Introduction: Navigating the Global Market for best alternators

In the ever-evolving landscape of automotive technology, sourcing the best alternators has become a critical challenge for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. As vehicles increasingly rely on robust electrical systems to support advanced functionalities, understanding the nuances of alternators—ranging from types and applications to performance specifications—can significantly impact operational efficiency and customer satisfaction. This guide offers a comprehensive analysis of alternators, delving into the various types available, their specific applications, and the best practices for vetting suppliers.

By navigating this essential resource, B2B buyers will gain actionable insights into the critical factors influencing alternator selection, including compatibility, electrical load requirements, and cost considerations. Moreover, the guide highlights reputable brands and manufacturers, ensuring that buyers can make informed decisions that align with their unique operational needs. Whether you’re in Brazil, Saudi Arabia, or beyond, this guide empowers you to enhance your procurement strategy, minimize downtime, and ultimately drive better performance for your fleet. With the right knowledge at your fingertips, sourcing high-quality alternators becomes not just a task, but a strategic advantage in today’s competitive market.

Inhaltsverzeichnis

- Top 3 Best Alternators Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best alternators

- Understanding best alternators Types and Variations

- Key Industrial Applications of best alternators

- 3 Common User Pain Points for ‘best alternators’ & Their Solutions

- Strategic Material Selection Guide for best alternators

- In-depth Look: Manufacturing Processes and Quality Assurance for best alternators

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best alternators’

- Comprehensive Cost and Pricing Analysis for best alternators Sourcing

- Alternatives Analysis: Comparing best alternators With Other Solutions

- Essential Technical Properties and Trade Terminology for best alternators

- Navigating Market Dynamics and Sourcing Trends in the best alternators Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best alternators

- Strategic Sourcing Conclusion and Outlook for best alternators

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding best alternators Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Hochleistungsgeneratoren | Produces up to 350 amps, designed for high electrical loads | Heavy-duty vehicles, high-performance cars | Vorteile: Superior power for demanding systems. Nachteile: Higher cost, requires larger gauge wiring. |

| Normale Lichtmaschinen | Standard output, uses carbon brushes, lower amperage capacity | Most standard vehicles | Vorteile: Kostengünstig, weit verbreitet. Nachteile: Shorter lifespan, less efficient at high speeds. |

| Überholte Lichtmaschinen | Rebuilt to OE specifications, cost-effective alternative | Fleet vehicles, budget-conscious applications | Vorteile: Comparable performance to new, lower price. Nachteile: Mögliche Schwankungen in der Qualität. |

| Bürstenlose Generatoren | No carbon brushes, longer lifespan, lower maintenance | Electric vehicles, advanced automotive tech | Vorteile: Higher efficiency, less wear. Nachteile: Initial investment can be higher. |

| Compact Alternators | Smaller size, lightweight, designed for space-constrained vehicles | Compact cars, motorcycles | Vorteile: Space-saving design, easier installation. Nachteile: Limited output, may not suit high-demand applications. |

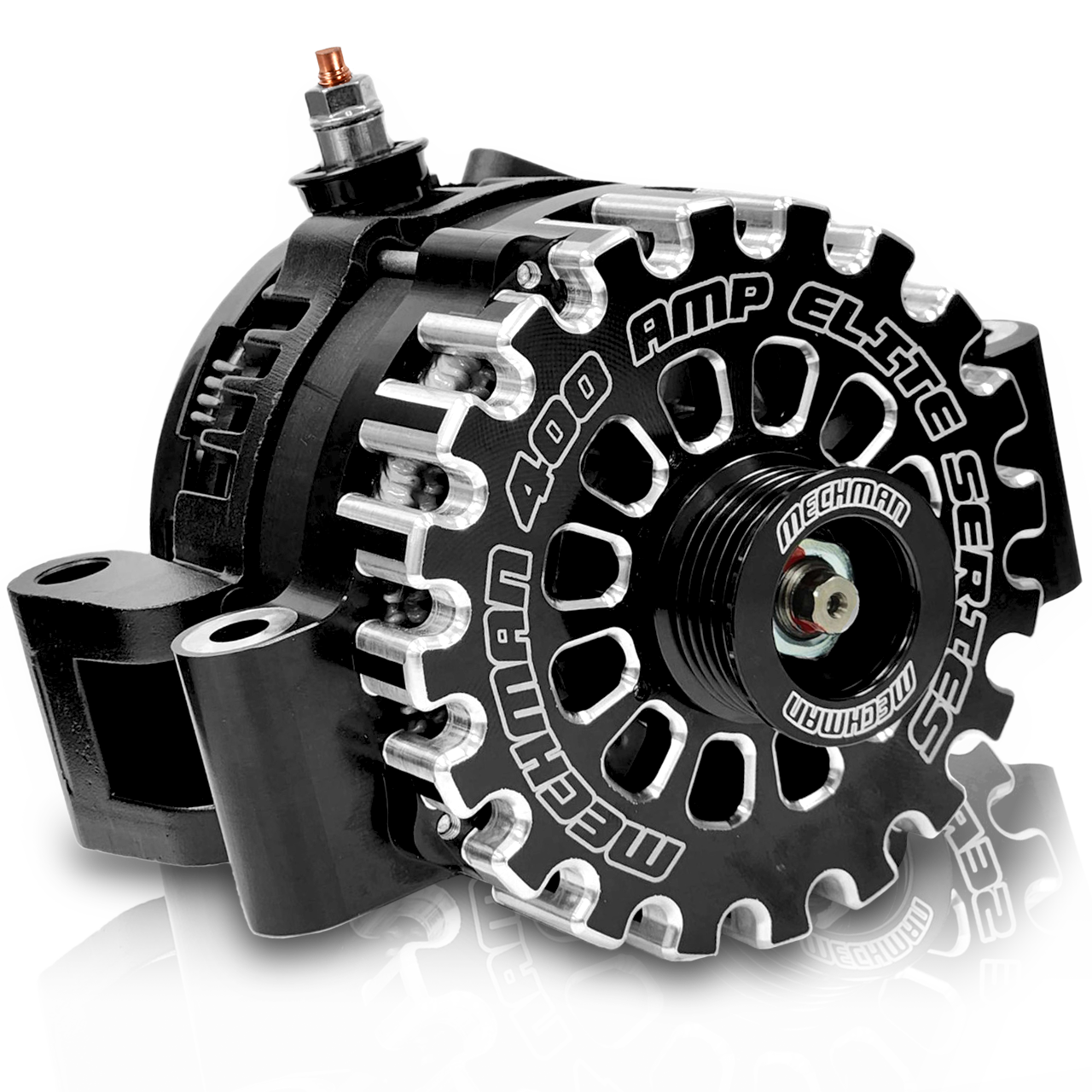

What Are High-Output Alternators and When Should You Use Them?

