Introduction: Navigating the Global Market for how alternators work

In today’s competitive landscape, understanding how alternators work is crucial for international B2B buyers seeking reliable power solutions. Whether your operations are in the bustling markets of Nigeria or the developing industries of Vietnam, sourcing the right alternator can significantly impact your machinery’s efficiency and longevity. This guide delves into the intricacies of alternator functionality, examining the various types and their applications across different sectors, including automotive, industrial, and renewable energy systems.

We will also address critical considerations such as supplier vetting processes, cost analysis, and maintenance best practices, providing you with a comprehensive framework for making informed purchasing decisions. By highlighting key performance indicators and potential challenges in the global market, this guide equips B2B buyers from Africa, South America, the Middle East, and Europe with the insights necessary to navigate their sourcing journey effectively.

Our goal is to empower you to identify high-quality alternators that meet your specific operational needs, ensuring that your investment translates into enhanced productivity and reduced downtime. With this knowledge, you can confidently engage with suppliers and make decisions that align with your business objectives.

Inhaltsverzeichnis

- Top 3 How Alternators Work Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how alternators work

- Understanding how alternators work Types and Variations

- Key Industrial Applications of how alternators work

- 3 Common User Pain Points for ‘how alternators work’ & Their Solutions

- Strategic Material Selection Guide for how alternators work

- In-depth Look: Manufacturing Processes and Quality Assurance for how alternators work

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how alternators work’

- Comprehensive Cost and Pricing Analysis for how alternators work Sourcing

- Alternatives Analysis: Comparing how alternators work With Other Solutions

- Essential Technical Properties and Trade Terminology for how alternators work

- Navigating Market Dynamics and Sourcing Trends in the how alternators work Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how alternators work

- Strategic Sourcing Conclusion and Outlook for how alternators work

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding how alternators work Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Conventional | Utilizes a rotating magnetic field to generate AC voltage, which is then rectified to DC. | Automotive, construction machinery, and generators | Vorteile: Zuverlässig, weit verbreitet. Nachteile: Bulkier and less efficient at low RPMs. |

| Brushless | Lacks brushes and slip rings, using electronic controls for voltage regulation. | High-performance vehicles, industrial applications | Vorteile: Längere Lebensdauer, weniger Wartung. Nachteile: Higher initial cost, complex design. |

| Permanent Magnet | Uses permanent magnets instead of electromagnets in the rotor. | Motorcycles, small engines, and some electric vehicles | Vorteile: Compact size, lightweight. Nachteile: Limited output capacity, sensitive to temperature changes. |

| Multi-Phase | Generates multiple AC outputs, typically three-phase. | Industrial machinery, high-power applications | Vorteile: Greater efficiency, smoother power delivery. Nachteile: More complex and expensive to implement. |

| Regulated | Features advanced voltage regulation systems to maintain output stability. | Renewable energy systems, hybrid vehicles | Vorteile: Enhanced battery life, consistent performance. Nachteile: More expensive, may require specialized knowledge for installation. |

Was sind die Merkmale herkömmlicher Lichtmaschinen?

