Introduction: Navigating the Global Market for alternator exploded view

In today’s competitive landscape, sourcing an alternator exploded view is essential for B2B buyers looking to optimize their automotive maintenance and repair processes. The challenge often lies in navigating a vast array of products and suppliers, which can lead to confusion and costly missteps. This guide serves as a comprehensive resource, covering various types of alternators, their applications, and the critical aspects of supplier vetting. By delving into detailed exploded views, buyers can gain a clearer understanding of component layouts, facilitating easier repairs and replacements.

Our guide empowers international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe—regions marked by diverse automotive markets and varying standards. It offers actionable insights into pricing strategies, quality assessments, and logistical considerations, enabling businesses to make informed purchasing decisions. Understanding the intricacies of alternator components not only enhances operational efficiency but also fosters better supplier relationships and quality assurance.

Moreover, this guide addresses the unique needs of different markets, ensuring that buyers are equipped with knowledge tailored to their specific operational contexts. Whether you’re a procurement specialist or a technical engineer, the insights provided here will enhance your ability to source effectively and maintain high standards in your automotive offerings.

Inhaltsverzeichnis

- Top 5 Alternator Exploded View Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator exploded view

- Understanding alternator exploded view Types and Variations

- Key Industrial Applications of alternator exploded view

- 3 Common User Pain Points for ‘alternator exploded view’ & Their Solutions

- Strategic Material Selection Guide for alternator exploded view

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator exploded view

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator exploded view’

- Comprehensive Cost and Pricing Analysis for alternator exploded view Sourcing

- Alternatives Analysis: Comparing alternator exploded view With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator exploded view

- Navigating Market Dynamics and Sourcing Trends in the alternator exploded view Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator exploded view

- Strategic Sourcing Conclusion and Outlook for alternator exploded view

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding alternator exploded view Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Delco Remy Series | Multiple series (10DN, 12Si, 15Si) with varying amperage | Automotive parts suppliers, repair shops | Pros: Widely used, reliable; Cons: Parts may be harder to find for older models. |

| Ford Motorcraft Series | Available in various sizes (1G, 2G, 3G) for different vehicles | Ford dealerships, automotive repair shops | Pros: OEM quality, extensive compatibility; Cons: Higher cost for original parts. |

| Chrysler Corporation Series | Includes round and square back designs | Chrysler service centers, aftermarket suppliers | Pros: Durable designs; Cons: Limited availability for some models. |

| Hochleistungsgeneratoren | Designed for enhanced performance and power output | Performance vehicle upgrades, racing applications | Pros: Increased power capacity; Cons: May require modifications to vehicle. |

| Tactical Diesel Alternators | Specific designs for military and heavy-duty applications | Defense contractors, heavy equipment manufacturers | Pros: Robust construction; Cons: Higher initial investment. |

What Are the Key Characteristics of Delco Remy Series Alternators?

The Delco Remy Series encompasses a range of alternators, including models like the 10DN and 12Si, each tailored for specific amperage needs. These alternators are recognized for their reliability and ease of replacement, making them a popular choice among automotive parts suppliers and repair shops. Buyers should consider the availability of parts, especially for older models, which may be less accessible in certain regions.

How Do Ford Motorcraft Series Alternators Stand Out?

Ford Motorcraft alternators are distinguished by their OEM quality and compatibility with various Ford vehicles, ranging from compact cars to trucks. This series includes several sizes, ensuring that buyers can find a suitable option for their specific needs. Although they tend to be pricier than aftermarket alternatives, their reliability and warranty support make them a worthwhile investment for dealerships and repair shops.

What Variations Exist in Chrysler Corporation Series Alternators?

Chrysler Corporation alternators feature both round and square back designs, catering to different vehicle models. Their durable construction ensures longevity, making them a preferred choice for Chrysler service centers and aftermarket suppliers. However, buyers should be aware that some models may have limited availability, which could affect repair timelines and inventory management.

Why Consider High Output Alternators for Performance Needs?

High output alternators are engineered to provide increased power capacity, catering to performance vehicle upgrades and racing applications. These units are ideal for businesses looking to enhance the electrical systems in modified vehicles. While they offer significant advantages in terms of power output, potential buyers should evaluate the necessity of vehicle modifications to accommodate these high-performance parts.

What Are the Benefits of Tactical Diesel Alternators for Heavy-Duty Applications?

Tactical diesel alternators are specifically designed for military and heavy-duty applications, emphasizing robust construction to withstand harsh environments. These units are crucial for defense contractors and heavy equipment manufacturers seeking reliable power solutions. Although the initial investment may be higher than standard alternators, their durability and performance in demanding conditions often justify the cost for B2B buyers in these sectors.

