Einleitung: Navigieren auf dem globalen Markt für Auto-Starter-Reparaturkosten

In der heutigen wettbewerbsintensiven Automobilbranche ist es für internationale B2B-Einkäufer unerlässlich, die Feinheiten der Kosten für die Reparatur von Autoanlassern zu verstehen. Ganz gleich, ob Sie Teile für eine Fahrzeugflotte in Nigeria beschaffen oder Zulieferer in Brasilien evaluieren, die Herausforderung, die Reparaturkosten genau abzuschätzen, kann sich erheblich auf Ihr Endergebnis auswirken. Dieser Leitfaden bietet eine umfassende Untersuchung der Kosten für die Reparatur von Autoanlassern und geht dabei auf die verschiedenen Arten von Anlassern, gängige Anwendungen und die entscheidenden Faktoren ein, die die Preisgestaltung in den verschiedenen Regionen beeinflussen.

Auf Ihrem Weg durch diesen komplexen Markt werden Sie wertvolle Erkenntnisse über die Prüfung von Lieferanten gewinnen und erfahren, wie Sie Qualität, Zuverlässigkeit und preisliche Wettbewerbsfähigkeit beurteilen können. Wir werden auch detaillierte Aufschlüsselungen von Reparatur- und Ersatzkosten liefern, die Ihnen helfen, fundierte Entscheidungen zu treffen, die Ihren betrieblichen Anforderungen und Budgetvorgaben entsprechen. Dieser Leitfaden konzentriert sich auf die besonderen Anforderungen von Einkäufern aus Afrika, Südamerika, dem Nahen Osten und Europa und hilft Ihnen, Ihre Einkaufsstrategie zu optimieren, damit Sie den besten Wert für Ihre Investition erhalten.

Mithilfe der in diesem Leitfaden enthaltenen Informationen können Sie die Herausforderungen bei der Beschaffung von Autoanlasserkomponenten selbstbewusst angehen und letztendlich die Effizienz Ihrer Abläufe verbessern und die Rentabilität Ihres Unternehmens steigern.

Inhaltsverzeichnis

- Top 3 Auto Anlasser Reparatur Kosten Hersteller & Lieferanten Liste

- Einleitung: Navigieren auf dem globalen Markt für Auto-Starter-Reparaturkosten

- Verständnis Auto Anlasser Reparatur Kosten Arten und Variationen

- Wichtigste industrielle Anwendungen von Autoanlasser-Reparaturkosten

- 3 Gemeinsame Benutzer Pain Points für ‘auto starter repair cost’ & ihre Lösungen

- Strategischer Leitfaden zur Materialauswahl für die Reparatur von Autoanlassern

- Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für die Reparatur von Autoanlassern

- Praktische Anleitung zur Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘auto starter reparaturkosten’.’

- Umfassende Kosten- und Preisanalyse für die Reparatur von Autoanlassern Kostenbeschaffung

- Analyse der Alternativen: Vergleich der Kosten für die Reparatur des Autoanlassers mit anderen Lösungen

- Wesentliche technische Eigenschaften und Fachterminologie für die Reparatur von Autoanlassern

- Marktdynamik und Beschaffungstrends im Bereich der Kosten für die Reparatur von Autoanlassern

- Häufig gestellte Fragen (FAQs) für B2B-Käufer von Autoanlasser-Reparaturkosten

- Strategische Beschaffung Schlussfolgerung und Ausblick für die Reparaturkosten von Autoanlassern

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Verständnis Auto Anlasser Reparatur Kosten Arten und Variationen

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Neuer Anlasser Ersatz | Brandneue Teile, höhere Zuverlässigkeit | Kfz-Werkstätten, Flottenservices | Vorteile: Hohe Zuverlässigkeit, Garantieabdeckung. Nachteile: Höhere Anfangskosten. |

| Überholter Anlasser | Überholte Komponenten, kostengünstiger | Kleine Werkstätten, unabhängige Mechaniker | Vorteile: Geringere Kosten, umweltfreundlich. Nachteile: Mögliche Schwankungen in der Qualität. |

| Reparatur des Anlassers | Reparatur von spezifischen Komponenten, arbeitsintensiv | Fachgeschäfte, Heimwerker | Vorteile: Kostengünstig bei kleineren Problemen. Nachteile: Zeitaufwendig, geht möglicherweise nicht auf die zugrunde liegenden Probleme ein. |

| OEM vs. Aftermarket-Teile | Erstausrüster vs. Drittanbieter | Autohäuser, unabhängige Werkstätten | Vorteile: OEM garantiert Passform und Qualität. Nachteile: Der Ersatzteilmarkt bietet zwar niedrigere Preise, aber unterschiedliche Qualität. |

| Diagnostische Dienstleistungen | Umfassende Tests zur Ermittlung von Startproblemen | Fuhrparkmanagement, Kfz-Diagnose | Vorteile: Verhindert unnötige Reparaturen und spart Geld. Nachteile: Zusätzliche Vorabkosten für die Diagnose. |

Was sind die wichtigsten Merkmale neuer Anlasser-Ersatzteile?

Beim Austausch eines neuen Anlassers werden fabrikneue Komponenten eingebaut, die höchste Zuverlässigkeit und Leistung gewährleisten. Diese Option eignet sich besonders für Kfz-Werkstätten und Flottendienste, die Wert auf Langlebigkeit und minimale Ausfallzeiten legen. Beim Kauf sollten B2B-Käufer Faktoren wie Garantieleistungen und den Ruf des Lieferanten berücksichtigen, da diese den Gesamtwert der Investition erheblich beeinflussen können.

Wie sind überholte Anlasser im Vergleich zu neuen Anlassern?

Bei überholten Startern handelt es sich um überholte Komponenten, die wieder funktionsfähig gemacht wurden und in der Regel weniger kosten als neue Starter. Sie sind ideal für kleine Werkstätten und unabhängige Mechaniker, die ihren Kunden kostengünstige Lösungen anbieten möchten. Käufer sollten die Kosteneinsparungen gegen die potenziellen Qualitätsschwankungen abwägen; die Beschaffung bei seriösen Lieferanten kann die mit minderwertigen Teilen verbundenen Risiken mindern.

Wann ist eine Anlasserreparatur eine sinnvolle Option?

Bei der Anlasserreparatur werden bestimmte Komponenten repariert, anstatt das gesamte Gerät auszutauschen, was sie zu einer kostengünstigen Lösung für kleinere Probleme macht. Diese Option eignet sich am besten für Fachgeschäfte und Heimwerker, die über die erforderlichen Fähigkeiten und Werkzeuge verfügen. Sie kann jedoch zeitaufwändig sein und behebt möglicherweise nicht die zugrunde liegenden Probleme. Daher sollten B2B-Käufer den Gesamtzustand des Anlassers beurteilen, bevor sie sich für eine Reparatur entscheiden.

Was sollten Käufer über OEM- und Aftermarket-Teile wissen?

Für B2B-Einkäufer ist die Wahl zwischen OEM- (Original Equipment Manufacturer) und Aftermarket-Teilen entscheidend. Erstausrüsterteile garantieren Passgenauigkeit und hohe Qualität und sind daher die bevorzugte Wahl für Händler und Werkstätten, die großen Wert auf Kundenzufriedenheit legen. Andererseits können Aftermarket-Teile erhebliche Kosteneinsparungen bieten, obwohl ihre Qualität und Kompatibilität variieren kann. Käufer sollten bei dieser Entscheidung die spezifischen Bedürfnisse ihrer Kundschaft berücksichtigen.

Wie können Diagnosedienste die Entscheidung für eine Anlasserreparatur verbessern?

Diagnosedienste bieten umfassende Tests zur Ermittlung der Ursachen von Startproblemen, so dass Unternehmen unnötige Reparaturen vermeiden können. Dieser Ansatz ist besonders für das Flottenmanagement und die Kfz-Diagnose von Vorteil, da er langfristig zu erheblichen Kosteneinsparungen führen kann. Käufer sollten sich jedoch auf die zusätzlichen Vorlaufkosten einstellen, die mit diesen Diensten verbunden sind, was letztlich zu einer fundierteren Kaufentscheidung führen kann.

Wichtigste industrielle Anwendungen von Autoanlasser-Reparaturkosten

| Branche/Sektor | Spezifische Anwendung der Kosten für die Reparatur von Autoanlassern | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Autoreparaturwerkstätten | Bewertung der Reparaturkosten für Anlasser in verschiedenen Fahrzeugen | Optimierte Servicepreise stärken das Vertrauen und die Bindung der Kunden | Zuverlässige Lieferanten für Ersatzteile, Transparenz der Arbeitskosten |

| Flottenmanagement | Budgetierung von Erstreparaturen für mehrere Fahrzeuge | Verbesserte Zuverlässigkeit der Flotte und geringere Ausfallzeiten | Großeinkaufsvereinbarungen, Qualitätssicherung für Teile |

| Transport & Logistik | Bewertung der Anfangsreparaturkosten für Lieferfahrzeuge | Gewährleistet rechtzeitige Lieferungen und betriebliche Effizienz | Schneller Zugang zu Ersatzteilen, Verständnis für regionale Preise |

| Baumaschinen | Verwaltung der Kosten für die Anfangsreparatur von Schwermaschinen | Minimiert Projektverzögerungen und Betriebsunterbrechungen | Verfügbarkeit von Spezialteilen, lokale Reparaturkompetenz |

| Landwirtschaftlicher Sektor | Schätzung der Kosten für die Erstinstandsetzung von landwirtschaftlichen Fahrzeugen | Steigert die Produktivität und verringert die Ausfallzeiten von Maschinen | Beschaffung langlebiger Teile, Verständnis für saisonale Anforderungen |

Wie profitieren Kfz-Werkstätten davon, die Kosten für die Anlasserreparatur zu verstehen?

