Introduction: Navigating the Global Market for what is the starter

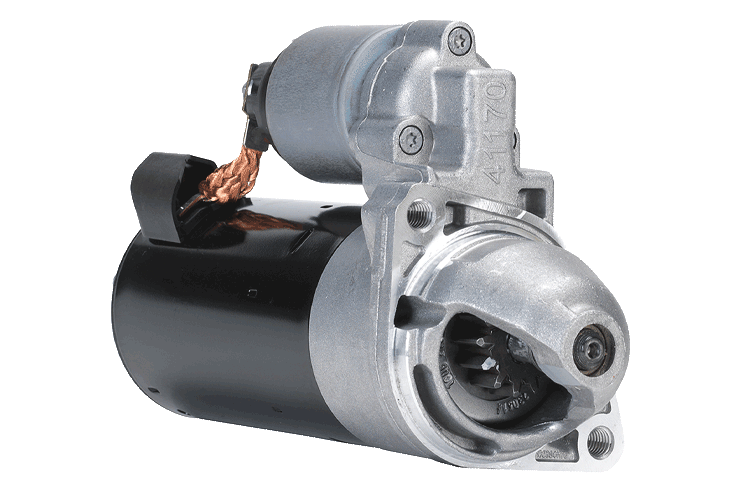

When it comes to sourcing reliable starter motors for vehicles, international B2B buyers often face the challenge of ensuring quality and compatibility across diverse markets. Understanding what a starter is and its critical role in automotive operations is essential for making informed purchasing decisions. This guide delves into the intricacies of starter motors, examining various types, their applications, and the vital aspects of supplier vetting. Buyers will find detailed insights into how starters function, the common causes of failure, and the importance of selecting the right components to avoid costly repairs.

As the automotive market continues to evolve, especially in regions like Africa, South America, the Middle East, and Europe—including key players like Germany and Vietnam—buyers must navigate a complex landscape of suppliers and products. This comprehensive resource empowers B2B buyers by providing actionable insights into the cost factors associated with starter motors, as well as strategies for effective sourcing. With a focus on quality assurance and long-term reliability, this guide will equip you with the knowledge needed to make strategic purchasing decisions, ensuring that your operations remain efficient and competitive in the global marketplace.

Inhaltsverzeichnis

- Top 4 What Is The Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is the starter

- Understanding what is the starter Types and Variations

- Key Industrial Applications of what is the starter

- 3 Common User Pain Points for ‘what is the starter’ & Their Solutions

- Strategic Material Selection Guide for what is the starter

- In-depth Look: Manufacturing Processes and Quality Assurance for what is the starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the starter’

- Comprehensive Cost and Pricing Analysis for what is the starter Sourcing

- Alternatives Analysis: Comparing what is the starter With Other Solutions

- Essential Technical Properties and Trade Terminology for what is the starter

- Navigating Market Dynamics and Sourcing Trends in the what is the starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is the starter

- Strategic Sourcing Conclusion and Outlook for what is the starter

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

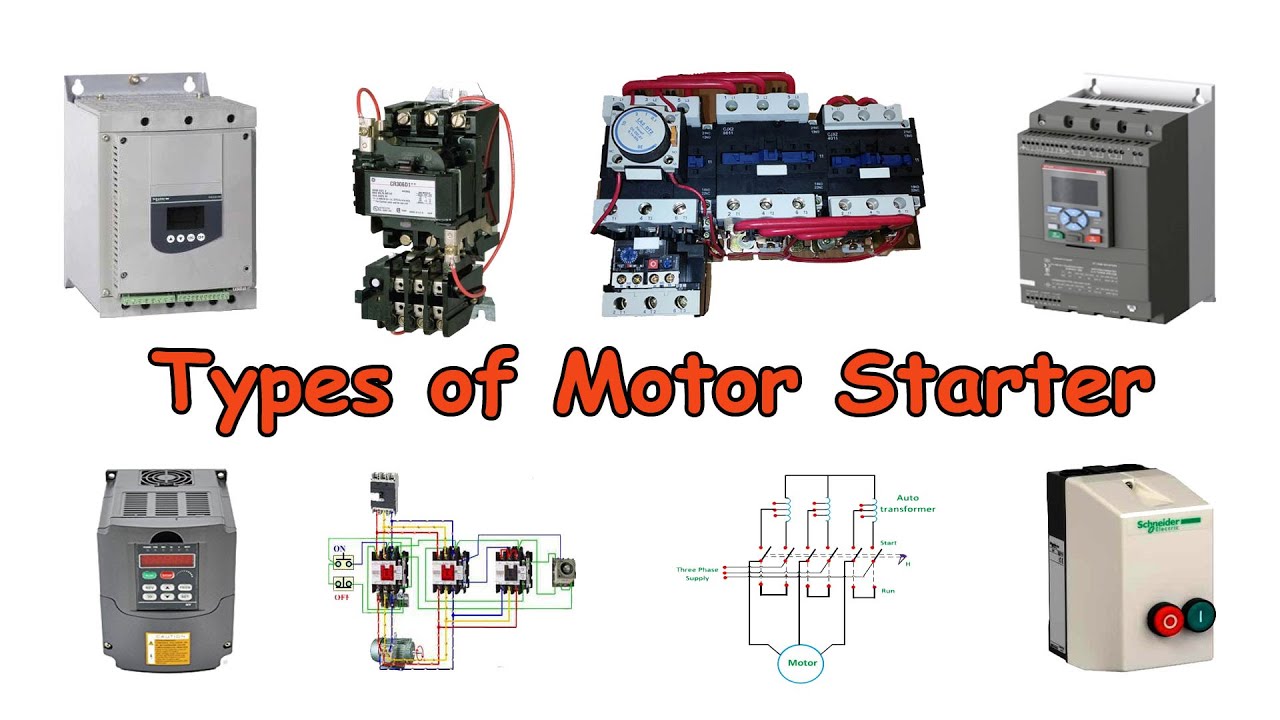

Understanding what is the starter Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Herkömmlicher Anlasser | Uses a solenoid for engagement and relies on a battery | Automotive repair shops, OEMs | Vorteile: Kostengünstig, weit verbreitet. Nachteile: Limited lifespan, prone to failure under heavy use. |

| Untersetzungsgetriebe-Anlasser | Employs a gear reduction mechanism for higher torque output | Heavy-duty vehicles, construction machinery | Vorteile: Greater torque, compact design. Nachteile: Higher initial cost, more complex installation. |

| Hochleistungsstarter | Entwickelt für Rennsport- oder Hochleistungsfahrzeuge | Motorsport teams, performance upgrades | Vorteile: Enhanced reliability, improved starting in extreme conditions. Nachteile: Expensive, may require specialized knowledge for installation. |

| Mini-Starter | Smaller, lightweight design optimized for space-constrained applications | Sports cars, compact vehicles | Vorteile: Platzsparend, leicht. Nachteile: Lower torque output, may not be suitable for larger engines. |

| Integrated Starter-Alternator | Combines starter and alternator functions in one unit | Hybrid vehicles, modern automotive applications | Vorteile: Space-efficient, improves fuel efficiency. Nachteile: Higher repair costs, complex design may complicate servicing. |