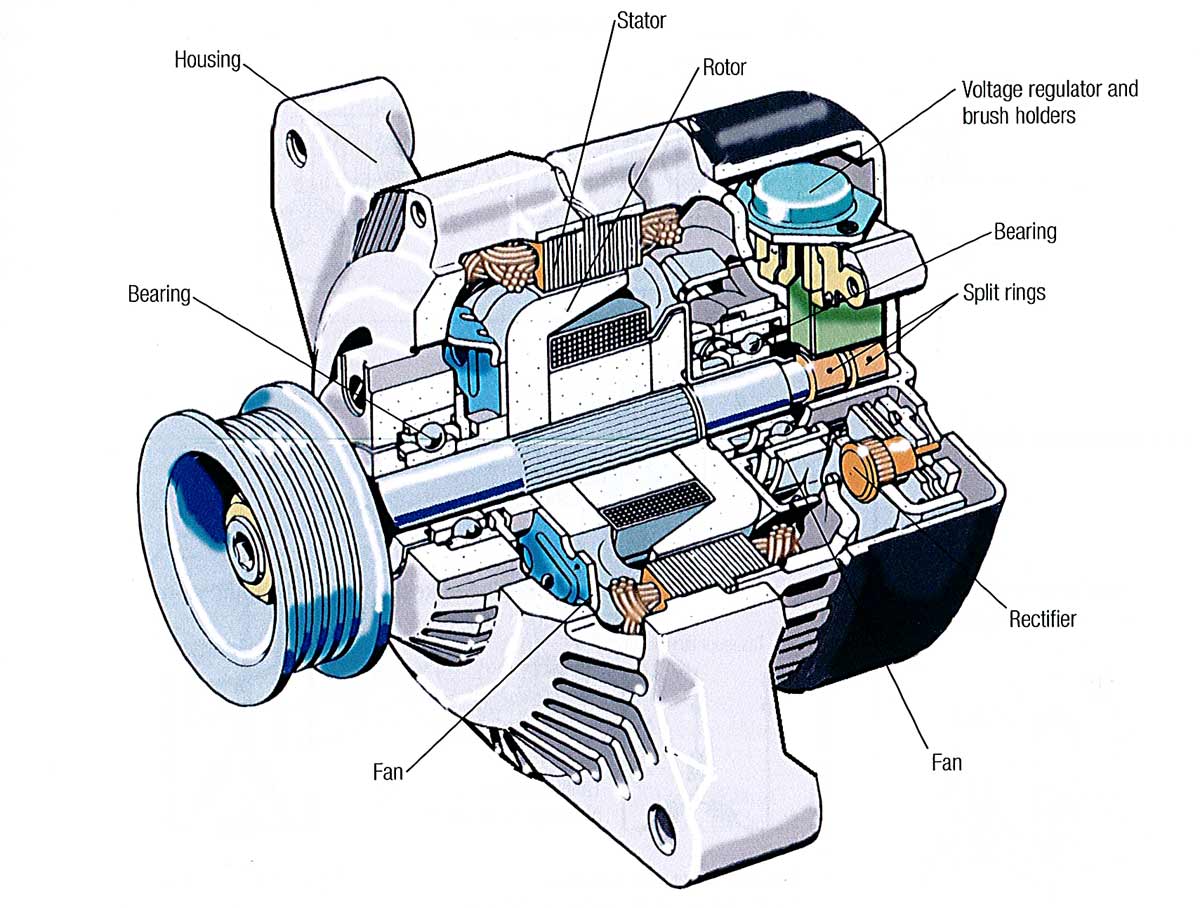

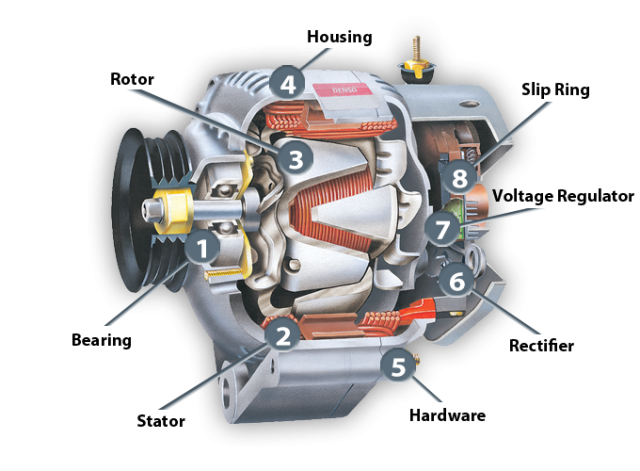

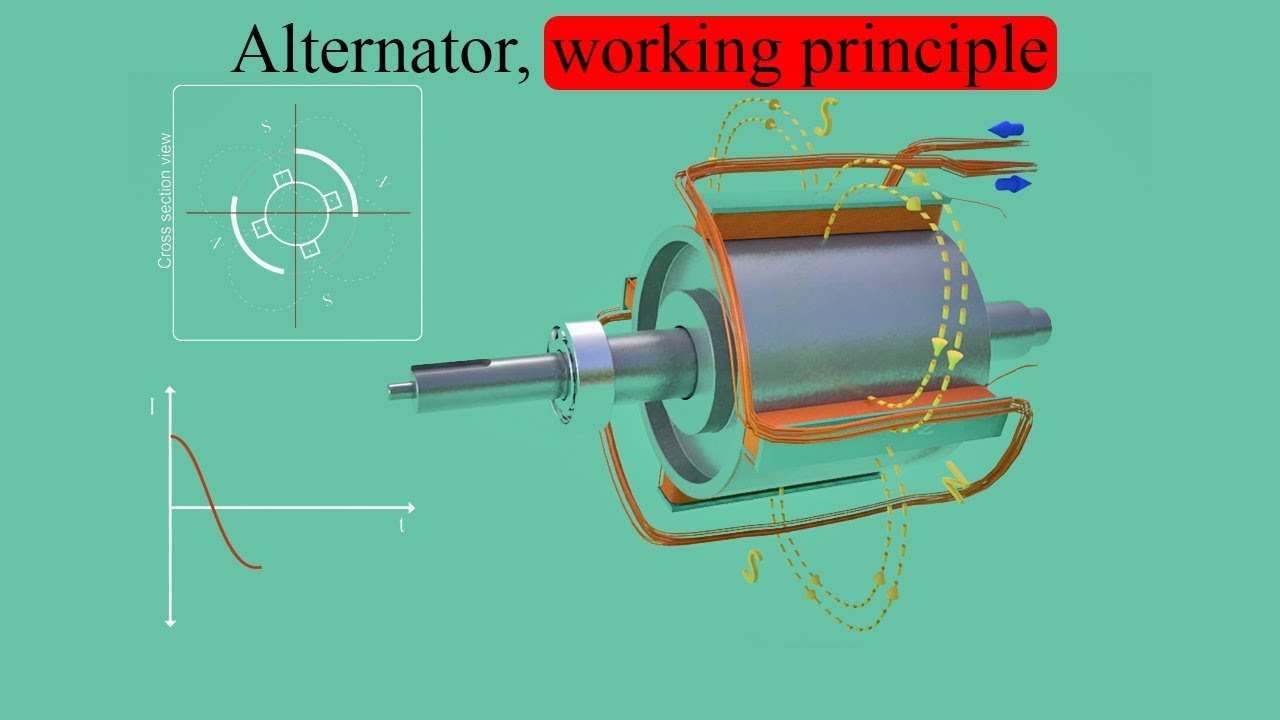

Conventional alternators are the most commonly used type in vehicles and various machinery. They operate by utilizing a rotating magnetic field to generate alternating current (AC), which is then converted to direct current (DC) through a rectifier. These alternators are known for their reliability and ease of replacement, making them suitable for standard automotive applications and construction equipment. However, they can be bulkier and less efficient at low RPMs, which may affect performance in specific use cases.

How Do Brushless Alternators Differ from Other Types?

Brushless alternators are designed to eliminate the wear and tear associated with brushes and slip rings, instead relying on electronic controls for voltage regulation. This innovation results in a longer lifespan and reduced maintenance requirements, making them ideal for high-performance vehicles and industrial applications. Despite their advantages, brushless alternators come with a higher initial cost and a more complex design, which might deter some buyers. Companies should weigh these factors against their operational needs.

What Advantages Do Permanent Magnet Alternators Offer?

Permanent magnet alternators utilize permanent magnets in the rotor, allowing for a more compact and lightweight design. These features make them particularly suitable for motorcycles and small engines, where space and weight are critical factors. However, their output capacity is limited, and they can be sensitive to temperature fluctuations, which may affect performance in extreme conditions. B2B buyers should consider their specific application requirements when evaluating this type.

Why Choose Multi-Phase Alternators for Industrial Applications?

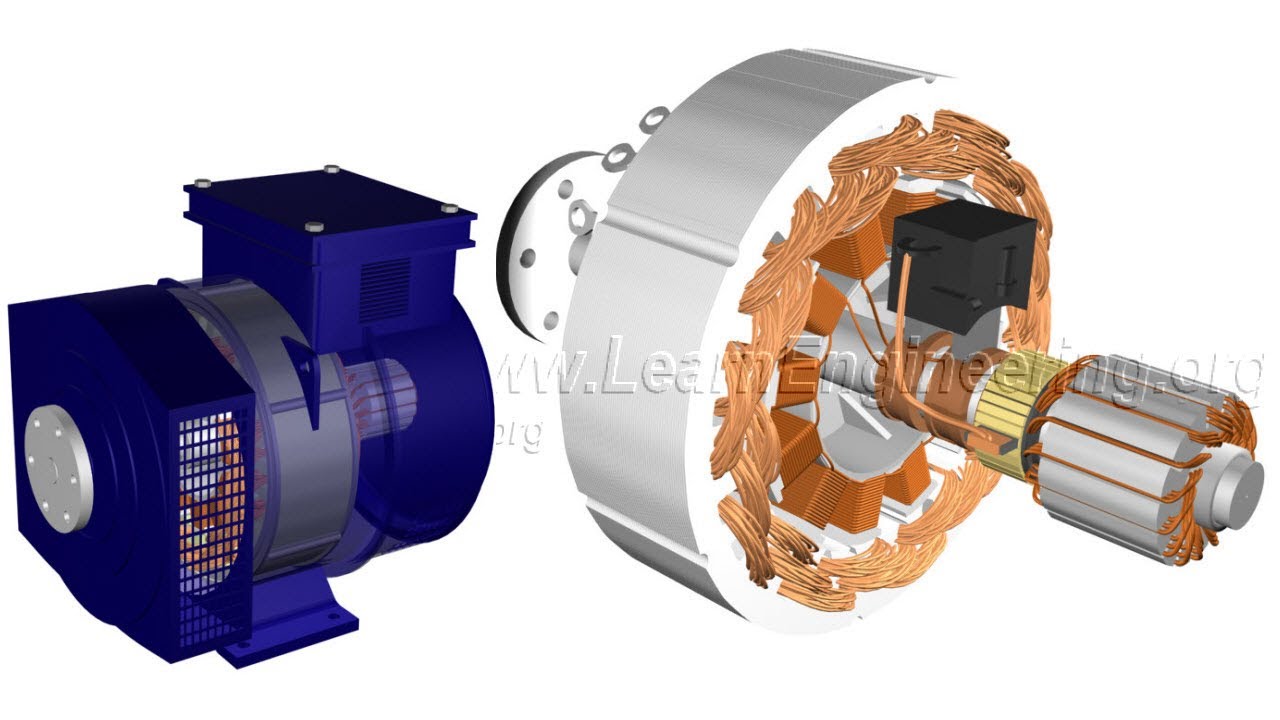

Multi-phase alternators produce multiple AC outputs, commonly in three-phase configurations, which provide greater efficiency and smoother power delivery. This feature makes them highly beneficial for industrial machinery and high-power applications where consistent performance is crucial. However, the complexity and cost associated with multi-phase systems can be significant, requiring careful consideration during the purchasing process, especially for companies with budget constraints.