Kfz-Werkstätten nutzen den Einblick in die Kosten für Anlasserreparaturen, um ihr Serviceangebot zu optimieren. Indem sie die mit Anlasserreparaturen verbundenen Kosten genau einschätzen, können diese Betriebe wettbewerbsfähige Preise festlegen, die das Vertrauen und die Loyalität der Kunden fördern. Dies ist besonders wichtig in Regionen, in denen die Preissensibilität hoch ist, wie z. B. in Teilen Afrikas und Südamerikas. Werkstätten müssen sicherstellen, dass sie zuverlässige Lieferanten für Anlasserteile haben und die Arbeitskosten transparent machen, um enge Kundenbeziehungen aufzubauen.

Welchen Wert hat das Fuhrparkmanagement durch Einblicke in die Starter-Reparaturkosten?

Flottenmanagementunternehmen profitieren erheblich davon, wenn sie die Kosten für die Reparatur von Autoanlassern kennen, da sie dadurch in der Lage sind, ein effizientes Budget für die Wartung mehrerer Fahrzeuge aufzustellen. Dieser proaktive Ansatz trägt dazu bei, die Zuverlässigkeit des Fuhrparks zu erhöhen und Ausfallzeiten zu minimieren, was für die betriebliche Effizienz entscheidend ist. Für internationale Einkäufer, insbesondere im Nahen Osten und in Europa, kann der Abschluss von Großeinkaufsvereinbarungen mit Ersatzteillieferanten zu erheblichen Kosteneinsparungen führen und gleichzeitig die Qualitätssicherung für alle bei der Reparatur verwendeten Teile gewährleisten.

Wie können Transport- und Logistikunternehmen ihre Betriebsabläufe mit dem Wissen über Starter-Reparaturkosten optimieren?

In der Transport- und Logistikbranche ist die Bewertung der Anfangsreparaturkosten für Lieferfahrzeuge von entscheidender Bedeutung für die Aufrechterhaltung des Betriebsablaufs. Ein gut gewarteter Fuhrpark gewährleistet pünktliche Lieferungen, was sich direkt auf die Kundenzufriedenheit und den Ruf des Unternehmens auswirkt. Unternehmen müssen sich darauf konzentrieren, Ersatzteile schnell zu beschaffen und regionale Preisunterschiede zu verstehen, um die Reparaturkosten effektiv zu verwalten. Dies ist besonders wichtig in Regionen, in denen der Zugang zu Autoteilen erschwert ist, wie in Teilen Afrikas und Südamerikas.

Warum ist das Verständnis der Kosten für Starterreparaturen für das Baumaschinenmanagement von entscheidender Bedeutung?

In der Bauindustrie ist das Management der Kosten für die Reparatur von Startern für schwere Maschinen entscheidend, um Projektverzögerungen zu vermeiden. Ein defekter Anlasser kann den Betrieb aufhalten, was zu höheren Kosten und möglichen Projektüberschreitungen führt. Unternehmen in diesem Sektor sollten der Beschaffung von Spezialteilen Vorrang einräumen und sich um lokales Reparatur-Know-how bemühen, um minimale Ausfallzeiten zu gewährleisten. Die Kenntnis der Reparaturlandschaft hilft Bauunternehmen, ihre Budgets effektiver zu planen, insbesondere in abgelegenen Gebieten, wo die Verfügbarkeit von Geräten eine Herausforderung darstellen kann.

Welche Auswirkungen haben die Kosten für Starterreparaturen im Agrarsektor?

In der Landwirtschaft ist die Abschätzung der Reparaturkosten für Anlasser von landwirtschaftlichen Fahrzeugen von entscheidender Bedeutung für die Aufrechterhaltung der Produktivität während der Hochsaison. Ein Ausfall des Anlassersystems kann zu erheblichen Verzögerungen im Betrieb führen, was sich auf die Ernten und die Gesamtproduktion auswirkt. Landwirtschaftsbetriebe müssen sich auf die Beschaffung langlebiger Teile konzentrieren, die rauen Bedingungen standhalten, und die saisonalen Anforderungen kennen, um die Risiken zu minimieren. Dieses Wissen hilft Landwirten und landwirtschaftlichen Betreibern, ihre Budgets für die Instandhaltung von Maschinen effektiv zu optimieren, damit sie auf dem Markt wettbewerbsfähig bleiben.

3 Gemeinsame Benutzer Pain Points für ‘auto starter repair cost’ & ihre Lösungen

Szenario 1: Unvorhersehbare Reparaturkosten mit Auswirkungen auf die Budgetplanung

Das Problem: B2B-Einkäufer in der Kfz-Reparaturbranche stehen oft vor der Herausforderung unvorhersehbarer Reparaturkosten im Zusammenhang mit Anlasserproblemen. Wenn für ein Flottenfahrzeug eine Anlasserreparatur erforderlich ist, können die Kosten je nach Marke und Modell des Fahrzeugs, den Lohnkosten und der Art des Problems erheblich variieren. Diese Schwankungen können zu Schwierigkeiten bei der Budgetierung und Finanzprognose führen, insbesondere bei Unternehmen, die mehrere Fahrzeuge verwalten. Ein plötzlicher Anstieg der Reparaturkosten kann die Betriebsbudgets belasten und den Cashflow stören, so dass es für Unternehmen wichtig ist, eine zuverlässige Methode zur Schätzung dieser Ausgaben zu finden.

Die Lösung: Um die Unvorhersehbarkeit der Reparaturkosten für den Anlasser zu verringern, sollten B2B-Kunden in umfassende Diagnosewerkzeuge investieren, mit denen sich genau feststellen lässt, ob der Anlasser die Ursache des Problems ist oder ob andere Komponenten beteiligt sind. Durch die Einführung eines standardisierten Verfahrens zur Beurteilung von Fahrzeugproblemen können Unternehmen das Rätselraten bei Reparaturen reduzieren. Darüber hinaus kann der Aufbau von Beziehungen zu seriösen Lieferanten, die klare Preisstrukturen für Teile und Arbeit anbieten, zu einem besser vorhersehbaren Kostenmodell beitragen. Einkäufer sollten auch in Erwägung ziehen, ihre Mitarbeiter in der grundlegenden Anlasserdiagnose zu schulen, damit sie eine erste Einschätzung vornehmen können, die als Grundlage für Kaufentscheidungen und Budgetzuweisungen dienen kann.

Szenario 2: Schwierigkeiten bei der Beschaffung hochwertiger Ersatzstarter

Das Problem: Viele B2B-Einkäufer tun sich schwer mit der Beschaffung qualitativ hochwertiger Ersatzstarter, die den Anforderungen ihres vielfältigen Fuhrparks entsprechen. Der Markt ist überschwemmt mit Optionen, die von preiswerten Aftermarket-Teilen bis hin zu OEM-Komponenten reichen, und ohne das richtige Wissen kann es passieren, dass Käufer unzuverlässige Teile kaufen, die zu weiteren Problemen führen. Dies erhöht nicht nur die Reparaturkosten, sondern trägt auch zu den Ausfallzeiten der Fahrzeuge bei, was sich letztlich auf die Serviceleistungen und die Kundenzufriedenheit auswirkt.

Die Lösung: Um diese Herausforderung zu meistern, sollten B2B-Einkäufer gründliche Nachforschungen über Lieferanten anstellen, die auf Kfz-Teile spezialisiert sind, und dabei besonders auf Bewertungen und Beurteilungen zur Produktqualität achten. Der Aufbau von Partnerschaften mit Lieferanten, die Garantien und Gewährleistungen anbieten, kann ebenfalls von Vorteil sein, da dies ein Sicherheitsnetz bietet, falls das Teil vorzeitig ausfällt. Darüber hinaus sollten Einkäufer ein klares Lastenheft erstellen, in dem die wesentlichen Anforderungen an den Ersatz für den Anlasser, einschließlich Kompatibilität, Garantiebedingungen und Leistungskennzahlen, aufgeführt sind. Dieses Dokument kann mit potenziellen Lieferanten geteilt werden, um sicherzustellen, dass nur die am besten geeigneten Optionen in Betracht gezogen werden, was den Beschaffungsprozess rationalisiert.

Szenario 3: Mangelnde Transparenz bei Reparaturdienstleistungen

Das Problem: Ein häufiges Problem für B2B-Kunden ist die mangelnde Transparenz der Preisgestaltung und der von den Werkstätten angebotenen Leistungen. Bei der Beantragung von Anlasserreparaturen stoßen Unternehmen oft auf vage Kostenvoranschläge, die sie über die endgültigen Kosten im Unklaren lassen. Dieser Mangel an Klarheit kann zu Misstrauen zwischen Unternehmen und Dienstleistern führen, was den Entscheidungsprozess erschwert und möglicherweise zu überhöhten Preisen oder unnötigen Reparaturen führt.

Die Lösung: Um dieses Problem zu lösen, sollten B2B-Käufer bevorzugt mit Werkstätten zusammenarbeiten, die detaillierte Kostenvoranschläge und Aufschlüsselungen der Arbeits- und Ersatzteilkosten vorlegen. Bevor sie sich zu einer Reparatur verpflichten, können sie einen schriftlichen Kostenvoranschlag anfordern, in dem alle Aspekte der Dienstleistung aufgeführt sind, einschließlich der Diagnosegebühren, der Preise für Ersatzteile und der Arbeitspreise. Darüber hinaus kann die Einholung mehrerer Angebote von verschiedenen Dienstleistern dem Käufer helfen, Kosten und Leistungen besser zu vergleichen. Dieser Ansatz fördert nicht nur das Verantwortungsbewusstsein der Werkstätten, sondern gibt den Unternehmen auch die Möglichkeit, fundierte Entscheidungen zu treffen, die mit ihren Budgetvorgaben in Einklang stehen. Die regelmäßige Überprüfung von Reparaturkosten und -erfahrungen kann auch zu besseren langfristigen Beziehungen mit vertrauten Dienstleistern führen.

Strategischer Leitfaden zur Materialauswahl für die Reparatur von Autoanlassern

Welche Materialien werden bei der Reparatur von Autoanlassern üblicherweise verwendet?

