Einführung: Auf dem globalen Markt navigieren – Wie viel kostet es, einen Anlasser auszutauschen?

In today’s competitive automotive market, understanding how much it costs to change a starter is crucial for B2B buyers seeking reliable solutions for their fleet or repair services. Whether operating in Africa, South America, the Middle East, or Europe, sourcing quality starters and services at competitive prices can pose significant challenges. This guide aims to demystify the costs associated with starter replacements, offering a comprehensive breakdown that includes types of starters, applications, and factors influencing pricing.

We delve into essential considerations such as the differences between new and remanufactured starters, labor costs, and the implications of vehicle type on pricing. Additionally, this guide provides insights into supplier vetting processes, ensuring that international buyers can confidently engage with trustworthy vendors. By equipping decision-makers with the knowledge to navigate the complexities of starter replacements, we empower them to make informed purchasing decisions that enhance operational efficiency and minimize downtime.

With an authoritative and solution-oriented approach, this guide is tailored to meet the needs of global B2B buyers, helping them to not only understand the financial implications but also to identify quality suppliers that align with their business goals. As the automotive landscape continues to evolve, staying informed is key to maintaining a competitive edge.

Inhaltsverzeichnis

- Top 5 How Much Does It Cost To Change A Starter Manufacturers & Suppliers List

- Einführung: Auf dem globalen Markt navigieren – Wie viel kostet es, einen Anlasser auszutauschen?

- Verstehen, wie viel kostet es, einen Anlasser zu wechseln Typen und Varianten

- Wichtige industrielle Anwendungen Wie viel kostet es, einen Anlasser auszutauschen?

- 3 häufige Probleme von Nutzern zum Thema ‘Wie viel kostet der Austausch eines Anlassers?’ und ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für die Kosten einer Starteraustausch

- Ein genauer Blick: Fertigungsprozesse und Qualitätssicherung – Wie viel kostet es, einen Anlasser auszutauschen?

- Praktischer Leitfaden zur Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet es, einen Anlasser auszutauschen?’

- Umfassende Kosten- und Preisanalyse für die Kosten für den Austausch eines Anlassers Beschaffung

- Alternativenanalyse: Vergleich der Kosten für den Austausch eines Anlassers mit anderen Lösungen

- Wichtige technische Eigenschaften und Fachbegriffe für die Kosten für den Austausch eines Anlassers

- Navigieren durch Marktdynamiken und Beschaffungstrends im Sektor „Wie viel kostet es, einen Anlasser auszutauschen?“

- Häufig gestellte Fragen (FAQs) für B2B-Käufer: Wie viel kostet es, einen Anlasser auszutauschen?

- Strategische Beschaffung Fazit und Ausblick Wie viel kostet es, einen Anlasser auszutauschen?

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Verstehen, wie viel kostet es, einen Anlasser zu wechseln Typen und Varianten

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Economy-Starter | Aftermarket parts, budget-friendly, lower lifespan | Small fleets, cost-sensitive buyers | Vorteile: Kostengünstig; Nachteile: Shorter lifespan. |

| OEM (Original Equipment) Starters | Manufacturer-approved, higher quality, reliable performance | Dealerships, premium vehicle service | Vorteile: Guaranteed fit; Nachteile: Höhere Kosten. |

| Leistungsstarke Anlasser | Specialty parts for performance vehicles, enhanced durability | Rennteams, Leistungssportgeschäfte | Vorteile: Überlegene Leistung; Nachteile: Expensive. |

| Wiederaufbereitete Anlasser | Rebuilt from used parts, lower cost, variable quality | Budget-conscious fleets | Vorteile: Kosteneinsparungen; Nachteile: Potential reliability issues. |

| DIY Starter-Ersatzkits | Parts-only kits for self-installation, requires expertise | Independent garages, DIY enthusiasts | Vorteile: Lower labor costs; Nachteile: Risk of improper installation. |

Was sind Economy-Starter und wann sollten B2B-Einkäufer sie in Betracht ziehen?

Economy starters are aftermarket components designed for cost-sensitive applications. These starters often come at a lower price point, making them attractive for businesses with tight budgets, such as small fleets or repair shops focused on affordability. While they can save money upfront, B2B buyers should be mindful of their shorter lifespan and potential reliability issues, which may lead to increased long-term costs.

Why Are OEM Starters Preferred by Dealerships and Premium Vehicle Services?

OEM starters are manufactured by the original vehicle makers, ensuring compatibility and reliability. They are often favored by dealerships and premium vehicle services due to their high quality and warranty coverage. B2B buyers in this segment benefit from the assurance of using parts that meet the manufacturer’s specifications, although they come at a higher price. This investment can be justified by the reduced risk of failures and the associated costs of warranty claims.

How Do High-Performance Starters Cater to Specialized Markets?

High-performance starters are designed for racing and performance vehicles, offering enhanced durability and efficiency. They are suitable for businesses involved in motorsports or high-performance automotive services. While these starters provide superior performance, they come with a premium price tag. B2B buyers must weigh the benefits of improved performance against the higher costs, ensuring they align with their business objectives.

What Should Buyers Know About Remanufactured Starters?

Remanufactured starters are rebuilt from used parts and offered at a lower price point than new components. They are suitable for budget-conscious fleets that require a cost-effective solution without the need for top-tier performance. However, the quality can vary significantly, posing a risk of reliability issues. B2B buyers should conduct thorough research and select reputable suppliers to mitigate these risks and ensure acceptable performance levels.

Are DIY Starter Replacement Kits a Viable Option for Independent Garages?

DIY starter replacement kits provide a cost-effective solution for independent garages and DIY enthusiasts. These kits typically include all necessary components for self-installation, allowing businesses to save on labor costs. However, buyers should consider the technical expertise required to install these kits properly. An improper installation can lead to electrical issues and further repair costs, making it crucial for B2B buyers to assess their capabilities before opting for this route.

Wichtige industrielle Anwendungen Wie viel kostet es, einen Anlasser auszutauschen?

| Branche/Sektor | Spezifische Anwendung: Wie viel kostet es, einen Anlasser auszutauschen? | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Understanding starter replacement costs for service pricing | Enables competitive pricing, attracting more customers | Need for reliable parts suppliers with warranty options |

| Transport & Logistik | Fleet management and maintenance budgeting for starter replacements | Verringert Ausfallzeiten und gewährleistet betriebliche Effizienz | Bulk purchasing agreements to lower costs |

| Landwirtschaftliche Maschinen | Cost analysis for starter replacement in farm equipment | Enhances equipment reliability, minimizing harvest delays | Availability of OEM vs. aftermarket parts |

| Bergbauarbeiten | Evaluating costs for heavy machinery starter replacements | Maintains productivity, preventing operational interruptions | Consideration of rugged parts suitable for harsh conditions |

| Baumaschinen | Budgeting for starter replacements in construction machinery | Ensures timely project completion, avoiding costly delays | Sourcing durable parts that comply with safety standards |

How Is ‘How Much Does It Cost to Change a Starter’ Relevant in the Automotive Repair Sector?

In the automotive repair industry, understanding the costs associated with starter replacements is critical for service providers. By accurately pricing these services, repair shops can remain competitive and transparent with customers. This knowledge helps in creating service packages that cater to different vehicle types, ensuring that clients receive tailored solutions. International buyers, especially those in regions like Africa and South America, must consider the availability of parts and the expertise of local mechanics to ensure quality service.

What Role Does Starter Replacement Cost Play in Transportation & Logistics?

For businesses in transportation and logistics, managing a fleet requires precise budgeting, particularly for maintenance costs like starter replacements. By understanding these costs, fleet managers can allocate resources effectively, minimizing vehicle downtime and ensuring timely deliveries. International buyers in regions with diverse terrains, such as the Middle East and Africa, should also evaluate the accessibility of parts and local labor costs to mitigate unexpected expenses and delays.

