Einführung: Navigieren auf dem globalen Markt für neue und wiederaufbereitete Anlasser

Wenn es darum geht, neue oder wiederaufbereitete Anlasser für Fahrzeuge zu beschaffen, stehen internationale B2B-Einkäufer vor einer entscheidenden Herausforderung: Sie müssen ein Gleichgewicht zwischen Kosteneffizienz und Zuverlässigkeit finden. Diese Entscheidung kann sich erheblich auf die betriebliche Effizienz auswirken, insbesondere in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, wo unterschiedliche Marktbedingungen und Fahrzeuganforderungen vorherrschen. Dieser umfassende Leitfaden befasst sich mit den Feinheiten von neuen und wiederaufbereiteten Startern und untersucht ihre jeweiligen Typen, Anwendungen und Leistungskennzahlen.

Käufer erhalten Einblicke in die Prozesse der Lieferantenüberprüfung, Kostenvergleiche und Überlegungen zur Garantie und erhalten so das nötige Wissen, um fundierte Kaufentscheidungen zu treffen. Das Verständnis des Remanufacturing-Prozesses, bei dem Anlasser nach Werksspezifikationen wiederhergestellt werden, kann Einkäufern helfen, die potenziellen Vorteile von Remanufacturing-Optionen - wie etwa reduzierte Kosten und Umweltvorteile - zu schätzen und gleichzeitig die Vorteile neuer Anlasser mit garantierter Qualität und Zuverlässigkeit abzuwägen.

Dieser Leitfaden soll Ihnen bei der Navigation durch diese komplexe Landschaft verwertbare Erkenntnisse und Strategien vermitteln, die auf Ihr spezifisches Marktumfeld zugeschnitten sind, und sicherstellen, dass Sie Entscheidungen treffen, die Ihren betrieblichen Zielen entsprechen. Mit dem Fokus auf Qualität, Langlebigkeit und Kosten werden Sie besser in der Lage sein, die richtige Einstiegslösung auszuwählen, die den individuellen Bedürfnissen und Anforderungen Ihres Unternehmens gerecht wird.

Inhaltsverzeichnis

- Top 2 Neue Vs Remanufactured Starter Hersteller & Lieferanten Liste

- Einführung: Navigieren auf dem globalen Markt für neue und wiederaufbereitete Anlasser

- Neue und wiederaufbereitete Anlasser - Typen und Variationen

- Wichtige industrielle Anwendungen von neuen und wiederaufbereiteten Startern

- 3 häufige Schmerzpunkte von Nutzern bei der Frage ‘neuer vs. wiederaufbereiteter Anlasser’ und ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für neue und wiederaufbereitete Anlasser

- Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für neue und wiederaufbereitete Anlasser

- Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘neue vs. wiederaufbereitete Anlasser’.’

- Umfassende Kosten- und Preisanalyse für neue und wiederaufbereitete Anlasser Beschaffung

- Analyse der Alternativen: Vergleich zwischen neuen und wiederaufbereiteten Startern und anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für neue und wiederaufbereitete Anlasser

- Marktdynamik und Beschaffungstrends im Bereich neuer und wiederaufbereiteter Anlasser

- Häufig gestellte Fragen (FAQs) für B2B-Käufer von neuen und wiederaufbereiteten Startern

- Strategische Beschaffung - Schlussfolgerung und Ausblick für neue und wiederaufbereitete Anlasser

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Neue und wiederaufbereitete Anlasser - Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Neuer OEM-Starter | Brandneu, hergestellt nach den Standards der Erstausrüstung | Autohäuser, Flottenmanagement | Vorteile: Garantierte Qualität, neueste Technologie. Nachteile: Höhere Kosten, längere Vorlaufzeiten. |

| Überholter Anlasser | Gründlich überarbeitet mit neuen Komponenten und strengen Tests | Autowerkstätten, Aftermarket-Verkauf | Vorteile: Kostengünstig und umweltfreundlich. Nachteile: Die Qualität variiert je nach Hersteller. |

| Überholter Anlasser | Nur ausgefallene Komponenten werden ersetzt, weniger umfangreich als bei der Wiederaufbereitung | Kleine Garagen, DIY-Mechaniker | Vorteile: Kostengünstiger als neu. Nachteile: Entspricht möglicherweise nicht den OEM-Standards, kürzere Lebensdauer. |

| Nachrüstbarer Anlasser | Nicht-Originalteile, die in Qualität und Preis stark variieren können | Unabhängige Werkstätten, preisbewusste Käufer | Vorteile: Möglicherweise niedrigerer Preis. Nachteile: Uneinheitliche Qualität, möglicherweise keine Garantie. |

| Hochleistungsstarter | Verbessertes Design für mehr Zuverlässigkeit und Leistung | Rennsportteams, Autohäuser für Hochleistungsfahrzeuge | Vorteile: Überlegene Leistung, maßgeschneidert für spezifische Anwendungen. Nachteile: Teuer, Nischenmarkt. |

Was sind die Merkmale von neuen OEM-Startern?

Neue OEM-Anlasser (Original Equipment Manufacturer) werden von Grund auf neu hergestellt, um bestimmte Fahrzeugstandards zu erfüllen. Sie sind ideal für Unternehmen, die Wert auf Qualität und Zuverlässigkeit legen, wie z. B. Autohäuser und Flottenmanagementunternehmen. Die Anschaffungskosten sind zwar höher, aber die garantierte Leistung und Langlebigkeit machen sie zu einer lohnenden Investition. B2B-Käufer sollten ihr Budget und die Nutzung des Fahrzeugs berücksichtigen, um festzustellen, ob der Aufpreis gerechtfertigt ist.

Wie sieht es mit der Eignung von wiederaufbereiteten Startern aus?

Überholte Anlasser sind aufgrund ihres ausgewogenen Verhältnisses von Kosten und Zuverlässigkeit eine beliebte Wahl. Diese Einheiten werden umfassend zerlegt, gereinigt und mit neuen Teilen wieder zusammengebaut, um sicherzustellen, dass sie die OEM-Spezifikationen erfüllen oder übertreffen. Sie eignen sich gut für Kfz-Werkstätten und den Ersatzteilmarkt und bieten eine zuverlässige Alternative zu einem Bruchteil der Kosten neuer Anlasser. Käufer sollten den Ruf des Wiederaufbereitungsunternehmens prüfen, um die Produktqualität sicherzustellen, da diese erheblich schwanken kann.

Was sollten Käufer über überholte Anlasser wissen?

Überholte Anlasser sind oft preiswerter als neue oder wiederaufbereitete Modelle, was für kleine Werkstätten und Heimwerker interessant ist. Beim Wiederaufbau werden jedoch in der Regel nur die defekten Komponenten ausgetauscht, wodurch die ursprüngliche Leistung des Anlassers möglicherweise nicht wiederhergestellt wird. Dies kann zu einer kürzeren Lebensdauer und potenziellen Kompatibilitätsproblemen führen. B2B-Käufer sollten die unmittelbaren Kosteneinsparungen gegen die potenzielle Notwendigkeit eines häufigeren Austauschs abwägen.

Warum sollten Aftermarket-Starter für preisbewusste Einkäufe in Betracht gezogen werden?

Aftermarket-Anlasser bieten eine Reihe von Optionen zu unterschiedlichen Preisen, was sie für unabhängige Werkstätten und preisbewusste Käufer attraktiv macht. Die Qualität kann jedoch uneinheitlich sein, und die Garantien sind möglicherweise nicht so robust wie bei OEM- oder wiederaufbereiteten Startern. B2B-Käufer sollten gründliche Nachforschungen über Hersteller und Kundenrezensionen anstellen, um Fallstricke in Bezug auf die Zuverlässigkeit zu vermeiden.

Wann sind Hochleistungsstarter notwendig?

Hochleistungsanlasser sind für spezielle Anwendungen, wie z. B. den Rennsport oder den Einsatz unter schweren Bedingungen, konzipiert. Diese Anlasser enthalten oft fortschrittliche Materialien und Technik, um die Leistung zu verbessern, so dass sie sich für Rennteams und leistungsstarke Kfz-Werkstätten eignen. Sie können zwar erheblich teurer sein, aber die Vorteile in Bezug auf Leistung und Zuverlässigkeit können die Investition für Unternehmen in Nischenmärkten rechtfertigen. Käufer sollten bei der Erwägung dieser Optionen ihre spezifischen Bedürfnisse und die zu erwartende Investitionsrendite berücksichtigen.

Wichtige industrielle Anwendungen von neuen und wiederaufbereiteten Startern

| Branche/Sektor | Spezifische Anwendung von neuen und wiederaufbereiteten Startern | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Austausch von Anlassern in verschiedenen Fahrzeugen | Kostengünstige Lösungen für Kundenreparaturen | Qualitätssicherung, Garantiebedingungen, zentrale Rückgabebestimmungen |

| Herstellung von schwerem Gerät | Anlasser für Baumaschinen | Erhöhte Zuverlässigkeit und reduzierte Ausfallzeiten | OEM-Spezifikationen, Kompatibilität mit Gerätemodellen |

| Transport & Logistik | Anlasser für Flottenfahrzeuge | Verbesserte betriebliche Effizienz und Kosteneinsparungen | Großeinkaufsoptionen, Garantieunterstützung, Wartungsdienste |

| Landwirtschaftliche Geräte | Anlasser für Traktoren und Landmaschinen | Höhere Produktivität und geringere Reparaturkosten | Verfügbarkeit bestimmter Modelle, Zuverlässigkeit der Lieferanten |

| Bergbauarbeiten | Anlasser für schwere Bergbauausrüstung | Gesicherte Leistung unter rauen Bedingungen | Einhaltung von Industriestandards, Lieferfristen |

Wie werden neue und wiederaufbereitete Anlasser in verschiedenen Branchen eingesetzt?

Unter Kfz-Werkstätten, Die Wahl zwischen neuen und wiederaufbereiteten Startern hat erhebliche Auswirkungen auf das Serviceangebot. Wiederaufgearbeitete Anlasser sind eine kostengünstige Option für Reparaturen, die preisbewusste Kunden anspricht und gleichzeitig Qualität und Zuverlässigkeit gewährleistet. Die Werkstätten müssen sicherstellen, dass ihre Lieferanten Garantien anbieten und Qualitätsstandards einhalten, um das Vertrauen der Kunden zu gewinnen.