High-output alternators are engineered to deliver superior charging power, often exceeding 200 amps. This capability makes them essential for heavy-duty vehicles and high-performance cars equipped with advanced electrical systems, such as high-end audio setups and additional lighting. B2B buyers should consider the vehicle’s total electrical load when choosing this type, as these alternators can help ensure optimal performance without overloading the system.

How Do Regular Alternators Compare to Other Types?

Regular alternators are the standard choice for most vehicles, utilizing carbon brushes to generate electrical power. While they are cost-effective and readily available, they tend to have a shorter lifespan and may not perform well under high-speed conditions. B2B buyers should assess their specific needs, as these alternators are suitable for conventional applications but might not meet the demands of more power-hungry setups.

What Advantages Do Remanufactured Alternators Offer?

Remanufactured alternators present a viable alternative for buyers looking for quality without the new price tag. These units are rebuilt to meet original equipment specifications and typically offer similar performance to new alternators at a fraction of the cost. For fleet operators or budget-conscious businesses, remanufactured options can provide significant savings. However, buyers should ensure they source from reputable manufacturers to mitigate quality concerns.

Why Choose Brushless Alternators for Advanced Applications?

Brushless alternators are designed without carbon brushes, which enhances their efficiency and longevity. This type is particularly suitable for electric vehicles and advanced automotive technologies that require consistent power delivery. B2B buyers looking to invest in cutting-edge technology should consider the initial investment against the long-term benefits of reduced maintenance and improved performance.

What Are the Benefits of Compact Alternators?

Compact alternators are specifically designed for space-constrained applications, such as motorcycles and small cars. Their lightweight and smaller size facilitate easier installation and can be a crucial factor for OEMs looking to optimize vehicle design. However, buyers should be mindful of their limited output capabilities, ensuring they align with the electrical demands of their specific applications.

Key Industrial Applications of best alternators

| Branche/Sektor | Specific Application of best alternators | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Powering assembly line machinery | Ensures continuous operation and reduces downtime | Compatibility with existing machinery and electrical load |

| Landwirtschaft | Driving irrigation systems | Enhances efficiency and reliability of water supply | Durability under harsh conditions and voltage requirements |

| Bauwesen | Supporting heavy machinery like cranes | Maximizes productivity and safety on job sites | High output capacity and maintenance support |

| Erneuerbare Energien | Operating solar or wind energy systems | Facilitates energy storage and grid integration | Adaptability to varying energy loads and environmental conditions |

| Transport | Powering electric vehicles (EVs) | Supports the transition to sustainable transport options | Weight considerations and compatibility with battery systems |

How Are Best Alternators Used in Automotive Manufacturing?

In the automotive manufacturing sector, best alternators are integral to powering assembly line machinery. These alternators convert mechanical energy into electrical energy, ensuring that machines operate seamlessly without interruptions. By maintaining a steady power supply, they reduce downtime, which is critical for maximizing production efficiency. Buyers should consider the compatibility of alternators with existing machinery and the electrical load requirements to ensure optimal performance.

What Role Do Best Alternators Play in Agriculture?

In agriculture, best alternators are essential for driving irrigation systems that supply water to crops. These systems require reliable power to operate pumps and other equipment, ensuring efficient water management. The use of high-performance alternators helps farmers mitigate risks associated with crop failure due to insufficient irrigation. When sourcing, buyers must prioritize durability, as these alternators often operate in harsh environmental conditions, and they should meet specific voltage requirements for agricultural applications.

How Do Best Alternators Enhance Construction Operations?

Best alternators are vital for supporting heavy machinery such as cranes and excavators in the construction industry. By providing reliable power, they enhance productivity and ensure safety on job sites, where equipment must operate under demanding conditions. The ability to quickly recharge batteries and power various electrical components is crucial. Buyers should focus on high output capacity alternators and ensure that they come with robust maintenance support to minimize downtime.

In What Ways Do Best Alternators Support Renewable Energy Initiatives?

In the renewable energy sector, best alternators are used to operate solar and wind energy systems, facilitating energy storage and grid integration. They convert generated energy into a usable form, ensuring that systems remain efficient and responsive to varying energy loads. Buyers in this sector should look for alternators that can adapt to different energy outputs and withstand environmental factors, such as temperature fluctuations and moisture, to guarantee longevity and reliability.

How Are Best Alternators Transforming the Transportation Sector?

In the transportation sector, particularly with the rise of electric vehicles (EVs), best alternators play a crucial role in powering vehicle systems. They are designed to support the transition to sustainable transport options by efficiently managing the electrical load required for various components. Buyers must consider weight constraints and ensure compatibility with existing battery systems to optimize performance and efficiency in EV applications. This focus on electrical management is critical for enhancing the overall driving experience and vehicle reliability.

3 Common User Pain Points for ‘best alternators’ & Their Solutions

Scenario 1: Compatibility Challenges with High-Performance Vehicles

Das Problem:

B2B buyers often struggle with selecting alternators that are compatible with high-performance vehicles. For instance, a fleet manager looking to upgrade the alternators for a line of modified trucks may face challenges in ensuring that the new units can handle the increased electrical load from advanced systems like navigation, lighting, and high-capacity audio systems. The risk is twofold: choosing an incompatible alternator can lead to system failures or underperformance, and the replacement process can incur significant downtime and costs.

Die Lösung:

To mitigate compatibility issues, it is crucial for buyers to conduct thorough research on the specific electrical requirements of their vehicles. Begin by reviewing the vehicle’s manual to ascertain the original alternator specifications, including size, output voltage, and amperage. When upgrading to a high-output alternator, ensure that it has the same or higher amperage rating than the vehicle’s total electrical load. Additionally, consider reaching out to suppliers who specialize in high-performance automotive parts; they can provide tailored recommendations and may even offer custom solutions for unique needs. Using a compatibility checker tool available from many manufacturers can streamline the selection process, ensuring that the chosen alternator meets all operational requirements.

