Einführung: Navigieren auf dem globalen Markt für den Einbau eines Starters im Auto

Die Automobilindustrie steht vor großen Herausforderungen, wenn es darum geht, die Komplexität der Kosten für den Einbau eines Anlassers in ein Auto zu verstehen. Für B2B-Einkäufer in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa kann es entmutigend sein, die Feinheiten der Beschaffung von Anlassern - einschließlich Kosten, Typen und Zuverlässigkeit der Lieferanten - zu verstehen. Dieser umfassende Leitfaden soll den Prozess des Anlassereinbaus entmystifizieren und bietet Einblicke in die verschiedenen verfügbaren Anlassertypen, ihre Anwendungen bei unterschiedlichen Fahrzeugmarken und -modellen sowie die Faktoren, die die Einbaukosten beeinflussen.

Auf diesen Seiten finden internationale Einkäufer praktische Informationen zur Prüfung von Lieferanten, zum Verständnis von Preisstrukturen und zum Erkennen der Anzeichen, dass ein Anlasser ausgetauscht werden muss. Durch die Behandlung dieser kritischen Aspekte versetzt dieser Leitfaden B2B-Akteure in die Lage, fundierte Kaufentscheidungen zu treffen, die mit ihren betrieblichen Anforderungen und Budgetvorgaben in Einklang stehen. Ganz gleich, ob Sie in Nigeria lokale Lieferanten bewerten oder in Saudi-Arabien die Installationskosten für eine Fahrzeugflotte einschätzen, diese Ressource dient als strategisches Werkzeug zur Verbesserung Ihres Beschaffungsprozesses und zur Sicherstellung einer optimalen Leistung für Ihre Fahrzeuganlagen. In einem sich ständig weiterentwickelnden Markt ist es wichtig, das richtige Wissen zur Hand zu haben, um sich einen Wettbewerbsvorteil zu sichern.

Inhaltsverzeichnis

- Top 6 Wie viel kostet es, einen Anlasser im Auto zu installieren Hersteller & Lieferanten Liste

- Einführung: Navigieren auf dem globalen Markt für den Einbau eines Starters im Auto

- Wie viel kostet der Einbau eines Anlassers in ein Auto Typen und Variationen

- Industrielle Schlüsselanwendungen für den Einbau eines Anlassers im Auto

- 3 häufige Benutzer Schmerzpunkte für ‘wie viel, um einen Anlasser im Auto zu installieren’ & ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für den Einbau eines Anlassers im Auto

- Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Wie viel kostet der Einbau eines Starters im Auto?

- Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet der Einbau eines Starters im Auto’.’

- Umfassende Kosten- und Preisanalyse für den Einbau eines Starters im Auto Sourcing

- Analyse der Alternativen: Vergleich der Kosten für den Einbau eines Starters im Auto mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für den Einbau eines Anlassers im Auto

- Navigation der Marktdynamik und der Beschaffungstrends in der Branche "Wie viel kostet der Einbau eines Starters im Auto?

- Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Einbau eines Starters im Auto

- Strategische Beschaffung Schlussfolgerung und Ausblick für den Einbau eines Anlassers im Auto

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Wie viel kostet der Einbau eines Anlassers in ein Auto Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard-Ersatz | Einfacher Austausch des Anlassers unter Verwendung von Originalteilen. | Allgemeine Kfz-Werkstätten. | Vorteile: Kostengünstig; leicht zu beschaffen. Nachteile: Möglicherweise fehlen erweiterte Funktionen. |

| Hochleistungsstarter | Verbesserte Komponenten für mehr Haltbarkeit. | Leistungsstarke Autohäuser; Rennteams. | Vorteile: Verbesserte Zuverlässigkeit und Leistung. Nachteile: Höhere Anschaffungskosten. |

| Rebuild/Wiederaufbereitung | Überholte Anlasser mit ausgetauschten Komponenten. | Budgetbewusste Reparaturmöglichkeiten. | Vorteile: Kostengünstig und umweltfreundlich. Nachteile: Unterschiedliche Qualitätssicherung. |

| Aftermarket-Optionen | Nicht-OEM-Teile mit unterschiedlicher Qualität und Preisgestaltung. | Unabhängige Werkstätten. | Vorteile: Oft billiger; vielfältige Möglichkeiten. Nachteile: Risiko von Kompatibilitätsproblemen. |

| Integrierte Startsysteme | Anlasser kombiniert mit fortschrittlicher Elektronik. | Händler von Luxusfahrzeugen; OEMs. | Vorteile: Verbesserte Funktionalität; zugeschnitten auf moderne Fahrzeuge. Nachteile: Hohe Wiederbeschaffungskosten. |

Was sind die Merkmale von Standard-Ersatzstartern?

Standard-Ersatzstarter sind so konzipiert, dass sie Originalteile des Herstellers (OEM) mit ähnlichen Spezifikationen ersetzen. Sie werden in der Regel in allgemeinen Kfz-Werkstätten verwendet und sind ideal für alltägliche Fahrzeuge, die keine speziellen Komponenten erfordern. B2B-Käufer sollten auf die Verfügbarkeit dieser Anlasser achten, da sie in großem Umfang auf Lager sind und leicht beschafft werden können. Ihre Erschwinglichkeit macht sie zu einer beliebten Wahl, aber Käufer sollten sich darüber im Klaren sein, dass sie möglicherweise keine fortschrittlichen Funktionen oder Verbesserungen bieten.

Wie unterscheiden sich Hochleistungsstarter von Standardoptionen?

Hochleistungsanlasser sind mit verbesserten Komponenten ausgestattet, die eine höhere Haltbarkeit und Effizienz bieten. Sie werden häufig in Hochleistungswerkstätten und von Rennteams eingesetzt, wo Zuverlässigkeit unter extremen Bedingungen von größter Bedeutung ist. B2B-Käufer, die an diesen Produkten interessiert sind, sollten ihre spezifischen Leistungsanforderungen prüfen und sicherstellen, dass die Anlasser mit Hochleistungsanwendungen kompatibel sind. Sie haben zwar einen höheren Preis, aber die verbesserte Zuverlässigkeit und Leistung können die Investition für leistungsorientierte Unternehmen rechtfertigen.

Was sind die Vorteile von überholten/überholten Startern?

Bei überholten oder wiederaufbereiteten Startern handelt es sich um überholte Komponenten, die strengen Tests und dem Austausch von Verschleißteilen unterzogen wurden. Sie bieten eine kostengünstige Lösung für budgetbewusste Reparaturbetriebe und fördern gleichzeitig die ökologische Nachhaltigkeit durch die Wiederverwendung von Komponenten. B2B-Einkäufer sollten sicherstellen, dass sie diese Teile von seriösen Lieferanten beziehen, die eine Qualitätssicherung bieten. Obwohl sie im Allgemeinen zuverlässig sind, kann die Qualität variieren, weshalb es wichtig ist, den Ruf des Lieferanten zu überprüfen.

Warum sollten Sie sich für Aftermarket-Optionen für Anlasser entscheiden?

Bei Aftermarket-Anlassern handelt es sich um Nicht-OEM-Teile, die sich in Qualität und Preis erheblich unterscheiden können. Sie werden häufig von unabhängigen Werkstätten bevorzugt, die nach wettbewerbsfähigen Preisen und vielfältigen Optionen suchen. B2B-Käufer sollten gründliche Nachforschungen anstellen, um die Kompatibilität mit bestimmten Fahrzeugmodellen sicherzustellen und Probleme zu vermeiden. Die niedrigeren Kosten können verlockend sein, aber es ist wichtig, den Preis mit den potenziellen Risiken in Bezug auf Qualität und Zuverlässigkeit abzuwägen.

Was sind integrierte Starter-Systeme und ihre Anwendungen?

Integrierte Anlassersysteme kombinieren Anlasser mit fortschrittlichen elektronischen Komponenten, die vor allem für moderne Luxusfahrzeuge entwickelt wurden. Diese Systeme werden häufig von Händlern und Erstausrüstern von Luxusfahrzeugen verwendet und bieten eine verbesserte Funktionalität und Effizienz. B2B-Käufer sollten sich darüber im Klaren sein, dass diese Systeme zwar Spitzentechnologie bieten, aber auch mit höheren Ersatzkosten verbunden sind. Es ist wichtig, die langfristigen Vorteile einer verbesserten Leistung gegen die Vorabinvestition abzuwägen, wenn man diese Option in Betracht zieht.

Industrielle Schlüsselanwendungen für den Einbau eines Anlassers im Auto

| Branche/Sektor | Spezifische Anwendung der Kosten für den Einbau eines Anlassers im Auto | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Abschätzung der Kosten für die Installation und den Austausch von Startern | Verbessert das Serviceangebot und die Kundenzufriedenheit | Verfügbarkeit von Qualitätsteilen, qualifizierter Arbeit und wettbewerbsfähigen Preisen |

| Flottenmanagement | Budgetierung für den Austausch von Startern bei verschiedenen Fahrzeugtypen | Reduziert Ausfallzeiten und Wartungskosten | Großeinkaufsoptionen, Garantien und zuverlässige Lieferanten |

| Vertrieb von Automobilteilen | Bereitstellung genauer Kostenvoranschläge für Erstausstattungen für Einzelhändler | Steigert den Umsatz durch fundierte Kundenentscheidungen | Vielfältiger Bestand, Beschaffung von Qualitätsteilen und regionale Preisgestaltung |

| Fahrzeugbau | Einbeziehung der Kosten für die Erstinstallation in das Produktionsbudget | Rationalisierung von Fertigungsprozessen und Kostenmanagement | Zuverlässigkeit der Lieferanten, Qualitätssicherung und Einhaltung von Normen |

| Autovermietung | Bewertung der Kosten für den Austausch von Startern für Flottenfahrzeuge | Sicherstellung der betrieblichen Effizienz und des Kundenvertrauens | Kostengünstige Beschaffung, Teileverfügbarkeit und Servicevereinbarungen |

Wie profitieren Kfz-Werkstätten vom Verständnis der Kosten für den Anlassereinbau?

Kfz-Werkstätten können Einblicke in die Kosten für den Einbau von Anlassern nutzen, um ihr Serviceangebot zu verbessern. Indem sie transparente Preise für den Austausch von Anlassern anbieten, können sie das Vertrauen und die Zufriedenheit ihrer Kunden verbessern. Werkstätten müssen die Zugänglichkeit von Anlasserteilen, die Komplexität des Einbaus und lokale Markttrends berücksichtigen, um eine wettbewerbsfähige Preisgestaltung zu gewährleisten. Mit diesem Wissen können sie ihren Betrieb rationalisieren und die Rentabilität steigern.