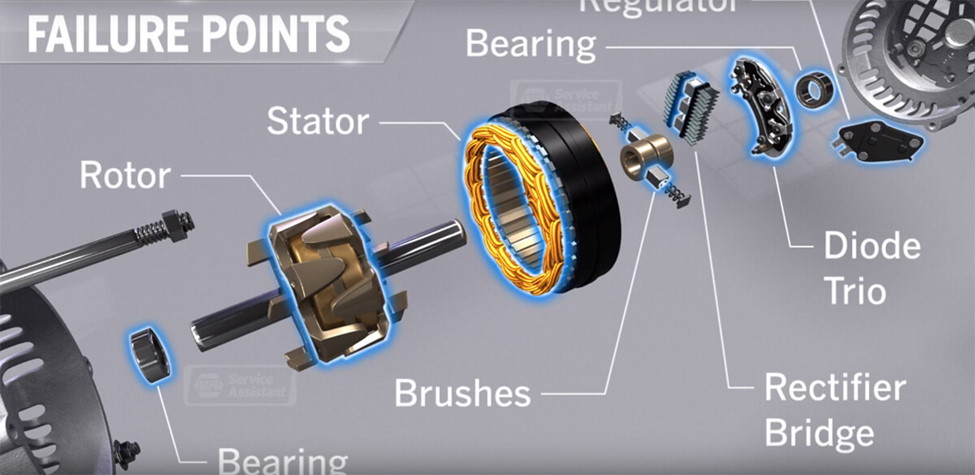

Illustrative image related to how alternators work

What Are the Benefits of Regulated Alternators?

Regulated alternators incorporate advanced voltage regulation systems that maintain stable output, which is essential for applications in renewable energy systems and hybrid vehicles. The ability to enhance battery life and ensure consistent performance is a significant advantage for B2B buyers looking for reliability in their energy systems. However, the higher costs and potential need for specialized installation knowledge may pose challenges for some businesses. Buyers should evaluate the long-term benefits against initial investments.

Key Industrial Applications of how alternators work

| Branche/Sektor | Specific Application of how alternators work | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilindustrie | Vehicle power generation and battery charging | Ensures reliable vehicle operation and reduces downtime | Quality of components, compatibility with vehicle models |

| Erneuerbare Energien | Wind turbine systems | Converts mechanical energy from wind into usable electricity | Langlebigkeit in rauen Umgebungen, Effizienzwerte |

| Marine | Stromversorgung für elektrische Bordsysteme in Schiffen | Provides reliable power for navigation and safety systems | Size and weight constraints, corrosion resistance |

| Bauwesen | Backup power for heavy machinery | Minimizes operational interruptions and enhances productivity | Fuel efficiency, maintenance needs, and ease of installation |

| Telekommunikation | Stromversorgung für Fernmeldetürme | Ensures uninterrupted service in remote locations | Voltage stability, environmental resilience, and support |

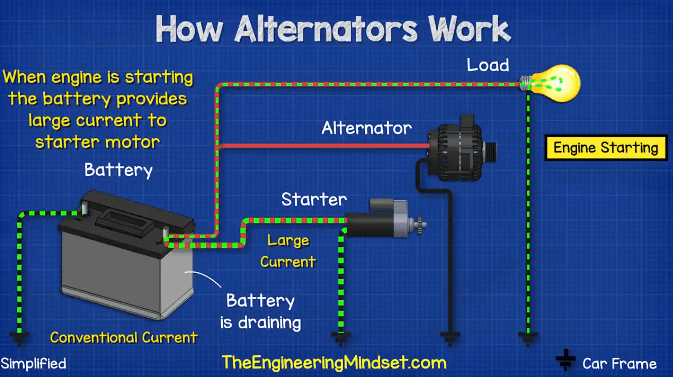

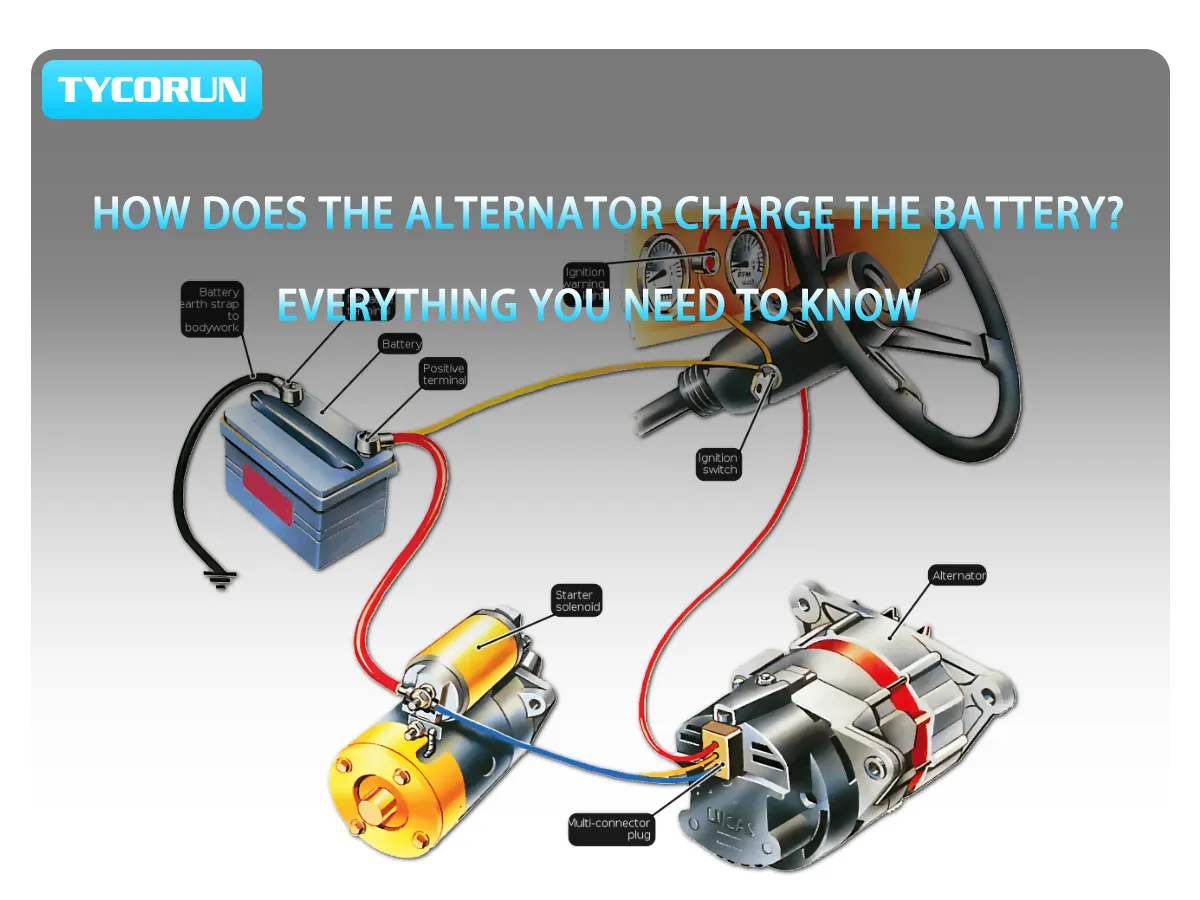

How Do Alternators Support the Automotive Industry?

