht die Kundenzufriedenheit | Zuverlässige Diagnosewerkzeuge, geschulte Techniker, hochwertige Ersatzteile |

| Transport & Logistik | Sicherstellung der Betriebsbereitschaft der Fahrzeuge durch regelmäßige Wartung | Minimierung von Verzögerungen und Betriebskosten | Großeinkaufsvereinbarungen, Garantieüberlegungen, lokale Lieferanten |

| Landwirtschaft | Landmaschinen effizient starten | Erhöht die Produktivität in kritischen landwirtschaftlichen Jahreszeiten | Verfügbarkeit von Teilen in entlegenen Gebieten, Kompatibilität mit verschiedenen Maschinen |

| Bergbau | Antrieb von schweren Maschinen und Fahrzeugen in schwierigen Umgebungen | Gewährleistet einen kontinuierlichen Betrieb und reduziert die Wartungskosten | Robuste Komponenten, Zuverlässigkeit der Lieferanten und Serviceunterstützung |

| Bauwesen | Sicherstellen, dass Geräte wie Generatoren und Bagger voll funktionsfähig sind | Verhindert Projektverzögerungen und steigert die Produktivität auf der Baustelle | Qualitätssicherung, Lieferzeiten für Ersatzteile und Kundendienst |

Wie wirken sich Probleme mit dem Anlasser oder der Lichtmaschine auf die Kfz-Reparatur aus?

In der Kfz-Reparaturbranche ist die Diagnose von Anlasser- und Lichtmaschinenproblemen von entscheidender Bedeutung für eine effektive Leistungserbringung. Die Werkstätten müssen schnell feststellen, ob das Nichtstarten eines Fahrzeugs auf eine Fehlfunktion des Anlassers, der Lichtmaschine oder der Batterie zurückzuführen ist. Dies verkürzt nicht nur die Zeit, die ein Fahrzeug in der Werkstatt verbringt, sondern erhöht auch die Kundenzufriedenheit, da zeitnahe Lösungen angeboten werden. B2B-Einkäufer in diesem Sektor sollten die Beschaffung zuverlässiger Diagnosewerkzeuge und hochwertiger Ersatzteile in Betracht ziehen, um effiziente Reparaturen zu gewährleisten und einen guten Ruf zu erhalten.

Welche Rolle spielen Anlasser- und Lichtmaschinenprobleme in Transport und Logistik?

In der Transport- und Logistikbranche ist die Zuverlässigkeit von Flottenfahrzeugen von größter Bedeutung. Probleme mit Anlassern und Lichtmaschinen können zu unerwarteten Ausfällen und damit zu kostspieligen Verzögerungen führen. Regelmäßige Wartung und schnelle Diagnose sind unerlässlich, damit die Fahrzeuge einsatzbereit bleiben. B2B-Einkäufer sollten sich nach Lieferanten umsehen, die Großeinkaufsvereinbarungen für Teile anbieten, um eine ständige Versorgung mit wichtigen Komponenten zu wettbewerbsfähigen Preisen sicherzustellen. Darüber hinaus kann die Berücksichtigung von Garantieleistungen die Langlebigkeit und Zuverlässigkeit der beschafften Teile sicherstellen.

Warum sind Starterprobleme in der Landwirtschaft von Bedeutung?

Landmaschinen arbeiten oft unter anspruchsvollen Bedingungen, und Startprobleme können die Produktivität während der entscheidenden Pflanz- und Erntezeiten erheblich beeinträchtigen. Für Landwirte ist es von entscheidender Bedeutung, dass Traktoren und andere Geräte zuverlässig anspringen. B2B-Einkäufer in dieser Branche müssen bei der Beschaffung von Komponenten darauf achten, dass diese nicht nur langlebig, sondern auch in ländlichen Gebieten leicht erhältlich sind, um Ausfallzeiten zu minimieren. Ein weiterer wichtiger Aspekt ist die Kompatibilität mit verschiedenen Maschinentypen, da in landwirtschaftlichen Betrieben häufig unterschiedliche Geräte zum Einsatz kommen.

Wie wirken sich Probleme mit Anlassern und Lichtmaschinen auf den Bergbau aus?

Im Bergbau ist die Zuverlässigkeit schwerer Maschinen entscheidend für den kontinuierlichen Betrieb. Ausfälle von Anlassern und Lichtmaschinen können zu erheblichen Ausfallzeiten führen, die die Produktivität beeinträchtigen und die Betriebskosten erhöhen. Bergbauunternehmen benötigen robuste Komponenten, die rauen Umgebungen standhalten können. B2B-Einkäufer sollten sich auf die Beschaffung bei Lieferanten konzentrieren, die für ihre Zuverlässigkeit und ihren Service bekannt sind, um sicherzustellen, dass Probleme schnell behoben werden können, damit es zu möglichst wenig Unterbrechungen kommt.

Welche Auswirkungen haben Probleme mit Anlassern und Lichtmaschinen im Baugewerbe?

Baustellen sind in hohem Maße von Geräten wie Generatoren und Baggern abhängig, die jederzeit einsatzbereit sein müssen. Probleme mit Anlassern und Lichtmaschinen können zu unerwarteten Verzögerungen und höheren Kosten führen. B2B-Einkäufer in diesem Sektor sollten bei der Beschaffung von Komponenten der Qualitätssicherung Vorrang einräumen und die Vorlaufzeiten für die Lieferung von Teilen berücksichtigen. Ein zuverlässiger Kundendienst ist ebenfalls von entscheidender Bedeutung, um sicherzustellen, dass etwaige Probleme schnell gelöst werden können und die Projekte im Zeit- und Kostenrahmen bleiben.

3 häufige Schmerzpunkte von Benutzern bei Problemen mit dem Anlasser oder der Lichtmaschine und deren Lösungen

Szenario 1: Diagnose des richtigen Komponentenfehlers

Das Problem:

B2B-Einkäufer, insbesondere Fuhrparkmanager oder Fahrzeugwartungsdienstleister, stehen oft vor der Herausforderung, zu diagnostizieren, ob ein Startproblem durch den Anlasser, die Lichtmaschine oder die Batterie verursacht wird. Diese Unklarheit kann zu Fehldiagnosen führen, die unnötigen Austausch von Teilen und verschwendete Arbeitskosten zur Folge haben. Ein Fuhrparkmanager in Nigeria könnte beispielsweise häufige Fahrzeugausfälle aufgrund schlecht koordinierter elektrischer Systeme erleben, was zu Verzögerungen bei der Leistungserbringung und erhöhten Betriebskosten führt.

Die Lösung:

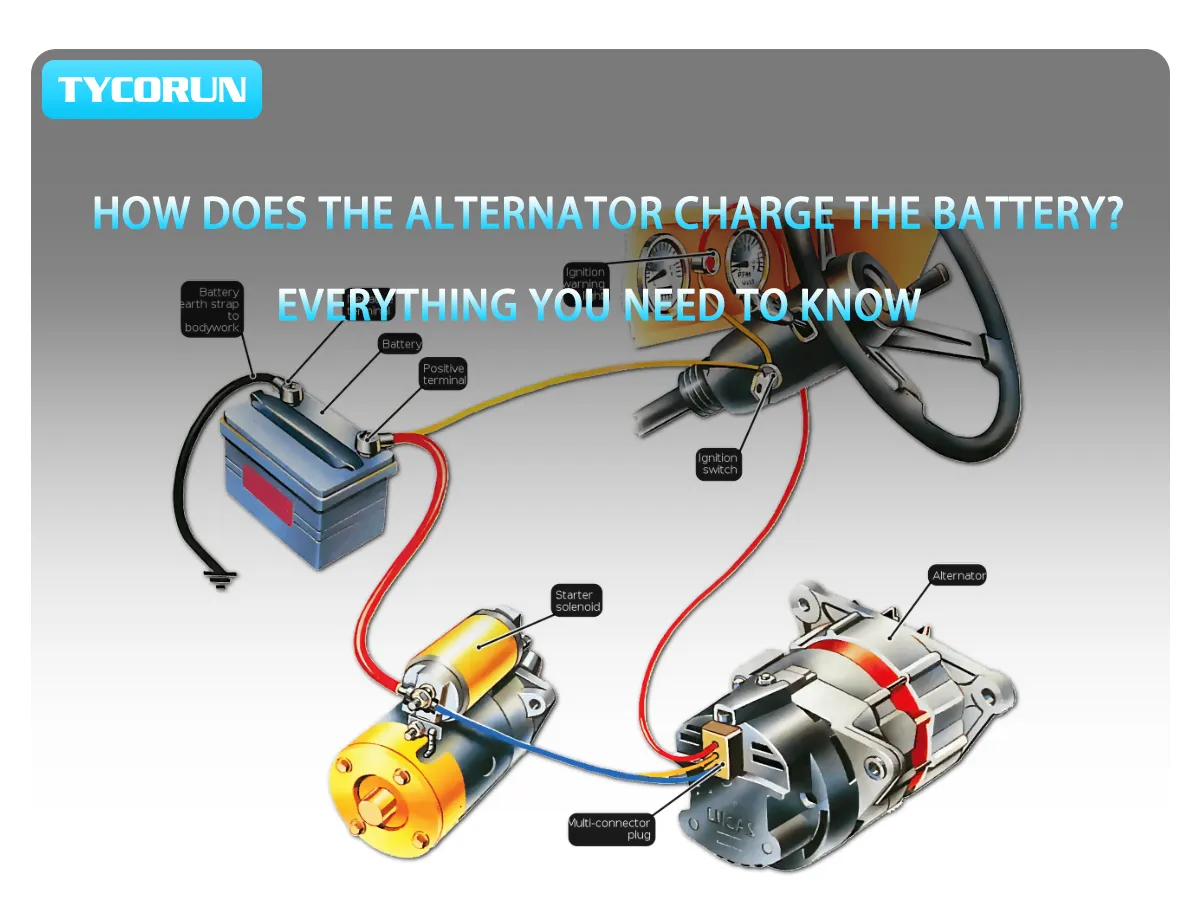

Um das Problem genau zu diagnostizieren, sollten Sie eine systematische Fehlersuche durchführen. Führen Sie zunächst einen Starthilfetest durch: Wenn das Fahrzeug mit Starthilfekabeln anspringt, aber nach dem Abklemmen abstirbt, ist wahrscheinlich die Lichtmaschine defekt. Springt es dagegen überhaupt nicht an, liegt das Problem möglicherweise am Anlasser oder an der Batterie. Verwenden Sie Diagnosegeräte wie Multimeter, um die Ausgangsspannung der Lichtmaschine und den Zustand der Batterie zu überprüfen. Fördern Sie außerdem regelmäßige Wartungsprüfungen, bei denen auch die elektrischen Komponenten in Verbindung miteinander getestet werden. Dieser proaktive Ansatz minimiert nicht nur die Ausfallzeiten, sondern hilft auch bei der Budgetierung notwendiger Reparaturen oder Ersatzbeschaffungen und gewährleistet die Zuverlässigkeit des Fuhrparks.

Szenario 2: Bewältigung von Umweltproblemen mit Auswirkungen auf die Leistung

Das Problem:

In Regionen mit extremen Wetterbedingungen - wie der hohen Luftfeuchtigkeit in Südamerika oder den eisigen Wintern in Deutschland - sehen sich B2B-Käufer häufig mit einem beschleunigten Verschleiß von Anlassern und Lichtmaschinen konfrontiert. Ein Bauunternehmen in Deutschland könnte beispielsweise nach einem besonders strengen Winter feststellen, dass die Ausrüstung aufgrund einer korrodierten Lichtmaschine nicht anspringt, was zu kostspieligen Projektverzögerungen und geringerer Produktivität führt.

Die Lösung:

Um die Auswirkungen auf die Umwelt zu verringern, sollten Sie die Beschaffung von Hochleistungsstartern und -generatoren in Erwägung ziehen, die speziell für extreme Wetterbedingungen ausgelegt sind. Diese Komponenten verfügen in der Regel über verbesserte Dichtungen und korrosionsbeständige Materialien. Empfehlen Sie den Käufern außerdem, regelmäßige Inspektionen durchzuführen, die auch die Reinigung und den Schutz der elektrischen Anschlüsse vor Feuchtigkeit und Korrosion umfassen. Die Aufklärung der Kunden über die Bedeutung der saisonalen Wartung - wie die Überprüfung des Flüssigkeitsstands und des Zustands der Batterie - kann ebenfalls dazu beitragen, die Lebensdauer dieser Komponenten zu verlängern, was letztendlich die ungeplanten Wartungskosten reduziert und die Projektlaufzeiten verkürzt.

Szenario 3: Verständnis von Installations- und Kompatibilitätsproblemen

Das Problem:

B2B-Einkäufer, vor allem in der Kfz-Reparaturbranche, haben oft mit Installationsproblemen bei Anlassern und Lichtmaschinen zu kämpfen. Ein unsachgemäßer Einbau kann zu einer falschen Ausrichtung oder Überspannung der Riemen führen, was wiederum vorzeitige Ausfälle zur Folge haben kann. Eine Reparaturwerkstatt im Nahen Osten könnte beispielsweise häufig mit Kundenbeschwerden über wiederholte Ausfälle bei neu installierten Lichtmaschinen konfrontiert werden, was zu Unzufriedenheit und potenziellen Geschäftseinbußen führt.

Die Lösung:

Um den Herausforderungen bei der Installation zu begegnen, ist es wichtig, die Bedeutung der Einhaltung der Herstellerspezifikationen während des Installationsprozesses zu betonen. Bieten Sie Schulungen für Techniker zu korrekten Ausrichtungsverfahren und Drehmomentangaben für Anlasser und Generatoren an. Fördern Sie die Verwendung von OEM-Teilen (Original Equipment Manufacturer), da diese für bestimmte Fahrzeugmodelle entwickelt wurden und in der Regel besser passen, wodurch die Gefahr von Einbaufehlern verringert wird. Darüber hinaus kann die Einführung einer Checkliste für die Qualitätskontrolle bei der Installation dazu beitragen, dass alle Komponenten korrekt installiert werden, was die Kundenzufriedenheit erhöht und die Zahl der wiederholten Serviceanrufe verringert. Diese proaktive Strategie stärkt nicht nur den Ruf der Werkstätten, sondern fördert auch langfristige Kundenbeziehungen.

Leitfaden für die strategische Materialauswahl bei Problemen zwischen Anlasser und Lichtmaschine

Welche Materialien werden üblicherweise in Startern und Generatoren verwendet?

Bei der Lösung von Problemen mit Anlassern und Lichtmaschinen spielen die in ihrer Konstruktion verwendeten Materialien eine entscheidende Rolle für die Leistung, Haltbarkeit und allgemeine Effektivität. Das Verständnis der Eigenschaften, Vorteile und Grenzen dieser Materialien ist für internationale B2B-Einkäufer unerlässlich, insbesondere für diejenigen, die in unterschiedlichen Umgebungen wie Afrika, Südamerika, dem Nahen Osten und Europa tätig sind.

Was sind die wichtigsten Eigenschaften von Kupfer in Startern und Generatoren?

Kupfer wird aufgrund seiner hervorragenden Leitfähigkeit häufig für elektrische Verbindungen in Startern und Lichtmaschinen verwendet. Es hat einen hohen Schmelzpunkt von ca. 1.984°F (1.085°C) und bietet eine gute Korrosionsbeständigkeit, insbesondere wenn es beschichtet ist.

Vorteile: Die hohe Leitfähigkeit von Kupfer gewährleistet eine effiziente elektrische Übertragung, die für die Leistung von Anlassern und Lichtmaschinen unerlässlich ist. Dank seiner Formbarkeit lassen sich Drähte und Steckverbinder leicht formen.

Nachteile: Kupfer ist jedoch im Vergleich zu anderen Metallen relativ teuer, und seine Korrosionsanfälligkeit in rauen Umgebungen kann zu Ausfällen führen, wenn es nicht richtig behandelt wird.

Auswirkungen auf die Anwendung: In Regionen mit hoher Luftfeuchtigkeit oder Salzwasserbelastung sind korrosionsbeständige Beschichtungen notwendig, um die Lebensdauer von Kupferbauteilen zu verlängern.

Überlegungen für internationale Käufer: Die Einhaltung von Normen wie ASTM B170 für Kupferdraht ist unerlässlich. Käufer sollten auch die örtlichen klimatischen Bedingungen berücksichtigen, die die Leistung von Kupfer beeinträchtigen können.

Wie schneidet Aluminium bei der Verwendung in Anlassern und Lichtmaschinen ab?

Aluminium ist ein weiteres gängiges Material, insbesondere für die Gehäuse von Anlassern und Lichtmaschinen. Es hat eine geringere Dichte als Kupfer und ist daher leichter und einfacher zu handhaben.

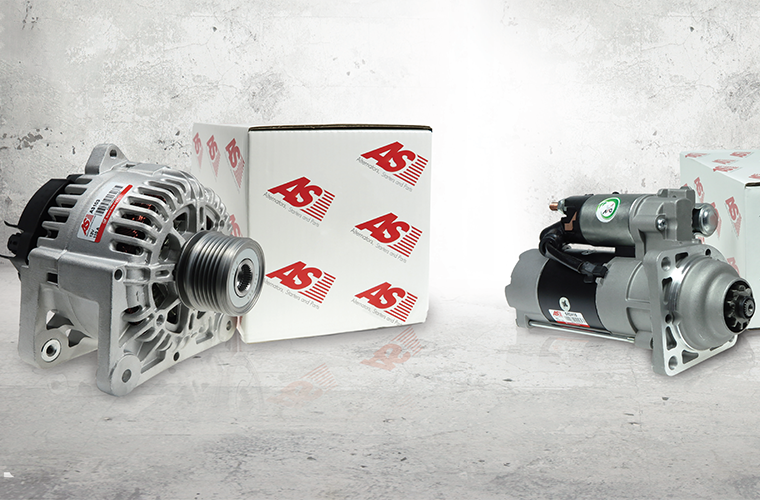

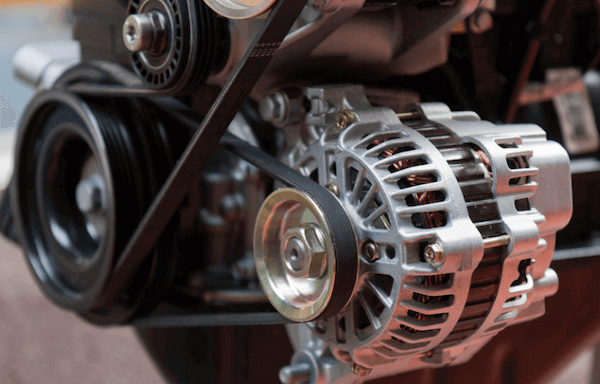

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Vorteile: Aluminium ist kostengünstig und bietet eine gute Korrosionsbeständigkeit, insbesondere wenn es eloxiert ist. Sein geringes Gewicht kann die Kraftstoffeffizienz von Fahrzeugen verbessern.