Scenario 2: Cost vs. Quality Dilemma in Alternator Selection

Das Problem:

Many B2B buyers, particularly those managing fleets in regions with limited access to quality automotive parts, grapple with the dilemma of cost versus quality when selecting alternators. Opting for cheaper alternatives might seem financially prudent in the short term, but these components can lead to frequent failures, resulting in higher long-term costs due to repairs and replacements, as well as potential operational downtime.

Die Lösung:

To navigate this dilemma, B2B buyers should prioritize a value-based approach rather than a cost-based one. Start by evaluating the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, warranty, and potential downtime costs. Seek out reputable manufacturers known for durability and performance, such as Wilson or Denso, and compare their warranty offerings. Additionally, consider investing in remanufactured alternators from trusted brands. These often provide a balance between cost and quality, offering performance that meets original equipment specifications at a reduced price. Establishing relationships with reliable suppliers can also lead to better pricing on bulk orders, enhancing overall cost-effectiveness.

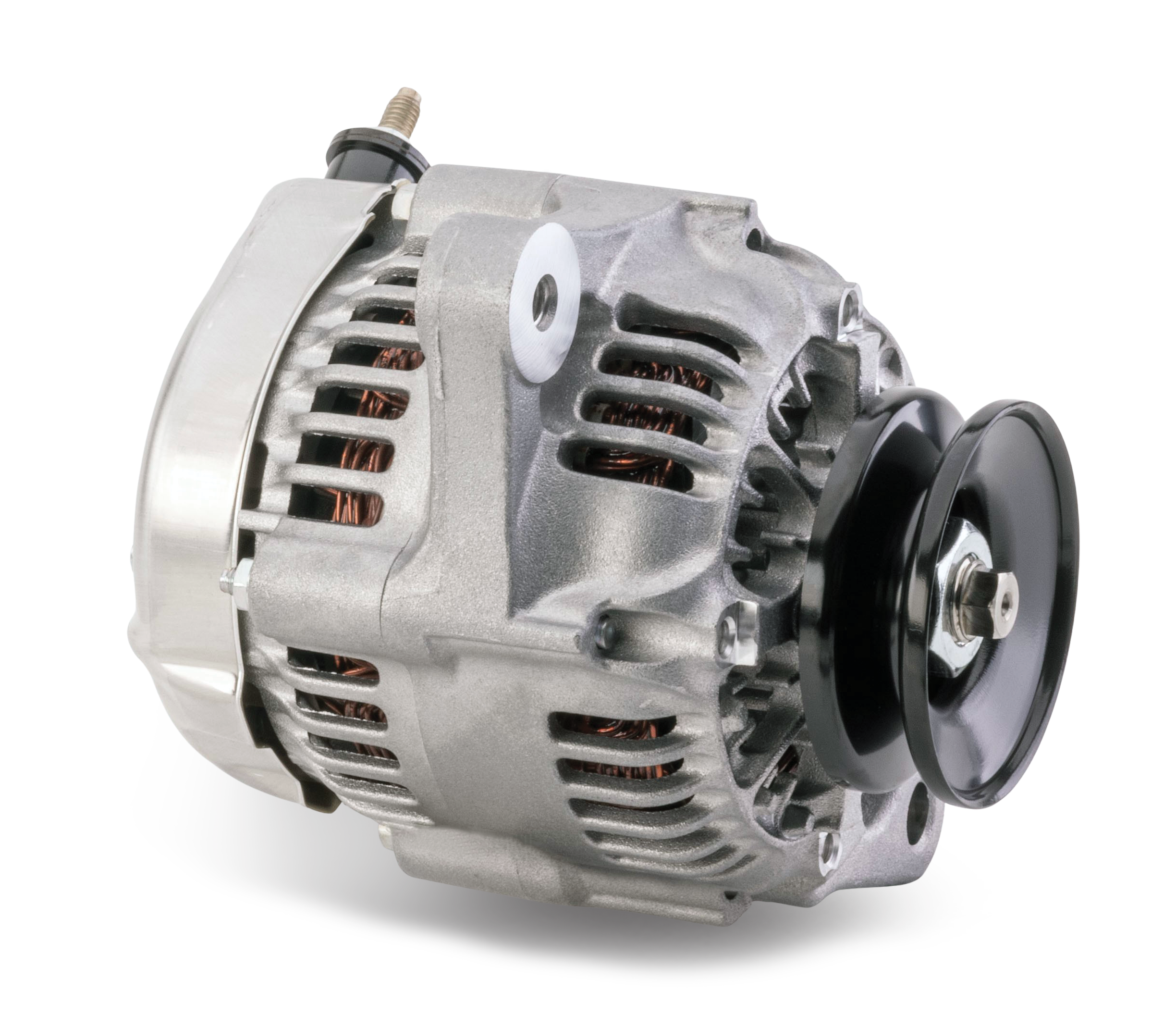

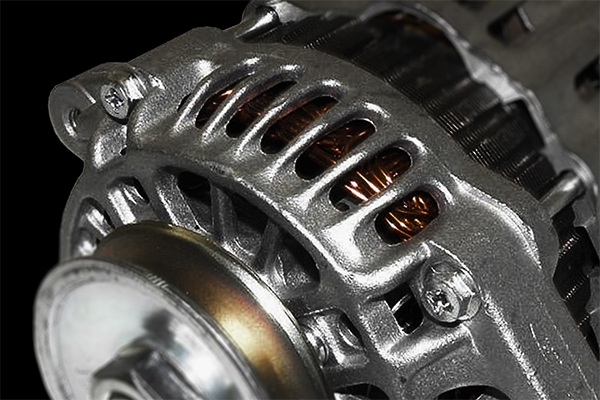

Illustrative image related to best alternators

Scenario 3: Insufficient Knowledge About Alternator Types

Das Problem:

B2B buyers frequently encounter confusion over the different types of alternators available, such as high-output versus regular alternators. This lack of knowledge can lead to misinformed purchases that do not meet the electrical demands of their vehicles, potentially resulting in inadequate performance and increased wear on vehicle components. For example, a construction company operating heavy machinery may unknowingly select a standard alternator for equipment requiring a high-output variant, leading to operational inefficiencies.

Die Lösung:

To address this knowledge gap, buyers should invest time in educating themselves about the various types of alternators and their applications. Online resources, such as manufacturer websites and industry-specific forums, can provide valuable insights into the functional differences between high-output and regular alternators. Additionally, engaging with technical sales representatives can facilitate informed discussions about specific applications and requirements. When selecting an alternator, always assess the total electrical load of the vehicle and choose an alternator that can handle at least 50% more than the maximum demand. This proactive approach not only ensures optimal performance but also extends the lifespan of both the alternator and the vehicle’s electrical system.

