Introduction: Navigating the Global Market for how to know if its battery or alternator

In the fast-paced world of automotive maintenance, knowing whether a vehicle’s issues stem from the battery or alternator is crucial for B2B buyers, especially those sourcing parts and services across diverse markets in Africa, South America, the Middle East, and Europe, including Germany and Saudi Arabia. This guide, “How to Know if It’s Battery or Alternator,” addresses a common challenge: the difficulty in diagnosing electrical problems that can disrupt operations and lead to costly downtime. By providing a thorough examination of the symptoms, troubleshooting methods, and essential maintenance tips, this resource empowers international buyers to make informed purchasing decisions.

The guide delves into the intricacies of battery and alternator functionalities, outlining their respective roles in vehicle performance. It also highlights the importance of supplier vetting, ensuring that buyers can identify reliable partners who offer high-quality components. Additionally, it covers cost considerations, enabling businesses to budget effectively while securing the best value for their investments. With actionable insights tailored for a global audience, this comprehensive resource not only enhances the understanding of these critical automotive components but also supports strategic sourcing decisions that optimize fleet reliability and operational efficiency.

Inhaltsverzeichnis

- Top 3 How To Know If Its Battery Or Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to know if its battery or alternator

- Understanding how to know if its battery or alternator Types and Variations

- Key Industrial Applications of how to know if its battery or alternator

- 3 Common User Pain Points for ‘how to know if its battery or alternator’ & Their Solutions

- Strategic Material Selection Guide for how to know if its battery or alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how to know if its battery or alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if its battery or alternator’

- Comprehensive Cost and Pricing Analysis for how to know if its battery or alternator Sourcing

- Alternatives Analysis: Comparing how to know if its battery or alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how to know if its battery or alternator

- Navigating Market Dynamics and Sourcing Trends in the how to know if its battery or alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to know if its battery or alternator

- Strategic Sourcing Conclusion and Outlook for how to know if its battery or alternator

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding how to know if its battery or alternator Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Sichtprüfung | Check for corrosion, swelling, or physical damage | Automotive repair shops, parts retailers | Vorteile: Schnell und einfach; Nachteile: Kann zugrundeliegende Probleme übersehen |

| Spannungsprüfung | Measure voltage output with a multimeter | Automotive diagnostics, fleet management | Pros: Accurate; Cons: Requires equipment and expertise |

| Jump-Start Test | Assess functionality by jump-starting the vehicle | Automotive service providers | Pros: Simple diagnostic; Cons: Not definitive for alternator issues |

| Belastungstest | Simulate real operating conditions to evaluate performance | Batterielieferanten, Kfz-Werkstätten | Pros: Comprehensive; Cons: Time-consuming and requires special tools |

| Diagnostische Werkzeuge | Utilize advanced electronic testers for detailed analysis | Automotive service centers, fleet operators | Pros: Detailed insights; Cons: Higher cost and complexity |

What Are the Key Features of Visual Inspection for Battery and Alternator Diagnosis?

Visual inspection is the first step in diagnosing battery and alternator issues. It involves checking for physical signs of wear, such as corrosion on terminals, swelling of the battery case, or frayed wires. This method is suitable for automotive repair shops and parts retailers, as it offers a quick way to identify obvious problems. While this approach is easy and requires no special tools, it may overlook deeper electrical issues that could affect performance.

How Does Voltage Testing Help Distinguish Between Battery and Alternator Problems?

Voltage testing involves using a multimeter to measure the voltage output of the battery and alternator. A healthy battery typically shows a voltage between 12.4 to 12.7 volts when the engine is off and around 13.8 to 14.2 volts when the engine is running, indicating proper alternator function. This method is essential for automotive diagnostics and fleet management, as it provides precise data on electrical system health. However, it requires knowledge of electrical systems and access to testing equipment.

What Is the Jump-Start Test and Its Utility in Diagnosis?

The jump-start test is a practical method to determine whether the battery or alternator is at fault. By connecting a functioning battery to the vehicle, one can observe if the vehicle starts and continues running without the jump leads. This test is commonly used by automotive service providers, as it is straightforward and can quickly identify a dead battery. However, it does not conclusively diagnose alternator issues, as a faulty alternator may still allow the vehicle to start temporarily.