Bei der Reparatur von Autoanlassern spielt die Auswahl der Materialien eine entscheidende Rolle bei der Bestimmung von Leistung, Haltbarkeit und Gesamtkosten. Nachfolgend finden Sie eine Analyse verschiedener gängiger Materialien, die in Autoanlasserkomponenten verwendet werden, mit Schwerpunkt auf ihren Eigenschaften, Vorteilen, Nachteilen und Überlegungen für internationale B2B-Käufer.

Welchen Einfluss hat Kupfer auf die Leistung des Anlassers?

Kupfer wird aufgrund seiner ausgezeichneten elektrischen Leitfähigkeit häufig in Automobilanlassern verwendet, insbesondere in Wicklungen und Steckern. Es hat einen hohen Schmelzpunkt (1.984°F oder 1.085°C) und kann erheblichen thermischen und elektrischen Belastungen standhalten, was es ideal für Starteranwendungen macht.

Vorteile: Die hohe Leitfähigkeit von Kupfer sorgt für eine effiziente Energieübertragung und damit für eine bessere Leistung des Anlassers. Außerdem lässt es sich relativ leicht verarbeiten und ermöglicht unkomplizierte Fertigungsprozesse.

Nachteile: Der größte Nachteil von Kupfer ist seine Korrosionsanfälligkeit, insbesondere in feuchten oder salzhaltigen Umgebungen. Dies kann im Laufe der Zeit zu erhöhten Wartungskosten und möglichen Ausfällen führen.

Auswirkungen auf die Anwendung: Die Kompatibilität von Kupfer mit verschiedenen elektrischen Systemen macht es für eine Vielzahl von Fahrzeugen geeignet. In Regionen mit hoher Luftfeuchtigkeit, wie z. B. in Teilen Afrikas und Südamerikas, können jedoch zusätzliche Schutzbeschichtungen erforderlich sein.

Überlegungen für internationale Käufer: Die Käufer sollten sicherstellen, dass die lokalen Normen für elektrische Komponenten eingehalten werden. So ist beispielsweise die Einhaltung der ASTM-Normen für elektrische Leitfähigkeit in Märkten wie Brasilien und Nigeria entscheidend.

Wie trägt Stahl zur Haltbarkeit des Anlassers bei?

Stahl, insbesondere Kohlenstoffstahl, wird aufgrund seiner Festigkeit und Haltbarkeit häufig für die Konstruktion von Anlassergehäusen und Getrieben verwendet. Er kann hohen Drücken und Temperaturen standhalten und eignet sich daher für verschiedene Anwendungen in der Automobilindustrie.

Vorteile: Stahl bietet hervorragende mechanische Eigenschaften, einschließlich hoher Zugfestigkeit und Schlagfestigkeit. Außerdem ist er im Vergleich zu anderen Werkstoffen relativ preiswert, was ihn zu einer kostengünstigen Wahl macht.

Nachteile: Stahl ist anfällig für Rost und Korrosion, wenn er nicht richtig behandelt wird. Dies kann zu einem vorzeitigen Ausfall führen, insbesondere in rauen Umgebungen.

Auswirkungen auf die Anwendung: Aufgrund seiner Robustheit eignet sich Stahl für schwere Anwendungen, z. B. in Lkw und Geländewagen. Sein Gewicht kann jedoch bei kleineren Fahrzeugen, bei denen eine Gewichtsreduzierung von entscheidender Bedeutung ist, ein Nachteil sein.

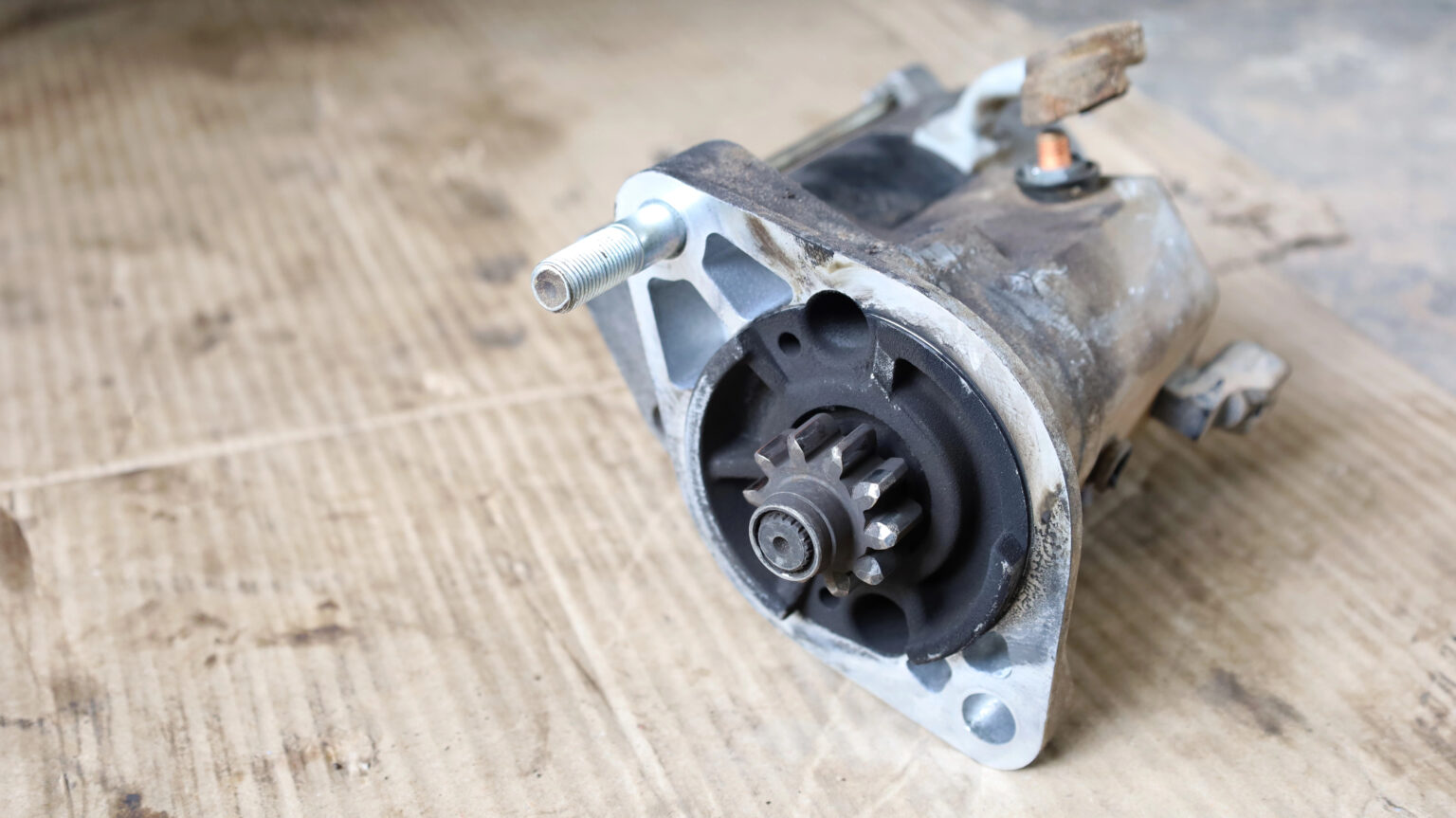

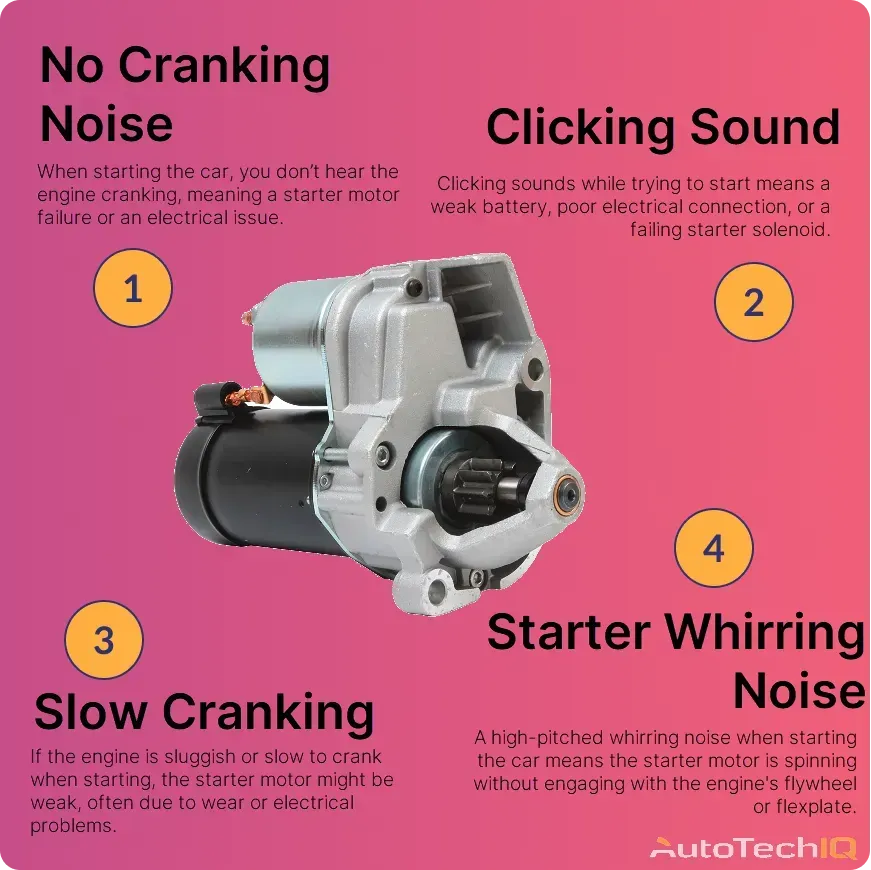

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Überlegungen für internationale Käufer: Die Einhaltung internationaler Normen wie z. B. der DIN für mechanische Eigenschaften ist von entscheidender Bedeutung. Käufer im Nahen Osten und in Europa sollten auch die lokale Verfügbarkeit von korrosionsbeständigen Beschichtungen berücksichtigen.

Welche Rolle spielt Aluminium in Starterkomponenten?