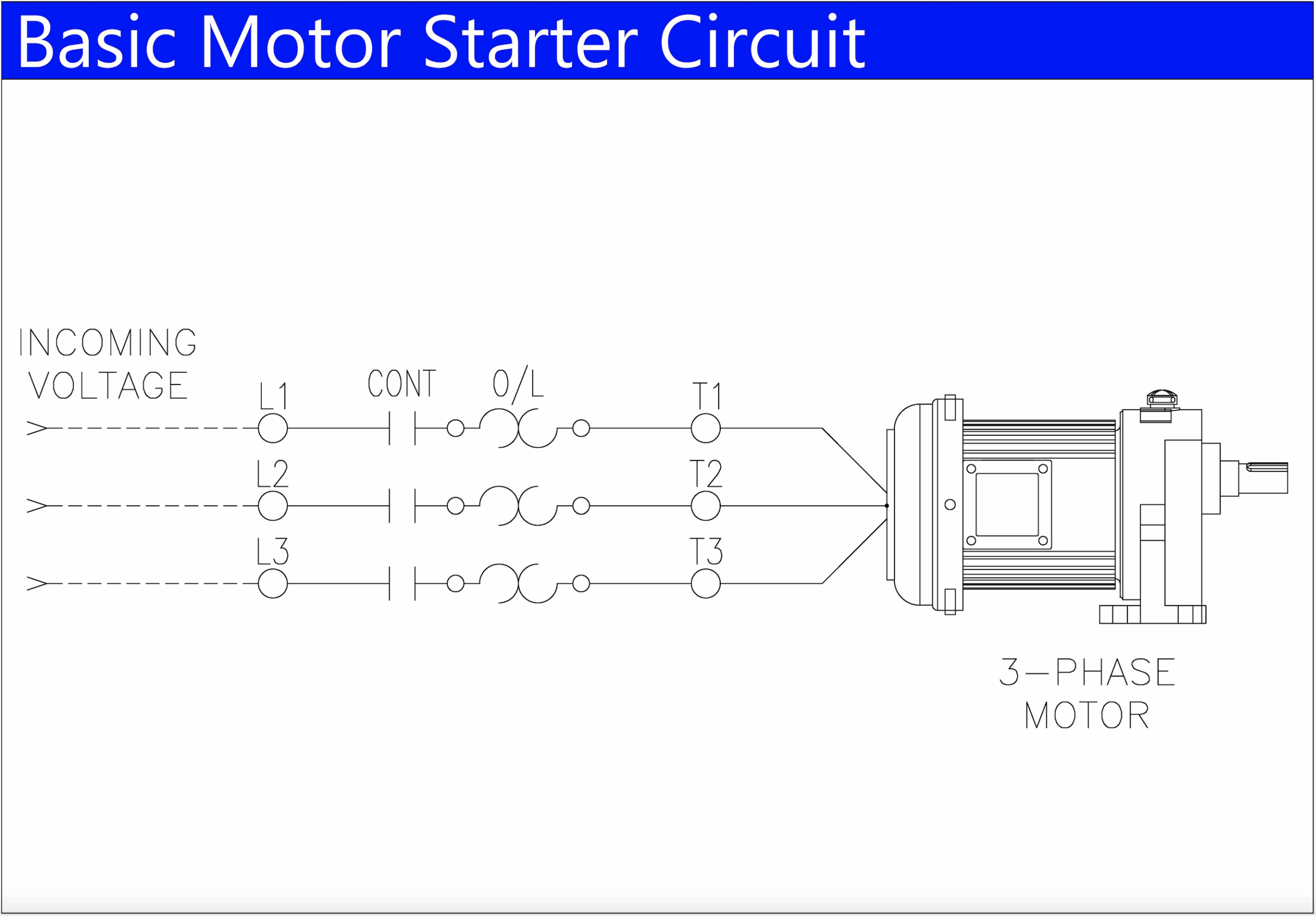

What Are the Key Characteristics of Conventional Starters?

Conventional starters are the most prevalent type in the automotive industry. They operate using a solenoid to engage the starter motor, drawing power from the vehicle’s battery to initiate engine ignition. This type is particularly suited for standard vehicles and is widely available, making it a cost-effective choice for automotive repair shops and OEMs. Buyers should consider the lifespan and potential failure rates, especially in high-usage scenarios.

How Do Gear Reduction Starters Enhance Torque Output?

Gear reduction starters utilize a gearing mechanism to amplify the torque produced by the starter motor, making them ideal for heavy-duty vehicles and construction machinery. Their compact design allows for installation in tight spaces, which is a significant advantage in industrial applications. However, the initial investment is higher, and the installation process can be more complex, requiring skilled technicians.

What Makes High-Performance Starters Suitable for Racing?

High-performance starters are engineered to withstand the rigorous demands of racing and high-performance vehicles. They offer improved reliability and can operate effectively in extreme conditions, making them essential for motorsport teams and performance enthusiasts. While they provide significant advantages in terms of performance, their cost can be prohibitive, and installation may require specialized knowledge.

Why Choose Mini Starters for Compact Vehicles?

Mini starters are designed to be lightweight and compact, making them perfect for sports cars and other vehicles with limited space. Their reduced size allows for easier installation, but they typically deliver lower torque output compared to conventional starters. B2B buyers should assess whether the application requires high torque or if the space-saving features justify the trade-offs.

How Do Integrated Starter-Alternators Benefit Modern Vehicles?

Integrated starter-alternators combine the functions of a starter and an alternator into a single unit, a design increasingly found in hybrid vehicles. This innovation enhances fuel efficiency and saves space, making it a favorable option for modern automotive applications. However, the complexity of these systems can lead to higher repair costs, and servicing may require specialized knowledge, which is a critical consideration for B2B buyers in the automotive sector.

Key Industrial Applications of what is the starter

| Branche/Sektor | Specific Application of what is the starter | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Production of vehicles | Ensures reliable engine start-up for quality assurance | Compliance with international automotive standards |

| Landwirtschaftliche Geräte | Traktoren und Mähdrescher | Facilitates quick engine start, crucial for time-sensitive operations | Durability in harsh environments and availability of parts |

| Baumaschinen | Heavy-duty machinery | Promotes operational efficiency and reduces downtime | Compatibility with various engine types and support services |

| Schiffsindustrie | Boats and ships | Provides reliable starting systems for safety and efficiency | Resistance to corrosion and reliability in extreme conditions |

| Erneuerbare Energien | Wind turbines and solar trackers | Enhances operational reliability in energy production | Adaptability to various energy systems and maintenance support |

How is ‘what is the starter’ utilized in automotive manufacturing, and what are the benefits for businesses?

In the automotive manufacturing sector, starters are integral to the production of vehicles. They ensure that engines can reliably start, which is essential for quality assurance during assembly. A malfunctioning starter can lead to production delays, impacting delivery schedules and customer satisfaction. B2B buyers in this sector must consider compliance with international automotive standards and the availability of replacement parts, as these factors directly affect production efficiency and operational costs.

What role does the starter play in agriculture equipment, and why is it crucial for businesses?