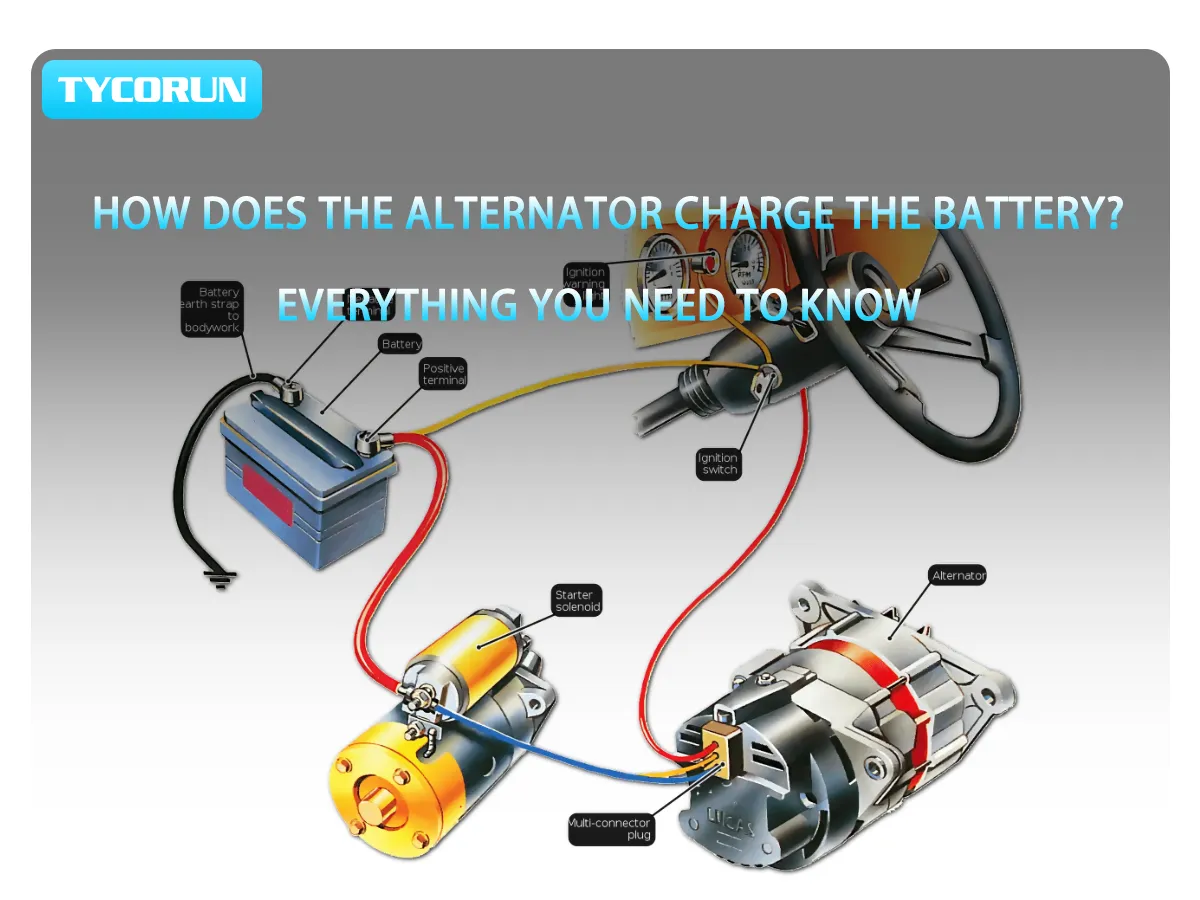

Illustrative image related to how to know if its battery or alternator

Why Is Load Testing Important for Battery and Alternator Evaluation?

Load testing simulates real-world operating conditions to evaluate a battery’s ability to deliver power under stress. This is particularly useful for battery suppliers and automotive workshops, as it provides a comprehensive assessment of battery health and performance. While this method is thorough and can uncover latent issues, it requires specialized equipment and can be time-consuming compared to other diagnostic methods.

How Do Diagnostic Tools Enhance the Evaluation Process for B2B Buyers?

Advanced diagnostic tools offer in-depth analysis of electrical systems, pinpointing issues with batteries, alternators, and starters. These tools are invaluable for automotive service centers and fleet operators, providing detailed insights that can lead to informed purchasing decisions for replacement parts. While they offer comprehensive data, the cost and complexity of these tools may be a barrier for smaller operations without dedicated technicians.

Key Industrial Applications of how to know if its battery or alternator

| Branche/Sektor | Specific Application of how to know if its battery or alternator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Diagnostic services to identify battery or alternator issues | Reduces downtime and repair costs by quickly diagnosing issues | Access to reliable diagnostic tools and trained technicians |

| Transport & Logistik | Fleet maintenance and management of vehicles | Enhances fleet reliability and reduces operational disruptions | Availability of parts and skilled labor for repairs |

| Erneuerbare Energien | Wartung von Elektrofahrzeugen und Hybridsystemen | Ensures optimal performance and longevity of electric systems | Sourcing high-quality batteries and charging systems |

| Landwirtschaft | Maintenance of farm machinery and equipment | Minimizes equipment failure and maximizes productivity | Reliable supply chains for durable batteries and alternators |

| Bauwesen | Power supply management for construction equipment | Increases efficiency by ensuring equipment is always operational | Access to robust power solutions and local service providers |

How is ‘How to Know if It’s Battery or Alternator’ Used in the Automotive Repair Industry?

In the automotive repair sector, understanding whether a vehicle’s issues stem from the battery or alternator is crucial for effective diagnostics. Mechanics utilize various testing methods, including jump-start tests and multimeter readings, to assess the health of these components. This knowledge allows repair shops to provide precise solutions, enhancing customer satisfaction and reducing unnecessary part replacements. For international buyers, sourcing high-quality diagnostic tools and training for technicians is essential to maintain service standards.

Illustrative image related to how to know if its battery or alternator

What Role Does Battery and Alternator Diagnosis Play in Transportation & Logistics?

In the transportation and logistics industry, fleet managers rely on the effective functioning of vehicles to ensure timely deliveries. Regular diagnostic checks help identify battery or alternator problems before they lead to breakdowns. This proactive approach minimizes operational disruptions, leading to cost savings and improved service reliability. Buyers in this sector should consider sourcing durable components and establishing relationships with local repair services to ensure quick turnaround times for maintenance.

How is Battery and Alternator Diagnosis Critical in Renewable Energy Applications?

With the rise of electric vehicles and hybrid systems, the renewable energy sector requires a clear understanding of battery and alternator functionality. Regular diagnostics ensure these systems operate efficiently, extending their lifespan and enhancing performance. Businesses need to source high-quality batteries and charging solutions that meet specific energy needs. International buyers must also navigate local regulations and standards for electric vehicle components.

Why is Battery and Alternator Maintenance Important for Agriculture?

In agriculture, the reliability of machinery is paramount for productivity. Farmers must ensure that their equipment, often reliant on batteries and alternators, is operational at all times. Regular diagnostic checks can prevent equipment failures, allowing farmers to maintain productivity during peak seasons. Buyers should focus on sourcing robust batteries and alternators that can withstand harsh agricultural environments, ensuring longevity and reliability.

How Does Construction Equipment Benefit from Battery and Alternator Diagnosis?

Construction sites demand reliable power sources for machinery. Understanding whether electrical issues arise from the battery or alternator can prevent costly downtime. Regular diagnostics ensure that equipment remains operational, thereby enhancing overall project efficiency. Buyers in this sector should prioritize sourcing durable and high-performance power solutions, along with access to local service providers for prompt maintenance and repairs.