In der Schwermaschinenbau sind zuverlässige Anlasser für Baumaschinen von entscheidender Bedeutung. Neue Anlasser können für hochwertige Maschinen bevorzugt werden, während wiederaufbereitete Optionen eine zuverlässige, kostengünstigere Alternative darstellen können. Die Käufer müssen sicherstellen, dass die Anlasser den OEM-Spezifikationen entsprechen, um Kompatibilitätsprobleme zu vermeiden, die zu Betriebsausfällen führen könnten.

Für Transport- und Logistikunternehmen, ist die Leistung der Flottenfahrzeuge von größter Bedeutung. Der Einsatz von überholten Startern kann die Wartungskosten senken und gleichzeitig sicherstellen, dass die Fahrzeuge betriebsbereit bleiben. Käufer sollten Großeinkaufsvereinbarungen in Betracht ziehen, um sich günstige Preise zu sichern, und Lieferanten bevorzugen, die umfassenden Garantiesupport und Wartungsdienste anbieten.

In der Landmaschinen Traktoren und Landmaschinen sind für eine optimale Produktivität in hohem Maße auf zuverlässige Anlasser angewiesen. Wiederaufbereitete Anlasser können erhebliche Einsparungen bieten und gleichzeitig die erforderliche Leistung erbringen. Käufer sollten sich auf die Verfügbarkeit bestimmter Modelle und die Zuverlässigkeit der Lieferanten konzentrieren, um den rechtzeitigen Zugang zu Ersatzteilen während kritischer Pflanz- oder Erntezeiten zu gewährleisten.

Zum Schluss, Bergbaubetriebe arbeiten oft unter extremen Bedingungen, bei denen die Zuverlässigkeit der Ausrüstung nicht verhandelbar ist. Anlasser für schwere Bergbauausrüstungen müssen rauen Umgebungen standhalten, weshalb Qualität ein zentrales Anliegen ist. Einkäufer sollten Lieferanten bevorzugen, die die Industriestandards einhalten und Lieferfristen garantieren können, um sicherzustellen, dass der Betrieb nicht aufgrund von Ausfällen der Ausrüstung unterbrochen wird.

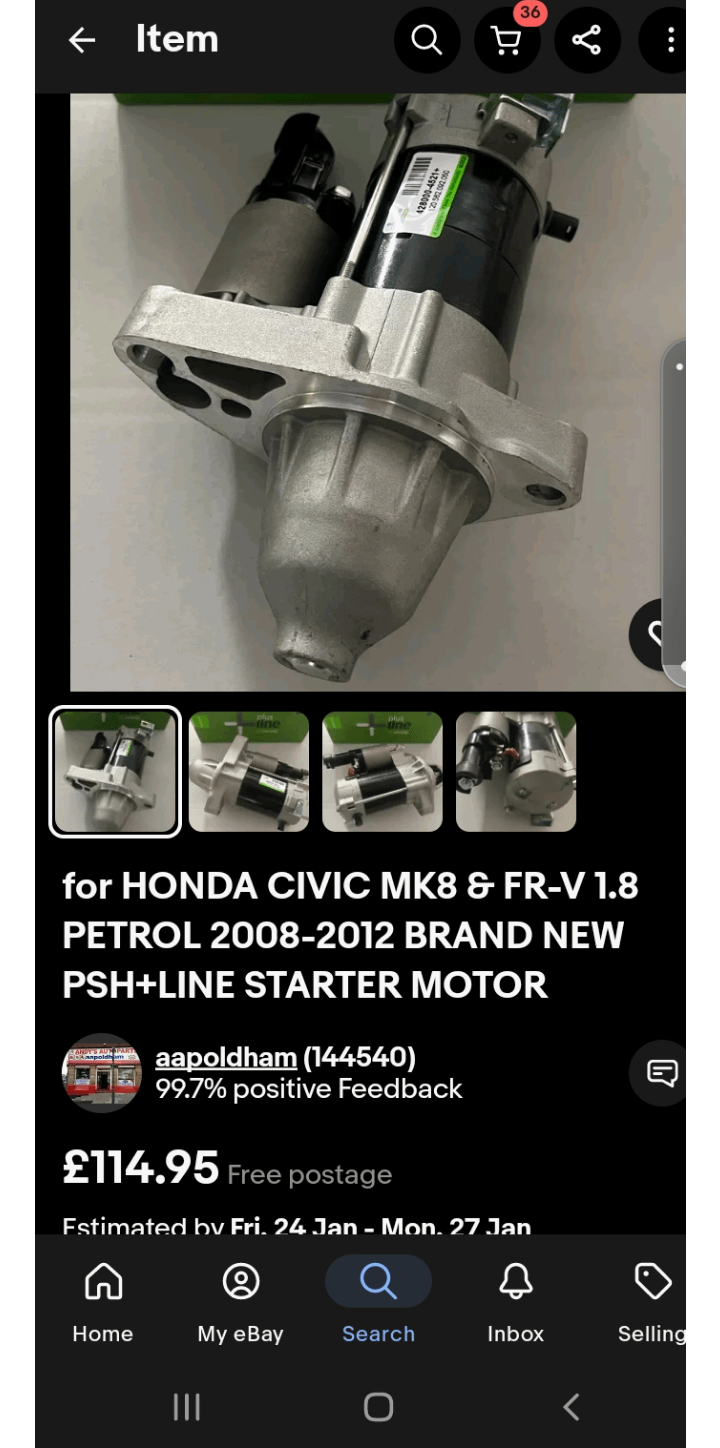

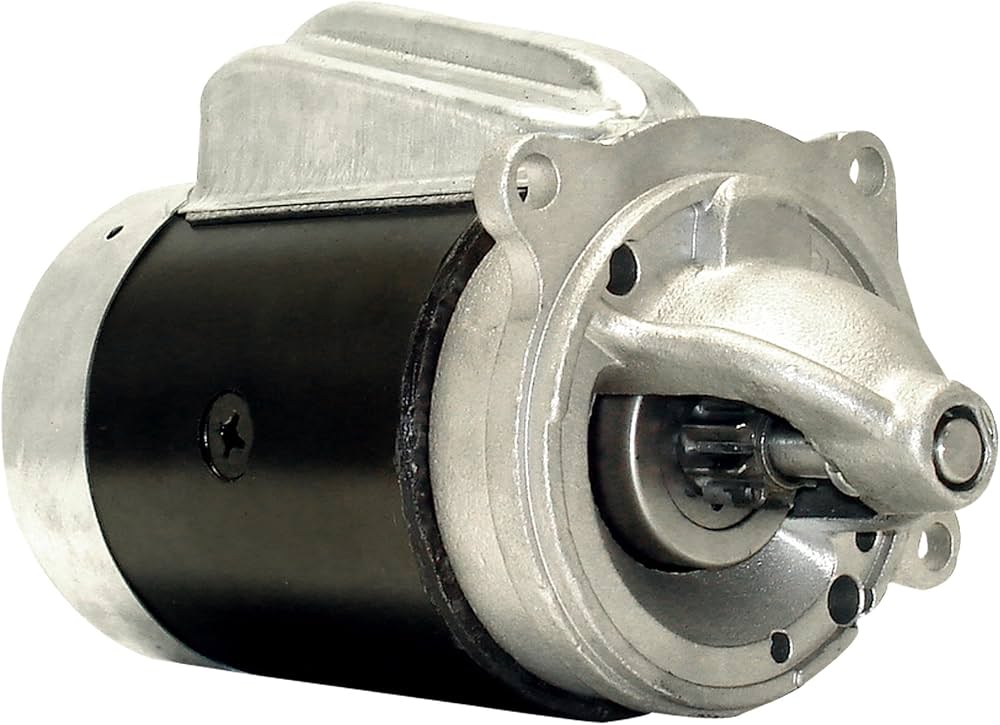

Anschauliches Bild zum Vergleich von neuem und wiederaufbereitetem Anlasser

3 häufige Schmerzpunkte von Nutzern bei der Frage ‘neuer vs. wiederaufbereiteter Anlasser’ und ihre Lösungen

Szenario 1: Kosteneffizienz bei Erstkäufen navigieren

Das Problem: B2B-Einkäufer stehen oft vor dem Dilemma, dass sie bei der Beschaffung von Startern für Flotten oder Geräte ein Gleichgewicht zwischen Qualität und Kosten finden müssen. Angesichts der in vielen Branchen vorherrschenden Budgetbeschränkungen wird die Entscheidung zwischen einem neuen und einem wiederaufbereiteten Anlasser zur Herausforderung. Käufer machen sich möglicherweise Sorgen über die Langlebigkeit und Zuverlässigkeit wiederaufgearbeiteter Einheiten und befürchten, dass die Entscheidung für eine billigere Alternative zu häufigerem Austausch und letztlich zu höheren Kosten auf lange Sicht führen könnte.

Die Lösung: Um dieses Kosten-Nutzen-Dilemma zu umgehen, sollten Käufer unbedingt gründliche Marktforschung betreiben, um Preise und Garantien zwischen neuen und wiederaufbereiteten Startern zu vergleichen. Wenden Sie sich an Lieferanten, die detaillierte Spezifikationen und Prüfzertifikate für ihre wiederaufbereiteten Produkte bereitstellen. Achten Sie auf wiederaufbereitete Anlasser, die eine mit neuen Geräten vergleichbare Garantie bieten, da dies oft auf ein hohes Maß an Qualität hindeutet. Berücksichtigen Sie außerdem die Gesamtbetriebskosten, einschließlich Installation und möglicher Ausfallzeiten. Durch die Berechnung der langfristigen Einsparungen durch wiederaufbereitete Optionen können Käufer fundierte Entscheidungen treffen, die mit ihrem Budget in Einklang stehen und dennoch Zuverlässigkeit gewährleisten.