Warum ist die Budgetierung von Starterwechseln für das Fuhrparkmanagement so wichtig?

Flottenmanagementunternehmen müssen die mit dem Austausch von Anlassern verbundenen Kosten abschätzen, um die Ausfallzeiten und Wartungskosten von Fahrzeugen zu minimieren. Wenn Flottenmanager die typischen Kosten kennen, können sie ihre Budgets effizient zuweisen und routinemäßige Wartungsarbeiten planen. Für diese Unternehmen ist es von entscheidender Bedeutung, Beziehungen zu zuverlässigen Ersatzteillieferanten aufzubauen, die hochwertige Anlasser zu wettbewerbsfähigen Preisen liefern können, um die betriebliche Effizienz zu gewährleisten.

Welche Rolle spielen die Autoteilehändler auf dem Markt für Anlasserersatzteile?

Kfz-Teilehändler sind entscheidend, wenn es darum geht, Händlern und Werkstätten genaue Kostenvoranschläge für den Einbau von Anlassern zu geben. Mit einem breit gefächerten Bestand an Anlassern und verwandten Komponenten können sie verschiedene Fahrzeugmarken und -modelle bedienen, was für B2B-Transaktionen unerlässlich ist. Händler sollten sich auf die Beschaffung qualitativ hochwertiger Teile und die Festlegung wettbewerbsfähiger Preisstrategien konzentrieren, um mehr Kunden anzuziehen und den Umsatz zu steigern.

Wie können Fahrzeughersteller die Kosten für den Einbau von Anlassern in die Produktion einbeziehen?

Für Fahrzeughersteller ist die Kenntnis der Kosten für den Einbau von Anlassern eine wesentliche Voraussetzung für eine effektive Produktionsplanung. Indem sie diese Kosten in ihren gesamten Herstellungsprozess einbeziehen, können sie die Abläufe rationalisieren und das Kostenmanagement verbessern. Die Hersteller müssen sicherstellen, dass sie mit zuverlässigen Lieferanten zusammenarbeiten, die qualitativ hochwertige Anlasser liefern können, die den Industriestandards entsprechen und so die Integrität ihrer Fahrzeuge erhalten.

Warum ist es für Autovermietungen wichtig, die Kosten für den Austausch des Anlassers zu ermitteln?

Autovermietungen profitieren von einer Bewertung der Kosten für den Austausch von Anlassern, um sicherzustellen, dass ihre Flotte einsatzbereit und für die Kunden vertrauenswürdig bleibt. Wenn sie die Kosten für den Austausch von Anlassern einplanen, können sie die Zuverlässigkeit ihrer Fahrzeuge aufrechterhalten und unerwartete Ausfälle minimieren. Kosteneffiziente Beschaffungsvereinbarungen mit Ersatzteillieferanten können Autovermietungen dabei helfen, ihre Ausgaben zu kontrollieren und gleichzeitig sicherzustellen, dass sie die notwendigen Teile für rechtzeitige Reparaturen vorrätig haben.

3 häufige Benutzer Schmerzpunkte für ‘wie viel, um einen Anlasser im Auto zu installieren’ & ihre Lösungen

Szenario 1: Die versteckten Kosten der Starter-Installation verstehen

Das Problem: B2B-Käufer, insbesondere in Regionen mit schwankenden wirtschaftlichen Bedingungen, sehen sich beim Einbau eines Anlassers in Fahrzeuge oft mit unerwarteten Kosten konfrontiert. Die Gesamtkosten können über den reinen Preis des Anlassers hinausgehen. Sie können auch Arbeitskosten, zusätzliche Teile oder sogar Diagnosegebühren umfassen, wenn das Anlasserproblem nicht auf den Anlasser selbst zurückzuführen ist. Für Unternehmen, die Fuhrparks verwalten, können sich diese versteckten Kosten erheblich auf ihr Betriebsbudget und ihre Rentabilität auswirken.

Die Lösung: Um unerwartete Kosten zu vermeiden, sollten B2B-Einkäufer einen umfassenden Ansatz zur Kostenabschätzung wählen. Beginnen Sie mit einer gründlichen Recherche über die spezifische Marke und das Modell der Fahrzeuge in Ihrem Fuhrpark, um die typischen Kosten für den Einbau eines Starters zu verstehen. Nutzen Sie Online-Ressourcen oder wenden Sie sich an vertrauenswürdige Lieferanten, um Preisinformationen für Teile und Arbeit zu erhalten. Ziehen Sie außerdem in Erwägung, in Diagnosewerkzeuge zu investieren, um Anlasserprobleme genau zu erkennen, bevor Sie mit der Reparatur fortfahren. Dieser proaktive Ansatz ermöglicht eine bessere Budgetplanung und minimiert das Risiko unvorhergesehener Ausgaben.

Szenario 2: Beschaffung zuverlässiger Starterteile für verschiedene Fahrzeugmodelle

Das Problem: Unternehmen, die verschiedene Flotten betreiben, haben oft Schwierigkeiten, zuverlässige Starterteile zu beschaffen, die mit verschiedenen Fahrzeugmodellen kompatibel sind. Diese Herausforderung wird in Regionen mit eingeschränktem Zugang zu hochwertigen Kfz-Teilen noch verschärft, was zu möglichen Verzögerungen bei Reparaturen und längeren Ausfallzeiten der Fahrzeuge führt. B2B-Einkäufer haben oft Schwierigkeiten, Anbieter zu finden, die Teile liefern können, die den OEM-Spezifikationen entsprechen und eine langfristige Leistung gewährleisten.

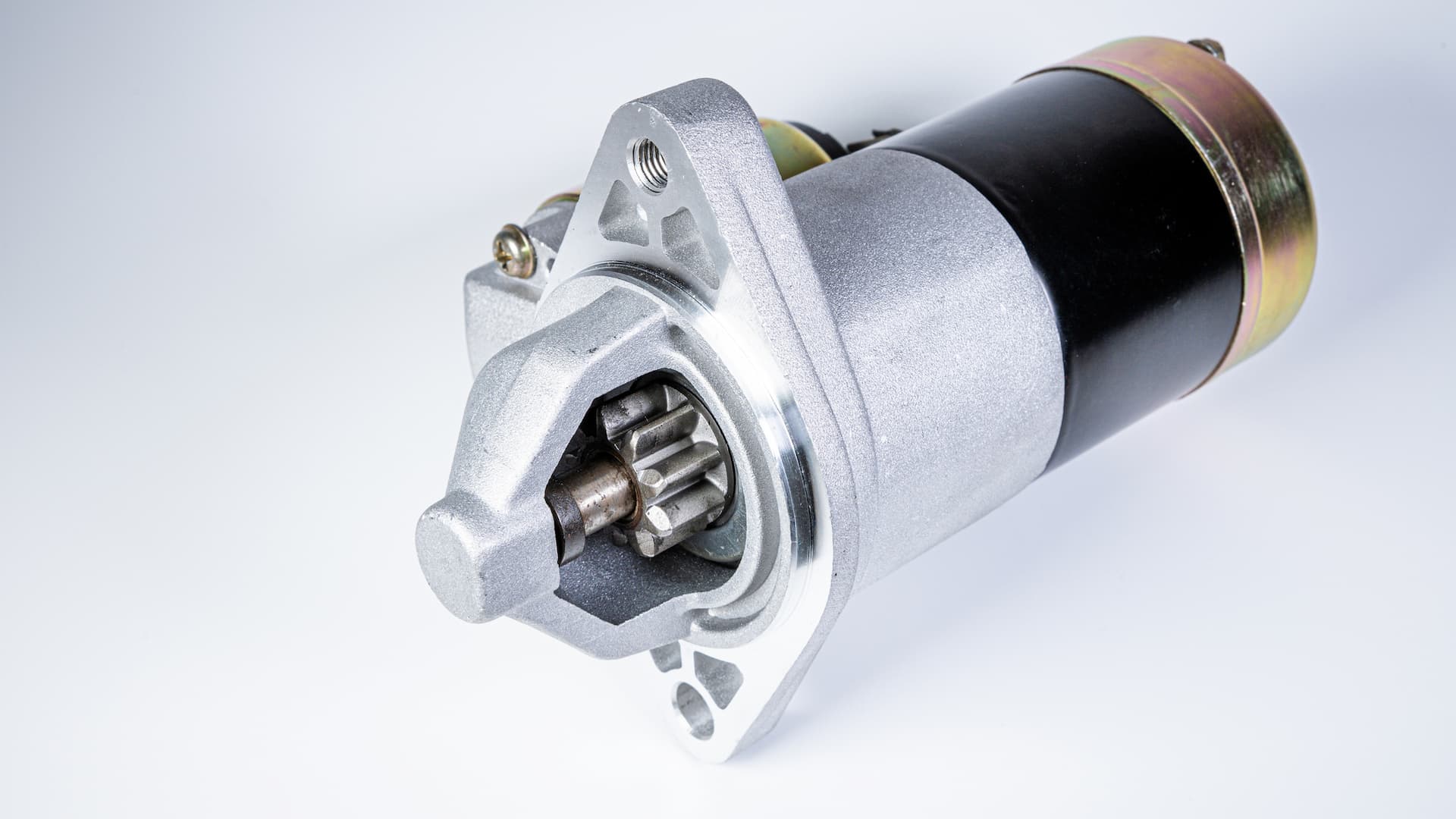

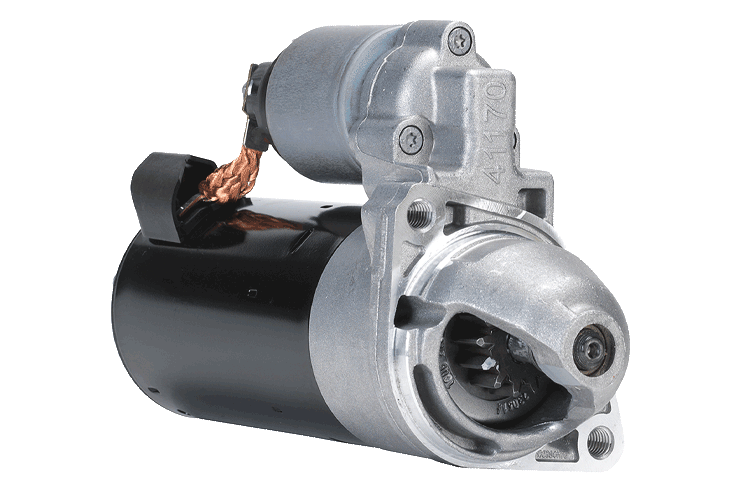

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Die Lösung: Bauen Sie Beziehungen zu seriösen Lieferanten auf, die auf Kfz-Teile spezialisiert sind und mehrere Fahrzeugmodelle bedienen können. Erstellen Sie eine Liste bevorzugter Lieferanten auf der Grundlage ihrer Zuverlässigkeit, Produktqualität und Preisgestaltung. Nutzen Sie die Technologie, indem Sie Bestandsverwaltungssysteme einsetzen, die die für jedes Fahrzeug benötigten Teile verfolgen und so einen rationalisierten Bestellvorgang ermöglichen. Ziehen Sie außerdem Großeinkaufsvereinbarungen mit Lieferanten in Erwägung, um günstigere Preise zu erzielen und eine kontinuierliche Versorgung mit Teilen zu gewährleisten, wodurch das Risiko von Ausfallzeiten verringert und die Zuverlässigkeit der Flotte sichergestellt wird.