3 Common User Pain Points for ‘how to know if its battery or alternator’ & Their Solutions

Scenario 1: Diagnosing Electrical Failures in Fleet Vehicles

Das Problem: Fleet managers often face the daunting task of diagnosing electrical failures in multiple vehicles, particularly when issues arise unexpectedly. For instance, a vehicle may suddenly fail to start, leaving drivers stranded and disrupting operations. In such scenarios, determining whether the cause is a dead battery or a malfunctioning alternator can be particularly challenging, especially when the symptoms overlap. This lack of clear differentiation can lead to unnecessary replacements, increased downtime, and inflated maintenance costs.

Illustrative image related to how to know if its battery or alternator

Die Lösung: To effectively identify whether the problem lies with the battery or the alternator, fleet managers should implement a systematic troubleshooting process. Begin with a simple jump-start test: connect a good battery to the vehicle in question. If the vehicle starts but dies shortly after disconnecting the jumper cables, the alternator is likely at fault. If it does not start at all, the issue may reside in the battery or starter. Additionally, investing in diagnostic tools such as a multimeter can provide precise voltage readings. A healthy alternator typically produces around 14 volts while the engine runs. If the voltage is significantly lower, the alternator may need replacement. Regular training for maintenance personnel on these diagnostic methods can further streamline the process, reducing vehicle downtime and maintenance costs.

Scenario 2: Managing Unexpected Equipment Downtime

Das Problem: In industries reliant on heavy machinery or transportation, unexpected equipment downtime due to battery or alternator issues can lead to significant losses. For example, a logistics company may find its delivery trucks immobilized due to electrical failures, delaying shipments and harming customer relationships. In many cases, quick identification of the root cause can prevent a minor issue from escalating into a major operational setback.

Die Lösung: To mitigate such risks, businesses should adopt a proactive approach by establishing a routine maintenance schedule that includes electrical system checks. Regular inspections can help identify early signs of battery wear, such as swelling or corrosion, and alternator problems indicated by unusual noises or flickering dashboard lights. Furthermore, integrating a predictive maintenance strategy, utilizing data analytics to monitor vehicle performance, can allow companies to anticipate potential failures before they occur. Partnering with reliable suppliers for high-quality batteries and alternators ensures that replacements are both effective and durable, minimizing the risk of future failures.

Scenario 3: Sourcing Reliable Replacement Parts

Das Problem: Sourcing replacement batteries or alternators poses a challenge for B2B buyers, particularly in regions where quality parts may be scarce or overpriced. Inconsistent supply chains can lead to delays in repairs, affecting the overall efficiency of operations. Moreover, the difficulty in discerning which part to purchase can result in costly mistakes, with businesses potentially investing in incorrect or subpar components.

Illustrative image related to how to know if its battery or alternator

Die Lösung: To streamline the sourcing of reliable replacement parts, B2B buyers should establish strong relationships with reputable suppliers who specialize in automotive components. It is crucial to conduct thorough market research to compare prices, quality, and warranty terms across different vendors. Utilizing online platforms that aggregate supplier reviews can aid in identifying trustworthy sources. Additionally, implementing a standardized parts specification system can help ensure that the correct parts are ordered consistently. Training procurement teams to recognize quality indicators—such as certifications and manufacturer reputations—can further enhance the reliability of purchases, thus reducing the likelihood of future electrical issues and ensuring smooth operational continuity.

Strategic Material Selection Guide for how to know if its battery or alternator

When determining whether a vehicle’s issues stem from the battery or alternator, understanding the materials involved in these components can significantly influence product selection and performance. Here, we analyze several common materials used in automotive batteries and alternators, focusing on their properties, advantages, limitations, and considerations for international B2B buyers.

What Are the Key Materials Used in Batteries and Alternators?

1. Lead-Acid (for Batteries)

Wichtige Eigenschaften: Lead-acid batteries are known for their high energy density and reliability. They typically operate effectively in a temperature range of -20°C to 50°C, making them suitable for various climates.

Vor- und Nachteile: Lead-acid batteries are relatively low-cost and have a proven track record in automotive applications. However, they are heavy and have a shorter lifespan compared to newer technologies like lithium-ion batteries. Additionally, they require regular maintenance to ensure optimal performance.

Auswirkungen auf die Anwendung: Lead-acid batteries are compatible with a wide range of vehicles and can handle high current loads, making them ideal for starting engines. However, their weight can impact fuel efficiency in smaller vehicles.

Überlegungen für internationale Käufer: Compliance with international standards such as ISO 9001 is crucial. Buyers from regions like Europe may prefer batteries that meet EU regulations on hazardous materials, while those in Africa may focus on cost-effectiveness and availability.

2. Lithium-Ion (for Batteries)

Wichtige Eigenschaften: Lithium-ion batteries offer a higher energy density and a longer cycle life than lead-acid batteries. They can operate efficiently in temperatures ranging from -20°C to 60°C, making them versatile for various environments.

Vor- und Nachteile: The lightweight nature of lithium-ion batteries enhances vehicle performance and efficiency. However, they are more expensive to manufacture and can pose safety risks if not handled properly.

Auswirkungen auf die Anwendung: Lithium-ion batteries are increasingly used in electric vehicles (EVs) and hybrid systems due to their efficiency and longevity. Their compatibility with regenerative braking systems is a significant advantage.

Überlegungen für internationale Käufer: Compliance with safety standards like UN 38.3 for transport is essential. Buyers in regions with developing markets may need to assess the availability of charging infrastructure for EVs.

3. Copper (for Alternators)

Wichtige Eigenschaften: Copper is a highly conductive material, making it ideal for electrical connections in alternators. It can withstand high temperatures and has excellent corrosion resistance.

Vor- und Nachteile: The high conductivity of copper ensures efficient energy transfer, which is critical for alternator performance. However, copper is more expensive than alternatives like aluminum and can be prone to corrosion if not properly insulated.

Auswirkungen auf die Anwendung: Copper components in alternators help maintain consistent voltage output, essential for vehicle electrical systems. The material’s durability contributes to the longevity of the alternator.

Überlegungen für internationale Käufer: Buyers should ensure compliance with electrical standards such as IEC 60228 for conductors. In regions like the Middle East, where high temperatures are common, selecting corrosion-resistant copper alloys can enhance performance.