Why Is Cost Analysis Important for Agriculture Machinery?

In agriculture, machinery reliability is paramount, and understanding starter replacement costs is essential for farmers to maintain operational efficiency. A sudden failure can lead to significant delays during critical harvest periods. By evaluating the cost of starter replacements, agricultural businesses can plan for repairs and budget accordingly. Buyers in regions like South America need to consider local suppliers’ capabilities to provide timely parts and service, ensuring that their machinery remains functional throughout the planting and harvesting cycles.

How Does Starter Replacement Cost Affect Mining Operations?

In mining operations, the cost of changing starters in heavy machinery directly impacts productivity. Understanding these costs allows for better financial planning and minimizes the risk of equipment failure, which can halt operations and lead to substantial financial losses. For international buyers, particularly in remote areas of Africa or the Middle East, sourcing durable and reliable starter parts is crucial, as machinery often operates in harsh conditions, demanding high-quality components.

What Is the Importance of Starter Replacement Cost in Construction Equipment?

For the construction industry, budgeting for starter replacements in machinery is vital to avoid project delays. Understanding these costs helps construction companies manage their finances and ensure that equipment is operational when needed. International buyers must consider sourcing from suppliers who can provide durable parts that meet local safety and performance standards, ensuring compliance while minimizing downtime during critical project phases.