In agriculture, starters are vital components in tractors and harvesters, enabling quick engine starts that are crucial for time-sensitive tasks such as planting and harvesting. The ability to start machinery promptly can significantly influence productivity and yield. Buyers in this sector should prioritize durability, as agricultural equipment often operates in harsh environments. Additionally, sourcing parts that are readily available can minimize downtime and ensure continuous operation during peak seasons.

How does the starter contribute to the efficiency of construction machinery?

Heavy-duty construction machinery relies heavily on starters for efficient operation. A reliable starter ensures that equipment can be quickly mobilized, reducing downtime on job sites. This efficiency can translate into cost savings and increased project throughput. Buyers should ensure that the starters they source are compatible with various engine types and come with robust support services, as this can mitigate potential operational disruptions.

What is the significance of starters in the marine industry?

In the marine industry, starters are critical for the reliable operation of boats and ships. They ensure that engines can start promptly, which is vital for safety and operational efficiency. Given the unique challenges of the marine environment, B2B buyers must seek starters that offer resistance to corrosion and are built to withstand extreme conditions. This reliability is essential for maintaining safety standards and operational readiness in maritime operations.

How are starters utilized in renewable energy applications, and what should buyers consider?

In renewable energy systems, such as wind turbines and solar trackers, starters play a crucial role in ensuring reliable performance. They enable the systems to operate efficiently, which is essential for maximizing energy production. Buyers in this sector should consider the adaptability of starters to various energy systems and the availability of maintenance support. This ensures that the systems remain operational and efficient, contributing to overall energy sustainability goals.

3 Common User Pain Points for ‘what is the starter’ & Their Solutions

Scenario 1: Understanding the Starter Motor’s Role in Vehicle Performance

Das Problem: B2B buyers, especially those in fleet management or automotive sales, often struggle with understanding the critical role of the starter motor in vehicle operation. This lack of knowledge can lead to misdiagnosis of vehicle issues, resulting in unnecessary repairs or even vehicle downtime. For example, a fleet manager might face challenges when a vehicle won’t start and could mistakenly believe the issue lies solely with the battery, overlooking potential starter motor failures. This not only affects operational efficiency but can also incur additional costs.

Die Lösung: To mitigate this issue, B2B buyers should invest time in training and educational resources about starter motors and their functionality. This includes understanding how the starter interacts with other components such as the battery and alternator. Engaging with reputable automotive training programs or workshops can provide valuable insights into troubleshooting techniques. Additionally, creating a checklist for diagnosing starting issues can help quickly identify if the starter motor is at fault. For instance, if a vehicle exhibits symptoms like clicking sounds without engine turnover, it could indicate a starter problem rather than a battery issue. By equipping their teams with this knowledge, businesses can streamline repair processes and reduce operational downtime.

Scenario 2: Sourcing Reliable Starter Motors for Diverse Vehicle Models

Das Problem: Sourcing starter motors that fit a wide range of vehicle models can be a daunting task for B2B buyers, particularly those operating in regions with diverse automotive markets like Africa and South America. Buyers often face challenges such as finding compatible starter motors that meet quality and performance standards, leading to concerns over reliability and potential returns.

Die Lösung: To effectively source starter motors, B2B buyers should partner with reputable suppliers that offer comprehensive catalogs with detailed specifications for each product. It’s essential to look for suppliers that provide warranties and quality assurance certifications. Additionally, utilizing online platforms that specialize in automotive parts can facilitate comparisons among various models and suppliers. Buyers should also consider establishing relationships with local distributors who understand regional vehicle preferences and can provide tailored advice. Implementing a robust inventory management system can help track stock levels and anticipate demand for various starter motor models, minimizing the risk of overstocking or shortages.

Scenario 3: Diagnosing Starter Motor Failures Efficiently

Das Problem: Businesses that rely on automotive services often encounter delays when diagnosing starter motor failures. Technicians may lack the necessary tools or knowledge to accurately identify issues, leading to extended vehicle downtime and increased repair costs. This is particularly problematic in service centers where efficiency is critical to maintaining customer satisfaction and profitability.

Die Lösung: Implementing a structured diagnostic process can significantly improve the efficiency of identifying starter motor issues. B2B buyers should invest in diagnostic tools specifically designed for automotive applications, such as multimeters and starter testers, which can quickly assess the starter motor’s functionality. Training staff on these tools and the common symptoms of starter failure—like unusual noises or intermittent starting—can enhance diagnostic accuracy. Moreover, creating a knowledge base or standard operating procedures for technicians can streamline the troubleshooting process. By fostering a culture of continuous learning and improvement, businesses can enhance their service quality and reduce turnaround times for repairs.

Strategic Material Selection Guide for what is the starter

Welche Materialien werden üblicherweise in Anlasser-Motoren verwendet?

When selecting materials for starter motors, it is essential to consider their properties, advantages, and limitations. The choice of material significantly impacts performance, durability, and cost, which are crucial for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

Was sind die wichtigsten Eigenschaften von Kupfer in Anlassern?

Copper is widely used in starter motors for its excellent electrical conductivity. It has a high melting point, typically around 1,984°F (1,085°C), and can withstand significant thermal stress. Its corrosion resistance is moderate, often requiring protective coatings for prolonged use in harsh environments.

Pro und Kontra:

Copper’s primary advantage is its superior conductivity, which ensures efficient power transfer. However, it is relatively expensive compared to alternatives like aluminum, and its weight can be a drawback in applications where weight reduction is critical.

Auswirkungen auf die Anwendung:

Copper is highly compatible with various electrical systems, making it ideal for starter motors. However, its susceptibility to corrosion in certain environments necessitates careful consideration in regions with high humidity or saline conditions.

Internationale Überlegungen:

B2B buyers should be aware of compliance with international standards such as ASTM B170 for copper wire. In regions like Europe, where regulations on material safety and environmental impact are stringent, sourcing high-quality copper is crucial.

Wie schneidet Aluminium als Werkstoff für Anlasser ab?

Aluminum is another common material in starter motors, particularly for housing and structural components. It has a melting point of approximately 1,221°F (660°C) and offers good corrosion resistance, especially when anodized or coated.

Pro und Kontra:

The lightweight nature of aluminum is a significant advantage, reducing overall vehicle weight and improving fuel efficiency. However, its conductivity is lower than copper, which can lead to inefficiencies in power transfer. Additionally, aluminum can be more challenging to machine, which may increase manufacturing complexity.