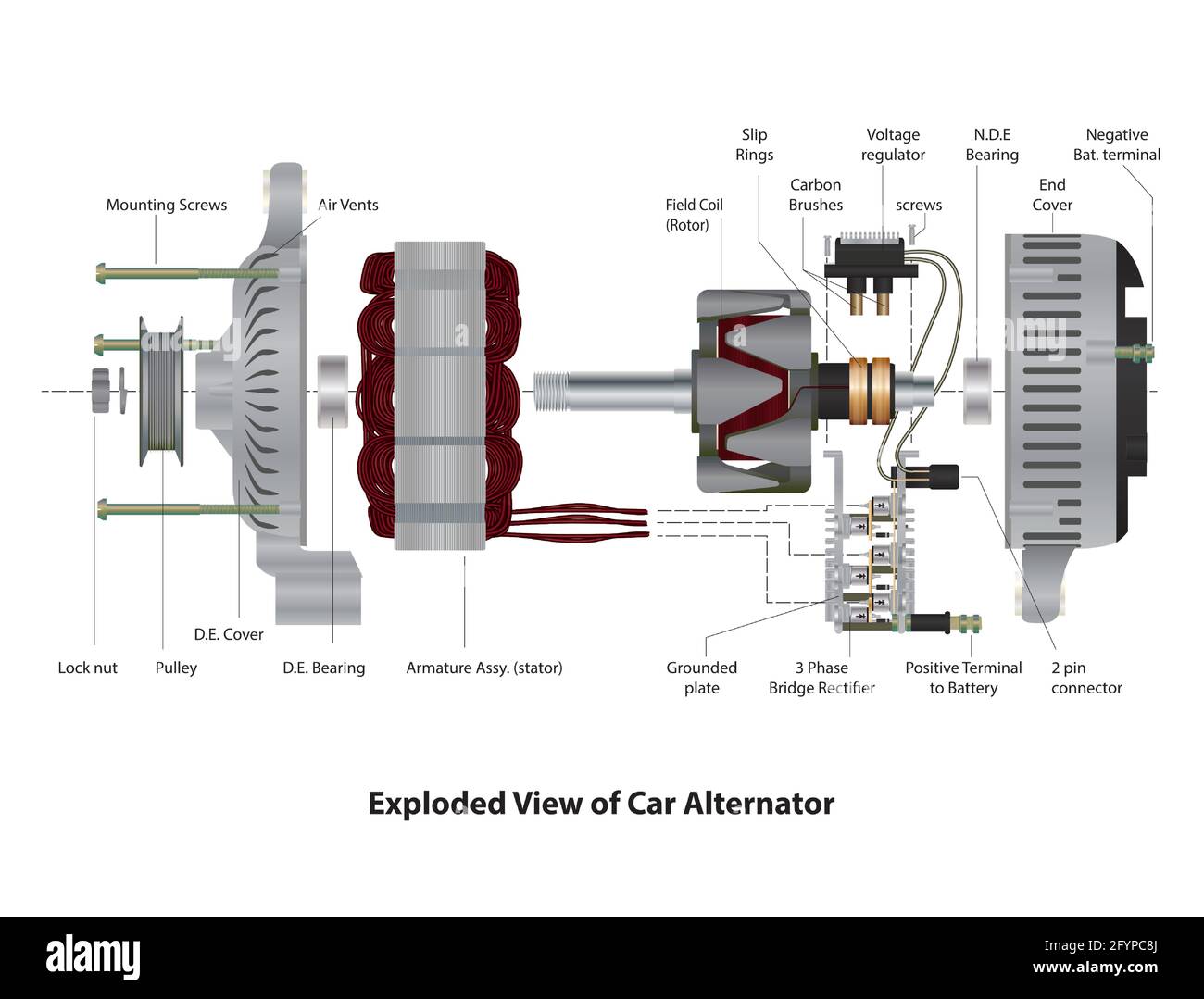

Illustrative image related to alternator exploded view

Key Industrial Applications of alternator exploded view

| Branche/Sektor | Specific Application of alternator exploded view | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Design and assembly of vehicle alternators | Enhanced understanding of components leading to improved efficiency in production. | Compatibility with existing vehicle models and compliance with international standards. |

| Stromerzeugung | Maintenance of diesel generator systems | Enables efficient troubleshooting and repair processes, minimizing downtime. | Sourcing quality parts that match specifications for reliability and performance. |

| Erneuerbare Energien | Integration with solar power systems | Facilitates the design of hybrid systems for optimized energy conversion and storage. | Consideration of environmental conditions and system scalability. |

| Schwere Ausrüstung | Repair of construction machinery | Reduces operational disruptions through efficient maintenance practices. | Availability of parts and technical support for international operations. |

| Meerestechnik | Maintenance of shipboard electrical systems | Ensures reliable power generation, critical for navigation and safety systems. | Compliance with maritime regulations and durability in harsh environments. |

How is the alternator exploded view used in automotive manufacturing?

In the automotive manufacturing sector, the exploded view of alternators is crucial for the design and assembly processes. It provides a detailed breakdown of all components, allowing engineers and assemblers to visualize the relationships between parts. This clarity enhances efficiency in production lines, ensuring that assembly teams can work more effectively. International buyers, particularly from regions with diverse vehicle models, must consider compatibility with existing systems and adherence to global automotive standards when sourcing alternators.

What role does the alternator exploded view play in power generation?

In power generation, particularly with diesel generator systems, an exploded view of the alternator is instrumental during maintenance and repair. It allows technicians to identify and troubleshoot issues quickly, minimizing downtime and ensuring that power generation remains uninterrupted. For international buyers in regions with variable power supply challenges, sourcing reliable alternator components that meet specific performance standards is essential to ensure operational efficiency.

How does the alternator exploded view facilitate renewable energy integration?

The integration of alternators with renewable energy systems, such as solar power, benefits significantly from exploded views. These diagrams assist engineers in designing hybrid systems that effectively combine solar energy with conventional power sources. This ensures optimized energy conversion and storage solutions. Buyers from diverse markets, including Africa and South America, should focus on sourcing components that can withstand local environmental conditions and offer scalability for future growth.

In what ways does the alternator exploded view aid heavy equipment maintenance?

In the heavy equipment sector, such as construction machinery, the exploded view of alternators is a valuable tool for repair and maintenance. It helps technicians quickly diagnose problems and perform repairs, thereby reducing operational disruptions. International buyers must prioritize sourcing parts that are readily available and supported by technical expertise to ensure that maintenance can be conducted efficiently across various regions.

Illustrative image related to alternator exploded view

Why is the alternator exploded view important in marine engineering?

In marine engineering, the exploded view of alternators plays a critical role in maintaining shipboard electrical systems. It provides a comprehensive overview of components, which is vital for ensuring reliable power generation necessary for navigation and safety. Buyers in this sector, especially from Europe and the Middle East, should focus on sourcing alternators that comply with maritime regulations and are designed for durability in harsh marine environments.

3 Common User Pain Points for ‘alternator exploded view’ & Their Solutions

Scenario 1: Difficulty in Understanding Complex Assembly Diagrams

Das Problem:

B2B buyers often struggle with the intricate details of alternator exploded views, particularly when sourcing parts for various automotive applications. These diagrams can be overwhelming due to their complexity, which may lead to confusion about component identification and assembly processes. This challenge is exacerbated for international buyers who may not have direct access to technical support or who face language barriers in technical documentation. As a result, they risk purchasing incorrect parts, leading to delays and increased costs.

