Introduction: Navigating the Global Market for replacing a starter motor

In the dynamic landscape of the automotive industry, sourcing reliable components such as starter motors is a critical challenge for B2B buyers operating across diverse markets. The reliability and efficiency of these essential parts can significantly impact vehicle performance and service delivery. This guide serves as a comprehensive resource for international buyers, addressing the complexities of replacing starter motors. It delves into various types and applications, offers insights into supplier vetting processes, evaluates cost considerations, and highlights best practices for procurement.

By navigating the intricacies of the global market for starter motors, this guide empowers businesses in regions such as Africa, South America, the Middle East, and Europe—specifically targeting markets like Saudi Arabia and Vietnam—to make informed purchasing decisions. Understanding the nuances of sourcing and replacing starter motors can lead to enhanced operational efficiency and reduced downtime, ultimately driving customer satisfaction and loyalty. Whether you are a fleet manager, auto parts distributor, or automotive service provider, this guide provides the essential knowledge and actionable strategies needed to optimize your sourcing efforts and ensure the longevity and reliability of your vehicles.

Inhaltsverzeichnis

- Top 2 Replacing A Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for replacing a starter motor

- Understanding replacing a starter motor Types and Variations

- Key Industrial Applications of replacing a starter motor

- 3 Common User Pain Points for ‘replacing a starter motor’ & Their Solutions

- Strategic Material Selection Guide for replacing a starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for replacing a starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacing a starter motor’

- Comprehensive Cost and Pricing Analysis for replacing a starter motor Sourcing

- Alternatives Analysis: Comparing replacing a starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for replacing a starter motor

- Navigating Market Dynamics and Sourcing Trends in the replacing a starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of replacing a starter motor

- Strategic Sourcing Conclusion and Outlook for replacing a starter motor

- Wichtiger Haftungsausschluss und Nutzungsbedingungen

Understanding replacing a starter motor Types and Variations

| Typ Name | Wichtigste Unterscheidungsmerkmale | Primäre B2B-Anwendungen | Kurze Vor- und Nachteile für Käufer |

|---|---|---|---|

| Standard Starter Motor | Conventional design, typically uses direct current | Kfz-Werkstätten, Flottenwartung | Vorteile: Weithin verfügbar, kostengünstig. Nachteile: Limited to specific vehicle models. |

| High-Torque Starter Motor | Enhanced power output for larger engines | Performance vehicles, heavy-duty applications | Vorteile: Improved starting power, suitable for demanding conditions. Nachteile: Höhere Kosten, erfordert möglicherweise Änderungen. |

| Mini Starter Motor | Compact size, lightweight, often used in custom builds | Racing, custom automotive shops | Vorteile: Platzsparend, effizient. Nachteile: May not fit all applications, limited torque. |

| Untersetzungsgetriebe Anlasser | Uses gears to increase torque and reduce size | Schwere Maschinen, Nutzfahrzeuge | Vorteile: Lightweight, high torque output. Nachteile: More complex installation, higher price point. |

| Permanentmagnet-Startermotor | Uses permanent magnets instead of coils | Elektrofahrzeuge, Hybridsysteme | Vorteile: Energy-efficient, compact. Nachteile: Höhere Anfangsinvestitionen, spezialisierte Anwendungen. |

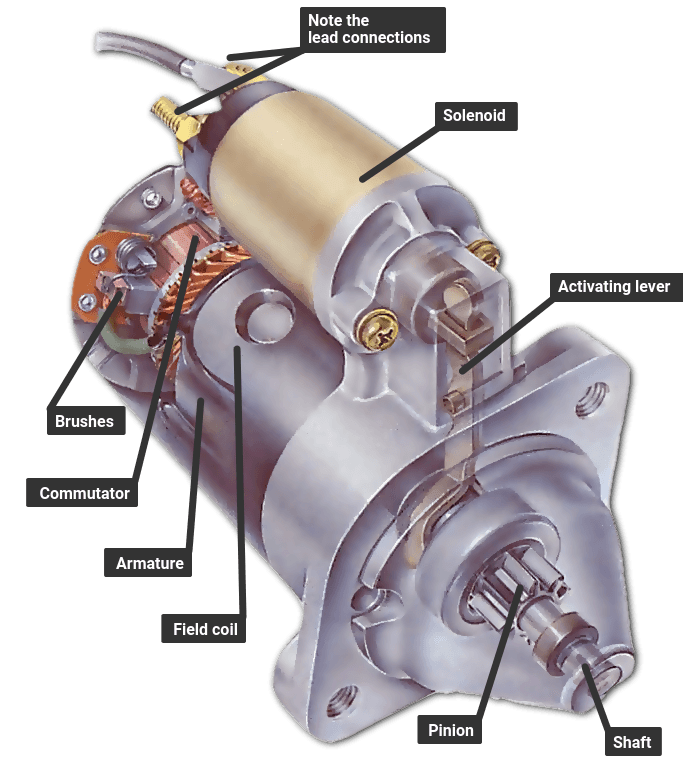

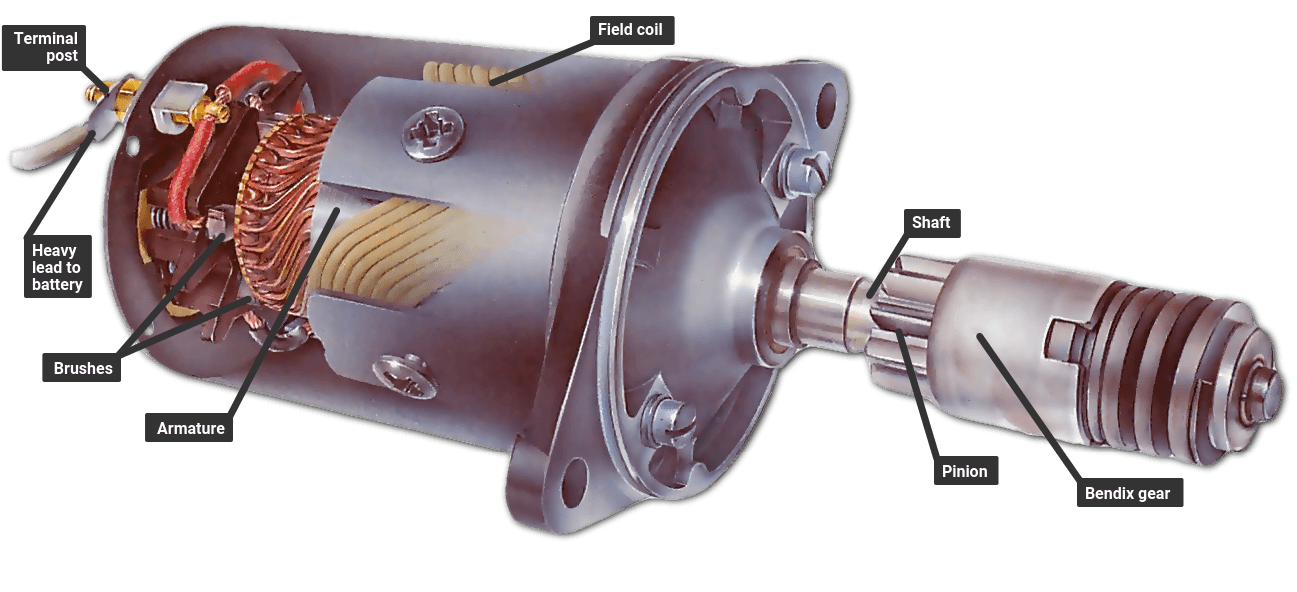

What are the characteristics of Standard Starter Motors?