Aluminium wird aufgrund seines geringen Gewichts und seiner korrosionsbeständigen Eigenschaften zunehmend für Starterkomponenten, insbesondere für Gehäuse und Halterungen, verwendet. Im Vergleich zu Stahl und Kupfer hat es einen niedrigeren Schmelzpunkt (1.221°F oder 660°C), bietet aber für viele Anwendungen eine ausreichende Festigkeit.

Vorteile: Der Hauptvorteil von Aluminium ist sein geringes Gewicht, das zur Gesamteffizienz des Fahrzeugs beiträgt. Außerdem ist Aluminium korrosionsbeständig, was den Wartungsbedarf reduziert.

Nachteile: Aluminium kann teurer sein als Stahl und erfordert unter Umständen komplexere Herstellungsverfahren. Außerdem hat es eine geringere Zugfestigkeit, was seine Verwendung in stark beanspruchten Anwendungen einschränken kann.

Auswirkungen auf die Anwendung: Aluminium eignet sich besonders für moderne Fahrzeuge, bei denen die Kraftstoffeffizienz im Vordergrund steht. In Regionen mit extremen Temperaturen kann sein niedriger Schmelzpunkt jedoch ein Problem darstellen.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Überlegungen für internationale Käufer: Käufer sollten sich über die spezifischen Aluminiumsorten informieren, die den lokalen Normen entsprechen, wie JIS in Japan oder ASTM in den USA, um Kompatibilität und Leistung sicherzustellen.

Wie verbessert Kunststoff das Design von Starter-Komponenten?

Kunststoffe, insbesondere technische Kunststoffe, werden für nicht strukturelle Komponenten von Anlassern, wie Abdeckungen und Isolatoren, verwendet. Diese Materialien sind temperaturbeständig und bieten elektrische Isolierung.

Vorteile: Kunststoffe sind leicht und können in komplexe Formen gegossen werden, was innovative Designs ermöglicht. Außerdem sind sie korrosionsbeständig und kostengünstig.

Nachteile: Die wichtigste Einschränkung von Kunststoffen ist ihre geringere thermische und mechanische Festigkeit im Vergleich zu Metallen, was ihre Verwendung in stark beanspruchten Bereichen einschränken kann.

Auswirkungen auf die Anwendung: Kunststoffkomponenten können das Gesamtgewicht reduzieren und damit die Effizienz des Fahrzeugs verbessern. Sie eignen sich jedoch nicht unbedingt für Hochleistungsanwendungen.

Überlegungen für internationale Käufer: Die Käufer sollten sicherstellen, dass die verwendeten Kunststoffe den für ihre Region geltenden Sicherheits- und Leistungsstandards entsprechen, z. B. den ISO-Normen für Materialsicherheit.

Übersichtstabelle zur Materialauswahl für die Reparatur von Autoanlassern

| Material | Typischer Anwendungsfall für die Reparaturkosten eines Autoanlassers | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Kupfer | Elektrische Wicklungen und Steckverbinder | Hervorragende elektrische Leitfähigkeit | Korrosionsanfällig | Mittel |

| Stahl | Gehäuse und Zahnräder | Hohe Festigkeit und Haltbarkeit | Anfällig für Rost und Korrosion | Niedrig |

| Aluminium | Gehäuse und Halterungen | Leicht und korrosionsbeständig | Geringere Zugfestigkeit | Mittel |

| Kunststoff | Abdeckungen und Isolatoren | Leicht und kostengünstig | Geringere thermische und mechanische Festigkeit | Niedrig |

Diese Analyse gibt einen umfassenden Überblick über die Materialauswahl für die Reparatur von Autoanlassern und bietet B2B-Käufern wichtige Einblicke in Leistung, Kosten und regionale Aspekte. Das Verständnis dieser Faktoren ist wichtig, um fundierte Kaufentscheidungen auf dem Markt für Autoreparaturen zu treffen.

Eingehender Blick: Herstellungsverfahren und Qualitätssicherung für die Reparatur von Autoanlassern

Was sind die wichtigsten Phasen des Herstellungsprozesses von Autoanlassern?

Die Herstellung von Autoanlassern umfasst mehrere wichtige Schritte, die die Produktion von zuverlässigen und effizienten Komponenten gewährleisten. Das Verständnis dieser Schritte kann B2B-Einkäufern helfen, die Fähigkeiten potenzieller Lieferanten zu bewerten.

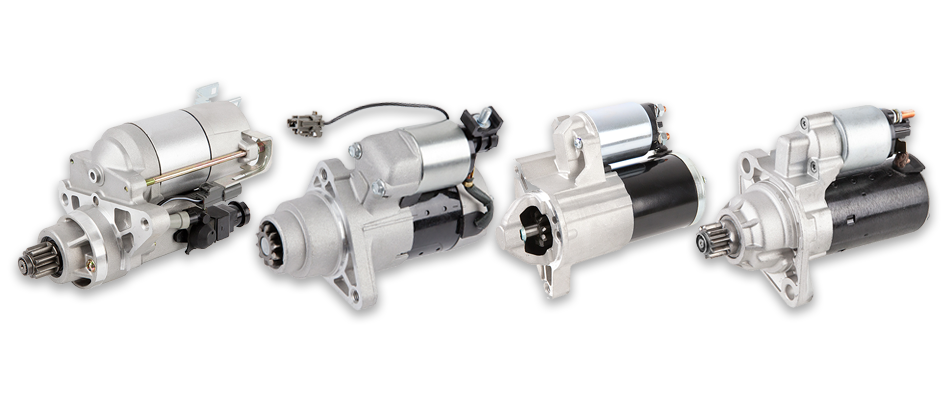

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Wie wird das Material für die Herstellung von Autoanlassern vorbereitet?

Der erste Schritt im Herstellungsprozess ist die Materialvorbereitung. Zu den Rohstoffen gehören in der Regel hochwertiger Stahl für das Gehäuse, Kupfer für die elektrischen Komponenten und verschiedene Legierungen für die internen Mechanismen. Die Zulieferer beziehen die Materialien häufig von zertifizierten Anbietern, um Qualität und Konsistenz zu gewährleisten. Diese Materialien werden ersten Kontrollen unterzogen, um ihre Spezifikationen und die Einhaltung internationaler Normen zu überprüfen.

Welche Umformtechniken werden in der Starterproduktion üblicherweise eingesetzt?

Sobald die Materialien vorbereitet sind, geht es in der nächsten Phase um die Formgebung. Techniken wie Stanzen, Zerspanen und Druckguss werden in der Regel eingesetzt, um die notwendigen Komponenten des Anlassers herzustellen. Das Gehäuse des Anlassers wird in der Regel aus Blech gestanzt, während der Anker und andere komplizierte Teile aus Präzisionsgründen maschinell bearbeitet werden können. Moderne Techniken wie die CNC-Bearbeitung werden zunehmend eingesetzt, um die Genauigkeit zu erhöhen und den Ausschuss zu verringern.

Wie werden Autoanlasser zusammengebaut?

Nach der Formgebung beginnt der Montageprozess. Diese Phase ist von entscheidender Bedeutung, da hier verschiedene Komponenten zu einem voll funktionsfähigen Anlasser zusammengefügt werden. Schlüsselkomponenten wie die Magnetspule, der Anker und die elektrischen Bürsten werden sorgfältig zusammengebaut, um die richtige Ausrichtung und Funktion sicherzustellen. Zur Verbesserung der Effizienz und Konsistenz werden häufig automatisierte Montagelinien eingesetzt. Die Montagearbeiter führen an verschiedenen Stellen Kontrollen durch, um Fehler frühzeitig zu erkennen.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Welche Veredelungstechniken werden bei Autostartern angewandt?

Veredelungsprozesse sind wichtig, um die Haltbarkeit und Leistung von Autostartern zu verbessern. Zu den gängigen Techniken gehören Oberflächenbehandlung, Lackierung und Isolierung. Oberflächenbehandlungen, wie z. B. Verzinkung, verhindern Korrosion und erhöhen die Langlebigkeit. Die Isolierung elektrischer Komponenten sorgt für Sicherheit und Leistung unter hohen Belastungen. Jeder Endbearbeitungsschritt ist entscheidend dafür, dass das Endprodukt den strengen Anforderungen von Automobilanwendungen gerecht wird.

Welche Qualitätssicherungsstandards sind für die Herstellung von Autoanlassern relevant?

Die Qualitätssicherung ist ein wichtiger Aspekt des Herstellungsprozesses von Autoanlassern. Die Einhaltung internationaler Normen wie ISO 9001 gewährleistet, dass die Hersteller einheitliche Qualitätsmanagementsysteme unterhalten. Diese Norm bietet einen Rahmen für kontinuierliche Verbesserung und Kundenzufriedenheit, was für B2B-Käufer, die zuverlässige Lieferanten suchen, von entscheidender Bedeutung ist.

Neben den ISO-Normen sind auch branchenspezifische Zertifizierungen wie die CE-Kennzeichnung und API-Normen (American Petroleum Institute) von Bedeutung. Die CE-Kennzeichnung weist auf die Einhaltung der europäischen Gesundheits-, Sicherheits- und Umweltschutznormen hin, während die API-Normen die Qualität und Leistung von Automobilkomponenten gewährleisten.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Was sind die wichtigsten Qualitätskontrollpunkte bei der Starterproduktion?

Die Qualitätskontrolle (QC) ist in den gesamten Herstellungsprozess integriert, um sicherzustellen, dass alle Komponenten den vorgegebenen Standards entsprechen. Zu den üblichen Kontrollpunkten gehören:

- Eingangsqualitätskontrolle (IQC): Die Materialien werden bei ihrer Ankunft geprüft, um sicherzustellen, dass sie den Spezifikationen entsprechen.

- In-Process-Qualitätskontrolle (IPQC): Während der Montage werden stichprobenartige Kontrollen durchgeführt, um Mängel oder Abweichungen von der Norm festzustellen.

- Endkontrolle (FQC): Die fertigen Starter werden strengen Funktions- und Sicherheitstests unterzogen, bevor sie für den Versand verpackt werden.

Welche gängigen Prüfverfahren werden in der Qualitätssicherung eingesetzt?

