Einleitung: Navigieren auf dem globalen Markt für Kosten für den Austausch des Anlassers

In der sich ständig weiterentwickelnden Landschaft der globalen Automobilinstandhaltung ist das Verständnis der Kosten für den Austausch eines Anlassers ist entscheidend für B2B-Einkäufer, die sich auf unterschiedlichen Märkten bewegen. Die Beschaffung zuverlässiger Anlasser zu wettbewerbsfähigen Preisen ist eine Herausforderung, insbesondere für Unternehmen, die in Afrika, Südamerika, dem Nahen Osten und Europa tätig sind. Dieser Leitfaden dient als unverzichtbare Ressource und bietet Einblicke in die verschiedenen Typen von Anlassern, ihre Anwendungen und die Faktoren, die die Ersatzkosten beeinflussen.

Bei der Lektüre dieses umfassenden Leitfadens werden Sie die wichtigsten Überlegungen für die Prüfung von Lieferanten entdecken, einschließlich der Qualitätssicherungspraktiken und der logistischen Herausforderungen, die in verschiedenen Regionen auftreten. Da die Kostenschätzungen je nach Fahrzeugtyp, Marktbedingungen und Lohnkosten sehr unterschiedlich ausfallen können, hilft dieser Leitfaden den Entscheidungsträgern, fundierte Kaufentscheidungen zu treffen. Indem wir Sie mit dem notwendigen Wissen ausstatten, wollen wir Ihren Beschaffungsprozess rationalisieren und letztlich die betriebliche Effizienz und Rentabilität steigern.

Ganz gleich, ob Sie einen Fuhrpark leiten oder eine Reparaturwerkstatt beaufsichtigen, dieser Leitfaden hilft Ihnen, sich in der Komplexität der Beschaffung von Anlassern zurechtzufinden, damit Sie den Anforderungen Ihrer Kunden gerecht werden und einen Wettbewerbsvorteil auf Ihrem Markt behalten können.

Inhaltsverzeichnis

- Top 7 Kosten für den Austausch des Anlassers Hersteller & Lieferanten Liste

- Einleitung: Navigieren auf dem globalen Markt für Kosten für den Austausch des Anlassers

- Kosten für den Austausch des Anlassers - Typen und Variationen

- Wichtigste industrielle Anwendungen der Kosten für den Austausch des Anlassers

- 3 häufige Schmerzpunkte für ‘Kosten für den Austausch des Anlassers’ und ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für die Kosten zum Austausch des Anlassers

- Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Kosten für den Austausch des Anlassers

- Praktische Anleitung zur Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘Kosten für den Austausch des Anlassers’.’

- Umfassende Kosten- und Preisanalyse für die Kosten für den Austausch des Anlassers Sourcing

- Analyse der Alternativen: Vergleich der Kosten für den Austausch des Anlassers mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für die Kosten für den Austausch des Anlassers

- Navigation der Marktdynamik und der Beschaffungstrends im Bereich der Kosten für den Austausch von Anlassern

- Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Austausch des Anlassers

- Strategische Beschaffung Schlussfolgerung und Ausblick für Kosten für den Austausch des Anlassers

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Kosten für den Austausch des Anlassers - Typen und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| OEM-Ersatzstarter | Hergestellt vom Erstausrüster (OEM). | Autowerkstätten, Fuhrparks | Vorteile: Garantierte Passform und Zuverlässigkeit. Nachteile: Höhere Kosten im Vergleich zu Aftermarket-Optionen. |

| Nachrüstbarer Anlasser | Von Drittfirmen hergestellt, oft mit unterschiedlichen Spezifikationen. | Freie Werkstätten, Teilehändler | Vorteile: Kostengünstig, vielfältige Möglichkeiten. Nachteile: Die Qualität kann sehr unterschiedlich sein. |

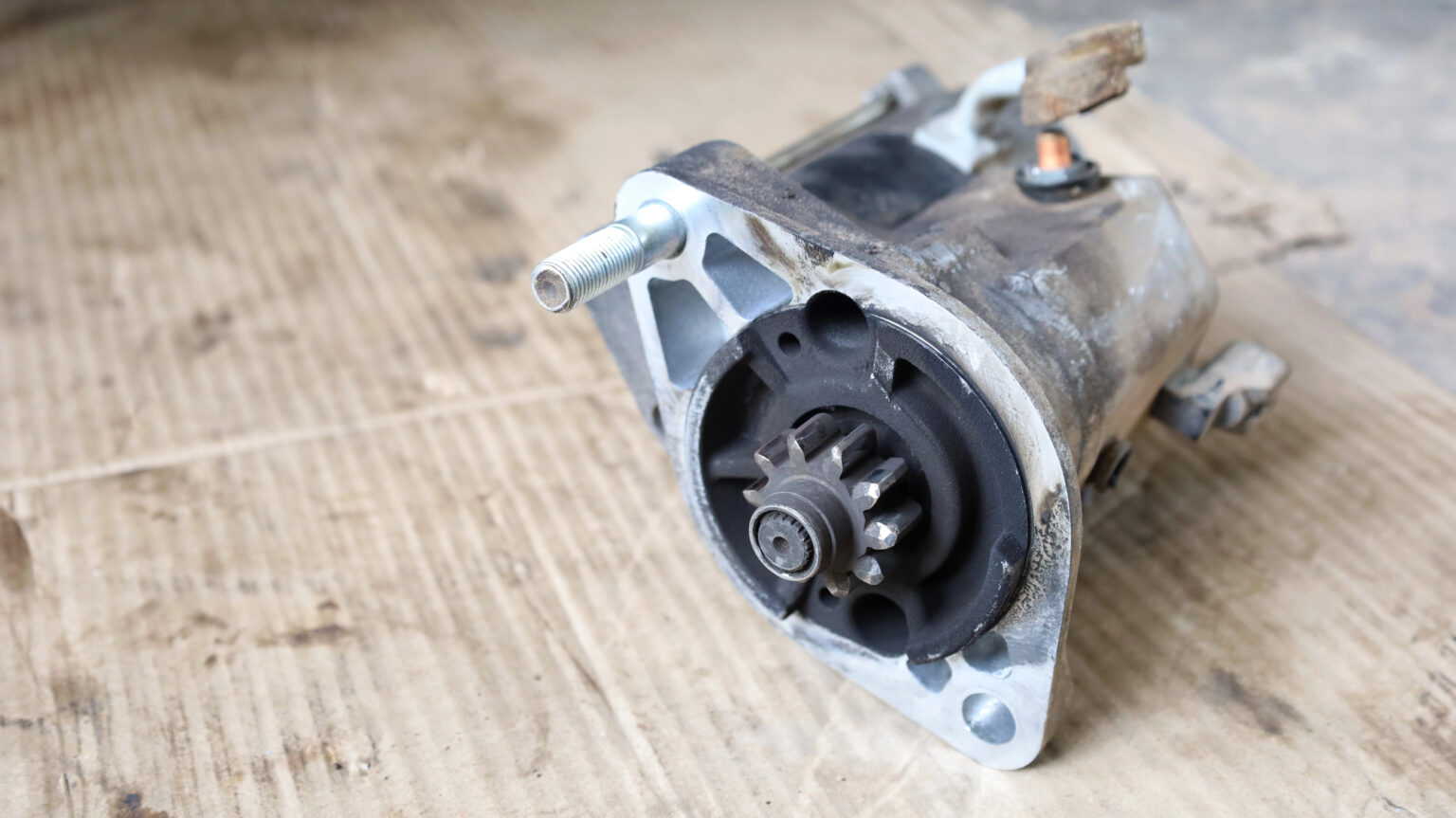

| Überholter Anlasser | Aus gebrauchten Startern umgebaut, auf Funktionalität geprüft. | Budgetbewusste Werkstätten | Vorteile: Geringere Kosten als bei neuen Anläufen. Nachteile: Möglicherweise kürzere Lebensdauer als bei Neuteilen. |

| Hochleistungsstarter | Entwickelt für mehr Leistung und Haltbarkeit, oft für den Rennsport. | Leistungsstarke Automobilsektoren | Vorteile: Erhöhte Zuverlässigkeit unter extremen Bedingungen. Nachteile: Höherer Preis, kann Änderungen erfordern. |

| Starter-Kits | Einschließlich Anlasser und notwendiger Installationskomponenten. | Instandhaltung des Fuhrparks, Heimwerker | Vorteile: Die All-in-One-Lösung vereinfacht den Einkauf. Nachteile: Kann für manche Käufer unnötige Teile enthalten. |

Was sind die Merkmale von OEM-Ersatzstartern?

OEM-Ersatzstarter werden von den Erstausrüstern hergestellt, um die Kompatibilität mit bestimmten Fahrzeugmodellen zu gewährleisten. Diese Anlasser werden nach den genauen Spezifikationen der Originalteile hergestellt und bieten eine zuverlässige Lösung für Unternehmen, die Wert auf Qualität und Zuverlässigkeit legen. B2B-Einkäufer, insbesondere Kfz-Werkstätten und Fuhrparkbetreiber, bevorzugen häufig OEM-Anlasser, weil sie garantiert passen und funktionieren. Allerdings können die höheren Kosten für budgetbewusste Betriebe ein Problem darstellen.

Wie unterscheiden sich Aftermarket-Starter von OEM-Optionen?

Aftermarket-Anlasser werden von Drittherstellern produziert und sind in einer breiten Palette von Spezifikationen und Preisklassen erhältlich. Diese Produkte können günstiger sein als die OEM-Optionen, was sie für unabhängige Werkstätten und Teilehändler attraktiv macht. Die Qualität von Aftermarket-Startern kann jedoch erheblich schwanken, so dass Käufer gründliche Nachforschungen anstellen und sich möglicherweise auf Rezensionen und Bewertungen verlassen müssen. Diese Schwankungen können sich auf die Gesamtzuverlässigkeit von Reparaturen auswirken, weshalb es für B2B-Käufer entscheidend ist, den Ruf der Hersteller vor dem Kauf zu beurteilen.

Welche Vorteile hat die Entscheidung für einen wiederaufbereiteten Anlasser?

Wiederaufgearbeitete Anlasser sind eine kostengünstige Alternative zu Neuteilen, da sie aus gebrauchten Anlassern neu aufgebaut und auf ihre Funktionalität geprüft werden. Diese Option ist für budgetbewusste Werkstätten interessant, die die Kosten im Griff haben müssen, ohne Abstriche bei der Qualität zu machen. Während wiederaufbereitete Anlasser erhebliche Einsparungen bieten können, sollten sich Käufer bewusst sein, dass sie im Vergleich zu fabrikneuen Anlassern eine kürzere Lebensdauer haben können. Für B2B-Käufer ist es wichtig, Garantieoptionen und Rückgaberegelungen zu prüfen, wenn sie wiederaufbereitete Teile in Betracht ziehen.

Was macht Hochleistungsstarter zu einer besonderen Wahl?

Hochleistungsanlasser sind speziell auf erhöhte Leistung und Haltbarkeit ausgelegt und werden häufig im Rennsport oder bei hochbelasteten Fahrzeuganwendungen eingesetzt. Diese Anlasser können extremen Bedingungen standhalten und sind daher ideal für leistungsstarke Fahrzeugbereiche, die Zuverlässigkeit unter Druck erfordern. Der höhere Preis kann jedoch einige Käufer abschrecken, und für den ordnungsgemäßen Einbau sind möglicherweise Änderungen am Fahrzeug erforderlich. Unternehmen, die in dieser Nische tätig sind, müssen die Vorteile der höheren Leistung gegen die damit verbundenen Kosten abwägen.

