Einleitung: Navigieren auf dem globalen Markt für die Kosten für den Austausch einer Lichtmaschine

In der wettbewerbsintensiven Landschaft der Fahrzeuginstandhaltung ist es für internationale B2B-Einkäufer entscheidend, die Kosten für den Austausch einer Lichtmaschine zu kennen. Die Beschaffung qualitativ hochwertiger Generatoren zu wettbewerbsfähigen Preisen kann eine große Herausforderung darstellen, insbesondere für Unternehmen, die in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa tätig sind. Dieser Leitfaden geht auf diese Herausforderungen ein, indem er eine umfassende Analyse der verschiedenen Faktoren liefert, die die Kosten für den Austausch einer Lichtmaschine beeinflussen, darunter der Fahrzeugtyp, regionale Marktunterschiede und die Zuverlässigkeit der Lieferanten.

In diesem Leitfaden gehen wir auf die Feinheiten der Generatortypen, ihre Anwendungen und die Bedeutung der Auswahl des richtigen Lieferanten ein. Durch die Bewertung von Schlüsselaspekten wie Arbeitskosten, die Qualität von Ersatzteilen und den potenziellen Bedarf an zusätzlichen Reparaturen können Käufer fundierte Entscheidungen treffen, die mit ihren betrieblichen Anforderungen übereinstimmen.

Darüber hinaus untersuchen wir die Anzeichen für einen Ausfall der Lichtmaschine und die Folgen eines vernachlässigten rechtzeitigen Austauschs, der zu erheblichen Ausfallzeiten und Reparaturkosten führen kann. Ganz gleich, ob Sie Fuhrparkleiter in Brasilien oder Kfz-Teilehändler in Saudi-Arabien sind, dieser Leitfaden vermittelt Ihnen die notwendigen Kenntnisse, um sich auf dem globalen Markt zurechtzufinden. Wir geben B2B-Einkäufern handlungsorientiertes Wissen an die Hand, um den Einkaufsprozess zu rationalisieren und letztlich Ihre betriebliche Effizienz und Rentabilität zu steigern.

Inhaltsverzeichnis

- Top 3 Liste der Hersteller & Lieferanten für den Austausch einer Lichtmaschine

- Einleitung: Navigieren auf dem globalen Markt für die Kosten für den Austausch einer Lichtmaschine

- Kosten für den Austausch einer Lichtmaschine Typen und Variationen

- Wichtige industrielle Anwendungen für den Austausch einer Lichtmaschine

- 3 häufige Benutzer Schmerzpunkte für ‘wie viel, um eine Lichtmaschine zu ersetzen’ & ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für den Ersatz einer Lichtmaschine

- Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für den Austausch einer Lichtmaschine

- Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet der Austausch einer Lichtmaschine’.’

- Umfassende Kosten- und Preisanalyse für den Ersatz einer Lichtmaschine Sourcing

- Analyse der Alternativen: Vergleich der Kosten für den Austausch einer Lichtmaschine mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für den Austausch einer Lichtmaschine

- Navigieren durch Marktdynamik und Beschaffungstrends in der Branche "Wie viel kostet der Austausch einer Lichtmaschine?

- Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Austausch einer Lichtmaschine

- Strategische Beschaffung Schlussfolgerung und Ausblick für die Kosten für den Austausch einer Lichtmaschine

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Kosten für den Austausch einer Lichtmaschine Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| OEM-Lichtmaschinen | Hergestellt vom ursprünglichen Fahrzeughersteller | Fuhrparkmanagement, Autohäuser | Vorteile: Garantierte Kompatibilität und Qualität. Nachteile: Höhere Kosten im Vergleich zu Aftermarket-Optionen. |

| Ersatzteil-Lichtmaschinen | Produziert von Drittanbietern | Unabhängige Werkstätten, Autoteilehändler | Vorteile: Kostengünstige Lösungen. Nachteile: Unterschiedliche Qualität und Garantiebedingungen. |

| Überholte Lichtmaschinen | Neuwertiger Zustand mit allen neuen Innenteilen | Autowerkstätten, Fuhrparkwartung | Vorteile: Bessere Qualität als nachgebaut, oft mit Garantie. Nachteile: Die OEM-Qualität kann dennoch nicht erreicht werden. |

| Überholte Lichtmaschinen | Reparatur von Original-Generatoren mit einigen neuen Teilen | Kleine Reparaturbetriebe, DIY-Mechaniker | Vorteile: Kostengünstiger als neu. Nachteile: Mögliche Probleme mit der Zuverlässigkeit und eingeschränkte Garantien. |

| Gebrauchte Lichtmaschinen | Gebrauchte Geräte aus Altfahrzeugen | Budgetbewusste Käufer, Werkstätten | Vorteile: Erheblich niedrigere Kosten. Nachteile: Hohes Ausfallrisiko, oft keine Garantie verfügbar. |

Was sind die Merkmale und die Eignung von OEM-Generatoren?

OEM-Generatoren (Original Equipment Manufacturer) sind speziell für die Fahrzeuge konzipiert, für die sie hergestellt wurden, und gewährleisten optimale Leistung und Langlebigkeit. Sie sind die erste Wahl für Unternehmen, die Flotten verwalten oder Autohäuser, die Wert auf Zuverlässigkeit und Herstellerspezifikationen legen. Während sie Kompatibilität und Qualität garantieren, können die höheren Kosten für Unternehmen mit kleinem Budget abschreckend wirken. B2B-Käufer sollten den langfristigen Wert einer Investition in OEM-Teile bedenken, insbesondere bei Fahrzeugen, die für ihren Betrieb wichtig sind.

Wie sehen Aftermarket-Generatoren für B2B-Anwendungen aus?

Aftermarket-Generatoren werden von Drittherstellern produziert und bieten eine breite Palette von Optionen zu unterschiedlichen Preisen. Sie werden häufig in unabhängigen Werkstätten und im Kfz-Teilehandel eingesetzt und sind für Unternehmen interessant, die ein ausgewogenes Verhältnis zwischen Qualität und Kosten suchen. Die Qualität kann jedoch erheblich schwanken, weshalb B2B-Käufer ihre Lieferanten sorgfältig prüfen sollten. Um sicherzustellen, dass Aftermarket-Generatoren den Betriebsstandards entsprechen, ist es wichtig, die Garantiebedingungen und Leistungsprüfungen zu prüfen.

Was macht wiederaufbereitete Generatoren zu einer sinnvollen Option?

Aufgearbeitete Generatoren werden in einen neuwertigen Zustand versetzt und verfügen über komplett neue interne Komponenten, was sie zu einer zuverlässigen Wahl für Autowerkstätten und Flottenwartungsdienste macht. Sie werden in der Regel mit einer Garantie geliefert, was B2B-Käufern Sicherheit gibt. Obwohl sie einen Mittelweg zwischen OEM- und Aftermarket-Optionen bieten, müssen die Unternehmen sicherstellen, dass sie von seriösen Lieferanten beziehen, um Qualitätsdiskrepanzen zu vermeiden.

Warum sollten Sie sich für überholte Lichtmaschinen entscheiden, und wo liegen ihre Grenzen?

Rebuilt-Generatoren sind Originalgeräte, die mit einigen neuen Teilen repariert wurden. Sie stellen eine kostengünstige Alternative für kleine Reparaturbetriebe und Heimwerker dar. Käufer sollten jedoch vorsichtig sein, denn die Zuverlässigkeit von nachgebauten Lichtmaschinen kann stark schwanken, und die Garantien sind oft begrenzt. B2B-Käufer sollten die Kosteneinsparungen gegen die potenziell höheren Ausfallraten abwägen, wenn sie überholte Optionen in Betracht ziehen.

Sind gebrauchte Lichtmaschinen das Risiko für preisbewusste Käufer wert?

Gebrauchte Lichtmaschinen werden aus Fahrzeugen geborgen und zu deutlich niedrigeren Preisen verkauft. Sie können für preisbewusste Käufer oder Werkstätten interessant sein, die ihre Kosten minimieren wollen. Das Risiko eines Ausfalls ist jedoch hoch, und in der Regel gibt es keine Garantie, was sie für Unternehmen zu einem Glücksspiel macht. B2B-Käufer sollten vorsichtig sein und die potenziellen Kosten bedenken, die mit dem Austausch einer ausgefallenen gebrauchten Lichtmaschine verbunden sind und die jede anfängliche Ersparnis zunichte machen können.

Wichtige industrielle Anwendungen für den Austausch einer Lichtmaschine

| Branche/Sektor | Spezifische Anwendung der Kosten für den Austausch einer Lichtmaschine | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Bereitstellung genauer Kostenvoranschläge für den Austausch von Lichtmaschinen | Verbessert das Vertrauen und die Zufriedenheit der Kunden | Qualität der Ersatzteile, Arbeitspreise und Garantieoptionen |

| Transport & Logistik | Budgetierung der Flotteninstandhaltung für den Austausch von Lichtmaschinen | Reduziert ungeplante Ausfallzeiten und Betriebsunterbrechungen | Rabatte bei Großeinkäufen und zuverlässige Lieferanten |

| Baumaschinen | Schätzung der Kosten für den Austausch von Lichtmaschinen für schwere Maschinen | Sicherstellung der Einhaltung von Projektfristen durch Minimierung von Geräteausfällen | OEM vs. Aftermarket-Teile, lokale Verfügbarkeit |

| Landwirtschaft | Planung für den Austausch von Lichtmaschinen in Landmaschinen | Erhöht die Produktivität durch geringere Ausfallzeiten der Geräte | Kompatibilität mit verschiedenen Maschinenmarken |

| Öffentliche Verkehrsmittel | Budgetierung für den Austausch von Lichtmaschinen in Bussen und Bahnen | Verbessert die Zuverlässigkeit der Verkehrsdienste | Langfristige Verträge mit Lieferanten für Kostenstabilität |

Wie wird die Frage ‘Wie viel kostet der Austausch einer Lichtmaschine’ in Kfz-Werkstätten verwendet?

Kfz-Werkstätten nutzen das Wissen um die Kosten für den Austausch von Lichtmaschinen, um ihren Kunden genaue Kostenvoranschläge zu unterbreiten. Diese Transparenz schafft Vertrauen und erhöht die Kundenzufriedenheit, da die Kunden eine klare Kommunikation über mögliche Kosten schätzen. Werkstätten müssen sich auf die Beschaffung qualitativ hochwertiger Teile konzentrieren, unabhängig davon, ob es sich um Erstausrüster- oder Nachrüstteile handelt, und bei der Festlegung des endgültigen Preises die Lohnkosten berücksichtigen. Ein effektives Kostenmanagement kann zu einer stärkeren Kundenbindung und zu Folgeaufträgen führen.