Standard starter motors are the most common type found in vehicles, operating on a straightforward design that uses direct current to engage the engine. They are primarily used in automotive repair shops and fleet maintenance operations, where the focus is on reliability and cost-effectiveness. B2B buyers should consider their availability and compatibility with specific vehicle models, as these motors are often designed for mass-produced vehicles. The main advantage is their affordability, but they may not suit specialized or high-performance applications.

When are High-Torque Starter Motors suitable for purchase?

High-torque starter motors are engineered for larger engines and high-performance applications, providing enhanced power output. They are particularly beneficial in performance vehicles and heavy-duty applications where starting under load is essential. B2B buyers should weigh the benefits of increased starting power against the higher costs and potential need for modifications to fit these motors. While they are ideal for demanding conditions, their specialized nature may limit their use in standard vehicles.

How do Mini Starter Motors differ from traditional options?

Mini starter motors offer a compact and lightweight alternative to traditional starters, making them popular in racing and custom automotive builds. Their design emphasizes efficiency and space-saving, appealing to B2B buyers in niche markets such as performance tuning. However, while they provide a significant weight advantage, their torque output may not match that of larger starters, which can limit their application. Buyers should assess compatibility with their specific setups and consider the trade-off between size and power.

What advantages do Gear Reduction Starter Motors provide?

Gear reduction starter motors utilize a gear system to increase torque while reducing the overall size of the starter. This design is especially advantageous for heavy machinery and commercial vehicles that require reliable starting under challenging conditions. B2B buyers should be aware of their lightweight construction and high torque output, which can enhance vehicle performance. However, the complexity of installation and higher price point may pose challenges for some buyers, necessitating careful evaluation of their application needs.

In what situations are Permanent Magnet Starter Motors the best choice?

Permanent magnet starter motors leverage the efficiency of permanent magnets instead of traditional coils, making them suitable for electric and hybrid vehicles. Their compact design contributes to energy efficiency, appealing to B2B buyers in the electric vehicle sector. While they offer significant benefits in terms of size and efficiency, the initial investment is typically higher, and their applications may be limited to specific vehicle types. Buyers should consider the long-term energy savings against the upfront costs when evaluating these starters.

Key Industrial Applications of replacing a starter motor

| Branche/Sektor | Specific Application of replacing a starter motor | Wert/Nutzen für das Unternehmen | Wichtige Überlegungen zur Beschaffung für diese Anwendung |

|---|---|---|---|

| Automobilbau | Replacement in assembly lines for production vehicles | Ensures operational efficiency and minimizes downtime | Compatibility with existing systems and regulatory compliance |

| Schwere Ausrüstung | Replacement in construction machinery | Erhöht die Zuverlässigkeit und reduziert die Wartungskosten | Durability under extreme conditions and availability of parts |

| Transport & Logistik | Replacement in fleet vehicles | Improves fleet reliability and reduces operational disruptions | Bulk purchasing options and warranty terms |

| Landwirtschaftliche Geräte | Replacement in tractors and harvesters | Increases productivity and reduces equipment failures | Adaptability to various environmental conditions and support |

| Bergbauarbeiten | Replacement in mining vehicles | Ensures safety and operational continuity in remote areas | Quality certifications and supplier reliability |

How is Replacing a Starter Motor Used in Automotive Manufacturing?

In the automotive manufacturing sector, replacing starter motors is crucial for maintaining the efficiency of assembly lines. A faulty starter can lead to significant downtime, affecting production schedules and delivery timelines. Businesses must ensure that replacement starters are compatible with a wide range of vehicle models and comply with industry regulations. International buyers should prioritize suppliers who can provide detailed specifications and certifications, ensuring that the parts meet the necessary quality standards.

What Role Does Starter Motor Replacement Play in Heavy Equipment?

Heavy equipment, such as bulldozers and excavators, relies on robust starter motors to function effectively in demanding environments. Replacing starter motors in this sector enhances the reliability of machinery, minimizing unexpected breakdowns and maintenance costs. Buyers should consider sourcing parts that are specifically designed for high-stress applications, ensuring durability and longevity. Additionally, access to timely replacement parts is vital for operations in remote locations, making supplier responsiveness a key consideration.

Why is Replacing Starter Motors Important for Transportation & Logistics?

In the transportation and logistics industry, fleet vehicles must operate without interruption to meet delivery schedules. Replacing starter motors promptly is essential to avoid operational disruptions that can lead to financial losses. Businesses benefit from establishing relationships with suppliers who can provide bulk purchasing options and favorable warranty terms. International buyers should also evaluate the logistical capabilities of suppliers to ensure timely delivery of parts, particularly in regions with challenging supply chains.

How Does Starter Motor Replacement Impact Agricultural Equipment?

For agricultural equipment, such as tractors and harvesters, replacing starter motors is vital for ensuring productivity during critical farming seasons. A malfunctioning starter can halt operations, leading to potential crop losses. Buyers in this sector should seek starter motors that can withstand various environmental conditions, from extreme heat to moisture. Reliable supplier support is essential for maintaining equipment performance, particularly in remote farming areas where downtime can be costly.

What Are the Considerations for Replacing Starter Motors in Mining Operations?

In mining operations, the reliability of vehicles is paramount for safety and efficiency. Replacing starter motors in mining vehicles ensures continuous operation in harsh and remote environments. Buyers need to prioritize quality certifications and supplier reliability, as equipment failures can lead to hazardous situations. It is also important to consider the availability of parts and support services, which can significantly impact operational continuity in mining sites.

3 Common User Pain Points for ‘replacing a starter motor’ & Their Solutions

Scenario 1: Sourcing the Right Starter Motor for Diverse Vehicle Models

Das Problem: B2B buyers in automotive repair and maintenance often face challenges when sourcing starter motors that fit a wide range of vehicle models. With variations in specifications across manufacturers, choosing the correct starter can lead to increased downtime and customer dissatisfaction if the wrong part is selected. This issue is exacerbated in regions with diverse vehicle populations, such as Africa and South America, where local shops may not have access to comprehensive catalogs or databases for cross-referencing parts.

Die Lösung: To mitigate this problem, B2B buyers should invest in robust parts management software that includes a comprehensive database of vehicle specifications and compatible starter motors. Leveraging technology like VIN decoding can help identify the exact starter required for each vehicle. Additionally, establishing strong relationships with reputable suppliers who provide detailed product specifications and support can enhance sourcing accuracy. Buyers should also consider maintaining a stock of the most commonly used starter motors to reduce lead times and ensure they can meet customer demands promptly.

Scenario 2: Difficulty in Diagnosing Starter Motor Issues

Das Problem: Many automotive repair professionals struggle with accurately diagnosing starter motor issues, particularly when symptoms overlap with other electrical problems, such as battery failures or wiring faults. This can lead to misdiagnosis, resulting in unnecessary replacements and increased operational costs. In regions with less access to advanced diagnostic tools, this challenge can be particularly pronounced.