Warum sollten Sie Starterkits für die Flottenwartung in Betracht ziehen?

Starterkits, die den Starter zusammen mit den erforderlichen Installationskomponenten enthalten, bieten eine praktische Komplettlösung für die Flottenwartung und Heimwerker. Diese Kits rationalisieren den Kaufprozess und stellen sicher, dass alle erforderlichen Teile verfügbar sind, wodurch die Wahrscheinlichkeit von Verzögerungen bei der Installation verringert wird. Auch wenn diese Option die Beschaffung vereinfacht, sollten Käufer darauf achten, ob das Kit Komponenten enthält, die sie möglicherweise nicht benötigen, was zu unnötigen Ausgaben führen könnte.

Wichtigste industrielle Anwendungen der Kosten für den Austausch des Anlassers

| Branche/Sektor | Spezifische Anwendung der Kosten für den Austausch des Anlassers | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Kfz-Reparatur | Austausch von Anlassern in Personenkraftwagen und Nutzfahrzeugen | Reduziert Ausfallzeiten und verbessert die Kundenzufriedenheit | Qualität der Teile, Garantie, Verfügbarkeit lokaler Lieferanten |

| Baumaschinen | Wartung von schweren Maschinen wie Baggern und Bulldozern | Sorgt für betriebliche Effizienz und reduziert Reparaturkosten | Kompatibilität mit bestimmten Maschinenmodellen, Zuverlässigkeit der Lieferanten |

| Transport & Logistik | Flottenmanagement und Wartung von Nutzfahrzeugen | Verbessert die Zuverlässigkeit des Fuhrparks und minimiert Betriebsunterbrechungen | Rabatte bei Großeinkäufen, Standardisierung von Teilen, Lieferzeiten |

| Landwirtschaft | Austausch von Anlassern in Landmaschinen wie Traktoren | Maximiert die Produktivität während kritischer Anbausaisonen | Zugang zu OEM-Teilen, lokale Serviceunterstützung, Kosteneffizienz |

| Bergbau | Austausch von Startern in schweren Bergbaumaschinen | Verhindert kostspielige Verzögerungen und gewährleistet einen kontinuierlichen Betrieb | Langlebigkeit der Teile, Serviceverträge, lokale Beschaffungsmöglichkeiten |

Wie werden die ‘Kosten für den Austausch des Anlassers’ in der Kfz-Reparaturbranche angewendet?

In der Kfz-Reparaturbranche sind die Kosten für den Austausch von Anlassern von entscheidender Bedeutung, um die Funktionsfähigkeit von Fahrzeugen, sowohl von Personen- als auch von Nutzfahrzeugen, zu gewährleisten. Ein defekter Anlasser kann zu erheblichen Ausfallzeiten führen, die sich auf die Kundenzufriedenheit und den Umsatz auswirken können. B2B-Einkäufer in dieser Branche müssen die Qualität von Ersatzteilen, Garantieangebote und die Zuverlässigkeit lokaler Lieferanten berücksichtigen, um sicherzustellen, dass diese eine rechtzeitige Reparatur durchführen können. Darüber hinaus ist es für eine genaue Kostenabschätzung und Beschaffung unerlässlich, die spezifischen Anforderungen an Anlasser für verschiedene Fahrzeugmarken und -modelle zu kennen.

Welche Rolle spielt der Austausch des Anlassers bei der Wartung von Baumaschinen?

In der Bauindustrie sind schwere Maschinen wie Bagger und Planierraupen für eine optimale Leistung in hohem Maße auf funktionierende Anlasser angewiesen. Die Kosten für den Austausch dieser Komponenten wirken sich direkt auf die Betriebseffizienz und die Reparaturbudgets aus. Einkäufer müssen auf die Kompatibilität von Anlassern mit bestimmten Maschinenmodellen und die Zuverlässigkeit der Lieferanten achten, da Verzögerungen bei Reparaturen zu Projektüberschreitungen führen können. Darüber hinaus ist die Beschaffung langlebiger Teile, die rauen Arbeitsbedingungen standhalten, entscheidend für die Minimierung von Ausfallzeiten und die Aufrechterhaltung der Produktivität.

Wie wirken sich die Kosten für den Austausch von Anlassern auf den Transport- und Logistikbetrieb aus?

Im Transport- und Logistikwesen hängt die Wartung von Nutzfahrzeugen von der Zuverlässigkeit der Anlasser ab. Die Kosten für den Austausch dieser Motoren können die Strategien des Flottenmanagements erheblich beeinflussen, da eine höhere Zuverlässigkeit zu weniger Betriebsunterbrechungen führt. B2B-Einkäufer sollten Rabatte beim Großeinkauf und die Standardisierung von Teilen in ihrer Flotte in Betracht ziehen, um die Wartungsprozesse zu rationalisieren. Darüber hinaus kann die rechtzeitige Lieferung von Ersatzteilen kostspielige Verzögerungen im Betrieb verhindern und so die Gesamteffizienz der Flotte verbessern.

Warum ist der Austausch des Anlassers für Landmaschinen so wichtig?

Für den Landwirtschaftssektor ist der rechtzeitige Austausch von Anlassern in Maschinen wie Traktoren von entscheidender Bedeutung, insbesondere in kritischen landwirtschaftlichen Jahreszeiten. Die Kosten für den Austausch dieser Komponenten können sich auf die Gesamtproduktivität auswirken, weshalb es für die Käufer entscheidend ist, OEM-Teile zu beziehen, die Kompatibilität und Zuverlässigkeit garantieren. Der Kundendienst vor Ort und die Kosteneffizienz sind ebenfalls von entscheidender Bedeutung, da sie Einfluss darauf haben, wie schnell die Landwirte nach einer Panne ihren Betrieb wieder aufnehmen können. Daher ist es für fundierte Kaufentscheidungen entscheidend, die Landmaschinenlandschaft zu verstehen.

Vor welchen Herausforderungen stehen die Bergbaubetriebe beim Austausch von Anlassern?

In der Bergbauindustrie ist die Zuverlässigkeit von Schwerlastmaschinen von größter Bedeutung, und der Ausfall von Anlassern kann zu erheblichen Betriebsunterbrechungen führen. Die Kosten für den Austausch dieser Motoren sind ein entscheidender Faktor für die Aufrechterhaltung eines kontinuierlichen Betriebs und die Minimierung von Ausfallzeiten. B2B-Einkäufer in diesem Sektor müssen der Haltbarkeit der Teile Priorität einräumen und Servicevereinbarungen in Betracht ziehen, die schnelle Reaktionszeiten für Reparaturen ermöglichen. Darüber hinaus können lokale Beschaffungsoptionen von Vorteil sein, um sicherzustellen, dass Ersatzteile schnell verfügbar sind, um Produktionsverzögerungen zu vermeiden.

3 häufige Schmerzpunkte für ‘Kosten für den Austausch des Anlassers’ und ihre Lösungen

Szenario 1: Unvorhersehbare Ersatzbeschaffungskosten für unterschiedliche Fahrzeugflotten

Das Problem: Internationale B2B-Einkäufer, die Fuhrparks verwalten, stehen vor der Herausforderung, dass die Kosten für den Austausch von Anlassern nicht vorhersehbar sind. Angesichts der Vielfalt an Fahrzeugen - von Kleinwagen bis hin zu großen Lastwagen und Luxus-SUVs - mit jeweils unterschiedlichen Anlasserspezifikationen kann die Schätzung der Austauschkosten entmutigend sein. Schwankungen bei den Ersatzteilpreisen, den Arbeitslöhnen und der regionalen Verfügbarkeit von Komponenten können zu erheblichen Diskrepanzen bei der Budgetierung führen und die betriebliche Effizienz und Rentabilität beeinträchtigen. Darüber hinaus können Käufer ohne ein klares Verständnis der gemeinsamen Probleme der verschiedenen Fahrzeugmodelle unbeabsichtigt höhere Kosten verursachen, indem sie Teile kaufen, die für ihre Flotte nicht optimal sind.

Die Lösung: Um diese unvorhersehbaren Kosten zu minimieren, sollten B2B-Einkäufer eine umfassende Beschaffungsstrategie für Ersatzteile entwickeln, die sowohl OEM- (Original Equipment Manufacturer) als auch Aftermarket-Optionen umfasst. Eine gründliche Marktforschung zu Anlassern für jeden Fahrzeugtyp im Fuhrpark hilft dabei, zuverlässige Lieferanten zu finden, die wettbewerbsfähige Preise und günstige Lieferbedingungen bieten. Die Einführung eines standardisierten Verfahrens zur Beurteilung des Zustands und des Ersatzbedarfs von Anlassern kann ebenfalls zu einer genaueren Budgetierung führen. Dazu gehören Routineinspektionen und der Einsatz von Diagnosewerkzeugen zur frühzeitigen Erkennung von Problemen, so dass ein geplanter Austausch anstelle von reaktiven Notreparaturen möglich ist. Ziehen Sie außerdem langfristige Vereinbarungen mit Lieferanten in Betracht, um die Preise zu sichern und eine gleichbleibende Verfügbarkeit der Teile zu gewährleisten.

Szenario 2: Fehldiagnose von Startproblemen, die zu unnötigen Kosten führt

Das Problem: Ein weit verbreitetes Problem für B2B-Käufer ist die Fehldiagnose von Anlasserproblemen, die zu einem unnötigen Austausch des Anlassers führt. Viele Unternehmen ziehen voreilige Schlüsse aus dem Ausfall des Anlassers, ohne das gesamte Anlassersystem gründlich zu prüfen. Dieses Versäumnis kann zu einem kostspieligen Austausch führen, wenn das eigentliche Problem eine schwache Batterie, eine fehlerhafte Verkabelung oder ein defektes Zündschloss sein könnte. Solche Fehltritte treiben nicht nur die Reparaturkosten in die Höhe, sondern tragen auch zu Ausfallzeiten des Fahrzeugs bei, was den gesamten Geschäftsbetrieb beeinträchtigt.