Szenario 2: Bewertung der Qualität und Zuverlässigkeit von wiederaufbereiteten Startern

Das Problem: Eine häufige Sorge von B2B-Käufern sind die Qualitätsunterschiede bei wiederaufbereiteten Startern. Nicht alle Wiederaufbereiter halten sich an die gleichen Standards, und die Käufer zögern möglicherweise, in Produkte zu investieren, die vorzeitig ausfallen könnten. Diese Unsicherheit kann zu Befürchtungen hinsichtlich der allgemeinen Zuverlässigkeit von wiederaufbereiteten Startern führen, insbesondere bei kritischen Anwendungen, bei denen Ausfallzeiten zu erheblichen finanziellen Verlusten führen können.

Die Lösung: Um Qualitätsprobleme zu vermeiden, sollten Käufer bevorzugt wiederaufbereitete Starter von renommierten Herstellern beziehen, die für ihre strengen Wiederaufbereitungsprozesse bekannt sind. Fordern Sie detaillierte Informationen über die Wiederaufbereitungsstandards an, einschließlich der Art der durchgeführten Tests und der Komponenten, die ersetzt oder überholt werden. Der Aufbau von Beziehungen zu vertrauenswürdigen Lieferanten, die Transparenz in ihren Prozessen bieten, kann ebenfalls für Sicherheit sorgen. Ziehen Sie außerdem in Erwägung, Bewertungen Dritter oder Branchenzertifizierungen in Anspruch zu nehmen, die die Qualität der wiederaufbereiteten Anlasser bestätigen. Diese Sorgfaltspflicht kann das Vertrauen in die Zuverlässigkeit der wiederaufbereiteten Optionen erheblich stärken.

Anschauliches Bild zum Vergleich von neuem und wiederaufbereitetem Anlasser

Szenario 3: Bewältigung von Herausforderungen bei der Kernrendite

Das Problem: Beim Kauf von wiederaufbereiteten Startern sehen sich B2B-Einkäufer oft mit der zusätzlichen Herausforderung konfrontiert, die Rückgabe des Kerns zu verwalten. Viele Lieferanten verlangen die Rückgabe des alten Anlassers als Kern, was den Einkaufsprozess verkomplizieren kann. Käufer können mit logistischen Problemen im Zusammenhang mit dem Versand konfrontiert werden sowie mit potenziellen zusätzlichen Kosten, wenn sie den Kern nicht rechtzeitig zurücksenden oder wenn der Kern beschädigt ist. Dies kann zu Frustration und unerwarteten Kosten führen, die sich auf das gesamte Projektbudget auswirken.

Die Lösung: Um die Herausforderungen bei der Rückgabe von Kernprodukten effektiv zu bewältigen, sollten Einkäufer die Rückgaberichtlinien mit den Lieferanten klären, bevor sie einen Kauf tätigen. Die Kenntnis des Zeitrahmens und der Bedingungen für die Rückgabe von Kernmaterial kann den Einkäufern helfen, sich angemessen vorzubereiten. Die Einführung eines rationalisierten Prozesses für die Abholung und Rücksendung von Hülsen - z. B. die Benennung eines speziellen Teammitglieds, das sich um die Logistik kümmert - kann einen Teil des Aufwands abnehmen. Außerdem sollten Einkäufer detaillierte Aufzeichnungen über die Rücksendung von Kernmaterial führen, einschließlich Versandbestätigungen, um Streitigkeiten oder unerwartete Kosten zu vermeiden. Durch proaktives Management von Kernrücksendungen können Einkäufer Komplikationen minimieren und eine bessere Kontrolle über ihre Lieferkettenprozesse behalten.

Strategischer Leitfaden zur Materialauswahl für neue und wiederaufbereitete Anlasser

Welche Materialien werden üblicherweise in neuen und wiederaufbereiteten Startern verwendet?

Bei der Bewertung der in neuen und wiederaufbereiteten Startern verwendeten Materialien ist es wichtig, die Auswirkungen der jeweiligen Materialwahl unter den Aspekten Leistung, Kosten und Haltbarkeit zu verstehen. Im Folgenden werden vier gängige Materialien für die Herstellung von Startern analysiert: Stahl, Aluminium, Kupfer und Kunststoffverbundwerkstoffe.

Anschauliches Bild zum Vergleich von neuem und wiederaufbereitetem Anlasser

Welchen Einfluss hat Stahl auf die Leistung des Anlassers?

Stahl wird aufgrund seiner hohen Festigkeit und Haltbarkeit überwiegend für das Gehäuse und die strukturellen Komponenten von Startern verwendet. Er ist in der Regel sehr temperaturbeständig und kann hohen Drücken standhalten, wodurch er sich für Anwendungen in der Automobilindustrie eignet.

Vorteile: Stahl bietet eine außergewöhnliche Haltbarkeit und Verschleißfestigkeit, was für Bauteile, die häufigen mechanischen Belastungen ausgesetzt sind, von entscheidender Bedeutung ist. Außerdem ist er relativ kostengünstig und weithin verfügbar, was ihn für die Hersteller zu einer attraktiven Option macht.

Nachteile: Nachteilig ist, dass Stahl schwerer ist als alternative Materialien, was sich auf das Gesamtgewicht des Anlassers auswirken kann. Außerdem ist er bei unsachgemäßer Behandlung anfällig für Korrosion, was zu einem vorzeitigen Ausfall führen kann.

Auswirkungen auf die Anwendung: Die Kompatibilität von Stahl mit verschiedenen Fahrzeugumgebungen macht ihn zu einer zuverlässigen Wahl für den Anfang. Internationale Käufer sollten jedoch sicherstellen, dass die einschlägigen Normen, wie z. B. die ASTM-Normen für Materialspezifikationen, eingehalten werden.

Welche Rolle spielt Aluminium in der Starterherstellung?

Aluminium wird aufgrund seines geringen Gewichts und seiner guten Korrosionsbeständigkeit häufig für die Konstruktion von Anlassergehäusen und einigen internen Komponenten verwendet.

Vorteile: Der Hauptvorteil von Aluminium ist sein geringeres Gewicht, was zu einer verbesserten Kraftstoffeffizienz von Fahrzeugen führen kann. Außerdem bietet es eine gute Wärmeleitfähigkeit, die dazu beiträgt, die beim Betrieb des Anlassers entstehende Wärme abzuleiten.

Nachteile: Aluminium ist zwar korrosionsbeständig, kann aber bei hoher Beanspruchung weniger haltbar sein als Stahl. Außerdem kann der Herstellungsprozess komplexer sein, was die Kosten erhöhen kann.

Auswirkungen auf die Anwendung: Für internationale Käufer, insbesondere in Regionen mit hoher Luftfeuchtigkeit oder korrosiven Umgebungen, können Aluminiumanlasser von Vorteil sein. Zur Qualitätssicherung sollten die Käufer jedoch die Einhaltung lokaler Normen wie DIN oder JIS überprüfen.

Wie verbessert Kupfer die elektrische Leistung von Startern?

Kupfer wird aufgrund seiner ausgezeichneten elektrischen Leitfähigkeit vor allem für die elektrischen Wicklungen und Verbindungen in Startern verwendet.

Vorteile: Die hohe Leitfähigkeit von Kupfer gewährleistet einen effizienten elektrischen Fluss, der für die Leistung des Anlassers entscheidend ist. Außerdem verfügt es über gute thermische Eigenschaften, die es ihm ermöglichen, die während des Betriebs entstehende Wärme zu bewältigen.

Nachteile: Der größte Nachteil von Kupfer ist seine Korrosionsanfälligkeit, insbesondere in rauen Umgebungen. Außerdem ist Kupfer in der Regel teurer als andere leitende Materialien, was sich auf die Gesamtkosten für den Einstieg auswirken kann.

Auswirkungen auf die Anwendung: Für B2B-Käufer, insbesondere in Regionen wie Afrika und Südamerika, wo die Umweltbedingungen sehr unterschiedlich sein können, muss die Wahl des Kupfers gegen das Korrosionspotenzial abgewogen werden. Die Einhaltung elektrischer Normen ist ebenfalls wichtig, um die Zuverlässigkeit zu gewährleisten.

Welche Vorteile bieten Kunststoff-Verbundwerkstoffe im Starterdesign?

Kunststoffverbundwerkstoffe werden in zunehmendem Maße für nichtstrukturelle Komponenten von Startern, wie Abdeckungen und Isolatoren, verwendet.

Anschauliches Bild zum Vergleich von neuem und wiederaufbereitetem Anlasser

Vorteile: Durch die Verwendung von Kunststoffverbundwerkstoffen können Gewicht und Herstellungskosten erheblich gesenkt werden. Außerdem bieten sie eine hervorragende Korrosionsbeständigkeit und können in komplexe Formen gegossen werden, was eine hohe Flexibilität bei der Konstruktion ermöglicht.

Nachteile: Allerdings halten Kunststoffverbundstoffe hohen Temperaturen möglicherweise nicht so gut stand wie Metalle, was ihren Einsatz in stark beanspruchten Bereichen einschränkt. Auch ihre langfristige Haltbarkeit kann ein Problem darstellen, insbesondere unter extremen Bedingungen.

Auswirkungen auf die Anwendung: Für internationale Käufer kann die Verwendung von Kunststoffverbundwerkstoffen aufgrund ihres geringen Gewichts und ihrer Kosteneffizienz attraktiv sein. Es muss jedoch unbedingt sichergestellt werden, dass diese Materialien den lokalen Normen für Automobilkomponenten entsprechen.