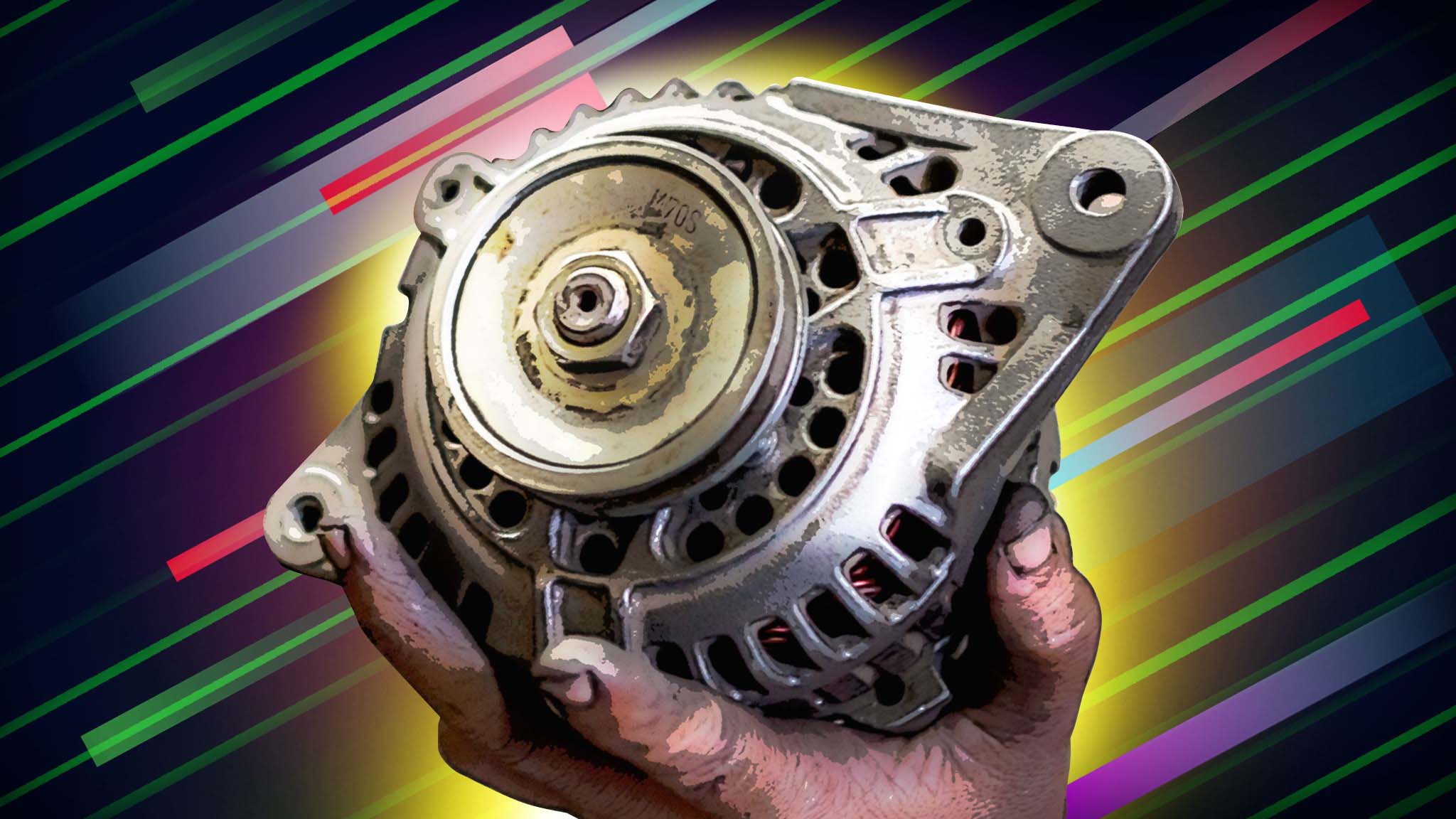

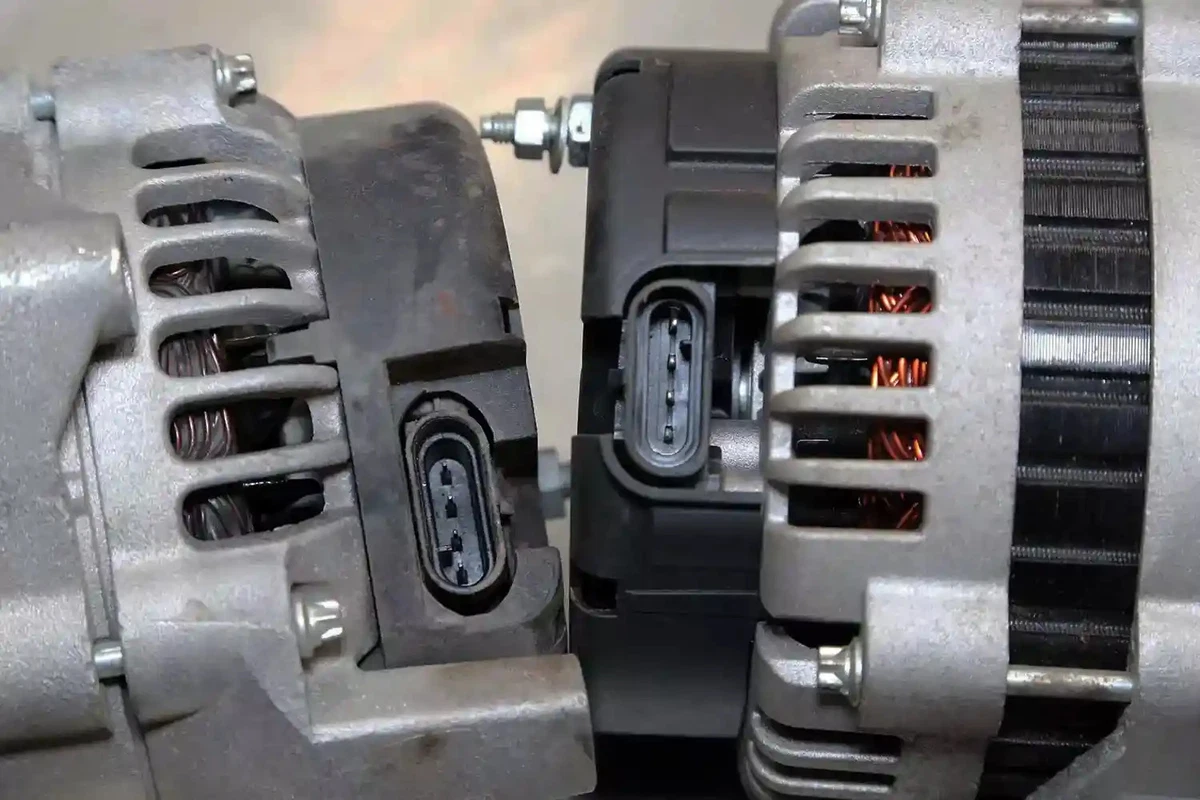

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

Welche Rolle spielen die Kosten für den Austausch einer Lichtmaschine in Transport und Logistik?

In der Transport- und Logistikbranche müssen Unternehmen regelmäßige Wartungsarbeiten, einschließlich des Austauschs von Generatoren, für ihren Fuhrpark einplanen. Genaue Kostenschätzungen helfen, ungeplante Ausfallzeiten zu reduzieren, die die betriebliche Effizienz erheblich beeinträchtigen können. Unternehmen bemühen sich häufig um Großabnehmerrabatte bei Lieferanten, um die Kosten effektiv zu verwalten und gleichzeitig die Qualität und Zuverlässigkeit der beschafften Generatoren zu gewährleisten. Dieser proaktive Ansatz minimiert Unterbrechungen und verbessert die Gesamtleistung des Fuhrparks.

Inwiefern sind die Kosten für den Austausch einer Lichtmaschine für Baumaschinen relevant?

Bauunternehmen sind häufig auf schwere Maschinen angewiesen, bei denen ein Ausfall der Lichtmaschine zu Projektverzögerungen führen kann. Durch die Schätzung der Kosten für den Austausch von Lichtmaschinen können diese Unternehmen ihre Budgets besser verwalten und sicherstellen, dass die Maschinen betriebsbereit bleiben. Für Baufirmen ist es entscheidend, die Vorteile von OEM-Teilen gegenüber Aftermarket-Optionen abzuwägen und dabei die lokale Verfügbarkeit und Kompatibilität mit verschiedenen Maschinenmarken zu berücksichtigen. Diese strategische Beschaffung trägt dazu bei, den Zeitplan für Projekte einzuhalten und das Risiko kostspieliger Maschinenstillstände zu verringern.

Warum ist die Planung des Austauschs von Lichtmaschinen in der Landwirtschaft wichtig?

In der Landwirtschaft sind die Maschinen für die Produktivität von entscheidender Bedeutung, so dass die Kosten für den Austausch von Lichtmaschinen bekannt sein müssen. Landwirte müssen diese Kosten einkalkulieren, um ihre Maschinen zu warten und unerwartete Ausfälle während kritischer Jahreszeiten zu vermeiden. Die Beschaffung kompatibler Generatoren, die zu verschiedenen Maschinenmarken passen, ist der Schlüssel zur Gewährleistung eines reibungslosen Betriebs. Durch die Planung dieser Kosten können landwirtschaftliche Betriebe ihre Effizienz steigern und ihre Erträge maximieren.

Wie profitiert der öffentliche Verkehr vom Verständnis der Kosten für den Austausch von Lichtmaschinen?

Öffentliche Verkehrssysteme müssen der Zuverlässigkeit Vorrang einräumen, weshalb die Kenntnis der Kosten für den Austausch von Generatoren für die Budgetierung und Wartungsplanung von entscheidender Bedeutung ist. Durch eine genaue Vorhersage dieser Kosten können die Verkehrsbehörden die Zuverlässigkeit der Dienste verbessern und Verspätungen minimieren. Der Abschluss langfristiger Verträge mit renommierten Lieferanten gewährleistet Kostenstabilität und Qualitätssicherung für wichtige Komponenten. Dieser strategische Ansatz verbessert die Gesamteffizienz der öffentlichen Verkehrsdienste, was letztlich der Gemeinschaft zugute kommt.

