Introduction: Navigating the Global Market for how much to replace alternator

Navigating the complexities of sourcing replacement alternators can be a daunting task for B2B buyers, especially given the wide variance in costs and quality across different markets. Understanding how much to replace an alternator involves more than just comparing prices; it encompasses evaluating supplier reliability, assessing the types of alternators available, and ensuring compatibility with diverse vehicle models. This guide aims to equip international buyers—particularly from regions like Africa, South America, the Middle East, and Europe—with the knowledge necessary to make informed purchasing decisions.

In this comprehensive resource, we will delve into the various types of alternators, their applications across different vehicle makes and models, and the critical factors influencing replacement costs. Additionally, we will provide insights on how to effectively vet suppliers, ensuring that you partner with reputable manufacturers and distributors who can meet your specific needs. By understanding the nuances of alternator replacement, including potential warranties and the implications of using aftermarket parts, you can mitigate risks and optimize your procurement strategy.

Ultimately, this guide serves as a valuable tool for B2B buyers seeking to navigate the global market for alternators, empowering you to make strategic decisions that enhance operational efficiency and drive long-term value.

Inhaltsverzeichnis

- Top 2 How Much To Replace Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how much to replace alternator

- Understanding how much to replace alternator Types and Variations

- Key Industrial Applications of how much to replace alternator

- 3 Common User Pain Points for ‘how much to replace alternator’ & Their Solutions

- Strategic Material Selection Guide for how much to replace alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how much to replace alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to replace alternator’

- Comprehensive Cost and Pricing Analysis for how much to replace alternator Sourcing

- Alternatives Analysis: Comparing how much to replace alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how much to replace alternator

- Navigating Market Dynamics and Sourcing Trends in the how much to replace alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how much to replace alternator

- Strategic Sourcing Conclusion and Outlook for how much to replace alternator

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding how much to replace alternator Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Neue Lichtmaschinen | Brand new parts, typically from OEM manufacturers | Fleet management, rental car services | Vorteile: Zuverlässigkeit, Garantieleistungen. Nachteile: Höhere Anschaffungskosten. |

| Überholte Lichtmaschinen | Rebuilt components with replaced internal parts | Autowerkstätten, Autohäuser | Vorteile: Kostengünstig, gute Qualität. Nachteile: Möglicherweise kürzere Lebensdauer als neu. |

| Ersatzteil-Lichtmaschinen | Third-party manufactured parts, often cheaper | Independent repair shops, custom builds | Vorteile: Affordable, variety of options. Nachteile: Quality can vary widely. |

| Gebrauchte Lichtmaschinen | Pre-owned parts from salvaged vehicles | Budgetbewusste Werkstätten | Vorteile: Low cost, quick availability. Nachteile: Limited warranty, uncertain reliability. |

| Hybrid/EV Alternators | Specialized components for electric/hybrid vehicles | Electric vehicle manufacturers, fleets | Vorteile: Advanced technology, energy-efficient. Nachteile: Höhere Kosten, begrenzte Verfügbarkeit. |

Was sind die Merkmale neuer Lichtmaschinen?

New alternators are sourced directly from original equipment manufacturers (OEMs), ensuring that they meet specific vehicle standards. These components are ideal for businesses managing fleets or rental services where reliability is paramount. Although they come with a higher price tag, the long-term benefits of warranty coverage and performance can justify the investment, particularly for companies prioritizing uptime.

How Do Remanufactured Alternators Compare?

Remanufactured alternators involve taking used units, disassembling them, and replacing worn-out components before reassembling. This option appeals to automotive repair shops and dealerships looking to balance quality with cost. While they provide a reliable solution at a lower price than new units, buyers should consider the warranty terms and the remanufacturing process’s quality, as these factors can significantly impact performance.

What Should Buyers Know About Aftermarket Alternators?

Aftermarket alternators are produced by third-party manufacturers and often available at lower prices than OEM parts. They are particularly popular among independent repair shops and custom vehicle builders. While they offer a broad range of options, the quality can vary. It is critical for buyers to research the manufacturer’s reputation and warranty offerings to ensure they are making a sound investment.

Why Consider Used Alternators?

Used alternators are salvaged from decommissioned vehicles and are the most budget-friendly option available. They are suitable for repair shops focused on cost-effective solutions for older vehicles. However, buyers must be cautious, as these parts often come with limited warranties and uncertain reliability. Ensuring that the used part has been tested can mitigate some risks associated with this option.

What Are the Unique Aspects of Hybrid/EV Alternators?

Hybrid and electric vehicle alternators differ significantly from traditional ones, often utilizing advanced technology like DC-to-DC converters. These components are crucial for businesses involved in electric vehicle manufacturing or fleet operations. While they tend to be more expensive and less widely available, their energy efficiency and performance benefits align with the growing demand for sustainable transportation solutions.

Key Industrial Applications of how much to replace alternator

| Branche/Sektor | Specific Application of how much to replace alternator | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Cost analysis for garage owners when replacing alternators | Optimizes repair pricing strategies and customer satisfaction | Availability of OEM vs. aftermarket parts, warranty terms |

| Flottenmanagement | Budgeting for fleet vehicle maintenance and repairs | Reduces downtime and enhances vehicle reliability | Supplier reliability, part quality, and service agreements |

| Transport & Logistik | Assessing costs for commercial vehicle alternator replacements | Ensures operational efficiency and minimizes unexpected costs | Bulk purchasing options, shipping logistics, and lead times |

| Baumaschinen | Evaluating alternator replacement costs for heavy machinery | Maintains equipment uptime, crucial for project timelines | Local parts availability, compatibility with existing machinery |

| Automobilbau | Understanding alternator replacement costs for assembly lines | Streamlines production costs and inventory management | Supplier contracts, production timelines, and quality assurance |

How is ‘how much to replace alternator’ relevant in the Automotive Repair industry?