Nachteile: Aluminium hat jedoch eine geringere elektrische Leitfähigkeit als Kupfer, was bei falscher Auslegung zu Energieverlusten führen kann.

Auswirkungen auf die Anwendung: Aluminiumbauteile müssen so konstruiert sein, dass sie der Wärmeausdehnung standhalten, die während des Betriebs auftritt, insbesondere in heißeren Klimazonen.

Überlegungen für internationale Käufer: Die Einhaltung internationaler Normen wie der DIN 1725 für Aluminiumlegierungen ist entscheidend. Die Käufer sollten sich über die lokale Verfügbarkeit von Aluminium und dessen Verarbeitungsprozesse im Klaren sein.

Welche Rolle spielt Stahl bei Startern und Generatoren?

Stahl wird häufig für die strukturellen Komponenten von Anlassern und Lichtmaschinen verwendet, z. B. für das Gehäuse und die Montagehalterungen.

Vorteile: Stahl bietet eine hohe Festigkeit und Haltbarkeit, so dass er sich für robuste Anwendungen eignet. Außerdem ist er im Vergleich zu Kupfer und Aluminium relativ preiswert.

Nachteile: Stahl ist jedoch anfällig für Rost und Korrosion, wenn er nicht ordnungsgemäß beschichtet wird, was im Laufe der Zeit zu strukturellen Mängeln führen kann.

Auswirkungen auf die Anwendung: In Umgebungen mit hoher Feuchtigkeit oder korrosiven Elementen können Schutzbeschichtungen oder Optionen aus rostfreiem Stahl erforderlich sein.

Überlegungen für internationale Käufer: Die Einhaltung von Normen wie ASTM A36 für Baustahl ist wichtig. Käufer sollten die örtlichen Vorschriften für die Verwendung von beschichtetem und unbeschichtetem Stahl berücksichtigen.

Warum wird Kunststoff in Startern und Lichtmaschinen verwendet?

Kunststoff wird häufig zur Isolierung und als leichte Alternative für nicht strukturelle Komponenten in Startern und Generatoren verwendet.

Vorteile: Kunststoff ist leicht, kostengünstig und bietet gute elektrische Isolationseigenschaften. Außerdem kann er in komplexe Formen gegossen werden und ermöglicht so vielseitige Designs.

Nachteile: Allerdings können sich Kunststoffe bei hohen Temperaturen oder UV-Licht zersetzen, was ihre Verwendung bei bestimmten Anwendungen einschränken kann.

Auswirkungen auf die Anwendung: In Umgebungen mit hohen Temperaturen ist die Auswahl hitzebeständiger Kunststoffe entscheidend für die Langlebigkeit.

Überlegungen für internationale Käufer: Die Einhaltung von Materialsicherheitsnormen wie ISO 9001 ist für die Gewährleistung der Qualität unerlässlich. Die Käufer sollten prüfen, welche Kunststoffsorten für ihre Anwendungen geeignet sind.

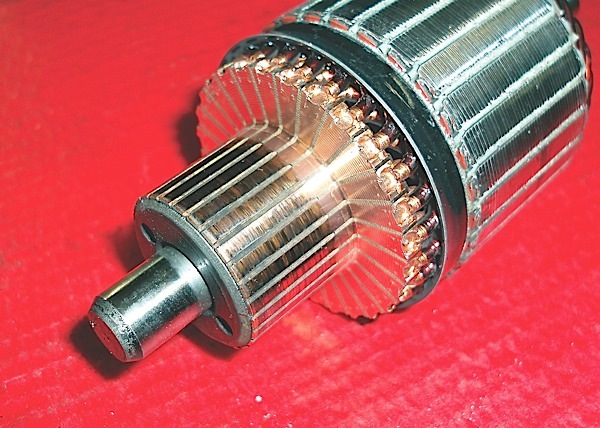

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Übersichtstabelle zur Materialauswahl für Anlasser und Lichtmaschinen

| Material | Typischer Anwendungsfall für Probleme zwischen Anlasser und Lichtmaschine | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse und Verkabelung | Hervorragende Leitfähigkeit | Hohe Kosten und Korrosionsanfälligkeit | Hoch |

| Aluminium | Gehäuse und Bauteile | Leicht und kostengünstig | Geringere Leitfähigkeit als Kupfer | Mittel |

| Stahl | Strukturelle Komponenten wie Gehäuse | Hohe Festigkeit und Haltbarkeit | Anfällig für Rost und Korrosion | Niedrig |

| Kunststoff | Isolierung und nicht-strukturelle Komponenten | Leicht und vielseitig | Zersetzt sich bei hohen Temperaturen | Niedrig |

Dieser strategische Leitfaden für die Materialauswahl bietet B2B-Einkäufern wichtige Einblicke und ermöglicht fundierte Entscheidungen, die die Leistung und Zuverlässigkeit von Startern und Generatoren in verschiedenen Betriebsumgebungen verbessern können.

Eingehender Blick: Fertigungsprozesse und Qualitätssicherung bei Problemen mit Anlassern und Lichtmaschinen

Was sind die wichtigsten Herstellungsverfahren für Anlasser und Lichtmaschinen?

Die Herstellung von Anlassern und Lichtmaschinen umfasst eine Reihe genau festgelegter Schritte, die hohe Qualität und Leistung gewährleisten. Das Verständnis dieser Prozesse ist für B2B-Einkäufer, die zuverlässige Komponenten für Automobilanwendungen suchen, entscheidend.

Was sind die wichtigsten Schritte im Herstellungsprozess?

-

Materialvorbereitung: Der Herstellungsprozess beginnt mit der Auswahl hochwertiger Rohmaterialien. Zunächst einmal sind Komponenten wie Kupfer für die Wicklungen, Stahl für die Zahnräder und hochwertige Kunststoffe für die Gehäuse üblich. Für Generatoren werden wegen ihres geringen Gewichts und ihrer hervorragenden Leitfähigkeit vor allem Aluminium und Kupfer verwendet. Häufig werden Materialtests durchgeführt, um die Einhaltung der Spezifikationen zu gewährleisten.

-

Formung: In dieser Phase werden die Rohmaterialien zu Teilen geformt. Techniken wie Stanzen, Schmieden und maschinelle Bearbeitung werden eingesetzt, um Komponenten wie den Rotor, den Stator und das Gehäuse herzustellen. Präzision ist dabei von größter Bedeutung, da schon geringe Abweichungen zu Leistungsproblemen führen können. Moderne Fertigungstechnologien wie CNC-Bearbeitung und Laserschneiden werden häufig eingesetzt, um die erforderlichen Toleranzen zu erreichen.

-

Montage: Bei der Montage werden die einzelnen Komponenten zusammengefügt. Automatisierte Montagelinien werden häufig eingesetzt, um die Effizienz und Genauigkeit zu verbessern. Die Komponenten werden in einer bestimmten Reihenfolge zusammengebaut, wobei häufig elektrische Verbindungen und mechanische Teile integriert werden müssen. Die Qualitätssicherung bei der Montage ist von entscheidender Bedeutung, da Fehler die Funktionalität der gesamten Einheit beeinträchtigen können.

-

Endbearbeitung: Nach der Montage werden die Bauteile einer Endbearbeitung wie Lackieren, Beschichten oder Polieren unterzogen. Dies verbessert nicht nur die Ästhetik, sondern bietet auch Schutz vor Korrosion und Verschleiß. Bei elektrischen Bauteilen ist die Isolierung entscheidend, um Kurzschlüsse zu verhindern. Die abschließende Prüfung stellt sicher, dass das Produkt alle Spezifikationen erfüllt.

Wie wird die Qualitätssicherung in den Fertigungsprozess integriert?

Die Qualitätssicherung (QS) ist ein wichtiger Bestandteil des gesamten Herstellungsprozesses, um sicherzustellen, dass jeder Anlasser und jeder Generator den internationalen Normen und den Erwartungen der Kunden entspricht.

Welches sind die einschlägigen internationalen Normen für die Qualitätssicherung?

B2B-Einkäufer sollten die verschiedenen internationalen Normen kennen, die die Fertigungsqualität regeln. ISO 9001 ist eine der anerkanntesten Normen, die sich auf Qualitätsmanagementsysteme konzentriert. Die Einhaltung der ISO 9001 gewährleistet, dass die Hersteller über Verfahren zur kontinuierlichen Verbesserung und Kundenzufriedenheit verfügen.