3 häufige Benutzer Schmerzpunkte für ‘wie viel, um eine Lichtmaschine zu ersetzen’ & ihre Lösungen

Szenario 1: Unerwartete Kostenüberschreitung beim Austausch der Lichtmaschine

Das Problem: B2B-Einkäufer, insbesondere diejenigen, die Fuhrparks oder die Fahrzeugwartung für Unternehmen verwalten, werden beim Austausch von Lichtmaschinen oft mit unerwarteten Kosten konfrontiert. Dies kann darauf zurückzuführen sein, dass die Arbeitsstunden falsch kalkuliert oder die zusätzlich benötigten Teile wie Keilriemen oder Kabelbäume unterschätzt wurden. In Regionen mit schwankenden Ersatzteilpreisen, wie z. B. in einigen Teilen Afrikas und Südamerikas, können diese Kosten schnell eskalieren und sich auf die Budgets und die betriebliche Effizienz auswirken.

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

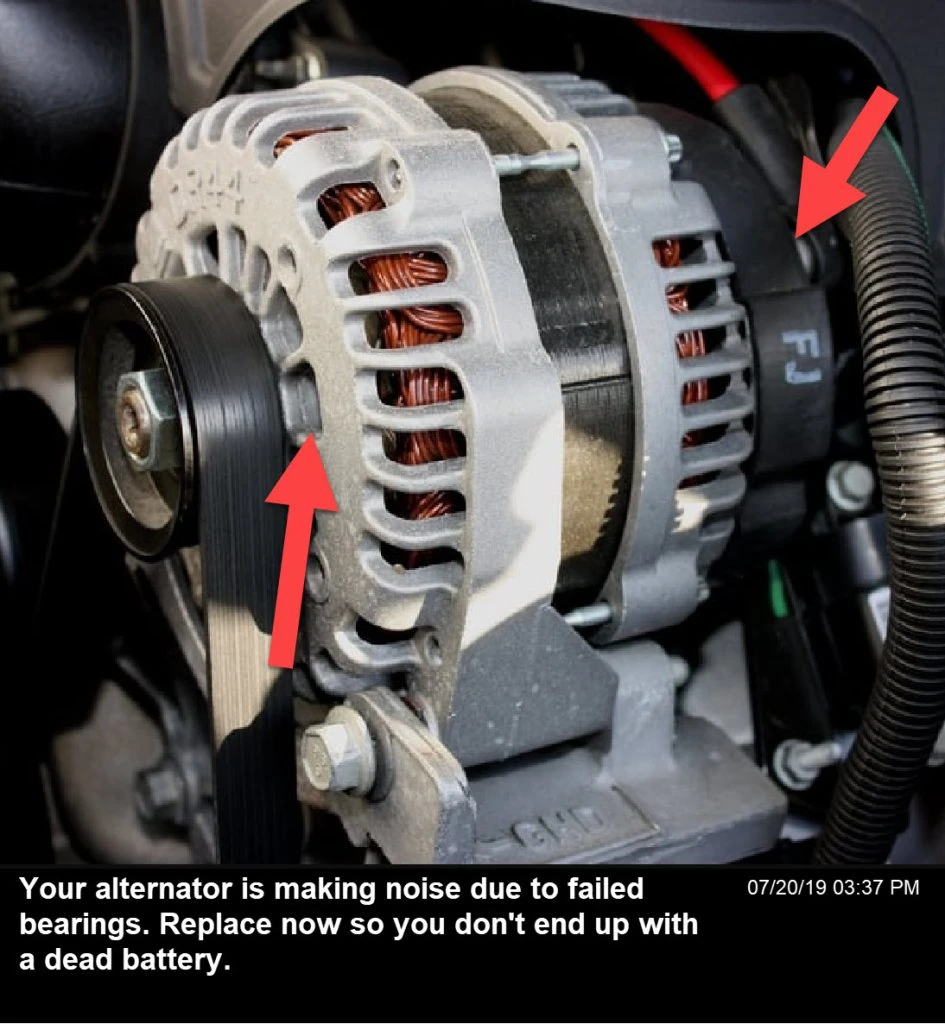

Die Lösung: Um unerwartete Ausgaben zu vermeiden, sollten Käufer einen umfassenden Wartungsplan aufstellen, der regelmäßige Fahrzeuginspektionen und -diagnosen beinhaltet. Durch proaktives Erkennen von Problemen mit der Lichtmaschine - wie z. B. ungewöhnliche Geräusche oder Warnleuchten am Armaturenbrett - bevor sie zu einem Totalausfall führen, können Unternehmen Reparaturen besser einplanen. Die Zusammenarbeit mit vertrauenswürdigen lokalen Lieferanten oder Vertragshändlern für Originalteile kann auch Preisstabilität und Zuverlässigkeit gewährleisten. Die Einholung detaillierter Kostenvoranschläge, in denen alle potenziellen Kosten, einschließlich Arbeitsaufwand, Ersatzteile und eventuelle Unwägbarkeiten, aufgeführt sind, ermöglicht eine fundierte Entscheidungsfindung und verhindert Budgetüberschreitungen.

Szenario 2: Schwierigkeiten bei der Beschaffung von Qualitätsgeneratoren

Das Problem: Auf vielen Märkten, insbesondere in Entwicklungsregionen, kann die Beschaffung hochwertiger Generatoren eine große Herausforderung darstellen. B2B-Einkäufer können auf gefälschte oder minderwertige Produkte stoßen, die vorzeitig ausfallen, was zu wiederholtem Austausch und längeren Ausfallzeiten der Fahrzeuge führt. Dies ist vor allem für Unternehmen problematisch, die auf ihren Fuhrpark in den Bereichen Logistik und Transport angewiesen sind, wo Zuverlässigkeit von größter Bedeutung ist.

Die Lösung: Um die Beschaffung von Qualitätsgeneratoren sicherzustellen, sollten Unternehmen vorrangig Beziehungen zu seriösen Lieferanten aufbauen, die OEM-Teile (Original Equipment Manufacturer) oder zertifizierte wiederaufbereitete Optionen anbieten. Gründliche Recherchen zur Überprüfung des Rufs des Lieferanten und Empfehlungen von Branchenkollegen können das Risiko des Kaufs minderwertiger Produkte erheblich verringern. Darüber hinaus kann die Einführung einer Garantierichtlinie für alle beschafften Teile zusätzliche Sicherheit bieten und vor möglichen Verlusten im Zusammenhang mit fehlerhaften Komponenten schützen.

Szenario 3: Mangelndes Wissen über die Gesamtbetriebskosten (Total Cost of Ownership)

Das Problem: Viele B2B-Einkäufer unterschätzen die mit dem Austausch von Lichtmaschinen verbundenen Gesamtbetriebskosten. Dieses Versäumnis kann zu einer finanziellen Belastung führen, insbesondere für Unternehmen, die in Regionen tätig sind, in denen die Arbeitskosten stark schwanken und die Ersatzteile wesentlich teurer sein können als erwartet. Die Käufer konzentrieren sich möglicherweise nur auf die Anschaffungskosten der Lichtmaschine selbst, ohne die langfristigen Auswirkungen ihrer Entscheidungen zu berücksichtigen.

Die Lösung: Um dieses Problem anzugehen, sollten Unternehmen einen ganzheitlichen Ansatz für die Kostenanalyse wählen, der nicht nur den Anschaffungspreis der Lichtmaschine, sondern auch Arbeitskosten, mögliche Ausfallzeiten und die voraussichtliche Lebensdauer des Ersatzteils berücksichtigt. Einkäufer können Tools wie Kostenrechner nutzen oder sich von Kfz-Fachleuten beraten lassen, um diese Kosten genau zu prognostizieren. Darüber hinaus können Investitionen in die Schulung des Wartungspersonals in Bezug auf den ordnungsgemäßen Einbau und die Pflege von Lichtmaschinen die Langlebigkeit der verwendeten Teile erhöhen und so die Gesamtkosten im Laufe der Zeit senken. Die regelmäßige Überprüfung und Aktualisierung von Beschaffungsstrategien auf der Grundlage von Gesamtkostenanalysen ermöglicht es Unternehmen, fundiertere und finanziell solidere Entscheidungen zu treffen.

Strategischer Leitfaden zur Materialauswahl für den Ersatz einer Lichtmaschine

Welche Materialien werden üblicherweise beim Austausch von Lichtmaschinen verwendet?

Beim Austausch einer Lichtmaschine spielt die Wahl der Werkstoffe eine wichtige Rolle für die Leistung, die Haltbarkeit und die Gesamtwirtschaftlichkeit. Im Folgenden analysieren wir vier gängige Materialien, die in Lichtmaschinenbauteilen verwendet werden, und konzentrieren uns dabei auf ihre Eigenschaften, Vor- und Nachteile sowie auf spezifische Überlegungen für internationale B2B-Käufer.

1. Aluminium

Wichtige Eigenschaften: Aluminium ist leicht und hat eine ausgezeichnete Korrosionsbeständigkeit. Es kann mäßigen Temperaturen standhalten und eignet sich daher für Anwendungen in der Automobilindustrie.

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

Vor- und Nachteile: Das geringe Gewicht von Aluminium trägt zu einer besseren Kraftstoffeffizienz bei, während seine Korrosionsbeständigkeit die Lebensdauer des Generators verlängert. Allerdings ist Aluminium im Vergleich zu anderen Metallen bei extremer mechanischer Beanspruchung weniger haltbar, was in anspruchsvollen Umgebungen zu strukturellem Versagen führen kann.

Auswirkungen auf die Anwendung: Aluminium ist mit verschiedenen Kfz-Flüssigkeiten und -Umgebungen kompatibel, was es zu einer vielseitigen Wahl macht. Es muss jedoch unbedingt sichergestellt werden, dass das verwendete Aluminium den spezifischen Automobilnormen entspricht, um ein vorzeitiges Versagen zu vermeiden.

Überlegungen für internationale Käufer: Käufer in Regionen wie Afrika und Südamerika sollten darauf achten, dass die lokalen Normen und Vorschriften für die Automobilindustrie eingehalten werden. Außerdem kann die Beschaffung von Aluminiumkomponenten, die den ASTM-Normen entsprechen, die Zuverlässigkeit erhöhen.

2. Stahl

Wichtige Eigenschaften: Stahl bietet eine hohe Zugfestigkeit und Haltbarkeit bei guter Temperaturbeständigkeit. Im Vergleich zu Aluminium ist er weniger anfällig für Verformungen unter mechanischer Belastung.

Vor- und Nachteile: Stahl ist aufgrund seiner Festigkeit ideal für Hochleistungsanwendungen und gewährleistet Langlebigkeit und Zuverlässigkeit. Stahl ist jedoch schwerer als Aluminium, was sich negativ auf die Kraftstoffeffizienz auswirken kann. Außerdem ist er anfällig für Korrosion, wenn er nicht richtig behandelt wird.