4. Aluminum (for Alternators)

Wichtige Eigenschaften: Aluminum is lightweight and resistant to corrosion, making it a popular choice for alternator housings. It can operate effectively in a wide temperature range.

Vor- und Nachteile: The lightweight nature of aluminum reduces overall vehicle weight, improving fuel efficiency. However, it has lower electrical conductivity compared to copper, which can affect performance.

Auswirkungen auf die Anwendung: Aluminum is often used in alternator casings, providing structural integrity while minimizing weight. However, it may require additional design considerations to ensure optimal conductivity.

Überlegungen für internationale Käufer: Compliance with standards such as ASTM B221 for aluminum extrusions is important. Buyers in Europe may prioritize aluminum products that meet recycling standards due to environmental regulations.

Illustrative image related to how to know if its battery or alternator

Übersichtstabelle zur Materialauswahl

| Material | Typical Use Case for how to know if its battery or alternator | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Lead-Acid | Automotive batteries for starting engines | Kostengünstig und zuverlässig | Shorter lifespan and heavier weight | Niedrig |

| Lithium-Ion | Batteries for electric and hybrid vehicles | High energy density and lightweight | Higher cost and potential safety risks | Hoch |

| Kupfer | Electrical connections in alternators | Ausgezeichnete Leitfähigkeit und Haltbarkeit | Higher cost and corrosion potential | Med |

| Aluminium | Housings for alternators | Leicht und korrosionsbeständig | Geringere Leitfähigkeit als Kupfer | Med |

This analysis provides a comprehensive overview of the materials involved in battery and alternator applications, equipping international B2B buyers with the insights needed for informed decision-making.

In-depth Look: Manufacturing Processes and Quality Assurance for how to know if its battery or alternator

What Are the Key Manufacturing Processes for Batteries and Alternators?

The manufacturing processes for batteries and alternators are intricate and tailored to meet stringent quality standards. Understanding these processes can help B2B buyers make informed decisions when sourcing components for their automotive needs.

What Are the Main Stages in Battery and Alternator Manufacturing?

-

Materialvorbereitung: The first step in manufacturing batteries involves sourcing high-purity raw materials. For batteries, this includes lead, sulfuric acid, and other chemical compounds. In the case of alternators, critical materials such as copper, aluminum, and various alloys are procured. Quality control begins at this stage, with suppliers often required to provide certificates of analysis to ensure material compliance with international standards.

-

Formung: The forming stage varies significantly between batteries and alternators. For batteries, lead plates are cast and then subjected to processes like rolling and stamping to achieve the required thickness and shape. In alternators, the stator and rotor components are formed through methods such as die-casting for aluminum parts and winding for copper coils. Precision is critical here, as any defects can lead to operational inefficiencies.

-

Montage: During assembly, components are put together using various techniques, including welding, soldering, and mechanical fastening. In battery production, plates are stacked and immersed in electrolyte solutions. For alternators, the rotor is fitted with bearings and assembled with the stator. This stage often employs automated systems to enhance consistency and efficiency.

-

Endbearbeitung: The finishing stage involves processes that ensure durability and performance. Batteries are often encapsulated to prevent leaks and corrosion, while alternators may receive coatings to withstand environmental factors. Both components undergo rigorous testing at this stage to ensure they meet performance specifications.

How Is Quality Assurance Implemented in Battery and Alternator Manufacturing?

Quality assurance (QA) is an essential aspect of manufacturing batteries and alternators, ensuring that products meet or exceed industry standards.

Welche internationalen Normen sind für die Qualitätssicherung relevant?

International standards such as ISO 9001 are crucial in the automotive sector. This standard focuses on quality management systems, ensuring that manufacturers maintain consistent quality throughout their processes. Other relevant standards include:

- CE-Kennzeichnung: Indicates conformity with health, safety, and environmental protection standards within the European Economic Area.

- API-Standards: Particularly relevant for alternators, these standards govern performance and safety in automotive applications.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle?

-

Eingangsqualitätskontrolle (IQC): This initial checkpoint ensures that raw materials meet specified requirements before they enter the production line. Suppliers must provide documentation, including material safety data sheets (MSDS) and compliance certificates.

-

In-Process-Qualitätskontrolle (IPQC): During manufacturing, regular inspections are conducted to monitor adherence to production parameters. This includes checks on dimensions, weight, and functionality of components at various stages.

-

Endkontrolle (FQC): Before products leave the factory, a comprehensive final inspection is performed. This includes performance testing under simulated operational conditions, ensuring that both batteries and alternators function as intended.

Welche gängigen Prüfverfahren werden in der Qualitätssicherung eingesetzt?

Several testing methods are employed to verify the quality and performance of batteries and alternators:

- Elektrische Prüfung: For batteries, this involves measuring voltage, capacity, and internal resistance. Alternators are tested for output voltage and current under load conditions.

- Umweltprüfungen: This includes subjecting products to extreme temperatures, humidity, and vibration to ensure reliability in various conditions.

- Haltbarkeitsprüfung: Components undergo stress tests to assess their longevity and performance over time, simulating real-world usage scenarios.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

B2B buyers must ensure that their suppliers adhere to stringent quality control measures. Here are actionable steps to verify supplier QC:

-

Lieferantenaudits: Conduct regular audits of suppliers to assess their adherence to quality standards. This can involve on-site visits to review processes and documentation.

-

Qualitätsberichte anfordern: Suppliers should provide detailed QC reports that outline testing procedures, results, and compliance with international standards.

-

Inspektionen durch Dritte: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing and quality control processes.

Was sind die Feinheiten der Qualitätskontrolle und Zertifizierung für internationale Käufer?

For B2B buyers from diverse regions, particularly Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital:

-

Lokale Verordnungen: Buyers should familiarize themselves with local regulations regarding automotive components, as these can vary significantly between regions. Compliance with local standards is as crucial as adherence to international norms.

-

Kulturelle Erwägungen: Communication styles and business practices differ across cultures. Establishing a rapport with suppliers can lead to better transparency regarding quality practices.