In the automotive repair sector, understanding the costs associated with alternator replacement is essential for garage owners. This knowledge enables them to create competitive pricing strategies that enhance customer satisfaction while maintaining profitability. By evaluating the price range of $600 to $1,500, repair shops can better manage their operational budgets and provide accurate estimates to clients. Additionally, sourcing considerations such as the choice between OEM and aftermarket parts can impact the overall cost and quality of service, making it crucial for repair shops to establish reliable supplier relationships.

Why is alternator replacement cost analysis important for Fleet Management?

For fleet management, an accurate assessment of alternator replacement costs is vital for effective budgeting and maintenance planning. Fleet operators must ensure that vehicles are reliable and operational to minimize downtime and maximize productivity. By understanding the average costs and potential fluctuations in pricing, fleet managers can allocate resources more effectively and anticipate maintenance needs. Key sourcing considerations include evaluating the reliability of suppliers and the quality of parts, as these factors directly impact vehicle performance and fleet efficiency.

How does understanding alternator costs benefit the Transportation & Logistics sector?

In the transportation and logistics industry, evaluating the costs associated with alternator replacements is critical for managing operational expenses. Commercial vehicles are the backbone of supply chains, and unexpected repairs can lead to significant delays and financial losses. By accurately forecasting alternator replacement costs, logistics companies can budget more effectively and avoid disruptions. Sourcing considerations such as bulk purchasing options and the reliability of parts suppliers play a crucial role in ensuring that companies can maintain their fleet without incurring excessive costs.

What role does alternator cost assessment play in Construction Equipment maintenance?

In the construction industry, evaluating the costs of alternator replacements for heavy machinery is essential for maintaining project timelines. Equipment uptime is critical; therefore, understanding the financial implications of replacing alternators helps construction firms avoid delays. Businesses must consider local parts availability and compatibility with existing machinery when sourcing replacements. This proactive approach to maintenance not only keeps equipment running efficiently but also supports the overall success of construction projects.

How does knowledge of alternator replacement costs impact Automotive Manufacturing?

In automotive manufacturing, understanding the costs associated with alternator replacements is crucial for optimizing production processes and managing inventory. Manufacturers need to streamline their operations while ensuring that quality standards are met. By analyzing replacement costs, manufacturers can negotiate better supplier contracts and improve their production timelines. Additionally, quality assurance processes must be in place to ensure that sourced parts meet the required specifications, reducing the risk of production delays and maintaining overall product integrity.

3 Common User Pain Points for ‘how much to replace alternator’ & Their Solutions

Scenario 1: Unexpected Costs of Alternator Replacement

Das Problem: A fleet manager in Nigeria faces an unexpected alternator failure in one of their delivery trucks. With the average replacement cost ranging from $600 to $1,500, this unplanned expense disrupts the budget. The manager is concerned not only about the immediate financial impact but also about the downtime this causes to their operations. Such disruptions can lead to missed deliveries and dissatisfied customers, which ultimately affect the business’s reputation and bottom line.

Die Lösung: To mitigate unexpected costs, fleet managers should implement a proactive maintenance schedule that includes regular diagnostics of the electrical systems, including the alternator. Investing in preventive maintenance can help identify signs of wear and tear before they lead to failure. Additionally, sourcing alternators from reliable suppliers that offer competitive pricing and warranties can help manage costs. Establishing relationships with multiple suppliers can also provide leverage for better deals and quicker turnaround times, ensuring that operations remain uninterrupted. Utilizing fleet management software can help track maintenance schedules and budget for potential repairs more effectively, allowing for smoother financial planning.

Scenario 2: Quality Concerns with Remanufactured Alternators

Das Problem: An automotive repair shop in Germany is experiencing customer complaints regarding the performance of remanufactured alternators. While these parts are often more affordable, some customers are returning with issues shortly after installation, leading to a loss of trust in the shop’s services. This situation highlights the challenge of balancing cost with quality and the need for reliable components in vehicle repairs.

Die Lösung: To address quality concerns, repair shops should thoroughly vet their suppliers of remanufactured parts. Establishing partnerships with reputable manufacturers who provide warranties and guarantees on their remanufactured alternators can alleviate concerns about reliability. Implementing a quality assurance process, where each remanufactured part is tested before installation, can further enhance customer confidence. Additionally, educating customers about the benefits and limitations of remanufactured parts can help set realistic expectations, fostering transparency and trust in the service provided.

Scenario 3: Navigating Warranty Limitations for Alternator Issues

Das Problem: A car rental company in South America finds itself frequently replacing alternators in its aging fleet, but many of these vehicles are just outside their warranty period. The company struggles to manage the high replacement costs while trying to maintain a reliable fleet for its customers. The challenge lies in understanding the warranty coverage and how to leverage it effectively to reduce out-of-pocket expenses.

Die Lösung: To navigate warranty limitations, rental companies should carefully review the warranty terms of each vehicle in their fleet. Engaging with manufacturers to discuss potential goodwill repairs for vehicles that are just out of warranty can sometimes yield positive results. Additionally, creating a database that tracks warranty expiration dates and expected maintenance needs can help companies plan ahead for potential repairs. Utilizing extended warranties, when available, can also provide a safety net for unexpected repairs. Finally, investing in newer vehicles that come with comprehensive warranties can significantly reduce the frequency of costly alternator replacements, ultimately enhancing the fleet’s reliability and customer satisfaction.

Strategic Material Selection Guide for how much to replace alternator

What Materials Are Commonly Used for Replacing Alternators?

When considering the replacement of alternators, the materials used in their construction and repair play a crucial role in performance, durability, and cost. Below, we analyze four common materials used in alternator replacements, focusing on their properties, pros and cons, and implications for international B2B buyers.

Was sind die wichtigsten Eigenschaften von Aluminium für die Herstellung von Lichtmaschinen?