Übersichtstabelle zur Materialauswahl für Einsteiger

| Material | Typischer Anwendungsfall für neue und wiederaufbereitete Anlasser | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Gehäuse und Bauteile | Hohe Haltbarkeit und Verschleißfestigkeit | Korrosionsanfällig | Mittel |

| Aluminium | Gehäuse und interne Komponenten | Leichtes Gewicht und gute Wärmeleitfähigkeit | Weniger haltbar bei Belastung | Mittel |

| Kupfer | Elektrische Wicklungen und Anschlüsse | Hervorragende elektrische Leitfähigkeit | Korrosionsanfälligkeit und höhere Kosten | Hoch |

| Kunststoffverbundwerkstoffe | Nicht-strukturelle Komponenten wie Abdeckungen und Isolatoren | Leicht und korrosionsbeständig | Begrenzte Hochtemperaturleistung | Niedrig |

Dieser Leitfaden zur Materialauswahl bietet B2B-Käufern ein umfassendes Verständnis der verschiedenen Materialien, die in neuen und wiederaufbereiteten Startern verwendet werden. Die Eigenschaften, Vorteile und Einschränkungen jedes Materials sollten in Bezug auf spezifische Anwendungen und regionale Normen sorgfältig geprüft werden, um eine optimale Leistung und Konformität zu gewährleisten.

Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für neue und wiederaufbereitete Anlasser

Was sind die typischen Herstellungsverfahren für Neueinsteiger?

Der Herstellungsprozess neuer Anlasser umfasst mehrere wichtige Schritte, von denen jeder für die Gewährleistung einer hohen Leistung und Zuverlässigkeit entscheidend ist. Im Folgenden finden Sie eine Aufschlüsselung der wichtigsten Schritte bei der Herstellung neuer Anlasser:

Anschauliches Bild zum Vergleich von neuem und wiederaufbereitetem Anlasser

-

Materialvorbereitung: Der Prozess beginnt mit der Beschaffung von hochwertigen Rohstoffen wie Stahl, Kupfer und Aluminium. Diese Materialien müssen bestimmte Normen für Haltbarkeit und Leitfähigkeit erfüllen. Die Lieferanten bieten oft Zertifizierungen zur Überprüfung der Materialqualität an, die B2B-Käufer überprüfen sollten.

-

Formung: In dieser Phase werden die Rohmaterialien zu den erforderlichen Komponenten geformt, einschließlich Gehäuse, Rotor und Stator. Techniken wie Druckguss und maschinelle Bearbeitung werden üblicherweise eingesetzt, um präzise Abmessungen zu erzielen. Moderne Technologien wie die CNC-Bearbeitung (Computer Numerical Control) gewährleisten eine hohe Genauigkeit bei der Formung komplexer Formen.

-

Montage: Sobald die einzelnen Komponenten geformt sind, werden sie zu einer kompletten Startereinheit zusammengebaut. Dieser Prozess umfasst in der Regel den Einbau des Ankers, der Bürsten und der Magnetspule. Automatisierte Montagelinien werden häufig eingesetzt, um die Effizienz und Konsistenz zu verbessern und menschliche Fehler zu minimieren.

-

Endbearbeitung: Nach der Montage werden die Anlasser einer Endbearbeitung unterzogen, die eine Lackierung, Beschichtung oder Galvanisierung zum Schutz vor Korrosion umfassen kann. Diese Endbearbeitung ist entscheidend für die Langlebigkeit und Ästhetik des Produkts.

Welche Maßnahmen zur Qualitätskontrolle werden bei der Herstellung neuer Starter eingesetzt?

Die Qualitätskontrolle (QC) bei der Herstellung von neuen Startern ist unerlässlich, um sicherzustellen, dass jedes Gerät die Leistungsspezifikationen und Zuverlässigkeitsstandards erfüllt. Hier sind einige der wichtigsten QC-Maßnahmen:

-

Einhaltung internationaler Normen: Die Hersteller halten sich häufig an internationale Normen wie ISO 9001, in der die Anforderungen an ein Qualitätsmanagementsystem festgelegt sind. Die Einhaltung dieser Norm zeigt, dass ein Hersteller Verfahren zur Gewährleistung der Produktqualität und der Kundenzufriedenheit eingeführt hat.

-

Branchenspezifische Zertifizierungen: Je nach Region müssen Starter auch bestimmte Industrienormen erfüllen, wie z. B. CE- (European Conformity) oder API-Zertifizierungen (American Petroleum Institute). Diese Zertifizierungen garantieren den Käufern, dass die Produkte den Sicherheits- und Leistungsvorschriften entsprechen.

-

Qualitätskontrollpunkte: Die Qualitätskontrolle ist in der Regel in verschiedene Kontrollpunkte unterteilt, darunter:

– Eingangsqualitätskontrolle (IQC): In dieser Phase wird die Qualität der Rohstoffe vor Beginn der Produktion bewertet.

– In-Process-Qualitätskontrolle (IPQC): Die kontinuierliche Überwachung während des Herstellungsprozesses gewährleistet, dass Abweichungen von den Spezifikationen frühzeitig erkannt werden.

– Endkontrolle (FQC): Die fertigen Produkte werden gründlich auf ihre Leistung und Zuverlässigkeit geprüft, wobei häufig automatisierte Prüfgeräte zum Einsatz kommen, die die Bedingungen in der Praxis simulieren. -

Gängige Prüfmethoden: Um sicherzustellen, dass die Anlasser unter verschiedenen Bedingungen ordnungsgemäß funktionieren, können die Hersteller verschiedene Prüfverfahren anwenden, z. B. elektrische Prüfungen, thermische Prüfungen und Vibrationsprüfungen. Diese Tests bestätigen, dass die Anlasser den Anforderungen verschiedener Fahrzeuge und Betriebsumgebungen gewachsen sind.

Wie unterscheiden sich wiederaufgearbeitete Anlasser in der Herstellung und Qualitätskontrolle?

Der Prozess der Wiederaufbereitung von Anfängern unterscheidet sich von der Produktion neuer Geräte und konzentriert sich auf die Wiederherstellung gebrauchter Komponenten in einen neuwertigen Zustand. Der typische Ablauf des Wiederaufbereitungsprozesses ist wie folgt:

-

Demontage: Der Wiederaufbereitungsprozess beginnt mit der sorgfältigen Demontage gebrauchter Anlasser. Jedes Bauteil wird auf Verschleiß und Beschädigung geprüft.

-

Reinigung und Inspektion: Die Bauteile werden gründlich gereinigt, um Ablagerungen und Verunreinigungen zu entfernen. Nach der Reinigung wird jedes Teil einer strengen Prüfung unterzogen, um festzustellen, ob es wiederverwendet werden kann oder ersetzt werden muss.

-

Ersatz von Schlüsselkomponenten: Im Gegensatz zum Wiederaufbau, bei dem nur defekte Teile ersetzt werden, werden bei der Wiederaufbereitung oft mehrere kritische Komponenten wie Lager, Bürsten und Magnetspulen durch neue Teile ersetzt, um die Leistung wiederherzustellen.

-

Wiederzusammenbau und Prüfung: Nach dem Austausch von Teilen wird der Anlasser wieder zusammengebaut und umfangreichen Tests unterzogen. Dies kann elektrische Leistungstests und Haltbarkeitsprüfungen beinhalten, um sicherzustellen, dass die wiederaufbereitete Einheit die OEM-Spezifikationen erfüllt oder übertrifft.

Was sind die Qualitätskontrollstandards für wiederaufbereitete Anlasser?

Die Qualitätssicherung bei wiederaufbereiteten Startern ist genauso wichtig wie bei neuen Startern, auch wenn der Ansatz leicht variiert:

-

Normen und Zertifizierungen: Auch wenn für wiederaufbereitete Anlasser nicht immer dieselben Zertifizierungen wie für neue erforderlich sind, halten sich viele namhafte Hersteller an die ISO 9001 und andere einschlägige Normen. Dies ist ein Zeichen für die Verpflichtung zu Qualität und Zuverlässigkeit.

-

Überlegungen zur Grundgebühr: Käufer von wiederaufbereiteten Startern sollten sich der Kernkosten bewusst sein, die bei der Rückgabe des alten Starters anfallen. Diese Praxis fördert nicht nur das Recycling, sondern stellt auch sicher, dass der Wiederaufbereiter über qualitativ hochwertige Komponenten verfügt, mit denen er in zukünftigen Produkten arbeiten kann.

-

Überprüfung der Qualitätskontrolle von Lieferanten: B2B-Käufer können die Qualitätskontrollmaßnahmen von Wiederaufbereitern überprüfen, indem sie Audits, Qualitätsberichte und Zertifizierungen von Drittanbietern anfordern. Diese Überprüfung ist von entscheidender Bedeutung, vor allem für internationale Käufer, die mit unterschiedlichen Qualitätserwartungen und gesetzlichen Standards konfrontiert sein können.

Wie können internationale B2B-Einkäufer die Qualität bei der Starter-Beschaffung sicherstellen?

Für B2B-Einkäufer, insbesondere in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, ist die Sicherstellung der Qualität bei der Beschaffung von Startern mit mehreren proaktiven Schritten verbunden:

-

Lieferantenaudits: Regelmäßige Audits bei den Lieferanten können dazu beitragen, die Einhaltung von Qualitätsstandards zu gewährleisten. Einkäufer sollten eine Checkliste erstellen, die auf internationalen und branchenspezifischen Normen basiert.

-

Anfordern von Dokumentation: Die Käufer sollten Unterlagen anfordern, die die Herstellungs- und Qualitätskontrollprozesse beschreiben, einschließlich Zertifizierungen, Prüfberichte und die Einhaltung von Normen wie ISO 9001.

-

Inspektionen durch Dritte: Die Beauftragung von Inspektionsdiensten durch Dritte kann eine unvoreingenommene Bewertung der Qualitätskontrollverfahren eines Lieferanten liefern. Dies ist besonders wertvoll, wenn man es mit internationalen Lieferanten zu tun hat, bei denen sprachliche und kulturelle Barrieren bestehen können.

-

Beziehungen aufbauen: Der Aufbau langfristiger Beziehungen zu vertrauenswürdigen Lieferanten kann zu einer besseren Kommunikation und Transparenz bei der Qualitätssicherung führen. Diese Zusammenarbeit kann das Vertrauen des Käufers in die erhaltenen Produkte stärken.

Durch die Kenntnis der Herstellungsverfahren und Qualitätskontrollmaßnahmen für neue und wiederaufbereitete Anlasser können B2B-Einkäufer fundierte Entscheidungen treffen, die mit ihren betrieblichen Anforderungen und Budgetvorgaben in Einklang stehen.

Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘neue vs. wiederaufbereitete Anlasser’.’

Einführung

Die Beschaffung von Startern - ob neu oder wiederaufbereitet - erfordert einen strategischen Ansatz, insbesondere für B2B-Einkäufer in verschiedenen Märkten wie Afrika, Südamerika, dem Nahen Osten und Europa. Dieser Leitfaden bietet eine Schritt-für-Schritt-Checkliste, die Ihnen hilft, fundierte Entscheidungen zu treffen. So können Sie sicherstellen, dass Sie den richtigen Anlasser auswählen, der Ihre betrieblichen Anforderungen erfüllt, und dabei Faktoren wie Kosten, Qualität und Zuverlässigkeit des Lieferanten berücksichtigen.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Es ist wichtig, die spezifischen technischen Anforderungen an den Anlasser zu kennen. Dazu gehören die Kompatibilität mit Fahrzeugmodellen, Spannungsspezifikationen und Leistungsstandards. Eine klare Definition dieser Parameter erleichtert den Auswahlprozess und stellt sicher, dass der Anlasser Ihren betrieblichen Anforderungen ohne zusätzliche Änderungen entspricht.

- Fahrzeug-Kompatibilität: Vergewissern Sie sich, dass der Anlasser zur Marke und zum Modell der Fahrzeuge in Ihrem Fuhrpark passt.

- Leistungsstandards: Achten Sie auf Starter, die die OEM-Spezifikationen erfüllen oder übertreffen, um Zuverlässigkeit zu gewährleisten.

Schritt 2: Bewertung der Budgetrestriktionen

Es ist wichtig, ein klares Budget für Ihre Beschaffung festzulegen. Neue Anlasser sind aufgrund ihres Herstellungsverfahrens in der Regel teurer, während wiederaufbereitete Anlasser erhebliche Einsparungen bieten können. Ein ausgewogenes Verhältnis zwischen Kosten und Qualität ist entscheidend, insbesondere in Regionen mit knappen Budgets.

- Kostenvergleich: Analysieren Sie den Preisunterschied zwischen neuen und wiederaufbereiteten Startern, die in der Regel zwischen 30% und 50% liegen.

- Total Cost of Ownership: Berücksichtigen Sie mögliche langfristige Einsparungen, wenn Sie sich für einen wiederaufbereiteten Anlasser entscheiden, der den Qualitätsstandards entspricht.

Schritt 3: Bewerten Sie die Glaubwürdigkeit von Lieferanten

Bevor Sie sich für einen Anbieter entscheiden, sollten Sie unbedingt dessen Referenzen prüfen. Dazu gehört die Überprüfung der Erfahrung, des Rufs und der Qualitätskontrollverfahren. Die Zusammenarbeit mit seriösen Lieferanten minimiert die Risiken, die mit minderwertigen Produkten verbunden sind.

- Qualitätssicherung: Erkundigen Sie sich nach den Prüfverfahren für wiederaufbereitete Anlasser, um sicherzustellen, dass sie die Zuverlässigkeitsstandards erfüllen.

- Zertifizierungen: Achten Sie auf Branchenzertifizierungen, die das Engagement des Lieferanten für Qualität und Leistung bestätigen.

Schritt 4: Prüfen Sie die Garantieoptionen

Garantien können Ihnen Sicherheit geben und Ihre Investition schützen. Sowohl neue als auch wiederaufbereitete Anlasser sollten mit Garantien ausgestattet sein, die das Vertrauen des Herstellers in seine Produkte widerspiegeln. Wenn Sie die Garantiebedingungen verstehen, können Sie das mit Ihrem Kauf verbundene Risiko besser einschätzen.

- Garantiedauer: Vergleichen Sie die Garantiezeiten für neue und wiederaufbereitete Anlasser.

- Einzelheiten zum Versicherungsschutz: Prüfen Sie, was die Garantie abdeckt - Teile, Arbeit oder beides - und welche Ausschlüsse es gibt.

Schritt 5: Umweltauswirkungen berücksichtigen

Die Entscheidung für wiederaufbereitete Anlasser kann die Umweltverschwendung erheblich reduzieren. Das Wissen um die ökologischen Vorteile Ihrer Kaufentscheidungen steht im Einklang mit globalen Nachhaltigkeitszielen und kann den Ruf Ihres Unternehmens verbessern.

- Praktiken der Nachhaltigkeit: Recherchieren Sie nach Lieferanten, die bei ihren Wiederaufbereitungsprozessen auf umweltfreundliche Praktiken Wert legen.

- Kern-Rückkehr-Programme: Prüfen Sie, ob die Lieferanten Anreize für die Rückgabe alter Starter bieten, was die Recycling-Bemühungen unterstützt.

Schritt 6: Plan für Installation und Support

Berücksichtigen Sie bei der Auswahl von Startern die Logistik der Installation und des laufenden Supports. Beurteilen Sie, ob Ihr Team über die nötigen Fähigkeiten verfügt, um die Installation durchzuführen, oder ob Sie professionelle Dienstleistungen in Anspruch nehmen müssen.

- Komplexität der Installation: Beurteilen Sie, wie einfach der Installationsprozess für die in Frage kommenden Starter ist.

- Technische Unterstützung: Bestätigen Sie die Verfügbarkeit von technischer Unterstützung durch den Lieferanten, um etwaige Installationsprobleme zu lösen.

Schritt 7: Treffen Sie eine informierte Entscheidung

Wägen Sie nach Abschluss Ihrer Recherche und Analyse alle Faktoren ab, um eine endgültige Entscheidung zu treffen. Achten Sie darauf, dass Ihre Wahl mit Ihren betrieblichen Anforderungen, Ihrem Budget und Ihren Qualitätserwartungen übereinstimmt.

- Dokumentation: Führen Sie Aufzeichnungen über alle Spezifikationen, Angebote und die Kommunikation mit den Lieferanten, damit Sie später darauf zurückgreifen können.

- Rückkopplungsschleife: Einrichtung eines Systems zur Erfassung von Rückmeldungen der Nutzer des Starters, um die Leistung und Zufriedenheit nach dem Kauf zu bewerten.

Wenn Sie diese Schritte befolgen, können B2B-Einkäufer sicher durch die Komplexität der Beschaffung von Startern navigieren und sicherstellen, dass sie die beste Option für ihre geschäftlichen Anforderungen auswählen.

Umfassende Kosten- und Preisanalyse für neue und wiederaufbereitete Anlasser Beschaffung

Was sind die wichtigsten Kostenkomponenten bei neuen und wiederaufbereiteten Startern?

Bei der Prüfung von Beschaffungsoptionen für Anlasser ist das Verständnis der Kostenstruktur entscheidend. Bei neuen Startern umfassen die Kostenkomponenten in der Regel Rohstoffe, Arbeitskräfte, Fertigungsgemeinkosten, Werkzeuge, Qualitätskontrolle, Logistik und die Marge des Lieferanten.

Anschauliches Bild zum Vergleich von neuem und wiederaufbereitetem Anlasser

-

Materialien: Für neue Anlasser werden neue Materialien benötigt, was vor allem bei hochwertigen Bauteilen kostspielig sein kann. Im Gegensatz dazu werden bei wiederaufbereiteten Startern eine Kombination aus wiederverwendeten Teilen und neuen Komponenten verwendet, was die Materialkosten erheblich senkt.

-

Arbeit: Die Arbeitskosten können je nach Komplexität der Anlasserkonstruktion variieren. Die Herstellung eines neuen Anlassers ist in der Regel mit einem höheren Arbeitsaufwand verbunden, da völlig neue Komponenten zusammengebaut werden müssen, während bei wiederaufbereiteten Anlassern die Arbeitskosten niedriger sind, da die vorhandenen Teile demontiert, gereinigt und wieder zusammengebaut werden müssen.

-

Fertigungsgemeinkosten: Bei neuen Startern können die Gemeinkosten, einschließlich der Kosten für Betriebsmittel und Anlagen, höher sein, da für die Produktion umfangreiche Maschinen und Verfahren erforderlich sind. Wiederaufgearbeitete Anlasser können niedrigere Gemeinkosten haben, da sie vorhandene Teile verwenden.

-

Werkzeuge: Die Herstellung neuer Anlasser erfordert oft spezielle Werkzeuge, die erhebliche Vorlaufkosten verursachen können. Wiederaufbereitete Anlasser erfordern möglicherweise nicht so viele Investitionen in neue Werkzeuge, was die Gesamtkosten senkt.

-

Qualitätskontrolle: Eine strenge Qualitätskontrolle ist sowohl für neue als auch für wiederaufgearbeitete Anlasser unerlässlich. Bei wiederaufgearbeiteten Aggregaten werden jedoch oft umfangreiche Testverfahren durchgeführt, um sicherzustellen, dass sie den Standards des Originalherstellers (OEM) entsprechen, was die Kosten erhöhen, aber auch die Zuverlässigkeit steigern kann.

-

Logistik: Die Versandkosten können je nach Größe und Gewicht des Anlassers variieren. Bei überholten Startern können die Versandkosten niedriger sein, da sie aufgrund der wiederverwendeten Komponenten oft leichter sind.

-

Marge: Die Lieferanten wenden in der Regel unterschiedliche Gewinnspannen für neue und wiederaufbereitete Anlasser an, wobei wiederaufbereitete Einheiten aufgrund der geringeren Produktionskosten oft einen niedrigeren Aufschlag haben.

Wie beeinflussen Preiseinflussfaktoren die Beschaffungsentscheidungen?

Mehrere Faktoren können den Preis von neuen gegenüber wiederaufbereiteten Startern beeinflussen:

-

Volumen und Mindestbestellmenge (MOQ): Größere Bestellungen können zu erheblichen Preisnachlässen führen, insbesondere bei wiederaufbereiteten Geräten, die aufgrund der niedrigeren Produktionskosten oft flexiblere Preisstrukturen aufweisen.

-

Spezifikationen und Anpassung: Kundenspezifische Spezifikationen können die Kosten erhöhen, insbesondere bei neuen Startern, da sie besondere Herstellungsverfahren erfordern. Wiederaufgearbeitete Anlasser können oft leichter an spezifische Anforderungen angepasst werden.