Die Lösung: Implementing a systematic diagnostic approach is essential for overcoming this challenge. B2B buyers should prioritize training technicians on using multimeters and other diagnostic tools to assess the electrical system thoroughly before concluding that a starter motor is faulty. Additionally, investing in training programs focused on common starter motor issues and their symptoms can empower technicians to make informed decisions. Encouraging a standardized diagnostic procedure—like checking battery voltage, ensuring clean connections, and testing the starter’s solenoid—can streamline operations and improve accuracy in diagnosing issues.

Scenario 3: Managing Labor Costs During Starter Motor Replacement

Das Problem: Labor costs associated with replacing starter motors can significantly impact the profitability of automotive repair businesses. In regions where skilled labor is scarce, the cost of hiring experienced technicians can be high. Additionally, lengthy replacement processes due to inefficiencies can further inflate labor expenses, leading to reduced margins for service providers.

Die Lösung: To manage labor costs effectively, B2B buyers should focus on optimizing their replacement processes. This can be achieved through the development of detailed standard operating procedures (SOPs) that outline each step of the starter motor replacement process, ensuring technicians work efficiently and consistently. Investing in training that emphasizes best practices and common pitfalls during installation can reduce the time spent on each job. Furthermore, utilizing high-quality starter motors that come with clear installation instructions can minimize the risk of errors, thus saving time and labor costs. Regularly reviewing and refining these SOPs based on technician feedback and performance metrics can lead to continuous improvement and cost savings.

Strategic Material Selection Guide for replacing a starter motor

When selecting materials for replacing a starter motor, it is essential to consider various factors that affect performance, durability, and cost. The following analysis covers four common materials used in starter motor components: steel, aluminum, copper, and plastic. Each material has unique properties that can influence the overall effectiveness of the starter motor in different applications.

What Are the Key Properties of Steel for Starter Motors?

Steel is widely used in starter motors due to its high tensile strength and durability. It typically has a temperature rating of up to 300°C and can withstand significant pressure, making it suitable for high-performance applications. Additionally, steel offers good corrosion resistance when treated with coatings.

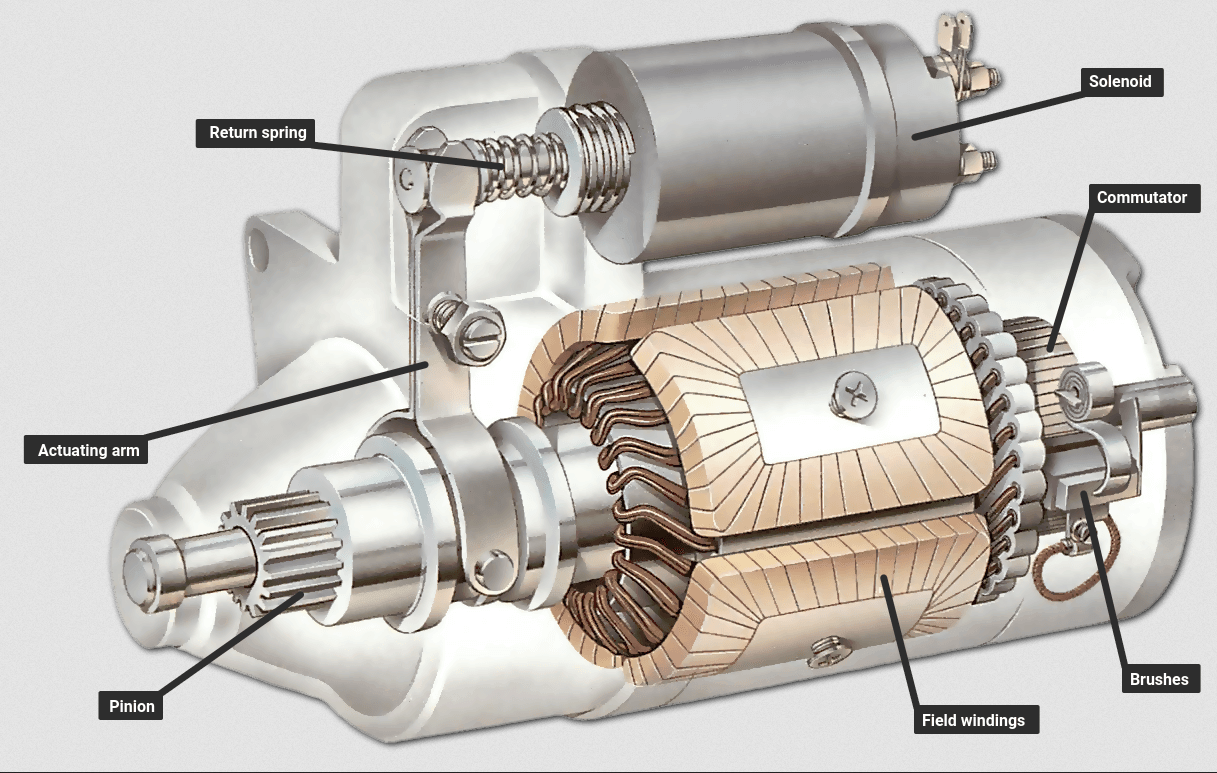

Illustrative image related to replacing a starter motor

Pros and Cons of Using Steel

The primary advantage of steel is its strength, which contributes to the longevity of starter motor components. However, steel can be heavier than alternative materials, potentially affecting the overall weight of the motor. Manufacturing complexity can also increase due to the need for precision machining and surface treatments.

Auswirkungen auf die Anwendung

Steel is compatible with various media, including automotive fluids and gases. However, its weight may be a concern in applications where weight reduction is critical, such as in performance vehicles.

Überlegungen für internationale Käufer

B2B buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM A36 for structural steel. In Europe, buyers may refer to EN standards for material specifications.

Illustrative image related to replacing a starter motor

Wie schneidet Aluminium als Werkstoff für Anlasser ab?

Aluminum is another popular choice for starter motors, known for its lightweight properties and excellent corrosion resistance. It typically has a temperature rating of around 200°C, making it suitable for moderate thermal applications.

Vor- und Nachteile der Verwendung von Aluminium

The lightweight nature of aluminum allows for easier installation and can enhance vehicle performance. However, aluminum is generally less strong than steel, which may lead to durability concerns in high-stress environments. The manufacturing process can be more complex due to the need for specialized techniques like die-casting.

Auswirkungen auf die Anwendung

Aluminum is ideal for applications where weight savings are essential, such as in electric vehicles. However, it may not be suitable for high-torque applications due to its lower strength.

Überlegungen für internationale Käufer

International buyers should be aware of standards such as ASTM B221 for aluminum extrusions. In regions like the Middle East, the preference for lightweight materials in automotive applications is growing.

What Role Does Copper Play in Starter Motor Applications?

Copper is primarily used for electrical connections within starter motors due to its excellent electrical conductivity. It can handle high currents and has a temperature rating of around 200°C.

Pros and Cons of Using Copper

The key advantage of copper is its superior conductivity, which ensures efficient power transfer to the starter motor. However, copper is susceptible to corrosion and can be more expensive than other materials. Additionally, its weight can be a drawback in applications where weight is a critical factor.

Auswirkungen auf die Anwendung

Copper is essential for electrical components, ensuring reliable operation. However, its susceptibility to corrosion means that protective coatings or alloys may be necessary for longevity.

Überlegungen für internationale Käufer

B2B buyers should consider compliance with standards such as ASTM B170 for copper wire. In regions like Europe, buyers may also look for RoHS compliance to ensure environmental safety.

How Does Plastic Contribute to Starter Motor Design?