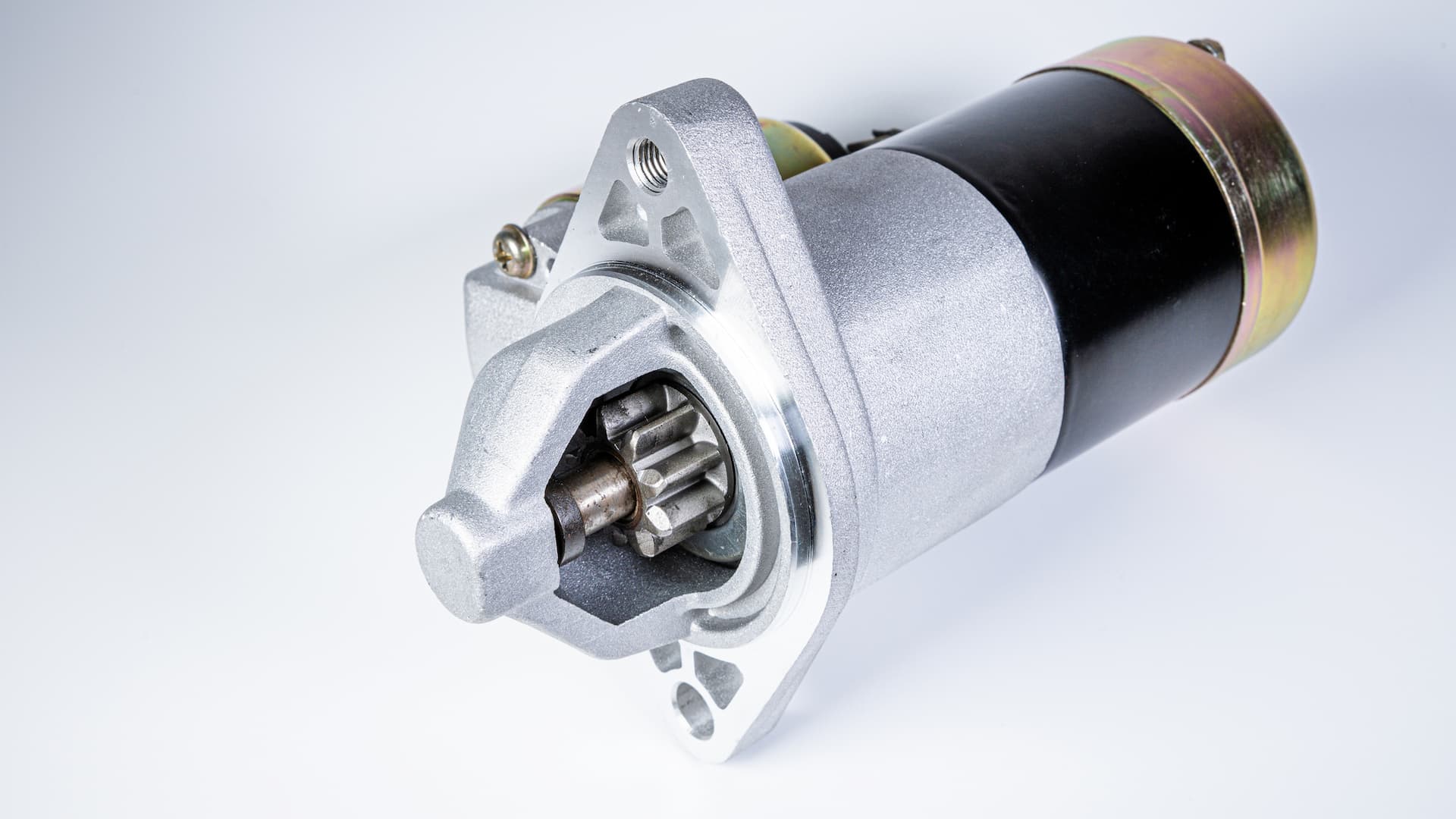

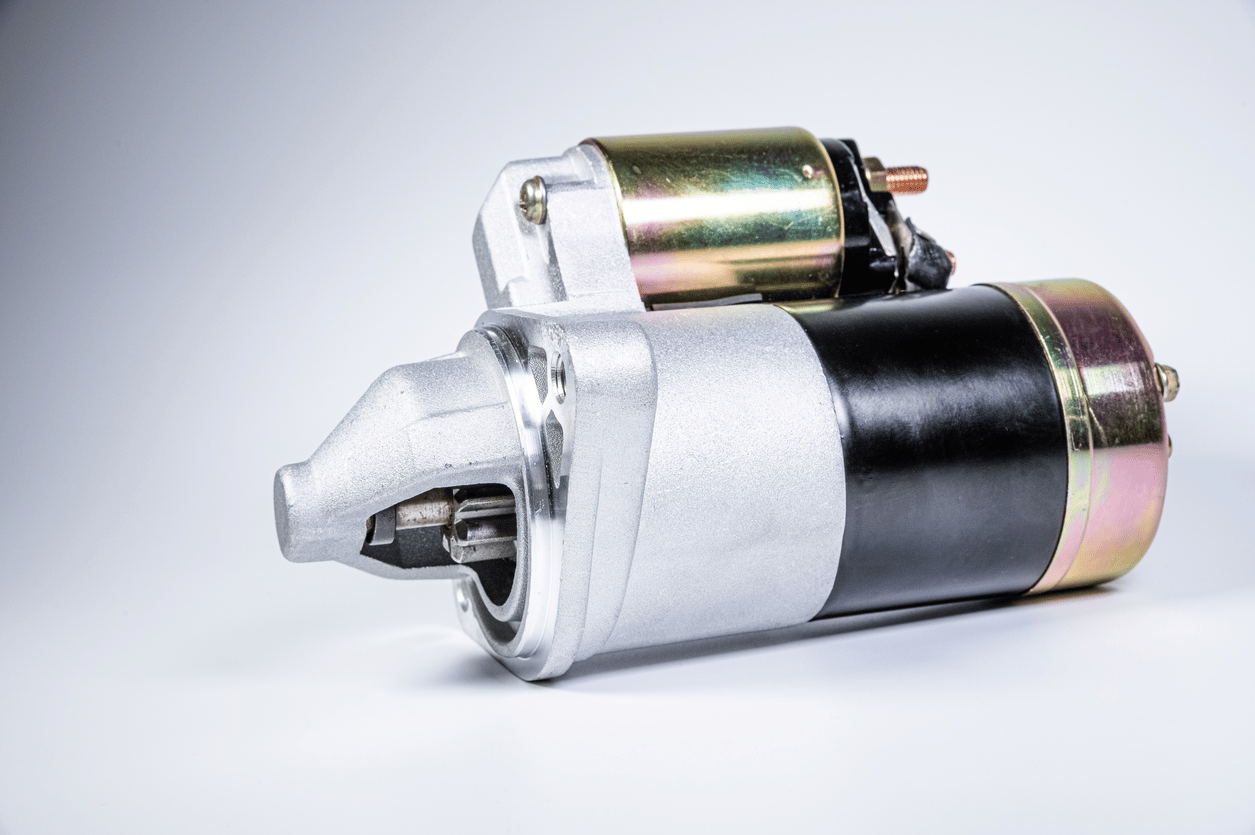

Illustratives Bild zu den Kosten für den Austausch des Anlassers

Die Lösung: Aus diesem Grund sollten B2B-Einkäufer ein systematisches Protokoll zur Fehlersuche einführen, bevor sie mit dem Austausch des Anlassers beginnen. Es ist wichtig, das Wartungspersonal darin zu schulen, die Anzeichen für verschiedene Ausfälle des Anlassersystems zu erkennen. Setzen Sie Diagnosegeräte ein, um die Batteriespannung zu prüfen, nach losen Verbindungen zu suchen und das Anlasserrelais und die Sicherungen zu untersuchen. Die Dokumentation dieser Prüfungen kann dabei helfen, eine Wissensbasis für künftige Referenzen aufzubauen. Die Zusammenarbeit mit erfahrenen Technikern oder Dienstleistern, die eine umfassende Diagnose durchführen können, kann die Genauigkeit ebenfalls verbessern. Durch die Förderung einer Kultur der gründlichen Bewertung und Dokumentation können Unternehmen unnötige Ausgaben reduzieren und ihre allgemeine Wartungseffizienz verbessern.

Szenario 3: Uneinheitliche Qualität von Aftermarket-Anlassern

Das Problem: Wenn B2B-Käufer kostengünstige Aftermarket-Anlasser in Betracht ziehen, stoßen sie häufig auf das Problem der uneinheitlichen Qualität. Diese Komponenten können zwar die Kosten erheblich senken, aber das Risiko, minderwertige Produkte zu kaufen, kann zu häufigen Ausfällen führen, die zusätzliche Arbeitskosten und Ausfallzeiten des Fahrzeugs verursachen. Dieses Dilemma ist besonders akut in Märkten, in denen gefälschte oder minderwertige Teile die Lieferkette überschwemmen, was eine Herausforderung für die Aufrechterhaltung der Betriebszuverlässigkeit und Sicherheit darstellt.

Die Lösung: Um die mit Aftermarket-Teilen verbundenen Risiken zu bekämpfen, müssen B2B-Einkäufer der Qualitätssicherung in ihren Beschaffungsprozessen Priorität einräumen. Gründliche Lieferantenbewertungen und die Beschaffung bei seriösen Herstellern mit nachgewiesener Erfolgsbilanz sind unerlässlich. Durch die Einholung von Zertifizierungen und Qualitätsgarantien kann sichergestellt werden, dass die Teile den Branchenstandards entsprechen. Der Aufbau von Partnerschaften mit Lieferanten, die Garantien oder Gewährleistungen anbieten, kann das Risiko eines vorzeitigen Ausfalls weiter verringern. Darüber hinaus können Informationen über Produktrückrufe und Bewertungen von anderen Unternehmen in ähnlichen Branchen helfen, fundierte Kaufentscheidungen zu treffen. Wenn Unternehmen den Schwerpunkt auf Qualität statt auf bloße Kosteneinsparungen legen, können sie durch höhere Zuverlässigkeit und geringere Austauschhäufigkeit langfristige Einsparungen erzielen.

Strategischer Leitfaden zur Materialauswahl für die Kosten zum Austausch des Anlassers

Wenn es um die Kosten für den Ersatz eines Anlassers geht, kann die Wahl der für die Konstruktion verwendeten Materialien einen erheblichen Einfluss auf Leistung, Haltbarkeit und Gesamtkosten haben. Diese Analyse untersucht vier gängige Materialien, die in Anlassern verwendet werden, und liefert Erkenntnisse, die für internationale B2B-Einkäufer in Afrika, Südamerika, dem Nahen Osten und Europa besonders relevant sind.

Was sind die wichtigsten Eigenschaften von Kupfer in Anlassern?

Kupfer wird aufgrund seiner hervorragenden Leitfähigkeit und seiner thermischen Eigenschaften häufig in elektrischen Anwendungen eingesetzt. In Anlasser-Motoren wird Kupfer vor allem für Wicklungen und Anschlüsse verwendet. Zu den wichtigsten Eigenschaften gehören hohe elektrische Leitfähigkeit, gute Wärmeleitfähigkeit und Korrosionsbeständigkeit.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

Vor- und Nachteile: Zu den Vorteilen von Kupfer gehört seine hervorragende Leitfähigkeit, die den Wirkungsgrad des Anlassers erhöht. Allerdings ist Kupfer im Vergleich zu anderen Materialien relativ teuer, und sein Gewicht kann bei Anwendungen, bei denen eine Gewichtsreduzierung entscheidend ist, ein Nachteil sein. Außerdem macht die Korrosionsanfälligkeit von Kupfer Schutzbeschichtungen erforderlich, was die Herstellung komplizierter machen kann.

Auswirkungen auf die Anwendung: Aufgrund seiner hohen Leitfähigkeit ist Kupfer für Hochleistungsanwendungen geeignet, insbesondere in Umgebungen mit schwankenden Temperaturen. Käufer in Regionen mit hoher Luftfeuchtigkeit oder korrosiven Umgebungen sollten jedoch zusätzliche Schutzmaßnahmen in Betracht ziehen.

Wie schneidet Aluminium als Werkstoff für Anlasser ab?

Aluminium wird aufgrund seines geringen Gewichts und seiner korrosionsbeständigen Eigenschaften zunehmend in Gehäusen und Komponenten von Anlassern eingesetzt. Zu den wichtigsten Eigenschaften von Aluminium gehören eine geringere Dichte als Kupfer, gute Wärmeleitfähigkeit und Oxidationsbeständigkeit.