Aluminum is widely used in alternator housings and components due to its lightweight and excellent corrosion resistance. It typically has a temperature rating of up to 150°C, making it suitable for automotive applications where heat is a concern.

Vorteile: Aluminum is durable and lightweight, which enhances fuel efficiency in vehicles. It also exhibits good thermal conductivity, aiding in heat dissipation.

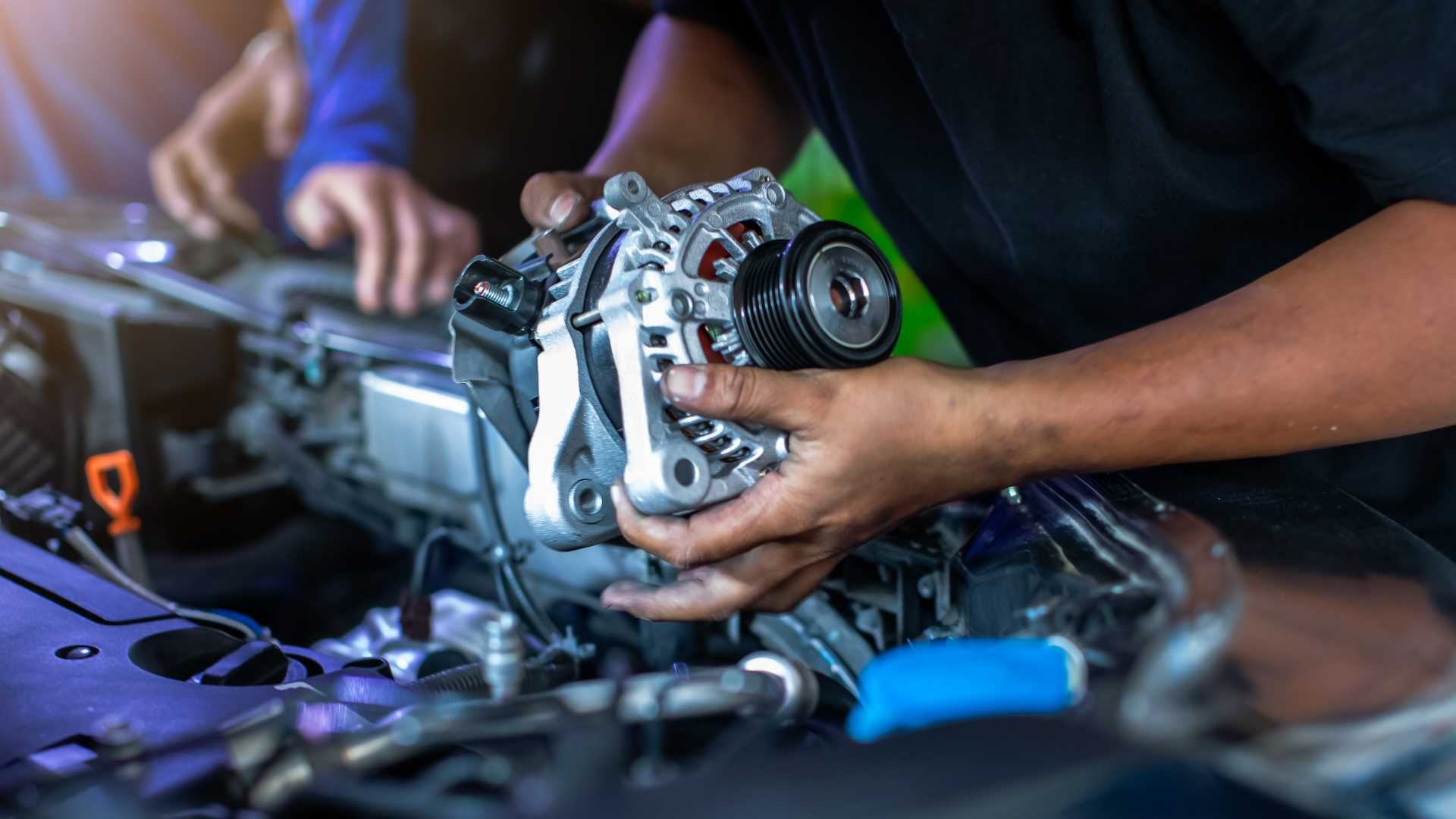

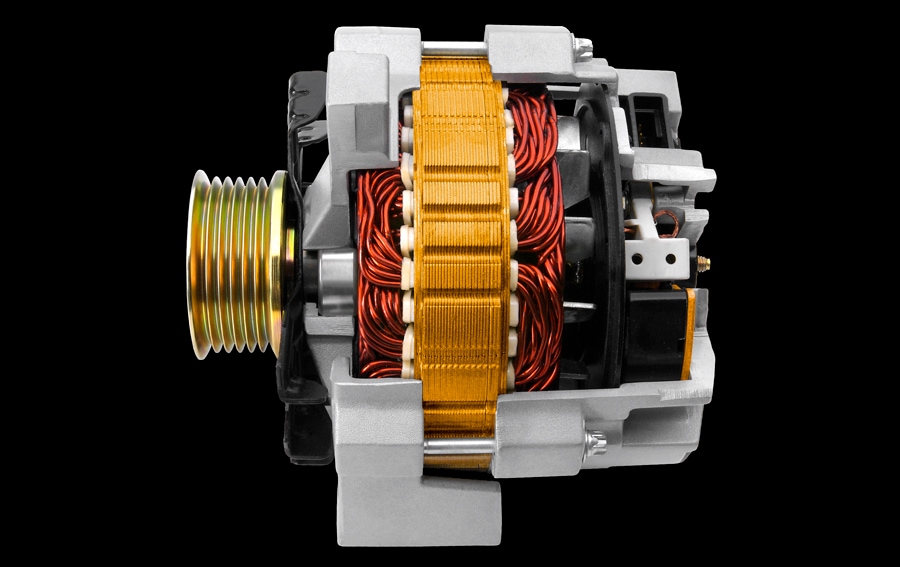

Illustrative image related to how much to replace alternator

Nachteile: While it is relatively inexpensive, aluminum can be prone to deformation under extreme stress. Additionally, it may not withstand high-pressure environments as effectively as other metals.