Prüfverfahren spielen eine entscheidende Rolle bei der Qualitätssicherung von Autostartern. Zu den gängigen Techniken gehören:

- Elektrische Prüfung: Vergewissert sich, dass alle elektrischen Anschlüsse ordnungsgemäß funktionieren und dass der Anlasser den Spannungsanforderungen entspricht.

- Haltbarkeitsprüfung: Simuliert reale Bedingungen, um zu beurteilen, wie der Anlasser unter verschiedenen Belastungen, einschließlich Temperaturschwankungen und Vibrationen, funktioniert.

- Funktionsprüfung: Überprüft, ob der Anlasser beim Einschalten ordnungsgemäß ein- und auskuppelt.

Wie können B2B-Käufer die Qualitätskontrollpraktiken ihrer Lieferanten überprüfen?

B2B-Einkäufer können mehrere Schritte unternehmen, um die Qualitätskontrollpraktiken potenzieller Lieferanten zu überprüfen:

- Lieferanten-Audits: Die Durchführung von Audits vor Ort ermöglicht es den Einkäufern, Herstellungsverfahren, Qualitätskontrollsysteme und die Einhaltung internationaler Normen zu bewerten.

- Anforderung von Qualitätsberichten: Einkäufer sollten nach Unterlagen fragen, die die Qualitätskontrollmaßnahmen, Prüfprotokolle und Ergebnisse des Lieferanten darlegen.

- Inspektionen durch Dritte: Die Einschaltung unabhängiger Prüfstellen kann eine unvoreingenommene Bewertung der Qualitätspraktiken des Lieferanten liefern.

Was sind die Feinheiten der Qualitätskontrolle für internationale Käufer?

Für internationale B2B-Einkäufer, vor allem aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, ist es wichtig, die Feinheiten der Qualitätskontrolle zu verstehen. Verschiedene Märkte können unterschiedliche Normen und Vorschriften haben. So müssen Produkte, die in die Europäische Union exportiert werden, die Anforderungen der CE-Kennzeichnung erfüllen, während nordamerikanische Käufer sich auf die SAE-Normen (Society of Automotive Engineers) konzentrieren können.

Einkäufer sollten sich auch über mögliche Kommunikationsbarrieren und kulturelle Unterschiede im Klaren sein, die sich auf die Qualitätssicherungspraktiken auswirken können. Die Festlegung klarer Erwartungen und die Aufrechterhaltung einer offenen Kommunikation können dazu beitragen, diese Klüfte zu überbrücken.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Schlussfolgerung: Bedeutung der Qualität bei den Kosten für die Reparatur von Autoanlassern

Zusammenfassend lässt sich sagen, dass die Herstellungsverfahren und Qualitätssicherungspraktiken für Autoanlasser für die Gewährleistung von Zuverlässigkeit und Leistung unerlässlich sind. B2B-Einkäufer müssen diese Faktoren bei der Bewertung potenzieller Lieferanten berücksichtigen, da sie sich direkt auf die Reparaturkosten und die allgemeine Zuverlässigkeit des Fahrzeugs auswirken. Durch das Verständnis der Fertigungsstufen, Qualitätskontrollstandards und Überprüfungsmethoden können Einkäufer fundierte Entscheidungen treffen, die auf ihre betrieblichen Bedürfnisse und Marktanforderungen abgestimmt sind.

Praktische Anleitung zur Beschaffung: Eine Schritt-für-Schritt-Checkliste für ‘auto starter reparaturkosten’.’

Einführung

Dieser Beschaffungsleitfaden soll B2B-Einkäufern dabei helfen, die Komplexität der Beschaffung von Reparaturdienstleistungen für Anlasser effektiv zu bewältigen. Das Verständnis der verschiedenen Faktoren, die sich auf die Reparaturkosten auswirken, und die notwendigen Schritte zur Bewertung potenzieller Lieferanten können zu fundierteren Kaufentscheidungen führen, die letztlich die Kosten senken und die betriebliche Effizienz verbessern.

Schritt 1: Identifizieren Sie Ihre spezifischen Bedürfnisse

Bevor Sie sich an Lieferanten wenden, sollten Sie klar definieren, was Sie für die Reparatur von Anlassern benötigen. Berücksichtigen Sie die Fahrzeugtypen in Ihrem Fuhrpark, die häufigsten Probleme und die erwarteten Durchlaufzeiten für Reparaturen. Diese Klarheit wird Ihnen helfen, effektiv mit potenziellen Lieferanten zu kommunizieren und sicherzustellen, dass sie Ihre speziellen Anforderungen erfüllen können.

Schritt 2: Forschung Marktpreise

Recherchieren Sie gründlich, um die typischen Kosten für die Reparatur von Autoanlassern in Ihrer Region zu ermitteln. Die Preise können je nach Fahrzeugmarke und -modell sowie den örtlichen Arbeitskosten erheblich variieren. Nutzen Sie diese Informationen, um ein Budget festzulegen und Angebote von Anbietern zu prüfen, damit Sie nicht zu viel für Dienstleistungen bezahlen.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Schritt 3: Bewerten Sie die Glaubwürdigkeit von Lieferanten

Beurteilen Sie die Referenzen und den Ruf potenzieller Lieferanten. Achten Sie auf Zertifizierungen, z. B. nach ISO- oder lokalen Automobilstandards, die auf ein Engagement für Qualität und Sicherheit hinweisen. Achten Sie außerdem auf Bewertungen oder Erfahrungsberichte früherer Kunden, insbesondere von Kunden in ähnlichen Märkten oder mit vergleichbaren Fahrzeugtypen.

Schritt 4: Überprüfen Sie die Reparaturfähigkeiten

Nicht alle Anbieter verfügen über das gleiche Fachwissen oder die gleiche Ausrüstung für die Reparatur von Autoanlassern. Vergewissern Sie sich, dass potenzielle Partner gut ausgerüstet sind, um die spezifischen Typen von Anlassern in Ihrem Fuhrpark zu behandeln. Dies kann bedeuten, dass Sie sich nach der Erfahrung mit bestimmten Marken oder Modellen und den für die Reparatur verwendeten Werkzeugen erkundigen.

Schritt 5: Detaillierte Angebote anfordern

Wenn Sie Lieferanten in die engere Wahl gezogen haben, sollten Sie umfassende Angebote einholen, in denen alle anfallenden Kosten aufgeführt sind. Darin sollten Arbeit, Ersatzteile und alle zusätzlichen Gebühren enthalten sein. Ein detaillierter Kostenvoranschlag hilft Ihnen, Angebote besser zu vergleichen und unerwartete Ausgaben im späteren Verlauf der Reparatur zu vermeiden.

Schritt 6: Erkundigen Sie sich nach Garantie und Support

Ein seriöser Anbieter sollte Garantien sowohl für Teile als auch für Arbeit anbieten. Erkundigen Sie sich nach der Dauer und den Bedingungen dieser Garantien, da sie sehr unterschiedlich sein können. Vergewissern Sie sich außerdem, dass der Anbieter kontinuierlichen Support oder Wartungsdienste anbietet, da dies auf lange Sicht Zeit und Geld sparen kann.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Schritt 7: Kommunikationskanäle einrichten

Eine wirksame Kommunikation ist für eine erfolgreiche Partnerschaft entscheidend. Bestimmen Sie die besten Methoden für die laufende Kommunikation mit dem von Ihnen gewählten Anbieter, sei es per E-Mail, Telefonanruf oder über ein Online-Portal. Die Einrichtung klarer Kommunikationswege erleichtert die rechtzeitige Aktualisierung des Reparaturstatus und aller Probleme, die während des Prozesses auftreten können.

Indem sie diese Schritte befolgen, können B2B-Einkäufer ihren Beschaffungsprozess für die Reparatur von Autoanlassern rationalisieren und sicherstellen, dass sie einen zuverlässigen Lieferanten auswählen, der ihren betrieblichen Anforderungen und ihrem Budget entspricht.

Umfassende Kosten- und Preisanalyse für die Reparatur von Autoanlassern Kostenbeschaffung

Was sind die wichtigsten Kostenkomponenten für die Reparatur von Autoanlassern?

Bei der Beschaffung von Dienstleistungen im Bereich der Anlasserreparatur ist es für B2B-Einkäufer entscheidend, die Kostenstruktur zu verstehen. Zu den primären Kostenkomponenten gehören:

-

Materialien: Die Kosten für Anlasserteile können erheblich variieren. Überholte Teile können zwischen $50 und $350 liegen, während neue Anlasser in der Regel zwischen $80 und über $350 kosten. Die Qualität des Materials wirkt sich direkt auf die Haltbarkeit und Leistung aus, weshalb es wichtig ist, die Lieferanten anhand der von ihnen angebotenen Teile zu bewerten.

-

Arbeit: Die Arbeitskosten können je nach der Komplexität des Anlassers im Fahrzeug variieren. Ein einfacher Austausch kann weniger als eine Stunde dauern, während kompliziertere Systeme mehrere Stunden Arbeit erfordern können, was zu Kosten von über $1.100 führen kann.

-

Fertigungsgemeinkosten: Hierunter fallen indirekte Kosten im Zusammenhang mit der Produktion, wie z. B. Betriebskosten, Versorgungsleistungen und Verwaltungskosten. Das Verständnis der Gemeinkosten eines Lieferanten kann den Einkäufern helfen, die allgemeine Preisstrategie zu beurteilen.

-

Werkzeuge: Für bestimmte Fahrzeuge kann Spezialwerkzeug erforderlich sein, was die Gesamtkosten der Reparatur erhöhen kann. Lieferanten, die in modernes Werkzeug investiert haben, können einen Aufpreis verlangen, aber dies führt oft zu effizienteren und qualitativ hochwertigeren Reparaturen.

-

Qualitätskontrolle (QC): Qualitätssicherungsprozesse sind unerlässlich, um sicherzustellen, dass die Starter die Leistungs- und Sicherheitsstandards erfüllen. Lieferanten, die strenge Qualitätssicherungsmaßnahmen durchführen, verlangen zwar einen höheren Preis, bieten aber oft auch eine größere Zuverlässigkeit.