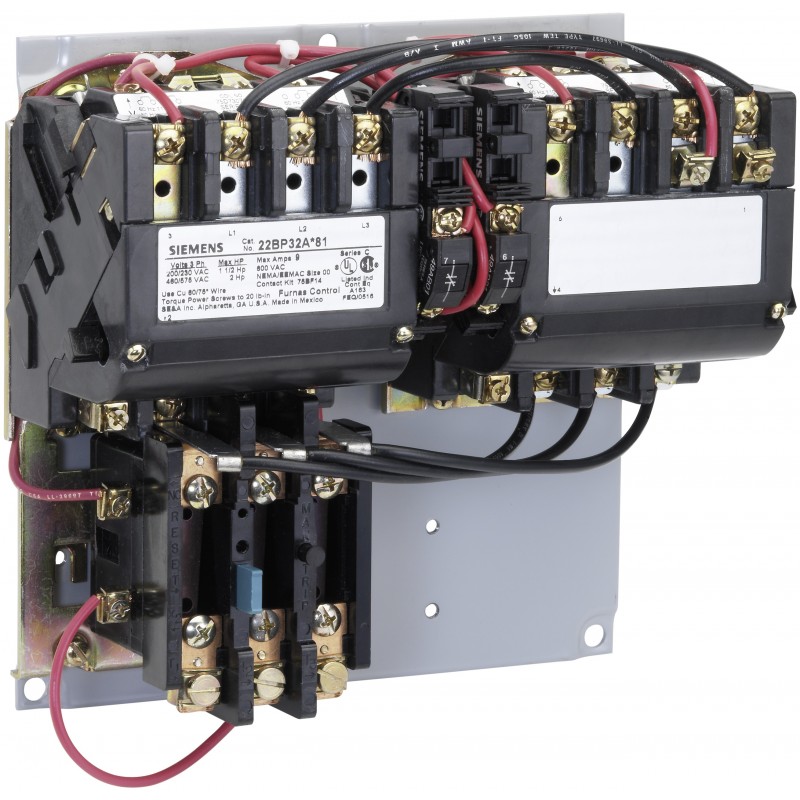

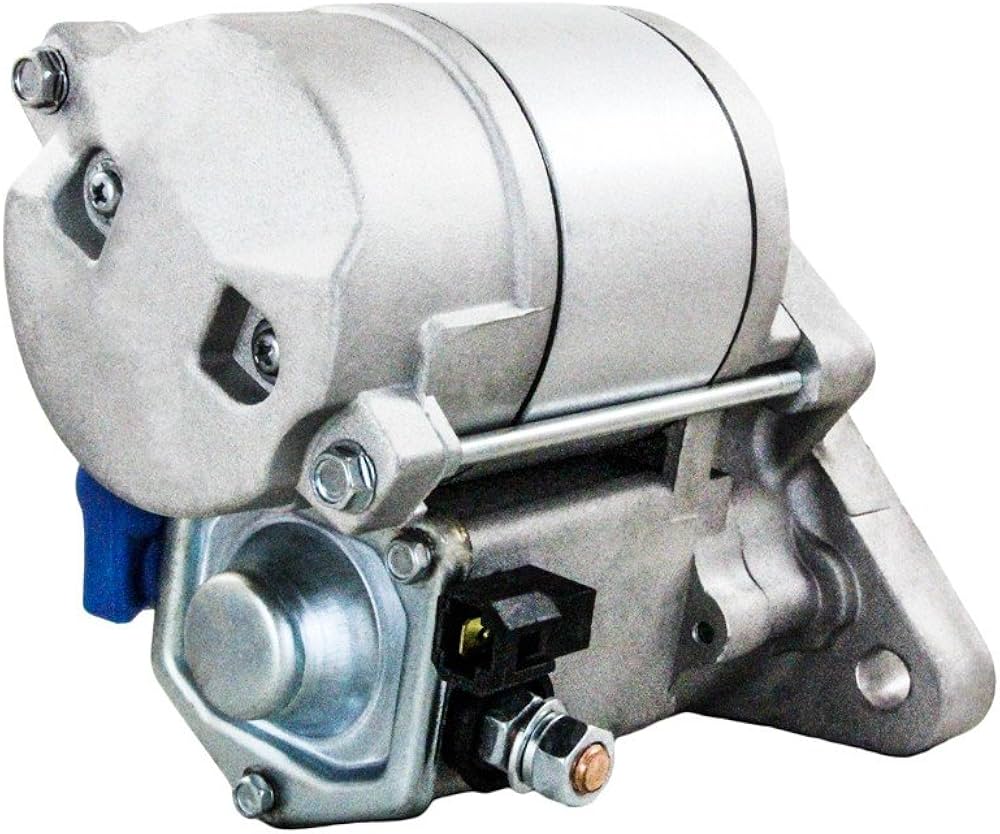

Illustrative image related to what is the starter

Auswirkungen auf die Anwendung:

Aluminum’s corrosion resistance makes it suitable for various environments, but it may not perform as well under extreme thermal conditions compared to copper. This is an important consideration for buyers in regions with high operational temperatures.

Internationale Überlegungen:

Buyers should ensure that aluminum components meet standards such as DIN 1725 for aluminum alloys. In markets like Germany, compliance with these standards is essential for product acceptance.

What Role Does Steel Play in Starter Motor Manufacturing?

Steel, particularly carbon steel, is often used in starter motor components such as the housing and mounting brackets. Steel has a high melting point of around 2,500°F (1,370°C) and excellent mechanical strength, making it suitable for structural applications.

Pro und Kontra:

Steel’s durability and strength are significant advantages, providing long-lasting performance. However, it is heavier than both copper and aluminum, which can negatively impact vehicle weight. Additionally, steel is prone to corrosion unless treated or coated.

Auswirkungen auf die Anwendung:

Steel’s mechanical properties make it ideal for components that experience high stress. However, its weight and potential for rusting in humid environments can limit its use in certain applications, especially in tropical regions.

Illustrative image related to what is the starter

Internationale Überlegungen:

B2B buyers should consider compliance with standards such as ASTM A36 for structural steel. In regions like South America and Africa, understanding local regulations regarding material sourcing and environmental impact is crucial.

What About Composite Materials in Starter Motors?

Composite materials, including reinforced plastics and carbon fiber, are increasingly being used in starter motors for non-structural components. These materials offer unique properties such as low weight and resistance to corrosion.

Pro und Kontra:

Composites can significantly reduce weight and improve fuel efficiency. However, they can be expensive to manufacture and may not provide the same mechanical strength as metals, limiting their use in high-stress applications.

Auswirkungen auf die Anwendung:

Composites are suitable for components that do not bear heavy loads but require resistance to corrosion. This makes them ideal for use in environments prone to chemical exposure.

Internationale Überlegungen:

Buyers should ensure that composite materials meet relevant standards, such as ISO 9001 for quality management. In regions like the Middle East, where extreme temperatures and humidity are common, selecting high-performance composites is essential.