In the automotive sector, alternators play a crucial role in vehicle power generation and battery charging. They convert mechanical energy from the engine into electrical energy, ensuring that all electrical systems, such as lights and infotainment, function optimally. For B2B buyers in this field, sourcing high-quality alternators is essential for reducing downtime and enhancing vehicle reliability. Compatibility with various vehicle models and the quality of components are vital considerations to ensure longevity and performance.

Welche Rolle spielen Generatoren in Anwendungen für erneuerbare Energien?

In the renewable energy sector, particularly in wind turbine systems, alternators are essential for converting mechanical energy generated by wind into electrical energy. This conversion is crucial for supplying power to the grid or for local consumption. B2B buyers must prioritize sourcing alternators that offer high durability and efficiency ratings, especially in regions with harsh weather conditions. The ability of these alternators to withstand extreme environments directly impacts the overall performance and reliability of renewable energy systems.

Wie werden Generatoren in der Schifffahrt eingesetzt?

Marine industries utilize alternators to power onboard electrical systems in vessels, ensuring reliable operation for navigation, communication, and safety equipment. Given the unique challenges of maritime environments, sourcing alternators that are compact yet powerful, and resistant to corrosion is essential. B2B buyers should focus on specifications that meet size and weight constraints while ensuring the alternators can operate efficiently in the salty marine atmosphere.

Why Are Alternators Important in the Construction Sector?

In construction, alternators are vital for providing backup power to heavy machinery, minimizing operational interruptions. This consistent power supply enhances productivity and ensures that construction projects remain on schedule. B2B buyers in this sector should consider factors such as fuel efficiency, maintenance requirements, and ease of installation when sourcing alternators. These considerations ensure that the machinery remains operational with minimal downtime, which is critical for project success.

How Do Alternators Enhance Telecommunications Infrastructure?

Telecommunications companies depend on alternators to supply power to remote communication towers, ensuring uninterrupted service in areas with unreliable power sources. The stability of the voltage output is crucial for maintaining the integrity of communication systems. B2B buyers must look for alternators that demonstrate environmental resilience and consistent performance to withstand various conditions. Additionally, support services for installation and maintenance can significantly impact the long-term reliability of these systems.

3 Common User Pain Points for ‘how alternators work’ & Their Solutions

Scenario 1: Understanding Alternator Specifications for Optimal Performance

Das Problem: B2B buyers often struggle with understanding the technical specifications of alternators, which can lead to purchasing the wrong type for their equipment. This confusion can stem from a lack of familiarity with terms like voltage, amperage, and the differences between AC and DC outputs. For instance, a buyer in the automotive sector may need an alternator that can handle specific electrical loads, but without a clear grasp of these specifications, they risk buying an alternator that underperforms or fails prematurely.

Die Lösung: To overcome this challenge, buyers should invest time in thoroughly researching alternator specifications and their implications for performance. Collaborating with manufacturers or suppliers who offer detailed product documentation can be immensely helpful. Create a checklist of critical specifications needed for your application, including voltage ratings, amperage output, and compatibility with your existing systems. Moreover, consider engaging with technical support teams from alternator manufacturers, as they can provide tailored advice based on your unique operational requirements, ensuring that you select the right alternator for optimal performance.

Scenario 2: Maintenance Challenges Leading to Unexpected Downtime

Das Problem: A common pain point for B2B buyers is the maintenance of alternators, which can be overlooked until a failure occurs. Companies, especially in industries such as transportation and manufacturing, often experience unexpected downtime due to alternator issues. This can be attributed to factors like inadequate maintenance protocols or a lack of understanding of how to troubleshoot common problems, leading to significant operational disruptions and financial losses.

Die Lösung: To address maintenance challenges, businesses should implement a proactive maintenance schedule that includes regular inspections and servicing of alternators. Train your maintenance personnel on common signs of alternator failure, such as unusual noises or fluctuations in electrical output. Develop a maintenance checklist that includes checking the condition of the drive belt, the integrity of electrical connections, and the functionality of the voltage regulator. By fostering a culture of preventive maintenance and providing training for staff, companies can significantly reduce the risk of unexpected downtime, thereby enhancing operational efficiency and cost-effectiveness.

Illustrative image related to how alternators work

Scenario 3: Integrating Advanced Technologies with Traditional Alternator Systems

Das Problem: As industries evolve, many B2B buyers face the challenge of integrating advanced technologies—like electric and hybrid systems—with traditional alternator setups. This integration can lead to confusion regarding compatibility and performance, particularly when attempting to combine different power sources. For instance, a company in the renewable energy sector may want to integrate solar power systems with vehicle alternators, but lack clarity on how to effectively do so without compromising efficiency.

Die Lösung: To facilitate successful integration, buyers should engage with experts in both traditional and modern electrical systems. It is essential to conduct a comprehensive analysis of your current setup and define clear goals for the integration process. Work closely with engineers and technical specialists who can recommend compatible alternators and provide insights on necessary modifications to existing systems. Additionally, consider investing in hybrid alternators designed for modern applications, which can help streamline the integration process. Establishing partnerships with knowledgeable suppliers and leveraging their expertise can ensure a smoother transition and optimal performance of your integrated systems.

Strategic Material Selection Guide for how alternators work

Welche Materialien werden üblicherweise in Lichtmaschinen verwendet?

When selecting materials for alternators, several key components must be considered, including the rotor, stator, rectifier, and housing. Each component requires materials with specific properties to ensure optimal performance and longevity. Below is an analysis of common materials used in alternators, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Which Materials Are Suitable for Rotor Components in Alternators?

Kupfer is often used for rotor windings due to its excellent electrical conductivity and thermal properties. Key properties include a high melting point (around 1,984°F or 1,085°C) and good corrosion resistance.

Vorteile: Copper is durable and has a high electrical conductivity, which enhances the efficiency of the alternator. Its thermal conductivity helps in dissipating heat generated during operation.

Nachteile: The primary disadvantage is its cost, which can be higher than alternatives like aluminum. Additionally, copper is heavier, which may affect the overall weight of the alternator.

Auswirkungen auf die Anwendung: Copper is compatible with high-frequency applications and can handle the thermal stresses associated with high-speed rotation.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM B170 (for copper) is essential. Buyers in regions like Africa and South America should also consider local sourcing options to mitigate costs.

What About Stator Components in Alternators?

Siliziumstahl is commonly used for the stator core due to its magnetic properties. This material has a high saturation magnetization and low hysteresis loss, making it ideal for the alternating magnetic fields in alternators.

Vorteile: Silicon steel is cost-effective and enhances the efficiency of the alternator by reducing energy losses. Its magnetic properties also contribute to better performance under varying loads.

Nachteile: While silicon steel is durable, it can be susceptible to corrosion if not properly coated, which could lead to performance degradation over time.

Auswirkungen auf die Anwendung: Silicon steel is highly compatible with the electromagnetic requirements of alternators, making it suitable for various applications.