Auswirkungen auf die Anwendung: Aluminum’s compatibility with various media makes it a versatile choice for alternators, but its performance can be compromised in extremely high-temperature scenarios.

Überlegungen für internationale Käufer: Buyers from regions like Africa and South America should ensure compliance with local automotive standards, as aluminum components may require specific certifications to meet durability expectations.

How Does Copper Contribute to Alternator Efficiency?

Copper is primarily used in the windings of alternators due to its superior electrical conductivity. It can handle high temperatures (up to 200°C) and is resistant to corrosion, making it ideal for electrical applications.

Illustrative image related to how much to replace alternator

Vorteile: The high conductivity of copper enhances the efficiency of the alternator, leading to better performance and reliability. Its durability also ensures a longer lifespan for the component.

Nachteile: Copper is more expensive than aluminum, which can increase the overall cost of alternator replacements. Additionally, it is heavier, which may affect vehicle weight and fuel efficiency.

Auswirkungen auf die Anwendung: Copper’s excellent conductivity is crucial for the effective functioning of alternators, especially in high-demand electrical systems.

Überlegungen für internationale Käufer: In Europe and the Middle East, compliance with electrical safety standards is paramount. Buyers should verify that copper components meet relevant certifications, such as DIN or JIS standards.

Welche Rolle spielt Stahl beim Bau von Lichtmaschinen?

Steel is often used for structural components of alternators, including the casing and mounting brackets. It has a high tensile strength and can withstand significant mechanical stress.

Vorteile: Steel is incredibly durable and provides excellent protection against physical damage. Its cost-effectiveness makes it a popular choice for manufacturers.

Nachteile: Steel is heavier than aluminum and can be prone to rust if not properly coated. Additionally, it has lower corrosion resistance compared to aluminum and copper.

Auswirkungen auf die Anwendung: Steel’s strength is beneficial for protecting internal components, but its weight can impact overall vehicle efficiency.

Überlegungen für internationale Käufer: Buyers should be aware of the corrosion resistance requirements in humid climates, particularly in regions like Nigeria and parts of South America, where moisture can lead to premature failure.

How Do Composite Materials Enhance Alternator Performance?

Composite materials, including reinforced plastics, are increasingly used in alternator components to reduce weight and improve thermal resistance. They can withstand temperatures up to 120°C and offer good electrical insulation.

Illustrative image related to how much to replace alternator

Vorteile: Composites are lightweight and can be molded into complex shapes, providing design flexibility. They are also resistant to corrosion and can reduce overall manufacturing costs.

Nachteile: While composites are durable, they may not withstand mechanical stress as well as metals, leading to potential failures under heavy loads.

Auswirkungen auf die Anwendung: Composites are ideal for non-structural components, but their limitations in high-stress situations should be considered.

Überlegungen für internationale Käufer: Buyers in Europe may prefer composites that meet specific environmental regulations, such as RoHS compliance, while those in the Middle East might focus on heat resistance.

Summary Table of Material Selection for Alternator Replacement

| Material | Typical Use Case for how much to replace alternator | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Bauteile | Leicht und korrosionsbeständig | Anfällig für Verformungen unter Belastung | Mittel |

| Kupfer | Elektrische Wicklungen | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und zusätzliches Gewicht | Hoch |

| Stahl | Strukturelle Komponenten und Verkleidungen | High durability and cost-effective | Schwerer und anfällig für Rost | Niedrig |

| Verbundwerkstoffe | Nicht-strukturelle Komponenten | Geringes Gewicht und Designflexibilität | Limited mechanical stress resistance | Mittel |

This strategic material selection guide serves as a valuable resource for international B2B buyers, enabling informed decisions when replacing alternators in various automotive applications.

In-depth Look: Manufacturing Processes and Quality Assurance for how much to replace alternator

Was sind die wichtigsten Phasen im Herstellungsprozess von Lichtmaschinen?

The manufacturing of alternators involves several meticulous stages, ensuring that the final product meets the high standards required for automotive applications. Here are the primary phases of the manufacturing process:

-

Materialvorbereitung: The initial stage involves sourcing high-quality raw materials such as metals (aluminum, copper) and plastics. Suppliers must ensure that materials meet specific standards to guarantee durability and conductivity. This often includes chemical composition analysis and mechanical testing to confirm material properties.

-

Formung: In this phase, the raw materials are shaped into components using techniques such as casting, stamping, or machining. For example, the rotor and stator are typically produced through precision machining to ensure they fit together perfectly. Advanced methods like computer numerical control (CNC) machining may be employed for high precision.

-

Montage: Once the individual components are ready, they undergo assembly. This stage involves fitting the rotor, stator, diodes, and other electrical components into the alternator housing. Automated assembly lines are often used to enhance efficiency, but manual assembly is also crucial for quality control, especially for complex components.

-

Endbearbeitung: The final stage includes surface treatments such as coating or painting to enhance corrosion resistance and aesthetics. This step may also involve applying insulation to electrical components to prevent short circuits. Quality checks are performed throughout this stage to ensure that the alternator meets all functional and safety standards.

Wie wird die Qualitätssicherung in die Herstellung von Lichtmaschinen integriert?

Quality assurance (QA) is critical in alternator manufacturing, as it directly impacts performance and reliability. Here’s how QA is typically structured:

-

Einhaltung internationaler Normen: Manufacturers often adhere to international standards like ISO 9001, which outlines the requirements for a quality management system. Compliance ensures that processes are consistently monitored and improved. Additionally, industry-specific standards such as CE marking for the European market or API standards for performance may be applicable, depending on the market.