Illustrative image related to what is the starter

Übersichtstabelle zur Materialauswahl für Anlasser

| Material | Typical Use Case for what is the starter | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Anschlüsse und Verkabelung | Hervorragende elektrische Leitfähigkeit | Hohe Kosten und hohes Gewicht | Hoch |

| Aluminium | Gehäuse und Bauteile | Leicht und korrosionsbeständig | Geringere Leitfähigkeit als Kupfer | Mittel |

| Stahl | Strukturelle Komponenten und Halterungen | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Korrosion | Mittel |

| Verbundwerkstoffe | Nicht-strukturelle Komponenten | Low weight and chemical resistance | Höhere Herstellungskosten | Hoch |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for starter motors, helping them make informed decisions that align with their operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for what is the starter

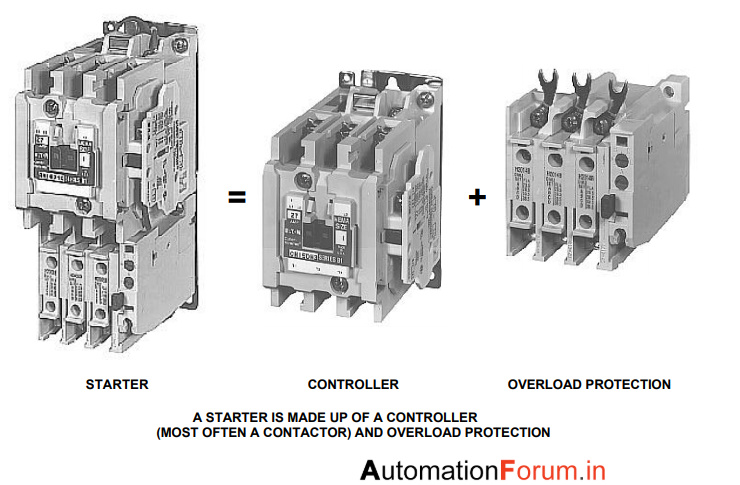

Was sind die wichtigsten Schritte im Herstellungsprozess eines Anlassers?

The manufacturing of starter motors involves several critical stages, each contributing to the overall performance and reliability of the final product. Understanding these stages is essential for B2B buyers seeking quality components for their automotive applications.

Wie wird das Material für die Anlasserproduktion vorbereitet?

The first stage in the manufacturing process is material preparation, which includes selecting high-quality raw materials such as copper for windings, steel for the casing, and specialized alloys for gears. These materials must meet stringent specifications to ensure durability and performance. Suppliers often conduct material inspections to verify that incoming materials conform to industry standards.

Welche Umformtechniken werden bei der Herstellung von Anlassern verwendet?

The forming process involves shaping the raw materials into the required components of the starter motor. Techniques such as stamping, forging, and machining are commonly employed. For instance, the casing is typically stamped from steel sheets, while the rotor and armature windings are machined to precise tolerances. Advanced manufacturing technologies, such as CNC machining, are often utilized to achieve the necessary accuracy and repeatability in component dimensions.

Wie werden Anlasser zusammengebaut?

Assembly is a crucial stage where individual components come together to form the complete starter motor. This process often involves the use of automated machinery for high-volume production, but manual assembly may be employed for lower volumes or specialized products. Key assembly steps include:

Illustrative image related to what is the starter

- Winding the Armature: Copper wire is wound around the armature to create the magnetic field necessary for motor operation.

- Installing the Solenoid: The solenoid, which activates the starter, is attached to the motor housing.

- Endmontage: All components, including gears and electrical connections, are assembled to create a functional starter motor.

Throughout this stage, operators must ensure that components are correctly aligned and securely fastened to prevent operational failures.

Welche Endbearbeitungsverfahren werden bei Anlassern angewandt?

Finishing processes enhance the durability and aesthetic appeal of starter motors. Common techniques include surface treatments such as painting, powder coating, and galvanization to protect against corrosion. Additionally, electrical components are often tested for insulation and conductivity before final assembly. These finishing touches are vital for ensuring the starter motor can withstand harsh operating conditions, particularly in markets with extreme climates.

What Quality Control Measures Are Essential for Starter Motor Production?

Quality assurance (QA) is integral to the manufacturing process, particularly in the automotive sector where reliability is paramount. Various international standards and industry-specific certifications guide the QA processes for starter motor production.

Welche internationalen Normen sollten B2B-Einkäufer berücksichtigen?

ISO 9001 is a widely recognized international standard for quality management systems, applicable across various industries, including automotive manufacturing. Compliance with ISO 9001 indicates that the manufacturer has established effective quality management practices to consistently produce high-quality products. Other relevant certifications include CE marking for compliance with European safety standards and API specifications for automotive components.

Illustrative image related to what is the starter

Was sind die wichtigsten Punkte der Qualitätskontrolle bei der Herstellung von Anlassern?

Quality control checkpoints throughout the manufacturing process help ensure that each starter motor meets quality standards. The following are critical checkpoints:

-

Eingangsqualitätskontrolle (IQC): This initial inspection phase involves checking the quality of raw materials before they enter the production line. This step is vital for preventing defects that could arise from subpar materials.

-

In-Process-Qualitätskontrolle (IPQC): During the manufacturing process, operators perform regular inspections to verify that components are being produced to specification. This includes monitoring dimensions, material properties, and assembly accuracy.

-

Endkontrolle (FQC): At the end of the production line, a comprehensive inspection ensures that each starter motor functions correctly and meets all performance criteria. Testing may include checking electrical connections, mechanical movement, and thermal performance.

What Testing Methods Are Commonly Used to Ensure Starter Motor Reliability?

B2B buyers should be aware of the testing methods used to validate the quality and performance of starter motors. Common testing methods include:

- Elektrische Prüfung: This involves checking the starter motor’s electrical resistance, current draw, and insulation integrity.

- Funktionsprüfung: The starter motor is subjected to operational tests to ensure it engages and disengages correctly and can start an engine under various conditions.

- Umweltprüfungen: To simulate real-world conditions, starter motors may undergo temperature and humidity tests to assess their performance in extreme environments.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

Ensuring that suppliers maintain rigorous quality control processes is essential for B2B buyers. Here are strategies to verify supplier QC:

-

Lieferanten-Audits: Conducting audits at the supplier’s facility allows buyers to assess quality management practices and production processes firsthand. This can include reviewing documentation, inspecting manufacturing equipment, and observing staff training programs.

-

Qualitätsberichte: Requesting quality assurance reports provides insight into the supplier’s performance history, including defect rates and compliance with international standards.

-

Inspektionen durch Dritte: Engaging third-party inspection services can offer unbiased evaluations of the supplier’s quality control processes and product quality. These inspections can be particularly beneficial when sourcing from international suppliers.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

International B2B buyers must navigate specific challenges related to quality control when sourcing starter motors from different regions, particularly in Africa, South America, the Middle East, and Europe. Key considerations include:

- Einhaltung gesetzlicher Vorschriften: Understanding local regulations and standards is essential for ensuring that products comply with regional safety and quality requirements.

- Transparenz der Lieferkette: Buyers should seek suppliers who provide clear visibility into their supply chain processes, including sourcing, manufacturing, and distribution.

- Kulturelle Unterschiede: Recognizing and addressing cultural differences in business practices can help foster better relationships with suppliers and improve communication regarding quality expectations.

By understanding the manufacturing processes and quality assurance practices associated with starter motors, B2B buyers can make informed decisions that enhance their procurement strategies and ensure product reliability.

Illustrative image related to what is the starter

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the starter’

To assist B2B buyers in sourcing starter motors effectively, this guide outlines essential steps to ensure a successful procurement process. By following this checklist, you can enhance your decision-making and align your purchasing strategies with your business needs.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Understanding the specific technical requirements of the starter motor is crucial. Consider factors such as voltage, power output, and compatibility with the intended vehicle types. This helps to avoid mismatches that could lead to operational inefficiencies or additional costs.