Plastic is often used for housing and insulation in starter motors, providing electrical insulation and lightweight properties. It typically has a temperature rating of around 100°C, making it suitable for low-heat applications.

Pros and Cons of Using Plastic

The primary advantage of plastic is its lightweight nature and resistance to corrosion. However, it may not withstand high temperatures or mechanical stresses as effectively as metals, which can limit its application scope.

Auswirkungen auf die Anwendung

Plastic is suitable for non-structural components and can improve overall vehicle efficiency by reducing weight. However, it may not be appropriate for high-stress areas of the starter motor.

Überlegungen für internationale Käufer

Buyers should ensure compliance with international standards like ASTM D638 for plastic materials. In markets such as Saudi Arabia, the focus on lightweight materials is increasing, making plastic a viable option.

Summary Table of Material Properties for Starter Motors

| Material | Typical Use Case for replacing a starter motor | Wesentlicher Vorteil | Wesentlicher Nachteil/Einschränkung | Relative Kosten (niedrig/mittel/hoch) |

|---|---|---|---|---|

| Stahl | Strukturkomponenten und Gehäuse | Hohe Festigkeit und Haltbarkeit | Schwere, komplexe Fertigung | Mittel |

| Aluminium | Lightweight components and casings | Leicht und korrosionsbeständig | Less strength than steel, complex to manufacture | Hoch |

| Kupfer | Elektrische Anschlüsse und Verkabelung | Hervorragende elektrische Leitfähigkeit | Corrosion-prone, higher cost | Hoch |

| Kunststoff | Insulation and non-structural parts | Leicht und korrosionsbeständig | Limited heat resistance and strength | Niedrig |

This comprehensive analysis provides B2B buyers with essential insights into material selection for replacing starter motors, ensuring informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for replacing a starter motor

What Are the Main Stages of Manufacturing Processes for Replacing a Starter Motor?

The manufacturing of starter motors involves several critical stages that ensure both functionality and reliability. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to replacing a starter motor

-

Materialvorbereitung: This initial phase involves sourcing high-quality raw materials, such as copper for electrical components, steel for housings, and various plastics for insulation. Suppliers often conduct rigorous quality checks to ensure materials meet specified standards. B2B buyers should prioritize suppliers that can provide certifications for their materials, as this can impact the longevity and performance of the starter motor.

-

Formung: The forming process shapes raw materials into the necessary components. Techniques such as stamping, machining, and casting are commonly employed. For instance, the housing of the starter motor may be die-cast for precision, while the armature might be machined to meet exact specifications. Manufacturers utilize Computer Numerical Control (CNC) machines for high accuracy and repeatability, which is vital for ensuring that parts fit together seamlessly.

-

Montage: During this stage, the individual components are assembled into a complete starter motor. This can involve manual assembly or automated processes, depending on the manufacturer’s scale. Automated assembly lines enhance efficiency and reduce human error, while manual assembly allows for more intricate adjustments. B2B buyers should inquire about the assembly methods used, as they can affect the overall quality and reliability of the starter motors.

-

Endbearbeitung: The finishing stage includes processes like painting, coating, and quality checks. This not only enhances the aesthetic appeal but also protects against corrosion and wear. For example, zinc plating may be applied to metal parts to improve durability. Additionally, this stage involves applying insulation materials to electrical components to prevent short circuits.

How Do Quality Assurance Practices Ensure the Reliability of Starter Motors?

Quality assurance (QA) is paramount in the manufacturing of starter motors, ensuring that every unit meets international standards and customer expectations.

-

Internationale Normen und Zertifizierungen: Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards assures B2B buyers that the manufacturer has a structured approach to quality management. Other relevant certifications may include CE marking for compliance with European health, safety, and environmental protection standards, and API specifications for automotive parts.

-

Kontrollpunkte der Qualitätskontrolle: Quality control is integrated at various stages of the manufacturing process. Common checkpoints include:

– Eingangsqualitätskontrolle (IQC): Materials are inspected upon arrival to ensure they meet specified requirements.

– In-Process-Qualitätskontrolle (IPQC): Ongoing checks during the manufacturing process monitor the quality of components and assemblies.

– Endkontrolle (FQC): Finished products undergo rigorous testing to confirm they function correctly and meet all specifications. -

Testing Methods: Various testing methods are employed to assess the performance and reliability of starter motors. Common tests include electrical continuity tests, load tests, and thermal cycling tests. These ensure that the motors can withstand operational stresses and have the required starting torque. B2B buyers should verify the testing methods used by suppliers to ensure they align with industry standards.

What Should B2B Buyers Look for to Verify Supplier Quality Control?

B2B buyers must conduct due diligence when selecting suppliers for starter motors to ensure they adhere to high-quality manufacturing and QA standards.

-

Lieferantenaudits: One effective way to verify a supplier’s quality control is through audits. Buyers can request to perform on-site inspections to assess the manufacturing processes and quality management systems in place. This firsthand observation can reveal much about a supplier’s commitment to quality.

-

Qualitätsberichte: Suppliers should provide regular quality reports detailing their QA processes, test results, and any corrective actions taken for non-conformance issues. These reports can help B2B buyers assess the reliability of the supplier and the quality of their products.

-

Inspektionen durch Dritte: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These inspections can be performed at various stages of the manufacturing process, providing additional assurance of product quality.

Was sind die Feinheiten der Qualitätskontrolle für internationale B2B-Käufer?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control that can affect their procurement decisions.

-

Kulturelle und regulatorische Unterschiede: Different regions may have varying standards and regulations regarding automotive components. Buyers must familiarize themselves with the local regulations in their markets to ensure compliance when importing starter motors.

-

Communication and Language Barriers: Effective communication is crucial in international transactions. B2B buyers should ensure that suppliers can provide clear documentation in the language of the buyer, especially regarding quality certifications and compliance reports.

-

Logistische Überlegungen: Quality control does not end at manufacturing. B2B buyers should also consider the logistics involved in transporting starter motors. This includes understanding the handling requirements to prevent damage during shipment, which can affect product integrity.

-

Supplier Reputation and Track Record: Finally, assessing a supplier’s reputation in the industry is essential. This can involve researching customer reviews, testimonials, and any history of compliance issues. A supplier with a strong track record of quality assurance is more likely to provide reliable products.

By understanding the manufacturing processes and quality assurance measures in place for starter motors, B2B buyers can make informed decisions, ensuring they procure high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘replacing a starter motor’

This guide serves as a comprehensive checklist for B2B buyers looking to procure the necessary components and services for replacing a starter motor. It emphasizes the importance of thorough preparation and supplier evaluation to ensure a successful replacement process.

Schritt 1: Definieren Sie Ihre technischen Spezifikationen

Before initiating the procurement process, clearly outline the technical specifications required for the starter motor. This includes the make, model, and any specific performance criteria relevant to your vehicle or machinery.

– Wichtige Überlegungen: Ensure compatibility with existing systems and performance standards to avoid costly mismatches.

Schritt 2: Erforschung von Markttrends und Preisgestaltung

Conduct thorough market research to understand the current trends and pricing for starter motors in your region. This information will help you gauge fair pricing and identify potential suppliers.

– Aktionspunkte: Utilize online platforms, industry reports, and trade publications to gather data. This will aid in budget formulation and negotiation strategies.