Auswirkungen auf die Anwendung: Stahl eignet sich für hochbelastete Anwendungen, erfordert aber möglicherweise zusätzliche Beschichtungen oder Behandlungen zur Verbesserung der Korrosionsbeständigkeit, insbesondere in feuchter Umgebung oder an der Küste.

Überlegungen für internationale Käufer: Käufer sollten die örtlichen Korrosionsbeständigkeitsnormen beachten und eventuell zusätzliche Schutzbeschichtungen für Stahlteile in Regionen mit hoher Luftfeuchtigkeit oder salzhaltiger Umgebung, wie z. B. im Nahen Osten, in Betracht ziehen.

3. Kupfer

Wichtige Eigenschaften: Kupfer ist ein hervorragender elektrischer Leiter und eignet sich daher ideal für elektrische Bauteile in Lichtmaschinen. Es hat eine gute Wärmeleitfähigkeit und Korrosionsbeständigkeit.

Vor- und Nachteile: Die hohe Leitfähigkeit von Kupfer gewährleistet eine effiziente Stromübertragung, die für die Leistung der Lichtmaschine entscheidend ist. Kupfer ist jedoch teurer als Aluminium und Stahl und kann schwerer sein, was sich auf das Gesamtgewicht des Fahrzeugs auswirkt.

Auswirkungen auf die Anwendung: Kupfer ist unverzichtbar für die Verkabelung und die elektrischen Verbindungen in Lichtmaschinen und gewährleistet eine optimale Leistung. Die Kompatibilität mit verschiedenen elektrischen Systemen ist ein wesentlicher Vorteil.

Überlegungen für internationale Käufer: Käufer sollten die Kostenfolgen von Kupfer bedenken und sicherstellen, dass die Lieferanten die internationalen elektrischen Normen erfüllen. Außerdem kann die Beschaffung von Kupferkomponenten, die den lokalen Vorschriften entsprechen, zukünftige Probleme verhindern.

4. Kunststoffverbundwerkstoffe

Wichtige Eigenschaften: Kunststoffverbundwerkstoffe sind leicht, korrosionsbeständig und haben gute Isoliereigenschaften. Sie können mäßigen Temperaturen standhalten, sind aber möglicherweise nicht für stark beanspruchte Anwendungen geeignet.

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

Vor- und Nachteile: Das geringe Gewicht von Kunststoffverbundwerkstoffen kann die Kraftstoffeffizienz verbessern, und ihre Korrosionsbeständigkeit verlängert die Lebensdauer der Bauteile. Allerdings bieten sie möglicherweise nicht die gleiche Festigkeit wie Metalle, was ihre Verwendung in kritischen strukturellen Anwendungen einschränkt.

Auswirkungen auf die Anwendung: Kunststoffverbundwerkstoffe werden häufig in nicht tragenden Bauteilen wie Gehäusen und Abdeckungen verwendet, um elektrische Komponenten zu isolieren und vor Umwelteinflüssen zu schützen.

Überlegungen für internationale Käufer: Internationale Einkäufer sollten sicherstellen, dass Kunststoffverbundwerkstoffe die einschlägigen Normen und Vorschriften für die Automobilindustrie erfüllen, insbesondere hinsichtlich der thermischen und mechanischen Eigenschaften.

Zusammenfassende Tabelle

| Material | Typischer Anwendungsfall für die Frage, wie viel der Austausch einer Lichtmaschine kostet | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Gehäuse und Bauteile | Leicht und korrosionsbeständig | Weniger haltbar bei extremer Belastung | Mittel |

| Stahl | Hochbelastete Komponenten | Hohe Zugfestigkeit | Schwerer und anfällig für Korrosion | Mittel |

| Kupfer | Elektrische Verkabelung und Anschlüsse | Hervorragende elektrische Leitfähigkeit | Höhere Kosten und höheres Gewicht | Hoch |

| Kunststoffverbundwerkstoffe | Nicht-tragende Abdeckungen und Gehäuse | Leicht und korrosionsbeständig | Begrenzte Festigkeit für kritische Teile | Niedrig |

Dieser strategische Leitfaden für die Materialauswahl bietet B2B-Einkäufern wichtige Einblicke in die Materialien, die für den Ersatz von Lichtmaschinen verwendet werden, und hilft ihnen, Kaufentscheidungen auf der Grundlage von Leistungs-, Kosten- und regionalen Erwägungen zu treffen.

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

Eingehender Blick: Fertigungsprozesse und Qualitätssicherung für den Austausch einer Lichtmaschine

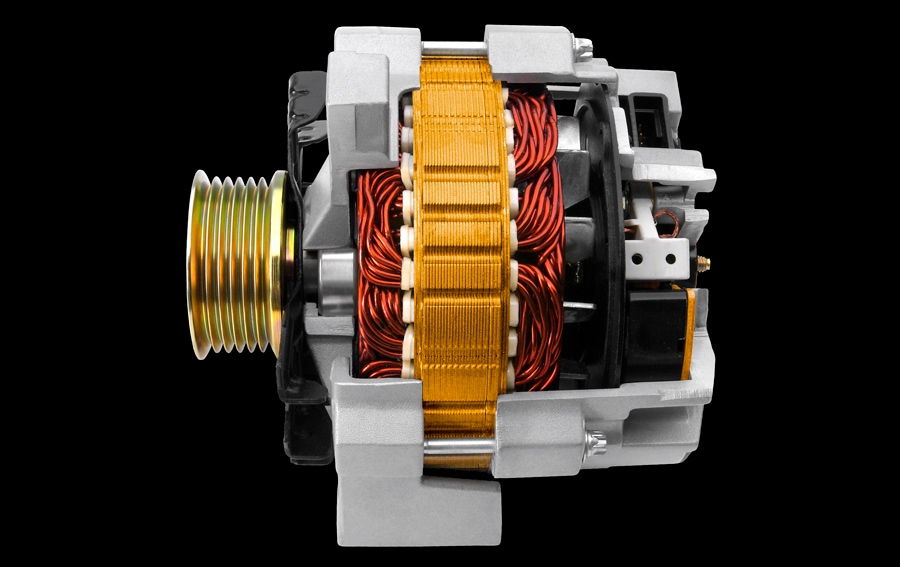

Was sind die wichtigsten Schritte im Herstellungsprozess von Wechselstromgeneratoren?

Der Herstellungsprozess von Generatoren umfasst mehrere kritische Phasen, die sicherstellen, dass das Endprodukt den Leistungsstandards und den Erwartungen an die Zuverlässigkeit entspricht. Zu diesen Phasen gehören Materialvorbereitung, Formgebung, Montage und Endbearbeitung. In jeder Phase werden spezielle Techniken eingesetzt, um qualitativ hochwertige Generatoren herzustellen, die den Anforderungen verschiedener Fahrzeugtypen gerecht werden.

Wie wird das Material für die Herstellung von Wechselstromgeneratoren vorbereitet?

Die Materialvorbereitung ist der wichtigste Schritt im Herstellungsprozess von Generatoren. In der Regel beziehen die Hersteller hochwertige Materialien wie Aluminium für das Gehäuse, Kupfer für die Wicklungen und verschiedene Stahllegierungen für die internen Komponenten. Die Auswahl der Materialien ist entscheidend, da sie hohen Temperaturen und mechanischen Belastungen standhalten müssen.

Sobald die Materialien beschafft sind, werden sie Verfahren wie Schneiden, Bearbeitung und Oberflächenbehandlung unterzogen. So können beispielsweise Aluminiumgehäuse stranggepresst oder druckgegossen werden, um die gewünschte Form und strukturelle Integrität zu erreichen. Kupferdrähte werden auf bestimmte Stärken gezogen, um eine optimale Leitfähigkeit bei möglichst geringem Gewicht zu gewährleisten. Diese sorgfältige Vorbereitung bildet die Grundlage für die anschließenden Umform- und Montageprozesse.

Welche Techniken werden bei der Formgebung und Montage von Generatoren eingesetzt?

Umformtechniken spielen eine wichtige Rolle bei der Gestaltung der Komponenten eines Generators. Das Stanzen wird üblicherweise eingesetzt, um den Rotor und den Stator aus Metallblechen herzustellen, während Wickelmaschinen verwendet werden, um Kupferdraht um den Statorkern zu wickeln. So wird sichergestellt, dass die elektrischen Komponenten richtig konfiguriert sind, um effektiv Strom zu erzeugen.

In der Montagephase werden verschiedene Komponenten wie Rotor, Stator, Lager und Gehäuse zusammengebaut. Häufig werden automatisierte Montagelinien eingesetzt, um die Effizienz und Präzision zu erhöhen. In dieser Phase werden wichtige Verbindungen hergestellt, einschließlich der Befestigung des Spannungsreglers und des Gleichrichters. In dieser Phase werden Qualitätskontrollen durchgeführt, um sicherzustellen, dass alle Komponenten korrekt passen und wie vorgesehen funktionieren.

Welche Veredelungsprozesse sind für Wechselstromgeneratoren entscheidend?

Die Veredelungsverfahren stellen sicher, dass die Generatoren nicht nur funktional, sondern auch ästhetisch ansprechend und langlebig sind. Zu diesen Verfahren kann die Lackierung oder Pulverbeschichtung des Äußeren gehören, um Korrosion zu verhindern und das Erscheinungsbild zu verbessern. Außerdem werden die Bauteile häufig einer Wärmebehandlung unterzogen, um ihre Festigkeit und Haltbarkeit zu verbessern.

Nach der Fertigstellung werden die Generatoren zu kompletten Einheiten zusammengebaut und einer Endkontrolle unterzogen. Dazu gehören die Prüfung der elektrischen Leistung und die Überprüfung, ob alle Bauteile den vorgegebenen Toleranzen entsprechen. Die Qualität der Endbearbeitung kann sich erheblich auf die Langlebigkeit und Zuverlässigkeit des Generators im Einsatz auswirken.

Welche Qualitätssicherungsmaßnahmen sind für die Herstellung von Generatoren unerlässlich?

Die Qualitätssicherung (QS) ist ein entscheidender Aspekt bei der Herstellung von Generatoren. Sie stellt sicher, dass die Produkte den internationalen Normen und den Erwartungen der Kunden entsprechen. Während des gesamten Herstellungsprozesses kommen verschiedene QS-Maßnahmen zum Einsatz, von der ersten Materialprüfung bis zur abschließenden Produktprüfung.

Welche internationalen Normen sollten B2B-Einkäufer beachten?