Überlegungen für internationale Käufer: Buyers should ensure compliance with standards such as DIN 46231 for electrical steel. In regions with high humidity, corrosion-resistant coatings are advisable.

How Do Rectifiers Utilize Materials?

Aluminium is often used in the construction of rectifiers due to its lightweight and good thermal conductivity. Its properties include a melting point of about 1,221°F (660°C) and moderate corrosion resistance.

Vorteile: Aluminum is less expensive than copper and offers a good balance of performance and weight, which is beneficial for automotive applications.

Nachteile: The main limitation is its lower electrical conductivity compared to copper, which can affect efficiency in high-load scenarios.

Auswirkungen auf die Anwendung: Aluminum’s properties make it suitable for rectifiers that need to dissipate heat efficiently while maintaining a lightweight structure.

Illustrative image related to how alternators work

Überlegungen für internationale Käufer: Compliance with JIS H 2000 standards for aluminum is crucial. Buyers should also consider local availability and potential tariffs on imported materials.

What Housing Materials Are Commonly Used in Alternators?

Kunststoffverbundwerkstoffe are frequently used for the housing of alternators due to their lightweight and corrosion-resistant properties. These materials can withstand temperatures up to 300°F (149°C) and are often reinforced for added strength.

Vorteile: Plastic composites are cost-effective and provide excellent insulation, reducing the risk of short circuits.

Nachteile: While durable, they may not withstand extreme mechanical stresses as well as metals, which could lead to structural failure.

Auswirkungen auf die Anwendung: Plastic composites are suitable for lightweight applications but may not be ideal for high-stress environments.

Überlegungen für internationale Käufer: Compliance with ISO 9001 for quality management systems is essential. Buyers should also consider the environmental impact of plastic materials in their regions.

Übersichtstabelle zur Materialauswahl für Generatoren

| Material | Typical Use Case for how alternators work | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Rotor windings | Hohe elektrische Leitfähigkeit | Höhere Kosten und höheres Gewicht | Hoch |

| Siliziumstahl | Stator core | Cost-effective, low energy loss | Korrosionsanfällig | Mittel |

| Aluminium | Rectifier components | Leichtes Gewicht, gute Wärmeleitfähigkeit | Geringere Leitfähigkeit als Kupfer | Mittel |

| Kunststoffverbundwerkstoffe | Housing of alternators | Corrosion-resistant, lightweight | May not withstand extreme stresses | Niedrig |

This strategic material selection guide provides insights into the materials used in alternators, helping international B2B buyers make informed decisions based on performance, cost, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how alternators work

Was sind die wichtigsten Phasen im Herstellungsprozess von Lichtmaschinen?

The manufacturing process of alternators involves several critical stages that ensure the production of high-quality components. Understanding these stages is essential for B2B buyers looking to source reliable alternators.

Materialvorbereitung: Welche Materialien werden bei der Herstellung von Lichtmaschinen verwendet?

The first stage in manufacturing alternators is material preparation. This includes the selection of high-quality raw materials such as copper for windings, silicon steel for the stator and rotor cores, and various metals for housing and components. The quality of these materials directly impacts the efficiency and longevity of the alternator.

During this stage, materials undergo rigorous testing to ensure they meet specific mechanical and electrical properties. Buyers should inquire about the sourcing and testing processes of raw materials, as this can significantly affect the final product’s performance.

Umformung: Wie werden Lichtmaschinenbauteile geformt?

The forming stage involves shaping the raw materials into the necessary components of the alternator. Techniques such as stamping, machining, and die-casting are commonly employed.

- Stanzen: This process is often used to create the stator and rotor cores from silicon steel sheets. Precision is crucial here to ensure that the magnetic properties are preserved.

- Bearbeitung: Components like the housing and pulley may undergo machining to achieve precise dimensions and surface finishes.

- Die-Casting: This technique is used for creating intricate parts that require a high degree of detail, such as the rectifier and voltage regulator housings.

It’s advisable for buyers to understand the capabilities of their suppliers in these areas, as precision in forming can affect the overall reliability of the alternator.

Assembly: How Are Alternator Components Integrated?

Once the components are formed, the assembly stage begins. This process includes the integration of the rotor, stator, rectifier, and other components into a cohesive unit.

Key techniques during assembly include:

- Wickeln: Copper wire is wound around the stator to create coils. The quality of winding affects the alternator’s efficiency.

- Soldering and Connection: Electrical connections are made using soldering techniques, ensuring robust and reliable electrical pathways.

- Endmontage: Components are assembled in a clean environment to prevent contamination, ensuring optimal performance and longevity.

Buyers should verify whether the assembly processes adhere to international standards, as this can impact the alternator’s performance in various applications.

Endbearbeitung: Welche Oberflächenbehandlungen werden angewendet?

The finishing stage involves applying surface treatments to enhance the durability and appearance of the alternator. This may include:

- Beschichtung: Protective coatings are applied to prevent corrosion and improve aesthetic appeal.

- Prüfung: Each alternator undergoes rigorous testing to ensure it meets performance specifications before being packaged for shipment.

Understanding the finishing techniques employed by suppliers can help buyers assess the expected lifespan and reliability of the alternators they intend to purchase.

What Quality Assurance Practices Are Essential in Alternator Manufacturing?

Quality assurance (QA) is a critical aspect of alternator manufacturing that ensures the final product meets industry standards and customer expectations.

Auf welche internationalen Normen sollten B2B-Einkäufer achten?

B2B buyers should ensure that their suppliers adhere to relevant international quality standards. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent product quality and customer satisfaction.

- CE-Kennzeichnung: Indicates compliance with European health, safety, and environmental protection standards, essential for buyers in Europe.

- API-Standards: For alternators used in specific applications, adherence to American Petroleum Institute (API) standards may be necessary.

Understanding these standards can help buyers make informed decisions and ensure that the alternators they procure meet regulatory requirements.

Was sind die wichtigsten Punkte der Qualitätskontrolle bei der Herstellung von Generatoren?

Quality control (QC) is integrated into various stages of the manufacturing process, with critical checkpoints established to monitor quality:

- Eingangsqualitätskontrolle (IQC): This stage involves inspecting raw materials before they are used in production. It ensures that only materials meeting specified standards enter the manufacturing process.

- In-Process-Qualitätskontrolle (IPQC): Regular inspections during the manufacturing process help identify any deviations from quality standards early, allowing for timely corrective actions.

- Endkontrolle (FQC): At this stage, the finished alternators undergo comprehensive testing to verify their performance and compliance with specifications.

Buyers should inquire about these QC checkpoints to ensure that the products they receive are of the highest quality.

Welche Prüfverfahren werden üblicherweise für Wechselstromgeneratoren verwendet?

Several testing methods are essential for evaluating the performance and reliability of alternators. Common methods include:

- Elektrische Prüfung: This includes measuring voltage output, current, and resistance to ensure that the alternator operates within specified parameters.

- Thermische Prüfung: Evaluates how the alternator performs under heat, ensuring it can withstand operational conditions without failure.

- Schwingungsprüfung: Assesses the durability of the alternator by simulating real-world operational conditions.

Understanding these testing methods allows buyers to evaluate the reliability of the alternators they are considering.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

Verifying a supplier’s quality control processes is crucial for B2B buyers looking to establish long-term partnerships. Here are effective strategies:

What Steps Can Buyers Take to Audit Supplier Quality Control?