Strategic Material Selection Guide for best alternators

What Are the Key Materials Used in Manufacturing High-Performance Alternators?

When selecting alternators for various applications, the choice of materials is crucial for ensuring optimal performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the manufacturing of alternators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Impact the Performance of Alternators?

Aluminum is a prevalent material in alternator housings and components due to its lightweight and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and is resistant to corrosion, making it suitable for various environmental conditions.

Vorteile: Aluminum’s lightweight nature enhances fuel efficiency in vehicles, while its thermal properties help dissipate heat effectively, reducing the risk of overheating. Additionally, aluminum is relatively inexpensive and easy to manufacture, allowing for cost-effective production.

Nachteile: While aluminum is durable, it is not as strong as some other metals, which may lead to structural issues under extreme stress. It can also be prone to wear and tear over time, especially in high-performance applications.

Auswirkungen auf die Anwendung: Aluminum is well-suited for automotive and light-duty applications, where weight savings and heat dissipation are critical. However, it may not be the best choice for heavy-duty applications requiring high strength.

Überlegungen für internationale Käufer: Buyers in regions like Africa and South America should ensure that aluminum components comply with international standards such as ASTM or ISO to guarantee quality and performance.

Welche Rolle spielt Kupfer für den Wirkungsgrad von Wechselstromgeneratoren?

Copper is often used in the windings and electrical connections of alternators due to its exceptional electrical conductivity, which is essential for efficient power generation. It can handle high temperatures and has a melting point of around 1,085°C.

Illustrative image related to best alternators

Vorteile: The high conductivity of copper allows for efficient energy transfer, reducing energy losses and improving overall performance. It is also highly durable and resistant to corrosion, making it suitable for various climates.

Nachteile: The primary drawback of copper is its cost, which is significantly higher than aluminum. Additionally, copper components can be heavier, potentially affecting fuel efficiency in automotive applications.

Auswirkungen auf die Anwendung: Copper is ideal for high-performance alternators used in heavy-duty vehicles and high-end audio systems, where maximum efficiency and reliability are paramount.

Illustrative image related to best alternators

Überlegungen für internationale Käufer: Buyers should be aware of fluctuations in copper prices and ensure that suppliers adhere to relevant standards, such as JIS or DIN, for quality assurance.

How Does Steel Contribute to the Durability of Alternators?

Steel is commonly used for the structural components of alternators, including the frame and rotor. Its high tensile strength and resistance to deformation make it a reliable choice for demanding applications.

Vorteile: Steel’s durability ensures that alternators can withstand significant mechanical stress and impact, making it suitable for heavy-duty applications. It is also relatively cost-effective compared to other metals.

Illustrative image related to best alternators

Nachteile: Steel is heavier than aluminum and copper, which can negatively impact fuel efficiency in automotive applications. Additionally, it is prone to rust and corrosion if not properly treated.

Auswirkungen auf die Anwendung: Steel is best suited for industrial and heavy-duty vehicle applications where strength and durability are critical, but its weight may limit its use in lighter vehicles.

Überlegungen für internationale Käufer: Buyers should look for corrosion-resistant coatings and ensure compliance with local and international standards to mitigate rust issues.

What Advantages Does Plastic Offer in Alternator Components?

Plastic is increasingly used in non-structural components of alternators, such as covers and insulators. It is lightweight, cost-effective, and resistant to corrosion.

Illustrative image related to best alternators

Vorteile: The use of plastic can significantly reduce the overall weight of the alternator, enhancing fuel efficiency. It is also resistant to various chemicals and moisture, making it suitable for diverse environments.

Nachteile: Plastic is less durable than metals and can be prone to cracking under extreme temperatures or mechanical stress. Its long-term performance in high-heat applications may also be questionable.

Auswirkungen auf die Anwendung: Plastic components are ideal for light-duty applications or in environments where corrosion is a concern, but they may not be suitable for high-performance or heavy-duty applications.

Überlegungen für internationale Käufer: Buyers should verify the quality of plastic materials and ensure compliance with relevant standards to avoid issues related to durability and performance.

Summary Table of Materials for Best Alternators

| Material | Typical Use Case for best alternators | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Aluminium | Automotive and light-duty applications | Leichtes Gewicht und gute Wärmeleitfähigkeit | Less strength than other metals | Niedrig |

| Kupfer | High-performance and heavy-duty applications | Hervorragende elektrische Leitfähigkeit | Hohe Kosten und hohes Gewicht | Hoch |

| Stahl | Industrial and heavy-duty vehicles | Hohe Zugfestigkeit und Haltbarkeit | Schwerer und anfällig für Rost | Mittel |

| Kunststoff | Non-structural components in various applications | Leicht und korrosionsbeständig | Weniger haltbar als Metalle | Niedrig |

This analysis provides valuable insights for B2B buyers in selecting the right alternator materials based on their specific needs and regional considerations. Understanding the properties and implications of each material can enhance decision-making and ultimately lead to better product performance and customer satisfaction.

Illustrative image related to best alternators

In-depth Look: Manufacturing Processes and Quality Assurance for best alternators

What Are the Main Stages of Manufacturing High-Quality Alternators?

The manufacturing process of alternators involves several critical stages that ensure the final product meets performance and durability expectations. These stages include material preparation, forming, assembly, and finishing.

Materialvorbereitung: Welche Materialien werden bei der Herstellung von Wechselstromgeneratoren verwendet?

The first step in manufacturing high-quality alternators involves sourcing the right materials. Key components include copper for windings, steel for the rotor and stator, and high-grade plastic or aluminum for housings. Manufacturers often prioritize materials that offer excellent conductivity, thermal resistance, and durability to withstand operational stresses. Suppliers typically conduct a thorough assessment of material quality, ensuring compliance with industry standards before moving on to the next stage.

How Are Alternator Components Formed and Assembled?

Once materials are prepared, the next step is forming. This involves processes such as die-casting for aluminum housings and stamping for metal components. Advanced techniques like CNC machining may be employed for precision parts. After forming, the components undergo assembly, which is often carried out using automated systems to ensure consistency and efficiency. Key elements, such as the rotor, stator, and voltage regulator, are meticulously assembled to create a complete alternator unit.

What Quality Control Measures Are Implemented During Alternator Manufacturing?