Szenario 3: Sicherstellung von Qualität und Compliance bei der Erstinstallation

Das Problem: B2B-Einkäufer müssen oft sicherstellen, dass der Einbau von Anlassern nach hohen Standards erfolgt und den örtlichen Vorschriften entspricht. Schlechte Einbaupraktiken können zu wiederkehrenden Problemen, Sicherheitsrisiken und potenziellen rechtlichen Konsequenzen führen, insbesondere in Regionen mit strengen Kfz-Vorschriften. Diese Herausforderung ist besonders dringlich für Unternehmen, die auf ihre Fahrzeuge für kritische Vorgänge angewiesen sind.

Die Lösung: Um qualitativ hochwertige Installationen zu gewährleisten, sollten Unternehmen ein solides Schulungsprogramm für ihre Techniker entwickeln, das sich auf bewährte Verfahren für Starter-Installationen konzentriert. Investieren Sie in kontinuierliche Weiterbildung, um Ihr Team über die neuesten Industriestandards und -vorschriften auf dem Laufenden zu halten. Ziehen Sie außerdem die Zusammenarbeit mit zertifizierten Kfz-Schulungsorganisationen in Betracht, um Workshops und Zertifizierungsprogramme für Ihre Mitarbeiter anzubieten. Führen Sie einen Qualitätssicherungsprozess ein, der regelmäßige Inspektionen und Feedbackschleifen umfasst, um sicherzustellen, dass die Installationen sowohl den Sicherheits- als auch den Betriebsstandards entsprechen. Dieses Engagement für Qualität wird nicht nur die Langlebigkeit der Startereinheiten erhöhen, sondern auch das Vertrauen und die Zuverlässigkeit bei Ihren Kunden und Interessengruppen fördern.

Strategischer Leitfaden zur Materialauswahl für den Einbau eines Anlassers im Auto

Was sind die wichtigsten Materialien für den Einbau eines Autostarters?

Bei der Installation eines Autoanlassers ist die Auswahl der richtigen Materialien entscheidend für eine optimale Leistung und Langlebigkeit. Im Folgenden analysieren wir vier gängige Materialien, die bei der Konstruktion von Startern verwendet werden, und ihre Bedeutung für B2B-Käufer, insbesondere in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa.

Was sind die wichtigsten Eigenschaften von Kupfer in Starteranwendungen?

Kupfer ist aufgrund seiner hervorragenden Leitfähigkeit ein weit verbreitetes Material für elektrische Bauteile in Startern. Es hat eine hohe Temperaturbeständigkeit, typischerweise um 200°C, und bietet eine gute Korrosionsbeständigkeit, insbesondere wenn es behandelt wird.

Vorteile: Die überragende elektrische Leitfähigkeit von Kupfer gewährleistet eine effiziente Stromübertragung, die für den zuverlässigen Betrieb des Anlassers unerlässlich ist. Außerdem lässt es sich relativ leicht in verschiedenen Formen und Größen herstellen.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Nachteile: Der Hauptnachteil sind die Kosten, denn Kupfer ist teurer als Alternativen wie Aluminium. Außerdem kann Kupfer korrosionsanfällig sein, wenn es nicht richtig isoliert ist.

Auswirkungen auf die Anwendung: Die Verträglichkeit von Kupfer mit hohen elektrischen Lasten macht es ideal für Starter, aber es erfordert eine sorgfältige Handhabung, um Oxidation zu vermeiden, insbesondere in feuchter Umgebung.

Überlegungen für internationale Käufer: Die Einhaltung internationaler Normen wie ASTM B170 für Kupferdraht ist unerlässlich. In Regionen mit hoher Luftfeuchtigkeit, wie in Teilen Afrikas und Südamerikas, sollten Käufer Kupfer mit Schutzbeschichtungen in Betracht ziehen, um die Haltbarkeit zu erhöhen.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Wie schneidet Aluminium im Vergleich bei Starterkomponenten ab?

Aluminium ist ein weiteres gängiges Material, insbesondere für Gehäuse und Verkleidungen. Es hat eine geringere Dichte als Kupfer und ist daher leichter und einfacher zu handhaben.

Vorteile: Aluminium ist kostengünstig und bietet eine gute Korrosionsbeständigkeit, insbesondere wenn es eloxiert ist. Sein geringes Gewicht kann zur Gesamteffizienz des Fahrzeugs beitragen.

Nachteile: Aluminium leitet zwar Strom, ist aber nicht so effizient wie Kupfer, was bei anspruchsvollen Anwendungen zu Leistungsproblemen führen kann. Außerdem kann die Herstellung komplexer werden, wenn komplizierte Konstruktionen erforderlich sind.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Auswirkungen auf die Anwendung: Aluminium eignet sich für Bauteile, die keine hohe Leitfähigkeit erfordern, aber leicht und korrosionsbeständig sein müssen.

Überlegungen für internationale Käufer: Die Käufer sollten darauf achten, dass das verwendete Aluminium Normen wie ASTM B221 entspricht. In Regionen wie dem Nahen Osten, wo die Temperaturen stark ansteigen können, sollten auch die Wärmeausdehnungseigenschaften von Aluminium berücksichtigt werden.

Welche Rolle spielt Stahl in Starterbaugruppen?

Stahl wird aufgrund seiner Festigkeit und Haltbarkeit häufig für strukturelle Komponenten von Startern verwendet. Er hat eine hohe Zugfestigkeit und kann erheblichen mechanischen Belastungen standhalten.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Vorteile: Stahl ist robust und hält den physischen Anforderungen des Startbetriebs stand. Außerdem ist er im Vergleich zu anderen Metallen relativ preiswert.

Nachteile: Stahl ist schwerer als Aluminium und Kupfer, was sich auf das Gesamtgewicht des Anlassers auswirken kann. Außerdem ist er anfällig für Rost, wenn er nicht ordnungsgemäß beschichtet ist.

Auswirkungen auf die Anwendung: Stahl ist ideal für Bauteile, die eine hohe Festigkeit erfordern, aber in korrosionsgefährdeten Umgebungen ohne entsprechende Behandlung nicht so gut funktionieren.

Überlegungen für internationale Käufer: Die Einhaltung von Normen wie DIN 17100 ist entscheidend. Käufer in feuchten Regionen sollten verzinkten oder rostfreien Optionen den Vorzug geben, um Rost zu vermeiden.

Wie wichtig ist Kunststoff im Starterdesign?

Kunststoffe werden in zunehmendem Maße für nicht-strukturelle Komponenten von Startern, wie Gehäuse und Isolatoren, verwendet. Sie bieten hervorragende Isolationseigenschaften und sind leicht.

Vorteile: Kunststoffe sind kostengünstig und können in komplexe Formen gegossen werden, was eine flexible Gestaltung ermöglicht. Außerdem bieten sie eine gute elektrische Isolierung.

Nachteile: Kunststoffe sind unter Umständen nicht so temperaturbeständig wie Metalle, was ihren Einsatz in Hochtemperaturbereichen des Starters einschränken kann.

Auswirkungen auf die Anwendung: Kunststoffe eignen sich für Bauteile, bei denen die Isolierung von entscheidender Bedeutung ist, aber ihre thermischen Grenzen müssen berücksichtigt werden.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Überlegungen für internationale Käufer: Die Einhaltung von Normen wie ISO 9001 ist wichtig für die Gewährleistung der Qualität. Die Käufer sollten auch die spezifischen thermischen und chemischen Beständigkeitseigenschaften des verwendeten Kunststoffs berücksichtigen.

Übersichtstabelle zur Materialauswahl für die Starterinstallation

| Material | Typischer Anwendungsfall für die Kosten für den Einbau eines Anlassers im Auto | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse und Verkabelung in Startern | Hervorragende Leitfähigkeit | Höhere Kosten, anfällig für Korrosion | Hoch |

| Aluminium | Gehäuse und Gehäuseteile | Leicht und kostengünstig | Geringere Leitfähigkeit als Kupfer | Mittel |

| Stahl | Strukturelle Komponenten | Hohe Festigkeit und Haltbarkeit | Schwerer, anfällig für Rost | Niedrig |

| Kunststoff | Isolatoren und nicht-strukturelle Komponenten | Gute Isolierung und Designflexibilität | Begrenzte Hitzebeständigkeit | Niedrig |

Diese Analyse bietet B2B-Einkäufern, die an der Installation von Startern beteiligt sind, wertvolle Einblicke in die Materialauswahl und zeigt auf, wie wichtig es ist, die Materialeigenschaften und regionale Aspekte zu verstehen.

Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Wie viel kostet der Einbau eines Starters im Auto?

Was sind die wichtigsten Schritte bei der Herstellung eines Autostarters?

Der Herstellungsprozess eines Autoanlassers umfasst mehrere wichtige Schritte, die jeweils entscheidend dafür sind, dass das Endprodukt den Leistungs- und Zuverlässigkeitsstandards entspricht. Zu den wichtigsten Phasen gehören die Materialvorbereitung, die Formgebung, die Montage und die Endbearbeitung.

Wie wird das Material für die Starterherstellung vorbereitet?

Die Materialvorbereitung ist der erste entscheidende Schritt. Die Hersteller verwenden für die Bauteile des Anlassers in der Regel Edelstahl und Kupfer, da diese Materialien eine hervorragende elektrische Leitfähigkeit und Festigkeit aufweisen. Die Materialien werden strengen Tests unterzogen, um sicherzustellen, dass sie bestimmte mechanische und elektrische Eigenschaften erfüllen. Dies kann Zugfestigkeitstests und Bewertungen der elektrischen Leitfähigkeit umfassen. Die Lieferanten sollten Zertifizierungen vorlegen, die die Qualität dieser Materialien belegen und die B2B-Einkäufer überprüfen können, um die Einhaltung ihrer eigenen Qualitätsstandards sicherzustellen.