- Torque Requirements: Identify the torque needed to start the engine effectively.

- Abmessungen und Gewicht: Ensure the starter fits within the designated space and meets weight constraints.

Schritt 2: Marktentwicklungen und Innovationen erforschen

Staying informed about the latest advancements in starter motor technology can provide a competitive edge. Innovations, such as integrated starter-generator systems used in hybrid vehicles, can impact your choices.

- Energieeffizienz: Look for starters that offer better energy consumption rates.

- Durability Enhancements: Consider materials and designs that improve longevity and reduce maintenance needs.

Schritt 3: Potenzielle Lieferanten bewerten

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product catalogs, and references from similar industries or regions to assess their reliability.

- Reputation des Lieferanten: Check reviews and testimonials from other businesses.

- Experience in Your Market: Ensure they have a proven track record in your specific region or industry.

Schritt 4: Überprüfung von Lieferantenzertifizierungen und Compliance

Confirm that the suppliers adhere to relevant industry standards and regulations. Certifications can be a strong indicator of product quality and safety.

- ISO-Zertifizierungen: Look for ISO 9001 or ISO 14001 to ensure quality management systems are in place.

- Lokale Compliance: Ensure they meet any local regulations applicable in your market.

Schritt 5: Muster zum Testen anfordern

Before finalizing a bulk order, request samples to evaluate the product firsthand. Testing the starter motor can provide insights into its performance and compatibility with your requirements.

- Leistungsprüfung: Assess how well the starter performs under different conditions.

- Installation Feasibility: Check how easily the starter can be integrated into your vehicles.

Schritt 6: Verhandeln Sie Bedingungen und Preise

Once you’ve selected a supplier, negotiate pricing and terms to ensure you receive the best value. Consider factors such as payment terms, delivery schedules, and warranty provisions.

Illustrative image related to what is the starter

- Mengenrabatte: Erkundigen Sie sich nach Rabatten für größere Bestellungen.

- Warranty and Return Policies: Ensure there are clear terms for replacements or returns in case of defects.

Schritt 7: Eine langfristige Beziehung aufbauen

Building a strong relationship with your supplier can lead to better support and preferential pricing in the future. Stay engaged and communicate regularly to address any issues or changes in your needs.

- Regular Check-ins: Schedule periodic reviews to discuss performance and any new products.

- Feedback Loop: Provide feedback on the product and service to foster improvement.

By following this structured checklist, B2B buyers can make informed decisions when sourcing starter motors, ultimately enhancing operational efficiency and reliability in their vehicle fleets.

Comprehensive Cost and Pricing Analysis for what is the starter Sourcing

What Are the Key Cost Components for Sourcing Starters?

When sourcing starter motors, understanding the cost structure is vital for B2B buyers. The primary cost components include:

Illustrative image related to what is the starter

-

Materialien: The raw materials used in manufacturing starters, such as steel for the housing, copper for windings, and various plastics, significantly influence the overall cost. The quality of these materials can also impact durability and performance, affecting long-term value.

-

Arbeit: Labor costs vary by region and supplier. In countries with lower labor costs, such as those in parts of Africa and South America, you might find more competitive pricing. However, ensure that the quality of workmanship is not compromised.

-

Fertigungsgemeinkosten: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help keep these costs down.

-

Werkzeuge: Initial tooling costs for starter production can be substantial, especially for custom designs or specifications. These are usually amortized over the production run, impacting the unit price.

-

Qualitätskontrolle (QC): Rigorous testing and quality assurance processes are essential for ensuring the reliability of starters. Suppliers with robust QC protocols may charge a premium, but this can lead to lower failure rates and reduced warranty claims.

-

Logistik: Shipping costs are influenced by the distance from the supplier, mode of transport, and the volume of the order. International shipping can add significant costs, particularly if duties and tariffs are involved.

-

Marge: Suppliers typically apply a markup to cover their costs and profit margins. This can vary widely based on market conditions, competition, and the supplier’s positioning.

What Influences Pricing for Starters in the B2B Market?

Several factors influence the pricing of starter motors in the international market:

-

Volumen und Mindestbestellmenge (MOQ): Larger orders often qualify for volume discounts. Understanding the MOQ can help you negotiate better pricing, especially for bulk purchases.

-

Spezifikationen und Anpassung: Custom specifications can drive up costs. Be clear about your requirements to avoid unnecessary expenses. Standard models may be more cost-effective.

-

Materialqualität und Zertifizierungen: Higher quality materials and recognized certifications (like ISO) may come at a premium but can enhance performance and longevity. Consider the total cost of ownership when evaluating these options.

-

Lieferantenfaktoren: The supplier’s reputation, location, and production capabilities can significantly affect pricing. Established suppliers may charge more but offer reliability and better support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining the responsibilities of buyers and sellers in international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact overall costs and logistics.

What Are Effective Tips for Negotiating Starter Prices?

For international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe, effective negotiation can yield better pricing:

-

Forschung Marktpreise: Gather intelligence on prevailing prices to establish a baseline for negotiations. This knowledge empowers you to challenge unrealistic pricing.

-

Konzentration auf die Gesamtbetriebskosten (Total Cost of Ownership): When negotiating, consider long-term costs, including maintenance and potential failure rates, rather than just the upfront price. A slightly higher initial cost can result in savings over the product’s life cycle.

-

Beziehungen nutzen: Building long-term relationships with suppliers can lead to better terms and pricing flexibility. Trust is a key component in B2B negotiations.

-

Seien Sie offen für Alternativen: If a supplier cannot meet your price expectations, explore alternatives such as different materials, designs, or payment terms that might reduce costs.

-

Lokale Lieferanten in Betracht ziehen: Especially for African and South American buyers, sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall value.

Haftungsausschluss zu Preisen

Prices for starter motors can vary widely based on market conditions, supplier relationships, and specific buyer requirements. It is advisable to obtain multiple quotes and conduct thorough due diligence before finalizing any purchase agreements.

Alternatives Analysis: Comparing what is the starter With Other Solutions

Introduction: Exploring Alternatives to Traditional Starter Motors

In the automotive industry, the starter motor is essential for initiating engine operation. However, as technology advances, various alternative solutions are emerging that can either supplement or replace traditional starter motors. Understanding these alternatives is crucial for B2B buyers seeking to optimize vehicle performance, reduce costs, or improve maintenance efficiency. This section compares the traditional starter motor with two viable alternatives: the Integrated Starter Generator (ISG) and the Push-Button Start System.

Vergleichstabelle

| Vergleichsaspekt | What Is The Starter | Integrierter Starter-Generator (ISG) | Push-Button Start System |

|---|---|---|---|

| Leistung | High torque for engine start | Provides quick starts and regenerative capabilities | Convenient, but relies on battery power |

| Kosten | Generally low cost | Higher initial investment, but potential savings on fuel | Moderate cost, varies by vehicle |

| Einfache Implementierung | Einfache Installation für die meisten Fahrzeuge | Requires integration with hybrid systems | Easy to install in modern vehicles |

| Wartung | Moderate; can fail and require testing | Low; integrated into the vehicle’s system | Low; minimal components to maintain |

| Bester Anwendungsfall | Konventionelle Fahrzeuge | Hybrid- und Mildhybridfahrzeuge | Modern vehicles with advanced features |

Detaillierte Aufschlüsselung der Alternativen

What is the Integrated Starter Generator (ISG)?