Quality control (QC) is a crucial aspect of the alternator manufacturing process, ensuring that each unit meets established performance standards.

Welche internationalen Normen sind für die Qualitätssicherung von Generatoren relevant?

Manufacturers often adhere to international quality standards such as ISO 9001, which emphasizes a quality management system that includes continuous improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) indicate compliance with European safety and environmental regulations. For specific applications, such as in the oil and gas industry, adherence to API (American Petroleum Institute) standards may also be required.

Was sind die wichtigsten Punkte der Qualitätskontrolle im Herstellungsprozess?

Quality control checkpoints are strategically integrated throughout the manufacturing process. The primary checkpoints include:

- Eingangsqualitätskontrolle (IQC): Dazu gehört, dass Rohstoffe und Komponenten bei ihrer Ankunft geprüft werden, um sicherzustellen, dass sie den vorgegebenen Normen entsprechen.

- In-Process-Qualitätskontrolle (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards early, allowing for immediate corrective actions.

- Endkontrolle (FQC): Each finished alternator undergoes rigorous testing to ensure it meets performance specifications. This may include electrical tests, thermal assessments, and noise level checks.

What Testing Methods Are Commonly Used to Ensure Alternator Reliability?

A variety of testing methods are employed to assess the performance and durability of alternators:

- Elektrische Prüfung: Ensures that the alternator produces the required voltage and current under specified loads.

- Thermische Prüfung: Evaluates the alternator’s ability to dissipate heat and operate efficiently under high-temperature conditions.

- Vibrationsprüfung: Assesses how well the alternator can withstand vibrations, which is crucial for automotive applications.

- Haltbarkeitsprüfung: Simulates long-term use to determine the lifespan and reliability of the alternator in real-world conditions.

Wie können B2B-Käufer die Qualitätskontrollprozesse ihrer Lieferanten überprüfen?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several approaches:

Worauf sollten Einkäufer bei Lieferantenaudits und -berichten achten?

Buyers should request detailed quality assurance reports and audit results from potential suppliers. These documents should outline the QC measures in place, including compliance with relevant international standards. A transparent supplier will provide insight into their manufacturing processes and any certifications they hold.

Illustrative image related to best alternators

Wie können Inspektionen durch Dritte die Qualitätssicherung verbessern?

Engaging third-party inspection services can further assure buyers of product quality. These independent entities conduct thorough assessments and testing of products before they are shipped, ensuring compliance with the agreed specifications. This additional layer of quality control can mitigate risks associated with overseas sourcing.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

Navigating quality control can be particularly complex for international buyers. Each region may have different standards and regulations, so it is crucial for buyers to understand these nuances:

- Regionale Compliance-Anforderungen: Buyers should familiarize themselves with the specific regulatory requirements in their regions, such as those mandated by the European Union or local governments in African and South American countries.

- Cultural Considerations in Quality Standards: Cultural differences may affect perceptions of quality and reliability. Establishing clear communication with suppliers can help bridge any gaps and ensure mutual understanding of quality expectations.

How Do Global Supply Chains Affect Alternator Quality Assurance?

In a globalized market, the supply chain can significantly impact the quality of alternators. Variations in manufacturing practices, material sourcing, and compliance with local regulations can lead to inconsistencies. B2B buyers should consider the entire supply chain when evaluating potential suppliers, looking for those who maintain rigorous quality standards throughout their operations.

Conclusion: Why Is Quality Assurance Critical for Alternators?

For B2B buyers, understanding the intricacies of alternator manufacturing and quality assurance is vital for making informed purchasing decisions. By focusing on manufacturers that adhere to international standards and implement robust QC measures, buyers can ensure they are sourcing reliable and high-performance alternators that meet their operational needs. Quality assurance is not just a checkbox; it is a critical component that affects the longevity, efficiency, and overall performance of alternators in various applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best alternators’

Einführung

When it comes to sourcing the best alternators for your business, a structured approach can significantly enhance your procurement process. This checklist serves as a practical guide for B2B buyers, ensuring that you consider all essential factors and make informed decisions tailored to your specific needs. By following these steps, you will improve your chances of obtaining high-quality alternators that meet your operational requirements.

Illustrative image related to best alternators

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Establishing clear technical specifications is the foundation of a successful procurement process. Identify the type of alternators you need based on your vehicle’s make, model, and electrical demands. Consider factors such as amperage output, compatibility with existing systems, and whether a new or remanufactured unit is required.

- Amperage Requirements: Ensure the alternator can handle the total electrical load of your application.

- Compatibility Check: Verify that the dimensions and mounting points align with your vehicle or machinery.

Schritt 2: Research Reputable Brands and Manufacturers

Not all alternators are created equal. Research leading brands and manufacturers that are recognized for their reliability and performance. Look for companies with a strong track record and positive reviews from customers in similar industries.

- Ruf der Marke: Investigate customer feedback and industry awards.

- Garantie und Support: Check the warranty terms and after-sales support offered by the brand.

Schritt 3: Lieferantenzertifizierungen bewerten

Before finalizing your supplier, ensure they possess the necessary certifications that attest to their product quality and safety standards. Certifications such as ISO 9001 can indicate a commitment to quality management systems, while others may focus on environmental standards.

- Qualitätssicherung: Verify that the supplier adheres to international quality standards.

- Einhaltung gesetzlicher Vorschriften: Ensure the alternators meet local regulations in your target markets.

Schritt 4: Muster anfordern und Tests durchführen

Before committing to a large order, request samples of the alternators you are considering. Testing these samples in real-world conditions will provide insights into their performance and reliability.

- Leistungsbewertung: Assess how well the alternator performs under load.

- Haltbarkeitsprüfung: Look for signs of wear and tear during initial usage.

Schritt 5: Preise und Konditionen aushandeln

Once you’ve identified a suitable supplier, engage in negotiations to secure the best possible pricing and payment terms. Be transparent about your requirements and volume expectations, as this can influence the supplier’s willingness to offer discounts.

Illustrative image related to best alternators

- Mengenrabatte: Inquire about pricing tiers based on order quantity.

- Flexible Zahlungsmöglichkeiten: Discuss payment terms that align with your cash flow needs.

Schritt 6: Establish Logistics and Delivery Schedules

Efficient logistics are crucial for timely procurement. Collaborate with your supplier to establish delivery schedules that align with your operational timelines. Ensure that you understand the shipping methods and costs involved.

- Shipping Methods: Determine whether air or sea freight is more suitable for your needs.

