Einleitung: Navigieren auf dem globalen Markt für Wie lange hält die Lichtmaschine im Auto?

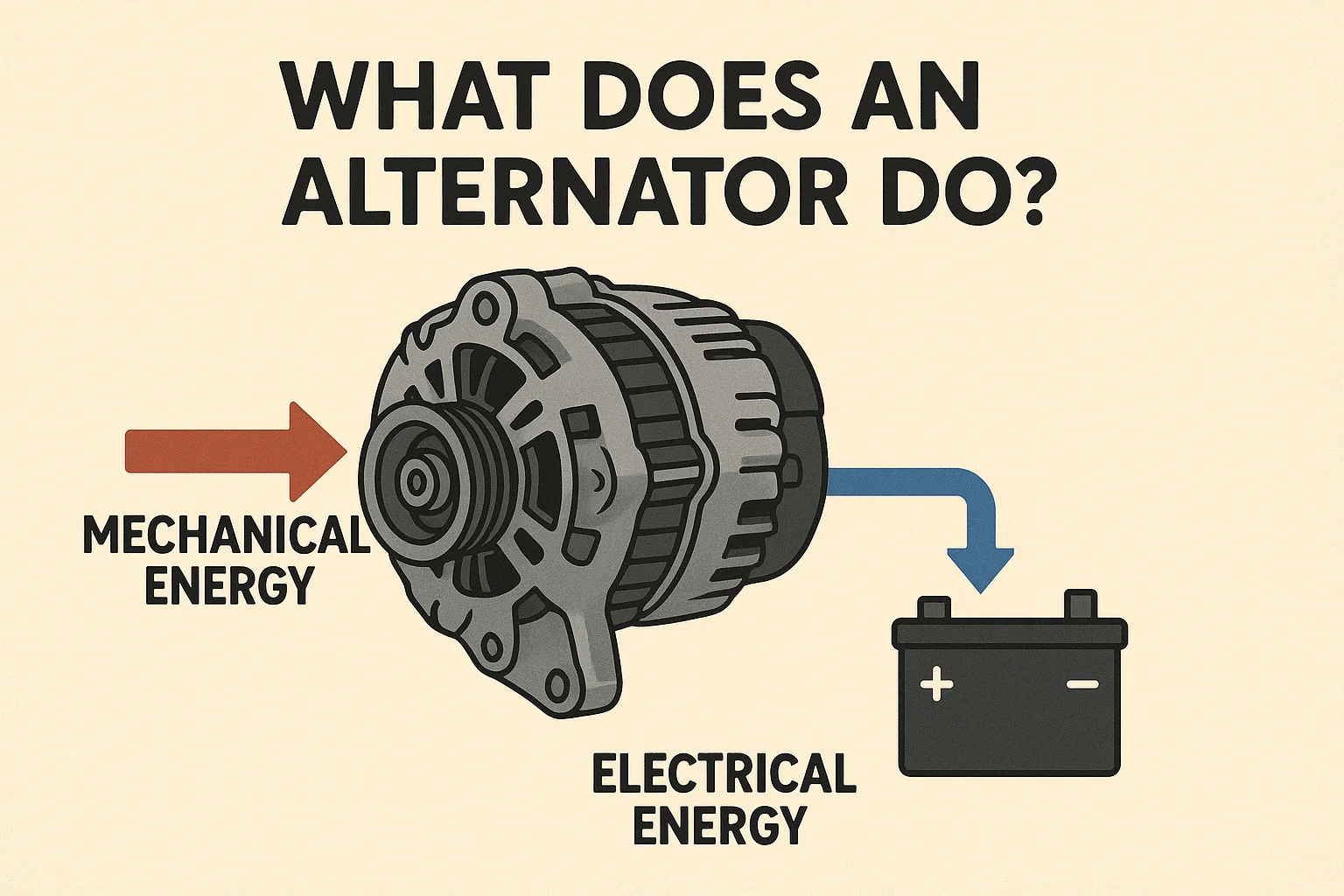

In der wettbewerbsorientierten Landschaft der Kfz-Teile ist es wichtig zu verstehen wie lange eine Lichtmaschine in einem Auto hält ist für B2B-Käufer, die zuverlässige Lösungen für die Fahrzeugleistung und -wartung suchen, von entscheidender Bedeutung. Lichtmaschinen sind wichtige Komponenten, die den reibungslosen Betrieb des elektrischen Systems des Fahrzeugs sicherstellen, indem sie die Batterie laden und verschiedene elektrische Systeme mit Strom versorgen. Ihre Lebensdauer kann jedoch erheblich variieren und wird von Faktoren wie Fahrgewohnheiten, Umweltbedingungen und Wartungspraktiken beeinflusst. Dieser Leitfaden befasst sich mit den Feinheiten der Langlebigkeit von Lichtmaschinen und gibt internationalen Käufern aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa - insbesondere Deutschland und Vietnam - das Wissen an die Hand, um fundierte Kaufentscheidungen zu treffen.

Der umfassende Umfang dieses Leitfadens befasst sich mit den verschiedenen Arten von Lichtmaschinen, ihren Anwendungen in verschiedenen Fahrzeugmodellen und den wichtigsten Überlegungen für die Beschaffung von Qualitätsteilen. Darüber hinaus gibt er Einblicke in die Prüfung von Zulieferern, die Bewertung der Kosteneffizienz und das Erkennen von Anzeichen für einen Generatorausfall, so dass Unternehmen die mit unerwarteten Ausfällen verbundenen Risiken minimieren können. Durch die Bereitstellung von umsetzbaren Erkenntnissen und Best Practices zielt diese Ressource darauf ab, die betriebliche Effizienz Ihres Fuhrparks oder Automobilunternehmens zu verbessern und sicherzustellen, dass Sie die richtigen, auf Ihre spezifischen Bedürfnisse zugeschnittenen Generatoren auswählen. Mit diesem Leitfaden können Sie sich auf dem globalen Markt sicher bewegen und sowohl die Leistung als auch die Kosteneffizienz Ihrer Beschaffungsstrategie optimieren.

Inhaltsverzeichnis

- Top 2 Wie lange hält die Lichtmaschine im Auto Hersteller & Lieferanten Liste

- Einleitung: Navigieren auf dem globalen Markt für Wie lange hält die Lichtmaschine im Auto?

- Wie lange hält eine Lichtmaschine im Auto? Typen und Variationen

- Wichtige industrielle Anwendungen von Wie lange hält die Lichtmaschine im Auto?

- 3 häufige Schmerzpunkte für ‘wie lange hält die Lichtmaschine im Auto’ & ihre Lösungen

- Leitfaden für die strategische Materialauswahl für Wie lange hält die Lichtmaschine im Auto?

- Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Wie lange hält eine Lichtmaschine im Auto?

- Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘wie lange hält die Lichtmaschine im Auto’

- Umfassende Kosten- und Preisanalyse für Wie lange hält eine Lichtmaschine im Auto Sourcing

- Analyse der Alternativen: Vergleich der Lebensdauer der Lichtmaschine im Auto mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für Wie lange hält die Lichtmaschine im Auto?

- Navigieren durch Marktdynamik und Beschaffungstrends im Sektor "Wie lange hält eine Lichtmaschine im Auto?

- Häufig gestellte Fragen (FAQs) für B2B-Käufer zu "Wie lange hält die Lichtmaschine im Auto?

- Strategische Beschaffung Schlussfolgerung und Ausblick für Wie lange hält die Lichtmaschine im Auto?

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Wie lange hält eine Lichtmaschine im Auto? Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard-Lichtmaschinen | Halten in der Regel 7-10 Jahre oder 80.000-150.000 Meilen | Allgemeine Kfz-Reparatur- und Wartungsbetriebe | Vorteile: Weithin verfügbar, kostengünstig; Nachteile: Begrenzte Lebensdauer bei intensiver Nutzung. |

| Hochleistungsgeneratoren | Konzipiert für hohen Strombedarf, häufig in umgebauten Fahrzeugen verwendet | Leistungsstarke Kfz-Werkstätten und Sonderanfertigungen | Vorteile: Erhöhte Leistungskapazität; Nachteile: Höhere Kosten, erfordert möglicherweise eine spezielle Installation. |

| Hochleistungsgeneratoren | Gebaut für Nutzfahrzeuge, konzipiert für extreme Bedingungen | Fuhrparkmanagement und gewerblicher Verkehr | Vorteile: Langlebig und robust; Nachteile: Schwerer und teurer. |

| OEM (Original Equipment Manufacturer) Lichtmaschinen | Hergestellt, um bestimmte Fahrzeugnormen zu erfüllen | Fahrzeughersteller und autorisierte Servicestellen | Vorteile: Garantierte Kompatibilität; Nachteile: In der Regel teurer als Nachrüstungsoptionen. |

| Ersatzteil-Lichtmaschinen | Ersatzteile von Drittherstellern | Unabhängige Werkstätten und Autoteilehändler | Vorteile: Oft günstiger; Nachteile: Variable Qualitäts- und Garantiebedingungen. |

Was sind die Merkmale von Standard-Lichtmaschinen?

Standard-Generatoren sind die gängigsten Typen in Fahrzeugen und haben in der Regel eine Lebensdauer von 7 bis 10 Jahren oder 80.000 bis 150.000 Meilen. Sie sind für die elektrischen Anforderungen durchschnittlicher Fahrzeuge ausgelegt und eignen sich daher für allgemeine Kfz-Reparatur- und Wartungsbetriebe. Beim Kauf sollten B2B-Käufer auf die Qualität des Teils, den Ruf der Marke und die Garantieoptionen achten, um Zuverlässigkeit und Leistung zu gewährleisten.

Wie unterscheiden sich Lichtmaschinen mit hoher Leistung?

Lichtmaschinen mit hoher Leistung sind für Fahrzeuge mit erhöhtem Strombedarf konzipiert, z. B. für Fahrzeuge, die mit Aftermarket-Audiosystemen oder anderem Zubehör mit hohem Stromverbrauch ausgestattet sind. Diese Lichtmaschinen bieten mehr Stromstärke als Standardmodelle und sind daher ideal für leistungsstarke Autowerkstätten und Sonderanfertigungen. Käufer sollten die spezifischen elektrischen Anforderungen ihres Fahrzeugs prüfen und die Kompatibilität mit bestehenden Systemen sicherstellen, wenn sie diese Optionen in Betracht ziehen.

Was macht Hochleistungs-Generatoren so einzigartig?

Hochleistungsgeneratoren sind speziell für Nutzfahrzeuge konzipiert, die unter extremen Bedingungen betrieben werden, wie z. B. Lkw und Busse. Sie zeichnen sich in der Regel durch eine höhere Haltbarkeit und eine längere Lebensdauer aus und sind daher für das Flottenmanagement und den kommerziellen Transportbetrieb unverzichtbar. B2B-Käufer sollten bei der Auswahl von Heavy-Duty-Modellen auf die Spezifikationen in Bezug auf die Belastbarkeit und die Umweltverträglichkeit achten.