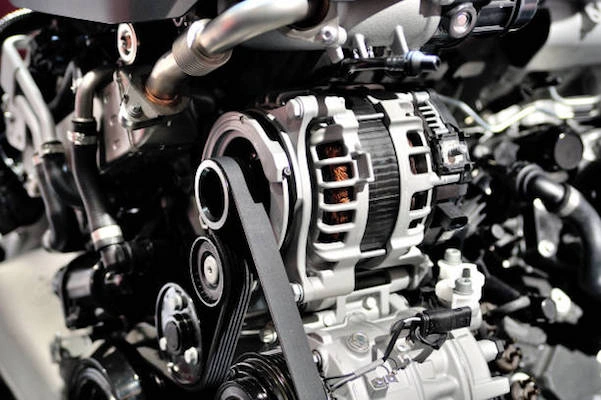

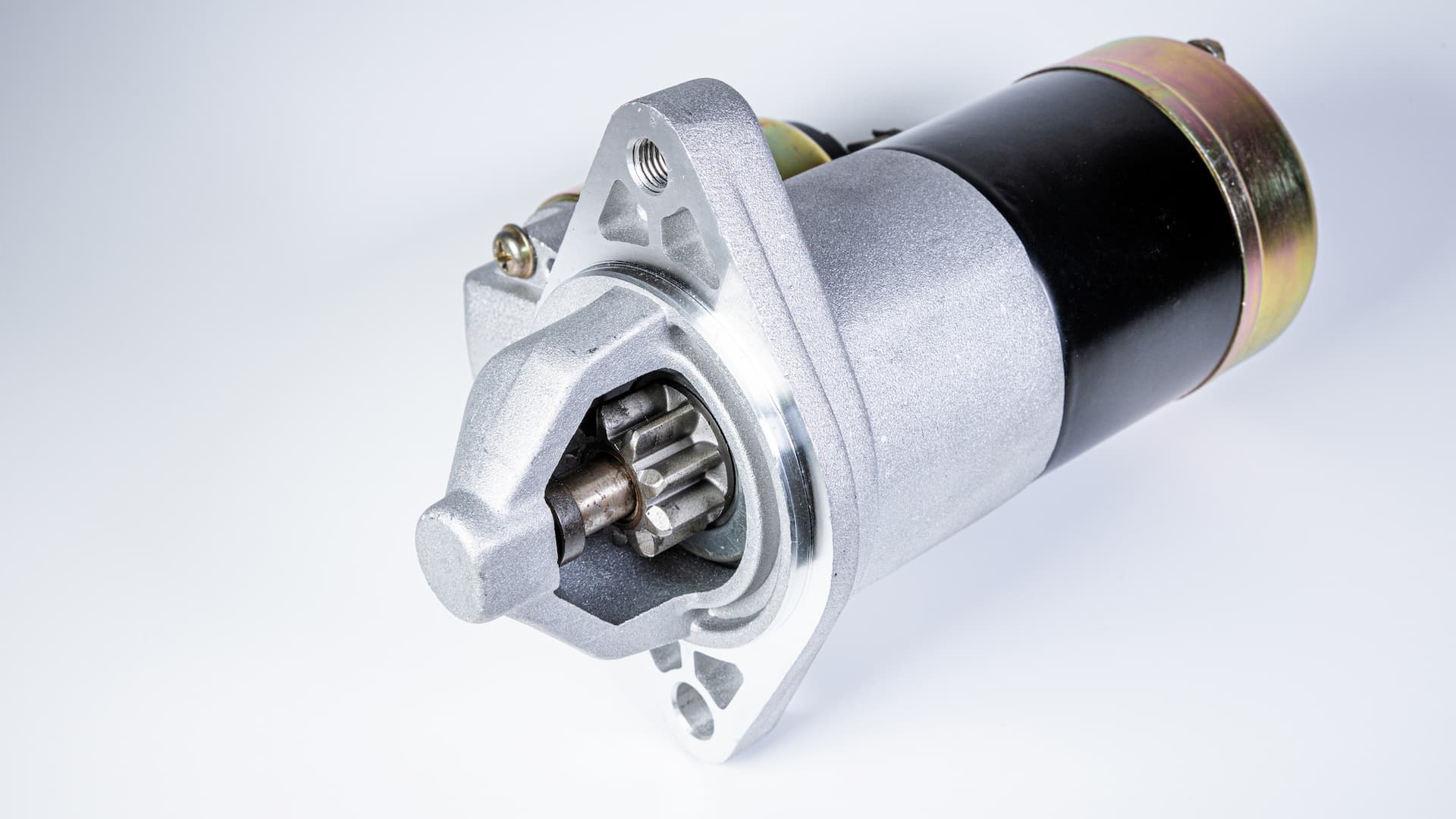

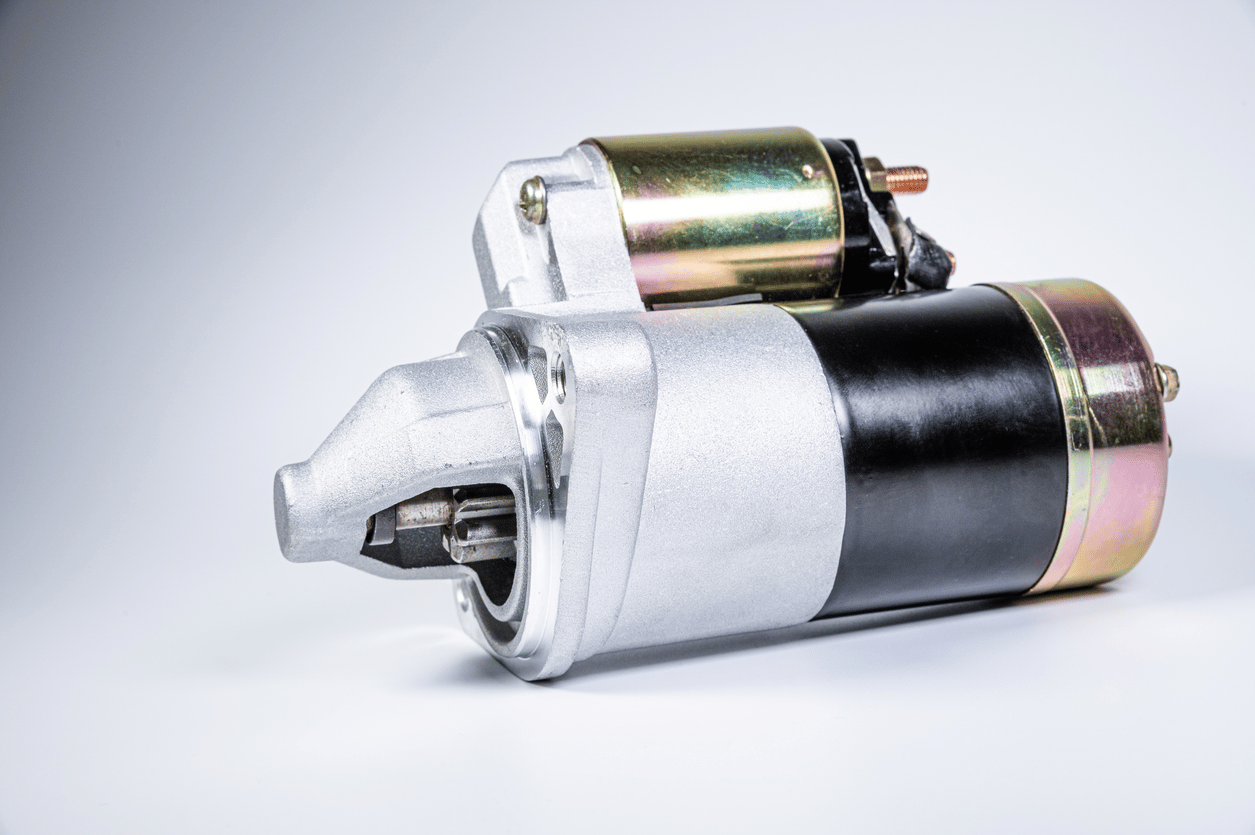

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

3 häufige Probleme von Nutzern zum Thema ‘Wie viel kostet der Austausch eines Anlassers?’ und ihre Lösungen

Scenario 1: Navigating Budget Constraints for Starter Replacement Costs

Das Problem: For many businesses operating fleets or managing multiple vehicles, budgeting for maintenance and repairs can be a significant challenge. A sudden need for starter replacement can strain financial resources, especially if the costs are not clearly understood upfront. Buyers may find themselves facing unexpected expenses, which could lead to delays in vehicle availability and operational inefficiencies. Additionally, the costs associated with labor, parts, and potential further repairs can vary widely, making it difficult to allocate the right budget without comprehensive information.

Die Lösung: To effectively manage and predict costs associated with starter replacements, B2B buyers should conduct thorough market research before any repairs are needed. Start by gathering data on the average costs of starter motors based on vehicle types within your fleet. Use online resources, industry reports, and engage with multiple automotive service providers to get a range of quotes. Establish relationships with trusted mechanics who can offer transparent pricing and possibly even bulk discounts for fleet servicing. Additionally, consider investing in a preventive maintenance program that includes regular inspections, which can help identify starter issues before they escalate into costly replacements. This proactive approach not only aids in budgeting but also minimizes downtime by ensuring vehicles remain operational.

Scenario 2: Understanding the Quality of Replacement Starters

Das Problem: When faced with the need to replace a starter, buyers often grapple with the decision between OEM (Original Equipment Manufacturer) parts and aftermarket options. The challenge lies in understanding which choice provides the best value without compromising vehicle performance or longevity. Poor quality replacements can lead to frequent failures, resulting in additional costs and lost productivity. Buyers may feel overwhelmed by the variety of options and the potential long-term implications of their choice.

Die Lösung: To make an informed decision, B2B buyers should prioritize quality over immediate cost savings. Research the reputation of aftermarket brands against OEM parts by consulting industry reviews and performance ratings. Engage with suppliers who can provide performance guarantees or warranties on their products, ensuring that you are protected against premature failures. Consider the total cost of ownership rather than the initial purchase price; investing in a higher-quality starter could save money in the long run by reducing replacement frequency and maintenance costs. Furthermore, establishing a partnership with a reputable auto parts supplier can provide insights into which parts have proven reliability and performance, streamlining the procurement process.

Scenario 3: Balancing DIY Repairs with Professional Services

Das Problem: Many businesses attempt to save costs by handling starter replacements internally, especially when they have in-house maintenance teams. However, without the proper expertise and tools, this approach can lead to improper installations, which may cause further damage to the vehicle’s electrical system. The challenge becomes clear: how to balance the desire to save on labor costs with the need for high-quality, reliable repairs that ensure vehicle safety and performance.

Die Lösung: To strike the right balance, B2B buyers should assess the skills and experience of their maintenance team. If they have the necessary expertise and tools, then sourcing the correct starter components and conducting the installation in-house can be a cost-effective approach. However, if there are any doubts about their capability, it is wise to partner with professional automotive services. Establish contracts with local auto repair shops that offer competitive rates for fleet maintenance and can provide warranties on their work. Furthermore, investing in training for your in-house team can enhance their skills and improve the quality of work while still allowing for some DIY repairs. This dual approach not only helps in managing costs but also ensures that repairs are executed to a high standard, maintaining the fleet’s reliability and performance.

Strategischer Leitfaden zur Materialauswahl für die Kosten einer Starteraustausch

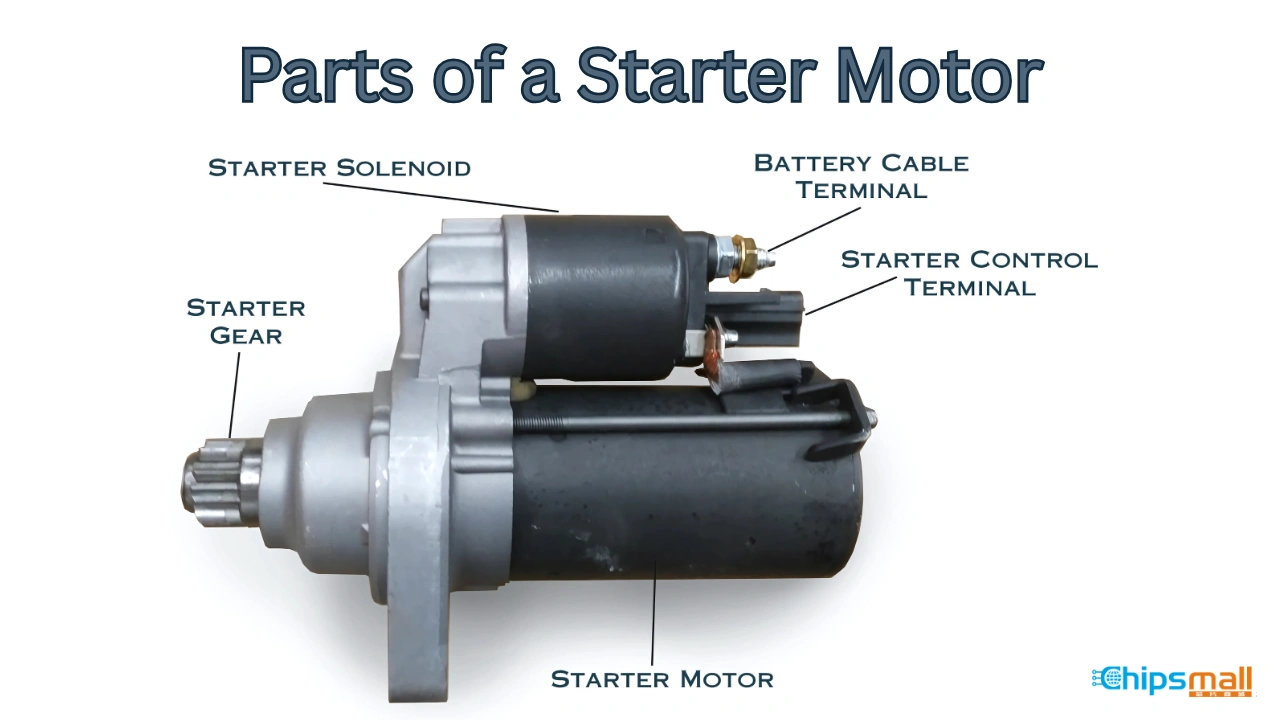

Welche Materialien werden üblicherweise für den Austausch von Anlassern verwendet?