-

Qualität und Zertifizierungen: Zertifizierungen können sich auf die Preisgestaltung auswirken; neue Anlasser werden in der Regel mit OEM-Zertifizierungen geliefert, während wiederaufbereitete Anlasser ihre Konformität durch strenge Tests und Qualitätssicherungsmaßnahmen nachweisen müssen.

-

Lieferantenfaktoren: Die Zuverlässigkeit und der Ruf des Lieferanten können die Preisgestaltung beeinflussen. Etablierte Anbieter können aufgrund der Vertrauenswürdigkeit ihrer Marke einen Aufschlag für neue Anlasser verlangen, während weniger bekannte Marken wettbewerbsfähige Preise für wiederaufbereitete Optionen anbieten können.

-

Incoterms: Das Verständnis der Incoterms ist für internationale Käufer unerlässlich. Die Kosten können je nach Versandbedingungen, Versicherung und Zuständigkeit für Zölle und Steuern erheblich variieren, was sich auf die Gesamtkosten auswirken kann.

Welche Tipps für Einkäufer können helfen, die Kosten zu optimieren?

Für internationale B2B-Einkäufer, insbesondere in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, gibt es einige Strategien zur Kostenoptimierung bei der Beschaffung von Vorspeisen:

-

Verhandlung: Nutzen Sie das Einkaufsvolumen, um bessere Preisbedingungen auszuhandeln. Wenden Sie sich an mehrere Lieferanten, um Angebote und Konditionen zu vergleichen.

-

Kosteneffizienz: Bewerten Sie die Gesamtbetriebskosten (TCO) und nicht nur den Anschaffungspreis. Berücksichtigen Sie Faktoren wie Langlebigkeit, Garantie und Wartungskosten.

-

Nuancen in der Preisgestaltung: Achten Sie auf Währungsschwankungen und Einfuhrzölle, die die Preisgestaltung beeinflussen können. Die Suche nach lokalen Anbietern kann auch zu günstigeren Preisen aufgrund geringerer Versandkosten führen.

-

Qualitätssicherung: Stellen Sie sicher, dass wiederaufbereitete Anlasser die OEM-Spezifikationen erfüllen oder übertreffen, um höhere langfristige Kosten im Zusammenhang mit Ausfällen oder Ersatz zu vermeiden.

-

Beziehungen zu den Lieferanten: Aufbau enger Beziehungen zu Lieferanten, um einen besseren Service, potenzielle Rabatte und Einblicke in neue Produkte oder Preisänderungen zu erhalten.

Zusammenfassend lässt sich sagen, dass das Verständnis der komplexen Kostenstrukturen und Preiseinflüsse zwischen neuen und wiederaufbereiteten Startern B2B-Einkäufer in die Lage versetzen kann, fundierte Beschaffungsentscheidungen zu treffen, die mit ihren betrieblichen Anforderungen und Budgetvorgaben in Einklang stehen.

Analyse der Alternativen: Vergleich zwischen neuen und wiederaufbereiteten Startern und anderen Lösungen

In der Automobilindustrie, insbesondere beim Austausch von Anlassern, stehen die Käufer oft vor der Wahl zwischen neuen und wiederaufbereiteten Anlassern. Es gibt jedoch auch alternative Lösungen, die bestimmten Bedürfnissen oder Vorlieben entsprechen können. In diesem Abschnitt werden praktikable Alternativen untersucht und mit den Standardoptionen neuer und wiederaufgearbeiteter Anlasser verglichen.

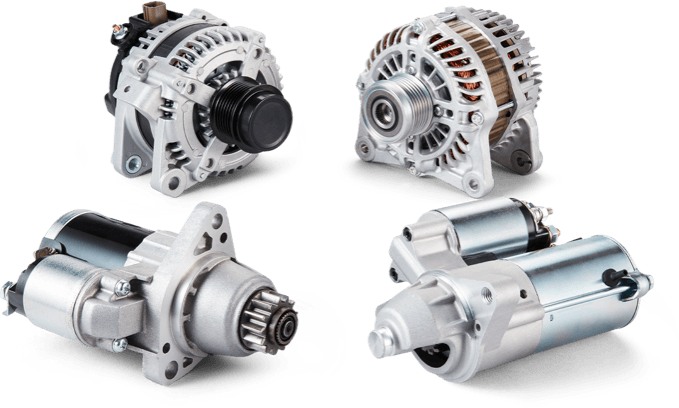

| Vergleichsaspekt | Neuer vs. überholter Anlasser | Aftermarket-Starterkits | DIY-Starter-Reparatur |

|---|---|---|---|

| Leistung | Hohe Zuverlässigkeit; erfüllt OEM-Standards | Variiert je nach Marke; kann in einigen Fällen über OEM liegen | Abhängig von den Fähigkeiten; entspricht möglicherweise nicht der OEM-Leistung |

| Kosten | Höhere Kosten; typischerweise $200-$500 | Moderate Kosten; reicht von $100-$300 | Geringe Kosten; nur wenige Teile erforderlich, aber zeitintensiv |

| Einfache Implementierung | Einfacher Einbau; erfordert einfache Werkzeuge | Unterschiedlich; in der Regel benutzerfreundlich, kann aber spezielle Tools erfordern | Komplex; erfordert mechanische Kenntnisse und Werkzeuge |

| Wartung | Minimal; neue Teile erfordern Standardwartung | Mäßig; abhängig von der Markenqualität | Hoch; laufende Anpassungen können erforderlich sein |

| Bester Anwendungsfall | Beste Voraussetzungen für langfristige Zuverlässigkeit und Garantie | Gut für preisbewusste Käufer, die Alternativen suchen | Geeignet für erfahrene Heimwerker, die Geld sparen wollen |

Wie schneiden Aftermarket-Starterkits im Vergleich zu neuen und wiederaufbereiteten Startern ab?

Aftermarket-Starterkits stellen eine kostengünstige Alternative dar und liegen preislich oft zwischen $100 und $300. Diese Kits können je nach Hersteller eine Leistung bieten, die den OEM-Spezifikationen entspricht oder diese sogar übertrifft. Die Qualität kann jedoch uneinheitlich sein, und die Käufer müssen sich sorgfältig über die Marken informieren, um die Zuverlässigkeit sicherzustellen. Der Einbau ist in der Regel einfach, aber für einige Kits sind spezielle Werkzeuge erforderlich, die die Gesamtkosten in die Höhe treiben können.

Sind selbst durchgeführte Anlasserreparaturen im Vergleich zu neuen und wiederaufbereiteten Anlassern eine sinnvolle Option?

Die Reparatur eines Starters im Eigenbau kann eine kostengünstige Alternative sein, vor allem, wenn der Besitzer über die notwendigen mechanischen Fähigkeiten und Werkzeuge verfügt. Dieser Ansatz verursacht in der Regel nur minimale Kosten, da der Schwerpunkt auf dem Austausch fehlerhafter Komponenten und nicht auf dem Austausch der gesamten Einheit liegt. Die Komplexität der Reparaturen kann jedoch hoch sein, und die Leistung entspricht möglicherweise nicht der von neuen oder wiederaufbereiteten Startern. Diese Option ist am besten für erfahrene Personen geeignet, die bereit sind, Zeit und Mühe in den Reparaturprozess zu investieren.

Anschauliches Bild zum Vergleich von neuem und wiederaufbereitetem Anlasser

Schlussfolgerung: Wie sollten B2B-Einkäufer die richtige Starter-Lösung auswählen?

Bei der Wahl zwischen neuen und wiederaufbereiteten Startern und ihren Alternativen sollten B2B-Käufer ihre spezifischen betrieblichen Anforderungen, Budgetbeschränkungen und die Bedeutung der Zuverlässigkeit berücksichtigen. Neue Anlasser bieten die höchste Gewähr für Qualität und Langlebigkeit und sind daher ideal für kritische Anwendungen. Aufgearbeitete Anlasser bieten ein ausgewogenes Verhältnis zwischen Kosten und Leistung, während Aftermarket-Kits und DIY-Reparaturen als wirtschaftliche Lösungen für weniger anspruchsvolle Situationen dienen können. Letztendlich wird die Bewertung der Gesamtbetriebskosten, einschließlich der Wartungs- und Leistungserwartungen, den Käufern dabei helfen, die beste Entscheidung für ihren Betrieb zu treffen.

Wesentliche technische Eigenschaften und Fachterminologie für neue und wiederaufbereitete Anlasser

Was sind die wichtigsten technischen Eigenschaften von neuen und wiederaufbereiteten Startern?

Bei der Bewertung von neuen und wiederaufbereiteten Startern ist es wichtig, einige kritische technische Eigenschaften zu kennen. Diese Spezifikationen wirken sich nicht nur auf die Leistung und Langlebigkeit der Anlasser aus, sondern beeinflussen auch die Kaufentscheidungen der B2B-Käufer.

1. Material Klasse

Die Materialqualität bezieht sich auf die Qualität der für die Herstellung des Anlassers verwendeten Materialien. Neue Anlasser werden in der Regel aus hochwertigen Materialien hergestellt, die den strengen OEM-Normen (Original Equipment Manufacturer) entsprechen. Im Gegensatz dazu können wiederaufbereitete Anlasser eine Kombination aus wiederverwendeten und neuen Teilen enthalten. Hochwertige wiederaufbereitete Anlasser enthalten oft Materialien in Erstausrüsterqualität, um eine zuverlässige Leistung zu gewährleisten. Für B2B-Einkäufer ist die Kenntnis der Materialqualität von entscheidender Bedeutung, um sicherzustellen, dass die von ihnen erworbenen Anlasser den Betriebsanforderungen standhalten und eine lange Lebensdauer aufweisen.