Warum sollten Sie sich für OEM-Generatoren entscheiden?

OEM-Generatoren werden nach den Original-Spezifikationen der Fahrzeughersteller hergestellt, um eine perfekte Passform und optimale Leistung zu gewährleisten. Diese Teile werden häufig von Fahrzeugherstellern und autorisierten Servicezentren verwendet. Sie garantieren zwar Kompatibilität, aber B2B-Käufer müssen die Vorteile der Zuverlässigkeit gegen die im Allgemeinen höheren Kosten im Vergleich zu Aftermarket-Optionen abwägen.

Was sind die Vor- und Nachteile von Aftermarket-Generatoren?

Aftermarket-Generatoren werden von Drittherstellern produziert und sind oft günstiger als OEM-Optionen. Sie sind in unabhängigen Werkstätten und im Kfz-Teilehandel für eine breite Palette von Fahrzeugen erhältlich. Käufer sollten jedoch auf die unterschiedlichen Qualitäts- und Garantiebedingungen achten, da diese die langfristige Leistung und Zuverlässigkeit erheblich beeinflussen können. Die Bevorzugung seriöser Marken kann die mit Aftermarket-Käufen verbundenen Risiken mindern.

Wichtige industrielle Anwendungen von Wie lange hält die Lichtmaschine im Auto?

| Branche/Sektor | Spezifische Anwendung von Wie lange hält die Lichtmaschine im Auto? | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Erbringung von Wartungs- und Diagnosedienstleistungen | Verbessert die Kundenzufriedenheit und -treue | Qualität der Teile, Diagnosewerkzeuge, Schulung der Mitarbeiter |

| Transport & Logistik | Fuhrparkmanagement und Fahrzeugwartung | Reduziert Ausfallzeiten und Betriebskosten | Großabnahmeoptionen, Garantiebedingungen und Serviceverträge |

| Fertigung & Produktion | Instandhaltung von Industriefahrzeugen | Sorgt für unterbrechungsfreien Betrieb und Produktivität | Kompatibilität mit verschiedenen Fahrzeugmodellen, Lieferfristen |

| Landwirtschaft | Wartung von Landmaschinen | Maximiert die Betriebszeit und Effizienz der Geräte | Kenntnis der spezifischen Maschinenanforderungen und des lokalen Klimas |

| Bergbau und Bauwesen | Zuverlässigkeit von schweren Maschinen und Fahrzeugen | Erhöht die Sicherheit und reduziert die Reparaturkosten | Verfügbarkeit von Spezialgeneratoren, lokale Unterstützungsdienste |

Wie nutzen Kfz-Werkstätten das Wissen über die Lebensdauer von Lichtmaschinen?

Kfz-Werkstätten nutzen das Wissen über die Lebensdauer von Lichtmaschinen, um proaktive Wartungsdienste anzubieten. Indem sie ihre Kunden über die typische Lebensdauer von 7 bis 10 Jahren bzw. 80.000 bis 150.000 Meilen informieren, können die Werkstätten sie zu rechtzeitigen Inspektionen und Austauschaktionen ermutigen. Dies erhöht nicht nur die Kundenzufriedenheit, sondern schafft auch eine langfristige Loyalität, da die Kunden die vorbeugende Pflege zu schätzen wissen. Internationale Einkäufer sollten die Beschaffung von Qualitätsgeneratoren und Diagnosewerkzeugen in Betracht ziehen, um sicherzustellen, dass sie umfassende Dienstleistungen anbieten können, die den verschiedenen Fahrzeuganforderungen gerecht werden.

Wie profitiert das Flottenmanagement von den Erkenntnissen über die Lebensdauer von Lichtmaschinen?

In der Transport- und Logistikbranche nutzen Flottenmanagementteams das Wissen über die Langlebigkeit von Lichtmaschinen, um regelmäßige Wartungsarbeiten zu planen und unerwartete Ausfälle zu vermeiden. Das Wissen, dass Generatoren aufgrund übermäßiger elektrischer Belastung oder schlechter Fahrgewohnheiten ausfallen können, ermöglicht es Managern, bessere Nutzungsrichtlinien und Wartungsroutinen einzuführen. Durch diese Voraussicht werden Ausfallzeiten minimiert, was zu erheblichen Betriebskosteneinsparungen führt. Bei der Beschaffung von Generatoren sollten Unternehmen auf Großeinkaufsoptionen und günstige Garantiebedingungen achten, um Kosteneffizienz und Zuverlässigkeit zu gewährleisten.

Welche Rolle spielt das Wissen über Wechselstromgeneratoren bei der Herstellung und Produktion?

In der Fertigung und Produktion ist die Instandhaltung von Industriefahrzeugen von entscheidender Bedeutung. Wenn man weiß, wie lange ein Generator hält, können die Wartungsteams den Austausch planen, bevor es zu Ausfällen kommt, und so sicherstellen, dass der Betrieb nicht unterbrochen wird. Dies ist besonders wichtig in Umgebungen, in denen die Zuverlässigkeit der Anlagen für die Produktivität von größter Bedeutung ist. Käufer in diesem Sektor sollten der Kompatibilität mit verschiedenen Fahrzeugmodellen Priorität einräumen und die Lieferzeiten berücksichtigen, um die betriebliche Effizienz zu erhalten.

Wie wird das Wissen über die Lebensdauer von Wechselstromgeneratoren in der Landwirtschaft angewendet?

Für landwirtschaftliche Betriebe kann die Kenntnis der Lebensdauer von Generatoren in Maschinen die betriebliche Effizienz erheblich beeinflussen. Eine regelmäßige Wartung, die sich an der typischen Lebensdauer orientiert, trägt dazu bei, die Betriebszeit der Maschinen zu maximieren und sicherzustellen, dass Aussaat- und Erntepläne ohne Verzögerungen eingehalten werden können. Internationale Käufer sollten die spezifischen Anforderungen an die Maschinen je nach Klima und Einsatzbedingungen vor Ort kennen, die sich auf die Lebensdauer und Leistung von Generatoren auswirken können.