-

Qualitätskontrollpunkte: Various checkpoints are established throughout the manufacturing process:

– Eingangsqualitätskontrolle (IQC): This involves testing raw materials upon arrival to verify they meet specified criteria.

– In-Process-Qualitätskontrolle (IPQC): Ongoing assessments are performed during production to catch defects early, including dimensional checks and functional tests.

– Endkontrolle (FQC): Before shipping, completed alternators undergo comprehensive testing, including load testing, electrical performance tests, and visual inspections for defects. -

Testing Methods: Common testing methods for alternators include:

– Elektrische Prüfung: To verify output voltage and current under various load conditions.

– Haltbarkeitsprüfung: Simulating real-world conditions to ensure the alternator can withstand vibration, temperature changes, and humidity.

– Safety Testing: Checking for electrical insulation and potential short circuits.

What Strategies Can B2B Buyers Use to Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers uphold rigorous quality standards. Here are some effective strategies:

-

Durchführung von Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s adherence to quality standards and operational efficiency. An audit checklist can include aspects like process documentation, equipment calibration, and employee training.

-

Anforderung von Qualitätsberichten: Buyers should ask suppliers for detailed quality reports that document testing results, compliance with standards, and corrective actions taken for any identified issues. This transparency can help assess the reliability of the supplier.

-

Inspektionen durch Dritte: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly important for international transactions, where buyers may not be able to visit the facility.

Was sind die Feinheiten der Qualitätskontrolle für internationale Käufer?

When dealing with international suppliers, especially in regions like Africa, South America, the Middle East, and Europe, several nuances should be considered:

-

Verständnis der regionalen Standards: Different regions may have varying quality standards and regulations. For instance, European standards may be more stringent compared to those in some developing countries. Buyers should familiarize themselves with these standards to ensure compliance.

-

Logistische Herausforderungen: Shipping alternators across borders can introduce risks such as damage during transit or delays in customs. Buyers should work with suppliers who have robust packaging and logistics strategies to mitigate these risks.

-

Kulturelle und kommunikative Hürden: Effective communication is crucial for successful partnerships. Buyers should establish clear lines of communication and ensure that there is mutual understanding regarding quality expectations and delivery timelines.

-

Langfristige Partnerschaften: Building long-term relationships with suppliers can foster better quality control. Suppliers are more likely to invest in quality improvements when they understand the importance of maintaining a reliable partnership.

Schlussfolgerung

Understanding the manufacturing processes and quality assurance mechanisms for alternators is essential for B2B buyers looking to make informed purchasing decisions. By focusing on the manufacturing stages, quality checkpoints, and verification strategies, buyers can ensure they partner with reputable suppliers who deliver reliable products. In the competitive global market, prioritizing quality assurance will help mitigate risks and enhance overall operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how much to replace alternator’

Einführung

This practical sourcing guide aims to equip B2B buyers with a comprehensive checklist for understanding the costs associated with replacing an alternator. Alternators are vital components in automotive systems, and their replacement can significantly affect vehicle performance and operational costs. By following this guide, buyers can make informed decisions when sourcing alternators and related services.

Schritt 1: Bewerten Sie die Anforderungen Ihres Fahrzeugs

Before initiating any procurement process, it is crucial to understand the specific requirements of your vehicle. This includes identifying the make, model, and year, as well as the type of alternator needed (new, remanufactured, or aftermarket). Knowing these details ensures compatibility and helps avoid costly mistakes.

- Tipp: Consult your vehicle’s manual or a trusted automotive specialist to determine the exact specifications for your alternator.

Schritt 2: Forschung Marktpreise

Understanding the market rates for alternators is essential for budget planning. The cost to replace an alternator typically ranges from $600 to $1,500, depending on various factors such as labor costs and parts availability.

- Tipp: Gather quotes from multiple suppliers or repair shops to establish a baseline price and identify any outliers that may indicate inflated costs.

Schritt 3: Lieferantenoptionen bewerten

Selecting the right supplier can make a significant difference in both cost and quality. Look for suppliers with a proven track record in the automotive parts industry. This may involve checking their certifications, reputation, and customer reviews.

- Tipp: Request references from businesses in similar regions or sectors to gauge the supplier’s reliability and service quality.

Schritt 4: Erkundigen Sie sich nach Garantie und Rückgabebedingungen

A robust warranty can provide peace of mind when sourcing alternators. Ensure that the supplier offers a warranty that covers defects and failures for a reasonable period. Additionally, understand their return policy in case the alternator does not meet your expectations or compatibility requirements.

- Tipp: Compare warranty offerings among suppliers to identify those that provide the best protection and service.

Schritt 5: Consider Installation Services

Evaluate whether the supplier offers installation services or if you will need to engage a separate mechanic. Some suppliers may include installation in their pricing, while others may charge it separately.

- Tipp: If choosing an external mechanic, ensure they are experienced in alternator replacements to avoid additional issues down the line.

Schritt 6: Review Delivery and Lead Times

Timely delivery is critical in minimizing vehicle downtime. Verify the supplier’s lead times for both parts availability and shipping. This is especially important if you are working on a tight schedule or have multiple vehicles needing service.

- Tipp: Ask about expedited shipping options if immediate replacement is required, and consider potential delays due to supply chain issues.

Schritt 7: Analyze Total Cost of Ownership

Finally, consider the total cost of ownership, which includes not only the purchase price but also installation, potential repairs, and maintenance. This holistic view will help you make a more informed decision that aligns with your budget and operational needs.

- Tipp: Factor in the long-term reliability and warranty terms when assessing the overall value of your chosen alternator solution.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing alternators, ensuring they make well-informed choices that enhance their operational efficiency.

Comprehensive Cost and Pricing Analysis for how much to replace alternator Sourcing

What Are the Key Cost Components for Replacing an Alternator?