- Lieferantenaudits: Conduct on-site audits to assess the manufacturing processes, quality control measures, and adherence to international standards. This direct evaluation can provide insights into the supplier’s operational integrity.

- Qualitätsberichte anfordern: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications. This transparency builds trust and ensures accountability.

- Beauftragung von Drittinspektoren: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is especially valuable for international buyers who may not be able to visit suppliers personally.

Was sind die Nuancen der QC-Zertifizierung für internationale Käufer?

When sourcing alternators internationally, buyers should be aware of specific certification nuances that may affect their purchase.

Illustrative image related to how alternators work

- Regionale Normen: Different regions may have varying standards and certifications. For example, CE marking is crucial for products sold within the European Union, while UL certification may be more relevant in North America.

- Trade Regulations: International trade regulations can impose additional requirements for quality assurance. Understanding these regulations ensures compliance and smooth logistics.

By keeping these factors in mind, B2B buyers can make informed decisions and establish reliable supply chains for alternators that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how alternators work’

Einführung

This practical sourcing guide is designed to assist B2B buyers in understanding and procuring the necessary components and knowledge related to how alternators work. As alternators play a critical role in various applications, including automotive and industrial systems, having a clear checklist will help you make informed decisions when sourcing or selecting alternators for your specific needs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before initiating the procurement process, it’s essential to clearly outline your technical specifications for the alternator. Consider factors such as power output, voltage requirements, and physical dimensions. This clarity ensures that you select an alternator that meets your operational needs and integrates seamlessly into existing systems.

Schritt 2: Recherche und Identifizierung zuverlässiger Lieferanten

Conduct thorough research to identify suppliers with a strong reputation in the alternator market. Look for companies that have experience in your specific industry and region. Utilize platforms like LinkedIn, industry forums, and trade shows to gather insights into potential suppliers and their credibility.

- Check for Industry Experience: Prioritize suppliers with a proven track record in manufacturing alternators for your application.

- Seek Recommendations: Leverage your professional network to obtain recommendations and feedback on suppliers.

Schritt 3: Lieferantenzertifizierungen bewerten

It is critical to verify that your potential suppliers hold relevant certifications and comply with international standards. Certifications such as ISO 9001 can indicate a commitment to quality management and consistent manufacturing processes.

- Dokumentation anfordern: Ask for copies of certifications and quality assurance processes to ensure compliance.

- Assess Regulatory Compliance: Ensure that the suppliers meet local and international regulatory requirements specific to your market.

Schritt 4: Analyze Product Quality and Performance

Investigate the quality and performance metrics of the alternators you are considering. Review technical data sheets, performance tests, and customer feedback to assess reliability and durability.

- Conduct Field Tests: If possible, test the alternators in real-world conditions to evaluate their performance.

- Review Warranty Policies: Look for suppliers offering robust warranty terms, which can indicate confidence in their product quality.

Schritt 5: Understand After-Sales Support and Service

After-sales support is a crucial aspect of the procurement process. Ensure that the supplier provides comprehensive technical support, maintenance services, and access to spare parts.

- Erkundigen Sie sich nach Schulungen: Check if the supplier offers training for your team on installation and maintenance.

- Assess Response Times: Evaluate the supplier’s responsiveness to inquiries and service requests, as timely support can minimize downtime.

Schritt 6: Verhandeln Sie die Allgemeinen Geschäftsbedingungen

Once you have identified a suitable supplier, engage in discussions to negotiate terms that meet your business objectives. This includes pricing, delivery schedules, and payment terms.

- Establish Clear Communication: Ensure that both parties have a mutual understanding of expectations and responsibilities.

- Document Everything: Keep a record of all agreements and terms to avoid future disputes.

Schritt 7: Finalize the Procurement Process

After negotiations, finalize the procurement process by placing your order and ensuring all logistics are in place for delivery. Confirm that all specifications are met in the order documentation.

- Double-Check Orders: Review the order details to confirm accuracy before shipment.

- Plan for Installation: Coordinate installation schedules and ensure that your team is prepared to integrate the new alternators into your systems.

Following this checklist will help you navigate the complexities of sourcing alternators effectively, ensuring that you select the right components that meet your operational needs.

Comprehensive Cost and Pricing Analysis for how alternators work Sourcing

Was sind die wichtigsten Kostenkomponenten bei der Beschaffung von Generatoren?

When considering the sourcing of alternators, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to how alternators work

-

Materialien: The core components of an alternator—such as copper for windings, silicon steel for the stator and rotor, and diodes for rectification—significantly influence costs. Prices for these materials can fluctuate based on global supply chain dynamics, impacting overall pricing.

-

Arbeit: Labor costs vary by region and can be a substantial part of the total cost. In regions with lower labor costs, such as certain parts of Africa and South America, buyers may find more competitive pricing. However, the level of expertise required for assembly and quality assurance can offset these savings.

-

Fertigungsgemeinkosten: This includes costs related to facilities, utilities, and administrative expenses. Efficient production processes can lower overhead costs, making it essential to evaluate potential suppliers on their operational efficiency.

-

Werkzeuge: Custom tooling for specialized alternators can be a significant upfront cost. Buyers should inquire about tooling costs, especially for custom specifications, as these can dramatically affect the price.

-

Qualitätskontrolle (QC): Ensuring that alternators meet international standards is critical, especially for buyers in markets like Europe. Robust QC processes may add to the cost but are essential for minimizing defects and ensuring reliability.

-

Logistik: Shipping and handling costs vary widely based on the supplier’s location and the buyer’s destination. Incoterms selected can also influence logistics costs, so understanding the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital.

-

Marge: Suppliers will typically include a profit margin in their pricing, which can vary based on competition and demand. Buyers should aim to negotiate this margin, especially when placing large orders.

Wie beeinflussen Preisbeeinflusser die Beschaffungsentscheidungen für Lichtmaschinen?

Numerous factors influence the pricing of alternators, making it important for buyers to understand these before making purchasing decisions.

-

Menge/Mindestbestellmenge: Minimum order quantities (MOQ) can significantly impact unit pricing. Higher volumes often lead to lower per-unit costs, so buyers should assess their needs and negotiate accordingly.

-

Spezifikationen und Anpassung: Custom specifications can lead to increased costs. It’s essential to define requirements clearly and discuss these with suppliers to understand how they affect pricing.

-

Materialien und Qualitätszertifizierungen: The choice of materials directly affects cost and performance. Opting for higher-quality materials may incur additional costs but can enhance the durability and efficiency of the alternator. Certifications (e.g., ISO, CE) can also add to costs but are often necessary for compliance in different markets.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may command higher prices but often deliver superior quality and reliability.

Was sind wirksame Einkaufstipps für die Preisverhandlung von Lichtmaschinen?

To optimize costs and secure favorable terms when sourcing alternators, buyers should consider the following strategies:

-

Verhandlung: Engage in open discussions about pricing, focusing on long-term relationships that can lead to better terms over time. Suppliers may be willing to offer discounts for repeat business or larger orders.

-

Kosteneffizienz: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and potential downtime. A slightly higher initial investment in a quality alternator may yield savings in the long run.

-

Preisgestaltung für internationale Käufer: International buyers should be aware of currency fluctuations and potential tariffs that may affect overall costs. Understanding local market conditions and supplier capabilities can provide leverage in negotiations.