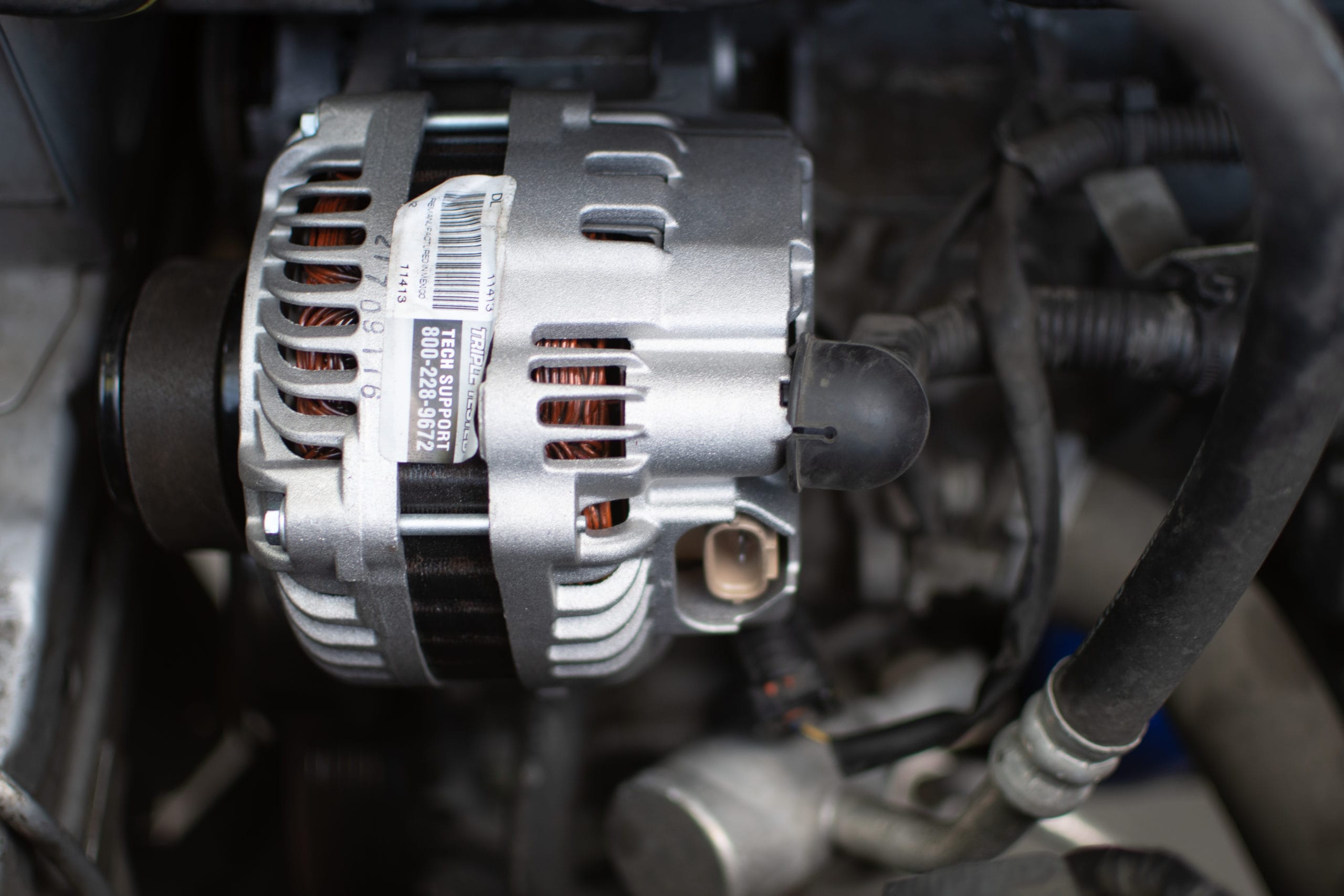

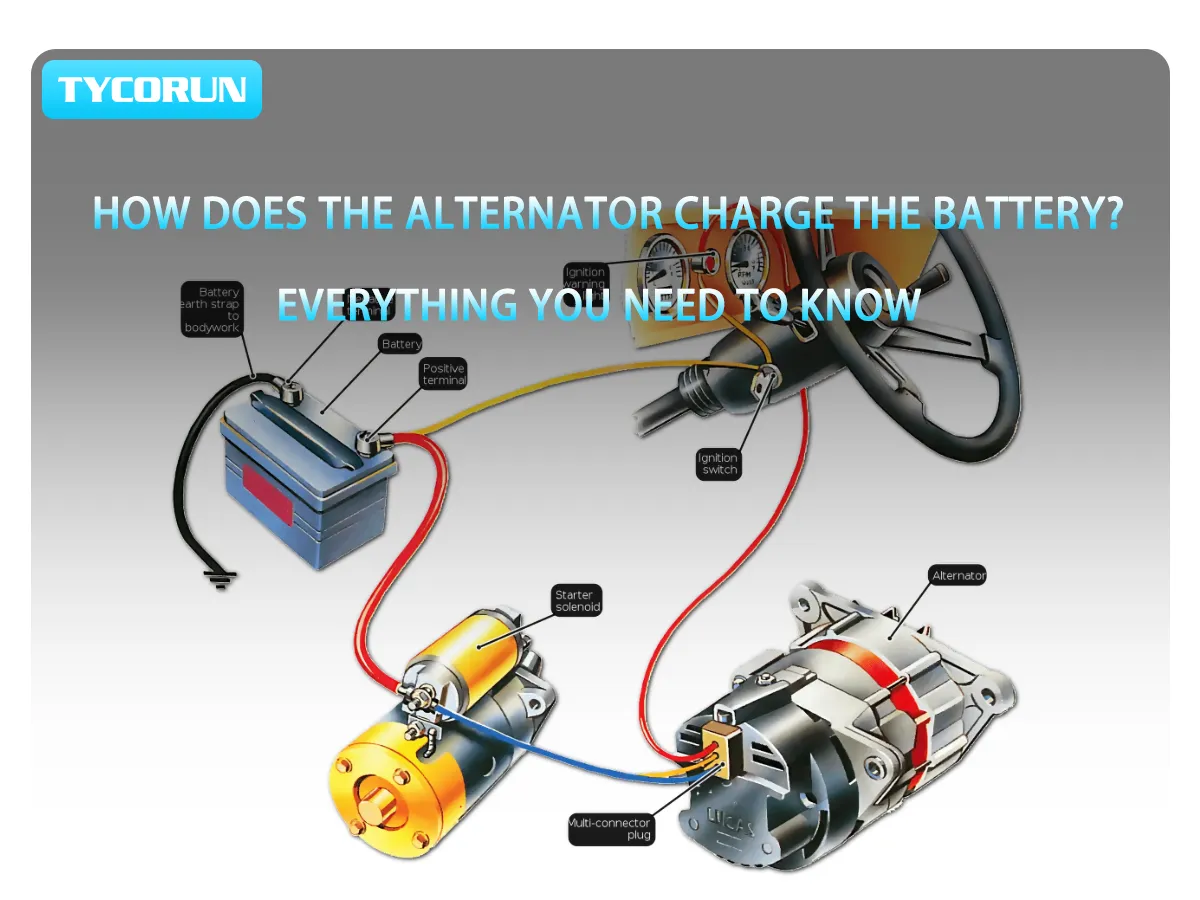

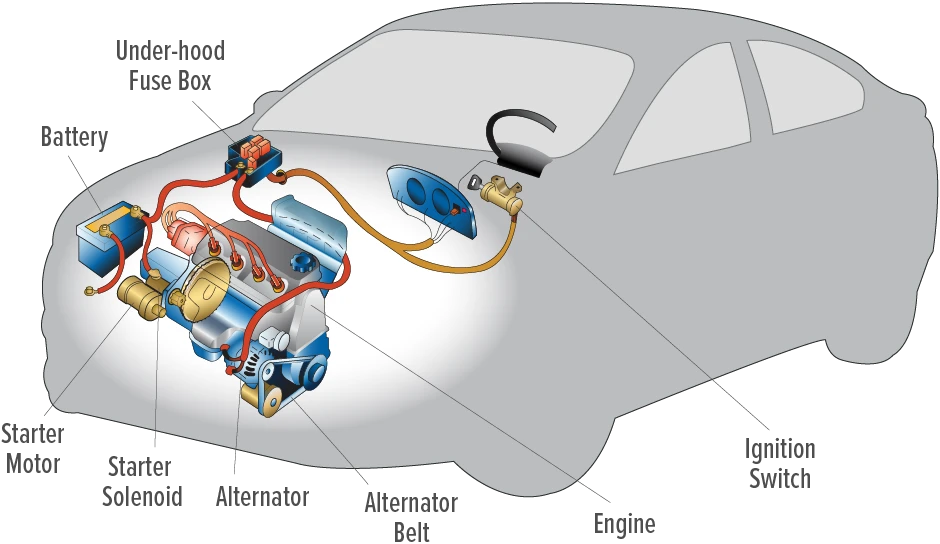

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Warum ist die Lebensdauer von Wechselstromgeneratoren im Bergbau und in der Bauindustrie so wichtig?

Im Bergbau und im Baugewerbe ist die Zuverlässigkeit von Schwermaschinen für die Sicherheit und das Kostenmanagement von entscheidender Bedeutung. Die Kenntnis der Lebensdauer von Generatoren hilft den Unternehmen, Ausfälle vorauszusehen und Wartungsarbeiten zu planen, wodurch das Risiko kostspieliger Reparaturen und Sicherheitsvorfälle verringert wird. Bei der Beschaffung von Generatoren müssen die Unternehmen die Verfügbarkeit von Spezialteilen und lokalen Kundendienstleistungen berücksichtigen, um einen schnellen Austausch zu gewährleisten und Betriebsunterbrechungen zu minimieren.

3 häufige Schmerzpunkte für ‘wie lange hält die Lichtmaschine im Auto’ & ihre Lösungen

Szenario 1: Verständnis der Variabilität der Lebensdauer von Wechselstromgeneratoren in verschiedenen Märkten

Das Problem: B2B-Käufer haben oft mit den unterschiedlichen Lebensdauern von Generatoren zu kämpfen, die von geografischen und klimatischen Bedingungen abhängen. So kann ein Generator in gemäßigten Klimazonen deutlich länger halten als in Regionen mit extremer Hitze oder Feuchtigkeit, wie etwa in Teilen Afrikas oder des Nahen Ostens. Diese Unstimmigkeiten können zu unerwarteten Wartungskosten und Ausfallzeiten führen und sich auf die betriebliche Effizienz und die Zuverlässigkeit des Fahrzeugs auswirken. Einkäufer fühlen sich möglicherweise überfordert, wenn sie versuchen, die angemessene Lebensdauer von Generatoren für ihren spezifischen Markt zu bestimmen, was sich auf die Bestandsverwaltung und Beschaffungsstrategien auswirkt.

Die Lösung: Um diese Herausforderung zu meistern, sollten B2B-Einkäufer eine gründliche Analyse der Umweltfaktoren durchführen, die die Leistung von Lichtmaschinen in ihren Zielmärkten beeinflussen. Beginnen Sie damit, Daten über die lokalen klimatischen Bedingungen, die durchschnittlichen Fahrgewohnheiten und die überwiegend verwendeten Fahrzeugtypen zu sammeln. Die Zusammenarbeit mit örtlichen Mechanikern oder Automobilexperten kann wertvolle Erkenntnisse über die in bestimmten Regionen auftretenden Probleme liefern. Durch die Spezifizierung von Generatoren, die für eine längere Lebensdauer unter rauen klimatischen Bedingungen ausgelegt sind - wie z. B. solche mit verbesserten Kühlsystemen oder verbesserten elektrischen Komponenten - können Käufer fundierte Kaufentscheidungen treffen. Darüber hinaus kann die Implementierung eines vorausschauenden Wartungsprogramms mit regelmäßigen Inspektionen dazu beitragen, potenzielle Probleme mit Lichtmaschinen zu erkennen, bevor sie zu Ausfällen führen, und so einen reibungsloseren Betrieb gewährleisten.

Szenario 2: Management der elektrischen Last in modernen Fahrzeugen

Das Problem: Mit der zunehmenden Ausstattung von Fahrzeugen mit fortschrittlicher Elektronik - von Infotainmentsystemen bis hin zu Fahrerassistenztechnologien - sind die Käufer von B2B-Fahrzeugen besorgt über die Belastung, die diese zusätzlichen elektrischen Lasten für die Lichtmaschinen bedeuten. Viele Käufer berichten, dass es schwierig ist, Generatoren zu finden, die den höheren Leistungsanforderungen gerecht werden, ohne die Lebensdauer zu beeinträchtigen, was zu höheren Ausfallraten und Ersatzkosten führt.

Die Lösung: B2B-Einkäufer sollten sich auf die Beschaffung von Lichtmaschinen konzentrieren, die speziell für den erhöhten Strombedarf ausgelegt sind. Die Suche nach Herstellern, die Lichtmaschinen mit hoher Leistung anbieten, kann Optionen bieten, die den Anforderungen moderner Fahrzeuge gerecht werden. Darüber hinaus sollten Einkäufer die Integration von Spannungsreglern in Betracht ziehen, die eine effektivere Steuerung der elektrischen Lasten ermöglichen. Die Schulung von Fuhrparkbetreibern im Umgang mit elektrischen Systemen, z. B. die Minimierung des Einsatzes von stromintensivem Zubehör bei ausgeschaltetem Motor, kann die Lebensdauer der Lichtmaschine ebenfalls verlängern. Regelmäßige Wartungsprüfungen, um sicherzustellen, dass alle elektrischen Verbindungen sicher und frei von Korrosion sind, erhöhen die Leistung und Zuverlässigkeit weiter.

Szenario 3: Erkennen von Frühwarnzeichen für den Ausfall eines Generators

Das Problem: Einer der größten Schmerzpunkte für B2B-Käufer ist der plötzliche Ausfall von Lichtmaschinen, oft ohne Vorwarnung. Dies kann zu ungeplanten Ausfallzeiten des Fahrzeugs führen, die die Produktivität beeinträchtigen und die Betriebskosten erhöhen. Viele Käufer sind sich der frühen Anzeichen eines Generatorausfalls nicht bewusst, was zu kostspieligen Notreparaturen oder sogar zum kompletten Austausch des Fahrzeugs führen kann.

Die Lösung: Um dieses Problem anzugehen, sollten B2B-Einkäufer in Schulungsprogramme für ihre Wartungsteams investieren, damit diese Frühwarnzeichen für einen Generatorausfall erkennen können. Zu den üblichen Anzeichen gehören das Abblenden der Scheinwerfer, ungewöhnliche Geräusche und Warnleuchten im Armaturenbrett. Ein regelmäßiger Inspektionsplan, der die Leistungsprüfung der Lichtmaschine und die Überprüfung der physischen Abnutzung umfasst, kann helfen, Probleme zu erkennen, bevor sie eskalieren. Darüber hinaus kann der Aufbau einer Beziehung zu zuverlässigen Lieferanten, die hochwertige Ersatzgeneratoren schnell liefern können, die Ausfallzeiten minimieren. Durch Aufklärung und proaktive Wartung können Käufer ihre betriebliche Effizienz steigern und die finanziellen Auswirkungen unerwarteter Ausfälle von Generatoren verringern.

Leitfaden für die strategische Materialauswahl für Wie lange hält die Lichtmaschine im Auto?

Welche Materialien beeinflussen die Lebensdauer einer Lichtmaschine in einem Auto?