2. Toleranz

Unter Toleranz versteht man die zulässige Abweichung von den Abmessungen und Spezifikationen der Anlasserkomponenten. Neue Anlasser werden nach präzisen Toleranzen gefertigt, um eine optimale Passform und Funktion zu gewährleisten. Überholte Anlasser können diese Toleranzen je nach Qualität des Überholungsverfahrens ebenfalls einhalten. Im B2B-Bereich sind enge Toleranzen entscheidend für die Kompatibilität mit verschiedenen Fahrzeugmodellen, um das Risiko von Einbauproblemen zu minimieren und die allgemeine Zuverlässigkeit zu erhöhen.

3. Leistungsstandards

Die Leistungsnormen legen fest, welche Anforderungen die Anlasser erfüllen müssen, z. B. in Bezug auf Startleistung, Haltbarkeit und Effizienz. Neue Anlasser entsprechen in der Regel den neuesten, von den Herstellern festgelegten Leistungsnormen, während wiederaufbereitete Anlasser diese Normen aufgrund strenger Tests oft erfüllen oder übertreffen. Für Unternehmen ist es wichtig, dass ein Anlasser diese Leistungskriterien erfüllt, um die Zuverlässigkeit des Fahrzeugs zu erhalten und Ausfallzeiten zu reduzieren.

4. Garantieabdeckung

Die Garantieleistung ist ein wichtiger Faktor bei der Kaufentscheidung. Neue Anlasser werden in der Regel mit einer Herstellergarantie geliefert, die oft zwischen einem und drei Jahren liegt. Wiederaufgearbeitete Anlasser bieten in der Regel auch Garantien, die vergleichbar oder sogar besser sein können, wie z. B. begrenzte lebenslange Garantien. B2B-Einkäufer sollten die Garantiebedingungen prüfen, da sie eine Qualitätsgarantie bieten und die langfristigen Kosten für den Austausch von Ersatzteilen verringern können.

5. Auswirkungen auf die Umwelt

Für viele Unternehmen wird es immer wichtiger, die Umweltauswirkungen von Anlasseroptionen zu verstehen. Wiederaufbereitete Anlasser stellen eine nachhaltigere Wahl dar, da sie Komponenten wiederverwenden und Abfall reduzieren. Dies kann ein wichtiges Verkaufsargument für Unternehmen sein, die ihre Initiativen zur sozialen Verantwortung der Unternehmen (CSR) verbessern wollen. B2B-Einkäufer sollten darauf achten, wie ihre Wahl mit den Nachhaltigkeitszielen übereinstimmt.

Was sind gängige Handelsbegriffe in der Starterbranche?

Die Vertrautheit mit der Branchenterminologie ist für eine effektive Kommunikation und Entscheidungsfindung auf dem Anlassermarkt unerlässlich. Im Folgenden finden Sie einige gängige Fachbegriffe, die für neue und wiederaufbereitete Anlasser relevant sind.

1. OEM (Original Equipment Manufacturer)

OEM bezieht sich auf Komponenten, die vom Originalhersteller des Fahrzeugs hergestellt wurden. Diese Teile sind so konzipiert, dass sie bestimmte Normen erfüllen, und werden oft wegen ihrer garantierten Kompatibilität und Zuverlässigkeit bevorzugt. B2B-Käufer sollten sich darüber im Klaren sein, dass OEM-Teile in der Regel einen höheren Preis haben, dafür aber eine bessere Leistung garantieren.

2. MOQ (Mindestbestellmenge)

MOQ bezieht sich auf die kleinste Menge eines Produkts, die ein Lieferant zu verkaufen bereit ist. Auf dem Einsteigermarkt ist das Verständnis der MOQ für die Verwaltung von Beständen und Kosten für Unternehmen von entscheidender Bedeutung. Lieferanten legen MOQs oft fest, um die Rentabilität zu gewährleisten, daher sollten Käufer Bedingungen aushandeln, die ihren betrieblichen Anforderungen entsprechen.

3. RFQ (Request for Quotation)

Eine Anfrage ist ein Dokument, das Einkäufer an Lieferanten senden, um Preise und Bedingungen für bestimmte Produkte, einschließlich Vorspeisen, anzufordern. Dieses Verfahren ermöglicht es Unternehmen, Kosten, Lieferzeiten und andere wichtige Faktoren zu vergleichen. Für B2B-Einkäufer ist die Anfrage ein entscheidender Schritt bei der Beschaffung.

4. Incoterms

Incoterms (International Commercial Terms) sind standardisierte Handelsbedingungen, die die Verantwortlichkeiten von Käufern und Verkäufern bei internationalen Transaktionen festlegen. Diese Bedingungen klären die Verantwortlichkeiten für den Versand, die Kosten und das Risikomanagement. B2B-Einkäufer, die an der grenzüberschreitenden Beschaffung von Vorspeisen beteiligt sind, müssen mit den Incoterms vertraut sein, um Missverständnisse zu vermeiden und reibungslose Transaktionen zu gewährleisten.

Durch die Kenntnis dieser technischen Eigenschaften und Handelsbedingungen können B2B-Einkäufer fundierte Entscheidungen über neue und wiederaufbereitete Anlasser treffen und sowohl die Leistung als auch die Kosteneffizienz in ihrem Betrieb optimieren.

Marktdynamik und Beschaffungstrends im Bereich neuer und wiederaufbereiteter Anlasser

Wie ist die aktuelle Marktdynamik bei neuen und wiederaufbereiteten Startern?

Der Weltmarkt für Kfz-Anlasser, insbesondere der Markt für neue bzw. wiederaufbereitete Anlasser, wird von mehreren wichtigen Faktoren bestimmt. Erstens treibt der steigende Fahrzeugbesitz in Regionen wie Afrika und Südamerika die Nachfrage nach zuverlässigen, kostengünstigen Ersatzteilen voran. B2B-Käufer in diesen Märkten entscheiden sich zunehmend für wiederaufbereitete Anlasser, da diese preisgünstiger sind - oft 30% bis 50% günstiger als neue Alternativen - und dennoch eine vergleichbare Qualität und Langlebigkeit bieten. Dieser Trend wird durch die zunehmende Komplexität moderner Fahrzeuge unterstützt, die fortschrittliche Technologien und Komponenten erfordern, deren Neuanschaffung kostspielig sein kann.

Neue Technologien beeinflussen auch die Trends in der Beschaffung. Die Digitalisierung der Lieferketten durch Plattformen, die den Zugang zu wiederaufbereiteten Teilen erleichtern, wird immer alltäglicher. Dies ist vor allem für internationale Einkäufer von Vorteil, die bei der Beschaffung von Teilen von traditionellen Lieferanten mit logistischen Problemen konfrontiert werden können. Darüber hinaus setzt sich der Trend zum Online-Einkauf durch, der es B2B-Käufern ermöglicht, Preise und Qualität effizienter zu vergleichen.

Eine weitere Dynamik ist die zunehmende Betonung von Garantieleistungen für wiederaufbereitete Anlasser, die oft denen von neuen Geräten entsprechen oder diese sogar übertreffen. Dies gibt den Käufern zusätzliche Sicherheit für ihre Investition. Darüber hinaus liegt der Schwerpunkt zunehmend auf der lokalen Beschaffung, insbesondere in Regionen wie dem Nahen Osten und Europa, wo die Käufer Lieferanten bevorzugen, die kürzere Lieferzeiten und geringere Versandkosten bieten können.

Wie beeinflussen Nachhaltigkeit und ethische Beschaffung die Entscheidung zwischen neuen und wiederaufbereiteten Startern?

Nachhaltigkeit wird zu einem entscheidenden Faktor im Entscheidungsprozess von B2B-Einkäufern in der Automobilbranche. Die Wiederaufbereitung von Startern verringert die Umweltauswirkungen erheblich, indem sie den Lebenszyklus bestehender Komponenten verlängert und damit die Abfallmenge verringert. Internationale Einkäufer, insbesondere in Regionen wie Nigeria und Brasilien, entscheiden sich für wiederaufbereitete Teile, um den wachsenden Umweltvorschriften und den Verbraucherpräferenzen für nachhaltige Praktiken gerecht zu werden.

Auch die ethische Beschaffung spielt eine wichtige Rolle. Die Einkäufer nehmen ihre Lieferketten zunehmend unter die Lupe, um sicherzustellen, dass Materialien und Prozesse nicht nur umweltfreundlich, sondern auch ethisch einwandfrei sind. Dazu gehören auch Zertifizierungen, die nachhaltige Praktiken und die verantwortungsvolle Beschaffung von Rohstoffen belegen. Wiederaufbereitete Starter verfügen oft über solche Zertifizierungen, die den Käufern Sicherheit bei ihrer Wahl geben.

Da die globalen Lieferketten von Unterbrechungen bedroht sind, kann die Möglichkeit, wiederaufbereitete Starter vor Ort zu beziehen, zu einer Verringerung der Transportemissionen führen und die lokale Wirtschaft unterstützen. Dieser doppelte Vorteil der Nachhaltigkeit und der ethischen Beschaffung ist besonders für internationale B2B-Einkäufer interessant, die ihr Corporate Social Responsibility (CSR)-Profil verbessern möchten.

Was ist der historische Kontext hinter dem Markt für neue und wiederaufbereitete Anlasser?

Das Konzept der Wiederaufbereitung hat sich in den letzten Jahrzehnten erheblich weiterentwickelt. Ursprünglich wurden wiederaufgearbeitete Komponenten mit Skepsis betrachtet und oft als minderwertig gegenüber neuen Teilen angesehen. Durch Fortschritte in der Technologie und Qualitätskontrolle hat sich der Aufbereitungsprozess jedoch gewandelt und ist zu einer echten Alternative zu neuen Komponenten geworden. Heute werden wiederaufbereitete Anlasser strengen Tests und Qualitätssicherungsprozessen unterzogen, die sicherstellen, dass sie die Standards der Originalhersteller (OEM) erfüllen oder übertreffen.

Der Wandel hin zu einer nachhaltigen Fertigungspraxis hat die Akzeptanz von wiederaufbereiteten Teilen weiter erhöht. Da die Umweltbedenken zugenommen haben, hat sich die Automobilindustrie darauf eingestellt, indem sie die Wiederaufbereitung als Lösung zur Reduzierung von Abfall und Ressourcenverbrauch fördert. Diese Entwicklung hat nicht nur kosteneffiziente Optionen für die Käufer geschaffen, sondern auch wiederaufbereitete Starter als verantwortungsvolle Wahl in einem zunehmend umweltbewussten Markt positioniert.