-

Logistik: Die Versandkosten können sich auf den Gesamtpreis auswirken, insbesondere bei internationalen Transaktionen. Faktoren wie Entfernung, Versandart und Zoll können die Logistikkosten in die Höhe treiben.

-

Marge: Die Gewinnspanne des Lieferanten ist ein wesentlicher Bestandteil der Preisstruktur. Die Kenntnis der branchenüblichen Gewinnspannen kann Einkäufern helfen, bessere Preise auszuhandeln.

Was beeinflusst die Preisgestaltung bei der Reparatur von Autoanlassern?

Mehrere Faktoren können die Preisgestaltung beeinflussen, insbesondere bei internationalen B2B-Käufern:

-

Volumen/MOQ (Mindestbestellmenge): Lieferanten bieten oft Rabatte für größere Bestellungen an. Die Kenntnis der Mindestbestellmenge kann Einkäufern helfen, ihre Einkäufe strategisch zu planen, um Kosten zu sparen.

-

Spezifikationen und Anpassung: Sonderanfertigungen oder bestimmte Fahrzeugmodelle können mit einem Aufpreis verbunden sein. Die Käufer sollten ihre Anforderungen klar definieren, um unnötige Kosten zu vermeiden.

-

Materialien und Qualitätszertifizierungen: Die Art der verwendeten Materialien (z. B. Erstausrüster- oder Nachrüstteile) kann den Preis erheblich beeinflussen. Zertifizierungen wie die ISO-Norm oder spezifische Automobilstandards können die Kosten in die Höhe treiben, gewährleisten aber Qualität und Zuverlässigkeit.

-

Lieferantenfaktoren: Der Ruf, der Standort und die Erfahrung eines Lieferanten können die Preisgestaltung beeinflussen. Etablierte Lieferanten verlangen zwar mehr, bieten aber oft einen besseren Service und eine bessere Produktqualität.

-

Incoterms: Das Verständnis der vereinbarten Incoterms kann sich auf die Gesamtkosten des Unternehmens auswirken. Bedingungen, die die Verantwortlichkeiten für den Versand festlegen, können zu unerwarteten Kosten führen, wenn sie nicht richtig ausgehandelt werden.

Was sind die besten Tipps für die Verhandlung von Kosten für die Reparatur von Autoanlassern?

Für B2B-Einkäufer, insbesondere aus Regionen wie Afrika, Südamerika, dem Nahen Osten und Europa, kann strategisches Verhandeln zu erheblichen Einsparungen führen:

-

Führen Sie Marktforschung durch: Machen Sie sich mit den Marktpreisen für die Reparatur und den Austausch von Autoanlassern vertraut. Dieses Wissen wird Ihnen bei den Verhandlungen helfen.

-

Gesamtbetriebskosten (TCO) bewerten: Berücksichtigen Sie nicht nur den Anschaffungspreis, sondern auch die langfristigen Kosten im Zusammenhang mit Qualität, Zuverlässigkeit und möglichen Ausfallzeiten. Ein billigerer Anlasser kann zu häufigeren Auswechslungen führen.

-

Aufbau von Beziehungen zu Zulieferern: Der Aufbau einer guten Beziehung zu den Lieferanten kann zu besseren Preisen und Bedingungen führen. Langfristige Partnerschaften führen oft zu günstigen Konditionen.

-

Mehrere Zitate nutzen: Die Einholung von Angeboten von mehreren Lieferanten kann bei Verhandlungen von Vorteil sein. Sie ermöglichen einen Vergleich und können zu besseren Preisen bei Ihrem bevorzugten Lieferanten führen.

-

Achten Sie auf preisliche Nuancen: In verschiedenen Regionen können die Preisnormen aufgrund der lokalen wirtschaftlichen Bedingungen, Zölle und Versandkosten variieren. Die Kenntnis dieser Nuancen kann bei der Aushandlung eines fairen Preises helfen.

Haftungsausschluss für indikative Preise

Die in dieser Analyse genannten Preise sind Richtwerte und können aufgrund zahlreicher Faktoren variieren, darunter Marktschwankungen, Standort und spezifische Fahrzeuganforderungen. Käufer sollten stets gründliche Nachforschungen anstellen und genaue, auf ihre Bedürfnisse zugeschnittene Angebote einholen, bevor sie eine Kaufentscheidung treffen.

Analyse der Alternativen: Vergleich der Kosten für die Reparatur des Autoanlassers mit anderen Lösungen

Alternative Lösungen für die Reparaturkosten von Autoanlassern verstehen

Bei der Betrachtung der Kosten für die Reparatur von Autoanlassern ist es für B2B-Einkäufer wichtig, alternative Lösungen zu bewerten, die die Kosten senken oder die betriebliche Effizienz verbessern könnten. In dieser Analyse wird die traditionelle Methode der Anlasserreparatur mit zwei praktikablen Alternativen verglichen: dem Austausch des Anlassers und der Aufrüstung des elektrischen Systems. Jede Option hat ihre eigenen Vorteile und Herausforderungen, die die Entscheidungsfindung von Unternehmen, die Flotten betreiben oder Kfz-Dienstleistungen anbieten, erheblich beeinflussen können.

Vergleichstabelle

| Vergleichsaspekt | Auto Starter Reparatur Kosten | Starter Ersatz | Elektrisches System Upgrade |

|---|---|---|---|

| Leistung | Wiederherstellung des vorhandenen Starters | Neuer Anlasser erhöht die Zuverlässigkeit | Verbessert die Gesamteffizienz des Systems |

| Kosten | $150 – $1.100 | $80 - $350 für Teile + Arbeit | $200 - $1.500 je nach Komponenten |

| Einfache Implementierung | Mäßig (abhängig vom Schaden) | Relativ einfach, insbesondere für gängige Fahrzeuge | Komplex, erfordert möglicherweise eine professionelle Installation |

| Wartung | Kann zukünftige Reparaturen erfordern | Im Allgemeinen wartungsarm | Höherer Wartungsaufwand durch neue Komponenten |

| Bester Anwendungsfall | Kostengünstig bei kleineren Problemen | Ideal für ältere oder stark beanspruchte Fahrzeuge | Am besten geeignet zur Verbesserung der Leistung und Langlebigkeit von Fahrzeugen |

Detaillierte Aufschlüsselung der Alternativen

Starter Ersatz

Der Austausch des Anlassers ist oft eine einfache Lösung, insbesondere bei Fahrzeugen mit zugänglichen Komponenten. Diese Methode kann kostengünstiger sein als die Reparatur eines defekten Anlassers, insbesondere wenn der Anlasser stark abgenutzt oder beschädigt ist. Ein neuer Anlasser kostet in der Regel zwischen $80 und $350, zuzüglich der Arbeitskosten, die je nach Ausführung des Fahrzeugs variieren können. Diese Option kann zwar die Zuverlässigkeit verbessern, erfordert aber dennoch einen qualifizierten Techniker für den Einbau, insbesondere bei komplexen Fahrzeugen.

Elektrisches System Upgrade

Die Aufrüstung des gesamten elektrischen Systems kann eine umfassendere Lösung für Unternehmen sein, die ihre Leistung verbessern wollen. Bei diesem Ansatz werden nicht nur Probleme mit dem Anlasser behoben, sondern auch die Effizienz der elektrischen Komponenten im gesamten Fahrzeug verbessert. Je nach den gewählten Komponenten können die Kosten zwischen $200 und $1.500 liegen. Diese Methode kann zwar zu erheblichen langfristigen Vorteilen und einer höheren Zuverlässigkeit führen, ist aber oft die komplexeste und erfordert unter Umständen einen professionellen Einbau. Außerdem kann sie aufgrund der Integration neuer Technologien einen höheren Wartungsaufwand mit sich bringen.

Schlussfolgerung: Die Wahl der richtigen Lösung für Ihr Unternehmen

Die Wahl der geeigneten Lösung für Probleme mit dem Anlasser hängt von den spezifischen Anforderungen Ihres Fuhrparks oder Ihres Servicebetriebs ab. Wenn Budgetbeschränkungen ein Hauptanliegen sind, kann die Reparatur des vorhandenen Anlassers die beste Option für kleinere Probleme sein. Wenn jedoch Zuverlässigkeit und langfristige Effizienz im Vordergrund stehen, könnte die Investition in einen neuen Anlasser oder eine Aufrüstung des elektrischen Systems zu besseren Ergebnissen führen. B2B-Einkäufer sollten bei dieser Entscheidung ihre betrieblichen Anforderungen, die Fahrzeugtypen und die potenzielle Kapitalrendite berücksichtigen und sicherstellen, dass die gewählte Lösung mit ihrer allgemeinen Geschäftsstrategie übereinstimmt.

Wesentliche technische Eigenschaften und Fachterminologie für die Reparatur von Autoanlassern

Was sind die wichtigsten technischen Eigenschaften, die die Kosten für die Reparatur von Autoanlassern beeinflussen?