-

Logistische Herausforderungen: International shipping can introduce complications such as damage during transit. Ensuring that suppliers package products adequately and provide insurance options can mitigate risks.

Schlussfolgerung

Understanding the manufacturing processes and quality assurance practices for batteries and alternators is essential for B2B buyers. By focusing on supplier quality control, international standards, and verification methods, buyers can ensure they source reliable and high-performance components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to know if its battery or alternator’

To assist B2B buyers in understanding whether an issue lies with a vehicle’s battery or alternator, this practical sourcing guide provides actionable steps. By following this checklist, you can make informed decisions when diagnosing electrical problems in vehicles, ensuring smooth operations and minimal downtime.

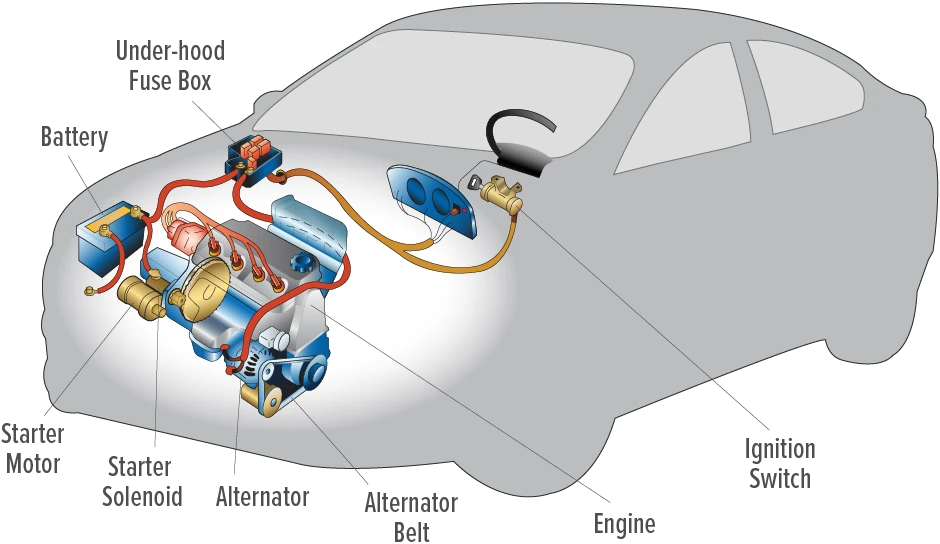

Schritt 1: Understand the Role of Each Component

Familiarize yourself with the functions of the battery, alternator, and starter. The battery provides initial power to start the vehicle, while the alternator generates electricity to recharge the battery and power electrical systems while the engine runs. Knowing how these components interact is crucial for effective troubleshooting.

Schritt 2: Identify Common Symptoms

Recognize the signs of failure for each component.

– Battery Issues: Look for slow engine cranking, clicking sounds, dim lights, or bloating of the battery case.

– Alternator Problems: Symptoms include flickering lights, a voltage gauge reading outside the normal range, and grinding noises.

Documenting these symptoms can help streamline the diagnosis and determine which part needs attention.

Illustrative image related to how to know if its battery or alternator

Schritt 3: Conduct Initial Diagnostic Tests

Perform basic tests to isolate the issue.

– Jump-Start Test: Use jumper cables to see if the vehicle starts. If it starts with a jump but dies when disconnected, the alternator may be faulty.

– Multimeter Check: Use a multimeter to measure voltage output. A healthy alternator should produce between 13.5 to 14.5 volts when the engine is running.

These preliminary tests provide clear indicators of which component might be malfunctioning.

Schritt 4: Evaluate Environmental Factors

Consider environmental influences that may affect component lifespan.

– Temperature Extremes: Extreme heat or cold can shorten battery life and impact alternator performance.

– Moisture Exposure: Water can corrode connections and internal parts. Ensure that components are installed in locations protected from such elements.

Understanding these factors can help you select components that are more resilient to specific conditions in your region.

Schritt 5: Consult Technical Documentation

Review manufacturer specifications and troubleshooting guides. This documentation can offer insights into expected performance metrics and common failure rates for specific models.

– Service Manuals: These often include diagnostic procedures and wiring diagrams.

– Technical Bulletins: Stay updated on recalls or known issues that may affect your vehicle models.

Accessing accurate information is essential for informed decision-making and effective repairs.

Schritt 6: Source Quality Components

When procuring replacement parts, prioritize quality and reliability.

– Lieferanten-Zertifizierungen: Ensure suppliers adhere to industry standards and provide warranties.

– Customer Reviews: Look for feedback from other businesses in similar sectors to gauge satisfaction and performance.

Choosing reputable suppliers can significantly impact the longevity and reliability of the components you purchase.

Schritt 7: Plan for Professional Inspection

Finally, consider scheduling a professional inspection if issues persist. Experienced technicians can conduct thorough diagnostics and recommend the best course of action.

– Comprehensive Vehicle Inspections: These services can identify underlying issues that may not be apparent during basic testing.

Investing in professional expertise can save costs in the long run by preventing further damage and ensuring proper repairs are made.

By following these steps, B2B buyers can effectively navigate the complexities of diagnosing and addressing battery and alternator issues, enhancing operational efficiency and vehicle reliability.

Comprehensive Cost and Pricing Analysis for how to know if its battery or alternator Sourcing

What Are the Key Cost Components in Sourcing Battery and Alternator Solutions?

When sourcing components for automotive electrical systems, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materialien: The quality of materials used significantly impacts costs. For batteries, lead, acid, and plastic are primary components, while alternators primarily consist of copper windings, aluminum casings, and electronic regulators. High-grade materials often lead to better performance and longevity but come at a higher price.

-

Arbeit: Labor costs vary by region and supplier. In manufacturing hubs, labor might be cheaper, but skilled labor for quality assembly can increase costs. Understanding local labor markets can aid in negotiating better terms.

-

Fertigungsgemeinkosten: This includes the costs associated with running the production facility, such as utilities and maintenance. Overhead can fluctuate based on location and operational efficiency.