- Vorlaufzeiten: Clarify production and delivery lead times to avoid disruptions.

Schritt 7: Monitor Supplier Performance Post-Purchase

After your purchase, it’s essential to monitor the supplier’s performance to ensure they meet your expectations. Regular feedback can help maintain a good relationship and facilitate future orders.

- Qualitätskontrollen: Implement a system for quality control on received alternators.

- Supplier Relationship Management: Maintain open lines of communication for ongoing support and potential future collaborations.

By following this structured approach, you can streamline your sourcing process for alternators, ensuring that you select the best products for your business needs.

Comprehensive Cost and Pricing Analysis for best alternators Sourcing

What Are the Key Cost Components for Sourcing Best Alternators?

When sourcing alternators, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Illustrative image related to best alternators

-

Materialien: The quality of materials used significantly influences the cost. Copper, aluminum, and specialized components such as rectifiers and voltage regulators are essential for high-performance alternators. Higher-grade materials can lead to increased durability and efficiency but also raise the overall cost.

-

Arbeit: Labor costs vary by region and manufacturing processes. Skilled labor is necessary for assembling alternators, particularly for high-output and custom designs. Countries with lower labor costs may offer competitive pricing, but this can come at the expense of quality.

-

Fertigungsgemeinkosten: This encompasses costs related to facilities, equipment, and utilities. Efficient manufacturing processes can help minimize overhead costs, enabling suppliers to offer more competitive pricing.

-

Werkzeuge: The initial investment in tooling for specialized alternator designs can be substantial. Custom designs or high-output alternators may require unique tooling, impacting the final price.

-

Qualitätskontrolle (QC): Rigorous QC processes are vital to ensure reliability and performance. Enhanced QC measures may increase costs but ultimately lead to fewer returns and better customer satisfaction.

-

Logistik: Shipping and handling costs can vary widely based on the origin and destination. For international buyers, understanding logistics costs, including tariffs and import duties, is essential for accurate budgeting.

-

Marge: Supplier profit margins can vary significantly based on brand reputation, product quality, and market demand. Established brands may command higher margins due to perceived reliability.

How Do Price Influencers Impact Alternator Sourcing?

Several factors can influence the pricing of alternators, especially for B2B buyers in diverse markets:

-

Volumen/MOQ (Mindestbestellmenge): Bulk purchases often result in lower per-unit costs. Suppliers typically offer discounts for larger orders, making it cost-effective for businesses with high demand.

-

Spezifikationen und Anpassung: Custom alternators designed for specific applications or higher performance can come with increased costs. Buyers should assess whether standard products meet their needs or if customization is necessary.

-

Materialqualität und Zertifizierungen: Alternators that comply with international quality standards or certifications (such as ISO) may be priced higher but offer better performance and reliability, which can reduce long-term operational costs.

-

Lieferantenfaktoren: Supplier reputation, reliability, and after-sales support can significantly affect pricing. Established suppliers may charge a premium for their products, justified by their track record of quality and service.

-

Incoterms: Understanding the agreed terms of sale (Incoterms) is crucial. These terms dictate responsibilities for shipping, insurance, and tariffs, affecting the overall cost structure for international buyers.

What Buyer Tips Can Help Navigate Alternator Sourcing Costs?

-

Verhandlung: Always negotiate pricing with suppliers. Building a relationship can lead to better terms, especially for repeat purchases. Leverage volume commitments to secure discounts.

-

Fokus auf Gesamtbetriebskosten (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, warranty claims, and potential downtime due to failures. Investing in higher-quality alternators can reduce TCO.

-

Verstehen Sie die Nuancen der Preisgestaltung für die internationale Beschaffung: International buyers must factor in currency fluctuations, shipping costs, and local regulations that may affect pricing. Researching local suppliers in Africa, South America, and the Middle East can sometimes yield better prices and shorter lead times.

-

Muster anfordern: When possible, request samples before committing to large orders. This practice allows buyers to assess quality and compatibility, ensuring they meet the necessary specifications.

Haftungsausschluss für indikative Preise

While this analysis provides insights into the cost structure and pricing influencers for alternators, it is important to note that actual prices can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier evaluations to obtain accurate pricing information tailored to your specific needs.

Alternatives Analysis: Comparing best alternators With Other Solutions

Understanding Alternatives in Power Generation Solutions

When considering power generation solutions for vehicles, it’s essential to evaluate various options available in the market. While alternators are the primary choice for converting mechanical energy into electrical power, alternative methods also exist that cater to specific needs and applications. This analysis compares the best alternators with other viable solutions, helping B2B buyers make informed decisions.

| Vergleichsaspekt | Best Alternators | High-Output Generators | Solarstromanlagen |

|---|---|---|---|

| Leistung | Provides steady electrical output (13-14.8V) | High power capacity, ideal for heavy loads | Sustainable energy, dependent on sunlight availability |

| Kosten | Moderate initial investment, varies by brand | Higher upfront costs due to complexity | Variable costs: installation and maintenance can be high |

| Einfache Implementierung | Simple installation with standard vehicle components | Requires professional setup and integration | Needs extensive installation, including panels and inverters |

| Wartung | Low maintenance, generally reliable | Requires regular servicing and checks | Minimal maintenance but dependent on weather conditions |

| Bester Anwendungsfall | Standard vehicles and light-duty applications | Heavy-duty vehicles, construction, and events | Eco-friendly applications, off-grid solutions |

Exploring High-Output Generators as an Alternative

High-output generators serve as a robust alternative to traditional alternators, particularly for applications requiring substantial power. They are capable of producing higher voltage outputs, which is beneficial for heavy-duty vehicles or equipment that demand more electricity. However, these generators come with a higher upfront cost and require professional installation, which can complicate their implementation. Additionally, they necessitate regular maintenance to ensure optimal performance, making them less ideal for casual users or standard vehicles.

Evaluating Solar Power Systems for Sustainable Energy Solutions

Solar power systems represent an innovative alternative, especially in regions with abundant sunlight. These systems harness solar energy to generate electricity, providing a sustainable and environmentally friendly power source. While they can significantly reduce long-term energy costs, the initial investment for installation can be substantial. Moreover, solar systems require space for solar panels and may necessitate complex installation processes involving inverters and batteries. Their performance is also dependent on weather conditions, which can limit their effectiveness in less sunny regions or during winter months.