Bei der Beurteilung der Lebensdauer einer Lichtmaschine in einem Fahrzeug spielt die Materialauswahl eine entscheidende Rolle. Die für die Konstruktion eines Generators verwendeten Materialien wirken sich direkt auf seine Leistung, Haltbarkeit und Wartungsanforderungen aus. Im Folgenden analysieren wir vier gängige Materialien, die in Generatorkomponenten verwendet werden, und konzentrieren uns dabei auf ihre Eigenschaften, Vor- und Nachteile sowie auf die Auswirkungen für internationale B2B-Käufer.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Wie wirkt sich Aluminium auf die Langlebigkeit von Lichtmaschinen aus?

Aluminium wird aufgrund seines geringen Gewichts und seiner Korrosionsbeständigkeit häufig für das Gehäuse von Lichtmaschinen und bestimmte interne Komponenten verwendet.

- Wichtige Eigenschaften: Aluminium hat eine ausgezeichnete Wärmeleitfähigkeit und einen Schmelzpunkt von etwa 660°C, wodurch es sich für Hochtemperaturanwendungen eignet. Außerdem ist es oxidationsbeständig, was dazu beiträgt, dass die Leistung über lange Zeit erhalten bleibt.

- Vor- und Nachteile: Das geringe Gewicht von Aluminium reduziert das Gesamtgewicht der Lichtmaschine und verbessert die Kraftstoffeffizienz. Allerdings kann Aluminium weniger haltbar sein als andere Metalle, was unter extremen Bedingungen zu Verschleiß führen kann. Es ist im Allgemeinen kostengünstig, aber der Herstellungsprozess kann komplex sein, insbesondere bei komplizierten Konstruktionen.

- Auswirkungen auf die Anwendung: Aluminium ist mit verschiedenen Kfz-Flüssigkeiten verträglich, aber seine geringere Zugfestigkeit hält möglicherweise in stark beanspruchten Umgebungen nicht gut stand.

- Überlegungen für internationale Käufer: Käufer in Regionen wie Afrika und Südamerika sollten aufgrund der unterschiedlichen klimatischen Bedingungen auf die Korrosionsbeständigkeit achten. Die Einhaltung von Normen wie der ASTM für Aluminiumlegierungen ist für die Gewährleistung der Qualität unerlässlich.

Welche Rolle spielt Kupfer bei der Funktion von Lichtmaschinen?

Kupfer wird aufgrund seiner hervorragenden elektrischen Leitfähigkeit hauptsächlich in den Wicklungen von Generatoren verwendet.

- Wichtige Eigenschaften: Kupfer hat eine Leitfähigkeit von 59,6 MS/m, was es zu einem der besten Materialien für elektrische Anwendungen macht. Außerdem hat es einen Schmelzpunkt von 1.984°F (1.085°C).

- Vor- und Nachteile: Die hohe Leitfähigkeit von Kupfer gewährleistet eine effiziente Energieübertragung, die für das Aufladen der Batterie entscheidend ist. Allerdings ist Kupfer schwerer und teurer als Alternativen wie Aluminium, was sich auf die Gesamtkosten der Lichtmaschine auswirken kann.

- Auswirkungen auf die Anwendung: Die überragende Leitfähigkeit von Kupfer erhöht die Leistung der Lichtmaschine, insbesondere in elektrischen Systemen mit hohem Stromverbrauch. Allerdings kann es zu Überhitzung führen, wenn es nicht richtig gehandhabt wird.

- Überlegungen für internationale Käufer: In Europa und im Nahen Osten sollten die Käufer darauf achten, dass die elektrischen Normen, z. B. die DIN, eingehalten werden, um Sicherheit und Zuverlässigkeit zu gewährleisten.

Wie trägt Stahl zur Langlebigkeit von Lichtmaschinen bei?

Stahl wird häufig für die strukturellen Komponenten eines Generators verwendet, einschließlich Halterungen und Tragrahmen.

- Wichtige Eigenschaften: Stahl hat eine hohe Zugfestigkeit und einen Schmelzpunkt von etwa 1.370°C (2.500°F). Außerdem ist er widerstandsfähig gegen Verformung unter Belastung.

- Vor- und Nachteile: Stahl ist aufgrund seiner Langlebigkeit ideal für stark beanspruchte Anwendungen. Allerdings ist er anfällig für Rost und Korrosion, wenn er nicht ordnungsgemäß beschichtet ist, was zu einem vorzeitigen Ausfall führen kann. Der Herstellungsprozess kann einfach sein, aber das Gewicht kann sich negativ auf die Kraftstoffeffizienz auswirken.

- Auswirkungen auf die Anwendung: Die Stärke des Stahls unterstützt die Komponenten des Generators, erfordert jedoch eine sorgfältige Prüfung der Korrosionsbeständigkeit, insbesondere in feuchter Umgebung oder an der Küste.

- Überlegungen für internationale Käufer: Käufer sollten auf verzinkten oder anderweitig behandelten Stahl achten, um Rost zu vermeiden, insbesondere in Regionen mit hoher Luftfeuchtigkeit, wie in Teilen Südamerikas und Afrikas.

Was ist mit Kunststoffen bei der Konstruktion von Lichtmaschinen?

Kunststoffe werden in zunehmendem Maße für nicht-strukturelle Komponenten und die Isolierung des Generators verwendet.

- Wichtige Eigenschaften: Kunststoffe können Temperaturen von bis zu 121°C (250°F) standhalten und sind gegen viele Chemikalien beständig, so dass sie sich für verschiedene Umgebungen im Automobilbereich eignen.

- Vor- und Nachteile: Das geringe Gewicht von Kunststoffen kann das Gesamtgewicht der Lichtmaschine verringern. Sie sind jedoch möglicherweise nicht so haltbar wie Metalle und können sich im Laufe der Zeit abnutzen, insbesondere bei großer Hitze oder Einwirkung von Ölen.

- Auswirkungen auf die Anwendung: Kunststoffe können eine wirksame Isolierung bieten, halten aber in stark beanspruchten Bereichen möglicherweise nicht stand. Ihre Kompatibilität mit Kfz-Flüssigkeiten ist im Allgemeinen gut, aber für eine optimale Leistung müssen bestimmte Sorten ausgewählt werden.

- Überlegungen für internationale Käufer: Die Käufer sollten sicherstellen, dass die verwendeten Kunststoffe den örtlichen Vorschriften und Normen entsprechen, wie z. B. JIS in Japan oder DIN in Deutschland, um Sicherheit und Leistung zu gewährleisten.

Übersichtstabelle zur Materialauswahl für Generatoren

| Material | Typischer Anwendungsfall für Wie lange hält die Lichtmaschine im Auto? | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und interne Komponenten | Leicht und korrosionsbeständig | Weniger haltbar bei extremer Belastung | Mittel |

| Kupfer | Wicklungen und elektrische Anschlüsse | Hervorragende elektrische Leitfähigkeit | Schwerer und teurer | Hoch |

| Stahl | Strukturelle Komponenten (Klammern, Rahmen) | Hohe Zugfestigkeit | Rostanfälligkeit ohne Beschichtung | Mittel |

| Kunststoffe | Isolierung und nicht-strukturelle Komponenten | Leicht und chemikalienbeständig | Weniger haltbar unter hoher Belastung | Niedrig |

Diese Analyse bietet wertvolle Einblicke in die Materialauswahl für Generatoren und hilft internationalen B2B-Einkäufern, fundierte Entscheidungen zu treffen, die auf ihre betrieblichen Anforderungen und regionalen Bedingungen abgestimmt sind.

Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Wie lange hält eine Lichtmaschine im Auto?

Was sind die wichtigsten Schritte im Herstellungsprozess eines Generators?

Der Herstellungsprozess von Lichtmaschinen ist ein komplexer und präziser Vorgang, der die Langlebigkeit und Zuverlässigkeit dieser wichtigen Automobilkomponente gewährleistet. Ein Verständnis der wichtigsten Herstellungsphasen kann B2B-Käufern helfen, die Qualität und Haltbarkeit der Produkte, die sie kaufen möchten, zu beurteilen.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Materialvorbereitung: Welche Materialien werden bei der Herstellung von Wechselstromgeneratoren verwendet?

In der ersten Phase geht es um die Auswahl und Vorbereitung hochwertiger Materialien. Zu den gängigen Materialien gehören:

- Kupfer: Wird aufgrund seiner hervorragenden elektrischen Leitfähigkeit für Wicklungen verwendet.

- Aluminium oder Stahl: Wird für das Gehäuse und die Rotorkomponenten verwendet und sorgt für Festigkeit und Haltbarkeit.

- Dämmstoffe: Unerlässlich, um Kurzschlüsse zu vermeiden und die Langlebigkeit der elektrischen Komponenten zu gewährleisten.

Diese Materialien werden strengen Tests unterzogen, um sicherzustellen, dass sie den Industrienormen entsprechen. Die Zulieferer setzen oft fortschrittliche Techniken wie die Spektrometrie ein, um die Materialzusammensetzung vor Beginn der Produktion zu analysieren.

Wie wird der Umformungsprozess bei der Herstellung von Wechselstromgeneratoren abgewickelt?

Der Umformungsprozess umfasst mehrere Techniken, um die vorbereiteten Materialien zu verwendbaren Komponenten zu formen und zu gießen. Zu den wichtigsten Verfahren gehören:

- Stanzen: Für die Herstellung von Rotor- und Statorteilen aus Blechen.

- Wickeln: Hierbei wird ein Kupferdraht um den Stator gewickelt, um das für die Stromerzeugung notwendige elektromagnetische Feld zu erzeugen.

- Gießen: Für bestimmte Bauteile können Aluminium- oder Magnesiumlegierungen in spezielle Formen gegossen werden, um die Leistung zu verbessern und das Gewicht zu reduzieren.

Diese Umformtechniken sind von entscheidender Bedeutung, da sie sich direkt auf die Effizienz und Haltbarkeit des Generators auswirken.

Wie sieht der Montageprozess für Lichtmaschinen aus?

Sobald die Bauteile geformt sind, beginnt der Montageprozess. Diese Phase wird in der Regel in einer sauberen, kontrollierten Umgebung durchgeführt, um Verunreinigungen zu vermeiden. Zu den wichtigsten Schritten der Montage gehören:

- Komponentenintegration: Einzelne Teile wie der Rotor, der Stator und der Spannungsregler werden sorgfältig zusammengebaut.

- Einbau von Riemen und Riemenscheiben: Die Lichtmaschine ist mit Riemen ausgestattet, die sie mit dem Motor verbinden, was für ihren Betrieb entscheidend ist.

- Endmontage: Dazu gehört das Anbringen des Gehäuses und das sichere Befestigen aller Komponenten.

Bei der Montage ist Präzision das A und O, denn schon kleine Fluchtungsfehler können zu einem vorzeitigen Ausfall führen.