-

Werkzeuge: Investment in specialized tools and machinery for manufacturing can be substantial. Buyers should consider whether the supplier has the latest technology, as this can affect both cost and quality.

-

Qualitätskontrolle (QC): Rigorous QC processes are essential for ensuring reliability. Suppliers that adhere to international standards (e.g., ISO certifications) may charge more but can offer assurance of quality.

-

Logistik: Shipping costs can vary widely based on distance, mode of transport, and packaging. International buyers should factor in potential customs duties and tariffs, which can influence the total cost.

-

Marge: Suppliers will add a margin to cover their costs and profit. Understanding the market average for margins in your region can help in negotiations.

What Influences Pricing for Battery and Alternator Components?

Several factors can influence pricing, especially for B2B buyers operating internationally.

-

Volumen und Mindestbestellmenge (MOQ): Higher order volumes often lead to better pricing. Suppliers may have a MOQ, which can affect pricing strategy. Buyers should assess their needs carefully to avoid excess inventory.

-

Spezifikationen und Anpassung: Custom specifications can drive up costs. If you require batteries or alternators tailored to specific requirements (like enhanced performance in extreme temperatures), expect to pay a premium.

-

Qualität und Zertifizierungen: Products with higher quality ratings or certifications (like CE or UL) typically command higher prices due to the assurance of performance and safety.

-

Lieferantenfaktoren: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the agreed terms of delivery (Incoterms) is critical. For example, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of goods.

What Tips Can Buyers Use to Negotiate Better Prices for Battery and Alternator Solutions?

International B2B buyers should leverage several strategies to ensure cost-efficiency in their sourcing processes.

-

Verhandlung: Always negotiate terms and prices. Suppliers expect some level of negotiation, especially for larger orders. Highlighting potential long-term partnerships can encourage suppliers to offer better pricing.

-

Cost-Efficiency and Total Cost of Ownership: Look beyond initial purchase price. Assess the total cost of ownership, which includes installation, maintenance, and operational costs over the product’s lifespan. A higher upfront investment in quality components may save costs in the long run.

-

Pricing Nuances in Different Markets: Be aware of regional pricing strategies. For example, in Europe, stringent environmental regulations may affect battery pricing due to the need for compliance with recycling standards. In contrast, suppliers in Africa and South America may offer more flexible terms due to different market dynamics.

Haftungsausschluss für indikative Preise

Prices for batteries and alternators can vary widely based on the factors outlined above. It’s essential for buyers to conduct thorough market research and obtain multiple quotes to ascertain the best value for their specific requirements. Always account for potential fluctuations in material costs and currency exchange rates, particularly when sourcing internationally.

Illustrative image related to how to know if its battery or alternator

Alternatives Analysis: Comparing how to know if its battery or alternator With Other Solutions

Exploring Alternatives for Diagnosing Battery or Alternator Issues

When it comes to identifying whether a vehicle’s electrical problems stem from the battery or the alternator, businesses often seek reliable methods that ensure efficient troubleshooting. While traditional methods like visual inspections and jump-start tests are common, various alternative solutions can also provide insights. This section will compare the standard method of diagnosing battery versus alternator issues with other viable technologies, helping B2B buyers make informed decisions.

Vergleichstabelle

| Vergleichsaspekt | How To Know If It’s Battery Or Alternator | Multimeter-Prüfung | Professionelle Diagnosewerkzeuge |

|---|---|---|---|

| Leistung | Moderate accuracy with basic symptoms. | High accuracy, precise readings. | Very high accuracy, comprehensive diagnostics. |

| Kosten | Low-cost; requires minimal tools. | Moderate; multimeter prices vary. | High; diagnostic tools can be expensive. |

| Einfache Implementierung | Simple procedures, accessible to most. | Requires basic electrical knowledge. | Requires trained personnel for optimal use. |

| Wartung | Low; occasional battery and alternator checks. | Low; multimeters are durable with proper care. | High; regular software updates and calibration needed. |

| Bester Anwendungsfall | Quick checks for non-professionals. | DIY enthusiasts and small repair shops. | Professional garages and larger automotive businesses. |

Eingehende Analyse von Alternativen

Multimeter-Prüfung

Using a multimeter to test battery and alternator functionality is a highly effective method that provides precise voltage readings. This approach allows technicians to assess whether the alternator is generating sufficient voltage while the engine is running. The primary advantage of this method is its accuracy; however, it requires some electrical knowledge to interpret the readings correctly. Additionally, while multimeters are relatively affordable, they do represent a higher initial investment than simple visual checks.

Professionelle Diagnosewerkzeuge

For businesses that require a high level of accuracy and detail in their diagnostics, professional diagnostic tools represent the pinnacle of automotive troubleshooting. These tools can perform a multitude of tests, not just limited to battery and alternator functions, but also encompassing the entire vehicle’s electrical system. While they offer unparalleled insights, the cost can be prohibitive for smaller operations, and they often necessitate trained personnel to operate effectively. Maintenance of these tools is also crucial, as software updates and calibrations are required to ensure ongoing reliability.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

When deciding on the best method to determine whether a vehicle’s issues are related to the battery or alternator, B2B buyers should consider their specific operational needs and budget constraints. For quick, straightforward checks, traditional methods still hold value. However, for more comprehensive and accurate diagnostics, investing in a multimeter or professional diagnostic tool may be warranted. Ultimately, the choice will depend on the scale of operations, technical expertise available, and the need for diagnostic precision, ensuring that businesses can maintain their vehicles efficiently and effectively.

Illustrative image related to how to know if its battery or alternator

Essential Technical Properties and Trade Terminology for how to know if its battery or alternator

What Are the Key Technical Properties to Consider When Diagnosing Battery or Alternator Issues?