Welche Formgebungstechniken werden bei der Starterproduktion verwendet?

Sobald die Materialien vorbereitet sind, werden sie umgeformt. Zu den wichtigsten Techniken gehören Druckguss und maschinelle Bearbeitung. Der Druckguss wird üblicherweise für die Herstellung des Anlassergehäuses verwendet, während Komponenten wie Anker und Magnetspule präzise bearbeitet werden. Diese Verfahren erfordern eine spezielle Ausrüstung, um enge Toleranzen zu erreichen und sicherzustellen, dass die Teile nahtlos zusammenpassen. Für B2B-Einkäufer kann das Verständnis dieser Verfahren Aufschluss über die Zuverlässigkeit und Langlebigkeit des Anlassers geben, den sie beschaffen.

Wie werden Vorspeisen zusammengebaut und fertiggestellt?

Wie sieht der Montageprozess für Autostarter aus?

Der Zusammenbau ist eine kritische Phase, in der die einzelnen Komponenten zu einer kompletten Startereinheit zusammengefügt werden. Erfahrene Techniker bauen den Anlasser zusammen und stellen sicher, dass jedes Teil korrekt ausgerichtet und befestigt ist. Bei diesem Prozess kommen häufig automatisierte Systeme zum Einsatz, um die Effizienz und Konsistenz zu verbessern. Qualitätssicherungsprüfungen während der Montage, wie z. B. die prozessbegleitende Qualitätskontrolle (IPQC), stellen sicher, dass etwaige Mängel frühzeitig erkannt werden, wodurch Abfall und Nacharbeit minimiert werden.

Welche Veredelungstechniken werden bei Starters angewendet?

Nach der Montage werden die Anlasser zum Schutz vor Korrosion und Verschleiß einer Endbearbeitung wie Lackierung oder Beschichtung unterzogen. Diese Veredelungen verbessern nicht nur die Ästhetik des Produkts, sondern tragen auch zu seiner Haltbarkeit bei. Internationale Einkäufer können anhand der angewandten Veredelungsmethoden beurteilen, wie gut das Produkt den Umweltbedingungen standhält, insbesondere in den verschiedenen Klimazonen in Afrika, Südamerika, dem Nahen Osten und Europa.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Welche Qualitätssicherungsstandards sollten B2B-Käufer berücksichtigen?

Qualitätssicherung ist in der Automobilindustrie, wo die Zuverlässigkeit von Bauteilen wie Anlassern von entscheidender Bedeutung ist, von größter Bedeutung. Internationale Normen wie ISO 9001 bieten einen Rahmen für Qualitätsmanagementsysteme, der sicherstellt, dass die Hersteller die Kundenanforderungen durchgängig erfüllen und die Zufriedenheit steigern. Darüber hinaus sind branchenspezifische Zertifizierungen wie die CE-Kennzeichnung für die europäischen Märkte und die API-Normen für die Leistung ein wichtiger Indikator für die Einhaltung von Vorschriften und Qualität.

Wie werden Qualitätskontrollpunkte in der Starterproduktion festgelegt?

Hersteller führen in der Regel mehrere Qualitätskontrollen während des gesamten Produktionsprozesses durch. Die Wareneingangskontrolle (IQC) prüft die Qualität der Rohstoffe, bevor sie in die Produktion gelangen. Die prozessbegleitende Qualitätskontrolle (In-Process Quality Control, IPQC) überwacht den Herstellungsprozess selbst, während die abschließende Qualitätskontrolle (Final Quality Control, FQC) die fertigen Produkte prüft. Diese Kontrollpunkte tragen dazu bei, dass etwaige Mängel erkannt und behoben werden, bevor das Produkt den Markt erreicht.

Welche gängigen Testmethoden werden in der Qualitätssicherung für Starter verwendet?

Die Testmethoden für Berufsanfänger sind vielfältig und rigoros. Zu den üblichen Tests gehören:

- Elektrische Prüfung: Misst die Spannung und den Strom des Anlassers, um sicherzustellen, dass er innerhalb der Spezifikationen arbeitet.

- Mechanische Prüfung: Bewertet die Festigkeit und Haltbarkeit von Bauteilen unter Belastung.

- Umweltprüfungen: Simuliert Bedingungen wie extreme Temperaturen und Feuchtigkeit, um die Widerstandsfähigkeit des Produkts zu überprüfen.

B2B-Einkäufer sollten sich nach den spezifischen Prüfverfahren erkundigen, die ein Hersteller anwendet, um sicherzustellen, dass die Starter die erforderlichen Leistungskriterien für ihre Anwendungen erfüllen.

Wie können B2B-Käufer die Qualitätskontrolle ihrer Lieferanten überprüfen?

Für B2B-Einkäufer, insbesondere solche, die auf internationalen Märkten tätig sind, ist die Überprüfung der Qualitätskontrollverfahren eines Lieferanten von entscheidender Bedeutung. Die Einkäufer können Audits durchführen, um die Fertigungsanlagen und Qualitätskontrollverfahren direkt zu beurteilen. Darüber hinaus kann das Anfordern von Qualitätssicherungsberichten und -zertifikaten einen weiteren Einblick in das Qualitätsengagement des Lieferanten geben.

Die Beauftragung von Inspektionsdiensten durch Dritte ist eine weitere wirksame Methode zur Überprüfung der Qualität. Diese Dienste können unabhängige Bewertungen des Herstellungsprozesses und der Endprodukte durchführen und so eine unvoreingenommene Bewertung der Einhaltung internationaler Normen vornehmen.

Was sind die Feinheiten der Qualitätskontrolle und Zertifizierung für internationale Käufer?

Internationale Käufer sollten sich der Nuancen bei der Qualitätskontrolle und Zertifizierung bewusst sein, die je nach Region unterschiedlich sein können. So ist zum Beispiel die Einhaltung der CE-Kennzeichnung für Produkte, die in Europa verkauft werden, von entscheidender Bedeutung, während es in anderen Regionen spezifische lokale Zertifizierungen geben kann. Die Kenntnis dieser Anforderungen stellt sicher, dass die importierten Produkte den rechtlichen und sicherheitstechnischen Anforderungen entsprechen.

In Regionen wie Afrika und Südamerika können auch lokale Vorschriften die Qualitätsstandards beeinflussen. Einkäufer sollten sich über die spezifischen Anforderungen ihrer Zielmärkte informieren, um Probleme bei der Einhaltung zu vermeiden, die zu kostspieligen Verzögerungen oder Strafen führen könnten.

Schlussfolgerung: Sicherstellung der Qualität in der Starter-Produktion

Zusammenfassend lässt sich sagen, dass die Herstellungsverfahren und Qualitätssicherungspraktiken für Anlasser komplex und vielschichtig sind. Wenn internationale B2B-Einkäufer diese Prozesse verstehen, können sie bei der Beschaffung von Anlassern fundierte Entscheidungen treffen und sicherstellen, dass sie zuverlässige Produkte auswählen, die ihren betrieblichen Anforderungen entsprechen. Die Zusammenarbeit mit Lieferanten, bei denen Qualität und die Einhaltung internationaler Normen im Vordergrund stehen, wird letztendlich zu einer besseren Leistung und Kundenzufriedenheit auf dem Automobilmarkt führen.

Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet der Einbau eines Starters im Auto’.’

Um den Beschaffungsprozess für den Einbau eines Autostarters effektiv zu gestalten, ist es wichtig, eine systematische Checkliste zu befolgen, die Qualität und Kosteneffizienz gewährleistet. Dieser Leitfaden richtet sich an B2B-Einkäufer in verschiedenen internationalen Märkten und hilft Ihnen, fundierte Entscheidungen über Beschaffungs- und Installationskosten zu treffen.

Schritt 1: Bewerten Sie die Spezifikationen Ihres Fahrzeugs

Bei der Suche nach einem Anlasser ist es wichtig, die Marke, das Modell und das Baujahr Ihres Fahrzeugs zu kennen. Unterschiedliche Fahrzeuge können bestimmte Anlassertypen erfordern, was sowohl die Kosten als auch die Verfügbarkeit beeinflussen kann. Vergewissern Sie sich, dass Sie die erforderlichen Spezifikationen haben, um den Kauf inkompatibler Teile zu vermeiden.

Schritt 2: Forschung Ersatzoptionen

Erkundigen Sie sich nach neuen und generalüberholten Startern. Neue Anlasser bieten in der Regel eine Garantie und Zuverlässigkeit, während generalüberholte Anlasser Kosteneinsparungen bieten können. Wägen Sie die Vor- und Nachteile jeder Option je nach Ihrem Budget und den Anforderungen des Fahrzeugs ab.

- Neue Vorspeisen: Höhere Kosten, aber oft auch zuverlässiger.

- Überholte Anlasser: Kostengünstig, aber achten Sie auf Garantien und Qualitätssicherung.

Schritt 3: Berechnen Sie die gesamten Installationskosten

Die Einbaukosten können je nach Arbeitsaufwand und Komplexität des Einbaus stark variieren. Informieren Sie sich über die örtlichen Werkstätten und deren Preisstrukturen, um einen genauen Kostenvoranschlag zu erhalten. Denken Sie daran, alle zusätzlichen Kosten, wie z. B. für Werkzeuge oder Diagnosedienste, zu berücksichtigen.

- Lohnkosten: Fragen Sie bei mehreren Dienstleistern nach den Stundensätzen.

- Faktoren der Komplexität: Stellen Sie fest, ob der Anlasser Ihres Fahrzeugs leicht zugänglich ist oder aufwendig demontiert werden muss.

Schritt 4: Identifizieren Sie seriöse Lieferanten

Die Suche nach einem zuverlässigen Lieferanten ist der Schlüssel zur Gewährleistung von Qualitätsteilen. Suchen Sie nach Lieferanten mit einem guten Ruf in der Branche, positiven Kundenrezensionen und einer nachgewiesenen Erfolgsbilanz. Fordern Sie Produktmuster oder detaillierte Spezifikationen an, um die Qualität zu überprüfen.

- Lieferantennachweise: Überprüfen Sie Zertifizierungen und die Einhaltung von Industriestandards.

- Referenzen: Fragen Sie nach Fallstudien oder Erfahrungsberichten von ähnlichen Unternehmen.

Schritt 5: Bewertung von Garantie- und Supportleistungen

Bevor Sie Ihren Kauf abschließen, sollten Sie die Garantiebedingungen der Anbieter prüfen. Eine solide Garantie kann Ihre Investition schützen und Ihnen Sicherheit geben. Prüfen Sie außerdem den Kundendienst, der Sie bei Problemen nach dem Kauf unterstützt.