When sourcing for alternator replacements, understanding the cost structure is crucial. The total cost typically encompasses several components:

-

Materialien: The primary cost driver is the alternator itself, which can range from $200 to $800 depending on the make and model of the vehicle. Additional materials, such as the accessory belt and electrical connectors, may also be included, contributing to the overall cost.

-

Arbeit: Labor costs can vary significantly by region and the complexity of the job. In general, labor rates range from $50 to $150 per hour, with the total time to replace an alternator usually taking between 1 to 3 hours.

-

Fertigungsgemeinkosten: This includes costs related to production facilities, equipment maintenance, and utilities. For large manufacturers, overhead costs are spread across numerous units, potentially lowering the per-unit cost.

-

Werkzeuge: Specialized tools may be required for alternator replacement, which can add to the initial cost. However, many repair shops already possess these tools, thus minimizing the impact on pricing for B2B buyers.

-

Qualitätskontrolle (QC): Ensuring the alternator meets specific standards can involve additional testing and inspection costs. This is particularly important for businesses that prioritize reliability and safety in their fleet operations.

-

Logistik: Shipping and handling costs can add up, especially for international transactions. Variability in shipping methods and distances can significantly affect total costs.

-

Marge: Suppliers typically add a profit margin to cover their operational costs and ensure profitability. Understanding the typical margins in the automotive parts industry can help buyers negotiate better prices.

How Do Price Influencers Affect Alternator Replacement Costs?

Several factors can influence the pricing of alternator replacements, especially for international B2B buyers:

-

Menge/Mindestbestellmenge: Ordering in bulk can lead to significant discounts. Suppliers often provide better pricing for larger orders, so it’s beneficial for businesses to consider their future needs when placing orders.

-

Spezifikationen und Anpassung: Custom alternators or those with specific certifications may command higher prices. Buyers should be clear about their specifications to avoid unnecessary costs.

-

Materialien und Qualitätszertifizierungen: Higher-quality materials and certifications (like ISO or OEM standards) can increase costs but may also result in better performance and longevity, affecting the total cost of ownership.

-

Lieferantenfaktoren: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their brand trustworthiness, while new entrants might offer lower prices to capture market share.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is essential for international transactions. Different terms can shift the responsibility for shipping and insurance costs, affecting the total price.

What Buyer Tips Should International B2B Buyers Consider?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

Illustrative image related to how much to replace alternator

-

Verhandlung: Always engage in negotiations. Many suppliers expect some back-and-forth on pricing, especially for bulk orders.

-

Gesamtbetriebskosten (TCO): Evaluate not just the upfront cost but the long-term expenses associated with the alternator, including maintenance and potential failure rates.

-

Nuancen in der Preisgestaltung: Be aware of local market conditions. Prices can fluctuate based on regional demand, currency exchange rates, and import tariffs, particularly in emerging markets.

-

Beziehungen zu den Lieferanten: Building strong relationships with suppliers can lead to better pricing and terms. Loyal customers often receive preferential treatment, including discounts and priority service.

-

Research Local Alternatives: Sometimes local manufacturers can provide competitive pricing and lower shipping costs. Exploring regional suppliers can yield significant savings.

In conclusion, understanding the comprehensive cost structure, price influencers, and buyer strategies is essential for international B2B buyers looking to replace alternators. With the right approach, businesses can optimize their purchasing decisions and ensure reliable vehicle performance.

Alternatives Analysis: Comparing how much to replace alternator With Other Solutions

Exploring Alternatives to Alternator Replacement: A Comprehensive Comparison

In the automotive industry, the reliability of electrical systems is paramount. The alternator plays a crucial role in maintaining the battery charge and powering various electrical components. However, when faced with a failing alternator, businesses may consider alternative solutions that can provide similar benefits. This section evaluates the cost and effectiveness of replacing an alternator against two viable alternatives: upgrading to a DC-to-DC converter and utilizing battery management systems (BMS) in electric vehicles (EVs).

| Vergleichsaspekt | How Much To Replace Alternator | DC-to-DC Converter | Batterie-Management-System (BMS) |

|---|---|---|---|

| Leistung | Essential for vehicle operation | Converts battery voltage efficiently; ideal for EVs | Manages battery health, optimizing performance |

| Kosten | $600 – $1,500 | $300 – $800 | $400 – $1,000 |

| Einfache Implementierung | Erfordert professionelle Installation | Moderate; may require technical expertise | Complex; needs specialized knowledge |

| Wartung | Low; typically replaced when failing | Low; minimal maintenance needed | Moderate; regular monitoring required |

| Bester Anwendungsfall | Traditional vehicles needing reliable power | EVs and hybrids requiring efficient power management | Fleets of EVs needing optimized battery usage |

Eingehende Analyse von Alternativen

DC-to-DC Converter

A DC-to-DC converter serves as an alternative to traditional alternators, particularly in electric and hybrid vehicles. It efficiently converts varying voltages from the battery to a stable output for the vehicle’s electrical systems. The primary advantages of using a DC-to-DC converter include its lower cost compared to alternator replacement and its streamlined design, which reduces the risk of failure. However, its implementation can be moderately complex, requiring technical expertise to ensure proper integration with existing vehicle systems. This solution is best suited for businesses operating fleets of electric or hybrid vehicles, where efficiency and reliability are critical.

Batterie-Management-System (BMS)

A Battery Management System (BMS) is essential in modern electric vehicles, overseeing the health and performance of the battery pack. It ensures optimal charge levels, enhances battery lifespan, and provides critical data on battery performance. While the initial investment for a BMS can be higher than replacing an alternator, the long-term benefits include improved battery efficiency and reduced operational costs. However, the complexity of installing and maintaining a BMS requires specialized knowledge, making it less feasible for smaller businesses or those without technical resources. A BMS is ideal for organizations managing large fleets of electric vehicles, where effective battery management can significantly impact operational efficiency.