The Integrated Starter Generator (ISG) combines the functions of a starter motor and an alternator, enabling it to start the engine and recharge the battery simultaneously. This technology is particularly beneficial for hybrid and mild hybrid vehicles, where it contributes to fuel efficiency by capturing and reusing energy during braking.

Vorteile: The ISG provides seamless starting capabilities, reduces engine load, and enhances fuel efficiency. Its ability to recover energy during deceleration makes it a sustainable choice for eco-conscious businesses.

Illustrative image related to what is the starter

Nachteile: The initial investment for ISG systems is higher compared to traditional starter motors. Additionally, their complexity may require specialized knowledge for installation and repair, potentially increasing service costs.

What is the Push-Button Start System?

The Push-Button Start System is a modern solution that allows drivers to start their vehicles with the press of a button, eliminating the need for traditional keys. This system often integrates with advanced security features and electronic control units, streamlining the ignition process.

Vorteile: The convenience of a push-button start enhances user experience and can improve vehicle security. It is typically easy to implement in newer vehicle models.

Nachteile: The reliance on battery power means that if the battery is weak, the system may not function effectively. The system’s complexity could also lead to higher repair costs if electronic components fail.

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

Selecting the appropriate starting solution depends on several factors, including vehicle type, budget constraints, and operational needs. For businesses operating conventional vehicles, traditional starter motors may suffice due to their lower costs and straightforward maintenance. However, if you are investing in hybrid technologies or modern vehicles, exploring options like Integrated Starter Generators or Push-Button Start Systems may provide enhanced performance and efficiency. Evaluating the total cost of ownership, including maintenance and potential fuel savings, will be vital in making an informed decision that aligns with your business goals.

Essential Technical Properties and Trade Terminology for what is the starter

What are the Key Technical Properties of a Starter Motor?

Understanding the technical properties of starter motors is crucial for B2B buyers, as these specifications can significantly influence performance, reliability, and compatibility with various vehicles. Here are some critical specifications to consider:

1. Drehmoment

The torque rating indicates the amount of rotational force the starter motor can generate. Typically measured in Newton-meters (Nm), this specification is vital because it determines the motor’s ability to crank the engine under varying conditions. A higher torque rating is essential for larger engines or those operating in extreme climates, ensuring reliable starts.

2. Nennspannung

Most starter motors operate at 12V, but some heavy-duty applications may require 24V systems. Understanding the voltage rating helps buyers select a starter compatible with the vehicle’s electrical system, preventing potential damage or failure.

3. Werkstoffgüte

The materials used in the construction of starter motors, such as copper for windings and steel for the housing, influence durability and efficiency. High-grade materials improve thermal conductivity and resistance to corrosion, which is critical for starters operating in harsh environments. Buyers should prioritize starters with robust material specifications for longevity.

Illustrative image related to what is the starter

4. Stromaufnahme

Current draw, measured in amperes (A), indicates how much electrical current the starter motor consumes during operation. A higher current draw can lead to battery drain issues. It’s essential for buyers to consider current draw, especially when sourcing parts for vehicles that may have limited battery capacity.

5. Dimensions and Mounting Specifications

The physical dimensions and mounting points of the starter motor are critical for ensuring proper fitment in various vehicle models. Buyers should refer to the OEM specifications to guarantee compatibility and avoid installation issues.

6. Einschaltdauer

The duty cycle refers to how long the starter motor can operate before it needs to cool down. A high-duty cycle rating is essential for applications where the engine may need to be started frequently, such as in commercial vehicles. Understanding this property can help buyers select a starter that meets their operational demands.

What are Common Trade Terms Related to Starter Motors?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to starter motors:

1. OEM (Originalgerätehersteller)

OEM parts are components made by the same manufacturer that produced the original parts used in a vehicle. Buyers often prefer OEM starters for their guaranteed compatibility and reliability, especially in high-performance or specialized applications.

2. MOQ (Mindestbestellmenge)

MOQ refers to the smallest number of units that a supplier is willing to sell in a single order. Understanding MOQ is crucial for buyers as it affects inventory management and procurement strategies. High MOQs can lead to increased upfront costs, especially for smaller businesses.

3. RFQ (Angebotsanfrage)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products, such as starter motors. Crafting a precise RFQ helps buyers obtain competitive quotes and compare different suppliers effectively.

4. Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with these terms is crucial for international transactions, as they clarify who bears the risk and costs at various stages of transport.

5. Ersatzteilmarkt

The aftermarket refers to parts and accessories that are not sourced from the original manufacturer. While aftermarket starters can be more cost-effective, buyers should assess their quality and compatibility with the vehicle.

6. Garantiezeitraum

The warranty period specifies the length of time a starter motor is covered for defects or failures. A longer warranty often indicates higher confidence in product quality, which can be an essential consideration for B2B buyers seeking reliable components.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing starter motors, ensuring they choose the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the what is the starter Sector

What Are the Current Market Dynamics and Key Trends Affecting the Starter Sector?

In recent years, the starter motor market has experienced significant growth, driven by various global factors. The increasing demand for automobiles, particularly in emerging markets such as Africa and South America, has spurred the need for efficient starter systems. This demand is further fueled by advancements in automotive technology, including the rise of electric vehicles (EVs) and hybrids, which often require sophisticated starter systems. The integration of starter motors with alternators in modern vehicles, notably in mild hybrids, exemplifies the trend towards multifunctional components, enhancing performance and efficiency.

International B2B buyers should also be aware of the increasing emphasis on technological innovation in the starter sector. Automation, IoT integration, and smart diagnostics are transforming how starter motors are manufactured and maintained. Companies that invest in these technologies can offer enhanced products that not only improve vehicle performance but also reduce maintenance costs for end-users. Additionally, as the automotive industry shifts towards sustainability, buyers are encouraged to look for suppliers who prioritize green manufacturing practices and energy-efficient products.

Another notable trend is the impact of geopolitical factors on sourcing strategies. Trade agreements and tariffs can affect the cost and availability of starter motors and their components. B2B buyers must navigate these complexities by diversifying their supply chains and considering local manufacturers to mitigate risks associated with international sourcing.

How Important Is Sustainability and Ethical Sourcing in the Starter Sector?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the starter motor sector. The environmental impact of automotive manufacturing, including starter systems, necessitates a shift towards more sustainable practices. This includes using recycled materials, minimizing waste, and adopting energy-efficient production methods. Buyers should prioritize suppliers who demonstrate a commitment to sustainability by obtaining certifications such as ISO 14001 for environmental management.

Moreover, ethical supply chains are crucial in ensuring fair labor practices and reducing the carbon footprint associated with manufacturing. Companies that adhere to ethical sourcing principles not only enhance their brand reputation but also appeal to environmentally-conscious consumers. As regulations around environmental impact become stricter globally, working with suppliers who prioritize sustainability will be essential for compliance and competitive advantage.