Vor- und Nachteile: Der Hauptvorteil von Aluminium ist sein geringes Gewicht, das zur Reduzierung des Gesamtgewichts eines Fahrzeugs und damit zur Verbesserung der Kraftstoffeffizienz beitragen kann. Allerdings hat Aluminium eine geringere elektrische Leitfähigkeit als Kupfer, was die Leistung bei hohen Belastungen beeinträchtigen kann. Außerdem ist Aluminium zwar korrosionsbeständig, aber im Vergleich zu anderen Metallen unter hohen Belastungen weniger haltbar.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

Auswirkungen auf die Anwendung: Aluminium eignet sich besonders für Automobilanwendungen, bei denen das Gewicht eine Rolle spielt. Die Käufer sollten darauf achten, dass das verwendete Aluminium bestimmte Normen für Festigkeit und Haltbarkeit erfüllt, insbesondere in Regionen mit unwegsamem Gelände.

Welche Rolle spielt Stahl beim Bau von Anlassern?

Stahl wird aufgrund seiner Festigkeit und Langlebigkeit häufig für Anlasserkomponenten wie Gehäuse und Zahnräder verwendet. Zu den wichtigsten Eigenschaften von Stahl gehören hohe Zugfestigkeit, Verformungsbeständigkeit und gute Verschleißfestigkeit.

Vor- und Nachteile: Der Hauptvorteil von Stahl ist seine Robustheit, da er hohen Belastungen und Stößen standhalten kann, was ihn ideal für schwere Anwendungen macht. Allerdings ist Stahl schwerer als Kupfer und Aluminium, was sich negativ auf das Fahrzeuggewicht auswirken kann. Außerdem ist Stahl anfällig für Rost, wenn er nicht ordnungsgemäß beschichtet oder behandelt wird, was zu erhöhten Wartungskosten führen kann.

Auswirkungen auf die Anwendung: Stahlteile eignen sich für Anlasser in schweren Fahrzeugen oder Maschinen, die in rauen Umgebungen eingesetzt werden. Internationale Käufer sollten die spezifischen Stahlsorten und die erforderlichen Beschichtungen zum Schutz vor Korrosion berücksichtigen, insbesondere in Küstenregionen oder feuchten Gebieten.

Wie passen Kunststoff- oder Verbundwerkstoffe in die Konstruktion von Anlassern?

Kunststoff- oder Verbundwerkstoffe werden in nicht strukturellen Komponenten von Anlassern wie Gehäusen und Isolatoren verwendet. Zu den wichtigsten Eigenschaften gehören geringes Gewicht, Korrosionsbeständigkeit und gute elektrische Isolierung.

Vor- und Nachteile: Zu den Vorteilen der Verwendung von Kunststoffen gehören Gewichtseinsparungen und Korrosionsbeständigkeit, was den Wartungsbedarf verringern kann. Allerdings halten Kunststoffe hohen Temperaturen und mechanischen Belastungen möglicherweise nicht so gut stand wie Metalle, was ihre Anwendung in Hochleistungsanlassern möglicherweise einschränkt.

Auswirkungen auf die Anwendung: Kunststoffkomponenten können bei Anwendungen von Vorteil sein, bei denen Gewichtsreduzierung und Korrosionsbeständigkeit im Vordergrund stehen. Käufer sollten sicherstellen, dass die verwendeten Kunststoffe bestimmte Temperatur- und Belastungswerte erfüllen, insbesondere in Regionen mit extremen Wetterbedingungen.

Übersichtstabelle zur Materialauswahl für Anlasser

| Material | Typischer Anwendungsfall für Kosten für den Austausch des Anlassers | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Wicklungen und Anschlüsse in Anlassermotoren | Hervorragende elektrische Leitfähigkeit | Hohe Kosten und hohes Gewicht | Hoch |

| Aluminium | Gehäuse und Leichtbaukomponenten in Automobilstartern | Leicht und korrosionsbeständig | Geringere elektrische Leitfähigkeit | Mittel |

| Stahl | Strukturelle Komponenten in Hochleistungsstartern | Hohe Festigkeit und Haltbarkeit | Schwerer und anfällig für Rost | Mittel |

| Kunststoff/Komposit | Nichttragende Bauteile wie Gehäuse und Isolatoren | Leicht und korrosionsbeständig | Begrenzte Temperatur- und Belastbarkeit | Niedrig |

Diese Analyse liefert wertvolle Erkenntnisse für internationale B2B-Einkäufer, die eine Materialauswahl für Anlasser in Betracht ziehen. Das Verständnis der Eigenschaften, Vorteile und Grenzen der einzelnen Materialien kann zu fundierten Kaufentscheidungen führen, die auf spezifische Anwendungsanforderungen und regionale Bedingungen zugeschnitten sind.

Eingehender Blick: Herstellungsprozesse und Qualitätssicherung für Kosten für den Austausch des Anlassers

Was sind die wichtigsten Schritte bei der Herstellung eines Anlassers?

Der Herstellungsprozess von Anlassern umfasst mehrere kritische Phasen, die sicherstellen, dass jedes Gerät die Leistungsstandards und Kundenerwartungen erfüllt. Für B2B-Einkäufer, die zuverlässige Anlasser beschaffen wollen, ist es wichtig, diese Phasen zu verstehen.

Materialvorbereitung: Welche Rohstoffe werden verwendet?

Der erste Schritt besteht in der Beschaffung von hochwertigen Rohstoffen. Startermotoren werden in der Regel aus Materialien wie folgenden hergestellt:

- Kupfer: Wird aufgrund seiner hervorragenden Leitfähigkeit für elektrische Wicklungen verwendet.

- Stahl und Aluminium: Aufgrund ihrer Festigkeit und ihres geringen Gewichts werden sie für das Gehäuse und die Komponenten verwendet.

- Plastik: Wird für bestimmte nicht-strukturelle Komponenten verwendet, die isolierend wirken und das Gewicht reduzieren.

Die Materialqualität ist von größter Bedeutung, da minderwertige Materialien zu Ausfällen und erhöhten Garantieansprüchen führen können. Die Zulieferer führen häufig eine Vorabprüfung der Materialien durch, um sicherzustellen, dass sie den vorgegebenen Standards entsprechen.

Wie werden Anlasser geformt und zusammengebaut?

Die Umformungsphase umfasst mehrere Schlüsseltechniken:

- Stanzen und maschinelle Bearbeitung: Stahl- und Aluminiumteile werden gestanzt und nach genauen Maßen bearbeitet, um Passgenauigkeit und Funktionalität zu gewährleisten.

- Wicklung: Um den Anker ist ein Kupferdraht gewickelt, der das für den Betrieb notwendige elektromagnetische Feld erzeugt.

- Gießen und Formen: Einige Bauteile, wie Gehäuse und Endplatten, können gegossen oder geformt werden.

Bei der Montage werden diese Komponenten zusammengefügt, in der Regel in einer sauberen Umgebung, um Verunreinigungen zu vermeiden. Automatisierte Montagelinien sind üblich, erhöhen die Effizienz und verringern menschliche Fehler. Die Komponenten werden in einer systematischen Reihenfolge montiert, und jeder Schritt wird zur Rückverfolgbarkeit dokumentiert.

Welche Veredelungsverfahren werden üblicherweise eingesetzt?

Veredelungsverfahren verbessern Haltbarkeit und Leistung. Zu den gängigen Techniken gehören:

- Oberflächenbehandlung: Die Bauteile werden häufig mit Beschichtungen versehen, um sie vor Korrosion und Verschleiß zu schützen.

- Ausgleichen: Der Anker kann dynamisch ausgewuchtet werden, um Vibrationen während des Betriebs zu reduzieren.

- Inspektion der Endmontage: Bevor der Anlasser verpackt wird, erfolgt eine gründliche Prüfung, um sicherzustellen, dass er alle Spezifikationen erfüllt.

Diese Verfahren stellen sicher, dass der Anlasser effizient arbeitet und eine lange Lebensdauer hat, was für B2B-Käufer, die Wert auf Zuverlässigkeit legen, entscheidend ist.

Auf welche Qualitätskontrollstandards sollten B2B-Einkäufer achten?

Qualitätssicherung ist bei der Herstellung von Anlassern unerlässlich. Die Einhaltung internationaler und branchenspezifischer Normen trägt dazu bei, dass die Produkte zuverlässig und sicher sind.

Welche internationalen Normen sind relevant?

- ISO 9001: Diese Norm legt Kriterien für ein Qualitätsmanagementsystem fest, das auf kontinuierliche Verbesserung und Kundenzufriedenheit ausgerichtet ist.

- CE-Kennzeichnung: Zeigt an, dass die europäischen Sicherheits-, Gesundheits- und Umweltschutznormen eingehalten werden, was für Käufer in Europa entscheidend ist.

- API-Standards: Für Motoren, die in der Öl- und Gasindustrie eingesetzt werden, kann die Einhaltung der Normen des American Petroleum Institute erforderlich sein.

Die Einhaltung dieser Normen ist eine Garantie dafür, dass sich ein Hersteller für Qualität und Zuverlässigkeit einsetzt.

Was sind die wichtigsten Kontrollpunkte für die Qualitätskontrolle?

Die Qualitätskontrolle (QC) ist in den gesamten Herstellungsprozess integriert:

- Eingangsqualitätskontrolle (IQC): Die Rohstoffe werden bei ihrer Ankunft geprüft, um sicherzustellen, dass sie den Spezifikationen entsprechen.

- In-Process-Qualitätskontrolle (IPQC): Während des Herstellungsprozesses werden regelmäßig Kontrollen durchgeführt, um Mängel frühzeitig zu erkennen.

- Endkontrolle (FQC): Die fertigen Anlasser werden strengen Tests und Prüfungen unterzogen, um ihre einwandfreie Funktion sicherzustellen.

Jeder dieser Kontrollpunkte trägt zur Minimierung von Mängeln bei und gewährleistet, dass nur qualitativ hochwertige Produkte auf den Markt kommen.

Wie können B2B-Einkäufer die Qualitätssicherung der Lieferanten überprüfen?

B2B-Einkäufer müssen bei der Überprüfung der Qualitätssicherungsprozesse potenzieller Lieferanten proaktiv vorgehen. Hier sind einige Strategien:

Illustratives Bild zu den Kosten für den Austausch des Anlassers

Was sollte bei Lieferantenaudits berücksichtigt werden?

Die Durchführung von Lieferantenaudits ist unerlässlich. Während eines Audits sollten die Einkäufer Folgendes bewerten:

- Herstellungsverfahren: Überprüfung der Einhaltung der dokumentierten Verfahren und Standards.

- Verfahren zur Qualitätskontrolle: Überprüfen Sie die bestehenden QC-Prozesse, einschließlich der Dokumentation von Inspektionen und Tests.

- Zertifizierungen: Achten Sie auf einschlägige Zertifizierungen wie ISO 9001 oder die CE-Kennzeichnung.

Regelmäßige Audits helfen dabei, potenzielle Probleme zu erkennen und sicherzustellen, dass die Lieferanten hohe Standards einhalten.

Wie können Käufer Inspektionen durch Dritte nutzen?

Die Beauftragung von Inspektionsdiensten durch Dritte kann eine unvoreingenommene Bewertung der Qualitätsprozesse eines Lieferanten liefern. Diese Dienste können durchführen:

- Fabrik-Audits: Bewertung der allgemeinen Fertigungskapazitäten und der Einhaltung von Normen.