Wie wird die Qualität bei der Herstellung von Wechselstromgeneratoren durch die Endbearbeitung sichergestellt?

Die Veredelungsphase umfasst mehrere Verfahren, die die Leistung verbessern und vor Umwelteinflüssen schützen sollen. Diese Verfahren können Folgendes umfassen:

- Beschichtung: Aufbringen von Schutzschichten zum Schutz vor Korrosion und Verschleiß.

- Ausgleichen: Sicherstellen, dass der Rotor richtig ausgewuchtet ist, um die Vibrationen während des Betriebs zu minimieren.

- Abschließende Inspektion: Eine gründliche Kontrolle auf Mängel oder Unstimmigkeiten, bevor das Produkt verpackt wird.

Die Endbearbeitung ist von entscheidender Bedeutung, um sicherzustellen, dass der Generator den verschiedenen Betriebsbedingungen standhält und über Jahre hinweg hält.

Welche Qualitätssicherungsmaßnahmen werden bei der Herstellung von Generatoren ergriffen?

Die Qualitätssicherung (QS) ist bei der Herstellung von Generatoren von entscheidender Bedeutung, da sie sich direkt auf deren Leistung und Lebensdauer auswirkt.

Welche internationalen Normen regeln die Qualität von Lichtmaschinen?

Die Hersteller halten sich häufig an internationale Normen wie ISO 9001, die einen Rahmen für Qualitätsmanagementsysteme bieten. Dies gewährleistet gleichbleibende Qualität und kontinuierliche Verbesserung während des gesamten Herstellungsprozesses. Weitere relevante Zertifizierungen können sein:

- CE-Kennzeichnung: Kennzeichnet die Einhaltung der europäischen Gesundheits-, Sicherheits- und Umweltschutznormen.

- API-Standards: Besonders wichtig für Generatoren, die in Hochleistungsanwendungen eingesetzt werden.

Diese Zertifizierungen erhöhen nicht nur die Glaubwürdigkeit des Herstellers, sondern sichern den Käufern auch die Zuverlässigkeit des Produkts zu.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Was sind die wichtigsten Punkte der Qualitätskontrolle bei der Herstellung von Generatoren?

Die Qualitätskontrolle (QC) ist in verschiedene Phasen des Herstellungsprozesses integriert. Zu den wichtigsten Kontrollpunkten gehören:

- Eingangsqualitätskontrolle (IQC): Bewertung von Rohstoffen bei ihrer Ankunft, um sicherzustellen, dass sie den vorgegebenen Standards entsprechen.

- In-Process-Qualitätskontrolle (IPQC): Kontinuierliche Überwachung während des Herstellungsprozesses, um Probleme frühzeitig zu erkennen und zu beheben.

- Endkontrolle (FQC): Umfassende Prüfung des Endprodukts, um sicherzustellen, dass es alle Spezifikationen und Leistungsstandards erfüllt.

Diese Kontrollpunkte stellen sicher, dass etwaige Mängel sofort erkannt und behoben werden, wodurch das Risiko von Fehlern im Feld minimiert wird.

Wie werden gängige Prüfverfahren zur Sicherstellung der Leistung von Generatoren eingesetzt?

Prüfverfahren sind entscheidend für die Überprüfung der Betriebseffizienz und Zuverlässigkeit von Generatoren. Zu den üblichen Prüfverfahren gehören:

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

- Prüfung des Spannungsausgangs: Misst die Fähigkeit der Lichtmaschine, unter verschiedenen Bedingungen eine ausreichende Spannung zu erzeugen.

- Belastungstest: Bewertet die Leistung des Generators unter verschiedenen elektrischen Lasten und simuliert den realen Einsatz.

- Wärmebildtechnik: Hilft bei der Erkennung von Überhitzungsproblemen, die zum Ausfall von Komponenten führen können.

Diese Tests sind unerlässlich, um sicherzustellen, dass die Generatoren den Anforderungen im täglichen Gebrauch standhalten.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

Für internationale B2B-Einkäufer, insbesondere für solche aus verschiedenen Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, ist die Überprüfung der Qualitätskontrollverfahren von Lieferanten von entscheidender Bedeutung. Einkäufer können mehrere Schritte unternehmen:

- Durchführung von Audits: Regelmäßige Audits bei den Lieferanten tragen dazu bei, die Einhaltung von Qualitätsstandards und -praktiken zu gewährleisten.

- Qualitätsberichte anfordern: Die Lieferanten sollten eine Dokumentation vorlegen, in der ihre QC-Prozesse und Testergebnisse ausführlich beschrieben sind.

- Inspektionen durch Dritte: Die Beauftragung unabhängiger Prüfer kann eine unvoreingenommene Bewertung der Herstellungs- und Qualitätssicherungsprozesse eines Lieferanten bieten.

Das Verständnis der Feinheiten von Qualitätszertifizierungen und -praktiken ist für Käufer von entscheidender Bedeutung, um Risiken im Zusammenhang mit Produktfehlern zu minimieren und sicherzustellen, dass sie qualitativ hochwertige Generatoren beziehen.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Schlussfolgerung: Wie wirkt sich die Qualitätssicherung auf die Lebensdauer eines Generators aus?

Zusammenfassend lässt sich sagen, dass die Herstellungsverfahren und Qualitätssicherungsmaßnahmen für Generatoren entscheidend für deren Lebensdauer und Leistung sind. Wenn B2B-Einkäufer diese Prozesse verstehen, können sie fundierte Entscheidungen treffen und sicherstellen, dass sie in zuverlässige Produkte investieren, die ihre betrieblichen Anforderungen erfüllen. Der Aufbau enger Beziehungen zu seriösen Lieferanten, die sich an internationale Standards halten, verbessert nicht nur die Produktqualität, sondern fördert auch langfristige Partnerschaften in der Automobilbranche.

Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘wie lange hält die Lichtmaschine im Auto’

In der Welt der Beschaffung von Kfz-Teilen ist das Verständnis für die Langlebigkeit und Zuverlässigkeit von Komponenten wie Lichtmaschinen entscheidend für die Aufrechterhaltung der Fahrzeugleistung. Dieser Leitfaden bietet eine umfassende Checkliste für B2B-Einkäufer, die Lichtmaschinen beschaffen möchten. So können sie fundierte Entscheidungen treffen, die die betriebliche Effizienz steigern und Ausfallzeiten reduzieren.

Schritt 1: Verstehen Sie die Lebensdauer von Lichtmaschinen

Bevor Sie eine Beschaffungsentscheidung treffen, sollten Sie sich mit der typischen Lebensdauer von Generatoren vertraut machen, die zwischen 7 und 10 Jahren oder 80.000 und 150.000 Meilen liegt. Anhand dieser Angaben können Sie die Erwartungen für die Austauschzyklen festlegen und Ihren Bestand entsprechend planen. Berücksichtigen Sie die Fahrbedingungen und -gewohnheiten Ihres Zielmarktes, da diese Faktoren die Langlebigkeit von Lichtmaschinen erheblich beeinflussen.

Schritt 2: Bewerten Sie die Anforderungen Ihres Fuhrparks

Ermitteln Sie die spezifischen Anforderungen Ihres Fuhrparks, einschließlich der Fahrzeugtypen und ihrer elektrischen Anforderungen. Fahrzeuge mit hohem Stromverbrauch, z. B. solche mit fortschrittlichen Infotainmentsystemen oder zusätzlichem Zubehör, benötigen möglicherweise robustere Generatoren. Dokumentieren Sie die erforderlichen Spezifikationen, um die Kompatibilität und Leistung Ihrer gesamten Flotte sicherzustellen.

Schritt 3: Lieferantenzertifizierungen bewerten

Es ist wichtig zu überprüfen, ob potenzielle Lieferanten die Industrienormen erfüllen und über einschlägige Zertifizierungen wie ISO 9001 oder gleichwertige Zertifikate verfügen. Diese Zertifizierungen zeigen, dass sie sich zu Qualität und Zuverlässigkeit verpflichtet haben, was für Automobilkomponenten entscheidend ist. Fordern Sie Unterlagen an, um diese Zertifizierungen zu bestätigen, und prüfen Sie, ob die Zulieferer bewährte Verfahren in der Fertigung anwenden.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Schritt 4: Analysieren Sie Leistungsnachweise und Bewertungen von Lieferanten

Informieren Sie sich über die Erfolgsbilanz potenzieller Lieferanten, indem Sie Kundenrezensionen und Fallstudien lesen. Wenden Sie sich an andere Unternehmen in Ihrer Branche, um deren Erfahrungen mit bestimmten Lieferanten zu erfahren. Die Zuverlässigkeit und der Kundenservice eines Lieferanten können Ihre Beschaffungsentscheidungen erheblich beeinflussen.

Schritt 5: Detaillierte Produktspezifikationen anfordern

Wenn Sie Generatoren in Erwägung ziehen, sollten Sie von den Lieferanten detaillierte Spezifikationen anfordern, einschließlich Leistungsabgabe, Kompatibilität und Garantieinformationen. Wenn Sie die technischen Details kennen, können Sie sicherstellen, dass die Generatoren Ihren betrieblichen Anforderungen entsprechen und das Risiko eines vorzeitigen Ausfalls minimieren. Achten Sie auf die verwendeten Materialien und die in den Generatoren eingesetzte Technologie.

Schritt 6: Vergleichen Sie Preise und Gesamtbetriebskosten

Der Preis ist zwar ein entscheidender Faktor, doch sollten auch die Gesamtbetriebskosten berücksichtigt werden, zu denen Installation, Wartung und mögliche Ausfallzeiten gehören. Günstigere Generatoren bieten nicht immer den besten Wert, wenn sie häufig ausgetauscht werden müssen oder zu Ineffizienzen im Betrieb führen. Erstellen Sie eine vergleichende Analyse, um die Anschaffungskosten gegen die langfristige Leistung abzuwägen.

Schritt 7: Einen Qualitätssicherungsprozess einrichten

Führen Sie einen Qualitätssicherungsprozess ein, um die Leistung von Generatoren nach dem Kauf zu überwachen. Regelmäßige Inspektionen und Leistungsbewertungen können dazu beitragen, potenzielle Probleme zu erkennen, bevor sie zu Ausfällen führen. Dieser proaktive Ansatz verlängert nicht nur die Lebensdauer der Generatoren, sondern gewährleistet auch die Zuverlässigkeit Ihres gesamten Fuhrparks.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Anhand dieser Checkliste können B2B-Einkäufer bei der Beschaffung von Generatoren fundierte Entscheidungen treffen, die letztlich die Zuverlässigkeit und Effizienz ihrer Fahrzeugflotten verbessern.

Umfassende Kosten- und Preisanalyse für Wie lange hält eine Lichtmaschine im Auto Sourcing

Bei der Beschaffung von Generatoren für Fahrzeuge ist es für internationale B2B-Einkäufer entscheidend, die Kostenstruktur und Preisdynamik zu verstehen. In diesem Abschnitt werden die wichtigsten Kostenkomponenten, preisbeeinflussende Faktoren und Tipps für Einkäufer beschrieben, um die Komplexität der Beschaffung von Generatoren zu bewältigen.