B2B-Einkäufer sollten nach Herstellern Ausschau halten, die internationale Normen wie die ISO 9001 einhalten, in der die Anforderungen an ein Qualitätsmanagementsystem festgelegt sind. Die Einhaltung dieser Normen bedeutet, dass der Hersteller Verfahren zur kontinuierlichen Verbesserung und Kundenzufriedenheit eingeführt hat.

Neben den ISO-Normen können je nach Einsatzgebiet der Generatoren auch branchenspezifische Zertifizierungen wie CE (Conformité Européenne) und API (American Petroleum Institute) von Bedeutung sein. Diese Zertifizierungen garantieren den Käufern, dass die Produkte strenge Qualitäts- und Sicherheitsanforderungen erfüllen.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle bei der Herstellung von Lichtmaschinen?

Die Kontrollpunkte der Qualitätskontrolle (QC) sind strategisch über den gesamten Herstellungsprozess verteilt, um Probleme frühzeitig zu erkennen und zu beheben. Zu den wichtigsten Kontrollpunkten gehören:

- Eingangsqualitätskontrolle (IQC): Prüfung von Rohstoffen und Komponenten bei ihrer Ankunft, um sicherzustellen, dass sie den Spezifikationen entsprechen.

- In-Process-Qualitätskontrolle (IPQC): Laufende Kontrollen während der Fertigung zur Überwachung der Prozesse und zur Erkennung von Fehlern in Echtzeit.

- Endkontrolle (FQC): Umfassende Prüfung und Inspektion der fertigen Generatoren, um sicherzustellen, dass sie den Leistungs- und Ästhetikstandards entsprechen.

Zu den gängigen Prüfverfahren gehören elektrische Leistungstests, Temperaturwechselprüfungen, Vibrationstests und Haltbarkeitsbewertungen. Diese Tests tragen dazu bei, dass die Generatoren unter verschiedenen Bedingungen zuverlässig funktionieren.

Wie können B2B-Einkäufer die Qualitätssicherung der Lieferanten überprüfen?

B2B-Einkäufer müssen proaktive Schritte unternehmen, um die Qualitätssicherungsprozesse potenzieller Lieferanten zu überprüfen. Die Durchführung von Audits ist eine wirksame Methode. Audits können die Einhaltung von Qualitätsstandards, Fertigungsverfahren und die allgemeine betriebliche Effizienz eines Lieferanten bewerten.

Darüber hinaus kann das Anfordern detaillierter Qualitätsberichte und Zertifizierungen einen Einblick in die Fähigkeiten eines Herstellers geben. Käufer sollten auch Inspektionen durch Dritte in Betracht ziehen, die eine unvoreingenommene Bewertung der Qualitätssicherungsprozesse und der Produktzuverlässigkeit des Lieferanten liefern können.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

Internationale Einkäufer müssen sich der Nuancen in der Qualitätskontrolle bewusst sein, die sich aufgrund regionaler Vorschriften und Normen ergeben können. So können sich beispielsweise in Afrika und Südamerika die lokalen Anforderungen von denen in Europa oder dem Nahen Osten unterscheiden. Käufer sollten sich mit diesen Abweichungen vertraut machen, um sicherzustellen, dass die Produkte den lokalen Vorschriften und Erwartungen entsprechen.

Darüber hinaus ist eine klare Kommunikation mit den Lieferanten hinsichtlich der Qualitätserwartungen unerlässlich. Dazu gehört die Festlegung akzeptabler Qualitätsniveaus und die Sicherstellung, dass die Lieferanten verstehen, wie wichtig die Einhaltung internationaler Qualitätsstandards ist. Durch die Förderung einer kooperativen Beziehung können die Einkäufer die Wahrscheinlichkeit erhöhen, qualitativ hochwertige Produkte zu erhalten, die ihren Spezifikationen entsprechen.

Schlussfolgerung: Sicherstellung der Qualität bei der Herstellung von Generatoren

Für B2B-Einkäufer ist es wichtig, die Herstellungsprozesse und Qualitätssicherungsmaßnahmen für Generatoren zu verstehen. Indem sie sich mit den Produktionsstufen und den relevanten Qualitätsstandards vertraut machen, können Einkäufer bei der Auswahl von Lieferanten fundierte Entscheidungen treffen. Durch die Implementierung gründlicher Überprüfungsprozesse wird außerdem sichergestellt, dass sie mit Herstellern zusammenarbeiten, die sich der Lieferung hochwertiger, zuverlässiger Generatoren verschrieben haben, die sowohl die Leistungs- als auch die gesetzlichen Anforderungen erfüllen.

Praktischer Beschaffungsleitfaden: Eine Schritt-für-Schritt-Checkliste für ‘Wie viel kostet der Austausch einer Lichtmaschine’.’

Einführung

Wenn B2B-Einkäufer den Austausch einer Lichtmaschine in Betracht ziehen, müssen sie sich mit verschiedenen Faktoren auseinandersetzen, die Kosten und Qualität beeinflussen. Dieser Leitfaden bietet eine praktische Checkliste, um Ihren Beschaffungsprozess zu optimieren und sicherzustellen, dass Sie bei der Beschaffung von Lichtmaschinen für Ihren Fuhrpark oder Ihr Wiederverkaufsgeschäft fundierte Entscheidungen treffen.

Schritt 1: Verstehen Sie Ihre Fahrzeuganforderungen

Bevor Sie mit der Suche beginnen, sollten Sie sich über die Spezifikationen der Fahrzeuge in Ihrem Fuhrpark informieren. Dazu gehört, dass Sie die Marke, das Modell und das Baujahr jedes Fahrzeugs kennen, da sich die Lichtmaschinen der verschiedenen Modelle erheblich unterscheiden. Mit diesen Informationen können Sie die richtigen Lieferanten auswählen und kostspielige Fehler vermeiden.

Schritt 2: Ein Budget festlegen

Legen Sie ein klares Budget für Ihr Lichtmaschinenaustauschprojekt fest. Die Kosten können je nach Lichtmaschinentyp (OEM oder Aftermarket), Arbeitsaufwand und zusätzlich benötigten Teilen, wie z. B. Serpentinenriemen, stark schwanken. Berücksichtigen Sie nicht nur die unmittelbaren Kosten, sondern auch die potenziellen langfristigen Einsparungen durch Qualitätskomponenten, die die künftigen Wartungskosten senken können.

Schritt 3: Recherche von Lieferantenoptionen

Ermitteln Sie mehrere Anbieter, die Ihre Anforderungen erfüllen können. Suchen Sie nach Anbietern, die einen guten Ruf für Qualität und Zuverlässigkeit haben. Nutzen Sie Plattformen wie Branchenverzeichnisse, Messen und Online-Bewertungen, um eine Liste potenzieller Anbieter zusammenzustellen.

- Lieferantenbewertungen: Prüfen Sie Bewertungen auf Plattformen wie Trustpilot oder Google Reviews.

- Branchenerfahrung: Bevorzugen Sie Lieferanten mit einer nachgewiesenen Erfolgsbilanz im Bereich der Automobilteile.

Schritt 4: Bewerten Sie die Produktqualität

Qualität sollte bei der Beschaffung von Lichtmaschinen oberste Priorität haben. Unterscheiden Sie zwischen OEM-, Aftermarket- und wiederaufbereiteten Optionen. OEM-Teile bieten in der Regel eine höhere Zuverlässigkeit, während Aftermarket-Teile in der Qualität variieren können.

- Garantie und Support: Vergewissern Sie sich, dass der Lieferant eine Garantie für seine Produkte gewährt, was ein Zeichen des Vertrauens in die Qualität ist.

- Zertifizierungen: Suchen Sie nach Lieferanten, die die internationalen Normen einhalten, um sicherzustellen, dass die Teile den Sicherheits- und Leistungsanforderungen entsprechen.

Schritt 5: Kostenvoranschläge anfordern und Kosten vergleichen

Sobald Sie eine Auswahlliste von Anbietern erstellt haben, sollten Sie detaillierte Angebote einholen, in denen die Kosten für die Lichtmaschinen, einschließlich der Arbeitskosten und aller zusätzlichen Teile, aufgeführt sind. Der Vergleich dieser Angebote gibt Aufschluss über die Preisgestaltung und hilft Ihnen, eine kosteneffiziente Entscheidung zu treffen.

- Aufschlüsselung der Kosten: Vergewissern Sie sich, dass die Kostenvoranschläge eine Aufschlüsselung von Teilen und Arbeit enthalten, damit Sie wissen, wohin Ihr Geld fließt.

- Versteckte Gebühren: Achten Sie auf versteckte Kosten, die die Gesamtkosten in die Höhe treiben könnten.

Schritt 6: Verfügbarkeit und Lieferzeiten prüfen

Bestätigen Sie die Verfügbarkeit der Generatoren und die voraussichtlichen Lieferzeiten. Verzögerungen bei der Lieferung von Teilen können sich auf Ihren Betrieb auswirken. Daher ist es wichtig, einen Lieferanten zu wählen, der Ihren Zeitplan einhalten kann.

- Lagerbestände: Lieferanten mit einem großen Lagerbestand können oft schneller liefern.

- Versandoptionen: Ziehen Sie Lieferanten in Betracht, die flexible Versandmethoden anbieten, um den rechtzeitigen Erhalt der Teile zu gewährleisten.

Schritt 7: Bauen Sie eine Beziehung zu Ihrem Lieferanten auf

Sobald Sie einen Lieferanten ausgewählt haben, sollten Sie sich auf den Aufbau einer starken Beziehung konzentrieren. Eine zuverlässige Partnerschaft kann zu besseren Preisen, bevorzugtem Service und Zugang zu neuen Produkten führen, sobald diese verfügbar sind.

- Kommunikation: Setzen Sie sich regelmäßig mit Ihrem Lieferanten in Verbindung, um über neue Angebote und mögliche Probleme informiert zu bleiben.

- Rückkopplungsschleife: Geben Sie Feedback zu den erhaltenen Teilen und dem erlebten Service, um eine für beide Seiten vorteilhafte Beziehung zu fördern.

Anhand dieser Checkliste können B2B-Einkäufer die Komplexität der Beschaffung von Generatoren effektiv steuern und sicherstellen, dass sie fundierte und strategische Beschaffungsentscheidungen treffen.

Umfassende Kosten- und Preisanalyse für den Ersatz einer Lichtmaschine Sourcing

Was sind die wichtigsten Kostenkomponenten beim Austausch der Lichtmaschine?

Wenn Sie den Austausch einer Lichtmaschine in Erwägung ziehen, werden die Gesamtkosten von mehreren Komponenten beeinflusst, die B2B-Käufer für eine effektive Budgetplanung kennen sollten. Zu den wichtigsten Kostenkomponenten gehören:

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

-

Materialien: Die Lichtmaschine selbst ist der größte Kostenfaktor, der je nach Marke und Modell zwischen $100 und $350 liegt. OEM-Teile sind in der Regel teurer als Aftermarket-Optionen, aber sie gewährleisten oft eine höhere Zuverlässigkeit.