Das Verständnis der kritischen Spezifikationen von Autoanlassern kann die Reparaturkosten und die allgemeine Entscheidungsfindung von B2B-Käufern erheblich beeinflussen. Hier sind wesentliche technische Eigenschaften, die Sie berücksichtigen sollten:

-

Werkstoffgüte

Die bei der Konstruktion von Startern verwendeten Materialien, wie Kupfer für die Wicklungen oder Edelstahl für die Gehäuse, wirken sich sowohl auf die Haltbarkeit als auch auf die Leistung aus. Hochwertige Materialien führen in der Regel zu einer längeren Lebensdauer des Anlassers, was langfristig die Reparaturkosten senken kann. Käufer sollten Startern aus robusten Materialien den Vorzug geben, um die Zuverlässigkeit zu gewährleisten, insbesondere in Regionen mit schwierigen klimatischen Bedingungen. -

Drehmoment-Spezifikationen

Die Drehmomentvorgaben geben vor, wie viel Kraft bei der Befestigung von Bauteilen aufgebracht werden muss, um sicherzustellen, dass Anlasser korrekt und ohne Schäden funktionieren. Wenn diese Spezifikationen bei der Installation nicht eingehalten werden, kann dies zu einem vorzeitigen Ausfall oder zu Betriebsproblemen führen. Die Kenntnis der Drehmomentanforderungen hilft Einkäufern, effektiv mit Mechanikern zu kommunizieren und eine ordnungsgemäße Installation sicherzustellen. -

Elektrischer Widerstand

Der elektrische Widerstand der Wicklungen des Anlassers wirkt sich auf dessen Effizienz und Leistung aus. Ein geringerer Widerstand ist oft gleichbedeutend mit einer besseren Leistung, insbesondere bei kalten Wetterbedingungen. B2B-Käufer sollten Anlasser mit optimalen Widerstandswerten in Betracht ziehen, um einen zuverlässigen Betrieb in unterschiedlichen Umgebungen zu gewährleisten, insbesondere in Regionen mit extremen Temperaturen. -

Stromstärke beim Anlassen (CA)

Die Anlasserstärke misst die Fähigkeit eines Anlassers, einen Motor unter kalten Bedingungen zu starten. Ein Anlasser mit einem höheren CA-Wert kann mit niedrigeren Temperaturen besser umgehen, was in kälteren Klimazonen entscheidend ist. Käufer sollten die Anforderungen ihres Fahrzeugs prüfen und Anlasser auswählen, die diese Spezifikationen erfüllen oder übertreffen, um eine zuverlässige Leistung zu gewährleisten. -

Kompatibilität mit OEM-Standards

OEM-Spezifikationen (Original Equipment Manufacturer) sind entscheidend, um sicherzustellen, dass Ersatzstarter wie vorgesehen passen und funktionieren. Komponenten, die den OEM-Standards entsprechen, bieten Sicherheit in Bezug auf Qualität und Kompatibilität. B2B-Einkäufer sollten vorrangig Anlasser beschaffen, die den OEM-Spezifikationen entsprechen, um mögliche Probleme und zusätzliche Kosten zu vermeiden.

Was sind gängige Fachausdrücke, die für die Kosten der Anlasserreparatur relevant sind?

Wenn Sie sich mit dem Branchenjargon vertraut machen, können Sie die Kommunikation und Verhandlung bei B2B-Transaktionen verbessern. Hier sind einige wichtige Begriffe, die Sie kennen sollten:

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

-

OEM (Originalgerätehersteller)

Bezieht sich auf Teile, die vom Originalhersteller des Fahrzeugs hergestellt wurden. Erstausrüsterteile gelten oft als hochwertiger und zuverlässiger als Aftermarket-Alternativen. Die Kenntnis der OEM-Spezifikationen hilft den Käufern, Kompatibilität und Leistung sicherzustellen, was sich auf die Reparaturkosten auswirken kann. -

MOQ (Mindestbestellmenge)

Dieser Begriff gibt die kleinste Stückzahl an, die ein Lieferant zu verkaufen bereit ist. Die Kenntnis der MOQ hilft den Einkäufern bei der effektiven Verwaltung des Lagerbestands und des Budgets, insbesondere für Unternehmen, die in Regionen tätig sind, in denen häufig Anlasserreparaturen anfallen. -

RFQ (Angebotsanfrage)

Eine Anfrage ist ein Dokument, das an Lieferanten geschickt wird, um Preise für bestimmte Produkte oder Dienstleistungen zu erfragen. Die Verwendung von RFQs kann zu wettbewerbsfähigen Preisen und besseren Verhandlungsergebnissen führen, die für eine effektive Verwaltung der Reparaturkosten unerlässlich sind. -

Incoterms (Internationale Handelsklauseln)

Die Incoterms definieren die Verantwortlichkeiten von Käufern und Verkäufern im internationalen Handel, insbesondere in Bezug auf Versand, Versicherung und Zölle. Ein Verständnis der Incoterms kann Käufern helfen, sich bei Importkosten und Logistik zurechtzufinden, was für Unternehmen, die Teile aus verschiedenen Regionen beziehen, von entscheidender Bedeutung ist. -

Garantiezeitraum

Dies bezieht sich auf die Dauer, während der ein Produkt gegen Mängel garantiert ist. Für B2B-Käufer ist es wichtig, die Garantiebedingungen zu verstehen, da sie sich auf die langfristigen Reparaturkosten auswirken und die Produktqualität sichern können.

Wenn B2B-Einkäufer diese technischen Eigenschaften und Handelsbegriffe kennen, können sie fundierte Entscheidungen über die Reparatur von Autoanlassern treffen und so Kosteneffizienz und Zuverlässigkeit in ihrem Betrieb gewährleisten.

Marktdynamik und Beschaffungstrends im Bereich der Kosten für die Reparatur von Autoanlassern

Was sind die wichtigsten Trends, die den Markt für Starter-Reparaturkosten beeinflussen?

Der weltweite Markt für die Reparatur von Autoanlassern wird von mehreren Schlüsselfaktoren beeinflusst, die seine Dynamik bestimmen. Erstens hat die steigende Zahl der Fahrzeuge auf den Straßen, insbesondere in Schwellenländern wie Nigeria und Brasilien, zu einer erhöhten Nachfrage nach Anlasserreparaturen und -austausch geführt. Da sich die Urbanisierung beschleunigt, muss sich der Wartungs- und Reparatursektor an den wachsenden Fahrzeugbestand anpassen. Darüber hinaus verändert der technologische Fortschritt bei Automobilsystemen, einschließlich der Integration von Elektrofahrzeugen und Hybridmodellen, die Landschaft. Diese Fahrzeuge erfordern häufig spezielle Anlasserkomponenten, was sich auf die Beschaffungsstrategien von B2B-Käufern auswirkt.

Ein weiterer wichtiger Trend ist die Verlagerung der Beschaffungsprozesse in Richtung Digitalisierung und E-Commerce-Plattformen. Internationale Einkäufer nutzen Online-Marktplätze für die Beschaffung von Auto-Starterkomponenten, was die Transparenz und den Wettbewerb unter den Lieferanten verbessert. Darüber hinaus wird die Datenanalyse zur Optimierung des Bestandsmanagements eingesetzt, so dass die Unternehmen Nachfrageschwankungen vorhersehen und ihre Beschaffungsstrategien entsprechend anpassen können.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

In Europa und im Nahen Osten veranlassen strenge Vorschriften zu Fahrzeugemissionen und Nachhaltigkeit die Hersteller dazu, sich auf umweltfreundliche Komponenten zu konzentrieren. Dieser Wandel beeinflusst nicht nur das Design von Startern, sondern wirkt sich auch auf die Beschaffung von Materialien aus, so dass es für Käufer unerlässlich ist, sich über die Compliance-Anforderungen in den verschiedenen Regionen zu informieren.

Wie wichtig sind Nachhaltigkeit und ethische Beschaffung im Bereich der Anlasserreparatur?

Nachhaltigkeit hat sich zu einem entscheidenden Faktor auf dem Markt für die Reparatur von Autoanlassern entwickelt, der durch das wachsende Bewusstsein für Umweltfragen und die Nachfrage der Verbraucher nach umweltfreundlicheren Produkten gefördert wird. Internationale B2B-Einkäufer müssen bei ihren Beschaffungsentscheidungen die Umweltauswirkungen berücksichtigen. Dazu gehört die Bewertung des Lebenszyklus von Anlasserkomponenten, von der Rohstoffgewinnung bis zur Entsorgung am Ende des Lebenszyklus. Die Verwendung von recycelten Materialien und die Einhaltung umweltfreundlicher Produktionsprozesse können den ökologischen Fußabdruck, der mit der Reparatur von Anlassern verbunden ist, erheblich verringern.

Ebenso wichtig ist die ethische Beschaffung, da die Einkäufer jetzt ihre Lieferketten auf die Einhaltung von Arbeitsnormen und fairen Handelspraktiken überprüfen. Dies ist besonders in Regionen wie Afrika und Südamerika wichtig, wo die Arbeitsbedingungen sehr unterschiedlich sein können. Einkäufer sollten nach Lieferanten suchen, die über Zertifizierungen wie ISO 14001 für das Umweltmanagement und die Fair-Trade-Zertifizierung verfügen, um sicherzustellen, dass ihre Beschaffung mit ethischen Standards übereinstimmt.

Außerdem steigt die Nachfrage nach “grünen” Zertifizierungen. Komponenten aus nachhaltigen Materialien oder solche, die mit erneuerbaren Energiequellen hergestellt werden, werden für B2B-Käufer immer attraktiver. Indem sie der nachhaltigen und ethischen Beschaffung Priorität einräumen, können Unternehmen ihren Ruf als Marke verbessern und die Erwartungen umweltbewusster Verbraucher erfüllen.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Wie hat sich der Sektor für die Reparatur von Autoanlassern im Laufe der Zeit entwickelt?

Die Reparatur von Autoanlassern hat sich in den letzten Jahrzehnten erheblich weiterentwickelt. Ursprünglich dominierten mechanische Systeme, doch die Einführung elektronischer Anlasser im späten 20. Jahrhundert revolutionierte die Branche, da sie eine höhere Effizienz und Zuverlässigkeit boten. Dieser Wandel erforderte eine Änderung der Reparaturpraktiken, da sich die Techniker auf komplexere elektrische Systeme einstellen mussten.

In den letzten Jahren hat der Aufstieg von Elektro- und Hybridfahrzeugen die Landschaft weiter verändert. Diese Fahrzeuge nutzen oft fortschrittliche Startertechnologien, die Spezialwissen und Komponenten erfordern, die früher nicht notwendig waren. Infolgedessen hat sich die Beschaffungsdynamik verschoben, und die Einkäufer müssen Lieferanten finden, die hochwertige, spezialisierte Teile liefern können.

Die zunehmende Bedeutung von Nachhaltigkeit und ethischer Beschaffung ist ebenfalls eine relativ neue Entwicklung, die einen breiteren gesellschaftlichen Wandel widerspiegelt. B2B-Einkäufer sind sich heute der ökologischen und sozialen Auswirkungen ihrer Beschaffungsentscheidungen bewusster, was die Lieferanten veranlasst, ihre Praktiken entsprechend anzupassen. Diese Entwicklung ist bezeichnend für einen Markt, der sich ständig an den technologischen Fortschritt und die veränderten Erwartungen der Verbraucher anpasst.