Was sind die wichtigsten Kostenkomponenten für Generatoren?

-

Materialien: Zu den wichtigsten Materialien bei der Herstellung von Generatoren gehören Metalle (Aluminium, Kupfer), Kunststoffe für die Gehäuse und verschiedene elektronische Komponenten. Die Qualität dieser Materialien wirkt sich direkt auf die Haltbarkeit und Leistung des Generators aus.

-

Arbeit: Die Arbeitskosten werden von der Region beeinflusst, in der die Produktion stattfindet. So kann die Herstellung in Ländern mit niedrigeren Arbeitskosten zu Einsparungen führen, was jedoch auch die Qualität beeinträchtigen kann. Qualifizierte Arbeitskräfte sind für den Zusammenbau komplizierter elektronischer Teile unerlässlich.

-

Fertigungsgemeinkosten: Dazu gehören Kosten für Einrichtungen, Versorgungsleistungen und indirekte Arbeit. Effiziente Herstellungsverfahren können die Gemeinkosten senken, was sich positiv auf die Preisgestaltung auswirkt.

-

Werkzeuge: Die Anfangsinvestitionen in die für die Produktion erforderlichen Werkzeuge und Ausrüstungen können erheblich sein. Kundenspezifische Werkzeuge für Spezialgeneratoren erhöhen die Anfangskosten, können aber langfristig zu einer besseren Preisgestaltung führen, wenn die Produktionsmengen die Investition rechtfertigen.

-

Qualitätskontrolle (QC): Strenge Qualitätskontrollverfahren stellen sicher, dass die Generatoren den Industriestandards entsprechen. Dies ist zwar mit zusätzlichen Kosten verbunden, aber es ist unerlässlich, um das Risiko von Ausfällen zu verringern, die zu kostspieligen Garantieansprüchen und Ersatzlieferungen führen können.

-

Logistik: Die Versandkosten variieren je nach Herkunft und Bestimmungsort der Produkte. Faktoren wie Entfernung, Transportart und Zölle beeinflussen die gesamten Logistikkosten erheblich.

-

Marge: Um die Rentabilität zu gewährleisten, schlagen die Lieferanten in der Regel auf ihre Kosten auf. Diese Marge kann je nach Marktbedingungen, Wettbewerb und wahrgenommenem Wert stark variieren.

Wie beeinflussen Preiseinflussfaktoren die Preisgestaltung von Wechselstromgeneratoren?

-

Volumen/MOQ (Mindestbestellmenge): Bei größeren Aufträgen sind die Preise aufgrund von Größenvorteilen oft günstiger. Die Einkäufer sollten ihren Bedarf abschätzen, um günstige Konditionen auszuhandeln.

-

Spezifikationen und Anpassung: Kundenspezifische Lichtmaschinen, die für bestimmte Fahrzeugmodelle oder Leistungsanforderungen entwickelt wurden, können zusätzliche Kosten verursachen. Die Käufer sollten ihre Anforderungen klar definieren, um genaue Angebote zu erhalten.

-

Materialien und Qualitätszertifizierungen: Wechselstromgeneratoren aus hochwertigen Materialien oder solche, die internationalen Zertifizierungen (z. B. ISO) entsprechen, sind zwar teurer, bieten aber eine höhere Zuverlässigkeit.

-

Lieferantenfaktoren: Der Ruf, die Zuverlässigkeit und die finanzielle Stabilität des Lieferanten können sich auf die Preisgestaltung auswirken. Etablierte Lieferanten können aufgrund ihrer nachgewiesenen Erfolgsbilanz mehr verlangen.

-

Incoterms: Die Kenntnis der Lieferbedingungen (z. B. FOB, CIF) ist für die Ermittlung der gesamten Anlandungskosten von wesentlicher Bedeutung. Käufer sollten Bedingungen aushandeln, die das Risiko und die Kosten minimieren.

Was sind die besten Praktiken für B2B-Einkäufer bei der Beschaffung von Lichtmaschinen?

-

Verhandlung: Führen Sie Gespräche mit mehreren Lieferanten, um Preise und Konditionen zu vergleichen. Nutzen Sie Ihre Kaufkraft, insbesondere wenn Sie ein Wiederholungskäufer sind.

-

Kosteneffizienz: Berücksichtigen Sie nicht nur den Kaufpreis, sondern auch die Gesamtbetriebskosten (TCO - Total Cost of Ownership). Dazu gehören die Kosten für Installation, Wartung und potenzielle Ausfallzeiten im Zusammenhang mit dem Ausfall eines Generators.

-

Preisgestaltung für internationale Käufer: Einkäufer aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa müssen Währungsschwankungen, Einfuhrzölle und lokale Vorschriften berücksichtigen, die sich auf die Endkosten auswirken können. Der Aufbau von Beziehungen zu lokalen Lieferanten kann helfen, diese Herausforderungen zu bewältigen.

-

Qualitätssicherung: Geben Sie der Qualität immer den Vorrang vor dem niedrigsten Preis. Eine billigere Lichtmaschine kann auf lange Sicht zu höheren Kosten durch Ausfälle und Ersatz führen.

-

Markttrends: Bleiben Sie über Markttrends auf dem Laufenden, z. B. über Verschiebungen bei den Materialkosten oder technologische Fortschritte bei der Konstruktion von Generatoren. Dieses Wissen kann bei Verhandlungen und Beschaffungsentscheidungen von Vorteil sein.

Haftungsausschluss zu Preisen

Die Preise für Generatoren können aufgrund der oben genannten Faktoren erheblich schwanken. Die angegebenen Schätzungen sind Richtwerte und können sich aufgrund von Marktbedingungen, Preisstrategien der Lieferanten und Schwankungen der Materialkosten ändern. Die Käufer werden aufgefordert, gründliche Marktforschung zu betreiben und mehrere Angebote einzuholen, um sich das bestmögliche Angebot zu sichern.

Analyse der Alternativen: Vergleich der Lebensdauer der Lichtmaschine im Auto mit anderen Lösungen

Alternativen für die Stromerzeugung in Fahrzeugen kennenlernen

In der Automobilindustrie spielt die Lichtmaschine eine entscheidende Rolle, denn sie erzeugt elektrische Energie zum Laden der Batterie und zur Unterstützung verschiedener Fahrzeugsysteme. Mit der Weiterentwicklung der Technologie rücken jedoch Alternativen zu herkömmlichen Lichtmaschinen immer mehr in den Vordergrund. Diese Alternativen können unterschiedliche Vorteile in Bezug auf Leistung, Kosten und Wartung bieten, so dass es für B2B-Käufer wichtig ist, ihre Optionen zu bewerten.

Vergleichstabelle

| Vergleichsaspekt | Wie lange hält die Lichtmaschine im Auto | Hybridelektrische Systeme | Start-Stopp-Systeme |

|---|---|---|---|

| Leistung | 7-10 Jahre oder 80.000-150.000 Meilen | Verbesserte Kraftstoffeffizienz und geringere Emissionen | Verbesserter Kraftstoffverbrauch und geringere Emissionen |

| Kosten | $100 - $800 als Ersatz | Höhere Anfangsinvestition, $1.500 - $4.000+ | Moderater Kostenanstieg, $200 - $600 für Systemintegration |

| Einfache Implementierung | Standardeinbau für die meisten Fahrzeuge | Komplexe Integration, erfordert Spezialwissen | Geringe Komplexität, kann bei bestehenden Modellen nachgerüstet werden |

| Wartung | Erfordert regelmäßige Inspektionen und gelegentlichen Austausch | Geringer Wartungsaufwand nach der Installation | Routinewartung für Batterie- und Systemprüfungen erforderlich |

| Bester Anwendungsfall | Allgemeine Verwendung in konventionellen Fahrzeugen | Stadtverkehr und umweltbewusste Flotten | Stadtfahrten mit häufigen Stopps, wie Taxis und Lieferfahrzeuge |

Detaillierte Aufschlüsselung der Alternativen

Hybridelektrische Systeme:

Hybridelektrische Systeme nutzen sowohl einen Verbrennungs- als auch einen Elektromotor, was die Kraftstoffeffizienz deutlich erhöht und die Emissionen reduziert. Diese Systeme können aufgrund ihres optimierten Energiemanagements länger halten als herkömmliche Lichtmaschinen. Sie sind jedoch mit einer höheren Anfangsinvestition verbunden und eignen sich daher eher für Unternehmen, die auf Nachhaltigkeit bedacht sind, oder für solche, die in städtischen Umgebungen arbeiten, wo Kraftstoffeinsparungen maximiert werden können. Der Wartungsaufwand ist in der Regel gering, aber die Installation erfordert spezielle Fachkenntnisse, was für Flottenbetreiber eine Herausforderung darstellen kann.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Start-Stopp-Systeme:

Start-Stopp-Systeme schalten den Motor automatisch ab, wenn das Fahrzeug stillsteht, und starten ihn wieder, wenn der Fahrer Gas gibt. Diese Technologie ist vor allem im Stadtverkehr von Vorteil, wo Fahrzeuge häufig anhalten und anfahren. Die Kosten für die Einführung von Start-Stopp-Systemen sind zwar moderat, doch die Vorteile sind ein geringerer Kraftstoffverbrauch und weniger Emissionen. Eine Wartung ist notwendig, um sicherzustellen, dass die Batterie und der Anlasser ordnungsgemäß funktionieren, aber dieses System kann oft in bestehende Fahrzeuge nachgerüstet werden, was den Fuhrparkmanagern Flexibilität bietet.

Fazit: Die richtige Lösung für Ihre Anforderungen auswählen

Bei der Auswahl der besten Stromerzeugungslösung für Ihren Fuhrpark sollten Sie Ihr Betriebsumfeld, Ihr Budget und Ihre Wartungsmöglichkeiten berücksichtigen. Herkömmliche Lichtmaschinen sind nach wie vor eine zuverlässige Option für viele Fahrzeuge, insbesondere für weniger anspruchsvolle Anwendungen. Wenn Ihr Fuhrpark jedoch in städtischen Gebieten mit starkem Stop-and-Go-Verkehr eingesetzt wird, kann die Prüfung von Hybrid- oder Start-Stopp-Systemen langfristig erhebliche Einsparungen und Umweltvorteile bringen. Letztendlich sollte die Entscheidung mit Ihren Geschäftszielen übereinstimmen, indem Sie Leistung, Kosten und Wartungsaspekte abwägen, um die Effizienz Ihrer Flotte zu optimieren.

Wesentliche technische Eigenschaften und Fachterminologie für Wie lange hält die Lichtmaschine im Auto?

Was sind die wesentlichen technischen Eigenschaften eines Generators?