-

Arbeit: Die Arbeitskosten können je nach geografischem Standort und der Komplexität des Fahrzeugs stark variieren. Im Durchschnitt liegen die Arbeitskosten zwischen $120 und $200 für einen Austausch, der normalerweise zwei bis drei Stunden dauert.

-

Fertigungsgemeinkosten: Hierunter fallen Kosten im Zusammenhang mit der Produktion von Generatoren, wie z. B. die Instandhaltung der Fabrik, Versorgungsleistungen und Löhne für Fabrikarbeiter. Diese Kosten können je nach Herstellungsregion schwanken und sich auf den Endpreis auswirken.

-

Werkzeuge: Für den Einbau oder die Herstellung können spezielle Werkzeuge und Maschinen erforderlich sein, die die Gesamtkosten erhöhen. Dies gilt insbesondere für kundenspezifische oder spezielle Generatoren.

-

Qualitätskontrolle (QC): Die Sicherstellung, dass jeder Generator den Qualitätsstandards entspricht, kann zusätzliche Kosten verursachen. Hochwertige Zertifizierungen können ebenfalls den Preis erhöhen, sind aber für die Zuverlässigkeit unerlässlich, insbesondere bei kritischen Anwendungen.

-

Logistik: Die Versandkosten können je nach Entfernung und den gewählten Incoterms erheblich variieren. Für den internationalen Versand können Zölle und Tarife erforderlich sein, die die Preisgestaltung weiter beeinflussen können.

-

Marge: Die Lieferanten werden in der Regel eine Gewinnspanne in ihre Preisgestaltung einbeziehen, die je nach Wettbewerb, Nachfrage und Marktstrategie des Lieferanten variieren kann.

Wie wirken sich Preisfaktoren auf die Kosten von Lichtmaschinen aus?

Mehrere Faktoren beeinflussen den Endpreis von Lichtmaschinen, insbesondere für internationale B2B-Käufer:

-

Volumen/MOQ (Mindestbestellmenge): Großeinkäufe können zu erheblichen Rabatten führen. Käufer sollten auf der Grundlage des voraussichtlichen Mengenbedarfs niedrigere Preise aushandeln.

-

Spezifikationen und Anpassung: Kundenspezifische Spezifikationen können die Kosten erhöhen, da spezielle Materialien oder Herstellungsverfahren erforderlich sind. Eine klare Kommunikation der Anforderungen ist entscheidend, um unerwartete Kosten zu vermeiden.

-

Materialien und Qualitätszertifizierungen: Qualitativ hochwertigere Materialien, die oft mit Zertifizierungen einhergehen, erhöhen natürlich die Kosten. Investitionen in Qualität können jedoch im Laufe der Zeit zu niedrigeren Gesamtbetriebskosten (TCO) führen, da die Ausfallraten sinken.

-

Lieferantenfaktoren: Die Wahl des Lieferanten kann die Preisgestaltung erheblich beeinflussen. Etablierte Lieferanten, die für ihre Qualität bekannt sind, können höhere Preise verlangen, bieten aber auch eine höhere Zuverlässigkeit und einen besseren Service.

-

Incoterms: Es ist wichtig, die Versandbedingungen zu kennen. CIF (Cost, Insurance, and Freight - Kosten, Versicherung und Fracht) mag im Vorfeld teurer erscheinen, kann aber eine bessere Deckung und Sicherheit bieten als EXW (Ex Works), bei dem der Käufer ein höheres Risiko trägt.

Was sind wirksame Einkaufstipps für Kosteneffizienz?

-

Verhandlung: Einkäufer sollten bereit sein, über den Preis zu verhandeln, insbesondere bei Großaufträgen. Nutzen Sie wettbewerbsfähige Angebote von mehreren Lieferanten, um Ihre Verhandlungsposition zu stärken.

-

Kosteneffizienz: Betrachten Sie die Gesamtbetriebskosten und nicht nur den Anschaffungspreis. Höhere Anschaffungskosten für einen zuverlässigen Generator können auf lange Sicht Geld sparen, da weniger Wartungsarbeiten anfallen und der Austausch seltener erforderlich ist.

-

Preisgestaltung für internationale Käufer: Verstehen Sie die Marktdynamik in Ihrer Region. In Afrika und Südamerika zum Beispiel können lokale Anbieter aufgrund niedrigerer Versandkosten und der Vertrautheit mit den lokalen Vorschriften bessere Preise bieten.

-

Garantie und Support: Erkundigen Sie sich immer nach den Garantiebedingungen und der Unterstützung nach dem Kauf. Eine längere Garantie kann auf ein größeres Vertrauen in die Haltbarkeit des Produkts hindeuten, was für B2B-Käufer ein entscheidender Faktor ist.

Haftungsausschluss

Die hier genannten Preise sind Richtwerte und können je nach geografischem Standort, Fahrzeugmarke und -modell sowie Anbieter variieren. Wenden Sie sich immer an mehrere Anbieter, um genaue und aktuelle Preise zu erhalten, die auf Ihre spezifischen Anforderungen zugeschnitten sind.

Analyse der Alternativen: Vergleich der Kosten für den Austausch einer Lichtmaschine mit anderen Lösungen

Untersuchung von Alternativen für den Austausch der Lichtmaschine

Wenn eine Lichtmaschine ausgetauscht werden muss, ziehen B2B-Käufer oft alternative Lösungen in Betracht, die ähnliche Ergebnisse erzielen können. Um eine fundierte Entscheidung treffen zu können, ist es wichtig, die Kosten, die Leistung und die Wartungsanforderungen dieser Alternativen zu kennen. Nachfolgend finden Sie einen Vergleich des Austauschs einer Lichtmaschine mit zwei praktikablen Alternativen: die Reparatur der vorhandenen Lichtmaschine und Installation eines Batteriemanagementsystems (BMS).

| Vergleichsaspekt | Wie viel kostet es, eine Lichtmaschine zu ersetzen? | Reparieren der vorhandenen Lichtmaschine | Installieren eines Batteriemanagementsystems (BMS) |

|---|---|---|---|

| Leistung | Stellt die volle Funktionalität wieder her | Kann teilweise Funktionalität wiederherstellen | Verbessert die allgemeine Lebensdauer und Effizienz der Batterie |

| Kosten | $350 - $900 | $150 - $300 | $200 - $500 |

| Einfache Implementierung | Mäßig (2-3 Stunden Arbeit) | Mäßig (1-2 Stunden Arbeit) | Mäßig bis hoch (variiert je nach System) |

| Wartung | Geringfügig nach der Ersetzung | Erfordert regelmäßige Kontrollen | Regelmäßige Software-Updates und -Überprüfungen erforderlich |

| Bester Anwendungsfall | Langfristige Zuverlässigkeit der Fahrzeuge | Kurzfristige Kosteneinsparungen | Verbesserte Batterieleistung in Elektrofahrzeugen |

Vor- und Nachteile der Reparatur der vorhandenen Lichtmaschine

Die Reparatur einer vorhandenen Lichtmaschine kann eine kosteneffiziente Lösung sein, vor allem, wenn nur kleinere Probleme vorliegen, wie ein defekter Riemen oder korrodierte Anschlüsse. Die durchschnittlichen Kosten für eine Reparatur liegen zwischen $150 und $300, was sie zu einer attraktiven Option für Unternehmen macht, die ihre Ausgaben minimieren wollen. Allerdings kann auf diese Weise die volle Funktionsfähigkeit nicht wiederhergestellt werden, und die Lichtmaschine kann erneut ausfallen, was zu zusätzlichen Kosten und Ausfallzeiten führt. Sie wird häufig für den kurzfristigen Einsatz oder in Situationen empfohlen, in denen das Fahrzeug voraussichtlich nicht mehr lange in Betrieb sein wird.

Vor- und Nachteile der Installation eines Batteriemanagementsystems (BMS)

Ein Batteriemanagementsystem (BMS) ist eine fortschrittliche Lösung zur Optimierung der Batterieleistung durch Überwachung und Verwaltung der Ladezyklen. Die Anfangsinvestition von $200 bis $500 kann zwar höher sein als einfache Reparaturen, aber ein BMS kann die Lebensdauer und Effizienz der Batterie erheblich verlängern, insbesondere bei Elektrofahrzeugen oder Flotten, die stark auf Batteriestrom angewiesen sind. Das BMS erfordert auch regelmäßige Wartung und Software-Updates, was die Implementierung für Unternehmen mit begrenzten technischen Ressourcen erschweren kann. Für Betriebe, die auf Nachhaltigkeit und langfristige Kosteneinsparungen ausgerichtet sind, kann ein BMS jedoch eine wertvolle Investition sein.

Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

Bei der Entscheidung über die beste Vorgehensweise bei Problemen mit der Lichtmaschine sollten B2B-Käufer ihre spezifischen Anforderungen, einschließlich Budgetbeschränkungen, die vorgesehene Lebensdauer des Fahrzeugs und die Betriebsumgebung, berücksichtigen. Wenn das Ziel darin besteht, die Zuverlässigkeit des Fahrzeugs langfristig aufrechtzuerhalten, kann der Austausch der Lichtmaschine die vernünftigste Lösung sein. Steht dagegen die Minimierung der unmittelbaren Kosten im Vordergrund und hat das Fahrzeug nur eine begrenzte Zukunft, könnte eine Reparatur der Lichtmaschine ausreichen. Für Unternehmen, die Elektrofahrzeuge betreiben oder die Batterieleistung verbessern wollen, kann die Investition in ein BMS langfristig den größten Nutzen bringen. Jede Option hat ihre Vorzüge und potenziellen Nachteile, so dass es wichtig ist, die Wahl mit den betrieblichen Zielen und finanziellen Überlegungen abzustimmen.

Wesentliche technische Eigenschaften und Fachterminologie für den Austausch einer Lichtmaschine

Was sind die wichtigsten technischen Eigenschaften beim Austausch einer Lichtmaschine?