Illustrative image related to replacing a starter motor

Schritt 3: Bewertung potenzieller Lieferanten

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Assessment Criteria:

– Experience: Look for suppliers with proven track records in your specific sector.

– Zertifizierungen: Verify any industry certifications or standards they comply with, ensuring product quality and reliability.

Step 4: Request Samples and Technical Documentation

Once you have shortlisted suppliers, request samples of the starter motors along with technical documentation. This step allows you to assess the quality and compatibility of the products.

– Documentation to Request:

– Installation manuals

– Warranty information

– Safety and compliance certifications

Step 5: Analyze Warranty and After-Sales Support

Evaluate the warranty terms and after-sales support provided by each supplier. A robust warranty can mitigate risks associated with product defects, while reliable support can ensure quick resolutions to any issues.

– Zu stellende Fragen:

– What does the warranty cover?

– How responsive is the supplier to service inquiries?

Step 6: Compare Logistics and Delivery Options

Logistics can significantly impact your procurement timeline and costs. Assess the delivery options offered by suppliers and their ability to meet your deadlines.

– Logistische Überlegungen:

– Shipping times and methods

– Costs associated with delivery

– Supplier location relative to your operations

Step 7: Finalize Purchase Agreement

After thorough evaluation, finalize the purchase agreement with your chosen supplier. Ensure that all terms, including pricing, delivery schedules, and warranty provisions, are clearly defined and agreed upon.

– Important Clauses:

– Payment terms

– Consequences for non-compliance or late delivery

– Conditions for returns or exchanges

By following this structured checklist, B2B buyers can streamline the procurement process for replacing a starter motor, ensuring they select the right products and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for replacing a starter motor Sourcing

Was sind die wichtigsten Kostenkomponenten beim Austausch eines Anlassers?

When sourcing a starter motor, understanding the comprehensive cost structure is crucial for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materialien: The cost of the starter motor itself is influenced by the quality and type of materials used. High-performance motors may incorporate advanced materials that enhance durability and efficiency, affecting the overall price.

-

Arbeit: Labor costs can vary significantly based on geographic location and the complexity of the starter motor’s design. In regions with higher labor costs, such as Europe, buyers may face increased prices compared to markets in Africa or South America.

-

Fertigungsgemeinkosten: This encompasses expenses related to factory operations, including utilities, rent, and salaries of non-production staff. Efficient manufacturing processes can help keep these costs down, translating to more competitive pricing.

-

Werkzeuge: Custom tooling for specific starter motor designs can be a significant upfront investment. Buyers should inquire about tooling costs, especially if they require specialized components or configurations.

-

Qualitätskontrolle (QC): Investing in robust QC processes ensures that the starter motors meet required specifications and certifications. While this may increase initial costs, it can reduce long-term expenses related to warranty claims and failures.

-

Logistik: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and customs duties can significantly impact the final price.

-

Marge: Suppliers will include a profit margin in their pricing. Understanding the typical margins within specific markets can aid in negotiation.

How Do Price Influencers Affect the Cost of Starter Motors?

Mehrere Faktoren können die Preisgestaltung von Anlassern beeinflussen, insbesondere für internationale B2B-Käufer:

-

Menge/Mindestbestellmenge: Purchasing in bulk often leads to lower per-unit costs. Buyers should assess their needs and negotiate minimum order quantities (MOQ) to optimize pricing.

-

Spezifikationen und Anpassung: Customized starter motors that meet specific vehicle requirements may incur additional costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materialien und Qualitätszertifizierungen: The choice of materials and the presence of quality certifications (like ISO) can affect prices. High-quality components may have higher upfront costs but can lead to lower maintenance expenses over time.

-

Lieferantenfaktoren: The reputation and reliability of the supplier play a critical role in pricing. Established suppliers with proven track records may charge premium prices but offer better warranties and customer service.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms define the responsibilities of buyers and sellers in shipping and logistics, impacting the total landed cost of the starter motors.

What Tips Can Help Buyers Negotiate Better Prices for Starter Motors?

Negotiating effectively is key to achieving cost-efficiency in purchasing starter motors. Here are some actionable tips:

-

Forschung Marktpreise: Familiarize yourself with average market prices for starter motors in your region. This knowledge empowers you during negotiations.

-

Bewertung der Gesamtbetriebskosten (TCO): Consider not just the purchase price but also long-term costs associated with maintenance, warranty, and potential replacements. This holistic view can justify a higher initial investment for better quality.

-

Beziehungen nutzen: Building strong relationships with suppliers can lead to better pricing and service. Frequent communication and trust can yield favorable terms and discounts.

-

Erkunden Sie mehrere Anbieter: Don’t settle for the first quote. Request quotes from multiple suppliers to compare prices and terms. This competition can drive down costs.

-

Klare Angaben zu den Spezifikationen: Ensure that all specifications are clearly communicated to avoid misunderstandings that could lead to additional costs.

Haftungsausschluss für indikative Preise

Prices for starter motors can vary widely based on numerous factors, including location, supplier, and specifications. The information provided here is for guidance only and does not constitute a fixed pricing structure. Buyers are encouraged to conduct thorough market research and obtain detailed quotes tailored to their specific needs.

Alternatives Analysis: Comparing replacing a starter motor With Other Solutions

In the automotive industry, finding the most effective solution for starting system failures is crucial for maintaining vehicle uptime and performance. While replacing a starter motor is a common approach, it’s beneficial to explore alternative solutions that may provide similar or enhanced functionality. This analysis compares the conventional method of starter motor replacement with two viable alternatives: using a high-performance battery and integrating a push-to-start system.

| Vergleichsaspekt | Replacing A Starter Motor | High-Performance Battery | Push-to-Start-System |

|---|---|---|---|

| Leistung | Restores original functionality; reliable for most vehicles. | Enhances overall engine performance; can reduce starting issues. | Streamlined starting process; can improve user experience. |

| Kosten | Moderate cost for parts and labor; can vary based on vehicle type. | Higher initial investment; potential long-term savings through reduced maintenance. | Higher upfront costs for installation and system integration. |

| Einfache Implementierung | Requires mechanical skills; straightforward for experienced technicians. | Simple installation; may require minimal vehicle modifications. | Complex installation; may require professional assistance for integration. |

| Wartung | Moderate; involves replacing parts periodically. | Low; batteries have longer life spans with proper care. | Low to moderate; requires regular checks on electronics and wiring. |

| Bester Anwendungsfall | Ideal for older vehicles or those with traditional starting systems. | Best for performance vehicles or those experiencing frequent starting issues. | Suitable for modern vehicles looking for advanced starting features. |

What Are the Benefits and Drawbacks of Using a High-Performance Battery?

High-performance batteries can significantly enhance a vehicle’s starting capabilities by providing a more reliable power source. They often feature advanced technologies that enable faster cranking speeds and greater power output. However, these batteries come with a higher upfront cost compared to standard batteries. They may also require specific maintenance practices to maximize their lifespan, which could pose challenges for some users. Overall, they are best suited for performance-oriented applications where reliability is paramount.

How Does a Push-to-Start System Compare to Traditional Starter Motor Replacement?

A push-to-start system offers a modern alternative to traditional ignition methods, allowing for a more convenient starting process. This system typically integrates electronic ignition with smart key technology, eliminating the need for a physical key. While it enhances user experience and provides a sleek, modern interface, the installation process can be complex and costly, requiring professional assistance. Furthermore, if the system fails, it may lead to significant inconvenience, as access to the vehicle may be restricted without proper functioning.