Conclusion: Selecting the Best Solution for Your Needs

When deciding between replacing an alternator and exploring alternatives like a DC-to-DC converter or a BMS, B2B buyers must consider their specific operational needs, vehicle types, and long-term goals. For traditional vehicles, replacing the alternator remains the most straightforward solution. In contrast, businesses investing in electric vehicles might find that upgrading to a DC-to-DC converter or implementing a comprehensive BMS offers greater efficiency and reduced long-term costs. Ultimately, the right choice will depend on a careful assessment of cost, performance requirements, and maintenance capabilities tailored to the unique demands of the business.

Illustrative image related to how much to replace alternator

Essential Technical Properties and Trade Terminology for how much to replace alternator

What Are the Key Technical Properties Relevant to Alternator Replacement Costs?

When considering the replacement of an alternator, understanding its technical specifications is crucial for making informed purchasing decisions. Below are critical specifications that buyers should be aware of:

1. Materialzusammensetzung

Alternators are primarily constructed from metals such as aluminum and copper. Aluminum is often used for the housing due to its lightweight and corrosion-resistant properties, while copper is essential for electrical components due to its excellent conductivity. Knowing the material composition is vital for assessing durability, weight, and performance, especially in harsh environments found in regions like Africa and South America.

2. Power Output (Amperage Rating)

The amperage rating indicates the maximum electrical current an alternator can produce. Common ratings range from 60 to 150 amps. Selecting an alternator with the correct power output is crucial to ensure it meets the electrical demands of the vehicle’s systems, especially as more modern vehicles incorporate advanced electronics. This factor can directly affect the reliability of the vehicle and the longevity of its electrical components.

3. Spannungsregelung

Most alternators operate at a standard voltage of 12 volts, but the regulation mechanism varies. High-quality alternators feature integrated voltage regulators that maintain consistent voltage levels, preventing damage to sensitive electronic components. Understanding the voltage regulation type can help buyers assess the reliability and compatibility of the alternator with their vehicles.

4. Lagertyp

The type of bearings used in an alternator can affect its performance and lifespan. Common types include ball bearings and roller bearings. Ball bearings are typically found in lower-cost alternators, while roller bearings may offer better performance and durability. This distinction can influence maintenance costs and the overall reliability of the alternator, which is vital for B2B buyers looking for long-term solutions.

5. Garantiezeitraum

The warranty period for an alternator can vary significantly based on the manufacturer and whether the part is OEM (Original Equipment Manufacturer) or aftermarket. A longer warranty often indicates a manufacturer’s confidence in the product’s reliability. Buyers should carefully review warranty terms, as they can impact total cost of ownership and potential future expenses.

What Are Common Trade Terms Associated with Alternator Replacement?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms relevant to alternator replacement:

1. OEM (Originalgerätehersteller)

OEM parts are made by the original manufacturer of the vehicle. They typically offer the highest compatibility and reliability. Understanding the difference between OEM and aftermarket parts can guide buyers in making cost-effective decisions without sacrificing quality.

2. MOQ (Mindestbestellmenge)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant for B2B buyers looking to purchase alternators in bulk. Awareness of MOQ can help businesses manage inventory costs and supplier relationships effectively.

3. RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products, such as alternators. Utilizing RFQs can streamline the procurement process and ensure competitive pricing, which is crucial for maintaining budget constraints.

4. Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international trade. Terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs, insurance, and liability during transit. Understanding these terms is essential for B2B buyers engaged in cross-border purchases.

5. Ersatzteilmarkt

Aftermarket parts are made by manufacturers other than the original vehicle manufacturer. While often less expensive than OEM parts, quality can vary significantly. B2B buyers should weigh the cost savings against potential risks associated with aftermarket parts.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding alternator replacements, ensuring optimal performance and cost-effectiveness in their automotive operations.

Illustrative image related to how much to replace alternator

Navigating Market Dynamics and Sourcing Trends in the how much to replace alternator Sector

What Are the Current Market Dynamics and Trends Affecting Alternator Replacement Costs?

The global market for automotive parts, including alternators, is influenced by several key drivers. As vehicle electrification accelerates, particularly in regions like Europe and parts of the Middle East, there is an increasing demand for high-quality alternators designed to support advanced electrical systems in hybrid and electric vehicles. This trend is further driven by rising consumer awareness regarding vehicle efficiency and the longevity of automotive components. In contrast, markets in Africa and South America are witnessing a different dynamic, where the focus remains on affordability and accessibility of replacement parts.

Emerging B2B technologies, such as digital marketplaces and AI-driven inventory management systems, are transforming sourcing practices. International buyers can now access a wider array of alternator options from suppliers around the globe, facilitating competitive pricing and enhanced product availability. Furthermore, the rise of remanufactured and aftermarket parts provides opportunities for cost savings, particularly for businesses operating in markets where OEM parts may be prohibitively expensive. With labor costs and the price of raw materials fluctuating due to geopolitical factors and supply chain disruptions, buyers must stay agile and informed about market conditions to navigate these complexities effectively.

How Is Sustainability Influencing Sourcing Practices for Alternators?

Sustainability is becoming a critical focus for B2B buyers in the automotive sector, including those sourcing alternators. The environmental impact of automotive parts manufacturing is significant, contributing to carbon emissions and waste generation. As a result, many buyers are now prioritizing suppliers that adhere to sustainable practices. This includes sourcing materials that are recyclable or made from recycled components, as well as engaging in ethical supply chain management.

Buyers are increasingly seeking out ‘green’ certifications, such as ISO 14001, which indicate a commitment to environmental management. This trend is particularly relevant in Europe, where regulatory frameworks are tightening around emissions and sustainability standards. Additionally, suppliers that offer remanufactured alternators not only reduce waste but also provide a cost-effective alternative for businesses looking to lower their environmental footprint while maintaining quality. As sustainability continues to shape purchasing decisions, companies that integrate ethical sourcing into their supply chain will likely gain a competitive advantage in the marketplace.