- Dauer der Garantie: Längere Garantien deuten oft auf eine höhere Qualität hin.

- Kundenbetreuung: Vergewissern Sie sich, dass der Anbieter reaktionsschnellen Support für die Fehlerbehebung bietet.

Schritt 6: Bestätigen Sie Lieferung und Lieferzeiten

Für die Planung des Einbaus ist es wichtig, die Vorlaufzeit für die Lieferung des Starters zu kennen. Stimmen Sie sich mit den Zulieferern ab, um realistische Liefertermine festzulegen, die mit den Zeitplänen Ihres Projekts übereinstimmen. Verzögerungen können den Betrieb stören, daher ist Klarheit entscheidend.

- Versandoptionen: Erkundigen Sie sich bei Bedarf nach einem beschleunigten Versand.

- Kommunikation: Aufrechterhaltung eines offenen Kontakts zu den Lieferanten, um den Auftragsstatus zu verfolgen.

Schritt 7: Installationsvereinbarungen abschließen

Sobald der Anlasser beschafft ist, planen Sie den Einbau. Unabhängig davon, ob Sie sich für den Selbsteinbau entscheiden oder einen Mechaniker beauftragen, stellen Sie sicher, dass der Einbau gemäß den OEM-Spezifikationen erfolgt. Dies wird die Leistung und Langlebigkeit des Anlassers maximieren.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

- DIY-Überlegungen: Vergewissern Sie sich, dass Sie über die notwendigen Werkzeuge und Kenntnisse verfügen.

- Professionelle Installation: Bestätigen Sie die Erfahrung des Mechanikers mit Ihrem Fahrzeugtyp.

Anhand dieser Checkliste können B2B-Einkäufer den Prozess der Beschaffung und Installation eines Autostarters rationalisieren und sicherstellen, dass sie eine optimale Leistung erzielen und gleichzeitig die Kosten effektiv verwalten.

Umfassende Kosten- und Preisanalyse für den Einbau eines Starters im Auto Sourcing

Was sind die wichtigsten Kostenkomponenten für die Installation eines Autostarters?

Bei der Analyse der Kosten, die mit der Installation eines Autostarters verbunden sind, müssen mehrere Komponenten berücksichtigt werden. Zu den wichtigsten Kostenkomponenten gehören Material, Arbeit, Fertigungsgemeinkosten, Werkzeuge, Qualitätskontrolle, Logistik und Gewinnspanne.

-

Materialien: Die Kosten für einen Anlasser selbst können je nach Marke und Modell des Fahrzeugs zwischen $80 und über $350 liegen. Die Preise für Ersatzteile können ebenfalls variieren und liegen zwischen $50 und $350. Die Wahl zwischen OEM-Teilen (Original Equipment Manufacturer) und Aftermarket-Komponenten kann die Materialkosten erheblich beeinflussen.

-

Arbeit: Die Arbeitskosten für den Einbau können sehr unterschiedlich sein. Professionelle Mechaniker können je nach Komplexität des Einbaus zwischen $150 und $1.100 berechnen. Bei einfacheren Fahrzeugen kann der Einbau weniger als eine Stunde dauern, während bei größeren oder luxuriösen Modellen mehr Zeit benötigt wird, was die Arbeitskosten erhöht.

-

Fertigungsgemeinkosten und Werkzeugbau: Dazu gehören die Kosten für den Betrieb, die Ausrüstung und die Wartung der Fabrik. In Regionen mit einer etablierten Automobilindustrie können diese Kosten aufgrund von Größenvorteilen niedriger sein. In aufstrebenden Märkten hingegen können die Gemeinkosten einen erheblichen Kostenfaktor darstellen.

-

Qualitätskontrolle (QC): Die Gewährleistung der Zuverlässigkeit der Vorspeise ist entscheidend. QC-Prozesse können die Gesamtkosten erhöhen, sind aber für die Aufrechterhaltung der Produktintegrität unerlässlich, insbesondere für B2B-Käufer, die auf Qualitätszertifizierungen Wert legen.

-

Logistik: Die Versand- und Bearbeitungskosten können je nach Entfernung und Transportart variieren. Internationale Käufer sollten die Zollgebühren und -tarife berücksichtigen, die die Gesamtkosten erhöhen können.

-

Marge: Die Anbieter berechnen in der Regel eine Marge, um ihre Betriebskosten und ihren Gewinn zu decken. Diese kann je nach Wettbewerb auf dem Markt und dem einzigartigen Nutzenversprechen des Anbieters variieren.

Wie wirken sich Preisfaktoren auf die Installationskosten für Starter aus?

Mehrere Faktoren beeinflussen den Preis von Erstausstattungen, insbesondere für internationale B2B-Käufer:

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

-

Volumen/MOQ (Mindestbestellmenge): Größere Bestellungen können zu Preisnachlässen führen, so dass es für Unternehmen kostengünstiger ist, in großen Mengen einzukaufen.

-

Spezifikationen und Anpassung: Kundenspezifische Starter, die für bestimmte Anwendungen entwickelt wurden, können aufgrund spezieller Herstellungsverfahren zusätzliche Kosten verursachen. Käufer sollten die Vorteile einer kundenspezifischen Anpassung gegen die möglichen Mehrkosten abwägen.

-

Materialqualität und Zertifizierungen: Qualitativ hochwertigere Materialien sind oft mit einem höheren Preis verbunden. Auch Zertifizierungen können die Kosten in die Höhe treiben, sind aber unter Umständen notwendig, um die örtlichen Vorschriften einzuhalten.

-

Lieferantenfaktoren: Der Ruf und die Zuverlässigkeit des Lieferanten können sich auf die Preisgestaltung auswirken. Etablierte Anbieter können aufgrund ihrer nachweislichen Erfolgsbilanz einen Aufschlag verlangen, während neuere Marktteilnehmer niedrigere Preise anbieten könnten, um Marktanteile zu gewinnen.

-

Incoterms: Das Verständnis der Incoterms ist für internationale Transaktionen von entscheidender Bedeutung. Begriffe wie FOB (Free on Board) oder CIF (Cost, Insurance, and Freight) können die endgültige Preisstruktur und die Verantwortung für die Transportkosten erheblich beeinflussen.

Was sind die wichtigsten Tipps für B2B-Einkäufer bei der Beschaffung von Start-ups?

Internationale B2B-Einkäufer sollten mehrere Strategien im Auge behalten, um ihren Beschaffungsprozess zu optimieren:

-

Verhandlung: Die Aufnahme von Verhandlungen kann zu einer besseren Preisgestaltung führen. Seien Sie bereit, über Mengenrabatte, Zahlungsbedingungen und andere Faktoren zu sprechen, die die Kosten beeinflussen können.

-

Kosteneffizienz: Berücksichtigen Sie die Gesamtbetriebskosten (TCO), zu denen nicht nur der Anschaffungspreis, sondern auch die Kosten für Installation, Wartung und mögliche Ausfallzeiten gehören. Günstigere Optionen können langfristig zu höheren Kosten führen, wenn sie häufig ausgetauscht werden müssen.

-

Preisnuancen für verschiedene Regionen: Käufer aus Afrika, Südamerika, dem Nahen Osten und Europa sollten sich der regionalen Preistrends und wirtschaftlichen Bedingungen bewusst sein, die sich auf die Einstiegskosten auswirken können. Auch Währungsschwankungen und die lokale Marktnachfrage können eine wichtige Rolle spielen.

Haftungsausschluss

Die in dieser Analyse genannten Preise sind Richtwerte und können je nach Standort, Anbieter und spezifischen Fahrzeuganforderungen variieren. Es ist für Käufer ratsam, gründliche Marktforschung zu betreiben und mehrere Angebote einzuholen, bevor sie eine Kaufentscheidung treffen.

Analyse der Alternativen: Vergleich der Kosten für den Einbau eines Starters im Auto mit anderen Lösungen

Alternative Lösungen für Startprobleme von Fahrzeugen verstehen

In der Automobilindustrie ist die Behebung von Startproblemen entscheidend für die Zuverlässigkeit und Leistung des Fahrzeugs. Der Austausch eines Anlassers ist zwar eine gängige Lösung, doch auch verschiedene Alternativen können effektive Ergebnisse liefern. Diese Analyse vergleicht den herkömmlichen Austausch des Anlassers mit anderen praktikablen Lösungen und hilft B2B-Käufern, fundierte Entscheidungen auf der Grundlage von Leistung, Kosten und einfacher Implementierung zu treffen.

Vergleichstabelle

| Vergleichsaspekt | Wie viel kostet der Einbau eines Starters im Auto? | Starthilfe-System | Batteriewechsel |

|---|---|---|---|

| Leistung | Hohe Zuverlässigkeit und langfristige Nutzung | Vorläufige Lösung | Hohe Zuverlässigkeit und Langlebigkeit |

| Kosten | $150 - $1.100 (einschließlich Arbeit) | $20 - $50 (Kabel) | $100 - $300 |

| Einfache Implementierung | Erfordert professionelle Installation | Einfach (DIY möglich) | Moderat (DIY oder professionell) |

| Wartung | Niedrig (nach der Installation) | Erfordert regelmäßige Kontrollen | Mäßig (abhängig von der Nutzung) |

| Bester Anwendungsfall | Langfristige Zuverlässigkeit im täglichen Einsatz | Notsituationen | Fahrzeuge mit alternden Batterien |