When considering the cost and process of changing a starter, the materials used in the construction of the starter motor and its components play a crucial role. Here, we analyze four common materials: aluminum, copper, steel, and plastic, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Impact Starter Replacement Costs?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. In starter motors, aluminum is often used for housings and end plates.

Vorteile: Aluminum’s lightweight nature reduces overall vehicle weight, contributing to better fuel efficiency. It also resists corrosion, which is essential for automotive applications exposed to various environmental conditions.

Nachteile: While aluminum is durable, it can be more expensive than steel and may not withstand high-impact stresses as effectively. Its manufacturing process can also be more complex, leading to higher production costs.

Auswirkungen auf die Anwendung: Aluminum starters are particularly beneficial in regions with high humidity or saline environments, such as coastal areas in Africa or South America, where corrosion resistance is paramount.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Überlegungen für internationale Käufer: Buyers should ensure compliance with international standards such as ASTM for material quality. The preference for aluminum may vary based on local manufacturing capabilities and cost considerations.

Welche Rolle spielt Kupfer in Anlasser-Motoren?

Kupfer wird aufgrund seiner hervorragenden elektrischen Leitfähigkeit vor allem in elektrischen Bauteilen von Anlassern, wie Wicklungen und Anschlüssen, verwendet.

Vorteile: Copper’s high conductivity ensures efficient power transfer, essential for the reliable operation of the starter motor. It also has good thermal conductivity, which helps dissipate heat during operation.

Nachteile: Copper is relatively expensive compared to aluminum and steel, which can increase the overall cost of starter replacement. Additionally, it is susceptible to corrosion if not properly insulated or protected.

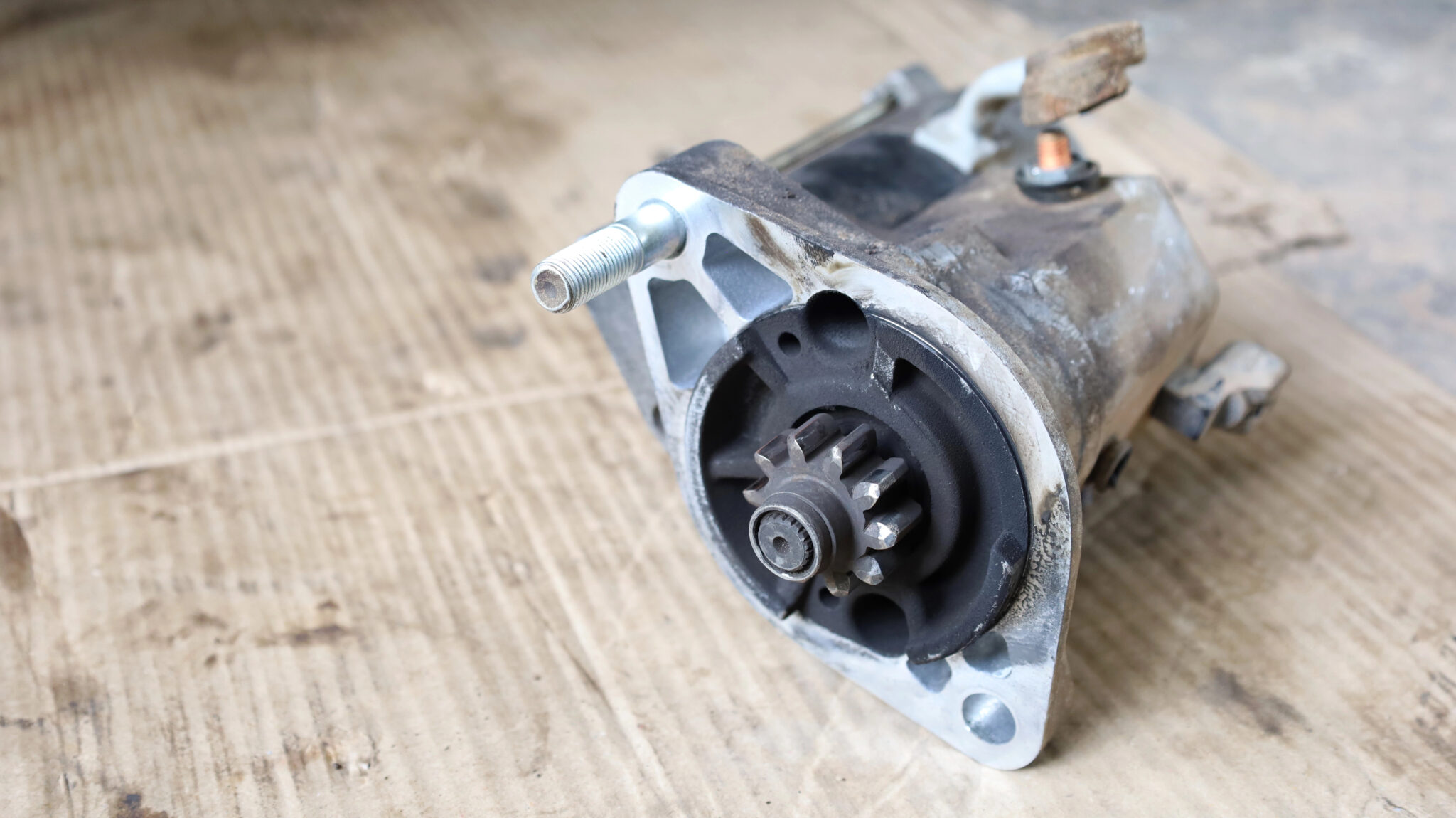

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Auswirkungen auf die Anwendung: The effectiveness of copper in electrical applications makes it vital for starters used in high-performance vehicles, which are common in Europe and the Middle East.

Überlegungen für internationale Käufer: Buyers should be aware of the copper market fluctuations and ensure compliance with local electrical standards, which may dictate specific conductivity requirements.

How Does Steel Affect Starter Replacement Costs?

Steel is often used for components that require high strength and durability, such as the starter motor’s casing and internal gears.

Vorteile: Steel is known for its strength and durability, making it suitable for heavy-duty applications. It is also cost-effective compared to aluminum and copper, which can lead to lower overall replacement costs.

Nachteile: Steel is heavier than aluminum, which may negatively impact vehicle weight and fuel efficiency. It is also prone to rust and corrosion if not properly treated or coated.

Auswirkungen auf die Anwendung: Steel starters are ideal for trucks and SUVs, which are prevalent in regions like Africa and South America where rugged use is common.

Überlegungen für internationale Käufer: Buyers should consider the availability of corrosion-resistant coatings to enhance steel’s performance in humid or coastal environments. Compliance with standards such as DIN for mechanical properties is also essential.

What is the Role of Plastic in Starter Components?

Plastic is commonly used in non-structural components of starters, such as covers and insulation parts.

Vorteile: Plastic is lightweight and can be molded into complex shapes, allowing for design flexibility. It is also resistant to corrosion and can be produced at a lower cost than metals.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Nachteile: Plastic components may not withstand high temperatures or mechanical stresses as effectively as metal counterparts. They can also degrade over time due to exposure to heat and chemicals.

Auswirkungen auf die Anwendung: Plastic is suitable for applications where weight reduction is critical, such as in compact cars, which are increasingly popular in urban areas of Europe and Asia.

Überlegungen für internationale Käufer: Buyers should ensure that plastics meet specific thermal and chemical resistance standards, particularly in high-temperature environments. Compliance with JIS standards may be relevant for buyers in Asia.