What Historical Context Should B2B Buyers Consider Regarding Alternator Replacement?

Understanding the evolution of alternators is essential for B2B buyers looking to make informed decisions about replacement costs. Traditionally, alternators were simple devices that primarily provided electrical power to vehicles. However, advancements in automotive technology have transformed them into complex components critical for vehicle performance, particularly with the advent of electric and hybrid vehicles.

As manufacturers continue to innovate, the materials and technologies used in alternators have evolved, leading to variations in quality and pricing. Buyers should be aware that older vehicles may require different sourcing strategies, as the availability of parts can differ significantly from newer models. Additionally, the rise of remanufactured and aftermarket options has reshaped the landscape, offering businesses more choices but also necessitating careful evaluation of quality and supplier reliability. By understanding these historical trends, B2B buyers can better navigate the current market dynamics and make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of how much to replace alternator

-

How do I determine the cost of replacing an alternator for my fleet vehicles?

The cost of replacing an alternator typically ranges from $600 to $1,500, depending on the vehicle make and model, labor rates, and geographical location. For fleet management, it is essential to factor in the total cost of ownership, which includes potential downtime and labor costs associated with the replacement. Establishing relationships with local mechanics or service centers can lead to bulk pricing or discounts, further optimizing expenses. -

What factors influence the price of alternator replacement in different regions?

Regional variations in labor costs, shipping fees, and the availability of parts significantly influence alternator replacement prices. For instance, in Africa or South America, logistical challenges may lead to higher shipping costs for imported parts. Additionally, currency fluctuations can impact the overall cost for international buyers. Understanding local market conditions and establishing relationships with regional suppliers can help mitigate these costs. -

What should I consider when selecting a supplier for alternators?

When choosing a supplier, consider their reputation, product quality, warranty offerings, and ability to meet your specific needs. Evaluate their experience in the automotive parts industry and customer service responsiveness. Additionally, review their logistics capabilities, including shipping times and costs, to ensure timely delivery of parts to your operations. -

How can I assess the quality of alternators from different suppliers?

To assess the quality of alternators, request product samples and compare them against established benchmarks. Look for certifications or compliance with industry standards, such as ISO or TS16949. Additionally, review customer testimonials and case studies to gauge reliability and performance. It’s also beneficial to inquire about warranties, as reputable suppliers will offer guarantees on their products. -

What are the minimum order quantities (MOQs) for purchasing alternators?

MOQs can vary significantly between suppliers. Some manufacturers may require a minimum order of 50 units, while others might accommodate smaller orders for international buyers. When negotiating terms, clarify your needs and explore the possibility of flexible MOQs, especially if you are a new buyer or testing a new product line. -

Mit welchen Zahlungsbedingungen muss ich bei der internationalen Beschaffung von Generatoren rechnen?

Payment terms can vary widely based on the supplier’s policies and your negotiation leverage. Common terms include payment upfront, a deposit with the balance upon delivery, or net 30/60 days after receipt. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect both parties involved. -

How can I ensure timely delivery of alternators for my business?

To ensure timely delivery, establish clear communication with your supplier regarding lead times and shipping methods. Utilize suppliers with a robust logistics network and track record of on-time deliveries. It’s also advisable to plan your inventory needs in advance, allowing for buffer stock to mitigate any unexpected delays in the supply chain. -

Welche Qualitätssicherungsmaßnahmen sollte ich bei der Beschaffung von Generatoren durchführen?

Implement a quality assurance (QA) process that includes inspections upon receipt, routine audits of supplier facilities, and regular performance evaluations of alternators. Establish clear specifications and standards for the products you order. Additionally, consider engaging third-party inspection services to verify product quality before shipment, ensuring that the alternators meet your operational requirements.

Top 2 How Much To Replace Alternator Manufacturers & Suppliers List

1. CarTalk – Alternator Replacement Cost

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: The cost to replace an alternator ranges from $600 to $1,500. An alternator is a critical component that maintains the charge of the battery and powers various electrical systems in the vehicle. It is driven by an accessory belt connected to the engine’s crankshaft. Signs of a failing alternator include a check engine light, dimming headlights, and the need for jump-starts. Alternators can fail du…

2. JD Power - Kosten für den Austausch der Lichtmaschine

Domäne: jdpower.com

Registriert: 1995 (30 Jahre)

Einleitung: Alternator replacement costs range from $350 to $900, with average parts costing $100 to $350, and luxury models costing $500 to $700. Labor costs can add $350 to $500, and additional $20 to $50 if the serpentine belt needs replacement. Rebuilt alternators are available and should have at least the same amp rating as the original. DIY installation can save on labor costs, but requires some skill a…

Strategic Sourcing Conclusion and Outlook for how much to replace alternator

In conclusion, understanding the costs associated with alternator replacement is essential for international B2B buyers looking to maintain or enhance their vehicle fleets. The price range of $600 to $1,500, influenced by factors such as part availability and labor rates, underscores the importance of strategic sourcing. Buyers should prioritize selecting reliable suppliers who offer quality parts, whether new, remanufactured, or aftermarket, to ensure optimal performance and longevity of their vehicles.

Additionally, as the automotive landscape evolves with the rise of electric vehicles (EVs) and hybrids, it’s crucial for businesses to stay informed about alternative power solutions that may reduce reliance on traditional alternators. This shift not only presents opportunities for cost savings but also aligns with sustainability goals.

For international buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging local networks and partnerships can facilitate better procurement strategies. By fostering relationships with trustworthy suppliers and staying abreast of market trends, businesses can enhance their operational efficiency and reduce unexpected maintenance costs. Embrace this opportunity to strategically source your automotive needs and position your fleet for future success.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

Illustrative image related to how much to replace alternator

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.