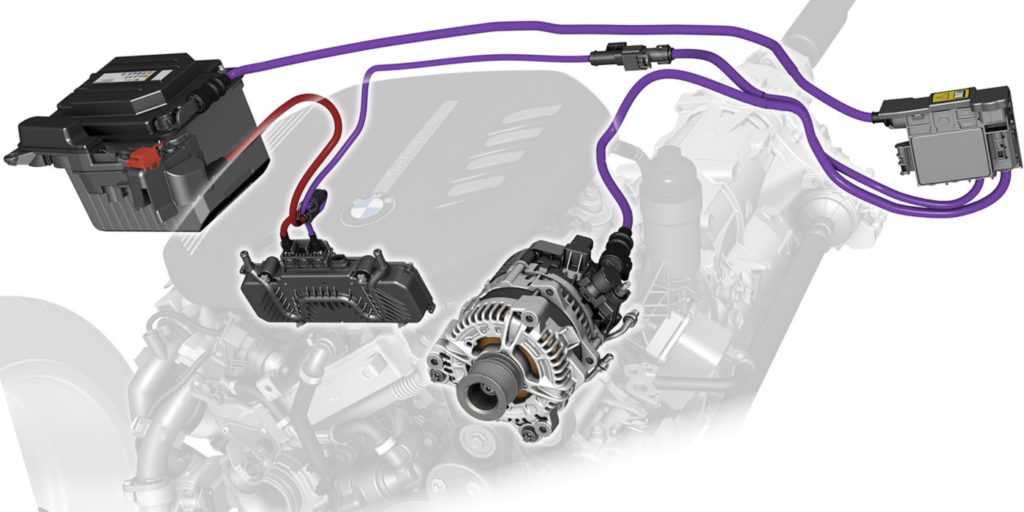

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Zusätzlich zu den ISO-Normen bieten branchenspezifische Zertifizierungen wie CE (Conformité Européenne) für die europäischen Märkte und API (American Petroleum Institute) für bestimmte Anwendungen in der Automobilindustrie eine zusätzliche Garantie für Produktqualität und Sicherheit.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle?

Die Kontrollpunkte der Qualitätskontrolle (QC) sind strategisch in den gesamten Herstellungsprozess integriert:

-

Eingangsqualitätskontrolle (IQC): Bei diesem Kontrollpunkt werden die Rohstoffe vor ihrer Verwendung in der Produktion geprüft. Die Überprüfung der Materialspezifikationen stellt sicher, dass nur qualitativ hochwertige Materialien in den Herstellungsprozess gelangen.

-

In-Process-Qualitätskontrolle (IPQC): Während der Produktion werden verschiedene Inspektionen durchgeführt, um die Qualität der Komponenten in verschiedenen Phasen zu überwachen. Dazu gehören Maßkontrollen, Funktionstests und Sichtkontrollen, um Mängel frühzeitig zu erkennen.

-

Endkontrolle (FQC): Sobald die Produkte zusammengebaut sind, werden Endkontrollen durchgeführt, um sicherzustellen, dass sie alle Spezifikationen erfüllen. Häufig werden Funktionstests durchgeführt, um die Leistung unter Lastbedingungen zu überprüfen.

Welche gängigen Prüfverfahren werden eingesetzt?

Um die Zuverlässigkeit und Leistung von Startern und Generatoren zu gewährleisten, werden in der Regel verschiedene Prüfverfahren angewandt:

-

Elektrische Prüfung: Dazu gehört die Überprüfung der Ausgangsspannung, der Stromaufnahme und der Widerstandsmessungen. Für den Anfang sind Lasttests entscheidend, um sicherzustellen, dass sie die Anforderungen des Motors erfüllen können. Bei Lichtmaschinen wird geprüft, ob sie in der Lage sind, die Batterie effektiv zu laden.

-

Mechanische Prüfung: Dabei werden die strukturelle Integrität und die Verschleißfestigkeit geprüft. Vibrationstests, Temperaturwechsel und Drehmomenttests werden durchgeführt, um reale Bedingungen zu simulieren.

-

Umweltprüfungen: Die Komponenten werden extremen Temperaturen, Feuchtigkeit und Korrosionstests unterzogen, um sicherzustellen, dass sie verschiedenen Betriebsumgebungen standhalten können.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

Für B2B-Einkäufer ist die Überprüfung der Qualitätskontrollverfahren eines Lieferanten unerlässlich, um die Zuverlässigkeit der gekauften Komponenten zu gewährleisten. Hier sind einige Strategien:

-

Lieferantenaudits: Die Durchführung von Audits vor Ort ermöglicht es den Einkäufern, die Herstellungsverfahren, die Qualitätskontrollmaßnahmen und die Einhaltung der Normen zu bewerten. Diese Beurteilung aus erster Hand kann Einblicke in die Fähigkeiten des Lieferanten geben.

-

Qualitätsberichte: Die Anforderung detaillierter Qualitätsberichte kann den Einkäufern helfen, die Leistungskennzahlen des Lieferanten zu verstehen, einschließlich der Fehlerraten, der Einhaltung von Normen und der Ergebnisse von Qualitätstests.

-

Inspektionen durch Dritte: Die Beauftragung von Inspektionsdiensten durch Dritte ermöglicht eine unvoreingenommene Bewertung der Qualitätskontrollverfahren des Lieferanten. Diese Organisationen können Audits und Tests durchführen, um die Angaben des Herstellers zu validieren.

Was sind die Besonderheiten bei der Qualitätskontrolle und Zertifizierung für internationale Käufer?

Internationale Käufer, insbesondere aus verschiedenen Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, sollten sich der Nuancen bei der Qualitätskontrolle und Zertifizierung bewusst sein.

-

Einhaltung gesetzlicher Vorschriften: In verschiedenen Regionen können unterschiedliche Vorschriften für Automobilkomponenten gelten. Es ist wichtig, dass die Einkäufer die lokalen Compliance-Anforderungen kennen und sicherstellen, dass die Lieferanten diese Standards erfüllen können.

-

Kulturelle Unterschiede bei den Qualitätserwartungen: Die Qualitätswahrnehmung kann von Region zu Region unterschiedlich sein. Die Käufer sollten ihre spezifischen Qualitätserwartungen klar kommunizieren, um Missverständnisse zu vermeiden.

-

Logistische Überlegungen: Versand und Transport können die Produktintegrität beeinträchtigen. Käufer sollten sicherstellen, dass ihre Lieferanten über robuste Verpackungs- und Handhabungsverfahren verfügen, um Schäden während des Transports zu minimieren.

Schlussfolgerung

Für B2B-Einkäufer ist es wichtig, die Herstellungsverfahren und Qualitätssicherungsprotokolle für Anlasser und Lichtmaschinen zu verstehen. Indem sie sich auf die Materialvorbereitung, die Formgebung, die Montage und die Endbearbeitung sowie auf strenge Qualitätskontrollmaßnahmen konzentrieren, können Einkäufer sicherstellen, dass sie zuverlässige Komponenten beziehen. Das Wissen um internationale Normen und Prüfstrategien wird den Einkäufern helfen, fundierte Entscheidungen zu treffen und letztlich ihre betriebliche Effizienz und Produktzuverlässigkeit auf dem wettbewerbsintensiven Automobilmarkt zu verbessern.

Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Probleme mit dem Anlasser oder der Lichtmaschine’

Einführung

Die Komplexität der Beschaffung von Komponenten für elektrische Systeme in Kraftfahrzeugen kann entmutigend sein, insbesondere wenn man zwischen Problemen mit Anlassern und Lichtmaschinen unterscheidet. Dieser Leitfaden bietet eine praktische Checkliste für B2B-Einkäufer, mit der sie fundierte Entscheidungen bei der Beschaffung von Lösungen für diese häufigen Probleme treffen können. Die Nuancen der einzelnen Komponenten zu verstehen und mit zuverlässigen Lieferanten zusammenzuarbeiten, ist entscheidend für die betriebliche Effizienz und die Kundenzufriedenheit.

Schritt 1: Erkennen Sie die Symptome des Scheiterns

Beginnen Sie damit, die Symptome zu verstehen, die Anlasser- und Lichtmaschinenprobleme unterscheiden. Symptome wie langsames Anlassen des Motors und Klickgeräusche deuten oft auf Anlasserprobleme hin, während das Abblenden der Scheinwerfer und Batteriewarnleuchten auf einen Ausfall der Lichtmaschine hindeuten können. Wenn Sie diese Symptome klar definieren, können Sie besser mit Lieferanten und Technikern kommunizieren.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Schritt 2: Definieren Sie Ihre technischen Spezifikationen

Legen Sie die spezifischen Anforderungen an die benötigten Anlasser oder Lichtmaschinen fest. Berücksichtigen Sie Faktoren wie Spannungswerte, Kompatibilität mit verschiedenen Fahrzeugmodellen und Umgebungsbedingungen, denen sie standhalten müssen. Die Angabe präziser technischer Spezifikationen vereinfacht den Beschaffungsprozess und stellt sicher, dass Sie die richtigen Komponenten für Ihren Bedarf erwerben.

Schritt 3: Potenzielle Lieferanten bewerten

Bevor Sie eine Verpflichtung eingehen, sollten Sie potenzielle Lieferanten gründlich prüfen. Informieren Sie sich über deren Unternehmensprofile, fordern Sie Fallstudien an und bitten Sie um Referenzen von anderen Unternehmen in Ihrer Branche oder Region. Suchen Sie nach Lieferanten, die sich auf Automobilkomponenten spezialisiert haben und nachweislich zuverlässig und qualitativ hochwertig sind.

- Zertifizierungen von Lieferanten: Vergewissern Sie sich, dass die Zulieferer über einschlägige Zertifizierungen verfügen, z. B. ISO- oder OEM-Normen.

- Kundenrezensionen: Prüfen Sie Zeugnisse und Bewertungen, um die Kundenzufriedenheit zu ermitteln.