-

Haftungsausschluss für Richtpreise: Prices for alternators can vary widely based on the factors discussed. Buyers should request detailed quotes and consider multiple suppliers to gain a comprehensive view of the market.

By understanding the intricacies of cost components and pricing influencers, B2B buyers can make informed decisions when sourcing alternators, ultimately leading to more strategic procurement and better value.

Alternatives Analysis: Comparing how alternators work With Other Solutions

Introduction: Understanding Alternative Solutions to Alternators

In the realm of electrical power generation and vehicle charging systems, alternators are a prevalent choice due to their efficiency and reliability. However, various alternatives exist, each presenting unique advantages and limitations. This analysis will compare the operational principles of alternators against two viable alternatives: DC generators and battery systems. By understanding these options, B2B buyers can make informed decisions tailored to their specific applications.

Vergleichstabelle

| Vergleichsaspekt | How Alternators Work | Gleichstromgeneratoren | Batteriesysteme |

|---|---|---|---|

| Leistung | Converts mechanical energy to DC efficiently | Provides stable DC output, limited to mechanical input | Limited by capacity, can provide steady power |

| Kosten | Moderate initial investment, long-term savings | Generally lower upfront costs, but higher operational costs | High initial investment, lifecycle costs vary |

| Einfache Implementierung | Relatively straightforward installation | Requires more complex setup and alignment | Simple installation, but space-consuming |

| Wartung | Low maintenance, periodic checks required | Higher maintenance due to moving parts | Minimal maintenance, depends on type (lead-acid vs. lithium) |

| Bester Anwendungsfall | Automotive applications, renewable energy systems | Small-scale applications, backup power | Portable power needs, energy storage solutions |

Detaillierte Aufschlüsselung der Alternativen

1. DC Generators

DC generators convert mechanical energy directly into direct current (DC) electricity. They are particularly advantageous for applications requiring stable DC output without the need for conversion, making them ideal for small-scale power generation. However, DC generators often involve higher operational costs due to the wear and tear of moving parts, requiring more frequent maintenance. Their complexity in setup can deter some users, especially in high-demand environments.

Illustrative image related to how alternators work

2. Battery Systems

Battery systems serve as energy storage solutions, providing a direct source of DC power. Their primary advantage lies in their versatility and portability, making them suitable for a wide range of applications, from electric vehicles to renewable energy storage. However, the initial investment can be substantial, particularly for high-capacity systems. Additionally, battery systems have a finite lifespan and require careful management to optimize performance, especially for lead-acid types.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

When selecting the appropriate power generation or storage solution, B2B buyers must evaluate their specific requirements, including performance needs, budget constraints, and maintenance capabilities. Alternators offer a balanced solution for applications that involve continuous mechanical energy input, such as in automotive or industrial environments. In contrast, DC generators may suit niche applications where simplicity and stability are paramount, while battery systems are ideal for portable and renewable energy needs. By aligning the choice with operational demands and financial considerations, buyers can ensure optimal performance and value from their investment.

Essential Technical Properties and Trade Terminology for how alternators work

Was sind die wichtigsten technischen Eigenschaften von Lichtmaschinen?

Understanding the critical specifications of alternators is essential for B2B buyers, especially when evaluating products for automotive, industrial, or renewable energy applications. Here are some key technical properties to consider:

1. Material Klasse

The materials used in alternators, such as copper for windings and aluminum for housings, significantly impact performance and durability. Copper offers excellent conductivity, ensuring efficient energy transfer, while aluminum is lightweight and corrosion-resistant. Selecting the right material grade can enhance the lifespan of the alternator and reduce operational costs.

2. Spannungsausgang

Alternators typically generate between 12V to 24V DC, depending on the application. Understanding the voltage requirements is crucial for compatibility with the electrical systems of vehicles or machinery. B2B buyers must ensure that the alternator’s voltage output matches their specific needs to avoid electrical failures or inefficiencies.

3. Rated Current (Amperage)

The rated current indicates the maximum output the alternator can provide, typically measured in amperes (A). This specification is vital for ensuring that the alternator can meet the power demands of the vehicle’s electrical system. A higher amperage rating allows for more accessories and electrical components to function simultaneously without overloading the system.

4. Efficiency Rating

The efficiency of an alternator reflects how well it converts mechanical energy into electrical energy. Higher efficiency ratings mean less energy loss as heat, which is crucial for optimizing fuel consumption and overall system performance. B2B buyers should prioritize high-efficiency alternators to reduce operational costs and improve energy management.

5. Operating Temperature Range

Alternators must operate effectively within specific temperature ranges. Understanding the operating temperature range helps buyers select alternators suitable for their environmental conditions, particularly in extreme climates. This specification is crucial for ensuring reliability and longevity in various applications.

Illustrative image related to how alternators work

6. Tolerance Levels

Tolerance levels define the acceptable variances in manufacturing specifications, such as size and electrical output. Tight tolerance levels ensure high-quality performance and compatibility with other components. B2B buyers should look for manufacturers that adhere to strict tolerances to minimize the risk of operational failures.

Was sind die gebräuchlichen Fachausdrücke im Zusammenhang mit Wechselstromgeneratoren?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of alternators, OEM products are designed to meet the specifications of original vehicle manufacturers. Buyers often prefer OEM parts for their reliability and compatibility.

2. MOQ (Mindestbestellmenge)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they can meet their supply needs without overcommitting resources. Negotiating favorable MOQs can lead to cost savings and better inventory management.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. This term is essential for B2B transactions, as it helps buyers compare costs and terms from different vendors. Providing detailed RFQs can lead to more accurate quotes and better supplier relationships.

4. Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and delivery. Familiarity with these terms helps B2B buyers understand their obligations and manage risks in global trade. Proper use of Incoterms can facilitate smoother transactions and reduce misunderstandings.

5. Vorlaufzeit

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for B2B buyers to plan their operations and inventory effectively. A shorter lead time can enhance supply chain efficiency and responsiveness to market demands.

6. Gewährleistungsfrist

The warranty period specifies the duration for which a manufacturer guarantees the performance of their product. For alternators, a longer warranty can indicate higher quality and reliability. Buyers should consider warranty terms when evaluating products to ensure they are protected against defects and failures.

Illustrative image related to how alternators work

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing alternators, ultimately improving operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the how alternators work Sector

What Are the Key Market Trends Influencing the Alternator Sector?

The global alternator market is witnessing robust growth driven by several factors, including the increasing demand for electric vehicles (EVs) and advancements in automotive technology. As countries prioritize sustainability, the shift towards EVs necessitates efficient power generation and management systems, with alternators playing a crucial role in hybrid and electric vehicles. Moreover, the automotive sector in Africa, South America, the Middle East, and Europe is expanding, leading to heightened demand for reliable and efficient alternators in traditional and emerging vehicle types.

Emerging trends in B2B sourcing include the integration of smart technology into alternators, enabling features such as real-time monitoring and predictive maintenance. This technological shift is essential for international buyers looking to enhance their operational efficiencies. Furthermore, the supply chain is increasingly focused on localization to mitigate risks associated with global disruptions, particularly in light of recent geopolitical tensions and the COVID-19 pandemic. Buyers are encouraged to develop strong relationships with local manufacturers and suppliers to ensure consistent quality and availability.