Für B2B-Käufer, die den Austausch einer Lichtmaschine in Erwägung ziehen, ist das Verständnis spezifischer technischer Eigenschaften von entscheidender Bedeutung, insbesondere für Fuhrparkmanager oder Kfz-Reparaturbetriebe. Hier sind einige wichtige Spezifikationen, die Sie beachten sollten:

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

-

Werkstoffgüte

Die Materialqualität einer Lichtmaschine hat einen erheblichen Einfluss auf ihre Haltbarkeit und Leistung. Zu den gängigen Materialien gehören Aluminium und Kunststoffverbundwerkstoffe, die leicht und dennoch robust sind. Hochwertige Materialien halten auch rauen Betriebsbedingungen stand und verringern die Wahrscheinlichkeit eines vorzeitigen Ausfalls. Für B2B-Käufer kann die Wahl von Generatoren aus höherwertigen Materialien zu langfristigen Kosteneinsparungen führen, da die Häufigkeit des Austauschs minimiert wird. -

Nennspannung

Lichtmaschinen arbeiten in der Regel mit einer Nennspannung von 12 oder 24 V. Dieser Wert gibt die elektrische Leistung an, die für die Stromversorgung der Fahrzeugsysteme erforderlich ist. Die Kompatibilität mit dem elektrischen System des Fahrzeugs ist von entscheidender Bedeutung, da eine nicht angepasste Spannung zu Ausfällen oder Schäden an der Ausrüstung führen kann. B2B-Einkäufer müssen die Spannungsanforderungen ihrer Flotte oder ihres Inventars bestätigen, um kostspielige Fehler zu vermeiden. -

Stromstärke Ausgang

Die Stromstärke einer Lichtmaschine, gemessen in Ampere (A), gibt an, inwieweit sie in der Lage ist, verschiedene Komponenten, wie z. B. Beleuchtung und Klimaanlage, mit Strom zu versorgen. Die Standardleistung reicht von 60 A bis über 200 A, je nach den Anforderungen des Fahrzeugs. Für Unternehmen ist die Auswahl einer Lichtmaschine mit der richtigen Stromstärke entscheidend, um eine optimale Leistung zu gewährleisten und eine Überlastung zu vermeiden, die zu einem Ausfall führen kann. -

Lagertyp

In Lichtmaschinen können verschiedene Arten von Lagern verwendet werden, z. B. Kugel- oder Rollenlager. Die Wahl hat Auswirkungen auf die Langlebigkeit des Generators und den Geräuschpegel während des Betriebs. Kugellager sind aufgrund ihrer geringeren Kosten und angemessenen Leistung weit verbreitet, während Rollenlager eine längere Lebensdauer bieten können. Die Kenntnis des Lagertyps kann Unternehmen dabei helfen, hochwertige Generatoren auszuwählen, die die Wartungskosten senken und die Zuverlässigkeit verbessern. -

Methode der Kühlung

Lichtmaschinen können luft- oder flüssigkeitsgekühlt sein. Die Kühlmethode wirkt sich auf die Leistung bei schweren Lasten und unter extremen Bedingungen aus. Für B2B-Einkäufer ist die Kenntnis der Kühlungsanforderungen entscheidend für die Auswahl von Generatoren, die in ihren spezifischen Umgebungen effizient arbeiten und somit einen zuverlässigen Betrieb gewährleisten.

Was sind gängige Fachbegriffe im Zusammenhang mit dem Austausch der Lichtmaschine?

Die Vertrautheit mit dem Fachjargon kann zu reibungsloseren Transaktionen und Verhandlungen beitragen. Hier sind einige wichtige Begriffe, die für den Austausch von Lichtmaschinen relevant sind:

-

OEM (Originalgerätehersteller)

Dieser Begriff bezieht sich auf Teile, die vom Originalhersteller des Fahrzeugs hergestellt werden. OEM-Generatoren sind oft teurer, garantieren aber Kompatibilität und Qualität. B2B-Einkäufer müssen bei der Beschaffung von Ersatzteilen die Vorteile von OEM-Teilen gegen die Kosteneffizienz abwägen. -

MOQ (Mindestbestellmenge)

MOQ gibt die kleinste Stückzahl an, die ein Lieferant zu verkaufen bereit ist. Das Verständnis der MOQ ist entscheidend für Unternehmen, die ihre Bestände effektiv verwalten wollen. Sie kann sich auf die gesamte Beschaffungsstrategie auswirken, insbesondere für Unternehmen, die Teile für große Flotten kaufen. -

RFQ (Angebotsanfrage)

Eine Anfrage ist ein Dokument, das an Lieferanten geschickt wird, um Preise und Verfügbarkeit für bestimmte Teile, einschließlich Generatoren, zu erfragen. Die Formulierung einer klaren Anfrage stellt sicher, dass die Lieferanten genaue und wettbewerbsfähige Angebote abgeben, was zu einer fundierten Kaufentscheidung beiträgt. -

Incoterms

In den Incoterms werden die Verantwortlichkeiten von Käufern und Verkäufern in Bezug auf Versand, Lieferung und Risikomanagement festgelegt. Das Verständnis dieser Bedingungen ist für internationale B2B-Transaktionen von entscheidender Bedeutung, da sie Klarheit über die Kosten und Verantwortlichkeiten beim Austausch einer Lichtmaschine schaffen. -

Garantiezeitraum

Die Garantiezeit bezieht sich auf den Zeitrahmen, in dem der Hersteller die Leistung des Generators garantiert. Für B2B-Einkäufer ist es wichtig, die Garantiebedingungen zu verstehen, da sie die langfristigen Kosten und Risikomanagementstrategien für den Austausch von Teilen beeinflussen. -

Ersatzteile

Aftermarket-Teile sind Komponenten, die nicht vom Originalfahrzeughersteller, sondern von Dritten hergestellt werden. Diese Teile können günstiger sein, sind aber von unterschiedlicher Qualität. B2B-Käufer sollten gründliche Nachforschungen anstellen, um die Zuverlässigkeit und Leistung von Aftermarket-Generatoren zu beurteilen, bevor sie eine Kaufentscheidung treffen.

Durch die Kenntnis dieser technischen Eigenschaften und der Fachterminologie können B2B-Einkäufer fundierte Entscheidungen über den Austausch von Lichtmaschinen treffen und so die betriebliche Effizienz und Kosteneffizienz in ihrem Kfz-Betrieb sicherstellen.

Navigieren durch Marktdynamik und Beschaffungstrends in der Branche "Wie viel kostet der Austausch einer Lichtmaschine?

Wie wirkt sich die aktuelle Marktdynamik auf die Kosten für den Austausch von Lichtmaschinen aus?

Im weltweiten Automobilsektor sind erhebliche Veränderungen zu beobachten, die sich auf die Kosten für den Austausch von Lichtmaschinen auswirken. Zu den wichtigsten Faktoren gehört die zunehmende Lebensdauer von Fahrzeugen, die mit zunehmendem Alter zu einer höheren Ausfallhäufigkeit von Lichtmaschinen führt, in der Regel zwischen 40.000 und 100.000 Meilen. Internationale B2B-Einkäufer, insbesondere aus Schwellenländern wie Afrika, Südamerika und dem Nahen Osten, konzentrieren sich zunehmend auf kostengünstige Beschaffungsstrategien. Sie sind auf der Suche nach Ersatzteilen, die ein gutes Preis-Leistungs-Verhältnis bieten, ohne Kompromisse bei der Qualität einzugehen. Darüber hinaus erleichtern technologische Fortschritte den Aufstieg von E-Commerce-Plattformen, die die Käufer direkt mit den Herstellern verbinden und so die Gemeinkosten senken und die preisliche Wettbewerbsfähigkeit verbessern.

Aufkommende Trends unterstreichen auch die Bedeutung der lokalen Beschaffung. So suchen Einkäufer in Regionen wie Brasilien und Saudi-Arabien zunehmend nach Lieferanten, die schnelle Durchlaufzeiten und lokalen Support bieten können. Diese Verlagerung wird auf logistische Herausforderungen und die Notwendigkeit zeitnaher Reparaturen in Märkten zurückgeführt, in denen Fahrzeugausfallzeiten den Geschäftsbetrieb erheblich beeinträchtigen können. Darüber hinaus gewinnt die Verwendung von wiederaufbereiteten Generatoren an Zugkraft, da diese Produkte oft ein ausgewogenes Verhältnis zwischen Kosten und Qualität bieten, was für preisbewusste Käufer attraktiv ist.

Wie können Nachhaltigkeit und ethische Beschaffung die Entscheidung über den Austausch von Lichtmaschinen beeinflussen?

Nachhaltigkeit wird zu einem entscheidenden Faktor auf dem Markt für Kfz-Teile, einschließlich Ersatzgeneratoren. Die Umweltauswirkungen der Herstellung und Entsorgung von Automobilkomponenten veranlassen die Einkäufer, Lieferanten zu suchen, die ethische Beschaffung und nachhaltige Praktiken in den Vordergrund stellen. Für B2B-Einkäufer ist das Verständnis des ökologischen Fußabdrucks der Lieferkette nicht nur für die Einhaltung gesetzlicher Vorschriften wichtig, sondern auch für den Ruf der Marke in einem zunehmend umweltbewussten Markt.

Die Einkäufer werden ermutigt, nach Lieferanten zu suchen, die ‘grüne’ Zertifizierungen und Materialien verwenden. Dazu können Hersteller gehören, die sich an die ISO 14001-Normen halten, die für effektive Umweltmanagementsysteme stehen. Durch die Beschaffung von Generatoren von Unternehmen, die sich auf die Reduzierung von Abfall und Energieverbrauch konzentrieren, können Unternehmen ihre Umweltauswirkungen verringern und gleichzeitig einen Kundenstamm ansprechen, der Wert auf Nachhaltigkeit legt. Darüber hinaus kann die Verwendung von wiederaufbereiteten Komponenten den Kohlenstoff-Fußabdruck, der mit der Produktion von Neuteilen verbunden ist, erheblich reduzieren, was sie zu einer überzeugenden Option für Käufer macht, die ihre Nachhaltigkeitsbilanz verbessern wollen.

Was ist der historische Kontext der Wechselstromgeneratorentechnologie und ihr Einfluss auf aktuelle Beschaffungstrends?

Die Lichtmaschine hat sich seit ihrer Einführung Anfang des 20. Jahrhunderts erheblich weiterentwickelt und ist von einfachen Gleichstromgeneratoren zu komplexen, hocheffizienten Wechselstromaggregaten übergegangen. Diese Entwicklung wurde durch die steigende Nachfrage nach elektrischer Energie in Fahrzeugen vorangetrieben, insbesondere durch die Zunahme fortschrittlicher elektronischer Systeme und Zubehörteile. Die Abhängigkeit von Generatoren hat sie in der Vergangenheit zu einer kritischen Komponente für die Fahrzeugfunktionalität gemacht, die eine regelmäßige Wartung und einen regelmäßigen Austausch erfordert.

Anschauliches Bild zum Thema "Wie viel kostet der Austausch einer Lichtmaschine?