Schritt 4: Muster anfordern und Qualitätskontrollen durchführen

Sobald Sie die Lieferanten in die engere Wahl gezogen haben, fordern Sie Muster ihrer Produkte an. Führen Sie gründliche Qualitätsprüfungen durch, um die Haltbarkeit und Leistung der Komponenten zu beurteilen. Dieser Schritt ist entscheidend, um sicherzustellen, dass die Produkte Ihren Qualitätsstandards entsprechen und den Anforderungen Ihres Betriebsumfelds gewachsen sind.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Schritt 5: Garantie- und Rückgaberegelungen verstehen

Machen Sie sich vor dem Kauf mit der Garantie- und Rückgabepolitik der Anbieter vertraut. Eine solide Garantie ist ein Zeichen für das Vertrauen des Anbieters in seine Produkte und gibt Ihnen Sicherheit im Falle von Mängeln oder Ausfällen. Vergewissern Sie sich, dass das Rückgaberecht flexibel genug ist, um unvorhergesehene Probleme nach dem Kauf zu lösen.

Schritt 6: Preise und Konditionen aushandeln

Führen Sie Gespräche, um Preise und Zahlungsbedingungen auszuhandeln. In einem B2B-Kontext ist es üblich, Rabatte bei Großeinkäufen oder günstige Zahlungsbedingungen anzustreben, die sich an Ihrem Cashflow orientieren. Seien Sie darauf vorbereitet, die Angebote mehrerer Lieferanten zu vergleichen, um sicherzustellen, dass Sie das beste Angebot erhalten.

Schritt 7: Einen Kommunikationsplan aufstellen

Schließlich sollten Sie einen klaren Kommunikationsplan mit dem von Ihnen gewählten Lieferanten aufstellen. Regelmäßige Aktualisierungen des Auftragsstatus, der Lieferfristen und möglicher Probleme tragen zur Aufrechterhaltung einer reibungslosen Arbeitsbeziehung bei. Eine effektive Kommunikation kann auch dazu beitragen, dass Probleme schneller gelöst werden und Ihr Betrieb nur minimal gestört wird.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Anhand dieser Checkliste können B2B-Einkäufer die erforderlichen Komponenten zur Behebung von Anlasser- und Lichtmaschinenproblemen sicher beschaffen, was letztlich zu einer höheren Zuverlässigkeit des Fahrzeugs und einer größeren Kundenzufriedenheit führt.

Umfassende Kosten- und Preisanalyse für Probleme bei der Beschaffung von Anlassern und Lichtmaschinen

Was sind die wichtigsten Kostenkomponenten bei Problemen mit dem Anlasser oder der Lichtmaschine?

Bei der Beschaffung von Komponenten für Anlasser- und Lichtmaschinenprobleme ist es für B2B-Einkäufer entscheidend, die Kostenstruktur zu verstehen. Zu den wichtigsten Kostenkomponenten gehören Material, Arbeit, Fertigungsgemeinkosten, Werkzeuge, Qualitätskontrolle (QC), Logistik und Gewinnspanne.

-

Materialien: Die Kosten für Rohmaterialien variieren je nach Qualität und Herkunft. Für den Anfang sind Komponenten wie Kupferwicklungen und Stahlgehäuse unerlässlich, während für Generatoren ähnliche Materialien mit zusätzlichen elektronischen Komponenten benötigt werden. Die Preise schwanken je nach den globalen Lieferketten, die durch geopolitische Faktoren oder Umweltvorschriften beeinflusst werden können.

-

Arbeit: Die Arbeitskosten sind von Region zu Region sehr unterschiedlich. In Ländern mit niedrigeren Arbeitskosten, wie etwa in Afrika und Südamerika, können die Hersteller wettbewerbsfähigere Preise anbieten. Dies kann jedoch auf Kosten der Qualität gehen, so dass ein Gleichgewicht zwischen Kosten und Zuverlässigkeit gefunden werden muss.

-

Fertigungsgemeinkosten: Dazu gehören die Kosten für die Anlage, die Versorgungsleistungen und die Wartung der Ausrüstung. Effiziente Produktionstechniken, wie z. B. die Automatisierung, können dazu beitragen, diese Kosten zu senken, erfordern aber möglicherweise erhebliche Vorabinvestitionen.

-

Werkzeuge: Spezialwerkzeuge für die Herstellung von Startern und Generatoren können erhebliche Kosten verursachen. Die Komplexität der Bauteile kann fortschrittliche Maschinen erforderlich machen, was zur Gesamtkostenstruktur beiträgt.

-

Qualitätskontrolle (QC): Die Sicherstellung, dass jede Einheit den Qualitätsstandards entspricht, ist von entscheidender Bedeutung, insbesondere bei Automobilkomponenten. Hohe Qualitätsstandards führen zwar zu höheren Kosten, können aber Rücksendungen und Gewährleistungsansprüche verringern und so langfristig Geld sparen.

-

Logistik: Die Transportkosten können den Preis erheblich beeinflussen, insbesondere bei internationalen Sendungen. Faktoren wie Incoterms, Versandmethoden und Entfernung können den Endpreis beeinflussen.

-

Marge: Die Lieferanten schlagen in der Regel eine Marge auf, um ihre Kosten und ihren Gewinn zu decken. Diese Marge kann je nach Ruf des Lieferanten, Marktnachfrage und Wettbewerb variieren.

Wie beeinflussen Preiseinflussfaktoren die Beschaffungsentscheidungen für Anlasser und Lichtmaschinen?

Bei der Beschaffung von Anlassern und Lichtmaschinen spielen mehrere preisbestimmende Faktoren eine entscheidende Rolle:

-

Menge/Mindestbestellmenge: Großeinkäufe führen oft zu niedrigeren Kosten pro Einheit. Einkäufer sollten Mindestbestellmengen (MOQs) in Betracht ziehen und größere Bestellungen nutzen, um bessere Preise auszuhandeln.

-

Spezifikationen und Anpassung: Kundenspezifische Spezifikationen können aufgrund von zusätzlichen Werkzeugen und Produktionsanpassungen zu höheren Kosten führen. Standardteile haben im Allgemeinen niedrigere Preise aufgrund von Größenvorteilen.

-

Materialien: Die Wahl der Materialien kann die Kosten drastisch beeinflussen. So kann die Entscheidung für hochwertige oder zertifizierte Materialien die Anschaffungskosten erhöhen, aber auch die Haltbarkeit verbessern und die Gesamtbetriebskosten (TCO) senken.

-

Qualität und Zertifizierungen: Komponenten, die internationalen Normen entsprechen oder über spezielle Zertifizierungen (z. B. ISO) verfügen, sind zwar teurer, aber oft auch zuverlässiger, so dass die mit Ausfällen verbundenen potenziellen langfristigen Kosten geringer sind.

-

Lieferantenfaktoren: Der Standort, der Ruf und die finanzielle Stabilität des Lieferanten können die Preisgestaltung beeinflussen. Internationale Einkäufer sollten eine Due-Diligence-Prüfung durchführen, um sicherzustellen, dass sie mit seriösen Herstellern zusammenarbeiten, um versteckte Kosten zu vermeiden.

-

Incoterms: Die Kenntnis der Incoterms ist entscheidend für die Bestimmung, wer die Kosten für Transport, Versicherung und Zölle trägt. Dieses Wissen kann sich erheblich auf die gesamten Anlandungskosten der Komponenten auswirken.

Welche Tipps für Einkäufer können helfen, eine kosteneffiziente Beschaffung sicherzustellen?

B2B-Einkäufer können mehrere Schritte unternehmen, um eine kosteneffiziente Beschaffung von Anlassern und Lichtmaschinen sicherzustellen:

-

Effektiv verhandeln: Nutzen Sie Ihre Beziehungen zu den Lieferanten, um die Preise auszuhandeln, insbesondere bei Großaufträgen. Der Aufbau langfristiger Partnerschaften kann zu besseren Konditionen und Preisen führen.

-

Gesamtbetriebskosten (TCO) bewerten: Konzentrieren Sie sich nicht nur auf die Anschaffungskosten, sondern berücksichtigen Sie auch die Gesamtbetriebskosten (TCO), einschließlich der Kosten für Wartung, Garantie und mögliche Ausfallzeiten. Die Investition in höherwertige Komponenten kann langfristig zu Einsparungen führen.

-

Preisnuancen für internationale Einkäufer verstehen: Käufer aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa sollten sich über Währungsschwankungen, Einfuhrzölle und lokale Vorschriften im Klaren sein, die sich auf die Preisgestaltung auswirken können.

-

Muster anfordern: Bevor Sie eine große Bestellung aufgeben, sollten Sie Muster anfordern, um Qualität und Kompatibilität zu prüfen. Dies kann kostspielige Fehler im Nachhinein verhindern.

-

Informiert bleiben: Halten Sie sich über Markttrends, Materialkosten und technologische Fortschritte auf dem Laufenden, um fundierte Kaufentscheidungen zu treffen.

Haftungsausschluss zu Preisen

Die Preise für Anlasser und Lichtmaschinen können aufgrund der oben genannten Faktoren stark variieren. Es ist wichtig, dass die Käufer gründliche Nachforschungen anstellen und mehrere Angebote einholen, um wettbewerbsfähige, auf ihre spezifischen Bedürfnisse zugeschnittene Preise zu erhalten.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Analyse der Alternativen: Vergleich von Anlasser- und Lichtmaschinenproblemen mit anderen Lösungen

Alternativen in elektrischen Fahrzeugsystemen verstehen

Bei Problemen mit dem Anlasser oder der Lichtmaschine ist es für B2B-Käufer entscheidend, gangbare Alternativen zu prüfen, die ähnliche Ergebnisse erzielen können. Diese Analyse vergleicht nicht nur Anlasser- und Lichtmaschinenprobleme, sondern bietet auch Einblicke in alternative Technologien, die helfen können, elektrische Probleme in Fahrzeugen zu lindern. Wenn Unternehmen diese Optionen kennen, können sie fundierte Entscheidungen treffen, die die betriebliche Effizienz steigern und Ausfallzeiten reduzieren.