Illustrative image related to what is the starter

B2B buyers are encouraged to seek out ‘green’ certifications and materials in their sourcing decisions. This includes evaluating the lifecycle of starter motors, from raw material extraction to end-of-life disposal. By opting for suppliers who incorporate sustainable materials, such as bio-based plastics or recyclable metals, buyers can significantly reduce their ecological impact while ensuring compliance with international environmental standards.

What Is the Evolution and Historical Context of Starter Motors?

The concept of the starter motor has evolved significantly since its inception. Invented by Charles Kettering in 1911, the electric starter revolutionized the automotive industry by eliminating the need for hand-cranking engines. This innovation made vehicles more accessible and user-friendly, accelerating the adoption of automobiles worldwide.

In the decades that followed, advancements in technology led to improved designs and functionalities. The introduction of the Bendix drive system by Vincent Bendix allowed for faster engagement and disengagement of starter gears, enhancing reliability. The evolution continued with the integration of starter motors into hybrid and electric vehicle systems, demonstrating the adaptability of starter technology to meet the changing demands of the automotive market.

For B2B buyers, understanding this historical context is vital, as it underscores the importance of innovation and adaptation in sourcing decisions. Suppliers that have a rich history of technological advancement may offer insights and reliability that newer companies cannot provide. Buyers should leverage this knowledge to make informed sourcing decisions that align with their strategic goals in an increasingly competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of what is the starter

-

How do I solve starting issues with my vehicle?

To resolve starting issues, first check the battery charge and connections, as low voltage is often the primary culprit. If the battery is functional, inspect the starter motor for signs of wear, such as unusual noises or failure to engage. Additionally, testing the solenoid and examining the wiring for corrosion or damage is crucial. If troubleshooting does not yield results, consider consulting a qualified technician to diagnose the problem accurately. -

What is the best starter motor for commercial vehicles?

The best starter motor for commercial vehicles typically combines high torque output with durability. Look for motors designed specifically for heavy-duty applications, often featuring advanced materials that withstand extreme conditions. Brands known for reliability and performance, such as Bosch, Denso, and Delco Remy, are recommended. When selecting a starter, consider factors like compatibility with your vehicle model, power requirements, and warranty terms to ensure optimal performance. -

What should I consider when sourcing starter motors internationally?

When sourcing starter motors internationally, evaluate the supplier’s reputation, certifications, and experience in the automotive sector. Consider their production capabilities, quality control processes, and adherence to international standards. Additionally, assess logistical considerations such as shipping times, costs, and customs regulations in your region. Establishing clear communication regarding specifications and expectations will also facilitate a smoother procurement process. -

Was sind die typischen Mindestbestellmengen (MOQ) für Anlasser?

Minimum order quantities for starter motors can vary widely based on the supplier and manufacturing capabilities. Generally, MOQs range from 50 to 500 units for bulk orders. It’s essential to discuss your needs directly with suppliers, as many may offer flexibility, especially for first-time customers or ongoing partnerships. Keep in mind that lower MOQs may lead to higher per-unit costs, impacting your overall budget. -

Welche Zahlungsbedingungen sind im internationalen Handel mit Kfz-Teilen üblich?

Common payment terms in international trade for automotive parts, including starter motors, typically include options like Letter of Credit (LC), Telegraphic Transfer (TT), or PayPal for smaller transactions. Payment terms may vary, but it’s common to negotiate a 30% deposit upfront with the balance due upon shipment or delivery. Ensure that the terms are clearly outlined in the purchase agreement to avoid disputes and ensure a smooth transaction. -

Wie kann ich die Qualitätssicherung (QA) für Anlasser sicherstellen?

To ensure quality assurance for starter motors, request product certifications and compliance documentation from your supplier. Conduct pre-shipment inspections to verify that the products meet your specifications and quality standards. Consider establishing a partnership with third-party quality control firms that can perform on-site inspections. Regular communication with the supplier regarding quality expectations and feedback can also help maintain product integrity over time. -

Welche logistischen Überlegungen sollte ich beim Import von Anlassern anstellen?

When importing starter motors, key logistics considerations include shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder familiar with automotive parts to navigate potential challenges. Be aware of tariffs, duties, and other regulatory requirements in your country to avoid unexpected costs. Planning for contingencies, such as delays or damages during transit, will also help mitigate risks associated with international shipping. -

How can I customize starter motors for specific applications?

Customizing starter motors typically involves discussing specific requirements with your supplier, such as torque specifications, mounting configurations, and electrical characteristics. Some manufacturers offer customization options to meet unique applications, particularly for specialized vehicles or machinery. Provide detailed specifications and any necessary prototypes to ensure the final product aligns with your operational needs. Collaborating closely with the supplier throughout the design and testing phases will facilitate successful customization.

Top 4 What Is The Starter Manufacturers & Suppliers List

1. Pueblo Tires – Car Starters

Domäne: pueblotires.com

Registriert: 1997 (28 Jahre)

Einleitung: This company, Pueblo Tires – Car Starters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Haynes - Anlasser

Domäne: us.haynes.com

Registriert: 1996 (29 Jahre)

Einleitung: Dieses Unternehmen, Haynes - Starter Motor, ist eine bemerkenswerte Einheit auf dem Markt. Für spezifische Produktdetails wird empfohlen, ihre Website direkt zu besuchen.

3. RAC - Anlasser

Domäne: rac.co.uk

Registriert: 1996 (29 Jahre)

Einleitung: Starter motor is an electric component essential for starting the engine in internal combustion vehicles. It works by receiving an electrical signal when the ignition is engaged, activating the starter motor and cranking the engine. Common causes of failure include broken solenoids, mechanical issues, electrical faults, overheating, and wear and tear. The starter motor is typically located at the …

4. eBay – Starters

Domäne: ebay.de

Registriert: 1995 (30 Jahre)

Einleitung: Starters are typically tough and long-lived. When they fail, they can leave you stranded until you find a replacement. Replacing a starter is simple, provided you don’t cut any corners. A starter is an electric motor that spins the engine over to start combustion. Modern starters have two jobs: they push forward a pinion gear to mesh with the ring gear on the flywheel and spin that pinion gear to …

Strategic Sourcing Conclusion and Outlook for what is the starter

The role of the starter motor in automotive systems cannot be overstated; it is essential for initiating engine function and ensuring operational efficiency. Understanding its components—such as the solenoid and pinion gear—is crucial for international B2B buyers looking to source quality starter motors. Key considerations include the importance of reliable suppliers, the need for rigorous quality control, and the potential for cost savings through strategic sourcing.

As the automotive industry evolves, particularly in emerging markets across Africa, South America, and the Middle East, buyers should prioritize partnerships with manufacturers who can provide innovative and durable solutions. The integration of advanced technologies, such as hybrid systems, presents new opportunities for sourcing, making it imperative to stay informed about industry trends.

In conclusion, fostering strong supplier relationships and embracing technological advancements will enhance your competitive edge. Now is the time to evaluate your sourcing strategies to ensure that you are equipped for the future of automotive components. Engage with reliable partners who can support your business objectives and navigate the complexities of the global market effectively.

Illustrative image related to what is the starter

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.