- Vorversandkontrollen: Überprüfung der Qualität der Produkte vor dem Versand, um sicherzustellen, dass sie den vereinbarten Spezifikationen entsprechen.

Kontrollen durch Dritte können die Risiken im Zusammenhang mit der Zuverlässigkeit der Lieferanten und der Produktqualität mindern.

Welche gängigen Prüfverfahren werden in der Qualitätssicherung eingesetzt?

Um sicherzustellen, dass die Starter die Leistungs- und Zuverlässigkeitsstandards erfüllen, werden verschiedene Prüfverfahren eingesetzt:

- Elektrische Prüfung: Überprüft die ordnungsgemäße Funktion, einschließlich Spannung und Stromaufnahme.

- Mechanische Prüfung: Bewertet die physische Integrität von Komponenten, einschließlich Drehmoment- und Vibrationstests.

- Haltbarkeitsprüfung: Simuliert reale Bedingungen, um die Leistung des Anlassers im Laufe der Zeit zu bewerten.

Die Anwendung dieser Prüfverfahren trägt dazu bei, dass das Endprodukt den Anforderungen des Endnutzers gerecht wird.

Welche Feinheiten der Qualitätskontrolle sollten internationale Einkäufer beachten?

B2B-Einkäufer, insbesondere aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, sollten sich der besonderen Nuancen bei der Qualitätskontrolle bewusst sein:

- Kulturelle Unterschiede: Das Verständnis der lokalen Fertigungskultur kann sich auf die Qualität auswirken. In einigen Regionen gibt es zum Beispiel unterschiedliche Ansätze für das Qualitätsmanagement.

- Einhaltung gesetzlicher Vorschriften: Jede Region kann eigene gesetzliche Anforderungen haben. Die Einkäufer sollten sicherstellen, dass die Lieferanten die lokalen Gesetze und Normen einhalten.

- Logistische Überlegungen: Versand und Handhabung können die Produktqualität beeinträchtigen. Die Käufer sollten darauf achten, wie die Produkte gelagert und transportiert werden, um Schäden zu minimieren.

Durch die Berücksichtigung dieser Faktoren können internationale Einkäufer bei der Auswahl von Lieferanten für Anlasser fundiertere Entscheidungen treffen.

Zusammenfassend lässt sich sagen, dass ein umfassendes Verständnis der Herstellungsverfahren und Qualitätssicherungspraktiken für Anlasser für B2B-Einkäufer entscheidend ist. Indem sie sich auf die Materialvorbereitung, die Formgebung, die Montage und die Endbearbeitung konzentrieren und die Einhaltung von Qualitätsstandards und effektiven Überprüfungsmethoden sicherstellen, können sich Käufer zuverlässige Produkte sichern, die ihre betrieblichen Anforderungen erfüllen.

Praktische Anleitung zur Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘Kosten für den Austausch des Anlassers’.’

Einführung

Dieser Leitfaden dient als praktische Checkliste für B2B-Einkäufer, die Komponenten beschaffen möchten, die mit den Kosten für den Austausch von Anlassern verbunden sind. Wenn Sie die Feinheiten der Beschaffung dieser Komponenten verstehen, können Sie fundierte Entscheidungen treffen, Ihr Budget optimieren und sicherstellen, dass Sie Qualitätsprodukte erhalten, die auf Ihre spezifischen Anforderungen zugeschnitten sind.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Legen Sie die technischen Anforderungen an die von Ihnen benötigten Anlasser klar dar. Dazu gehören Spezifikationen wie Spannung, Größe und Kompatibilität mit bestimmten Fahrzeugmarken und -modellen. Eine klar definierte Spezifikation hilft den Lieferanten, Ihre genauen Anforderungen zu verstehen, und verringert das Risiko, inkompatible Produkte zu erhalten.

- Berücksichtigen Sie den Fahrzeugtyp: Verschiedene Fahrzeuge können unterschiedliche Anlasserdesigns oder Spezifikationen erfordern.

- Ermitteln Sie den Energiebedarf: Vergewissern Sie sich, dass der Anlasser die erforderlichen Leistungsdaten für eine optimale Leistung aufweist.

Schritt 2: Führen Sie Marktforschung durch

Führen Sie eine gründliche Marktforschung durch, um potenzielle Lieferanten zu ermitteln. Nutzen Sie Branchenberichte, Fachmessen und Online-Plattformen, um Informationen über verschiedene Hersteller und Händler zu sammeln.

- Suchen Sie nach Bewertungen: Prüfen Sie Online-Bewertungen und Erfahrungsberichte, um die Zuverlässigkeit des Anbieters und die Produktqualität zu beurteilen.

- Analysieren Sie Preistrends: Wenn Sie die Marktpreise kennen, können Sie bessere Angebote aushandeln und überhöhte Preise vermeiden.

Schritt 3: Potenzielle Lieferanten bewerten

Bevor Sie sich zu einem Kauf verpflichten, sollten Sie die Anbieter gründlich prüfen. Fordern Sie Unternehmensprofile, Produktkataloge und Referenzen von anderen Unternehmen in Ihrer Branche an.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

- Überprüfen Sie die Zertifizierungen: Vergewissern Sie sich, dass die Lieferanten über die erforderlichen Zertifizierungen für Qualitätsstandards verfügen, insbesondere wenn Sie aus verschiedenen Regionen einkaufen.

- Erkundigen Sie sich nach der Garantiepolitik: Eine verlässliche Garantie ist ein Zeichen für das Vertrauen des Lieferanten in seine Produkte und gibt ihm Sicherheit.

Schritt 4: Verfügbarkeit und Lieferzeiten prüfen

Erkundigen Sie sich nach der Produktverfügbarkeit und den voraussichtlichen Lieferfristen. Das Wissen um diese Faktoren ist entscheidend für die Planung Ihres Betriebs und die Minimierung von Ausfallzeiten.

- Überprüfen Sie die Lagerbestände: Vergewissern Sie sich, dass der Lieferant über den erforderlichen Bestand verfügt, um Ihren Bedarf zu decken.

- Prüfen Sie die Versandoptionen: Beurteilen Sie die mit dem Versand verbundene Logistik, insbesondere bei internationaler Beschaffung, um unerwartete Verzögerungen zu vermeiden.

Schritt 5: Muster anfordern und Qualitätskontrollen durchführen

Bevor Sie Ihre Bestellung abschließen, sollten Sie Muster der Anlasser anfordern, um deren Qualität aus erster Hand zu beurteilen. Die Durchführung von Qualitätsprüfungen kann dazu beitragen, etwaige Unstimmigkeiten vor dem Großeinkauf festzustellen.

- Prüfen Sie die physischen Eigenschaften: Achten Sie auf Qualitätsmerkmale wie Verarbeitung, Gewicht und verwendete Materialien.

- Kompatibilität testen: Wenn möglich, testen Sie die Probe in einem entsprechenden Fahrzeug, um die ordnungsgemäße Funktion sicherzustellen.

Schritt 6: Verhandeln Sie die Allgemeinen Geschäftsbedingungen

Sobald Sie einen Lieferanten ausgewählt haben, verhandeln Sie die Vertragsbedingungen. Dazu gehören die Preisgestaltung, die Zahlungsbedingungen und die Liefertermine.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

- Klären Sie die Zahlungsmöglichkeiten: Besprechen Sie Zahlungsbedingungen, die für beide Seiten geeignet sind, und berücksichtigen Sie dabei Faktoren wie Anzahlungen und Zahlungsmodalitäten.

- Legen Sie Rückgaberichtlinien fest: Stellen Sie sicher, dass es klare Richtlinien für die Rückgabe oder den Umtausch im Falle von Mängeln oder Problemen gibt.

Schritt 7: Abschluss des Einkaufs und Pflege der Lieferantenbeziehungen

Nachdem Sie eine Einigung erzielt haben, schließen Sie Ihren Einkauf ab und bauen einen Kommunikationskanal mit Ihrem Lieferanten auf. Die Aufrechterhaltung einer guten Beziehung kann zu besseren Bedingungen bei zukünftigen Transaktionen führen.

- Geben Sie Feedback: Teilen Sie Ihre Erfahrungen mit dem Lieferanten, um eine Zusammenarbeit zu fördern.

- Behalten Sie die Markttrends im Auge: Wenn Sie über Veränderungen in der Branche informiert sind, können Sie Ihre Beschaffungsstrategie entsprechend anpassen.

Umfassende Kosten- und Preisanalyse für die Kosten für den Austausch des Anlassers Sourcing

Was sind die wichtigsten Kostenkomponenten beim Austausch eines Anlassers?

Bei der Bewertung der Kosten für den Austausch eines Anlassers spielen mehrere Komponenten eine wichtige Rolle für die Preisstruktur.

-

Materialien: Die Kosten für den Anlasser selbst variieren stark, je nachdem, ob es sich um ein neues, überholtes oder ein Nachrüstteil handelt. Die Preise können von $50 bis über $350 reichen und hängen von der Marke und dem Modell des Fahrzeugs ab. Außerdem können Zusatzteile wie Kabel oder Stecker die Materialkosten erhöhen.

-

Arbeit: Die Arbeitskosten können den Gesamtpreis erheblich beeinflussen und je nach Komplexität des Austauschs zwischen $150 und $1.100 liegen. Die für den Einbau benötigte Zeit variiert je nach Fahrzeugtyp; einige Anlasser sind leicht zugänglich, während andere unter anderen Motorkomponenten verborgen sein können.

-

Fertigungsgemeinkosten: Hierunter fallen die Kosten für die Produktionsanlagen, die Wartung der Anlagen und die Verwaltungskosten, die den Herstellern bei der Produktion von Anlassern entstehen. Diese Kosten können je nach Produktionsumfang und Effizienz des Herstellers variieren.

-

Werkzeuge: Für bestimmte Modelle sind möglicherweise Spezialwerkzeuge erforderlich, was die Anfangsinvestitionen der Hersteller erhöht und sich möglicherweise auf die Endkosten der Käufer auswirkt.

-

Qualitätskontrolle (QC): Die Gewährleistung der Zuverlässigkeit von Anlassern durch strenge Tests erhöht die Herstellungskosten. Produkte, die höhere Qualitätsstandards erfüllen, sind oft mit einem höheren Preis verbunden.

-

Logistik: Die Versandkosten können je nach Entfernung, Art des Transports und spezifischen Lieferanforderungen erheblich variieren. Internationale Käufer sollten mögliche Zölle und Abgaben berücksichtigen, die anfallen können.

-

Marge: Die Lieferanten kalkulieren in der Regel eine Marge ein, die ihre Betriebskosten und den gewünschten Gewinn widerspiegelt. Diese Marge kann je nach Marktbedingungen, Wettbewerb und der Positionierungsstrategie des Lieferanten variieren.

Was beeinflusst den Preis von Anlassern auf den internationalen Märkten?

Mehrere Faktoren können die Preisgestaltung von Anlassern beeinflussen, insbesondere für internationale B2B-Käufer:

-

Volumen und Mindestbestellmenge (MOQ): Der Einkauf in großen Mengen kann zu erheblichen Rabatten führen. Die Kenntnis der von den Lieferanten festgelegten Mindestmengen kann den Käufern helfen, bessere Bedingungen und Preise auszuhandeln.

-

Spezifikationen und Anpassung: Kundenspezifische Anlasser, die spezifischen Anforderungen entsprechen, können höhere Kosten verursachen. Die Käufer sollten ihre Spezifikationen klar mitteilen, um unerwartete Preiserhöhungen zu vermeiden.