Die Lösung:

To navigate the complexity of alternator exploded views, buyers should invest in high-quality, detailed diagrams that provide clear labels and annotations. It is beneficial to source exploded views from reputable manufacturers who offer them in multiple formats, such as PDFs and 3D models. These resources should include not only the exploded views but also supplementary documentation that explains the function of each component and its relation to others. Moreover, engaging with suppliers that provide virtual training sessions or webinars can enhance understanding. B2B buyers can also create a library of these resources to standardize knowledge across their teams, ensuring that everyone involved in the purchasing or assembly process has access to the same information.

Scenario 2: Inadequate Technical Support and Resources

Das Problem:

International B2B buyers often face challenges due to a lack of localized technical support when dealing with alternator exploded views. For instance, if a buyer in South America encounters an issue with sourcing or assembling components, the time zone differences and language barriers can complicate communication with suppliers. This situation may lead to prolonged downtimes, affecting their business operations and customer satisfaction.

Die Lösung:

To mitigate these issues, buyers should prioritize partnerships with suppliers that offer robust customer support across multiple time zones and languages. Establishing a dedicated support line or an online chat service can facilitate quicker resolution of queries. Additionally, buyers should request access to comprehensive online resources, including FAQs, instructional videos, and troubleshooting guides related to alternator assemblies. Creating a feedback loop with suppliers can also enhance service quality. This way, buyers can communicate their specific challenges, allowing suppliers to tailor their support resources to better meet the needs of their international clients.

Scenario 3: Sourcing Compatible Parts Across Different Regions

Das Problem:

Another common pain point for B2B buyers is ensuring that they source compatible alternator parts that align with the exploded view specifications. Buyers from different regions may encounter difficulties due to variations in part numbers, specifications, and even regulatory requirements, leading to the risk of ordering incompatible components. This challenge is particularly significant in regions like Africa or the Middle East, where parts availability may be inconsistent.

Die Lösung:

To address sourcing challenges, buyers should implement a systematic approach to part compatibility verification. This involves closely examining the specifications provided in the exploded views and cross-referencing them with parts catalogs from multiple manufacturers. Utilizing advanced software tools that allow for real-time inventory checks and compatibility assessments can significantly enhance accuracy in sourcing. Additionally, forming strategic alliances with local distributors can facilitate better access to genuine parts that meet the required specifications. Buyers should also consider investing in a centralized database that tracks all purchased parts, their compatibility, and supplier details to streamline future ordering processes. This proactive approach will help ensure that they consistently receive the right components and minimize the risk of operational disruptions.

Strategic Material Selection Guide for alternator exploded view

When selecting materials for alternator components, it’s essential to consider their properties, manufacturing complexities, and the specific needs of international markets. Below is an analysis of four common materials used in alternator exploded views, focusing on their performance, advantages, limitations, and considerations for B2B buyers in diverse regions.

Was sind die wichtigsten Eigenschaften von Aluminium für die Herstellung von Lichtmaschinen?

Aluminum is a popular choice for alternator housings and components due to its lightweight nature and excellent corrosion resistance. It typically withstands temperatures up to 150°C and pressures of about 300 psi, making it suitable for automotive applications. Additionally, aluminum is non-magnetic, which is crucial for components like rotors and stators that require magnetic field efficiency.

Vor- und Nachteile: The advantages of aluminum include its high strength-to-weight ratio and ease of machining, which simplifies manufacturing processes. However, the cost of aluminum can be higher than that of steel, and its lower thermal conductivity may impact performance under extreme conditions.

Auswirkungen auf die Anwendung: Aluminum’s corrosion resistance makes it ideal for regions with high humidity or salt exposure, such as coastal areas in Africa and South America. Buyers should ensure compliance with international standards like ASTM B221 for aluminum extrusions.

Wie schneidet Stahl als Material für Wechselstromgeneratoren im Vergleich ab?

Steel, particularly carbon steel, is often used in the construction of alternator shafts and other structural components. It offers high tensile strength and can withstand significant mechanical stress, with temperature ratings generally around 200°C.

Vor- und Nachteile: The primary advantage of steel is its durability and cost-effectiveness, making it a preferred choice for many manufacturers. However, steel is heavier than aluminum, which can affect the overall weight of the alternator. Additionally, steel is prone to corrosion unless treated, which may necessitate additional coatings or finishes.

Auswirkungen auf die Anwendung: Steel components are suitable for applications where high strength is critical, such as in heavy-duty vehicles. Buyers in regions like Germany and Saudi Arabia should consider compliance with DIN standards for steel products.

Welche Rolle spielt Kupfer bei der Funktion von Lichtmaschinen?

Copper is a critical material for alternator windings due to its excellent electrical conductivity, which is essential for efficient energy transfer. Copper can handle temperatures up to 200°C and has a high melting point, making it suitable for high-performance applications.

Vor- und Nachteile: The main advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, copper is relatively expensive compared to aluminum and steel, which can affect overall production costs. Its susceptibility to corrosion, especially in saline environments, may require protective coatings.

Auswirkungen auf die Anwendung: In regions with high electrical demands, such as urban centers in Europe, the use of copper can significantly improve the performance of alternators. Buyers should ensure that the copper used meets international standards like ASTM B170.

Why Consider Composite Materials for Alternator Components?

Composite materials, often a blend of polymers and fibers, are increasingly used in alternator manufacturing for components like covers and insulators. These materials can withstand temperatures up to 120°C and offer excellent electrical insulation properties.

Vor- und Nachteile: Composites are lightweight and can be molded into complex shapes, which allows for innovative designs. However, they can be more expensive than traditional materials and may not provide the same mechanical strength as metals.

Auswirkungen auf die Anwendung: Composites are particularly beneficial in applications requiring weight reduction, such as electric vehicles. Buyers should consider the specific regulatory standards for composites in their region, as these can vary significantly.