Häufig gestellte Fragen (FAQs) für B2B-Käufer von Autoanlasser-Reparaturkosten

-

Wie kann ich einen defekten Anlasser in meinem Fahrzeug diagnostizieren?

Um einen defekten Anlasser zu diagnostizieren, überprüfen Sie zunächst die Batterie und ihre Anschlüsse. Vergewissern Sie sich, dass die Batterie geladen ist und dass die Pole sauber und fest sind. Untersuchen Sie anschließend das Anlasserrelais und die Sicherungen auf Anzeichen von Schäden. Achten Sie beim Anlassen des Fahrzeugs auf ungewöhnliche Geräusche, wie z. B. ein Klicken oder Schleifen, die auf Probleme mit dem Anlasser hinweisen können. Wenden Sie sich bei Bedarf an einen professionellen Mechaniker, der eine gründliche Untersuchung durchführt, um festzustellen, ob der Anlasser oder ein anderes Bauteil das Problem verursacht. -

Wie hoch sind die durchschnittlichen Kosten für die Reparatur eines Autoanlassers?

Die Kosten für die Reparatur eines Autoanlassers können je nach Fahrzeugmarke und -modell, der Komplexität der Reparatur und den Arbeitskosten in Ihrer Region erheblich variieren. In der Regel liegen die Kosten für Ersatzteile zwischen $50 und $350, während sich die Arbeitskosten um weitere $150 bis $1.100 auf die Gesamtkosten erhöhen können. Es ist wichtig, dass Sie Angebote von mehreren Anbietern und Mechanikern einholen, um sicherzustellen, dass Sie den besten Preis und die beste Servicequalität für Ihr spezielles Fahrzeug erhalten. -

Wie kann ich seriöse Lieferanten für Autoanlasserteile finden?

Um seriöse Anbieter von Autoanlasserteilen zu finden, sollten Sie zunächst Online-Rezensionen und Bewertungen früherer Kunden einholen. Suchen Sie nach Anbietern, die eine starke Präsenz auf dem Markt haben und seit mehreren Jahren im Geschäft sind. Überprüfen Sie außerdem ihre Zertifizierungen und die Einhaltung internationaler Normen. Die Teilnahme an Branchenmessen oder Netzwerkveranstaltungen kann ebenfalls Gelegenheit bieten, potenzielle Lieferanten zu treffen und ihre Glaubwürdigkeit aus erster Hand zu beurteilen. -

Was sind die üblichen Zahlungsbedingungen für B2B-Autoteilegeschäfte?

Die Zahlungsbedingungen für B2B-Autoteilegeschäfte umfassen in der Regel Optionen wie Netto 30, Netto 60 oder sogar Vorauszahlung, je nach den Richtlinien des Lieferanten. Einige Lieferanten bieten Rabatte für frühzeitige Zahlungen oder größere Bestellungen an. Es ist wichtig, die Zahlungsbedingungen zu klären, bevor Sie einen Vertrag abschließen, um sicherzustellen, dass beide Parteien einverstanden sind. Erwägen Sie Treuhanddienste oder Zahlungspläne für größere Transaktionen, um Risiken zu minimieren. -

Was ist die Mindestbestellmenge (MOQ) für Autoanlasserteile?

Die Mindestbestellmengen (MOQ) für Autoanlasserteile können von Anbieter zu Anbieter sehr unterschiedlich sein. Einige haben eine Mindestbestellmenge von nur einer Einheit, während andere Bestellungen von Hunderten oder Tausenden von Einheiten verlangen. Erkundigen Sie sich bei der Beschaffung von Teilen immer im Voraus nach der Mindestbestellmenge, da diese Ihre Einkaufsstrategie und Bestandsverwaltung beeinflussen kann. Ziehen Sie außerdem in Erwägung, MOQs zu verhandeln, insbesondere wenn Sie ein neuer Käufer sind oder eine langfristige Partnerschaft anstreben. -

Wie kann ich die Qualitätssicherung bei der Reparatur von Autoanlassern gewährleisten?

Um die Qualität von Anlasserreparaturen zu gewährleisten, sollten Sie mit Lieferanten zusammenarbeiten, die Garantien auf ihre Teile und Dienstleistungen geben. Erkundigen Sie sich nach deren Qualitätskontrollverfahren und danach, ob sie sich an internationale Normen halten. Es ist auch von Vorteil, vor der Erteilung größerer Aufträge Produktmuster anzufordern, um die Qualität aus erster Hand beurteilen zu können. Ein regelmäßiger Austausch mit Ihrem Lieferanten über Ihre Qualitätserwartungen kann dazu beitragen, dass die Standards während der gesamten Partnerschaft gleich bleiben. -

Welche logistischen Überlegungen sollte ich bei der Beschaffung von Autoanlasserteilen anstellen?

Berücksichtigen Sie bei der Beschaffung von Autoanlasserteilen logistische Faktoren wie Versandzeiten, Kosten und Zollbestimmungen. Prüfen Sie die Versandoptionen und Lieferfristen des Lieferanten, um sicherzustellen, dass sie mit Ihren betrieblichen Anforderungen übereinstimmen. Machen Sie sich außerdem mit den Einfuhrzöllen und Steuern vertraut, die bei der Einfuhr von Teilen in Ihr Land anfallen können. Der Aufbau einer starken Beziehung zu einem zuverlässigen Logistikpartner kann den Prozess rationalisieren und dabei helfen, mögliche Herausforderungen zu bewältigen. -

Kann ich Autoanlasserteile für bestimmte Fahrzeugmodelle maßschneidern?

Ja, viele Lieferanten bieten Anpassungsmöglichkeiten für Autoanlasserteile an bestimmte Fahrzeugmodelle an. Wenn Sie eine Anpassung wünschen, sollten Sie Ihre Anforderungen, einschließlich der Spezifikationen und Leistungsstandards, klar formulieren. Seien Sie bereit, dem Lieferanten detaillierte technische Unterlagen oder Muster zur Verfügung zu stellen, damit er Ihre Anforderungen erfüllen kann. Kundenspezifische Teile können unterschiedliche Preise und Lieferzeiten haben. Besprechen Sie diese Faktoren im Voraus, um Überraschungen während des Beschaffungsprozesses zu vermeiden.

Top 3 Auto Anlasser Reparatur Kosten Hersteller & Lieferanten Liste

1. Facebook - Autoreparaturkosten

Domäne: facebook.com

Registriert: 1997 (28 Jahre)

Einleitung: Kosten für die Fahrt zur Werkstatt und den Austausch des Anlassers

2. CARFAX - Berichte zur Fahrzeughistorie

Domäne: carfax.de

Registriert: 1997 (28 Jahre)

Einleitung: CARFAX bietet Zugang zur weltweit größten Datenbank mit Informationen zur Fahrzeughistorie, einschließlich Details zu bekannten Unfällen, Schäden, Diebstahlberichten, Wartung und Inspektionen, manipulierten Kilometern, Importinformationen, Besitzerwechsel und offenen Rückrufaktionen. Der Service deckt Fahrzeuge aus mehr als 20 Ländern ab, darunter die USA und Kanada, und soll die Transparenz auf dem Gebrauchtwagenmarkt erhöhen...

3. Letzte Chance Autoreparaturen - Kosten für den Austausch des Anlassers

Domäne: letztechanceautoreparaturen.com

Registriert: 2009 (16 Jahre)

Einleitung: Kosten für den Austausch des Anlassers: Sparanlasser: $75 - $200, OEM-Anlasser: $150 - $400, Hochleistungsanlasser: $300 - $1000+. Arbeitskosten: Austausch von Basisanlassern für Fahrzeuge: $100 - $250, Komplexe Installationen: $300 - $600+. Kostenbeeinflussende Faktoren: Fahrzeugtyp und -modell, neue vs. wiederaufbereitete Anlasser, zusätzliche Reparaturen. Kosten für einen DIY-Anlasserwechsel: Nur Teile: $100 - $400, Zeitaufwand: 2-6 Stunden...

Strategische Beschaffung Schlussfolgerung und Ausblick für die Reparaturkosten von Autoanlassern

Zusammenfassend lässt sich sagen, dass es für internationale B2B-Einkäufer von entscheidender Bedeutung ist, die Dynamik der Kosten für Anlasserreparaturen zu verstehen, insbesondere wenn sie in verschiedenen Märkten wie Afrika, Südamerika, dem Nahen Osten und Europa tätig sind. Eine strategische Beschaffung kann die mit Anlasserreparaturen verbundenen Kosten erheblich senken, indem sie es den Einkäufern ermöglicht, zuverlässige Lieferanten zu identifizieren, günstige Konditionen auszuhandeln und hochwertige Komponenten zu wettbewerbsfähigen Preisen zu beschaffen.

Illustratives Bild zu den Kosten für die Reparatur des Autoanlassers

Die Schwankungsbreite der Reparaturkosten - von $50 für Ersatzteile bis zu über $1.100 für Arbeitskosten - macht deutlich, wie wichtig eine gründliche Marktforschung und Lieferantenprüfung ist. Durch die Nutzung datengestützter Erkenntnisse können Unternehmen fundierte Entscheidungen treffen, die die betriebliche Effizienz steigern und Ausfallzeiten minimieren.

Da sich die Automobilindustrie ständig weiterentwickelt, ist es von entscheidender Bedeutung, mit den aufkommenden Trends bei Startertechnologien und Reparaturmethoden Schritt zu halten. Wir ermutigen die Einkäufer, aktiv nach Partnerschaften mit renommierten Herstellern und Dienstleistern zu suchen, um sicherzustellen, dass sie auf ihren jeweiligen Märkten wettbewerbsfähig bleiben. Die Investition in eine strategische Beschaffung führt nicht nur zu Kosteneinsparungen, sondern fördert auch langfristige Beziehungen, die erhebliche betriebliche Vorteile bringen können.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.