Das Verständnis der technischen Spezifikationen einer Lichtmaschine ist für B2B-Einkäufer von entscheidender Bedeutung, insbesondere bei der Beschaffung von Komponenten für die Fahrzeugherstellung oder -reparatur. Hier sind einige wichtige Eigenschaften, die Sie beachten sollten:

1. Ausgangsspannung

Die Ausgangsspannung einer Lichtmaschine liegt normalerweise zwischen 12 und 14,5 V. Diese Angabe ist entscheidend, da sie die Fähigkeit der Lichtmaschine bestimmt, die Fahrzeugbatterie effektiv zu laden. Eine zuverlässige Ausgangsspannung sorgt dafür, dass alle elektrischen Systeme reibungslos funktionieren und das Risiko von Fahrzeugausfällen minimiert wird.

2. Nennstromstärke

Die Amperezahl gibt die Stromausgangsleistung der Lichtmaschine an, die bei Standardfahrzeugen in der Regel zwischen 60 und 150 Ampere liegt. Dies ist für B2B-Käufer von Bedeutung, da es die elektrische Last beeinflusst, die die Lichtmaschine bewältigen kann, insbesondere bei Fahrzeugen mit anspruchsvollen Systemen wie modernen Audiosystemen oder zusätzlicher Beleuchtung.

3. Lagertyp

Lichtmaschinen können entweder mit Kugel- oder mit Rollenlagern ausgestattet sein. Die Art des Lagers beeinflusst die Langlebigkeit und Leistung der Lichtmaschine. Kugellager bieten in der Regel eine höhere Geschwindigkeit und einen besseren Wirkungsgrad, während Rollenlager eine höhere Stabilität bei schweren Lasten bieten können. Das Verständnis dieser Unterschiede hilft bei der Auswahl des richtigen Generators für bestimmte Anwendungen.

4. Mechanismus der Kühlung

Wechselstromgeneratoren können entweder mit passiven oder aktiven Kühlsystemen ausgestattet sein. Die passive Kühlung beruht auf dem Luftstrom um das Gerät, während die aktive Kühlung zusätzliche Lüfter umfassen kann. Diese Angabe ist für B2B-Käufer von entscheidender Bedeutung, da wirksame Kühlmechanismen die Lebensdauer des Generators verlängern können, indem sie eine Überhitzung verhindern, insbesondere in extremen Betriebsumgebungen.

5. Montage Typ

Die Montagekonfiguration einer Lichtmaschine kann je nach Fahrzeugdesign variieren. Zu den gängigen Typen gehören seitlich und hinten montierte Optionen. Die Kenntnis der Montageart ist entscheidend für die Kompatibilität mit verschiedenen Fahrzeugmodellen und gewährleistet eine nahtlose Integration in den Herstellungs- oder Reparaturprozess.

Was sind gängige Handelsbegriffe im Zusammenhang mit Lichtmaschinen?

Die Vertrautheit mit dem Branchenjargon kann die Kommunikation und die Transaktionen zwischen Käufern und Lieferanten vereinfachen. Hier sind einige wichtige Begriffe:

1. OEM (Originalgerätehersteller)

OEM bezieht sich auf den Originalhersteller der Fahrzeugteile, einschließlich Lichtmaschinen. B2B-Einkäufer bevorzugen oft OEM-Teile wegen ihrer Zuverlässigkeit und Kompatibilität mit bestehenden Systemen, da sie sicherstellen, dass die Komponenten den ursprünglichen Spezifikationen entsprechen.

2. MOQ (Mindestbestellmenge)

Die Mindestbestellmenge gibt die kleinste Stückzahl an, die ein Lieferant zu verkaufen bereit ist. Die MOQ ist für B2B-Einkäufer von entscheidender Bedeutung, um den Bestand effektiv zu verwalten und die Kosteneffizienz des Einkaufs von Generatoren in großen Mengen zu beurteilen.

3. RFQ (Angebotsanfrage)

Eine Anfrage ist ein Dokument, das an Lieferanten geschickt wird, um Preisinformationen zu bestimmten Produkten, wie z. B. Generatoren, anzufordern. Dies ist ein wichtiger Schritt für B2B-Einkäufer, um Kosten zu vergleichen und Bedingungen auszuhandeln, bevor sie eine Kaufentscheidung treffen.

4. Incoterms (Internationale Handelsklauseln)

Incoterms sind international anerkannte Regeln, die die Verantwortlichkeiten von Käufern und Verkäufern bei internationalen Transaktionen festlegen. Das Verständnis dieser Bedingungen hilft B2B-Einkäufern bei der Navigation in Bezug auf Versand, Lieferung und Risikomanagement bei der Beschaffung von Generatoren von globalen Lieferanten.

5. Ersatzteile

Aftermarket-Teile sind Komponenten, die von anderen Herstellern als dem Erstausrüster produziert werden. Diese Teile sind oft kostengünstiger, können aber in der Qualität variieren. B2B-Einkäufer sollten die Vorteile und Risiken des Einsatzes von Aftermarket-Generatoren auf der Grundlage ihrer Anwendungsanforderungen abwägen.

Wenn B2B-Käufer diese technischen Eigenschaften und Handelsbegriffe kennen, können sie fundierte Entscheidungen über Lichtmaschinen treffen und so eine optimale Leistung und Zuverlässigkeit ihrer Fahrzeuge sicherstellen.

Navigieren durch Marktdynamik und Beschaffungstrends im Sektor "Wie lange hält eine Lichtmaschine im Auto?

Was sind die wichtigsten Marktdynamiken, die die Lebensdauer von Kfz-Generatoren beeinflussen?

Im Automobilsektor wird die Lebensdauer von Lichtmaschinen von verschiedenen globalen Faktoren beeinflusst, darunter technologischer Fortschritt, Verbraucherverhalten und regionale Marktdynamik. Mit einer durchschnittlichen Lebensdauer von 7 bis 10 Jahren bzw. 80.000 bis 150.000 Meilen wird die Haltbarkeit von Generatoren für internationale B2B-Käufer immer wichtiger. Die zunehmende Verbreitung von Elektro- und Hybridfahrzeugen führt zu Fortschritten in der Generatorentechnologie, wobei der Schwerpunkt auf Effizienz und Leistung liegt. In Regionen wie Afrika und Südamerika, wo der Zugang zu zuverlässigen Automobilkomponenten schwierig sein kann, ist die Beschaffung von hochwertigen Generatoren von entscheidender Bedeutung.

Zu den sich abzeichnenden Trends gehört die Integration intelligenter Technologien, wie z. B. Diagnosesysteme, die die Leistung von Generatoren in Echtzeit überwachen. Diese Innovation ermöglicht eine proaktive Wartung und verringert das Risiko unerwarteter Ausfälle. Außerdem steigt die Nachfrage nach Ersatzteilen, was die Hersteller dazu veranlasst, sich auf die Herstellung langlebiger und kostengünstiger Generatoren zu konzentrieren. Internationale Käufer sollten auch die Schwankungen der Rohstoffpreise beachten, die sich auf die Beschaffungsstrategien auswirken können.

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?

Wie können Nachhaltigkeit und ethische Beschaffung den Lichtmaschinenmarkt beeinflussen?

Die Umweltauswirkungen von Automobilkomponenten, einschließlich Generatoren, haben B2B-Einkäufer dazu veranlasst, der Nachhaltigkeit in ihren Beschaffungsstrategien Vorrang einzuräumen. Ethische Lieferketten werden immer wichtiger, da die Verbraucher Transparenz in Bezug auf die verwendeten Materialien und die beteiligten Produktionsprozesse fordern. Die Einkäufer werden ermutigt, nach Lieferanten zu suchen, die sich an grüne‘ Zertifizierungen halten, die sicherstellen können, dass die Materialien verantwortungsbewusst beschafft werden und die Herstellungsprozesse den ökologischen Fußabdruck minimieren.

Darüber hinaus stehen die Hersteller angesichts der weltweit verschärften Vorschriften für Kohlenstoffemissionen unter dem Druck, energieeffizientere Generatoren herzustellen. Dieser Wandel kommt nicht nur der Umwelt zugute, sondern verbessert auch die Marktfähigkeit der Produkte. B2B-Einkäufer sollten Partnerschaften mit Lieferanten in Erwägung ziehen, die sich zu nachhaltigen Praktiken verpflichten, da diese Beziehungen zu langfristigen Vorteilen führen können, einschließlich reduzierter Kosten und eines besseren Markenrufs.

Was ist der historische Kontext der Lebensdauer von Lichtmaschinen in der Automobiltechnik?

Die Entwicklung von Lichtmaschinen geht auf das frühe 20. Jahrhundert zurück, als Generatoren in erster Linie zum Betrieb von elektrischen Systemen in Kraftfahrzeugen verwendet wurden. Anfänglich hatten diese Systeme eine begrenzte Lebensdauer und Effizienz und mussten häufig ausgetauscht werden. Die Einführung der Lichtmaschine in den 1960er Jahren revolutionierte jedoch die elektrischen Systeme von Kraftfahrzeugen und sorgte für mehr Effizienz und Zuverlässigkeit.

Im Laufe der Jahre haben Fortschritte bei den Materialien und Herstellungsverfahren die Lebensdauer von Generatoren erheblich verlängert. Moderne Generatoren sind so konstruiert, dass sie härteren Bedingungen und höheren elektrischen Belastungen standhalten, was die steigende Nachfrage nach moderner Fahrzeugelektronik widerspiegelt. Das Verständnis dieses historischen Kontextes ermöglicht es internationalen B2B-Einkäufern, die technologischen Fortschritte zu verstehen, die zur aktuellen Lebensdauer von Generatoren beitragen, und so fundierte Beschaffungsentscheidungen in einem wettbewerbsintensiven Markt zu treffen.

Häufig gestellte Fragen (FAQs) für B2B-Käufer zu "Wie lange hält die Lichtmaschine im Auto?

-

Wie lange hält eine Lichtmaschine in einem Fahrzeug normalerweise?

Die Lebensdauer einer Lichtmaschine beträgt in der Regel zwischen 7 und 10 Jahren oder etwa 80.000 bis 150.000 Meilen und hängt von verschiedenen Faktoren ab. Dazu gehören Fahrgewohnheiten, Wartungspraktiken und Umweltbedingungen. Häufige Kurzstreckenfahrten können die Lichtmaschine belasten, während extreme Temperaturen den Verschleiß beschleunigen können. Regelmäßige Wartungsarbeiten, wie z. B. die Überprüfung der Riemen und der Batterie, können die Lebensdauer der Lichtmaschine verlängern und eine zuverlässige Leistung über einen längeren Zeitraum gewährleisten. -

Was sind die häufigsten Anzeichen für eine defekte Lichtmaschine?