Vergleichstabelle

| Vergleichsaspekt | Probleme mit dem Anlasser und der Lichtmaschine | Lithium-Ionen-Batterien | Hochleistungskondensatoren |

|---|---|---|---|

| Leistung | Unerlässlich für den Start und die elektrische Versorgung | Hohe Energiedichte, schnelleres Aufladen | Schnelles Entladen und Wiederaufladen möglich |

| Kosten | Moderate Ersatzkosten, abhängig vom Fahrzeugmodell | Höhere Anfangsinvestition, aber längere Lebensdauer | Geringere Anfangskosten, aber möglicherweise häufiger Austausch erforderlich |

| Einfache Implementierung | Für eine optimale Leistung ist eine professionelle Installation erforderlich | Kann in bestehende Systeme integriert werden | Einfach zu installieren, kann aber zusätzliche Schaltungen erfordern |

| Wartung | Regelmäßige Kontrollen erforderlich; kann aufgrund von Umweltfaktoren ausfallen | Minimale Wartung; langlebig | Erfordert die Überwachung von Leistungseinbußen |

| Bester Anwendungsfall | Ideal für traditionelle Verbrennungsmotoren | Geeignet für Elektro- und Hybridfahrzeuge | Effektiv für Leistungsoptimierung und Energiespeicherung |

Detaillierte Aufschlüsselung der Alternativen

Lithium-Ionen-Batterien

Lithium-Ionen-Batterien haben die Automobilindustrie revolutioniert, insbesondere bei Elektro- und Hybridfahrzeugen. Sie bieten eine hohe Energiedichte und ermöglichen im Vergleich zu herkömmlichen Blei-Säure-Batterien längere Reichweiten und kürzere Ladezeiten. Ihre Anschaffungskosten können jedoch erheblich höher sein. Außerdem benötigen sie zwar nur minimale Wartung, aber um ihre Langlebigkeit zu gewährleisten, müssen die Ladezyklen und die thermischen Bedingungen sorgfältig gesteuert werden. Für Unternehmen in Regionen wie Afrika und Südamerika, wo Elektrofahrzeuge auf dem Vormarsch sind, kann eine Investition in die Lithium-Ionen-Technologie im Laufe der Zeit zu erheblichen betrieblichen Einsparungen führen.

Hochleistungskondensatoren

Hochleistungskondensatoren bieten eine einzigartige Alternative, insbesondere bei Anwendungen, die eine schnelle Energieentladung erfordern, wie z. B. im Rennsport oder beim Leistungstuning. Diese Geräte können gespeicherte Energie schnell freisetzen und so das elektrische System des Fahrzeugs unterstützen. Ihre einfache Installation macht sie für Unternehmen interessant, die die Leistung ihres Fahrzeugs ohne umfangreiche Modifikationen steigern wollen. Allerdings haben sie im Vergleich zu Batterien in der Regel eine kürzere Lebensdauer und müssen möglicherweise häufiger ausgetauscht werden. Diese Option eignet sich am besten für Unternehmen, deren Schwerpunkt eher auf der Leistungssteigerung als auf der allgemeinen Zuverlässigkeit des Fahrzeugs liegt.

Schlussfolgerung: Wie sollten B2B-Einkäufer die richtige Lösung auswählen?

Die Wahl der richtigen Lösung für Probleme mit Anlasser und Lichtmaschine oder alternativen Technologien hängt von den spezifischen betrieblichen Anforderungen und der Art der eingesetzten Fahrzeuge ab. Für Unternehmen, die auf herkömmliche Verbrennungsmotoren angewiesen sind, ist die Wartung eines robusten Anlasser- und Lichtmaschinensystems von entscheidender Bedeutung. Umgekehrt können Unternehmen, die auf Elektro- oder Hybridmodelle umsteigen, feststellen, dass die Investition in Lithium-Ionen-Batterien trotz höherer Anfangskosten einen längerfristigen Nutzen bietet. Hochleistungskondensatoren können Nischenanwendungen bedienen, bei denen ein schneller Energiezugang von größter Bedeutung ist. Letztendlich sollten B2B-Käufer ihre betrieblichen Anforderungen, Budgetbeschränkungen und langfristigen Ziele bewerten, wenn sie die am besten geeignete Lösung für ihre Flottenmanagement- und Fahrzeugwartungsstrategien bestimmen.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Wesentliche technische Eigenschaften und Fachterminologie für Probleme zwischen Anlasser und Lichtmaschine

Welche technischen Schlüsseleigenschaften sollten B2B-Einkäufer in Bezug auf Anlasser- und Lichtmaschinenprobleme verstehen?

Bei der Bewertung von Anlassern und Lichtmaschinen für Kfz-Anwendungen ist die Kenntnis spezifischer technischer Eigenschaften für eine fundierte Kaufentscheidung unerlässlich. Hier sind einige wichtige Spezifikationen, die Sie berücksichtigen sollten:

-

Werkstoffgüte

Das in Anlassern und Lichtmaschinen verwendete Material kann die Haltbarkeit und Leistung erheblich beeinflussen. Zu den gängigen Materialien gehören Aluminium für Gehäuse und Kupfer für die Wicklungen. Höherwertige Materialien führen oft zu einer besseren Korrosionsbeständigkeit und Langlebigkeit, was in unterschiedlichen Klimazonen wie in Afrika und Südamerika entscheidend ist. Die Auswahl von Komponenten aus hochwertigen Materialien kann die Häufigkeit des Austauschs minimieren und die Betriebskosten senken. -

Toleranzwerte

Unter Toleranz versteht man die zulässige Abweichung von den vorgegebenen Maßen. Enge Toleranzen bei der Herstellung von Anlasserzahnrädern und Lichtmaschinenriemenscheiben gewährleisten optimale Passform und Leistung. Für B2B-Einkäufer ist das Verständnis der Toleranzwerte von entscheidender Bedeutung, da selbst geringfügige Abweichungen zu vorzeitigem Verschleiß, erhöhter Geräuschentwicklung und Ineffizienzen bei der Leistungsabgabe führen können. -

Nennstrom (Stromstärke)

Diese Angabe gibt an, wie viel Strom ein Anlasser oder eine Lichtmaschine liefern kann. Anlasser benötigen in der Regel eine höhere Stromstärke, um den Motor in Gang zu setzen, während Lichtmaschinen genügend Strom erzeugen müssen, um die Batterie aufzuladen. Die Käufer müssen sicherstellen, dass die Stromstärken den Anforderungen der Fahrzeuge in ihrer Flotte entsprechen oder diese übertreffen, um Ausfälle zu vermeiden und die Zuverlässigkeit zu gewährleisten. -

Spannung Ausgang

Lichtmaschinen sind für die Erzeugung einer bestimmten Ausgangsspannung ausgelegt, die bei den meisten Fahrzeugen zwischen 12 und 14,5 Volt liegt. Die Kenntnis der Ausgangsspannung ist für B2B-Käufer von entscheidender Bedeutung, da sie sich auf die Effizienz des elektrischen Systems und die Fähigkeit des Fahrzeugs auswirkt, Zubehör zu betreiben. Eine Lichtmaschine, die ständig zu wenig Spannung liefert, kann zu einer Entladung der Batterie und anderen elektrischen Problemen führen. -

Hitzebeständigkeit

Sowohl Anlasser als auch Lichtmaschinen erzeugen während des Betriebs Wärme, die bei unsachgemäßer Handhabung zum Ausfall von Komponenten führen kann. Die Bewertung der Hitzebeständigkeit von Materialien und der Konstruktion dieser Komponenten ist von entscheidender Bedeutung, insbesondere in Regionen mit extremen Temperaturen. Komponenten, die höheren Temperaturen standhalten können, haben in der Regel eine längere Lebensdauer, was die Wartungs- und Ersatzteilkosten senkt.

Welche Fachbegriffe sind für das Verständnis von Anlasser- und Lichtmaschinenproblemen wichtig?

Um sich im Beschaffungsprozess für Automobilkomponenten zurechtzufinden, muss man sich mit der Branchenterminologie vertraut machen. Hier sind einige gängige Begriffe, die B2B-Einkäufer kennen sollten:

-

OEM (Originalgerätehersteller)

Erstausrüsterteile sind Komponenten, die vom Fahrzeughersteller oder lizenzierten Herstellern produziert werden und den Originalspezifikationen entsprechen. Die Verwendung von OEM-Startern und -Generatoren gewährleistet Kompatibilität und Leistungsstandards. Käufer sollten die Vorteile von OEM-Teilen gegenüber Aftermarket-Optionen auf der Grundlage ihrer spezifischen Bedürfnisse und Budgetbeschränkungen abwägen. -

MOQ (Mindestbestellmenge)

MOQ bezieht sich auf die Mindestanzahl von Einheiten, die ein Lieferant für einen Auftrag benötigt. Die Kenntnis der MOQ ist entscheidend für die Verwaltung von Beständen und Cashflow. Für Unternehmen, die in Regionen mit schwankender Nachfrage tätig sind, kann das Aushandeln günstiger MOQs zu einer besseren Preisgestaltung und geringeren Lagerkosten führen. -

RFQ (Angebotsanfrage)

Eine Anfrage ist ein formelles Verfahren zur Einholung von Preisangeboten von Lieferanten. In ihr werden die Spezifikationen und Mengen der benötigten Produkte festgelegt. B2B-Einkäufer sollten RFQs nutzen, um sicherzustellen, dass sie wettbewerbsfähige Preise erhalten und die Lieferbedingungen, einschließlich Vorlaufzeiten und Lieferbedingungen, verstehen. -

Incoterms (Internationale Handelsklauseln)

Dies sind international anerkannte Begriffe, die die Verantwortlichkeiten von Käufern und Verkäufern im internationalen Versand festlegen. Das Verständnis der Incoterms ist für B2B-Transaktionen von entscheidender Bedeutung, da sie klären, wer für die Versandkosten, die Versicherung und die Risiken während des Transports verantwortlich ist. Die Vertrautheit mit diesen Bedingungen kann Käufern helfen, bessere Versandvereinbarungen auszuhandeln und unerwartete Kosten zu vermeiden. -

Vorlaufzeit

Die Vorlaufzeit ist die Zeitspanne von der Bestellung bis zum Erhalt der Produkte. Dieser Zeitrahmen kann je nach Lieferant und Komplexität der Komponenten erheblich variieren. Für B2B-Einkäufer ist die Kenntnis der Vorlaufzeiten entscheidend für die Planung des Lagerbestands und die Gewährleistung der rechtzeitigen Verfügbarkeit von Teilen, um die Ausfallzeiten von Fahrzeugen zu minimieren.