When evaluating whether an issue lies with a vehicle’s battery or alternator, understanding specific technical properties is crucial. Here are several critical specifications that should be prioritized:

-

Nennspannung

The standard voltage for automotive batteries is typically 12 volts. A healthy battery should maintain a voltage between 12.4 to 12.7 volts when fully charged. For alternators, the output voltage should be between 13.8 to 14.5 volts when the engine is running. Monitoring these voltage levels helps determine the health of both components. -

Amp Hour (Ah) Rating

This specification indicates how much current a battery can supply over a specified time. A higher Ah rating means a battery can store more energy, which is especially important for vehicles that require additional power for accessories. For alternators, the amp output indicates how much current it can provide to recharge the battery and power electrical systems. -

Temperaturtoleranz

Batteries and alternators have specified temperature ranges within which they operate effectively. Extreme temperatures can accelerate wear and reduce lifespan. Batteries generally perform poorly in extreme heat or cold, while alternators may fail to produce adequate power if overheated. Understanding these tolerances helps in selecting the right components for different climates. -

Zyklus Leben

This property refers to the number of charge and discharge cycles a battery can undergo before its capacity significantly diminishes. In contrast, alternators are not rated by cycle life but should be assessed for wear based on operational hours. Knowledge of cycle life is essential for fleet managers who aim to minimize replacement costs. -

Materialzusammensetzung

The materials used in batteries (e.g., lead-acid, lithium-ion) and alternators (e.g., copper windings, aluminum housings) can impact performance and durability. Understanding these materials can help buyers select components that offer the best longevity and efficiency for their specific applications.

What Trade Terms Are Essential for B2B Transactions in Automotive Components?

Navigating the automotive supply chain involves familiarity with specific jargon that can facilitate better communication and understanding. Here are some essential trade terms relevant to battery and alternator procurement:

-

OEM (Originalgerätehersteller)

Refers to products made by the same company that manufactured the original components in a vehicle. For B2B buyers, OEM parts often provide guaranteed compatibility and reliability, making them a preferred choice for replacements. -

MOQ (Mindestbestellmenge)

This term indicates the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is critical for businesses looking to manage inventory and avoid overstocking or understocking situations. -

RFQ (Angebotsanfrage)

This is a formal process where buyers ask suppliers for price quotations based on specified requirements. An RFQ is essential for B2B buyers to ensure they receive competitive pricing and can make informed purchasing decisions. -

Incoterms

International Commercial Terms (Incoterms) are pre-defined trade terms published by the International Chamber of Commerce. They clarify responsibilities regarding shipping, insurance, and tariffs between buyers and sellers. Familiarity with these terms helps mitigate risks associated with international transactions. -

Garantiezeitraum

This term defines the time frame during which a product can be returned or repaired under specific conditions. Understanding warranty periods for batteries and alternators can help buyers assess long-term value and protection against defects. -

Vorlaufzeit

This refers to the time taken from placing an order until the product is delivered. For B2B buyers, understanding lead times is crucial for inventory planning and ensuring timely availability of components for repairs or production.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding battery and alternator procurement, ultimately leading to enhanced operational efficiency and reduced costs.

Navigating Market Dynamics and Sourcing Trends in the how to know if its battery or alternator Sector

Market Overview & Key Trends in the Battery and Alternator Sector

The global battery and alternator market is witnessing significant transformations driven by technological advancements and evolving consumer demands. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly influenced by the push for electric vehicles (EVs) and renewable energy solutions. This shift is prompting manufacturers to innovate, focusing on high-efficiency batteries and alternators that can support advanced automotive technologies.

Emerging trends include the rise of smart batteries equipped with IoT capabilities, allowing for real-time monitoring and diagnostics. This technology not only enhances vehicle performance but also aids in predictive maintenance, reducing downtime for businesses reliant on fleets. Moreover, the expansion of e-commerce platforms is facilitating easier access to battery and alternator parts, enabling buyers to source products directly from manufacturers or distributors, often at competitive prices.

Another critical driver is the increasing regulatory focus on sustainability and environmental impact. Countries are implementing stricter emissions regulations, motivating automotive companies to adopt cleaner technologies. For B2B buyers, this means sourcing components that not only meet performance standards but also align with environmental regulations, thus enhancing their market competitiveness.

How Does Sustainability and Ethical Sourcing Impact the Battery and Alternator Market?

Sustainability has become a pivotal consideration in the battery and alternator sector, influenced by growing environmental awareness among consumers and regulatory bodies. The production and disposal of batteries can significantly impact the environment, prompting manufacturers to adopt more sustainable practices. B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to sustainability through ethical sourcing and environmentally friendly materials.

Ethical supply chains are essential in minimizing the ecological footprint of battery production. This involves sourcing raw materials such as lithium, cobalt, and nickel from suppliers who adhere to responsible mining practices, thus ensuring that their operations do not exploit labor or degrade local environments. Certifications such as ISO 14001 for environmental management systems and the Responsible Minerals Initiative (RMI) are gaining importance, offering B2B buyers a framework to evaluate potential suppliers.

Furthermore, the trend towards recycling and reusing battery components is gaining traction. As the lifecycle of batteries is scrutinized, businesses are encouraged to partner with suppliers who invest in battery recycling programs. This not only reduces waste but also provides a sustainable source of raw materials for new battery production, ultimately contributing to a circular economy.

What is the Evolution of the Battery and Alternator Technology?

The evolution of battery and alternator technology has been marked by significant milestones that have shaped the automotive landscape. Initially, lead-acid batteries dominated the market due to their low cost and reliability. However, as consumer demands for efficiency and performance increased, the industry shifted towards advanced battery technologies, such as lithium-ion, which offer higher energy density and longer life cycles.

The introduction of alternators in the early 1960s replaced generators, providing vehicles with a more efficient means of generating electrical power. This transition enabled modern vehicles to support an array of electronic features, from infotainment systems to advanced driver assistance technologies. Today, advancements in alternator technology focus on lightweight materials and compact designs, catering to the growing market for electric and hybrid vehicles.

As technology continues to evolve, the integration of smart features in both batteries and alternators is anticipated to revolutionize the sector further. Innovations such as regenerative braking and energy recovery systems are paving the way for more sustainable automotive solutions, aligning with global trends towards electrification and sustainability. For B2B buyers, understanding these technological advancements is essential for making informed sourcing decisions that meet both performance and environmental standards.