How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate solution for starting system failures, B2B buyers must consider several factors, including the type of vehicles in their fleet, budget constraints, and the specific requirements of their operations. For instance, companies operating older vehicles may find that replacing the starter motor remains the most cost-effective and straightforward solution. In contrast, businesses focused on performance and advanced technology might benefit from investing in high-performance batteries or push-to-start systems. Ultimately, the decision should align with the organization’s operational goals and maintenance capabilities, ensuring long-term reliability and efficiency.

Essential Technical Properties and Trade Terminology for replacing a starter motor

Was sind die wesentlichen technischen Eigenschaften für den Austausch eines Anlassers?

When considering the replacement of a starter motor, several technical properties are critical to ensure compatibility, performance, and durability. Understanding these specifications is vital for B2B buyers to make informed purchasing decisions.

1. Werkstoffgüte

The material grade of a starter motor typically refers to the type of metals used in its construction, such as aluminum for the housing and copper for the windings. High-grade materials ensure better resistance to corrosion, heat, and wear, which is essential for prolonged operational life. For B2B buyers, selecting a starter motor made from high-quality materials can significantly reduce maintenance costs and downtime.

2. Nennspannung

Most starter motors operate at 12V or 24V. The voltage rating determines the electrical system compatibility of the starter motor with the vehicle. Ensuring the correct voltage rating is crucial as an incorrect voltage can lead to failure, potentially damaging the vehicle’s electrical system. Buyers should verify the voltage specifications against their fleet requirements to prevent costly mistakes.

3. Drehmoment-Spezifikation

Torque specification indicates the amount of rotational force the starter motor can generate to start the engine. This is especially important in heavy-duty applications where higher torque is needed to crank larger engines. Understanding torque requirements helps buyers select a starter motor that meets the operational demands of their vehicles, ensuring reliable performance.

4. Abmessungen und Gewicht

The physical dimensions and weight of the starter motor are critical for installation compatibility. Dimensions must match the vehicle’s mounting points, and the weight can affect the vehicle’s overall performance. Buyers must cross-reference these specifications with the vehicle’s service manual to ensure a proper fit, especially in industries where space constraints are common.

5. Stromaufnahme

Current draw refers to the amount of electrical current the starter motor consumes during operation. A lower current draw can enhance battery life and reduce electrical load, making it an important specification for buyers looking to optimize their vehicle’s efficiency. This property is particularly relevant for fleets operating in regions with limited access to service facilities.

6. Bewertung der Dauerhaftigkeit

Durability ratings, such as IP (Ingress Protection) ratings, indicate how well the starter motor can withstand environmental factors like dust and moisture. A higher IP rating signifies better protection against harsh conditions, which is crucial for vehicles operating in diverse climates. Buyers should consider the environmental conditions their vehicles will face when selecting a starter motor.

Illustrative image related to replacing a starter motor

What Common Trade Terms Should B2B Buyers Understand When Replacing a Starter Motor?

Familiarity with industry jargon can enhance communication and negotiation processes in the B2B sector. Below are essential trade terms related to starter motor procurement.

1. OEM (Originalgerätehersteller)

OEM refers to parts produced by the original manufacturer of the vehicle. These parts are typically designed to meet the exact specifications of the vehicle, ensuring compatibility and reliability. Buyers often prefer OEM parts for their guaranteed quality, which can lead to better performance and reduced warranty claims.

2. MOQ (Mindestbestellmenge)

MOQ is the minimum number of units a supplier requires a buyer to purchase. Understanding MOQ is essential for buyers looking to manage inventory effectively. This term is crucial for B2B buyers who want to balance cost efficiency with inventory needs without overcommitting to excess stock.

3. RFQ (Angebotsanfrage)

An RFQ is a formal document issued by a buyer to solicit price proposals from suppliers. It typically includes specifications for the starter motor, quantities, and delivery timelines. RFQs are essential for comparing offers from multiple suppliers, enabling buyers to make informed decisions based on price and service offerings.

4. Incoterms (Internationale Handelsklauseln)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers involved in cross-border purchases, as it clarifies who bears the risk at each stage of the shipping process.

5. Garantiezeitraum

The warranty period refers to the timeframe during which the manufacturer guarantees the product against defects. Understanding warranty terms is crucial for buyers, as it provides assurance regarding the longevity and reliability of the starter motor. A longer warranty can indicate higher confidence in product quality.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when replacing starter motors, ultimately optimizing their operations and minimizing costs.

Navigating Market Dynamics and Sourcing Trends in the replacing a starter motor Sector

What Are the Key Trends Shaping the Replacing a Starter Motor Market?

The global market for replacing starter motors is driven by several factors, including the increasing number of vehicles on the road, the growing demand for automotive repairs and replacements, and advancements in automotive technology. In regions like Africa and South America, where vehicle ownership is on the rise, the need for efficient and reliable starter motor replacements is becoming more critical. Similarly, in the Middle East and Europe, stringent regulations on vehicle emissions and performance are pushing manufacturers to produce more efficient starter motors, thus influencing B2B sourcing decisions.