Übersichtstabelle zur Materialauswahl für den Austausch des Starters

| Material | Typischer Anwendungsfall für die Kosten einer Starteraustausch | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Starter motor housings and end plates | Leicht und korrosionsbeständig | More expensive and less impact-resistant | Mittel |

| Kupfer | Elektrische Wicklungen und Anschlüsse | Hervorragende elektrische Leitfähigkeit | Hohe Kosten und Korrosionsanfälligkeit | Hoch |

| Stahl | Gehäuse und interne Zahnräder | Stark und langlebig | Schwerer und anfällig für Rost | Niedrig |

| Kunststoff | Nicht-strukturelle Komponenten wie Abdeckungen | Leicht und kostengünstig | Weniger haltbar unter hoher Belastung | Niedrig |

This analysis provides insights into the materials commonly used in starter replacements, helping international B2B buyers make informed decisions based on performance, cost, and regional considerations.

Ein genauer Blick: Fertigungsprozesse und Qualitätssicherung – Wie viel kostet es, einen Anlasser auszutauschen?

Was sind die wichtigsten Herstellungsverfahren für Startermotoren?

When it comes to manufacturing starter motors, several stages are involved, each critical to ensuring quality and performance. Understanding these processes can help B2B buyers identify reliable suppliers and make informed purchasing decisions.

Was sind die wichtigsten Schritte bei der Herstellung von Anlassern?

-

Materialvorbereitung

The first stage involves sourcing and preparing the raw materials, typically metals like steel and aluminum, which are essential for producing starter motors. Manufacturers often prioritize high-grade materials to enhance durability and performance. This stage includes cutting, shaping, and treating materials to meet specific design specifications. -

Formung

The forming process involves shaping the prepared materials into components. Techniques such as stamping, casting, and machining are commonly used. For instance, stamped parts are created using high-precision dies, while cast components may be produced through sand casting or die casting methods. Each technique has implications for cost and quality, making it crucial for buyers to understand the methods employed by their suppliers. -

Montage

In this stage, individual components are assembled into a complete starter motor. This often requires precision engineering to ensure that parts fit together correctly. Automated assembly lines are increasingly common, enhancing efficiency and consistency. Manual assembly may still be employed for complex or high-end models, where skilled labor is necessary to ensure quality. -

Endbearbeitung

The finishing stage involves applying coatings and treatments to enhance the appearance and durability of the starter motor. Processes may include painting, anodizing, or applying protective seals to prevent corrosion. This stage is vital for ensuring that the product can withstand various environmental conditions, particularly for buyers operating in challenging climates.

Wie wird die Qualitätssicherung bei der Herstellung von Anlassern umgesetzt?

Quality assurance is critical in ensuring that starter motors meet the necessary performance and safety standards. B2B buyers must be aware of the quality control measures suppliers implement to ensure product reliability.

What Are the Relevant International Standards for Starter Motor Quality?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards indicates that a manufacturer has established processes to ensure consistent quality and continuous improvement.

Additionally, industry-specific certifications may apply. For example, CE marking is essential for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Buyers in the automotive sector may also consider the API (American Petroleum Institute) standards for parts used in combustion engines.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Was sind die wichtigsten Qualitätskontrollpunkte in der Produktion?

Die Qualitätskontrolle (QC) umfasst mehrere Kontrollpunkte während des gesamten Herstellungsprozesses:

-

Eingangsqualitätskontrolle (IQC)

At this stage, raw materials are inspected upon arrival to ensure they meet specified standards. This includes checking material properties, dimensions, and compliance with quality certifications. -

In-Process-Qualitätskontrolle (IPQC)

During the manufacturing process, IPQC involves monitoring production to detect any deviations from quality standards. Techniques such as statistical process control (SPC) are often employed to analyze data and identify trends. -

Endkontrolle (FQC)

Once the starter motors are assembled, FQC tests are conducted to verify that the final products meet performance specifications. Common tests include electrical testing, durability assessments, and operational checks to ensure functionality.

Wie können B2B-Einkäufer die Qualitätskontrollmaßnahmen von Lieferanten überprüfen?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies:

-

Lieferantenaudits

Conducting on-site audits allows buyers to assess manufacturing practices, quality control measures, and compliance with international standards. This firsthand evaluation helps establish trust and ensures that suppliers meet the required quality benchmarks. -

Qualitätsberichte

Requesting detailed quality reports from suppliers can provide insights into their QC processes. These reports should include information on testing methodologies, results, and any corrective actions taken in response to identified issues. -

Inspektionen durch Dritte

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality control processes. These inspections often cover IQC, IPQC, and FQC stages, ensuring that products meet the required specifications before shipment.

What Are the Common Testing Methods for Starter Motors?

Testing is a crucial aspect of quality assurance in starter motor manufacturing. Various methods are employed to ensure that each unit performs as expected:

-

Elektrische Prüfung

This involves checking the starter motor’s electrical components to ensure proper connectivity and functionality. Tests may include measuring resistance, voltage drop, and current draw to ensure compliance with specifications. -

Haltbarkeitsprüfung

Starter motors undergo rigorous durability testing to simulate real-world conditions. This may include thermal cycling, vibration tests, and endurance runs to assess how well the motor performs over time. -

Funktionelle Prüfung

Functional tests are conducted to confirm that the starter motor operates correctly within the vehicle’s ignition system. This includes testing cranking speed, engagement, and disengagement of the starter gear.

How Do Quality Control Nuances Affect International B2B Buyers?

International B2B buyers must be aware of the nuances in quality control that may affect their purchasing decisions:

-

Kulturelle Unterschiede

Quality expectations and manufacturing practices can vary significantly between regions. Buyers should consider local standards and practices when evaluating suppliers from different countries. -

Einhaltung gesetzlicher Vorschriften

Different countries have varying regulations regarding automotive components. Buyers should ensure that suppliers are compliant with the regulations applicable to their specific markets to avoid legal issues. -

Logistische Überlegungen

The logistics of shipping and handling can impact product quality. Buyers should discuss packaging and transportation methods with suppliers to ensure that products arrive in optimal condition.

Schlussfolgerung

Understanding the manufacturing processes and quality assurance measures for starter motors is essential for B2B buyers. By familiarizing themselves with the stages of production, international standards, quality control checkpoints, and testing methods, buyers can make informed decisions and select suppliers that meet their quality expectations. By prioritizing these factors, businesses can ensure that they receive reliable products that enhance their operations and customer satisfaction.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Praktischer Leitfaden zur Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet es, einen Anlasser auszutauschen?’

To assist B2B buyers in navigating the complexities of sourcing starter replacements, this checklist outlines essential steps to ensure informed decisions regarding costs and suppliers. Understanding the factors influencing starter replacement costs can significantly impact budgeting and procurement strategies.

Schritt 1: Assess Your Vehicle Requirements

Identify the specific make and model of the vehicles for which you need starter replacements. This is vital as different vehicles require different types of starters, which can vary significantly in price and availability. Additionally, consider the typical failure rates of starters in your fleet to anticipate future needs.

Schritt 2: Determine Your Budget

Establish a clear budget for starter replacements, considering both parts and labor costs. The price can range widely based on factors like the vehicle type and whether you choose new or remanufactured starters. By setting a budget, you can narrow down your options and avoid overspending.

Schritt 3: Recherche von Lieferantenoptionen

Conduct thorough research on potential suppliers for starter motors. Look for suppliers with a good reputation in the industry and those who specialize in the types of starters you need. Evaluate their experience, customer reviews, and any partnerships with manufacturers to ensure reliability.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Schritt 4: Request Quotes and Compare Prices

Reach out to multiple suppliers to obtain quotes for starter replacements. Ensure that the quotes include detailed breakdowns of part costs, labor charges, and any additional fees. Comparing these quotes will help you identify the most cost-effective solutions while ensuring quality standards are met.

Schritt 5: Verify Supplier Certifications and Warranty Policies

Before finalizing a supplier, verify their certifications and warranty policies on parts and labor. Certifications can indicate compliance with industry standards, while a solid warranty can protect your investment in case of defects or failures. This step is crucial for mitigating risks associated with poor-quality parts.