-

Materialqualität und Zertifizierungen: Hochwertige Materialien und die Einhaltung von Industriezertifizierungen können die Kosten erhöhen, bieten aber eine höhere Zuverlässigkeit und Langlebigkeit. Käufer sollten die Vorteile einer Investition in zertifizierte Teile gegen das Potenzial für minderwertige Alternativen abwägen.

-

Lieferantenfaktoren: Der Ruf, die Zuverlässigkeit und der Standort des Lieferanten können sich auf die Preisgestaltung auswirken. Etablierte Lieferanten mit einer nachgewiesenen Erfolgsbilanz verlangen möglicherweise mehr, bieten aber auch einen besseren Service und eine höhere Produktzuverlässigkeit.

-

Incoterms: Die Kenntnis der internationalen Handelsbedingungen (Incoterms) ist von entscheidender Bedeutung. Diese Bedingungen legen die Verantwortlichkeiten von Käufern und Verkäufern in Bezug auf Versand, Versicherung und Zölle fest, was sich auf die Gesamtkosten auswirken kann.

Was sind einige effektive Einkaufstipps für die Beschaffung von Anlassern?

B2B-Einkäufer, die ihren Beschaffungsprozess für Anlasser optimieren wollen, sollten die folgenden Strategien in Betracht ziehen:

-

Verhandlung: Führen Sie mit den Lieferanten Gespräche über die Preisgestaltung, insbesondere bei Großaufträgen. Nutzen Sie konkurrenzfähige Angebote von mehreren Lieferanten, um bei den Verhandlungen einen Vorteil zu erzielen.

-

Kosteneffizienz: Bewerten Sie die Gesamtbetriebskosten (TCO) und nicht nur den Anschaffungspreis. Berücksichtigen Sie Faktoren wie Garantie, erwartete Lebensdauer und das Potenzial für geringere Wartungskosten.

-

Preisgestaltung für internationale Käufer: Achten Sie auf Währungsschwankungen, Lieferzeiten und zusätzliche Gebühren, die bei der Beschaffung aus anderen Regionen anfallen können. Der Aufbau von Beziehungen zu lokalen Lieferanten kann helfen, einige dieser Herausforderungen zu bewältigen.

-

Untersuchung der lokalen Marktbedingungen: Die Kenntnis des lokalen Kfz-Teilemarktes in Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa kann Aufschluss über Preistrends und Verfügbarkeit geben.

-

Seien Sie vorsichtig mit Richtpreisen: Da die Preise je nach Marktlage schwanken können, sollten Sie die angegebenen Preise nicht als Festpreise, sondern als Richtwerte betrachten. Bestätigen Sie immer die endgültigen Kosten, bevor Sie einen Auftrag erteilen.

Durch ein gründliches Verständnis der Kostenstruktur und der preisbeeinflussenden Faktoren auf dem Anlassermarkt können B2B-Einkäufer fundierte Kaufentscheidungen treffen, die auf ihre betrieblichen Anforderungen und Budgetvorgaben abgestimmt sind.

Analyse der Alternativen: Vergleich der Kosten für den Austausch des Anlassers mit anderen Lösungen

Untersuchung von Alternativen zum Austausch eines Anlassers

In der Automobilbranche können die Kosten für den Austausch eines Anlassers beträchtlich sein, was die Käufer dazu veranlasst, alternative Lösungen in Betracht zu ziehen. Diese Alternativen können unterschiedliche Leistungsniveaus, Kosteneffizienz und einfache Implementierung bieten. Das Verständnis dieser Optionen kann B2B-Käufern helfen, fundierte Entscheidungen auf der Grundlage ihrer spezifischen betrieblichen Anforderungen und Budgetbeschränkungen zu treffen.

| Vergleichsaspekt | Kosten für den Austausch des Anlassers | Alternative 1: Starter-Reparatur | Alternative 2: Austausch der Batterie |

|---|---|---|---|

| Leistung | Stellt die volle Funktionalität wieder her | Stellt die Funktionalität wieder her, wenn dies möglich ist | Kann Startprobleme beheben, wenn diese mit der Batterie zusammenhängen |

| Kosten | $150 - $1.100 (einschließlich Arbeit) | $50 - $200 (wenn die Teile noch zu retten sind) | $100 - $300 (für eine neue Batterie) |

| Einfache Implementierung | Benötigt professionelle Hilfe | Kann DIY oder professionell sein | Generell einfaches DIY |

| Wartung | Geringe Nachinstallation | Erfordert regelmäßige Kontrollen | Regelmäßige Überwachung erforderlich |

| Bester Anwendungsfall | Vollständiger Ausfall des Anlassers | Geringe Mängel oder Abnutzung | Symptome einer schwachen Batterie |

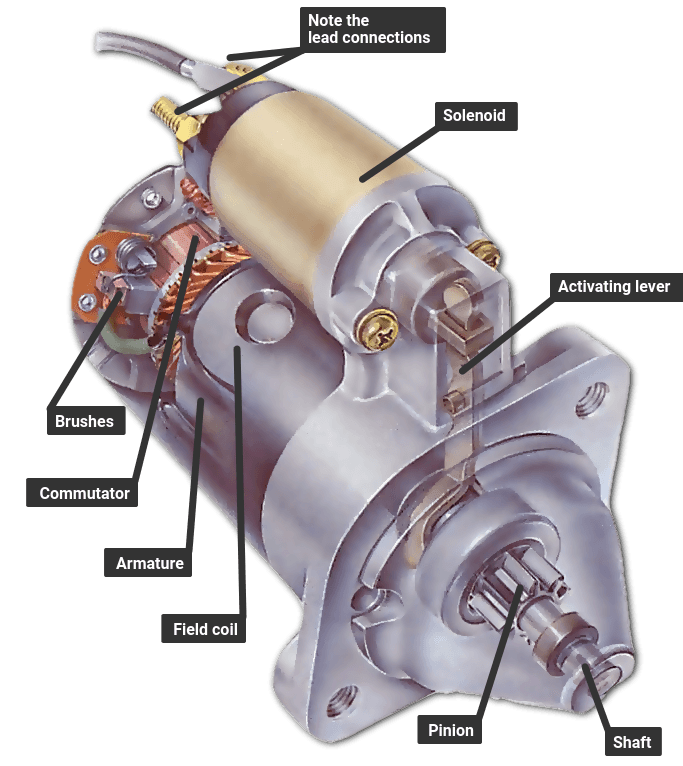

Die Starter-Reparatur als Alternative verstehen

Die Reparatur des Anlassers kann eine sinnvolle Alternative zum vollständigen Austausch sein, insbesondere wenn kleinere Probleme festgestellt werden. Diese Option umfasst in der Regel die Inspektion und Reparatur bestimmter Komponenten des Anlassers, wie z. B. Bürsten oder Magnetspulen. Die Kosten für eine Reparatur können zwischen $50 und $200 liegen, je nachdem, wie schwerwiegend das Problem ist und ob Teile wiederverwendet werden können. Der Hauptvorteil dieser Methode liegt in der Kosteneffizienz, da der Anlasser weiter verwendet werden kann, ohne dass ein kompletter Austausch erforderlich ist. Wenn der Anlasser jedoch stark beschädigt ist, ist eine Reparatur möglicherweise nicht möglich, und das Fahrzeug kann weiterhin Probleme mit der Zuverlässigkeit haben.

Bewertung des Batteriewechsels bei Startproblemen

Eine weitere Alternative ist der Austausch der Fahrzeugbatterie, insbesondere wenn die Startprobleme nicht nur mit dem Anlasser zusammenhängen. Eine neue Batterie kann zwischen $100 und $300 kosten, und ihr Austausch ist oft eine einfache Heimwerkeraufgabe. Diese Lösung ist vor allem dann sinnvoll, wenn das Fahrzeug Anzeichen eines elektrischen Defekts aufweist, wie z. B. sich abdunkelnde Lichter oder ein klickendes Geräusch beim Startversuch. Allerdings kann es irreführend sein, sich nur auf den Austausch der Batterie zu verlassen, wenn auch der Anlasser beschädigt ist, was zu wiederholten Problemen führen kann. Es ist wichtig, dass der Käufer die genaue Ursache der Startprobleme diagnostiziert, bevor er sich für diese Lösung entscheidet.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

Schlussfolgerung: Wie Sie die richtige Lösung für Ihre Bedürfnisse wählen

Bei der Suche nach der richtigen Lösung für die Startprobleme eines Fahrzeugs müssen B2B-Käufer die besonderen Umstände ihres Fahrzeugs berücksichtigen. Ist der Anlasser völlig funktionsunfähig, kann ein Austausch die effektivste Lösung sein. Weisen die Symptome hingegen auf geringfügigen Verschleiß oder Probleme mit der Batterie hin, könnte eine Reparatur oder ein Batteriewechsel die geeignetere und kostengünstigere Lösung sein. Durch eine gründliche Beurteilung des Zustands von Anlasser und Batterie kann der Käufer die am besten geeignete und finanziell vernünftigste Lösung wählen, die auf seine betrieblichen Anforderungen zugeschnitten ist.

Wesentliche technische Eigenschaften und Fachterminologie für die Kosten für den Austausch des Anlassers

Was sind die wichtigsten technischen Eigenschaften, die die Kosten für den Austausch eines Anlassers beeinflussen?

Bei der Bewertung der Kosten für den Austausch eines Anlassers spielen mehrere technische Eigenschaften eine entscheidende Rolle bei der Bestimmung sowohl des Preises als auch der Gesamtqualität des Ersatzteils. Das Verständnis dieser Eigenschaften kann B2B-Käufern helfen, fundierte Kaufentscheidungen zu treffen.

1. Werkstoffgüte

Die Materialqualität eines Anlassers bezieht sich in der Regel auf die Qualität der in der Konstruktion verwendeten Metalle, wie Aluminium, Kupfer oder Stahl. Hochwertige Materialien gewährleisten Haltbarkeit und Verschleißfestigkeit, was die Lebensdauer des Anlassers verlängern kann. Für B2B-Käufer kann die Investition in hochwertigere Materialien dazu führen, dass im Laufe der Zeit weniger Ersatzteile benötigt werden, was die langfristigen Betriebskosten senkt.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

2. Elektrische Spezifikationen

Die elektrischen Spezifikationen, einschließlich der Nennspannung und der Stromstärke, sind für das ordnungsgemäße Funktionieren eines Anlassers entscheidend. Ein Standardanlasser für Kraftfahrzeuge arbeitet normalerweise mit 12 Volt. Um mögliche Ausfälle zu vermeiden, ist es wichtig, dass der Anlasser die elektrischen Anforderungen des Fahrzeugs erfüllt. Käufer sollten Anlasser bevorzugen, die den OEM-Spezifikationen entsprechen oder diese übertreffen, um Kompatibilität und Zuverlässigkeit zu gewährleisten.

3. Drehmoment

Das Drehmoment gibt an, wie viel Rotationskraft ein Anlasser ausüben kann. Dies ist besonders wichtig für größere Motoren, die ein höheres Drehmoment benötigen, um den Startvorgang einzuleiten. Die Kenntnis der Drehmomentwerte kann Käufern helfen, Anlasser auszuwählen, die für bestimmte Motoranforderungen geeignet sind, und so Probleme wie das Durchbrennen oder Versagen des Anlassers verhindern.