Durch die Kenntnis dieser technischen Eigenschaften und Handelsbegriffe können B2B-Einkäufer fundiertere Entscheidungen bei der Lösung von Problemen mit Anlassern und Lichtmaschinen treffen, was letztlich zu einer verbesserten betrieblichen Effizienz und zu Kosteneinsparungen führt.

Marktdynamik und Beschaffungstrends im Sektor Probleme mit Anlassern und Lichtmaschinen navigieren

Was sind die aktuellen globalen Treiber, die den Markt für Anlasser- und Lichtmaschinenprobleme beeinflussen?

Der Sektor der Anlasser- und Lichtmaschinenprobleme erfährt derzeit erhebliche Veränderungen, die durch mehrere globale Faktoren bedingt sind. Erstens wird die steigende Nachfrage nach zuverlässigen Automobilkomponenten weitgehend durch das Wachstum der Fahrzeugproduktion angeheizt, insbesondere in den Schwellenländern in Afrika, Südamerika und dem Nahen Osten. In diesen Regionen steigt die Zahl der Fahrzeugbesitzer, was mit einem erhöhten Bedarf an Wartungs- und Reparaturdienstleistungen einhergeht. In Europa, insbesondere in Deutschland, liegt der Schwerpunkt auf der Elektrifizierung von Fahrzeugen, was fortschrittliche Anlasser- und Lichtmaschinentechnologien erfordert, die Elektro- und Hybridfahrzeuge unterstützen können.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Außerdem verändern die Fortschritte in der B2B-Technologie die Beschaffungslandschaft. Digitale Plattformen werden zu unverzichtbaren Werkzeugen für internationale Einkäufer, mit denen sie Preise, Qualität und Zuverlässigkeit der Lieferanten besser vergleichen können. Auch der Einsatz von künstlicher Intelligenz und maschinellem Lernen gewinnt an Zugkraft und ermöglicht es Unternehmen, potenzielle Ausfälle bei Startern und Generatoren vorherzusagen und so die Lagerverwaltung zu optimieren und Ausfallzeiten zu reduzieren.

Was sind die aufkommenden B2B-Technologietrends bei der Beschaffung von Automobilkomponenten?

Aufkommende B2B-Technologietrends haben einen erheblichen Einfluss auf die Beschaffungsstrategien im Bereich der Probleme zwischen Anlasser und Lichtmaschine. Ein bemerkenswerter Trend ist das Aufkommen von E-Commerce-Plattformen, die Hersteller direkt mit Käufern verbinden und so schnellere Beschaffungsprozesse und geringere Kosten ermöglichen. Darüber hinaus hilft die Integration von Datenanalysen den Unternehmen, die Marktnachfrage zu verstehen und ihre Bestände entsprechend anzupassen, um sicherzustellen, dass sie schnell auf Nachfrageschwankungen reagieren können.

Auch die Blockchain-Technologie ist auf dem Vormarsch und fördert die Transparenz und Rückverfolgbarkeit in der Lieferkette, was für internationale Käufer, die auf die Echtheit der Produkte und ethische Beschaffung achten, von entscheidender Bedeutung ist. Auf der Suche nach Wettbewerbsvorteilen investieren die Unternehmen zunehmend in Automatisierung und intelligente Fertigungsprozesse, um die Effizienz zu steigern und die Vorlaufzeiten zu verkürzen.

Warum sind Nachhaltigkeit und ethische Beschaffung im Bereich Anlasser und Lichtmaschinen wichtig?

Die Umweltauswirkungen von Automobilkomponenten, insbesondere von Anlassern und Lichtmaschinen, werden für die Unternehmen zu einem wichtigen Thema. Bei den Herstellungsprozessen werden häufig Materialien verwendet, die die Umwelt schädigen können. Folglich gewinnt die Bedeutung ethischer Lieferketten immer mehr an Bedeutung, da B2B-Käufer nun Lieferanten bevorzugen, die nachhaltige Praktiken anwenden. Dazu gehören die Beschaffung von Materialien von zertifizierten grünen Lieferanten und die Verwendung umweltfreundlicher Fertigungsverfahren.

Zertifizierungen wie ISO 14001, die sich auf wirksame Umweltmanagementsysteme konzentrieren, werden von internationalen Käufern zunehmend nachgefragt. Diese Zertifizierungen zeigen nicht nur das Engagement für Nachhaltigkeit, sondern helfen den Unternehmen auch bei der Einhaltung von Vorschriften, insbesondere in Europa, wo strenge Umweltstandards gelten. Im Zuge der Marktentwicklung werden Unternehmen, die grünen Zertifizierungen und nachhaltigen Materialien den Vorzug geben, wahrscheinlich einen Wettbewerbsvorteil erlangen und umweltbewusste Käufer anziehen.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

Wie hat sich der Markt für Probleme zwischen Anlasser und Lichtmaschine im Laufe der Zeit entwickelt?

Der Sektor der Anlasser- und Lichtmaschinenprobleme hat sich in der Vergangenheit stark verändert, vor allem aufgrund des technischen Fortschritts und der sich wandelnden Erwartungen der Verbraucher. In der frühen Automobilära waren diese Komponenten relativ einfach und hauptsächlich mechanisch. Mit dem Aufkommen elektronischer Systeme in Fahrzeugen nahm die Komplexität von Anlassern und Lichtmaschinen jedoch erheblich zu.

Die Einführung intelligenter Technologien wie Start-Stopp-Systeme und regeneratives Bremsen hat diese Komponenten weiter verändert und erfordert von den Herstellern kontinuierliche Innovationen. Mit der zunehmenden Beliebtheit von Elektro- und Hybridfahrzeugen steht der Sektor vor einer weiteren Entwicklung, die sich auf Komponenten verlagert, die die einzigartigen Anforderungen dieser fortschrittlichen Automobiltechnologien erfüllen können. Diese Entwicklung stellt B2B-Einkäufer vor Herausforderungen und Chancen, denn sie müssen über die neuesten Entwicklungen informiert sein, um strategische Beschaffungsentscheidungen treffen zu können.

Häufig gestellte Fragen (FAQs) für B2B-Käufer bei Problemen mit Anlasser und Lichtmaschine

-

Wie löse ich Probleme zwischen Anlasser und Lichtmaschine in meinem Fuhrpark?

Bei Problemen mit Anlasser und Lichtmaschine sollten Sie systematisch vorgehen. Führen Sie zunächst eine Reihe von Tests durch, um die defekte Komponente zu ermitteln. Eine gängige Methode besteht darin, dem Fahrzeug Starthilfe zu geben. Wenn es läuft, aber nach dem Trennen der Verbindung abstirbt, ist wahrscheinlich die Lichtmaschine defekt. Wenn es überhaupt nicht anspringt, liegt das Problem möglicherweise am Anlasser. Regelmäßige Wartung und Inspektionen können helfen, diese Probleme zu vermeiden. Es ist ratsam, mit einem zuverlässigen Kfz-Dienstleister zusammenzuarbeiten, der Sie bei der Diagnose und Lösung dieser Probleme effizient unterstützen kann, insbesondere wenn Ihr Fuhrpark in unterschiedlichen Umgebungen arbeitet. -

Wie kann man am besten hochwertige Anlasser und Lichtmaschinen beschaffen?

Bevorzugen Sie bei der Beschaffung von Anlassern und Lichtmaschinen Lieferanten mit einer nachgewiesenen Erfolgsbilanz in der Automobilzulieferindustrie. Achten Sie auf Hersteller, die internationale Qualitätsnormen erfüllen, z. B. ISO-Zertifizierungen. Fordern Sie Muster an, um die Qualität und Leistung ihrer Produkte zu beurteilen. Berücksichtigen Sie außerdem Lieferanten, die Garantien anbieten, da dies ein Zeichen des Vertrauens in ihre Produkte ist. Wenn Sie mit Lieferanten zusammenarbeiten, die die spezifischen Anforderungen Ihres Marktes - sei es in Afrika, Südamerika oder Europa - verstehen, können Sie auch bessere Anpassungsmöglichkeiten und Unterstützung erhalten. -

Was sollte ich bei der Auswahl von Lieferanten für Automobilkomponenten beachten?