In addition, the rise of digital platforms for procurement is transforming how businesses source alternators, providing greater transparency and access to suppliers worldwide. This digital transformation is critical for buyers in regions like Nigeria and Vietnam, where access to quality parts can often be a challenge.

How Does Sustainability Impact the Sourcing of Alternators in B2B Transactions?

Sustainability is becoming a cornerstone of B2B sourcing strategies, especially in the alternator sector. The environmental impact of manufacturing processes and materials used in alternators is under scrutiny, prompting businesses to seek eco-friendly alternatives. Buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as reducing carbon footprints and utilizing recyclable materials in their products.

Ethical sourcing is also gaining traction, with many companies committing to transparent supply chains that ensure fair labor practices and responsible resource extraction. Certifications such as ISO 14001 for environmental management and the use of green materials are becoming essential criteria in supplier selection. For B2B buyers, particularly those in regions with stringent regulatory frameworks, aligning with suppliers that prioritize sustainability can enhance brand reputation and customer loyalty.

Furthermore, as the global market shifts towards renewable energy sources, the integration of sustainable practices in the production of alternators becomes critical. Businesses that adopt these practices not only meet regulatory requirements but also position themselves as leaders in the industry, appealing to environmentally conscious consumers and stakeholders.

What Is the Historical Context of Alternators and Their Evolution in the Market?

The evolution of alternators has been marked by significant technological advancements since their inception in the early 20th century. Initially, generators were primarily used in vehicles, but the introduction of the alternator in the 1960s revolutionized the automotive industry by providing more efficient and reliable power generation. This shift allowed vehicles to run more electrical systems without overloading the battery, making alternators essential components in modern automotive design.

Over the decades, the technology behind alternators has continued to evolve, incorporating advancements such as electronic voltage regulation and improved materials that enhance performance and durability. With the increasing complexity of automotive electrical systems and the rise of hybrid and electric vehicles, the design and functionality of alternators are constantly being refined to meet the demands of contemporary vehicles.

In summary, understanding the historical context and current trends in alternator technology is vital for international B2B buyers. By staying informed, businesses can make strategic sourcing decisions that align with market demands and technological advancements, ensuring they remain competitive in the ever-evolving automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of how alternators work

-

1. How do I solve issues with alternator inefficiency in my operations?

To address alternator inefficiency, first, ensure regular maintenance checks on the alternator and its components. Verify the voltage regulator is functioning correctly, as it maintains optimal voltage levels. Additionally, inspect the connections and wiring for corrosion or damage, which can impede performance. If inefficiencies persist, consider consulting with your supplier for potential upgrades or alternative models tailored to your specific operational needs. -

2. What is the best alternator for commercial vehicles operating in extreme conditions?

When sourcing alternators for commercial vehicles in extreme conditions, prioritize those with robust construction and high-temperature resistance. Look for models designed with enhanced cooling systems and corrosion-resistant materials, which are crucial for durability in harsh environments. It’s advisable to consult with manufacturers who specialize in heavy-duty alternators and can provide customization options that meet your specific operational requirements. -

3. How can I verify the reliability of an alternator supplier?

To verify an alternator supplier’s reliability, conduct thorough research into their industry reputation, customer reviews, and case studies. Request references from existing clients, especially those in similar industries or regions. Evaluate their certification and compliance with international quality standards, such as ISO or CE. Additionally, consider their responsiveness and customer service record, as these factors often reflect their commitment to quality and reliability. -

4. What customization options are available for alternators?

Many manufacturers offer customization options for alternators, including voltage output specifications, size, and mounting configurations. You can also request modifications for specific applications, such as marine or heavy-duty uses. When discussing customization, provide detailed operational requirements to ensure the alternator meets your needs. Engage directly with suppliers to explore available options and potential lead times for customized products. -

5. What are the typical minimum order quantities (MOQs) for alternators?

Minimum order quantities (MOQs) for alternators can vary significantly depending on the manufacturer and the complexity of the product. Generally, MOQs range from 50 to 500 units for standard models, while custom configurations may have higher MOQs due to production adjustments. Always inquire about MOQs during negotiations and consider the potential for bulk discounts, which can lead to significant cost savings over time. -

6. What payment terms should I expect when sourcing alternators internationally?

When sourcing alternators internationally, payment terms can vary widely based on the supplier’s policies and your negotiation. Common terms include upfront deposits (typically 30-50%), with the balance due upon shipment or delivery. Letters of credit are also popular for larger transactions, providing security for both parties. Always clarify payment terms in advance to avoid misunderstandings and ensure smooth transactions. -

7. How can I ensure quality assurance (QA) when sourcing alternators?

To ensure quality assurance when sourcing alternators, request detailed product specifications and certifications from the supplier. Implement a pre-shipment inspection process to verify that the products meet your quality standards before they leave the factory. Additionally, consider working with third-party QA firms to conduct independent audits of the manufacturing process and product testing, ensuring compliance with international quality standards. -

8. What logistics considerations should I keep in mind when importing alternators?

When importing alternators, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose between air and sea freight based on urgency and budget, with air being faster but more expensive. Ensure compliance with local import regulations, including duties and taxes. It’s also wise to work with experienced logistics partners who can navigate the complexities of international shipping and ensure timely delivery.

Top 3 How Alternators Work Manufacturers & Suppliers List

1. The Engineering Mindset – Car Alternator

Domäne: theengineeringmindset.com

Registriert: 2015 (10 Jahre)

Einleitung: The car alternator is an essential component of every combustion engine vehicle’s electrical system. It generates electricity by converting mechanical energy from the engine into electrical energy. The alternator produces alternating current (AC) electricity, which is then converted into direct current (DC) by a rectifier for use in the vehicle’s electrical components. Key parts of the alternator …

2. Autoelectro – Alternator

Domäne: autoelectro.de

Registriert: 1999 (26 Jahre)

Einleitung: Alternator: Generates energy to feed the electrical system and charge the battery. Works with the battery to supply power for vehicle electrical components. Output: Direct Current (DC). Converts Alternating Current (AC) to DC via a rectifier. Components include: Regulator (controls power distribution), Rectifier (converts AC to DC), Rotor (spinning electromagnet), Slip Rings (provides power to rot…

3. HowStuffWorks – Alternators

Domäne: auto.wie-das-funktioniert.com

Registriert: 1998 (27 Jahre)

Einleitung: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation and non-magnetization. Key components include:

– Antriebsriemenscheibe, die an der Rotorwelle befestigt ist und mechanische Energie in elektrische Energie umwandelt.

– Several terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (…

Strategic Sourcing Conclusion and Outlook for how alternators work

In summary, understanding the operational mechanics of alternators is essential for B2B buyers looking to optimize their electrical systems, whether in automotive applications or broader industrial contexts. Key components like the rotor, stator, rectifier, and voltage regulator work in concert to ensure efficient energy conversion and battery management. Strategic sourcing of high-quality alternators can significantly enhance reliability and performance, reducing downtime and maintenance costs.

As international buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, it’s crucial to partner with reputable suppliers that prioritize innovation and quality. Investing in advanced alternator technology can lead to substantial long-term savings and improved operational efficiency.

Looking ahead, embracing cutting-edge advancements in alternator design and functionality will be pivotal for businesses aiming to stay competitive. Engage with suppliers who offer comprehensive technical support and tailored solutions to meet your specific needs. By prioritizing strategic sourcing, you position your business for success in a rapidly evolving marketplace.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.