Zusammenfassende Tabelle zur Materialauswahl für Lichtmaschinenbauteile

| Material | Typical Use Case for alternator exploded view | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Housings and rotors | Leicht und korrosionsbeständig | Higher cost and lower thermal conductivity | Mittel |

| Stahl | Wellen und Bauteile | High strength and cost-effective | Schwerer und anfällig für Korrosion | Niedrig |

| Kupfer | Wicklungen und Steckverbinder | Hervorragende elektrische Leitfähigkeit | Teuer und korrosionsanfällig | Hoch |

| Komposit | Abdeckungen und Isolatoren | Geringes Gewicht und Designflexibilität | Higher cost and lower mechanical strength | Mittel |

This strategic material selection guide provides B2B buyers with actionable insights into the properties and implications of various materials used in alternator manufacturing, helping them make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator exploded view

What Are the Main Stages of Manufacturing an Alternator Exploded View?

Manufacturing an alternator involves several critical stages that ensure the final product meets rigorous performance standards. These stages include material preparation, forming, assembly, and finishing.

-

Materialvorbereitung: The first step in the manufacturing process involves sourcing high-quality materials, including aluminum for housings, copper for windings, and various plastics for insulators. Suppliers must provide material certifications to ensure compliance with international standards. This initial stage is crucial as the quality of raw materials directly affects the performance and durability of the alternator.

-

Formung: This stage involves shaping the materials into their respective components. Techniques such as die-casting, stamping, and machining are commonly used to create parts like the stator, rotor, and housing. Advanced technologies like CNC machining can enhance precision, ensuring that components fit together seamlessly.

-

Montage: Once the components are formed, they are assembled into the final alternator unit. This stage may involve manual labor and automated processes, depending on the production scale. Proper assembly techniques are critical, as any misalignment can lead to performance issues.

-

Endbearbeitung: The last manufacturing stage includes surface treatment, coating, and quality checks. Finishing processes, such as anodizing or powder coating, enhance corrosion resistance and aesthetics. This stage also involves applying labels and part numbers for traceability.

Wie wird die Qualitätssicherung in den Fertigungsprozess integriert?

Quality assurance (QA) is an integral part of the manufacturing process for alternators, focusing on compliance with international standards and industry-specific regulations.

-

Einhaltung internationaler Normen: Many manufacturers adhere to ISO 9001, which sets out criteria for a quality management system. This certification ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Other certifications, such as CE for European markets and API for specific applications, can also be critical.

-

Kontrollpunkte der Qualitätskontrolle: Effective QA involves multiple checkpoints throughout the manufacturing process:

– Eingangsqualitätskontrolle (IQC): Kontrolle der Rohstoffe bei ihrer Ankunft, um sicherzustellen, dass sie den vorgegebenen Normen entsprechen.

– In-Process-Qualitätskontrolle (IPQC): Ongoing inspections during manufacturing to catch defects early. This includes monitoring critical dimensions and assembly processes.

– Endkontrolle (FQC): A thorough inspection of the finished alternators to verify performance specifications, including electrical testing and physical inspections. -

Testing Methods: Various testing methods are employed to ensure that alternators meet performance standards. Common tests include electrical load tests, vibration tests, and thermal cycling tests. These tests help simulate real-world conditions and verify that the alternator can perform reliably under various circumstances.

What Should B2B Buyers Look for to Verify Supplier Quality Control?

For B2B buyers, especially those sourcing from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are key aspects to consider:

-

Lieferantenaudits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. These audits should evaluate compliance with international standards and industry-specific certifications.

-

Qualitätsberichte: Requesting detailed quality reports from suppliers can help buyers understand their QC processes. These reports should outline testing results, inspection frequencies, and any corrective actions taken for non-conformities.

-

Inspektionen durch Dritte: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can verify that the supplier’s products meet required standards and specifications before shipment.

Are There Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges and considerations when it comes to quality control in alternator manufacturing. Understanding these nuances can help mitigate risks:

-

Cultural and Regional Variances: Different regions may have varying standards and expectations for quality. Buyers should familiarize themselves with the local regulations and industry practices in the supplier’s country to ensure alignment.

-

Communication Barriers: Language and cultural differences can lead to misunderstandings in quality expectations. Establishing clear communication channels and documentation can help bridge these gaps.

-

Logistik- und Lieferkettenfaktoren: Variability in shipping times and customs regulations can impact the quality assurance process. Buyers should account for these factors and discuss them with suppliers to ensure timely delivery of compliant products.

Conclusion: How Can B2B Buyers Ensure High-Quality Alternators?

B2B buyers looking to procure alternators must prioritize understanding the manufacturing processes and quality assurance measures in place. By focusing on material quality, rigorous QC checkpoints, and supplier transparency, buyers can significantly reduce risks and ensure they receive high-quality products that meet their operational needs. Establishing strong relationships with reputable suppliers and leveraging third-party inspections can further enhance confidence in product quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator exploded view’

To facilitate your procurement of alternator exploded views, this guide provides a systematic checklist designed to streamline your sourcing process. By following these actionable steps, B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, can ensure they make informed and effective purchasing decisions.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before starting your search, clearly outline the technical specifications required for the alternator exploded views you need. This includes the make and model of the alternators, specific components required, and any unique features that may be pertinent to your operations. Having precise specifications helps in narrowing down potential suppliers and ensures that you receive the correct documentation for your needs.

Schritt 2: Führen Sie Marktforschung durch

Research the market to identify potential suppliers and manufacturers who specialize in alternator exploded views. This step is vital as it helps you understand the landscape, including which suppliers have the best reputation and what variations in pricing exist. Focus on suppliers that operate in your target regions, as they may offer insights into local market conditions and requirements.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key factors to consider include:

– Supplier Experience: Look for suppliers with a proven track record in providing alternator exploded views.

– Industry Certifications: Ensure they possess relevant certifications that guarantee quality and compliance with international standards.

Schritt 4: Request Samples and Documentation

Once you have shortlisted potential suppliers, request samples of their exploded views along with any relevant technical documentation. This allows you to assess the quality and clarity of the illustrations, which is essential for effective usage in assembly or repair processes. Ensure the documentation includes:

– Detailed Component Listings: Confirm that every part is labeled and described.

– Compatibility Information: Check that the exploded views are relevant to your specific alternators.