Häufige Anzeichen für eine defekte Lichtmaschine sind das Abblenden der Scheinwerfer, Warnleuchten am Armaturenbrett und ungewöhnliche Geräusche wie Heulen oder Quietschen. Andere Symptome können Startschwierigkeiten oder häufiges Abwürgen des Fahrzeugs sein. Wenn Sie eines dieser Anzeichen bemerken, sollten Sie die Lichtmaschine umgehend überprüfen lassen, um weitere Schäden zu vermeiden und die Betriebsbereitschaft des Fahrzeugs zu gewährleisten. -

Welche Faktoren beeinflussen die Lebensdauer eines Generators?

Wie lange eine Lichtmaschine hält, hängt von mehreren Faktoren ab, unter anderem von der Qualität der Lichtmaschine selbst, dem Gesamtzustand des Fahrzeugs und den elektrischen Anforderungen, die an sie gestellt werden. Fahrzeuge mit hoher elektronischer Beanspruchung oder häufigen Kurzfahrten können die Lichtmaschine schneller verschleißen. Außerdem können Umweltfaktoren wie extreme Hitze oder Kälte die Leistung beeinträchtigen. Regelmäßige Inspektionen und Wartungen können einige dieser Auswirkungen abmildern und die Lebensdauer verlängern. -

Wie kann ich die Lieferanten von Qualitätsgeneratoren überprüfen?

Bei der Beschaffung von Generatoren ist eine gründliche Due-Diligence-Prüfung potenzieller Lieferanten unerlässlich. Achten Sie auf Hersteller mit einer nachgewiesenen Erfolgsbilanz, positiven Kundenrezensionen und Qualitätszertifizierungen wie ISO-Normen. Fordern Sie Muster an, um die Fertigungsqualität und Leistung zu beurteilen. Achten Sie außerdem auf Lieferanten, die eindeutige Garantien und Kundendienstleistungen bieten, da dies ein Zeichen für Zuverlässigkeit und Kundenzufriedenheit ist. -

Wie hoch ist die typische Mindestbestellmenge für den Kauf von Lichtmaschinen in großen Mengen?

Die Mindestbestellmengen (MOQs) für Generatoren können je nach Lieferant und Region erheblich variieren. Im Allgemeinen liegen die MOQs zwischen 50 und 500 Stück, je nach Hersteller und Produktlinie. Es ist ratsam, mit den Lieferanten Bedingungen auszuhandeln, um die MOQs mit Ihren Einkaufskapazitäten in Einklang zu bringen. Einige Lieferanten bieten Flexibilität für Erstbestellungen oder Probeläufe, um eine Arbeitsbeziehung aufzubauen. -

Mit welchen Zahlungsbedingungen muss ich bei der internationalen Beschaffung von Generatoren rechnen?

Die Zahlungsbedingungen können bei internationalen Lieferanten sehr unterschiedlich sein. Zu den üblichen Vereinbarungen gehören Vorauszahlungen, Akkreditive oder die Zahlung bei Lieferung. Es ist wichtig, diese Bedingungen zu klären, bevor Sie einen Vertrag abschließen. Stellen Sie sicher, dass die Zahlungsmethode sicher ist und Schutz vor Betrug bietet. Ziehen Sie außerdem in Erwägung, bei größeren Transaktionen einen Treuhandservice in Anspruch zu nehmen, um Ihre Investition zu schützen. -

Welchen Einfluss haben Logistik und Versand auf die Beschaffung von Generatoren?

Die Logistik spielt eine entscheidende Rolle bei der rechtzeitigen Beschaffung von Generatoren. Faktoren wie Versandmethoden, Frachtkosten und Einfuhrzölle können die Gesamtkosten und Lieferfristen erheblich beeinflussen. Arbeiten Sie mit Lieferanten zusammen, die über etablierte Logistiknetzwerke verfügen und transparente Versandoptionen anbieten können. Berücksichtigen Sie die Gesamtkosten, einschließlich Versand- und Zollgebühren, um fundierte Kaufentscheidungen zu treffen. -

Auf welche Qualitätssicherungsmaßnahmen sollte ich bei Lieferanten von Lichtmaschinen achten?

Die Qualitätssicherung ist bei der Beschaffung von Generatoren von entscheidender Bedeutung, um Zuverlässigkeit und Leistung zu gewährleisten. Achten Sie auf Lieferanten, die strenge Testverfahren für ihre Produkte anwenden, einschließlich elektrischer Tests und Haltbarkeitsprüfungen. Zertifizierungen von anerkannten Normungsorganisationen können ebenfalls auf ein Engagement für Qualität hinweisen. Regelmäßige Audits und Feedbackschleifen können dazu beitragen, die Qualität über einen längeren Zeitraum zu erhalten und sicherzustellen, dass die Generatoren Ihre Spezifikationen und Leistungsanforderungen erfüllen.

Top 2 Wie lange hält die Lichtmaschine im Auto Hersteller & Lieferanten Liste

1. Ford - Einblicke in die Lebensdauer von Lichtmaschinen

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Durchschnittliche Lebensdauer der Lichtmaschine für den Ford Fusion: 180.000 Meilen gelten als hoch für eine Lichtmaschine. Zu den häufigen Problemen gehören verschlissene Bürsten im Spannungsregler, die in der Regel rund 200.000 Kilometer halten (etwa 124.274 Meilen). Einige Nutzer berichten, dass auch bei höheren Laufleistungen keine Probleme mit der Lichtmaschine auftreten, was darauf hindeutet, dass die Lichtmaschine bei ordnungsgemäßer Wartung deutlich länger halten kann.

2. Savannah Toyota - Austausch der Lichtmaschine

Domäne: savannahtoyota.com

Registriert: 1996 (29 Jahre)

Einleitung: Der Generator versorgt alle elektronischen Bauteile eines Fahrzeugs mit Strom, während der Motor läuft, und fungiert als Generator, der den Benzinmotor als Energiequelle nutzt. Er hält in der Regel zwischen 80.000 und 150.000 Meilen (etwa sieben Jahre). Die durchschnittlichen Kosten für einen neuen Generator liegen je nach Fahrzeugtyp zwischen $500 und $1.000. Anzeichen für einen defekten Generator sind unter anderem eine Batteriewarnleuchte, schwache Scheinwerfer, bu…

Strategische Beschaffung Schlussfolgerung und Ausblick für Wie lange hält die Lichtmaschine im Auto?

Die Lebensdauer eines Generators - in der Regel 7 bis 10 Jahre oder 80.000 bis 150.000 Meilen - ist für internationale B2B-Käufer von entscheidender Bedeutung. Faktoren wie Fahrgewohnheiten, Klimabedingungen, elektrische Belastung und Wartungspraktiken beeinflussen diese Lebensdauer erheblich. Durch die strategische Beschaffung hochwertiger Generatoren und Komponenten können Unternehmen die Zuverlässigkeit ihrer Fahrzeuge erhöhen und unerwartete Ausfallzeiten minimieren, was letztlich zu Kosteneinsparungen und einer verbesserten betrieblichen Effizienz führt.

Für B2B-Einkäufer in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa ist es wichtig, in zuverlässige Lieferanten und Hersteller zu investieren. Der Vorrang von Qualität vor Kosten kann zu langfristigen Vorteilen führen, da langlebige Generatoren die Häufigkeit des Austauschs und des Wartungsbedarfs verringern.

Mit Blick auf die Zukunft ist es wichtig, über neue Technologien und Trends in der Automobilindustrie informiert zu sein, die die Leistung von Generatoren beeinflussen können. Wenn Sie mit Lieferanten zusammenarbeiten, die Innovation und Nachhaltigkeit in den Vordergrund stellen, sichern Sie nicht nur Ihre Lieferkette, sondern positionieren Ihr Unternehmen auch für den Erfolg in einem sich entwickelnden Markt. Setzen Sie noch heute auf strategische Beschaffung, um sicherzustellen, dass Ihr Betrieb auch in den kommenden Jahren reibungslos und effizient läuft.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.

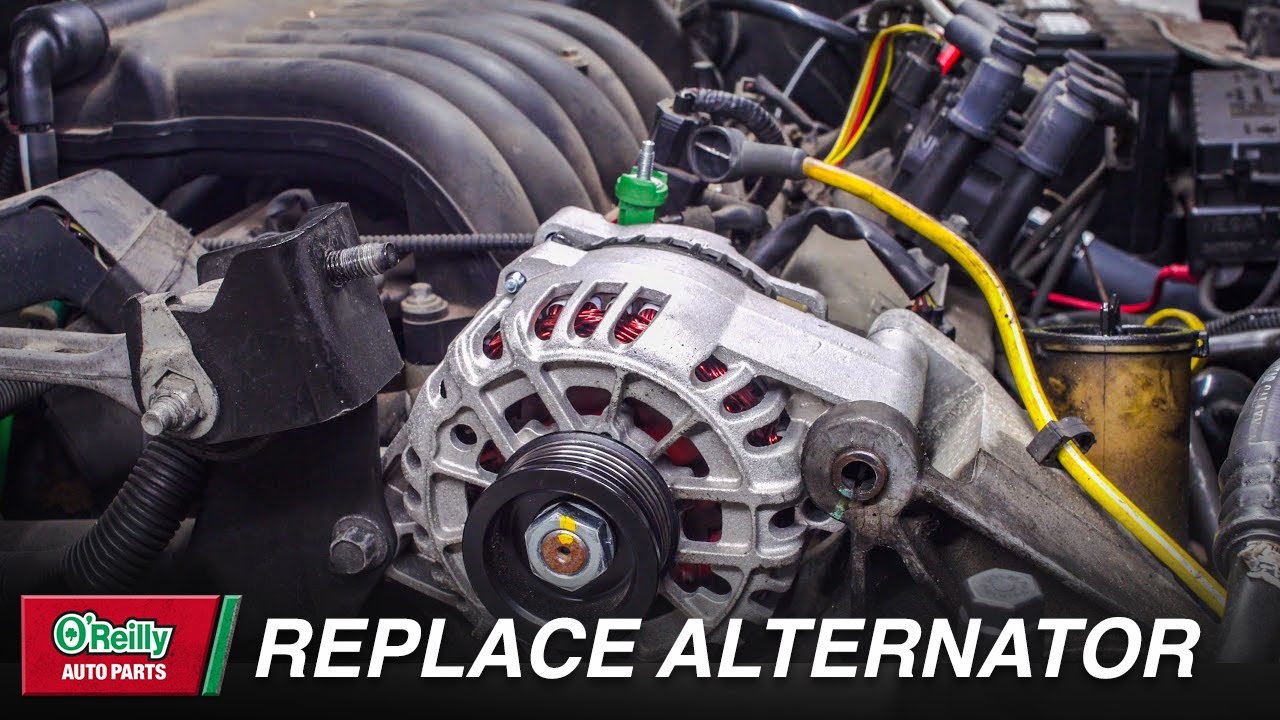

Illustratives Bild zu Wie lange hält die Lichtmaschine im Auto?