4. Toleranzwerte

Toleranzwerte geben an, mit welcher Präzision die Teile gefertigt werden. Höhere Toleranzen führen zu einer besseren Passform und Leistung und minimieren das Risiko eines mechanischen Versagens. Für B2B-Einkäufer kann die Auswahl von Startern mit präzisen Toleranzen zu einer verbesserten Effizienz und Zuverlässigkeit der von ihnen gewarteten Fahrzeuge führen, was für die Aufrechterhaltung der Kundenzufriedenheit unerlässlich ist.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

5. Hitzebeständigkeit

Die Hitzebeständigkeit ist eine Eigenschaft, die die Leistung und Langlebigkeit eines Anlassers beeinflusst. Anlasser, die höheren Temperaturen standhalten können, fallen unter extremen Bedingungen seltener aus und sind daher eine zuverlässige Wahl für Regionen mit rauem Klima. Käufer sollten hitzebeständige Anlasser in Betracht ziehen, um die Betriebssicherheit in verschiedenen Umgebungen zu gewährleisten.

6. Integrationsmerkmale

Zu den Integrationsmerkmalen gehören Aspekte wie integrierte Magnetspulen oder fortschrittliche elektronische Steuerungen, die die Leistung des Anlassers verbessern. Diese Merkmale können die Effizienz des Anlassens erhöhen und die Wahrscheinlichkeit eines Ausfalls verringern. Käufer sollten nach Startern mit modernen Integrationsmerkmalen Ausschau halten, da diese oft langfristig einen besseren Wert und eine bessere Leistung bieten.

Wie lauten die gängigen Fachausdrücke im Zusammenhang mit den Kosten für den Austausch des Anlassers?

Das Verständnis des Branchenjargons ist für eine effektive Kommunikation und Verhandlung auf dem B2B-Markt unerlässlich. Im Folgenden finden Sie einige gängige Fachbegriffe, die für die Kosten des Austauschs eines Anlassers relevant sind.

1. OEM (Originalgerätehersteller)

OEM-Teile werden vom Fahrzeughersteller oder von autorisierten Zulieferern hergestellt. Diese Teile garantieren in der Regel Kompatibilität und Qualität, was sie für viele B2B-Käufer zur bevorzugten Wahl macht. Sie können zwar teurer sein als Aftermarket-Alternativen, aber die Zuverlässigkeit, die sie bieten, kann die Investition rechtfertigen.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

2. MOQ (Mindestbestellmenge)

Die Mindestbestellmenge (MOQ) ist die kleinste Anzahl von Einheiten, die ein Lieferant zu verkaufen bereit ist. Die Kenntnis der Mindestbestellmenge ist für B2B-Einkäufer von entscheidender Bedeutung, um ihre Bestände effektiv zu verwalten und Überbestände zu vermeiden. Lieferanten können MOQs festlegen, um die Rentabilität ihrer Produktionskosten zu gewährleisten.

3. RFQ (Angebotsanfrage)

Eine Anfrage ist ein Dokument, das an Lieferanten geschickt wird, um Preisangebote für bestimmte Produkte oder Dienstleistungen einzuholen. Für B2B-Einkäufer kann eine Anfrage für Anlasser Preisvergleiche und Verhandlungen erleichtern, was letztlich zu besseren Beschaffungsentscheidungen führt.

4. Incoterms (Internationale Handelsklauseln)

Die Incoterms sind eine Reihe von internationalen Regeln, die die Verantwortlichkeiten von Käufern und Verkäufern bei internationalen Transaktionen festlegen. Das Verständnis der Incoterms ist für B2B-Käufer, die grenzüberschreitende Käufe von Anlassern tätigen, von entscheidender Bedeutung, da sie die Verantwortlichkeiten für den Versand, das Risikomanagement und die Kostenverteilung festlegen.

5. Ersatzteile

Aftermarket-Teile werden von anderen Unternehmen als dem Originalhersteller produziert. Sie können zwar Kosteneinsparungen bieten, aber die Qualität kann erheblich schwanken. B2B-Käufer sollten die potenziellen Risiken und Vorteile der Verwendung von Aftermarket-Teilen gegen ihre spezifischen Bedürfnisse und Budgetbeschränkungen abwägen.

6. Garantiezeitraum

Die Garantiezeit gibt den Zeitraum an, in dem ein Produkt gegen Mängel garantiert ist. Eine längere Garantiezeit ist oft ein Zeichen des Vertrauens in die Haltbarkeit des Produkts. Für B2B-Käufer kann die Berücksichtigung der Garantie ein beruhigendes Gefühl vermitteln und sie vor unerwarteten Kosten im Zusammenhang mit dem Ausfall von Teilen schützen.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

Wenn B2B-Einkäufer diese technischen Eigenschaften und Handelsbedingungen verstehen, können sie fundiertere Entscheidungen über die Kosten und die Auswahl von Anlassern treffen und so eine optimale Leistung und einen optimalen Wert für ihren Betrieb sicherstellen.

Navigation der Marktdynamik und der Beschaffungstrends im Bereich der Kosten für den Austausch von Anlassern

Was sind die wichtigsten Marktdynamiken und Trends, die die Kosten für den Austausch von Anlassern beeinflussen?

Auf dem globalen Automobilmarkt vollziehen sich erhebliche Veränderungen, die die Kosten für den Austausch von Anlassern beeinflussen. Ein Hauptfaktor ist die zunehmende Komplexität der Fahrzeuge, insbesondere durch die Integration fortschrittlicher elektronischer Systeme und Hybridtechnologien. Diese Komplexität macht häufig spezielle Anlasser erforderlich, was sich auf die Beschaffungsstrategien und Kosten auswirkt. In Regionen wie Afrika und Südamerika, wo die Automobilmärkte schnell wachsen, ist die Nachfrage nach erschwinglichen und dennoch zuverlässigen Anlassern von größter Bedeutung.

Neue Technologien wie E-Commerce-Plattformen und digitale Supply-Chain-Management-Tools revolutionieren die Art und Weise, wie internationale Einkäufer Anlassermotoren beschaffen. Diese Plattformen bieten einen besseren Überblick über Preise, Verfügbarkeit und Zuverlässigkeit der Lieferanten, so dass Käufer aus dem Nahen Osten und Europa schnell fundierte Entscheidungen treffen können. Darüber hinaus gewinnt der Trend zu wiederaufbereiteten Anlassern, die eine kostengünstige Alternative zu Neuteilen darstellen, zunehmend an Bedeutung. Dieser Trend senkt nicht nur die Kosten, sondern spricht auch umweltbewusste Käufer an, die nach nachhaltigen Optionen suchen.

Darüber hinaus wird das wirtschaftliche Umfeld durch Störungen in der globalen Lieferkette beeinflusst, einschließlich Schwankungen bei den Rohstoffkosten und Verzögerungen beim Versand. Einkäufer müssen flexibel bleiben und ihre Beschaffungsstrategien anpassen, um diese Risiken zu mindern. Die Kenntnis der lokalen Marktbedingungen und der Fähigkeiten der Lieferanten ist entscheidend für strategische Einkaufsentscheidungen, insbesondere für Unternehmen in Schwellenländern wie Nigeria und Vietnam.

Wie können sich Nachhaltigkeit und ethische Beschaffung auf die Kosten für den Austausch von Anlassern auswirken?

Das Thema Nachhaltigkeit gewinnt in der Automobilzulieferindustrie zunehmend an Bedeutung, auch bei Anlassern. Die Umweltauswirkungen von Herstellungsverfahren und Materialien, die in Anlassern verwendet werden, stehen auf dem Prüfstand und zwingen die Unternehmen, umweltfreundlichere Verfahren anzuwenden. Für B2B-Einkäufer ist es wichtig, den ökologischen Fußabdruck ihrer Lieferanten zu verstehen. Dazu gehört die Bewertung der Materialbeschaffung, des Energieverbrauchs während der Produktion und der Recyclingfähigkeit von Anlassern am Ende ihres Lebenszyklus.

Illustratives Bild zu den Kosten für den Austausch des Anlassers

Auch ethische Beschaffungspraktiken gewinnen zunehmend an Bedeutung. Einkäufer bevorzugen jetzt Lieferanten, die sich für faire Arbeitsbedingungen und Transparenz innerhalb ihrer Lieferketten einsetzen. Zertifizierungen wie ISO 14001 für Umweltmanagement und ISO 26000 für soziale Verantwortung werden zu entscheidenden Indikatoren für das Engagement eines Lieferanten für Nachhaltigkeit.

Indem sie sich auf Lieferanten mit ‘grünen’ Zertifizierungen oder solche, die nachhaltige Materialien verwenden, konzentrieren, können internationale B2B-Einkäufer nicht nur einen Beitrag zum Umweltschutz leisten, sondern auch ihren Markenruf verbessern. Zu den langfristigen Vorteilen gehören der Aufbau von Kundentreue und die potenzielle Senkung der mit der Abfallentsorgung und der Einhaltung von Vorschriften verbundenen Kosten.

Welche Bedeutung hat die Entwicklung in der Anlasserindustrie für B2B-Einkäufer?

Die Anlasserindustrie hat sich im Laufe der Jahrzehnte unter dem Einfluss des technischen Fortschritts in der Automobilindustrie und der sich ändernden Verbraucherwünsche erheblich weiterentwickelt. Ursprünglich waren Anlasser einfache, mechanische Geräte. Mit dem Aufkommen elektronischer Zündsysteme und verbesserter Batterietechnologie sind Anlasser jedoch anspruchsvoller geworden und verfügen über Merkmale wie integrierte Magnetspulen und fortschrittliche Materialien zur Leistungssteigerung.

In der Vergangenheit lag der Schwerpunkt vor allem auf Kosten und Verfügbarkeit. Heute müssen B2B-Einkäufer Faktoren wie Zuverlässigkeit, Kompatibilität mit modernen Fahrzeugen und die Nachhaltigkeit des Beschaffungsprozesses berücksichtigen. Mit der zunehmenden Verbreitung von Elektrofahrzeugen (EVs) ändert sich auch die Rolle des Anlassers, was zu neuen Marktchancen für innovative Anbieter führt.

Das Verständnis dieser Entwicklung ist für B2B-Einkäufer von entscheidender Bedeutung, um fundierte Entscheidungen über die Beschaffung von Anlassern zu treffen, die den aktuellen und zukünftigen Anforderungen der Automobilindustrie entsprechen. Die Verlagerung hin zu Elektro- und Hybridfahrzeugen wird den Anlassermarkt weiter prägen. Daher ist es für Einkäufer unerlässlich, über technologische Fortschritte und Markttrends informiert zu bleiben.

Häufig gestellte Fragen (FAQs) für B2B-Käufer zu den Kosten für den Austausch des Anlassers

-

Wie kann ich feststellen, ob ein Anlasser ausgetauscht werden muss?

Um festzustellen, ob ein Anlasser ausgetauscht werden muss, sollten Sie zunächst die Symptome beobachten. Häufige Anzeichen sind, dass der Motor nicht anspringt, ungewöhnliche Geräusche (wie Klicken oder Schleifen) oder unregelmäßige Anlasserdrehzahlen. Überprüfen Sie außerdem die Batterie und die Kabelanschlüsse auf Korrosion oder Schäden, da diese häufig Anlasserprobleme vortäuschen können. Wenn die Batterie funktionstüchtig ist und die Anschlüsse sicher sind, sollten Sie einen Mechaniker aufsuchen, um sich zu vergewissern, dass der Anlasser tatsächlich die Ursache des Problems ist, bevor Sie mit dem Austausch beginnen. -

Wie hoch sind die durchschnittlichen Kosten für den Austausch eines Anlassers?