Schritt 6: Evaluate the Availability of Parts

Ensure that the suppliers you are considering have a reliable supply chain for the starter motors you need. Delays in parts availability can lead to increased downtime for vehicles, affecting overall operational efficiency. Confirm lead times and stock levels for the specific starters required for your fleet.

Schritt 7: Consider Professional Installation Services

Evaluate whether you will be handling installation in-house or if you need to outsource this task. Professional installation can often save time and prevent costly mistakes, especially for complex vehicles. If outsourcing, ensure that the service provider is qualified and experienced in handling your specific vehicle types.

By following these steps, B2B buyers can make well-informed decisions regarding the procurement of starter replacements, ensuring that they secure quality parts at competitive prices while maintaining operational efficiency.

Umfassende Kosten- und Preisanalyse für die Kosten für den Austausch eines Anlassers Beschaffung

What Are the Key Cost Components Involved in Changing a Starter?

When evaluating the costs associated with changing a starter, it’s essential to break down the various cost components that contribute to the overall expense. These components include:

-

Materialien: The primary material cost is the starter motor itself, which can vary significantly based on type and quality. Economy starters may range from $75 to $200, while OEM options can go from $150 to $400. High-performance or specialty starters could exceed $1,000.

-

Arbeit: Labor costs depend on the complexity of the installation. Basic vehicles may incur labor charges between $100 and $250, while luxury or performance cars could see costs ranging from $300 to $600 or more. This variance is largely due to the accessibility of the starter and the time required for the installation.

-

Fertigungsgemeinkosten: This includes expenses related to the production of the starter, such as factory costs, administrative expenses, and other indirect costs. Depending on the manufacturer, these costs can significantly impact the final price.

-

Werkzeugbau und Qualitätskontrolle (QC): Specialized tools may be required for installation, particularly for complex vehicles. Additionally, quality control measures ensure that the starter meets necessary standards, contributing to the overall cost.

-

Logistik: Shipping and handling costs can vary based on the location of the supplier and the delivery method. International shipments may incur additional fees, impacting the total cost for buyers in regions like Africa or South America.

-

Marge: Suppliers typically include a markup to cover their operating costs and profit margin, which can vary widely depending on market conditions and competition.

What Factors Influence the Price of Starter Replacement?

Numerous factors can influence the price of starter replacement, particularly for B2B buyers looking to source parts internationally:

-

Volumen und Mindestbestellmenge (MOQ): Purchasing in bulk can often lead to significant discounts. Suppliers may offer better pricing for higher volumes, making it essential for businesses to assess their needs and negotiate accordingly.

-

Spezifikationen und Anpassung: Custom starters tailored to specific vehicle models may come at a premium. Buyers should weigh the necessity of customization against budget constraints.

-

Materialien und Qualitätszertifizierungen: The choice of materials directly impacts durability and performance. Higher-quality starters, often accompanied by certifications, may cost more but can offer greater longevity and reliability.

-

Lieferantenfaktoren: The reputation and location of the supplier can influence pricing. Local suppliers may have lower logistics costs, while international suppliers might offer more competitive pricing but could involve longer shipping times and additional tariffs.

-

Incoterms: Understanding the terms of shipping and delivery (such as FOB, CIF, etc.) is crucial for budgeting. These terms dictate who bears the costs and risks at various stages of transport, impacting the total cost of ownership.

What Are the Best Buyer Tips for Cost Efficiency?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, strategic purchasing can lead to substantial savings:

-

Preise aushandeln: Always engage in negotiations with suppliers. Discussing bulk purchasing or long-term contracts may yield favorable terms.

-

Berücksichtigen Sie die Gesamtbetriebskosten (Total Cost of Ownership, TCO): Assess not just the upfront costs but also long-term expenses related to maintenance, warranty, and potential replacements. A higher initial investment in quality parts may lead to lower overall costs over time.

-

Research Local vs. International Suppliers: While international suppliers may offer lower prices, consider local options that could reduce logistics costs and delivery times.

-

Bleiben Sie über Markttrends auf dem Laufenden: Keeping abreast of market conditions, material costs, and emerging technologies can provide leverage in negotiations and purchasing decisions.

Haftungsausschluss für indikative Preise

The price ranges provided are indicative and can fluctuate based on market dynamics, supplier terms, and specific vehicle requirements. It’s advisable for buyers to conduct thorough research and obtain multiple quotes to ensure the best pricing for their needs.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Alternativenanalyse: Vergleich der Kosten für den Austausch eines Anlassers mit anderen Lösungen

Exploring Alternatives to Changing a Starter: Cost and Performance Comparisons

When faced with a failing starter, B2B buyers often seek cost-effective solutions that ensure vehicle reliability. While changing a starter is a common approach, several alternatives may also address ignition issues effectively. Understanding these options can aid in making informed purchasing decisions, particularly in diverse international markets.

| Vergleichsaspekt | Wie viel kostet es, einen Anlasser auszutauschen? | Alternative 1: Austausch der Batterie | Alternative 2: Starter-Reparatur |

|---|---|---|---|

| Leistung | Essential for engine cranking; necessary if starter fails. | Improves starting power; critical if battery is weak. | Restores functionality at a lower cost if minor issues exist. |

| Kosten | $250 – $1,000+ (parts + labor) | $100 – $300 (parts + labor) | $50 – $200 (parts + labor) |

| Einfache Implementierung | Requires professional installation; may involve complex labor. | Generally straightforward; can be DIY or professional. | Can be complex depending on the issue; professional recommended. |

| Wartung | Requires no ongoing maintenance once replaced. | May require periodic checks; battery lifespan varies. | May need re-evaluation if symptoms recur; repairs might not last long. |

| Bester Anwendungsfall | Best for vehicles with confirmed starter failure. | Ideal for vehicles showing slow starts or electrical issues. | Suitable for minor starter issues or budget-conscious buyers. |

What Are the Advantages and Disadvantages of Battery Replacement?

Battery replacement is often a viable alternative when a vehicle shows signs of starting issues. A weak battery can mimic starter failure, leading to confusion. The average cost for a battery replacement ranges from $100 to $300, which is significantly lower than replacing a starter. Additionally, battery replacement can be performed by the owner or a professional, making it a flexible option. However, if the starter is the actual issue, replacing the battery will not resolve the underlying problem, leading to further costs down the line.