Schritt 5: Verify Supplier Capabilities

Assess the supplier’s capacity to meet your order volume and delivery timelines. This is particularly important for larger projects or ongoing needs. Inquire about:

– Produktionskapazität: Ensure they can handle both current and future demands.

– Vorlaufzeiten: Understand their average turnaround time for orders to avoid delays in your operations.

Schritt 6: Verhandeln Sie Bedingungen und Preise

Once you have selected a supplier, it’s time to negotiate terms and pricing. Aim for a win-win agreement that reflects fair pricing for the quality offered. Consider discussing:

– Mengenrabatte: If you’re ordering in large quantities, inquire about potential price reductions.

– Zahlungsbedingungen: Clarify payment schedules and conditions to maintain cash flow.

Schritt 7: Finalize the Agreement and Monitor Delivery

After negotiations, finalize the contract with clear terms regarding delivery schedules, quality expectations, and after-sales support. Once the order is placed, maintain communication with the supplier to monitor the delivery process and address any potential issues proactively. This ensures that you receive your alternator exploded views on time and as specified.

By following this step-by-step checklist, B2B buyers can navigate the procurement of alternator exploded views efficiently, ensuring that they acquire the necessary documentation to support their automotive or machinery repair and assembly needs.

Comprehensive Cost and Pricing Analysis for alternator exploded view Sourcing

What Are the Key Cost Components in Alternator Exploded View Sourcing?

When sourcing alternator exploded views, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materialien form the foundation of costs, with varying prices for different metals and components used in alternators. For instance, high-quality copper and aluminum are often used in windings, affecting the overall cost. Arbeit costs depend on the location of manufacturing, with varying wage rates across regions such as Africa, South America, the Middle East, and Europe.

Produktionsgemeinkosten encompasses indirect costs like utilities, rent, and administrative expenses. Additionally, Werkzeug costs can be significant, especially for custom components or unique designs. Quality control measures are essential for ensuring product reliability, especially in markets where certification and compliance are critical.

Logistik costs also play a vital role in the total cost structure. These can vary based on the distance from the manufacturer to the buyer, shipping methods, and associated tariffs or duties. Finally, manufacturers typically add a Rand to ensure profitability, which can vary based on market conditions and competition.

How Do Price Influencers Affect Alternator Exploded View Sourcing?

Several factors influence pricing for alternator exploded views. Volumen und Mindestbestellmenge (MOQ) are significant; larger orders often lead to discounts due to economies of scale. Customization requests for specific designs or specifications may increase costs, as they require additional tooling and engineering work.

Die Wahl der Materialien directly impacts pricing. For instance, using premium materials can enhance performance but at a higher price point. Quality and certification standards are also critical; products with higher certifications typically command higher prices due to the assurance of quality they provide.

Lieferantenfaktoren such as reputation, reliability, and production capabilities can further influence costs. Buyers should consider whether they are dealing with established suppliers or newer entrants to the market. Lastly, Incoterms dictate the responsibilities of buyers and sellers in shipping and logistics, impacting overall pricing. Understanding these terms can help buyers negotiate better deals.

What Are Effective Buyer Tips for Negotiating Alternator Exploded View Prices?

B2B buyers should adopt strategic approaches when negotiating prices for alternator exploded views. First, conduct thorough market research to understand the average pricing and available suppliers in different regions. This knowledge empowers buyers to negotiate effectively and avoid overpaying.

Betrachten Sie die Gesamtbetriebskosten (TCO), which includes not only the purchase price but also costs related to maintenance, logistics, and potential downtime. This holistic view can justify higher initial costs if they lead to lower operational costs over time.

Negotiation tactics should include discussing volume discounts, potential for future orders, and flexibility in payment terms. Building a relationship with suppliers can also lead to better deals and preferential treatment.

For international buyers, it’s important to be aware of Preisnuancen that may arise due to currency fluctuations, tariffs, or local market conditions. Buyers from regions such as Africa, South America, the Middle East, and Europe may face unique challenges, including differing regulatory environments and logistical complexities.

What Should Buyers Remember About Indicative Prices?

Buyers should always be cautious of indicative prices. The cost of alternator exploded views can fluctuate based on market dynamics, raw material prices, and supplier conditions. It is advisable to request formal quotations that reflect current conditions and to consider locking in prices when favorable. This approach can safeguard against future price increases and ensure budget adherence.

In conclusion, understanding the comprehensive cost structure, price influencers, and effective negotiation tactics can significantly enhance the sourcing process for alternator exploded views, ensuring that buyers make informed decisions that align with their business objectives.

Alternatives Analysis: Comparing alternator exploded view With Other Solutions

Exploring Alternative Solutions to Alternator Exploded Views

When considering solutions for understanding and servicing alternators, B2B buyers should evaluate various approaches beyond the traditional alternator exploded view. This analysis compares the exploded view method with two viable alternatives: 3D CAD Models and Interactive Augmented Reality (AR) Applications. Each solution offers unique advantages and challenges, making it essential to assess their performance, cost, ease of implementation, maintenance, and best use cases.

| Vergleichsaspekt | Alternator Exploded View | 3D CAD Models | Interactive AR Applications |

|---|---|---|---|

| Leistung | High visual clarity for disassembly | Highly detailed, customizable | Real-time interaction and immersive experience |

| Kosten | Generally low, depending on format | Medium to high, requires software | High due to technology investment |

| Einfache Implementierung | Easy to create and share | Requires skilled personnel | Requires AR hardware and software setup |

| Wartung | Low, primarily for static views | Medium, updates needed for new designs | High, software and hardware upkeep required |

| Bester Anwendungsfall | Manual repair guides, training | Design prototyping, engineering | Training, remote assistance, immersive learning |

What Are the Pros and Cons of 3D CAD Models?

3D CAD models provide a highly detailed and customizable alternative to exploded views. They allow engineers and technicians to manipulate parts in a virtual space, enhancing understanding of complex assemblies. The primary advantage of this approach is the ability to visualize modifications and simulate mechanical interactions, which is invaluable during the design and prototyping phases. However, the cost can be prohibitive, especially for smaller businesses, as it requires specialized software and skilled personnel to operate it effectively. Additionally, CAD models need regular updates to reflect design changes, which can lead to increased maintenance efforts.