Die richtige Wahl für Ihre Geschäftsbedürfnisse

Selecting the right power generation solution hinges on understanding the specific requirements of your application and operational context. For standard vehicles and everyday use, investing in high-quality alternators is often the most practical choice due to their reliability and ease of installation. Conversely, for heavy-duty needs or unique power demands, high-output generators may be more suitable, albeit with higher costs and maintenance responsibilities. Lastly, if sustainability is a priority and conditions permit, solar power systems can provide a long-term solution that aligns with eco-friendly goals. By evaluating these alternatives against your operational needs, B2B buyers can make informed decisions that enhance efficiency and reduce costs.

Essential Technical Properties and Trade Terminology for best alternators

What Key Technical Properties Should B2B Buyers Consider for Alternators?

When purchasing alternators, understanding specific technical properties is crucial for ensuring compatibility and performance. Here are some essential specifications that B2B buyers should focus on:

-

Electrical Output (Amperage Rating)

– Definition: The amperage rating indicates the maximum amount of electrical current the alternator can produce, typically measured in amps.

– Bedeutung: Selecting an alternator with the appropriate amperage is vital to meet the electrical demands of the vehicle’s systems. Insufficient output can lead to battery drain and electrical failures, impacting overall vehicle reliability. -

Spannungsregelung

– Definition: This refers to the alternator’s ability to maintain a stable output voltage, generally between 13.5 to 14.8 volts for most vehicles.

– Bedeutung: Proper voltage regulation prevents overcharging or undercharging the battery, which can extend battery life and improve the performance of electrical components. A reliable voltage regulator is essential for maintaining optimal electrical system health. -

Methode der Kühlung

– Definition: Alternators can have different cooling mechanisms, including air cooling or water cooling, which help dissipate heat generated during operation.

– Bedeutung: Effective cooling is crucial for high-output alternators that generate more heat. Understanding the cooling method can help in selecting an alternator that matches the operating conditions of the vehicle, especially in regions with extreme temperatures. -

Size and Fitment

– Definition: The physical dimensions of the alternator, including mounting points and overall size, which must be compatible with the vehicle’s engine compartment.

– Bedeutung: Ensuring the alternator fits correctly is essential for installation and operation. Mismatched sizes can lead to installation challenges and potential damage to the vehicle’s electrical system. -

Werkstoffgüte

– Definition: The quality of materials used in the construction of the alternator, including housing, bearings, and internal components.

– Bedeutung: Higher-grade materials enhance durability and resistance to wear, which is particularly important for alternators operating in demanding environments. Investing in quality materials can reduce the frequency of replacements and maintenance costs. -

Lebenszyklus und Garantie

– Definition: The expected operational lifespan of the alternator and any warranty coverage provided by the manufacturer.

– Bedeutung: A longer lifecycle and robust warranty indicate reliability and can significantly impact total cost of ownership. Understanding warranty terms helps buyers evaluate the risk associated with their investment.

What Are Common Trade Terms in the Alternator Industry?

Familiarity with industry terminology can streamline the purchasing process and enhance communication between buyers and suppliers. Here are several key terms:

Illustrative image related to best alternators

-

OEM (Originalgerätehersteller)

– Definition: Refers to parts made by the original manufacturer of the vehicle, meeting the same specifications as the parts originally installed.

– Bedeutung: OEM alternators are often preferred for their guaranteed compatibility and performance, making them a reliable choice for vehicle repairs. -

MOQ (Mindestbestellmenge)

– Definition: The smallest number of units a supplier is willing to sell in a single order.

– Bedeutung: Understanding the MOQ helps businesses gauge the feasibility of purchasing in bulk, affecting inventory management and cash flow. -

RFQ (Angebotsanfrage)

– Definition: A formal document sent to suppliers requesting pricing and terms for specific products.

– Bedeutung: An RFQ allows buyers to compare offers from different suppliers, ensuring competitive pricing and favorable terms. -

Incoterms (Internationale Handelsklauseln)

– Definition: A set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping goods.

– Bedeutung: Knowing the applicable Incoterms can clarify shipping responsibilities, costs, and risks, which is vital for international transactions. -

Ersatzteilmarkt

– Definition: Refers to parts and accessories made for vehicles that are not produced by the OEM.

– Bedeutung: Aftermarket alternators can often provide cost-effective alternatives to OEM parts, though buyers should ensure quality and compatibility. -

Re-manufactured Alternators

– Definition: Alternators that have been restored to working condition, often involving the replacement of worn-out parts and rigorous testing.

– Bedeutung: These can offer a more economical option without sacrificing performance, making them an attractive choice for cost-sensitive buyers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they meet their operational needs while optimizing costs.

Navigating Market Dynamics and Sourcing Trends in the best alternators Sector

What Are the Current Market Dynamics and Key Trends in the Best Alternators Sector?

The global alternators market is experiencing significant growth, driven by the increasing demand for reliable automotive electrical systems. Factors such as the rising number of vehicles on the roads, especially in developing regions like Africa and South America, and the surge in electric vehicle (EV) production are pivotal. Countries like Brazil and Saudi Arabia are witnessing a boom in automotive manufacturing, which directly influences the need for high-performance alternators.

Emerging technologies in the automotive sector are shaping sourcing trends for B2B buyers. The integration of advanced features, such as smart alternators equipped with diagnostic capabilities, is becoming increasingly common. These innovations not only enhance performance but also offer buyers the ability to monitor system health in real-time, making it easier to manage maintenance schedules. Additionally, the trend towards high-output alternators is gaining momentum, particularly in vehicles with advanced electrical systems that require more power.

For international buyers, understanding the dynamics of local markets is essential. In Africa, for example, the demand for affordable and durable alternators is high due to the challenging road conditions and limited access to maintenance services. In contrast, European markets are leaning towards premium brands that offer advanced technologies and reliability. This divergence in preferences necessitates a tailored approach to sourcing, ensuring that suppliers align with regional demands.

How Does Sustainability and Ethical Sourcing Impact the Best Alternators Sector?

Sustainability is becoming a crucial consideration in the alternators market, particularly as environmental regulations tighten globally. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. The production of alternators can have environmental implications, particularly concerning the sourcing of raw materials and the energy consumed during manufacturing.

Ethical supply chains are gaining traction, with buyers seeking manufacturers that adhere to responsible sourcing practices. This includes the use of recycled materials and adherence to labor standards that promote fair working conditions. Certifications such as ISO 14001 for environmental management and the Responsible Business Alliance (RBA) certification are becoming essential benchmarks for B2B buyers in evaluating potential suppliers.