Frequently Asked Questions (FAQs) for B2B Buyers of how to know if its battery or alternator

1. How do I determine if the issue is with the battery or alternator?

To identify whether your vehicle’s problem lies with the battery or the alternator, begin with a simple jump-start. If the vehicle starts but dies shortly after, the alternator may not be charging the battery adequately. If it does not start at all, the issue might be with the starter or battery. Additionally, look for signs such as dim lights, clicking sounds, or a dashboard warning light that can indicate which component is failing. Regular inspections can help prevent unexpected failures and maintain operational efficiency.

2. What are the common signs of a failing battery or alternator?

Common indicators of a failing battery include slow engine cranking, dim headlights, and a swollen battery case. In contrast, a failing alternator may manifest through flickering lights, unusual noises, or a battery warning light on the dashboard. Identifying these signs early can help avoid costly repairs and downtime. Ensuring that your team is trained to recognize these symptoms can lead to quicker resolutions and improved vehicle uptime.

3. What testing methods can I use to check the battery and alternator?

To test the battery, you can use a multimeter to measure the voltage; a healthy battery should read between 12.4 to 12.7 volts when the engine is off. For the alternator, while the engine runs, the voltage should ideally range from 13.8 to 14.4 volts. An alternative method involves disconnecting the battery while the engine is running; if the vehicle stops, the alternator is likely faulty. However, this method can be risky and is not recommended for all vehicles, so using a multimeter is the safest approach.

Illustrative image related to how to know if its battery or alternator

4. How do I select a reliable supplier for automotive batteries and alternators?

When sourcing batteries and alternators, prioritize suppliers with a proven track record in quality and reliability. Look for certifications, customer reviews, and case studies that demonstrate their experience in the automotive industry. Ensure they can provide comprehensive product specifications, warranty information, and after-sales support. Establishing a good rapport with suppliers can facilitate better communication and more favorable terms, ultimately enhancing your supply chain efficiency.

5. What are the minimum order quantities (MOQ) for batteries and alternators?

Minimum order quantities can vary significantly among suppliers and regions. Typically, automotive parts suppliers may have MOQs ranging from 50 to 500 units, depending on the type of product and the supplier’s inventory capabilities. It is advisable to discuss your specific needs and negotiate MOQs based on your purchasing power and expected demand. Understanding these terms can help you manage inventory more effectively and reduce overhead costs.

6. What payment terms should I expect when sourcing batteries and alternators internationally?

Payment terms can vary widely, but common arrangements include upfront payments, net 30 or net 60 terms, and letters of credit for larger orders. It is crucial to establish clear payment terms with your supplier before finalizing any transactions. Consider using secure payment methods that protect both parties, such as escrow services or verified payment platforms. Understanding these terms can help mitigate financial risks and ensure smooth transactions.

7. How do I ensure quality assurance (QA) for batteries and alternators?

To ensure quality assurance, request detailed product specifications, testing certifications, and compliance with international standards from your suppliers. Implement a rigorous inspection process upon receipt of goods, including visual inspections and performance tests. Establishing a clear QA protocol can prevent defective products from reaching your customers, thereby maintaining your brand reputation and customer satisfaction. Collaborate with suppliers to develop a quality control plan that meets your specific needs.

8. What logistics considerations should I keep in mind when importing batteries and alternators?

Logistics for importing batteries and alternators require careful planning due to their weight and potential hazardous materials. Ensure compliance with international shipping regulations and customs requirements, which may vary by region. Choose reliable freight forwarders experienced in handling automotive parts to avoid delays. Additionally, factor in lead times, shipping costs, and potential tariffs when budgeting for your imports to ensure a smooth supply chain operation.

Top 3 How To Know If Its Battery Or Alternator Manufacturers & Suppliers List

1. Nissan Altima - Leistungsdiagnose

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: The discussion revolves around diagnosing issues related to a 2009 Nissan Altima that has no power. Key components mentioned include the battery, alternator, and starter. The battery provides power to the vehicle’s electronics and the starter, while the alternator charges the battery when the engine is running. Symptoms of a dead battery include no lights or power, and a potential bad alternator m…

2. Alternator Testing – Risks of Battery Disconnection

Domäne: mechanics.stackexchange.com

Registriert: 2009 (16 Jahre)

Einleitung: The text discusses a technique to test an alternator by removing a 12V battery lead while the vehicle is running. It highlights that this method is not recommended due to potential damage to the vehicle’s electronics and the alternator itself. The text emphasizes that the battery plays a crucial role in filtering AC spikes and transients, and removing it can lead to damaging the ECU and other comp…

3. Protyre – Automotive Services & Tyres

Domäne: protyre.co.uk

Registriert: 1999 (26 Jahre)

Einleitung: Protyre offers a range of automotive services including battery checks and replacements, as well as a wide selection of tyres from premium brands like Michelin, Pirelli, Goodyear, and Bridgestone, mid-range options from Firestone, Avon, Sumitomo, and Hankook, and economy choices from Ovation, Budget, and Autogrip. They provide services such as MOTs, car servicing, vehicle repairs, and free safety …

Strategic Sourcing Conclusion and Outlook for how to know if its battery or alternator

In summary, understanding the signs of battery, alternator, or starter failure is crucial for maintaining vehicle reliability and performance. For B2B buyers in automotive sectors across Africa, South America, the Middle East, and Europe, leveraging strategic sourcing to procure high-quality replacement components can significantly reduce downtime and enhance operational efficiency. Key indicators, such as slow engine cranking or dimming headlights, can guide your troubleshooting efforts, while the jump-start test offers a practical method to isolate issues.

Engaging with trusted suppliers who provide robust warranties and support can help ensure that you are equipped with reliable parts that meet the demands of your market. As the automotive landscape continues to evolve, staying informed about component technologies and maintenance best practices will empower your business to make strategic purchasing decisions.

We encourage international buyers to prioritize quality and reliability when sourcing automotive parts. By doing so, you can enhance your service offerings and foster long-term customer satisfaction. Explore partnerships with reputable suppliers to strengthen your supply chain and optimize your operational capabilities moving forward.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Illustrative image related to how to know if its battery or alternator

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.