How Do Interactive Augmented Reality Applications Enhance Learning?

Interactive AR applications represent a cutting-edge solution that combines digital elements with the real world, allowing users to visualize alternator components in their actual environment. This technology provides an immersive learning experience, making it particularly effective for training purposes and remote troubleshooting. Users can interact with the model, zoom in on parts, and even receive guided instructions on assembly or disassembly. However, the initial investment in AR technology can be significant, and the need for ongoing software and hardware maintenance may deter some companies from adopting this solution. Furthermore, the effectiveness of AR applications can be limited by the availability of compatible devices.

Wie können B2B-Einkäufer die richtige Lösung auswählen?

Selecting the right solution depends on the specific needs and resources of the business. For companies focused on training and interactive learning, AR applications may provide the most value despite the higher costs. On the other hand, businesses requiring straightforward repair guides might find that the traditional alternator exploded view suffices, given its low cost and ease of use. 3D CAD models can be ideal for organizations involved in product development and design but may require a greater investment in technology and training.

Ultimately, B2B buyers should assess their goals, budget, and the technical capabilities of their teams before deciding on the most suitable approach for understanding and servicing alternators.

Essential Technical Properties and Trade Terminology for alternator exploded view

Understanding the intricate details of alternator exploded views is essential for B2B buyers involved in the automotive or electrical components industries. This section aims to elucidate the technical properties and trade terminology relevant to alternator assemblies, ensuring informed decision-making in procurement and supply chain management.

What Are the Key Technical Properties of Alternator Exploded Views?

-

Werkstoffgüte

– Definition: The material grade indicates the quality and specifications of the materials used in alternator components, such as aluminum for housings and copper for windings.

– Bedeutung: High-grade materials enhance durability and performance. For B2B buyers, understanding material grades helps in assessing the longevity and reliability of the alternators, which is crucial for maintaining operational efficiency and reducing replacement costs. -

Electrical Tolerance

– Definition: This refers to the acceptable range of electrical measurements, such as voltage and current output, that the alternator must adhere to.

– Bedeutung: Tighter tolerances often correlate with higher performance. For international buyers, especially in regions with varying electrical standards, knowing the tolerance levels is vital for compliance and ensuring compatibility with local systems. -

Stromstärke

– Definition: The amperage rating indicates the maximum electrical current the alternator can produce.

– Bedeutung: This rating is critical for determining the alternator’s suitability for specific applications. B2B buyers should match amperage ratings with the power requirements of the vehicles or machinery to avoid underperformance or electrical failures. -

Weight Specifications

– Definition: The weight of the alternator can influence installation and overall vehicle dynamics.

– Bedeutung: Lighter alternators may improve fuel efficiency in automotive applications. Buyers need to consider weight specifications to ensure they meet vehicle design and performance standards. -

Dimensional Tolerances

– Definition: These are the permissible limits of variation in the size of alternator components.

– Bedeutung: Dimensional tolerances ensure proper fitment and function within the assembly. For manufacturers and assemblers, adhering to these specifications can prevent assembly issues and enhance product reliability.

Which Trade Terms Are Essential for Understanding Alternator Procurement?

-

OEM (Originalgerätehersteller)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Bedeutung: Understanding OEM specifications is crucial for buyers to ensure they are sourcing components that meet original design standards, thereby maintaining quality and compatibility in their products. -

MOQ (Mindestbestellmenge)

– Definition: The minimum quantity of a product that a supplier is willing to sell.

– Bedeutung: Knowing the MOQ is essential for budgeting and inventory management. For international buyers, understanding MOQ can affect shipping costs and storage capabilities. -

RFQ (Angebotsanfrage)

– Definition: A document sent to suppliers to request pricing for specific products or services.

– Bedeutung: An RFQ allows buyers to gather competitive pricing and terms from multiple suppliers, facilitating better purchasing decisions. It is a critical step in the procurement process. -

Incoterms (Internationale Handelsklauseln)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in international transactions.

– Bedeutung: Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, costs, and risks. This knowledge is particularly important for international transactions, ensuring smooth logistics and compliance. -

Ersatzteilmarkt

– Definition: Refers to parts or accessories sold after the initial sale of the vehicle.

– Bedeutung: Understanding the aftermarket landscape is vital for buyers looking to source alternative or replacement components. It allows for cost-effective solutions and broader options in procurement.

Navigating the complexities of alternator exploded views and associated terminology is crucial for B2B buyers seeking to optimize their procurement processes. By understanding these technical properties and trade terms, businesses can ensure they make informed decisions that enhance operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the alternator exploded view Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Exploded View Sector?

The alternator exploded view sector is experiencing transformative changes driven by advancements in technology, increased demand for electric vehicles (EVs), and the need for enhanced efficiency in automotive components. Global drivers such as the push for energy efficiency and sustainability are prompting manufacturers to innovate and optimize alternator designs. This is particularly relevant for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where growing automotive markets are increasingly adopting advanced technologies.

Emerging trends in sourcing include a shift towards digital platforms for procurement and collaboration. B2B buyers are increasingly leveraging online marketplaces and supplier networks to access a wider range of alternator components and exploded views, facilitating quicker decision-making and better inventory management. Furthermore, as the automotive sector embraces electric and hybrid vehicles, there is a heightened focus on sourcing high-output alternators that cater to the unique requirements of these vehicles.

International buyers should also note the increasing importance of local sourcing to mitigate supply chain disruptions, especially in the wake of global events that have impacted logistics. Regional suppliers in Africa and South America are stepping up to meet local demand, providing opportunities for buyers to strengthen their supply chains while supporting local economies.

Illustrative image related to alternator exploded view

How Does Sustainability and Ethical Sourcing Impact the Alternator Exploded View Sector?

As environmental concerns become paramount in global trade, sustainability and ethical sourcing are gaining traction in the alternator exploded view sector. The automotive industry is under pressure to reduce its carbon footprint, which has led to an increased focus on sustainable materials and manufacturing processes. B2B buyers should prioritize suppliers that adopt eco-friendly practices, such as utilizing recycled materials in the production of alternators and components.