Illustrative image related to best alternators

Moreover, the growing emphasis on electric vehicles is pushing manufacturers to innovate with “green” materials that minimize environmental impact. High-performance alternators designed for electric and hybrid vehicles often utilize lightweight materials and energy-efficient manufacturing processes. Buyers who prioritize these products not only contribute to sustainability efforts but also position themselves favorably within a market that increasingly values eco-friendly practices.

What is the Evolution of the Best Alternators Market?

The alternators market has evolved significantly since its inception in the early 20th century. Initially designed to replace inefficient generators, alternators quickly became integral to automotive electrical systems, providing a reliable power source for vehicles. The introduction of high-output alternators in the late 20th century marked a pivotal shift, allowing vehicles with advanced electrical systems to function efficiently.

In recent years, the focus has shifted towards enhancing the performance and durability of alternators. Technological advancements have led to the development of smart alternators that can communicate with vehicle systems, enabling real-time monitoring and diagnostics. This evolution not only improves vehicle performance but also enhances the overall user experience, making it a critical factor for B2B buyers when selecting alternators for their fleets or automotive production lines. As the market continues to grow, understanding these historical trends will be essential for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of best alternators

-

How do I identify the right alternator for my vehicle?

To identify the right alternator for your vehicle, start by checking the vehicle’s make, model, and year. Consult the owner’s manual for specifications regarding amperage and dimensions. Assess the electrical load requirements based on the vehicle’s accessories and usage. If your vehicle has been modified or requires a higher output, consider high-performance alternators. Always ensure compatibility with your vehicle’s existing electrical system to prevent potential damage or inefficiency. -

What is the best alternator brand for heavy-duty applications?

For heavy-duty applications, brands like Denso, Remy, and Wilson Alternators are highly regarded. These manufacturers offer high-output alternators designed to withstand demanding conditions and provide reliability. Denso is known for its advanced engineering, while Remy excels in remanufactured options that meet OE standards. It’s crucial to evaluate the specific performance requirements of your application and select a brand that aligns with those needs. -

Welche Faktoren sollte ich bei der internationalen Beschaffung von Lichtmaschinen berücksichtigen?

When sourcing alternators internationally, consider factors such as supplier reliability, product quality, and compliance with international standards. Evaluate the supplier’s experience in exporting to your region, particularly in Africa, South America, the Middle East, and Europe. Assess their ability to meet your customization needs and minimum order quantities (MOQs). Additionally, research their logistics capabilities to ensure timely delivery and consider the impact of tariffs or trade agreements on overall costs. -

Wie kann ich die Lieferanten von Lichtmaschinen überprüfen?

To vet suppliers for alternators, start by reviewing their certifications, such as ISO standards or industry-specific accreditations. Check customer reviews and testimonials to gauge their reputation in the market. Request samples to assess product quality firsthand. Additionally, consider visiting their manufacturing facilities or participating in trade shows to engage directly with the suppliers. Establish clear communication regarding your requirements and ensure they can meet your quality assurance standards. -

What are the typical payment terms for purchasing alternators from international suppliers?

Payment terms can vary widely depending on the supplier and the relationship established. Common arrangements include advance payments, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that offer you protection and flexibility, such as a partial advance with the balance due upon receipt of goods. Ensure clarity on currency exchange rates and transaction fees, especially when dealing with international transactions, to avoid unexpected costs. -

Was ist die Mindestbestellmenge (MOQ) für Lichtmaschinen?

The minimum order quantity (MOQ) for alternators typically depends on the supplier and the specific product line. Some suppliers may have an MOQ as low as 10 units, while others may require orders of 50 or more to accommodate manufacturing efficiencies. Always clarify the MOQ upfront and consider whether it aligns with your purchasing strategy. If you are new to a supplier, negotiating a lower MOQ for initial orders may help establish a business relationship. -

How do I ensure quality assurance for the alternators I purchase?

To ensure quality assurance for your alternators, request detailed specifications and certifications from your supplier. Implement a quality control process that includes inspecting samples before bulk orders. Consider third-party inspections or audits to validate compliance with international standards. Establish a clear return policy for defective products and maintain open communication with your supplier to address any quality concerns promptly. -

What are the logistics considerations when importing alternators?

When importing alternators, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with your region’s import/export regulations. Assess the total shipping costs, including duties and taxes, to avoid surprises. Ensure that the supplier provides the necessary documentation for customs clearance, such as invoices and certificates of origin. Planning ahead for potential delays in transit can also help ensure timely availability of your products.

Top 3 Best Alternators Manufacturers & Suppliers List

1. Denso – Quality Automotive Parts

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: This company, Denso – Quality Automotive Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Mechman – High Output Alternators

Domäne: mechman.com

Registriert: 1996 (29 Jahre)

Einleitung: Mechman Alternators are U.S.A made high output alternators with options for 1-year, 2-year, and lifetime extended warranties. They offer a range of products including 24 Volt and 48 Volt alternators, engine stands, bracket kits, pulleys, plugs and harnesses, and voltage control. The alternators have outputs ranging from 150a to 370a and are designed for various applications. Notable products inclu…

3. AC Delco – Cadillac Alternators

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Cadillac Dhs-Dts-Deville, Lichtmaschinenmarken: AC Delco, Duralast

Strategic Sourcing Conclusion and Outlook for best alternators

In summary, strategic sourcing of alternators is crucial for B2B buyers seeking reliable and high-performance solutions. Key considerations include understanding the specific electrical load requirements of your vehicles, selecting between new and remanufactured options, and ensuring compatibility with existing systems. High-output alternators are particularly advantageous for modern vehicles equipped with advanced electrical systems, making them a worthwhile investment for industries reliant on heavy machinery and performance vehicles.

Illustrative image related to best alternators

As the global market for automotive parts continues to evolve, businesses in Africa, South America, the Middle East, and Europe must prioritize quality sourcing to maintain operational efficiency. By forging strong partnerships with reputable manufacturers and suppliers, buyers can secure superior alternators that enhance vehicle performance and longevity.

Looking ahead, it is essential to stay informed about emerging technologies and innovations in alternator design, as these advancements can significantly impact operational capabilities. Now is the time to evaluate your sourcing strategies and make informed decisions that align with your business goals. Engage with trusted suppliers, explore new markets, and ensure your fleet is powered by the best alternators available.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.

Illustrative image related to best alternators