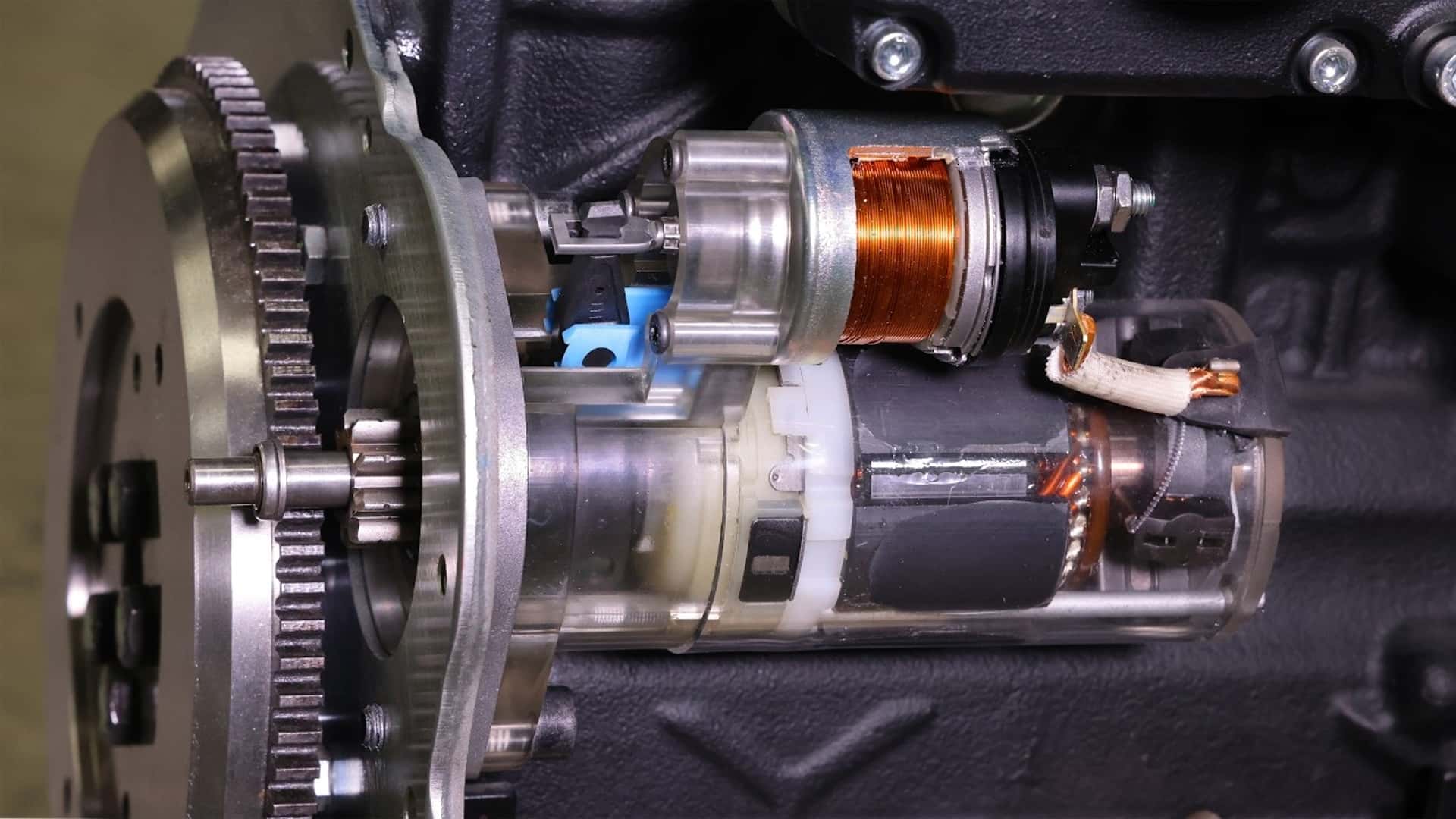

Illustrative image related to replacing a starter motor

Emerging technologies such as e-commerce platforms and supply chain digitization are transforming how businesses source starter motors. International B2B buyers are increasingly leveraging online marketplaces to identify and procure high-quality components from global suppliers. This shift is not only streamlining the purchasing process but also fostering competitive pricing and improved product availability. Additionally, there is a noticeable trend toward the integration of smart technologies in starter motors, such as advanced diagnostics and performance monitoring systems, which can enhance vehicle reliability and reduce maintenance costs.

Furthermore, the market dynamics are also influenced by geopolitical factors, trade policies, and economic fluctuations, particularly in developing regions. As international buyers navigate these complexities, understanding local market conditions and supplier capabilities becomes crucial for effective sourcing.

How Can Sustainability and Ethical Sourcing Impact the Starter Motor Replacement Industry?

The environmental impact of automotive components, including starter motors, is a growing concern among B2B buyers. The production and disposal of these components can contribute to pollution and resource depletion, making sustainability a key consideration in sourcing decisions. Companies are increasingly seeking suppliers who adhere to environmentally friendly practices, such as using recycled materials and reducing waste during manufacturing.

Ethical sourcing is also gaining prominence in the industry. Buyers are looking for suppliers that comply with fair labor practices and demonstrate a commitment to social responsibility. This trend is particularly significant for international buyers from regions like Africa and South America, where issues of labor rights and environmental degradation may be more pronounced.

Illustrative image related to replacing a starter motor

To align with these values, many companies are pursuing certifications that validate their commitment to sustainability, such as ISO 14001 for environmental management and SA8000 for social accountability. These certifications not only enhance a company’s reputation but can also lead to improved market access and customer loyalty. By prioritizing sustainability and ethical sourcing, businesses can differentiate themselves in a competitive market while contributing positively to global environmental and social challenges.

How Has the Starter Motor Industry Evolved Over Time?

The starter motor industry has undergone significant evolution since its inception in the early 20th century. Initially, starter motors were manually operated, requiring significant effort to start an engine. The introduction of electric starter motors revolutionized the automotive industry, providing a more convenient and reliable means of starting vehicles.

As technology progressed, starter motors became more compact and efficient, integrating advanced materials and engineering techniques. The advent of electronic control systems has further enhanced their performance, allowing for more precise operation and improved energy efficiency. In recent years, the rise of electric and hybrid vehicles has led to innovations in starter motor design, focusing on lightweight materials and higher torque outputs.

This historical context is essential for B2B buyers, as understanding the evolution of starter motors can inform purchasing decisions and supplier evaluations. Buyers should consider not only the technical specifications of starter motors but also the historical trends that have shaped the industry, as these factors can influence product performance and reliability in the long term.

Frequently Asked Questions (FAQs) for B2B Buyers of replacing a starter motor

-

Wie kann ich Probleme mit einem defekten Anlasser lösen?

To address problems with a faulty starter motor, first, diagnose the issue by listening for sounds when you turn the ignition. If there’s no sound or only a clicking noise, check the battery connections and ensure they are clean and secure. If the battery is charged and connections are intact, the starter motor may need replacement. Always consult the vehicle’s service manual for specific troubleshooting steps and consider professional assistance if needed. -

Welches ist der beste Anlasser für schwere Nutzfahrzeuge?

The best starter motor for heavy-duty vehicles often includes features like higher torque ratings, durability against extreme conditions, and compatibility with specific vehicle models. Look for brands known for reliability and quality, such as Bosch, Denso, or Delco Remy. Ensure the starter motor you choose meets or exceeds OEM specifications to guarantee performance and longevity in demanding environments. Always consider the unique requirements of your fleet or equipment when selecting a starter motor. -

Wie kann ich die Lieferanten von Anlassern auf internationalen Märkten überprüfen?

When vetting suppliers for starter motors, consider their industry reputation, certifications (like ISO), and customer reviews. Request samples to evaluate quality and compatibility with your vehicles. It’s also wise to check their manufacturing capabilities, lead times, and compliance with international standards. Engaging in thorough background checks and establishing communication with past clients can provide insights into their reliability and service levels. -

What are typical minimum order quantities (MOQs) for starter motors?

Minimum order quantities for starter motors can vary significantly based on the supplier and the type of motor. Generally, MOQs range from 50 to 500 units, depending on the manufacturer and customization options. For bulk purchases, negotiating lower MOQs is often possible. Ensure that the MOQ aligns with your inventory needs and that you have a plan for storage and distribution in your market. -

What payment terms are standard when purchasing starter motors internationally?

Standard payment terms for international purchases of starter motors typically include options like Letter of Credit (LC), advance payment, or net 30/60/90 days. Terms can vary based on the supplier’s policies and the buyer’s creditworthiness. It’s essential to clarify payment methods upfront and ensure that they align with your cash flow and financial strategy. Consider using escrow services for added security during the transaction. -

How do I ensure quality assurance (QA) when sourcing starter motors?

To ensure quality assurance when sourcing starter motors, request detailed specifications and certifications from your suppliers. Implement a quality control process that includes inspecting samples before bulk orders, and consider third-party inspection services to verify compliance with your quality standards. Establishing clear communication regarding your expectations and conducting regular audits can also help maintain quality throughout the procurement process. -

What logistics considerations should I keep in mind for importing starter motors?

When importing starter motors, consider shipping methods, customs regulations, and potential tariffs in your destination country. Ensure that your supplier can provide necessary documentation, such as bills of lading and certificates of origin. It’s also crucial to plan for potential delays in shipping and customs clearance. Working with a reliable logistics partner can facilitate smoother transportation and compliance with international shipping laws. -

Are customization options available for starter motors, and how do they impact lead times?