Moreover, the certification of ‘green’ materials is becoming a critical factor in procurement decisions. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability. By sourcing from certified suppliers, international buyers not only ensure compliance with environmental regulations but also enhance their brand reputation in markets increasingly driven by eco-conscious consumers.

Ethical supply chains are also essential, particularly in regions where labor practices may be scrutinized. Buyers should engage with suppliers who demonstrate a commitment to fair labor practices, transparency, and community engagement. This not only minimizes risks associated with supply chain disruptions but also aligns with the growing demand for corporate social responsibility in business practices.

What Is the Historical Context of the Alternator Exploded View Sector?

The alternator exploded view sector has evolved significantly since the introduction of the first automotive alternators in the early 20th century. Originally designed to provide electrical power for vehicle lighting, alternators have since transformed into complex components that support a wide range of electrical systems in modern vehicles. The advent of digital technologies in the late 20th century allowed for more precise designs and improved efficiency, paving the way for the sophisticated exploded views that facilitate easier assembly and maintenance.

Over the decades, as automotive technology advanced with the integration of electronic systems, the complexity of alternators increased. This evolution reflects broader trends in the automotive industry, including the shift towards electric and hybrid vehicles, which require more powerful and efficient alternators. Today, the focus on high-output alternators and the demand for detailed exploded views continues to shape the sector, providing B2B buyers with opportunities to optimize their sourcing strategies and meet the evolving needs of the automotive market.

Illustrative image related to alternator exploded view

Frequently Asked Questions (FAQs) for B2B Buyers of alternator exploded view

-

How do I solve compatibility issues when sourcing alternator exploded views?

To address compatibility issues, start by identifying the specific models and manufacturers of the alternators you are dealing with. Ensure that the exploded views you source correspond to the correct series and type of alternator. Request technical specifications and cross-reference them with your existing systems. Communicate directly with suppliers to confirm compatibility, as they often have detailed knowledge about their products. This proactive approach minimizes errors and ensures that you receive the correct parts, reducing downtime. -

What is the best way to evaluate suppliers for alternator exploded views?

When evaluating suppliers, consider factors such as their industry reputation, years of experience, and customer reviews. Request samples of their exploded views to assess clarity and detail. Additionally, inquire about their manufacturing processes and quality assurance protocols. Establish communication with existing clients to gather feedback on their experiences. Look for certifications that validate their adherence to international standards, particularly if you are sourcing from different regions like Africa or Europe. -

Can I customize alternator exploded views for specific projects?

Yes, many suppliers offer customization options for alternator exploded views. Discuss your specific requirements with potential suppliers, including any unique features or components you need highlighted. Customization may involve adapting the design to fit particular applications or including additional technical information. Ensure that you clarify timelines and any associated costs upfront. This collaboration can enhance the relevance of the exploded views to your projects, making them more useful for your team. -

What are typical minimum order quantities (MOQs) for alternator exploded views?

MOQs for alternator exploded views can vary widely depending on the supplier and the complexity of the diagrams. Some suppliers may have a low MOQ for standard views, while others might require larger orders for custom designs. It’s essential to discuss your needs with the supplier to find a mutually agreeable MOQ. If you anticipate ongoing projects, negotiating a favorable MOQ can lead to cost savings and better pricing structures over time. -

What payment terms should I expect when sourcing alternator exploded views internationally?

Payment terms vary by supplier and region, but common practices include upfront deposits (typically 30% to 50%) with the balance due upon delivery or after inspection. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Negotiate terms that align with your cash flow needs and ensure clarity on potential additional costs such as taxes or shipping fees, which can impact the total expense. -

How can I ensure quality assurance for alternator exploded views?

To ensure quality assurance, request detailed documentation of the supplier’s QA processes. Look for suppliers who have established quality management systems, such as ISO certifications. It’s also beneficial to conduct a factory audit or request third-party inspections for large orders. Establishing clear specifications and expectations upfront can help mitigate discrepancies in the final product. Additionally, maintaining ongoing communication throughout the production process allows for timely adjustments if needed. -

What logistics considerations should I keep in mind when sourcing alternator exploded views?

Logistics play a critical role in the timely delivery of alternator exploded views. Consider the shipping methods available and the potential lead times associated with international freight. Work with suppliers who can provide reliable shipping options and track shipments. Additionally, be aware of customs regulations and duties in your country, as these can affect delivery times and costs. Planning for logistics early in the procurement process can help avoid delays and ensure a smooth transaction. -

How do I handle disputes with suppliers regarding alternator exploded views?

In the event of a dispute with a supplier, maintain open lines of communication to resolve issues amicably. Document all correspondence and agreements to reference during discussions. If disagreements persist, consult your purchase agreement for dispute resolution clauses, which may include mediation or arbitration. It’s advisable to establish a clear escalation process before entering into agreements to streamline resolution. Building a strong relationship with your suppliers can also facilitate smoother conflict resolution in the future.

Top 5 Alternator Exploded View Manufacturers & Suppliers List

1. Facebook – Alternator Components Diagram

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: This is an exploded view diagram of an alternator, showing various components: Pulley (driven by engine belt), Fan (cools components), Drive End Housing (front housing supporting rotor shaft), Thrust Plate (controls axial movement of rotor shaft), Rotor Shaft (central rotating shaft), Rotor (contains field windings), Slip Rings (conduct current to rotor windings), Ring Bearing (supports rotor shaf…