Zu den Schlüsselfaktoren bei der Überprüfung von Lieferanten gehören ihr Ruf in der Branche, ihre Produktionskapazität, ihre Qualitätssicherungsprozesse und die Einhaltung internationaler Vorschriften. Untersuchen Sie ihre Geschichte, Kundenrezensionen und Zertifizierungen. Es ist von entscheidender Bedeutung, die Fähigkeit des Unternehmens zu beurteilen, Ihre spezifischen Anforderungen zu erfüllen, einschließlich Mindestbestellmengen (MOQ) und Anpassungsoptionen. Eine klare Kommunikation über Preise, Lieferzeiten und Kundendienst kann ebenfalls zu einer erfolgreichen Partnerschaft beitragen. Besuche vor Ort oder Audits können Ihr Vertrauen in die Arbeit des Unternehmens weiter stärken. -

Wie kann ich mit Lieferanten günstige Zahlungsbedingungen aushandeln?

Bei der Aushandlung von Zahlungsbedingungen müssen Sie sowohl Ihren Cashflow-Bedarf als auch die Anforderungen des Lieferanten verstehen. Schlagen Sie zunächst Bedingungen vor, die Ihrem Geschäftszyklus entsprechen, z. B. 30 oder 60 Tage netto, und seien Sie offen für Vorschläge des Lieferanten. Das Angebot von Teilzahlungen im Voraus kann für Lieferanten ein Anreiz sein, längeren Zahlungsfristen zuzustimmen. Der Aufbau einer soliden Beziehung, die auf Vertrauen und gegenseitigem Nutzen beruht, kann ebenfalls zu besseren Konditionen führen. Seien Sie bereit, über das Auftragsvolumen und das Potenzial für eine langfristige Partnerschaft zu sprechen, was Ihre Verhandlungsposition stärken kann. -

Welche logistischen Überlegungen sollte ich bei der Einfuhr von Kfz-Teilen anstellen?

Berücksichtigen Sie beim Import von Kfz-Teilen die Versandmethoden, Zollbestimmungen und mögliche Zölle. Wählen Sie Logistikpartner mit Erfahrung im Umgang mit Kfz-Teilen, um eine pünktliche Lieferung und die Einhaltung der Vorschriften zu gewährleisten. Schätzen Sie die gesamten Anlandungskosten ein, einschließlich Versand, Zollgebühren und Versicherung, um unerwartete Ausgaben zu vermeiden. Berücksichtigen Sie auch die Vorlaufzeiten für die Herstellung und den Versand, insbesondere wenn Sie von internationalen Lieferanten beziehen. Eine klare Logistikstrategie kann dazu beitragen, den Betrieb zu rationalisieren und Risiken im Zusammenhang mit Verspätungen oder beschädigten Waren zu minimieren. -

Wie kann ich die Qualitätssicherung (QA) bei zugekauften Kfz-Teilen sicherstellen?

Die Implementierung eines soliden Qualitätssicherungsprozesses beinhaltet die Festlegung klarer Qualitätsstandards und -kennzahlen, die die Lieferanten erfüllen müssen. Verlangen Sie von den Lieferanten eine Dokumentation ihrer Qualitätssicherungsprozesse, z. B. Prüfberichte und Konformitätsbescheinigungen. Regelmäßige Audits und Inspektionen sowohl des Herstellungsprozesses als auch der Endprodukte können die Qualitätskontrolle weiter verbessern. Die Einrichtung einer Feedback-Schleife, in der Sie Probleme melden können und sofortige Lösungen erhalten, trägt zur Aufrechterhaltung hoher Qualitätsstandards in Ihrer Lieferkette bei. -

Welche Anpassungsmöglichkeiten sollte ich für Anlasser und Lichtmaschinen in Betracht ziehen?

Kundenspezifische Anpassungen können die Leistung und Kompatibilität von Startern und Lichtmaschinen mit bestimmten Fahrzeugmodellen verbessern. Besprechen Sie mit Ihrem Lieferanten Optionen wie Spannungswerte, Montagekonfigurationen und Steckertypen. Erkundigen Sie sich auch nach Möglichkeiten der Markenkennzeichnung, wie z. B. Private Labeling, um Ihre Marktpräsenz zu stärken. Kundenspezifische Merkmale wie verbesserte Haltbarkeit für extreme Klimabedingungen oder erhöhte Effizienz können ebenfalls von Vorteil sein. Eine enge Zusammenarbeit mit Ihrem Lieferanten bei diesen Aspekten kann zu Produkten führen, die die Bedürfnisse Ihrer Kunden besser erfüllen. -

Was sind die häufigsten Anzeichen für einen Ausfall des Anlassers oder der Lichtmaschine in Fahrzeugen?

Häufige Anzeichen für einen Anlasserausfall sind ein klickendes Geräusch beim Versuch, das Fahrzeug zu starten, ein nicht anspringender Motor oder ungewöhnliche Geräusche wie Schleifen. Bei Lichtmaschinen können Symptome wie das Abblenden der Scheinwerfer, ein flackerndes Armaturenbrett oder eine leere Batterie nach kurzem Gebrauch auftreten. Die Überwachung dieser Anzeichen kann Fuhrparkleitern dabei helfen, proaktive Maßnahmen zu ergreifen, wie z. B. die Planung von Inspektionen oder den Austausch der Batterie, um Ausfallzeiten zu minimieren. Wenn Sie Ihre Fahrer über diese Symptome aufklären, können sie Probleme frühzeitig melden und so eine rechtzeitige Wartung und Reparatur ermöglichen.

Top 3 Starter Vs Alternator Probleme Hersteller & Lieferanten Liste

1. Nissan Altima - Leistungsdiagnose

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Die Diskussion dreht sich um die Diagnose von Problemen im Zusammenhang mit einem 2009er Nissan Altima, der überhaupt keinen Strom hat. Die wichtigsten Komponenten erwähnt gehören: 1. Die Batterie: Versorgt die gesamte Elektronik und den Anlasser mit Strom. Es wird vermutet, dass eine leere Batterie das Hauptproblem darstellt. 2. Lichtmaschine: Lädt die Batterie auf, wenn der Motor läuft; eine defekte Lichtmaschine kann die Batterie nicht aufladen, was zu einer leeren Batterie führt...

2. Capitol Chevy - Batterie-, Anlasser- und Lichtmaschinen-Probleme

Domäne: capitol-chevy.com

Registriert: 1999 (26 Jahre)

Einleitung: Der Text beschreibt die Symptome von Problemen mit der Batterie, dem Anlasser oder der Lichtmaschine eines Fahrzeugs. Es werden spezifische Symptome und ihre wahrscheinlichen Ursachen beschrieben: 1. Schwache oder flackernde Lichter weisen auf eine defekte Lichtmaschine hin. 2. Wenn das Armaturenbrett leuchtet, das Fahrzeug aber nicht anspringt, deutet dies auf einen defekten Anlasser hin. 3. Eine erfolgreiche Starthilfe deutet auf ein Batterieproblem hin. 4. Eine Starthilfe, die nicht funktioniert, kann auf eine Anlasserp...

3. Facebook - Fehlersuche bei Problemen mit der Elektrik Ihres Autos

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Dieses Unternehmen, Facebook - Troubleshooting Your Car's Electrical Issues, ist ein namhaftes Unternehmen auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

Strategische Beschaffung Schlussfolgerung und Ausblick für Probleme mit Anlasser und Lichtmaschine

Wie kann die strategische Beschaffung Ihr Verständnis für Anlasser- und Lichtmaschinenfragen verbessern?

Bei der Lösung von Problemen mit Anlassern und Lichtmaschinen spielt die strategische Beschaffung für internationale B2B-Einkäufer eine entscheidende Rolle. Das Verständnis des Zusammenspiels zwischen diesen Komponenten ist für eine effektive Fehlersuche und Wartung unerlässlich. Durch die Beschaffung hochwertiger Teile und Dienstleistungen können Unternehmen Ausfallzeiten reduzieren, die Zuverlässigkeit von Fahrzeugen erhöhen und letztlich die Betriebskosten senken.

Darüber hinaus kann das Erkennen der häufigsten Fehlerursachen - wie Umweltfaktoren und unsachgemäße Installation - zu besseren Kaufentscheidungen führen. Die Zusammenarbeit mit seriösen Anbietern sichert nicht nur den Zugang zu zuverlässigen Produkten, sondern fördert auch Partnerschaften, die kontinuierliche technische Unterstützung und Beratung bieten können, die auf die spezifischen regionalen Bedürfnisse zugeschnitten sind.

Der Blick in die Zukunft zeigt, dass sich die Automobilbranche mit Fortschritten in den Bereichen Technologie und Nachhaltigkeit weiterentwickelt. Internationale Einkäufer, insbesondere aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, werden ermutigt, strategische Beschaffungspraktiken zu nutzen, um wettbewerbsfähig zu bleiben. Dieser proaktive Ansatz optimiert nicht nur die Leistung des Fuhrparks, sondern entspricht auch den globalen Trends zu Effizienz und Nachhaltigkeit.

Machen Sie den nächsten Schritt in Ihrer Beschaffungsstrategie, indem Sie Ihre Lieferanten bewerten und sicherstellen, dass sie den Anforderungen der heutigen Herausforderungen in der Automobilindustrie gerecht werden. Gehen Sie mit Zuversicht in die Zukunft, denn Sie wissen, dass fundierte Beschaffungsentscheidungen zu erheblichen langfristigen Vorteilen führen können.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

Anschauliches Bild im Zusammenhang mit Problemen zwischen Anlasser und Lichtmaschine

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.