Detaillierte Aufschlüsselung der Alternativen

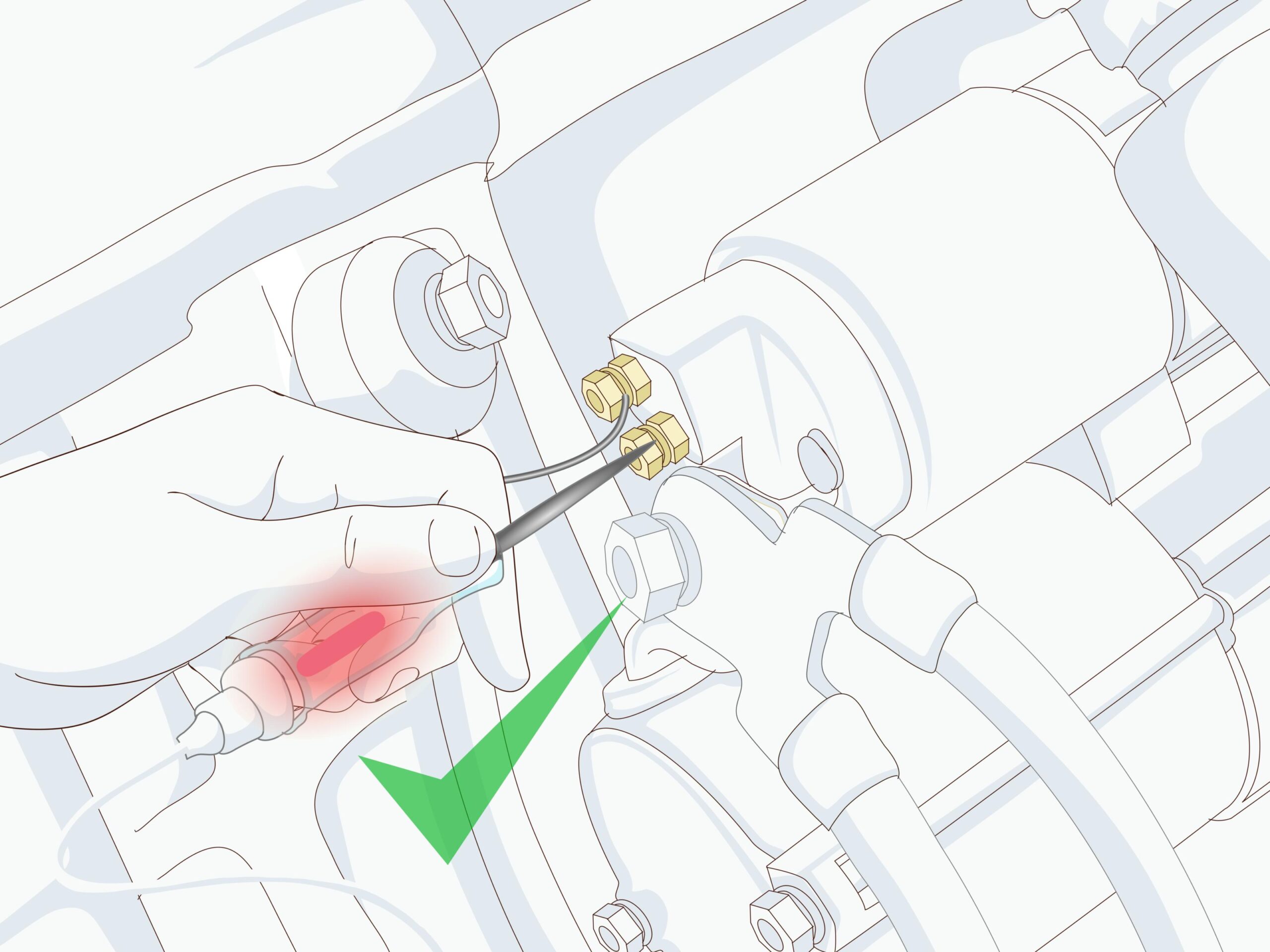

1. Starthilfe-System

Starthilfe ist eine schnelle und wirksame Methode, um ein Fahrzeug vorübergehend in Gang zu bringen. Bei dieser Methode werden Starthilfekabel verwendet, um eine funktionierende Batterie aus einem anderen Fahrzeug an die leere Batterie anzuschließen.

Vorteile:

– Kostengünstig: Ein Satz Starthilfekabel ist relativ preiswert und daher eine attraktive kurzfristige Lösung.

– Benutzerfreundlichkeit: Die meisten Fahrzeughalter können diese Aufgabe mit minimaler Schulung durchführen.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Nachteile:

– Vorläufige Lösung: Diese Methode behebt nicht die zugrunde liegenden Probleme mit dem Anlasser oder der Batterie und funktioniert möglicherweise nur ein- oder zweimal.

– Sicherheitsrisiken: Falsche Anschlüsse können zu elektrischen Gefährdungen oder Schäden an den beteiligten Fahrzeugen führen.

2. Batteriewechsel

In Fällen, in denen das Startproblem auf eine defekte Batterie und nicht auf den Anlasser selbst zurückzuführen ist, kann der Austausch der Batterie eine praktikablere Lösung darstellen. Eine neue Batterie sorgt für einen zuverlässigen Betrieb des Fahrzeugs und kann häufig Probleme beheben, die einen Ausfall des Anlassers vortäuschen.

Vorteile:

– Langfristige Verlässlichkeit: Eine neue Batterie kann mehrere Jahre halten, je nach Nutzung und Wartung.

– Verbesserte Leistung: Frische Batterien sorgen für eine bessere Startleistung und Gesamtleistung des Fahrzeugs.

Nachteile:

– Höhere Anfangskosten: Der Austausch einer Batterie kann kostspielig sein, insbesondere bei Hochleistungsbatterien oder Spezialbatterien.

– Komplexität der Installation: Manche Nutzer entscheiden sich für den Selbsteinbau, andere benötigen professionelle Hilfe, was die Gesamtkosten in die Höhe treibt.

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

Bei der Beurteilung der Lösung von Startproblemen bei Fahrzeugen müssen B2B-Käufer ihre spezifischen Bedürfnisse berücksichtigen, einschließlich Kosten, Leistung und einfacher Umsetzung. Während der Einbau eines neuen Anlassers eine zuverlässige langfristige Lösung darstellt, können Alternativen wie Starthilfe oder Batteriewechsel in bestimmten Situationen sofortige Abhilfe schaffen. Durch die Abwägung der Vor- und Nachteile jeder Option können Unternehmen strategische Entscheidungen treffen, die mit ihren betrieblichen Zielen und Budgetvorgaben übereinstimmen.

Wesentliche technische Eigenschaften und Fachterminologie für den Einbau eines Anlassers im Auto

Was sind die wichtigsten technischen Eigenschaften, die bei der Installation eines Autostarters zu beachten sind?

Bei der Beschaffung von Startern für den Fahrzeugeinbau sind mehrere technische Eigenschaften entscheidend, um Kompatibilität, Leistung und Haltbarkeit zu gewährleisten. Das Verständnis dieser Spezifikationen kann B2B-Käufern helfen, fundierte Entscheidungen zu treffen.

1. Material Klasse

Die Materialqualität eines Anlassers ist ausschlaggebend für seine Festigkeit und Verschleißbeständigkeit. Anlasser werden in der Regel aus hochwertigem Stahl oder Aluminium hergestellt und mit verschiedenen Beschichtungen versehen, um Korrosion zu verhindern. Eine höhere Materialgüte gewährleistet eine bessere Leistung und Langlebigkeit und verringert die Häufigkeit des Austauschs. Dies ist besonders wichtig für B2B-Kunden, die ihre Betriebskosten und Ausfallzeiten minimieren wollen.

2. Drehmoment-Spezifikationen

Die Drehmomentangaben geben die Höhe der Drehkraft an, die bei der Befestigung des Anlassers am Motor aufgebracht werden sollte. Das richtige Drehmoment ist wichtig, um Schäden an den Komponenten während der Installation zu vermeiden. Für B2B-Käufer gewährleistet die Einhaltung dieser Spezifikationen, dass der Anlasser effizient funktioniert und zukünftige mechanische Ausfälle verhindert werden, wodurch die Kundenzufriedenheit erhöht wird.

3. Nennspannung

Die meisten Fahrzeugstarter arbeiten mit einem 12-Volt-System, aber einige Anwendungen können andere Spannungswerte erfordern. Um die Kompatibilität mit dem elektrischen System des Fahrzeugs zu gewährleisten, ist es wichtig, die Spannungsanforderungen zu kennen. Der Käufer muss sich vergewissern, dass der Anlasser die Spannungsanforderungen erfüllt, um elektrische Probleme zu vermeiden, die zu kostspieligen Reparaturen führen könnten.

4. Stromstärke beim Anlassen

Die Anlasserstromstärke bezieht sich auf die Stromstärke, die der Anlasser beim Anlassen des Motors aufnimmt. Für größere Motoren oder Fahrzeuge unter extremen Bedingungen ist eine höhere Anlasserstromstärke erforderlich. B2B-Käufer sollten die Motorgröße und die zu erwartenden Betriebsbedingungen berücksichtigen, um einen Anlasser mit ausreichender Anlassstromstärke auszuwählen, der eine zuverlässige Leistung gewährleistet.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

5. Abmessungen und Gewicht

Die Abmessungen und das Gewicht des Anlassers wirken sich auf die Einbaubarkeit und die Gesamtleistung des Fahrzeugs aus. Käufer sollten sich vergewissern, dass die Größe des Anlassers in den vorgesehenen Platz im Motorraum passt und mit den Einbaukonfigurationen kompatibel ist. Darüber hinaus können leichtere Anlasser zu einer verbesserten Kraftstoffeffizienz beitragen, was für Fuhrparkbetreiber eine wichtige Überlegung darstellt.

Was sind gängige Fachbegriffe im Zusammenhang mit der Installation von Startern?

Das Verständnis des Branchenjargons ist für eine effektive Kommunikation und Verhandlung unerlässlich. Hier sind einige Schlüsselbegriffe, mit denen B2B-Einkäufer vertraut sein sollten:

1. OEM (Original Equipment Manufacturer)

OEM bezieht sich auf Teile, die vom Hersteller der ursprünglichen Fahrzeugkomponenten hergestellt wurden. Die Verwendung von OEM-Startern garantiert, dass die Käufer Teile erhalten, die speziell für ihre Fahrzeuge entwickelt wurden, um Kompatibilität und Leistung zu gewährleisten. Dies ist besonders wichtig in Märkten, in denen Zuverlässigkeit an erster Stelle steht.

2. MOQ (Mindestbestellmenge)

MOQ ist die kleinste Menge eines Produkts, die ein Lieferant zu verkaufen bereit ist. Für B2B-Einkäufer ist es wichtig, die MOQ zu kennen, um die Lagerbestände zu optimieren und den Cashflow effektiv zu verwalten. Einkäufer sollten MOQ-Bedingungen aushandeln, um sicherzustellen, dass sie ausreichende Mengen kaufen können, ohne zu viele Ressourcen zu binden.

3. RFQ (Request for Quotation)

Eine Anfrage ist ein formelles Dokument, das an Lieferanten geschickt wird, um Preise und Bedingungen für bestimmte Produkte anzufordern. Mit einer Anfrage können B2B-Einkäufer Angebote von mehreren Anbietern vergleichen und so fundierte Kaufentscheidungen treffen. Dieses Verfahren ist wichtig, um auf wettbewerbsintensiven Märkten die besten Preise und Konditionen zu erzielen.

4. Incoterms (Internationale Handelsklauseln)

Die Incoterms sind eine Reihe internationaler Regeln, die die Verantwortlichkeiten von Käufern und Verkäufern beim Versand von Waren festlegen. Das Verständnis dieser Bedingungen ist für B2B-Transaktionen von entscheidender Bedeutung, da sie vorschreiben, wer die Kosten und Risiken beim Transport trägt. Die Vertrautheit mit den Incoterms kann Käufern helfen, unerwartete Gebühren und Verzögerungen zu vermeiden.