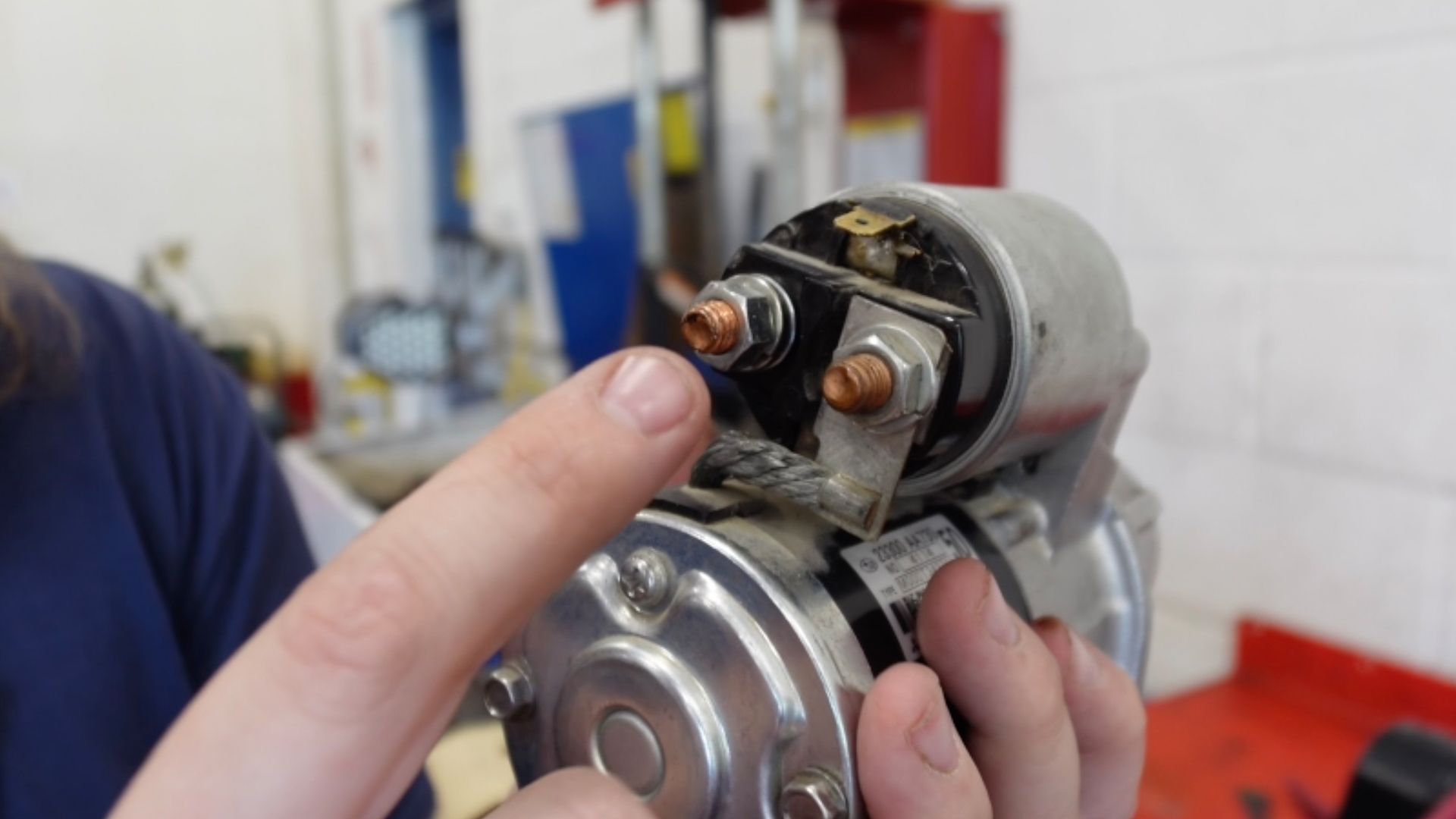

What Should Buyers Know About Starter Repair?

Starter repair involves diagnosing and fixing specific issues within the starter system, such as faulty wiring or solenoid problems. This option is generally less expensive, with costs ranging from $50 to $200, depending on the nature of the repair. It is particularly advantageous for budget-conscious buyers or those experiencing intermittent starting problems. However, repairs may not offer the same longevity as a full replacement, and recurring issues could arise, necessitating further investment.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Wie können B2B-Einkäufer die richtige Lösung für ihre Bedürfnisse auswählen?

When selecting between changing a starter and exploring alternatives, B2B buyers should consider several factors: the specific symptoms their vehicle is exhibiting, the overall condition of the vehicle, and budget constraints. If the vehicle consistently fails to start and diagnostics confirm starter issues, replacement is likely the best path. Conversely, if symptoms point to a weak battery or minor starter problems, exploring alternatives like battery replacement or starter repair can save costs while maintaining vehicle functionality. Ultimately, the decision should align with the buyer’s operational needs and long-term vehicle reliability goals.

Wichtige technische Eigenschaften und Fachbegriffe für die Kosten für den Austausch eines Anlassers

What Are the Key Technical Properties Influencing Starter Replacement Costs?

Understanding the technical properties of starter motors is essential for B2B buyers when evaluating costs and quality. Here are several critical specifications to consider:

-

Werkstoffgüte

The material grade of a starter motor affects its durability and performance. Common materials include high-carbon steel for the housing and copper for the windings. Higher-grade materials offer better resistance to wear and corrosion, which can lead to longer service life and lower total cost of ownership. For B2B buyers, investing in higher-grade materials may result in fewer replacements and reduced downtime. -

Drehmoment

Torque rating indicates the amount of rotational force a starter can provide to crank the engine. This specification varies by vehicle type; heavier vehicles require starters with higher torque ratings. For businesses managing fleets, understanding torque ratings ensures the right starter is selected, optimizing performance and reliability in diverse vehicle conditions. -

Spannungs-Kompatibilität

Most starter motors operate on either 12V or 24V systems, depending on the vehicle. Selecting the correct voltage is crucial for performance and safety. B2B buyers should ensure compatibility with existing vehicle systems to prevent damage and ensure effective operation, particularly in international markets where vehicle standards may vary. -

Stromaufnahme

The current draw indicates how much electrical power the starter consumes during operation. A starter with a high current draw may lead to quicker battery depletion, especially in cold weather. For B2B buyers, understanding current draw can influence decisions regarding battery specifications and overall vehicle efficiency. -

Lebensdauer

The expected service life of a starter motor can vary significantly based on usage and environmental conditions. OEM starters typically have a longer lifespan than aftermarket options. For businesses, considering service life helps in budgeting for maintenance and replacements, ultimately affecting operational costs.

What Are Common Trade Terms Related to Starter Replacement Costs?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms relevant to starter replacements:

-

OEM (Originalgerätehersteller)

OEM refers to parts made by the vehicle’s original manufacturer. These parts are designed to meet specific performance standards and are often preferred for their reliability. B2B buyers should weigh the cost differences between OEM and aftermarket parts, as OEM typically offers superior performance but at a higher price. -

MOQ (Mindestbestellmenge)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it can affect inventory costs and purchasing strategies. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or frequent reorders. -

RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For businesses looking to procure starter motors, issuing an RFQ can help compare prices and terms from multiple suppliers, ensuring competitive pricing. -

Incoterms (Internationale Handelsklauseln)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects like shipping, insurance, and risk transfer. For B2B buyers, understanding Incoterms is crucial when importing starter motors to ensure clarity on costs and responsibilities throughout the supply chain. -

Garantieleistungen

Warranty coverage refers to the guarantee provided by the manufacturer regarding the performance and lifespan of the starter motor. B2B buyers should carefully review warranty terms to assess the risk of replacement costs and ensure they are protected against defects or premature failures.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions about starter motor replacements, leading to better cost management and operational efficiency.

Navigieren durch Marktdynamiken und Beschaffungstrends im Sektor „Wie viel kostet es, einen Anlasser auszutauschen?“

What Are the Key Market Drivers Influencing Starter Replacement Costs?

The global automotive repair market is experiencing significant shifts driven by technological advancements, economic factors, and changing consumer preferences. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. One of the primary drivers is the increased reliance on advanced automotive technology. As vehicles become more sophisticated, the complexity of starter systems has grown, leading to higher costs for parts and labor. Additionally, the rising demand for electric vehicles (EVs) is reshaping the market, as the components and maintenance needs of EV starters differ significantly from traditional combustion engines.

Another noteworthy trend is the growing emphasis on sourcing practices. B2B buyers are increasingly seeking transparency in their supply chains, prompting suppliers to provide detailed information about the origin and quality of their products. The shift towards e-commerce platforms for sourcing parts also simplifies procurement processes, enabling buyers to compare prices and access a wider range of options. Furthermore, fluctuations in raw material prices and supply chain disruptions due to geopolitical tensions can impact the overall costs associated with starter replacements. Buyers must remain vigilant and adaptable to these changes to make informed purchasing decisions.

How Is Sustainability and Ethical Sourcing Shaping the Starter Replacement Industry?

Sustainability and ethical sourcing are becoming essential considerations for B2B buyers in the automotive sector. The environmental impact of automotive parts production, including starters, has prompted a shift towards greener practices. Buyers are increasingly prioritizing suppliers who adopt sustainable manufacturing processes, use recyclable materials, and minimize waste. This focus not only addresses environmental concerns but also aligns with the growing consumer demand for eco-friendly products.