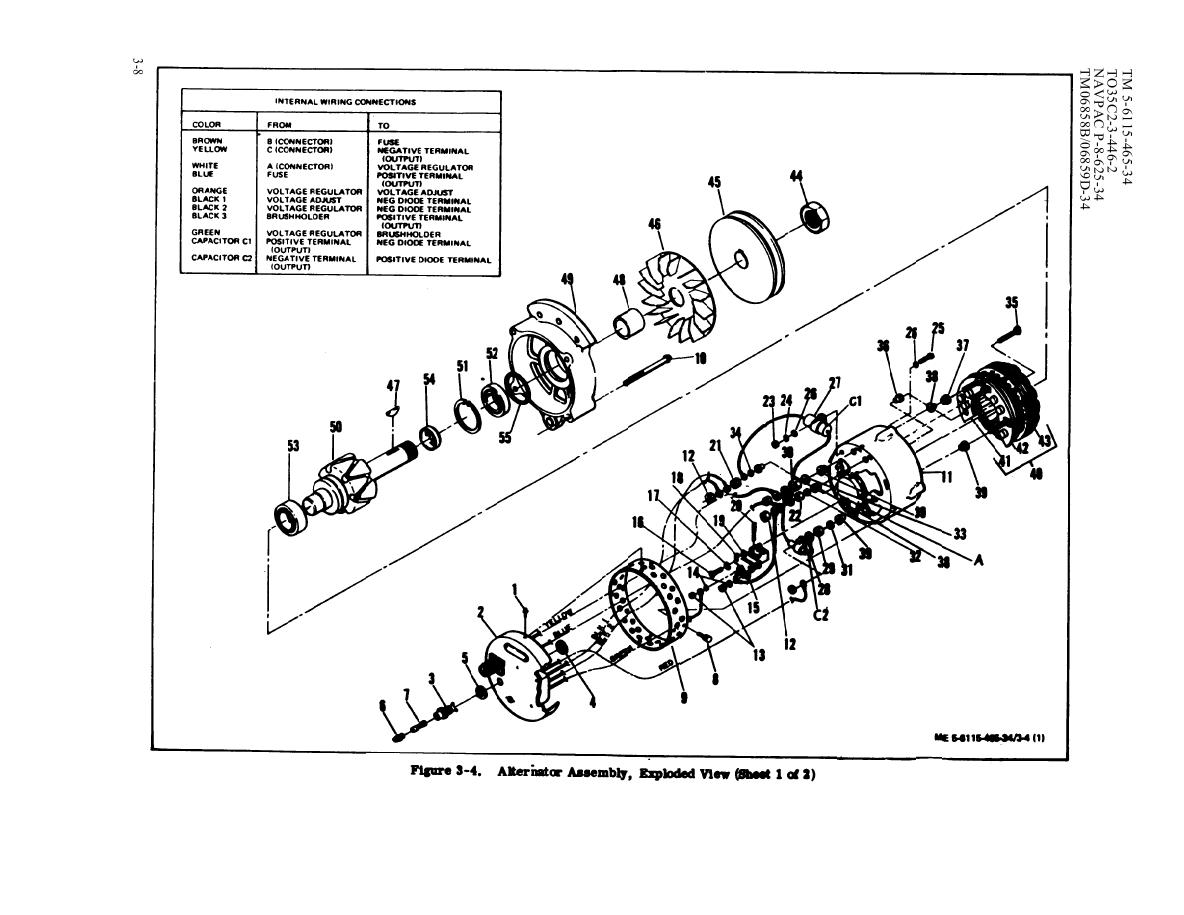

2. Tactical – Diesel Generator Set 30kW

Domäne: dieselgenerators.tpub.com

Registriert: 1998 (27 Jahre)

Einleitung: Generator Set Diesel Engine Driven Tactical Skid Mtd. 30 Kw 3 Phase 4 Wire 120/208 and 240/416 Volts

3. Electude – Alternator Essentials

Domäne: electude.com

Registriert: 2005 (20 Jahre)

Einleitung: Eine Lichtmaschine ist ein wichtiges Bauteil in einem Kraftfahrzeug, das mechanische Energie in elektrische Energie umwandelt und so Strom für die elektrischen Verbraucher und die Batterie des Fahrzeugs erzeugt. Zu den wichtigsten Komponenten gehören:

– Pulley: Transfers mechanical energy from the engine to the alternator.

- Rotor: Erzeugt das Magnetfeld zur Erzeugung des Wechselstroms.

– Stator: The static part where voltage is generat…

4. LinkedIn – Car Alternator Key Parts

Domäne: linkedin.com

Registriert: 2002 (23 Jahre)

Einleitung: Car Alternator Exploded View

Key Parts:

1. Freewheel Pulley & Spacer – Transfers engine belt drive while reducing vibrations.

2. D.E. Bracket & Retainer Plate – Provides front support and housing for the rotor.

3. Rotor – Rotating electromagnet that induces current in the stator.

4. Stator – Stationary winding where AC voltage is generated.

5. Bearings – Enable smooth rotor rotation.

6. S.R.E. B…

5. Adobe – Car Alternator 3D Illustration

Domäne: stock.adobe.com

Registriert: 1986 (39 Jahre)

Einleitung: Car alternator exploded view isolated on white background, 3D illustration. Dimensions: 5500 x 3000px. File type: JPEG. Category: Technology. License type: Standard or Extended. Keywords: alternator, auto, automotive, electric generator, electric motor, electromechanical, rotor, stator, motor, spare part, car, vehicle, winding, aluminium, energy.

Strategic Sourcing Conclusion and Outlook for alternator exploded view

In the dynamic landscape of automotive components, the importance of strategic sourcing for alternators cannot be overstated. Understanding the intricacies of alternator exploded views provides B2B buyers with a comprehensive perspective on assembly, maintenance, and replacement parts. By leveraging detailed diagrams and specifications, companies can enhance their procurement processes, ensuring they select high-quality components that align with their operational needs.

For international buyers, particularly in Africa, South America, the Middle East, and Europe, the opportunity to source efficiently and effectively is pivotal. Engaging with reputable suppliers who offer extensive exploded view resources can streamline inventory management and reduce downtime. Moreover, it empowers businesses to make informed decisions, ultimately leading to cost savings and improved product reliability.

As we look to the future, the integration of advanced technologies and sustainable practices in alternator manufacturing is set to redefine the industry. It is crucial for B2B buyers to stay abreast of these developments and adapt their sourcing strategies accordingly. Embrace the opportunity to enhance your supply chain resilience—connect with trusted partners today to ensure your business remains competitive in this evolving market.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.