5. Gewährleistungsbedingungen

Die Garantiebedingungen legen die Dauer und den Umfang des Schutzes fest, der für den Anlasser angeboten wird. Käufer sollten die Garantiedetails genau beachten, um ihre Rechte und die im Falle von Mängeln verfügbare Unterstützung zu verstehen. Eine solide Garantie kann für Sicherheit sorgen und die langfristigen Kosten senken.

Wenn B2B-Einkäufer diese technischen Eigenschaften und Handelsbedingungen kennen, können sie bei der Beschaffung von Startern für den Fahrzeugeinbau eine fundiertere Entscheidung treffen, was letztlich zu einer höheren betrieblichen Effizienz und Kundenzufriedenheit führt.

Anschauliches Bild zum Thema: Wie viel kostet der Einbau eines Anlassers im Auto?

Navigation der Marktdynamik und der Beschaffungstrends in der Branche "Wie viel kostet der Einbau eines Starters im Auto?

Was sind die wichtigsten Trends, die die Kosten für den Einbau eines Autostarters beeinflussen?

Der Markt für den Austausch von Automobilstartern wird von verschiedenen globalen Faktoren beeinflusst, darunter technologischer Fortschritt, steigender Fahrzeugbesitz in Schwellenländern und die zunehmende Komplexität moderner Fahrzeuge. Die Nachfrage nach Elektrofahrzeugen (EVs) verändert den Anlassermarkt, da traditionelle Verbrennungsmotoren nach und nach ersetzt werden. Dieser Wandel erfordert von den Zulieferern eine Anpassung, wobei der Schwerpunkt auf der Beschaffung von Startern liegt, die mit Hybrid- und vollelektrischen Systemen kompatibel sind.

In Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa ist die Marktdynamik unterschiedlich. In Afrika und Südamerika beispielsweise trägt die wachsende Mittelschicht zu einem höheren Fahrzeugbesitz bei, was zu einer höheren Nachfrage nach einem erschwinglichen Anlasserwechsel führt. Auf den europäischen Märkten hingegen steigt der Besitz von Luxusfahrzeugen, die aufgrund von Spezialteilen und Arbeitsaufwand oft mit höheren Austauschkosten verbunden sind.

Aufkommende B2B-Technologietrends wie digitale Beschaffungsplattformen und fortschrittliche Lieferkettenmanagementsysteme spielen ebenfalls eine entscheidende Rolle. Diese Technologien ermöglichen es internationalen Einkäufern, Preise zu vergleichen, die Glaubwürdigkeit von Lieferanten zu überprüfen und Beschaffungsprozesse zu rationalisieren. Die Zunahme des elektronischen Handels mit Kfz-Teilen ermöglicht Käufern aus Entwicklungsregionen den Zugang zu einer breiteren Palette von Produkten und Lieferanten, was den Wettbewerb erhöht und die Preise senkt.

Wie beeinflussen Nachhaltigkeit und ethische Beschaffung den Markt für Erstinstallationen?

Nachhaltigkeit ist in der Automobilbranche zu einem zentralen Thema geworden, das sich auf die Art und Weise auswirkt, wie Unternehmen an die Beschaffung und den Einbau von Autoanlassern herangehen. Die Auswirkungen der Automobilherstellung auf die Umwelt, einschließlich des Ressourcenverbrauchs und der Abfallerzeugung, haben die Unternehmen dazu veranlasst, nach nachhaltigen Verfahren zu suchen. B2B-Einkäufer bevorzugen zunehmend Lieferanten, die sich durch umweltfreundliche Materialien und Prozesse für eine Verringerung ihres CO2-Ausstoßes einsetzen.

Ethische Beschaffung ist ebenso wichtig, zumal Verbraucher und Unternehmen gleichermaßen Transparenz in den Lieferketten fordern. Unternehmen, die Zertifizierungen für ‘grüne’ Materialien vorlegen oder die Einhaltung ethischer Arbeitspraktiken nachweisen können, sind für anspruchsvolle internationale Käufer eher interessant. Dieser Trend ist vor allem in Regionen wie Europa von Bedeutung, wo die Einhaltung von Umweltstandards durch den Gesetzgeber zunehmend gefordert wird.

Auch die Bedeutung von Zertifizierungen wie ISO 14001 (Umweltmanagement) oder Fair Trade kann die Kaufentscheidung beeinflussen. Durch die Zusammenarbeit mit Lieferanten, die diese Standards einhalten, können Einkäufer ihren Ruf als Marke verbessern und gleichzeitig einen positiven Beitrag zu globalen Nachhaltigkeitsbemühungen leisten.

Was ist der historische Kontext der Starterinstallation in der Automobilindustrie?

Die Entwicklung der Anlasser für Kraftfahrzeuge geht auf das frühe 20. Jahrhundert zurück, als die Handkurbelanlasser durch elektrische Anlasser ersetzt wurden, was den Betrieb von Fahrzeugen revolutionierte. Mit der Einführung des elektrischen Anlassers wurden der Komfort und die Zuverlässigkeit beim Starten von Verbrennungsmotoren erheblich verbessert. Mit der Weiterentwicklung der Fahrzeugtechnologie nahm auch die Komplexität der Anlasser zu, so dass moderne Fahrzeuge heute über integrierte elektronische Systeme verfügen.

In den letzten Jahrzehnten hat die Automobilindustrie einen Entwicklungsschub bei Hochleistungsanlassern erlebt, die für spezielle Fahrzeuganwendungen wie schwere Lastkraftwagen und Luxusautos konzipiert sind. Diese Entwicklung hat zu einer Diversifizierung des Anlassermarktes geführt, wobei die Hersteller eine breite Palette von Produkten anbieten, die auf unterschiedliche Fahrzeugspezifikationen und Kundenbedürfnisse zugeschnitten sind.

Das Verständnis dieses historischen Kontextes hilft B2B-Einkäufern, die technologischen Fortschritte zu verstehen, die die aktuellen Beschaffungstrends und Preisstrukturen auf dem Markt für Start-up-Installationen beeinflusst haben. Da die Branche weiterhin innovativ ist, wird es für strategische Kaufentscheidungen entscheidend sein, über diese Entwicklungen informiert zu bleiben.

Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Einbau eines Starters im Auto

-

Wie kann ich feststellen, ob ein Anlasser das Problem bei meinem Fahrzeug ist?

Um festzustellen, ob der Anlasser die Ursache für die Startprobleme Ihres Fahrzeugs ist, gehen Sie bei der Fehlersuche systematisch vor. Prüfen Sie die Batteriespannung; sie sollte mindestens 12,4 Volt betragen. Prüfen Sie die Batteriepole auf Korrosion und stellen Sie sicher, dass sie fest angeschlossen sind. Achten Sie auf klickende Geräusche, wenn Sie versuchen, den Motor zu starten, was auf einen defekten Anlasser hindeuten kann. Wenn das Fahrzeug mit Starthilfe anspringt, aber danach nicht mehr anspringt, liegt das Problem möglicherweise an der Batterie oder der Lichtmaschine. Die Konsultation eines qualifizierten Mechanikers kann weitere Klarheit schaffen. -

Wie hoch sind die durchschnittlichen Kosten für den Einbau eines Anlassers in ein Auto?

Die Kosten für den Einbau eines Anlassers hängen von verschiedenen Faktoren ab, z. B. von der Fahrzeugmarke und dem Fahrzeugmodell, den Lohnkosten in Ihrer Region und davon, ob Sie sich für einen neuen oder einen überholten Anlasser entscheiden. In der Regel liegen die Kosten für einen neuen Anlasser zwischen $80 und über $350, während der Arbeitsaufwand weitere $150 bis $1.100 zu den Gesamtkosten beitragen kann. Es ist ratsam, Angebote von mehreren Lieferanten oder Dienstleistern einzuholen, um wettbewerbsfähige Preise und einen hochwertigen Service sicherzustellen. -

Welche Faktoren beeinflussen den Preis für eine Erstinstallation?

Mehrere Faktoren können den Preis für den Einbau des Anlassers beeinflussen. Dazu gehören die Marke und das Modell des Fahrzeugs, da einige Fahrzeuge komplexere Anlassersysteme haben, die einen höheren Arbeitsaufwand erfordern. Auch der Zustand des vorhandenen Anlassers und die Frage, ob ein Austausch oder eine Überholung erforderlich ist, können sich auf die Kosten auswirken. Darüber hinaus beeinflussen die regionalen Arbeitspreise und die Verfügbarkeit von Ersatzteilen die Gesamtpreisgestaltung, so dass eine gründliche Marktforschung unerlässlich ist. -

Wie kann ich zuverlässige Lieferanten für Starterteile finden?

Um vertrauenswürdige Lieferanten für Anlasserteile zu finden, sollten Sie B2B-Plattformen nutzen, die geprüfte Lieferantenlisten anbieten. Suchen Sie nach Lieferanten mit positiven Bewertungen und einer starken Erfolgsbilanz in der Kfz-Teileindustrie. Auch die Teilnahme an Fachmessen und branchenspezifischen Foren kann Aufschluss über seriöse Hersteller geben. Es ist wichtig, Muster anzufordern oder Qualitätsprüfungen durchzuführen, um sicherzustellen, dass die Produkte Ihren Spezifikationen entsprechen, bevor Sie einen Großeinkauf tätigen. -

Wie hoch sind die Mindestbestellmengen (MOQ) für Starterteile?

Die Mindestbestellmengen können von Anbieter zu Anbieter sehr unterschiedlich sein. Einige Hersteller verlangen Mindestbestellmengen von nur 10 Stück, während andere die Schwelle bei 100 oder mehr Stück ansetzen, insbesondere bei kundenspezifischen Teilen. Es ist wichtig, die Mindestbestellmengen bei den ersten Verhandlungen zu klären und zu prüfen, ob sie mit Ihren geschäftlichen Anforderungen übereinstimmen. Verhandlungen mit Lieferanten können manchmal zu günstigeren Bedingungen führen, insbesondere bei Erstbestellungen. -

Mit welchen Zahlungsbedingungen muss ich rechnen, wenn ich Vorspeisen international beschaffe?

Die Zahlungsbedingungen können je nach Lieferant und Art der Transaktion sehr unterschiedlich sein. Zu den üblichen Bedingungen gehören Vorauszahlung, Netto 30 oder bei größeren Aufträgen sogar Akkreditive. Bei der Beschaffung von Vorspeisen von internationalen Lieferanten ist es wichtig, die Zahlungsbedingungen im Voraus zu besprechen, um Missverständnisse zu vermeiden. Ziehen Sie sichere Zahlungsmethoden und Treuhanddienste in Betracht, um Ihre Investitionen zu schützen, insbesondere bei neuen Lieferanten. -

Wie kann ich die Qualitätssicherung (QA) für Starterteile gewährleisten?