The importance of ethical supply chains is highlighted by the need for compliance with international standards. Buyers are encouraged to seek suppliers with certifications such as ISO 14001 for environmental management and ISO 9001 for quality management. These certifications indicate a commitment to sustainable practices and can serve as a competitive advantage in the marketplace. Additionally, sourcing from local manufacturers can reduce transportation emissions, further enhancing sustainability efforts. By prioritizing sustainable and ethical sourcing, B2B buyers can contribute to a more responsible automotive industry while also enhancing their brand reputation.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

What Has Been the Evolution of Starter Replacement Costs?

The evolution of starter replacement costs has been influenced by various technological and market factors over the decades. Initially, starter motors were relatively simple components, making repairs straightforward and cost-effective. However, as automotive technology advanced, starters became more complex, integrating electronic components that require specialized knowledge for diagnosis and repair. This shift has led to an increase in both parts and labor costs.

In recent years, the rise of remanufactured starters has provided an alternative for cost-conscious B2B buyers. These products offer a balance between affordability and performance, allowing businesses to manage expenses without compromising on quality. As a result, the market has seen a growing acceptance of remanufactured components, particularly in regions where cost sensitivity is high. Understanding these historical trends is essential for international buyers looking to navigate the current landscape effectively and make informed sourcing decisions.

Häufig gestellte Fragen (FAQs) für B2B-Käufer: Wie viel kostet es, einen Anlasser auszutauschen?

-

1. How much does it typically cost to replace a starter in different regions?

The cost to replace a starter can vary significantly depending on the region due to labor rates and parts availability. In general, you might expect to pay between $250 and $1,000 for parts and labor combined. In Africa and South America, prices may be lower due to reduced labor costs, while in Europe and the Middle East, costs might be on the higher end due to stricter regulations and higher quality parts. It’s essential to source local suppliers for accurate estimates tailored to your region. -

2. What factors influence the cost of starter replacement?

Several factors affect the cost of starter replacement, including the vehicle’s make and model, the type of starter (new vs. remanufactured), and the complexity of the labor involved. Additionally, local market conditions and the availability of parts can impact pricing. Understanding these factors can help you budget accurately and identify the best suppliers who offer competitive pricing based on your specific needs. -

3. Can I negotiate payment terms with suppliers for starter parts?

Yes, negotiating payment terms with suppliers is common in B2B transactions. Many suppliers may offer flexible terms, such as net 30 or net 60 days, particularly for larger orders. It’s advisable to discuss your purchasing volume and establish a relationship with suppliers to gain favorable terms. Always ensure that any agreed terms are documented in your purchase agreement to avoid misunderstandings later on. -

4. What should I consider when vetting suppliers for starter replacement parts?

When vetting suppliers, consider factors such as their reputation, experience in the industry, quality certifications, and customer reviews. It’s also beneficial to assess their supply chain reliability, including lead times and logistics capabilities. Request samples of their products to evaluate quality before placing larger orders. Building a strong relationship with a trustworthy supplier can lead to better pricing and service. -

5. Is there a minimum order quantity (MOQ) when sourcing starters?

Many suppliers have a minimum order quantity (MOQ) for starter parts, which can range from a few units to several hundred, depending on the supplier and the type of part. It’s important to clarify the MOQ during negotiations, as this can affect your overall procurement strategy. If your needs do not meet the MOQ, consider forming a purchasing group with other businesses to meet the requirement. -

6. How can I ensure quality assurance (QA) for starter parts?

To ensure quality assurance for starter parts, request certifications and quality control documentation from your suppliers. Establishing a QA process, such as inspecting parts upon arrival and conducting tests where feasible, can help ensure that you receive reliable products. Additionally, consider suppliers who offer warranties or guarantees on their parts, as this can provide further assurance of quality. -

7. What logistics considerations should I keep in mind when sourcing starters internationally?

When sourcing starters internationally, consider logistics factors such as shipping costs, customs duties, and lead times. Work with suppliers who have experience in international shipping to navigate potential challenges. It’s also crucial to understand local regulations in both your country and the supplier’s country to avoid delays. Establishing clear communication with your logistics partner can streamline the process. -

8. Are there customization options available for starter parts, and how do they affect pricing?

Many suppliers offer customization options for starter parts, such as specific voltage requirements or unique mounting configurations. Customization can impact pricing, often leading to higher costs due to the additional engineering and production processes involved. Discuss your specific needs with potential suppliers to understand the options available and the associated costs, ensuring you receive a product tailored to your requirements without overspending.

Top 5 How Much Does It Cost To Change A Starter Manufacturers & Suppliers List

1. Facebook – Car Repair Cost

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Kosten für die Fahrt zur Werkstatt und den Austausch des Anlassers

2. Starter Replacement – Cost Overview

Domäne: letztechanceautoreparaturen.com

Registriert: 2009 (16 Jahre)

Einleitung: Starter Replacement Cost: Economy starters: $75 – $200, OEM starters: $150 – $400, High-performance starters: $300 – $1000+. Labor costs: Basic vehicle starter replacement: $100 – $250, Complex installations: $300 – $600+. Average total cost ranges from $250 – $1,000+. Factors affecting cost include vehicle type, new vs remanufactured starters, and potential additional repairs.

3. CarTalk – Leitfaden zum Austausch des Anlassers

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: Cost of replacing a starter: $600 to $900 for common vehicles; $900 to $1,400 for luxury models. Symptoms of a failing starter include clicking sounds, screeching noises, and intermittent functionality. Starters can be new, remanufactured, or repaired; remanufactured starters are commonly used. Modern vehicles with stop-start systems have redesigned starters that are robust and not prone to premat…

4. Denso – Starter Replacement for 2007 Toyota Tundra

Domäne: tundras.com

Registriert: 2000 (25 Jahre)

Einleitung: Starter replacement for a 2007 Toyota Tundra; quoted cost: $1500 (labor: $900, part: $650); part number: Denso 428000-4640; vehicle mileage: 174,000; potential alternative costs: OEM starter around $200, non-OEM under $200; labor costs may vary by mechanic; difficulty level: high, may require removal of exhaust manifold.

5. CarBuzz - Kosten für den Austausch des Anlassers

Domäne: carbuzz.de

Registriert: 2003 (22 Jahre)

Einleitung: Starter motor replacement cost ranges from $450 to $600 on average. For specific models like the Toyota Tundra (2000-2005) V8, costs can be between $650 and $900 due to labor-intensive installation. The Honda Civic’s starter replacement cost is estimated between $490 and $760. Factors affecting costs include labor time (1.5 to 2.5 hours for most starters, up to 4 hours for valley-mounted starters)…

Strategische Beschaffung Fazit und Ausblick Wie viel kostet es, einen Anlasser auszutauschen?

In summary, understanding the costs associated with starter replacement is essential for B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe. Key factors influencing these costs include the type of vehicle, the choice between new and remanufactured starters, and labor rates that vary by region and complexity of the job. By strategically sourcing quality parts and skilled labor, businesses can optimize their operational efficiency while minimizing downtime and repair costs.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Investing in professional services ensures not only reliable installation but also the longevity of the components, protecting your fleet’s performance. As you navigate the complexities of starter replacement, consider establishing partnerships with reputable suppliers and service providers to enhance your procurement strategy.

Looking ahead, the automotive parts market is evolving, with increasing access to advanced technologies and competitive pricing models. Embrace these changes by staying informed and proactive in your sourcing decisions. For international buyers, now is the time to leverage your market knowledge and network to secure the best value for your investment in starter replacements. Make informed choices that will drive your business forward.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Illustratives Bild zum Thema „Wie viel kostet es, einen Anlasser auszutauschen?“

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.