Many suppliers offer customization options for starter motors, including modifications to fit specific vehicle models or performance enhancements. However, customization can impact lead times, potentially extending them from a few weeks to several months, depending on the complexity of the requests. It’s essential to discuss customization needs upfront with your supplier and understand how it may affect your overall procurement timeline.

Top 2 Replacing A Starter Motor Manufacturers & Suppliers List

1. Toyota - Anleitung zum Austausch des Anlassers

Domäne: reddit.com

Registriert: 2005 (20 Jahre)

Einleitung: 2007 Toyota Corolla starter replacement; relatively simple process depending on accessibility; typically involves two bolts and a connector; estimated time for replacement is about 30 minutes if accessible; cost of a new starter around $150; advice to diagnose before replacing parts; check for issues like dirty battery terminals.

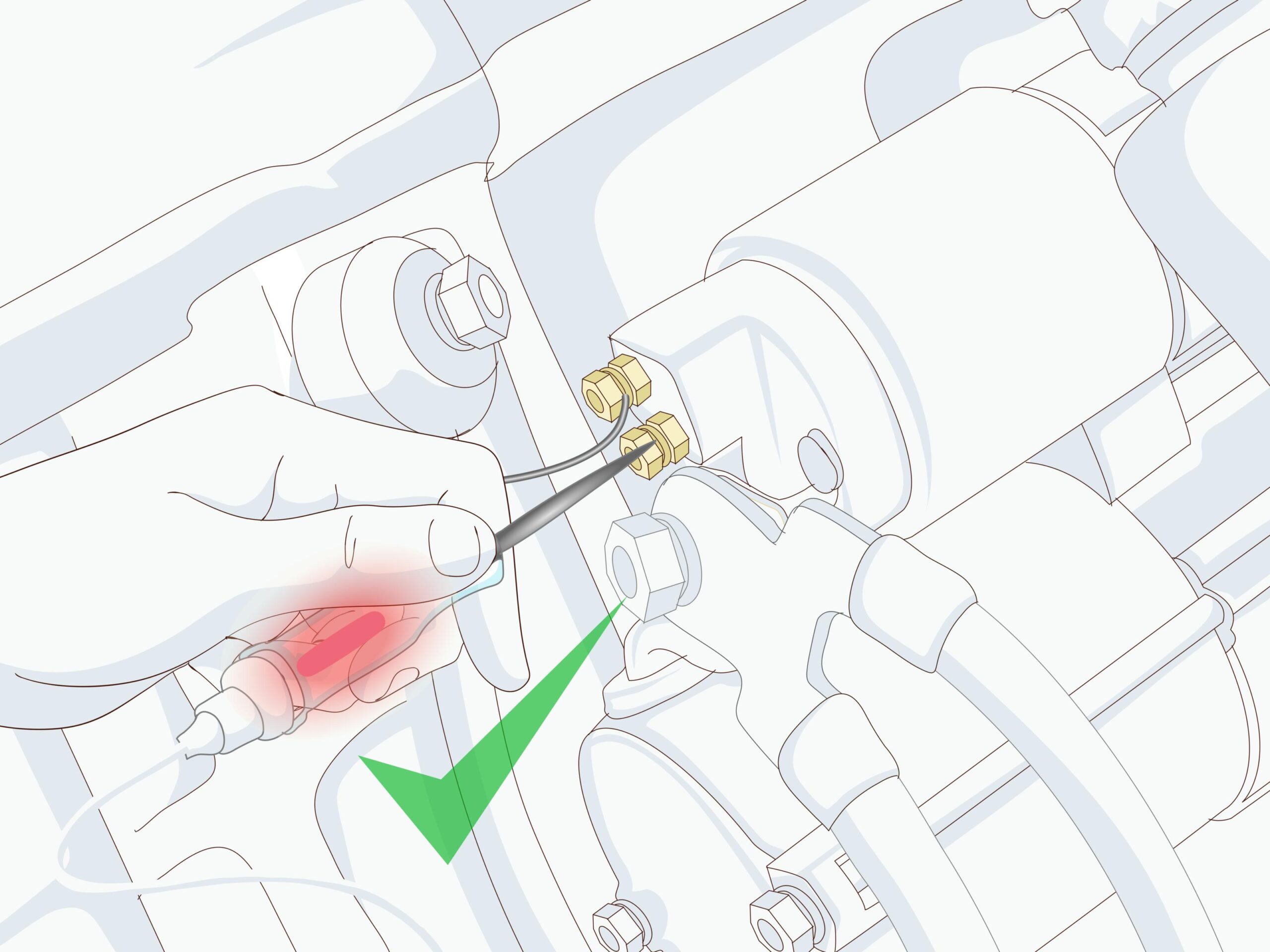

2. WikiHow – Car Starter Installation Guide

Domäne: wikihow.com

Registriert: 2004 (21 Jahre)

Einleitung: How to Install a Car Starter: 14 Steps, co-authored by Tom Eisenberg, Owner and General Manager of West Coast Tires & Service, with over 10 years of auto industry experience. Steps include: 1. Disconnect the battery. 2. Jack up the vehicle if necessary. 3. Locate the starter. 4. Disconnect wiring to the solenoid. 5. Remove the starter retaining bolts and the starter. 6. Compare the new starter to …

Strategic Sourcing Conclusion and Outlook for replacing a starter motor

In conclusion, strategic sourcing is essential for international B2B buyers looking to replace starter motors efficiently and cost-effectively. By focusing on quality suppliers, understanding regional market dynamics, and leveraging bulk purchasing, businesses can significantly enhance their operational efficiency. The value of a reliable starter motor extends beyond just vehicle functionality; it impacts overall fleet reliability and reduces downtime, making it crucial for maintaining business continuity.

As you navigate the complexities of sourcing starter motors, prioritize partnerships with manufacturers who offer quality assurance and after-sales support. Engage with suppliers who understand the unique demands of your market, whether in Africa, South America, the Middle East, or Europe.

Looking ahead, the automotive industry will continue to evolve, presenting opportunities for innovation and sustainability. By embracing strategic sourcing practices today, you position your business to adapt to future challenges and seize new growth opportunities. Take action now to streamline your sourcing process and ensure your fleet remains operational and efficient.

Wichtiger Haftungsausschluss und Nutzungsbedingungen

⚠️ Wichtiger Haftungsausschluss

Die in diesem Leitfaden enthaltenen Informationen, einschließlich der Angaben zu Herstellern, technischen Spezifikationen und Marktanalysen, dienen ausschließlich zu Informations- und Bildungszwecken. Sie stellen keine professionelle Beschaffungsberatung, Finanzberatung oder Rechtsberatung dar.

Obwohl wir alle Anstrengungen unternommen haben, um die Richtigkeit und Aktualität der Informationen zu gewährleisten, übernehmen wir keine Verantwortung für Fehler, Auslassungen oder veraltete Informationen. Marktbedingungen, Unternehmensdaten und technische Standards können sich ändern.

B2B-Käufer müssen ihre eigene unabhängige und gründliche Due Diligence durchführen. bevor Sie Kaufentscheidungen treffen. Dazu gehören die direkte Kontaktaufnahme mit Lieferanten, die Überprüfung von Zertifizierungen, die Anforderung von Mustern und die Einholung professioneller Beratung. Das Risiko, sich auf die Informationen in diesem Leitfaden zu verlassen, trägt ausschließlich der Leser.

Illustrative image related to replacing a starter motor