Mit der fortschreitenden Entwicklung der Automobiltechnologie sind die Erwartungen an die Leistung und Zuverlässigkeit von Lichtmaschinen gestiegen. Dieser Wandel spiegelt sich in den aktuellen Beschaffungstrends wider, bei denen B2B-Einkäufer nicht nur auf die Kosten achten, sondern auch auf die Qualität und die technologische Raffinesse von Generatoren. Das Aufkommen intelligenter Generatoren, die in Fahrzeugmanagementsysteme integriert sind, unterstreicht die Notwendigkeit für Einkäufer, über technologische Fortschritte informiert zu bleiben. Das Verständnis dieses historischen Kontextes ermöglicht es internationalen Einkäufern, fundierte Entscheidungen über Beschaffungs- und Ersatzteilstrategien zu treffen, die sowohl ihren betrieblichen Anforderungen als auch den Markterwartungen gerecht werden.

Zusammenfassend lässt sich sagen, dass die Marktdynamik bei Ersatzgeneratoren ein ausgeprägtes Bewusstsein für Beschaffungstrends, Nachhaltigkeitserwägungen und den historischen Kontext der Automobiltechnologie voraussetzt, die allesamt entscheidend für fundierte Kaufentscheidungen in der B2B-Landschaft sind.

Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Austausch einer Lichtmaschine

-

Wie kann ich die Kosten für den Austausch einer Lichtmaschine in meinem Fahrzeug ermitteln?

Um die Kosten für den Austausch einer Lichtmaschine zu ermitteln, müssen Sie Faktoren wie die Arbeitskosten, den Preis der Lichtmaschine selbst und alle zusätzlichen Teile berücksichtigen, die möglicherweise ersetzt werden müssen (z. B. den Keilriemen). Die Arbeitskosten liegen in der Regel zwischen $120 und $200, während die Kosten für die Lichtmaschine je nach Fahrzeugmarke und -modell zwischen $100 und $350 liegen können. Insgesamt müssen Sie mit Kosten zwischen $350 und $900 rechnen. Es ist ratsam, Angebote von mehreren Lieferanten und Dienstleistern einzuholen, um wettbewerbsfähige Preise zu erhalten. -

Was sind die Anzeichen dafür, dass eine Lichtmaschine ausgetauscht werden muss?

Zu den wichtigsten Anzeichen für eine defekte Lichtmaschine gehören abgedunkelte Scheinwerfer, ungewöhnliche Motorgeräusche, Schwierigkeiten beim Starten des Fahrzeugs und aufleuchtende Warnleuchten am Armaturenbrett. Wenn diese Symptome auftreten, ist es wichtig, die Lichtmaschine sofort überprüfen zu lassen, um weitere Schäden am Fahrzeug zu vermeiden. Für B2B-Käufer kann das Wissen um diese Anzeichen bei den Verhandlungen über Reparaturen oder Austausch helfen und sicherstellen, dass die Fahrzeuge betriebsbereit bleiben. -

Welche Faktoren beeinflussen die Lebensdauer eines Generators?

Die Lebensdauer einer Lichtmaschine kann sehr unterschiedlich sein und liegt normalerweise zwischen 40.000 und 100.000 Meilen. Zu den Faktoren, die dies beeinflussen, gehören Fahrgewohnheiten, Klimabedingungen und die elektrische Belastung der Lichtmaschine. Für Unternehmen, die einen Fuhrpark betreiben, kann die regelmäßige Überwachung dieser Bedingungen dazu beitragen, den Austausch vorwegzunehmen und so eine bessere Budgetierung und Wartungsplanung zu ermöglichen. -

Wie kann ich die Lieferanten von Lichtmaschinen überprüfen, um die Qualität sicherzustellen?

Überprüfen Sie die Zertifizierungen, Kundenrezensionen und Garantieangebote der Anbieter. Bitten Sie um Muster oder Referenzen von früheren Kunden, um die Produktqualität zu beurteilen. Vergewissern Sie sich, dass es sich um Erstausrüster- oder hochwertige Aftermarket-Teile handelt und dass sie über transparente Rückgabebedingungen verfügen. Auch die Zusammenarbeit mit lokalen Handelsverbänden oder Branchennetzwerken kann Aufschluss über zuverlässige Lieferanten geben. -

Wie hoch sind die Mindestbestellmengen (MOQs) für Generatoren?

Die Mindestbestellmengen für Lichtmaschinen können je nach Lieferant und Region variieren und liegen oft zwischen 5 und 50 Stück. Klären Sie bei der Beschaffung von Generatoren die Mindestbestellmengen mit potenziellen Lieferanten ab, um sicherzustellen, dass sie mit Ihren Einkaufsanforderungen übereinstimmen. Einige Lieferanten bieten möglicherweise Flexibilität auf der Grundlage Ihrer Geschäftsbeziehung oder langfristiger Verpflichtungen, weshalb es wichtig ist, Ihre Anforderungen offen zu besprechen. -

Mit welchen Zahlungsbedingungen muss ich beim Kauf von Lichtmaschinen rechnen?

Die Zahlungsbedingungen können von Lieferant zu Lieferant sehr unterschiedlich sein. Üblich sind jedoch Vorauszahlungen, Teilzahlungen bei Auftragsbestätigung oder 30/60 Tage netto nach Lieferung. Verhandeln Sie immer Zahlungsbedingungen, die Ihrem Cashflow entsprechen und gleichzeitig sicherstellen, dass sich der Lieferant bei der Transaktion sicher fühlt. Ziehen Sie bei internationalen Einkäufen die Verwendung von Akkreditiven in Betracht, um das Risiko zu mindern. -

Wie wirken sich Logistik und Versand auf die Kosten von Lichtmaschinen aus?

Logistik und Versand können die Gesamtkosten von Lichtmaschinen erheblich beeinflussen, insbesondere bei internationalen Käufen. Faktoren wie Versandart, Entfernung und Zollgebühren sollten in Ihrem Budget berücksichtigt werden. Wenn Sie sich für einen Sammelladungsverkehr oder lokale Lieferanten entscheiden, können Sie die Kosten senken. Überprüfen Sie stets die Lieferfristen, um Verzögerungen in Ihrer Lieferkette zu vermeiden. -

Auf welche Qualitätssicherungsmaßnahmen sollte ich bei Lichtmaschinen achten?

Erkundigen Sie sich bei der Beschaffung von Generatoren nach den Qualitätssicherungsprozessen des Lieferanten. Achten Sie auf Zertifizierungen, die auf die Einhaltung internationaler Normen wie ISO 9001 hinweisen. Fragen Sie außerdem, ob die Generatoren strengen Tests auf Leistung und Zuverlässigkeit unterzogen werden. Die Einführung eines Qualitätssicherungsprotokolls in Ihrem Beschaffungsprozess kann dazu beitragen, kostspielige Ausfälle zu vermeiden und Ihre betriebliche Effizienz zu steigern.

Top 3 Liste der Hersteller & Lieferanten für den Austausch einer Lichtmaschine

1. Toyota RAV4 - Kosten für den Austausch der Lichtmaschine

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: 2006 Toyota RAV4 Lichtmaschine Ersatz; Kosten: $450 (einschließlich Arbeit); Benutzer unsicher, ob Preis angemessen ist.

2. JD Power - Kosten für den Austausch der Lichtmaschine

Domäne: jdpower.com

Registriert: 1995 (30 Jahre)

Einleitung: Die Kosten für den Austausch einer Lichtmaschine liegen zwischen $350 und $900, je nach Fahrzeugmodell und je nachdem, ob weitere Teile ersetzt werden müssen. Die Kosten für die Lichtmaschine allein liegen in der Regel zwischen $100 und $350, wobei Luxusmodelle $500 bis $700 kosten. Die Arbeitskosten können sich auf weitere $350 bis $500 belaufen, wenn der Austausch in einem Autohaus erfolgt. Überholte Lichtmaschinen sind erhältlich und sollten die Amperezahl des Originals erreichen oder übertreffen...

3. CarTalk - Kosten für den Austausch der Lichtmaschine

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: Die Kosten für den Austausch einer Lichtmaschine liegen zwischen $600 und $1.500. Eine Lichtmaschine ist ein wichtiges Bauteil, das mechanische Kraft in elektrische Energie umwandelt, den Motor und die Beleuchtung antreibt und die Batterie lädt. Zu den Symptomen einer defekten Lichtmaschine gehören eine Motorprüfleuchte, abgedunkelte Scheinwerfer und die Notwendigkeit einer Starthilfe. Lichtmaschinen können aufgrund von mechanischem Verschleiß oder dem Ausfall elektrischer Komponenten ausfallen. ...

Strategische Beschaffung Schlussfolgerung und Ausblick für die Kosten für den Austausch einer Lichtmaschine

Zusammenfassend lässt sich sagen, dass es für internationale B2B-Einkäufer von entscheidender Bedeutung ist, die mit dem Austausch von Lichtmaschinen verbundenen Kosten zu verstehen, insbesondere wenn sie in verschiedenen Märkten wie Afrika, Südamerika, dem Nahen Osten und Europa tätig sind. Die Gesamtkosten können aufgrund von Faktoren wie Fahrzeugmarke und -modell, Arbeitskosten und der Wahl zwischen OEM- und Aftermarket-Teilen erheblich variieren. Die strategische Beschaffung von hochwertigen Generatoren kann nicht nur die Kosten senken, sondern auch die Zuverlässigkeit gewährleisten, die für die Aufrechterhaltung der betrieblichen Effizienz unerlässlich ist.

Die Investition in Qualitätskomponenten, wie z. B. wiederaufbereitete Lichtmaschinen, kann zu erheblichen Einsparungen führen und gleichzeitig die mit minderwertigen Teilen verbundenen Risiken mindern. Darüber hinaus kann das Erkennen der Anzeichen einer defekten Lichtmaschine den Käufern helfen, fundierte Entscheidungen zu treffen und so möglicherweise kostspielige Notreparaturen zu vermeiden.

Mit Blick auf die Zukunft sollten sich internationale Einkäufer darauf konzentrieren, starke Beziehungen zu seriösen Lieferanten aufzubauen, um ihre Beschaffungsstrategien zu verbessern. Indem sie bei ihren Beschaffungsprozessen Qualität und Zuverlässigkeit in den Vordergrund stellen, können Unternehmen ihre Abläufe rationalisieren und ihr Endergebnis verbessern. Bleiben Sie bei Ihren Beschaffungsbemühungen proaktiv und nutzen Sie Marktkenntnisse, um fundierte Kaufentscheidungen zu treffen, die Ihr Unternehmen voranbringen.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.