Zusammenfassend lässt sich sagen, dass die Dynamik des Sektors für neue und wiederaufbereitete Starter von wirtschaftlichen Faktoren, technologischen Fortschritten, Nachhaltigkeit und ethischer Beschaffung beeinflusst wird. Für internationale B2B-Einkäufer ist es entscheidend, diese Trends zu verstehen, um fundierte Kaufentscheidungen zu treffen, die mit ihren betrieblichen Anforderungen und Unternehmenswerten übereinstimmen.

Häufig gestellte Fragen (FAQs) für B2B-Käufer von neuen und wiederaufbereiteten Startern

-

Wie kann ich entscheiden, ob ich einen neuen oder einen überholten Anlasser kaufen soll?

Bei der Entscheidung zwischen einem neuen und einem überholten Anlasser sollten Sie Ihr Budget, Ihre Qualitätsanforderungen und Ihre Dringlichkeit berücksichtigen. Neue Anlasser bieten die Sicherheit fabrikneuer Komponenten und werden in der Regel mit einer Garantie geliefert. Wiederaufbereitete Anlasser hingegen bieten eine ähnliche Zuverlässigkeit zu einem geringeren Preis und sind daher eine attraktive Option für preisbewusste Käufer. Vergewissern Sie sich, dass Sie die Qualitätskontrollstandards und Prüfverfahren des Herstellers kennen, da diese die Leistung und Lebensdauer des Anlassers erheblich beeinflussen können. -

Was sind die Kostenunterschiede zwischen neuen und wiederaufbereiteten Startern?

Wiederaufbereitete Anlasser kosten in der Regel 30% bis 50% weniger als ihre neuen Gegenstücke, was sie zu einer attraktiven Wahl für Unternehmen macht, die ihre Kosten senken wollen. Bedenken Sie jedoch, dass die Rücksendung des alten Anlassers mit Kosten verbunden ist, die sich auf die Gesamtkosten auswirken können. Es ist ratsam, die Preise mehrerer Anbieter zu vergleichen und die Versandkosten zu berücksichtigen, insbesondere bei internationalen Bestellungen, damit Sie eine fundierte Kaufentscheidung treffen können. -

Auf welche Qualitätssicherungsmaßnahmen sollte ich bei wiederaufbereiteten Startern achten?

Bei der Beschaffung von wiederaufbereiteten Startern ist die Qualitätssicherung entscheidend. Achten Sie auf Lieferanten, die detaillierte Informationen über ihre Wiederaufbereitungsprozesse bereitstellen, einschließlich Demontage, Inspektion und Wiederzusammenbau mit neuen Teilen. Prüfen Sie außerdem, ob die Anlasser strengen Tests unterzogen werden, um die OEM-Spezifikationen zu erfüllen oder zu übertreffen. Viele seriöse Anbieter bieten ähnliche Garantien wie für neue Anlasser, was als Indikator für ihr Vertrauen in die Produktqualität dienen kann. -

Wie kann ich bei der Beschaffung von Startern die Kompatibilität mit meinem Fahrzeug sicherstellen?

Um die Kompatibilität sicherzustellen, sollten Sie bei der Kommunikation mit den Lieferanten die Marke, das Modell und das Baujahr Ihres Fahrzeugs angeben. Viele wiederaufbereitete Anlasser sind so konzipiert, dass sie in eine Vielzahl von Fahrzeugen passen, aber die Spezifikationen können variieren. Erkundigen Sie sich außerdem nach dem Katalog oder der Datenbank des Anbieters, in der kompatible Teile aufgeführt sind. Dieser proaktive Ansatz kann dazu beitragen, kostspielige Fehler zu vermeiden und sicherzustellen, dass Sie den richtigen Anlasser für Ihre Anwendung erhalten. -

Was muss ich bei der internationalen Beschaffung von Vorspeisen in Bezug auf Lieferzeiten und Logistik beachten?

Die Lieferzeiten können je nach Standort des Lieferanten, Produktionskapazität und Versandoptionen variieren. Klären Sie bei der internationalen Beschaffung die erwarteten Lieferzeiten und berücksichtigen Sie mögliche Verzögerungen beim Zoll. Arbeiten Sie mit Lieferanten zusammen, die Erfahrung im internationalen Versand haben, um eine reibungslose Logistik zu gewährleisten. Ziehen Sie auch den Einsatz von Spediteuren oder lokalen Händlern in Betracht, die den Prozess beschleunigen und Sie bei der Einhaltung der lokalen Vorschriften unterstützen können. -

Gibt es Mindestbestellmengen (MOQs), die ich bei der Beschaffung von Vorspeisen beachten sollte?

Viele Lieferanten haben Mindestbestellmengen (MOQs), die je nach Art der Vorspeise und den Richtlinien des Lieferanten stark variieren können. Es ist wichtig, die MOQs im Vorfeld zu besprechen, um Ihren Bedarf mit den Anforderungen des Lieferanten in Einklang zu bringen. Wenn Ihr Bedarf geringer ist, bieten einige Lieferanten Flexibilität oder alternative Lösungen an, z. B. die Kombination von Bestellungen oder die Beschaffung bei verschiedenen Herstellern, um Ihren Bedarf zu decken, ohne die MOQs zu überschreiten. -

Welche Zahlungsbedingungen werden von den Lieferanten für den Anfang üblicherweise angeboten?

Die Zahlungsbedingungen können von Lieferant zu Lieferant sehr unterschiedlich sein, insbesondere bei internationalen Geschäften. Zu den üblichen Bedingungen gehören Vorauszahlung, Netto 30 oder Akkreditive. Besprechen Sie die Zahlungsoptionen während der Verhandlungen, um Bedingungen zu finden, die Ihren Cashflow-Bedürfnissen entsprechen. Berücksichtigen Sie außerdem mögliche Wechselkursschwankungen und Transaktionsgebühren, die die Gesamtkosten beeinflussen können. Die Festlegung klarer Zahlungsbedingungen im Vorfeld kann dazu beitragen, Vertrauen aufzubauen und den Einkaufsprozess zu rationalisieren. -

Wie kann ich potenzielle Lieferanten von wiederaufbereiteten Startern überprüfen?

Die Überprüfung der Lieferanten ist entscheidend für die Qualität und Zuverlässigkeit der Produkte. Recherchieren Sie zunächst den Ruf des Unternehmens anhand von Online-Bewertungen und Branchenreferenzen. Erkundigen Sie sich nach Zertifizierungen in Bezug auf Qualitätsstandards, wie ISO oder ähnliche Akkreditierungen. Fordern Sie außerdem Produktmuster an, um die Qualität aus erster Hand zu beurteilen. Eine direkte Kommunikation kann auch dazu beitragen, die Reaktionsfähigkeit des Lieferanten und seine Bereitschaft, auf Ihre spezifischen Bedürfnisse einzugehen, zu beurteilen, was Ihnen weitere Sicherheit bei der Auswahl gibt.

Top 2 Neue Vs Remanufactured Starter Hersteller & Lieferanten Liste

1. Anlasser-Optionen - Jeep Wrangler TJ

Domäne: wranglertjforum.com

Registriert: 2015 (10 Jahre)

Einleitung: - Fahrzeug: 1999 Jeep Wrangler TJ SE 2.5L automatisch

- Starter-Optionen:

1. Aftermarket-Marken: BBB Industries, Remy, FVP (Preisspanne: $108-177 CAD)

2. Wiederaufgearbeitet: AC Delco Anlasser ($185 CAD)

3. Aufgearbeiteter Denso-Anlasser ($243 CAD mit $95-Kernrückerstattung)

- Andere Überlegungen:

- Zögern, einen gebrauchten OEM-Starter bei eBay zu kaufen

- Schwierigkeiten bei der Suche nach einem neuen OEM-Anlasser

- Lokaler Wiederaufbau...

2. Delco - Gold Aftermarket-Batterie

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Dieses Unternehmen, Delco - Gold Aftermarket Battery, ist ein namhaftes Unternehmen auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

Strategische Beschaffung - Schlussfolgerung und Ausblick für neue und wiederaufbereitete Anlasser

In der wettbewerbsintensiven Landschaft der Automobilkomponenten hat die Wahl zwischen neuen und wiederaufbereiteten Startern erhebliche Auswirkungen auf die strategische Beschaffung. Neue Anlasser bieten die Sicherheit von Werksspezifikationen und den neuesten Konstruktionsverbesserungen, ideal für Käufer, die Wert auf Zuverlässigkeit und Leistung legen. Wiederaufbereitete Anlasser stellen jedoch eine kostengünstige Alternative dar, die aufgrund strenger Prüf- und Qualitätskontrollverfahren eine ähnliche Langlebigkeit und Qualität bietet. Für budgetbewusste Unternehmen, vor allem in den Schwellenländern Afrikas, Südamerikas und des Nahen Ostens, können wiederaufbereitete Optionen erhebliche Einsparungen ermöglichen, ohne dass die Leistung darunter leidet.

Als internationaler B2B-Einkäufer ist es wichtig, Ihre Beschaffungsstrategien unter Berücksichtigung von Faktoren wie Kosten, Qualität und Umweltauswirkungen zu bewerten. Die Bevorzugung von Lieferanten, die sich an strenge Wiederaufbereitungsstandards halten, kann die Widerstandsfähigkeit und Nachhaltigkeit Ihrer Lieferkette verbessern.

Mit Blick auf die Zukunft wird der Trend zu umweltfreundlichen Lösungen den Markt für Kfz-Teile wahrscheinlich prägen und wiederaufbereitete Anlasser zu einer zunehmend attraktiven Option machen. Wenden Sie sich an seriöse Anbieter, um herauszufinden, wie sowohl neue als auch wiederaufbereitete Anlasser mit Ihren Geschäftszielen in Einklang gebracht werden können, damit Sie fundierte Entscheidungen treffen können, die den Wert und die Effizienz Ihres Betriebs steigern.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.