Legen Sie klare Spezifikationen und Normen fest, denen die Produkte entsprechen müssen, um die Qualität von Ersatzteilen sicherzustellen. Fordern Sie Qualitätszertifikate und Konformitätsunterlagen von den Lieferanten an. Führen Sie regelmäßige Inspektionen und Tests der Teile bei Erhalt und vor der Auslieferung durch. Der Aufbau einer engen Beziehung zu Ihren Lieferanten kann auch eine bessere Kommunikation in Bezug auf die Qualitätserwartungen und alle auftretenden Probleme erleichtern. -

Welche logistischen Aspekte sollte ich bei der Einfuhr von Vorspeisen beachten?

Berücksichtigen Sie beim Import von Vorspeisen Faktoren wie Versandmethoden, Zollbestimmungen und Vorlaufzeiten. Es ist wichtig, mit Logistikanbietern zusammenzuarbeiten, die Erfahrung im Umgang mit Kfz-Teilen haben, um eine rechtzeitige und sichere Lieferung zu gewährleisten. Machen Sie sich mit den in Ihrer Region geltenden Einfuhrzöllen und -tarifen vertraut, um unerwartete Kosten zu vermeiden. Darüber hinaus kann eine offene Kommunikation mit Ihren Lieferanten bezüglich der Versandpläne dazu beitragen, Verzögerungen zu vermeiden und einen reibungsloseren Importprozess zu gewährleisten.

Top 6 Wie viel kostet es, einen Anlasser im Auto zu installieren Hersteller & Lieferanten Liste

1. Austausch des Anlassers - Kostenübersicht

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Austausch des Anlassers, Arbeitsaufwand, Diagnose, Teilepreis um $220, Preisaufschlag, Preise variieren je nach Standort und Dienstleister.

2. Facebook – Autoreparaturkosten

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Kosten für die Fahrt zur Werkstatt und den Austausch des Anlassers

3. AAA - Anleitung zum Austausch des Anlassers

Domäne: aaa.com

Registriert: 1990 (35 Jahre)

Einleitung: Durchschnittliche Kosten für den Austausch eines Anlassers: $700 - $1.200; Ersatzteilkosten: unter $100 bis über $400; Arbeitskosten: $100 - $250 pro Stunde; Arten von Anlassern: Getriebeuntersetzung (effizienter, teurer) und Direktantrieb (weniger effizient, billiger); Häufige Symptome von Anlasserproblemen: langsames Anlassen, Auto springt nicht an, Klick- oder Schleifgeräusche, Anlasser läuft nach dem Anlassen des Motors, Rauch aus dem Motor,...

4. CarTalk - Kosten für den Austausch des Anlassers

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: Kosten für den Austausch eines Anlassers: $600 bis $900 für normale Fahrzeuge; $900 bis $1.400 für Luxusmodelle. Zu den Symptomen eines defekten Anlassers gehören Klickgeräusche, Quietschen und intermittierende Funktion. Anlasser können neu, wiederaufbereitet oder repariert sein, wobei wiederaufbereitete Anlasser üblich sind. Moderne Fahrzeuge mit Stopp-Start-Systemen verfügen über überarbeitete Anlasser, die robust sind und nicht zu einem vorzeitigen Ausfall neigen...

5. Letzte Chance Autoreparaturen - Kosten für den Austausch des Anlassers

Domäne: letztechanceautoreparaturen.com

Registriert: 2009 (16 Jahre)

Einleitung: Kosten für den Austausch des Anlassers: Sparanlasser: $75 - $200, OEM-Anlasser: $150 - $400, Hochleistungsanlasser: $300 - $1000+. Arbeitskosten: Austausch von Basisanlassern für Fahrzeuge: $100 - $250, Komplexe Installationen: $300 - $600+. Kostenbeeinflussende Faktoren: Fahrzeugtyp und -modell, neue vs. überholte Anlasser, zusätzliche Reparaturen (Batterie, Verkabelung, Schwungrad). DIY-Kosten: Nur Teile: $100 - $400, Zeitaufwand...

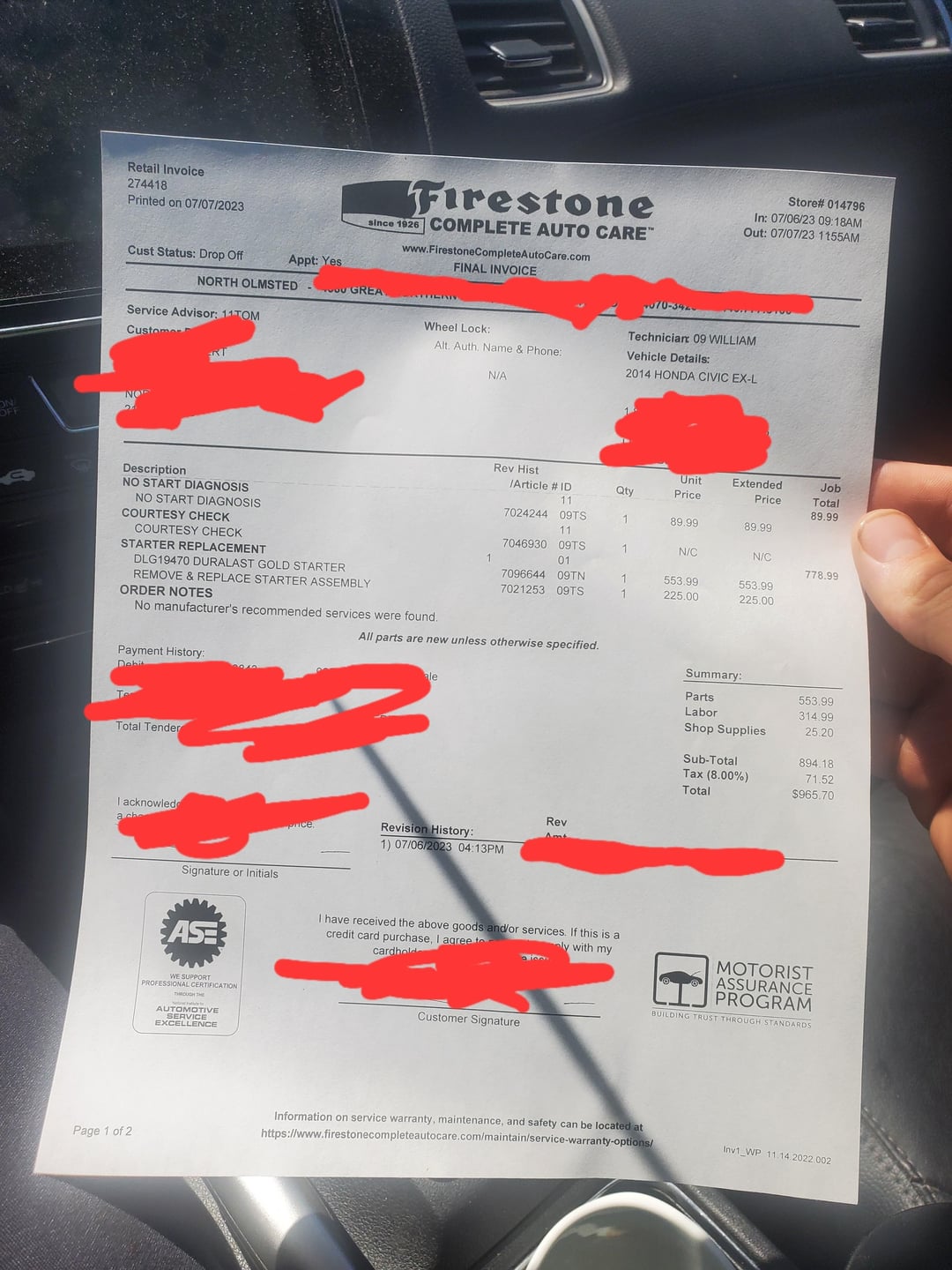

6. CarBuzz - Kosten für den Austausch des Anlassers

Domäne: carbuzz.de

Registriert: 2003 (22 Jahre)

Einleitung: Die Kosten für den Austausch des Anlassers liegen im Durchschnitt zwischen $450 und $600, wobei für bestimmte Modelle wie den Toyota Tundra (2000-2005) aufgrund des arbeitsintensiven Einbaus Kosten zwischen $650 und $900 anfallen. Die Kosten für den Austausch des Honda Civic werden auf zwischen $490 und $760 geschätzt. Zu den Faktoren, die sich auf die Kosten auswirken, gehören die Arbeitszeit (1,5 bis 2,5 Stunden für die meisten Anlasser, bis zu vier Stunden für im Tal montierte Anlasser) und der Preis.

Strategische Beschaffung Schlussfolgerung und Ausblick für den Einbau eines Anlassers im Auto

Zusammenfassend lässt sich sagen, dass die Kosten für den Einbau eines Starters in ein Fahrzeug je nach Fahrzeugmarke, Modell und Komplexität des Einbaus stark variieren können. Für B2B-Einkäufer ist eine strategische Beschaffung entscheidend. Durch das Verständnis der beteiligten Komponenten und der typischen Preisspannen - von $50 für Teile bis zu über $1.100 für umfassende Dienstleistungen - können Einkäufer fundierte Entscheidungen treffen, die ihre Betriebsbudgets optimieren.

Darüber hinaus kann das Erkennen der Bedeutung von Diagnosen vor dem Austausch unnötige Ausgaben verhindern und sicherstellen, dass Beschaffungsentscheidungen sowohl kostengünstig als auch effizient sind. Die Zusammenarbeit mit vertrauenswürdigen Lieferanten, die hochwertige Teile und zuverlässigen Service bieten, kann die Betriebssicherheit und die Kundenzufriedenheit verbessern.

Internationale B2B-Einkäufer aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa sollten dieses Wissen in ihre Einkaufsstrategien einfließen lassen. Indem sie bei der Beschaffung von Starterkomponenten und Dienstleistungen auf Qualität und Kosteneffizienz setzen, können sich Unternehmen auf ihren jeweiligen Märkten wettbewerbsfähig positionieren. Setzen Sie sich mit lokalen Zulieferern in Verbindung und suchen Sie nach Partnerschaften, die Ihren betrieblichen Anforderungen entsprechen, um nachhaltiges Wachstum und Effizienz in Ihrem Kfz-Service zu gewährleisten.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.