Die Kosten für den Austausch eines Anlassers können je nach Fahrzeugmarke und -modell stark variieren und reichen von $150 bis über $1.100. Zu den Faktoren, die diese Kosten beeinflussen, gehören die Komplexität des Einbaus, die Art des Anlassers (neu oder überholt) und die Lohnkosten in Ihrer Region. Bei Großeinkäufen können Sie durch Verhandlungen mit Lieferanten bessere Preise erzielen. Holen Sie immer Angebote von mehreren Anbietern ein, um wettbewerbsfähige Preise zu erhalten, die auf Ihre spezifischen Fahrzeuganforderungen zugeschnitten sind. -

Welche Faktoren sollte ich bei der internationalen Beschaffung von Anlassern berücksichtigen?

Bei der internationalen Beschaffung von Anlassern sind Faktoren wie die Zuverlässigkeit des Lieferanten, die Produktqualität, die Einhaltung der lokalen Vorschriften und die Versandlogistik zu berücksichtigen. Es ist wichtig, die Lieferanten zu überprüfen, indem Sie ihre Zertifizierungen, Kundenrezensionen und früheren Exporterfahrungen kontrollieren. Prüfen Sie außerdem, ob sie in der Lage sind, Kundendienst und Garantiebedingungen zu bieten. Die Kenntnis der lokalen Marktdynamik in Ihrer Region wird ebenfalls zu einem reibungslosen Beschaffungsprozess beitragen. -

Wie kann ich die Qualität von Anlassern bei Lieferanten überprüfen?

Um die Qualität von Anlassern zu überprüfen, fordern Sie vom Lieferanten Muster oder Zertifizierungen an, z. B. nach ISO- oder anderen Industrienormen. Führen Sie bei Erhalt gründliche Inspektionen durch und achten Sie dabei auf die Materialqualität und die Leistungsspezifikationen. Die Beauftragung eines externen Qualitätssicherungsunternehmens kann ebenfalls eine unvoreingenommene Bewertung liefern. Die Erstellung einer Checkliste für die Qualitätskontrolle auf der Grundlage Ihrer Betriebsstandards trägt dazu bei, die Konsistenz der Lieferungen zu gewährleisten. -

Was sind die typischen Zahlungsbedingungen im B2B-Geschäft für Anlasser?

Typische Zahlungsbedingungen bei B2B-Transaktionen für Anlasser können variieren, umfassen aber oft Optionen wie 30%, 50% oder 100% Vorauszahlung, je nach den Richtlinien des Lieferanten und Ihrer Verhandlungsstärke. Viele Lieferanten akzeptieren auch Akkreditive oder Zahlung bei Lieferung als sichere Methoden. Es ist ratsam, die Zahlungsbedingungen im Voraus zu klären, um Missverständnisse zu vermeiden und einen reibungslosen Ablauf der Transaktion zu gewährleisten. -

Wie hoch ist die Mindestbestellmenge (MOQ) für Anlasser von Lieferanten?

Die Mindestbestellmengen (MOQ) können von Lieferant zu Lieferant sehr unterschiedlich sein und von 10 bis zu mehreren hundert Stück reichen, je nach den Fähigkeiten und dem Produktionsumfang des Lieferanten. Erkundigen Sie sich bei Verhandlungen mit Lieferanten nach der Flexibilität bei den MOQs, insbesondere wenn Sie einen neuen Markt oder eine neue Produktlinie testen. Einige Lieferanten bieten niedrigere Mindestbestellmengen für Erstbestellungen oder in Aktionszeiträumen an, was die Verwaltung von Lagerbeständen und Cashflow erleichtert. -

Wie wirkt sich die Logistik auf die Kosten der internationalen Beschaffung von Anlassern aus?

Die Logistik kann die Gesamtkosten der internationalen Beschaffung von Anlassern erheblich beeinflussen. Faktoren wie Versandmethoden, Frachtkosten, Zollgebühren und Lieferfristen können die Gesamtkosten beeinflussen. Bei größeren Bestellungen kann Seefracht kostengünstiger sein, während Luftfracht zwar schneller, aber auch teurer sein kann. Es ist wichtig, mit Logistikpartnern zusammenzuarbeiten, die die Komplexität des internationalen Handels verstehen, um eine rechtzeitige Lieferung und die Einhaltung der örtlichen Vorschriften zu gewährleisten. -

Wie hoch sind die üblichen Zollsätze für die Einfuhr von Anlassern?

Die Zollgebühren für die Einfuhr von Anlassern können von Land zu Land variieren und hängen von Faktoren wie dem Ursprungsland, Handelsabkommen und der spezifischen Klassifizierung des Produkts nach internationalen Tarifcodes ab. Es ist wichtig, sich über die Zollsätze in Ihrem Zielmarkt zu informieren und mit einem Zollmakler zusammenzuarbeiten, um den Importprozess effizient zu gestalten. Darüber hinaus kann die Kenntnis möglicher Ausnahmeregelungen oder Zölle bei der Budgetierung und Kostenanalyse für Ihre Beschaffungsstrategie hilfreich sein.

Top 7 Kosten für den Austausch des Anlassers Hersteller & Lieferanten Liste

1. Reddit - Kosten für den Austausch des Anlassers

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: Der Preis für den Austausch des Anlassers variiert; in einigen Kommentaren wird ein Preis für das Teil von etwa $220 genannt, wobei die Arbeitskosten angemessen sind, aber der Aufschlag auf die Teile überhöht ist.

2. Last Chance Auto Repairs – Kosten für den Austausch des Anlassers

Domäne: letztechanceautoreparaturen.com

Registriert: 2009 (16 Jahre)

Einleitung: Kosten für den Austausch des Anlassers: Sparanlasser: $75 - $200, OEM-Anlasser: $150 - $400, Hochleistungsanlasser: $300 - $1000+. Arbeitskosten: Austausch von Basisanlassern für Fahrzeuge: $100 - $250, Komplexe Installationen: $300 - $600+. Kostenbeeinflussende Faktoren: Fahrzeugtyp und -modell, neue vs. überholte Anlasser, zusätzliche Reparaturen (Batteriewechsel, Reparaturen an der Verkabelung usw.). Heimwerker-Kosten: Nur Teile: $100 - $400...

3. Facebook - Autoreparaturkosten

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Kosten für die Fahrt zur Werkstatt und den Austausch des Anlassers

4. CARFAX - Berichte zur Fahrzeughistorie

Domäne: carfax.de

Registriert: 1997 (28 Jahre)

Einleitung: CARFAX bietet Zugang zur weltweit größten Datenbank mit Informationen zur Fahrzeughistorie, die Berichte über bekannte Unfälle, Schäden, Diebstahlberichte, Wartung und Inspektionen, manipulierte Kilometerstände, Importinformationen, Besitzerwechsel, Taxi- oder Mietwagennutzung und offene Rückrufaktionen enthält. Der Service ist für Fahrzeuge aus über 20 Ländern, darunter die USA und Kanada, verfügbar und soll die Transporte...

5. AAA - Anleitung zum Austausch des Anlassers

Domäne: aaa.com

Registriert: 1990 (35 Jahre)

Einleitung: Durchschnittliche Kosten für den Austausch eines Anlassers: $700 - $1.200. Ersatzteilkosten: unter $100 bis über $400. Arbeitssätze: $100 - $250 pro Stunde. Typen von Anlassern: Getriebestarter (effizienter, teurer) und Direktantriebsstarter (weniger effizient, billiger). Häufige Symptome von Anlasserproblemen: Langsames Anlassen, Auto springt nicht an, Klick-/Schleifgeräusche, Anlasser läuft nach dem Anlassen des Motors, Rauch aus dem...

6. Austausch des Anlassers - Kostenübersicht

Domäne: carbuzz.de

Registriert: 2003 (22 Jahre)

Einleitung: Die Kosten für den Austausch des Anlassers liegen im Durchschnitt zwischen $450 und $600. Konkrete Fahrzeugbeispiele sind der Toyota Tundra (2000-2005) mit Austauschkosten von $650 bis $900 aufgrund der arbeitsintensiven Installation und der Honda Civic mit Kosten von $490 bis $760. Zu den Faktoren, die sich auf die Kosten auswirken, gehören der Arbeitsaufwand (1,5 bis 2,5 Stunden für die meisten Anlasser, bis zu vier Stunden für im Tal montierte Anlasser), der...

7. CarTalk - Anleitung zum Austausch des Anlassers

Domäne: cartalk.com

Registriert: 1995 (30 Jahre)

Einleitung: Kosten für den Austausch eines Anlassers: $600 bis $900 für normale Fahrzeuge; $900 bis $1.400 für Luxusmodelle. Zu den Symptomen eines defekten Anlassers gehören Klickgeräusche, Quietschgeräusche und intermittierende Funktion. Die Reparatur eines Anlassers ist oft nicht kosteneffektiv; ein Austausch ist vorzuziehen. Neue Anlasser sind selten; in der Regel werden wiederaufbereitete Anlasser mit einer Garantie von 30 Tagen bis zu einem Jahr verwendet. Moderne Fahrzeuge mit ...

Strategische Beschaffung Schlussfolgerung und Ausblick für Kosten für den Austausch des Anlassers

Bei der Navigation durch die Kostenlandschaft für den Austausch von Anlassern müssen sich internationale B2B-Einkäufer auf eine strategische Beschaffung konzentrieren, um den Wert zu maximieren und die Ausgaben zu minimieren. Die Variabilität der Ersatzteilkosten, die von der Fahrzeugmarke, dem Modell und der Komplexität der Arbeit abhängt, unterstreicht die Bedeutung einer gründlichen Marktanalyse. Durch den Aufbau von Beziehungen zu vertrauenswürdigen Lieferanten können Unternehmen qualitativ hochwertige Komponenten zu wettbewerbsfähigen Preisen erwerben und so eine zuverlässige Fahrzeugleistung bei gleichzeitiger Aufrechterhaltung der betrieblichen Effizienz sicherstellen.

Das Wissen um die Feinheiten der Anlasserkomponenten und mögliche Reparatur- oder Ersatzszenarien kann auch zu erheblichen Kosteneinsparungen führen. Wenn man zum Beispiel erkennt, wann ein einfacher Austausch von Teilen ausreicht, kann man unnötige Ausgaben für den kompletten Austausch des Anlassers vermeiden. Darüber hinaus kann die Förderung von Partnerschaften mit lokalen Mechanikern und Dienstleistern in bestimmten Regionen die logistische Effizienz verbessern und Ausfallzeiten reduzieren.

Mit Blick auf die Zukunft ist es für B2B-Einkäufer aus Afrika, Südamerika, dem Nahen Osten und Europa unerlässlich, agil zu bleiben, da sich die globalen Lieferketten weiter entwickeln. Indem sie die strategische Beschaffung in den Vordergrund stellen und sich über Markttrends auf dem Laufenden halten, können Unternehmen nicht nur ihre Abläufe rationalisieren, sondern sich auch für künftiges Wachstum positionieren. Setzen Sie sich noch heute mit Lieferanten in Verbindung, um innovative Lösungen zu finden, die Ihren Anforderungen entsprechen und Ihr Unternehmen voranbringen.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.